AMBITIOUS PLANS FOR GROWTH AT EBB GROUP

AMBITIOUS PLANS FOR GROWTH AT EBB GROUP

Handled with care

Fully qualified, friendly drivers trained in paper and board handling ensure your order arrives safely.

EBB Service is based on investment in state-of-the-art route planning, real time vehicle tracking and the latest vehicles that comply with Euro 6 emissions standards meaning increased engine efficiency, better fuel economy and reduced CO2 emissions.

Delivered with care

We take responsibility for your order until the moment it’s delivered to you.

Next day and, in some cases, same day deliveries from our warehouse straight to your door (no third party involved).

T: +353 1 401 0008

E: dublinsales@ebbgroup.com

T: +44 28 9600 1480

E: belfastsales@ebbgroup.com

The paper and board industry witnessed a significant downturn in production and consumption in 2023, more severe than during the pandemic, according to the Confederation of European Paper Industries (CEPI). The organisation pointed to a 13% drop in paper and board production among CEPI member countries, totalling 74.3 million tonnes. Consumption also fell by 15% compared to the previous year, a decrease that’s being attributed to external factors such as a challenging economic environment, prolonged destocking by industry customers and high energy costs. That decline in paper is being felt right across the industry, says Chris Sandwell, Group Sales & Marketing Director at EBB Group. Diversification into other areas means the company isn’t reliant on the paper side of the business; going forward the consumption of board looks very promising and there are other avenues to explore in 2024. Since purchasing UniBoard in 2019, EBB Group has increased turnover from €15 million to over €30 million. Capacity across both its Dublin and Belfast operations has also increased and employee wise, numbers have gone from nine to over 30. For more on EBB’s success in Ireland and its plans going forward, turn to page 19. Elsewhere in this issue, we take a look at new technology at Anglo Printers and a new exhibition at the National Print Museum. On page 14, Quentyn Taylor at Canon outlines how print firms can reduce the threat of cyber attacks in 2024 and on page 22, Ella Faulkner answers the question – how do you know what prices to set for your products and services?

As always, we’d love to hear from you. If you have any thoughts on this issue, please drop us a line at editor@irishprinter.ie. Enjoy!

Ideally located 5 minutes from the M50, 2 minutes from the M3

With 48,000 square feet spread across two warehouses, we provide Expert Packaging Solutions and Trade Finishing Services such as: Laminating | Die Cutting, Window Patching | Gluing & Handwork

TEL: 01 254 1985

E: patrick@venturefinishing.ie

| www.venturefinishing.ie

In recent years, Antalis has been showcasing its range of sustainable substrates for traditional POS and display applications by using them to create every element of its own exhibition stands. An early example, Sustainable Street, was created for display at the VM & Display Show and subsequently won the top prize for sustainability at the World Exhibition Stand Awards. Over the past few years, exhibitions have come under scrutiny for the volume of waste they produce. A study by Ecobooth revealed that 100,000 tonnes of waste was burnt or sent to landfill from the UK events industry in just one year. Specification Consultant at Antalis, Claire White, said: “Waste and sustainability are clearly huge challenges for the events industry; as exhibitors ourselves, as well as suppliers of substrates for exhibition stand manufacture, we have been working hard to find solutions to this issue and I am delighted to say that we’ve experienced some incredible successes.”

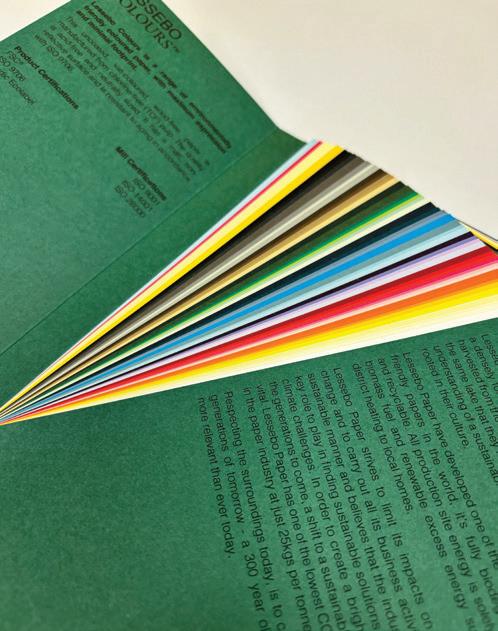

EBB has added a new range of environmentally friendly, uncoated, coloured paper to its portfolio. Lessebo Colours comes in 48 shades and is manufactured by Lessebo Paper at its mill located in a densely forested area of Småland, Sweden and is, says EBB, one of the most climate-friendly papers in the world. At the mill, timber is harvested from the same forest and water is used from the same lake that they have been using since 1693. Lessebo Paper also has one of the lowest CO2 emissions in the paper industry, at just 25kg of CO2 per tonne of paper. EBB is stocking 40 colours plus a Design White, with the option to order the remaining eight shades from mill stock. The range is available from 80gsm to 350gsm in a variety of sizes and there’s also the option to have stock embossed with one of 18 di erent textures.

Mimaki’s first DTF (Direct to Film) printer, the TxF150-75, has surpassed the milestone of 300 units sold across EMEA. With the highest sales in the UK, France, Italy, Iberia and the DACH region, the company says this fastpaced adoption of the TxF150-75 not only demonstrates the quality of the printer, but also the rising popularity of the DTF printing method. The unit o ers a solution to common DTF issues such as poor ink ejection and white ink clogging, through its built-in circulation system and degassed ink pack. It also provides an e icient printing process with minimal need for intervention, filling the gap in the market for a stable, reliable DTF solution. Mimaki also announced the TxF300-75 in August 2023, which features all the same capabilities of the TxF150-75 but

Late last year, Sappi announced that it was ceasing production of paper at Lanaken Mill, situated on the Albert Canal in north-eastern Belgium. The company stated that the persistent global economic downturn is proving to be much tougher than anticipated with depressed markets, geopolitical instability and weak economic growth, combining to put significant pressure on Sappi, particularly in Europe. The closure of the site will complete in the

Experts predict that by 2026, the market for direct-to-film (DTF) printing will be worth an estimated $1.7 billion, due in part to the increasing demand for more intricate and customised designs

has a maximum print speed that’s three times faster. With 100 orders to date, the company is also seeing significant interest in this system.

second quarter of 2024 and details regarding the financial impact once all closure elements are taken into account will be provided during the first quarter financial results announcement. Sappi says its focus now includes reducing exposure to the graphic paper segment while expanding its presence in packaging, speciality papers, pulp and biomaterials.

