7 minute read

MODERNISED TANKERS FOR Esso

set for other and perhaps adjacent authorities. It is likely that the points raised in this context are highly topical because they come at a time when local authorities are trying hard to make their minds up about proposals that have been put to them for pre-payment, self-service projects.

It is the considered opinion of the author that a move from post-payment system where there is continuously provided surveillance to a pre-payment unmanned station is too big a step to take. If stations are required to be unmanned to save Jabour costs and labour availability, and to avoid the employment tax, then as a first move in this direction a pre-payment type of station ought to be (especially in built-up areas) provided with some form of remote surveillance.

Advertisement

The flexibility of this new pre-payment system will give to the filling station operators the freedom to use or not to use the automatic, remote surveillance equipment as required and at varying times of the day or night. It would certainly provide a more economically v!able station t~an the provision of a single coin-operated mstru!11ent wh1c.h can, at best, only provide an emergency service. In this new concept there is no reason w~y most, if not all, o~ the petrol dispensers should not be m use at the same time. Certainly there could be prov1s10n for the sales of all grades of petrol sold at that station. All that is needed to allow all of the dispensers to be in use at the same time is for the single money acceptance unit to be equipped with a memory unit.

At many conventional petrol stations at the present time, the relief of pressure during the daytime is effected and encouraged by spreading the sale time to include the late evening and night. Any means whereby petrol could be obtained over an increased period, or more conveniently, might be a useful practice to encourage in the still expanding trade of retail petrol sales.

From a theoretical standpoint, the new pre-payment self-service arrangement seems to offer great prospects for the future and to provide another new threshold for the maketing side of the petroleum industry. It remains, of course, for a prototype station to be established in a suitable location to evaluate its possibility. But it is suggested that this might be one of the most exciting ideas to be presented to the trade in recent years. It will be for the trade to make use of it and to exploit the promise it offers.

From the Petroleum Times.

Modernised Tankers for Es so

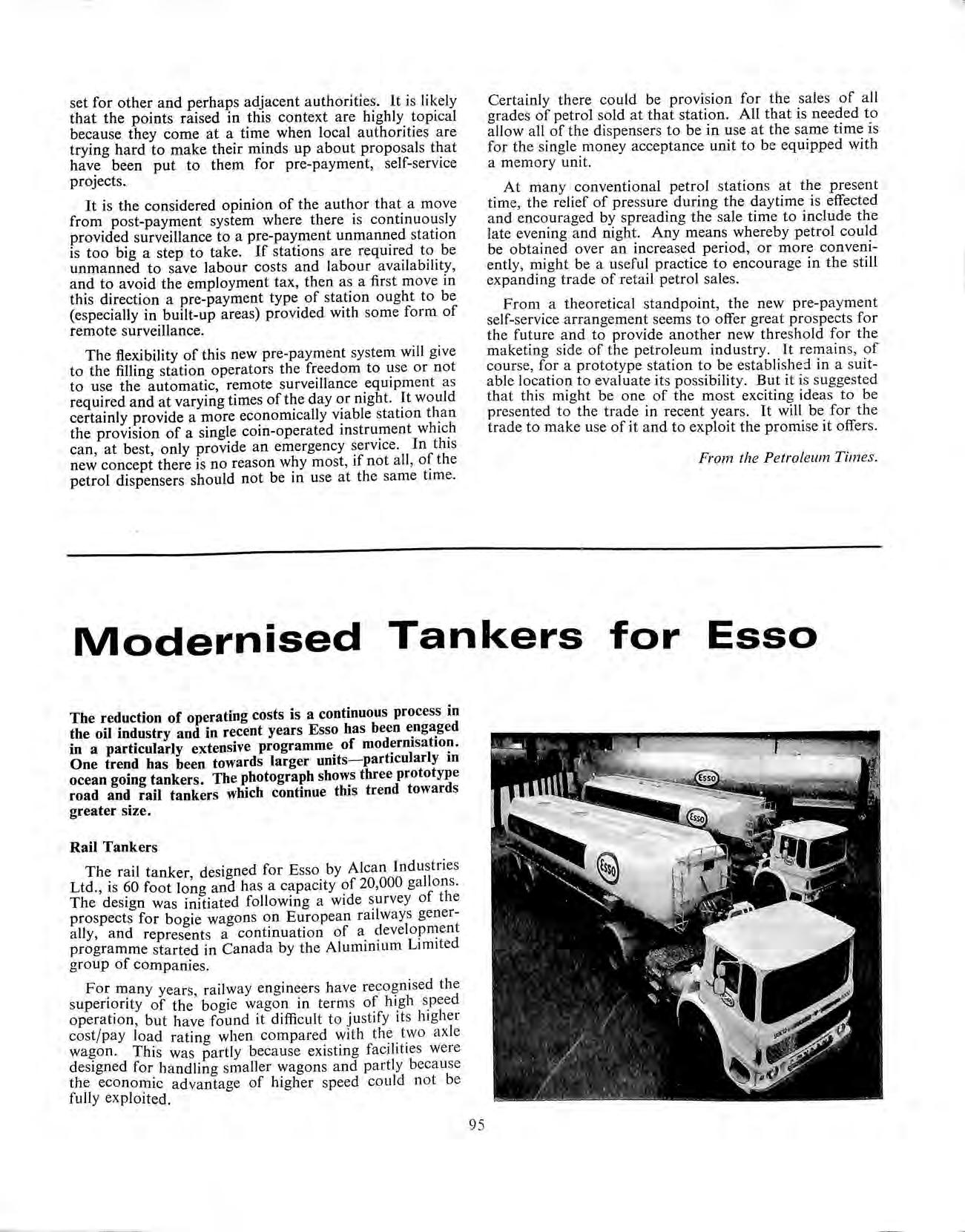

The reduction of operating costs is a continuous process in the oil industry and in recent years Esso has been ~ng3:ged in a particularly extensive programme of modermsat10n. One trend has been towards larger units-particularly in ocean going tankers. The photograph shows three prototype road and rail tankers which continue this trend towards greater size.

