16 minute read

Light duty diesel engine tips

from Auto Service Professional - August 2020

by EndeavorBusinessMedia-VehicleRepairGroup

A brief overview of common issues

By Mike Mavrigian

SShops that don’t necessarily specialize in diesel engine repair and maintenance need to do their homework to stay abreast of both previous and current diesel engine control systems in order to service their light truck/towing customers. Here we’ve included a selection of various tips and tricks to help you get your feet wet in the diesel light truck market. COMMON ISSUES AND DIAGNOSING HARD-START

Today’s light duty diesel engines, featured in 1/2-ton to 1-ton trucks and their SUV and passenger car counterparts, are wonderful machines capable of great fuel mileage and producing plenty of torque... when they run properly, that is.

One of the common problems regarding diesels is the issue of hard-starts or no-starts, especially in cold ambient temperatures. As temperatures drop, the engine oil begins to thicken. While engine oil in a gasoline engine is intended to only lubricate the internals (main bearings, rod bearings, oil rings, cylinder walls, valvetrain etc.), in various diesel engine designs, the oil is also used to run a high pressure fuel pump that provides fuel pressure to the injectors.

When the oil viscosity is too thick to run through the small orifices in the high pressure pump, the injectors may not operate properly.

When a customer’s diesel experiences a hardstart, the first item to check is the engine oil

Diesel engines are the powerplant of choice for those who tow and require plenty of pulling torque. GM, Ford and Chrysler all vie for the business, and the need for shops to keep abreast of current diesel engine expertise is growing.

— not only oil level, but the condition of the oil. Oil that is too thick also causes a drag at the bearings, resulting in the starting system to battle against the extra draw demand.

Regardless of what someone’s uncle or cousin recommends as the proper engine oil, it’s best to simply follow the engine maker’s recommendation, based on current weather conditions. For example, in cold temperatures, the manufacturer might recommend a CG-4 rated full synthetic oil.

If the oil is OK but the crank speed is low, obviously check the battery state of charge/ condition and output, as well as all cable con

nections. A slow crank can make it impossible for the engine to turn over fast enough to generate adequate cylinder pressure.

Most diesel engines feature a glow plug system. The glow plugs are powered by a dedicated relay and assist in engine starting. They provide elevated heat in each cylinder to work along with cylinder compression to ignite the lowignition point of the diesel fuel. The glow plug relay operates with a timer that allows voltage to activate the glow plugs for a specified number of seconds. If the relay sticks, the glow plugs can over-run and eventually burn out. Glow plugs can be checked by testing for resistance/continuity and comparing to specifications.

Excess resistance or no continuity is a definite sign that the glow plug(s) are not operating properly. Glow plug modules provide power to the plugs. If the module is bad or connections are poor, no or inadequate power will be available to the plugs. Problem engines of note include GM’s 6.2L and 6.5L engines where excess engine heat can kill the module.

Another example is Ford’s 7.3L Navistar engine where the module can cut off if two or more glow plugs are bad. Any of these problems (oil type/condition, glow plugs, glow plug relays and glow plug control modules) will be exaggerated with low ambient temperatures.

Of course, it’s common knowledge that diesel fuel is very susceptible to water contamination, requiring regular replacement of the fuel filter/water separator and draining of the fuel bowl. Filters should be changed at least once each year. If water is in the fuel (not actually mixed but present), in cold weather this can cause the fuel to gel and block fuel flow.

It’s imperative to maintain fuel cleanliness and to take advantage of adding approved fuel conditioner additives to reduce the effects of condensation in the tank and lines. In some cases, the fuel pump might be blamed for hard starting or engine dying after starting. Instead of assuming that the pump is bad, check for air in the fuel system. Air may be entering the system through a fault in lines or line connec

