The •

MICKEY'S PETROL PUMP EURODISNEY VOLUME33 No. 2

Journal of the Association for Petroleum and Explosives Administration

IFPS95-11

I __.,. I 1! 1 l\i I 111 I ,) O SAFETY INTERLOCKS 0 TRANSPARENT MONITORING 0 UNAUTHORISED DELIVERY DETECTION 0 REMOTE DIAGNOSTICS SCULLY 'INTELLICHECK' CONTROLLER MODEM RETAINED PRODUCT INDICATION VAPOUR RECOVERY INTERLOCK I I ORDER POINT e AUTOMATIC LOW LEVEL REORDER TANK LEVEL The Scully Retail Site Vehicle Controlled Overfill Prevention System (RSVP) employs S_cully's unique Dynamic Sel_f-Check®concept to automatically and continuously test the A pulsing signal simulates wet cond1t1ons on the sensors to continuously and automatically test their ab1l 1ty to respond 111 case of an overfill. -Ull UK 9 New St reet , Daventry, Northants NN11 4B T E ngland Tel : +44 (0)1327 704333 Fax : +44 (0)1 327 30046 5

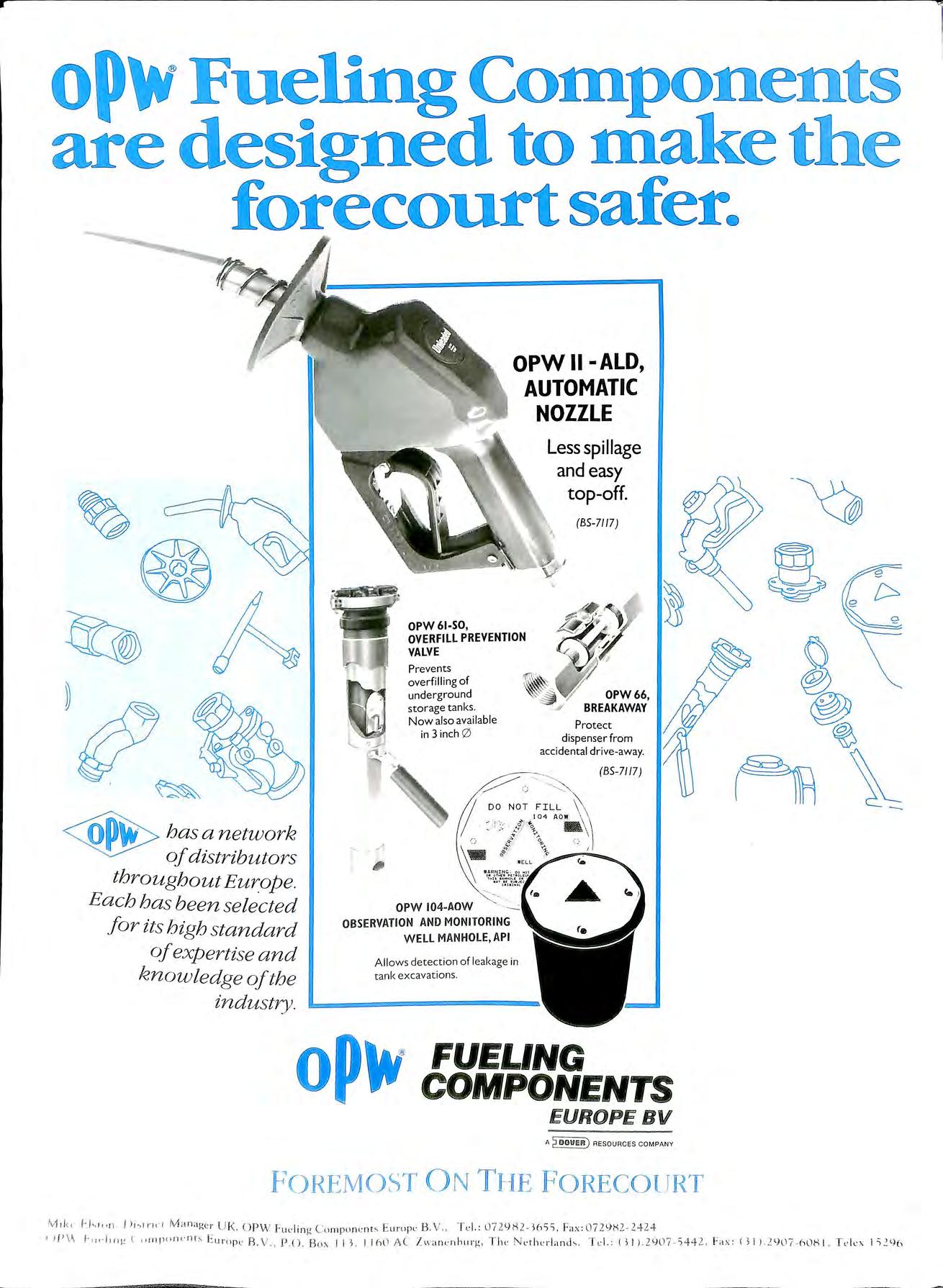

has a network of distrib u tors throughout Europ e Each has been selected for its high standard ofexpertise and know ledge ofthe industry.

jv

OPW 11-ALD, AUTOMATIC

OPW61-SO, OVERFILL PREVENTION VALVE Less spillage and easy top-off. (BS-7117) Pre vents overfilling of underground storage tanks. Now also avail abl e OPW66 ./ BREAKAWAY' in 3 inch 0 A llo ws dete ct io n of le ak age in ta nk ex cava ti o ns Prote ct dispenser from accidental drive-away oP\V FUEi.iNG COMPONENTS EUROPEBV A 2O OH' GR) RESOURCES COMPANY FOHEMOST O N TifE FORECOURT M ik , lcl" " fl I ) j ,f ne t Manager U K OPW Fuc lin i:; C um pu n cn t' Euru pc· B V., Te l.: 072 9R Z- ) fiS S, Fax : 0 729H2 24 2 4 1 1i ' \.\ I·11 .- l ( • "nl"' 11 '' 111 Euro pe B. V ., P O Bcix I J ). I I fill AC Zwancnhu r g , Th e: Net h e r lan d" T c l. : ( l 1) 2907-'i44 2, Fa." ( l I ) 2 lJl17 fiOt-1 I Tc k x I 'i 2 96

NOZZLE

JAMES LUKE AND ASSOCIATES Safety & Training Consultants to the Petroleum Retail Industry SALUKI HOUSE Postbox 41 BILLINGSHURST WEST SUSSEX RH14 ova Tel: 01403 871471 Fax: 01403 871425 1 obn ull & 1Ltb. Comprehensive service for liquid fuel & LPG installations Consultancy, design, installation, maintenance, decommissioning & gas-free certificates Pressure Systems &gulations Surveys FIRST HANGINGS BLABYROAD ENDERBY LEICESTER LE9 SAQ Tel 0533 862287 Fax 0533 751232 MEMBER APEA, LPGA, CORGI REGISTERED TUBEFLOW LTD SPECIALISTS IN PETROL PUMP, TANK AND PIPEWORK INSTALLATIONS AND ASSOCIATED WORKS APPROVED CONTRACTORS TO THE PETROLEUM INDUSTRY AND LOCAL GOVERNMENT AUTHORITIES 29 TEMPLE STREET LONDON E2 6QQ Tel: 071-739 9538 Fax: 071-729 6108 MEMBER A.P.E.A. D D C BUILDERS LTD FOR SERVICE QUALITY & RELIABILITY WE OFFER A COMPLETE SERVICE ON MAINTENANCE AND IMPROVEMENT WORKS TO THE PETROLEUM RETAIL MARKET D D C BUILDERS LTD 7 ST CLAIR CLOSE cLAYHALL ILFORD ESSEX IG5 OPA Tel: 081-550 5216 Fax: 081.,550 6095

BUILDING AND CIVIL ENGINEERING CONTRACTORS TO THE OIL COMPANIES FOR 24 YEARS C.R. RICHARDSON (CONTRACTORS) LTD DESIGN & BUILD COMPLETE REDEVELOPMENTS MAINTENANCE & REPAIRS Anerley Court, Half Moon Lane , Tel: 01732 838608 Hildenborough , Kent TN11 9HU Fax: 01732 838064 RIETBERG DOUBLE WALLED SAFETY CONTAINERS Ri etberg Containers for Hazardous Liquids r-- --, Suitable to feed or Haza rdous liquids Conta iner collect, store and transport infla mmable and other water polluting liqu i d s • Double walled steel conslruclion • Inside and out side hol d ip gaivon ised • leak age indicator • Explosion blast proof o Volumes from 80 I up lo 7500 I 0 Perm ission for fran sportali on on roods (ADR) an d rail (R ID) 0 Var ious desi gns to meet your demands o O ptions: complete stain less steel co nstruction , acid proof inside coa ti ng 0 Models available Fuel Con taine r th e mobile petrol slotion Ch emical s Conta iner for fresh C hemica ls !Hazardou s liqu ids Conta in er for waste oil ond o:her wa ter polluting liq uids Pleose co n1oct us for f urth er info r ma tr on RIETBE RG WERKE G M BH l CO KG SEPPELER GRUPPE IRHIElf_!llERtrO _ BAHNHO FSrR 55 D 333 9 7 RIETBERG fEl (0 52 44} 9 8 3 0 FAX (0 5 2 44} 9 83 2 01 TRAINING IN-COMPANY SHORT COURSES Flexible arrangements to meet your requirements at competitive rates • Electrical requirements for Petrol l'illing Station s (New HSE code HS(G) 41) • I6th EDITION IEE WIRING REGULATIONS • Electricity at Work Regulations 1989 • Inspection and Testing of Electrical Installation s f'resc11/a _· TERRY HEDGELAND BA , FI E IE MIOA Origin al author of the highly !ucccssful IEE ISth Edition 2-day short course Phone: 0737 553328 PETROL FILLING STATIONS: e CERTIFICATES OF ELECTRICAL INSPECTION & TESTING to HS(G) 41 & LACOTS requ i rem ents EMERGENCY LIGHTING: e COMPLETION CERTIFICA TES based on model in BS 5266: Part l : 198 8 e PERIODIC INSPECTION AND TEST CERT/FICATES ba sed on model in BS 5266 : Part l : 1988 FIRE ALARM SYSTEMS: e INSTALLATION & COMMISSIONING CERTIFICATES based on model in BS 5839: Part l: 1988 e CERTIFICATES OF TESTING based on model in BS 5839: Part l: 1988 £9.87 [ £8 40 ]+VAT per pod e PRACTICAL GUIDE TO ELECTRICAL INSTALLATION TESTING £16.i}S Prices include p&p Order w ith cheque paya ble!;; UNEEDA PUBLICATIONS, 5 HIGHWOLD, CHIPSTEAD, SURREY CR5 JLG Compl ete the coupon and we 'll int ro duce you lo th e mos t advanced , eff ective techniques fo r comba ti ng subsu rface co nt aminat io n With a uniqu e range of processes in clud ing German and Ameri ca n te chn olog ies , Mi lle r Environmen tal specia lise rn the investi ga ti on and re mova l of pollutants such as petro leu m pro ducls solven ls an d chemic al contamrnatron. Our me thods are fast cosl effective , safe and desig ned not to interrupt your business Miller En vironm ental Miller House Whitwood Enterpris e Park Whitwood Lane Whitwood , Ca st lefo rd W Yorks WF10 5P X Telephon e: (0977) 555427 Fax : (0977 )555684 MILLER MI LLER GRO UP C I VIL ENG I NEE RI N G -CONSTRUCTION D EV E LO PMENTS EN V l RON M EN T A L HOM E S MIN I N G Title _ Company _____ Add ress Tel

Bayliss urport) Ltd etroleum Engineers Petrol, Fuel Oil and Electrical Installations . • 11/12 HODFAR ROAD, SANDY LANE INDUSTRIAL ESTATE, STOURPORT-ON-SEVERN DY13 9QB TELEPHONE: 01299 824541-2-3 FAX: 01299 827638 SPECIALISING IN ALL ASPECTS OF FORECOURT PETROLEUM INSTALLATIONS AND SERVICING FULLY ACCREDITED TO BS EN ISO 9002: 1994 LZ S 51\FEGUARD · £7 f...4. v 0 BS 5750 Part 1/ISO 90001 Approved !§ 0 We do not compromise on quality where environmental issues are concerned. -"' Internal pipework and ove rflow prevention val v es can be su p plied, fitted and tested at o ur w o rk s t o ensu re the integrity of the syst e m. C OK ON AN ZINN LIMI S t ation Road Works Hadleigh , Suffo l k, IP? 5PN . .. 11 i + tel: 04 73 823061 fax : 04 73 8241 64 I I i f

Emco Wheaton Gold Valve? That will do nicely. The Emco Wheaton A1100 OPS is fast becoming the market leader Overfill Prevention Valve VERSATILE. Can be installed in any position within a full 360 degree rotation, without any risk of fouling suction pipes etc simply the best valve all round! DURABLE. Floats are internal and protected by a metal shroud which prevents damage during installation or inspection. FAIL-SAFE. In the event of the valve not resetting, it will close during the next fill preventing a dangerous and costly overfill other valves can fail in the open position. ' VAPOUR TIGHT. Emco Wheaton have not had to introduce a bottom seal recently, because the A1100 valve has always been fitted with one. DIPSTICK FRIENDLY. Dipstick can be used whether tank is full or empty. FAST SERVICE. The A1100 is assembled and tested in the UK . Therefore we are able to respond quickly to demands from our two UK stockists For further information on the Emco Wheaton range of products for Ser vice Stations , please contact Rob Laird at our Margate Offic e. ® Emco Wheaton Retail Europe Enterprise Ro ad, Westwood Industrial Estate Margate, Kent , CT9 4JR ' WH \I ' Tel ep hon e: 01843 221555 Fa x: 01843 295444 NASH Nash & p tn h h h ar ers ave bee n wo rking in partnershi p wit t e Retail Pe trol · d I · d e um 111 u s try for almost thirty yea rs, p an.n m g an d eve loping . t 1 · d ie a 1 m s tallation s from a s tra1 ght forwar pump ch a n ge to E . , u1op e s la rges t fdlm g s tation. Every step f I 0 t 1e way, from feas ibility studi es and sur veymg, projec t m a n ag · · f · e m e n t and co mm.1ss10111ng, we take ca 1e o eve1y d eta il. W I tl 1e 1e r a mai o r o il compan y o r a n ind ividu a l d ea le r, o ur cli ents · d are ass ured o f th e Na sh co mmitm e nt to qu a lity a n ad h e re n ce t BS 0 5750, backed b y up-to th e-minute techn o logy, 1nn o vaho 1 d 1 a n ex pe rti se Fro m a g re r· I P e n 1e d s ite to a fu ll y ope rat io n a l 111 s ta ll ation, Na s h & a rtn e rs de li ve i crea ti ve ye t hi g hl y prac ti cal solutio ns • AR C H ITECTS • SU IN EYOR S Pl ANN ER S PROJ EC I MA N A C.ER S * l' RO PF.R T Y CONSU i TA N TS '\/ !\ '-> H & p I\ fn /\J f lh I TD+ Station A pproa ch + So uth ga te+ Ch ic hester+

GCS G c s a rage onsultancy ervices Ltd Cert. No. FM 23290 Nafur.al Inspection Coun:::il for ElectricallnstallationConl:racting UNIT 10 MERTHYR TYDFIL INDUSTRIAL PARK PENTREBACH MERTHYR TYDFIL MID GLAMORGAN CF48 4DR TELEPHONE (0443) 692008 FAX (0443) 692159 FUEL PUMPS AND TANKS FUEL MONITORING AND METERING EQUIPMENT PROJECT MANAGERS/ENGINEERS We a.re delighted to inform you tha.t the British Sta.nda.rds Institution ha.s approved our Quality Management System a.nd a.warded us BS5750 Part 2 Credita.tion. ·-·-·-·-·-· We shall continue to assess and inspect our Quality System to ensure that we meet the rigorous demands of our industry 1973 21 YEARS OF SERVICE TO THE PETROLEUM INDUSTRY 1994

