UPGRADING A FEED MILL 47

City Group commissioned a 111-ton-per-hour facility of which 40 tons are for cattle, 50 tons for poultry and 21 tons for aquafeed, all across nine lines, with a total 720,000 tons per year.

THE IMPORTANCE OF THE SOURCE OF YEAST 23

The advantage of primary-grown yeasts as source for yeast-based prebiotics.

BOOSTING SHRIMP DEFENSES WITH NUCLEOTIDES AND SINGLECELL PROTEIN 37

A trial to determine the efficacy of bacteria-based nucleotides and singlecell protein in managing EHP in shrimp.

NOVEL APPLICATION OF BLACK SOLDIER FLY LARVA PUREE 54

A study assessed the feasibility of integrating BSFL puree into the feeds of crabs.

Editorial: editor@aquafeed.com

Editor/Publisher: Lucía Barreiro

Consulting Editor: Suzi Dominy

Technical Editors:

Peter Hutchinson, Albert Tacon, Ph.D

Assistant Editor: Marissa Yanaga

Conferences and webinars: info@aquafeed.com

Advertising enquiries/request media pack: sales@aquafeed.com

Accounts & all other enquiries: info@aquafeed.com

SUBSCRIBE

Digital editions are free to industry subscribers. You may also purchase print copies. Subscribe at Aquafeed.com to receive your own digital copy of our publications.

https://bit.ly/AQUASUBSCRIBE

Aquafeed Media, S.L.U., Ames, 15220 A Coruña, Spain.

Aquafeed

1998-2024

and Quillaja saponaria extract as dietary additives to improve aquaculture productivity by supporting

AQ: Dainichi started as a feed business, but today it is a vertically integrated company. Where is the company today in terms of farmed species?

DC: In 1982, we began as a feed company, and today, we are vertically integrated into raw materials, aquafeeds, aquaculture production, and more. Currently, we are farming red seabream (Pagrus major), yellowtail (Seriola quinqueradiata; Hamachi), and bluefin tuna (Thunnus orientalis).. We also farm a small amount of Sakura masu (Oncorhynchus masou), a domestic Japanese trout. Sakura masu is primarily sold in the local market, especially to schools and nursing homes for their lunches and dinners. About 20% of our other seafood

production is exported, with the remainder sold domestically. We are increasingly focusing on expanding our export market.

AQ: How about the aquafeed production?

DC: On a dry weight basis, we produce about 14,000 metric tons annually. We manufacture moist pellets using cold extrusion, combining pilchards, anchovies, and frozen fish with a binder and fishmeal to form moist pellets. This was our original feed formulation. We then began purchasing feed from large feed companies. Currently, we import raw materials from Central America, which are then sold to a feed mill

that process and manufacture feed for us. We use this feed to grow our own fish as well as supply it to our contracted farmers. One of our main feed partners is Nihon Nosan.

In Japan, selling feed comes with the responsibility of buying back the fish, so this has made us more involved in the handling, processing, and marketing of seafood, not just aquaculture feeds.

AQ: Dainichi was one of the first companies that committed to fish-free feeds. What has been achieved so far in these years?

DC: We have been involved in the F3 Challenge since its inception, and for the third challenge, we developed a fishmeal and fish oil-free diet for carnivorous fish. We tested this diet with red seabream, achieving growth results that, while not as good as the control group, were satisfactory. The economic feed conversion ratio (eFCR) was favorable.

This led us to consider the impact of El Niño in South America and other associated risks, prompting us to invest in a Malaysian alternative protein company that produces black soldier flies for use in our aquafeeds. Currently, the production of this alternative protein is limited as the company scales up, which restricts the current inclusion levels in the diet.

We aim to conduct various tests on different species and inclusion levels, but we are constrained by the availability of raw materials. Our supplier is expected to reach a production level of one container per month next year, providing us with greater flexibility.

AQ: How do you see the commercialization of this red seabream fed with fish-free feeds in terms of consumers and retailers?

DC: Our ASC-certified red seabream is sold at Costco in Japan. We are gradually expanding this market, which requires consumer education and scaling up our production.

One observation we made with the F3 diet fed fish is that the taste will vary depending on the ingredients used and whether you're used to eating fish or not. In an in-house taste test with senior employees, we found that they thought the fish lacked “umami” and that the texture or “hagotai” wasn't as good, though they appreciated the fish’s smell. Conversely, our new employees thought the F3 fed fish tasted really good.

"We have participated in the F3 sessions since the beginning. We intend to gradually incorporate more alternative ingredients into our formula fish feeds."

This suggests that people less accustomed to eating fish might prefer this product, offering us a unique storytelling angle.

AQ: Dainichi also grows bluefin tuna. What kind of feeds are you using?

DC: Kinki University (aka Kindai) successfully closed the cycle of tuna in their hatchery creating sustainable bluefin. Currently, we are using both tuna from Kindai’s hatchery as well as wild-caught tuna for grow-out. Unlike countries like Spain, where they catch 50-kilo fish and ranch them till they are 70-80 kg, we start farming our tuna at a much smaller size and after three to three and a half years, we harvest at 40-70 kilos.

Currently, we are using a variety of forage fish in our tuna feed because it improves survival rates and enhances taste. For raising our tuna, we purchase large quantities of frozen fish and store them in freezers which does incur high running costs. In contrast, extruded pellets can be stored in a dry warehouse, reducing costs. In the near future, we plan to retry extruded pellets to further explore their potential benefits.

AQ: How are you diving into this volatility context in terms of ingredients?

DC: We use domestically produced fishmeal and other ingredients that are derived from byproducts, such as byproducts from a squid processing plant. Squid viscera contain 20 ppm of cadmium, but we have successfully

developed a processing method to eliminate this. Once removed, the finished product is used as a palatant in fish feed.

We have maintained supplier relationships for nearly 15 years. For ingredients like soy, in Japan, it's easier to purchase it through large trading companies, especially if you're milling your own feed. Overall, we have managed well amid the current volatility.

AQ: Dainichi also provides consulting services to farmers. What are the main farmers' needs in the country?

DC: We were one of the first companies to provide this kind of service to aquaculture farmers. In Japan, the majority of farms are family-owned, traditional operations. However, we're now seeing a shift. The younger generation often prefers to move to the city rather than continue in aquaculture, and many owners are ready to retire, leaving their fish lots behind. That's where we step in, offering economic and technical support to these farms.

AQ: What are your projections for growth for the aquaculture business?

DC: The exportation of Hamachi has greatly increased, so we aim to more extensively farm this species. Another species we are working on with Kinki University is Burihira. Occasionally you will find this fish in the wild, but this is a genetic crossbreed of Hamachi (Seriola quinqueradiata) and Hiramasa (Seriola aureovittata). Hamachi is considered to be “in season” during the winter months when it has high levels of fat. Although it is in the same genus as yellowtail, the difference between Hiramasa and Hamachi is that it matures like white meat. If it is prepared well, it can be eaten as sashimi for a long time. By producing Burihira, we hope to achieve a product that can have a consistent fat level and excellent taste year-round. Regarding fish-free feeds, we have participated in the F3 sessions since the beginning. We intend to gradually incorporate more alternative ingredients into our formula fish feeds.

Nutreco opened a state-of-the-art fish and poultry feed production facility in Ibadan, Oyo State, Nigeria, through its operating company trading under the names Skretting and Trouw Nutrition. The new EUR 25 million facility was built on 170,000 square meters of land and has the capacity to manufacture 125,000 metric tons of extruded fish and animal feeds per year.

Cermaq Canada has committed to a nutritional innovation trial of Cargill’s salmon feed with Veramaris algal oil across several Cermaq farms in British Columbia. The introduction of algal oil aims to reduce the need for marine fish oils in salmon feed. The feeding period began in May and focus on introducing the new feed to salmon close to harvest size.

AmiNova is a new feed formulation concept that allows even more precise nutrition, resulting in better utilization, higher efficiency, and lower nutrient release to the environment. Traditionally, aquaculture feeds have been formulated based on crude protein and, subsequently, on digestible protein. With AmiNova, Skretting is introducing a new way of formulating, based on an ideal digestible amino acid profile. By evaluating the total amino acid level that is effectively ingested by the fish and removing the unnecessary excess, the nutritional needs of fish are met with increased precision and efficiency.

Aker BioMarine has entered into an agreement with American Industrial Partners (AIP) and Aker Capital for the sale of Aker BioMarine’s ownership position in the Feed Ingredients business, based on an enterprise valuation of USD 590 million. The acquiring party will be a newly established company owned 60% by AIP and 40% by Aker Capital. Earlier this year, Aker BioMarine announced a strategic review of its ownership position in the Feed Ingredients business. The transaction will create significant shareholder value and is an important step in crystallizing value and enabling a focused Aker BioMarine within the human health and nutrition business.

Five prominent international companies, BioMar, Aller Aqua, Aqquua, Dainichi Corporation and Yuehai Feed Group, have committed to testing the winning products of the F3 Krill Replacement Challenge within their commercial operations, signaling a significant milestone for the future of fish feed. The companies, that made the commitment during the F3 - Future of Fish Feed Meeting this week in San Francisco.

The partnership links BESTMIX® Software's feed formulation with the Sustell™ full life cycle assessment (LCA) platform, allowing customers to generate and share their feed footprints easily. With this solution, feed producers can report the environmental impact of their feed with the click of a button, leveraging existing data in their trusted BESTMIX software suite. This integration assists feed producers in addressing future demands of feed labeling while simultaneously helping farmers accurately quantify the environmental impact of products such as eggs, meat, milk, and farmed seafood.

The shipping company Eidsvaag AS will build two new feed vessels for feed suppliers Skretting and Cargill. Due to be delivered in 2026, the vessels will have dieselelectric propulsion systems with large battery packs and engines with fuel flexibility so they can run on biodiesel if so desired. The two ships will be part of the Fjordfrende partnership established in 2019. Here, competitors Skretting and Cargill are collaborating to deliver fish feed via 14 vessels operated by the shipping company Eidsvaag AS. By working in this way, the companies avoid having to run separate transport routes in and out of the same fjords along the Norwegian coast, thereby significantly reducing CO2 emissions.

The Dutch manufacturer and seller of specialty feed additives has entered the aquafeed industry. The collaboration between Bluejais and Balaraman has led to the development of two in-feed concepts and one water treatment solution. These solutions help support productivity, mitigate risks, and promote sustainable practices in shrimp and fish farming.

Bühler, in partnership with Premier Tech, introduces the CHRONOS OML-1140 B automatic open-mouth bagging station. Engineered to accommodate an array of products such as animal and aquafeed pellets, aqua and feed mash, and freeflowing products, this fully automatic bagging station enhances productivity by ensuring consistent operation, precise bagging performance, as well as the highest product and operational safety standards.

Rothamsted Research Limited has granted Yield10 Bioscience an exclusive global, commercial license to advanced technology for producing sustainable omega-3 products in Camelina sativa. Yield10 is executing a plan to use engineered Camelina to commercially produce omega-3 oil and meal products targeting the aquafeed, pet food, and nutritional markets for omega-3 fatty acids. Over the last decade, the Rothamsted team, led by Professor Johnathan Napier, science director, has demonstrated the production of omega-3 oils in Camelina seed and conducted evaluations of the oils in salmon feeding.

The first 2024 anchovy season in Peru’s northcentral fishing zone ended in June with more than 98% of the quota fulfilled (2.35 million tons). The marine ingredients industry sees this as a positive sign for the fishing and feed sectors, considering that Peru accounts for around one-fifth of the global fishmeal supply in an average year. A second fishing season will take place later in the year, based on independently set quotas taking into account the

The Finnish mycoprotein company has completed a funding package that enables it to start constructing a unique food-grade mycoprotein factory in Kirkkonummi, Finland. The factory, which is set for completion by the end of 2025 and projected to cost EUR 33 million, will convert food industry side streams into Enifer’s sustainable PEKILO® fungibased protein ingredients. The plant will be the world's first commercial plant with a capacity of up to 3,000 tons per year to produce such a mycoprotein ingredient from sidestream raw materials.

Nutreco recently celebrated the opening of its Garden of the Future, the new hub for its Phytotechnology program. Located in Thurgau, Switzerland, the groundbreaking facility gathers all of Nutreco’s phytotechnology activities, from discovery and experimental cultivation to plant development and production, under one roof.

Nutreco’s initiative is completely different from anything the industry has produced in the past. It is focused on creating phytotechnology solutions, called Phyto-complexes, plants or plant metabolites, that when added to feed, have physiological impacts that consistently support the performance, health and welfare of aquatic species, farm and companion animals.

