16 minute read

A background and tech tips

from Auto Service Professional - July/August 2015

by EndeavorBusinessMedia-VehicleRepairGroup

Ford Powerstroke diesel

Engine background and tech tips

By Mike Mavrigian

As anyone familiar with diesel engine operation knows, a diesel engine differs from other liquid fuel engines in one major respect: The fuel/air charge is ignited by cylinder pressure and heat, instead of via an electrical ignition system (diesel-fueled engines don’t use spark plugs). On its downstroke, a piston draws air into the cylinder. On the compression stroke, the fuel injection system (depending on how it’s timed) spits fuel into the combustion area, and the resulting cylinder pressure (and residual heat from previous frings) combusts the fuel/air mix, etc.

Diesel heads generally don’t feature combustion chambers (fat decks with no chambers). Instead, the combustion chamber is afforded by the piston’s “bowl” cavity. Partly because of the serious cylinder pressures and forces exerted on the bottom end, diesel components (blocks, cranks, rods, pistons) are, for lack of a better term, heavy-duty and very beefy in construction. As compared to gas engines, just about everything on a diesel is bigger, heavier and more massive.

Ford Powerstroke

Ford’s Powerstroke diesel engine lineup includes a series of V8s. While the engines were built by International, Ford’s chosen name for their diesel engines is Powerstroke. The naturally aspirated International 6.9L/7.3L IDI (indirect injection), from 1982 to 1994 (the 6.9L ran from 1982-1987, and the 7.3L from 1987 to 1993.

Shown above is the Ford Powerstroke 6.0L, featured in 2003-2009 vehicles.

Powerstroke 6.4L, featured in 2008-2010.

Courtesy Ford

The Powerstroke 6.4L features twin turbochargers. Note the location of the high pressure turbo and low pressure turbo, along with a fuel cooler and dual EGR coolers.

Starting with mid-1994, they switched to the turbocharged Navistar 7.3L, which was used until early 2003.

The Navistar 7.3 turbo engine was an outstanding engine platform. Then came the Navistar 6.0L turbo from 2003-2007. This was followed by the twin-turbo 6.4L from 2008-2010. The 2011 model features a Ford-built 6.7L single-turbo diesel. Cylinder heads are cast iron, except for the 6.7L, which features aluminum heads and a strong CGI (compacted graphite) block. Well over 2 million of the 7.3L engines remain in service today.

Powerstroke tech tips

SHORT IN INJECTOR

Some 2011-2012 F-Super Duty vehicles equipped with the 6.7L diesel engine may exhibit DTC P1291 and/or P1292 due to an internally shorted fuel injector. An internal short in an injector may be caused by fuel being contaminated with DEF (diesel exhaust fuid) or by fuel gelling.

Remove the fuel conditioning module mounted flter. Allow the flter and flter bowl to dry for at least two hours. If the flter turned white, this indicates that the fuel is contaminated by DEF.

In this case, the complete high pressure fuel system and diesel fuel control module (DFCM) needs to be replaced and the system fushed.

If the flter did not turn white, inspect the wiring harness for chafng near the EGR cooler. Repair the harness as needed. If no chafng is found, disconnect each fuel injector electrical connector for injectors 1, 4, 6 and 7 (for P1291). Disconnect injectors 2, 3, 5 and 8 for P1292.

Check for continuity between the injector electrical pins and the injector body. If

PART P/N Injector return hose BC3Z-9A564-A Fuel injector (cyl 1, 2, 7, 8) BC3Z-9H529-A Fuel injector (cyl 3, 4, 5, 6) BC3Z-9H529-B

Ford Powerstroke injectors are very costly, so rebuilding makes economic sense. A wet ultrasonic cleaner is ideal for cleaning multiple injectors and their components.

Unlimited Diesel specializes in rebuilding and modifying Ford Powerstroke diesel fuel injectors. This is a popular and proftable service to consider adding for both daily drivers and performance and racing customers. continuity is present, replace the injector(s) and the injector(s) return hose.

DEAD ENGINE = A REAL DANGER

This is a fairly common and critically severe glitch on Ford trucks equipped with the 7.3L Powerstroke diesel engines. Your customer is driving along, minding his own business, when WHAM... the engine simply shuts off, as though someone hit a master kill switch. No engine power, no power assist brakes, no power steering, no nothing (at least the lights still work). This is simply a very dangerous situation, especially if you’re in traffc or descending a hill, or (and I shudder to think about this) pulling a big trailer down a hill.