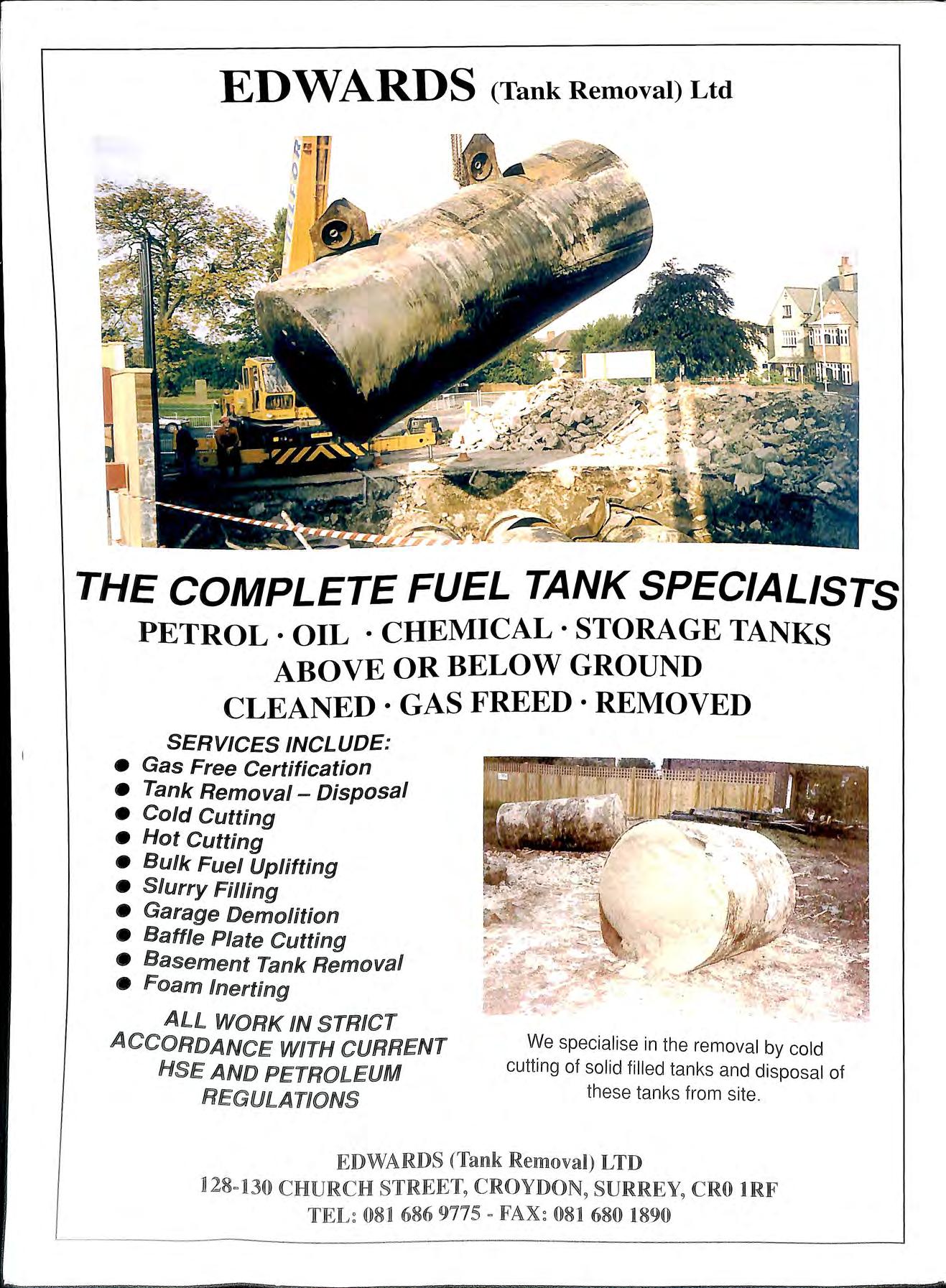

ED WARDS (Tank Removal) Ltd THE COMPLETE FUEL TANK SPECIALISTS PETROL · OIL · CHEMICAL · STORAGE TANKS ABOVE OR BELOW GROUND CLEANED·GASFREED·REMOVED S ER VI C E S INCLUDE: • Ga s Fre e C ertifi cation • Ta n k Re mova l - Disposal • Cold Cu t ting • Hot C u tting • Bulk Fuel Upli ft ing • Slurry Filling • Garage Demolition • Baffle Plate Cutting • Basement Tank Removal • Foam lnerting ALL WORK IN STRICT ACCORDANCE WITH CURRENT HSE AND PETROLEUM REG ULATI ONS We specialise in the removal by cold cutting of solid filled tanks and disposal of t hese tank s from site .EDWARD§ (Tank Removal) LTD ] Jl 30 CHURCH STREET, CROYDON, §URREY9 CRO 1RF mn 686 9775 mn 680 1890

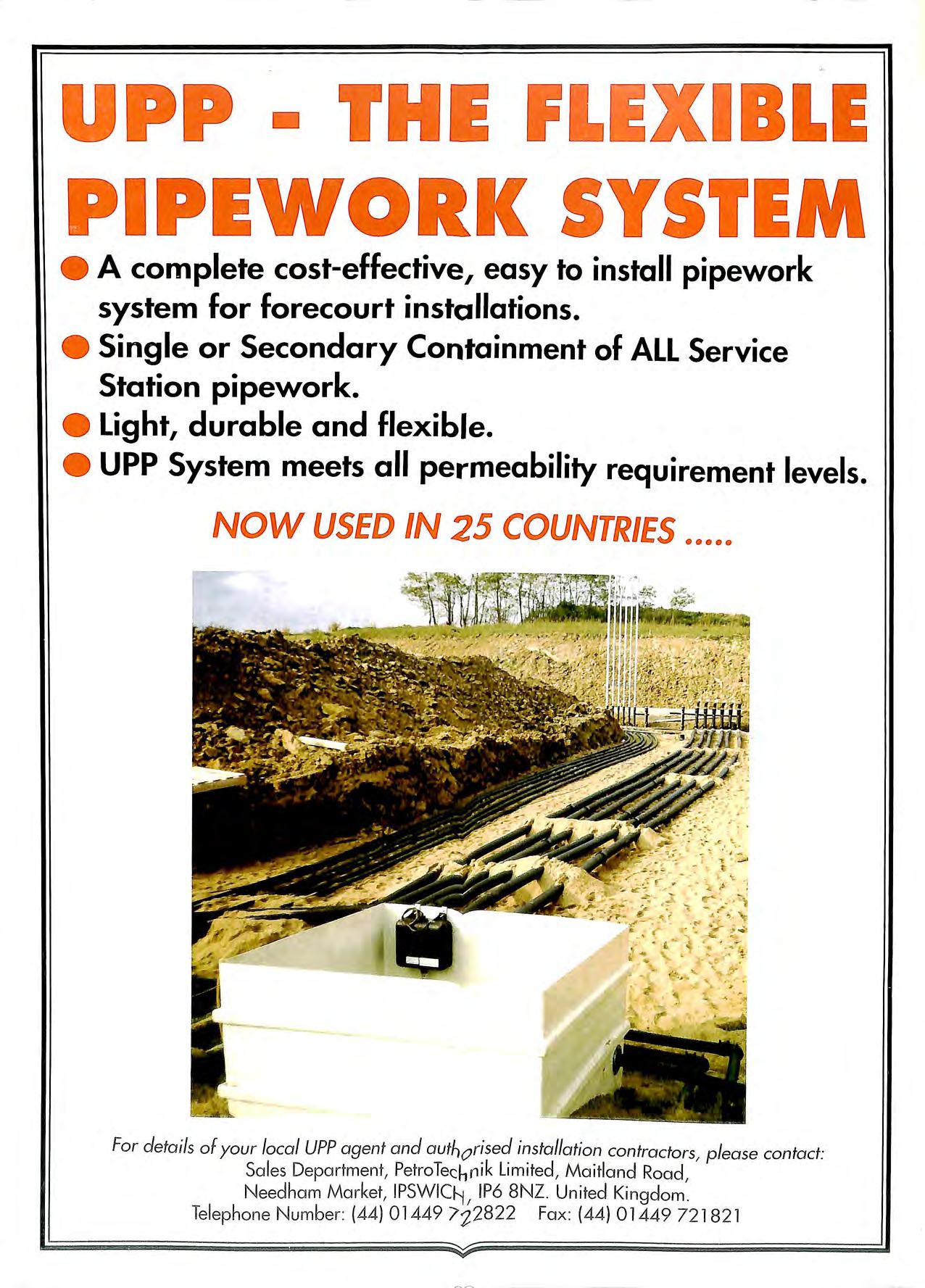

ENVIROFLEX: For fuel delivery. Total secondary containment for suction or pressure systems, or Monoflex for direct burial suction systems. Easy to install and maintain, compatible with all fuels and additives currently on the market. UL listed.

For offset-fill , vent and vapour recovery. Robust and easy to use, this leak-free petrol and additive resistant system is based on Durapipe 's patented electrofusion jointing method .

from

NEW

from TOTA L CONTAINMENT INC.

and SUPPLIED BY THE DISTRIBUTORS for further information cm either, or both, of these products call FORECOURT EQUIPMENT SPECIALISTS PURFLEET COMMERCIALS LIMITED 520 London Road West Thurrock Esse x RM 16 1BE. Tel : (0708) 863931 Fa x: (0 708 ) 868 226

It you were losing

chocolate bars a year

•••

This is w hat 0.1 % fuel lo ss represents to a typical forecourt operator. Most sites are losing many more times this amount each year!

Perro Vend' s Si teSentinel forecourt monitoring system guards against wetstock loss, leaks, theft, shore deliveries co mention just a few! SiteSentiner

It cells you throu gh accurate printouts and easy to understand graphical analysis, not only how much fuel you are losing on a day by day basis but indicates where in the system th e loss is.

It is a modular sys tem th at can be tailored to your present needs and expanded lacer.

SiteSentinel is already provin g a winne r in Am erica b eca us e

is easy to understand and use, and pays for itself in rea l savings

4!1000

I mo "llm."f:'lilllm'I 0

... you'd past a guard! In one package SiteSentinel offers you: .... Automatic Inventory ... Auto-Calibration Petro I/end .... Auto-Reconciliation Ud ... Approved Tank Testinig - Every Day 76 Leeds Road, Newton Bar, Wakefie l d, WF1 20F T l eak Detection TEL : (0924) 291919 F AX : (0924) 376511 .., Trend Analysis Package

it

POWERED BY EXPERIENCE c s SPECIALIST ELECTRICAL ENGINEERS & CONTRACTORS TO THE PETROLEUM INDUSTRY • Close-circuit TV • Fire Alarms & Emergency Lighting • Planned Maintenance • Inspection & Testing • Forecourt Earthing S ystems S & OJEC Cv11t n1do r s' ;\ssoc1i1tin11 REl;iSTEHE D i\ fEi\ !HEll LTD MEMBER OF A.P.E.A National Inspec tion Council for Elec tr cal Installation Co ntractin g • •1c&1c APffiCMDCONTRACTOR HEAD OFFICE : PROJECT HOUSE · THE DRIVE . WORTHING · WEST SUSS EX · BN11 SLL TEL: 0903 700321

