Quarterly Journal of The Association for Petroleum Acts Administration

OCTOBER, 1968 Volume 7 No . 4

LETIN

E. V. BEEBY

J. BEER

J. BIRKS

R. L. BLOOR

J. W. FRID H. GRIFFITHS D. HALL

THE ASSOCIATION FOR PETROLEUM ACTS ADMINISTRATION

Chairman: C. T. PEACOCK Vice-Chairman: B. W. C. THACKER

Council:

Rugby R.D.C. 2071

G. H. HARVEY

Worcester City 23156 J. W. HEWISON

Chesterfield B. 2825

T. KERR

Dudley C.B. 55433

Havant and Waterloo U.D.C. 6311

Glanford Brigg R.D.C. 2041

Kidderminster B. 3080 H.R. MELLOR Blackpool C.B. 23848

Cambridge City 58977

C.R.PESKETT Godalming B. 191/2

Walsall C.B. 25661 R. E. J. RODEN Birmingham City 021-23.6 9944

Newcastle-under-Lyme B. 60161 J. SHORT Paisley Burgh 5400

Officers:

Hon. Secretary/Treasurer:

Hon. Editor: L.A. CAVE R. P. HOLDAWAY

Liaison Officer: G.N.DEAN

Hon. Electrical Adviser:

Hon. Legal Adviser: J. A. SHARP P. D. WADSWORTH

EAST MIDLAND NORTHERN

NORTH WESTERN ScornsH

Soum EASTERN

SoUTH EAST MIDLAND WEST MIDLAND YoRKSHIRI!

Branch Secretaries: J. BIRKS, B. W. C. THACKER, H. R. MELLOR, J. SHORT, C. R. PESKETT, R. E. DUST, G. H. HARVEY, C. T. PEACOCK,

OCTOBER, 1968

The Bulletin

Published quarterly by the Association for Petroleum Acts Administration

Opinions expressed in this journal are not necessarily the views of the Association

Editor: R. P. HOLDAWAY WEIGHTS AND MEASURES DEPT GUILDHALL, SHREWSBURY

Subscription: 30s. per annum

CONTENTS

TALKING POINT 86 NOTES AND NEWS 86 LETTERS 88

CONVEYANCE OF INFLAMMABLE LIQUIDS-C. L. DAVIDS 88 W. C. R. DALE 89

BANISH PUMPS-M. J. CHAPMAN 91 SELF SERVICE-J. G. FRENCH 93 W

THE NATURE OF PETROLEUM SPIRIT AND ITS HAZARDS-J. R. HUGHES 98

THE TESTING OF NEW AND EXISTING PETROLEUM SPIRIT STORAGE TANKS-J. BEER 102 GAS PRESSURE TESTING OF T ANKS-C. L. DAVIDS 106 BRANCH MEETINGS : EAST MIDLAND SOUTH EASTERN THROUGH THE PIPELINE LEGAL PROCEEDINGS

Chairman: C. T. PEACOCK Honorary Secretary/Treasurer: L. A. CAVE Liaison/Advertisement Officer: G. N. DEAN

106 108 109 I 10

Volume 7 Number 4

talking point

THE MODEL CODE

The long awaited Model Code, Parts I and II, made its appearance during August. Both parts have been prepared by the Standing Advisory Committee on Dangerous Substances, and an appendix to Home Office Circular No. 182/1968 (Fire Service Circular No. 36/1968) adequately summarises the more important revisions made to the previous edition circulated some ten years ago.

On a first reading of its provisions our reaction was almost one of disbelief. To anyone brought up on the sacrosanctity of the twenty feet safety distance, the use of steel only for the construction of tanks, the need for concrete or brick chambers, the provision of wells at can stores and the strict siting and layout of storage tanks at major installations, this is liberalisation indeed.

As expected, selfcservice, both attended and unattended, receives a special mention. The general note advising licensing authorities to bear in mind that local conditions may make a site unsuitable for self-service operation and suggesting that regard should be paid to surrounding risks and the layout of the installation, goes a long way to allay our anxiety regarding a 4/- minimum delivery from an unattended self-service pump.

It is emphasised that the code is issued only for guidance. Nevertheless, we believe it the duty of licensing authorities to carefully consider the recommendations made and if needs be, adopt those provisions necessary and essential for the public safety.

Over the past few years the Association has published numerous Codes and Conditions, and these have, par- ticularly in the absence of any up-to-date official direction, been welcomed by members. That these codes followed conventional lines cannot be denied, but circumstances prevented the expression of a more advanced viewpoint.

Development in the technological field will continue and there will be a need to keep the Model Code under review. 1:his. has the machinery and the will to go on with its policy 0f keeping abreast of such developments and to this end we welcome an invitatiori from the Institute of Petroleum that a sub-committee of the Association's Technical Committee should meet periodically with representatives of the Institute's Working Party 'A' to discuss mutual problems.

notes and news

New Members

Amersham

RDC Bucks. H

Blandford Forum MBC Dorset s Bolton CBC Lanes. F Brackley RDC Northants. H Bridgwater MBC Somerset H Easthampstead RDC Berks. H Hazel Grove and Bramhall UDC Cheshire s Merthyr Tydfil CBC Glamorgan F Wigan CBC Lanes. F

Officers

C. L. Davids, Greater London Council p L. C. Eden, Bullingdon RDC Oxon s L. Wilson, Denton U DC Lanes. H

Associate Members

A. J. Bayliss & Sons, Pump and Tank Engineers, 30 Clee Avenue, Kidderminster.

Hampshire County Fire Brigade, Chief Fire County Fire Brigade Headquarters, The Castle, Wmchester, Hants.

Kent County Fire Brigade, Chief Fire Officer, County Fire Headquarters, Tovil, Maidstone, Kent.

Lancashire County Fire Brigade, Chief Fire Officer, Fire Brigade Headquarters, Fulwood, Preston, Lanes.

Arieh Menchikovsky, Operations Sonol Israel Ltd., P.O.B. 214, 8 Habankim Street, Haifa, Israel.

Somerset County Fire Brigade, Chief Fire Officer, Hestercombe House, Cheddon Fitzpaine, Taunton, Somerset.

S. Stam, Representative, OPW-Dover (Europa) N.V. Bijlmereerstraat I, Hoofddorp, Netherlands.

Retirements

Mr. R. Bentley, O.B.E., Ch.ief Fire C?fficer, Bolton Fire Brigade, has retired after 20 years service.

Mr. F. G. Jones, M.B.E., Chief Public Inspector, Cuckfield R.D.C., has retired on: grounds of ill health.

We wish these gentlemen a long and happy retirement.

86

Appointments

Mr. R. H. Eveleigh, Deputy Borough Engineer, Pontefract, has been promoted Borough Engineer and Surveyor.

Mr. G. A. Hodgkinson, Chief Fire Officer, Dewsbury, has been appointed Chief Fire Officer, Bolton, in succession to Mr. R. Bentley.

Mr. R. E. Platt, Deputy Chief Public Health Inspector, Crewe, has been appointed Chief Public Health Inspector and Cleansing Superintendent in succession to Mr. J. Gaskell, appointed Deputy Director of Cleansing, City of Westmmster.

Mr. R. S. Relf, Deputy Chief Public Health Inspector, Cuckfield R.D.C., succeeds Mr. F. G. Jones as Chief Public Health Inspector.

Mr. P. West, Deputy Chief Public Health Inspector, Godstone R.D.C., has been appointed Chief Public Health Inspector in succession to the late Mr. A. H. Sewell.

Obituary

We regret to report the death of:

Mr. R. L. Bloor, Chief Inspector of Weights and Measures, Kidderminster. Mr. Bloor was a founder member of the Association (previously the West Midlands Petroleum Group) and had been a member of its Council since its inception in 1958. He was Chairman of the Education and Publications Committee and will be remembered by many students who attended Attingham College, as one who so efficiently and quietly contributed to their welfare and comfort. His loss is a heavy blow to this Association. We offer sincere condolences to his widow and family.

Mr. T. B. Hine, Chief Inspector of Weights and Measures, Canterbury C.B.C.

Mr. A. H. Sewell, Chief Public Health Inspector, Godstone R.D.C.

Change of Address

Associate Members

Engineering Services (Glasgow) Ltd., 8 Incle Street, Paisley. (D. M. Campbell, General Manager).

Publications

The Inflammable Liquids (Conveyance by Road) Regulations, 1968, S.I. 1968 No. 927-9d.

The Inflammable Liquids (Conveyance by Road) (Labelling) Regulations, 1968, S.I. 1968 No. 928-l/3d.

Model Code of Principles of Construction and Licensing Conditions (Part I) for the storage of Cans, Drums and other Receptacles-Petrol Filling Stations. H.M.S.O., 3/- net.

Model Code of Principles of Construction and Licensing Conditions (Part 2) for Distributing Depots and Major Installations. H.M.S.O., 2/- net.

Report of H.M. Inspector of Explosives for the year ended 31st December, 1967. H.M.S.O., 5/- net.

Avoidance of Water Pollution by Oil-Enquiries to the Secretary, Oil and Industries Working Group, Institute of Petroleum, 61 New Cavendish Street, London, W.l.

Secretary's Notes

The following back numbers of The Bulletin can be obtained from the Hon. Secretary, 5/- each:

April 1964 Vol. 2 No. 4 1

October 1964 Vol. 3 No. 2 1 January 1965 Vol. 3 No. 3 2 April 1965 Vol. 3 No. 4 6 July 1965 Vol. 4 No. 1 I

January 1966 Vol. 5 No. 1 1 April 1966 Vol. 5 No. 2 11 July 1966 Vol. 5 No. 3 I October 1966 Vol. 5 No. 4 9

Will all Members, Associate Members and Bulletin Subscribers in arrears with their subscriptions please arrange clearance before 31 st October, 1968.

The Technical Committee is now actively engaged in revising the Association's various Recommendations, Codes and Conditions in the light of the new Home Office Model Code.

World's Biggest Ship Named

In a burst of champagne, a wail of sirens and a flutter of pigeons at Yokohama, the '._Vorld's ship _was named Universe Ireland by the wife of the Pnme Mm1ster of Ireland.

The Universe Ireland, 312,000 tons deadweight, is the first of three tankers to be delivered to National Bulk Carriers Inc. (NBC) of the United States for the Gulf Oil Corporation.

