THAT’S A WRAP

Turning visions into reality in vehicle wrapping

PRIMED FOR

Turning visions into reality in vehicle wrapping

The Factory’s LISA DOOLEY on doing the right thing

BIG AMBITIONS at NORTHSIDE GRAPHICS

SPOILT FOR CHOICE

ANTALIS IRELAND is expanding its offering to Irish customers

Once

Brian Breheny at Antalis Ireland talks about bringing more choice of materials to the industry

A

What

Lisa Dooley at The Factory

24 Careers

Mark Needham’s first role set the stage for a career that’s all about pushing

to issue 5 of Irish Printer for 2024.

At Northside Graphics, apprentices make up roughly 15% of the total workforce. Career progression is encouraged at the Belfast print firm and just recently Glenn Nelson, who started his career as an apprentice and was named a ‘Rising Star’ at the 2022 Irish Print Awards, was promoted to Production Manager. In 2021 the firm launched a Training Academy in conjunction with Belfast Met, offering apprenticeships to candidates aged 16-24. It was a proactive move for a print firm that’s making strides to get more people into the industry. For more on Northside Graphics, go to page 13.

On page 16, Brian Breheny talks about how providing a greater choice of materials to the industry is helping to differentiate Antalis Ireland from the competition. The company has ambitious growth plans for its packaging and visual communications businesses and the recent appointment of Iain Cunningham as Head of Packaging in Ireland is, says Brian, a great example of that ambition. Elsewhere in this issue, we take a look at P+D’s recent wins at this year’s POPAI Awards, including a bronze award in the Display of the Year category, a first for an Irish company, chosen from the very best of the temporary displays across all categories. On page 20, Lisa Dooley talks about gaining a new perspective on the family business and the importance of fostering sustainability amongst the team at The Factory. After finishing college, she decided she wanted to achieve two things – to work in collaboration and to do something with a sense of purpose. At The Factory, she can say with certainty that she is fulfilling that dream. Finally, on page 24 Mark Needham at Rostrum Design talks about his first ever role in the print industry and how it paved the way for a career that’s all about pushing creative boundaries.

As always, we’d love to hear from you. If you have any thoughts on this issue, please drop us a line at editor@irishprinter.ie. Enjoy!

Editor: Denise Maguire

Email: editor@irishprinter.ie

Creative Director: Jane Matthews

Designer: Lenny Rooney

Production: Nicole Ennis

Contact: Irish Printer, Ashville Media Group, Unit 55, Park West Road, Park West, Dublin 12, D12 X9F Tel: (01) 432 2200

Web: www.irishprinter.ie

Printed by: McGowans Print

Printed on: HP Indigo 10000 using Novatech paper supplied by Antalis.

All rights reserved. Every care has been taken to ensure that the information contained in this magazine is accurate. The publishers cannot, however, accept responsibility for errors or omissions. Reproduction by any means in whole or in part without the permission of the publisher is prohibited. © Ashville Media Group 2024. All discounts, promotions and competitions contained in this magazine are run independently of Irish Printer. The promoter/advertiser is responsible for honouring the prize. ISSN 0790-2026

Papago is available in an extensive range across a choice of 34 colours; perfect for the most demanding applications.

● Laser

● Inkjet

● Copier

● Offset

● Pre-print

The Papago cut-size range is FSC® certified and the folio range is PEFC 100% certified.

For more information or samples, contact your local branch.

