Crown Bakeries

DOUBLING DOWN IN LAMINATED AND SWEET BAKED GOODS

www.commercialbaking.com DIGITAL EDITION

ISSUE Q1 | ABA’S ERIC DELL | C-SUITE MENTAL HEALTH| HURDLE TECHNOLOGY FEB 2023

Find out more at www.jkingredients.com or call us at 973-340-8700 Our Clean Label line of SOR-Mate products will keep your cakes, muffins, and other baked goods mold-free without the need for artificial preservatives all while enhancing the flavor! CL NG Clean Label Non GMO Kosher Pareve KP We make Clean Labels a piece of cake! Effective alternative to chemical preservatives! Introducing SOR-Mate

Many players, one team. www.syntegon.com

Many players working hard to ensure the productivity, safety, and sustainability of our machines are always at their best. One team dedicated to providing exemplary service — every time.

Expertise

Confidence in a product starts with trusting the people behind it. And no one has more experience than the engineers and operations team behind Shaffer.

Innovation

For more than 30 years, Shaffer has revolutionized horizontal mixers - from the first open-frame mixer in 1993, to today’s cutting edge sanitary designs and dough cooling technology.

937.652.4480 | info@shaffermixers.com | shaffermixers.com FOLLOW US 24/7 PARTS & SERVICE +1 888.508.1298 service@shaffermixers.com YOUR BAKERY. YOUR MIXER. Quality mixers, processing equipment and service. Global innovation and resources.

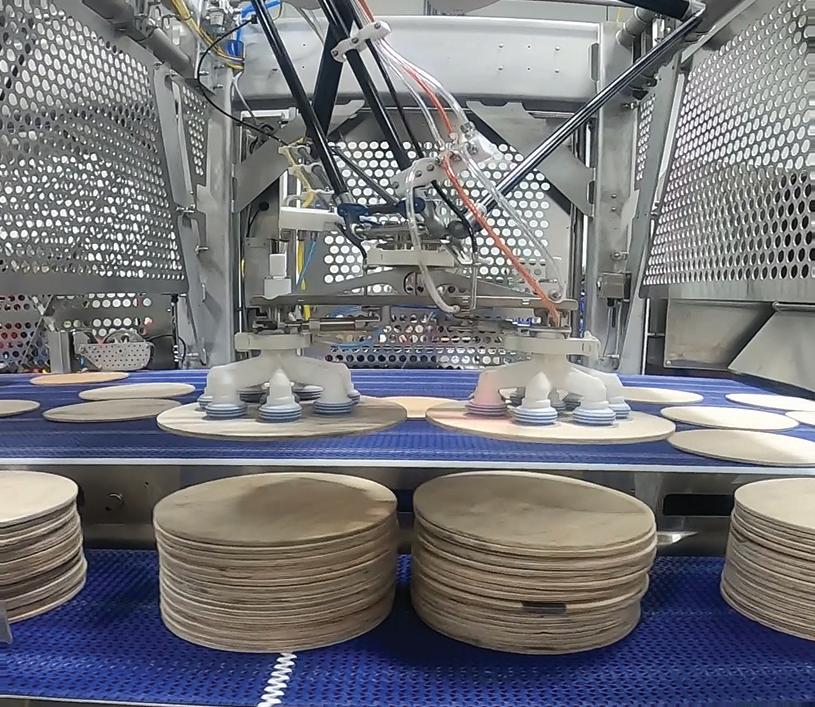

AIM TECHNOLOGY FOR PIZZA

Automation for pizza handling that no one else can deliver.

Active Integrated Motion™ (AIM™) technology transforms frozen pizza handling by enabling automation in washdown environments.

Intralox® AIM solutions include sorting, switching, and merging equipment that deliver maximized, reliable throughput and gentle product handling to your pizza packaging lines.

© 2022 Intralox, L.L.C. 5011057_EN

Scan QR code to learn more.

AVANT FOOD MEDIA

Paul Lattan President - Principal Steve Berne Vice President - Principal

Joanie Spencer Director of Content - Partner

COMMERCIAL BAKING

Paul Lattan Publisher | 816.585.5030 | paul@avantfoodmedia.com

Steve Berne Director of Media | 816.605.5037 | steve@avantfoodmedia.com

Joanie Spencer Editor-in-Chief | 913.777.8874 | joanie@avantfoodmedia.com

Mari Rydings Editorial Director mari@avantfoodmedia.com

Jordan Winter Creative Director jordan@avantfoodmedia.com

Olivia Siddall Multimedia Specialist olivia@avantfoodmedia.com

Annie Hollon Managing Editor annie@avantfoodmedia.com

Evan Bail Associate Editor evan@avantfoodmedia.com

Maggie Glisan | Bella Foote Contributors info@commercialbaking.com

OUR

American Society of Baking

Commercial Baking is published by Avant Food Media, 1703 Wyandotte St., Suite 300, Kansas City, MO 64108. Commercial Baking considers its sources reliable and verifies as much data as possible, although reporting inaccuracies can occur. Consequently, readers using this information do so at their own risk. Commercial Baking is distributed with the understanding that the publisher is not liable for errors and omissions. Although persons and companies mentioned herein are believed to be reputable, neither Avant Food Media nor any of its employees accept any responsibility whatsoever for their activities. Commercial Baking magazine is printed in the USA and all rights are reserved.

No part of this magazine may be reproduced or transmitted in any form or by any means without written permission of the publisher. All contributed content and advertiser supplied information will be treated as unconditionally assigned for publication, copyright purposes and use in any publication or digital product and are subject to Commercial Baking ’s right to edit.

Commercial Baking , ISSN 2767-5319 / USPS Publication Number: 25350, is published quarterly in February, April, August, and October, with special issues in June and December, in print and digital formats by Avant Food Media, 1703 Wyandotte St., Suite 300, Kansas City, MO 64108. POSTMASTER: Send address changes to Commercial Baking, c/o Avant Food Media, 1703 Wyandotte St., Suite 300, Kansas City, MO 64108.

Circulation is tightly controlled, with print issues sent only to hand-verified industry decision makers and influencers. To apply for a free subscription, please visit www.commercialbaking.com/subscription