The vessel which is listed at 148,8 JO gross tons, was built by Ishikawajima-Harima Heavy Industries o[ Japan at a cost of about £9,000,000. Her overall length 1s 1,135 feet, breadth 173 feet and draught 78 feet.

New Thinking for Fuel Tank

Eurogauge Co., Ltd., is now . advocatmg the use .of capacitance equipment for all 011 storage tank gaugmg and control.

Advantages of the are stat_ed to _includ_e the intrinsically safe probe c1rcmtry-depth umt meters-no maintenance and no nsk of creepmg aries, as interconnections are by cable only. In '.1dd1t1on minimum and maximum level probes may also be mst_alled independently of depth measuring probes and ancillary equipment.

The depth indicator unit may be located at a. distance of up to 50 yards from the storage tank and reqmres only a low electricity supply outlet.

New Fire Fighting Technique

A new technique for fighting fires on supertankers is now in operation at BP's Isle of Gram _refinery. the fire-fighting tug Keverne. It is fitted with a 60ft. tripod tower designed and built by John I. Thorny_croft & Ltd., to carry a remote-controlled fire-fightmg momtor.

As tankers increase in size a serious problem faces operators of fire-fighting tugs. wl!en thrown horizontally will reach only 100 feet m still air, about I 50 feet if directed downwards. Directing the jet high into the air will have some measure of success in still air, though the slightest air disturbance is liable to deflect and scatter the foam. To be really effective the jet must be sited at least 50 feet above the waterline.

l._

87

LATCHED AUTOMATIC CUT-OFF NOZZLES

I share Mr. Hewison's experience and misgiving regarding item (vi) of the Home Office Circular-the 'drive away' test. Tests in Margate were carried out with the Elaflex Type ZVA 19 Mark 7 nozzle on three occasions. In the first instance the nozzle tested made a dent in the rear wing of the car concerned, in the second the flexible hose between pump and nozzle stretched, broke and had to be replaced; the petrol tank on the car was pulled from its mounting and the filling pipe bent out of shape. When testing the third nozzle the flexible hose lashed back, hit an adjacent petrol pump and smashed the glass casing and dial.

It was very clear there ought to be some better way of carrying out such tests because, quite apart from the resulting damage, the relationship between enforcement officer and garage proprietor became a little strained ; particularly when the proprietor, not unnaturally, pointed out that while he is required to exhibit notices forbidding cars to be refuelled with an engine running, these tests required a car (with engine running) to fracture the nozzle coupling with consequent spillage of a small amount of petrol.

Correspondence with the Home Office elicited the opinion that provided satisfactory assurances as to the safeguards built into the equipment and the tests carried out by the manufacturers themselves on each piece of equipment are received, there is no reason why a licensing authority should not regard the manufacturer's statements as sufficient evidence that the nozzle in question meets the requirements laid down.

Conveyance of Inflammable Liquids

A GUIDE TO THE REGULATIONS

C. L. DAVIDS, LI.Fire E.

. The object of this guide is to indicate when the regulat10ns apply, and what the exemptions are. Details of the requirements can be obtained from the regulations.

These regulations do not replace the existing Petroleum Spirit (Conveyance by Road) Regulations, 1957 or The Carbon Disulphide (Conveyance by Road) Regulations 1958 '

I. The Petroleum (Inflammable Liquids) Order, 1968

Came into force on I st August, 1968, and applies certain sections of The Petroleum (Consolidation) Act, 1928 to: (a) Certain liquids named in the order. (All Inflammable).

It was further pointed out, that upon any destructive test, there is no guarantee that any replacements would work and in this situation a reasonable view might be, that if the device is satisfactory when it is new, then it will continue to be satisfactory throughout its working life.

Under the circumstances I propose, therefore, to add an additional condition to our licences to store petroleum spirit, requesting initial production of a certificate from the manufacturers before a latched nozzle is fitted, and 'at such other times as the Chief Petroleum Officer may request'. This is a solution, but to my mind, far from satisfactory.

Margate

CAR PORTS

U. A. BANCROFT

I would very much appreciate the observations and comments of your readers on a conflicting point arising out of legislation with respect to Car Ports.

The Petroleum Regulations classify a small domestic garage as a petroleum store and impose certain conditions and restrictions which conflict with Building Regulations in respect of such garages and car ports. How do we enforce compliance with both forms of legislation ?

The difference being thus: a car port attached to a dwelling is permissible when covering a door and/or window, yet the Petroleum Regulations state that an isolation of ten feet is required between a dwelling and a door opening into a petrol store.

I have in the past reg uired any door or window covered by a garage to have a fire resistance of half an hour but can find no authority to continue this practice in the light of the third amendment to the Building Regulations. Sutton in Ashfield U.D.C. F. H. MOLYNEUX

(b) Any mixture containing any of these liquids if the Flash Point of the mixture is below 73°F.

(c) Certain solutions named in the order if the Flash Point is below 73°F.

This Order gives the Secretary of State power to make the following Regulations:

2. The Inflammable Liquids (Conveyance by Road) Regulations, 1968

Came into force on lst October, 1968, and makes operational requirements for the conveyance of the liquids mentioned above. It does not apply Petroleum Spirit or Mixture, or to Carbon Disulphide.

Reference: Regn. I Regn. 2 Regn. 3 Regn. 4 Regn. 5

Regn. 7(h) Regn. 7(a) Schedule Regn. 7

REQUIREMENTS

Prevention of spillage.

No smoking or naked flame.

No unsafe lights or substances. Fire extinguisher required.

Vehicle owner must ensure that employees are acquainted with Regulations.

EXEMPTIONS

If total quantity on vehicle is not more than 250 kilos (551.3 lbs.).

If all the liquid is contained in "Receptacles" as defined.

No exemptions for Acetaldehyde or for Tank Wagons.

letters

88

3. The Inflammable Substances (Conveyance by Road) (Labelling) Regulations, 1968.

Came into force on lst October, 1968, and make requirements for labelling vehicles and containers used for all the liquids mentioned above (Para. 1) and, in certain cases, Petroleum Spirit (and Mixture), and Carbon Disulphide.

REQUIREMENTS

Reference: Regn. 2, Schedule I Part I

Schedule 4 Regn. 2(2) Schedule 1, Part 2 Regn. 3

Schedule 2, Para. 3 Regn. 3, Schedule 2 Paras. 1 and 2 Regn.4

Regn. 5(1)

Regn. 5(2) Schedule 3 Regn. 3

Regn. 6(a) Schedule 3 Regn. 6(b) Schedule 3

Details:

All Vehicles including Tank Wagons and Petroleum, to display "Flame Symbol" (20 ems. sq.) fore and aft, centrally, high as possible. Flame Symbol-details and sizes.

Tank Wagons only, not Petroleum, labeJied with name of substance carried (letters 10 or 5 ems.). Containers, including Petroleum, must display "Flame Symbol" (10 ems. sq.).

Containers, excluding Petroleum must be labeIIed with name of substance. '

Owners must ensure that employees are acquainted with Regulations.

EXEMPTIONS

Vehicles not Tank Wagons: If total quantity not more than 250 kilos provided containers comply with Regulations, or if all the liquid is contained in "Receptacles" as defined.

Containers, if they contain not more than I kilo or if a "Receptacle" as defined or an outer container with not more than 30 kilos of "Receptacles".

Winchesters: "Flame Symbol" only required.

Note.-None of the above exemptions apply to Acetaldehyde, Carbon Disulphide or to Tank Wagons.

Petroleum Spirit

Labelling containers is required by Section 5 Petroleum Act. The above Regulations require that the "Flame Symbol" also be displayed if they apply to the conveyance of that Petroleum Spirit.

The of petroleum spirit is subject to the Spmt (Conveyance by Road) Regulations, 1957, however, do not apply if the quantity conveyed ts not more than 32 gallons in cans or 50 gallons in one steel barrel.

exemption is _carried on in the above Regulations, so tf the total quantity of Petroleum Spirit carried is not more than these amounts, none of the Regulations apply to the Petroleum Spirit (or mixture).

Carbon Disulphide

The Conveyance of Carbon Disulphide is subject to the Carbon Disulphide (Conveyance by Road) Regulations, 1958, as amended by the Regulations of 1962.

The exemption under these regulations is not more than 28 lbs. total with not more than 7 lbs. in one container. This exemption is continued.

Hence the above Regulations (i.e. The Inflammable (Conveyance by Road) (Labelling) Regulat10ns). will not apply to Carbon Disulphide if the total quantity on the vehicle is within the exemption quoted.

A.D.R.

W. C. R. DALE. A.F.lnst.Pet.

On 29th December, 1967, Portugal acceded to a European Agreement concerning the International Carriage of Dangerous Goods by Road (A.D.R.). She was the fifth country to do so. This meant that the Agreement came into force one month later on 29th January, 1968, and the technical Annexes to the Agreement became operative a further six months afterwards on 29th July, 1968.

The British Government has made no secret of its intention to adopt and adapt suitable provisions of the Annexes and to include them in domestic legislation. It has been part of the task of the Standing Advisory Committee on Dangerous Substances to advise the Home Secretary on this matter.

The Petroleum (Inflammable Liquids) Order, 1968

The A.D.R. Annexes became operative on 29th July, 1968. It is not surprising therefore to find the Petroleum (Inflammable Liquids) Order, 1968, taking effect from lst August, 1968.

The Order applies some of the of the Petroleum (Consolidation) Act, 1_928, to liquids and 5 solutions, all of which are hsted (with alternative names) in the to the Order. Most ticularly the provisions _of Sect10n 6 of the Act are apphed to the liquids and solut10ns. '!'he of 1s thus empowered to make Regulat10ns govermng their conveyance be road.

The Petroleum (Carbon Disulphide) Order, 1968

Jn order to clear the way for Regulations, a little tidying up operation was necessary. The Petroleum (Carbon Disulphide) Order, 1968, achieves this by excluding disulphide in cou.rse of conveyance from the provisions of Sect10n 5 c:>f Petroleu_m (Consohdat1<;m) Act, 1928. Thus the of yarymg sets of labellmg requirements to carbon disulphide m course of conveyance is avoided. It will be recalled !hat the (Carb?n Disulphide) Order, 1958, apphed Sect1011 5 (with some modification) and Sectton 6 of the 1928 Act to carbon disulphide.