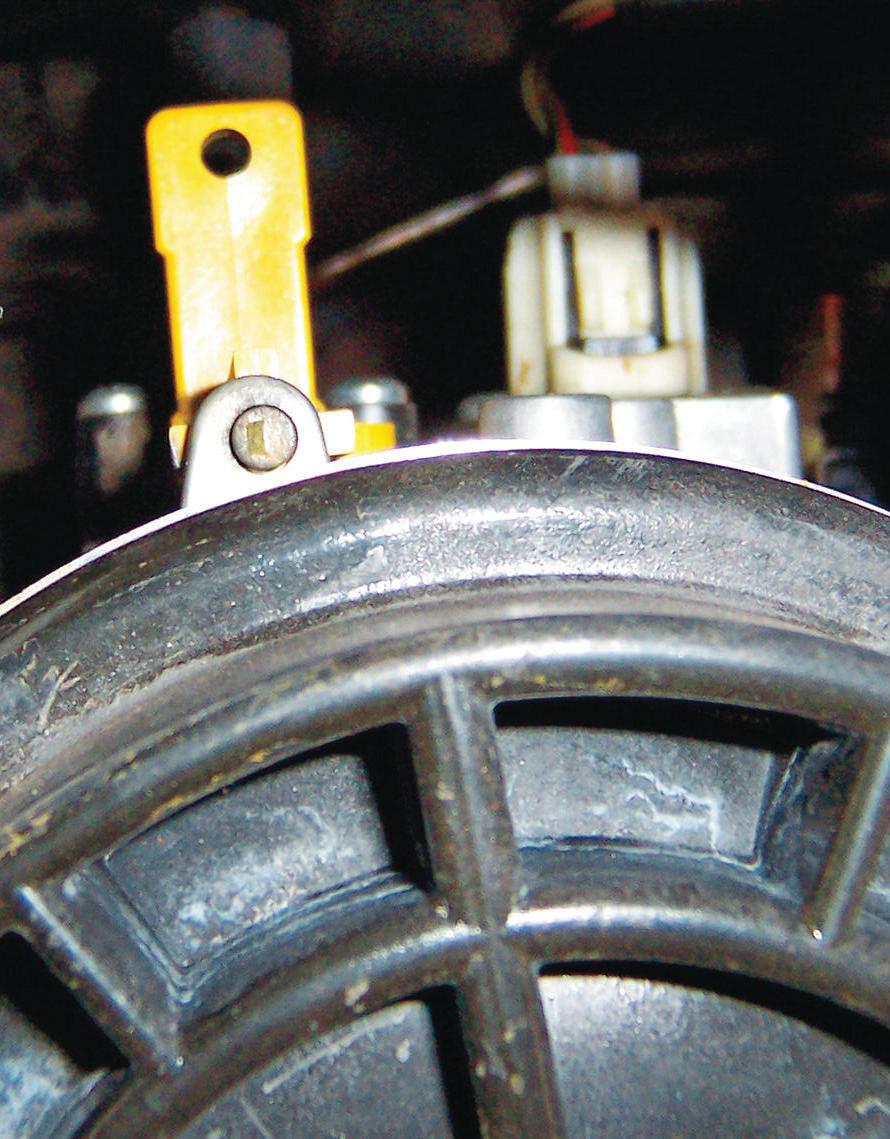

On Ford Navistar 7.3 engines, the fuel bowl features a yellow drain cock. Adjacent to this, note a white connector. This is a connection that provides current to the fuel bowl heater. It’s not uncommon for this connector to experience a short, which will kill power to the ECM. Unless the vehicle is operated in extreme cold conditions, disconnect this to prevent unexpected engine shut-off.

tions. Check by installing a clear hose to the fuel return line. Crank the engine and inspect the hose. If you see air bubbles, that’s a telltale sign that air is entering the inlet side of the pump.

A bad injector solenoid can be the cause of inadequate fuel delivery to the injectors. When the ignition is turned to the on position, you should be able to hear a click noise at the solenoid, If not, suspect the solenoid. If it clicks but there’s no delivery to the injectors, suspect a bad pump, assuming the lines and filter(s) are free of obstructions.