6

COMMUNITY

FIND US ON FEBRUARY 2023 Q1

MEDIA Magazines Website Newsletters Podcasts Webinars Videos | digital edition

OUR

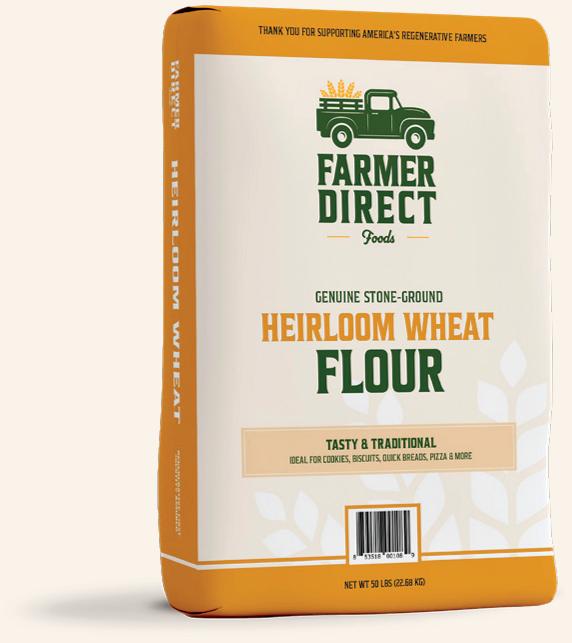

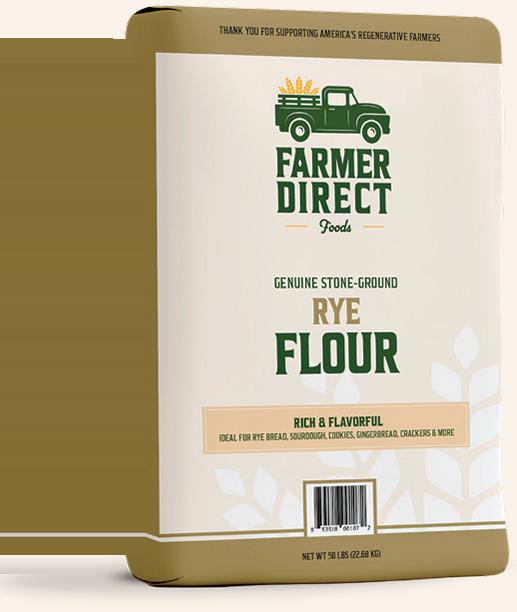

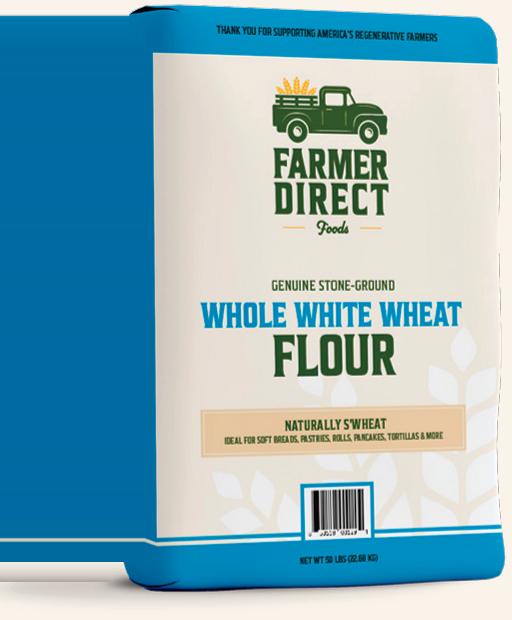

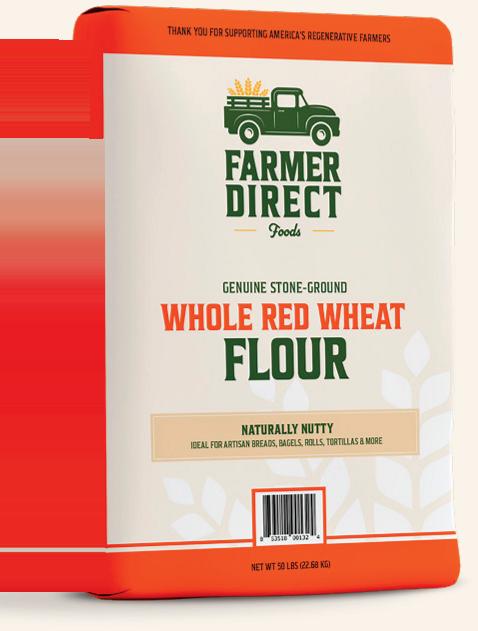

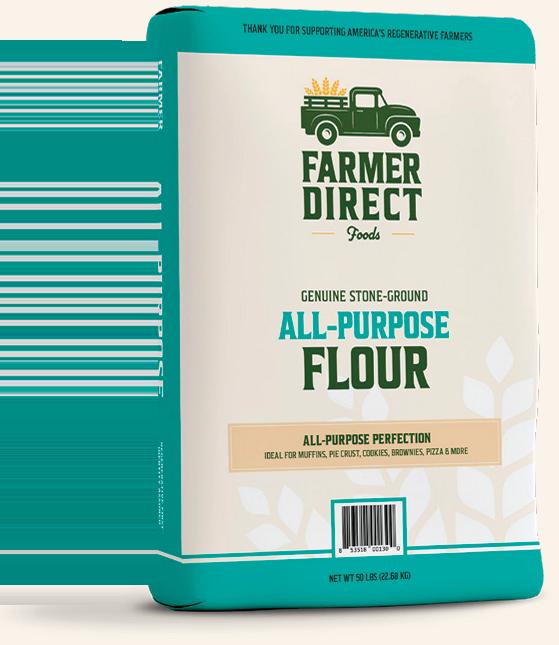

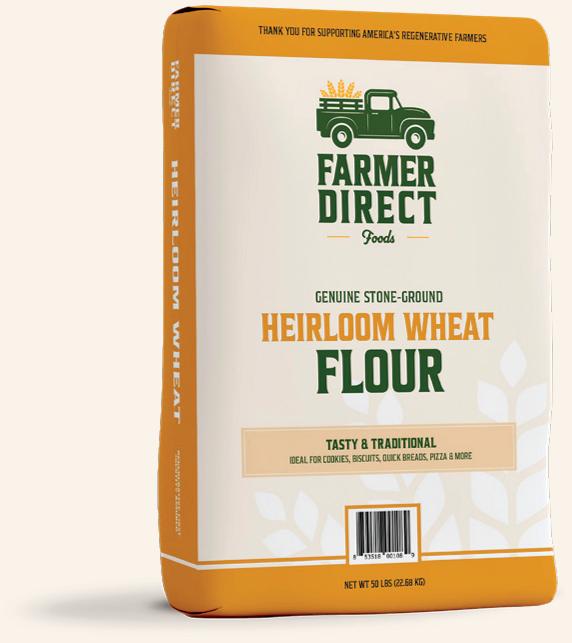

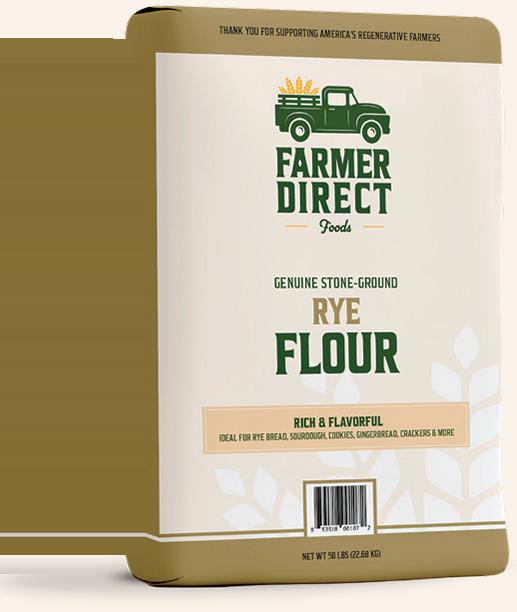

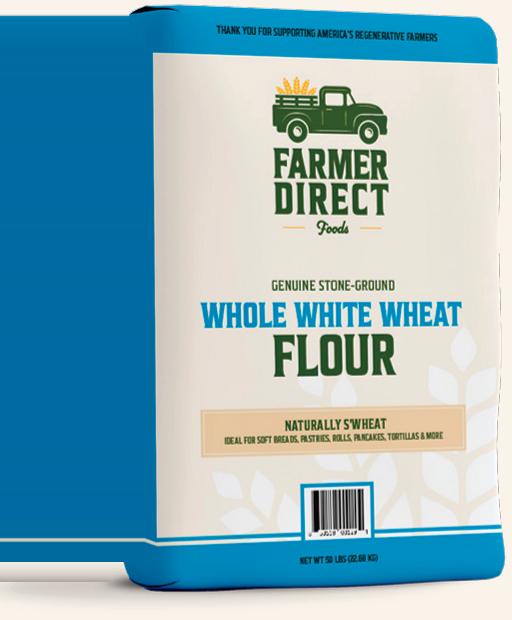

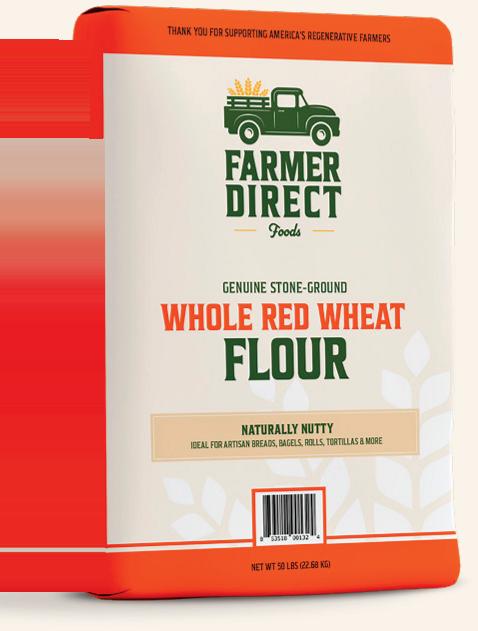

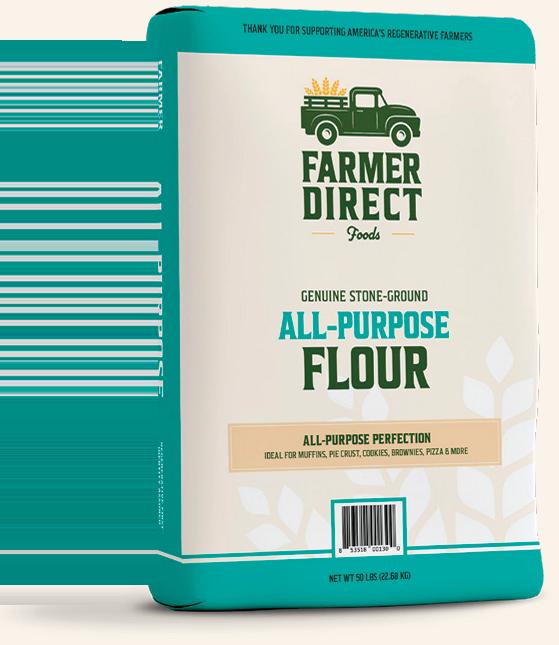

NATURALLY GOOD. RIGHT FROM THE START.