The likely cause? The fuel bowl heater circuit. The heating element inside the fuel bowl shorts out, killing fuse #30 (30 amp). Unfortunately, the same fuse powers the wastegate solenoid, injector driver and the PCM power diode. Some designer at Ford ran the fuel heater and the PCM on the same circuit. When the fuel bowl heater shorts out, it kills the engine in its tracks, without warning.

The ideal cure: Replace the fuel heater element and the 30 amp fuse. In practical terms, simply unplug the white two-wire connector at the rear of the fuel bowl and replace the fuse. Unless your customer is operating in sub-zero temps, he doesn’t need the fuel bowl heater anyway. This is a very dangerous scenario. Try stopping and steering a heavy and dead 2002 F-350 dually diesel crew cab truck with no steering or braking assist on a busy freeway. It happened to me once, and all I can say is that it’s not fun. The 7.3L Powerstroke is a great engine, but that wiring glitch is nothing to laugh at.

My advice: Unplug the fuel heater connector before it causes a problem.

In addition, regardless of whether or not the fuel bowl heating element shorted, a kill-engine occurrence (also fuse #30) might also be caused by the wiring bundle that is located over the left side valve cover. These wires may have been rubbing, resulting in a shorted wire. With the batteries disconnected, lift the wire bundle up away from the valve cover and look for rub marks and chafed wires and small arc spots on the valve cover. Repair any damaged wire(s) and thoroughly insulate the wire harness to prevent future shorts.

Fuse 30 provides power to the fuel heater/water in fuel sensor, the waste gate solenoid control and the PCM power diode.

When diagnosing a no-start, frst inspect the wiring near the fuel heater/water in fuel sensor and the waste gate solenoid control to see if there are any chafed or worn-through/bare wires. Unplug both the fuel bowl heater connector and the wastegate solenoid connector and replace the fuse. Connect the fuel bow heater. If the fuse blows, you’ll verify that the culprit was the fuel bowl heater circuit. If it does not blow, connect the wastegate solenoid connector. If the fuse blows, inspect that circuit. Once a component is unplugged and the fuse doesn’t blow, then that component is likely the cause of the short. If both components are unplugged and the PCM power diode has been removed and the fuse still blows, then you have a short in the wiring itself and the harness would need to be traced for any rubbed through wires or chafe marks, or replace the harness.

The fuel bowl heater connector is seen here (white connector next to the yellow drain valve lever). To eliminate concerns of fuel bowl heater shorts, which can shut down the PCM, many techs recommend simply disconnecting this white connector and taping it off.

BUZZ BUZZ

Some 2011-2012 F-Super Duty 250-450 trucks equipped with the 6.7L Powerstroke engine may exhibit an underhood buzzing noise while the engine is running, and for up to 30 seconds after the engine is shut off. This may be due to the wastegate control valve vacuum harness causing the wastegate control valve to resonate.

With the buzzing noise present, disconnect the vacuum hoses from the wastegate control valve. If the buzzing stops, replace the wastegate control valve vacuum harness. This involves removing the throttle body, the air cleaner outlet pipe and the three wire harness retainers. This provides access to remove and replace the vacuum harness. The vacuum harness is available as P/N BC3Z-9D430-E.

DIESEL SURGE

Diesel engines (we’ll cite Ford’s 7.3L, 6.0L, etc., as examples) typically feature a dedicated high-pressure oil system that operates the fuel injectors. The high pressure side typically runs at about 500 psi at idle, 1,200 psi at about 3,300 rpm and about 3,600 psi under full-load acceleration.

This system involves a high pressure oil pump and an IPR (injection pressure regulator). Sticking (or wear) problems with the high pressure control regulator can cause engine surging (most commonly noticeable at lower rpm and at idle), as well as intermittent engine shut-off during low speed braking and/or when approaching a fnal stop. If the engine cuts out during a stop, with the transmission placed in neutral or park, the engine fres up again, but dies again when approaching a fnal stop. Other symptoms can include intermittent diffcult starting, a slight stumble when the accelerator pedal is nailed while the engine is turning around 1,000-1,500 rpm and/or annoyingly extended cold-cranking in freezing temperature. Granted, various injector issues could cause some of these problems, but if a customer’s truck enters the shop with the surging/intermittent shut-off issues, defnitely inspect the high pressure oil system.

