12 minute read

Technical

from Auto Service Professional - August 2020

by EndeavorBusinessMedia-VehicleRepairGroup

DEALING WITH ADVANCED DRIVER ASSIST SYSTEMS

ADAS technology presents new shop challenges

By Edwin Hazzard

TThe automotive industry is always evolving. It seems that new technology is always arriving in our service bays. I remember back when SRS (supplemental restraint systems) first appeared with many service techs feeling a little overwhelmed. New technologies always seem to present new challenges. An automobile manufacturer’s biggest and foremost concern is the topic of safety. When the OEMs design an automobile they implement the strictest of guidelines that will help keep the driver and their occupants safe.

Fast forward to present day and we now have systems in place to assist drivers while on the road. The new system or technology is called ADAS. This stands for advanced driver assist system. This system is responsible for aiding the driver while driving on the road.

This system does not make driving decisions for the driver. This system will alert the driver of impending driving conditions especially when traffic is nearby. I believe in the nottoo-distant future you will be seeing a full self-driving vehicle where the ADAS system will be making all the decisions for the driver or pretty much most of the decisions.

Current ADAS systems not only help in the decision-making process for the drivers but as a service technician and a shop owner decisions are needed to be made as well.

Should a shop take on this new technology? Does the shop want to stay competitive? Does the shop want to stay ahead of the curve? These questions and many more need to be considered with this new technology.

With the ADAS systems now in vehicles it presents new challenges in training, tooling and equipment along with a legal and a liability challenge. These new systems must be properly serviced with the utmost precision and accuracy. The reason for this is that when a part has to be repaired or replaced on that subsystem, that part or system has to be accurately calibrated. In order to do this the shop has to have the correct service information, service tools, and training.

There is absolutely no room for error. An improper repair on an ADAS system could alter the way the driver responds to a driving incident. Finding out that the system has not been repaired correctly and has contributed to an automobile accident is where the legal and liability issue comes into play.

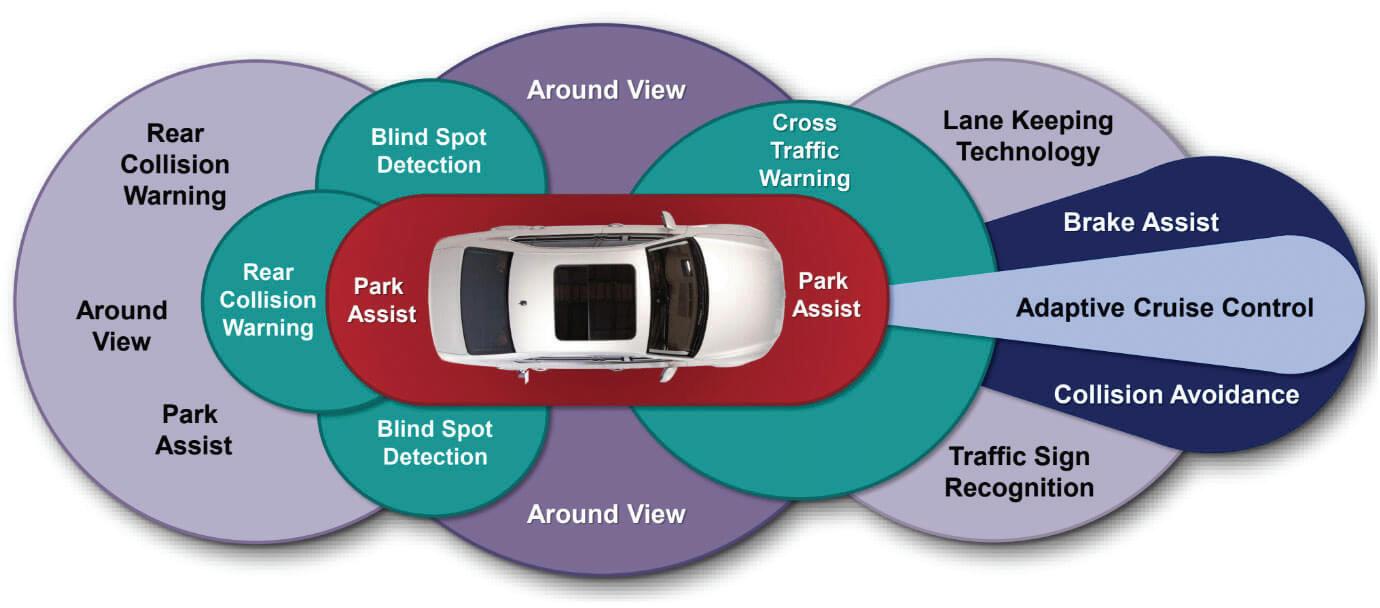

ADAS systems may include a complex array of assist features.

COURTESY OF GREG SMITH EQUIPMENT

OEM AND AFTERMARKET TOOLS There has been great debate on what service information and or service tools need to be used in a proper ADAS repair. Should your tools be OEM specific or will an aftermarket tool do the job correctly? What about the calibration stands and targets? Can they be OEM or aftermarket? This is where the big debate is residing.