OUR DIFFERENCE MAKES ALL THE DIFFERENCE

Farmer Direct Foods produces premium, whole-grain flours that are regeneratively-farmed, milled and sold with intention and integrity Our flours are exactly what we say they are traced straight back to our farmers’ ancestral wheat fields and minimally processed to assure we preserve the natural nutrition, deep flavor, and complete character of the grain

It’s time for a wheat renaissance. Farmer Direct Foods is leading a return to wholesome ingredients that are better for consumers, farmers and the earth.

KOSHER

NO PRESERVATIVES

NON-GMO VERIFIED

REGENERATIVELY FARMED

STONE-GROUND WHOLE WHEAT

SUPPORTS AMERICAN FARMERS

us to request a sample today! FARMERDIRECTFOODS.COM 5641 EAST MARIPOSA ROAD, NEW CAMBRIA, KS 67470 | 785-823-8787

Contact

From the flower, to the bee hive, to you. A natural source of a wide array of nutrients, including trace amounts of 7 vitamins, 11 minerals, 5 antioxidants and 17 amino acids. A familiar flavor that everyone loves. Consumers are looking for an all-natural sweetener they can trust. Give them honey.

Contact keith@honey.com to learn how to formulate with honey.

HONEY IS A NaturalWonder

PLUS: Look for QR codes that contain exclusive digital content throughout the issue.

18

Crown Bakeries: Jewel in the Crown Crown Bakeries’ Smyrna, GA, facility boosts production, culture and R&D for its whole network.

36 Eric Dell: Driving Forward

42 Critical Issues: Mental Health

51 Product Development: Hurdle Technology

COMMERCIAL BAKING 9

IN THIS ISSUE

Features

Cover: Crown Bakeries’ renovation of the Smyrna, GA, facility expanded its portfolio into laminated and sweet goods. Read more on page 18.

Photo by Olivia Siddall | Avant Food Media

Customized solutions from the beginning. Committed partnership that never ends.

Our experience helps you select the perfect equipment to meet your specific needs.

Our skill createsa creates a custom stom solution,builttodelive solution, built to deliver unbeatable bea performanceand performance and longevity. gevit

Our service delivers accessible, responsive support ble, respons anytime you need it. ytime youneed

Peerless: World-class food equipment and service. Driving innovation, sanitation, quality and longevity.

Our customized solutions drive your innovative food creations.

Peerless Food Equipment

500 S. Vandemark Road, Sidney, OH 45365-0769 USA

(937) 492-4158, (877) 795-7377 | peerlessfood.com

COMMERCIAL BAKING 11 90 106 TRENDS Category Outlook: 59 Bread | Bun | Roll Category Outlook: 67 Bars International Market 90 INNOVATIONS Category Insight: 75 Bread | Bun | Roll Category Insight: 83 Bars Commercial Baking Channel 103 Supplier Solutions 106 Ad Index 112 QUICK READS Editor’s Note 12 Seen and Heard 15 Business Intel 97 The Last Word 114 75 Departments IN THIS ISSUE

Don’t Pour from an Empty Cup

It’s February, but my New Year’s resolution is still a work in progress.

I’ve made some strides by eating better and keeping my cookie intake at a reasonable level, and I’ve signed up for my first half-marathon since before the pandemic. But the “get more sleep” part needs a little work. Let me put it this way: If this were the ’80s, the National Anthem would be fading to snow on my TV as I write this.

Some people think, “Self-care is for softies.” But consider this advice a friend once gave me: You can’t pour from an empty cup.

Yes, there’s work to be done and companies to run. The best leaders put their teams first, but if we don’t take care of ourselves, we’ll eventually have nothing left to give.

It’s been a rough couple of years, and while we’re all ready for a reset, we’re not out of the woods just yet. We’ve got to be all-in on finding innovative solutions to the ongoing challenges and prepare for the new ones coming our way. Doing that requires a full cup. Innovation comes from critical thinking, and that demands clarity.

JOANIE SPENCER Editor-in-Chief | joanie@avantfoodmedia.com

Resolutions don’t usually make it past January, but I hope you will consider joining me in a commitment to take better care of ourselves so we can give the best of what we have to offer to our companies, our teams and the industry in 2023.

FEBRUARY 2023 Q1 12

A NOTE FROM THE EDITOR

Proven to Lower Energy Costs

ePAN® designs from American Pan have been proven to save bakeries money on every bake. In fact, one customer reduced gas usage by almost 8% year over year by switching to an ePAN.

amount of dedicated space. ePANs can fit on your line and save you money from the

Energy solutions like wind turbines and solar panels are a major investment and require a large amount of dedicated space. ePANs can fit on your existing bakery line and save you money from the very first bake. Here’s how:

DECREASED OVEN TEMPERATURE

Oven temperatures have decreased by up to 85°F when using ePANs.

REDUCED BAKING TIME

Bakingtimeshavebeenreducedbyupto45seconds. Baking times have been reduced by up to 45 seconds.

REDUCED WEIGHT OF BAKING TRAYS & TINS

Traysandtinsareupto30%-50%lighter,requiringles Trays and tins are up to 30%-50% lighter, requiring less energyfrombakerysystemsandemployeesforhandl energy from bakery systems and employees for handling

+1.937.652.2151 | info@americanpan.com americanpan.com Visit us in Hall B1 - Stand 110!

MYIIIJ:fjl MY ••• "'--... ••••••• ••••••• SOLUTION. handtmann Ideas for the future. www.handtmann.us I www.handtmann.ca

Seen Heard AND

Bacon | owner | Freedom Foods, LLC

During a Pack EXPO’s 2022 Emerging Brands Summit, discussing how brands can best approach potential co-manufacturers

Photo by Tim Calabro | The White River Valley Herald

On the value of authenticity during the Authors@Wharton speaker series, as recorded on the ReThinking podcast with Adam Grant

COMMERCIAL BAKING 15

“I would prefer not to be sold on your business. I would prefer [brands] to share honesty, integrity and respect, and understand what you’re looking for.”

Cathy

“If you’ve got to tell somebody you’re in charge, you’re not in charge. When you’re preoccupied with that, you’re not free to meet people where they are. That’s what being authentic is all about.”

Carla Harris | senior client advisor, Morgan Stanley | former chair, National Women’s Business Council

“The sales and R&D parts of our company are one and the same. We’ve brought our R&D into preliminary sale conversations, and I think it’s brought this very fresh approach to the sales process that ultimately gets customers closer to what they actually want in a more responsive and effective manner.”

Jonathan Potts | regional sales manager | Companion Baking

WHEN PROOFING FLOOR SPACE IS TIGHT...

SEEN AND HEARD

“I know a lot of emerging brands are into digital, but in retail, brick-and-mortar is still a huge market. And once you get in there, there’s a lot of upside.”

Robert Berg | founding member | Iridescent Data

During an Emerge CPG webinar on targeting the right brick-and-mortar customer base

LOOK UP.

If you’re looking for a high capacity proofer that takes maximum advantage of minimum floor space, look no further. Our CapStep Proofer’s only limit … is your ceiling.

When your pans or peel boards enter the CapStep Proofer, they will be raised upward. When the pans reach the top of our system, they are gently moved over to the downward section by a transfer conveyor and lowered one level. This process continues – one Step at a time – until your product is ready to leave the proofer.

CapStep’s PLC controlled temperature and humidity HVAC and mechanical movement system is built for heavy-duty long life.

CapStep PROOFER

“In this whole startup world, you have to have patience every day because things do not go according to plan. And that’s been a big area of growth for me.”

Rebecca Abel | owner | D’Vine Cookies During season five of Troubleshooting Innovation podcast

capwayautomation.com

Call us today at 1.877.222.7929. We’ll help you take the next Step in automated bakery proofing systems.

JEWEL IN THE

CROWN

Crown Bakeries’

Smyrna, GA, facility boosts production, culture and R&D for its whole network.