Paper & Materials, Delivered Nationally

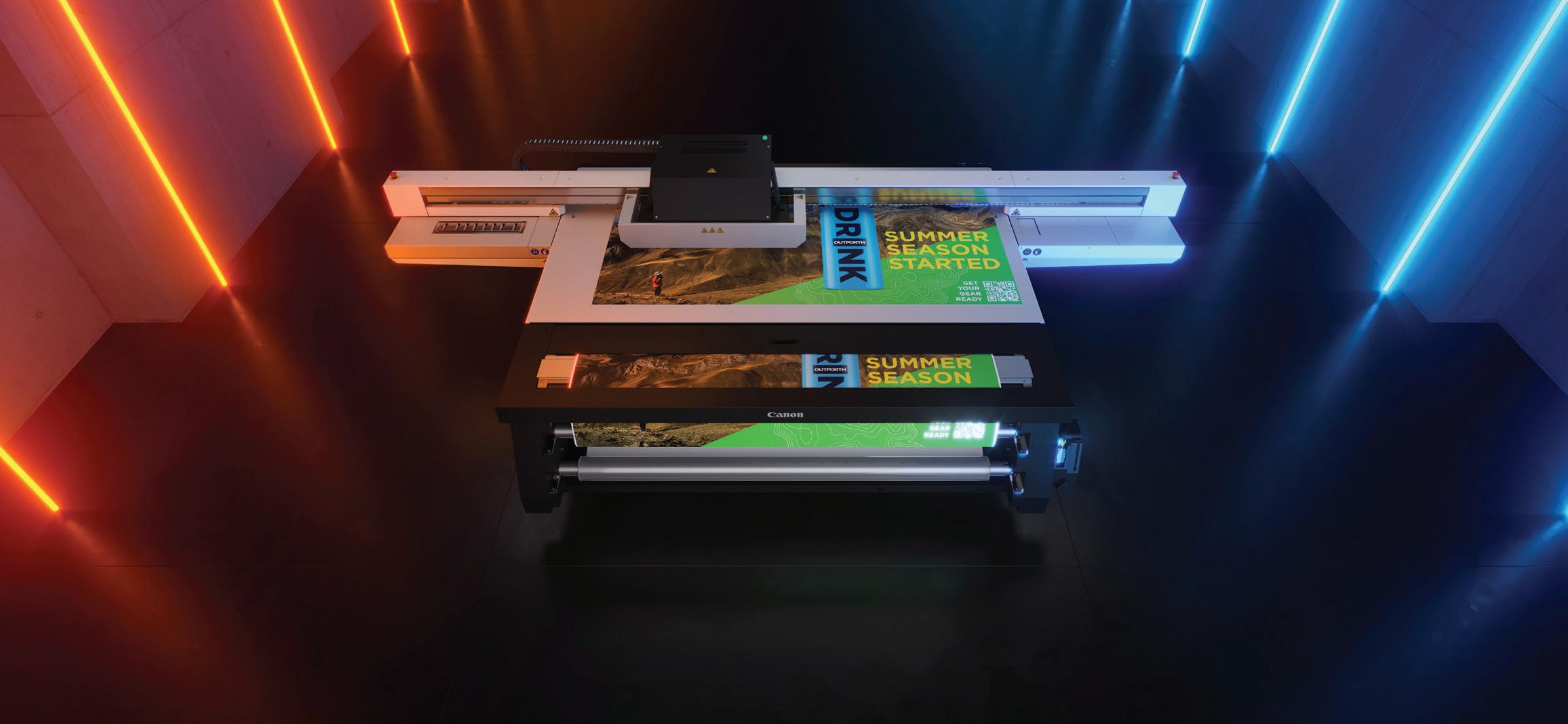

Canon has added its FLXflow technology to the Arizona 1300 series, offering the original ‘Hold’ functionality along with the new optional ‘Float’ and ‘Instant Switch’ functionalities to improve media handling. The Hold functionality works by keeping the media in place with a patented airflow technique. Using automatic measurement and adjustment of airflow levels to firmly and accurately hold various types of media in place, the functionality results in flexible positioning with far less masking. The new Float functionality pushes air from the table upwards to create a cushion, enabling the easy positioning of heavy or challenging substrates and reducing the risk of media damage or waste. It also results in the smoother registration of all types of media, with a ‘floating without drifting’ ability enabling several pieces of media to be precisely positioned at the same time. ‘Instant Switch’ allows the operator to easily change from Hold to Float by using the foot pedal(s) for simple operability of the printer.

Trimwel has launched its new, own-brand range of tapes, glues and abrasives. Called ‘Trimweld’, the range includes bonding adhesives and glues designed for high-strength structural bonding of composites, metal and thermoplastics. The range has, says Trimwel Managing Director Nick Little, been tailor-made for the signage industry.

» CJV200 Series

Using the same print engine as the 330 Series, the CJV200 Series is Mimaki’s new range of entry-level eco-solvent integrated printer/cutters. Designed to be more accessible for printers of varying levels of experience to operate and maintain, the model include an “ink saving function” that reduces ink consumption, a quicker print-head cleaning time and Mimaki’s Dot Adjustment System (DAS).

» TS330-3200DS

The TS330-3200DS is a 3.2-metre-wide hybrid printer, capable of both direct sublimation printing on fabric and sublimation transfer printing on paper. It supports a wide range of applications and can also be used to print interior fabrics like curtains, carpets and bedspreads.

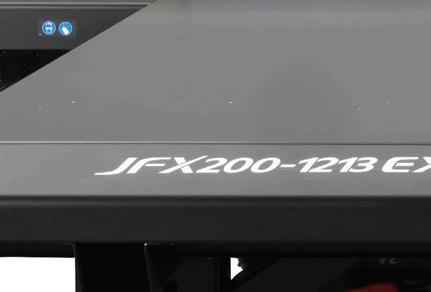

Mimaki Europe has announced four new printers for sign graphic, industrial and textile applications. The CJV200 series, a range of roll-to-roll print and cut eco-solvent machines, the TS330-3200DS, a hybrid direct and transfer sublimation printer alongside an entry-level flatbed UV printer, the JFX200-1213 EX, and Mimaki’s latest direct-to-film (DTF) solution, the TxF300-1600, will be commercially available in Europe in November 2024.

» JFX200-1213 EX

The JFX200-1213 EX is an entry-level flatbed UV inkjet printer designed to meet the needs of businesses seeking a mid-size printing solution. With a print area of 1.2 m x 1.3 m, it sits between Mimaki’s smaller-format UJF Series and the larger-format JFX Series.

» TxF300-1600

This is the latest addition to Mimaki’s Direct-toFilm (DTF) line of printers, which increases productivity by 30% compared to the TxF30075. With a maximum print width of 1.6 metres, the TxF300-1600 extends its application to large-scale interior fabrics, such as curtains and floor mats.

SKSC (Smurfit Kappa Security Concepts) has announced the promotion of Allister Carlile to the position of Production and Technical Manager. Allister will oversee all aspects of production operations and will be the main technical advisor for the business. With SKSC for over 20 years, his previous role as Finishing Manager saw him responsible for all of the finishing processes required to encode security documents. As part of his new remit, he will oversee the full production process flow from pre-press and IT, print, personalisation and finishing. His promotion reflects SKSC’s commitment to recognising and nurturing talent from within the company. “The future at SKSC is exciting,” said Allister. “We continue to be recognised at home and abroad for our excellence in terms of service and the added value that our team bring to projects. I look forward to joining the Committee of Management and ensuring that SKSC remains at the forefront of technological advancements in the industry.”