“We know that plants influence animal physiology. The previous technologies were all developed with that single molecule idea to kill bacteria. We are now talking about a new approach using a plant to tackle an animal problem, not targeting pathogens,” Emma Wall, director of development & deployment at Nutreco Exploration, explained.

Phyto-complexes are developed in direct response to existing market issues, identified in close collaboration with global Trouw Nutrition and Skretting customer-facing teams. Many of Nutreco’s Phyto-

complexes come from plants that haven’t been cultivated before, which requires the team at the Garden of the Future to have a high level of plant production expertise to create vertically integrated plant supply chains for these new plants.

A practical example of the application of this technology in aquafeeds was presented by Alex Obach, director of innovation at Skretting.

Shrimp mainly use glucose for metabolic energy purposes, however, shrimp diets were usually formulated with high levels of protein. That extra protein was being used for energy, it made aquafeeds expensive and the nitrogen excess ended up in the environment. Therefore, shrimp diets have been changing in the past few years to low protein levels. The request from Skretting to the Discovery team was a solution to ensure shrimp is utilizing the glucose that is available for metabolic purposes in a more efficient way. The team found a plant that improves the animal’s nutrient intake.

“The applications in aquaculture are very wide. There is potential to optimize the physiology of the animal, it can help them be more robust and can help with welfare, health and productivity. We look at what the main issues are, where we also have heritage and we can really make a big difference with functional nutrition. It can vary from environmental stressors to pathogenic stressors and handling and all sorts of different approaches,” Charles McGurk, research and development director science at Skretting Aquaculture Innovation, told Aquafeed.com.

In terms of aquafeed application, the products are able to go through the extrusion process and will be incorporated into Skretting aquafeeds.

The fish feed market is changing. In recent years, the production of floating fish feed has accounted for more than 65% of the fish feed market. The farmer kept increasing this demand because of a higher conversion rate than sinking feed, easiness to monitor the feed consumption and a reduced chance of infection by fish diseases.

On the other hand, sinking aquafeed for fish and shrimp produced by extrusion used to be a niche market, but is now seeing continuous growth. The main reason is that extrusion offers flexibility in choosing raw materials and a better feed conversion ratio (FCR) due to extrusion’s cooking properties.

During production, 40% of the fish feed quality is affected by the formulation, and the rest is directly affected by the machine that is used. For example, 40% of the production quality is directly affected by the extrusion process, 20% by the conditioning process, 15% by the die profile and specification, and the rest 5% by the cooling profile of the pellets. No matter the farmer’s preference for floating, slow or fast sinking feed, CPM’s new TwinTech extruder has it covered.

Enhanced gearbox technology: Powered by CPM’s field-tested gearbox technology, the TwinTech extruder features a high-speed, heavy-duty gearbox capable of achieving rotational speeds of up 600 RPM. This allows for increased processing capacity and efficiency. The gearbox is equipped with an air cooler that can prevent lubricant oil thinning, thus ensuring that the friction between moving gear is kept in optimal condition, and the production can last longer without disruption from the overheating gearbox.

Energy-efficient design: The TwinTech extruder is powered by a permanent magnet synchronous motor (PMSM), which is highly efficient and about 50% smaller

than traditional air-cooled motors. This motor design contributes to energy savings, reduced noise pollution (up to 30% lower) and the option for water cooling to maintain motor efficiency and stability.

Density control unit: An optional feature, the density control unit, allows TwinTech to produce different types of fish feed, including sinking and slow-sinking feeds. This unit utilizes positive pressure inside the cutter chamber, so it does not disrupt the cooking process and pressure build-up inside the extrusion barrel, thus the capacity is not severely affected. This versatility allows manufacturers to produce a wide range of fish feed with a single machine.

Advanced pre-conditioning and cooking systems:

The TwinTech extruder introduces a new thermal hydrator and updates the differential diameter conditioner to improve the hydration and retention time of materials. A good cooking in the pre-conditioning can generate up to 35% degree of cook to starches. These systems are designed to enhance the cooking process by ensuring efficient steam integration and retention, leading to better processing efficiency and product quality.

Jean-Benoît Darodes de Tailly, Alban Caratis, Nadège Richard, Phileo by Lesaffre

In the current landscape of intensive shrimp farming, optimizing costs while maintaining high productivity has become a critical balancing act. With profit margins growing increasingly slim, shrimp farmers are under tremendous pressure to maximize efficiency and minimize losses. One of the most daunting challenges impeding this goal is the White Feces Syndrome (WFS), a pervasive gastrointestinal issue primarily affecting the hepatopancreas, the shrimp’s largest and most crucial organ. WFS is a multifactorial syndrome that generally arises from a disruption of the intestinal balance rather than a single pathogen, complicating its prevention and treatment. Numerous factors are believed to trigger WFS, including bacterial infections

combined with parasitic infestations, poor water quality, chronic stress, or low-quality diets. This makes WFS a poorly understood and complex condition that poses significant difficulties for farmers.

Traditional responses to WFS often involve costly treatments and interventions, further squeezing already tight profit margins. This situation underscores the necessity for cost-effective, preventative solutions that address and alleviate the root causes of WFS.

What makes yeast probiotics promising candidates?

Yeast probiotics are well-known for their efficacy in alleviating various gut disorders in both animals and humans. They are frequently included in commercial

medicines and supplements aimed at treating conditions like diarrhea and irritable bowel syndrome (IBS). Their application in managing gut disorders in shrimp farming, however, is still emerging, with limited but promising research. The observed benefits of live yeast in shrimp farming are likely due to its combined prebiotic, probiotic and postbiotic actions. Yeast cell walls contain α-mannans and 1.3/1.6 β-glucans which are known to have beneficial effects on shrimp gut health and immunity (Ran et al., 2015). The same β-glucans might also have a beneficial impact on lipid metabolism, a key component of the shrimp’s hepatopancreas, as reviewed by Machuca et al. (2022). The metabolic byproducts of live yeast such as organic acids and vitamins can also influence the microbial community within the hepatopancreas, crucial for the availability of digestive enzymes and efficient nutrient absorption. The same components have also been documented to reduce gut inflammation and oxidative stress, as well as improve gut integrity in aquaculture species (Ran et al., 2015; Rohani et al., 2022).

Yeast probiotics, therefore, play an important role in stabilizing the gut environment and preventing pathogenic infections from escalating, which is crucial for managing conditions like WFS and opens new avenues in the search for solutions to mitigate WFS.

Approach to reproducing WFS under experimental conditions

Research on WFS under experimental conditions presents several challenges, notably due to the absence of a universally accepted protocol and the multifactorial and complex pathogenesis of the condition described earlier.

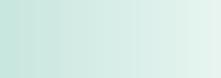

To evaluate the potential of Actisaf SC47, Phileo’s reference yeast probiotic, in mitigating the impact of WFS, Phileo by Lesaffre, with the support of ShrimpVet lab (2023), developed an adaptation of the co-infection model originally proposed by Caro et al. (2021, Fig. 1).

This model leverages the unique combination of pathogenic Vibrio bacteria and Enterocytozoon hepatopenaei (EHP), an intracellular microsporidian parasite, to induce WFS. As illustrated in Figure 1, EHP acts as a primary infection, disrupting the normal digestive and absorptive functions of the hepatopancreas as well as its role in immunity. This disruption intends to create an open door for secondary infections and intensifies the impact of opportunistic bacteria like Vibrio spp., contributing to the development of WFS.

For the study, twenty experimental units were mobilized and distributed into four groups, each with five replicates. Shrimp were housed in 350L tanks,

with 60 shrimp per tank, stocked at an average weight of 1.5 grams. The trial spanned 57 days, aiming to accurately assess within this experimental framework the efficacy of Actisaf SC47 in mitigating WFS when applied either through feed or in granulated form in water. Considering the kinetic progression of WFS, two sampling points were conducted at 16 and 26 days after the initial infectious challenge. At both sampling points, the co-infection model effectively induced WFS in the positive control, as illustrated in Figure 2. Typical symptoms of WFS were observed in the shrimp, marked by the presence of white, stringy fecal strands and a general reduction

in feed intake and gut content. These external observations were also coherent with microscopic findings, revealing a disrupted hepatopancreas (HP) architecture, demonstrating the model’s effectiveness in replicating the syndrome under experimental conditions.

Hepatopancreas health management, crucial for controlling WFS

In contrast, Actisaf® supplementation both through water and feed was found to have a substantial protective effect against the incidence of WFS symptoms when compared to the positive control (Fig. 3, 4).

Microscopic analyses revealed that live yeast administration helped maintain the structural integrity and nutrient reserves of the HP in infected shrimp. To document these improvements, hepatopancreas health scores were implemented between groups, evaluating measurable factors such as lipid droplet content (i.e., energy storage), tubule deformation, and the proportion of aggregated transformed microvilli (ATM) inside the tubules (Sriurairatana et al., 2014). Additionally, a general hepatopancreas health score was calculated from the 3 metrics mentioned above to provide a summary of the HP health status.

Actisaf® supplementation in both water and feed resulted in a significantly lower proportion of deformed tubules compared to the positive control (Fig. 4A). Additionally, both supplemented groups showed numerical improvements in lipid droplets content and lower ATM presence. This resulted in higher health scores for both groups

supplemented with Actisaf® compared to the positive control (Fig. 4B).

This preservation of HP health status in Actisaf®treated shrimp suggests they maintained more normal nutrient uptake, energy storage capabilities and immune status compared to the positive control group, despite similar loads of Vibrio and EHP in the hepatopancreas. These findings are significant, indicating that Actisaf® can enhance resistance to WFS even under substantial pathogen presence, offering protective effects against damage.

The healthier the hepatopancreas, the greater the benefits

The improvement of the hepatopancreas condition also resulted in substantial performance gains. Both water and feed applications of Actisaf® led to significantly higher survival rates compared to the positive control group, with increases of 43% and

22%, respectively (Fig.5A). Additionally, survivors in the feed application group exhibited a 12% increase in final body weight compared to the positive control group, matching the weight of unchallenged shrimp (Fig. 5B).

Feed conversion ratios (FCR) were notably lower in Actisaf®-supplemented groups compared to the positive control and were on par with the negative control, reflecting the improved hepatopancreas condition and enhanced lipid reserves as previously described. Moreover, the coefficient of variation in shrimp size, reflecting size uniformity, was numerically lower in groups supplemented with Actisaf® compared to the positive control. This suggests that Actisaf® supports more consistent growth despite the presence of EHP, which typically causes size disparities.

Conclusion

White Feces Syndrome poses a significant global challenge for shrimp farmers, with annual industry costs estimated close to at least a billion dollars –a figure that is likely to grow even more as we continue to shift toward more intensive production practices. The supplementation of Actisaf® has shown remarkable abilities in providing protection to the hepatopancreas of shrimp during WFS outbreaks, resulting in substantial performance improvements in infected shrimp. Lesaffre has filed a patent for the use of Actisaf® against White Feces Syndrome.

Just as yeast probiotics are used in human and livestock health to combat gastrointestinal diseases, their strategic application in aquaculture underscores the potential for biological interventions. More research is now needed to fully understand the modes of action and interactions between pathogens and yeast to develop even more effective strategies.

References available on request

More information: Jean-Benoît Darodes de Tailly Global Program Manager –Aquaculture

Phileo by Lesaffre j.darodesdetailly@phileo.lesaffre.com

Alban Caratis

Global Species Manager –Aquaculture

Phileo by Lesaffre a.caratis@phileo.lesaffre.com

Nadège Richard Global R&D Manager –Aquaculture & Insects

Phileo by Lesaffre n.richard@phileo.lesaffre.com

For additional information about fermentation solutions for shrimp farming, visit Program Aquasaf Shrimp.

I-Tung Chen, Maria Mercè Isern-Subich, Waldo G. Nuez-Ortín, Adisseo SAS

Shrimp farming encounters various challenges, with disease posing the most significant issue. Furthermore, concerns about environmental impact, market prices, and animal quality also require attention. To meet the rising demand for aquafeeds, there is a need for cost-effective and innovative ingredients. The use of functional feed additives with health-promoting properties such as organic acids has garnered attention. These additives help control pathogen loads and reduce the severity of disease, resulting in better survival, growth rates, and feed conversion efficiencies. Ultimately, health-promoting additives help farmers achieve higher profitability.

Organic acids first deliver pathogen inhibition capabilities. They can disrupt the structure and function of bacterial cell membranes, impairing pathogen colonization in the digestive tract of shrimp. This translates into a more balanced gut microbiome, as shown by reductions of harmful bacteria like Vibrio spp. and increases in beneficial species such as Cetobacterium and Bacillus spp. (Silva et al., 2023). A more balanced gut microbiome is key to increasing disease resistance. In addition, organic acids contain high levels of energy and are readily absorbed and used for ATP production by digestive cells, resulting in enhanced villi development (Lim et al., 2015). They can also stimulate the secretion of gastric acid and digestive enzymes, aiding in protein digestion and mineral absorption in shrimp (Silva et al., 2016). Supplementation of organic acids to shrimp feeds has proved to not only improve survival but also growth and feed efficiency via improved nutrient digestibility (Su et al., 2014; Silva et al., 2013).