BY JOANIE SPENCER

BY JOANIE SPENCER

18

FEBRUARY 2023 Q1

FEATURED BAKERY: CROWN BAKERIES

19

Photo by Olivia Siddall Avant Food Media

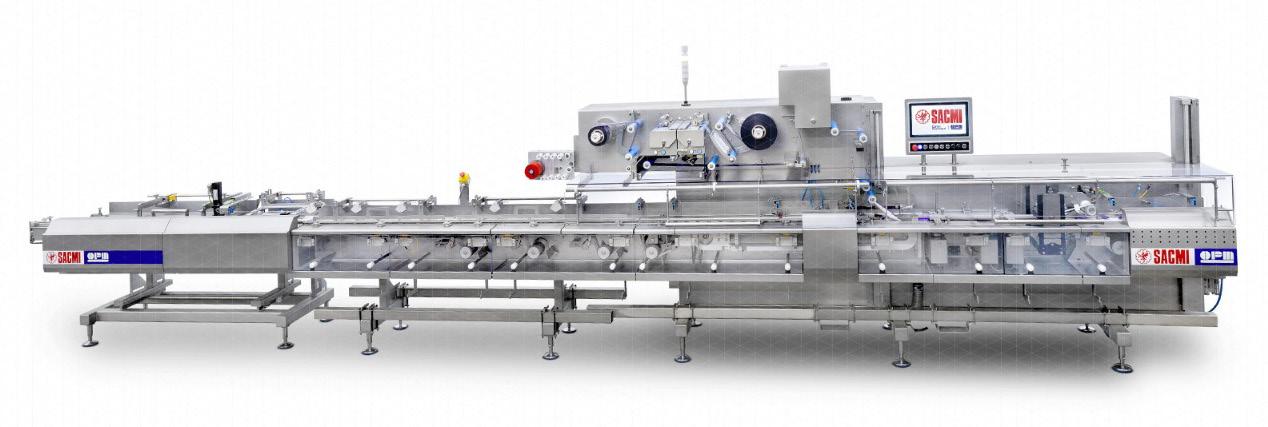

Mike Schlegel loves his job. As a director of R&D for Nashville, TN-based Crown Bakeries, he comes to work every day in a veritable product development playground in Crown’s newly renovated Smyrna, GA, facility, one of nine in the company’s network. Providing a space for collaborative innovation was the goal here. Well, at least one of them. To truly understand the impact of this approximately $20 million transformation, we must go back to the beginning … and take a peek at the future.

Crown Bakeries — born out of the bun and roll powerhouse previously known as Tennessee Bun Company — was founded in the mid-90s by industry icon and current American Bakers Association (ABA) board chair Cordia Harrington, who serves as the bakery’s CEO. Before the company rebranded as Crown Bakeries in 2021, brothers Yianny and George Caparos, two Baking Hall of Famers with decades of experience in croissant and sweet goods production, came on board when it recapitalized under Arbor Investments. From that acquisition, Yianny became Crown’s president and George took on the role of chief development officer.

In 2020, between the Caparos’ arrival and the company’s rebranding, Crown Bakeries acquired the Smyrna bakery from Specialty Bakers, a producer of tea cakes and sweet goods. No one can say for sure which came first — the plan to get into the laminated and sweet baked goods market or the availability of the Smyrna plant — but when the stars aligned, Crown Bakeries began charting a new course.

In this facility, the Caparos brothers saw potential, especially with existing assets including a Rademaker USA

20

CROWN BAKERIES

Photo by Olivia Siddall Avant Food Media

FEBRUARY 2023 Q1

Before it rebranded with its new name, Crown Bakeries acquired a Smyrna, GA, producer of tea cakes and other sweet goods, bringing Crown into the laminated and sweet goods market.

T: +1 3306502345 Effective &profitable breadproduction V: Modular concept y'f' Wide product variety vf' Excellent dough quality www.rademaker.com E: info@rademakerusa.com

laminated dough production line that had been greatly underutilized. Like those reality TV house flippers who can see the promise that awaits a fixer upper, George and Yianny walked through the Smyrna bakery and instantly envisioned Crown’s entry into the thaw-and-serve croissant game.

“That’s how we really look at all our new facilities,” said Chance Delany, director of strategic analysis for Crown Bakeries. “We look at a potential partner and say, ‘This is what we think it can look like in the future.’ Crown had a lot of clients who were looking for capacity with frozen croissants, and we saw that we could easily get into that market with this facility.”

With a long history of relationships on the laminated side, Yianny not only saw the opportunity to fill immediate needs for customers; he also recognized it as a launch pad into the category and a chance for serious growth.

“The acquisition of the Smyrna facility kickstarted our capabilities to bring Crown into the croissant business,” Yianny said. “It diversified our product mix and customer base. It allowed us to go back to those areas where we had long, tenured relationships, and that allowed us to grow exponentially in a new market.”

In less than two years, Crown entered the laminated and sweet baked goods game in a big way.

