INSIGHTS AND INSPIRATION FOR THE RETAIL BAKING COMMUNITY

INSIGHTS AND INSPIRATION FOR THE RETAIL BAKING COMMUNITY

AVANT FOOD MEDIA

Paul Lattan President 816.585.5030

Steve Berne Executive Vice President 816.605.5037

Joanie Spencer Vice President 913.777.8874

CRAFT TO CRUMB

Paul Lattan Publisher paul@avantfoodmedia.com

Steve Berne Director of Sales steve@avantfoodmedia.com

Erin Zielsdorf Account Executive erin@avantfoodmedia.com

Joanie Spencer Editor-in-Chief joanie@avantfoodmedia.com

Mari Rydings Editorial Director mari@avantfoodmedia.com

Jordan Winter Creative Director jordan@avantfoodmedia.com

Olivia Siddall Multimedia Specialist olivia@avantfoodmedia.com

Annie Hollon

Digital Editor annie@avantfoodmedia.com

Maddie Lambert Associate Editor maddie@avantfoodmedia.com

Beth Day | Maggie Glisan Contributors info@crafttocrumb.com

INSIGHTS AND INSPIRATION FOR THE RETAIL BAKING COMMUNITY

www.crafttocrumb.com/subscribe

Craft to Crumb is published by Avant Food Media, 1703 Wyandotte St., Suite 300, Kansas City, MO 64108. Craft to Crumb considers its sources reliable and verifies as much data as possible, although reporting inaccuracies can occur. Consequently, readers using this information do so at their own risk. Craft to Crumb is distributed with the understanding that the publisher is not liable for errors and omissions. Although persons and companies mentioned herein are believed to be reputable, neither Avant Food Media nor any of its employees accept any responsibility for their activities. The Craft to Crumb mini-mag is produced in the USA and all rights are reserved.

Click or Scan here for Catalog

Tielman North America is focused on providing environmentally friendly products for industrial bakeries, retailers, and catering services that offer a customized and innovative alternative to plastic and aluminum.

Our Pak-Well muffin trays are fully bakeable and are made with sustainable materials such as bagasse and bamboo pulp.

Bagasse, also known as sugarcane pulp, is a material extracted from sugarcane that is 100% compostable and is a sustainable alternative to conventional plastic and aluminum packaging.

Designed to withstand high temperatures, Pak-Well was carefully crafted with a focus on its bakeability throughout its development and production.

Craft to Crumb

A Note From The Editor

JOANIE SPENCER

JOANIE SPENCER

Editor-in-Chief

joanie@avantfoodmedia.com

One thing I love about the baking industry is how much of themselves bakers put into their craft. I can identify with that because I do the same thing. There are pieces of me — breadcrumbs, if you will — sprinkled throughout everything I write.

I think that’s what endeared me most to Boichik Bagels, the Berkeley, CA, bakery founded by Emily Winston. As a New Jersey native raised in a Jewish family, this formally trained mechanical engineer was meant to open a bagel bakery … right down to the serendipitous discovery of her flagship factory.

Emily’s upbringing — in terms of culture and faith — was not only foundational for launching Boichik Bagels, but it also served as much of the driving force behind its growth and success. When The New York Times puts your bagel up against the classic New York staple, that’s a sign you’re doing what you’re meant to do.

Of course, Emily doesn’t consider herself a baker but more of an engineer who happens to bake. Then again, in my experience, the best bakers think like engineers … and their products reveal pieces of who they are.

Here’s to putting ourselves into the products we make.

Welcome to Boichik Bagels.

Bagels have moved from simple schmear carriers to the star of the show.

BY ANNIE HOLLONThe traditional lineup of baked goods wouldn’t be complete without the classic bagel. Savory or sweet, bagels are having a major moment, spurring conversation online and serving not only as a carrier for classic toppings (lox, anyone?) and flavorpacked schmears but also as the main event.

Bagels are on the rise, growing in conversation and consumption. According to Tastewise, bagels have seen a 27.16% increase in social discussions in the last year.

Photo courtesy of Ess-A-Bagel

Photo by Robert Skversky

Photo courtesy of Magnolia Bakery

Photo courtesy of Ess-A-Bagel

Photo by Robert Skversky

Photo courtesy of Magnolia Bakery

“Overall, all single-serve breakfast items — donuts, muffins, bagels, etc. — are on trend and growing,” said Heather Prach, VP of education and industry relations at the International Dairy Deli Bakery Association. “With pricing top of mind for consumers, bagels are filling and easy to eat in many ways: alone, as sandwiches, with desserts or with dips.”