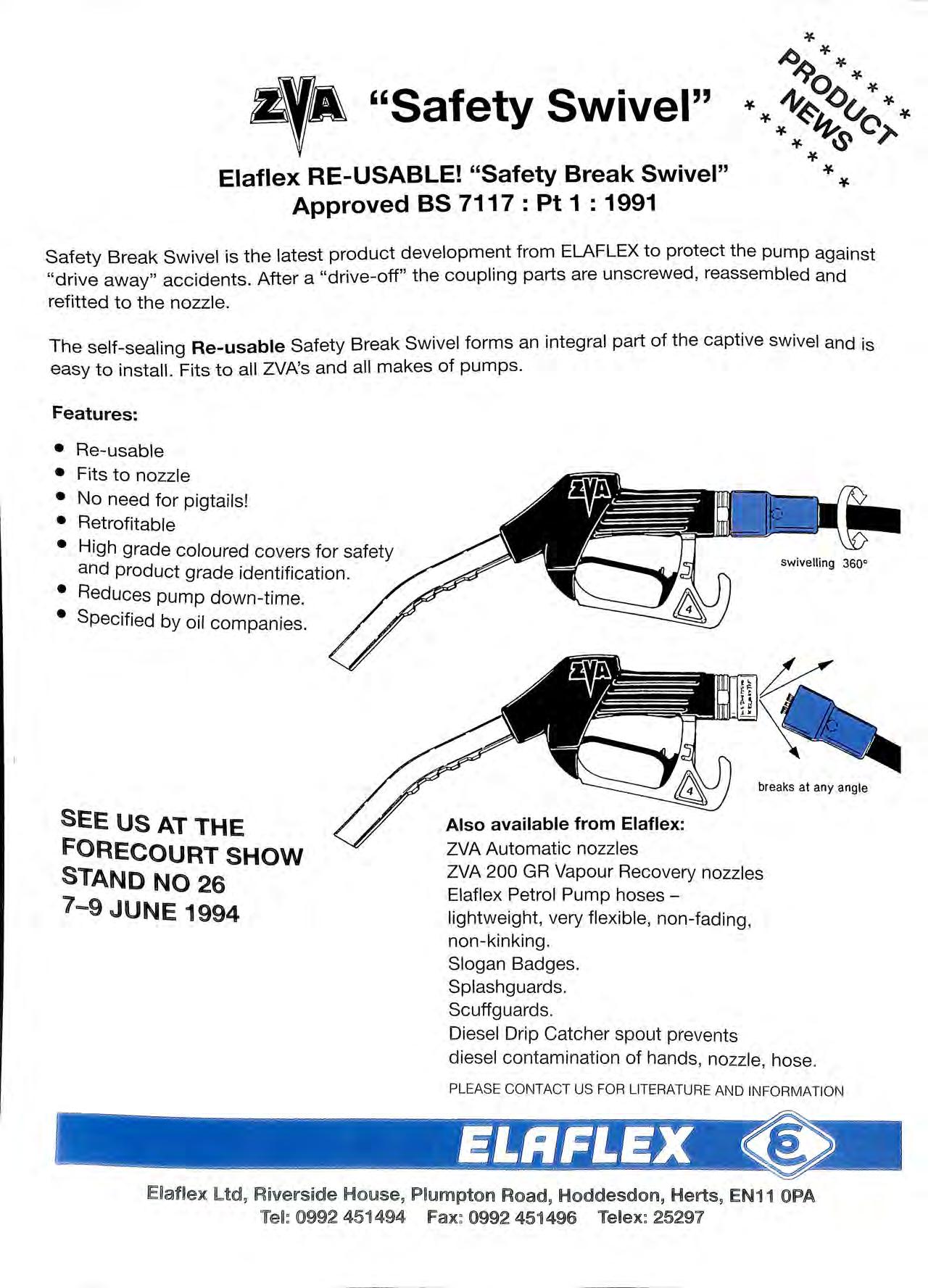

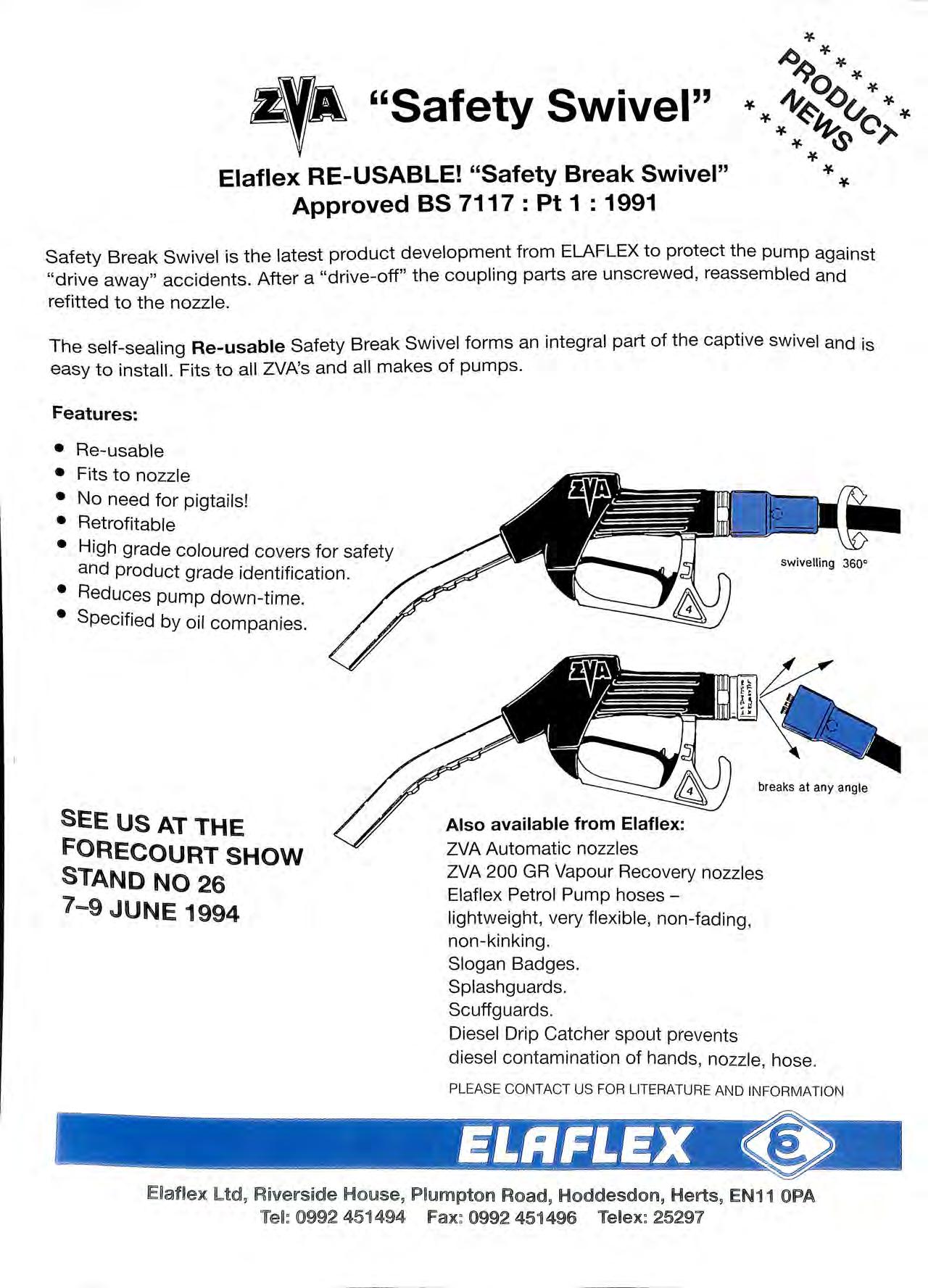

zy1A "Safety Swivel" Elaflex RE-USABLE! "Safety Break Swivel" Approved BS 7117 : Pt 1 : 1991 Safety Break Swivel is the latest product development from ELAFLEX to protect the pump against " drive away" accidents. After a "drive off" the coupling parts are unscrewed, reassembled and refitted to the nozzle. The self-sealing Re-usable Safety Break Swivel forms an integral part of the captive swivel and is easy to install. Fits to all ZVA's and all makes of pumps. Features: • Re-usable • Fits to nozzle • No need for pigtails! • Retrofitable • High grade coloured covers for safety and product grade identification. • Reduces pump down-time. • Specified by oil companies. SEE US AT THE FOREC OURT S HOW STAN D NO 26 7-9 JUNE 1994 br eaks at any angle Also available from Elaflex : ZVA Automatic nozzles ZVA 200 GR Vapour Recovery nozzles Elaflex Petrol Pump hoses lightweight, very flexible, non-fading, non-kinking Slogan Badges Splashguards Scuffguards Diesel Drip Catcher spout prevents diesel contaminat ion of hands , nozzle , hose PL EAS E CONTAC T US FO R LITERATURE AN D INFORMAT IO N ltdi Riveirs ode H o 1UJ sei Ro adi H oddesdoni Herts i EN11 OPA 0992 45 1494 Faix: 0992 45 1496 Telex : 25297

Talking Point

As this edition goes to press, the whole Industry has united on all sides to fight the proposals made by the Department of Environment for the enforcement of the proposed VOC Emission Directives on stage 1. The D of E changed its mind and proposed not only a change of enforcing agency to the environmental health officer but has suggested this cost be borne by industry.

This Association, along with the PRA, the IP, UKPIA and Licensing Authorities have all condemned the proposals and are asking that the petroleum licensing authority be the enforcing authority.

Apart from the futility of having dual enforcement, it is a recipe for confusion and as has been suggested a public safety liability. The general proposals goes against the governments policy of stopping unfair burdens on business.

Let us hope that common sense prevails and a civil servant somewhere gets the message!

VOLUME33 Number2 MAY 1995 £8.00 (Free to Members) Contents TALKING POINT NOTES&NEWS PROSECUTIONS

TO EDITOR The Bulletin Published by the Association for Petroleum and Explosives Administration

company Limited by Guarantee registered in England No. 2261660 ISSN 0263 4597 17 18 22 23

LETTER

A

Opinions expressed in this Journal are not necessarily the views of the Association