The Inflammable Liquids (Conveyance by Road) Regulations 1968

The Secretary of State has not been slow to make Regulations in pursuance of his new powers the Inflammable Liquids Order. The of what promises to be a series is the Inflammable L1qu1ds (Conveyance by Road) Regulations, 1968.

The purpose of the Regulations is to impose certain elementary safety preca_uti<;>ns in co1?nection with the carriage of There is the usual ban on smoking and potential 1gmt1on sources; care must now be taken to avoid spilling, and a fire extinguisher must be carried. The owner of a vehicle has a duty to acquaint his employees with the provisions of the Regulations.

89

If one is conveying acetaldehyde, there is no exemption which one may enjoy. The same is true if one uses a tank wagon or tank trailer for the conveyance of any quantity, no matter how small, of an inflammable liquid. On the other hand, one is not caught by the Regulations if: either (a) all inflammable liquids (except acetaldehyde) conveyed are in receptacles containing not more than 1 kilogram, the receptacles are packed according to the Schedule and each package contains not more than 30 kilograms;

or (b) the total quantity of inflammable liquids (except acetaldehyde) conveyed does not exceed 250 kilograms.

These Regulations do not apply to petroleum spirit, petroleum mixture or carbon disulphide. This might be expected because adequate similar provision is already made in respect of these substances by the Petroleum Spirit (Conveyance by Road) Regulations, 1957, and the Carbon Disulphide (Conveyance by Road) Regulations, 1958 and 1962. The effect, however, is that one can convey on a single vehicle, 50 gallons of petrol in a barrel, 28 lbs. of carbon disulphide in seven pound containers and 250 kilograms of any other inflammable liquid except acetaldehyde and yet have no need to comply with the safety requirements of any of the three sets of Regulations.

The Regulations are effective from lst October, 1968.

The Inflammable Substances (Conveyance by Road) (Labelling) Regulations, 1968

To meet a long felt need that the fire service, the police and any other emergency service should have adequate warning that a particular vehicle is carrying a dangerous load of inflammable liquids, the Secretary of State has introduced the Inflammable Substances (Conveyance by Road) (Labelling) Regulations, 1968.

The purpose of the Regulations is to ensure that vehicles conveying inflammable liquid by road are marked with a suitable fire service symbol and the name(s) of the liquid(s) being conveyed. Containers have to be similarly marked but the size of the required symbol is reduced. The symbol selected is the "Flame" sign which is recognised internationally as indicating that a container has inflammable contents.

On a vehicle, the "Flame" symbol has to be placed in a clearly visible position at the front and rear. The positions selected must approximate to the front centre or the rear centre of the vehicle and each must be at the highest practicable point. If the vehicle is a tank wagon or tank trailer, the carrying tank has to be marked with the name of the substance conveyed. Moreover, ifthe carrying tank is compartmented and each compartment contains a different inflammable liquid, then each compartment has to be separately marked with the name of the liquid.

Each outer container of an inflammable liquid has to be marked with the "Flame" symbol and the name of the liquid within it. There is a minor relaxation of this requirement where an outer container encloses not more than six Winchester Quarts packed in the special way laid down in Schedule 3. Jn such a case, the name of the substance can be omitted from the container if no acetaldehyde or carbon disulphide is in the package; this should be a great help to suppliers of laboratories who frequently need to send

out Winchester Quarts of various liquids in a single package.

If a container holds not more than 30 kilograms in individual 1 kilogram units packed in the manner specified in Schedule 3 and does not include acetaldehyde or carbon disulphide, the container does not have to be marked. Moreover, if the only containers on a vehicle comply with the provisions of Schedule 3 and do not contain acetaldehyde or carbon disulphide, the vehicle itself does not have to be marked. The vehicle similarly does not have to be marked if (a) the total quantity of inflammable liquids conveyed does not exceed 250 kilograms, (b) the load does not include acetaldehyde or carbon disulphide and (c) each individual vessel exceeding I kilogram is marked.

Vessels containing acetaldehyde or carbon disulphide or more than I kilogram of other inflammable liquid have to be marked except that vessels in an outer container do not have to be labelled if the outer container is itself marked as required.

Under Section 5 of the Petroleum (Consolidation) Act, 1928, petroleum spirit or mixture containers in course of conveyance have to have a statutory label affixed. There is therefore little point in marking them additionally with the name of the spirit, etc. Suitable exemption is therefore made from this requirement of the Regulations. However, if the vessels exceed 1 kilogram in capacity, they still have to exhibit the "Flame" symbol.

It should be noted that the Regulations do not apply at all to petroleum spirit or petroleum mixture or carbon disulphide if the quantity conveyed is less than the exemption limits laid down in the Petroleum Spirit (Conveyance by Road) Regulations or Carbon Disulphide (Conveyance by R?ad) Regulations, as appropriate. Thus, a vehicle carrymg 50 gallons of petrol in a barrel, 28 lbs. of carbon disulphide in seven pound containers and 250 kilograms of any other inflammable liquid except acetaldehyde need not be marked. The appropriate marking would, however, appear on all vessels exceeding I kilogram in capacity containing the inflammable liquid.

The Regulations are effective from lst October, 1968.

General

There will be more Regulations dealing with. the conby r?ad of inflammable liquids. d.eal111g with vehicle construction are already under d1scuss10n. laying down operational safeguards in.greater detail have yet to be considered. At the same time the task of defining other classes of hazardous substances is proceeding.

Enforcement

The duty of enforcing the Inflammable Liquids (Conveyance by Road) Regulations and the Inflammable Substances (Conveyance by Road) (Labelling) Regulations in a district is laid on the local authority empowered to grant petroleum spirit licences in that district. It is likely that new Orders dealing with other classes of substances will be made in due course under Sect1011 19 of the Petroleum (Consolidation) Act, 1928. If this happens then the petroleum spirit licensing authorities may confidently expect further duties in this field to be laid upon them.

90

BANISHES PUMPS

Contributed by M. J. CHAPMAN Field Sales Development Manager, BP Retail Division Shell-Mex and BP Ltd., Birmingham

Contributed by M. J. CHAPMAN Field Sales Development Manager, BP Retail Division Shell-Mex and BP Ltd., Birmingham

A "l?umples_s" petrol service station has been opened by BP m At Westley Road Service Station, Acocks Green, there are no conventional pumps or islands. Instead, the motorist fills up from electncally operated overhead hoses which are from a canopy covering the whole refuelling area. This development a further stage in BP's proof_ evaluat1<?n of methods and equipment which 1s auned at 1mprovmg forecourt service to the motorist.

(a) The Pump Unit, consisting of a pump driven by a flameproof motor and a metering unit with a transmitter, totaliser and daily totaliser, is housed off the forecourt and alongside the buildings. In the event of a power failure there is provision for manual operation.

(b) The Hose Reel Assembly is mounted beneath the canopy in such a way that the components can be inspected from outside; it contains the main valve, reduction gear, friction clutch , flameproof motor, hose and nozzle.

(c) The Volume Indicator is suspended from the rear edge of the canopy adjacent to the buildings where it can easily be seen by the motorist and the attendant. It includes a device for transmitting and receiving volume information from the pump unit. There is a lso a lamp on the fascia which lights up when the pump motor starts. If this light flashes when the motor starts then there is air in the line which is then banished by purging There is a lso a telecounter in the sales office which repeates the volume indication.

(d) Control System A unit within the m a in building controls the whole electrical system. There are also two buttons situated on the outside wall of the building close to the sales office. The upper one lowers and raises the hose from the canopy and the second is the limiting device overrider.

Westley Road Service Station retails three grades of petrol: BP Super (99 Octane); BP (9_5 Octane) and BP Reaular (91 Octane). The motonst dnves on to one of the 0 three eighteen feet circles on the forecourt each coloured according to the grade of petrol which can be served within a particular circle; red for BP Super, blue for BP Blend and green for BP Regular. The forecourt a ttendant then lowers the hose to head height from the canopy by pressi ng the button on wall. The action of pulling the hose down from_ head height the car's filler cap automatically zero1ses the volume (also colour coded) , sta rts the pump. m?tor a nd lights the "delivery" lamp on the volume 111d1cator.. ln sales office a "delivery" light on the tele-counter 1s also ltghted.

Why do away with petrol pump s ? Because the extra forecourt should, in BP's view, provide a refuellmg operation and less vehicle congestion. If this is then _it _will become possible to contain forecourt activity w1thm a smaller area than is now for efficient site operation. Clearly the greatest potential for the system lie s in town s and cities where la nd costs are high and intensive site development is required. ,

The is manufactured by the Tokyo Tatsuno c:;ompany Limited of J apan, where there mstall at ions in operation. Westley R oad Service Stat10n 1s the first of its kind in Europe. With this the basic of the pump are se parated mto four parts wluch are so sited as to leave the forecourt area completely open:

\. • ,. : · '"!..

91

During refuelling, the amount in gallons being dispensed is recorded both on the volume indicator and also on the telecounter. On completion the attendant places the nozzle in its holder so that it points upwards, presses a button on the hose itself just above the nozzle which is then returned to head height. As a result, the motor stops and the " delivery" light on the volume indicator goes out. At the same time , on the telecounter in the office, the " delivery" light goes out, the "delivery fini shed" light comes on and a buzzer sound s. The telecounter attendant then pres ses a re-set button which results in the " delivery finished" light going out and the buzzer stopping. The forecourt attendant meanwhile presses the button on the wall and the hose is returned to the reel housing beneath the canopy.

If another car is waiting in the circle for the sa me grade of petrol, it is possible to refuel the second car without going through the procedure of press ing the ascend button and then pulling down the hose to re-start the motor. Instead, on completion of the refuelling of the first car, the attendant presses a second button on the ho se-the re-set button. When this is done, the motor stops, the indicator " delivery" light goes out, the "delivery finished" light on the telecounter comes on and the buzzer sounds. When the telecounter operator presses the re-set button on this occasion, the volume indicator is automatically zeroised , the pump motor re-starts and the " deli very" light

comes on. At the end of this refuelling operation, if no other car is waiting for the same grade of fuel, the procedure previously described is carried out. It is also P<;>ssible to operate the system entirely from the forecou:t one attendant only; in which case the telecoun.ter is switched out a nd simply records petrol sales cumulatively. have no plan s to re-equip other sites on the se lines until the completion of a full evaluation of the S{'stem which is being undertaken later this year.

emphasis, of course, will be placed on motorists' react10n to the new style service.

