Functional

Insect-based

Feed

Functional

Insect-based

Feed

YEAST-BASED SUPPLEMENTATION SUPPORTS THE PERFORMANCE AND MUCOSAL BARRIERS OF EUROPEAN SEABASS

A novel yeast cell wall product supports fish health and perform

SPRAY-DRIED PLASMA AS A FUNCTIONAL PROTEIN FOR AQUAFEEDS 12

A highly digestible and functional protein ingredient to benefit productivity, health, and survival while reducing reliance on marine ingredients.

EGG POWDER AS HEALTH MODULATOR IN SHRIMP AQUACULTURE 22

A sustainable and nutritionally viable alternative to conventional marine protein sources in shrimp diets.

MANAGING VIBRIOSIS PRESSURE IN SHRIMP WITHOUT ANTIBIOTICS 50

A blend of organic acids and MCFAs can boost shrimp's immune response and gut health helping them manage pathogenic bacteria.

Editorial:

editor@aquafeed.com

Editor/Publisher: Lucía Barreiro

Consulting Editor: Suzi Dominy

Technical Editors: Peter Hutchinson, Albert Tacon, Ph.D

Assistant Editor: Marissa Yanaga

Conferences and webinars: info@aquafeed.com

Advertising enquiries/request media pack: sales@aquafeed.com

Accounts & all other enquiries: info@aquafeed.com

SUBSCRIBE

Digital editions are free to industry subscribers. You may also purchase print copies. Subscribe at Aquafeed.com to receive your own digital copy of our publications.

https://bit.ly/AQUASUBSCRIBE

Aquafeed Media, S.L.U., Ames, 15220 A Coruña, Spain. Copyright© Aquafeed Media, S.L.U., 1998-2024 All rights reserved. Privacy

September 16 - 18, 2025 Expo Center Norte, São Paulo, Brazil

March 10 - 12, 2026 BITEC Exhibition Center Bangkok, Thailand

June 2 - 4, 2026 Jaarbeurs, Utrecht, The Netherlands

AQ: Yuehai Feeds produces feeds for different markets. Where is the company today in terms of markets and species served?

XZ: Guangdong Yuehai Feed Group is a high-tech enterprise that integrates research and development, production, and sales. Its main focus is on aquatic animal feed, hatchery, feed premix, aquatic biological agents, and aquaculture production. It is a major producer of high-quality aquafeed in China, with more than 30 subsidiaries located in coastal areas such as Guangdong, Guangxi, Zhejiang, Fujian, and Shandong. The company is also actively exploring overseas markets, such as Vietnam. Its annual production capacity is 1 million tons.

AQ: Yuehai recently started the construction of a new feed mill in Vietnam. Why did you decide to invest in this country? What is the expected production capacity and species to serve?

XZ: Vietnam boasts an ideal climate and plentiful water sources, making it a prime location for aquaculture. The feed market has a capacity of 3 to 4 million tons, with a focus on shrimp, marine fish, tilapia, and other species. Yuehai has established two shrimp feed production lines and one fish feed production line, with an hourly output of 10 tons. Upon completion of the first phase of the project, it will achieve an annual production capacity of 100,000 tons, including 30,000 tons of shrimp feed and 70,000 tons

of extruded feed. The long-term plan of this project is ultimately achieving an annual production capacity of 200,000 tons.

AQ: Yuehai was one of the first companies that committed to producing fish-free feeds in 2017. What has been achieved so far?

XZ: In recent years, Yuehai has made significant technological advancements in reducing the use of fishmeal and fish oil in the feeds of various species, including shrimp, pompano, perch, and snakehead fish. However, the current special fish feed formulas have not yet achieved a true "zero" fishmeal.

AQ: How is the company diving into the current volatile market conditions for all feed ingredients? Are you prioritizing local ingredients? How do you deal with high fishmeal prices?

XZ: Our team has a professional raw material procurement team that analyzes and tracks the trends of international and domestic raw material markets in a timely manner. We prefer to use local raw materials in our formulations due to their advantages, such as low transportation costs. In response to high fishmeal prices, we fully utilize alternative protein sources like poultry byproduct meal, pork meal, single-cell protein, enzymatic plant protein, and insect protein in our formulations to replace fishmeal. Simultaneously, we carefully balance the functional additives in these feeds. The use of functional additives and multiple protein complexes in the formulation can effectively reduce the use of fishmeal without impacting the growth and health of aquatic animals.

AQ: Sustainability is becoming a key issue for aquafeeds. What are the company's main sustainability objectives?

XZ: Yuehai has always been guided by the corporate vision to Maintain harmony between aquaculture and the environment, make food and health complement with each other, contributing to the high-quality development of the aquatic industry. In recent years, Yuehai has been promoting low-protein and high-efficiency feed technology and developing precise nutritional feed formulas to fully utilize the

nutrients in the feed for the growth of aquatic animals. This not only reduces the emission of ammonia nitrogen from aquatic animals but also reduces water pollution and helps protect fishery resources.

AQ: Yuehai also owns farms. What are the current species the company is farming? In which markets are they commercialized?

XZ: Yuehai has dozens of breeding bases (farms) across the country, with a total area of tens of thousands of hectares. These bases are mainly engaged in joint breeding with customers. Some of the important

• Yuehai Xuwen Excellent Shrimp Hatchery Base: With an investment of over RMB 20 million, this base integrates broodstock cultivation and larval breeding, producing 20 billion shrimp zoea and over 1.5 billion larvae.

AQ: Yuehai has an extensive research network. What are the current research lines that the company is working on?

XZ: The technical team's research is primarily focused on disease resistance and the functionality of aquafeeds. We are also advancing precision nutrition by determining

Highlights of recent news from Aquafeed.com

Vitapro has introduced a series of logistical improvements to strengthen its service offerings by enhancing the traceability of the shrimp feed supply chain. These innovations were implemented at the Nicovita plant in Milagro. This transformation in the value chain is the result of a projected USD 2 million investment, which in its first phase, incorporated inventory management software that, combined with an optimized racking system, achieves better results with fewer resources. Additionally, the company plans to take the first steps toward green logistics by reducing CO2 emissions by 30% through the transition from fuelpowered forklifts to electric ones.

Phytase HiPhorius™ has been approved for all finfish and poultry species for fattening or reared for laying or reared for breeding and sows of all Suidae species in the European Union. It is a new-generation phytase that can help farmers achieve more sustainable and profitable animal protein production through more efficient phosphorous utilization and faster more efficient removal of the potent antinutrient phytate.

Calanus finmarchicus is a tiny marine copepod rich in essential nutrients abundant in the Norwegian Sea. The companies are now introducing it as a readyto-use copepod for fish and shrimp hatcheries. With a size of 2-4 mm, it can be used as feed for transition after hatchery and in combination with dry feeds, it can help as a feed uptake enhancer.

Yield10 Bioscience signed a Memorandum of Understanding (MoU) and license agreement with Nuseed Nutritional US Inc., the seed technologies platform of Nufarm, granting Nufarm a commercial license to certain omega-3 intellectual property assets, materials and know-how for producing oil in camelina. Nuseed Nutritional already produces plantbased oil products, Aquaterra® for aquafeeds from Nuseed omega-3 canola.

Building on the success of Essential Nitrogen, Cargill Aqua Nutrition is introducing the second phase: Effective Energy. This phase integrates the Essential Nitrogen concept into a comprehensive framework that combines tank data, commercial data, and formulation data. By leveraging Cargill’s collective knowledge and learning from its knowledge across different species, the company is able to refine its approach, ensuring even greater precision and efficiency in its formulations. The result is a robust nutrition physiology engine capable of generating customized nutritional plans for virtually every farming site and stocking condition.

Given feedback received from international partners about their state of preparations to comply with the EU Deforestation Regulation, the Commission proposed giving concerned parties additional time to prepare. If approved by the European Parliament and the Council, it would make the law applicable on December 30, 2025, for large companies and June 30, 2026, for microand small enterprises. Since all the implementation tools are technically ready, the extra 12 months can serve as a phasing-in period to ensure proper and effective implementation.

Covering an area of 10,000 square meters, the plant will process a diverse range of specialized animal nutrition products, including vitamins, minerals, and innovative feed additives. The new production unit will serve customers in Egypt, the Middle East, Southern Europe and Africa.

The company achieved the Generally Recognized as Safe (GRAS) status of its innovative microbial protein, PRO-DG™, for use in crustacean feed in the U.S. String Bio’s PRO-DG™ contains approximately 70% protein derived from methanotrophic bacteria, manufactured through the company’s patented String Integrated Methane Platform (SIMP®).

The company has secured £14 million in funding to accelerate its operations and scale production. The company has successfully reached the commercial scale of its sustainable marine omega3 product, NaturAlgae, at its demonstrator site in Scotland. By repurposing nutrient-rich byproducts from whisky distillation, the company grows microalgae, providing an eco-friendly source of omega-3s.

Insect producer Loopworm has successfully secured the ISO 22000, GMP+, and HACCP certifications for LoopFactory, a 6,000-ton-per-year insect protein production unit in Bangalore.

Arthro Biotech has become the only black soldier fly insect protein producer in India to receive EU TRACES certification. The company currently produces 500 tons of insect protein annually with plans to launch the new 5,000-ton factory in September 2025.

Albert Heijn, a Dutch retail chain, has started selling sustainably farmed shrimp supplied by a value chain consortium. The consortium has developed innovative shrimp feed, crafted by Skretting Ecuador for Cofimar. The feed incorporates alternative ingredients such as Veramaris algal oil and Protix insect meal. Moreover, these shrimp are ASC-certified and imported by Klaas Puul.

The company has taken decisive actions to successfully navigate the current market conditions in Western North America which has seen a flat USA market and 40% reduction in the British Columbia salmon aquaculture industry since 2020.

The French insect company filed a safeguard plan as it failed to find enough financing for expansion plans.

“Facing a complex economic and financial conjecture, which is characterized by the drying up of funding usually directed to high-growth companies, Ÿnsect has obtained the opening of a ‘procédure de sauvegarde’,” the company said in a statement.

Safeguarding facilitates the reorganization of the company to allow economic activity to continue, jobs to be maintained and debts to be paid.

Javier Polo, APC LLC & APC Europe S.L., Joe Crenshaw, APC LLC, Fco. Javier Alarcón, Lifebioencapsulation SL

Global aquaculture and aquafeed production have had continuous growth for decades. To keep up with growing demand, aquafeed producers need a sustainable supply of multiple ingredients to produce functional water-stable feeds that meet the nutritional requirements for a specific life stage of a given aquatic species for supporting efficient growth and productivity, while minimizing nutrient waste that contributes to a higher carbon footprint. Animal protein ingredients derived from the meat industry contribute to sustainability and can help reduce reliance on the use of less sustainable marine-sourced ingredients like fish or krill meal.

Animal protein ingredients including meat and bone meal, meat meal, poultry-byproduct meal, feather meal and blood meal can provide an economical

source of protein in feed formulations but may have limitations due to variations in protein and ash content. Digestibility of protein in these ingredients can be affected by processing with prolonged heat treatment used by rendering processes versus rapid drying, with shorter heat treatment processes like spray-drying. For example, animal blood ingredients are high in protein content (>75%) but the digestibility can vary depending upon the processing method. The apparent protein digestibility of blood products by trout was reported to be significantly higher for spray dried products vs rendered blood products using steam tube drying or ring drying methods (Bureau et al., 1999). Spraydried blood plasma (SDP) had the highest dry matter and protein digestibility among the spray-dried blood products (Table 1).

Animal blood collected and used to produce SDP and its co-product spray-dried blood cells (SDBC) is done hygienically and the rapid drying with short-duration heat processing conditions may contribute to their higher dry matter and protein digestibility versus that of rendered blood meal products. Therefore, spray-dried blood products may provide a more consistent higher digestible protein content than traditionally rendered blood products.

Unique properties of spray-dried plasma protein

Spray-dried blood cells have long been used in aquafeeds as an ingredient with very high protein content (>92%)

that is highly digestible and can help reduce reliance on fishmeal. Spray-dried plasma contains lower protein content (70-80%) than SDBC but has a diverse profile of functional proteins including albumen, immunoglobulins, transferrin, growth factors, peptides and others that have been demonstrated in mammalian studies to have beneficial modulatory effects on the immune system response to stress and pathogens. Although SDP has been used less extensively in aquafeeds than SDBC, several studies using various aqua species have demonstrated that the unique proteins in SDP can benefit aquaculture productivity, survival, and health indices, particularly during stressful periods of the life cycle (Table 2).

Species

Trout Used water ↑Protein digestibility, biomass, survival

Trout Yersinia ruckeri

et al., 2014

↑Survival, ADG Aljaro et al., 2003

Nile tilapia Cold stress ↑Monocytes, plasma protein, cold resistance Araujo et al., 2017

Seabream Fingerling ↑BW uniformity, ADG, feed efficiency, Gisbert et al., 2015 ↓oxidative stress

Salmon Smoltification process ↑BW uniformity, ADG Gisbert et al., 2013

Salmon Piscirickettsia salmonis (SRS) ↑ADG, TGC Campbell et al., 2019

Eel Redhead Disease ↑ADG, feed efficiency APC internal report, 2000

Grouper White Spot Disease ↑Survival South China Sea Fisheries Institute, 1997

Shrimp Latex bead

Shrimp White Spot Syndrome Virus

Shrimp Vibrio parahaemolyticus

↑Phagocytic activity Russell & Campbell, 2000

↑Survival & ADG

↑Survival & hepatopancreas histological status

Russell & Campbell, 2000

Chuchird et al., 2021 (White Feces Syndrome)

Shrimp Seawater ponds

↑ increase or improve; ↓ decrease or reduce

↑Survival, ADG, FCR, PER Cano et al., 2023

Recent studies (Tapia-Paniagua et al ., 2020; Reyes-López et al., 2021; Fernández-Alacid et al., 2022) with gilthead seabream (Sparus aurata) have been completed to better understand the mechanisms associated with the beneficial effects of SDP in aquafeed on productivity, health, and survival. At the intestinal level, SDP in feed increased seabream growth, the density of intestinal globlet cells at both day 20 and 95 of the study, and the intestinal Lactobacillus genus populations while decreasing Vibrio genus populations at day 20 (Tapia-Paniagua et al., 2020).

In another study (Fernández-Alacid et al., 2022), the mucosal immune response by challenging skin mucus antibacterial capacity and systemic immune response through their ex vivo splenocytes was done in seabream fed diets with or without SDP. Results suggested that dietary SDP favorably modulated the systemic immune response and improved skin mucosa.

Table 3. Composition of tested trout and shrimp diets

Furthermore, a comprehensive interactive skinmucous multi-omics-based analysis of seabream fed diets with or without SDP (Reyes-López et al., 2021) revealed a skin profile favoring fish fed SDP associated with biological mechanisms of gene expression, biogenesis, vesicle function, protein transport and localization to the membrane. Mucous showed an enhanced protective role with higher antioxidant and antimicrobial properties for fish fed SDP. Histologically skin thickness and number of mucous cells increased along with a positive effect on SDP-fed fish growth and health. Collectively these results indicate a synergistic mechanism of fish skin and mucous to improve tissue development, innate defenses and environmental recognition for fish fed SDP.

The demonstrated benefits of SDP on immunity, health, survival, and productivity of various aqua species recently led to its selection by the Fish Free Feed (F3) scientific committee as a test ingredient among

APC takes what was once considered a low value by-product and transforms it into highly digestible protein ingredients that help animals thrive.

Through sustainable practices, we manufacture spray dried plasma that serves as a valuable tool for the aquaculture industry to benefit productivity, health and survival while reducing reliance on marine ingredients.

Spray dried plasma can be used at neutral to better ingredient cost with a lower carbon footprint, while providing feed technology benefits for pellet durability and water stability.

Spray dried plasma

Superior Nutrition

Health & Productivity Impacts Feed Technology Benefits

Learn More

Selected by the Fish Free Feed (F3) scientific committee as a Top 10 Finalist in the 2024 Krill Replacement Challenge.

9 others in a controlled research study contest designed to find alternatives to krill meal in feed for salmon (study in progress, results pending).

Feed technology properties of SDP

Besides the demonstrated nutritional and health benefits of SDP in aquafeed, it must be economical to use in diet formulations and provide manufacturers with desirable technological properties to successfully produce a final feed product with adequate stability in water. Spray-dried plasma has long been used for its excellent emulsification, binder, and gelling capacity properties in pet food.