THE NEED FOR LICENSING 24

NEW PIPE CONCEPT 27 OVERFILL PREVENTION 28 LEAK INVESTIGATION & REMEDIATION 30

NEW MEMBERS 34

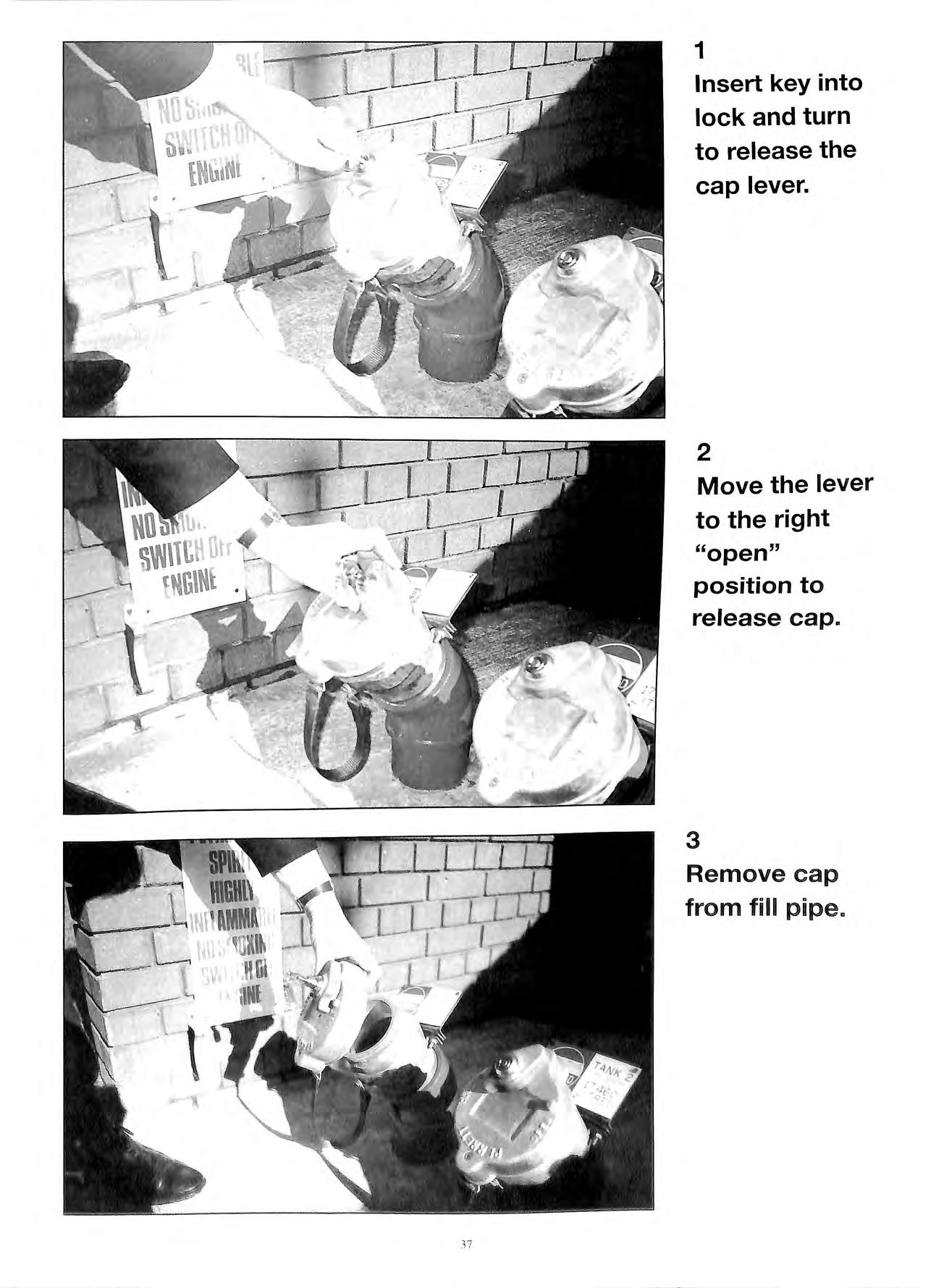

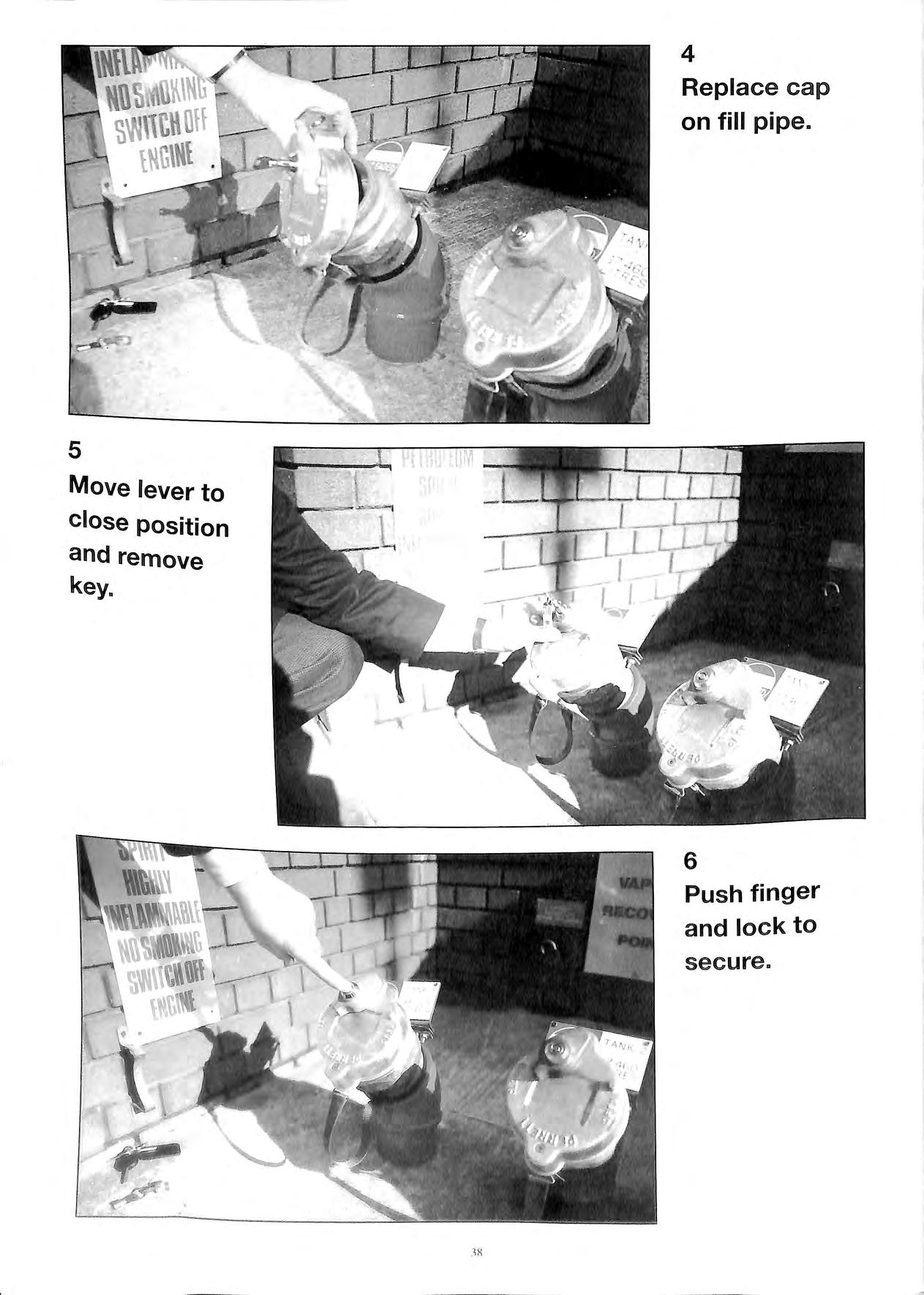

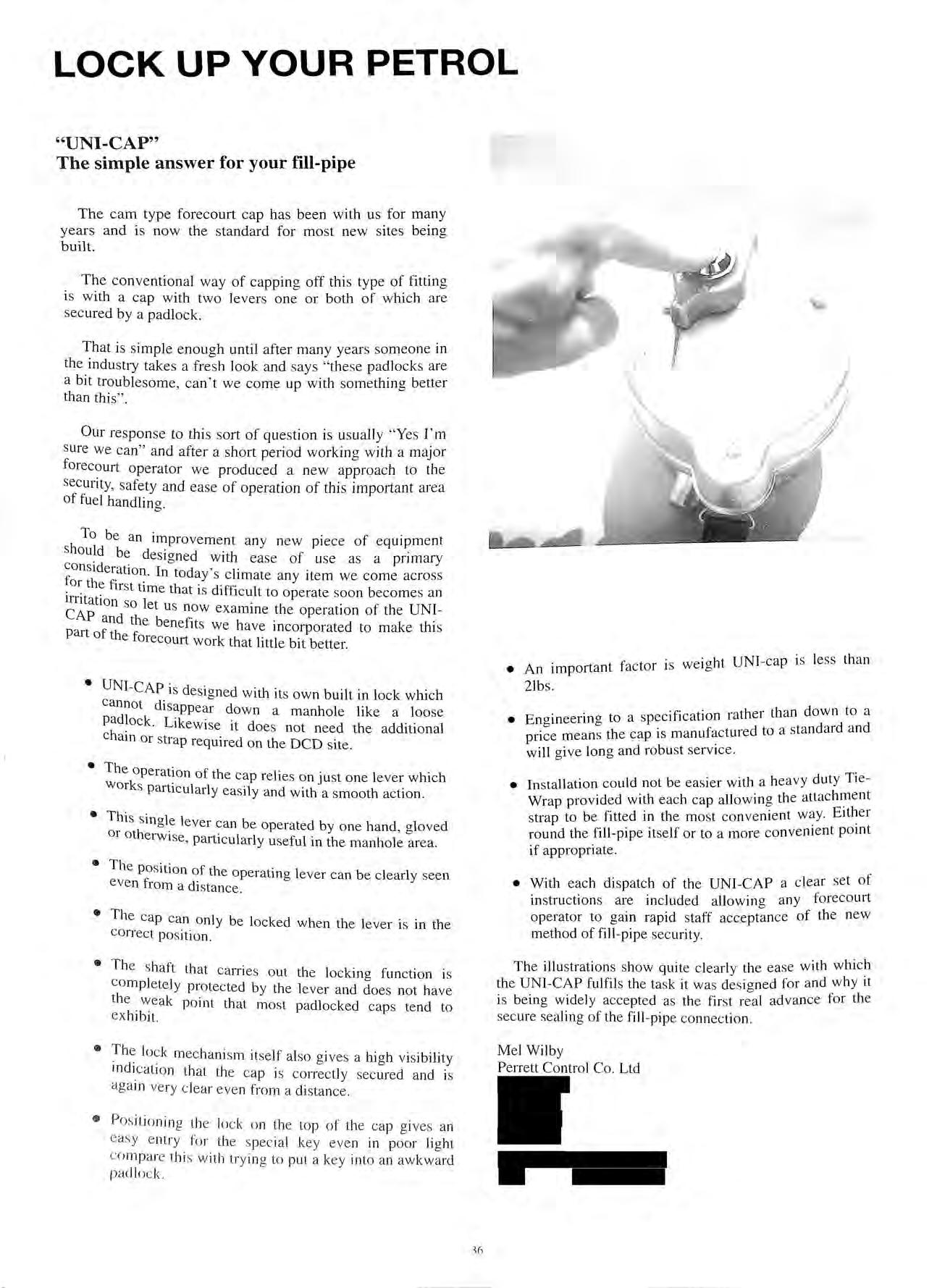

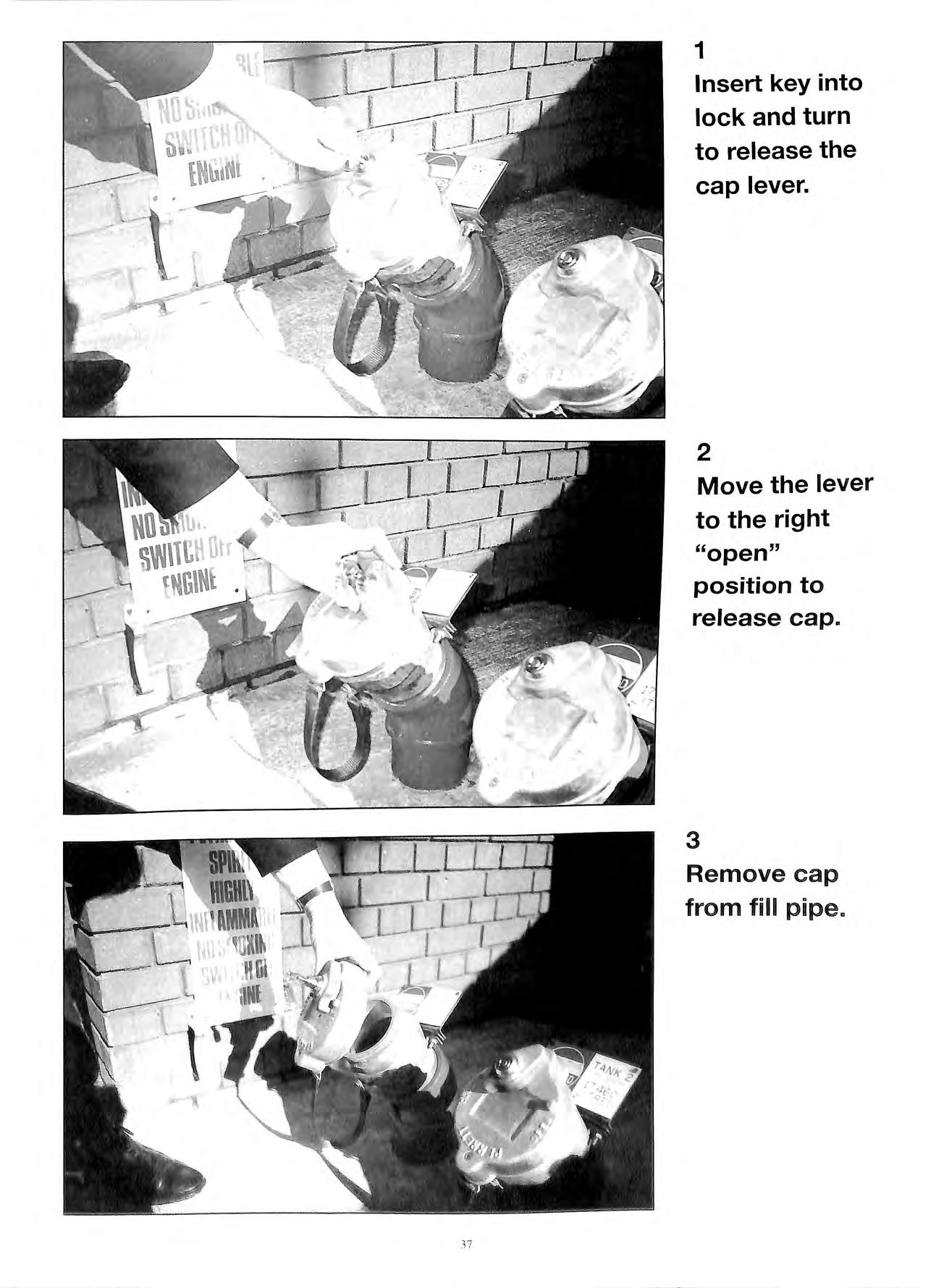

LOCK UP YOUR PETROL IRISH BRANCH E. Riney Texaco Ltd ADVERTISING SEC. R. G. Green Honorary Secretary: Mr. D. Bucknall EASTERN BRANCH Mrs B. Jacketts Cookson & Zinn Ltd 36 HUMBERSIDE BRANCH P. C. Lusmore MIDLAND BRANCH L. Lloyd Veeder Root NORTHERN BRANCH M. Silman Honorary Editor: Mr. J. A. J. Thompson. 17 NORTH WESTERN BRANCH H. Reid Pump Services (Manchester) Ltd SOUTHERN BRANCH J. Luke Membership Sl."crctary: Mr. B. J. Thompson

REQUIRES

INDUSTRY

The Association is currently playing a key role in shaping guidance for the safe keeping. of spirit at filling stations and is now looking to provide administrative support for its working groups, branches and council members.

In addition to this administration work, which will be interpretative as well as of a servicing nature, it is expected that the successful applicant will our databases and training programme and and advice to the council of the associat10n on maintaining its lead position.

This will be a challenging and exciting new position. Applicants will need to have excellent organisational and word processing skills and be able to present information and documents to a high standard.

Initially it is anticipated that the successful applicant will work from home and it is recognised that some help with office equipment may be needed.

A full driving licence and own transport would be an advantage.

The salary for this post which will be on a 2 year contract will be in the range of£ 11,250 -£ 13,000.

Please send C.V. to:Mr D. W. Bucknall

Humberside County Council,

If you wish to have a talk about this position please above. The closing date for applications 1 be Fnday the 30th June 1995.

FRANKLIN PUMPS

Franklin EI appointm ectnc Inc are pleased to announce the Product M.r Kavanagh to the Brendan K· lil their Petroleum Products D1v1s10n. Petroleum I has many years experience in the . n ustry lil Ireland and in recent years in Europe 111 gen.era.I. B_rendan will be responsible for the. Marketing <tnd D1stnbut1on of Frankl1.n'. FE p . S b ··bi p . d J h . s et10" u mers1 e umps an a so I e1r FX )) · f . • 100 motors and new Stage two Vapour Recovery system. Brendan is also a long time supporter of lhe APJ-·.A He may he contacted on Tel: 353 I 2865412 or htx i;; I 2866970.

APEA CONFERENCE AND EXHIBITION BIRMINGHAM

Please reserve these dates in your diary:- Monday and Tuesday 25 and 26 September 1995. These are the dates for the APEA Conference and Exhibition to be held at the Metropole hotel in Birmingham.

This year the exhibition will be larger than before will be on for two full days with workshops to the exhibition, the exhibition is being attended by all the Petrol Pump Manufacturers. The conference on the second day will be used to launch the new HSE Guidance on risk assessment and will have the first presentation on this subject to be given by the HSE. In addition new innovations and construction methods involving petrol station development are being presented for the first time, also included some views from other european countries to make this the premier event for forecourt engineering in Europe.

The Annual Pre Conference Dinner will also be held on Monday evening 25 September and details can be obtained from our Hon Secretary.

TANKER DRIVERS SACKED OVER JET 4-STAR FUEL FRAUD

CONOCO has terminated the contracts of two Jet service station operators and dismissed nine tanker drivers after an internal investigation found that unleaded petrol was beino mixed with four-star fuel and sold at the higher price. "'

The fraud, which could have damaged the engines of cars filling up with the fake four-star, was designed to take advantage of the lower tax on unleaded fuel.

Customs and Excise, which works out tax on fuel delivered to the station rather than that sold from the pumps, was collecting only the tax for unleaded fuel, about 25p a gallon less than on four-star petrol.

The drivers were paying premium price for cheap fuel and running the risk of damaging their engines while the retailer was picking up an extra 25p a gallon in profit.

IRISH BRANCH AGM

notes & news

THE APEA

AN ADMINISTRATOR TO HELP IT FORGE AHEAD IN ITS POSITION AS THE LEAD ASSOCIATION FOR THE DOWNSTREAM PETROLEUM

IK

Chairman: Vice Chairman: Secretary: Treasurer: Mr. Bill Flynn Mr Gabriel Howley Mr Nathaniel McCoy Mr Mark Elmore Branch representative is Mr Des Kavanagh Other members: Mr Brian ()"Grady Mr Dennis Whelan Mr Enda Riney Mr Dennis Bergin

EUROPEAN PETROLEUM ENGINEERING EXHIBITION & CONFERENCE

BERLIN 6 -8 APRIL 1995

The APEA recently assisted exhibition organisers Expoconsult with arrangements for the conference at the above event. The APEA also took a stand at the E.P.E. Exhibition to promote the Association.

The conference was held over two half day sessions and on each day was attended by over forty delegates from 14 countries.

Speakers at the Thursday afternoon programme were:

Bernard Barnette of Elf Antar, France with a presentation on Transportable Service Stations for Europe;

Jamie Thompson of L.F.C.D.A., UK with a presentation on the need for Common Safety Standards at European Service Stations;

Richard Smith of Marley Pumps, USA with a presentation on the advantages of using Submersible Pumping Systems.

Speakers at the Friday morning programme were: Jari from Finland with a presentation on the of underground elements of the service station;

Dr Falckenberg of Elaflex, Germany with a presentation of the current developments with Stao-e 2 Vapour Balancing; e

John of Groundwater Technology Ltd., UK with a presentation on Leak Investigation and Cost Effective Cleanup.

The exhibition was held alongside two other exhibitions over three days, although only 23 stands were present in the E.P.E. hall other specialist forecourt equipment exhibitors were to be found in the adjacent Tankstelle exh1b1t1on (similar to the UK Forecourt Show).

APEA stand attracted a large variety of v1s1tors 111clud111g those members visiting the exhibition from the l!K and mainland Europe. A number of new members were signed up at the exhibition with several more people taking _the APEA Info packs for consideration. Several of the present expressed an interest in the possibility of c1ttend111g the APEA exhibition in September.

HEALTH AND SAFETY AT WORK ETC. ACT 1974; PETROLEUM LICENCE APPEAL. VIEWS FARM, GREAT MILTON, OXFORDSIDRE. DETERMINATION

In May of 1994 the licensee of the above private Petroleum Installation appealed against Oxfordshire County Councils Petroleum Licence Condition which required tanks over thirty years old to be tested annually. Views Farm lies on a minor road West of the Village Great Milton and about 7 miles East of Oxford. In addition to general farming, there are six holiday flats converted from farm buildings. The Petroleum Installation consists of a single underoround tank of about five hundred and thirty gallons capacity with a hand operated mechanical pump mounted above it in a small padlocked shed.

Deliveries of four hundred gallons are made every six to eight weeks. Petroleum is not for but is in cars and agricultural equipment associated with the !he age of the tank was unknown. Similarly the exact dimensi?ns and orientation of the tank and the nature of the matenals surroundino it are similarly unknown. The licensee's submissionewas based firstly on the cost and secondly on his belief that inventory checking alone would be an adequate indication of a leak from his underground petroleum tank In his submission he also cited the Governments deregulation policy towards small businesses. As neither party sought a formal hearing, one of Her Majesty's Inspectors of Health and Safety was appointed to enquire into and report on. the circumstances of the appeal and for that purpose submissions from both parties and carried out a site inspection. This resulted in a report to the Secretary of State.

The relevant factors contained within the report were:The tank is of unknown age and is stored in unknown ground conditions.

The tank has not been tested since 1984.

Continuous inventory checking has not been carried out to an appropriate level of accuracy.

The tank is relatively small, five hundred and thi1ty gallons. The water table is relatively low and the strata fractured. There are 110 known nu\jor under?round voids in the vicinity which is rural and well ventilated.

TI · ·t ll·it1011 is not for public use. but there are offices 1e ms a ' T and holiday flats in close prox11111ty to the tac1 ity.

ESSO PURCHASE FORECOURT FACTS 2000

Esso has oiven the 0() ahead t· th . I . 1 e e , or e imp ernentat1on o · Forecourt Facts 2000 on a further 37 sites.

After trialling the Forecourt Facts 2000 Back Office system from Meggitt Petroleum Systems IMPS) at 5 sites. has commissioned a 37 sites with bespoke features. MPS has been work111g closely with Esso to -;upply a_ suitable product. and will continue to develop the -;ystem tor Esso and support the 42 installations in the corning months.

Based upon these factors part of the inspectors cl · 1ce 1 "t is ·ipparent to me that as the tank 1s nl state : s11 • ' k aoe but at least twenty years old, should be tested un nown ' e ' · · cl". tely It is equally apparent that 1t 1s unacceptable 1111me 1a ·· · . for it to remain free of any test requirement. The · t e C)I. s•'p·11·,·1te leoislat1on (the Water Resources Act ex1s enc · ' e 1991 ) guards against the hazards of release into water courses. The size_ ol the_ tank. the absence of · \. 01·cts· ,·111d nature ot the slle argue against the ma101 · · of test recommended tor prl'm1ses. but thl' proximity of offices the public 111 this case argue strongly for a regular test .

The inspectors report concluded with tht' recommendation that the appeal should he allowed subject to the following t'omlitiPn:

·The tanks should he tested for leakage in the manor prescribed hy the licensing a_uthority and thereafter al in ten als not t'xcccd111g two years".

I I i I I

Jl)

PILLOWS

Oil absorbent pillows are used throughout industry to collect floating oil in interceptors and drainage culverts. The pillows attract and absorbs oil until they are an unsightly hazardous mess which has to be carefully removed and incinerated.

Formula One Bioremediation Pillows are impregnated with oil digesting bacteria and will preferentially absorb oil and cause accelerated breakdown of absorbed hydrocarbons under bacterial action. Under normal interceptor conditions the pillows remain clean and exhausted pillows are easily disposed of since the oil and grease is rendered harmless by bacterial action.

Designed for continuous absorption of small amounts of oil but may also be used to absorb excess oil from casual spillage.

Technical Information

The pillows are constructed from specially treated oleophillic properties together with hydrophobic filament yarn. The choice of fibre and the construction has been optimised to give an exceptionally high void volume of 9_2% for maximum absorption. The hydrophobic, anti-static fibre treatment enables all the void volume to be used for absorbing oil whilst in contact with water.

. bonding provides high tensile strength, dimensional stability and prevents breakdown when fully w.ith oil. Nutrients support the action of natural bactena m promoting degradation of absorbed oil and grease.

. The enhanced naturally occurrina bacteria used in the pillows evolved from trials carried on the Exxon Valdez in Prince William Sound, Alaska in I989. They are used t . . b · ex ens1vely m the USA for auamented ioreclamatio f rf o b n o su ace 011 contaminated soil. They have approved by the US Environmental Protection Aaency n.) and a r . b Na re Isted 111 the Emergency Response files of the t1onal Contingency Plan (NCPJ.

Other features:-

• Easily install d d . P d. · e an needs no mamtenance other than eno 1c repla ( cement approx. every 6 months)

• Product is saf d · ·' e an needs no Haz-chem labelling

• Non toxic

• Easy t d" 0 Ispose of after use

Further inform t" 537. Ascot a.ion. Formula One Marketing, PO Box · Bei kshire. SLS 9TP. Telephone 01344 484965.

DESIGN AND OPERATION OF TRUCK COMPUTER SYSTEMS FOR ROAD TANKERS

Model Code of Safe Practice Part 20

The demand for road tanker on-hoard computer (OTC! '-V<.,lt"llJs JS. developing rapidly in Europe OTC systems llli<"JI <He with equipment al loading terminals and al service

stations, provide tractor/trailer monitoring and control, and transmit data to central point for routing, despatch control, invoicing etc. Since most petroleum terminals and some service stations cater for more than one road tanker operator, guidelines are required to ensure the maximum degree of compatibility and safe operation of the OTC equipment being installed by the various users.

This Code of Practice has therefore been prepared with the active participation of representatives drawn from both European oil industry and OTC equipment manufacturers. It provides guidance on the design and operation of truckbased OTC systems. Adherence to its recommendations will enable systems to be compatible and provide a hiah degree of interoperability without applying unreasonable constraints or inhibiting further technical development.

0471957097 104pp January 1995 £65.00 Available from the Institute ofPetroleum, London, UK.

NORTH WEST BRANCH - ANNUAL GENERAL MEETING

Twenty-two members attended the North West branch AGM on 21.3.95. In the business section of the meeting, the following were elected

Chairman: Mr Mel Churm (Cameron Technical Services Ltd)

Secretary: Mr Harry Reid (Pump Services (Manchester) Ltd)

Treasurer: Mr J O'Reilly (Pump Services (Manchester) Ltd)

Branch Rep: Mr H Reid (Pump Services (Manchester) Ltd)

Committee: Mr Mike Marczynski (Tankclean Ltd) Mr Martyn Jowett (Cheshire Fire Brigade)

A presentation was given by Mr John Stevens, Operations Manager North, of Groundwater Technology Ltd covering site contamination and remediation techniques available to carry out site clean ups. The suitability, effectiveness, timescale and cost of the different approaches were presented. Lively discussion followed concerning responsibility, authority and risk when confronted with site leakage and contammat10n. This was a new subject for the branch and proved to be of interest and value to the members.

Harry Reid updated the members on the progress of the new guidance to replace HS( G J41 . This covered the work done to date, the scope and format of the Technical Coordinating Body guidance document. the sectors that are dealing with the various subjects which are to be included in the document, a record of the meetings held (and those planned, and risk assessment. This generated a great deal of valuable discussion and exchange of ideas between licensing authorities and contractors.