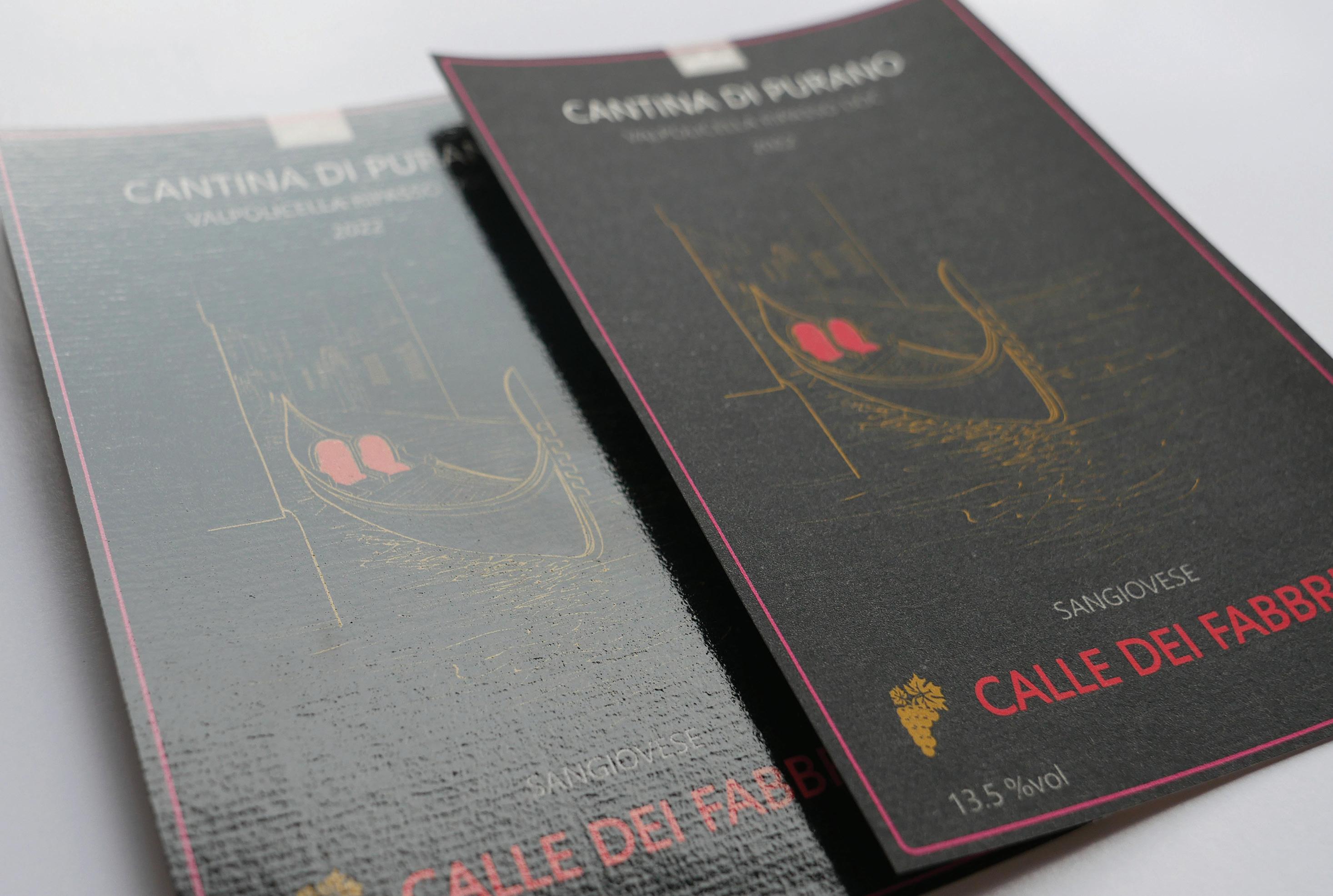

HEIDELBERG and Gallus have announced a new matte finishing technology for digital inkjet. Gallus Group, a subsidiary of HEIDELBERG, says the new technology, which was previously unachievable with digital inkjet, is set to transform the wine and spirit labels market, bringing the possibilities of inkjet technology to the wine label market for the first time.

The two companies say Gallus MatteJet technology delivers fast, cost-effective and high-quality matte finishing capabilities, integrated directly into the digital inkjet process. It will allow converters to achieve a high-end matte finish at the touch of a button, without changing inks or adding overprint varnish, eliminating the need for external finishing processes or separate conventional machines. By removing one of the key barriers traditionally restricting the expansion of inkjet printing Gallus says the new process, which has been designed to integrate with Gallus’ Digital Printing Unit, presents a huge opportunity for converters to now access a highly profitable market segment.

“By unlocking matte finishing for digital inkjet, we’ll be able to make an entirely new market segment accessible to converters without the sizeable investment into separate offset solutions – boosting profitability and exemplifying our commitment to building a new era of flexibility that will enable our industry to thrive long-term,” said Dario Urbinati, CEO, Gallus Group.