“While continuing to serve the graphic

paper market through its competitive assets, the overall priority of the European business will be to grow the packaging and specialities segment specifically within flexible packaging, functional papers, self-adhesives including glassine, labels as well as dye-sublimation categories. The transfer of production to other Sappi facilities increasing capacity utilisation has commenced and there will be no disruption to our customers.”

Features

Agfa launches its hybrid Anapurna H3200 Inkjet Printer

Agfa has introduced the next generation of its Anapurna H3200 wide-format hybrid printer, boasting an almost 70% increase in printing speed compared to its predecessor. Agfa says the newest version of the 3.2m Anapurna H3200 is ideal for sign shops and digital printers, empowering them to swiftly tackle a wide range of print jobs.

The new Anapurna H3200 made its debut at the C!Print exhibition in Lyon and featured alongside Agfa’s Tauro H3300,

Duplo launches new booklet maker

Ideal for medium to high volume production, Duplo’s newest booklet maker delivers a versatile range of applications such as A4 landscape, catalogues, textbooks and calendars with automated precision, on demand up to 5,200 booklets per hour. The DBM700 is available with two or four stitching heads and gives a perfect-bound look and feel, according to Duplo. The company adds that the system represents a leap forward when it comes to expanding customers’ capabilities while achieving exceptional results, adding that it costs about 20% more than its predecessor, the DBM-600. Aimed at users looking for a step-up in automation, Duplo says the new booklet maker helps users create high-quality booklets with ease, streamline their operations and improve revenue.

» Six-colour plus white ink set and UV LED curing

» Print shuttle and print engine redesigned to achieve significant productivity increase

» Fast-firing print heads ensure rapid throughput – up to 66 m2/hour in production mode

» Superior print quality on flexible and rigid materials

» Continuous board feeding capacity

» Capability to print up to four boards printed simultaneously

» Improved image quality, particularly noticeably in darker solid tones

HS. Additionally, Agfa will showcase the advanced capabilities of the new Anapurna hybrid printer at FESPA in Amsterdam on 19-22 March.

DBM-700 – the details

» Max Booklet Thickness: 6mm (30 sheets of 80gsm, 120 page book)

» 10mm (50 sheets of 80gsm, 200 page book) when using DBM-700S

» Flat Sheet Size: Max: W 356mm x L 610mm Min: W 105mm x L 170mm

» Finished Untrimmed Booklet Size 1-up Production: Max: W 356mm x L 305mm Min: W 105mm x L 85mm

» Folding Capacity: 2-30 sheets. 50 sheets with DBM-700S

» Max Stitching Capacity: 5mm (50 sheets of 80gsm)

» Stitching Heads: Standard Fitting: 2x Hohner 43/6S

» 2x2 stitch

» Optional 4 Hohner Flat/Loop Heads

Konica Minolta has launched the Plockmatic MPS XL, a multi-purpose stacker capable of stacking a wide range of media sizes. The company says this long-sheet stacking greatly expands the banner-stacking capabilities of the company’s AccurioPress color production machines. The new Stacker can dock and undock from the production press system, while a stacking table that can be operated while undocked from the press – when connected to power – provides easy lifting, transportation and managing of heavy paper stacks. The new product is currently compatible with the Konica Minolta AccurioPress C14000, C12000, C7100, C7090, C4080 and C4070 digital production presses.