The next meeting is scheduled for the 14th June when the main will he from ERA Technology and will include a summary of the services they provide and rrincipal areas of expertise. test and assessment for forecourt machinery. and testing polymer pipev. ork for rurol station usage .

BIOREMEDIATION OIL ABSORBENT

'.II

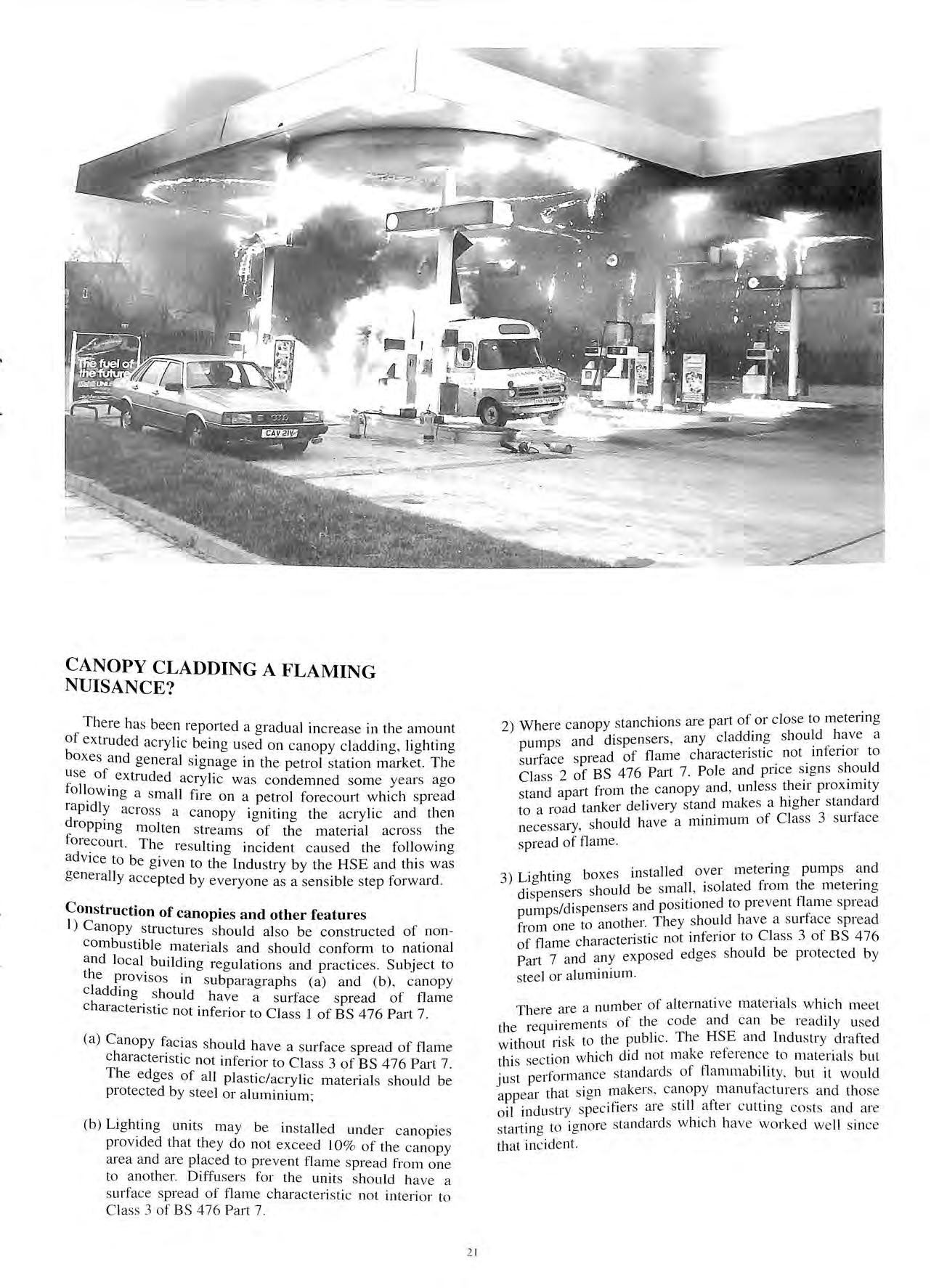

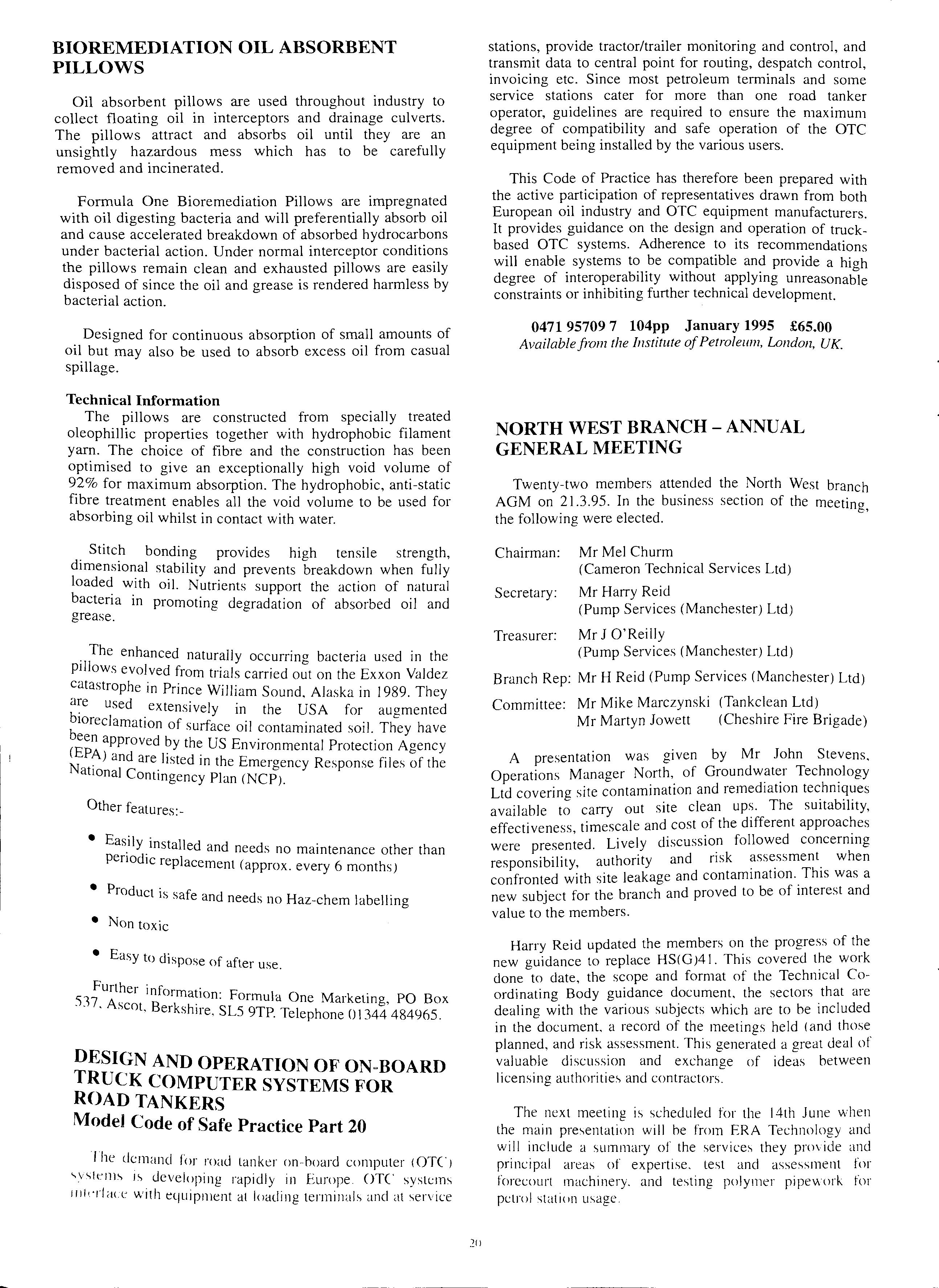

CANOPY CLADDING A FLAMING NUISANCE?

There has been reported d of extruded a . I' b . a gia ual mcrease 111 the amount boxes and y tc emg used on canopy cladding, lighting use of e t"' dedral signage 111 the petrol station market. The x ru e acryhc d followin was con emned some years aao g a small fire 01 1 f "' rapid ly 1 a pet1 o orecourt whJCh spread ac1oss a cano . 1 dropping 1 PY igmtmg t 1e acryhc and then mo ten streai f h · forecourt Th _ . ' ns. o. t e matenal across the advice to. b e 1esult111g mc1dent caused the following <>enerall e given to the Industry by the HSE and this was "' y accepted by everyone as a sensible step forward.

Construction of . I) C canopies and other features

c~i~~~i~ti~\~ctures_. shou ld also be constructed of non- and local b ials and should conform to national the p. Ll1 mg regulations and practices. Subject to I OVISOS 111 sub h cladding sh Id pai·agrap s_ (a) and (b), canopy charactei;sticou . have a surface spread of flame not mfenor to Class 1 of BS 476 Part 7.

(a) Canopy facias sho Id characteristic uf have a surface spread of flame The edges 111 en?r to Cl.ass 3 of BS 476 Part 7. protected b t 11 pl_ast1c/~cryhc material s should be Y s ee 01 aJumm1um;

(b) Lightin<> units ma b . "' y e mstalled under cano ies provided that th ey do not exceed l 0'11 f I p area and are placed to preven t flame 1ef.canopy to anoth o·r+ 1om one er: t .u sers for the units should have a su1 face sp1ead of flame characterist ic not interi o. t Class 3 of BS 476 Part 7. 1 0

2) Where canopy stanchions are part of or close to metering pumps and dispensers, any cladding should have a surface spread of flame characteristic not inferior to Class 2 of BS 476 Part 7. Pole and price signs should stand apart from the canopy and , unless their proximity to a road tanker delivery stand makes a higher standard necessary, shou ld have a minimum of C lass 3 surface spread of flam e

3) Lighting boxes installed over metering pumps and dispensers should be small , isolated from the metering pumps/dispensers and positioned to prevent flame spread from one to another. They should have a surface spread of flame characteristic not inferior to Class 3 of BS 4 76 Part 7 and any exposed edges should be protected by steel or aluminium.

There are a number of alternative mate ri als which mee t the requirements of the code and can be readily used without risk to the pubhc. The HSE and Indu stry drafted th is section which did not make reference to material s but just perform ance standard s of flammabilit y, but it would appear that sign makers, canopy manufacture rs and those oil industry specifiers are still after c utting costs and are starting to ignore sta ndards which hav e worked we ll sin ce that incide nt.

.J

2 1

Prosecutions

EXPLOSIVES (FIREWORKS) PROSECUTION

At Gloucester Magistrates Court on 13th March 1995 Mohammed Amjad Shafi pleaded guilty to the supply of fireworks to a boy under the age of 16 on the 27th October 1994, contrary to the Fireworks (Safety) Regulations 1986. Mr Shafi was fined £500.

The prosecution was a result of a survey carried out by the Trading Standards Department of Gloucestershire County Council. A 13 year-old boy, under strict supervision of Trading Standards officers, entered Mr Shafi's shop and he chose a selection box of fireworks for £4.95. He was not asked his age or for any identification, he was obviously under the age of 16, and Mr Shafi should not have made the sale.

MOBIL OIL SUBSIDIARY IN COURT

Prime Garages Limited were recently prosecuted by Essex County Council Trading Standards for offences under The Petroleum (Consolidation) Act 1928 Section 1(3) and The Health & Safety Act 1974 Section 33(3).

A Petroleum Officer was called to the company's Witham premises in an attempt to find a petroleum leakage as a manhole was contaminated with persistent petroleum vapour.

A contractor on the site found a length of box section meta! which had been jammed into the overflow pipe thus keepmg permanently open the overflow valve.

'!'he company were unable to provide the required site register to identify notification of work to be carried out or the contractor concerned.

_The company were represented by Counsel and pleaded guilty to a breach of the site licence conditions.

They f" Wit med £300 with £ 150 prosecution costs at ham Magistrates' Court on 15th March 1995.

YORKSHIRE & HUMBERSIDE BRANCHAGM

its TAhe Yorkshire & Humberside Branch of the APEA held nnual Gen I M . SYFRS T . . era eetmg on 28th March I 995 at the rammg Centre, Sheffield.

The meeting corn was attended by thirty members and menced with th b . . reports and 1 . e usmess which included the were all r _ le ection of the officers. The serving officers e e ected to serve the Branch again for 1995/96:

Chairman

Treasurer

Secretary & Branch Representative Auditor

Clive Sweeting David James Philip Lusmore Peter Walker

After the business meeting there followed a seminar on tank and pipework testing with local tank testing companies

A local authority viewpoint on the H:4uirement for testing was also given. At the conclusion of 1hl' presentations a yuestion time session was held in which 1lw llll:"lllbers keenly participated. The meeting closed with I lw < ha1nnan thanking the speakers and memhers for a very , 11il1w,1<1st11

OPW61- SO 400C VAPOUR TIGHT OVERFILL PREVENTION VALVE

US Manufacturers of Overfill Prevention Valves, have been required to provide a vapour-tight version to fulfil CARB and San Diego Air Pollution Control District Regulations.

It should be noted that these areas mandate both Stage J and Stage 2 Vapour Recovery on all service stations, and the requirement for vapour tight OPV's is to specifically minimise Fugative Hydrocarbon Emission, rather than to solve UST vapour pressure problems caused by inefficient Stage 1B manifolded systems.

Both the CARB test and the San Diego Test require a 90 day pressure decay trial, and the San Diego test is considered the more vigorous, requiring a so called "10 inch" test over 90 days. This entails installing the valve leaving for 90 days, and then testing the whole system fo; vapour leakage under I O" wcg pressure. Zero leakage is required.

To date, only ONE manufacturer has achieved both the CARB and the San Diego Certification. The OPW 61 so 400C successfully passed the latter in December I 994 and is now available for installation in the UK.

What was a very minimal leak path, through the float linkage, has been solved by modifying the dynamic sealing arrangement in the internal pivot and shaft area. In addition, cold weld bonding compound is supplied for installing top and bottom tubes.

Specifiers of Overfill Prevention Valves should check that the valve they are installing has been certified vapour tight to the above Approval Standards.

It is also worth recording, that the OPW 6 I SO overfill Prevention Valve, continues to be the single most reliable mechanical valve on the market, with a reliability record directly proportional to the quality of the installer.

LINK HAMPSON THE DISTRIBUTION CHAIN IS RE-FORGED

Link Hampson. a division of UTC, has built an enviable reputation, over the last thirty-five years, for the supply _of quality parts to the petroleum forecourt industry. Our aim has always been to provide the best possible equipment. and the best customer service, to the UK Retail market.

Link Hampson has recently restructured its organization to optimize this approach. Alan Gee retired at the end of March after 30 years sterling service with Link Hampson. David Brewer is now concentrating on the OPW range of Distribution products.

We have recently recruited Ged Norris who will focus his efforts on the Retail side of our business, Ged was previously with Emco Wheaton for more than twenty years and has considerable experience in the petroleum industry. He is presently serving as chairman of the PVE/1 in panel. which formulates the official UK viewpoint on m erfill prevention devices for the European standard which is currently being drafted,

ll

Link Hampson represent OPW Fuelling Components and EBW International , both of whom are leading manufacturers in the Retail sector. Our mi ssion is to provide comprehensive and innovative solutions, fast efficient service and technically superior products for the safe handling of petroleum liquid and vapour. Whether you require the latest information on vapour-tight overfill valves , or advice on installation of Stage lB vapour recovery equipment to comply with the EC directive , Link Hampson will be able to help you.

Letter to the Editor

Dear Sir,

I noted with great interest the report of pipe joint failur e s in polyethelene pipe which featured in the February issue As we were involved rn one of the two site s I feel some further information would be of interest to your readers.

We , as cont1:actors, put together the original offset fill sy stem e arly in 1993 On completion of the works the system as a whole failed to hold pre ssure. Despite several te sts being applied it ultimately would not pass the test required by the local Petroleum Officer.

The manufacturer of the pipework s ystem decided to replace the offset fill s in their entirety, a differe nt sy ste m was brouaht toaethe1· seve · 1 · I b · · b b ia palls were , eheve imported from Europe.

In view of the previous failure of the system the oil company concerned, quite rightly, insisted that the manufacturer be responsible for the installation through to its ' conclusion. The manufacturers ' staff were on site throughout all of the remaining works to supervise all of the assembly procedures and ensure that the system as a whole would pass the tests which were finally applied. We can be confident therefore that pipe preparation was carried out as instructed. Recent investigations indicate that proper fusion did not occur, indeed this was found on several joints. Once full excavation took place a number of other problems were revealed all of which are , I understand, being scrutinised elsewhe;e and no doubt will be reported on in due course.