When these driveability problems began to appear, the “off-the-cuff” reaction was to replace the fuel flter, suspecting that it was moisture-contaminated. While it’s imperative to regularly replace diesel fuel flters anyway (especially in cold climates),

Circle 115 on Reader Service Card

if the frst few flter changes don’t solve the glitch, suspect the high pressure oil control valve or regulator. The high pressure oil system runs at very high pressure, and any interruption in pressure fow will cause the PCM to attempt fuel enrichment changes.

NOTE: While it’s certainly easier to replace a sticking control valve, the high pressure control valve is usually rebuildable (basically just disassemble, clean and reassemble). Also be sure to check the high pressure oil rail and its connections for external leakage (which will not only make

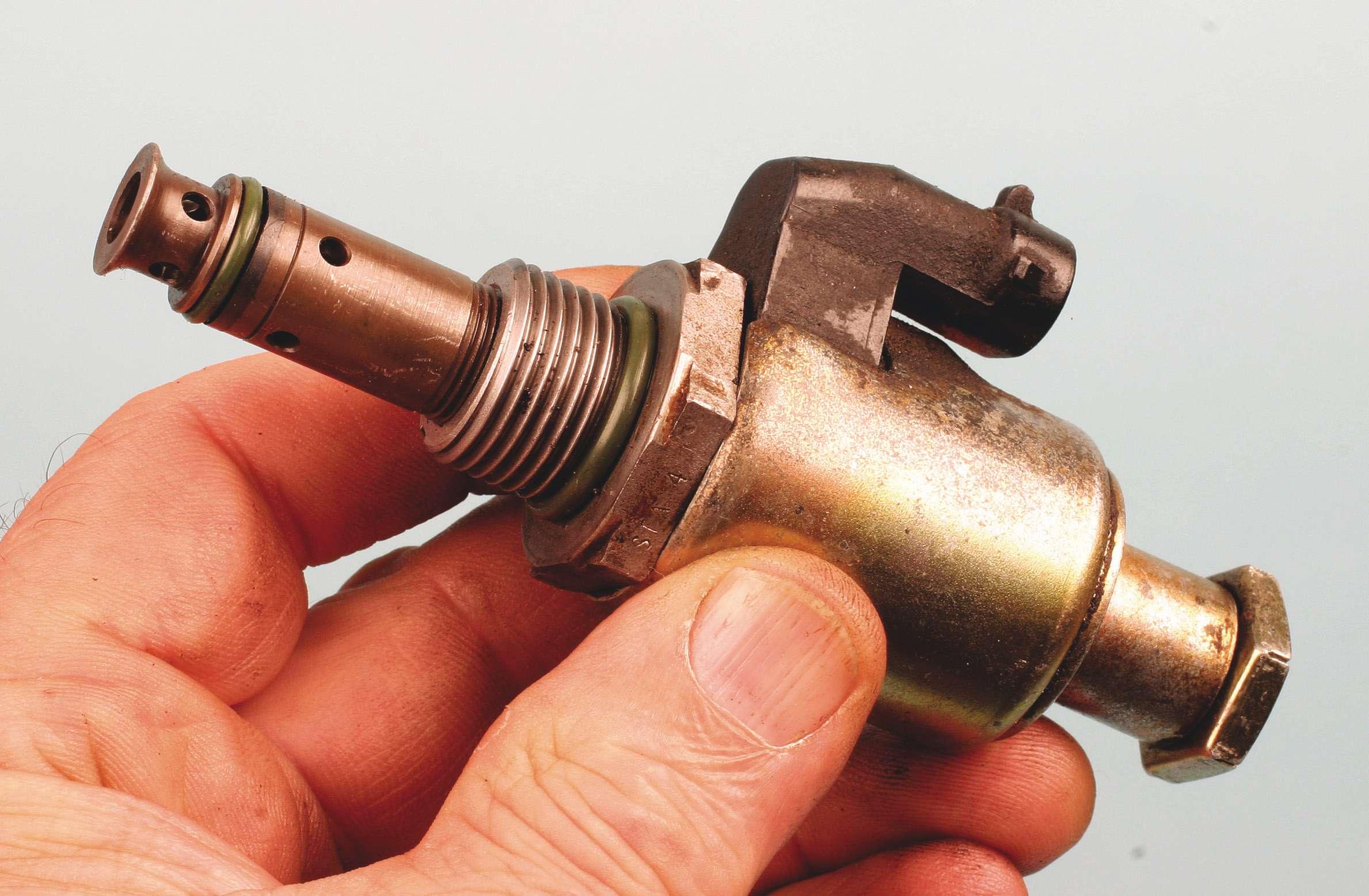

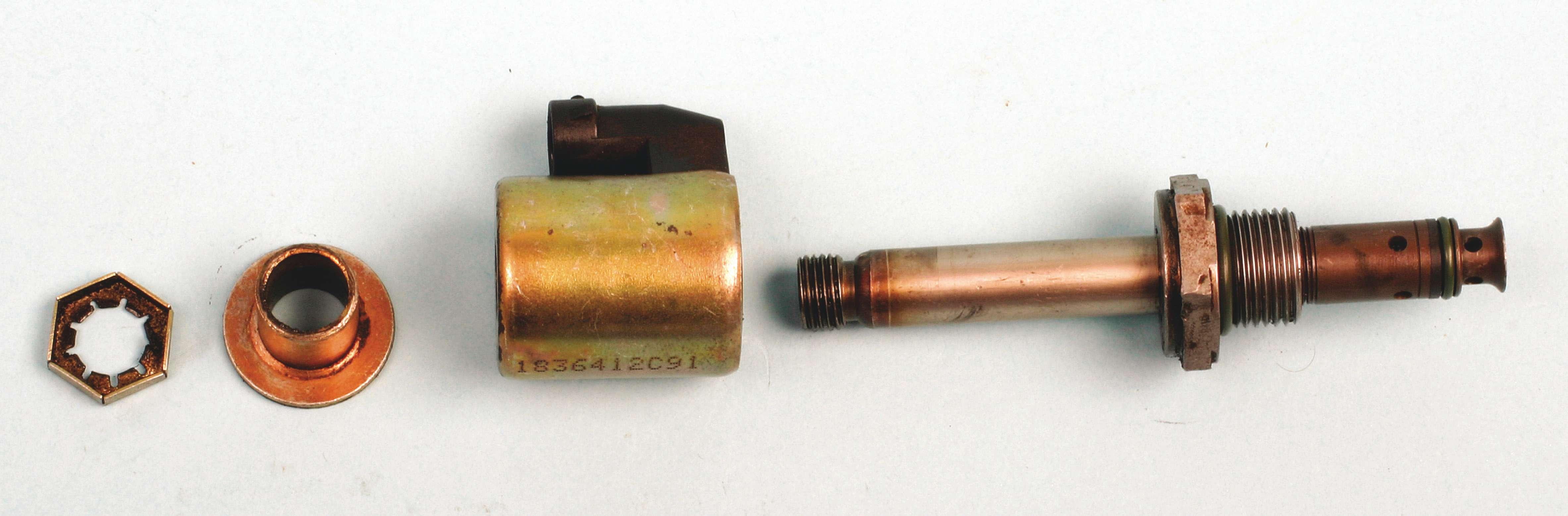

Diesel engines (such as the Ford variations) feature a high pressure oil control valve that “regulates” the dedicated high pressure oil system to operate the fuel injectors.

The tiny orifces in the high pressure oil control valve can easily become contaminated, especially if improper oil is used or if oil changes are infrequent.

Depending on the design of the high pressure oil control valve, the valve may be disassembled and cleaned (the best cleaning method is to use an ultrasonic cleaning tank). an oil mess at the rear of the intake manifold, but will cause pressure drops).