Diesel fuel injectors run at high pressures. This may be 300 psi or higher, depending on engine design. If the injectors are gummed up/ dirty, this will result in a lean mixture which

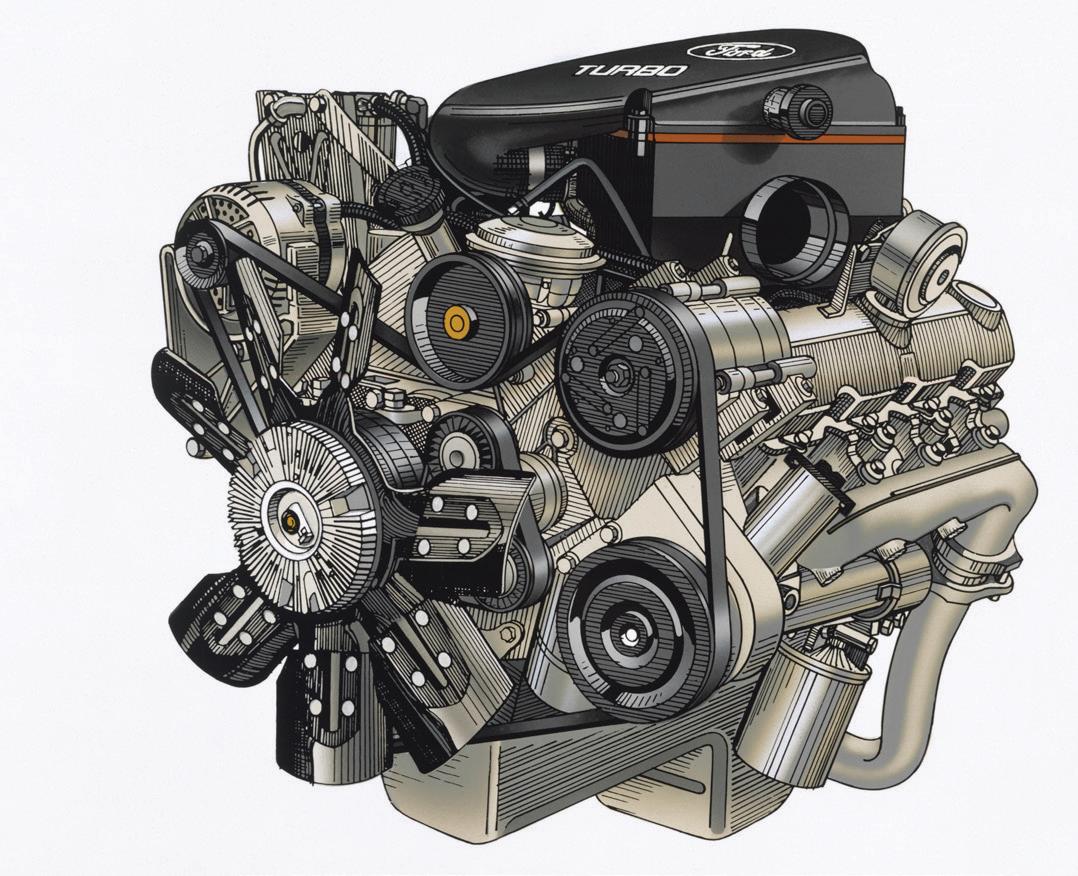

COURTESY OF FORD MOTOR CO.

Despite the current engines that feature highly sophisticated management systems, the venerable 7.3L single-turbo Navistar engine utilized in the Ford Powerstroke line was in production 1994-early 2003 and is still very popular due to its reputation for reliability.

should create a rough idle and white smoke at the exhaust outlet. Faulty glow plugs and/ or a bad glow plug module can also result in white smoke, which may clear up once the engine reaches normal operating temperature. Black smoke indicates a rich condition. Keep in mind that black smoke can also be caused by a restriction in the air inlet, so check the inlet and air filter. DIESEL EMISSIONS SYSTEMS The now-mandated diesel exhaust “after-treatment” is designed to reduce and remove harmful emissions particulates.