A study was recently completed to demonstrate the technological properties of SDP in single screw extruded feeds for trout and shrimp. Formulations for this study were done by the Wittaya Aqua consulting group through their AquaOp Feed program using local ingredient prices. Feed was manufactured at the Unit of Experimental Diets of the University of Almeria (Spain) in 8-kg batches and technological properties of the feeds were measured. The composition of the trout and shrimp diets is presented in Table 3. In both trout and shrimp test diets, SDP was used to replace 1.5% wheat gluten as a primary binder in the control diets. Trout test diets also used SDP and SDRC to reduce fishmeal ingredients and replace soy protein concentrate in the control trout diet. In the shrimp test diet, SDP also allowed for a reduction in the fishmeal compared to the control diet.

Both trout and shrimp test diets containing SDP had a lower ingredient cost per ton and a lower carbon footprint (around 6% less) than their respective control diet. Technological parameters (Table 4) were measured on 3 samples for all parameters, except

for flowability (n = 6) and hardness (n = 10). Values presented are means ± stdev. Treatment differences within trout or shrimp diets were analyzed by PROC GLM (SAS).

In trout diets, SDP pellets had lower density and hardness with higher durability and water stability, but with a higher degree of flowability, although both trout diets had a good angle of repose rating. Water stability of trout pellets was significantly higher with SDP. In shrimp diets, SDP pellets had greater density and lower hardness, but pellet durability, water stability and flowability were not different among treatments.

Spray-dried plasma can be used in trout and shrimp diet formulations at neutral to lower ingredient cost per ton of feed with a lower carbon footprint while maintaining similar or better pellet durability and water stability.

Conclusion

Spray-dried plasma is a highly digestible and functional protein ingredient with multiple applications in various aquaculture species to benefit productivity, health, and survival while reducing reliance on marine ingredients. It is sustainable, and economical in practical formulations and lowers the carbon footprint while providing acceptable durability and water-stable aquafeeds.

References available on request.

More information: Dr.

Javier Polo Senior Vice President –Research & Development

E: javier.polo@apc-europe.com

Pierrick Kersanté, Eakapol Wangkahart, Raquel T. Pereira, BCF Life Sciences

In aquaculture, the utilization of amino acids is commonly considered according to the essential and non-essential amino acids categories and in the perspective of equilibrating physiological requirements in essential amino acids (AA) through the addition of crystalline amino acids in diets. Progressively and mainly thanks to knowledge evolution in the animal nutrition industry, the gap between traditional AA classification and physiological importance has led to the emergence of the “functional amino acids” concept. Functional AAs are defined as those which participate and regulate key metabolic pathways to improve growth and health

in mammals and fish. This AA group encompasses arginine, cysteine, glutamine, glutamate, glycine, leucine, proline, and tryptophan regardless of their

The functional AA concept also has led to a paradigm shift regarding the classification of AA as nutritionally dispensable or indispensable. It has been proposed that animals have dietary requirements for not only indispensable but also dispensable AAs to achieve maximum growth and health. Indeed, this approach encourages discussion regarding whether AA requirements in animals could be underestimated under

certain conditions and/or if ratios between dispensable or indispensable AAs have been taken into account, as they should.

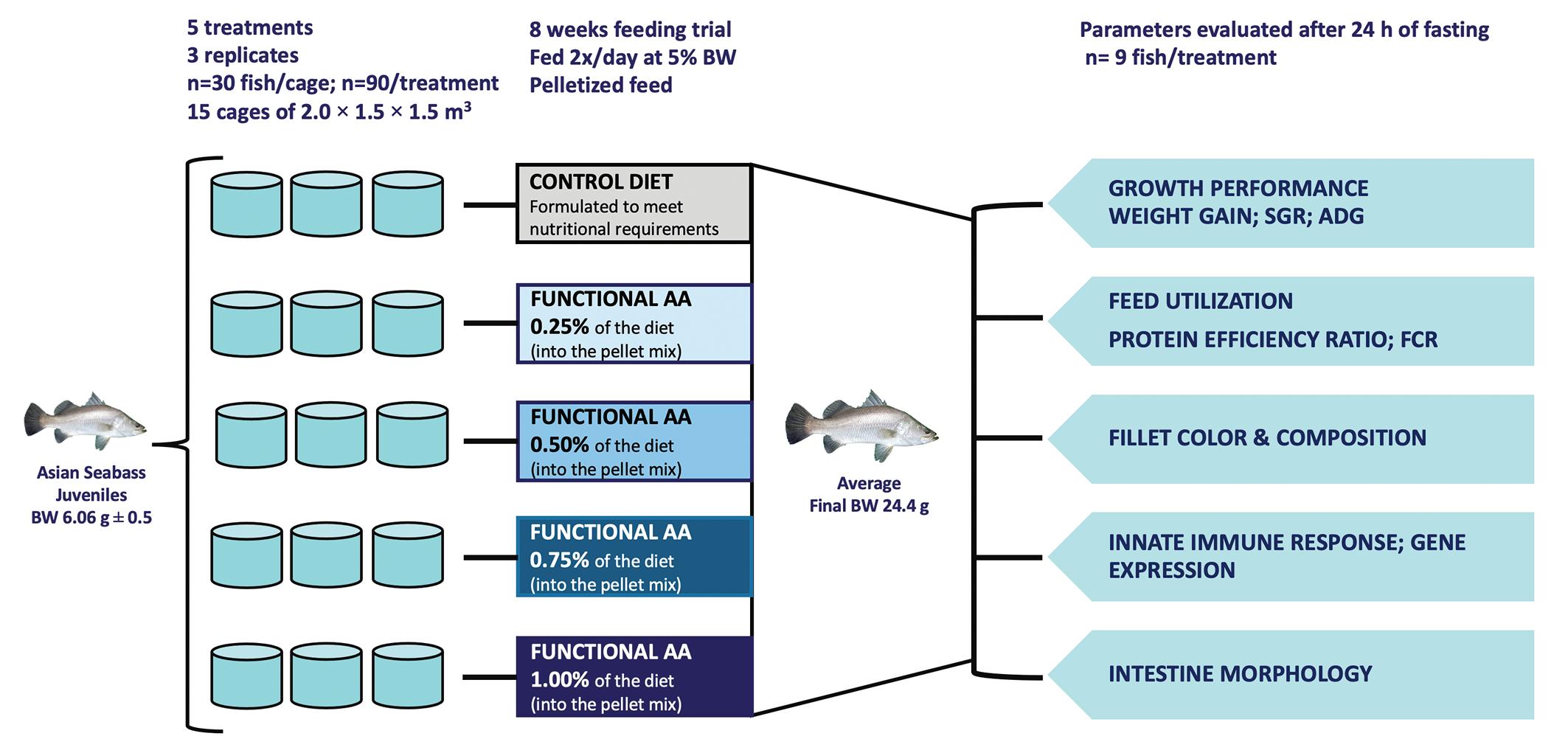

In order to explore the concept of functional amino acids and their benefits in fish nutrition, this study aimed to evaluate the dose-response effects of supplementing functional AA for Asian seabass (Lates calcarifer) on growth and health.

The mix of 17 functional AA (FAAM) used in this study was obtained from extensive hydrolysis of poultry keratin, commercial name Kera-Stim®50.

All fish were obtained from Chachoengsao province, Thailand and acclimatized for two weeks prior to the feeding trial. Fish weighing 6.06±0.05 g were randomly distributed into fifteen floating cages (2.0×1.5×1.5 m3), in a larger cement tank (7x10x1.5 m3) with a density of 30 fish per cage. Fish handling and experimental conditions have been approved by the ethics committee at Mahasarakham University, Thailand. Fish were assigned to five isonutrient diets (41% protein, 9% lipid), a control, and four diets supplemented with different FAAM levels: 0.25% (FAAM0.25), 0.50% (FAAM0.50), 0.75% (FAAM0.75) and 1.0% (FAAM1.0). Fish were fed to apparent satiation

twice a day for eight weeks. Samples were collected at the end of the feeding trial after 24 hours of fasting. During the feeding trial, water quality parameters were measured and suitable for fish culture (dissolved oxygen was 7.71±0.81 mg/L, temperature was 26.2±0.7°C, pH was 7.37±0.30, alkaline was 215.33±0.03 mg/L, and ammonia nitrogen was lower than 0.02 mg/L).

Parameters evaluated

Growth performance evaluations included weight gain (WG), specific growth rate (SGR), average daily gain (ADG), feed conversion ratio (FCR) and protein efficiency ratio (PER).

Digestive efficiency was evaluated based on midgut morphology and digestive enzyme activity. For health, the innate immune response and antioxidant capacity were measured in serum. Lastly, fillet yield and composition were also quantified (Fig. 1).

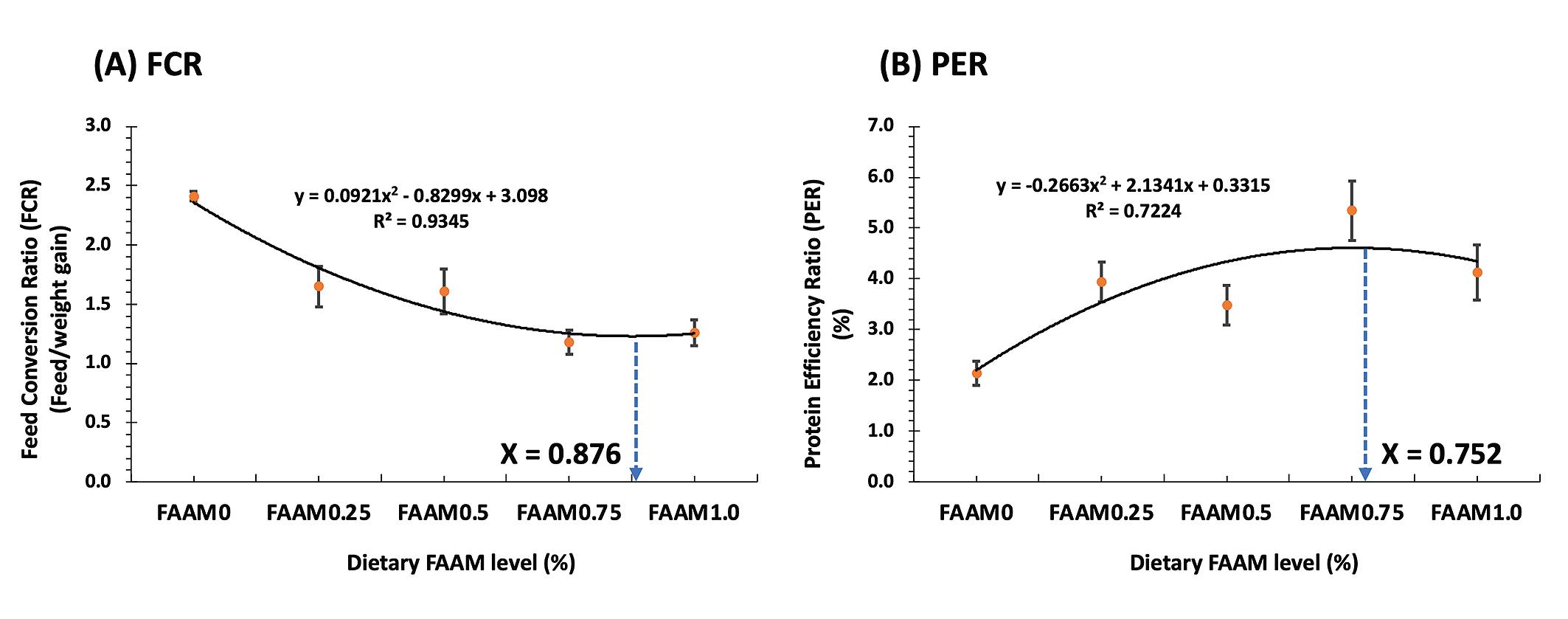

Growth performance and fillet quality

Overall, fish fed the FAAM0.75 and FAAM1.0 diets resulted in significant (P < 0.05) improvement in most growth and feed utilization parameters (Table 1, Fig. 2). A regression analysis indicated an ideal inclusion of 0.876% for feed conversion and 0.752% for protein

efficiency ratio (Fig. 3). Body condition indexes were also improved in relation with FAAM supplementation with higher carcass yield but also higher concentration of protein and lipid deposition into the fillet. These physical characteristics were also measurable on the fillet color with an increase of the chromatic parameter of lightness (L* value), as shown in Table 1.

Gut morphology and digestive efficiency

In this study, the main highlights were the midgut histomorphology including the mucosal fold height, width, thickness, and goblet cells were increased in fish fed

with supplemented FAAM diets, which fostered the gut cells for better mucosal epithelium development (Fig. 4). In parallel, digestive enzyme activity (amylase, protease, and lipase) was also boosted by the supplementation of ≥ FAAM0.50.

Antioxidant capacity and innate immune response

Antioxidant and innate immune-related enzymes were also evaluated and were significantly increased in fish fed FAAM0.75 and FAAM1.0 citing lysozyme, myeloperoxidase, catalase, and glutathione peroxidase (Fig. 5).

These results showed that Asian seabass supplemented with a mix of functional amino acids had improved growth and promoted better health, similar to a previous study in Nile tilapia. Overall, the supplementation of FAAM led to better gut villi and muscle layer development as well as improved digestion efficiency. Furthermore, the unique mix of functional amino acids reinforced immune response and antioxidant capacity. Together, these improvements were translated into higher growth performance and fillet quality. For most parameters evaluated, it is needed an inclusion of at least ≥0.75% to access the benefits.

These findings provide interesting insights into the optimal inclusion level of FAAM in diets of Asian seabass of 0.876% obtained from regression analysis.

Since 2018, BCF Life Sciences, a pioneer of the circular economy, has been leading the research on shrimp and fish with a unique functional mix of 17 amino acids obtained from extensive poultry keratin hydrolysis. In pursuing more sustainable and challengeoriented feed formulation, these results reinforce the benefits of supplementing functional amino acids above and beyond traditional approaches, especially for carnivorous species.

The complete article recently published in the journal Fish and Shellfish Immunology 2024 (impact factor 4.1) is fully available on request.

More information:

Pierrick Kersanté

R&D Aquaculture Manager

BCF Life Sciences

E: pkersante@bcf-lifesciences.com

Eakapol Wangkahart

Associated Professor

Laboratory of Fish Immunology and Nutrigenomics

Mahasarakham University, Thailand

E: eakapol.w@msu.ac.th

Raquel T. Pereira

Consultant

E: raqueltpr@outlook.com

Jordi Ysamat, VEOS Group

Shrimp farming, particularly of Penaeus vannamei, is a rapidly growing sector within aquaculture, driven by the global demand for seafood. However, the sustainability and efficiency of shrimp feeds remain critical challenges, particularly due to the heavy reliance on traditional marine protein sources such as fishmeal and squid meal. While these ingredients are nutritionally effective, they are subject to supply constraints, high costs, and environmental concerns linked to overfishing. As the aquaculture industry looks for more sustainable feed options, one promising alternative is egg powder, a nutritionally rich and readily available ingredient. Egg powder is abundant in essential amino acids, cholesterol, and phospholipids – nutrients crucial for shrimp growth, health, and disease resistance.

This study explores the potential of egg powder as a sustainable and nutritionally viable alternative to conventional marine protein sources in shrimp diets. Additionally, we examine the health benefits of egg powder’s bioactive compounds and their role in modulating shrimp immunity and stress tolerance, thus enhancing aquaculture productivity.

Nutritional composition of egg powder vs. marine protein sources

Marine proteins, such as fish and squid meal, are traditionally the cornerstone of shrimp feed due to their high-quality amino acid profile, digestibility, and beneficial fatty acids. When comparing marine proteins to egg powder, the proximate composition of both

ingredients – such as moisture, crude protein, and crude fiber – are within a similar range. However, egg powder offers a higher crude fat content and a lower ash content compared to marine sources (Fig. 1).

The lipid profile of egg powder is particularly advantageous, as it contains bioactive lipids, including cholesterol and phospholipids, which play critical roles in shrimp growth and development. Unlike marine species, shrimp cannot synthesize cholesterol de novo (Teshima & Kanazawa, 1971; Su et al., 2023). As a result, shrimp depend on dietary cholesterol, and the requirement generally ranges from 0.2% to 1.0% of the diet (Castille et al., 2004). Egg powder, as a costeffective and cholesterol-rich ingredient, can meet these dietary requirements and potentially reduce the need for expensive purified cholesterol supplements.

phospholipid

One of the significant nutritional advantages of egg powder is its high cholesterol content. Studies have shown that inadequate cholesterol in shrimp diets leads to reduced growth performance and higher mortality rates (National Research Council, 2011). In low fishmeal diets, which naturally contain less cholesterol, it is often necessary to supplement with purified cholesterol or other cholesterol-containing ingredients to support optimal growth (Coutteau et al., 2002). However, purified cholesterol is expensive, and the use of egg powder can offer a cheaper and equally effective

alternative (Tuna Keleştemur et al., 2022).