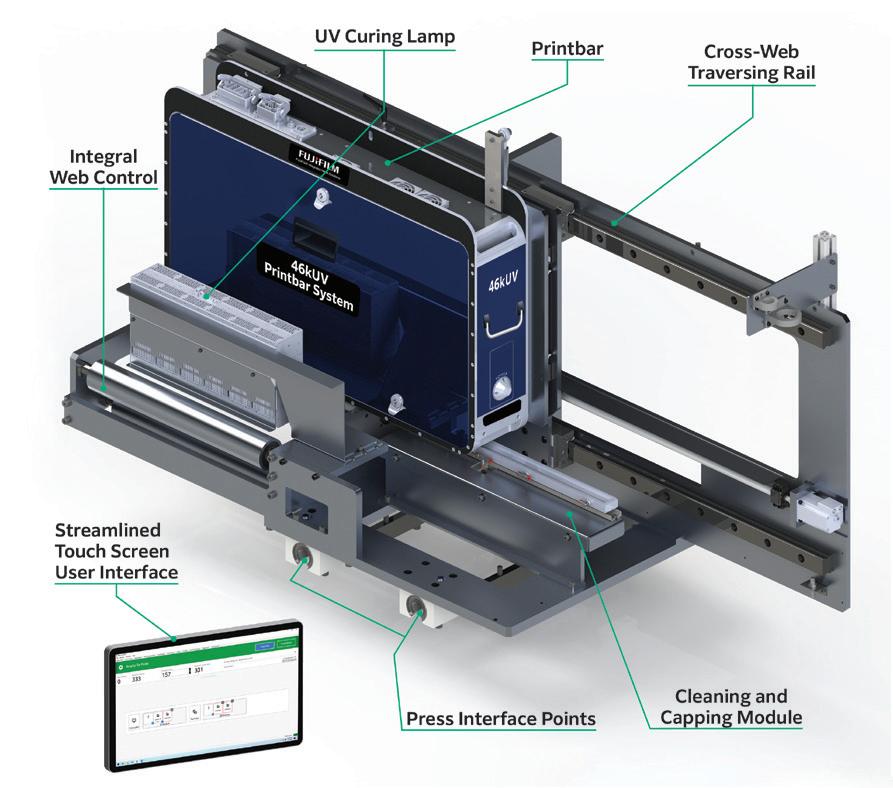

Fujifilm has announced the launch of its 46kUV Inkjet Printbar System, a new, integrated print solution for industrial production operations across a wide range of labels and packaging materials. The new System features a drop-ondemand design to streamline workflow with fast, industry-leading printing speeds of up to 150m per minute. It uses Fujifilm’s SAMBA printhead technology which, says the company, leverages the precision of silicon MEMS processing and sputtered PZT. The system also has a native resolution of 1200 dpi to cover a broad range of today’s label quality needs. It’s available in various print widths including 254mm, 330mm, 432mm and 508mm to integrate into traditional printing processes, minimising the need for extensive training and process changes.

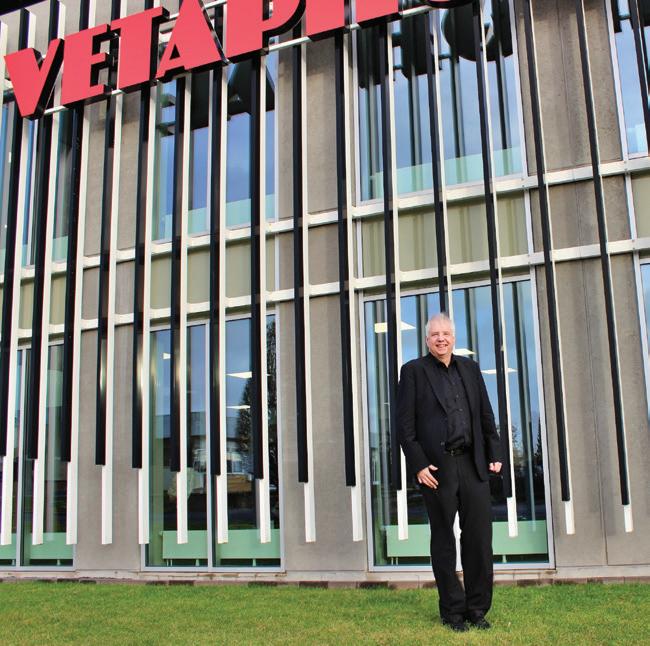

2024 marks Jan Eisby’s 25th year at Vetaphone, a family business that was established in 1951 by his father Verner. The company is represented in more than 100 countries around the world and since 1999, sales turnover has increased more than tenfold. “The packaging market has seen dramatic changes over the past 25 years with the growth of filmic substrates and the development of new printing techniques like digital that have replaced the more conventional o set, gravure and flexo methods in certain sectors. At Vetaphone, we have always invested heavily in R&D and that allows us to reflect these market changes by continually developing our technology – this applies to everything from narrow web corona to sophisticated plasma treatment systems for special applications, and many others in between,” Jan said. Looking ahead, Jan sees an exciting and challenging future for packaging with developments in new production techniques, new substrates, new ‘intelligent’ packaging products to match changing consumer habits and a marked improvement in environmental practices around the world. “Plastic now has a bad image in many people’s eyes, so it’s incumbent on those who work in the industry to change this perspective. That’s why Vetaphone has always believed in education because it is the only way that people, whoever they are, can make the right decisions.”

Northside Graphics has been acquired by a UK private equity firm

Northside Graphics has been acquired by Bestport Private Equity, a private equity investment firm based in London. Since 2010, Northside has been operated by Gary and Neil White who, aided by Managing Director Richard Campbell, have led the transformation of the business to focus on online digital printing. With a staff of over 70 Northside, who won three accolades at the Irish Print Awards in 2021, operates four ‘upload and print’ websites in the UK and Ireland – DigitalPrinting.ie, TradeDigitalPrint.ie, DigitalPrinting.co.uk and TradeDigitalPrint.co.uk. It’s expected that Bestport’s investment will help Northside to accelerate its Ireland and UK growth plans through a combination of organic growth and strategic acquisitions.

Former Astron CEO David Mitchell will assume the role of Chairman on the Board of Northside. Mitchell previously acted as Chairman in print and document management focused businesses M2 digital Limited, Euro Druck Services and Dublinbased pharma services business Perigord. Gary and

Neil White will remain as consultants and NonExecutive Directors within the Northside business, with Richard Campbell continuing as Managing Director. Richard Campbell said: “Our business has achieved exceptional growth and success in recent years and we have every confidence that this will continue going forward with Bestport as our majority shareholder. Bestport’s investment paves the way for further expansion and investment across all areas of the business, ensuring our customers continue to benefit from exceptional quality, service, the fastest turnaround times and an even greater range of innovative products.”

James Stoddart, Managing Partner at Bestport, added: “The demanding nature of the B2B market means dynamic businesses like Northside are well positioned to scale – especially given the fantastic business that Gary and Neil White have built, which puts the customer at the forefront of all they do. We’re delighted to partner with the Northside team as they continue their impressive run of growth and expand the business across the UK and Ireland.”

One of the industry’s leading and most reliable coated paper brands is now available from GPMI.

Crafted in Italy at Cartiere del Garda

l Three excellent finishes, across a choice of over 250 sizes and weights

l Longstanding reputation for quality and reliability

l FSC® certified Paper & Materials, Delivered Nationally gloss silk velvet

CoverUp has invested in an EFI Matan 5m UV LED dedicated roll-to roll printer from CMYUK

Dublin-based print firm CoverUp has added an EFI Matan 5m UV LED roll-to-roll printer from CMYUK to its line-up. In 2022, the firm acquired an EFI VUTEk Q5r, also from CMYUK, which has significantly boosted its production efficiency allowing for faster turnaround times and greater volumes. It joins a plant list that includes a 3.2m UV LED digital flatbed printer, dye sublimation technology, CNC router and a digital cutting table.