Gallus MatteJet technology delivers fast, cost-effective and high-quality matte finishing capabilities

Waste generated from Metsä Board’s mills is being used as raw material in animal bedding. Its mills manufacture folding boxboards, food service boards and white kraftliners. Dry fibres from the production of these products is now being used for bedding for cattle and horses – an action that’s in line with the company’s 2030 sustainability targets. New types of bedding fibres are a renewable alternative to peat commonly used in animal farms in Finland, the availability of which will decrease in the coming years. After use, the bedding can be spread on arable land, increasing the soil’s carbon stock.

Reusing old toner cartridges at Fujifilm

Fujifilm has established its first Circular Manufacturing Centre in The Netherlands to promote resource circulation in Europe. As a first step, the new centre will collect used toner cartridges from printers sold in Europe and re-manufacture them into new toner cartridges. In the future, Fujifilm Business Innovation plans to expand these re-manufacturing processes to other products, such as multifunction printers and spare parts for production printers. Fujifilm Manufacturing Europe B.V. also supplies all its own electricity from on-site wind power generation and from a purchased wind power generation company, so the new centre is also capable of achieving virtually zero CO2 emissions from the electricity it uses.

Busy students were targeted with a Berocca vitamin boost campaign as they returned to UCD recently. The 3D build, located on campus, was created by McGowans Print and delivered by Talon Ireland.

Ideally located 5 minutes from the M50, 2 minutes from the M3 DAMASTOWN INDUSTRIAL ESTATE, D15 RYY9

We provide Trade Finishing Services such as: Gluing | Die Cutting, Window Patching | Laminating & Handwork with 48,000 square feet spread across two warehouses

EXPERTS IN PRODUCING CARTONS FOR THE MEDICAL DEVICE AND PHARMA SECTORS.

TEL: 01 254 1985 E: patrick@venturefinishing.ie | www.venturefinishing.ie

Belfast-based signage and branding specialists, Off the Wall Creative, designed and created social media walls across the three campuses at Ulster University, just in time for Welcome Week. SL Ocean Hollywood Yellow (1000mm x 2600mm) and SL Ocean Hollywood Blue (1000mm x 2600mm) from the Dazzler range were used to create the impressive walls. The OTWC team also fabricated and installed portals at the University, designed to connect all three campuses.

Antalis has launched a new Xerox Premium NeverTear paper featuring a Biomaster coating. The synthetic paper has been designed to create durable documents in the most challenging environments. The addition of Biomaster antimicrobial protection provides a more hygienic solution to relevant applications. Antalis says the new paper is waterproof, tear proof, greaseproof and alcohol resistant. Its coated white matt polyester film makes it suitable for laser printing and it also has high durability without the need for lamination or encapsulation. It can be cleaned with soapy water, bleach or safely disinfected with a variety of alcohol and solvent based agents. The Biomaster treatment is food and water safe and has been independently tested to meet the ISO22196. The new coating is currently available on the Xerox Premium NeverTear Matt White products from 95-350 micron and there are plans to extend this throughout the range.

Our new high definition digital spot UV sensory coater is not just another machine. Sight and touch combine to offer a new experience, all at the touch of a button. The design-driven technology is fully automated and easy to use. With two cameras and 600dpi inkjet, it's fast, accurate and gives stunning tactile results. Suitable for a wide range of applications including larger sheets (max 364mm x 740mm) and supplied with Duplo's proven feeding technology as standard.

Once again, P+D triumphs at the annual POPAI

At the 2024 POPAI Awards P+D brought home an impressive four awards, including bronze in the Display of the Year category, a first for an Irish company and chosen from the very best of the temporary displays across all categories.

In the ‘Grocery & General Merchandise – Temporary Display’ category, P+D won gold for its Jägermeister FSDU, along with bronze in the ‘Display of the Year – Temporary Display’ category. Commenting on the display, judges said: “This stands out a mile. A great unit, absolutely met the brief, with impressive ROL.”

P+D also scooped a silver award in the ‘Short Run – Temporary Display’ category for the Italicatessen Wow Displays, with judges saying: “An impressive display that has a premium look and feel! Beautiful design that shouts authentic Italian food and lets the products sell themselves.” The print firm also took home silver in the ‘Home, Garden & Consumer Electronics – Temporary Display’ category for its Kärcher Window Vac FSDU. Judges described the display as a great way to launch a new colour-way into the market. “Clear branding and reason to buy help to convince the shopper at point of purchase.”

There’s huge demand for online print in Ireland; since September, we’ve seen double digit growth which is very encouraging

RICHARD CAMPBELL at Northside Graphics chats to Irish Printer about a changing market and why it’s all about being in the right place at the right time

It’s been a productive year at Northside Graphics. The Belfast based digital print specialist – which operates four online web-to-print brands across Ireland and the UK – was acquired by Bestport, a UK private equity investment firm, earlier this year. The move has facilitated the appointment of a number of senior figures, along with investment in a Xerox Iridesse. Business is booming, says Managing Director Richard Campbell. “We’re out the door with work at the moment and we’re also busier than we were this time last year. There’s huge demand for online print in Ireland; since September, we’ve seen double digit growth which is very encouraging.”

With so many people leaving the industry, we’re bucking the trend by recruiting apprentices and giving them every opportunity to progress and build a career at Northside

Business in Northern Ireland is also very encouraging, with Northside Graphics experiencing double digit growth there too. The potential is huge, says Richard. “The only real issue we have is finding skilled staff, that’s our biggest problem. Demand for our products increased by about 30% in September and that has put huge demand on the team. We’re lucky in that we have a number of outsource partners that we work with, to ensure we never let our customers down.” Production staff are the most difficult to find. “In terms of minimum wage, I think both Ireland and the UK are in the same boat. The rate for both regions increased at the start of the year and that’s had a knock-on effect. It’s pushed expectations up – you can’t get people to work for minimum wage now, you have to offer more to get anyone through the door.”