Egg powder is also rich in phospholipids, particularly phosphatidylcholine (PC), which has been proven to support shrimp growth and survival during the early life stages. Juvenile and larval Penaeus vannamei have a higher dietary requirement for phospholipids due to their rapid growth rates and insufficient endogenous synthesis (Coutteau et al., 1996). The addition of phospholipids at levels of 0.5% to 1.5% has been shown to significantly improve growth and survival in juvenile shrimp. Egg powder, with its naturally high phospholipid content, can meet these requirements, making it a valuable ingredient for shrimp feeds.

compounds and health benefits

Egg powder not only serves as an alternative protein source but also offers bioactive compounds that can enhance shrimp health. The presence of antioxidants like lutein and zeaxanthin, along with antimicrobial proteins such as ovotransferrin and ovomucin, contribute to improved disease resistance and immune function in shrimp.

One important bioactive compound in egg powder is astaxanthin (Ax), a carotenoid that enhances shrimp pigmentation and provides various health benefits, such as improved maturation, stress resistance, and immune function (Merchie et al., 1998; Pan et al., 2001). Shrimp cannot synthesize astaxanthin de novo, making dietary sources essential. Carotenoids in egg powder can be bioconverted by shrimp into astaxanthin, contributing to desirable flesh pigmentation and overall improved health (Hertrampf & Piedad-Pascual, 2000).

Egg yolk lipids in particular have been shown to promote shrimp growth, improve lipid utilization, and reduce mortality (Kiosseoglou, 2003; Zorriehzahra et al., 2016). This positions egg powder as a dual-purpose feed ingredient – both as a protein and fat source, and as a health-promoting agent.

Table 2

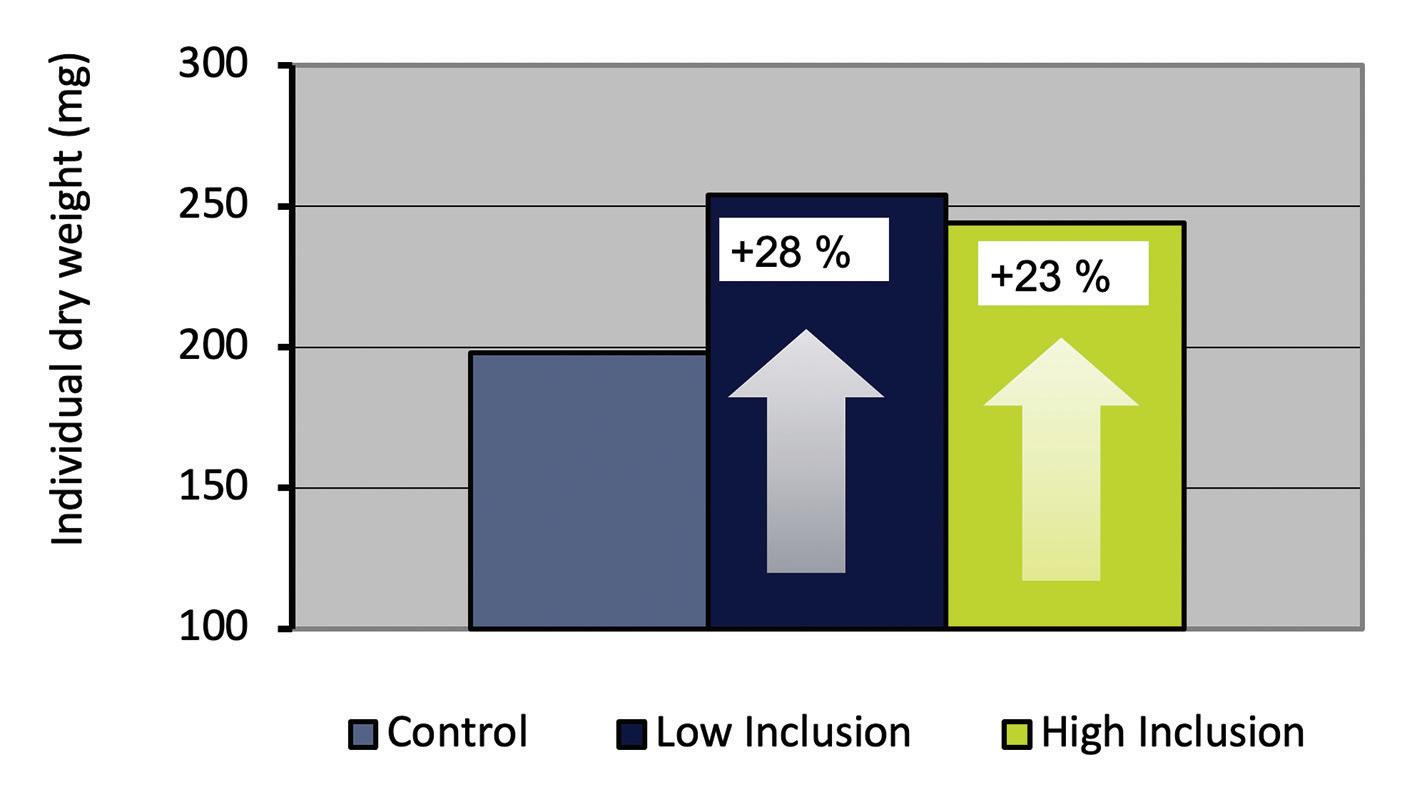

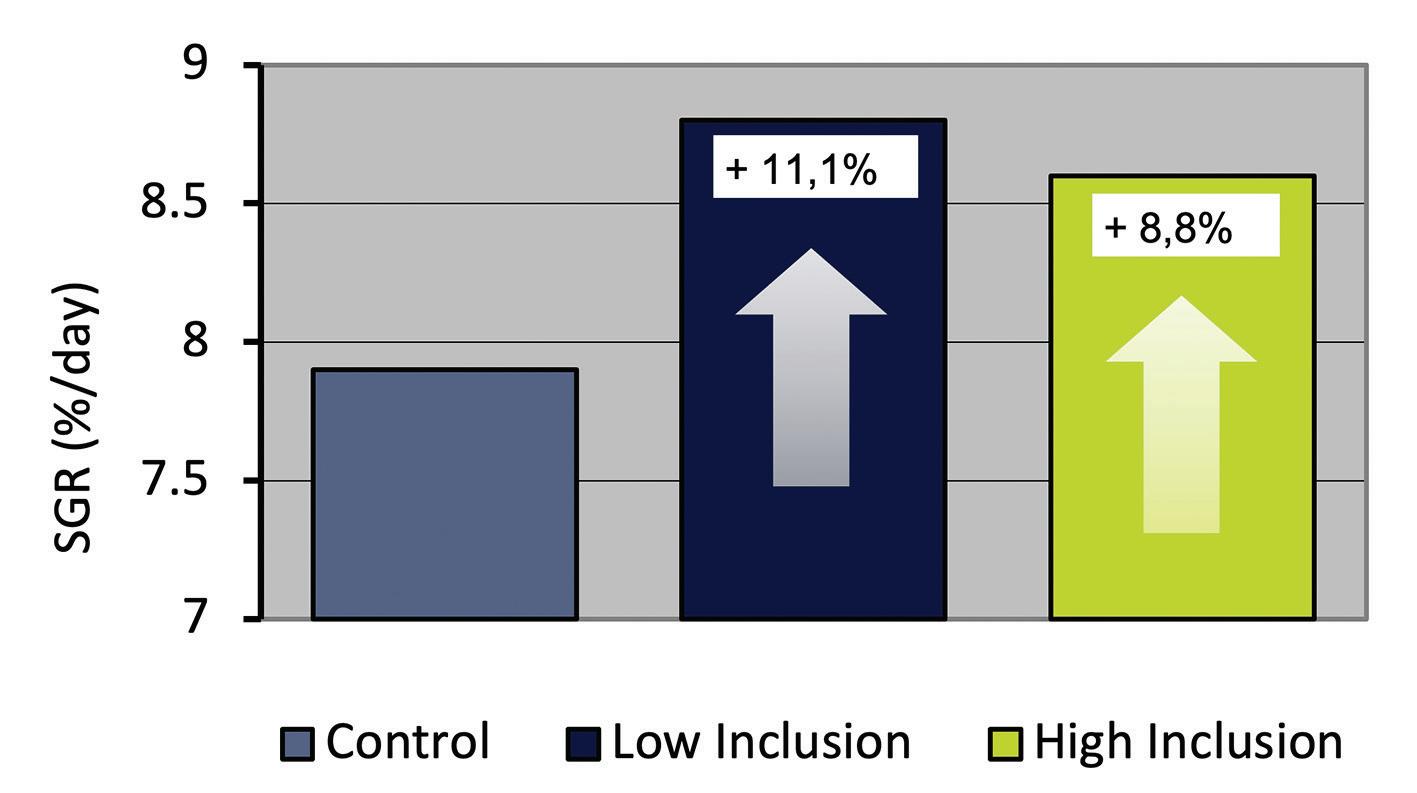

Feeding trial: Evaluating egg powder for Penaeus monodon post larvae

A comprehensive feeding trial was conducted by the Laboratory of Aquaculture & Artemia Reference Center, Ghent University, to investigate the effects of egg powder (ACTIPRO 44EP) on the growth and survival of

Penaeus monodon postlarvae. This trial explored the efficacy of egg powder (ACTIPRO 44EP) as partial replacement for marine meals.

Materials and methods

Specific pathogen-free Penaeus monodon postlarvae were used in a 4-week trial. Three experimental diets were formulated (Table 1), including a control diet with traditional marine meals and two test diets containing moderate (12.5%) and high (19%) inclusion levels of egg powder (ACTIPRO 44EP) (Table 2). The trial employed a randomized block design with three independent recirculating systems, each consisting of five 30-liter tanks stocked with 80 shrimp per tank.

Results

The results showed no significant differences in survival rates among treatments, with an average survival rate of 85%. However, shrimp fed diets containing egg powder exhibited superior growth performance. After four weeks, shrimp fed a moderate level of egg powder (12.5%) had the highest individual wet and dry weights, surpassing those fed the control diet (Fig. 2, Table 3). The specific growth rates (SGR) ranged from 8.0% to 9.8%, indicating satisfactory growth for post larval shrimp (Fig. 3).

The trial also highlighted the potential of egg powder to replace marine meals without compromising shrimp health or performance. The moderate inclusion of egg powder (12.5%) yielded better growth results compared to higher levels (19%), suggesting that excessive inclusion may not provide additional benefits.

Conclusion

This study demonstrates the potential of egg powder as a sustainable and nutritionally viable alternative to traditional marine protein sources in shrimp feeds. Egg powder offers a rich profile of essential amino acids, cholesterol, and phospholipids that are crucial for the growth, health, and disease resistance of shrimp.

Its inclusion in shrimp diets can significantly reduce the reliance on fish and squid meals, addressing both cost and environmental concerns. Moreover, egg powder’s bioactive compounds, including antioxidants and antimicrobial proteins, offer additional health benefits, improving immune function, pigmentation, and stress resistance. By incorporating egg powder into shrimp feeds, aquaculture can enhance both the sustainability and productivity of shrimp farming, contributing to the long-term viability of the industry.

References available on request.

More information: Jordi Ysamat Technical Sales Manager ACTIPRO VEOS Group E: jordi.ysamat@veos.es

Michel van Spankeren, Protix

In line with the European Green Deal, the European Union envisions a more sustainable aquaculture sector by 2030. In real terms, the Green Deal targets a 55% cut in greenhouse gas emissions within the next six years. It’s a big ask that calls for game-changing approaches.

According to the journal Nature, feed production is responsible for 57% of total CO2 emissions in aquaculture. The independent research group SINTEF reports an even higher figure for Norwegian-farmed salmon, with feed accounting for up to 83% of emissions. Given that feed is the primary driver of carbon emissions in aquaculture, it is crucial to focus on reducing its environmental footprint.

The key challenge for feed manufacturers in aquaculture is to develop lower-footprint feeds without compromising feed quality. On top of that, sustainable feeds must also be economically viable, allowing aquaculture producers to stay competitive while shifting toward greener solutions. Balancing these factors –sustainability, performance, and cost – is not easy for feed manufacturers in aquaculture today.

Insect ingredients, especially the black soldier fly ingredients, offer a viable solution. Insect protein and lipids made from the black soldier fly (Hermetia illucens) are suitable for many aquaculture species, including both fish and shrimp.

Black soldier fly ingredients have a proven low footprint. The renowned and independent German Institute of Food Technologies (DIL) has carried out a Life Cycle Analysis (LCA) on insect meal (ProteinX) and insect fats (LipidX) from Protix. The results show that ProteinX lowers CO2 emissions by as much as 89% compared to soy protein concentrate, while LipidX insect fat virtually halves land use, using 99.9% less than coconut oil.

The sustainability scores of black soldier fly ingredients are unparalleled because the score is achieved through two elements. First, organic waste is collected and

repurposed as feed for the black soldier fly, turning waste into valuable proteins and other nutrients. Second, the production of animal feed and other solutions takes place in vertical farms, significantly reducing land use, water consumption, and CO2 emissions compared to traditional methods.

Multiple studies have shown black soldier fly ingredients to be safe, compatible and highly nutritious. What’s especially noteworthy is that these ingredients not only meet standard nutritional requirements but also provide additional health benefits, including positive effects on stress management, the mucosal barrier, wound healing and liver health. A recently published study by the Institute of Marine Research (IMR) in Norway highlights these advantages, which are particularly relevant given the current biological challenges faced by farmers in net pen production worldwide.

Protix, the world leader in insect ingredients, offers science-backed insect ingredients like ProteinX® and LipidX® for healthy, sustainable nutrition. Our industrial-scale, stateof-the-art plant in the Netherlands, operational since 2019, ensures a reliable supply of consistently high-quality ingredients for your formulations.

This is our invitation to visionaries and innovators alike: connect and join the future of food today!

www.protix.com | info@protix.com

New study

This is confirmed in a recent initiative from Aller Aqua in collaboration with the Norwegian University of Life Sciences, and Norwegian salmon producer Austevoll Melaks AS. The consortium tested black soldier fly protein (ProteinX from Protix) as a potential aquafeed ingredient. Benchmark trials compared salmon fed a traditional fish diet and a diet with the inclusion of black soldier fly meal. The salmon fed with insects proved superior on several counts.

First of all, there was an improvement in both the slaughter yield of the whole fish and fillet yield. The raw fillets had improved firmness and fillet integrity (less gaping), improved color and fewer dark melanin spots. But the proof is in the eating. A test panel tasted baked fillets and two-thirds of participants preferred salmon fed with back soldier fly ingredients.

Value creation

These remarkable results present exciting opportunities for various value chain partners to begin incorporating black soldier fly ingredients. Now is the time to integrate these insects into feed, and fully explore their potential, turning that value into long-term commercial benefits.

Collaboration

By working together in commercial-scale production and diving into elements such as health benefits, increasing yield, better quality and consumer benefits, the value of black soldier fly ingredients can be unlocked. We can achieve a scenario where the insect industry meets the aquaculture sector's demand for a low-footprint ingredient that is commercially attractive.

The black soldier fly holds tremendous potential to create a lower footprint for the aquafeed industry. However, it is important to recognize that not all insect ingredients yield the same results. At Protix, a unique production process guarantees consistently highquality ingredients. This means that the impressive outcomes seen in studies are specific to Protix products and cannot be directly applied to those from other suppliers. Since 2009, Protix has been refining and perfecting its black soldier fly ingredients to deliver exceptional results.

As the European Union sets ambitious targets for more sustainable food production by 2030, with a goal of reducing greenhouse gas emissions by 55%, the spotlight falls on aquaculture feed, which contributes a staggering 57-83% of these emissions. The black soldier fly emerges as a game-changing solution, transforming organic waste into high-quality protein and fats while significantly cutting land and water use, and CO2 emissions. Recent studies not only validate the safety and nutritional benefits of black soldier fly ingredients but also highlight their positive impacts on fish health and quality, making them a superior choice for aquaculture feeds. Let’s commence collaborations and large-scale trials. Embracing this innovative approach not only aligns with environmental goals but also promises long-term commercial benefits for all stakeholders, paving the way for a sustainable and resilient future in aquaculture.

More information:

Michel van Spankeren Business Development Manager Protix

E: Michel.vanSpankeren@protix.com

Gil De Clercq, Entobel

Black soldier fly (BSF) larvae meal is widely regarded for its high protein content (>55%), which supports the growth and metabolism of aquatic species. BSF meal has a well-balanced amino acid profile, similar to high-grade fishmeal, and its protein molecular weight distribution is dominated by free amino acids and di-/tripeptides, making it highly digestible. Additionally, with an average of 13% fat content, including the medium chain lauric acid, BSF meal enhances energy supply, improves palatability, and provides antibacterial properties in aquafeed formulations. Shrimp species and fish like pangasius, tilapia, rainbow trout, and Atlantic salmon are commonly fed with diets containing BSF meal, demonstrating successful outcomes.