The Matan 5 replaces an older HP printer and is designated for all of CoverUp’s mesh printing needs. “We decided to dedicate the Matan 5 to mesh because it’s a challenging material that tends to create a lot of overspray,” says Anthony Byrne, Operations Director at CoverUp. “This way, we avoid exposing the Q5r to any of these issues.”

CoverUp was the first in the world to purchase an EFI VUTEk FabriVU 340i in-line dye sublimation printer in 2018, when it replaced an M-Tex printer. Over the years the firm, which is one of the country’s largest finishers of banners and building wraps, has built a trusted relationship with CMYUK for its materials supply, so when it came to purchasing a new EFI VUTEk Q5r, there was never any doubt about where to go.

When looking for a printer dedicated to mesh work, Anthony contacted Sue Hayward (Commercial Director, CMYUK) for some advice. He didn’t have the budget for a new model, but wondered whether CMYUK had something to offer from its exdemonstration, second users or refurbished large format printing equipment. Sue located a refurbished Matan 5 printer from EFI and arranged an online virtual demonstration for Anthony, given the printer was in Israel. After witnessing its impressive

performance with mesh, Anthony immediately decided to purchase it. A fast installation was crucial, so CMYUK delivered and installed the printer in five weeks.

On-site training went very smoothly. “We were well up with it since the RIP was the same as the one used by the Q5r, so there wasn’t much new to learn. We just had to get used to the loading and cleaning processes. By the end of the first day, we were operational and even started printing specific jobs. When it comes to maintenance, mesh requires more frequent filter changes due to its messier nature. Other than that, the maintenance is pretty much the same as the Q5r,” he says.

Previously we were managing two rolls a day, but can now complete five to six

The EFI Matan 5 offers output up to 353 sq m per hour with a true resolution of 600dpi. It supports a portfolio of Matan optional features and software, which can transform it into an all-in-one multi-purpose printer. Additionally, a single operator roll loader maximises efficiency by 300%, ensuring that only 40cm of material is wasted per roll, boosting savings and overall productivity. “After installing the Matan 5, the speed of our mesh output work has tripled. Previously we were managing two rolls a day, but now can complete five to six,” says Anthony.

The investment has enabled CoverUp to expand its customer base and enhance throughput speed. “With the addition of the Matan 5 to our production, we anticipate this positive trend going forward. We’re pleased to serve as a dynamic print supplier to the trade, operating behind the scenes. Furthermore, our extensive finishing services guarantee that we can meet all customer requirements comprehensively.”

Anglo Printers has invested in a MBO CoBo-Stack from Komori – a completely automatic collaborative robot that needs no protective cage. The robot delivers perfectly stacked pallets of printed products post folding; it picks up the stacks from the table and deposits them on pallets, reducing physical demands on operators. The pallets can be positioned on both sides of the delivery, allowing for uninterrupted operation. While the MBO CoBo-Stack is filling one pallet, the operator can move the loaded pallet away and prepare the next empty pallet.

Along with the robot, Anglo has also purchased the new 100th anniversary edition of the MBO K-80 Super KTL Folding Machine, with A80 Delivery.

According to Managing Director Padraic Kierans, the new equipment means shorter delivery times, high precision folding, mark free delivery, automatic stacking and convenient operation.

Investment in new technology at Anglo Printers is allowing for greater e iciencies and outputs

The Apressia delivers a brilliant, fast and very productive paper and board cutting and stacking system

Investment in a new Komori Apressia CTX132

Guillotine Flowline, a system that incorporates six machines combined into one flow, is also allowing Anglo to further automate its processes. “The Apressia delivers a brilliant, fast and very productive paper and board cutting and stacking system. Using Smartcutter, our prepress team send JDF info from our prepress workflow to the Apressia and the cuts are performed automatically, without any human intervention post loading. It’s an excellent system and we’re delighted with its efficiency and output so far,” says Padraic.

The Apressia CTX132 Guillotine Flowline is a combination of six machines – Apressia Lift 127, Apressia Paper Jogger 114L, Apressia CTX132, Apressia Turning Gripper BDG3e, Apressia Front Table Loading BAVB and Apressia Unloader 120. The six machines work as one to bring automation and robotic assistance to the guillotining of print jobs. It is, says Padraic, the first of its kind in Ireland.

The system can receive CIP3/4 data files from the prepress department, setting out precisely how the cuts are to be positioned for a particular job. Then, all the necessary data is sent to the Flowline for automatic cutting and removal of paper waste for recycling. Sheets are then pushed in and out of the Guillotine before moving to the Unloader for folding or packing.

The arm of the Turning Gripper is robotic and enables fully mechanical lifting and turning of the paper pile in the Guillotine bed. This automation will, says Padraic, bring huge benefits to Anglo Printers. “It will speed up production and enable us to guillotine larger jobs much quicker and more accurately. It also frees up staff to work on other jobs and machines, while the robotic sequences and task scheduling moves and lifts the paper through the guillotining processes.”

Quentyn Taylor at Canon outlines how print firms can reduce the threat of cyber attacks in 2024

As technology rapidly evolves, so do cyberattacks. Therefore, the biggest challenge for the print industry next year is to understand how their business is being targeted and information exploited, so businesses can work at pace to deliver ground-breaking innovation to reduce the threat and deter attackers. For instance, ransomware is a well-established technique used by cyber criminals that continues to evolve with new technology. In 2024, we will see the nature of ransomware become more diversified as criminals move down the value chain to smaller enterprises. Businesses can also expect the ‘dwell time’ of attacks to reduce dramatically, as attackers want to stay under the radar. This is because smaller organisations are easier to target, as they don’t have the robust resources or cyber resilience in place to establish a proper cybersecurity team or defence mechanisms. It is suspected that virtually every company will be impacted in some way in 2024 as ransomware criminals start to impact the smaller companies that make up the supply chain of the largest companies. Companies need to understand who is in their supply chain and how they can insulate themselves from this risk. This can be achieved by a combination of diversification/removal of single points of failure, as well as rolling training and assessments out to key critical parts of the value chain.