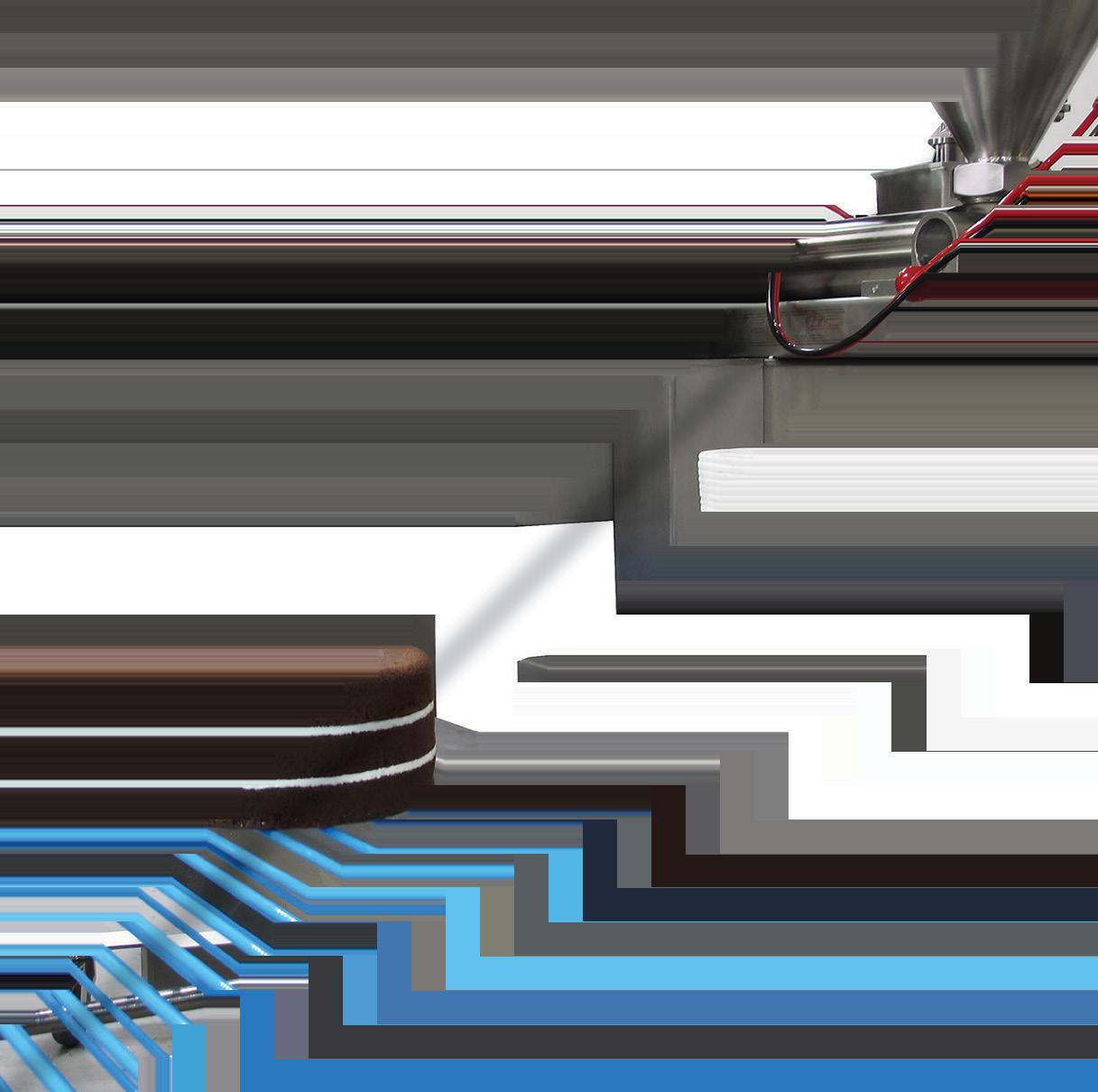

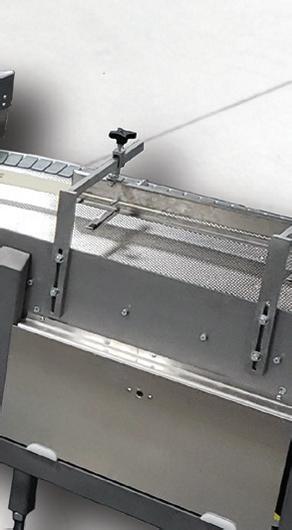

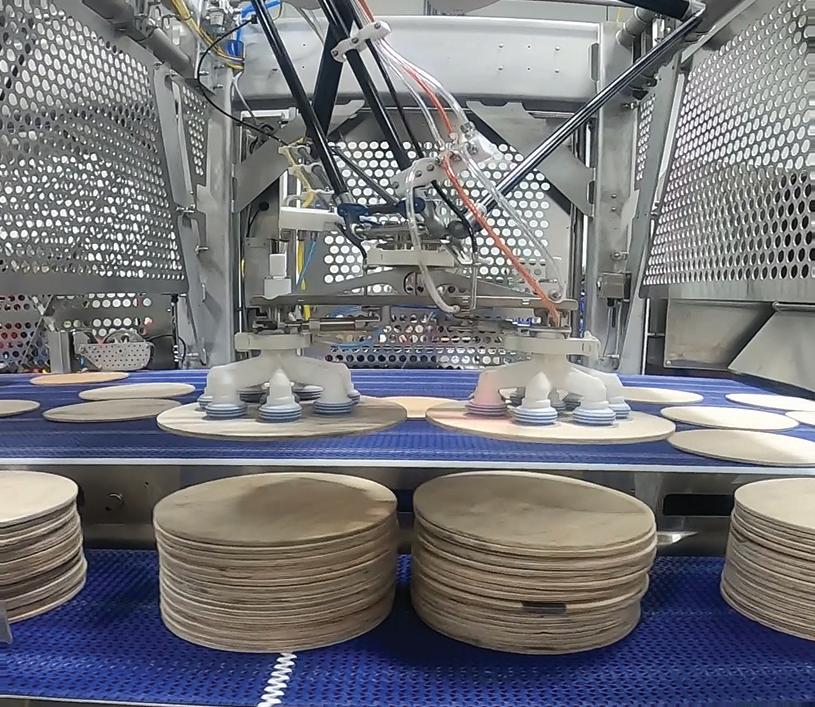

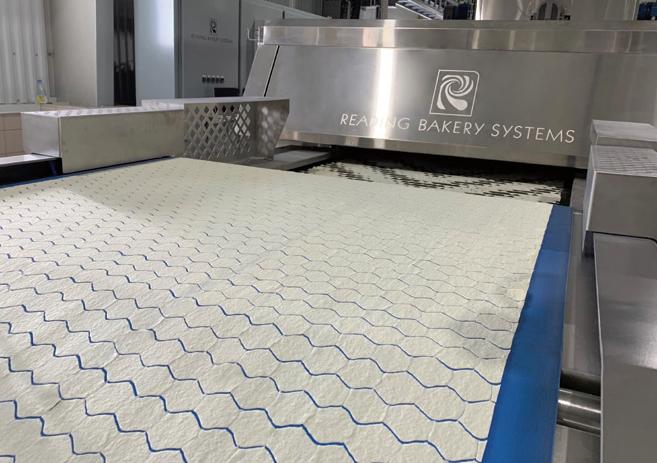

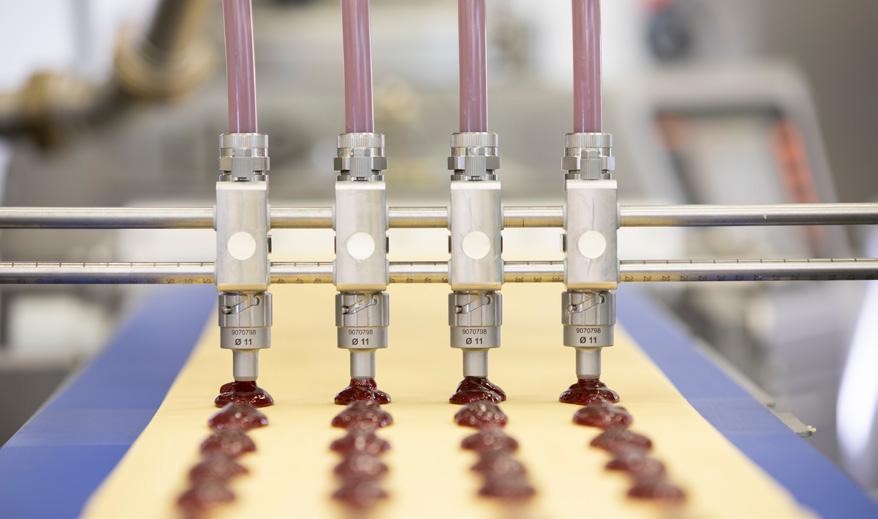

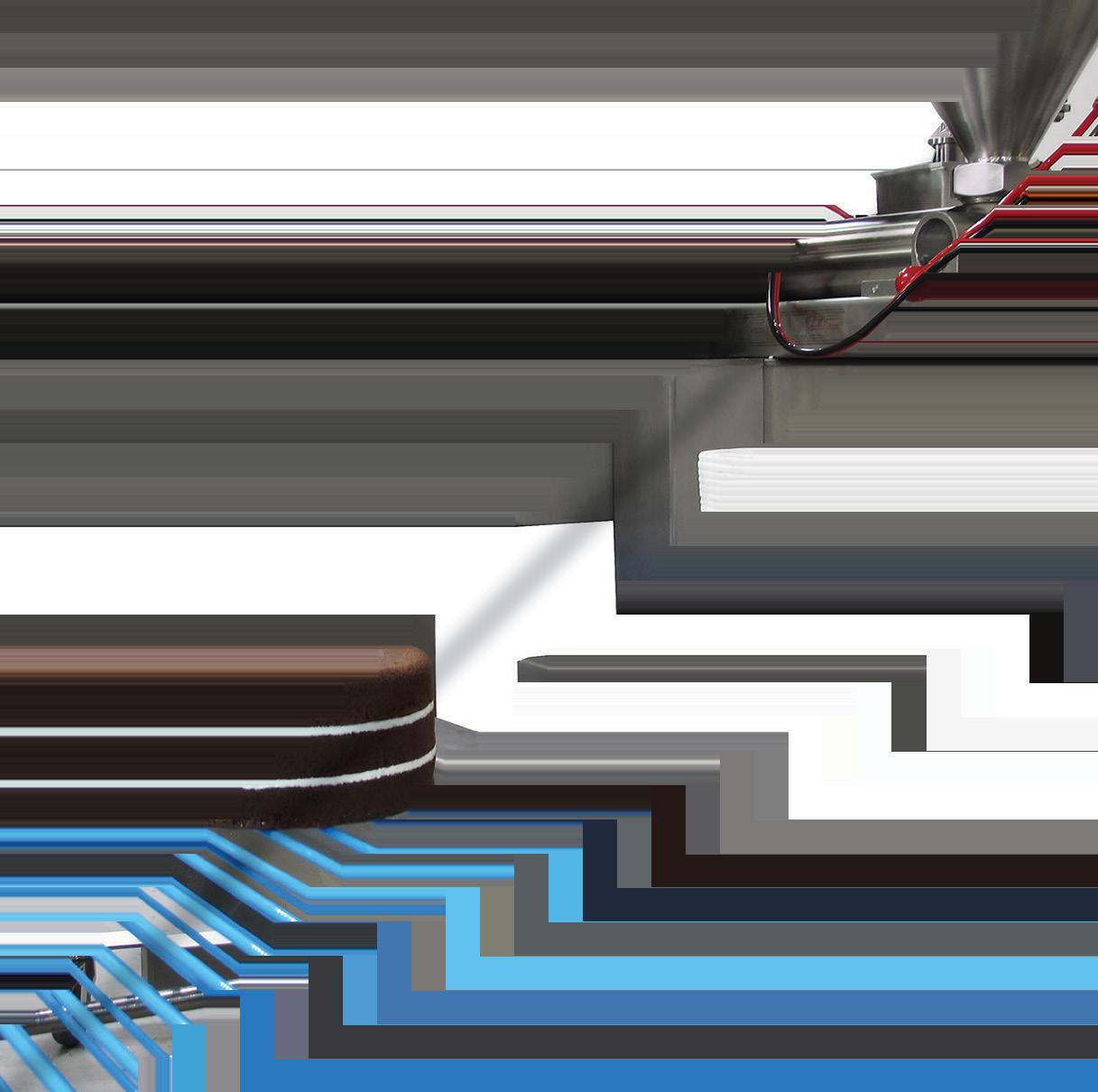

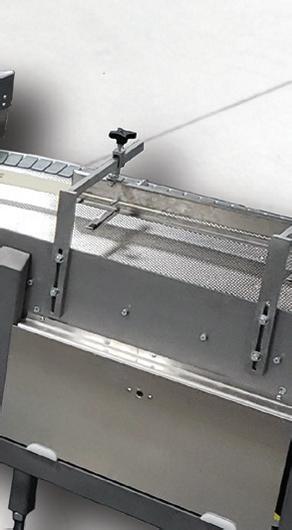

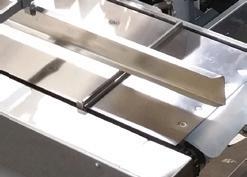

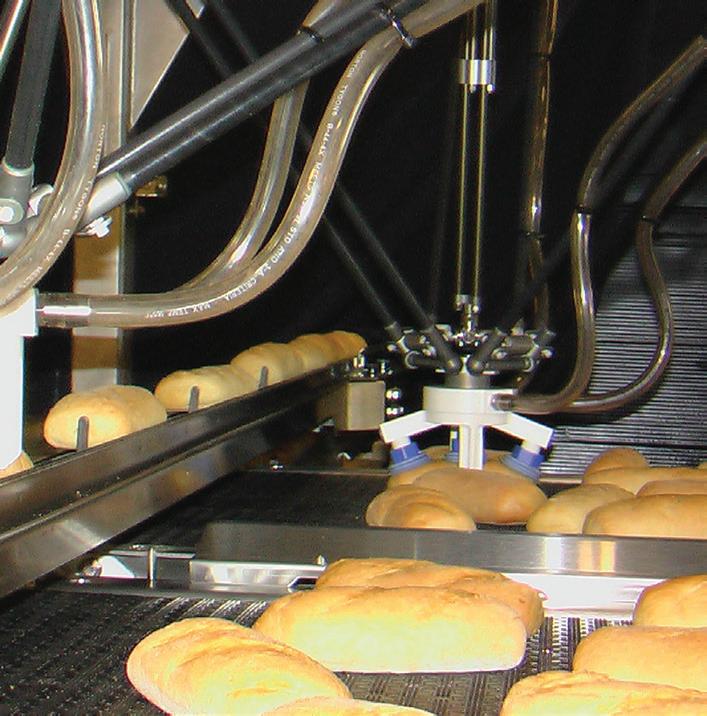

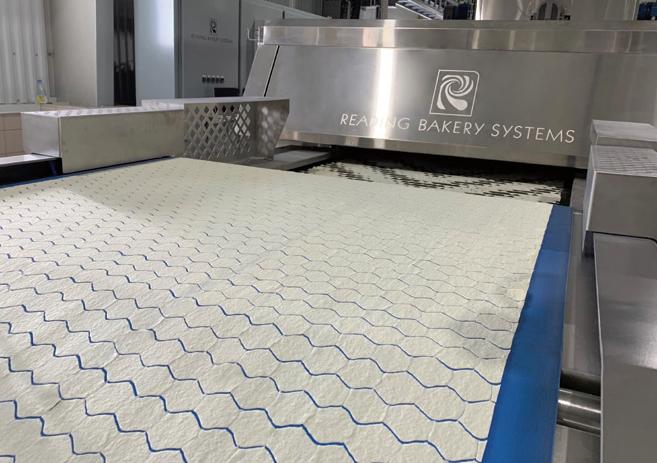

Today, the Smyrna bakery produces custom-finished frozen croissants on a Rademaker line and mini cinnamon rolls with the help of some RONDO modular pieces, as well as battered baked goods, including mini muffins and tea cakes, on an Auto-Bake line from Middleby Bakery.

The quick entry allowed the company to double down on its investment by not only upgrading the existing equipment but also completely overhauling the entire facility and building a state-ofthe-art R&D lab. It also allowed for the installation of three more Rademaker high-speed croissant lines in Crown Bakeries’ Music City, TN, and Pleasant Prairie, WI, facilities.

The growth has already generated capital to renovate 30,000 sq. ft. in the Smyrna facility, adding more production space and up to two more lines, which are currently projected to be up and running next year.

The timing of the May 2020 acquisition meant the equipment had to be overhauled in the height of the pandemic. That was no simple feat, considering business travel and onsite interaction had practically dissolved. Luckily, Crown and the Caparos brothers already had long-standing business relationships with the equipment

vendors. So, when the bakery called, the OEMs answered.

The Rademaker line — a key piece of equipment for croissant production — needed some TLC to get the bakery in business fast. The Rademaker team spent several weeks at the bakery to accomplish that, as did teams from other OEMs including AMF Bakery Systems, Bundy Baking Solutions and Auto-Bake.

“We were in the heart of the pandemic, and they were all here with us, doing the renovations and upgrades we needed to be operational in a short timeframe,” Yianny recalled. “We were so fortunate to have OEMs who partnered with us and supported us, especially during that challenging time, to get the equipment up to standard and make this a successful run.”