An essential but underexposed component of BSF meal is chitin, a compound found in the exoskeleton of the larvae. Studies have suggested that chitin can promote gut health, enhance microbiota, and boost the immune function in fish and shrimp, leading to an improvement of overall health and performance.

For producers like Entobel, who specialize in BSF larvae meal, it is essential to understand the balance between the benefits and potential drawbacks of chitin to ensure its proper use in aquaculture feed formulations. The advantages, such as its prebiotic effects and immuneboosting properties are outlined below. However, excessive amounts of chitin can reduce nutrient digestibility, leading to lower performance outcomes. Currently, there are no established species-specific guidelines for maximum chitin inclusion levels in aquaculture diets. For now, we rely on existing studies to provide an indication of safe limits. For example, diets for whiteleg shrimp and Atlantic cod can tolerate up to 5% chitin without negative effect on growth (Rimoldi et al., 2019), while rainbow trout show good performance

with up to 3% chitin, but growth is impaired when levels exceed 4.5% (Pascon et al., 2024).

To contextualize, at a 20% inclusion rate of H-Meal, Entobel’s BSF meal, the chitin content is typically 1% in the feed formulation, remaining well within the safe range indication found by available research, thus avoiding the adverse effects of higher chitin levels.

The ideal gut microbiota for aquatic species is not definitively established, as it varies across species. However, research shows a strong correlation between gut microbiota composition and gastrointestinal health, with a consensus that a diverse microbial community fosters a healthy gut.

Chitin has a potential prebiotic effect when it can be broken down by chitinolytic activity in the stomach or the intestinal tract. Enzymes such as chitinase and chitobiase, as well as certain bacterial species in the gut, vary in their ability to degrade chitin, depending on the species (Ringo, 2012). The breakdown of chitin results in the production of di-and trisaccharides including chitosan and fermentation products such as propionate and butyrate, short-chain fatty acids, which benefit the intestinal lining. Chitin is also being reported to have a bacteriostatic effect on several pathogenic gram-negative bacteria (Pascon et al., 2024), which also helps modulate the gut microbiota towards preferential bacteria.

Studies have shown that species such as whiteleg shrimp, Atlantic cod and salmon, red seabream, and Japanese flounder a.o. exhibit this chitinolytic activity, leading to fermentation products that contribute to chitin's prebiotic effects (Ringo et al., 2016). The inclusion of 1% of dietary chitin in the diet of Atlantic salmon has

led to an increase in beneficial bacteria like Lactobacillus and Carnobacterium, which can enhance digestion and nutrient absorption while reducing harmful bacteria like Vibrio and Aeromonas (Askarian et al., 2012).

Other species where a rise of beneficial bacterial diversity was observed were whiteleg shrimp, rainbow trout, tilapia, Japanese seabass (Ringo et al., 2011). These shifts in gut flora enhance immune responses and strengthen the intestinal barrier, leading to greater protection against infections (Zhou et al., 2014).

A moderate amount of chitin in the diet is recognized for its immunostimulatory properties in aquatic species. It triggers immune responses by interacting with immune receptors or through its degradation products, which mimic pathogen-associated patterns (Komi et al., 2017). Studies indicate that chitin can enhance both non-specific immune responses and disease resistance in various species.

Chitin promotes the production of cytokines and activates the innate immune system by stimulating macrophages and natural killer cells, aiding aquatic

species in fighting off infections (Esteban et al., 2001; Ringo et al., 2012).

Today, for example, chitin has been successfully used as an immunostimulant in shrimp aquaculture to prevent diseases. In 2005, a study from Wang & Chen showed an improved immune function of whiteleg shrimp, resulting in better survival rates against Vibrio alginolyticus

Also in fish, yellowtail for instance, chitin injections increased protection against P. piscicida (Kawakami et al., 1998). Another study involving common carp revealed that chitin enhanced immune responses such as lysozyme and phagocytic activity and respiratory rates (Gopalakannan & Arul, 2006). In rainbow trout, dietary chitin supplementation has been shown to protect against Vibrio anguillarum (Sakai et al., 1992).

According to available research, chitin, a key component of BSF larvae meal, may offer promising benefits in aquaculture, particularly in enhancing gut health, modulating microbiota and boosting the immune system of fish and shrimp. However, potential drawbacks, including reduced nutrient digestibility, underscore the importance of managing the chitin inclusion in feed formulations. While existing research indicates that moderate amounts of chitin can be safely utilized, there is a need for species-specific guidelines to fully harness its benefits without compromising growth and performance. Consequently, further scientific research is essential to explore the dose-response relationship as well as to substantiate the potential benefits. Studies that focus on chitin from insect sources, compared with chitin derived from crustaceans are also needed to fully explore its unique properties. By backing up the potential of insectderived chitin with solid scientific evidence, we can unlock new opportunities for sustainable and effective aquaculture practices.

More

information:

Gil De Clercq International Sales Manager Entobel E: info@entobel.com

Jasmine Perez, Juan F. Paredes, Marty Riche, Paul S. Wills, Florida Atlantic University, Arthur L. Bondoux, Radu Popa, Stratium

Over the last decade, global aquaculture production has surged, supplying over half of the fish consumed worldwide today. FAO predicts that aquaculture is set to continue its rapid growth, potentially doubling by 2050. Aquaculture has traditionally relied on fishmeal (FM) as a primary protein source due to its outstanding nutritional profile. However, the growth of the aquaculture industry comes with a significant challenge as meeting the supply-demand of fishmeal appears untenable. This limited supply has pushed fishmeal prices to record highs, reaching as much as $1,880 per metric ton (World Bank). Thus, concerns over availability and rising costs underscore the pressing need to identify alternative ingredients to support the continued supply for the growth of the aquaculture industry.

Insect protein, particularly the one derived from Black Soldier Fly (BSF) larvae (Hermetia illucens), appears to be a promising alternative. BSF larvae can be reared on organic waste, requiring minimal water and agricultural land, as they are typically farmed in vertical systems within warehouses in urban or suburban areas, in contrast to traditional protein sources, which often require vast expanses of land.

Stratium LLC, the supplier of the product used in this study, produces Black Soldier Fly Meal (BSFM) by processing live larvae through a method that includes drying, grinding, and defatting the raw material. The resulting Stratium BSFM contains 49% crude protein on a dry matter basis and offers a well-balanced amino acid profile. Additionally, BSFM appears to be a suitable option for carnivorous species, instead of plant-based alternatives, as BSFM does not show high cellulose content or deficiencies in essential amino

like

and methionine, which et ., 2020). Furthermore, scientific literature suggests positive effects on growth in species such as golden ., 2023), Japanese seabass (Yang ., 2021) with optimal inclusion levels depending on the species. For these reasons, the objective of this study was to estimate the maximum BSFM level in diets for ) that can replace FM without negatively affecting growth performance and

A feeding trial was conducted with 400 juvenile red drum (initial mean weight=39g SD=2.8g) to

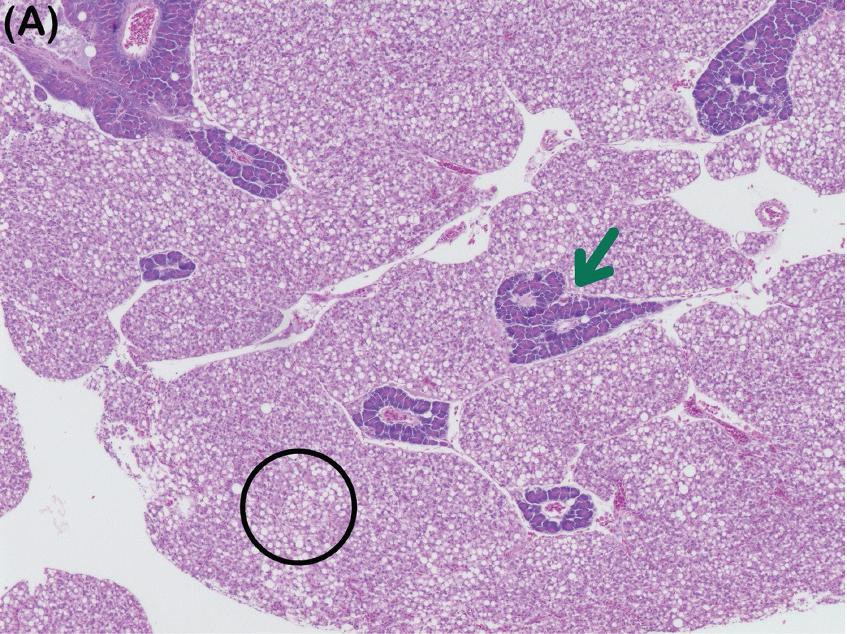

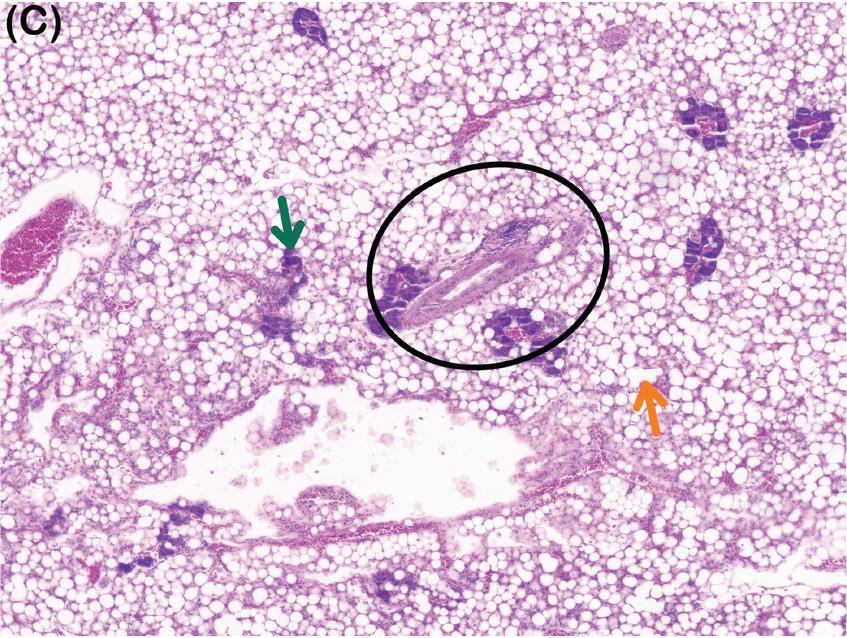

Figure 1. Histological images of juvenile red drum liver with BSFM substituting fishmeal levels at 0%, 50%, 100%.

Hematoxylin & eosin staining, 10x magnification. Green arrows represent pancreatic exocrine tissue. Orange arrows represent coalescing/degeneration vacuoles. Black circles highlight inflammatory responses or tissue health. (A) Liver of red drum fed the Control diet presented discrete margins in lipid vacuoles indicating adequate welfare in red drum. Pancreatic exocrine tissue presented discrete margins and held its tissue integrity. (B) Red drum fed with the BSFM50 diet presented mild vacuolization in the liver with coalescing traits. Pancreatic exocrine tissue was smaller but presented discrete margins and maintained tissue integrity. (C) Severe coalescing traits and possible fibrotic tissue were found in the liver of the red drum fed diet BSFM100, suggesting a high increase in fat storage. Pancreatic exocrine tissue presented signs of degradation by lymphocytes.

evaluate growth performance and liver response using diets with different levels of BSFM. To this end, five diets were formulated to meet the nutritional requirements of red drum, replacing FM protein at 0% (Control), 25% (BSFM25), 50% (BSFM50), 75% (BSFM75), and 100% (BSFM100) with BSFM as a protein substitute. Diets were randomly assigned to 20 tanks (250 liters each) within a recirculating aquaculture system. The tanks were maintained under a controlled 12-hour:12-hour light:dark cycle, with fish fed twice at 5%/day of their mass body weight (MBW) over eight weeks with feeding ratios adjusted every two weeks. Water parameters were kept as follows during the trial: pH: 8.08 ± 0.5, temperature: 28 ± 0.5°C, and salinity: 30.5 ± 0.6‰. At the end of the trial, growth performance was analyzed, and liver samples were collected for histomorphological analysis.

At the end of the 8-week trial, there was no significant difference between fish fed the Control and BSFM25 diets based on percentage weight gain (Table 1). Food conversion ratio (FCR) and protein efficiency ratio (PER) were the lowest and highest, respectively, in fish fed with BSFM25 diet. A second degree polynomial regression model suggested a 28% FM replacement with BSFM would result in a maximum of 2.3 kg MBW.

Preliminary histomorphology analysis of the liver suggested differences in lipid vacuole deposition between fish fed the Control and those fed BSFM100 diet with the latter exhibiting larger lipid vacuoles (Fig. 1A-C). Fish fed the BSFM50 diet showed similar histomorphology to the Control group.

The liver is a crucial organ for histomorphological analysis in studies related to nutrition, toxicity, and disease. Its central role in protein and lipid metabolism, detoxification, and nutrient processing makes it highly responsive to dietary changes, providing valuable insights into overall health in feeding studies. The results suggested that fish fed the BSFM50 diet displayed minor alterations in lipid deposition compared to the Control group, suggesting that this level of BSFM substitution did not lead to increased hyper-vacuolization. However, as BSFM substitution levels rose to BSFM75 and BSFM100, signs of hyper-vacuolization were observed, indicating liver stress and inflammatory responses. The liver of fish fed BSFM100 presented severe vacuolization, lipid vacuole degradation, fibrotic tissue formation, and lymphocyte aggregation (Fig. 1C).

Table 1.

Results are presented as means ± S.E.M. Different superscript letters denote statistically significant differences between groups, as determined by one-way ANOVA (p < 0.05) followed by Tukey's post hoc test.

These effects suggest an inflammatory response that could impair liver functions (Rašković et al., 2011). Additionally, such liver response correlated with poor growth parameters, including FCR, PER, and the lowest weight gain in fish fed BSFM100 diet, indicating an overall negative impact on growth performance.

Conclusion

This study showed that BSFM is a suitable protein source for aquafeed formulations in juvenile red drum, replacing FM at levels up to 50% without causing detrimental histomorphological changes. Thus, BSFM proves to be a viable ingredient capable of reducing fishmeal dependency while maintaining fish growth.

This work was supported by the U.S. Department of Agriculture Research Services by Cooperative Agreement Number 59-6034-9-007 with Florida Atlantic UniversityHarbor Branch Oceanographic Institute, Stratium, Duke Energy, and Florida Coastal Conservation Association.

More information: Dr. Juan F. Paredes Researcher, Aquatic Animal Nutrition HBOI-FAU E: ParedesJ@fau.edu

Eric Leclercq, Lallemand Animal Nutrition

Farmed fish are often exposed to infectious and noninfectious deleterious factors and abrupt environmental fluctuations. These successive insults exacerbate the risk of cumulative damages and disease – often resulting in lingering poor performance without clear treatments or diagnostic protocols.

Functional feeds are widely used as preventive strategies to optimize fish health and performance. Ultimately, this positively contributes to the volume, cost and quality of the harvest. Backed by decades of successful application in aquaculture, yeast cell wall (YCW) products demonstrate some of the most sweeping benefits, particularly within the diverse landscape of functional ingredients. A new player in this category, OPTIWALL, shows promising results in European seabass according to a new trial.

YCW contains mannan-oligosaccharides (MOS) and β-glucans, which, upon ingestion, are recognized at the gut level triggering a cascade of immune and homeostatic processes in support of gut function and integrity, and fish health. However, MOS and β-glucans are complex macromolecules that can widely vary in structure and properties depending on the strain and its origin.

It is essential to go further than the MOS and β-glucans levels and deploy a well-documented product with a consistent manufacturing process and certified origin from a specialist provider. OPTIWALL is a novel YCW product from Lallemand Animal Nutrition, a leading producer and provider of microbial-based solutions for animal nutrition. The product originates from a

single yeast strain, manufacturing plant and production process. It is down-processed to maximize the desired functionalities for the target application. The result is an affordable, consistent and effective product to support fish health and performance.

A 2-month trial was performed in a commercial farm in Portugal in 2023, testing different levels of OPTIWALL supplementation in juvenile European seabass (starting bodyweight 11g; 22°C; 36 ppt) in quadruplicate. A baseline commercial diet for juvenile seabass was produced (20% fishmeal; 15% land animal and 32% plant material; 46% crude protein; 16% crude fat; 21 MJ/kg) and supplemented with OPTIWALL at a dose of 0.0, 1.5, 3.0, and 4.5 kg/T feed, which were hand-fed to visual appetite over the trial’s duration.