Statista revealed a steady increase in bagel consumption among the US population. While 202.07 million Americans consumed bagels in 2020, that figure is projected to jump to 205.34 million by the close of this year.

Dollar gains equally reflect the category’s success. According to Circana, bagels in the perimeter reached $306.01 million in sales the 52 weeks ending May 19, 2024, which is a 4.5% increase vs. a year ago.

With bagels gaining traction among all types of consumers, bakers are finding new ways to appeal to interests and trends while remaining true to what’s expected from the traditional boiled-and-baked product.

Melanie Frost, CEO of Ess-aBagel, a New York City shop that’s been rolling out bagels since 1976, noted growing consumer demand for gluten-free and vegan baked goods.

“Bagels made with whole grains, seeds and alternative grains are

205.34 million In 2024,

consumers are expected to eat bagels.

Source: Statista

also gaining popularity,” Frost said. “Scooped-out bagels are also trending as they provide a way for customers to lower their calorie intake while satisfying their bagel cravings.”

Consumers also seek new or nostalgic flavors that please the palate. In New York City, along with its other locations around New York state and Connecticut, PopUp Bagels, a fairly new name in the Northeastern bagel game that’s quickly gaining ground, keeps its baked goods simple and its toppings complex.

Adam Goldberg, founder and CEO, shared that the brand leans into new schmear flavors as a way to accent its classic offerings: Everything (its most popular flavor), sesame, salt, plain and poppy seed.

“Our bagels never change; we just make different schmears every week,” he explained, noting that while there’s consumer interest in sweet and salty schmears, spicy flavors are gaining ground. “Once a month or so we have some form of a spicy schmear, whether it’s a spicy salt, jalapeño or hot honey.”

Across the country, Calic Bagel is leaning into the savory and innovating by turning schmear from a topping to an inclusion. The Los Angeles bagel shop is best known for its savory hand-rolled bagels stuffed with cream cheese, available in Signature, Habanero and Pizza flavors.

Cross-brand partnerships can provide a path for innovation that draws in consumers looking for unique flavor experiences.

“Collaborations with other brands, including bakeries, ice cream shops and beverage companies, allow for creative flavor combinations and expanded market reach,” Frost shared. “Ess-a-Bagel has partnered with Magnolia Bakery, Baileys, PIX11 and other local brands to amplify our reach.”

Ess-a-Bagel’s partnership with Magnolia Bakery led to the Banana Pudding Bagel, which featured a cream cheese spread inspired by Magnolia’s signature banana pudding and a classic bagel dyed banana yellow.

Over at PopUp Bagels, collaborations with brands such as Utz, Old Bay and Frank’s Red Hot and big names such as Dominique Ansel keep customers coming back. A partnership with BuzzFeed’s Tasty gained positive reactions from customers not only for the schmear flavors but for PopUp Bagels teaming up with a major media brand.

“Collaborations are a way to have fun and experiment with new things,” Goldberg explained. “And at the same time, both our brand and theirs build some excitement on what we’re doing.”

While out-of-the-box schmear flavors catch consumer attention, classic bagel flavors such as plain, sesame, poppy seed,

cinnamon raisin and Everything remain in demand.

“However, there has been a surge in demand for pumpernickel and some unique and innovative flavors,” Frost shared.

In addition to taste, bagels with unconventional colors can also draw the eyes and dollars of consumers.

“Bagel companies are expanding their offerings beyond traditional flavors, offering unique options such as Cinnamon French Toast, Jalapeño Cheddar, Blueberry and dessert-inspired flavors,” Frost explained. “Colored bagels have also gained popularity, with green bagels for St. Patrick’s Day and pink bagels for Valentine’s Day being favored. Customers are drawn to the playfulness of these options.”

Bakers don’t have to restrict colorful bagels solely to holidays. In the Kansas City metro area, Meshuggah Bagels matches its New Yorkstyle bagels with abstract colors, offering red and gold bagels as a nod to the Kansas City Chiefs and brightening its display case with vibrant tie-dye bagels.

With a whirlwind of colors, flavors and inclusions, the future of bagels is shaping up to be promising.