As a service technician and one who has been in this industry for many years, I have my own opinion on this debate. However, I’m not going to go into this debate in this article. I merely want you as service technicians and shop owners to think about this.

One of the questions or statements I have received is if you use OEM tools in an independent repair shop for ADAS-based repairs, and if you’re not OEM-trained, meaning you don’t have OEM dealership training, is this an issue for legality? Another question or statement I have received is if you use an aftermarket tool for an ADAS repair in an independent repair shop, is that repair up to OEM standards? Is that an issue for legality?

These questions and many more have not truly been answered. Only you can make concise decisions. One thing I do know is that an improper ADAS repair opens the door for the lawyers. And that is never a good thing.

Let’s say that you would like to get involved with this new technology in your shop. What do you need, where do you get it, and how much will this cost? Those are questions that have to be answered.

There’s a plethora of different choices and options from which to choose. We do know that an aftermarket scan tool may give you more options than an OEM tool in terms of vehicle coverage. As with any diagnostic tool, you need to determine based on what your shop generally works on the most what would work best for you.

If, for example, your shop specializes in a couple different makes then your best bet may be to choose the OEM tool for those makes. If your shop works on many different makes then perhaps the aftermarket tool would be a better choice. Personally, if I worked on all different makes and models I would choose both if my budget would allow it. This also goes for service information and calibration frames and targets required for ADAS.

Another thing that needs to be considered is the available space that is allowed for ADAS calibrations. This reason alone is why a lot of shops don’t get involved with ADAS repairs. Remember, to perform a proper calibration you have to have the correct space and area as well as the right pitch in the floor. You can have all the tooling that’s needed but you might not have adequate shop floor space. The area

that’s needed is part of the proper calibration and repair procedure. Remember I said that an ADAS repair has to be precise. There is no margin for error.

PERFORMING AN ADAS REPAIR Let’s take a quick look at performing an ADAS repair.

When doing an ADAS calibration there are two types that could be done. One is called a static calibration, meaning the calibration is

Figure 1: A 2013 Dodge Dart with the front fascia removed.

done with a scan tool in a service bay. Also a static calibration refers to technological features that can be calibrated in a specifically tailored workshop environment, without having to drive the car in question.

This approach requires the use of sensitive, specialized equipment like a CSC (Camera and Sensor Calibration) tool.

The other calibration is called a dynamic calibration. That is done using a scan tool and driving the vehicle following certain driving requirements. Dynamic ADAS is sometimes referred to as Mobile Calibration. This method relates to the fact that the calibration is performed with the aid of a hand-held unit plugged directly into the vehicle. Then, once the unit is attached, the vehicle will have to be driven at a manufacturer-prescribed speed over a set distance in optimum weather conditions.

Having been exposed to this test, the system becomes accustomed to the road as it should be and is ready to react and respond to unexpected issues. As with static advanced driver assistance systems, the vehicle manufacturer will stipulate specific parameters for calibration of dynamic systems.

Remember the days of driving vehicles and trying to reset the emissions monitors? This is kind of this same idea. If a component is repaired or replaced and requires that both types of calibrations are needed it is imperative that both are performed. Doing one without doing the other is an improper repair.

Here’s an example: did you know that if you remove a front bumper fascia to get to a radiator or A/C condenser, that after completing the repair an ADAS calibration is required? If there are sensors or a front camera in that bumper and it has been disturbed it will need to be calibrated! (See Figure 1.)

Figure 2: A 2015 Chevrolet Colorado rear back-up camera.

On page 14, there is a photo of the front fascia removed on a 2013 Dodge Dart. The active shutter solenoid needed to be replaced. This particular vehicle did not have any type of sensors or camera, so a calibration was not needed.

However, this vehicle does have a rear backup camera that’s used for parking assist. Note that vehicles that just have a rear camera are considered ADAS-equipped vehicles.

Any vehicle that helps or assists a driver is considered an ADAS vehicle (see Figure 2). This is a 2015 Chevrolet Colorado with a rear back-up camera system.

Notice the lines in the camera picture. Those lines are there to help assist the driver upon backing up. THE ALL-IMPORTANT SCAN TOOL The question that a lot of technicians and shop owners ask when considering performing ADAS repairs is “what do I need to efficiently perform ADAS repairs in our shop?”

An important tool to consider is the scan tool. It is extremely important to have a sufficient scan tool to be able to perform a pre- and post-scan. Most of the popular scan tools on the market have that capability in their software. The reason a pre- and post-scan is important is you can have a record that you can share with the customer of the pre- and post-repairs. Also an ADAS recalibration report is another good idea toward documentation (see Figure 3 and Figure 3-1).

ADAS Recalibration Report

2016 Chevrolet Tahoe (4WD) Demo 5.3L V8 (L83)

VIN Odometer License

Camera System Front View

Functional Tests

April 06, 2020 8:47 PM

Input Values

Fill in values entered to run the test

Results

Values received by the vehicle

Figure 3-1: An example of a calibration report.

Equipment Used and Additional Notes

Fill in hardware information and serial numbers when available

Technician

Signature

Figure 3: An example of a pre-scan report.