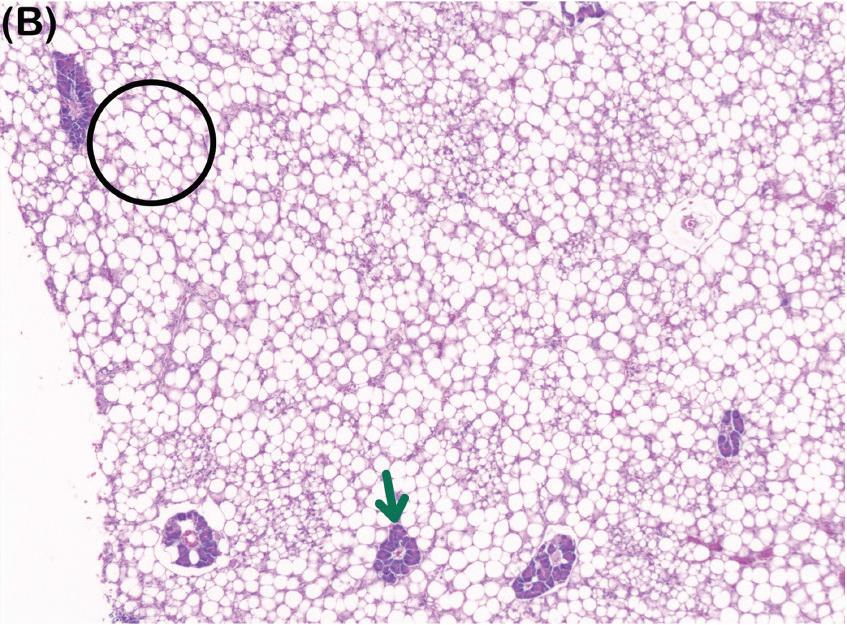

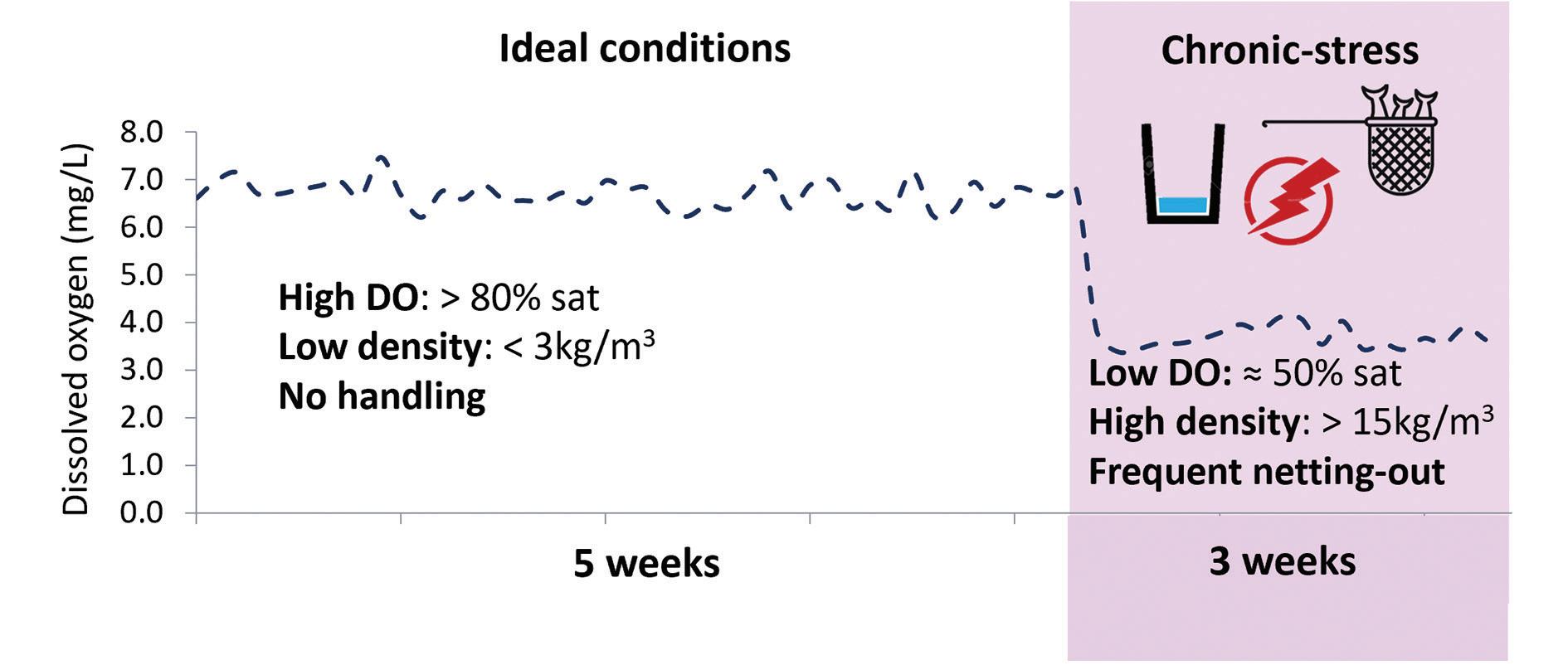

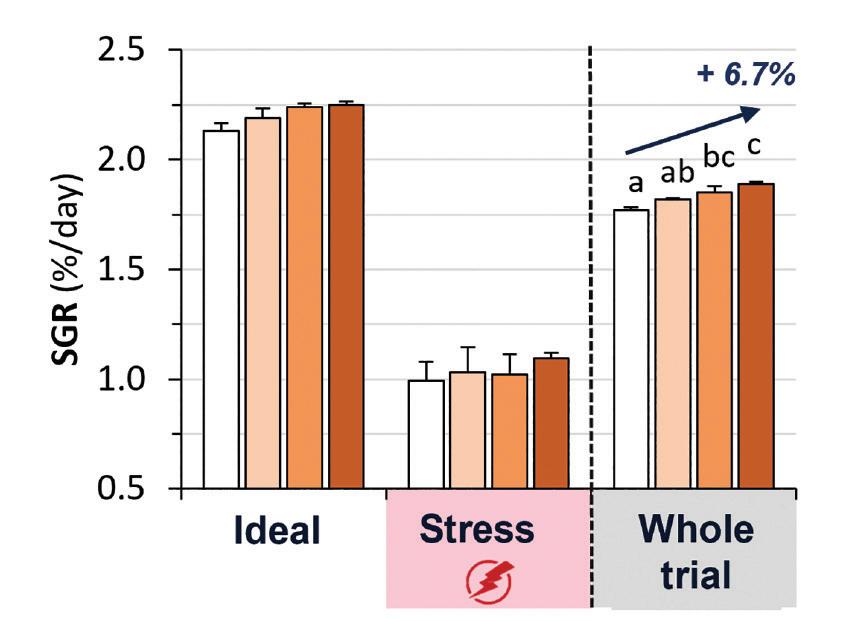

Fish were first reared under ideal conditions for 5 weeks and then chronically exposed to stressors for 3 weeks in the form of repeat handling (1 min. netting out twice weekly) and high-density-low oxygen levels by reducing the tanks‘ water level (Fig. 1). The study evaluated the diet’s effects on production performance and on the gut and skin responses over the ideal and demanding trial periods:

l Growth and performance were assessed at the end of each period

l Specific biomarkers of gut immune response and protection were evaluated (fecal levels of calprotectin and mucins)

l Gut and skin health and mucosal activity were assessed: skin mucus excretion was quantified, skin mucus quality was analyzed for its anti-microbial property, and classical gut and skin histology was performed.

OPTIWALL improves growth and feed performance

The trial showed that specific growth rates and feed conversion improved with increasing intake of OPTIWALL by up to 6.7% and 8.3 % respectively over the trial duration with YCW 4.5 (Fig. 2).

During the challenge phase, as expected, growth and FCR markedly deteriorated across all groups however, the loss of FCR was clearly mitigated in the YCW 4.5 group.

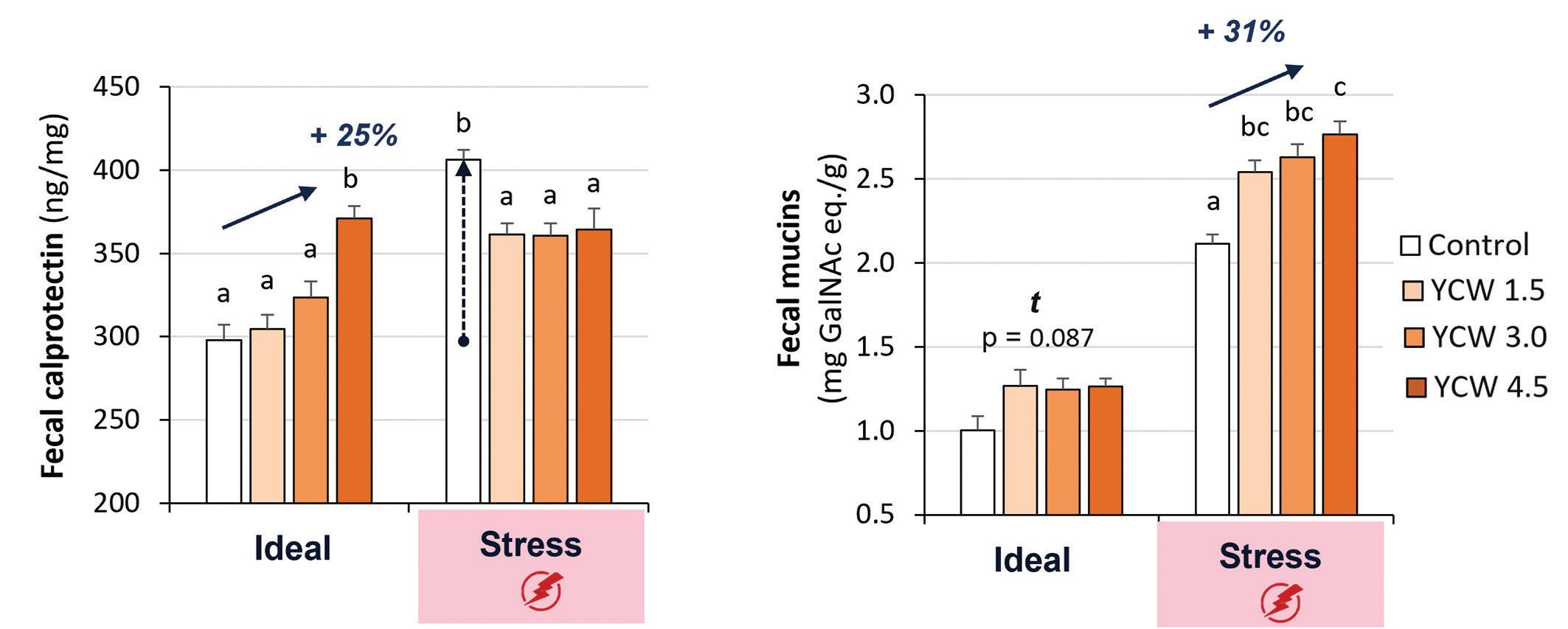

Effect on the gut barrier

Calprotectin (CP) is secreted by white blood cells as a marker of immune activation elicited by stressors, tissue injury or microbial presence. It has beneficial properties at physiological levels supporting gut barrier defense and integrity. Mucin is a constituent of secreted mucus, making it a marker of mucus

excretion levels and an essential gatekeeper of mucosal protection and function.

Under the ideal phase of the trial, fecal CP increased with increasing YCW intake, indicating YCW detection and reinforcement of gut defenses as supported by higher mucin levels at the end of Phase I (Fig. 3). This was verified at the end of the stress-exposure phase when OPTIWALL was shown to potentiate increased gut mucus excretion in a dose-dependent manner, as well as lower CP levels indicating reduced susceptibility and potential disturbance of the gut to the inflicted stressors.

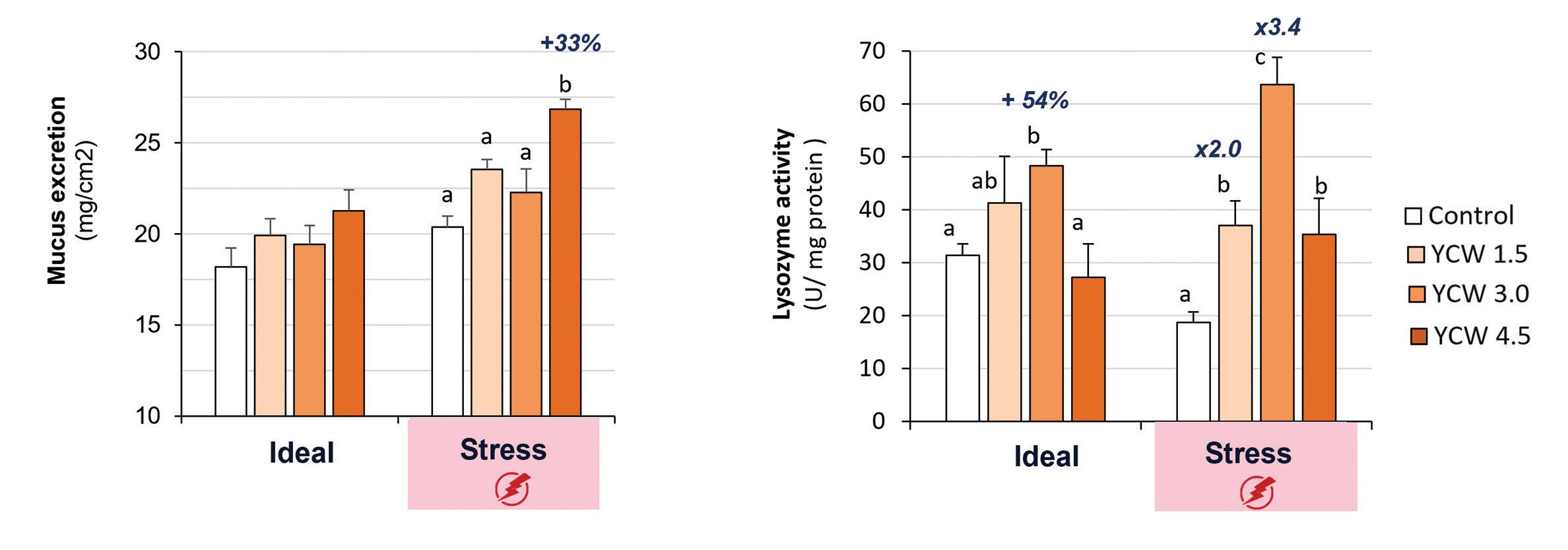

Improved skin barrier

As observed in the gut, skin mucus excretion increased with OPTIWALL intake in a dose-dependent manner (Fig. 4). This was particularly marked following stress

exposure (+37% excretion), when skin protection is most needed. Interestingly, the antimicrobial (lysozyme) activity of the mucus was also promoted by OPTIWALL when exposed to stressful conditions. However, at the higher dose tested, there was an apparent dilution of the antimicrobial activity related to the higher excretion level. Interestingly, in the group without supplementation (control), exposure to stress did not promote skin mucus excretion but tended to reduce its antimicrobial activity confirming the benefits of functional feed ingredients.

The new trial confirms the potential of the novel YCW OPTIWALL as an effective functional supplement to support seabass health and performance. This was particularly marked under stressful conditions when OPTIWALL supported gut and skin defense mechanisms at a time when it was most needed. In-feed incorporation can be selected between 1.5 to 4.5 kg/T feed depending on the level of protection and performance targeted.

Mediterranean seabass and seabream aquaculture have grown and intensified considerably in the last decades, but operations are exposed to ever-increasing biological risks and related costs. In that context, evidence-based, preventive health solutions become an essential tool to help achieve the production target and schedule with minimal reliance on medication. As a yeast-based ingredient optimized for animal health and performance, OPTIWALL provides broad and cost-effective benefits in support of fish robustness and farm performance. For more information, please visit lallemandanimalnutrition.com

More information: Eric Leclercq Global Aquaculture R&D & Fish Application Manager Lallemand Animal Nutrition

Guillermo Bardera, Marleen Dehasque, Waldo Nuez-Ortin, Adisseo

Lecithin plays a critical role in shrimp feed formulations, primarily due to its high phospholipid content, which is essential for shrimp growth and development. Phospholipids improve the absorption and transport of dietary fats and fat-soluble nutrients, contributing to better feed efficiency and nutrient utilization. Additionally, its emulsifying properties help stabilize the feed, allowing fats and oils to mix evenly within the feed particles, which further enhances nutrient uptake by shrimp.

Beyond its nutritional benefits, lecithin can also serve as a cost-effective source of energy in shrimp diets, especially when its market prices are low. During periods of lower prices, feed manufacturers can increase lecithin inclusion to reduce dependence on more expensive energy sources, thereby optimizing feed costs without compromising quality. However, this advantage is often offset by significant fluctuations in lecithin prices across different regions, particularly in

areas where major shrimp producers are concentrated, such as Southeast Asia and Latin America. Lecithin prices can vary dramatically, sometimes soaring to as much as USD 3 per kilogram, which can substantially raise feed production costs.