Despite the evolution of cyberattacks, businesses remain dangerously behind in the uptake of security technology. Many businesses still rely on outdated legacy infrastructure that provides limited protection and in some cases, is without any authentication or authorisation process. So, the first step towards robust cyber hygiene, is to become familiar with the cyber premise of your business and establish a foundational understanding of information security. By implementing the basics, businesses can protect their data from the free reign of cybercriminals. Simple measures include isolating printers from open networks, which makes it more difficult

Companies need to understand who is in their supply chain and how they can insulate themselves from this risk

By establishing a forward-thinking plan for their data, that includes quantum-safe algorithms and encryption, businesses can be on the front foot of their protection and stay vigilant to the rapidly changing landscape

for criminals to redirect the print route, with valuable information sent to their own device. Additionally, organisations should look to use different authentication methods for different types of data. Businesses must be clear about which of their assets require the most protection and isolate sensitive data from other vulnerabilities. Put simply, you wouldn’t use the same key to unlock a storage cupboard which also unlocks your safe. So, it’s essential that this same approach is taken with cybersecurity.

We’re already seeing crucial regulations taking place. For instance, in the UK the security industry has an encouraging outlook on 2024 with the PSTI (The Product Security and Telecommunications Infrastructure) Act, set to come into effect in April. This policy will enforce minimum security requirements for consumer IoT products and aims to improve the transparency of products that are compliant under the Act. This PSTI will also act as a preface to the developing Cyber Resilience Act (CRA) that is expected to be implemented in 2027. As a leader in information security, Canon is directly involved in the development of the CRA and is committed to advocating for increased industry action. As a result, Canon believes new regulations and policies for the technology sector must be developed with security at its core. Businesses should be able to make more informed decisions about the tools they are using and what protections are available. As regulation becomes stronger, we expect to see more vendors step into their duty of care and design products with not just innovation in mind, but security and accessibility as well. In 2024, Canon is taking its own measures to improve its cybersecurity offering. At Canon we continue to focus on expanding our toolkit so that we can provide our partners with an all-inclusive security offering. With the ISO 27001 certification in information security, Canon is dedicated to covering all aspects of information security, from policy compliance to proactive risk management and integrated defences – covering all bases for a robust and resilient workflow.

Artificial Intelligence (AI) will continue to dominate conversation in 2024 and will have its own implications for the security industry. Fortunately, AI has not yet transformed the nature of cybercrime, with most criminals using the same tried and true approaches.

Therefore, the advantage of AI technology, for now, remains on the side of the defenders. AI driven capabilities can help businesses identify and mitigate risks and automate the process of recovery and repair. However, it is important that with this new technology, businesses do not neglect the basics of a strong security infrastructure. Processes such as multi-factor authentication, patching and perimeter assessments, remain crucial in responding to imminent cyberthreats. When it comes to security and cyber hygiene, it is important to remain agile to emerging technologies. In the coming years, conversations around quantum computing will continue to develop. So, businesses will need to pre-empt the transformative effect that quantum computers will have on information security. By establishing a forward-thinking plan for their data, that includes quantum-safe algorithms and encryption, businesses can be on the front foot of their protection and stay vigilant to the rapidly changing landscape. In light of these developments, the stakes of cyber insurance are also much higher. Businesses should consider the full extent to which their current policies protect them from emerging threats and future technologies. As the lines of responsibility become more nuanced and the terms of cover differ from case to case, the true value of cyber insurance will be found in well-rounded services, such as breach investigations and ongoing risk management.

Looking forward to 2024, it is essential that all businesses prioritise cyber hygiene. Action should be taken immediately to implement basic defences such as multi-factor authentication and reviewing the logs that are already generated. Additionally, for businesses of any size, simplicity is key for a good cyber defence. Start by investigating your cyber footprint and understanding what your business looks like to an attacker. Don’t forget the suppliers and up and down stream suppliers who may also be targeted. By establishing a strong plan that covers all bases and sticking to it, businesses can be proactive in preventing cyberattacks. Finally, investing in the security skills of your workforce and ensuring all employees are familiar with the business’s defence is crucial. Once trained in cybersecurity, employees can act as your best line of defence as they will learn to mitigate risks when they arise.

Quentyn Taylor is the Senior Director of Information Security and Global Response at Canon EMEA