One lesson to be learned, I believe, is that the problem as a whole has to be understood before jumping to conclusions as to who is to bl ame

As far as the rest of the report was concerned I believe th at this contains very sensible comments, a well thought out carefully manufactured, thoroughly tested product, ' · · d proper backed up with suitable techmcal expertise an . h l d 'th an installat10n tra1mna procedures will , w en coup e wi by an bestablished contractor whose skilled engineers are . . 'll d l' an end product properly motivated and trained wi e iver which meets the need s of the market place. I feel sure that all of your readers will subscribe to that view

Yours faithfully, K. S. Holmes Installation Manager Gilbarco

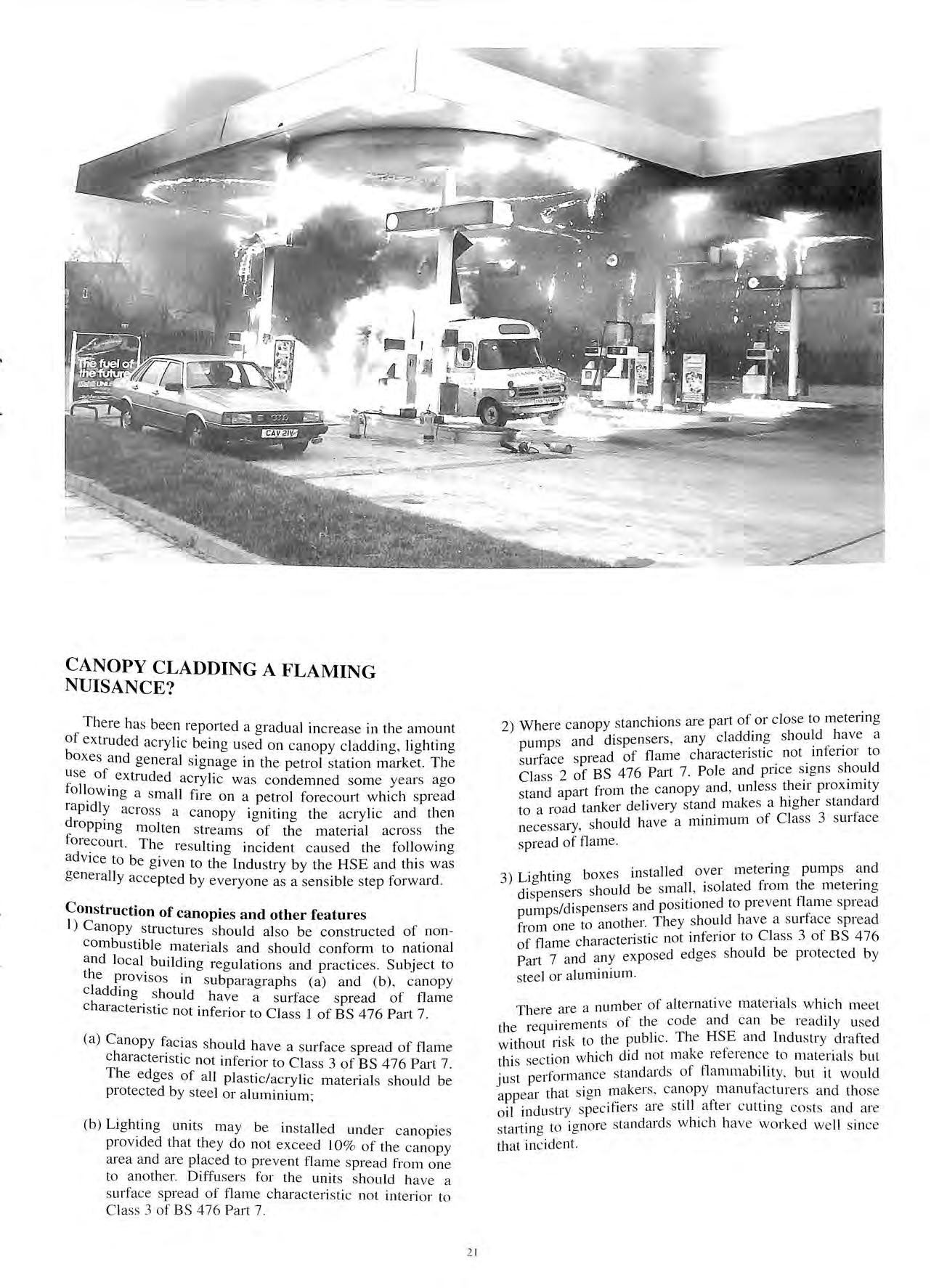

TestNW VEHICLE INCLUDES STATE OF THE ART ELECTRONICS TO PROVIDE INSTANTANEOU S DATA ON THE CONDITION Tank leak detection saves more OF THE TANK(S) UST 2000P TEST IS CARRIED OUT ON THE TANK CONTAINING PRODUCT VEHI CLE IS EQUIPPED TO CARRY OUT LINE TESTS than just money concern a re underground petrol storage tanks should be leakfree. equirement to run down the tank(s) or uplift * There 1s nor h disposal of product to fill with water, a_nd ence no contaminated water required nd ex erienced staff carry out the work in * Health & Safety requirements * The test method cannot harm the tank as no pressure is created or exerted on the tank shell or product * This test method does not involve any o ve rfill operation TestNW Test Nort h West U mited, E1, Cass idy Courrti Ka n sas Ave ntU e 9 Man(C h esteir M5 2QW 061 8771969 Fax: 8481193

THE NEED FOR LICENSING

By. Bryan Catcheside Senior Petroleum Inspector London Fire Brigade

This burgeoning organization, the APEA, includes in its membership practitioners whose skills we, as petroleum inspectors, have come to admire and respect over the years.

• There is the architect who ingeniously squeezes the proverbial quart into the pint pot.

• The manufacturer and his design team whose innovation continues to advance the science of storage and handling of a very dangerous material.

• The installation contractor who lays a veritable "Clapham Junction" of pipework with remarkable accuracy and precision.

• And the oil company engineer who unenviably walks that perilous tightrope between the requirements of the licensing authority on the one hand, and the dictates of his marketing overlords on the other.

So where does the humble petroleum inspector fit into this scenario? Perhaps it is sometimes overlooked that this much maligned individual who, in some quarters present company excepted of course! might be regarded as a great deal lower than the angels, and just a little higher than a traffic warden, in fact represents the interests of our absent guest, all important member of the public. Licensing are the arbiters of public safety representing the interests of that two thirds of the adult population who a ?riving licence and, by inference. use petrol 1 mg stat10ns on a regular basis. That is no mean responsibility!

of first began to have its impact on the citizens ra a century and a half ago. Up until then primitive whale, seal and fish oils were used to fuel the oil as m at that time. The introduction of petroleum oils new fuel for the more advanced type of oil sue as the D I becorn· up ex and the Ventas which were mg avallable h d 1 As the d saw t e ec me of the fatty oils as fuels. emand for pet 1 ·1 in their d . ro eum 01 increased the oil barons es1re to d ' ' their crude .1 uce as much kerosme as possible from gasoline in : mcorp_orated large proportions of heavy highly flam ebir kerosme fractions rendering the product ma le and d spec1f1cation st· angerous to store. The lack of flashpoint res. notably a prescribed minimum I , . u te Ill ma oss of life which . . ny serious f1res and a widespread campaigned was documented in a national press which C vigorously f 1862 · control. senes of A ·t. saw. the mtroduction of the first of a . . c s controllmg pet. 1 . h . . . m1111mum fl· ·h 10 eum wn m1tially a as pomt of 730F b . '. , London·s first p t 1 emg prescn bed and · e ro eum Inspectorate came into being.

Now there is 'l t· · b 1 replace the. '..' c.e1 am ocy ol_op1111011 which seeks to Ii h cun cnt and long stand mg system of petroleum censmo y IO'"ll tl I e '"'' dU 1ont1es Wit 1 self-regulation ·md I pr orose t< 1 t I · · ' .• ·. > pu o l 11s meeting today the proposition that the ' .ise l<>r self · I · · · · · -regu at1<m 1s tlawed and that the current

system of licensing, though requmng overhaul, best represents the interests of the public and the industry alike.

Perhaps there are those who, as a result of technical advances and innovation, have become complacent about the dangers attached to petroleum spirit and thus interpret "prevention" in its other meaning, that is, "hindrance". It may, therefore, be as well to remind ourselves precisely what sort of "animal" we are dealing with and that petroleum spirit:

• Gives off flammable vapour at very low temperatures

• That the vapour is explosive at concentrations of 2-8% in air, which means that 1h pint of petrol in a drainage system may produce an explosive atmosphere for anything up to, and beyond, a mile.

• Is a pollutant.

• Is carcinogenic .

• Is anaesthetic.

• Has a high calorific value, burning with intense radiant heat.

The proponents for self-regulation argue that licensing is outmoded for the following reasons:-

I. That the present form of licensing under the Petroleum (Consolidation) Act produces inconsistency of approach from authority to authority.

2. That onerous and often unnecessary licence conditions are applied to premises which are subject to licensing.

3. That the concept of risk assessment relegates Petroleum Act approval of sites to the status of an unnecessary formality.

4. That the licensing of premises for the storage of petroleum places an undue burden of cost upon the industry.

5. That the petroleum industry is capable_ of _regulating itself in keeping with statutory safety gu1dehnes.

Well, Jet us take a closer look at those points upon which their argument is based.

Any progressive Licensing Authority would readily acknowledge that the Petroleum (Consolidation) 1928 and its associated regulations require a major overhaul and that this has been the case for some considerable t1111e · There has been inconsistency of approach in the policies _of various authorities and up and down the country with regard to hoth technical matters and the application of licence conditions hut. in the main. this has heen as a result

of the law itself which delegates to each licensing authority the responsibility to implement such requirements and conditions as it deems fit to ensure the safe keeping of petroleum spirit in its own specific area.

Since 1928 the growth of the industry, the advance of technology and marketing requirements and the nationwide mobility of contractors has rendered the Petroleum Act a vehicle for confusion and inconsistency and one has every sympathy with those who are critical of this aspect of the licensing system. Dinosaurs resistant to change, when clearly reform of the legislation is imperative, deserve the obscurity of extinction. However, there is clearly now an opportunity to combine the experience and advice of all disciplines associated with the industry to formulate more realistic and practical legislation reflecting modern day requirements but not at the expense of delegating the maintenance of standards of public safety to those who are directly influenced by market forces.

With regard to risk assessment I see its introduction as a welcome, important and progressive adjunct to a revised and upd?ted licensing procedure. Reflecting the identity and reqmrements relevant to specific licensed premises and licensing, together with an efficient and readily accessible appeals procedure, an even more effective means of risk management.

In today's whenever change is proposed, cost may always be 1dent1fied as a prime mover and, more often than not, the primary consideration. There are therefore two important considerations to be borne in proposing an alternative to the cuITent system of licensing.

Firstly, what price safety? There is a natural reluctance to commit capital to a safety policy because there is no visible productive return for such expenditure; in other words a positive preventative policy does not attract investment because its success manifests itself as an apparent negative! To the despair of the safety manager in industry for example, the general cry of his board of directors is "nothing ever goes wrong: there must be little risk; so why do we need to spend the money?"

But a member of the public is entitled to expect gove1:nment to apply high standards of safety at any premises to which he has lawful access. It is inevitable that institution and maintenance of those standards will mvolve cost.

The second major consideration must be the evaluation of the true cost of the alternative system, that of selfregulation.

In recent years we have witnessed the cost-related demise of in-house expertise in the oil companies. Design, and approval application, has been placed in the hands of companies; the lowest tender is accepted With _Imle heed to the ramifications regarding quality; and 0 11 engineer has become a rare species, with for ever larger areas. In consequence, direct sup.erv1s1on and quality control has been more difficult to mai t · · d 1· · n am an mes of communication more convoluted and to It is my contention that the negative ellects _of 111 the London area have been mitigated by of my own authority of monitoring all stages of 111stallat1on work on the premise that prevention must be pro-active and that critical aspects of installation work are permanently covered-over on completion and. as such. not

capable of further scrutiny. Only when an inspector is satisfied that the premises are to the requisite standard of completion will the necessary licence be issued.

An example of irregularities found by one of my teain of inspectors can be drawn from a recently developed flagship site with an associated convenience store where it was found that:

1. Disused tanks were being removed in a dangerous manner contrary to safety guidelines.

2. Drains were installed without trapped gullies.

3. A drainage run was found to be unconnected.

4. The petroleum separator was incorrectly installed.

5. Underpump connections were not to approved specification.

6. Interstitial space monitors were omitted.

All these points were discovered and as a res_ult of the direct intervention of the inspector dunng routme monitoring of the work in progress. This, therefore,. the question "in the event of the demise of the licensing system, who would assume the vital for expert in-house quality control?" It is my that the overall cost to the industry would be considerably higher than under the present licensing system manhours and expertise involved would, of necessity, mvolve an increase in staffing levels.

It is, however, with the concept of self-regulation as being an appropriate method of safe.ty that I fake full issue with those who advocate its mtroduct10n.

In this country we have an unwritten Constitutio? of which we are justly proud. Enshrined in that unwntten constitution is the doctrine of the. "freedom the individual", very laudable in its own nght and a prmc1ple that we would all defend.

H r to quote Nelson Mandela in a recent speech, oweve. 1 ,, "there are those who interpret freedom as icence unquote, licence in the wrong meaning of the word.

In recent months much has been1 ?ihven the I et by our captains of rndustry w 11c pomt-up examp es s · , , · d h I f II bi'J"ity 1 ·n the context ol self-1egulat10n an t e mman a a · tl f market forces. I count mysell amongst those 111 uence o It' 1 who contend that the whole of se -regu at1?n 1s an d · 111·cety which is bemg constantly undermmed by aca em1c · almost daily examples of its excesses.

The recent Audit Commission repo.rt on Fire Brigades I .. i·ecommended that greater emphasis be placed on fire ldS d" revention with a commensurate 1vers1on ot lunds to that of activity. by the very of the ·d must be pro-active and encourage dialogue not. WOI • d' may I yenture to suggest. the 1spens.mg or guidance notes from an office. only to emerge wearing a policeman's hat when a catastrophe has occurred.

The strength of the licensing system is that it is proactive and that it is directly administered in accmdance with the principles of good government. by a lucal authority as an independent arbiter or public safety.

As distinct from the concept of self-regulation the petroleum licence is an aide-memoir for the safe keeping of petroleum, enforceable at law. It can be tailored to reflect the conditions applicable to particular premises and updated to include alterations and modifications to the premises when they are completed to a prescribed standard.

It ensures that the premises are individually scrutinized and provides the medium for rapid feed-back and coordinated action in the event of:-

• suspected loss of stock.

• leakage.

• failure of items of equipment.

• problems associated with delivery and the associated conveyance regulations.

• complaints from members of the public.

In addition to the pro-active policy of close monitoring, the licence creates and maintains a continuing and all important dialogue regarding safety at the site for which it

is issued. Such dialogue may involve the licen see, contractors, architects and oil company engineers. Dialogue with the licensee occurs at least once annually through the medium of the annual inspection, and transfer of the licence enables the new licensee to have an instant overview of the requirements specific to his new premises.

Dialogue promotes on-going co-operation between the licensee and the licensing authority through the medium of the petroleum officer to maintain high , uniform standards of safety in the area concerned. (Appropriate revisions of legislation, previously mentioned, will ensure that uniformity is applied nationwide.)

In conclusion , I submit that the strengths of an updated licensing system would provide the necessary focus to optimize public safety, rather than the alternative selfmanagement system which would prove to be as expensive in application as it would be vague as a means of control.

' . ! - '.