“The global bagel market is set to grow significantly from 2023 to 2031, driven by innovation in flavors, ingredients, and production techniques like par-baked and frozen options, catering to evolving consumer preferences,” Frost said.

From increasing healthier options to bagel toppings evolving along with shifting dietary preferences, the sky’s the limit.

Unlock a world of baking excellence with Farmer Direct Foods' artisan whole wheat flours.

As artisans ourselves, we understand that every crumb counts, and that's why we're dedicated to providing you with the highest-quality flour for your culinary masterpieces.

Experience the difference of our direct sourcing approach. Our partnership with American wheat farmers ensures unparalleled quality, freshness, and authenticity in every bag of our flour.

From muffins that melt in your mouth to cookies that redefine indulgence, our flour transforms your recipes into exquisite works of edible art. The secret ingredient for success? Farmer Direct Flour.

Our team of technical experts and seasoned baking educators are here to assist you in every step of the process. Whether it's recipe development or transitioning your ingredients, we've got your back.

Game-changing innovation often starts with an inkling, that quiet voice that prods, “What if?” Deciding whether to pursue the answer isn’t always cut and dried. Rarely is it easy. But once the quest begins, turning back isn’t an option, especially when the idea starts taking shape.

That’s how Boichik Bagels in Berkeley, CA, got its start ... from an inkling. When New Jersey native Emily Winston, the bakery’s founder and CEO, learned her favorite New York City bagel chain had closed its doors for good, a sense of nostalgia nudged her just enough to make her wonder, “What if I could make an authentic New York-style bagel?”

Emily was raised Jewish in suburban New Jersey, and bagels have been

a fixture throughout her life. After earning a degree in mechanical engineering from Cornell University, she went to work for General Motors and eventually landed in the Bay Area, far from her favorite bagel shop.

“When I came to the Bay Area, I bemoaned the lack of good bagels,” Emily said. “I decided I wouldn’t eat bagels until I went home for a visit. Then I got the terrible news that H&H Bagels, my ‘Holy Bagel,’ my gold standard of bagels on the Upper West Side, had closed its doors. I was distraught.”

After tasting New York-style bagels from a San Francisco pop-up, Emily began to think she could create an even more authentic product. She began experimenting with recipes

Craft to Crumb Boichik Bagels

and plying her monthly potluck dinner group and martial arts school friends with bagels created in her kitchen.

“It became an obsessive hobby,” Emily admitted.

After five years of trial and error, Emily was confident she’d perfected a boil-and-bake bagel recipe reminiscent of her East Coast childhood.

She obtained a cottage food license to sell bagels out of her home kitchen, and she brought bagels to the Eat Real Festival. They were such a hit that a local reporter proclaimed them “the best in the state of California.”

That’s when bagel connoisseurs descended on Emily’s home, forming lines that stretched for blocks.

“It would take me seven hours of work with my KitchenAid mixer and electric oven to make nine dozen bagels,” Emily recalled.

“I decided that if I was going to make bagels, I wanted a bagel shop with real equipment. I did a lot of soul-searching to figure out what I wanted to do. Continuing the cottage food thing didn’t make sense, and a commissary kitchen didn’t make sense. The only thing that made sense to me was to open my own shop.”

Storefronts in the Bay Area can be hard to come by, and rent isn’t cheap, but fate stepped in. Months earlier, Emily had been introduced to Noah Alper, founder

of the iconic Noah’s Bagels chain. He called her out of the blue one day to let her know the corporation that purchased Noah’s Bagels had closed the brand’s original location on College Avenue in Berkeley. He thought she should take a look.

“It was bashert,” Emily said, using the Yiddish word for meant to be. “It was a great location. I had to take it.”

The first Boichik Bagels brickand-mortar location opened in the compact 1,200-square-foot space in November 2019. The company’s name — derived from the Yiddish word boychik, which is a term of endearment for a cute little boy — honors her Jewish grandmother who, after seeing Emily with extremely short hair for the first time several years earlier, exclaimed, “Oy! Such a boychik !”

Emily Winston shares why she chose to raise money via crowdfunding vs. using venture capital or a bank loan.

“It took a leap of faith,” Emily said of the move. “I didn’t even have all the money when I signed the lease. It was one of those crazy things where you have to act and trust the path will fall into place as you’re walking.”