DOC: Diesel oxidation catalyst. Similar to a catalytic converter in a gasoline engine system, a DOC is designed to oxidize carbon monoxide, hydrocarbons and diesel particulate matter (DPM) to CO2 and H2O. When exhaust temperatures reach approximately 392 degrees Fahrenheit, the catalyst “lights off,” initiating the conversion. The DOC is the first component in the after-treatment process. It serves as a flowthrough “filter” that begins the oxidation process (regeneration) of cleaning up hydrocarbons and CO, as well as any unburned fuel (and any oil carried by the fuel).

DPF: Diesel Particulate Filter. After the DOC, exhaust enters the DPF, which is intended to grab any exhaust soot that the DOC didn’t oxidize. Any soot trapped in the DPF is oxidized when exhaust temperature reaches about 400 degrees F. This is referred to as passive regeneration that takes place automatically as exhaust tem

perature rises.

Be aware that the DPF may require maintenance. As a result of the oxidation process, ash begins to slowly build up inside the DPF, and can eventually cause an increase in exhaust back pressure. If ash is allowed to build up, enough can be trapped to harden and plug the DPF. A clue to DPF contamination is shorter regeneration intervals. The DPF can be removed and cleaned (unless clogged to the point of requiring replacement). If the DPF is due for cleaning, it makes sense to also clean the DOC at the same time.