Bacti-Nil®Aqua is a blend of organic acids specifically designed for aquatic species. Previous research has shown that cost-effective supplementation of BactiNil®Aqua in shrimp feeds reduced Vibrio presence in hepatopancreas, resulting in less tissue damage and a significant improvement in survival (MoralesCovarrubias et al., 2022). Such control of pathogen loads also reflects in growth performance, with Bacti-Nil®Aqua showing growth-promoting effects under high-density rearing stress (Nuez-Ortín et al., 2020).

A recent peer-review publication led by the National Institute of Oceanography and Fisheries (NIOF, Cairo, Egypt) evaluated the growth-promoting effect of Bacti-Nil®Aqua supplementation to white shrimp (Penaeus vannamei) subject to the natural biotic and abiotic fluctuations of pond rearing (Eissa et al., 2022). Healthy juvenile shrimp with an average weight of 3g were stocked in twelve hapa nets (1 x 1 x 1m) within an earthen pond, with a density of 40 shrimp/m2 per hapa in triplicates. The control group was fed a basal diet containing 30% fishmeal (38% crude protein, and 10% crude fat), while the treatment groups received the same basal diet but supplemented with 0.2% and 0.3% Bacti-Nil®Aqua. Feed was given three times daily, and the feeding rates were adjusted biweekly depending on the total biomass of each hapa.

After 60 days of feeding, results indicated that Bacti-Nil®Aqua supplementation significantly improved the survival and growth of shrimp. The

dose-response effect was primarily found in survival, with improvements of 65.2% and 72.5% in the 0.2% and 0.3% inclusions, respectively. Average daily gains (ADG) were increased by 32% and 50% with the 0.2% and 0.3% inclusions, respectively (Fig. 1), while specific growth rates (SGR) were improved by 14% and 21%. The dose response was also effective in reducing

the feed conversion ratios (FCR), with improvements of 14% and 23%.

Interestingly, shrimp fed with Bacti-Nil®Aqua showed a significantly higher whole-body protein content. The protein efficiency ratio (PEV) and protein productive value (PPV) were also improved, indicating that the shrimp were able to utilize dietary protein

more effectively with the addition of Bacti-Nil®Aqua (Table 1). This is likely the consequence of a more functional hepatopancreas with improved absorptive and digestive capacity.

Conclusion

Supplementing shrimp diets with Bacti-Nil®Aqua effectively reduces pathogen loads. This leads to a more stable gut microbiota, ultimately promoting optimal growth and feed efficiency of shrimp. This research further corroborates the efficacy of BactiNil®Aqua as a strategy to achieve farm profitability.

References

Lim, C., Lückstädt, C., Webster, C. D., & Kesius, P. (2015). Organic acids and their salts. Dietary Nutrients, Additives, and Fish Health, 305-319.

Su, X., Li, X., Leng, X., Tan, C., Liu, B., Chai, X., & Guo, T. (2014). The improvement of growth, digestive enzyme activity and disease resistance of white shrimp by the dietary citric acid. Aquaculture International, 22, 1823-1835.

da Silva, B. C., do Nascimento Vieira, F., Mouriño, J. L. P., Ferreira, G. S., & Seiffert, W. Q. (2013). Salts of organic acids selection by multiple characteristics for marine shrimp nutrition. Aquaculture, 384, 104-110.

da Silva, B. C., Vieira, F. D. N., Mouriño, J. L. P., Bolivar, N., & Seiffert, W. Q. (2016). Butyrate and propionate improve the growth performance of Litopenaeus vannamei. Aquaculture Research, 47(2), 612-623.

Nuez-Ortín, W. G., Isern-Subich, M. M. & Guérin, M. (2020) Organic acids - synergy at work to prevent vibriosis and promote growth in shrimp. Aqua Culture Asia Pacific, May/ June 2020, 45-47

da Silva, V. G., Favero, L. M., Mainardi, R. M., Ferrari, N. A., Chideroli, R. T., Di Santis, G. W., ... & de Pádua Pereira, U. (2023). Effect of an organic acid blend in Nile tilapia growth performance, immunity, gut microbiota, and resistance to challenge against francisellosis. Research in Veterinary Science, 159, 214-224.

Eissa Et Al, E. S. H. (2022). Effects of dietary supplementation of Bacti-nil® Aqua on growth performance, feed utilization, immune responses, and body composition of the Pacific white shrimp, Litopenaeus vannamei. Egyptian Journal of Aquatic Biology and Fisheries, 26(4), 1289-1304.

More information: I-Tung Chen R&D Project Manager Aquaculture Health

Maria Mercè Isern-Subich

Global Product Manager

Aquaculture Health Adisseo SAS

Waldo G. Nuez-Ortín Global R&D Manager Adisseo SAS E: waldo.nuezortin@adisseo.com

SINGLE SCREW EXTRUSION SYSTEM OPTIMIZES FLEXIBILITY AND MARKET OPPORTUNITIES

Optimize the return on your capital investment with a single screw extrusion system. Buy one system and cost-effectively deliver product to multiple market opportunities.

• One system capable of economy up to super premium fresh meat petfood

• Aquatic feeds that range from floating to sinking shrimp feed

• Capitalize on high margin petfood treat opportunities

• Significantly lower operating cost per ton versus competitive systems

An Extru-Tech Single Screw Extrusion System provides all the flexibility and production efficiencies at around half the cost of competitive extrusion systems with high operating costs.

Contact Extru-Tech today at 785-284-2153 or visit us online at extru-techinc.com

Valentin Eckart, Biochem

As aquafeed formulations continue to adapt due to the ever-changing availability of raw materials, yeast has become a valued aquafeed ingredient. While its use as a protein-rich raw material (single-cell protein) and is still in its infancy, its prebiotic application is widely known.

There are fundamental differences that determine whether a yeast source is good or not as good as a prebiotic. One of the most important parts of a yeast cell to look at for this purpose is its cell wall. It consists mainly of two types of structural polysaccharides – mannans and glucans. These are prevalent in all yeast species, but for the current review, the focus is on Saccharomyces cerevisiae. It is the most common yeast species used for prebiotic reasons as it is readily available on the market. There are three main sources of S. cerevisiae. Brewer's yeast and alcohol or ethanol yeast are both byproduct yeasts used in the fermentation process to produce alcohol from sugar. The third source

is primarily grown yeast, which is produced specifically for use as a feed additive, for example.

Previous comparative analyses have shown that primary cultured yeast's mannan and glucan content is up to 50% higher than byproduct yeasts. This is mainly due to contamination with other “glucans” from residual plant components in the culture medium, which is usually found in byproducts. As these plant polysaccharides are often included in the analysis of total glucans, this leads to major inaccuracies when comparing yeast products. The misinterpretation leads to the assumption of a high content of “yeast glucans” (ß-1,3-1,6-glucans), which, in contrast to e.g. “plant glucans” from the culture medium, are valuable prebiotic immunity boosters.

The other functional component of yeast cell walls (YCW), mannan oligosaccharides (MOS), play a crucial role in fighting infectious diseases. By inhibiting the

adhesion of gram-negative bacterial pathogens to the host's intestinal walls, they reduce the risk of infections and diseases. Fewer intestinal infections mean less proliferation of pathogens and, therefore, less excretion of pathogens into the culture water. This preventive effect makes MOS the more important component of YCW. This protective shield means that the host has to invest less energy in its bacterial defense mechanisms. The energy saved can contribute to better health and growth. In order to differentiate yeast sources according to their MOS content, it is therefore necessary to investigate their efficiency in binding pathogens.

For this reason, two commercial YCW products were selected – one based on a primary-grown yeast (TechnoMos®), and another based on an ethanol yeast (ethanol-YCW). Pathogen binding efficiency was evaluated by sedimentation of pathogens from a liquid medium and by the microscopically observed binding affinity of the pathogens to the YCW particles. To demonstrate the potential benefits for a wide range of aquaculture species, Vibrio harveyi was selected as a warm-water shrimp pathogen and Aeromonas salmonicida as a cold-water fish pathogen. The bacterial solution was added to peptone-filled Eppendorf tubes either alone or in combination with one of the two YCW products to demonstrate pathogen binding and sedimentation. In addition, the sedimentation of the YCW products themselves was analyzed. No sedimentation was detected in Eppendorf tubes containing only bacteria. Therefore, the difference in sedimentation between the YCW product alone and the product with bacteria solution as a bound pathogen was calculated. TechnoMos® showed significantly higher sedimentation of V. harveyi and A. salmonicda compared to the tested ethanol-YCW (Fig. 2).

In a second step, the sedimented "pellets", which contained both the product and the bacteria, were vortexed, placed on microscope slides and photographed. Typical bacterial clusters (Fig. 1a) around yeast cell fragments were interpreted as bound bacteria. The diameter of these bacterial layers was measured and compared in Figure 3. The layers of bound bacteria were clearly twice as thick in the TechnoMos® samples, which is why an approximate 100% higher pathogen binding capacity is assumed.

Figure 2. Sedimentation of bound bacteria. The sedimentation of V. harveyi mixed with TechnoMos® was 300 % higher compared to the ethanol yeast cell wall (YCW) product. For A. salmonicida there was still a measurable difference of 100 %. Stars between bars mark statistically significant differences. (p < 0.001; n=3)

Figure 3. Layer of bound bacteria. Either with V. harveyi or A. salmonicida , TechnoMos® showed a significantly thicker layer of bound bacteria in comparison to the tested ethanol YCW. Stars between bars mark statistically significant differences. (p < 0.001; n=3)

As already mentioned, YCW products made from primary cultured yeast can have a higher MOS content. However, up to 50% higher MOS content will not be the only reason for the approximately 100% higher binding

capacity for pathogens. In addition to the MOS content, the differences in the binding capacity of yeast products against pathogenic bacteria are closely linked to product quality factors such as particle size, extraction method and product purity. Residues from the production of beer and alcohol can lead to clumping of yeast cells in byproduct yeasts. As a result, the product particles often appear larger and the binding sites for MOS may be blocked (Fig. 1b).

Changes in the cell structure of ethanol or brewer's yeast can also reduce their ability to bind pathogens. During their use for alcohol production, ethanol – a cytotoxin – accumulates around the yeast cells, forcing them to form a thicker cell wall for self-protection. It is likely that this thick cell wall is more challenging to autoor hydrolyze and, consequently, fewer MOS particles are exposed during this processing step. As a result, byproduct-based yeast products are more likely to have inefficient MOS, which have a lower ability to bind and remove pathogens from the gut.

In contrast, primary-grown yeast products such as TechnoMos® are cultivated under optimal conditions to produce yeast for feed or food additives. The product is easier to purify and the cell wall is thinner and much easier to break down into its functional building blocks, such as MOS. This is in line with the results from the present study, which highlights the advantage of primary-grown yeasts as the best source for yeastbased prebiotics.

More information:

Valentin Eckart Product Manager Aqua Application Biochem E: veckart@biochem.net

Gerred Fuchs, Anpario

In the realm of aquaculture, where the health and performance of aquatic species are paramount, a previously overlooked factor plays a crucial role: gut health. Many decades ago, the gut was only appraised for its digestive functions. However, when reciprocal actions between the gut, its endogenous microbes, and the host were determined, it became evident that the role goes way beyond mere energy uptake. Many studies have elucidated the significance of the gut and its microbiota in the role of managing the health, disease, and performance of aquaculture species.

The significance of gut health in aquaculture

The gut is a complex system of tissues and organs that serves as a foundation for fish health, as it is responsible for food digestion, nutrient absorption, metabolism and energy production, and the prevention of various diseases through defense mechanisms and immune responses.

The colonization of fish gut commences early in the larval stage and continuously strives towards achieving a complex assemblage of gut-associated microbes. Approximately 100,000,000 bacterial cells belonging to over 500 different species are reported to populate the gastrointestinal tract of fish. A well-balanced and diverse gut microbiome is known as a state of eubiosis, which has a profound impact on metabolic and immune homeostasis, thus directly affecting the health and performance of aquaculture species. A zebrafish (Danio

rerio) model determined that over 200 genes were regulated by the gut microbiota, demonstrating the relevance of gut health for the overall well-being of an aquatic species.