Those upgrades provided the efficiency needed to crank out orders that were

22

FEBRUARY 2023 Q1 CROWN BAKERIES

From left: Yianny Caparos, president; Chance Delany, director of strategic analysis; Mike Schlegel, director of R&D; George Caparos, chief development officer; and Kory Mickelson, chief commercial officer.

Photo by Olivia Siddall | Avant Food Media

-=--- ----

coming in fast — and maintain the high quality that Crown Bakeries products are known for.

While some bakeries rely on internal teams to improve or rebuild equipment, Crown’s relationships with its vendors allowed the OEMs to do that heavy lifting.

Rademaker enhancements brought next-level efficiency to the laminated production, but that was just the beginning, as more improvements were made on the other side of the operation.

After the Auto-Bake team recalibrated the batter line’s oven and replaced its chains and added degreasers, production efficiency and product quality significantly improved for the entire line. Delany estimated the Auto-Bake team rebuilt more than 50% of the machine to achieve those results.

Ultimately, Crown created a winning combination: operational expertise of its employees on the plant floor paired with the top equipment manufacturers for those specific machines.

By focusing workforce development on product proficiency, operators can recognize when a croissant or sweet good is out of spec, but if there’s an issue with the equipment, they can rely on the supplier for help in repairing it.

“Because our leadership is so tight with our vendors’ leadership, we can easily convey our specific needs,” Delany said. “There’s no one who knows the machines better than the OEMs, especially with the labor market so tight today. You can’t lose sight of your OEMs, or you’ll risk losing sight of the machines and how they work.”

Upgrades played a huge role in the renovation, but Crown also invested in new technology on the plant floor.