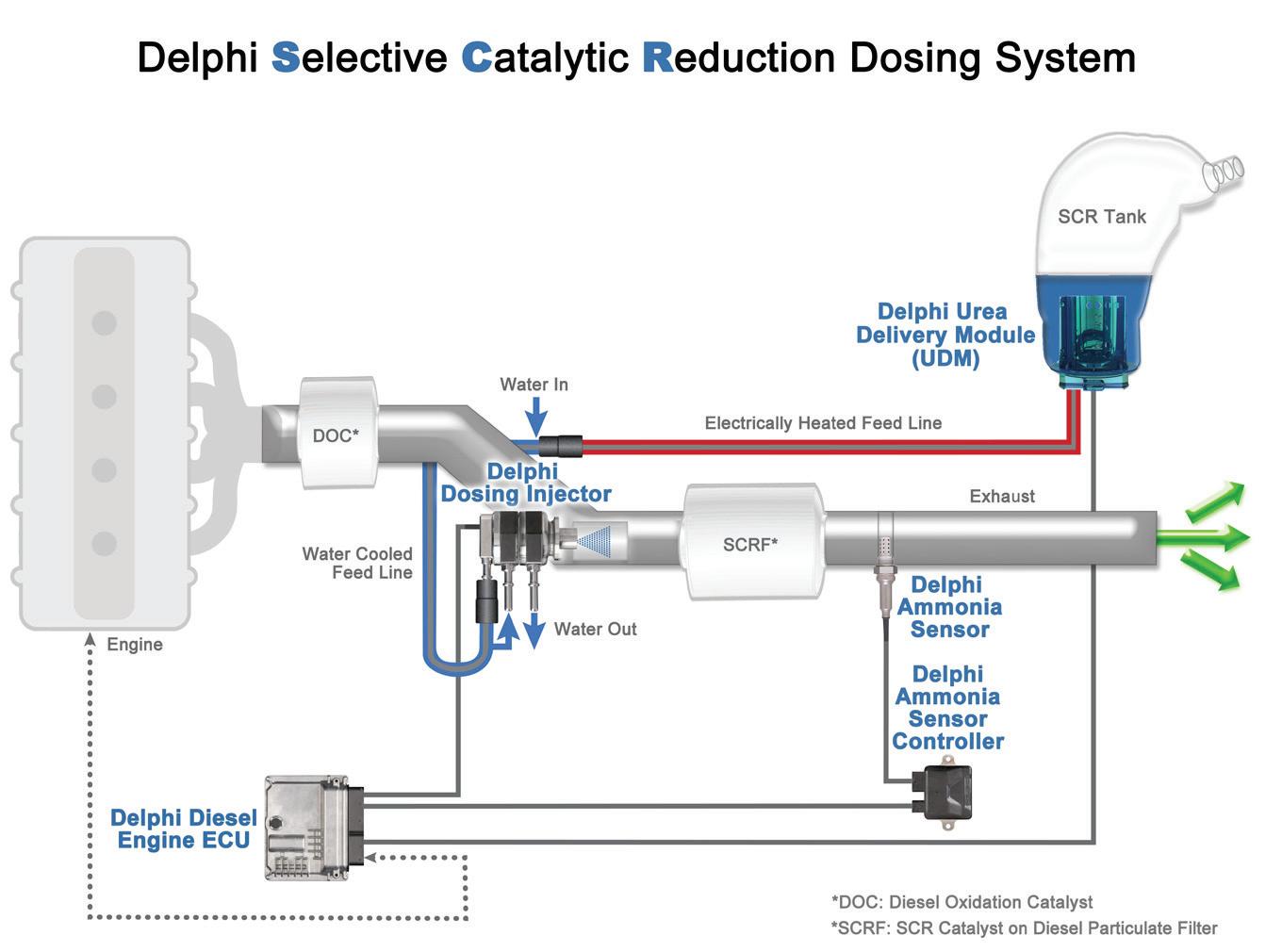

DEF: Diesel Exhaust Fluid (DEF) consists of a mixture of high-purity urea and deionized water. Controlled by a “dosing” module, DEF is injected into the diesel engine’s exhaust stream. DEF consists of a mixture of 32.5 percent highpurity synthetic urea and 67.5 percent deionized water. DEF dosing is controlled by the engine’s ECU. When heated, DEF splits into ammonia

and carbon dioxide, which is then atomized and vaporized. Once DEF enters the exhaust, the water in the DEF vaporizes, leaving ammonia molecules to travel to the catalytic converter where it neutralizes NOx molecules. This reaction converts NOx to harmless nitrogen and water, substantially cleaning up diesel emissions.

All diesel-equipped vehicles that feature an SCR (Selective Catalytic Reduction) system utilize DEF injection.

SCR: Selective Catalyst Reduction. The use of SCR systems reportedly provides an additional benefit of a 3 percent to 5 percent increase in diesel fuel economy. This is a result of enhanced combustion as exhaust temperature rises, especially in the heavy-duty applications. SCR is the final component in the after-treatment system. DEF is dosed into the SCR catalyst, serving to further reduce NOX as oxides of nitrogen pass through the SCR filter.

THE SMOKE DECODER The color of the vehicle’s observed exhaust can also provide helpful telltales in determining a drivability or engine problem. Below are potential clues based on exhaust smoke color. MISCELLANEOUS DIESEL TECH TIPS Following are selected examples regarding a few specific diesel engines and common issues.

DODGE RAM CUMMINS 6.7L

Cummins 6.7L turbochargers: Carbon buildup inside the turbo can prevent proper movement of the nozzle and will often set a P2262 insufficient boost code.

If no DTC is found but the vehicle fails state smog or emission test due to incomplete readiness monitors, check and see if the customer has disconnected battery power prior to the emission test. If so, ask how many miles have been driven since. Check with the vehicle’s service manual to see exactly how the vehicle needs to be driven to complete the readiness monitors.

The following criteria need to be satisfied to make certain the vehicle can complete the testing procedure, these include. • Fuel level at 1/4 tank or more. • Battery voltage 12 to 16 volts. • Coolant temp over 140 degrees F

EXHAUST COLOR

Black Black Black Black Black Black Blue Blue Blue Blue Blue Blue White (steam) White White White

LIKELY CAUSE

Dirty air filter Air intake blockage or leak Fuel contamination Fuel injection system malfunction Turbocharger malfunction Exhaust system/malfunction Dirty air filter or restricted intake Plugged turbo oil drain tube Crankcase ventilation system Valve seals/guides Rings or pistons or cylinders Exhaust system malfunction Coolant leaking in combustion chamber Internal engine damage Fuel issues Valves out of adjustment

REMEDY

Clean/replace filter Check system/repair Check fuel quality Check fuel system Check /repair Check and repair DOC/DPF/SCR Check and repair/replace Repair Repair/replace Repair/replace Repair/replace Check and repair DOC/DPF/SCR Repair Repair Check fuel and injection system Check adjustment

The DEF fill point for GMC and Chevy light trucks is located underhood adjacent to the passenger-side firewall. Especially for trucks equipped with 4-wheel-drive that sit high, accessing this fill point can require a bit of an arm stretch.