A print apprenticeship scheme at Belfast Metropolitan College is helping to plug that skills gap at print firms across Northern Ireland. Northside Graphics has been proactive in taking on apprentices and in 2021, launched its specialist Training

Academy, despite challenges posed by the pandemic. Full-time apprenticeships were offered to candidates aged 16-24 in conjunction with Belfast Met, who delivered training at Northside’s premises. All successful candidates gained GQA Levels 2, 3, and 4 in Printing over three years as part of the Training Academy. “This year, we’ve had an intake of five new apprentices. They’re all excellent and very much interested in a career in the industry. Ian Cairns at Belfast Met is a fantastic tutor, he does great work for the industry.”

Apprentices make up approximately 15% of the total workforce at Northside Graphics. Career progression is very much encouraged; just recently, Glenn Nelson, who started his career as an apprentice at Northside, was promoted to Production Manager. He was also named a ‘Rising Star’ at the 2022 Irish Print Awards. “Glenn started with us nine years ago as an apprentice. That’s how I entered the industry and it’s great to see the next generation following the same pattern. With so many people leaving the industry, we’re bucking the trend by recruiting apprentices and giving them every opportunity to progress and build a career at Northside.” On their first day at Northside, apprentices don’t hear about print.

All that growth is thanks to the online business. We were selling the right thing in the right space at the right time. Since then, digital print has only continued to grow

has also disappeared. There must have been 20 or 30 B2 printers at one stage and today, we’re down to just one or two. The number of print businesses has dwindled hugely, but we’re making great efforts to get people into the industry.”

“I talk to them about the internet. At the end of the day, we’re an e-commerce business. I talk a little bit about print, but I find that if you go into that side too much, their eyes glaze over whereas if you talk about the internet, they’re totally with you.”

Thirty-two years ago, Richard began his print career as an apprentice at Graham & Heslip. He came up as a print finisher, working across various businesses including the Northern Whig newspaper, where he stayed for 11 years. He worked his way up to Production Manager and when he left, he transitioned into the digital side of the industry. The biggest change he’s seen in his 32 years is the move away from litho. “When I started, I was working in a B1 litho printer. It was one of around nine in Northern Ireland at the time; now we’re down to two. That just shows where the print sector has gone over the past three decades. The B2 market

We

might do better and maybe it’ll take longer, but it can be done. The demand is there and we’re ready to grow

In 2011 Richard, along with Gary and Neil White, bought Northside Graphics. They launched their first online brand in 2013. Over the past 11 years, it’s gone from a £2.5 million business to a £10 million business. “All that growth is thanks to the online business. We were selling the right thing in the right space at the right time. Since then, digital print has only continued to grow.” The Bestport acquisition earlier this year has given the firm the expertise and tools to grow. Gary and Neil White are still involved in the business but to a lesser degree, while new Chairman David Mitchell has brought a new perspective to the business. “David is ex Astron and his expertise has been invaluable. The acquisition has allowed us to invest in the new Iridesse and recruit new senior staff, including a new finance director and marketing manager. The digital print market is huge, particularly in the UK. There are so many opportunities there and now, we’re well placed to take advantage of them.”

Investment in the Xerox Iridesse will allow the print firm to bring longsheet work in-house. “When we looked at the amount of work we were outsourcing and the lost profit associated with that, it was a nobrainer. The machine will pay for itself in less than two years.” The new press will also allow the firm to expand its capabilities. “Foiling is the obvious one – foiling doesn’t work with our Indigo machines, but it works with dry toner which we now have with the Iridesse.”

Richard’s ambition is to double turnover at Northside Graphics over the next two to three years. “I know it’s a big statement and whether we do it or not is another thing, but that’s our aspiration. We might do better and maybe it’ll take longer, but it can be done. The demand is there and we’re ready to grow.”

Brian Breheny at Antalis Ireland chats about embracing digitisation and bringing more choice of materials to the industry

How is the Irish print industry performing?

The Irish print industry is now a modern, well-diversified sector that caters to all segments of the Irish economy – tech, pharma, food, retail, education, health etc. It is performing well in many different sectors where we see opportunities. Packaging and sustainable signage products are just two areas of focus for us.

What do you see as the main challenges facing print firms?

Hiring skilled staff and increasing business costs.

What are the ambitions at Antalis in 2024 and beyond?

We have a strong ambition to grow by bringing more choice of materials to the industry. Antalis is constantly updating its product portfolio to offer, for example, more sustainable products. New products and services will also assist customers in being more efficient and even help them diversify into new markets. We have also embraced digitisation and e-commerce to make buying from us easier for our customers. We have a webshop at antalis.ie where customers can conduct system-tosystem ordering.

Are there new segments that you want to expand into?

We have ambitious growth plans for our packaging and visual communications businesses. The recent appointment of Iain Cunningham as Head of Packaging in Ireland is a great example. Iain will be instrumental in expanding the company’s market share across Ireland’s packaging sector; his extensive experience makes him exceptionally well-suited to drive growth in this sector.

Antalis Packaging already supports customers across Ireland; we can work with anyone who wants help packing, protecting, storing, dispatching or transporting goods, both new and existing packaging customers.