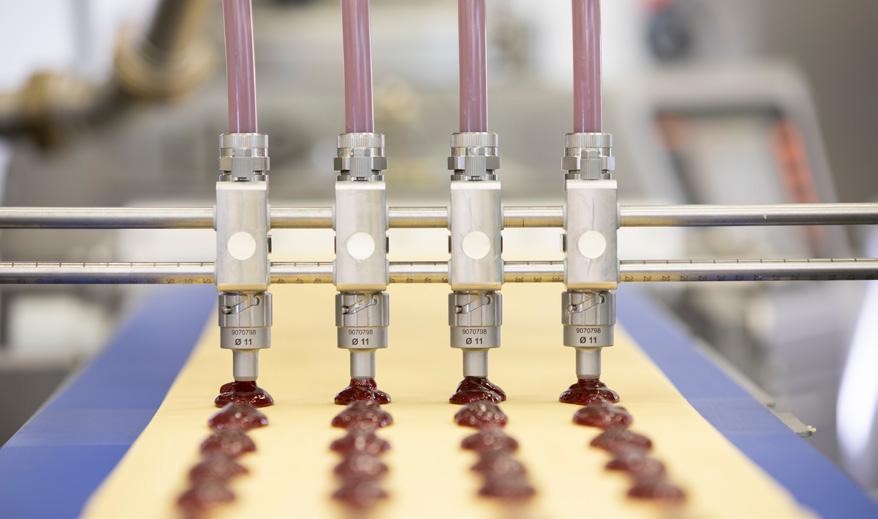

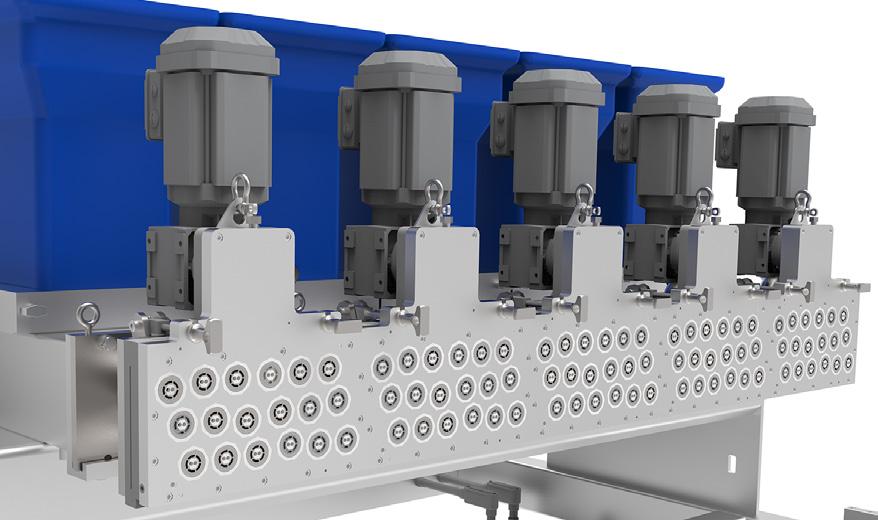

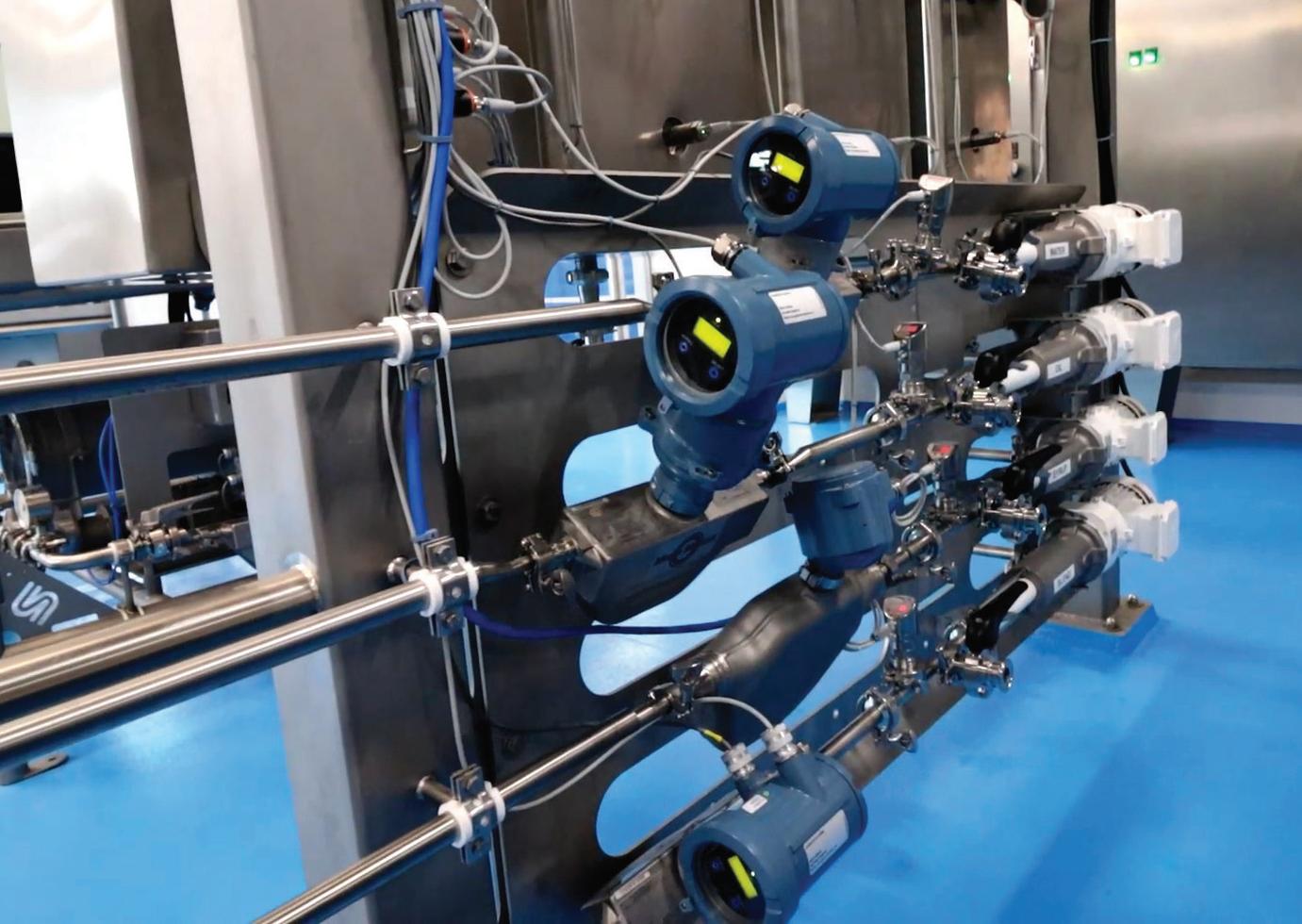

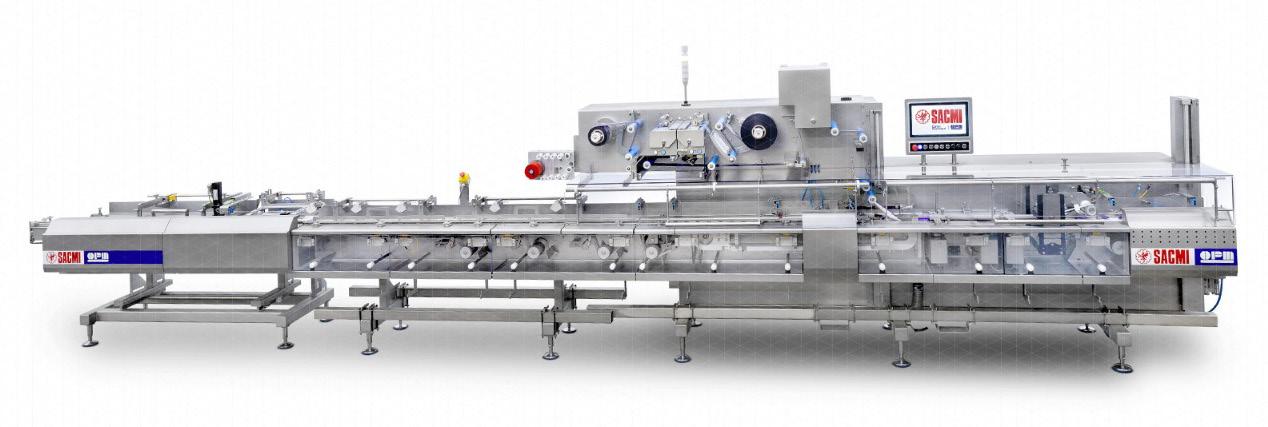

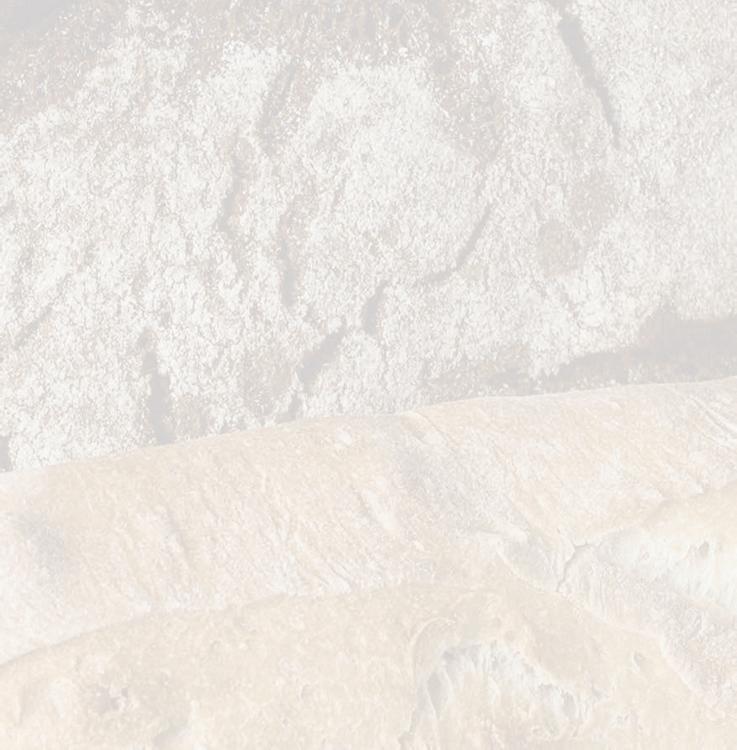

On the batter line, new Yamamoto scales and Syntegon packaging lines run different configurations based on bulk or retail. Although the Smyrna plant is known for its product flexibility, the scale on the batter line was well suited for the packaging upgrade.

“When you’re making the investment to automate packaging, it’s because you have enough scale, and you’re committing to that capability,” said Larry Murray, regional director of operations. “Without that scale, you’d need to index the line for flexibility in packaging. But we have the opportunity to have scale on this line.”