Maintaining optimal lecithin levels in shrimp feeds, typically between 2-3% (20-30kg/ton feed), becomes particularly challenging when prices are high. Producers may be forced to reduce lecithin content or seek alternative feed ingredients, which can negatively impact shrimp growth rates and overall feed efficiency. The volatility in lecithin pricing is driven by a range of factors, including fluctuations in global soybean production, trade policies, regional demand, and logistical challenges. As a result, feed manufacturers must carefully balance cost management with the nutritional requirements of shrimp, ensuring that any adjustments to lecithin levels do not compromise the performance quality of the feed.

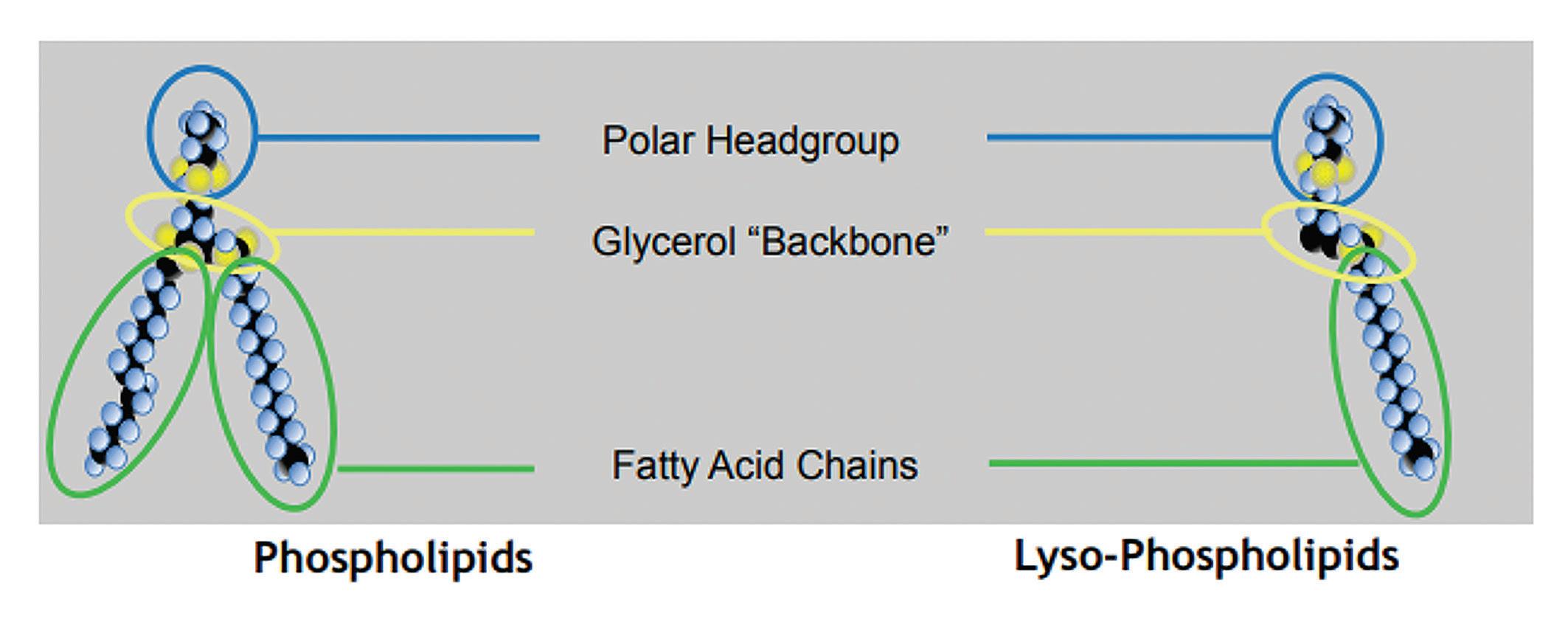

The role of lyso-phospholipids as a strategy to replace lecithin in shrimp feed

Lyso-phospholipids (LPL), also known as lysolecithin, are produced through the enzymatic hydrolysis of phospholipids, during which one of the fatty acid tails is removed. As a result, LPL molecules are more hydrophilic than phospholipids, enhancing their ability to act as effective oil-in-water emulsifiers in the digestive tract of shrimp (Fig. 1). Typically, lecithin consists of approximately 40% phospholipids, with a residual LPL content of around 2%. However, after enzymatic hydrolysis, the phospholipid content decreases while the LPL fraction increases to about 15%. Lyso-phospholipids can be added to shrimp feed either in liquid form or as a powder with a carrier.

Lyso-phospholipids offer a wide range of applications in feed formulations. They can be supplemented to improve feed efficiency and shrimp performance or used to reduce overall feed costs while maintaining optimal growth. In this context, LPL are particularly valuable as a replacement for lecithin, specifically targeting lecithin’s role in emulsification and its ability to enhance fat digestion and utilization. By improving the efficiency of lipid absorption, LPL help maintain growth and feed conversion rates even when lecithin levels are reduced from 2-3% to 1%, providing a cost-effective alternative for feed producers. LPL-based additives are used at a lower inclusion than that of lecithin (0.5-2 vs 10-30 kg/ton feed, respectively).

Is full replacement of lecithin in shrimp feeds possible?

To assess the full replacement of lecithin in shrimp feeds with an LPL-based additive (AQUALYSO®), two different trials were conducted at different dietary phospholipid levels, low and medium.

In this first trial, three different diets were tested: a control diet containing 2% lecithin, with fat content at 8% and phospholipids at 1.14%; a second diet with 0% lecithin, resulting in fat content reduced to 7% and phospholipids to 0.16%; a third diet with 0% lecithin, similar in fat and phospholipid content to the second diet but supplemented with 0.1% of AQUALYSO®. Cholesterol levels remained consistent across all diets at 0.08% (Table 1).

Statistical differences are indicated by letters when not sharing the same one are considered significant (One-way ANOVA, post-hoc Tukey HSD, p < 0.05).

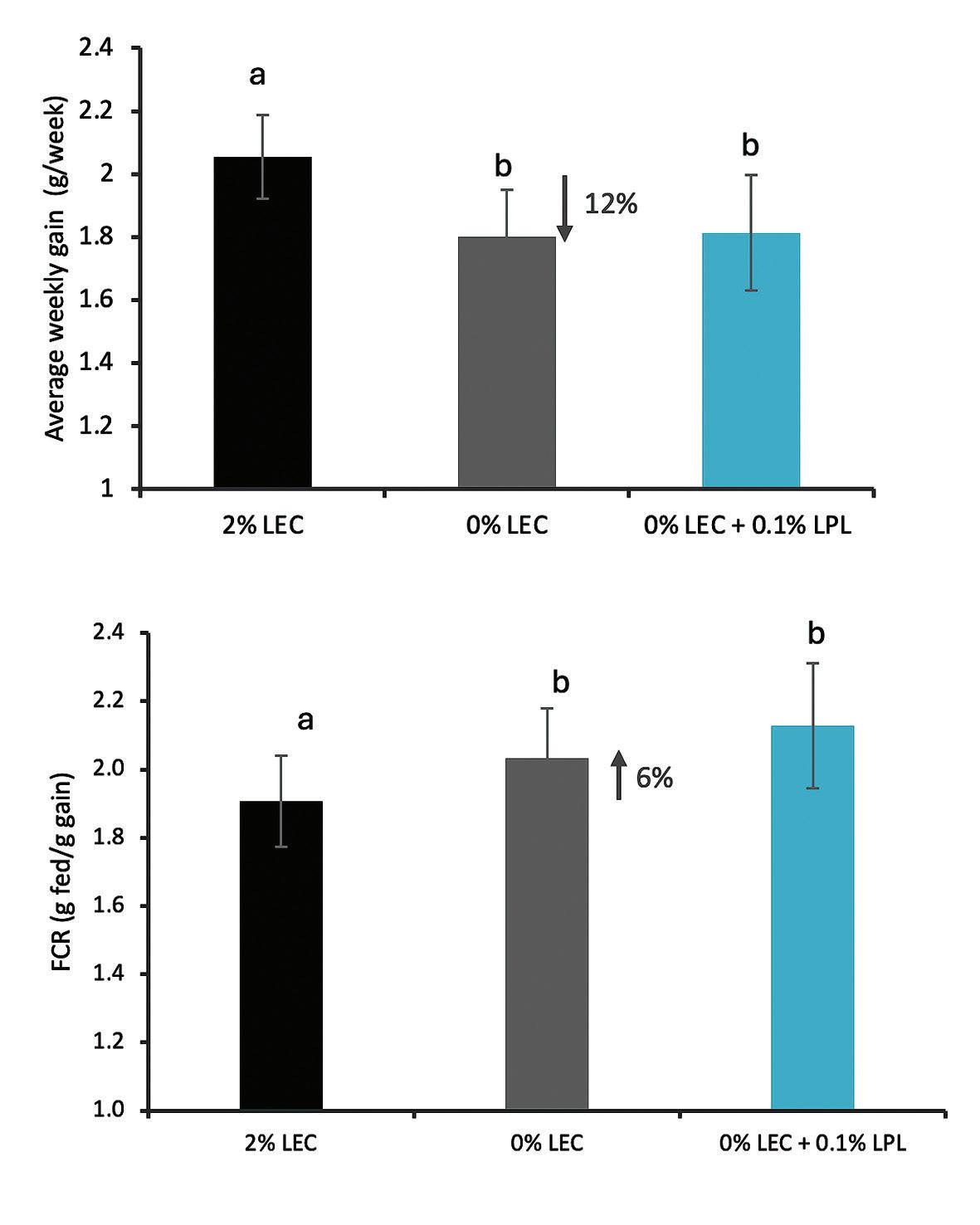

Shrimp were housed in 30-L tanks, 5 shrimp per aquaria, and 10 replicates per diet. Shrimp were fed for six weeks (8 meals per day to satiation), during which their average body weight increased from 3 to 15 g. As anticipated, the removal of lecithin negatively impacted weekly growth gain and feed conversion ratio (FCR). LPL supplementation did not mitigate this effect, likely due to the low phospholipid levels in the diet (Fig. 2).

Trial 2. Full replacement of lecithin in shrimp diets with medium phospholipids content In this trial, basal feed was reformulated with the objective of increasing phospholipids and fat content. Four different new diets were tested: a control diet with 2% lecithin and 1.9% phospholipid; a 0% lecithin diet in which phospholipids dropped to 0.9% (much higher than Trial 1); and two 0% lecithin diets with 0.9% phospholipid content and supplemented with 0.1% and 0.2% of AQUALYSO®. Fat and cholesterol levels were consistent across treatments at 7% and 0.09%, respectively (Table 2).

Shrimp were stocked in 30-L aquaria, 5 shrimp per aquaria, and 9 replicates per experimental diet were considered. Shrimp were fed for 6 weeks (8 meals/ day to satiation), average body weight increased from 6 to 23 g.

As expected, the removal of lecithin from shrimp diets resulted in a noticeable reduction in both average weekly weight gain and feed efficiency. However, when the LPL-based additive was included in the diet, it effectively compensated for the absence of lecithin, maintaining both weekly gain and feed efficiency at levels comparable to the control diet (2% lecithin) (Fig. 3).

3. Average weekly gain (g/week) and feed efficiency (g wt gain/g fed) results of Trial 2 comparing a 2% lecithin diet (control), 0% lecithin diet (negative control) and two experimental diets with 0% lecithin and 0.1-0.2% LPL supplementation, respectively. Statistical differences are indicated by letters when not sharing the same one are considered significant (One-way ANOVA, post-hoc Tukey HSD, p < 0.05).

Results show that the LPL-based additive AQUALYSO® can fully replace lecithin in shrimp feeds under certain conditions.

While lyso-phospholipids can replace the emulsifying capacity of lecithin, full lecithin replacement is feasible as long as the diet can maintain the minimum level of phospholipids required for shrimp growth and performance. This means that phospholipids should be sourced from other ingredients.

This approach offers flexibility in feed formulation while reducing dependency on lecithin during periods of price increase or low availability.

More information:

Guillermo Bardera

R&D Project Manager

Adisseo

Marleen Dehasque

Global Product Manager

Aquaculture

Adisseo

Bradley A. Saville, GreenSage Prebiotics Inc., William Riley, WWR & Associates, Ltd., Sandra Saville, GreenSage Prebiotics Inc.

Increasing demand for sustainable sources of protein has led to an expansion in world aquaculture production, which is projected to increase by 27% by 2032 (FAO, 2024). The sub-sector of marine aquaculture is projected to more than double by 2050 (DNV, 2021). Most total aquaculture production is projected to continue to occur in China and Southeast Asia, while the North Atlantic and Chile are primary locations for farmed salmon production.

Growth in aquaculture production is contingent upon the increased availability of sustainable feed ingredients and upon the deployment of strategies to manage and mitigate infections that reduce growth and harvest quality and lead to premature mortality. Disease is the most pressing issue affecting aquaculture producers. Aquatic diseases are caused by pathogenic bacteria, viruses, and parasites, among other factors. Challenges with water quality and contamination of ponds by external sources may contribute to infections and the

rapid growth of pathogens. The problem is more acute with intensive aquaculture systems – yet these intensive aquaculture systems theoretically play an important role in maximizing the use of land and water resources. Finding a proper balance between land/water use and health/productivity is essential.

Prebiotics – compounds that selectively feed beneficial bacteria within the body – can play an important role in supporting digestive and immune health in aquaculture species. Prebiotics are typically carbohydrates –oligosaccharides produced from polymers such as cellulose, mannan, galactan, and xylan, or naturally occurring fructans that may be extracted from chicory root, asparagus, onions, and other plants. The resulting prebiotics (e.g., fructo-oligosaccharides – FOS; xylo-oligosaccharides – XOS; galactooligosaccharides – GOS; and mannan-oligosaccharides – MOS) all have different structures and thus, different levels of functionality and efficacy within the body.

Vibrio parahaemolyticus, Tenacibaculum anguillarum maritimum, finnmarkense

Moritella viscosa Piscirickettsia salmonis

Aeromonas salmonicida Yersinia ruckeri

Even the same type of prebiotic can have materially different performance if the degree of polymerization (number of subunits) differs. Thus, a careful assessment of each prebiotic product is required to establish efficacy and dose for a particular species, application, and intended health benefit.

GreenSage Prebiotics uses residues from coconut production to produce a novel prebiotic, PretegoTM, that supports digestive and immune health in aquatic and terrestrial animals and may have long-term benefits for human health as well. The product is mainly comprised of a mixture of carbohydrates produced from the fiber fraction of copra meal.

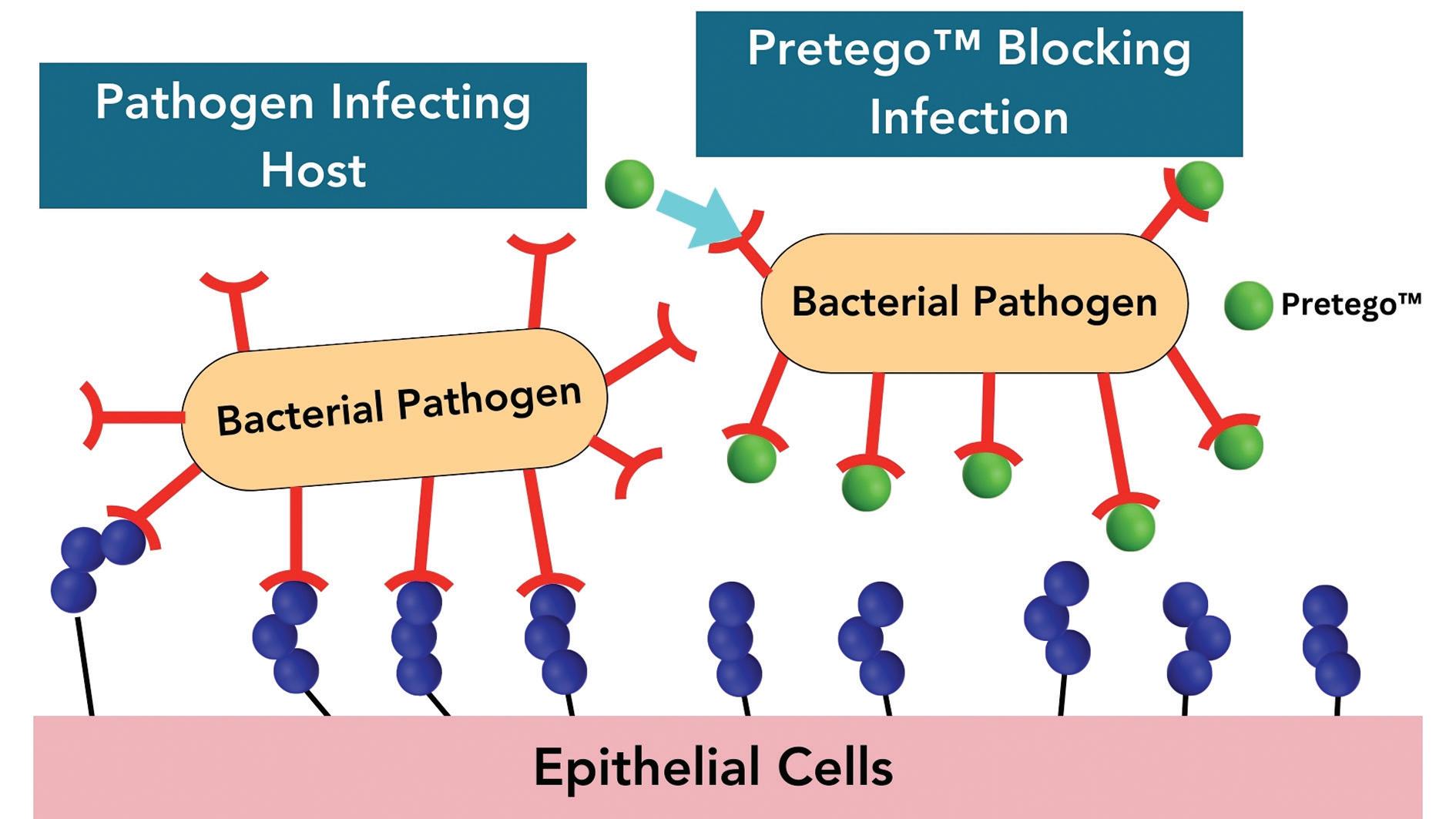

PretegoTM is unique and distinct from other prebiotics, owing to its ability to inhibit the growth of certain bacteria, particularly those that bind to mannose receptors that line the digestive tract. PretegoTM acts like a molecular decoy, blocking the binding step that is a precursor to infection.