The advantages of the new system on stations with cramped, narrow forecourts where maximum use can ?e made of the available space are obvious. Doubly .so, as is hoped, the system can be adapted to blendmg 111 accordance with BP's policy of making five g'.ades of petrol of varying Octane number and price at each nozzle in order to meet the individual requtrements of each make and model of car.

.Finally,Westley Road Service Station has been equipped with a refuelling system for which no prev10us st a ndards existed in the United Kingdom. We in BP would therefore like to place on record our thanks to the of T.rade, the Home Office and the Birmingham City Council for their helpfulness and co-operation in thi s unique development.

92

ATTINGHAM 1968

Self Service

J. G. FRENCH, BP Retail Division

I would like to say first of all how happy my colleague and I are to have been invited to talk to you today. Not unnaturally there is sometimes confusion in people's minds how we all into an oil company organisation. I thmk I can explam it best by saying that Mr. Wicks is an engineer and is responsible for the technical development of all types of liquid dispensing equipment used in the retail market-in his case for the three Brands, Shell, BP, an.d National Benzole. I have no such qualification, I am s11nply a marketing man and as such it is my job to try and consider the needs of the modern motorist, analyse them, and relate them to dealer's requirements and then to formulate Company policy.

Self-Service-General

Our subject to-day is Self-Service. There is a tendency for people to look on self-service as some new marketing gimmick. Self-service is not an American invention and it is not In country we have become very' conversant with self-service stores and supermarkets and with ve!1ding ?iachines selling everything from hot coffee to tickets. And_ we now have it in petrol retailingon a comparatively small scale at present. I believe 1t. 1s important at the outset to be clear that two quite different methods of petrol retailing are developing in this country to-day. Firstly, there is post-payment self-service may, 1 be likened to a supermarket operaThe second 1syre-pay11?ent self:service which may be likened to a vendmg machme but mstead of giving a laundry service it dispenses motor spirit.

Post-Payment Self-Service

Let us look at the advantages of this system to the motorist.

F_irstly is a healthy and increasing competition bu1ldmg up 111 the petrol market on the High Streetboth amongst dealers and amongst oil companies. One of the most effective weapons for meeting competition is by cutting price either directly by reducing the retail price or by offering trading stamps-often treble and quadruple. Thus, the first advantage to the motorist is one of savings.

Secondly, on a well-designed site, a post-payment opershould be capable of meeting the requirements of a high flow rate of customers since the motorist does not have to wait whilst the attendant serves the vehicle in front of him, but can get out of the car and help himself.

Thirdly, there is no obligation to tip and the customer can have as much or as little "service" as he wishes. Observation of motorists on self-service sites has shown that they tend to take more care of their cars than do many attendants, especially if the latter are unskilled or disinterested.

Lastly, the motorist has no embarrassment if he only wants one gallon of petrol.

For the dealer the advantages are equally obvious. With the rising costs of labour especially since the introduction of S.E.T. and the difficulty of obtaining good quality staff, there is a continual manning problem.

The competitive advantage gained has already been referred to.

By reducing staff and having only one person at the till both stock and cash control are improved.

Because of the nature of the operation those staff that are required are able to work in better conditions. The console operator is in a warm kiosk or shop and the forecourt supervisor, where one is required, works under a canopy. With better working conditions the dealer is able to recruit higher quality staff, thereby improving the impression which thf'. has of his business. Selfservice petrol reta1lmg 1s modern, and consequently a a modern image is projected. Because the motorist has to get out of his car and pay at the console_ he can then_ be subjected to impulse buymg of merchand1se-accessones, cigarettes, sweets, etc.

The advantages to the oil company follow. An improved Brand image, sales, and, on maxim that "self-service 1s better than no service , an improvement in the customer's attitude towards the company. It would be quite wrong t_o that post-payment selfservice is right for every site. It 1s not. In the same way that supermarkets are usually in the best positions on the High Street, so must our sites be most carefully selected. With canopy, extra _and a console postpayment system is costly. lf this capital, together with the reduced profit margin which the dealer if he reduces the retail price, are to be offset, the site must be selected to command a high throughput. Those dealers who have made a success of self-service know that you only have one chance .. If the drives in first time and finds the equipment 1s sunple to use he will call again. Signalisation and signing are therefore of I?ararnount importance and 1 know from expenence that many dealers do not u_nderstand. this I hasten to say that l am not recomrnendmg a proliferation of unnecessary advertisements and meaningless notices. There is still a lot of work to be done in this field, especially on the instructions on the pumps themselves, and we are working closely in conjunction with the Board of Trade to this end.

Finally, on the subject of post-payment self-service, a few words on layout. Whilst a large forecourt is not essential, it is certainly preferable. In order to avoid confusion and c<?ngestion, to maintain control, and to speed up the operat1011, a controlled traffic flow is most desirable.

We publish a selection of papers presented to students at the mid-week school held in May

We publish a selection of papers presented to students at the mid-week school held in May

93

This can best be achieved by clearly marked entrances and exits and by defining with the aid of white lines the exact position of each re-fuelling point. The most experi- enced operators tend to favour the use of blender pumps for self-service, hence the motorist can drive to any vacant pump and from it select whichever grade suits his requirement. In this way waiting time is reduced to the minimum and the possibility of queuing at any one particular pump is overcome. Pumps should be sufficiently well,-spaced to allow two re-fuelling positions at each one. It is a normal requirement that the console is so sited that the operator has a clear view of each vehicle on the forecourt. When an autoshop is provided, it must be laid out so that the customer enters the shop, makes any purchases he may wish, and walks out via the console operator. This requires very careful design study. Lubricating oil sales can take place either from the oil stands on the island, from vending machines, or at the console. Air and water can be provided either on the island or at a "service point" away from the island. This will depend on the space available and on the predicted customer flow.

Pre-payment Self-service

Now we turn to pre-payment self-service. As you know, the number of vehicles on the road in the United Kingdom increases annually. In 1967 it was 14 million and by 1980 it is estimated that it will be approximately 30 million. The consequent congestion on the roads has led more people to travel at night, and with more car owners and more leisure time, a greater number are out for weekend jaunts. However, service station proprietors are finding it very difficult to find staff prepared to work long hours; and with ever-rising labour charges, as well as S.E.T., they are having difficulty in providing 24 hour petrol service to motorists which is at the same time profitable to themselves. Hence the increasing interest in "After Hours Self-Service". The aim may be defined as providing a 24 hour petrol service, seven days a week, at selected sites where it would not otherwise be profitable to do so. These will normally be in towns and cities and on busy highways, but after hours self-service may well have an application in tourist areas governed by seasonal trade such as the Scottish Highlands.

Usually the station will provide a manned service by day and the pumps will be switched to "After Hours Self-Service" during the evening and on weekends. However, my Company are carrying out experiments with a wh?llY station. This is not thought to have a nationwide application, but rather to meet the requirements of special areas where there arc particular labour problems and other economic factors to be considered. ?f these is due to be opened next month at B1llencay 111 Essex. You may be interested in the sales through note-acceptors for the first three months at the first five in the country offering after hours self-service. Already 111 these early days the average monthly sales have reached a figure in excess of 2,000 gallons per unit. This demonstrates that motorists do use these machines and that they do fulfil a social need. There is no cash advantage _in from them since petrol is retailed at full pnce .. Basically there are two types of machine 111 machine and the note-acceptor. When which to use the following factors have to be considered. Firstly, the size of the purchase-the £1

equates to the average purchase of approximately 3-} gallons and provides a better return to the service station operator. However, the 5/- machine provides a satisfactory "get you home" service. Secondly, availability of currency. How many of you have two half-crowns in your pocket? 1 am sure you will all have plenty of £1 notes ! Finally, decimalisation. There are comparatively few 10/notes in circulation and these will be discontinued in 1971 with the introduction of decimal currency. Half crowns will disappear also and existing machines will have to be converted to take either the I 0 new penny piece (2/-) or the 50 new penny piece. The note acceptor is capable of conversion when currency is altered but it may be more costly than the coin operator.

The machine being used by the National Benzole Retail Division of Shell-Mex and BP is the Beck 5/- machine. The BP Retail Division are using the Wayne £1 note acceptor linked to a Wayne Blender specially modified for this purpose.

There are four fundamental requirements which any equipment must satisfy.

1. lt must be safe.

2. lt must be secure.

3. lt must be simple to use.

4. It must be reasonably priced.

This last point need not concern us to-day. Mr. Wicks will be talking more fully on the first three though there is one po!nt I would like to develop a little before handing over to htm. Almost the first lesson which we have learned was that if the installation was to be successful, the instructions had to be clear and concise. We believe that we have done this, though with further experience we may make alterations. The principles we have followed are:

(a) Clear identification of the pump by use of a globe.

(b) Overall instruction board.

(c) Instructions on note acceptor.

(d) Instructions on pump.

(e) Special instructions required by Local Authorities, e.g. fire precautions, etc.