That’s an inkling at work.

The retail shop was an instant success, especially with transplanted New Yorkers who craved an authentic taste of home. In 2021, The New York Times ran the article, “The Best Bagels are in California (Sorry, New York),” heaping praise on Boichik Bagels.

“The article blew the roof off the place,” Emily said. “I had to do some more soul-searching. I could sit with my one fabulously successful bagel shop, or I could go into the unknown ... I started thinking about building a commissary.”

Automatically move pans, trays and boards from conveyors or racks, depanning, andauto tray feeding to conveyors.

Top and side bordering, drizzle, or drawing for round cakes, sheet cakes, muffins, cupcakes and cookies.

Primarypackaging,secondarypacka rimary packaging, secondary packaging, end of line palletizing and depalletizing.

Her vision included finding a way to automate more of the manual production tasks, specifically hand rolling and forming dough and moving full bagel boards from the line to baking racks. This level of automation was unheard of for a retail bagel operation, but Emily was convinced it was possible. She just needed the right equipment suppliers ... and about $5 million.

For the equipment, she partnered with BakTek, a supplier of bagel forming equipment, and Apex Motion Control, which supplies cobots and robots to the baking industry.

A small business bank loan was out of reach for the capital investment needed, and for various reasons, Emily didn’t want to accept venture capital. So, she tried crowdsourcing and raised over $1 million in her first outing.

The 18,000-square-foot bakery opened in March 2023. Its main attraction is the two-lane BakTek bagel forming line that’s seamlessly integrated with Apex’s Baker-Bot cobot, which moves bagel boards from the line to baking racks. The system is housed behind a floor-to-ceiling, wall-length window that allows customers to view the production process in action. As an added bit of fun, Emily asked Apex to program the cobot arm so it waves to its audience.

Emily Winston talks about the benefits of using automation in artisan baking.

“I designed the line myself,” Emily said, “and BakTek and Apex worked together to put the two lines together. Putting industrial equipment on display is something no one else has done. It’s the main show for customers. Watching automation at work is a really neat thing. It’s fun and very satisfying.”

The opening of the commissary bakery was quickly followed by two additional retail stores and three outpost locations. Emily likens Boichik’s growth strategy to one of her favorite childhood strategy games, Civilization, in which players must build cities.

“I feel like that’s what I’m doing,” she said. ”I’ve got my maps, and we’re sending out our bagel armies to conquer. It’s fun, and the world wants more good bagels.”

The commissary bakery is the hub. It has 12,000 square feet of production space and 1,000 square feet of retail space with customer seating. Office space and ancillary functions round out the rest of the square footage. The bakery produces about 10,000 bagels daily for Boichik’s retail locations, outposts, wholesale customers and online orders, which ship nationwide.

“I would rather make all dough in one spot and have quality control and scale it efficiently

versus everyone making their own dough,” Emily said.

When it comes to bagel flavors, Boichik sticks to the basics. Plain, Everything, onion, sesame, salt and pepper, poppy seed, egg, cinnamon raisin, pumpernickel, and pumpernickel raisin swirl are menu mainstays, along with a few others. The retail stores also offer bialys and an assortment of cream cheeses, lox, cookies, bagel chips, sandwiches, salads and coffee.

While Emily fully embraces her mechanical engineering background, she’s adamant about not being called a baker.

“I consider myself an engineer who wandered into baking,” she said. “I’m not afraid of getting equipment, figuring it out and maintaining it. I love it. To me, that’s fun. I don’t bake. I have a phenomenal baking staff.”

That staff includes head baker Armando Carapia, who oversees the entire production process, from dough mixing to packaging to truck loading. He watches carefully as bagel dough moves from the customized mixer to the bagel forming line, troubleshooting the technology as needed.

When the bagels are proofed and ready for baking, Boichik’s lead baker Battumur Dorj manages the old-school New York boil-and-bake method, which includes handflipping bagel boards as they rotate in the Reed revolving rack oven.

Learn how Apex’s BakerBot helped Boichik scale up its artisan bagel production.

Emily has also surrounded herself with a solid operations and support team.

Rob Soviero, Boichik’s COO, oversees the bakery’s overarching operations and human resources functions, and Cheryl Lew, Emily’s longtime mentor, serves as head pastry chef and advisor.