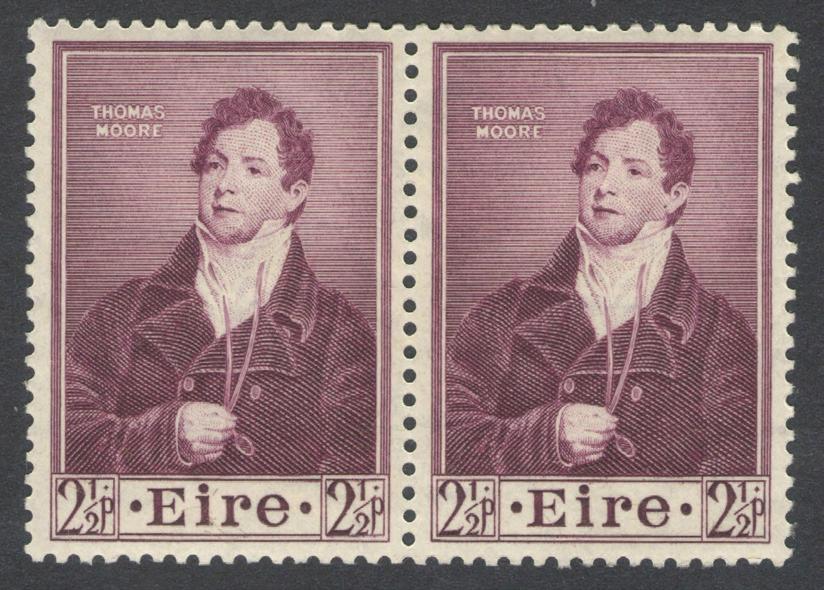

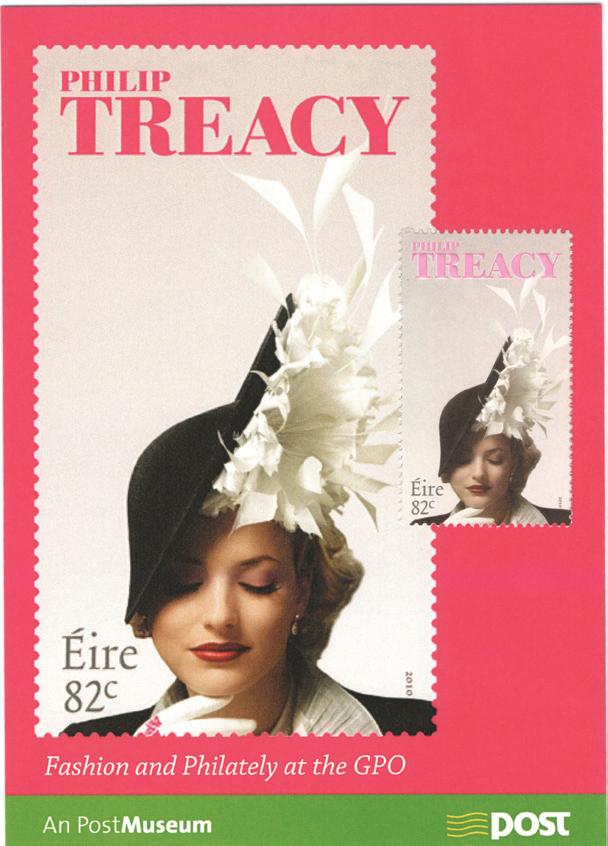

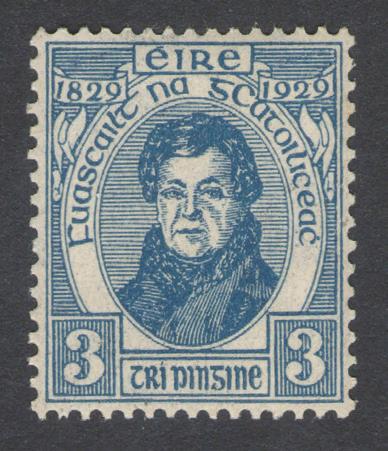

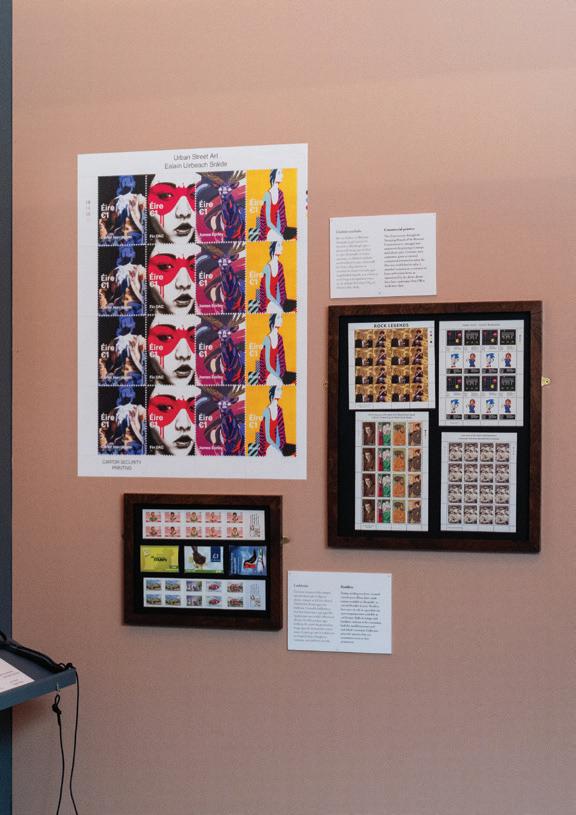

A new exhibition marking the centenary of Irish postage stamps is currently on display at the National Print Museum

A new exhibition at the National Print Museum explores the role of stamps in charting the evolution of Irish cultural identity over the last century. ‘Miniature Masterpieces: 100 years of Irish Stamps’ is a joint exhibition between An Post and the National Print Museum that celebrates a century of postage stamps in Ireland. Dedicated to the history, design and production of these miniature masterpieces and Irish cultural ambassadors, the exhibition displays not only a wide selection of Irish stamps but also original artwork, design proofs, printing plates and other treasures from the An Post Museum & Archive, some of which will be on public display for the first time. Supported by the Government of Ireland, Miniature Masterpieces will run at the National Print Museum until May 2024. Visitors will be able to view on a digital database the range of stamps issued by the Post Office since the printing of the first official Irish stamp in 1922 and chart the evolution of Irish cultural identity as represented in stamp design over the last century. From the official overprinting in Irish of British King George V stamps and the symbolism of the first Irish stamp designs in 1922-23, to today’s confident expressions of Irish identity in fashion, music and urban street art – the exhibition explores the changing interpretation of Ireland and its

‘Miniature Masterpieces: 100 years of Irish Stamps’ is a joint exhibition between An Post and the National Print Museum

culture through stamp design.

“This exhibition acknowledges the contribution of all involved in Irish stamp production but, above all, it pays tribute to the stamp itself and invites our visitors to take time to think about this unassuming fragment of coloured paper,” said the exhibition’s curator, Stephen Ferguson, who is the Company Archivist & Museum Curator at An Post. “At first glance, a stamp is just an everyday object in the corner of a letter but, on closer inspection, it’s a work of art, a symbol of identity and a unique prism through which we can view and reflect on the formation and development of the Irish State.”