In aquaculture production, supporting optimum gut health can have a beneficial impact on health and performance. Optimal gut health is associated with the proliferation of beneficial bacteria, as well as assisting in natural digestive processes and endogenous enzyme secretions. This aids in the absorption and utilization of nutrients, consequently improving feed conversion and growth performance. Ensuring a healthy gut, both the gut structure and microbial population, can be fundamental in maximizing aquaculture productivity which is of great importance, particularly with rising costs of raw materials and feed manufacture.

In farmed environments, conditions can adversely affect gut health, leading to dysbiosis caused by improper nutrition, gut inflammation, pathogenic bacteria and parasites, and stress due to pollutants, suboptimal water quality, and the rigors of production.

Gut health problems can be hard to predict; however, risk-mitigating strategies such as using phytogenic feed additives can be key to supporting optimal gut health and performance of aquaculture species.

The effect of oregano essential oil and Quillaja saponaria extract on gut health and performance Phytogenic feed additives can provide an unwavering

number of benefits, with a well-documented efficacy in improving the health status and growth performance across numerous aquaculture species. Anpario’s Orego-Stim Forte (OSF) is specifically designed for use within aquaculture, comprising a unique source of 100% natural oregano essential oil (OEO) and Quillaja saponaria (QS) extract. Both OEO and QS contain multiple compounds that work in synergy to offer several well-documented properties, including antioxidant, antimicrobial, immunomodulatory, growthpromoting, and anti-inflammatory functions.

The effect of OSF on gut health can be categorized into the emerging concept of “forward microbiomics”, which involves manipulating the gut microbiota to improve fish health and overall performance. The antimicrobial properties of OSF are attributed to the carvacrol and thymol compounds in OEO, and the triterpenoid saponins in QS. Besides directly inhibiting the growth of pathogenic bacteria, including species of Vibrio, Aeromonas, Streptococcus, Francisella, OEO and QS have demonstrated efficacy in increasing the growth of beneficial bacteria in the gut, such as species of Lactobacillus, Bacillus, and Bifidobacterium, which may exclude pathogens from colonizing in the gut, thus exhibiting a prebiotic effect. This has a significant impact on the health status of the host by modulating the immune system and other aspects of metabolism.

The immune system of fish is directly influenced by the gut microbiota, hence the importance of supporting gut health for optimal performance. By manipulating the gut microbiota, OEO can improve the gut structure and the gastrointestinal epithelium (GIE), consisting of intestinal epithelial cells (IECs) held together by tight junctions, which play a tremendous part in gut health and integrity. In various fish species, supplementation of OEO and QS has been effective in improving functions associated with the GIE including intracellular signaling, regulating immune responses (Th1 and Th2) and permeability of the intestinal barrier, and preventing the infection of pathogens and environmental pollutants. Numerous studies show that supplementing OEO in fish diets increases the turnover rate of IECs, which, in turn, improves pathogen clearance and prevents infection. Additionally, OEO and QS increase goblet cell count and production of mucus, subsequently improving the first line of defense against pathogens in the gut.

of nutrient digestion and absorption occurs. However, fish's ability to digest and utilize nutrients is affected by the digestive enzymes secreted, the structure of the digestive tract, and the intestinal microbiota composition, diversity, and abundance. Several studies in fish have demonstrated the beneficial effects of supplementing OEO and QS to improve growth rate, mainly via improving intestinal histomorphometry and increasing secretions and activities of digestive enzymes. Supplementation of OEO and QS in fish improves histomorphometry by increasing villi height and width, thus improving intestinal absorption capacity and nutrient utilization. Additionally, this improved histomorphometry may be attributable to the antimicrobial activity of OEO and QS, causing a reduction of harmful bacteria in the gut and a consequent reduction of mucosal damage. Therefore, the reduction in energy expenditure for cell replacement in the intestinal mucosa may have encouraged its greater development. The activities of endogenous digestive enzymes are often used as a

benchmark for determining the digestive capacity and nutritional status of fish. Supplementation of OEO and QS in fish and shrimp diets has been shown to increase the secretions and stimulate activities of lipase, amylase, and protease enzymes, which generally correlate to improved growth indices.

Orego-Stim Forte improves the growth performance of juvenile ballan wrasse Ballan wrasse (Labrus bergylta), as cleaner fish, are acknowledged as a sustainable and effective

management tool for the biological control of sea lice in salmon farming. A study using 1,350 L. bergylta was conducted over an 83-day period by an independent research provider, Otter Ferry Seafish, located in Scotland, UK. This trial concluded that OSF (OEO + QS) supplementation, at both concentrations, improves the specific growth rate (SGR) and feed conversion ratio (FCR) of L. bergylta (Fig. 1). The greatest SGR and FCR improvements were seen in the diet containing 0.35% OSF, which is 13.2% and 10.7%, respectively, more advantageous compared to the control.

The effect of Orego-Stim Forte on the survivability of shrimp challenged with Vibrio parahaemolyticus Vibrio parahaemolyticus is ubiquitous to many aquaculture environments and can cause diseases such as white feces syndrome (WFS) and acute hepatopancreatic necrotic disease (AHPND) in whiteleg shrimp (Litopenaeus vannamei), resulting in significant losses for the shrimp farming industry. This trial used 20 tanks, containing 80 shrimp per tank with four replicates, and was conducted by Nong Lam University, in Vietnam. In Figure 2, the mortality of L. vannamei challenged with V. parahaemolyticus showed a decreasing tendency with increasing administration doses of OSF, thus supporting the antimicrobial activity of OEO and QS. A significant difference was observed between the control and OSF diet at 0.35% (D3), which demonstrates the efficacy of OEO and QS for in-vivo scenarios.

Concluding remarks

After being overshadowed for many years, we now understand the significance of gut heath and its

influence on overall well-being and performance of aquaculture species. However, due to biotic and abiotic factors adversely affecting gut health in farmed environments, it is crucial for aquaculturists to implement risk mitigating strategies such as the use of phytogenic feed additives. The antimicrobial, immunomodulatory, anti-inflammatory, antioxidant, and growth promoting natural properties of OEO and QS, makes them highly effective, yet sustainable solutions for improving gut health and performance of aquaculture species.

References available on request.

More information: Gerred Fuchs Aqua Technical Sales Manager Anpario plc E: gerred.fuchs@anpario.com

Edwin Chow, Christian Cordts, Berg & Schmidt

Shrimp farming: Why prevention is better than medicine!

Intensive shrimp farming is now commonly practiced in many parts of the world, but a high stocking density is often associated with a high risk of disease outbreaks. The use of antibiotics for disease prevention and growth promotion in animal farming is now universally discouraged as it contributes to one of the most serious public health challenges of modern times – antimicrobial resistance (AMR). As such, several substances with antimicrobial and health-promoting activities such as herbal extracts, organic acids, carotenoids, and immunostimulants have been extensively studied as antibiotic alternatives for their potential application in disease prophylaxis and overall health improvements in cultured shrimp (Chuchird et al., 2015, 2023; Bussabong et al., 2021; Rairat et al., 2023). At Berg & Schmidt, with our knowledge and expertise in functional lipids and through considerable R&D, we have confirmed that the right combination of fatty acid monoglycerides and selected phytochemicals in the shrimp feed will work in synergy to support the functioning of the immune system, to help protect shrimp against hostile threats while maintaining performance.

Defining monoglycerides, phytochemical and essentiality

The use of fatty acid monoglycerides, a molecule of glycerol linked to a fatty acid through an ester bond, is generally preferred over free fatty acids for several reasons. Firstly, monoglycerides are active across a wide pH range due to the absence of an ionizable functional

group. Secondly, unlike free fatty acids, which undergo significant absorption in the upper digestive tract, monoglycerides remain intact until reaching the small intestine, where they can exert their beneficial effects. Lastly, free fatty acids often have a strong odor, which is not the case for monoglycerides (Yoon et al., 2018; Jackman et al., 2020; Gomez-Osorio et al., 2021; Szabó et al., 2023). Unlike free fatty acids, monoglycerides exert antimicrobial activity principally via membrane disruption due to the amphipathic property (Hyldgaard et al., 2012; Churchward et al., 2018; Wang et al., 2018; Yoon et al., 2018) and the antibacterial activity of monoglycerides is generally superior to their free fatty acid counterparts (Kollanoor et al., 2007; Batovska et al., 2009). Phytochemicals are well-recognized for their antimicrobial potential through multiple mechanisms including membrane disruption as well as inhibitions of cell division, ATPase, biofilm formation, and quorum sensing (Vasconcelos et al., 2018; Doyle and Stephens, 2019). Through thorough in vitro screening, we have been able to select compounds which show synergy in the chosen matrix.

Fatty acid monoglycerides and phytochemicals: Optimal combination for multiple targets

Given the evidence of monoglycerides and phytochemicals in promoting the good health and performance of aquatic animals is plentiful, a positive impact on aquatic animal production through dietary supplementation with a combination of these compounds can be anticipated. LipoVital Protect, one of our recent innovations, utilizes a unique blend of

short- and medium-chain fatty acid monoglycerides and a selected phytochemical. This results in maintaining production rates while enhancing the animal’s health due to the positive impact on their hepatopancreas and gut.

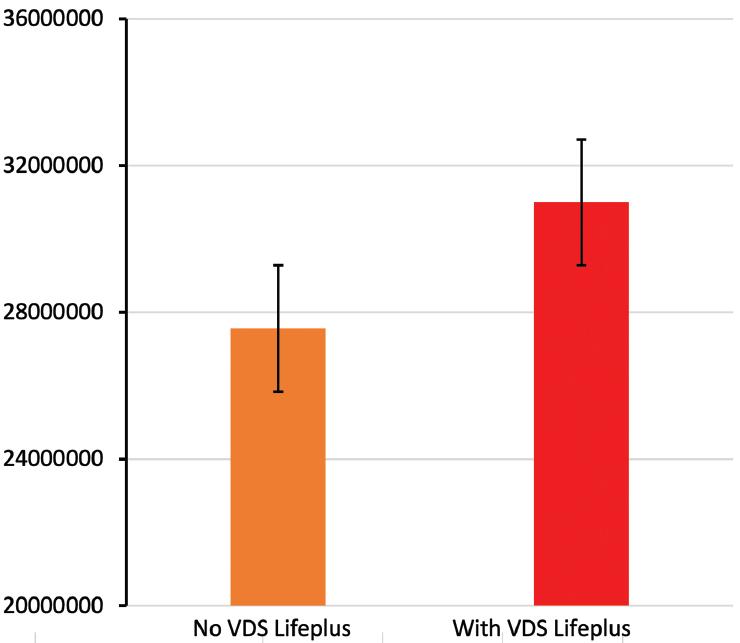

In order to document the in vivo effect of LipoVital Protect, a study was conducted in Pacific white shrimp at the National Centre for Aquaculture and Marine Research (Ecuador, South America) to investigate the beneficial effects in improving shrimp health and increasing tolerance under bacterial infection pressure. The selected pathogen for this study was Vibrio parahaemolyticus, the causative agent of AHPND, one of the most damaging diseases in shrimp aquaculture.

In Experiment 1, juvenile shrimp were divided into 2 groups with 6 replicates and fed with diets supplemented with 0 (control) and 0.3% LipoVital Protect for 56 days. The final body weight and survival rate were determined. In Experiment 2, the juvenile shrimp from Experiment 1 were subjected to Vibrio. parahaemolyticus challenge (Vibrio parahaemolyticus concentration at 1.0x106 CFU/mL), then the survival rate, intestinal Vibrio count and histopathological change of the hepatopancreas were analyzed. Following the 56-day feeding trial, the results revealed that the survival, FCR and biomass of the LipoVital treated shrimp were significantly higher than the control shrimp (Table 1). Compared to the control, shrimp fed with LipoVital Protect had 9% more biomass, were 15% more efficient and exhibited 3.3% better survivability. In the Vibrio parahaemolyticus challenge, the survival

and mortality rate after V. parahaemolyticus challenge showed that shrimp fed with LipoVital Protect had a significantly reduced mortality than the control treatment (Fig. 2); Histological analyses of sampled shrimp showed that infection rates were strongly reduced in shrimp fed with LipoVital Protect. The presence of Vibrio parahaemolyticus was dramatically reduced and lead to a far milder AHPND development during the trial.

Table 1. The survival rate, feed conversion ratio (FCR), and final average weight of Pacific white shrimp juvenile following the 56 day-feeding trial under normal conditions from 2 groups: PC and LVPA1 (Initial average weight of shrimp – 2.0 ± 0.5g)

PC: Positive control, basal diet, no Vibrio parahaemolyticus challenge; LVPA1: LipoVital Protect group, LipoVital Protect supplemented at 0.3%, no Vibrio parahaemolyticus challenge

Figure 1. The cumulative mortality rate of Vibrio parahaemolyticus challenge from two groups: NC and LVPA2. NC: Negative control, basal diet, Vibrio parahaemolyticus challenge; LVPA2: LipoVital Protect group, Lipovital Protect supplemented at 0.3%, Vibrio parahaemolyticus challenge.