W. K. WICKS. Shell Mex and BP Ltd.

As Mr._ French has just said, I am delighted to have the opportumty to talk to you to-day on the subject of selfservice, with particular reference to equipment and safety. Apart from the old shilling's worth on a hand operated pump way back in the 1930's, self-service as we know it to-day was developed in Sweden by the Co-operatives in the late 50's, and this subsequently spread to Denmark and other European Countries. They concentrated on a modern sophisticated post-payment system, much as we know it here in the U.K. The first site to open for selfservice in the U.K. was at Plymouth using Swedish equipment. A very close second was at Southampton where the first British equipment was used. Both the sites were postpayment and the equipment used will be described a little later. Pre-Payment Self-Service Systems followed postpayment as a natural development. Australia led the way

94

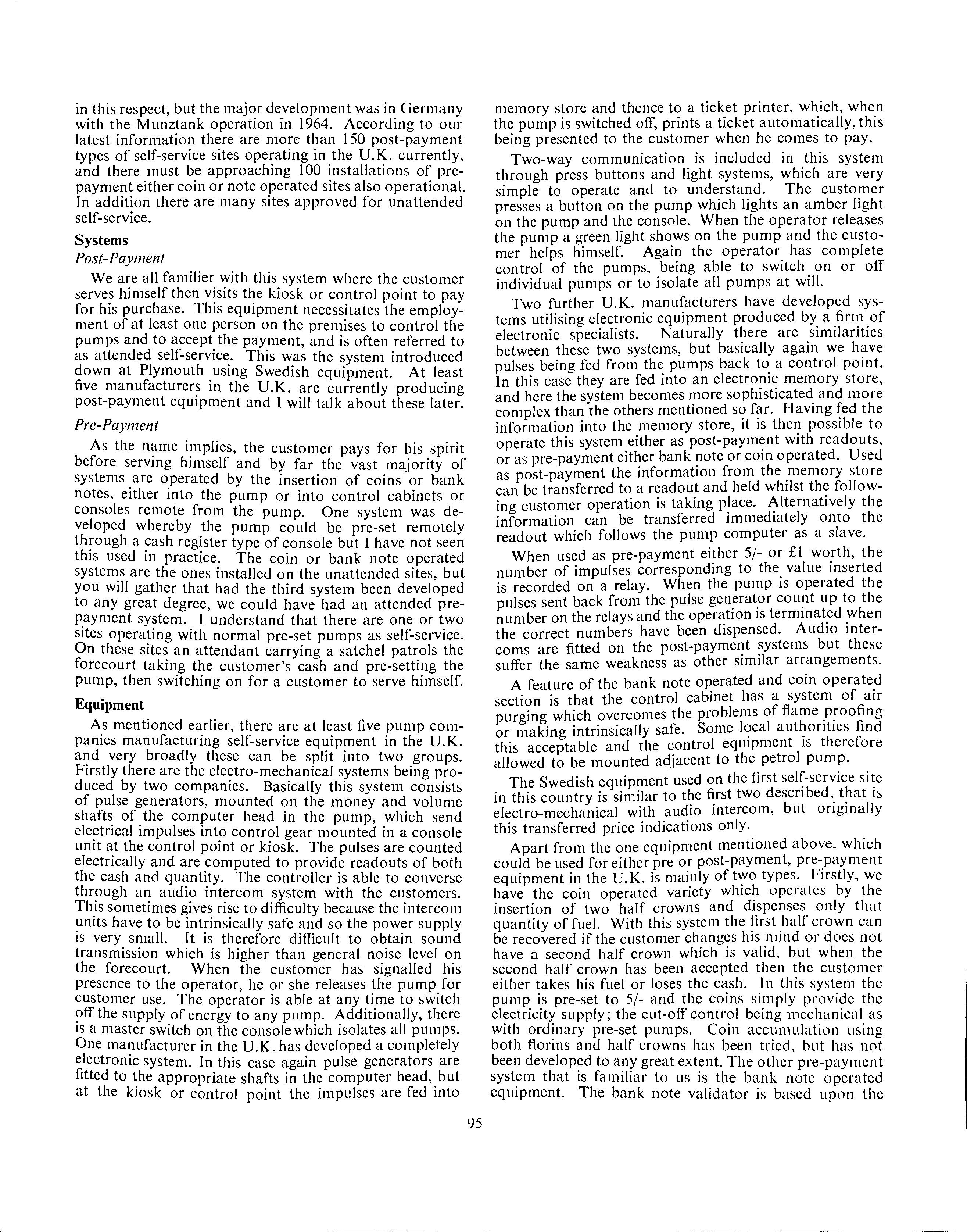

in this respect, but the major development was in Germany with the M unztank operation in 1964. According to our latest information there are more than 150 post-payment types of self-service sites operating in the U.K. currently, and there must be approaching 100 installations of prepayment either coin or note operated sites also operational. In addition there are many sites approved for unattended self-service.

Systems Post-Payment

We are all familier with this system where the customer serves himself then visits the kiosk or control point to pay for his purchase. This equipment necessitates the employment of at least one person on the premises to control the pumps and to accept the payment, and is often referred to as attended self-service. This was the system introduced down at Plymouth _using Swedish equipment. At least five manufacturers in the U.K. are currently producing post-payment equipment and I will talk about these later.

Pre-Payment

As the i!nplies, the customer pays for his spirit before serving himself and by far the vast majority of systems are operated by the insertion of coins or bank notes, either into the pump or into control cabinets or consoles remote from the pump. One system was developed whereby the pump could be pre-set remotely through a cash register type of console but I have not seen this used in practice. The coin or bank note operated systems are the ones installed on the unattended sites, but you will gather that had the third system been developed to any great degree, we could have had an attended prepayment system. I understand that there are one or two sites operating with normal pre-set pumps as self-service. On these sites an attendant carrying a satchel patrols the forecourt taking the customer's cash and pre-setting the pump, then switching on for a customer to serve himself.

Equipment

As mentioned earlier, there are at least five pump companies manufacturing self-service equipment in the U. K. aI?d very broadly these can be split into two groups. F1rstly there are the electro-mechanical systems being produced by two companies. Basically this system consists of pulse generators, mounted on the money and volume shafts of the computer head in the pump, which send electrical impulses into control gear mounted in a console unit at the control point or kiosk. The pulses are counted electrically and are computed to provide readouts of both the cash and quantity. The controller is able to converse through an audio intercom system with the customers. This sometimes gives rise to difficulty because the intercom have to be intrinsically safe and so the power supply 1s very small. It is therefore difficult to obtain sound transmission which is higher than general noise level on the forecourt. When the customer has signalled his presence to the operator, he or she releases the pump for customer use. The operator is able at any time to switch ?If the supply of energy to any pump. Additionally, there is a master switch on the console which isolates all pumps. One manufacturer in the U.K. has developed a completely electronic system. In this case again pulse generators are fitted to the appropriate shafts in the computer head, but at the kiosk or control point the impulses are fed into

memory store and thence to a ticket printer, which, when the pump is switched off, prints a ticket automatically, this being presented to the customer when he comes to pay.

Two-way communication is included in this system through press buttons and light systems, which are very simple to operate and to understand. The customer presses a button on the pump which lights an amber light on the pump and the console. When the operator releases the pump a green light shows on the pump and the customer helps himself. Again the operator has complete control of the pumps, being able to switch on or off individual pumps or to isolate all pumps at will.

Two further U.K. manufacturers have developed systems utilising electronic equipment produced by a firm of electronic specialists. Naturally there are similarities between these two systems, but basically again we have pulses being fed from pumps back to. a control point. In this case they are fed mto an electronic memory store, and here the system becomes more sophisticated and more complex than the others mentioned SC? f'.1r. Having the information into the memory store, 1t 1s then possible to operate this system either as post-payment with readouts, or as pre-payment either bank note or coin operated. Used as post-payment the information from the memory store can be transferred to a readout and held whilst following customer operation is taking p!ace. the information can be transferred onmediately onto the readout which follows the pump computer as a slave.

When used as pre-payment either 5/- or £1 worth, the number of impulses corresponding to the. value inserted is recorded on a relay. When the pump 1s operated the pulses sent back from the pulse up to the number on the relays and the operation 1s terminated when the correct numbers have been dispensed. Audio intercoms are fitted on the post-payment systems but these suffer the same weakness as other similar arrangements.

A feature of the bank note operated and coin operated section is that the control cabinet has a system of ,air purging which overcomes the problems of flame p:oofing or making intrinsically safe. Some IC?cal find this acceptable and the control equipment 1s therefore allowed to be mounted adjacent to the petrol pump.

The Swedish equipment used on the first in this country is similar to two descnbed,_ 1s electro-mechanical with aud10 intercom, but ongmally this transferred price indications only.

Apart from the one equipment mentioned above, which could be used for either pre or post-payment, pre-payment equipment in the U.K. is mai_nly of t'_"o types. F1rstly, we have the coin operated variety operates by the insertion of two half crowns and dispenses only that quantity of fuel. With this system the _half crown can be recovered if the customer changes his mmd or does not have a second half crown which is valid, but when the second half crown has been accepted then the customer either takes his fuel or loses the cash. In this system the pump is pre-set to 5/- and the coins simply provide the electricity supply; the cut-off control being mechanical as with ordinary pre-set pumps. Coin accumulation using both florins and half crowns has been tried, but has not been developed to any great extent. The other pre-payment system that is familiar to us is the bank note operated equipment. The bank note validator is based upon the

95

American Dollar Changer, and is an anglicised, sophisticated version of the equipment which is used extensively in the U.S.A. This device scans a section of the bank note in great detail and is usually adjusted to reject about 5 % of valid notes. This means that very old, dirty and creased bank notes would be rejected.

The systems in operation are basically very simple. When a valid note has been accepted this simply supplies energy to the pump, which is mechanically pre-set, and cuts off automatically when the correct volume to the monetary value has been dispensed. In this respect it is similar to the coin operated 5/- version. In the bank note system a three minute timing device has been incorporated, the operation being completely cancelled at the end of this period.

Another system being developed and to be evaluated in the near future is a mechanical ticket printer built into the pump. Some form of intercom will be built into the system which will of course be post-payment. When the pump is freed by the operator the customer serves himself and at the end of the sale a ticket is issued automatically, which is presented to the operator for payment. This equipment will have power re-set which means that the customer will only have to remove the nozzle from the pump, serve himself, and return the nozzle to the pump, which is about as simple as the operation can be made.

A system is being developed using remote pumps with a readout on the nozzle end of the hose. In this system hose reels underground or suspended from canopies could be incorporated.

Yet another system under development will use blender pumps on a post-payment system during day time operation, and will switch to bank note or credit card unattended operation at other times.

These last two systems are not being developed in the U.K. and are very much in the development stage, so we need not concern ourselves with details at this time.

Nozzle

When self-service was tirst introduced into the U.K. it was suggested by some authorities that a nozzle should be produced which would ·not operate until it was placed in the fill pipe of the vehicle. It should be designed so that it would cut off automatically when the level of liquid rose up to the end of the nozzle, and should cut off in the event of blow back. It should also be impossible to grasp the trigger when taking it out of the pump.