“I’ve been here since day one,” Cheryl said. “This is the most successful — and the most modern — business I’ve ever consulted with. Emily’s driving the bus; I put gas in sometimes.”

On the day of Craft to Crumb ’s visit, Cheryl was focused on a couple of ancillary offerings. She was experimenting with black and pink cookies for Valentine’s Day — a raspberry and chocolate variation of the bakery’s standard black and white cookies — and conducting a final trial run of the challah program before its rollout to stores.

Currently, the factory runs one shift, and daily bagel production is

“It took a leap of faith. It was one of those crazy things where you have to act and trust the path will fall into place as you’re walking.”

Emily Winston | founder and CEO | Boichik Bagels

Craft to Crumb Boichik Bagels

a fraction of what the automated line is capable of.

“I built this space for growth,” Emily said. “Right now, we’re not running a full shift, but eventually, we will run almost non-stop. The BakTek dough line can run up to 12,000 bagels per hour, so we’ve got a lot of room. The infrastructure is also in place for the addition of a second complete baking line.”

The bakers fire up the kettle and oven at 2 a.m. every day. Production starts with the cold-proofed bialy dough rounds, which are shaped, filled with an onion filling and baked. Then, it’s all-handson-deck for the bagels. The first batches are earmarked for the outpost locations, which receive finished product. Those bagels are loaded on a box truck that starts deliveries at 6 a.m.

“Our outpost model makes it faster, easier and less expensive to build out stores and expand our reach,” Emily explained. “We don’t need to train as many bakers, and the staff can focus on selling bagels, cream cheese, lox, sandwiches, coffee, cookies and other items. We bake as close to delivery time as possible so our outpost customers receive the freshest bagel possible.”

Once the outpost orders are filled, bakers turn their attention to orders from the retail stores, which bake bagels on-site every day. Each store receives racks of proofed and formed bagels every afternoon for baking off the next morning,

along with cream cheese, lox, bagel chips, cookies and Boichik Bagels merchandise.

Emily is ramping up the retail and wholesale sides of the business simultaneously.

“We’re doing retail and wholesale together because it makes for a stronger business,” she explained. “If one falls down, the other piece is there to support it. Both channels should make the company money. Plus, I want to find out if there’s a future in nationwide distribution.”

While Emily’s initial mission was to introduce authentic New York bagels to the West Coast, it’s never been just about the bagels. She also wanted to create the sense of community that bagels helped forge during her East Coast upbringing.

“For me, bagels are a nostalgic food,” Emily said. “At Jewish events, they are a life cycle thing. You’re a part of life cycle events, and you’re a part of people’s lives

and traditions. With Boichik Bagels, I wanted to bring that here.”

She does that by hosting events such as Mahjong Mondays, Saturday morning bakery tours and pop-up bagel stands.

As she thinks about the future, Emily is already entertaining yet another inkling: What if she could replicate the traditional boil-andbake method with machinery and still produce a quality artisan bagel?

“I want to create a fully automated artisan-level baking line that uses a stone-deck tunnel oven,” she said. “I call it artisan at scale. The bagels must be awesome. That’s the whole point of this enterprise. I think I can replicate the boil-andbake system with machinery and still get that same awesome product at the end of the line. I want to be the one who gets there and makes that happen with existing technology.”

Game-changing innovation often starts with an inkling.

n Short product path, gentle processing of product

n Intact inclusions – even blueberries!

n Easy to disassemble, clean, and assemble

n No divider oil needed

n Graphic touch display in multiple languages

n Programmable recipes – repeatable quality

n Favorable financing

n Arrange a test today!