Visitors will be able to view on a digital database the range of stamps issued by the Post Office since the printing of the first official Irish stamp in 1922

CEO of the National Print Museum, Carla Marrinan Funder added: “At the National Print Museum, we are dedicated to championing print and making its impact upon the world visible to all. Through our working collection of printing presses, we strive to preserve the knowledge and craft of letterpress and to draw attention to the presence of print and design in the overlooked objects we use every day. The Miniature Masterpieces exhibition does just this by examining the role of Irish postage

stamps in representing Ireland and its people over the last century and encouraging people to look differently at themselves and the world around them.

“It also invites visitors to consider the continued value of the postage stamp as a miniature representative of Ireland across the world and to envisage how it will continue to evolve in this digital age. We look forward to welcoming people of all ages to our exhibition and hope they will enjoy delving into the fascinating story of Ireland’s postage stamps.”

An illustrated exhibition booklet, Miniature Masterpieces – Cultural identity, artistic expression and a century of Irish stamps, by the exhibition’s curator, Stephen Ferguson, draws on additional material held in the An Post Museum & Archive and elsewhere to accompany what is the first major display of Irish philatelic material for many years. In response to the rich heritage of Irish design celebrated in Miniature Masterpieces, the National Print Museum has collaborated with graphic designer Niall McCormack and letterpress printer Mary Plunkett to create an original artwork. Inspired by the work of celebrated designer Patrick Scott and the distinctive Irish landscape, McCormack has designed a limited-edition letterpress print that responds to the design and printing processes found in Irish stamps. According to McCormack, it is a contemporary piece that captures the importance of the landscape to ideas of Irishness.

Produced by Mary Plunkett in a limited edition of 50 on the National Print Museum’s Vandecook #4 press, the print is available to purchase (€40) at the National Print Museum and online shop. All proceeds go to the National Print Museum, a registered charity.

We have taken turnover from € 15 million to over €30 million

Business is varied across the different sub-sectors of the industry. Since the start of 2023, we’re seeing a lack of demand and confidence in the paper market. On the paper side, we ended 2023 on a quiet note and that inactivity has continued into 2024. Over the past 18 months, the decline in consumption of printed papers across Europe has been well publicised and has had a significant impact on local markets. Last year alone, we saw a significant decline in paper across Europe; you would expect to see single digit decline every year but we’re seeing dramatic falls. On the packaging side, business has been affected by over ordering at end user level. That’s balancing out now and we’re going back to more normal levels of consumption. We’re very confident about the consumption of board; paper is less predictable and all we can hope for is a slow-down in decline. I don’t think we’ll see growth there.

We’re certainly concerned but from our perspective we believe that we will continue on our growth trajectory, whether that’s organically or through acquisition in Ireland or the UK. We are more diversified now than we have ever been and still very much focused on maintaining high local stocks and excellent service.

We’re into year five now and it’s been very successful for us. In that time, we’ve been able to double the size of the company and we’ve taken turnover from €15 million to over €30 million. We relocated our Dublin operation from its original premises into a state-of-the-art facility in Dublin and we also have a small operation in Belfast. Capacity has increased from 4000 pallets to 13,000 pallets of availability on the floor in Ireland, specifically for the Irish market. Employee wise, we’ve gone from nine to over 30 and that’s across the Dublin and Belfast facilities. With UniBoard, we inherited a business that used third party transport for its distribution. We flipped that and today, 95% of our distribution is carried out in-house. UniBoard has been a

great acquisition; it’s now fully incorporated and benefits from being part of the Group, but is still very much about local presence and management.

Recruiting can be a challenge but we’re fortunate in that we’ve got a very settled work team now, both in Dublin and Belfast. We’re not looking to recruit at the moment. Our focus is on developing the team and ensuring we provide customers with the very best service.

Our mill suppliers across Europe and the rest of the world are facing challenges around higher input costs. That’s having knock-on effects on the rest of the market, so we’re tasked with meeting the demands of our customers along with demands from our mill manufacturers. In the past 12 months, we have seen mills across Europe being forced

price of raw materials. Our customers are very important to us, as are our suppliers. As a stock merchant, we need buy-in from both.

You recently recruited a compliance manager. How important is sustainability to the Group?

We’re focused on being better at what we do best, which is offering our clients an excellent service

to close down, which reduces choice and volumes across the industry. In 2023 one of our key suppliers, Sappi, closed two of its mills due to falling returns. If European paper manufacturers can’t get higher returns, I think they’ll opt out of making paper. If they can’t afford to opt out, they’ll be forced to go by the wayside. So that’s our biggest challenge over the next six to nine months – dealing with customers that aren’t getting the returns they want and the rising

It’s extremely important for us and we demonstrate it in lots of ways. Our fleet of low emissions vehicles comply to the Euro 6 emissions standard, meaning increased engine efficiency, better fuel economy and reduced CO2 emissions. Our customers want us to be as sustainable as possible and so investment in initiatives and processes that improve our sustainability credentials is key. Mill manufacturers in Europe are also spending a lot of money on sustainability in order to comply with European legislation. Currently, some of the legislation that’s being imposed on European manufacturers is not being imposed on manufacturers outside Europe. It’s a fine balance between supporting our European mill suppliers and understanding their requirements from a legislative point of view. As a company we must take sustainability seriously, from both a customer and supplier perspective. We created the new compliance role to ensure we’re fully up to speed with the sustainability agenda and that we make the right decisions based on the correct information. There’s a lot of greenwashing out there so it’s essential that we make informed choices and understand the legislation and the facts.

Do you think there’s a lot of greenwashing in

No, I don’t think so. I think in general, there’s a lot of greenwashing in everyday life. Our raw materials are trees and water, so we’re at the forefront. We’re always going to be a high profile sector. I think some of the greenwashing that goes on is down to ignorance. People just don’t understand the topic very well and that’s why we have created the new compliance manager role within our business.