It’s also important to remind customers that only specifed engine oil should be used in diesel applications, in part because of the special anti-foaming additives in the oils, critical for maintaining an adequate and constant pressure to the injectors to prevent aeration and sub-par injector spray patterns (these anti-foaming agents can break down in the 3,000- to 5,000-mile range). Citing the Ford examples, several oils are appropriate and should carry an API rating of CF-4/SH or CG-4/SH or higher. One example is Shell Rotella-T 15W40

I SMELL SOMETHING

Some 2008 Super Duty vehicles equipped with the 6.4L Powerstroke engine may exhibit an exhaust odor inside the cabin and/or exhaust smoke may be visible from the front of the vehicle. Inspect the turbocharger to exhaust down pipe connection for a leak.

1. Remove the turbocharger oil supply tube banjo ftting bolts and copper sealing washers. Discard the old copper washers. 2. Remove the bolt and the turbocharger oil supply tubing and plug openings.

Remove and discard the oil supply line gasket. 3. Remove the fve bolts and the turbo heat shield. 4. Verify that the exhaust leak is coming from the turbo to exhaust down pipe connection by inspecting for exhaust soot around the connection. 5. Remove and discard the two exhaust down pipe to diesel oxidation catalyst (DOC) fasteners. 6. Hand-start new fasteners by a couple of turns. 7. Remove and discard the turbocharger to exhaust down pipe clamp and turbo to down pipe gasket. 8. Install a new gasket to the turbocharger. 9. Align the down pipe fange to the turbo fange. 10. Install a new clamp over the fanges and latch the clamps’s T-bolt.