HIGH TEMP APPLICATION? CHOOSE PERMATEX RED.

Permatex ® Red Gasket Makers’ advanced formulations are engineered to withstand the extreme thermal cycling of high temperature applications. ULTRA: High temp performance.

NEW!

OPTIMUM: Max temp performance. Up to 750 ºF. THE RIGHT STUFF ® : Fastest return to service. High temp performance.

2010 - 2018 CHEVY SILVERADO/ FORD POWERSTROKE

GMC SIERRA On 6.0L fuel injectors: Prior to installing the If DTC P2463 is stored and the customer cominjector, it is critical to remove any oil or debris plains that check engine light is on and that that may have fallen into the threaded injector the truck has reduced power, check with a scan clamp hole in the cylinder head. Failure to do tool and observe DFP regeneration status. Also so can cause the injector not to be fully seated, check to see the last time DPF was regenerated. which can lead to compression leakage in the If the vehicle is equipped with a driver inforfuel system and catastrophic damage. mation center display, check to see if a DPF 6.0L fuel injection control modules: Fuel warning message is displayed. injection control modules and glows plugs can

If the DPF status shows that regeneration is both cause hard start or rough running on a needed, or the driver information center discold engine. Here’s one way to tell the difference: plays a DPF message, then manually command if there’s white smoke coming out of the exhaust a regeneration as the system will not be able to after a long crank, it indicates unburned fuel automatically complete a regeneration. and points to the glow plugs as the problem. If

Talk to your customer and ask them about there’s no smoke, the FICM is the problem. their driving routine. Do they drive short trips? 6.4L piezo fuel injectors: If one of the injecDo they routinely drive at low speeds? Are they tors leaks, the fuel will enter the crankcase and ignoring the DPF message? raise the oil level. To check for excess oil, you

Explain to the customer that in order for can “short stick” the oil dipstick. Simply insert the filter to clean itself sufficiently, the vehicle the dipstick part way until the bottom edge of needs to be driven over 35 miles an hour until the handle contacts the top of the dipstick tube. the message clears itself. The system is set up 6.4L high pressure fuel pumps: If you to monitor certain conditions and determine must remove or install the high-pressure lines when the filter needs to regenerate. If the filfrom the pump to the cylinder heads, take speter is not allowed to regenerate, then it will be cial care to hold the pump fitting in place with damaged and require replacement. a wrench while using another wrench on the line. Failure to do so can result in catastrophic damage to the pump.

6.4L horizontal fuel condi

tioning modules: The PCM cannot monitor the flow of fuel volume supplied from the HFCM to the high-pressure pump. Restricted fuel filters (or anything else that may limit the flow of low-pressure fuel to the high-pressure pump) can cause catastrophic pump failure, which may result in debris in the fuel rails and injectors. The 6.4L engine used in Ford Powerstroke applications is Remind diesel owners that a blue fill cap on any late model diesel powered truck indicates the DEF fill. This known for common EGR and DPF issues. The Exhaust Gas Recircuis a good point to mention if the DEF fill is located next lation (EGR) system consists of a to the fuel fill, as found on many Ford applications. pair of EGR coolers and an EGR

COURTESY OF DELPHI

Note that the selective catalyst reduction (SCR )tank runs through a heated feed line, using an injector to provide a dose of DEF into the exhaust prior to the SCR catalyst on diesel particulate filter (SCRF).

valve. Exhaust gas enters the lower (horizontal) EGR cooler from the driver’s side exhaust manifold. Exhaust gas then passes through the vertical EGR cooler. This cooler connects to the EGR valve that controls exhaust that enters the intake manifold. The DPF, located near the front of the exhaust system connects to the catalytic converter.