COURTESY OF SOUTHEAST MOBILE TECH

PASS FAIL NA

Cert ID/No.

Date

COURTESY OF SOUTHEAST MOBILE TECH

Date: 1/22/2020 3:11 PM

2008 Chevrolet Avalanche (RWD) 5.3L V8 SFI (LMG)

Pre Scan Vehicle System Report

VEHICLE INFORMATION

VIN 3GNEC22069G170465

YEAR 2008

MAKE Chevrolet

MODEL Avalanche (RWD)

ENGINE 5.3L V8 SFI (LMG)

SYSTEM

LICENSE

CODE SCAN RESULTS Systems Analyzed: 20

Engine

Transmission

Antilock Brakes

Airbag

Body Control Module

Door Switch Driver

Door Switch Passenger

Fuel Pump

HVAC

Instrument Panel Cluster

Keyless Entry

Parking Assist Module

Passenger Presence System

Radio

Rear HVAC/RSA

Rollover Sensor

Seat Module

Theft Deterrent

Tire Pressure Monitor

Vehicle Communication Interface

OBDII

Engine

P0121 | Throttle Position (TP) Sensor 1 Performance (Symptom 00) Test Failed Since DTC Clear.

COURTESY OF AUTEL

Figure 4: An example of a calibration stand.

These are example screens of a pre-scan of a customer’s vehicle and recalibration report. Performing this task will eliminate any potential confusion between the shop and the customer. It’s also good to have this record in case of any litigation or liability concerns. If, for example, there is a problem with the vehicle that you’re working on that’s not covered as an ADAS repair you can point that out to your customer that this issue is currently in your vehicle and it could possibly be a selling point as an added repair.

Along with having a scan tool to do your pre- and post-scans, it is extremely important that the tool you are using is up-to-date. You can’t expect to perform a calibration on a vehicle that’s newer than what your scan tool software covers. This same also goes for service information. Another tool that is a must is a calibration frame or calibrating equipment (see Figure 4). Along with the scan tool, this is probably the most expensive part of your ADAS repair tools. There are multiple companies from which you can purchase the calibration frames and equipment. Depending on what your budget is, this will go a long way in making that decision.

CALIBRATION TOOLING A lot of repair shops might not want to make a big investment in tooling, so the shop might call in a mobile tech. Mobile techs don’t really have the room to carry around a big calibration frame in their vehicle. A lot of them may even construct their own calibration type frame.

A lot of the OEM manufacturers don’t use a calibration frame but use a different type of apparatus. As an example, MLM Diagnostics out

Figure 5: A 2016 Audi Q5 calibration setup.

of Hudson, N.H., uses OEM calibrating equipment and tooling for ADAS calibrations. These might consist of a calibration type setup that runs on the floor along the side of the vehicle. Figure 5 shows a setup for a 2016 Audi Q5.

Other types of calibrating equipment might consist of a tripod of different variations, seen in Figure 6 for a Nissan. My recommendation is to do your homework and research the different options that are out there. The targets that you need can either be purchased from the company that you bought the calibration frame or equipment from or you can purchase them from an OEM source. Some shops only purchase their targets on an as-needed basis.

Figure 6: Here’s a Nissan calibration tripod.

Figure 7: A calibration target.

Figure 7 is an image of a calibration target. As I mentioned before, the other thing to consider is to have an area that is set up to properly accommodate performing a static calibration. Each manufacturer has their own recommendations on the size needed. It’s important to consult your service information on this.

Entering the world of ADAS repairs can be a scary and frightening adventure but at the same time can be an exciting and possibly prosperous opportunity. The number one thing that a repair shop needs to consider when performing an ADAS repair is the fact that they need to have the proper equipment, the proper training and the proper service information. Whenever an ADAS type repair is made it is extremely important to follow the recommended service information to a “T.”

As I stated earlier, if the proper procedures are not followed it could open up the doors for a legal investigation, especially if the vehicle is involved in an accident and with injuries. Investigators will be able to tell if an improper repair was performed to the vehicle that contributed to the accident. When it comes to performing an ADAS repair or calibration that difference between a calibration that’s not accurate compared to one that is accurate can be a matter of seconds.

COURTESY OF BEISSBARTH MEBBBAR BESSER

This is no different than when inflatable restraint systems came onboard. Remember that all of the impact sensors had to be placed in the correct area? Remember that the seat belts had to be working properly and installed correctly? Remember how important it was to calibrate the seat weight sensors?

ADAS systems are no different. As with supplemental restraint systems, the ADAS systems are there to protect your customers. Keeping your customers safe and sound is the key for having them return to your shop for future service. A happy customer is a repeat customer. And that is what automotive repair is all about. ■

Edwin Hazzard owns South East Mobile Tech in Charleston, S.C., which is a mobile diagnostic and programming service providing technical service to many automotive and body repair shops. He has 37 years’ experience in the automotive industry. He currently is an automotive trainer, a board member of TST (Technician Service Training), a member of the MDG (Mobile Diagnostic Group), a member of the Professional Tool and Equipment advisory board for Pten magazine, a committee member of Nastaf, and is a beta tester for multiple tool makers.