Wayne Tank & Pump Company spent a great deal of time and money in developing a nozzle which would satisfy all the conditions called for. They built-in electronic sensing devices so that it sensed when a car was in front of the pump. There were other devices built into it, so that it would not operate until it was placed into an opening. It cut off as required in the event of blow back or fill up. This development cost that Company many of pounds, but it did not prevent a customer placmg a nozzle into a metal pipe similar to a car fill pipe and, what was worse, it could not be made reliable. The sensing devices were far too delicate for a piece of equipment which receives somewhat rough handling in quite norm.al operation. The significant point of course was that 1t could not be made reliable and thus would have created a hazard. The next development was carried out

by a continental manufacturer. In an attempt to satisfy some of the conditions, they produced a nozzle which had an external bar running underneath the spout, and which operated a moving fulcrum arrangement within the nozzle body. In theory this nozzle would not operate until it was placed into an opening, but the opening could be anything from a vehicle fill pipe to a section of chain link fence. In practice this nozzle proved to be most unreliable as the bar quickly became damaged due to being pressed against the sides of the vehicle fill pipe, and knocked against the pump when being replaced in its holder.

Far from being a safety feature this arrangement became an additional hazard as the customers failed to make the nozzle operate when in the fill pipe after a very short period of time in use, and therefore took it out and started fiddling with it. This often resulted in petrol being sprayed anywhere but into the proper place.

For these reasons, some of the authorities who had asked for this arrangement changed their requirement. The majority of pump manufacturers and certainly my own company strongly recommend that this nozzle is not used for self-service and generally a preference for the type of nozzle which has an inbuilt inertia device is stated. latter nozzles will not operate until the nozzle is pomted downwards below the horizontal, they cut-off automatically at very slow speeds in the event of blow back or fill up conditions, that is where the level of spirit rises above the end of the spout. We consider these nozzles to be eminently satisfactory and this would appear to be borne out by experience on the continent, particularly in Germany, where they have been used on the many thousands of coin operated machines installed on sites in that country.

In addition to the safety features built into these nozzles, in practice it has been found that customers serving themselves are more careful with their own vehicle than an attendant would be, and one rarely sees even the dribbles a.t the end of the running down a vehicle on self-service sites, whereas this often happens with attenadnts who tend to become somewhat careless.

Simplicity in operation or use

Ha_ving talked about the equipment used on self-service sites m the U.K. I would now like to turn to the three subjects which Mr. French said I would be developing, but I would like to reverse the order. First then let us consider simplicity of handling.

In the case of post-payment self-service equipment we have the. audio intercom whereby a customer may contact at any time the operator if he be in doubt or where any aspect of using the equipment is concerned. Additionally, the instructions on the pump have been designed after much consultation between the Board of Trade, the Equipment Manufacturers and the Operators (and by that I mean the Oil Companies who have developed self-service as a policy), but we are not suggesting that we have reached the ultimate in simplicity of use for post-payment selfservice systems. For instance, there are complications if a customer should require more than allowed by the limiting device, where either the override has to be operated or details of that sale cancelled and he should start again. There are further complications where blending pumps are used, as there are so many controls that some have to be placed on one side of the pump and the remainder on the

96

other side. In spite of this, however, operation of this type of equipment has been simplified to the extent that it is rare that a customer needs instruction after the first time of using.

Developments are proceeding as with the ticket printer pump mentioned earlier where we have reached about the ultimate in simplicity as the customer has nothing to do other than take a nozzle out of the pump, serve himself, replace the nozzle and take the automatically printed ticket to the kiosk for payment.

I think it would be fair at this point to give credit to our equipment manufacturers in the U.K. who have worked (very often in the face of opposition from authorities) to produce equipment which the public will find uncomplicated. Their developments have sometimes been sidetracked and complicated by marketing requirements of the oil companies and individual customers, but in spite of any difficulties, they have produced reliable equipment in most cases which has been sufficiently simple to use and self-service sites in the main are very popular and successful.

Security

When we talk of security we are referring mainly to those pre-payment systems particularly on an unattended basis. In the case of coin operated pumps, the pump casings are fitted with special locks and within the outer casing is a further coin box again fitted with a special lock.

Mechanical strength is built into this inner coin box, and we know of no case where insurance companies have asked for increased premiums where these equipments have been installed on sites.

Bank note operated equipment presents a different problem because cash values are proportionately higher. Here we have two slightly different problems, one being where the validator and control gear are sited remotely from the pump. The equipment manufacturer in this case has made the cabinet sufficiently strong to protect the delicate electronic gear of the note validator, and additionally to act as a safe for the money contained therein. The cabinet is constructed of heavy gauge steel plate, and designed in such a way that it is impossible to insert a lever between the side of the cabinet and the door, so that a grip can be obtained, thus forcing the door open. In addition to this, in most cases, the cabinet is built into either a block of masonry or the front of a building; but other than the prevention of the cabinet being hauled away, the building into masonry is not entirely necessary, due to construction of the cabinet. In the second case, we have the air purged cabinet which can be mounted on a post adjacent to the pump; here again the cabinet i.s in heavy gauge steel plate, and the door similarly constructed so that it is impossible to insert a le':'er 1?etween the cabinet and door edge with a view to forcmg 1t open. Again this cabinet can be built into a masonry block 1f so required, but of course, care would have to be exercised to ensure that the air passages are kept clear.

No doubt we could all think up many schemes whereby alarms are set off in the event of damage to the cabinets, but experience to date has shown that the construction of cabinets themselves, the siting of the pumps and t.he mtensity of illuminations on sites where this sort of equipment is installed, are sufficient deterrents to dissuade the

petty thief and vandal. Should there be an organised gang who are determined to break into this sort of equipment, then quite obviously they could succeed, but it would not be a simple matter for them, and it should be realised that in spite of all the sophisticated alar1:1s and up-todate designs of safes, many burglanes are still committed.

It must be safe

Safety is a topic which is uppermost in all our minds when we construct a filling station, whether it be attendant service or self-service, whether it be attended self-service, or unattended self-service. Safety is achieved by devices built into the equipment, and by codes of and licensing conditions desigi:ied to ensure that the is installed and operated m a safe manner. In the eqmpment we have pre-set devices which terminate delivery of product on either attendant operated pumps or on selfservice pumps. In the case of attendants, they. set the before the and this 1s able by the simple mampulat10n of a knob on the side of the pump. In the case of self-service, I have described this feature in the coin operated and the bank note operated pumps, where the pre-set is by the manufacturer and terminates mechanically the dehvery of products.

Limiting devices at quantities prescribed by the authorities are fitted to many pumps, thus ensuring that no more than the prescribed amount of product i:iay be dispensed in any one operation without some deliberate action being taken upon the pa!t ?f the pump operator. These limiting devices may be bmlt mto attendant operated or self-service equipment.

The safety nozzles incorporating the cut-?ff device which will prevent overspilling and mertia which will not allow products to flow until the nozzle is pointed below the horizontal. I described the nozzle developed for self-service earlier in my talk.

Finally, we have the principles of constructio_n. and licensing conditions which you gentlemen admm1ster. There has been lack of guidance on this subject in the past, but I shall be most disappointed if a new model code containing guidance on both attended and unattended selfservice is not available before the end of July. Indeed, when asked recently in the House of Commons for a date when this document would be available, the Home Office spokesman stated that it should be published in about three months from the end of March. In the meantime, advice can be obtained from the Home Office, and we must hope that any such advice that is sought and given will be based on the new model code. In the absence of any realistic guidance from the recognised authority, your Association produced some documents with which L am sure you are all familiar, and which have undoubtedly helped to fill the gap created by events overtaking legislation. When I spoke to a meeting of your Association at Huyton-with-Roby in April I made it quite clear that, whilst I could not agree with all the conditions contained in those documents, l appreciate the hard work and thought that went into the production of them, and expressed the view that the Industry and the Local Authorities should be grateful to those people who made the effort to produce them. Experience often shows that whilst intentions have been good, regulations framed to-day can quickly become obsolete.

97

The Nature of Petroleum Spirit and its Hazards

J. R. HUGHES. B.Sc., F.lnst.Pet. Chief Safety Engineer, British Petroleum Co. Ltd.

J. R. HUGHES. B.Sc., F.lnst.Pet. Chief Safety Engineer, British Petroleum Co. Ltd.

Nature of "Petroleum Spirit"

Petroleum-spirit, far from being a simple entity, consists of a large number of compounds. Chemically, therefore, it is neither feasible nor desirable to be able to make a complete analysis. Petroleum in its natural state, from which petroleum-spirit (gasoline) is derived, consists principally of a mixture of hydrocarbons of differing molecular weight and molecular structure which may be classed in three main groups (Table 1).

TABLE 1

Some lower boiling-point compounds in the three main groups of hydrocarbons present in crude petroleum

On analysis, a typical crude oil will be found to contain about 85 per cent wt. carbon and 13 per cent wt. hydrogen. Other elements, such as oxygen, nitrogen and sulphur may be combined with carbon and hydrogen, and small amounts of various metals, such as vanadium and nickel, may be present in the form of complex organo-metallic compounds.