In vitro studies conducted at the Centre for Aquaculture Technologies (Prince Edward Island, Canada; now Onda) established that PretegoTM inhibits several pathogens that are a major concern in aquaculture (Table 1).

A series of feeding and challenge studies were conducted on shrimp and salmon to assess the impact of PretegoTM on health and survival. These studies were conducted at ShrimpVet (Vietnam) and the University of Plymouth (England).

Feeding study with shrimp

A 42-day feeding trial was conducted at the ShrimpVet Demonstration Farm located in Can Gio, Ho Chi Minh City, Vietnam. The trial design consisted of 4 groups: Treatment 1/Control group (T1), Treatment 2 (T2): 0.30 wt% test product (PretegoTM), Treatment 3 (T3): 0.50 wt% PretegoTM, Treatment 4 (T4): 0.65 wt% PretegoTM, with 5 replicate tanks per treatment and 2 extra tanks for T1 (control). At the beginning of the trial, 60 specific pathogen-free (SPF) shrimp (L. vannamei) with an average body weight of 2.41 ± 0.49 g/shrimp were stocked into 22 tanks with 400 L of brackish water in each tank.

After 42 days of feeding, shrimp survival rate and growth performance were evaluated. Survival of T3 (89.33 ± 7.78%) and T4 (97.33 ± 2.24%) shrimp were statistically better than the T1 control animals (78.06 ± 4.14%), while T2 shrimp (82.50 ± 2.15%) had a slightly higher average survival rate compared to T1 shrimp, although not significantly different. T4 was most effective at improving the survival rate of the shrimp over the 42-day growth study (P<0.05), followed by T3 (P<0.05).

Increasing the inclusion rate of PretegoTM was correlated with improved growth performance and feed efficiency in L. vannamei (Table 2). Treatment 4, with the highest inclusion rate of 0.65%, demonstrated significantly better outcomes in final biomass, final mean weight, average daily gain, specific growth rate, and feed conversion ratio (P<0.05), while total feed consumption was similar across all treatments.

Overall, GreenSage Prebiotics’ novel product, PretegoTM improved survival, biomass yield, mean weight, growth rates, and feed efficiency in L. vannamei under grow-out conditions.

Values are presented as Mean±SD. Values with the same superscript (a and b) in the same row

EMS/AHPND challenge study with shrimp

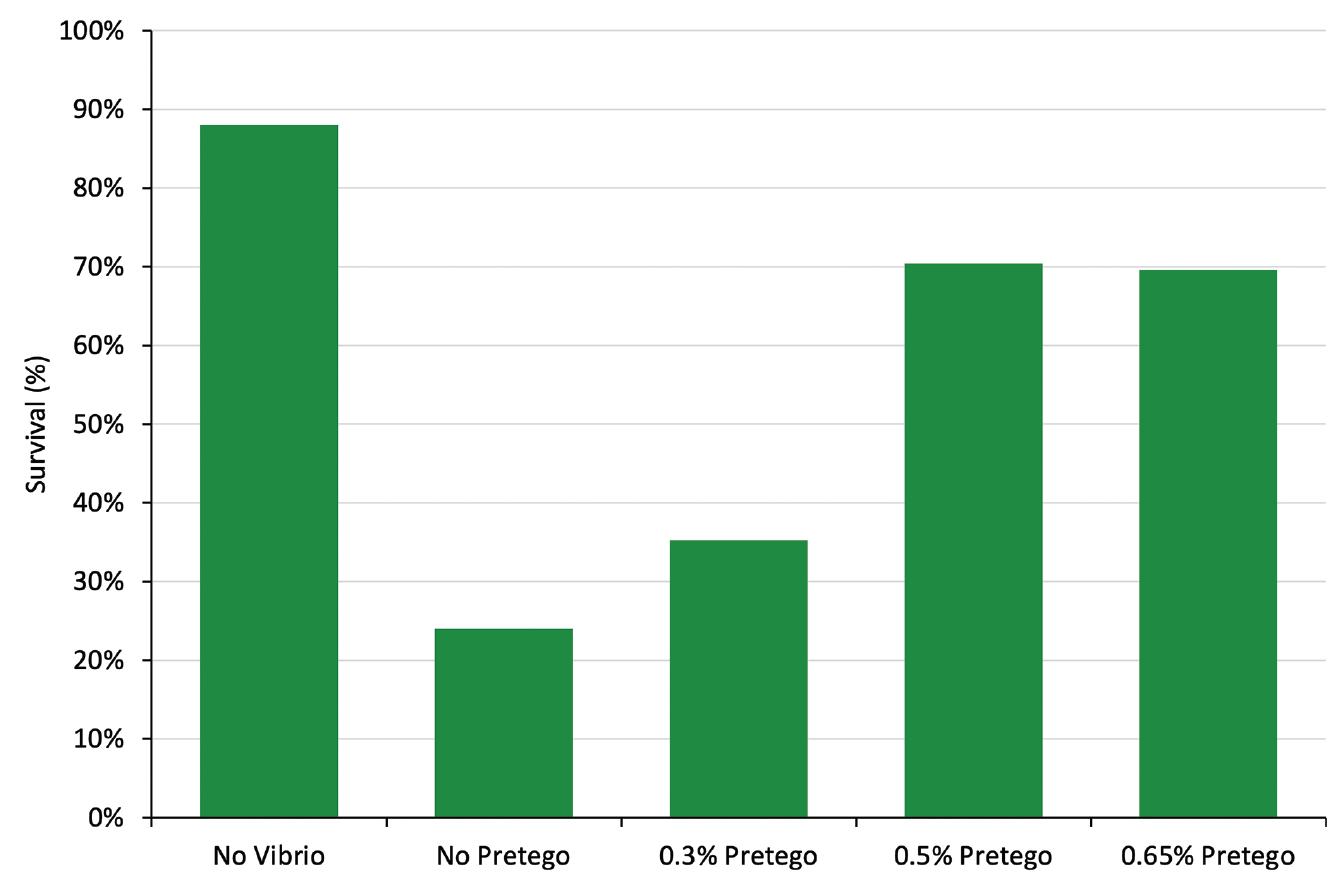

This trial was conducted at ShrimpVet Laboratory in Vietnam. Following a 6-week feeding period at the ShrimpVet Demonstration Farm, shrimp were transferred to the Ho Chi Minh City laboratory to conduct an EMS/AHPND challenge trial. Shrimp (L. vannamei) were divided into 5 groups – a positive control (PC) dosed with Vibrio parahaemolyticus but not treated with PretegoTM, a negative control (NC) group not exposed to Vibrio nor treated with PretegoTM, and three treatment groups exposed to Vibrio and dosed with either 0.3%, 0.5%, or 0.65% PretegoTM.

The trial was conducted under laboratory conditions in a recirculating aquaculture system (RAS) in 90 L rectangular plastic tanks. Each tank was filled with 75 L of brackish water (20‰). Twenty-five shrimp (average weight=15.23 g) were stocked into each tank. Each RAS system included aeration, a biological filtration system for wastewater treatment, and a clean water regeneration system.

After 8 days post-challenge by immersion in Vibrio parahaemolyticus, survival rates for the Negative Control and Positive Control groups were 88% and 24%, respectively. Consumption of PretegoTM materially increased shrimp survival to as high as 70% following exposure to Vibrio parahaemolyticus (Fig. 2).

The results demonstrated the effectiveness of the novel prebiotic product developed by GreenSage. PretegoTM supplemented in the feed at 0.5% or 0.65%

significantly improved the survival of white-leg shrimp against EMS/AHPND infection. This study established that the PretegoTM has a considerable impact on improving the resilience of shrimp to an EMS/AHPND infection, highlighting its potential as an effective immune enhancing supplement in shrimp aquaculture.

The mucosal barriers of fish are an important first line of defense against pathogen invasion. Functional feed additives have the potential to improve fish health and welfare by improving mucosal physiology and barrier function. In this study conducted at the University of Plymouth, the efficacy of PretegoTM on Atlantic salmon (Salmo salar) growth and health was investigated. Atlantic salmon parr (ca. 11.68 ± 0.11g) were fed either a control diet or diets supplemented with one of three levels of PretegoTM (0.25, 0.35 or 0.5%). Diets were manufactured by Skretting using commercially relevant formulations that met the nutritional requirements of salmon. Fish were reared in a freshwater RAS system for 70 days, with 3 replicated tanks per treatment group. Fish were fed at 1.0-3.5% of biomass per day. Fish growth performance and feed conversion were determined at the conclusion of the trial, and fish skin and intestinal samples underwent histological assessment. While there were trends suggesting improvement in feed conversion and growth rate over the 70-day study, these improvements were

not statistically significant. Nonetheless, there were statistically significant increases in the mucosal fold length (an indicator of improved nutrient absorption; Fig. 3), and the histological appraisal revealed that PretegoTM significantly increased goblet cell counts in the intestine and skin, which is indicative of improved disease barrier function. Samples from the trial midpoint revealed that benefits started to emerge as early as day 35, with elevated mucosal fold length, intestinal goblet cell levels, and skin goblet cell levels compared to the control fish.

Pretego supports the digestive and immune health of shrimp, salmon, and other aquaculture species. Pretego improves survival and growth when added to aquaculture feed at levels from 0.30 to 0.65%.