What are some of the new products/technologies that Antalis has launched this year?

We have launched quite a few new products in 2024. One of the things that stands out is the new Ultima GC1, a blue-white premium paperboard that is FSC® certified. This sustainable paperboard is coated on both sides and is made with a high percentage of SBS pulp, which offers numerous benefits such as high stiffness and a smooth top surface.

Another popular product is Xanita aspect, an innovative paper-based board with high strength and rigidity designed exclusively for the wide-format printing industry. It sets a new standard for eco-friendly signage solutions, exhibition and POS work and offers a superior alternative to conventional honeycomb boards.

Antalis has recently refreshed our renowned ranges of Curious, Keaykolour, Olin, Rives and Conqueror brands from our creative papers range. These innovative, premium papers offer a breadth and depth of tactility, impactful colours and eye-catching effects that are perfect for creating standout. What’s more, all Antalis’ creative papers are carbon balanced by us as standard, via World Land Trust.

Antalis Packaging already supports customers across Ireland; we can work with anyone who wants help packing, protecting, storing, dispatching or transporting goods, both new and existing packaging customers

How important is sustainability at Antalis and what steps are you taking to lower your carbon footprint?

Sustainability is critical to us. Paper is one of the most sustainable products in the world today. Over 70% of our suppliers are registered on Sedex and/or EcoVadis platforms and 88% of our paper products are FSC® certified. In April, Antalis Group was awarded a gold medal under the EcoVadis assessment for our sustainable performance. This puts us in the top 5% of companies accessed worldwide by EcoVadis. Antalis also recently published its ESG 2023 report, which confirmed our ongoing commitments to the environment, social responsibility and governance. The company has implemented strategic actions and made tangible improvements to demonstrate our commitment to integrating sustainable practices throughout our operations worldwide.

A new exhibition at the National Print Museum uses letterpress and linocut printing to portray an area of Dublin and its inhabitants

Running from 12 November – 20 December 2024, a new exhibition at the National Print Museum showcases artist Susan Leen’s book, ‘Rinn Aun – The Place of the Tide’, which is inspired by the neighbourhood of Ringsend and its relationship with its maritime environment. Leen’s book uses letterpress and linocut printing to portray the stories and memories of local inhabitants, collected through weeks of interviews. The book is printed letterpress on the Museum’s Vandercook No. 4 and bound using traditional techniques. The exhibition will examine the design processes used by Leen in making the book. Typography, linocuts and other

The book is printed letterpress on the Museum’s Vandercook No 4 and bound using traditional techniques

elements celebrate the historical diversity of sea life in the area and contrast it with the present situation of the community and ecosystem. It will feature various artists proofs and sketches, exploring why certain choices in design were made and how these choices can prove to be impactful communication tools. The exhibition is supported by the Design & Crafts Council of Ireland and will launch for Irish Design Week 2024.

The process of swapping packaging from plastic to fibrebased materials now has a name. But what exactly does it mean? Two Sides investigates

Demand is driven by the growing desire of consumers, brand owners and governments, to replace single-use fossil-based plastics with more sustainable packaging alternatives

There’s a new word in the print and packaging industry. Whether it’s in the agendas of board room meetings or discussions at industry events, ‘paperisation’ is being hailed as the latest trend in packaging. Defined as the increased use of paper-based materials, often switching from fossil-fuel-based materials, you could argue that paperisation has been around for years. The process of swapping plastic for fibre-based materials has dominated the packaging industry, with supermarket aisles now full of food, drink and FMCG products stored and displayed in recyclable and compostable paper and card. And the trend isn’t going away anytime soon.

The rise in paperisation – or ‘paperfication’ – was very much in evidence at London Packaging Week 2024, where conversations included the use of paper in secondary packaging applications such as stretch wrap, adhesive tape and packing materials.

Among the many fibre-based secondary applications on show were Seaman Paper’s SeaStretch, a manual wrapping material that can also be used as filler for stuffing boxes, filling voids and providing protective cushioning. Produced using paper sourced from responsibly managed forests, SeaStretch has a stretch capacity of around 30%.

Another interesting material at the event was Ranpak’s RecyCold climaliner, a recyclable, renewable and biodegradable paper-based product that offers sustainable thermal protection for temperature-sensitive food and drinks for up to 48 hours.

Of course, the most visible result of paperisation is in primary packaging and the number of brands and products shifting their packaging across to paper and card is getting

bigger by the day. The latest names to make the switch include Amazon, which is replacing the plastic bubble wrap in its envelopes with protective paper lining and Marks & Spencer using paper-based packaging for its garlic baguettes.

This increased demand for paper-based materials is expanding the market for biodegradable and compostable packaging. A recent Smithers report concluded that the global market is forecast to grow at 8.8% CAGR to 2029, reaching an incredible 11.7 million tonnes.

“Consumption of biodegradable and compostable polymers for packaging will continue growing at a faster rate than petrochemical-based thermoplastic materials,” states the report. “Demand is driven by the growing desire of consumers, brand owners and governments, to replace single-use fossil-based plastics with more sustainable packaging alternatives.”

Of course, there are many business benefits to ‘paperising’ your packaging, with a number of reports concluding that switching to fibre-based packaging is not only good for the reputation of a brand, but also its bottom line. A survey conducted by GlobalData in 2023 found that 74% of consumers are willing to pay more for eco-friendly packaging, while the Two Sides European Packaging Preferences 2020 study found that 46% of respondents buy more from retailers who are removing plastic from their packaging.