Compound Formula Paraffins

Methane CH, Ethane CH 3 CH 3 Propane CH 3 CH 2CH 3

Butane CH 3 CH 2 CH2CHa

Pentane CH 3 (CH 2)aCHa

Naphthenes

Cyclopentane C5H10

Cyclohexane C 0H 12

Aromatics

Benzene Ca Ho

Toluene CaH5CHa

Normal state Gas Gas Gas Gas Liquid Liquid Liquid Liquid Liquid Liquid

Boiling point at normal atmospheric pressure op -259 -128 --44 31 97 121 176 176 232 291 98

oc -162.0 -89.0 --42.2 -0.6 36.1 49.4 80.0 80.0 111.1 143.9

I

l J.,•. I Fig. 1

t1Toppcd11

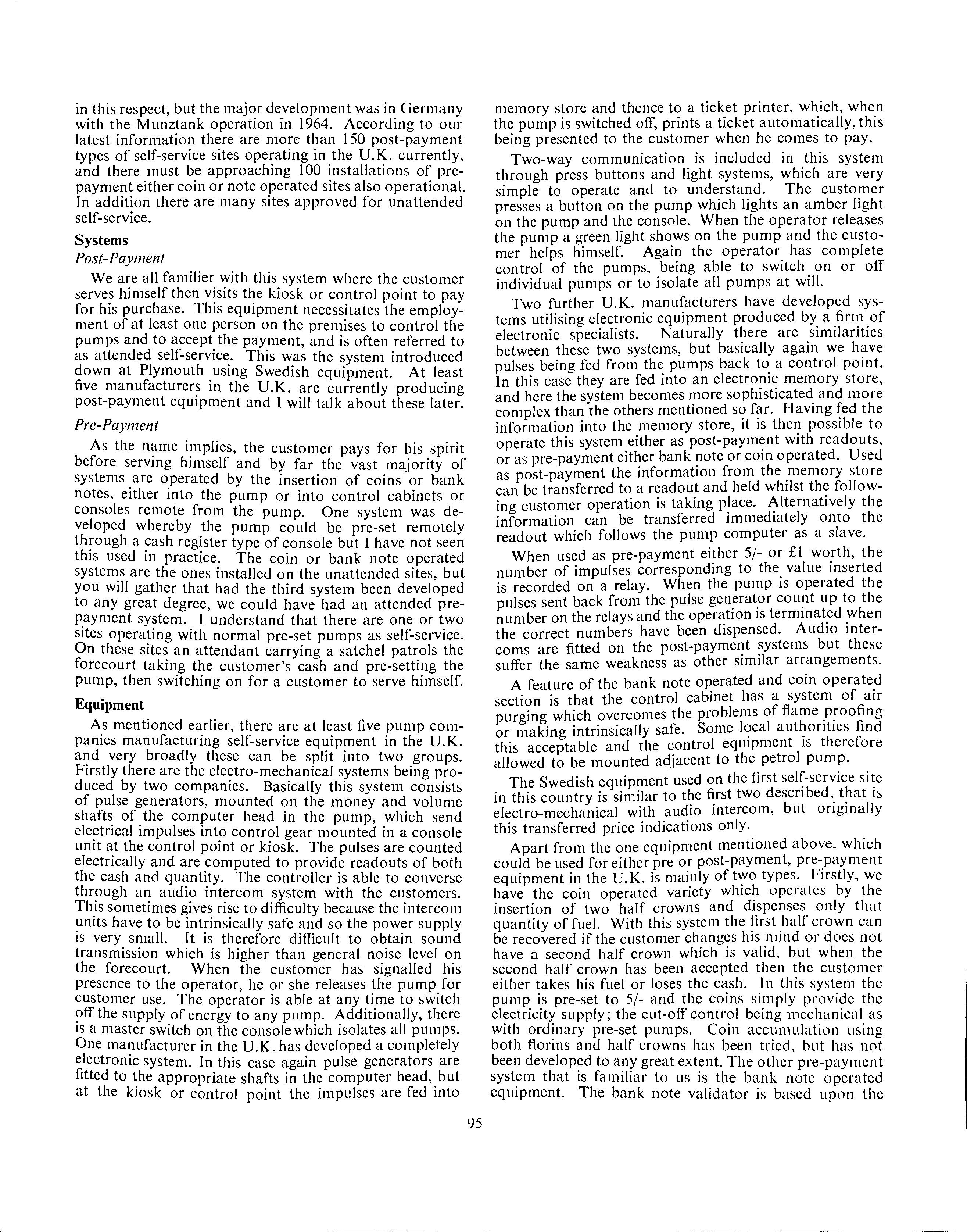

!n the secondary stage, the "topped" crude from the distillation is heated in a pipe still furnace and discharged into the main fractionating column at substantially atmospheric pressure. In this column, which is provided with a number of fractionating trays, separation occurs into different fractions or "cuts" according to their boiling ranges.

The fraction boiling between about 80° and l40°C (176° and 284°F) is a heavy gasoline suitable as a blending component for motor gasoline and for upgrading by catalytic reforming operations. The next fraction is naphtha, boiling between about 140° and 180°C (284° and 356°F), used partly in the manufacture of white spirits but more often as a feedstock for up-grading gasoline by catalytic reforming. Kerosine is within the approximate boiling range 180° to 250°C (356° to 482°F). The raw kerosine fraction is further refined by solvent extraction

Ortho-xylene CaH4(CH3}a

I I Distillatei:; f'or Final

residue

l

Bi en

Fuel oil blends

For practical purposes it is preferable to visualize crude oil as consisting of fractions having a smooth continuous gradation of boiling points rather than as a mixture of individual chemical compounds. Crude oil is separated into its constituent parts by the process of fractional distillation, often carried out in a three-stage distillation process (Fig. 1).

rtd(Methane) rla:lh (Ethane) diotillato

crude

Lubricating oil

production M.d/or

catalJ'tic cracking

I

(Prillll3ry or rrazsurc ctage) (Secondar,y or atmo::ipheric stage) (Third or '\"n.ouum otacc)

The P.rimary stage, a flash evaporation of the preheated cr1;1de od under about 50 lbf/in2 (3.5kgf/cm2) pressure brmgs about the removal of the lightest fractions. These consist of the gases methane and ethane and primary flash distillate, from which in a further ("stabilization") stage of distillation are obtained the gases propane and butane and a product known as stabilized light gasoline which has an al?I?roxmate boiling range of 30° to 80°C (86° to 76 °F). is used in blending motor gasolme and aviat10n turbme gasoline.

to improve its lamp burning characteristics. Gas oil is taken off in the fractions boiling between about 250° and 340°C (482° and 644°F). The atmospheric residue which remains may represent about 50 per cent by volume of the crude oil charge. It is often used directly as a major component of heavy fuel oil, but it may also be processed further in a third stage of distillation carried out under vacuum. This final stage may be operated either to produce a heavy gas oil and a range of raw lubricating-oil cI.istillates (often paraffin waxes) or to give a smgle broad waxy disttllate or long-range heavy gas oil used as feedstock for catalytic cracking. The final vacuum residue may either be used as a component of heavy fuel oil or as base material to give a bitumen or road asphalt. products are usually not in the desired proportions or of adequate quality to satisfy the req1;urements of the market and they may, therefore, be subjected to further various refining processes. Some of (such as thermal and catalytic cracking) change the botlmg. range of .the products so as to yield, for example, more hght fractions at the expense of heavy fractions. Other processes, such as catayltic reforming, alter the molecular a given boiling-range product so as to .make more suitable for its end use, say, as motor while others such as hydrofining and autofining aim to remove or reduce the content of unwanted sulphur compounds.

Crude oil can therefore be made to yield, by separation, by conversion and by refining processes, a very wide range of products. Some of these are finding a new importance feedstocks for the rapidly developing petrochemical mdustry. Unfortunately, there are no universally accepted definitions of petroleum products but "A Glossary of Terms" published by the Institute of Petroleum, provides a useful reference for the interpretation of terms m common use.

The term "petroleum-spirit" is rarely used in the petroleum industry. It is defined in Section 23 of the Petroleum (Consolidation) Act, 1928, as "such petroleum as when treated in the manner set forth in Part II of the Second Schedule to this Act gives off an inflammable vapour at a temperature of less than 73°F (22.8°C)." In other words, it is "such petroleum which has a flash-point of less than 73°F, since "flash-point" is the temperature to which the petroleum must be heated to give off sufficient vapour to form a mixture with air that can be ignited momentarily by a flame".

The arbitrary nature of this definition is apparent when one considers the historical basis for choosing 73°F. In early days of oil-refining, when kerosine replaced coza oil or rapeseed oil for lighting, the flash-point test was used to distinguish between safe and unsafe oils. The steps. which Jed to the determination of the division point provide an interesting example of the origin of some of our traditional methods and specification limits. The Petroleum Act of 1862 stated: "petroleum for the purpose of this Act shall be any substance that gives off an inflammable vapour at Jess than 100 degrees of Fahrenheit's thermometer". No test apparatus was described, however, and the Act remained practically inoperative. In 1869 a Act was passed which a flash-pomt testmg apparatus designed by Sir Frederick A?el. It was soon found, however, that the results from this apparatus were not sufficiently repeatable and that

considerable skill was required for its use. In 1875, therefore, the Government asked Sir Frederick Abel to redesign the test equipment and make it suitable for use by "persons who have had comparatively little experience in conducting delicate experiments" He was also asked to say whether the then existing limit of 100°F (37.8°C) afforded adequate protection to the public. He reported that the limit 100°F by the old apparatus did afford sufficient protection, and he also redesigned the apparatus which is the presentday Abel closed flash-point tester. From extensive experiments he determined that the new apparatus gave results which were, on average, 27°F (15°C) lower than the results obtained with the old apparatus, and he therefore recommended that the Act should be revised to set a limit of 73°F (22.8°C); this was done in 1879. The temperature and the apparatus have remained unchanged to the present day for defining "petroleum spirit".

Sir Frederick Abel could scarcely have realised the tremendous implications of his recommendations. The international character of the petroleum industry makes it desirable that there should be a universally agreed definition for flammable liquids generally. The United States of America, France, Germany and the United Kingdom all have different classifications for flammable (synonymous with "inflammable") liquids, but there are indications in Europe at least, of moves towards an agreement for a' common classification. Such an agreement is "The European Agreement concerning Intert?-ational Carriage of Dangerous Goods by Road (abbreviated to ADR) to which the United Kingdom is a signatory. Under this Agreement, dangerous substances !isted under several classes, but as far as are concerned only the following categories of dangerous substances" are relevant:

(i) Liquefied petroleum gases, which come within Class Id of the Class Illa of the classification which include-

(a) "Liquids not miscible with water which have a flash-point below 21°C (69.8°F), e.g. .Petroleum volatile products from the distillation of petroieum and other crude oils, coal, legnite, shale, wood and peat tars;

(b) "Liquids not miscible with water which have a flash-point between 21°C (6?.8°F) ar:id 5.5°C (131 inclusive, e.g. petroleum oils (for or engines), heavy benzols, white spmt (turpentme substitute), solvent naphtha;

(c) "Liquids not miscible with 0 wluch have. a flash-point above 55°C (131 F) exceedmg but including 100°C (212°F), e:g. ce.rtam. tars a.nd · their distillation products, heatmg oils, diesel oils, and certain gas oils".