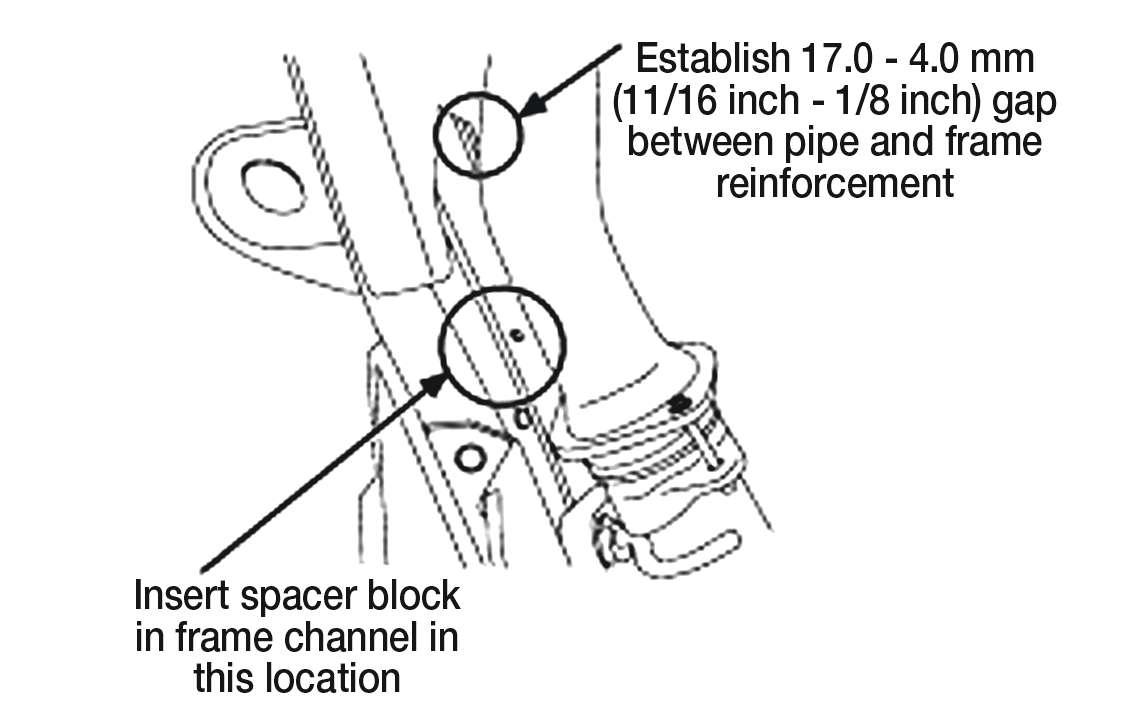

11. While maintaining exhaust down pipe fange alignment to the turbo fange, tighten the clamp nut by approximately 1-inch. 12. Establish an 11/16-inch clearance between the exhaust down pipe to the frame, using a temporary piece of material such as wood. Place this temporary spacer between the frame and down pipe. 13. Confrm fange alignment and tighten the down pipe clamp to 11 ft.-lbs. 14. Torque the exhaust down pipe to diesel oxidation catalyst fasteners evenly to 30 ft.-lbs. Remove the temporary spacer from between the frame and down pipe. 15. Position the turbo heat shield and install the fve bolts, tightening these to 8 ft.-lbs. 16. Install a new oil supply line gasket and apply clean engine oil. Position the turbo oil supply line tube and install the bolt, tightening to 10 ft.-lbs. 17. Install two new copper sealing washers and the oil supply tube banjo fttings on the turbo oil supply fttings. Tighten to 28 ft.-lbs. Verify that the oil supply tube does not contact the turbo actuator linkage.

CAUTION: Use only new banjo bolts that feature a green hex head. The green-headed bolts do not contain a check valve. When viewed from the inner end, the correct bolt design will appear open. Using incorrect banjo bolts may result in turbocharger damage.

As shown above, when positioning the exhaust downpipe, temporarily install a spacer to establish a clearance of 11/16-inch between the frame and the pipe. P/N PART W711407-S900 Down pipe to DOC fasteners (two needed) 7C3Z-5A231-AC Turbo to down pipe clamp 7C3Z-6L612-B Turbo to down pipe gasket W302474 Oil supply line gasket (two needed)

Beefng it up

If your customer expresses an interest in obtaining an increase in power and torque, the most immediate and easiest approach is to install a quality re-program kit. If he or she wants to go further, consider the bottom-end (rotating and reciprocating components). Your shop may or may not be willing or able to perform an engine rebuild to accommodate these upgrades, but following are a few tips.