For those who work with packaging day in day out, the trend of paperisation may not be anything new, but the fact that it now has a name means that companies all over the globe are taking the sustainability of their packaging very seriously. Which is a very good thing for both the industry and the world in general.

The business was founded by my parents Brendan and Gina Dooley back in 2000. As a family business, I was often roped into helping out throughout my teenage years. I went on to study Graphic Design (Visual Communications) in TUD and then pursued a Masters in Design in NCAD. As print and graphic design go hand in hand, it was an organic move to join the family business full-time in 2019.

The funny thing is, when I was younger I never saw myself joining the family business. I had my sights set on doing my own thing and making my own mark in the world. I guess children often think what their parents are doing is in no way interesting or cool. When I returned home in my late 20s after education and a little travel, I saw the business with a new perspective. I understood that the enterprise, even though small, was trailblazing in terms of sustainability. From the early days, plant-based ink and rainwater were used in the lithographic printing process and there was always consideration given to sourcing papers responsibly. This was done, not for any inherent commercial gain, but because it was the right thing to do. That mindset of questioning the status quo is still very much present in the organisation and this is what I like most about working at The Factory. It is incredibly fulfilling to work at something that has a sense of purpose.

It’s always been at the core of the business. In the early days, it was more in the background. My dad tells stories of being called a ‘hippie’ after telling clients of certain sustainable measures being implemented. This was, of course, before there was a general awareness of the importance of sustainable development like there is today. In more recent years, the goal is to share our sustainability journey in the hope that it could potentially inspire other businesses to make positive change. We want to prove that pursuing sustainability is not only the right thing to do, but it’s also good for business. There’s the obvious cost-saving to be gained through being careful with resources and mitigating waste,

As 80% of a printed product’s carbon footprint is determined at the design stage, we developed a sustainable graphic design methodology which we call The FACTORY Method

along with energy saving, especially if you generate your own energy. There’s an initial investment in time and money but by thinking long term and managing a business in-line with the ‘triple-bottom-line’ (people, planet and profit), you get a much more efficient, futureproofed operation. Sustainability underpins everything we do. We are generating most of our own renewable energy, we manage land for biodiversity and we promote workplace wellness. We also ensure all of our operations are as sustainable as possible by sourcing the most environmentally friendly materials and we provide our orders in plastic-free packaging. As 80% of a printed product’s carbon footprint is determined at the design stage, we developed a sustainable graphic design methodology which we call The FACTORY Method. We have published the method on our website so it’s open source and available for others to implement. See: thefactory.ie/the-factory-method

In terms of professional success, I think it’s fostering the importance of sustainability amongst our team and encouraging them to play their part in realising our vision for the business. I truly believe we can achieve so much more when working with others. When I joined

the business in 2019 as Creative Director, the team came together and developed an eco action plan. This was basically a detailed list of actions that were focused on being as sustainable as we could. We ticked off each item one-by-one and in the relatively short time of two years, we were producing 65% of our energy on-site with a solar array and small wind turbine. We also began managing our surrounding land for biodiversity by planting native trees and sowing wildflower seeds, along with installing an owl box and five beehives. Workplace wellness was also prioritised as we switched to a four day work-week and implemented what we call ‘Wellness Wednesdays’. On Wellness Wednesdays, we do yoga or go for a walk or play a game for 30/45 minutes in the morning to foster wellbeing and team morale. I am so proud of what we have created here at The Factory and this success was only possible by working together.

your dream job? Or are you currently in it?

When I completed my education I realised I wanted to do two things – to work in collaboration and to do something with a sense of purpose. I was so fortunate that I had the opportunity to create my dream job rather than searching for it. This is also down to my parents being open to change and new ideas, not to mention being so progressive themselves. I should also say this role has been so rewarding because of the supportive and talented team I work with, along with the wonderful clients and exciting projects that come our way.

We want to prove that pursuing sustainability is not only the right thing to do, but it’s good for business

This is such a difficult question as I could name so many films but the one I am going to mention is an old black and white film from 1957. I mention it as not too many people have seen it… or remembering seeing it! The film is called ‘Twelve Angry Men’ and the whole movie is filmed in just one room. Despite this, you are gripped from start to finish. Such fantastic dialogue, well worth the watch.

Again such a tough question, but this one I cannot answer with just one mention. I love Bob Dylan, Joni Mitchell, The Beatles, Patti Smith and Leonard Cohen. You can also throw in some 90s icons like Radiohead, Nirvana, Mazzy Star, Blur and Oasis. More recent artists that I listen to are an eclectic mix – Lisa Hannigan, Andrew Bird, Pheobe Bridgers, Mick Flannery, The National, Courtney Barnett, Sufjan Stevens, Bibio, Fionn Regan, Villagers, Bon Iver, Fontaines DC and there is lots more I am forgetting!

My son. He is not even two yet but he already has the best sense of humour. I think he gets it from his dad, but don’t tell him I said that!

Perhaps the ability to remove carbon from our atmosphere or stop our planet from heating up, essentially the ability to save the world I guess. That would be nice.

I would like to be remembered as being true to myself and kind.

What you make it.

The right tools will help print firms and wrappers turn a client’s vision into reality, writes TERRY RAGHUNATH

With its ability to produce instantly dry output, users benefit from being able to print and cut in parallel, while its white ink option allows customers to explore a wider range of wrapping options

Vehicle wrapping has emerged as one of the stand-out growth areas of recent times, with those in the market taking full advantage of increasing demand for this sort of work. Demand has increased partly due to a spike in interest from private customers, with more clients approaching print service providers with ideas of how to wrap and decorate their own vehicles.