Craft to Crumb

Special Section: Advertorial

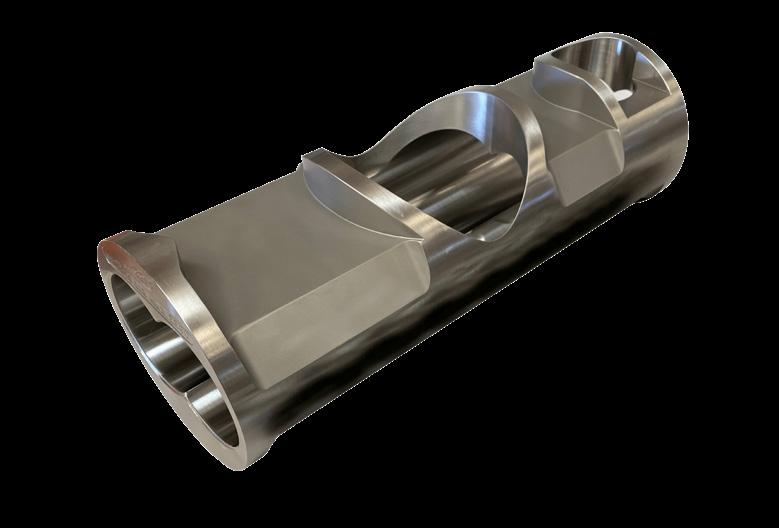

Some of the baking industry’s best innovation comes from a combination of deep roots and new ideas. That’s a perfect way to describe Henry & Sons, a family-owned manufacturer of VEMAG replacement parts and new technology.

The company was founded in 1980 by Dave Henry, an industry veteran who got his start working with Roger Reiser. When Dave launched Henry & Sons, his first priority was simply servicing existing machinery for customers. But Dave’s commitment to quality and stellar customer relationships led to a demand for the company to make VEMAG replacement parts. That began the 44-year journey of this innovative family business, led today by Dave’s son, Mark Henry, who serves as president. Today the third generation — Mark’s son, Morgan Henry — is now on the team.

With more than 2,000 replacement parts and patented original equipment designs all made in the USA, Henry & Sons is heading toward the future with quality in mind and service at the heart of all we do.

Henry & Sons understands that replacing VEMAG parts is not a quick fix. The team takes time to identify and refine problematic parts and incorporate improved design and materials to yield a more dependable, longer-lasting part. This is not a “one size fits all” solution.

More than 2,000 VEMAG replacement parts

Patented Zero Contact Technology

Industry-Changing ERGO Housing

All stainless-steel combinations result in superior food s afety and longer lasting parts

All parts made in the USA

Henry & Sons’ stellar reputation is not only about manufacturing high-quality replacement parts but also repairing and rebuilding all VEMAG vacuum fillers. With American-made parts developed in a California manufacturing facility, any broken VEMAG machine can be rebuilt or repaired correctly in the Henry & Sons facility. All rebuilt VEMAGs go through rigorous performance testing before the machine is returned, ready for production.

• Real-world improvements remove potential weaknesses from original design

• Machines sent to the Henry & Sons facility can receive a quick repair/rebuild turnaround

In 1998, Henry & Sons released the first AC-30 Vacuum Filler. In 2018, with a complete redesign, Henry & Sons released the new AC-30E vacuum filler with state-of-the-art, proven dual-drive servo technology and a first-of-its-kind, 100% climate-controlled environment, this is game-changing vacuum filler technology.

*Figures can vary depending on product, product temperature and feed screw selected

• All electronic components cooled, dried and heated with air circulating between control enclosure and rear-drive enclosure

• Climate-control technology ensures prolonged machine life, dependability and performance

• Metal-detectable wear components provide food safety assurance

• Redundant double-screw design and quick-tooling changes allow easy product changeover with reduced downtime

• Easy-to-access components for efficient cleaning and sanitation

• Manufactured in the USA with American-made parts

Sottoriva

Sottoriva

water meters, water chillers, dough mixers, dough feeders, roll/bun dividers, roll lines, bread dividers, conical rounders, bread proofers, bread moulders, proof boxes, retarders, baking ovens

Joining a startup bagel shop after working for the world’s largest bakery for 30 years would be considered a significant career move by some. For Armando Carapia, head baker at Boichik Bagels in Berkeley, CA, it was the right move at the right time.

Before joining Boichik, Armando had spent most of his baking career with Horsham, PA-based Bimbo Bakeries USA (BBU), producing a variety of baked goods, including bagels for the Thomas’ brand. He enjoyed his job and had no plans to leave.

But plans change, sometimes unexpectedly. In 2019, BBU announced it would shutter the Bay Area bakery where Armando worked and move its operations to Canada.

“They asked me to move with them,” Armando said. “But I didn’t want to move to Canada. My family is here, and I wanted to find a good job here.”

He started applying for local bakery positions, including the head baker job at Boichik Bagels, where founder and CEO Emily Winston had just opened her first brick-and-mortar location. At the time, the shop produced authentic New York-style

Armando Carapia shares why Boichik Bagels is the perfect fit for his baking experience.