I •

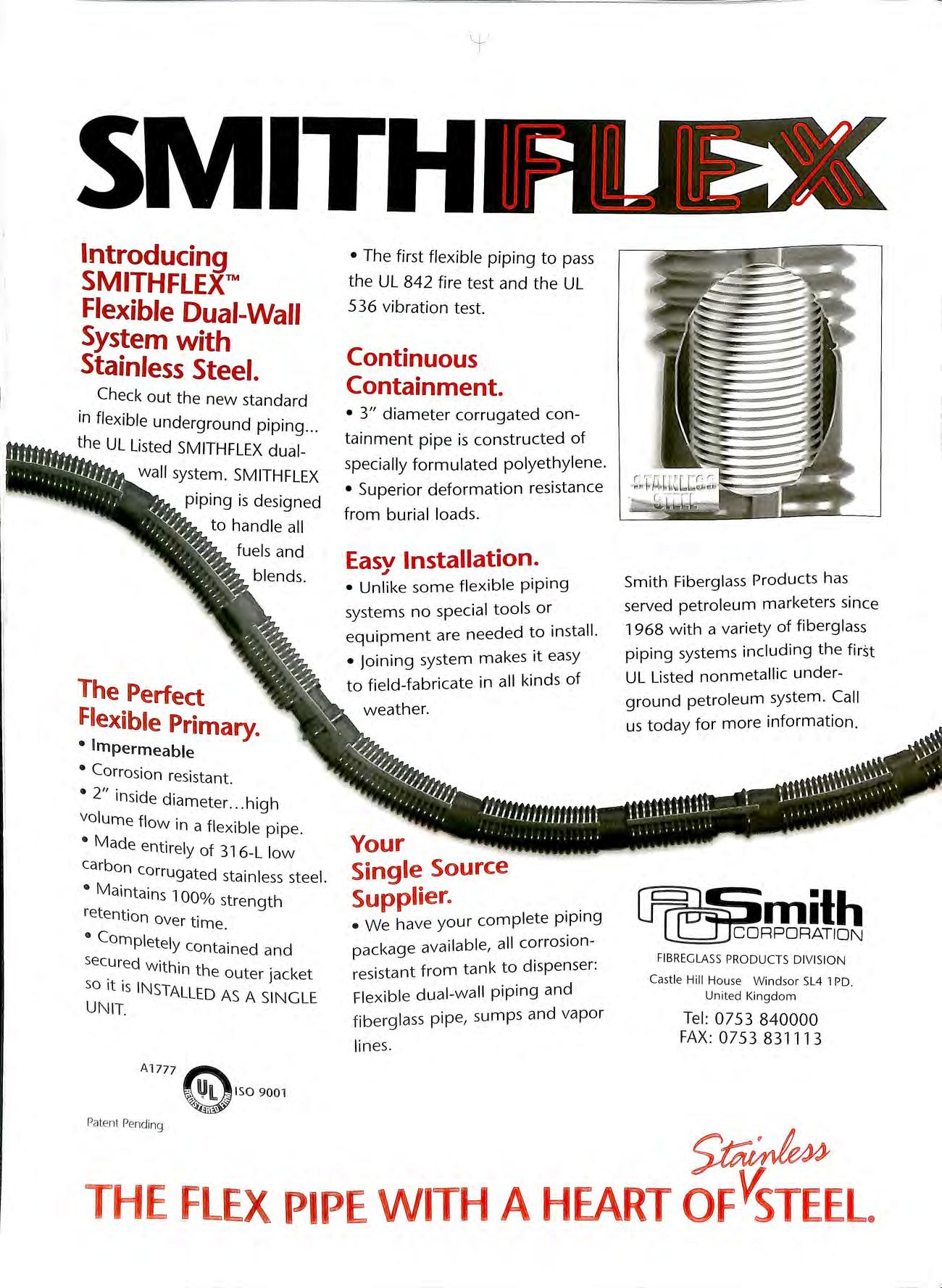

A NEW PIPING CONCEPT BECOMES REALITY

by John Munday

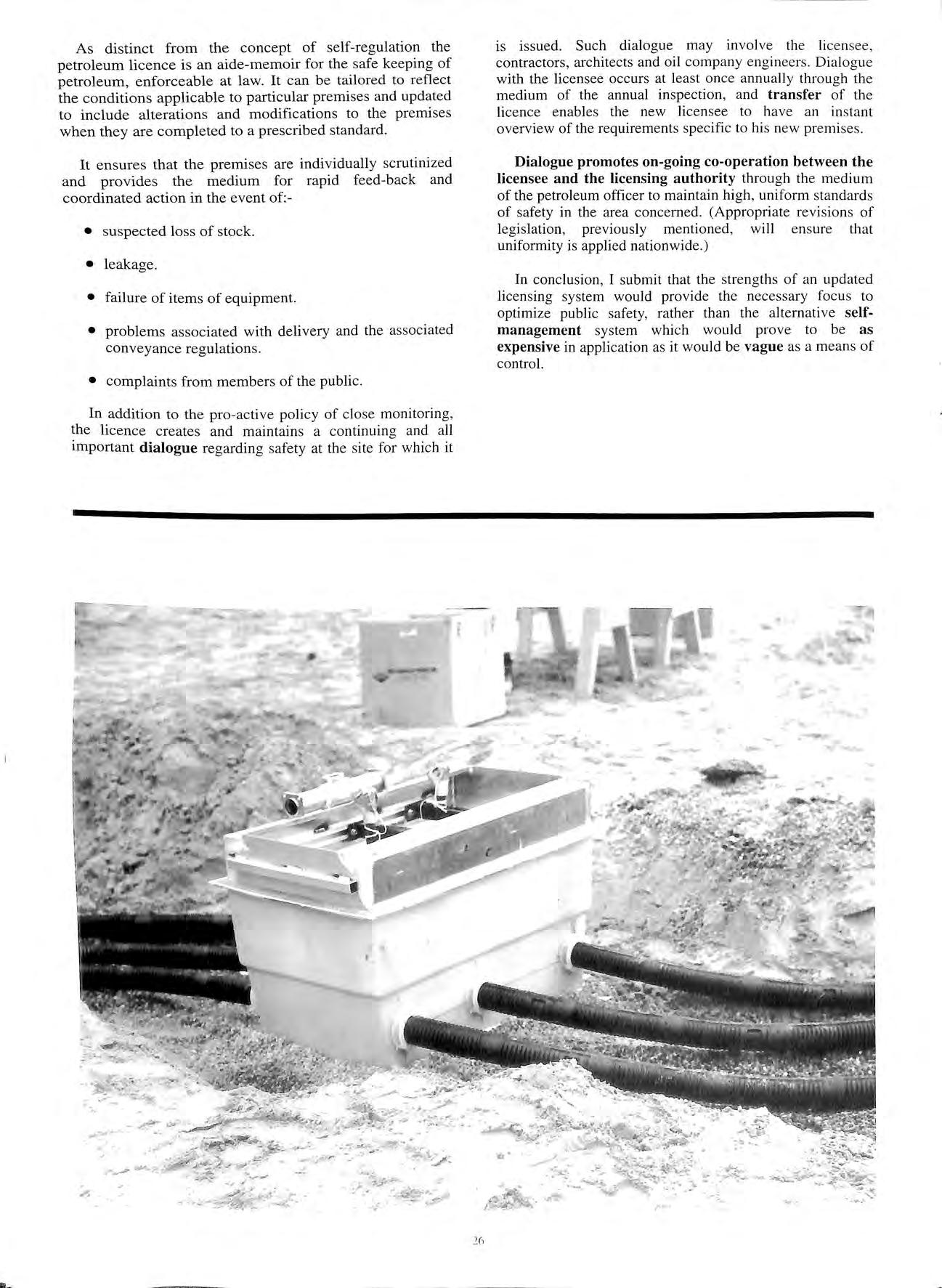

In recent years, around the world, service station owners and operators have become incre as ingly concerned about the piping and tanks beneath the ground at their premi ses. There are, of course, excellent reasons for this interest.

People of the world, as well as environmental agencies have ga ined increasing insight into .the problems of so il contamination and its effects. Peoples and governments need to work together to protec t the environment from contamination.

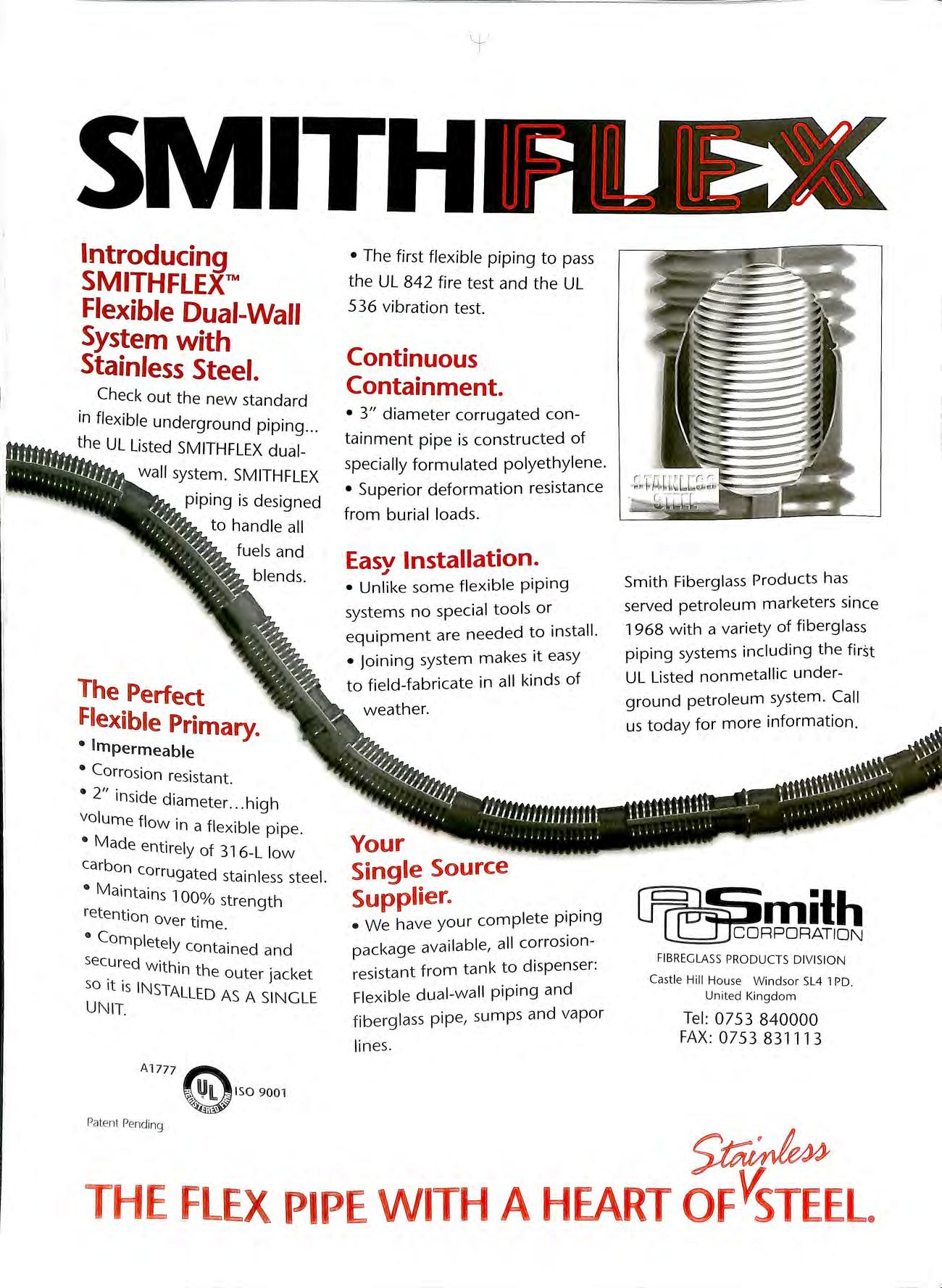

Smith Fiberglass Products Inc. , from the U.S.A. , h as served the service station indu stry for more than 25 years. The Company has recently introduced a new concept in flexible dual-wall underground piping; the new design addresses problems faced by the owner/operator and help s fulfil gove rnmental requirements.

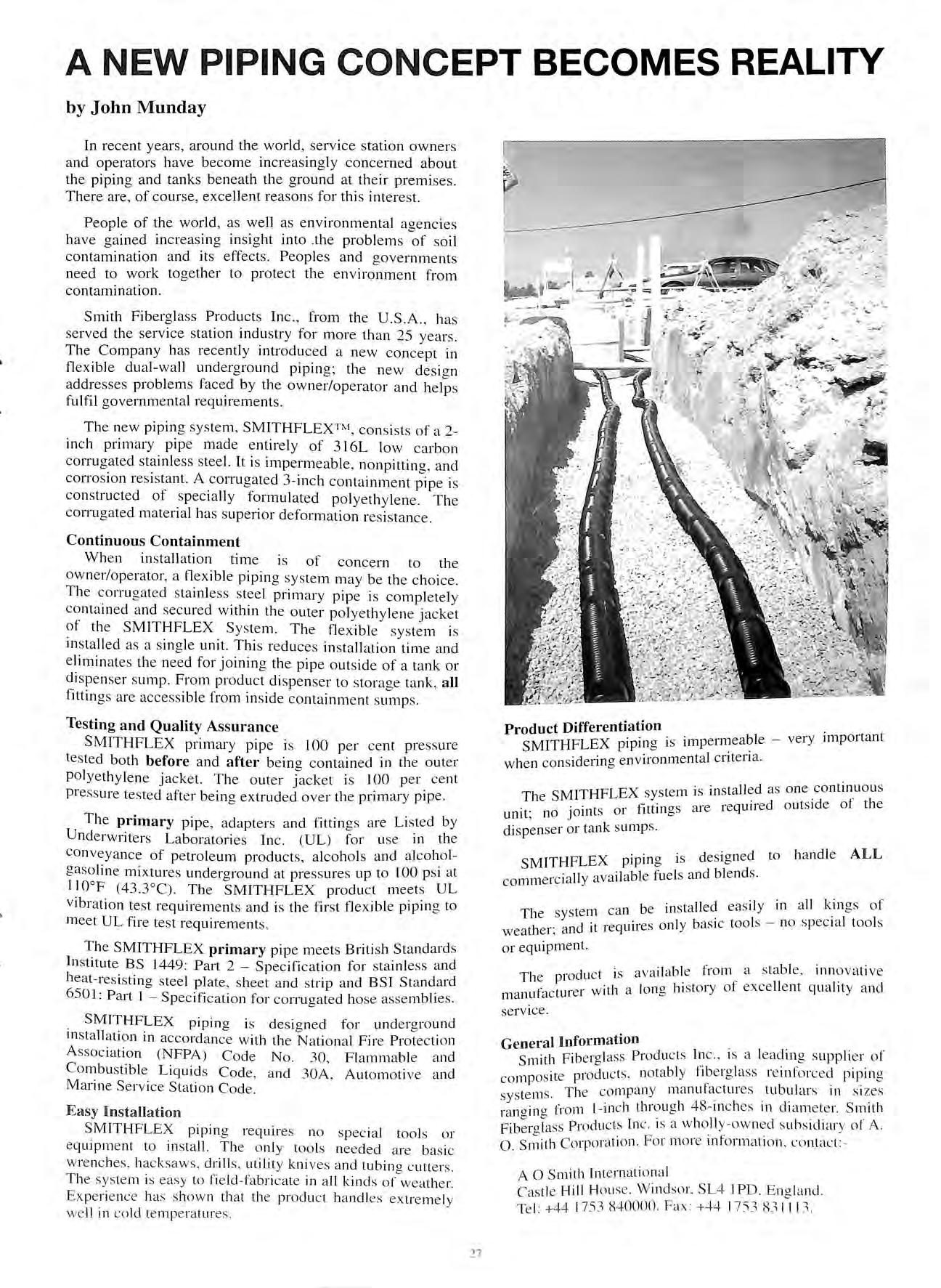

The new piping system, SMITHFLEXn1 consists of a 2inch primary pipe made entirely of 3 I 6L low carbon corrugated stainless steel. It is impermeable , nonpitting , and corrosion res istant. A corrugated 3-inch containment pipe is constructed of specially formulated polyethylene. The coITugated material has superior deformation resistance.

Continuous Containment

Wh en installation time is of concern to the owner/operator, a flexible piping sys te m may be the cho ice. Th e co rru ga ted stainless stee l primary pipe is completely contained a nd sec ured within the outer polyethylene jacket of the SMITHFLEX System. The flexible system is 111 stalled as a si ngle unit. Thi s reduces in sta llation time and eliminates the need for joinin g the pipe outside of a tank or dispenser sump. From produ c t dispenser to s torage tank, all fittings are accessible from in s ide containment sump s.

Testing and Quality Assurance

SMITHFLEX primary pipe is I 00 per cent pres sure te sted both before and after being co ntained in the outer polyethylene jacket. The o uter jacke t is I 00 per cent press ure te sted after bein g extruded over the primary pipe.

The primary pipe , adapters and fittings are Li s ted by Underwriters Laboratorie s Inc (UL) for use in th e co nveya nce of petrol e um products, alcohols and alcoholgasoline mixture s underaround at pressures up to I 00 ps i at 110°F (43.3°C). The SMITH FLEX product meet s UL vibration te st requirements and is the first flexible pipin g to meet UL fire test requirement s .