With this has come all manner of innovations among print companies and wrappers as they seek to stretch the boundaries – and indeed the vinyl and films they work with – to decorate everything from cars, vans and lorries to motorcycles, boats and even rockets.

While the possibilities are seemingly endless, the onus is on print companies, wrappers and anyone else in this sector to ensure they are in a strong position to support customers with their ideas and help turn their visions into a reality.

HP recently hosted a dedicated webinar on this exact subject, exploring the ways printers and wrappers can grow their business. The session looked at growth within the wrapping sector in recent years, including some of the most important trends those in the market need to be aware of and took a closer look at some of the technology from HP to help them along their way.

There was insight into how to build and grow a successful wrapping business from Justin Pate, Chief Executive Officer of US-based The Wrap Institute. Having started out working as a freelance wrapper in New York in the mid 1990s, specialising in wrapping tour buses for hip-hop stars, Justin has evolved his business over the years to the point where it now employs a team of staff working on all manner of projects for high-end clients such as global music megastar Rihanna.

Speaking about building his business, Justin referenced a somewhat unusual analogy, comparing a wrapping facility to a restaurant or cafe. He said making customers feel the same way about the wrapping shop as they do their favourite restaurant will encourage them to return time and time again.

He went on to set out more similarities between the culinary and wrapping worlds, suggesting that

elements of a wrap shop can be tied in with how a restaurant operates. For example, he set out how the wrapping services you offer are similar to a restaurant menu; some are basic but can be produced more easily and at a lower cost, allowing you to make a painless profit.

One particular analogy he used is a Caesar Salad. One of the most common dishes on menus across the US, this starts out as a relatively basic dish and is simple to produce but can also be customised and expanded with other ingredients – similar to additional options on wrap jobs such as chrome films and handle and wing mirror wraps.

Of course, to produce such delights, you need to have the right kitchen and ingredients – or printer and consumables if you prefer – to hand. Focusing on this, the webinar delves into some of the options available from HP, primarily within its HP Latex division.

First up is the HP Latex 800W, which allows users to print vehicle wraps at speeds of around 18sq m/hr in quality mode. The machine can print on media as wide as 1.63m. With its ability to produce instantly dry output, users benefit from being able to print and cut in parallel, while its white ink option allows customers to explore a wider range of wrapping options.

Also highlighted in the webinar are the HP Latex 2700 and HP Latex 2700W printers, both of which can print on two rolls running next to each other. The machines have the ability to print on a host of materials including vinyl, with both devices having a top speed of 69sq m/hr for four-pass printing in indoor signage mode, 49sq m/hr at six-pass in quality signage mode and 38sq m/hr at eight-pass in high-quality SAV printing mode.

To view the ‘Become a Master of Wrapping with HP Latex’ webinar in full, click here: https://largeformat.hp.com/uk/webinars?bmtid=gb-fy24-gsb16843-2&jumpid=af_gb_af_mk_zi_ gb-fy24-gsb16843-2_aw_xsource=lfr&medium=mastersofwrappingblog

Terry Raghunath is Business Development Manager at HP

Mark Needham’s first role in the print industry paved the way for a career that’s about pushing creative boundaries

It seems like a lifetime ago, but my first job in print was as a point-of-sale designer at Smurfit Kappa Display. Coming from a background in structural drafting, it was a bit of a sidestep, but it provided me with a unique opportunity to gain a strong foundational understanding of the design and print industry. The role involved learning the intricacies of design from senior structural designers and the technical aspects of printing from printers and graphic designers. Having worked for the Smurfit Group on two separate occasions, this first time was for a little over six years.

The biggest lesson I took from the experience came from observing senior staff members, who consistently emphasised the critical importance of attention to detail. They may not have realised it then, but I was paying close attention and learning from their approach! In print design, even the smallest error can compromise the quality of an entire project, making a meticulous approach essential.

What I enjoyed most about the role was the comradery, the learning curve, the brainstorming of ideas and the satisfaction that came from

transforming abstract concepts into tangible, wellexecuted products. The team I worked with functioned seamlessly to fulfill design and print projects. Our collaborative environment led to some fantastic ideas coming to life and even resulted in winning a Smurfit Design and Innovation award on a European stage. However, the challenge of aligning client expectations with the practical limitations of print and material capabilities sometimes made the job demanding. Nevertheless we persevered, and these challenges provided invaluable lessons that sharpened the teams’ problem-solving skills and instilled a determination to persist until a solution was found. Ultimately, the whole experience whetted my appetite for a career in print and design. It inspired me to pursue further growth in the field, learning from industry experts while continually exploring new techniques and pushing creative boundaries –even to this day.

Mark Needham is Structural Designer at Rostrum Design

Our collaborative environment led to some fantastic ideas coming to life and even resulted in winning a Smurfit Design and Innovation award on a European stage

This revolutionary inline trimmer handles everything from business cards to oversized sheets with precision. It slits, trims, perforates, creases, and delivers full-bleed output for professional results.

first of its kind

•Full Bleed

▪ Brochures 4 / 6 / 8 page

▪ Business Cards

▪ Pro Quality Postcards / Posters

▪ Concert Tickets & Coupons

•Seamless Integration

• Cost-Effective