The ADR Agreement is not in final form but the Office Advisory Committee on Dangerous .111 advising the Home Secretary on the extent to which legislation is necessary concerning dangerous substances is naturally paying due regard to the ADR Agreement since it is a party to the Agreement.

ln a paper to Administrators of Petroleum Acts, it is perhaps excusable to have emphasized legal distinctions, but to revert to the physical nature of petroleum-spirit and for a better understanding of the hazards in handling and storing petroleum-spirit, we should consider now the properties of vapour pressure volatility and flammability.

99

--.._

Vapour Pressure and Reid Vapour Pressure

When a liquid evaporates, molecules leave the liquid and enter the space above it. If the liquid evaporates in a closed container, the number of molecules in the space above the liquid will eventually reach a maximum at a given temperature. The pressure exerted on the container wall is the sum of the pressure of the air and vapour molecules, and the pressure exerted by the vapour is called the vapour pressure of the liquid at that temperature. Further evaporation of the liquid is possible only by reducing the pressure in the vapour space (by withdrawal of vapour) or by an increase of temperature. Boiling of a liquid is characterized by a rapid and continuous evolution of vapour and implies either that the liquid is open to the atmosphere or that the vapour is being continuously withdrawn froid the container. A liquid boils when its vapour pressure equals that of the gas in contact with it.

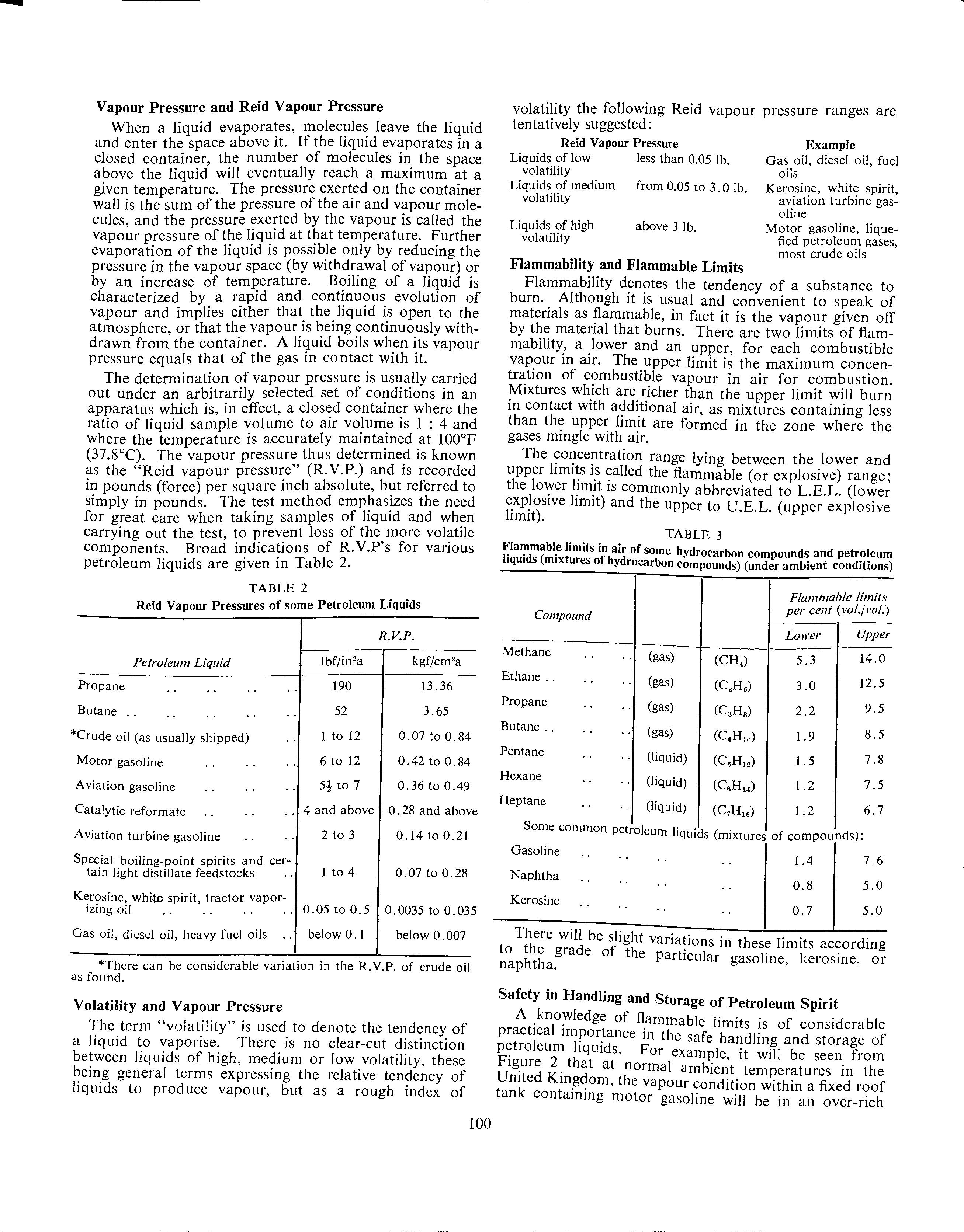

The determination of vapour pressure is usually carried out under an arbitrarily selected set of conditions in an apparatus which is, in effect, a closed container where the ratio of liquid sample volume to air volume is 1 : 4 and where the temperature is accurately maintained at 100°F (37.8°C). The vapour pressure thus determined is known as the "Reid vapour pressure" (R.V.P.) and is recorded in pounds (force) per square inch absolute, but referred to simply in pounds. The test method emphasizes the need for great care when taking samples of liquid and when carrying out the test, to prevent loss of the more volatile components. Broad indications of R. V.P's for various petroleum liquids are given in Table 2.

TABLE 2

Reid Vapour Pressures of some Petroleum Liquids

R.V.P.

Petroleum Liquid lbf/in2a kgf/cm•a

Propane 190 13.36

Butane .. 52 3.65

*Crude oil (as usually shipped) I to 12 0.07 to 0.84

Motor gasoline 6 to 12 0.42 to 0.84

Aviation gasoline St to 7 0.36to0.49

Catalytic reformate 4 and above 0. 28 and above

Aviation turbine gasoline 2 to 3 0.14 to 0.21

Special boiling-point spirits and cerI to 4 0.07 to 0.28 tain light distillate feedstocks

Kerosine, white spirit, tractor vaporizing oil · · 0.05 to 0.5 0.0035 to 0.035

Gas oil, diesel oil, heavy fuel oils below 0.1 below 0.007

*There can be considerable variation in the R.V.P. of crude oil as found.

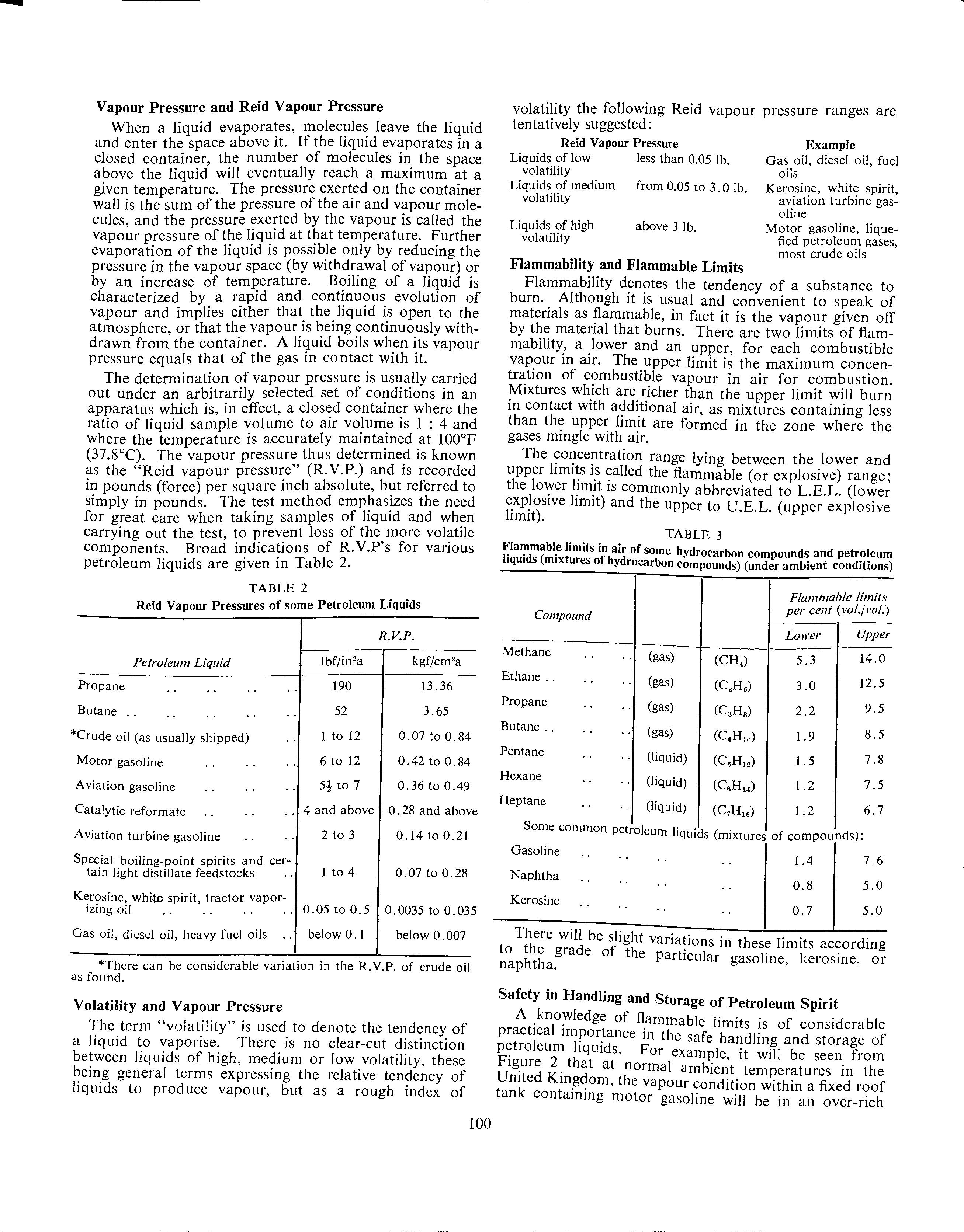

Volatility and Vapour Pressure