Conclusion

This study highlights the benefits and potential of using LipoVital Protect as a feed additive in shrimp aquaculture in challenged and unchallenged situations. Better growth performance and an improved health status of shrimp can be achieved at a dietary inclusion level of 0.3% of LipoVital Protect. With the increasing pressure for more intensive and productive shrimp farming, the use of fatty acid monoglycerides and a phytochemical combination will be the optimal strategy to reduce pathogenic pressure and antibiotic usage with sustainable in-feed support.

References available on request.

More information: Edwin Chow Global Species Manager Aqua Regional Commercial & Technical Manager Berg & Schmidt Asia Pte Ltd. E: edwin@berg-schmidt.com.sg

Christian Cordts

Global Director Product Management Berg & Schmidt Animal Nutrition E: ccordts@an.berg-schmidt.com

Brett Laudato, VDS

In the aquaculture industry, the animal’s health begins in the gut. As the industry faces slowing output growth and increasing disease outbreaks, finding innovative solutions to boost gut health is more crucial than ever. According to the 2022 SOFIA FAO report, the aquaculture industry's growth has slowed significantly, from 6.1% annually between 2000 and 2010 to just 2.0% projected for 20202030, partly due to disease outbreaks exacerbated by intensive farming techniques. Enter the superheroes of aquaculture gut health: beta glucans, shortchain fatty acids (SCFAs), and medium-chain fatty acids (MCFAs).

The importance of gut health

The gut is one of the primary entry points for pathogens, making it a critical area of study for disease management in aquaculture animals (Bøgwald & Dalmo, 2014). Understanding the role of beta-glucans, SCFAs, and MCFAs in promoting gut health is essential for developing effective disease prevention strategies.

Not all beta-glucans are the same

Types of beta-glucans

Beta-glucans, found in cereal grains, yeast and fungi, come in two main types: β-(1,3)/(1,4)-glucan from grains and β-(1,3)/(1,6)-glucan from yeast and fungi (Murphy et al., 2020; Markovina et al., 2020). Each type offers unique health benefits. In human studies, β-(1,3)/(1,4)-glucans have shown cholesterol-lowering and blood glucose-reducing effects, while β-(1,3)/(1,6)-glucans are known for their immunomodulatory and antimicrobial properties (Murphy et al., 2020).

Benefits in aquaculture

In aquaculture, β-(1,3)/(1,6)-glucans are particularly beneficial. These glucans prime the innate immune system, helping fish and other aquatic animals better withstand stress and infections (Pogue et al., 2021).

SCFAs: Small but mighty

What are SCFAs?

Short chain fatty acids (SCFAs) are a type of fatty acid with fewer than six carbon atoms. The commonly studied SCFA in aquaculture are formic, acetic, propionic, and butyric acids (Hoseinifar et al, 2017).

Reducing gut pH

The first benefit of SCFA is to lower the gut pH, inhibiting harmful bacteria and enhancing digestive enzyme activity (Khorshidi et al., 2022; Lim et al., 2015). However, the increased digestive enzyme activity effect appeared species-specific and not yet observed directly in crustaceans (Yarahmadi et al., 2022).

Increasing mineral bioavailability

The second benefit of SCFAs is that they improve the bioavailability of dietary minerals by modifying the cellular transport mechanisms and forming chelates, enhancing the absorption of important minerals and phosphorus (Hoseinifar et al., 2017).

Energy source for gut cells

SCFAs serve as a direct energy source for gut epithelial cells, with 95-99% absorbed rapidly (Hoseinifar et al., 2017; Tran et al., 2020). They are used to generate ATP and serve as substrates in intermediary metabolism (Abdel-Latif et al., 2020), thus, making the gut villi longer leading to better nutrient absorption.

MCFAs: Powerful effects

What are MCFAs?

Medium chain fatty acids (MCFAs) are saturated fatty acids with 6 to 12 carbon chains. Common MCFAs include caproic (C6), caprylic (C8), capric (C10), and lauric (C12) acids.

Energy metabolism

Like SCFAs, MCFAs are absorbed directly and transported to the liver for energy metabolism (Wang et al., 2020). This efficiency results in better animal growth performance.

Antimicrobial properties

Lauric acid, in particular, has shown effectiveness against various pathogens due to its ability to generate reactive oxygen species and damage pathogen cell membranes (Yang et al., 2018).

Synergistic benefits of gut health superheroes

Combining beta-glucans, SCFAs, and MCFAs in aquaculture diets offers an opportunity to enhance gut health, improve growth performance, and increase disease and stress resistance in aquatic animals. The combination was shown to be effective in fish growth performance and indicated a potential ability to steer toward a healthier gut microbiome (Arciuch-Rutkowska et al., 2024).

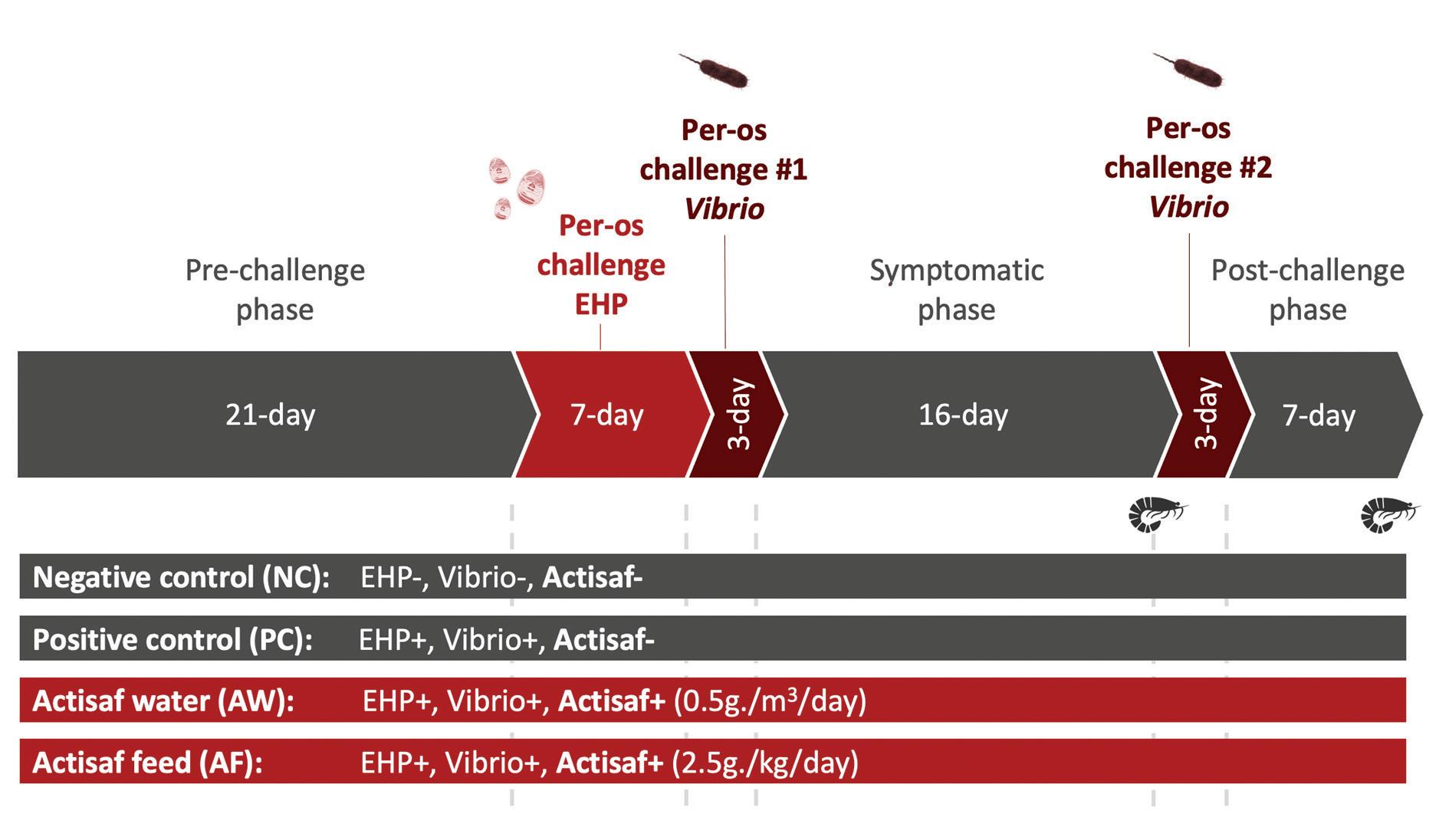

As for shrimp, the results of the feeding trial of L. vannamei fed with a combination of beta-glucan, SCFA and MCFA (VDS LifePlus) had positive effects on the growth parameters in terms of average body weight (9.2% improvement from Control) and FCR (5.8% improvement from Control). At the immunity parameters in particular, shrimp fed with VDS LifePlus marked an upward bias on parameters of total hemocyte counts (THC), phenoloxidase activity (POA), and intracellular respiratory burst (IRB) and the haemolymph bacteriostatic activity (Fig. 1). Also, the result of a White Spot Syndrome Virus (WSSV) challenge test of shrimp fed with VDS LifePlus showed better survival than the shrimp fed without VDS LifePlus (Fig.2).

In conclusion, these gut-health superheroes may offer a solid solution to improve immunity and nutrient absorption and boost overall environmental stress resilience in fish and shrimp. References available on request.

and without VDS LifePlus under a WSSV challenge

More information: Brett Laudato Aquaculture R&D VDS, N.V. E: Brett@vdspremix.be

The old adage tells us that we are what we eat, and a mounting body of science would agree. But while the knowledge and application of nutritional science in the feed industry has focused heavily on designing diets to enhance the health and physical characteristics of the target species, very little attention has been given to the effect of those diets on the end consumer. Unless this changes, fish farmers could be left behind the curve of public demand. Thanks in part to an aging population, the advent of COVID and a consequent heightened interest in preventive medicine, consumers are becoming increasingly aware of the role of food and nutrition in health and longevity. A recent Mintel report, (The Global Trends Driving the Evolution of Healthy Eating), found a global shift toward health-conscious eating: 68% of U.K. consumers and 74% of Canadians said they were eating healthily more or most of the time, and more than two-thirds of both Thailand and India’s consumers rank healthy eating as a priority post-pandemic. The ready availability of information via the internet is rapidly fanning the trend. A myriad of online gurus who promote food as medicine have gained celebrity status, racking up thousands of followers on social media platforms, their books, courses and conference appearances. Consequently diet-related terms, like metabolic disorder, chronic inflammation, and nutrient dense foods, have become common in popular articles and everyday parlance. People are reading labels, and the role of both macro- and micro-ingredients is attracting ever greater scrutiny.

Other sectors of the protein industry have begun to wake up to this. Although undoubtedly supported by animal welfare and environmental concerns, the health benefits claimed for beef and dairy products from forage fed cows is a prime example. Grass fed has become a strong marketing point. Grass fed butter is claimed to have more than 25% more omega-3 fatty acids than regular butter, and higher levels of vitamin K2, while grass-fed milk up to five times the level of conjugated linoleic acid (CLA) than regular dairy. Seafood, you might argue, is already a highly nutritious,

healthy option, representing an important source of protein, essential fatty acids and micro-nutrients, such as copper, iron, iodine, manganese, zinc, calcium, selenium and vitamins D and B complex, and that is true. But could it be better?

The industry recognized that the move away from dependence on fishmeal and oil towards alternative protein and lipid sources, particularly grain and legumes, diminished the long chain fatty acid profile of some farmed fish. Feed formulators successfully addressed this through fortification of DHA and EPA. Yet the perception that farm raised is inferior to wild caught persists. What this shows, beyond the really poor job the industry does in promoting itself, is the potential of passing the benefits of feed supplementation up the food chain to the end consumer.

Is there an opportunity for the feed industry to be proactive in developing diets that enhance the nutritional value of the fish they feed, not just as a marketing advantage, but to improve the health and wellbeing of communities worldwide – particularly in low income and food deficit regions? It would be naive to think it’s simple. Certainly there is a need for cost-benefit analyses, and fundamental research to determine the effect of optimized nutrient profiles in fish on the consumer. FAO statistics show aquatic foods contributed some 17% of protein consumed in 2019, reaching 23% in lower-middleincome countries and more than 50% in parts of Asia and Africa. Yet despite the acknowledged importance of fish in the diet, there have been shockingly few studies to quantify the impact of fish consumption on the nutritional status of individuals, let alone look at what nutritionally enhanced fish might contribute.

As aquaculture companies rush to comply with environmental and social standards that mesh with consumer expectations, the industry would do well to give consideration to maximizing the health benefits of its products, both as a business strategy and as a moral imperative.