Signaled by a series of sensors, the EGR and DPF systems work together to help the engine meet emission standards. Sensors monitor the exhaust gas temperature prior to the DPF, inside the DPF and after exhaust leaves the DPF. In addition, an exhaust back pressure sensor is located on the DPF. When the sensors determine that the DPF has reached a predetermined threshold of soot contamination, the regen process begins, alerting the driver that regen has started.

When regen begins, the EGR valve opens to allow hot exhaust into the engine in order to increase exhaust gas temperature, which in turn raises the temperature of the DPF. At a predetermined trigger point, the engine’s fuel injectors release excess fuel during the exhaust stroke, sending fuel into the exhaust system, which burns soot out of the DPF. Once the filter clean-out trigger point is reached, the regen process stops. Naturally, while regen takes place, fuel economy will be reduced, since extra fuel is being used to clean the filter.

Because fuel is being sprayed into the cylinders during the exhaust stroke, fuel wash down and oil dilution occurs. Even with a properly functioning EGR and DPF, a gallon (or more) of fuel can be introduced into the crankcase, revealed by an overfill on the oil dipstick. For this reason, it’s vital for your

COURTESY OF CUMMINS

The late model Cummins 6.7L engine found in heavy-duty Ram trucks outputs 1,000 ft.-lbs. of torque and as much as 400 hp. The high pressure fuel pump produced a whopping 29,000 psi of pressure.

customers to understand that the engine oil and oil filter should be changed at least every 5,000 miles. Ignore Ford’s spec of the 10,000 mile oil change interval.

POWERSTROKE HIGH PRESSURE PUMP

Neglecting recommended fuel filter replacement is a known problem for the 2008-2010 Ford Powerstroke 6.4L engine. Failing to follow the filter change per the service manual can damage the high pressure fuel pumps. The dreaded DTC P0088 (fuel rail/system pressure too high) indicates that the fuel pressure control valve in the pump is sticking. The pressure control valve cannot be repaired or replaced on its own, as it’s integral to the pump assembly. If DTC P0088 is stored, this indicates the need to replace the high pressure fuel pump. Replacement pumps can be costly, at $1,000- $1,600. Ford techs are seeing high pressure pump issues due to metal debris contamination. One likely cause is the failure to perform proper maintenance.

The low pressure fuel pump/water separator/filter unit is mounted near the tank, on the frame. A water drain valve petcock is located on this unit, which allows draining water from the fuel. Ford recommends draining water every 30 days. However, due to the unit’s location and the owners’ negligence in not routinely opening this drain, water builds up in the fuel, contaminating and diluting lubrication for the high pressure pump. In the end, the metal debris contaminates the entire fuel system, often requiring replacement of the entire fuel system, at a parts and labor cost of about $6,000. The need to perform routine maintenance of the fuel system cannot be overemphasized.

POWERSTROKE INJECTOR SHORT

Some 2011-2012 F-Super Duty vehicles equipped with the 6.7L diesel engine may exhibit DTC P1291 and/or P1292 due to an internally shorted fuel injector. An internal short in an injector may be caused by fuel being contaminated with DEF (diesel exhaust fluid) or by fuel gelling.

Remove the fuel conditioning module mounted filter. Allow the filter and filter bowl to dry for at least two hours. If the filter turned white, this indicates that the fuel is contaminated by DEF. In this case, the complete high pressure fuel system and diesel fuel control module (DFCM) needs to be replaced and the system flushed.

If the filter did not turn white, inspect the wiring harness for chafing near the EGR cooler. Repair the harness as needed.

If no chafing is found, disconnect each fuel injector electrical connector for injectors 1, 4, 6 and 7 (for P1291).

Disconnect injectors 2, 3, 5 and 8 for P1292. Check for continuity between the injector electrical pins and the injector body. If continuity is present, replace the injector(s) and the injector(s) return hose. ■

PART P/N

Injector return hose……….…BC3Z-9A564-A Fuel injector (cyl 1, 2, 7, 8)…...BC3Z-9H529-A Fuel injector (cyl 3, 4, 5, 6)…...BC3Z-9H529-B