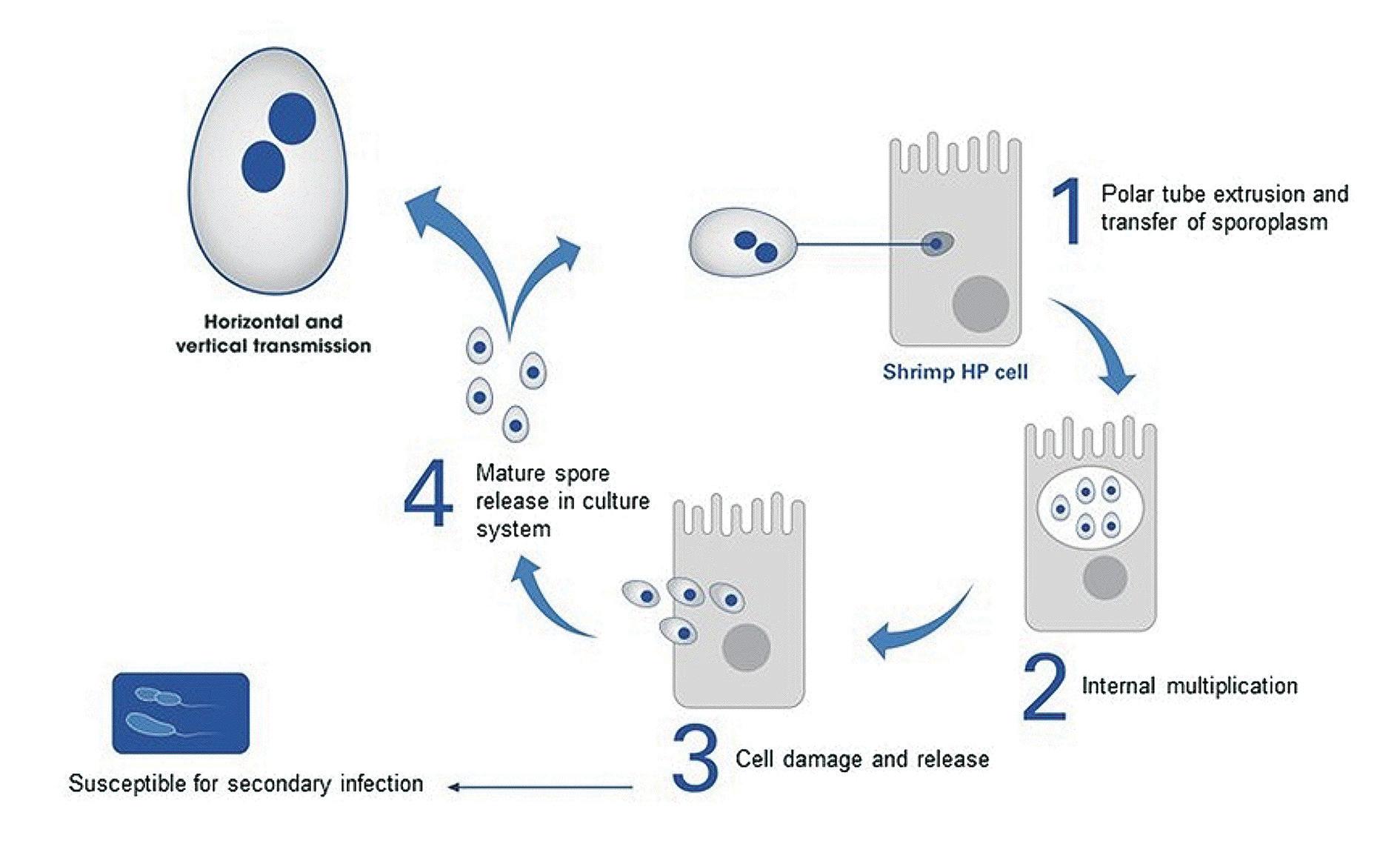

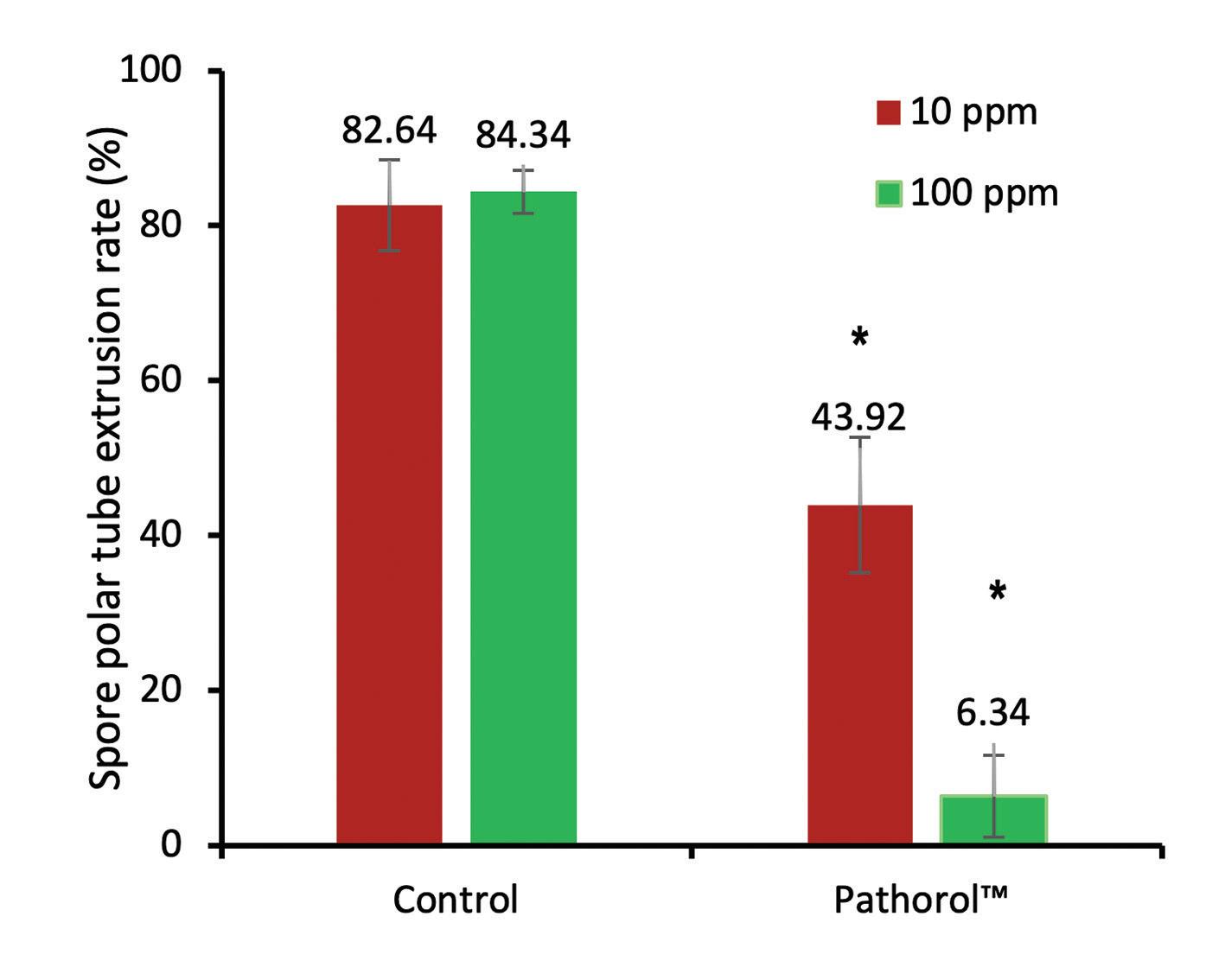

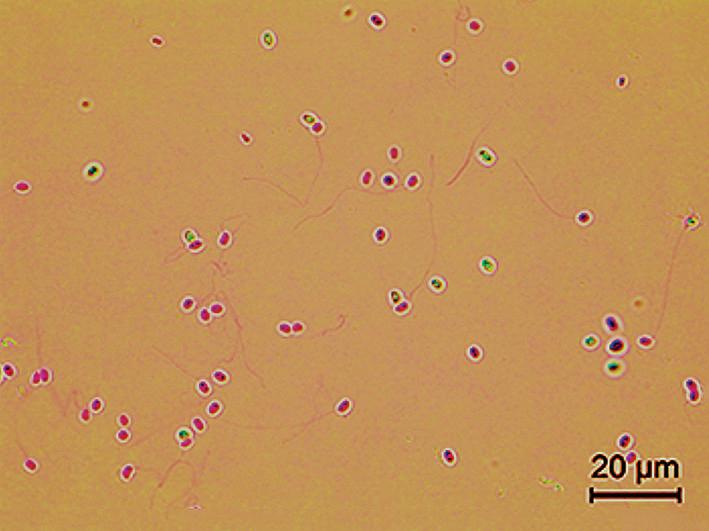

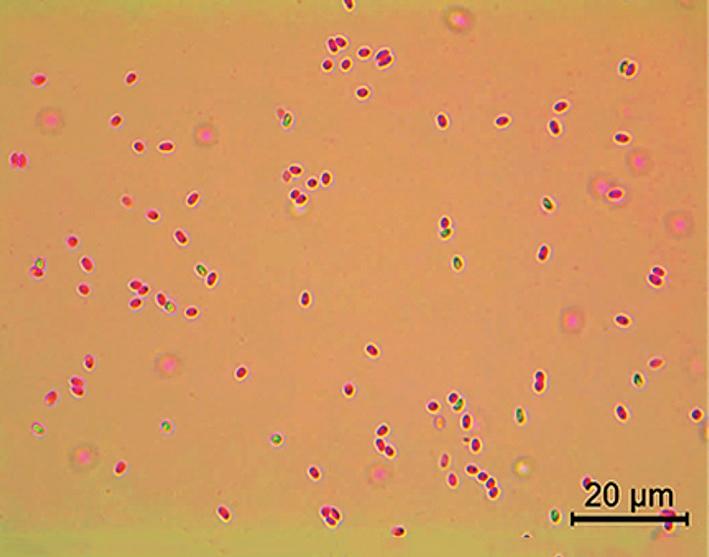

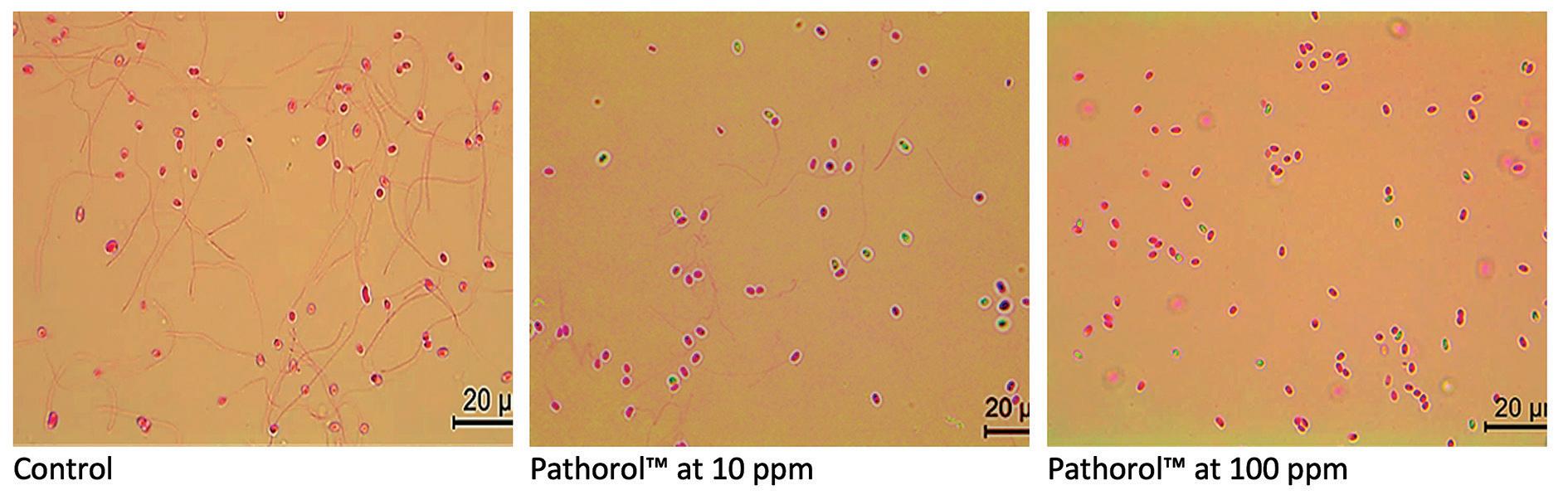

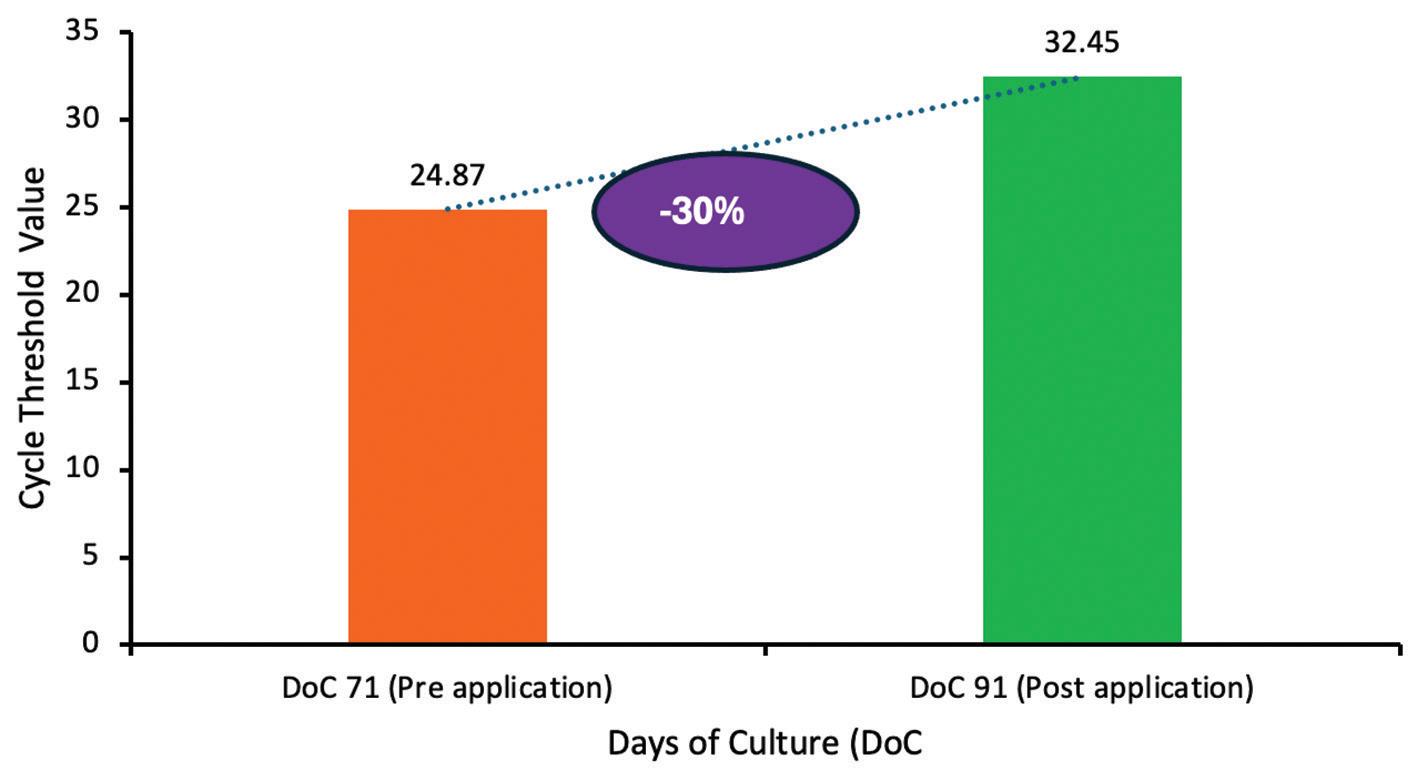

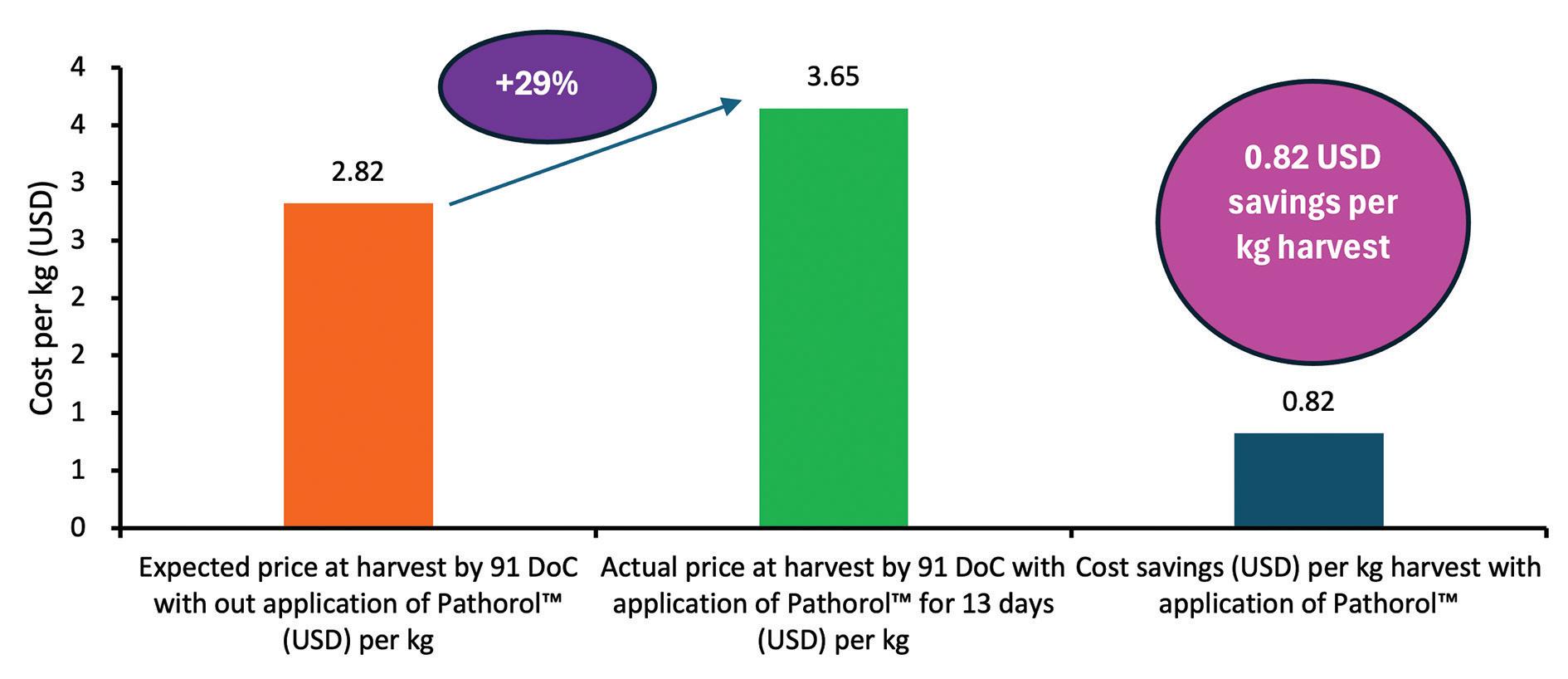

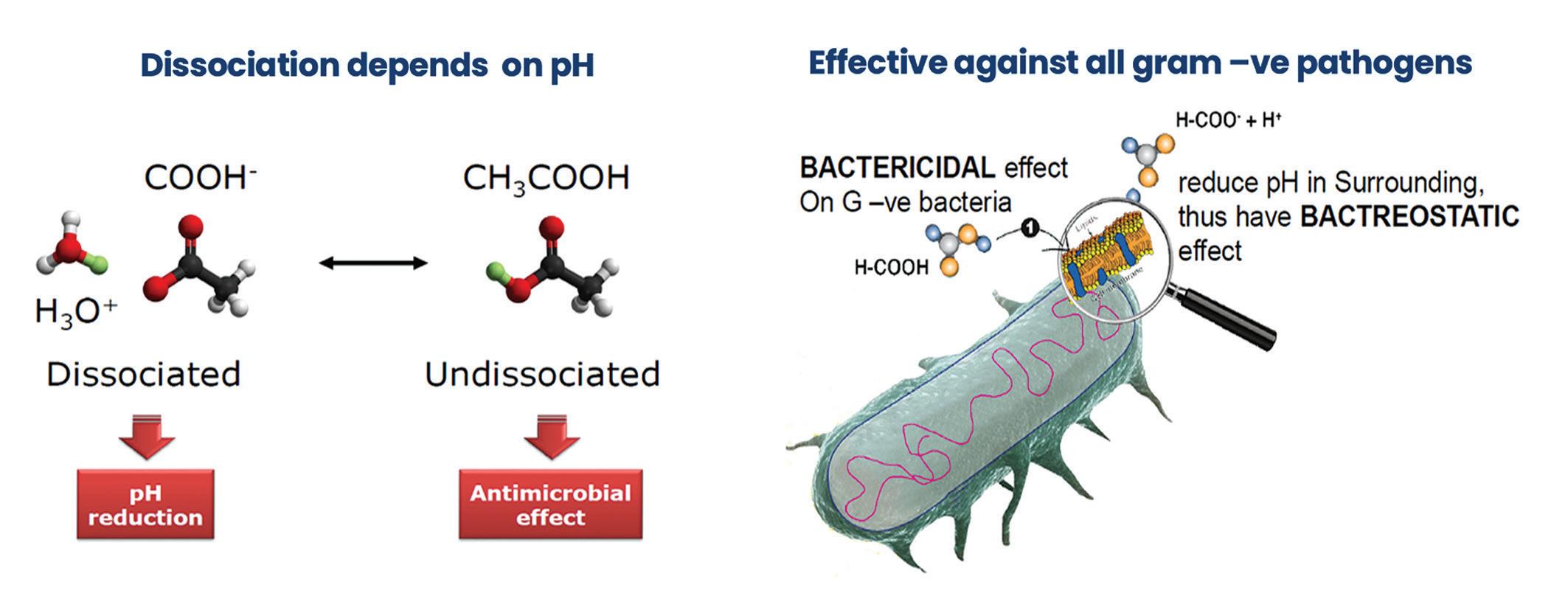

PretegoTM supports aquaculture production during the grow-out phase and during periods when there is a high risk of infection.