Suzi Dominy is the founder and consulting editor of Aquafeed.com and a media consultant. E: suzi.dominy@gmail.com

Stijn Bruwiere, Katelijne Bekers, MicroHarvest

Aquaculture is currently one of the fastest-growing food systems globally, with production in 2022 achieving a record of 130.9 million tonnes, up by 8.1 million tonnes in 2020. In brackish water aquaculture, the production of whiteleg shrimp (Penaeus vannamei) is reported to be the most important commercial species in the world, especially in Southeast Asia, China, India, and Latin America. However, the intensification of shrimp cultivation leads to rapid disease emergence and environmental impacts, limiting shrimp production and expansion worldwide. Aquaculture forums emphasize sustainable methodologies for shrimp cultivation for more awareness.

Given the growth of the shrimp industry and the prevention of disease outbreaks, there is increasing interest in incorporating sustainable and innovative protein sources into shrimp feed. Nucleotides and single-cell protein (SCP) have been the subject of several studies; the supplementation of these products in aquafeed can lead to improved disease resistance survival and growth of shrimp. Integrating these innovations can lead to healthier, more productive shrimp farming practices.

Enterocytozoon hepatopenaei (EHP) is an infectious microsporidian parasite affecting hepatopancreas tubule cells of Penaeid shrimp species. EHP can be transmitted horizontally through cannibalism and cohabitation in shrimp ponds. The infection leads to shrimp's slow growth and a wide size distribution, impacting economic sustainability and profitability. Digestive enzymes, metabolism, immunity and growth responses are affected by EHP infection, resulting in reduced enzyme activity, altered metabolic variables, and poor growth. Many studies on the development and application of feed additives

have also been conducted to determine effective approaches to screening, control, and mitigation solutions against EHP infection.