Our ambitions are to grow and be profitable. We aim to increase our market share and develop sales in new areas. I think we’re very much focused on being better at what we do best, which is offering our client base an excellent service.

How do you know what prices to set for your products and services? Ella Faulkner gives her take on how to set your print package pricing

It’s true that price is far from the only factor in a customer deciding to choose your print services. The quality of your work, speed of delivery, expert advice, ease of relationship and your ability to fit in last minute jobs when they really need it can all be important in deciding which print shop to use.

However, even if it’s not the deciding factor, price will always be a factor. If the price is too low, not only do you miss out on income you could be enjoying, you also potentially set expectations for the future, making it difficult to raise prices later because you’re seen as being at the ‘budget’ end of the market. Price too high and people may either choose not to use you in the first place or take their business elsewhere.

By understanding your true value to customers, you can gain a clearer understanding of where you should pitch your print prices

Print package pricing, then, is about balance. But how do you achieve it? There are many factors that play into setting your print pricing. Cost can be one issue for printers. No business will last long selling products and services for less than they cost to supply. So as a baseline, it is vital to understand the cost of your business, its print materials and crucially for print shops, how those costs break down across the packages you offer. An ink or toner cartridge, for example, has a certain cost, but you’ll get lots of individual prints out of each one, so you need to understand the cost per item.

Your costs will be divided into the fixed cost of things like print shop rent, vehicles, equipment hire or monthly purchase costs and wages. Variable costs will include energy, papers, vinyls, inks and other print essentials. Print management software can make it easier to identify individual unit costs.

Then there is value; what is it that customers value most about what

you do? It may be that you offer huge print runs at rock bottom prices, in which case you will need to price keenly and keep a constant eye on the competition to ensure you’re always one step ahead.

On the other hand, your business may be built on niche capabilities or the ability to produce work of a quality that beats your peers. Here, you may be able to charge more for the work you do because price isn’t your only competitive advantage. By understanding your true value to customers, you can gain a clearer understanding of where you should pitch your print prices.

You should also consider what your competitors are doing. We are not suggesting that you should look at your closest competitor and simply do what they do; there are too many variables that may set you apart to make that a wise strategy. But it is important to be at least aware of what the competition is doing so you can factor it into your calculations if necessary. And if low print package pricing is one of your major selling points, you will need to be extra vigilant to ensure you are always competitive.

Finally, but perhaps something that should be considered before anything else, is margin. Every company is in business to create customers and sell to them and it can only keep doing that if it earns more than it spends. That means factoring in a profit margin on each of your print packages so that each one earns you a little more than it costs to produce.

Going into further detail on this final point, there are several ways that printers can ensure a healthy profit margin. You can reduce costs by shopping around or ordering in bulk and you can change your perceived value by choosing a higher quality print material or promoting its durability, waterproofing, ecocredentials or UV resistance.

But out of all the above factors, none is more variable than margin. By choosing your approach to profit, you should finally be able to settle on a price for your print packages. Options here include bulk discounts. Consider pricing individual projects higher than bulk orders, where set up times per unit will be much less, so you protect profit margin for both types of order.

Also look at loss leaders; try to undercut the market by offering at or below cost prices on some print packages, where you know you can recoup any losses through cross sells, upsells and repeat business.

Linked to this is loyalty building – increasing margin for first-time customers and offering discounts to longer standing customers helps lock in loyalty. The opposite of this is to try out introductory offers to attract customers to you and away from competitors. Once a price conscious customer is with you though, you will need to keep offering value to stop them wandering off again.

Be aware of what the competition is doing so

you can factor it into your calculations

Another great way to lock in repeat business is to give trade customers preferential account terms, such as a line of credit giving them a few additional days/weeks to pay, loyalty offers and the occasional freebie to say thank you. In return, you could secure larger trade accounts.

Finally, consider whether your customers make regular orders of certain products. If so, you can offer tiered print packages with scaled prices so they can pay a flat fee every month to get the print they need. This is great for customers that want to even out their print spend to achieve monthly cost consistency and equally good in terms of protecting your profit margins.

The Production Print Manager at MJ Flood Ireland on solving problems and finding a balance between work and home life

How did you get into the print industry?

I began my career in the print industry when I joined MJ Flood as a service engineer. I’ve always been interested in figuring out how things work and fixing them, so I was drawn to the technical challenges and problem-solving aspects of the role. Over time, I developed my skills and became the lead production print specialist.

What do you like and dislike about the industry?

I love the constant innovation and how the industry keeps evolving. However, the competitive nature of the market means that those who cannot afford to move with the times are often left behind.

How has the industry changed since you first started?

Since I began my career in the print industry, there has been a significant shift towards digitalisation and automation. The adoption of digital printing technologies has revolutionised the way businesses approach printing.

What do you see as your biggest success in life?

Finding a balance between my career achievements and personal fulfilment. Whether it’s nailing a big project at work or spending quality time with loved ones, striking that balance has been key to my happiness.

What’s the worst job you’ve ever had?

It was probably when I worked in a bookmakers many years ago. The job just wasn’t for me, plus I was never really into gambling.

What’s your dream job?

Leading the professional printing division at Konica Minolta Europe. I’m all about technology and innovation and being at the forefront of that in a leadership role would be incredible.

Favourite film?

A very difficult question to answer, but one I keep going back to is ‘Whiplash’. I was heavily involved in music in my early years and there is just something about this film that really resonates with me.

What’s your favourite band/musician? Vulfpeck.

Who or what makes you laugh?

My wife never fails to crack me up. She doesn’t even mean to half the time, but some of the stuff she comes out with is just hilarious.

What superpower would you most like to have?

If I could choose a superpower, it would be the ability to teleport. I do a lot of travelling in my role, so the ability to cut out long drives and flights would allow me to get a lot more done. Also, who wouldn’t want the ability to snap their fingers and instantly be transported to The Bahamas?!

How would you like to be remembered?

As someone who made a positive difference in the print industry in Ireland and beyond.

Life is…

An adventure.