PISTONS

OE pistons are generally cast and feature a steel insert in the top ring groove to prevent ring pounding and microwelding. Aftermarket forged/CNC-fnished slugs are readily available to accommodate higher cylinder pressures and heat, especially for applications that run super-high turbo boost and/or nitrous oxide injection (as but one example, Mahle refers to their design as a Ni resist insert). The Mahle DI (direct injection) piston is designed with a cooled ring carrier cooling duct formed by a steel plate. This sheet metal channel is welded directly to the ring carrier. Oil is circulated through the passage to assist in piston cooling. This welded steel design places the cooling gallery closer to the top ring groove for better cooling of the piston crown and the top ring carrier. Having a steel inert in the top ring groove prevents the ring from pounding itself (and the ring groove) to death. In the aftermarket forged piston offerings, it’s too diffcult to incorporate a steel insert, so the ring lands are hard anodized to aid in longevity. However, this should be considered race-only, and not really recommended for street use where

the engine won’t be torn down, cleaned and inspected on a regular basis. With forged pistons (since they’re CNC machined anyway), custom dome confgurations are readily available, including valve notching when needed. To give you some idea of the “beefness” aspect, piston wrist pins are healthy, to say the least. In terms of piston coatings, naturally, as with gas or alcohol applications, anti-friction skirt coating is always a good move (some slugs include this as standard while optional coating is always available).

It’s safe to assume that when you move to a forged piston, piston-to-wall clearance will need to increase. Ross Pistons noted that (naturally, depending on bore diameter), clearance with forged slugs will typically be in the 0.010-inch - 0.013-inch range. Always check with your piston manufacturer for their recommended wall clearance.

NOTE: The easiest (and least expensive) method of increasing diesel power in today’s light trucks is with the addition of a “re-program.” Basically, the performance programs out there all perform the same general task — they increase the amount of delivered fuel. The added program alters the signals generated by the onboard ECU to control injector timing, fuel pressure and fuel injector pulse duration.

However, all consumers are not wellinformed, and the simple addition of some programs can cause damage if the truck owner doesn’t understand what’s happening, and if he doesn’t compliment the new program with increased air intake and a freer-fowing exhaust system. Depending on the program, when hammering the engine at WOT, exhaust gas temperature (EGT) can elevate to dangerous levels and can result in damage to the turbo, pistons, rings, rods, crank, and well, you get the picture. Simply adding more fuel (without a complimentary increase in air, any extra fuel will be unburned (telltale black smoke billowing out of the exhaust). This raises EGT and, over enough time and abusive operation, will result in mechanical damage. If your customer intends to run a custom fuel control program, make sure that he consults with the program maker to understand the risks and to be advised regarding any additional performance mods that will safeguard the engine. A properly tuned control package from a reputable and knowledgeable manufacturer will provide a great boost in power while avoiding engine damage. And if the customer does over-extend himself and discovers the mechanical limits, then he’s a prime candidate in your shop for an upgrade that will better withstand the abuse (forged rods, forged pistons, billet cam, etc.).

Example of an aftermarket forged steel rod for the Powerstroke 6.0L. The offset big end design, to accommodate clearance issues, is also featured on 6.4 and 6.7L engines. Note that rod center lengths and bore diameters differ among engine displacement versions.

CONNECTING RODS

OE rods may be forged or powdered metal (the Ford Powerstrokes, for instance, began using PM rods in late 1998 to 2003 7.3L engines). The cracked cap PM rods in the 7.3L Powerstroke have a tendency to fail if turbo boost is cranked up, or simply due to high mileage fatigue over time.

Generally speaking, OE rods are probably good for up to about 400-500 hp (depending on the brand and specifc engine). Beyond that, it’s time to step up to some aftermarket forged rods using high tensile strength rod bolts (ARP or A-1, for example). Of course, if you plan to add some stroke, you’ll need length-specifc aftermarket rods anyway. This isn’t rocket science. If you’re building for serious power, there’s no debate... just buy quality steel forged rods. Steel rod makers that offer diesel units include (but are not limited to) Carillo, Crower and others. ●

See more on diesel engine issues on our website at www.autoserviceprofessional.com.