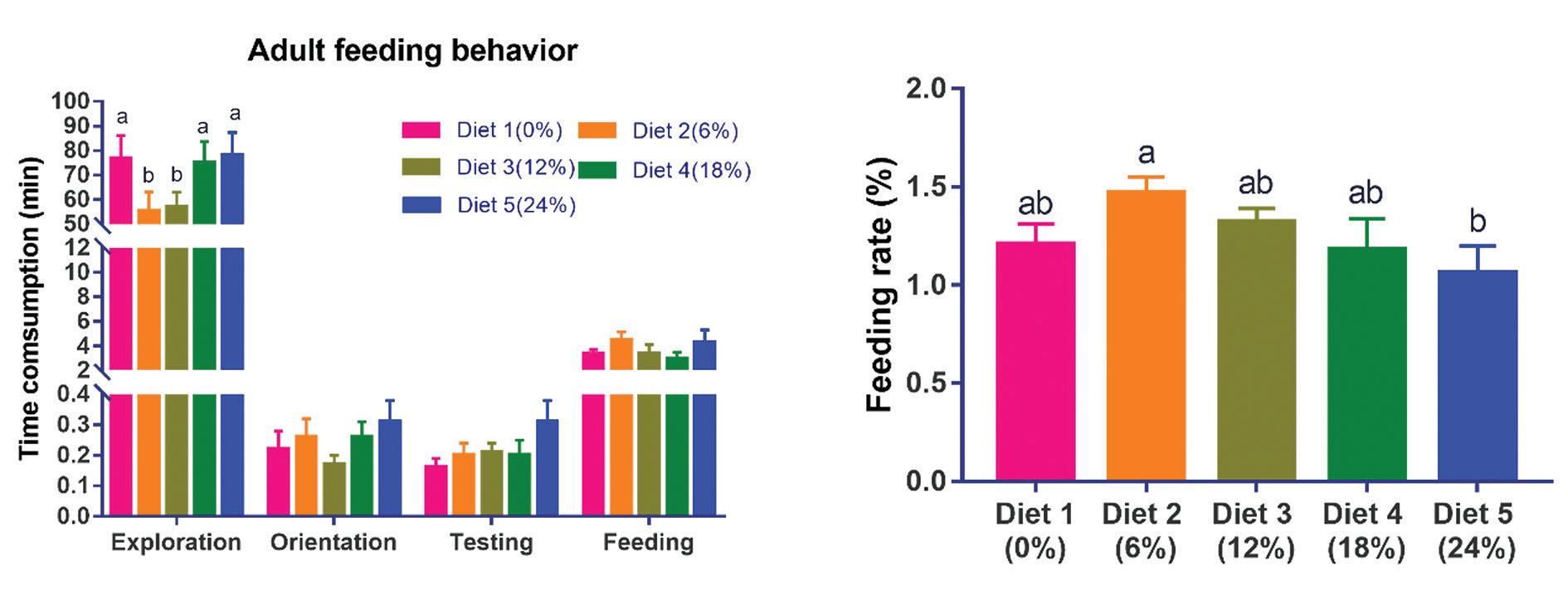

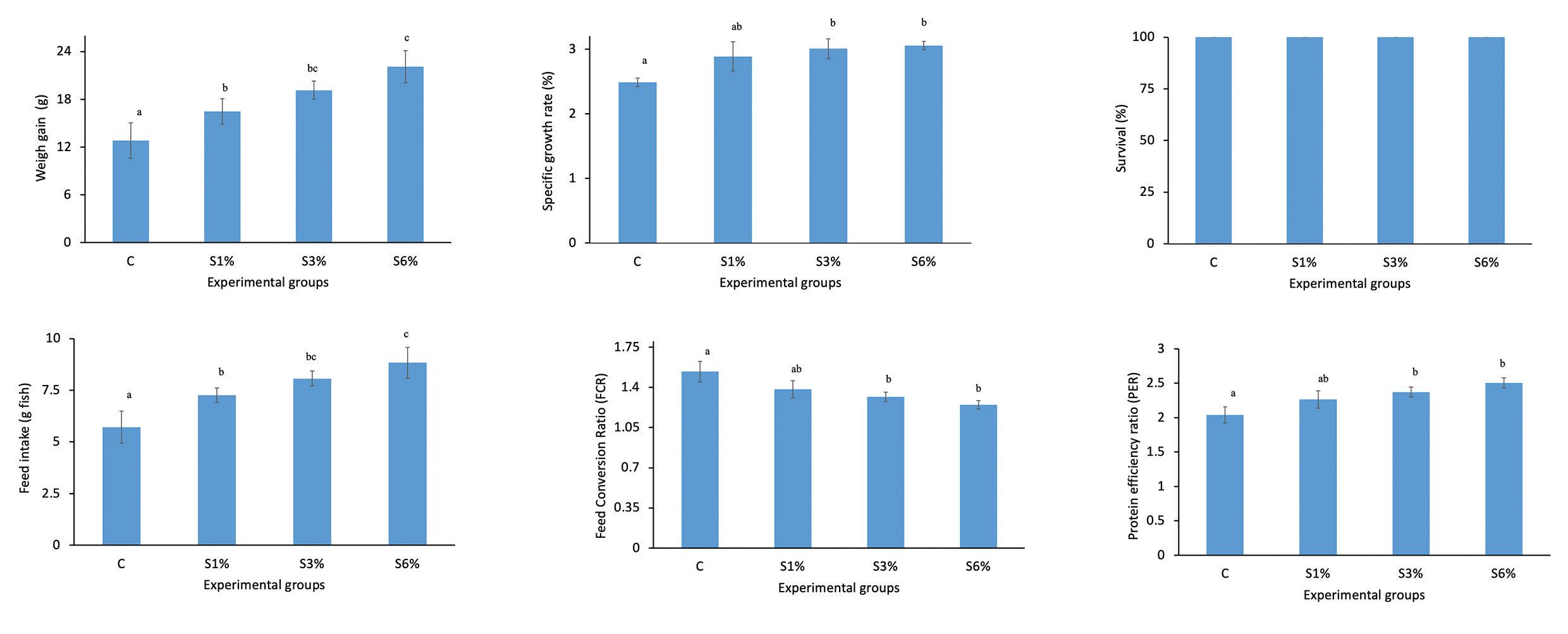

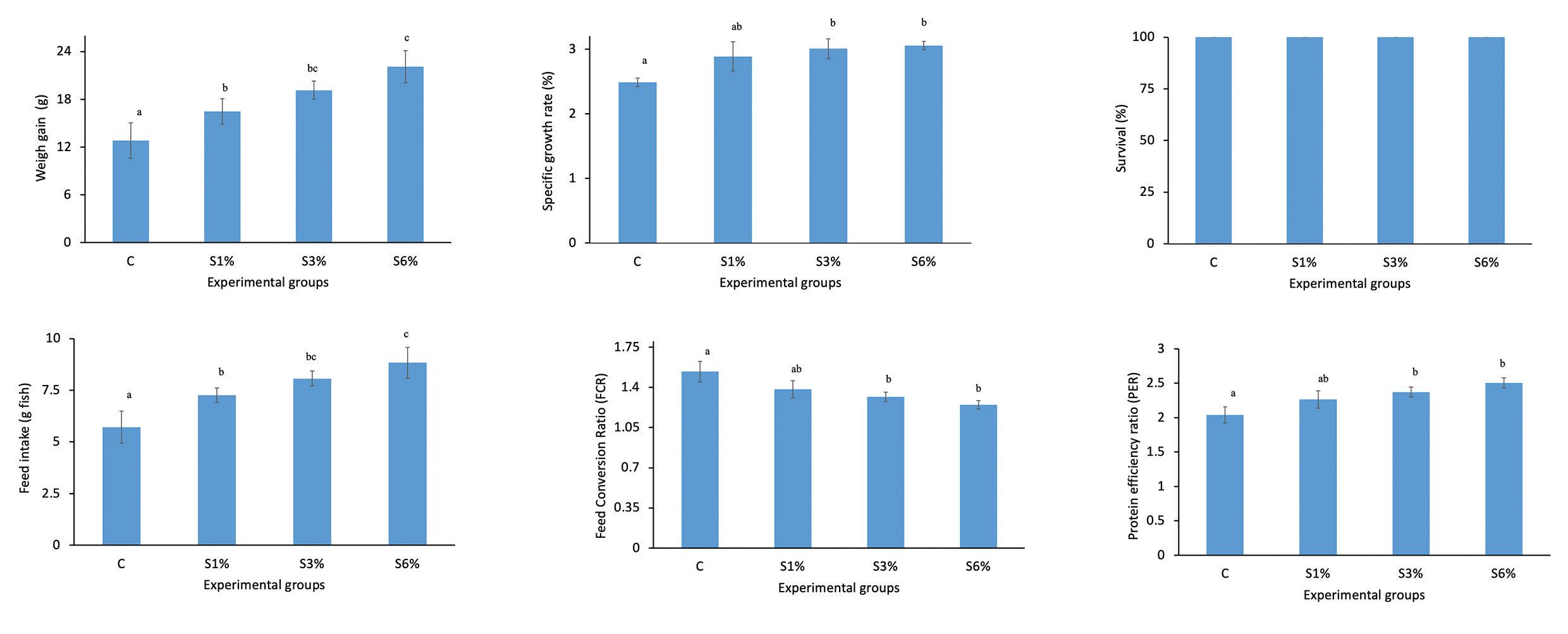

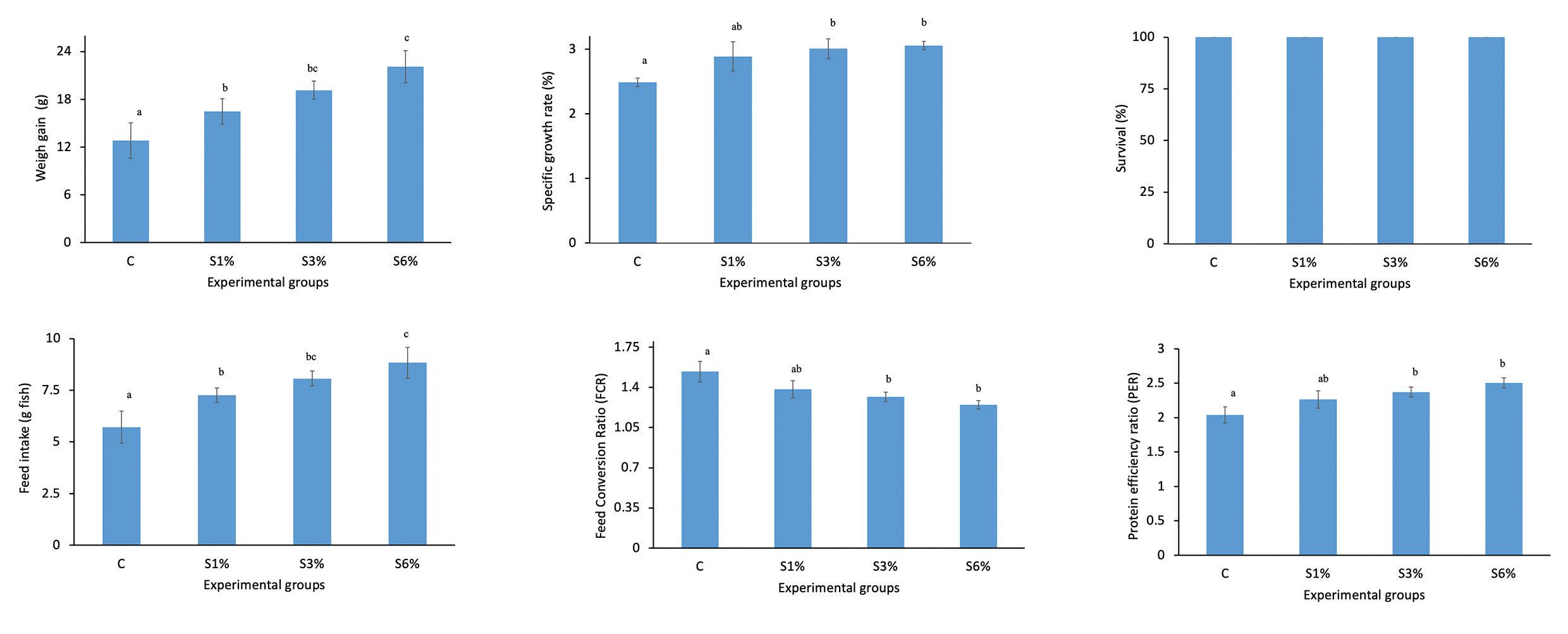

MicroHarvest conducted a study in partnership with ShrimpVet laboratory in Vietnam to determine the efficacy of bacteria-based nucleotides (HILIX) and single-cell protein (SCP) in suppressing or eradicating EHP in white leg shrimp within controlled laboratory challenge conditions. Fifty shrimp (approximately 1.36 grams) were stocked in each experimental tank filled up with 20 ppt seawater in a static water system. Trial groups were tested in five replicates; shrimp fed a control diet for positive control (Group 1), shrimp fed HILIX on top of basal mix at 0.04% (Group 2), shrimp fed HILIX on top of basal mix at 0.08% (Group 3), shrimp fed MPX-Boost reformulation of basal mix at 5% (Group 4), and shrimp fed MPY-Boost reformulation of basal mix at 5% (Group 5). After a feeding period of 2 weeks, shrimp were challenged with EHP-contaminated feces top-coated on feed pellet for 7 consecutive days. Then, shrimp were closely monitored for mortality record and their response to EHP infection in terms of growth over a 28-day period.

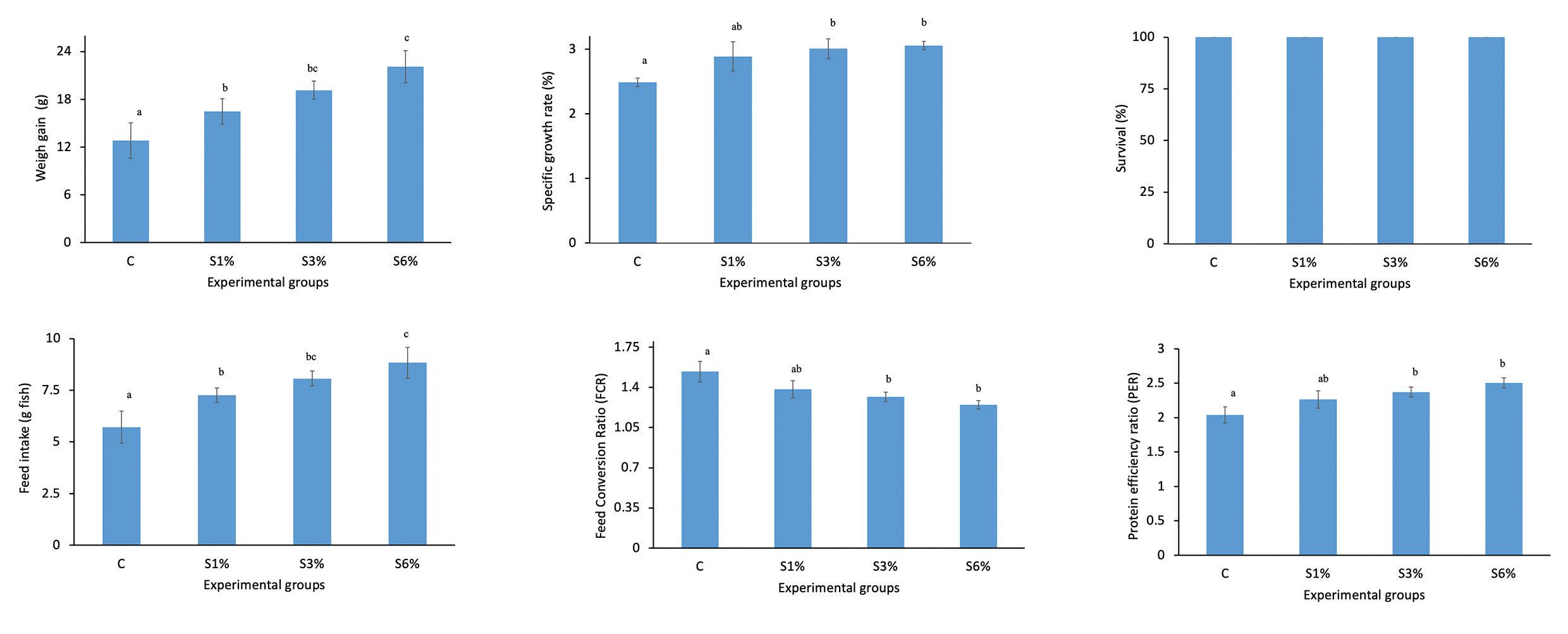

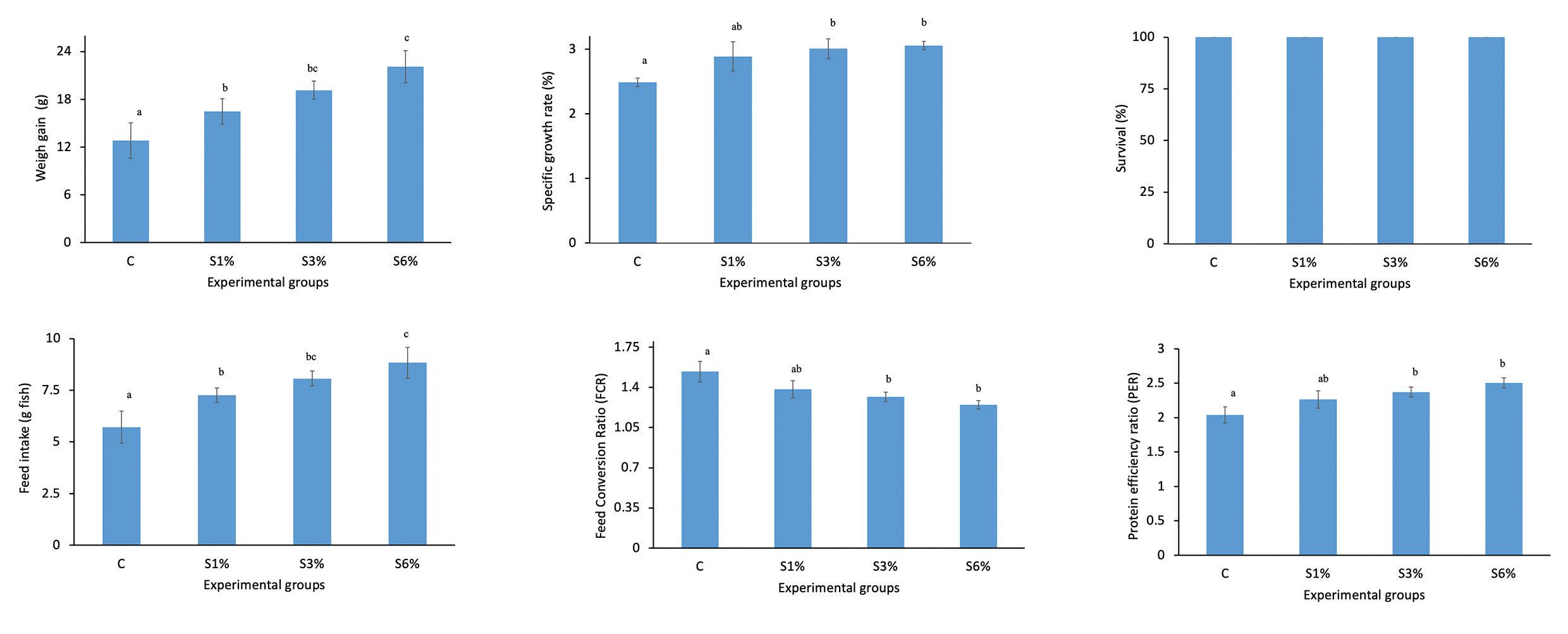

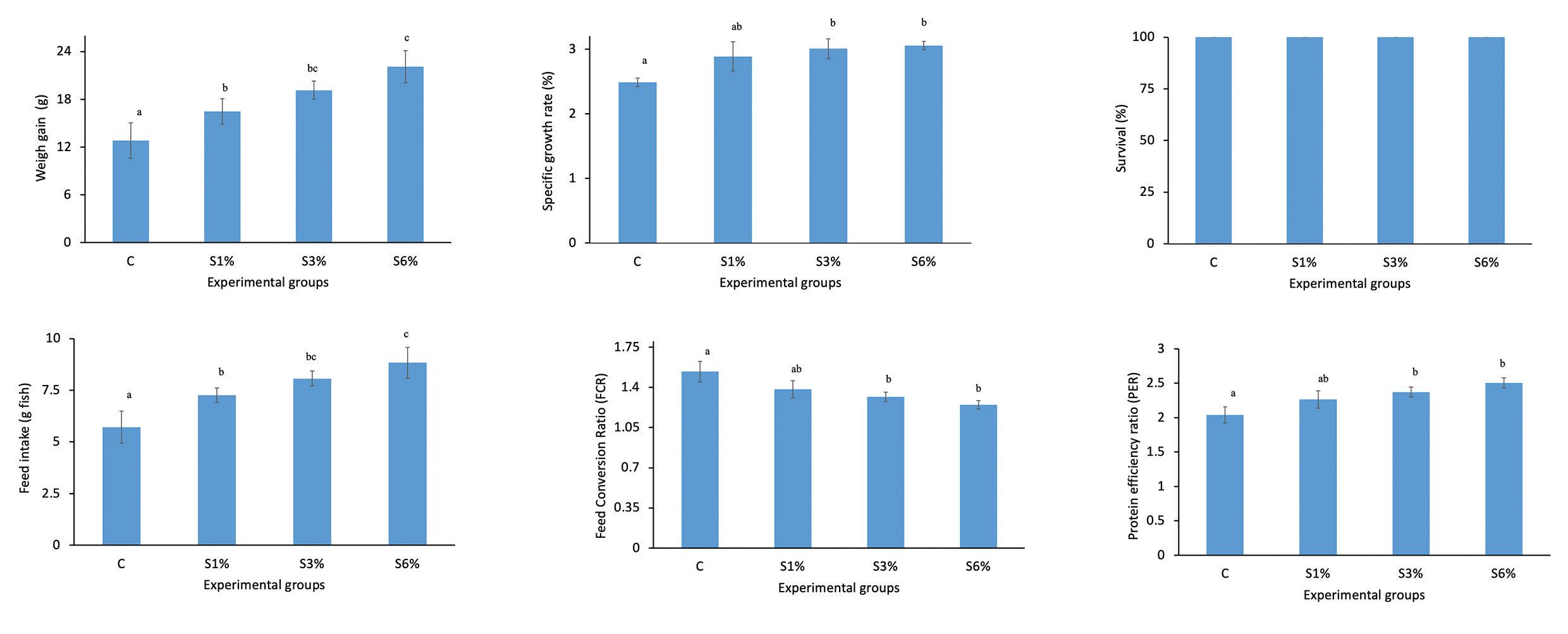

Survival rate and growth performance parameters, including final mean weight (FMW), mean weight gain (MWG), average daily growth (ADG), specific growth rate (SGR), and feed conversion ratio (FCR) were recorded and calculated at the end of the trial. Interestingly, statistical analysis revealed significant differences (p < 0.05) in survival rates among groups (Fig 1). Supplementation with HILIX at 0.08% (Group 3), MPX-Boost at 5% (Group 4), and MPY-Boost at 5% (Group 5) all tended to suppress EHP infection in shrimp.