Rail Tankers

The rail tanker designed for Esso by Alcan Industries Ltd., is ?O foot lo~g and has a c~pacity ?f 20,000 gallons. The design was initiated followmg a wide survey of the prospects for bogie wagons on European railways generally, and represents a continuation of a. ?evelop~ent programme started in Canada by the Alum1mum L1m1ted group of companies.

For many years railway engineers have recognised the superiority of the' bogie wagon in terms of high speed operation, but have found it difficult to justify its higher cost/pay load rating when compared with th~. t.wo axle wa~on. This was partly because existing fac1ltt1es were designed for handling smaller wagons and partly because the economic advantage of higher speed could not be fully exploited.

95

As with all forms of transport, the more expensive light weight constructions are only economically viable when the operation is intensive.

It is considered that, in comparison with the best twoaxle steel tankers at present in service, the aluminium bogie tanker affords an increased payload capacity per train of 15 per cent, with an ultimate corresponding drop in capital expenditure on locomotives and in direct operating costs. The owner will also require fewer wagons, resulting in lower maintenance charges, a quicker turn-round time and, eventually lower haulage charges. Painting maintenance is reduced to negligible proportions because there is no necessity to paint the aluminium tank. The tank structure is self-supporting, having no through longitudinal understructure, all bending and end loads being taken by the shell itself. It is roughly elliptical in cross-section. Stub under-frame structures at each end transmit shunting and tractive forces to the tank shell and support the vertical forces developed in the steel cradles carrying the tank on the bogie pivots. The shell has no transverse framing except for an internal stiffening ring at mid-length to control shape.

Road Tankers Both the Saro Ltd., road tankers are designed and built by Glostera Hawker Siddeley company and are of a capacity of 5,300 gallons. One is an aluminium alloy and the other is glass-reinforced plastic.

They follow the same basic standard design configura-tion, i.e. derived from curved side rectangle, supported on integral twin box section under-structure members. Along the top of the aluminium alloy tank run two 'U' section members, with corrugated bulkheads or baffles bridging these and the understructure. These are positioned in such a manner that in conjunction with under-structure and top members they structure of the tank. provide the load-carrying beam The tank body is manufactured from 8 contain s.w.g. (4 m.) N.S.5 material and is designed to this liquid load only, although obviously some additional beam strength is derived from this structure. The bodies of the glass-reinforced filament wound on a machine designed plastic tanks are and manufactured by Gloster-Saro Ltd., which enables the barrel or tube of tanks to be automatically produced. The formation of the tank barrels takes place on a rotating mandrel by laying on bands of glass rovings automatically wetted with resin at a helix angle of 45 degrees. hoop and beam strength. This gives the appropriate Alternately crossing layers are built up to a barrel thickness of approximately 3/8 inch and finally an automatic sanding process gives a smooth external finish. The tank interior has a high gloss finish reflected from the finish of the metal mandrel. Under-structure top members and all attachments a composite are resin unit. bonded to the tank bodies, forming

The glass fibre tank has particularly good thermal insulation properties. This characteristic could be useful in carrying those grades of fuel oil that must be kept above ambient temperatures.

Through the Pipeline

by OTTO

WHERE IS ALL THIS GAS GOING ?

Petroleum officers should reflect before they share in the general beneath the excitement at the discovery of natura! g~s North Sea. The gas is methane and hqmd methane is subject to the licensing provisions of the Petroleum Acts. There is little comfort in the thought that there is a difference of some 300 degrees Fahrenheit of cold between liquid and gaseous methane.

It is obvious that in order to keep distribution costs down to a minimum the winter peak loads must be ironed out so far as the national gas distribution pipelines are concerned. This will entail storages of methane near centres of consumption. The only sensible way of storing methane is as a liquid at a temperature of - 258 degrees Fahrenheit.

Faced with a proposal to store liquid methane in aboveground tanks, most petroleum officers will ponder on the lessons to be learned from the disastrous fire at Cleveland, Ohio, in October, 1941. Methane escaped as a liquid into city sewers and vapour spread as a cloud twelve feet high. To Cleveland the subsequent explosion and fire was truly shattering. It impressed the U.S. Bureau of Mines sufficiently for that body to recommend that no similar plant should be within half a mile of human habitation.

The frozen earth "tanks" for the storage of liquid methane have brighter prospects, however, subject to engineering difficulties being successfully surmounted. The only foreseeable failure of these underground or in-ground "tanks" appears to be failure of the roof. If this occurs heat for boil off of methane can only come from above. Boil off should therefore be relatively slow. Once the temperature of methane vapour exceeds -148 degrees Fahrenheit it becomes less dense than air and will diffuse rapidly. Lateral spread of vapour and liquid will probably be extremely limited. If fire ensued the heat generated would have but little effect on the boil off rate of the methane and there would be no reason why the fire should not be left to burn itself out. To enable this to be done buildings, etc., should be sufficiently remote as not to be likely to suffer damage from radiated heat. A distance of 100 feet or the "tank's" diameter, whichever is the greater measured from the edge reasonable minimum. of the tank, suggests itself as a

Perhaps the day will dawn when all those unsightly gas holders will have disappeared and the Gas Board's only storage will be underground. If any museum wants a gas holder, let it be kept in someone else's parish.

96