The SMITHFLEX primary pipe meets British Standards In st itute BS 1449: Part 2 Specification for stainl ess and heat- res istin g steel plate , s heet and strip a nd BSI Standard 6501: Part I Specification for corrugated ho se assemblies.

SMTTHFLEX pipin o is desioned for under <>ro und b b b 111 stallation in accorda nce with the National Fire Protec ti o n Association (N FPA) Code No. 30, Flammable a nd Comb ust ibl e Liquids Code, and 30A, Automotive a nd Marine Service Station Code Easy

Installation

SMITHFLEX pipin g req uires no spec ial tools o r eq uipm ent to install. The o nl y tool s needed a re ba s ic wrenc hes , hacksaws. drills utility kniv es and tubing c utters. T he sys te m is easy to fi e ld -fabricate in a ll kind s of weat he r Ex pe ri e nce has s hown that the produ c t ha ndl es ext re me ly we ll in co ld temperatures.

Product Differentiation

SMITHFLEX piping is very importa nt when con sidering environmental cntena.

The SMITHFLEX system is in stalled as one ·01·11ts or fittin<>s a.re required o uts id e ot the umt ; no J o di spenser or tank sumps.

SMITHFLEX piping is de sig ned to ha ndl e ALL commercially available fu e ls and bl e nd s.

TI t 1 ca n be in stalled easily in all kings of 1e sys en ' , , 1 h d ·t 1·equires only basic tool s no spec 1<1 tools weat e1 , an 1 or equipment.

The product is ava ilabl e from a stab le, inn ovat iv e ·t11 a lon 0 a hi story of excelle nt quality and manufacture r w1 · serv ic e.

General Information

.

Smith Fiberglass Products is a lead 111 g s uppli e r o l composite produ cts. notably t1berglass reinforc ed piping ste ms. The company manufactures tubulars in s izes sy · 48 1 ranaina from L 111 c h through me 1es 111 diamete r. S mith Products Inc. is a wholl y-o wned s ub s idi a ry of A. o. Corporation For more information. contac t :

A o Sm ith [n ternationa l Castle Hill Hou se. Windsor. SL4 I PD. E ngland Te l: +44 17'53 840000. Fax +44 1753 83 111 3.

27

OVERFILL PREVENTION

By Peter Edgington

I have read with some interest the correspondence generated between various manufacturers following the article on Overfill Prevention Devices published in issue 3 Volume 32 of the APEA Bulletin. Having noted some of the statements made I could not let them pass without adding a further view point and correcting some misconceptions. My own views are based on using such equipment in operational service and are the result of assessing, testing and recommending such equipment for a major oil company over a 25 year period worldwide. During this time I have examined systems operating on a variety of principles including mechanical, hydraulic, pneumatic, electrical and hybrids of them for installation in both above and below ground tanks and road tankers. In all cases the methods of operation are similar. Rising fuel level is detected in a tank or compartment by a sensing device which relays a signal to a shutdown valve. The valve may form either an integral part of the sensing unit or be located remotely from it.

The main issues raised in the correspondence are:

1. The relative merits of mechanical and electromechanical systems for overfill prevention.

2. The preferred point at which to shut down the flow of fuel should this be necessary.

3. Standardisation and compatibility between electrical systems.

I "."ould like to offer my comments on these points based on this experience.

OPERATING PRINCIPLES

I make no apology for being biased. As a result of eval · uatmg over 30 different manufacturers systems I strongly favour the electro-mechanical approach employing a sensor signalling a remote shut down valve for station application. The electrical system must a continuous and automatic self-checking Ircuit My " . · reasons ior supporting such a system are:

operations and closing valves -a true fail safe operation in every sense.

Versatility Should changes be necessary in system layout or additional functions be required these can be incorporated in most cases without major re-design or inconvenience.

Integration With electronics gradually taking over more functions at a service station data communication, control of deliveries, leak detection, product reconciliation and in the near future vehicle data capture systems, integration of an electrically based overfill prevention system with the latter becomes an obvious choice.

Cost The cost of installing an electro-mechanical system in one vehicle and the I0-15 service stations it normally serves is competitive with installing a mechanical system in each tank at the same number of service stations. Recent figures I have seen indicate a 15% savincr by using an electro-mechanical system. 0

Operational Experience

Electro-mechanical systems of the type described and using similar operating principles have now been in service in some countries for over twenty years with an excellent safety and reliability record.

PREFERRED POINT FOR SHUT DOWN

The advantage of stopping fuel supply at the road tanker should an overfill be detected is:-

(a) The vehicle compartment valve can be used for shutdown thus simplifying conversion and minimising cost.

(b) (c)

The delivery line hose is automatically drained of fuel thus avoiding the need to do this later once the cause of the overfill has been established.

forms part of the system, the reliability of such a system is far superior to that of a mechanical system with integral sensing and shu.t down. In one European Country in which I was able to directly compare performance of the two systems, failures averages once per week with mechanical systems but virtually ceased once an electromechanical system was introduced and this wasm · · onitored over a 12 month period.

Reliability E ven though a mechanically operated valve Safety

The and continuous self-checking electrical circuit used for signalling gives an unparalleled degree of safety. Electrical supply failure. component failures. attempts to by-pass or insert non-proprietary equipment are immediately recognised hy a controller which reacts hy stopping all

Deliveries can still take place in other tanks the cause of the overfill is investigated thus avmdmg delays.

As pointed out by one of the the weak point of the electrically operated system 1s the use of a mechanically operated "dependant" valve. I accept this up to a point but my own experience has shown t_hese to be exceptionally reliable with very few occas10ns o_ccurrmg in which failure to close arose except when signalled. Those cases that I have personally encountered have usually been caused by foreign matter on the valve seat from either disintegrating seals or solids from a badl_y_ flushed tank compartment after maintenance. In any case If this was shown to be a major problem a "belt and braces" approach could be considered in which the road tanker outlet valve was also made to operate as a secondary hack up. However I would emphasise that experience to date has shown this to be unnecessary and the expense of this additional safe guard is not justified.

28

A further point in support of using the compartment bottom valve for shut down is that on an average working day the valve would be operated for up to 2--4 loadings and as many off loadings. Compare this with the same incidence of use for an integrated mechanical valve in an underground tank which may only be required to operate should an overfill situation arise. It is this comparative lack of use which causes many of the operating problems with integrated mechanical valves.

STANDARDISATION AND SYSTEM COMPATIBILITY

The lack of standardisation and compatibility between electrical systems offered by different suppliers is of concern and a valid criticism but in practice it has been overcome because of the attractiveness of the electromechanical system and the advantages it offers.

To achieve cross compatibility between systems it is necessary for government agencies/petroleum industry or similar_ to issue a standard specification which all suppliers in a given country should meet. To date this has been impossible to achieve as equipment has come on to the market before the authorities have had time to react and produce such requirements. Once equipment is in use it is then too late to obtain acceptance of a standard specification as no manufacturer is neither prepared to back track or modify equipment in order to comply nor is he prepared to release proprietary information such as methods of electrical signalling which must be disclosed. In practice the problem has been solved by those oil companies who wish to ad?pt an system specifying their own reqmrements which have to be met by all those contracted to supply product to them.

However attempts are now being made in Europe to produce a common standard covering overfill prevention systems for use at service stations when offloadincr from road tankers, this is known as CEN 221. Yariousc- study groups have been formed to draft requirements for different applications and the U.K. are well represented on these groups.

I would now like to comment on specific points raised by the two mechanical equipment manufacturers which I find difficult to accept.

OPW claim that mechanical equipment has a low incidence of reported failure. This is not my experience, but perhaps the key word is "reported". Not all incidents are reported for obvious reasons as no driver will willingly do this as it reflects adversely on his competence to do his job. Invariably only major incidents get reported i.e. those involving a large fuel spillage or where the incident is witnessed by other parties. I am also surprised that the failures when diagnosed were invariably due to incompetent or incorrect installation. I find this statement extraordinary. Again my experience shows that poor installation only represents a small percentage of the total failure rate. What about failures in service caused by sticking/jamming of moving parts due to solids contamination, gum deposits from fuel, corrosion, floats losing buoyancy and ice built up in winter. On several occasions I have encountered problems at service station rebuilds in which a new mechanical device had to be replaced several times before an acceptable one was found so there could also be a quality control problem with some manufacturers.

The major criticism I have with mechanical systems is that when you connect up to off load a vehicle you never know with confidence whether the overfill device will operate when required to do so in an emergency. Some companies have attempted to introduce procedures which require a daily check of mechanical equipment by physically making sure that floats and moving parts_ etc are free to operate. However you can imagine the reception that such a procedure receives from fore-court personnel and the willingness to do this soon lapses once the problem of accessibility to do this have to be faced.

From the remarks made by Emco-Wheaton on the ability to bypass the electronic circuit in systems using dummies it is apparent that of the automatic and continuous self-checking electncal circuit is not fully understood. With such a system any attempt to by-pass, change with unacceptable or insert a dummy would result in the electncal signature being transmitted back to the on the road tanker. This would result m a non-permissive signal being given and the off-loading would immediately stop and could not proceed until the cause of the in-correct signal had been fully diagnosed fault corrected. I know that on occasions special been supplied by some manufacturers to enable to proceed from road tankers which are not yet eqmppe with the electrical-mechanical systell!· In these additional safeguards are incorporated in the _electnhca . d "d t'fi s these vehicles t us circuit which recogmses an 1 en 1 ie enablincr them to deliver product. b

Finally I find it ironic that the two m_echanical . . I b t lectromc systems w IC suppliers are so cnuca a ou e ., 1 . h d tanker to stop i ue operate a mechanical valve m t e roa facturer markets delivery flow as I one ove1fill their own items of eqmpment for are the major prevention systems and between t Iem eyldwide Do the . d k bottom va ves wor · suppliers of roa er , f confidence in these and criticisms therefore imply. lack 0 .,... knowledcre the . f qmpment? io my ctheir own 0 e nts one of the most reliable bottom valve_s m and have an excellent record components m a road tan Id ·de I would have thought vice wor WI • over many years ser ther than criticise those nufacturers ra that the two ma h . 1 should be prmsmg rather companies which use sue va ves than condemning them.

29

LEAK INVESTIGATION AND COST EFFECTIVE REMEDIATION

Eur Ing John Waters Groundwater Technology International Ltd Epsom, United Kingdom

1.0 INTRODUCTION

The operation of petroleum retailing sites with underground storage tanks, pipelines, dispensing pumps, vents, drainage and oil/water separators is potentially hazardous. The hazards give rise to occupational, safety and environmental risks which may have significant economic consequences and may directly impact the oil company's profitability.

Companies have historically given a higher priority to the safety issues, but over the past decade there has been an increasing realisation of the consequence of the environmental risks. In the United Kingdom, Shell has now gone on public record as saying that one third of it's retail service station network is contaminated by leakage from tanks and pipelines (Reference 1).

I propose to discuss the impact of spillage and leakage from petrol station sites, particularly covering the issues of contaminated soil and groundwater. My paper gives a brief summary covering assessment and remediation techniques than may be applied on such sites.

2.0 THE MECHANISMS OF CONTAMINATION

In order to assess and remediate the impact of potentially liquids, it is important to understand the migrat10n pathways and the influence of geology, hydrogeology and the contaminant characteristics.

Petroleum spirit may drain from an underground storage or leak from a pipeline or damaged drainage pipe. ere. the volume of loss is sufficient to exceed the capacity of the soil flow will be initiated. In the zone of the subsurface the contamination me will mig t d . d disper 1. ra e own under the mfluence of gravity an se aterally along lines of least resistance.

The migratio f . . phases: n ° contammat1on occurs in four different

• absorbed (s · meaied onto the soil matrix);

• vapour;

• phase separat d . e matenal Oiquid); and

• dissolved in the g1 oundwater.

The volume ors 1 will increase unrt · 1n:1Pacted by absorbed contamination volume of the 1 1 t ere is a change in the subsu1t'ace or the oss proves t b . 1·f· further enlarge · o e msu · 1c1ent lo sustam ment. The P . f slrala or. in the ea, resence o . tower I , " 1,. se of products which have a spec1f1c 1 enslly ess than one s 1 r· . . · · uc 1 as uel oil the water table will cha11°e !he m1grat1on . tl . ' . . "' P<1 iway. In the latter case. the ml will out on the W'tle · t· bi d . . · ' ' <1. e an typically migrate laterally

under the influence of the prevailing hydraulic gradient. This phase separated material will in tum provide the primary source for dissolved phase contamination of the groundwater body.

As a result of volatilisation, vapours will be created which will diffuse through the soil matrix emerging at ground level and dissipating into the atmosphere. The vapours will find the path of least resistance and often are first detected in cellars or service trenches.

3.0 SITE ASSESSMENTS

On some sites, it will be obvious that surface spillage and leakage has occurred, but the impact of the loss on the subsoil and the groundwater resource may be less obvious. On other sites, impact may be noted in adjacent water courses or in service trenches. The presence of hazardous and potentially explosive concentrations in such utility areas can have significant health and safety implications.

In the above situations, a site assessment is the obvious course of action in order to investigate the scale of spillage impact. The assessment can take a number of forms, such as:

• desk study;

• soil vapour survey;

• soil and groundwater sampling; and

• groundwater monitoring.

Site assessments are not solely conducted because of obvious signs of contamination and A. number .of the major oil companies have policies which mclude site assessments for any sites that they propose purchase, sell or redevelop. The site assessment provides a. of limiting potential environmental and m1?1m1smg the financial implications of ownmg and operatmg land where potentially contaminative products are stored and distributed.

3.1 Desk Study

The desk study typically includes the following:

• historical review of previous and current land use:

• site infrastructure details;

• plans of services. tanks and pipes etc.:

• relevant operational records:

• petroleum licensing authority records:

\()

• anecdotal information from site operatives;

• geology;

• hydrogeology;

• local abstraction boreholes;

• aquifer type; and

• site reconnaissance.

The desk study should recommend whether future site assessment will be required and what scope of work are likely to be most appropriate.

3.2 Soil Vapour Survey

. A .soil. survey !s a screening tool for the mvest.1gat1on of sites potentially contaminated by volatile orgamc compounds (VOCs) or semi-volatile oroa · d T · II · to me co.mpoun s. yp1ca a gnd of small diameter holes are dnlled the site surface to a depth of around 1m. Representative samples of the vapour held withi th ·i · I d · n e soi matnx are ana yse usmg a photo=ionisation detector (PIO) or a gas chromatograph (GC). The so1'l \'apoLt · · r su1 vey 1s a app1f·oahch and the results can be mapped to oive an m 1cat1on o t e areal extent of 1 cont·1111 · , t' 1 to • • • • < < ma ion p ume. 1:he. causes httle site disturbance yet allows a s1gmf1cant number of sampling Jocat1 · . t b ff I . . . ons o e cost e ect1ve y mvest1gated ma one day survey.

3.3 Soil and Groundwater Sampling

The collection and analysis of represe t· t. 1 · n a 1ve soi and groundwater samples 1s an esse 11 t1·al ·t 'f' · f h · s ep to the quantt 1cat1on o t e impact of spillage or J k TI ·i , · ea age. le soi s<1mples can be collected directly fr<)m tl t·· , d · · 1 · le sur <1ce or at epth Jrom tna pits and boreholes.

Where groundwater is encountered the t)). h l b <1e o es can e converted to momtonng wells with the s ·i·ee d . c n size an pack chosen be compatible with the adjacent subsml. In the cas.e of .fuel oil which has migrated down to water table it :-VIII be necessary to investigate the thickness a?d. chemical composition of the product. The thickness of 011 recorded in the monitoring well will need to be for pore pressure effects which overestimates the thickness of fuel actually on the water table.

analysis should be designed to target on the _likely contammants from the desk study. For a luel storage site. this may include total petroleum hydrocarbons. volatile organic chemicals. such as benzene. as well as other potentially contaminative products that may have been used on the site over the years.

Quality control must he maintained in all stages of the sampling. transport, analysis and reporting Every care must he taken to ensure samples are representative. that they are preserved correctly. immediately placed in cool storage to minimise the loss of volatiles. properly labelled and logged both on site and at the laboratory. Chai;1 of custody documentation must track every stage of this process to ensure defensible results.

3.4 Groundwater Monitoring

In cases where phase separated material and/or dissolved contamination arc identified. it may be necessary to undertake a programme of groundv.•ater monitoring. The

programme may be designed to establish whether the extent of the impact on the groundwater is increasing/decreasing with time or migrating off-site.

A groundwater monitoring programme can also be employed to confirm that a remediation programme has met the cleanup targets. Such a programme may need to be designed in consultation with the appropriate environmental regulator.