These groups achieved significantly higher survival rates (70.80%, 74.00%, and 70.80% respectively) compared to the control group (60.40%), showing improvement of 17.22%, 22.52%, and 17.22% when compared to shrimp fed on control feed (Group 1).

Growth performance results are presented in Table 1. Shrimp fed special diets with HILIX or SCP supplements

grew significantly better (p < 0.05) than those on a standard (control) diet. Final weights ranged from 9.27 to 11.09 grams and all treated groups displayed improved feed conversion (FCR: 1.00 - 1.25). Notably, Group 4 (MPX-Boost) thrived the most, followed by Groups 5 (MPY-Boost), 3 (HILIX 0.08%), and 2 (HILIX 0.04%). Interestingly, Groups 3 and 4 had the most

Table 1. Growth performance parameters after 51 days of culture (Duncan, P < 0.05)

Values are presented as mean ± standard deviation (N = 5). Different letters on the same column indicate significant differences (P < 0.05).

consistent shrimp sizes. These results suggest HILIX and SCP supplementation significantly improves growth and feed efficiency, potentially benefiting shrimp farmers by requiring less feed per shrimp during the grow-out culture and promoting uniform size distribution.

Conclusion

Overall, this study delivers compelling evidence that HILIX and SCP supplements significantly enhance shrimp health and economic outcomes. Shrimp fed these supplements displayed improved survival rates, faster growth, and higher resistance to the EHP infection. Notably, the 0.08% HILIX inclusion in feed proved particularly effective in combating EHP. By

reducing EHP proliferation and preventing retarded and varied growth, HILIX, MPX-Boost, and MPY-Boost supplementation paves the way for sustainable and profitable shrimp farming practices.

References are available by request.

More information: Stijn Bruwiere Business Development Manager Feed MicroHarvest E: stijn.bruwiere@microharvest.com

Amine Chaabane, Laboratoires Phodé

Most socio-economic projections state that the world will be more than 9 billion by 2050. This unstoppable growth has already presented challenges in terms of food security, in the context of political instability, global warming and climate change.

The protein supply for humans historically relied on animal farming and fisheries, but there’s a limit to both of these activities. Fisheries, on one side, depend on fish stocks. When overexploited (which has unfortunately become common since the 1980s), fish stocks can collapse, and never recover from human activities. This makes fish an uncontrollable and unpredictable protein source. Livestock farming keeps growing in numbers and industry actors while also improving in technology and yield, yet it still requires land, and animals are mostly fed cereal-made feed that also uses arable land. The need for arable land has contributed to environmental disasters such as deforestation.

Those factors led to the huge development of aquaculture in the past 30 years, overtaking fisheries in terms of global production volumes in 2022, as very recently showcased by the FAO. Aquaculture emerged as a promising alternative, reducing pressure

on species fished for human consumption, and requiring no land area.

Aquaculture feeds also rely on ingredients like cereals with an important share of soy as well as fisheries products like fishmeal and fish oil. The sustainability of feed ingredients is thus an important challenge for the industry if aquaculture aims to be reliable in the long term.

In this context, upcycling agricultural byproducts used to produce human food is a very interesting perspective on the sustainable development of ingredients for aquafeeds. Interesting byproducts include those of the wine industry, such as grape pomace, and specific extracts (oligo-procyanidins from grape seeds, for example) that could be beneficial supplements to marine fish diets. Known for their antioxidant properties, these extracts improve fish antioxidant status and flesh quality.

Laboratoires Phodé, a French company specializing in designing and manufacturing sensory additives made from plant extracts, has thus conducted a study on the effect of a wine byproduct concentrate, Olpheel Anti-Ox, on the antioxidant status and fillet quality

of European seabass (Dicentrarchus labrax) at the University of Almeria, Spain.

Materials and methods

The objective of this preliminary study was to test different biological effects of a wine byproduct concentrated extract specifically rich in oligoprocyanidines (Olpheel® Anti-Ox, OAO, Laboratoires Phodé, France) in feeds for juvenile European sea bass (Dicentrarchus labrax), on three different aspects: the oxidative status of fish, the functionality of intestinal microbiota, and oxidation of fillets after fish sacrifice and one week storage. A total of 120 juvenile seabass with an average body mass of 46.35 ± 0.12 g were equally divided into 6 groups under controlled environmental conditions of salinity (37‰), temperature (19°C) and photoperiod (10L:14D). Experimental feeds (control diet

and a diet supplemented with 80 ppm of OAO) were prepared using a lab-scale extrusion machine. The daily ration was distributed into 4 daily meals, ensuring that the amount offered in each experimental unit was fully ingested. The feeding trial lasted 5 weeks.

Results displayed significantly higher levels of superoxide dismutase (SOD) in the OAO group with 7.38 ± 0.63 U SOD/mg SP compared to the control group with 6.80 ± 0.34 (Table 1). The significantly higher levels of SOD can be the net result of an increased expression of genes coding such enzymes. These results were the first indication of the positive effect of OAO on antioxidant status.

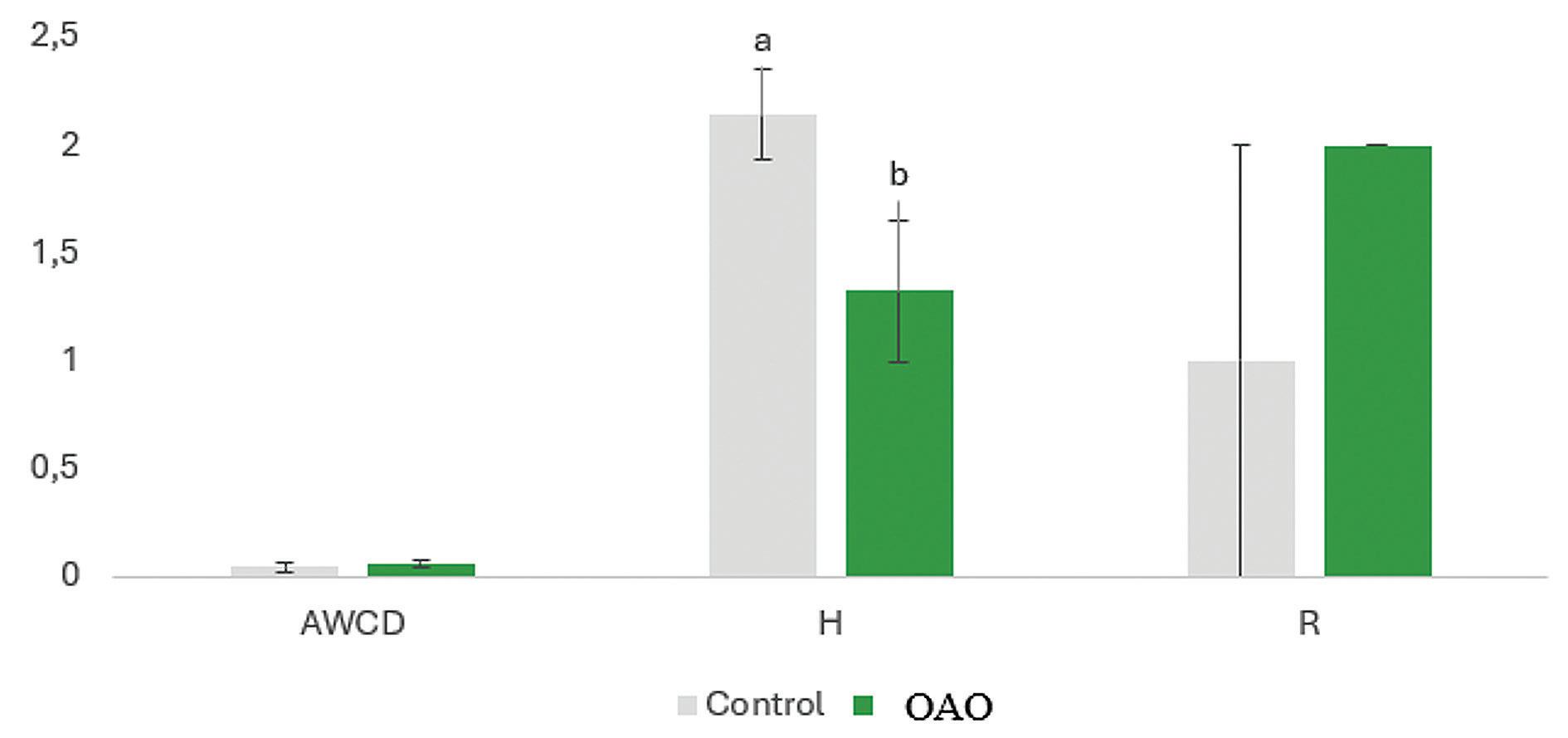

Regarding microbiota, a significant effect of OAO on the microbial profile was evidenced (Fig. 1) as a reduced

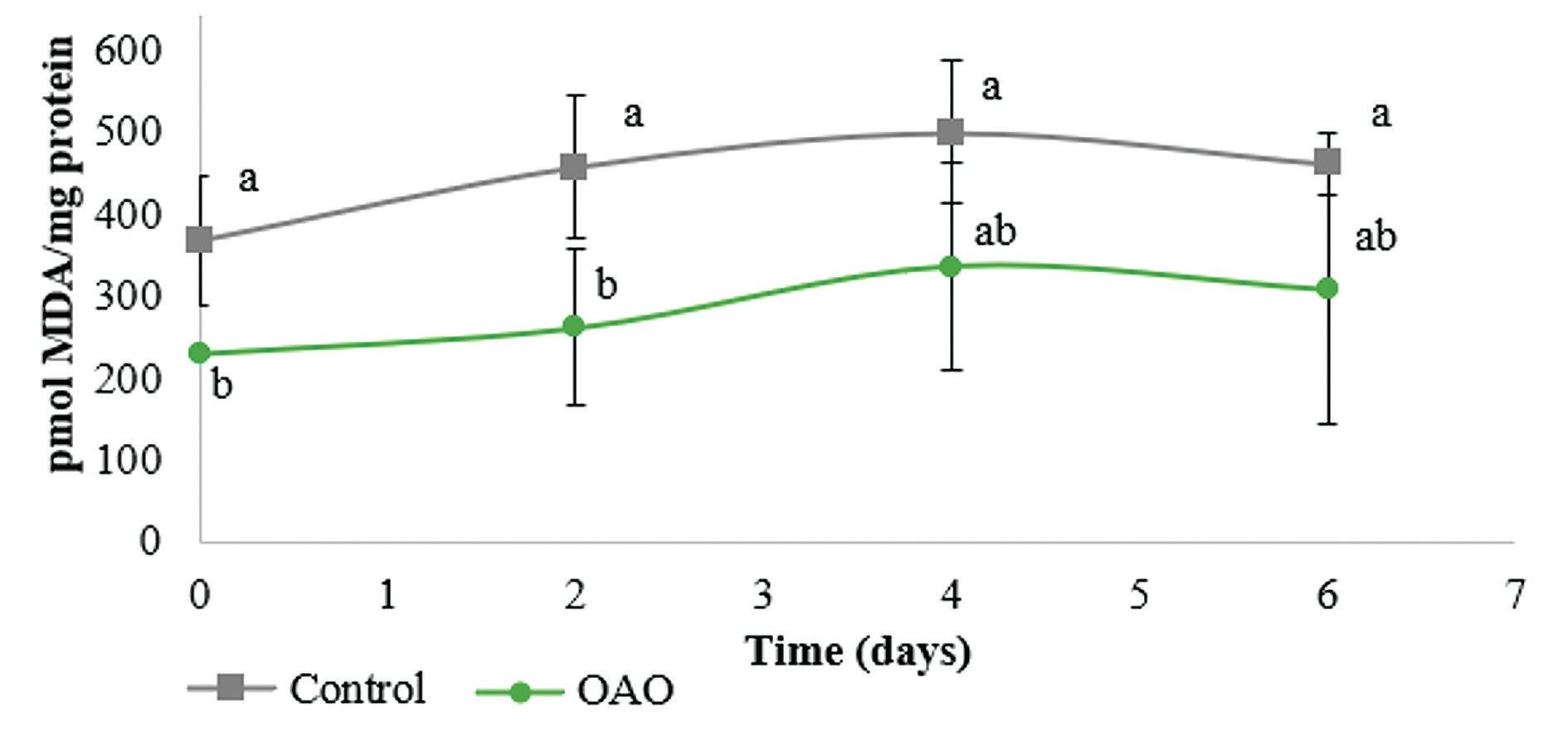

acid-reactive substances (TBARS) content in fillets of D.

(fed on experimental diets) after different durations of cold storage (4°C): 0, 2, 4, 6. Values are presented as mean ± SD. Values not sharing a common letter differ significantly between treatments, with p<0.05.