“I make our custom-made bagels and challah bread by hand. I enjoy it.”

Armando Carapia | head baker | Boichik Bagels

bagels by hand using the traditional boil-and-bake method.

Emily was looking for an experienced baker to oversee operations in the 1,200-square-foot space. When Armando walked through the door, the pieces fell into place.

“I found this small business that was just starting out making bagels by hand,” Armando said. “I was used to making bagels with machines. Bimbo had an 80-foot tunnel oven that produced tons of bagels every minute.”

Boichik had some equipment, but it was older and often required a little coaxing to run. Armando wasn’t intimidated by the laborintensive work or the lack of automation. He embraced the opportunity to learn every facet of the small bakery and served in every capacity, from baker to fix-it man.

Boichik Bagels grew quickly over the next few years. In March 2023, it moved into an 18,000square-foot facility with a highly automated front-end production process consisting of a customized LP mixer and bowl lift, a two-lane BakTek bagel forming line, and an integrated Apex Motion Control Baker-Bot cobot that picks and places bagel boards from the line onto baking racks.

Armando and his team immediately reaped the labor-saving benefits and efficiencies the technology brought to the previously manual production process.

“I enjoy the robot and the mixer,” Armando said. “They make it easier for us. There’s no more lifting.”

While the new system reduced the physical attention required, the production process still requires a baker’s touch and eye.

“You must always have your hands on it,” Armando said. “The machine will do about 80 percent, and I will do about 20 percent, checking it all the way.”

A true baker, Armando grabs every opportunity to get his hands in the dough — literally.

“I make our custom-made bagels and challah bread by hand,” he said. “I enjoy it.”

As head baker, Armando is also responsible for training new employees, both in the technology and the artisan baking process. He welcomes the opportunity to pass along the knowledge he’s gained after 30 years.

“I teach them to go step-by-step with focus,” he said. “I teach them how to roll the dough by hand. My job is really easy because everyone knows what to do. When I am sick, I do not worry because I know they will do a good job.”

Despite his position as head baker, Armando sees himself as a student.

“I never stop learning,” he said.

When Armando walked through the doors of Boichik Bagels five years ago, he was simply a baker searching for a good job. He had no idea his next adventure would offer him the best of both baking worlds — producing New York-style bagels using Old World techniques with a technological twist.

Avant Food Media offers highly rated, award-winning media products in the bakery space.

crafttocrumb.com

Overall Excellence — Website of the Year

Troubleshooting Innovation podcast

Regional Gold Award | Central region | Online — Podcast

Rated 4.6/5 stars on Apple Podcasts

Commercial Baking ’s Innovations Annual

Regional Silver Award | Central region | Print — Special Issue or Supplement A

Your time is precious, and quality matters in bakery media. We invite you to tune in and subscribe now.

Boichik Bagels produces 10, 000 New York-style bagels daily from its commissary bakery to supply its retail stores, outpost locations, wholesale accounts and nationwide online orders. In true NYC bagel shop fashion, Boichik keeps the flavors simple and the quality high.

by Peter Sussman

Craft to Crumb Look | Listen

Keep up on industry trends and troubleshooting tips with the latest multimedia content.

Anne Marie Halfmann, marketing director for Dawn Foods, examines the company’s Chocolate Mania movement and various chocolate innovations in the baking industry. www.dawnfoods.com

Owner Björn Tielman discusses the benefits of the company’s baking cups, trays and cases. These sustainably produced, compostable materials can be fully customized. www.tielman.com

Video tutorials help bakers prep for the Retail Bakers of America’s Certified Master Baker practical exam. Sponsored by Puratos, Hobart, MIWE and Rondo. www.crafttocrumb.com/cmb-study-hall

www.crafttocrumb.com/advertise

Paul Lattan

paul@avantfoodmedia.com

816.585.5030

Steve Berne steve@avantfoodmedia.com

816.605.5037 Erin Zielsdorf erin@avantfoodmedia.com

937.418.5557

“THIS IS MY MASTERPIECE I’M BRINGING INTO THE WORLD, AND I WANT IT TO BE AWESOME AND BEAUTIFUL IN ALL OF THESE DIFFERENT DIMENSIONS.”

— EMILY WINSTON | FOUNDER AND CEO | BOICHIK BAGELS

Emily Winston shares how she’s bringing happiness to her corner of the bagel world.