24

FEBRUARY 2023 Q1 CROWN BAKERIES

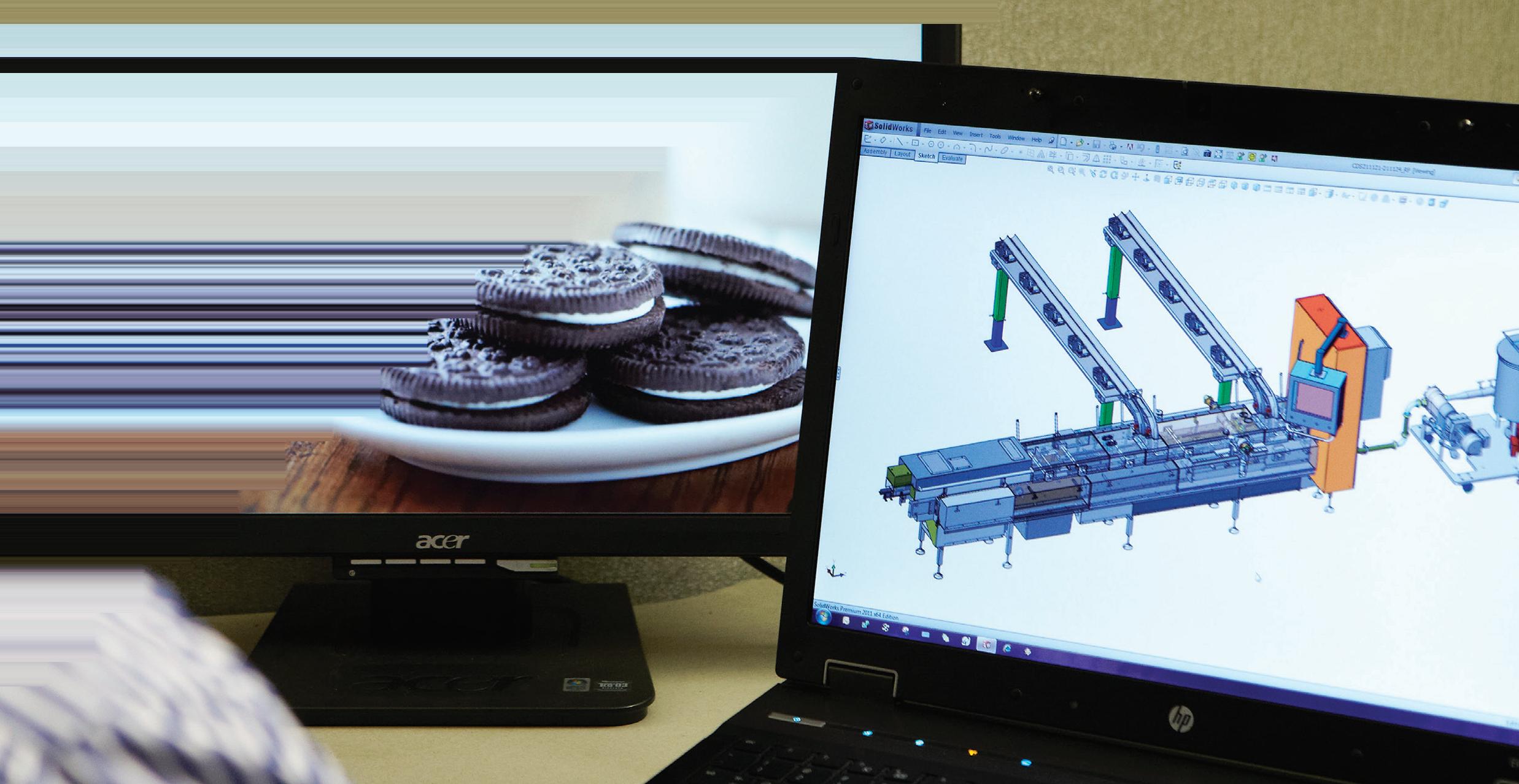

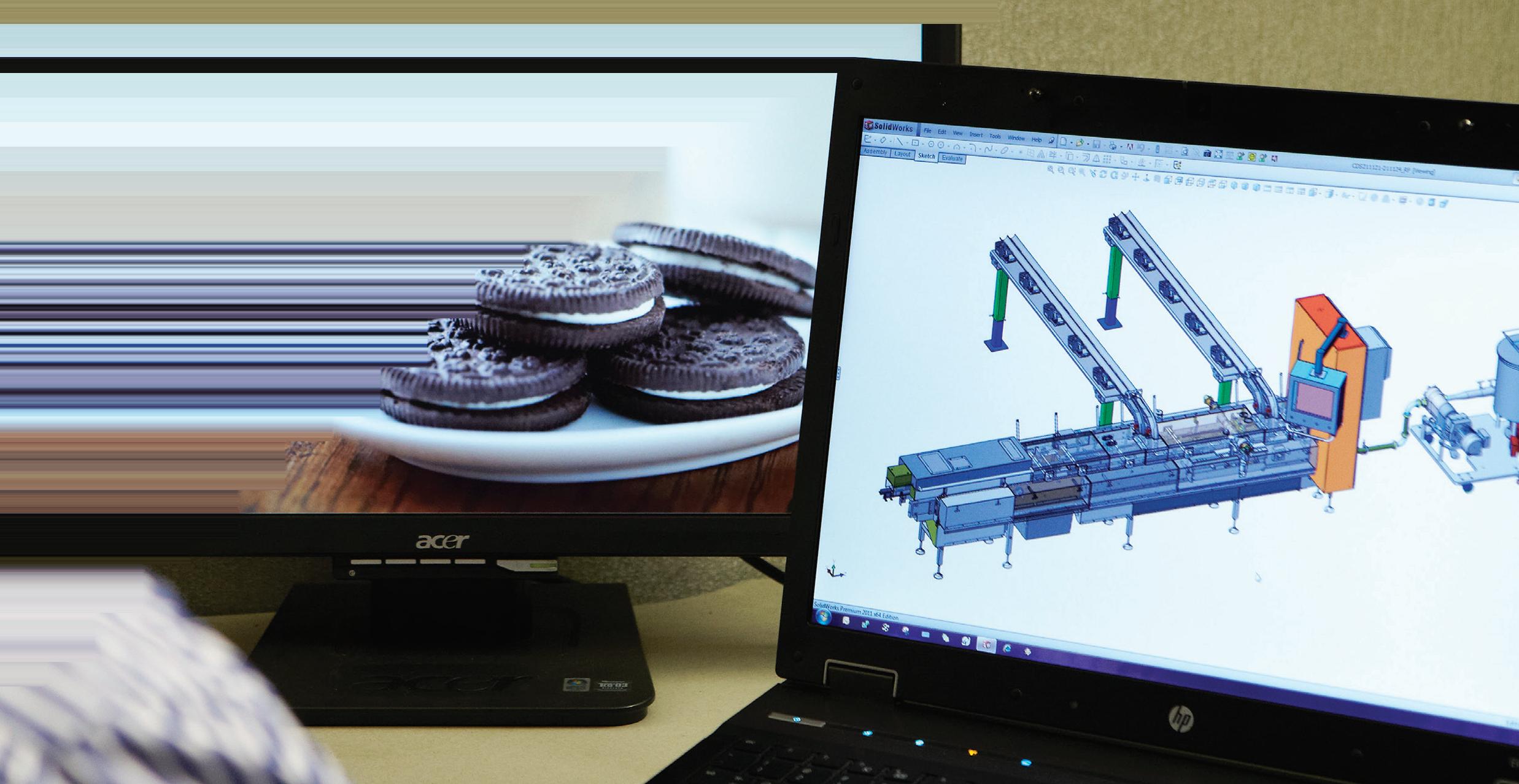

Photo by Nigel Marson

—Below Investment in the R&D lab ensures the team has a playground for innovation.

RONDO industrial solutions –More than 30 years of experience www.rondo-online.com Designed to meet the most stringent hygiene criteria. In 24-hour operation, the RONDO ASTec lines uniquely combine gentle processing of dough with the utmost precision. More about ASTec lines RONDO North America RONDO Inc. Moonachie, N.J. 07074 / USA Tel. +1 201 229 9700 info.us@rondo-online.com

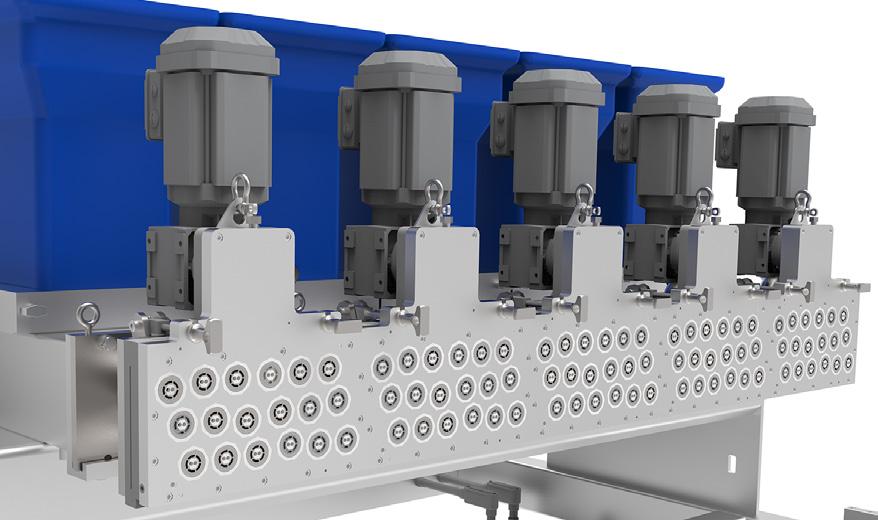

On the laminated side, Crown invested in three new Empire Bakery Equipment high-speed bowl mixers to complement the Oakes mixers on the batter line.

Meanwhile, the Rademaker equipment still has the flexibility needed to hand-pinch or automate, depending on product type and shape.

“We have particular customers that require something unique,” Murray said. “Some customers need a specific shape for croissants that are made for sandwiches, for example, and now we have the ability to do that on this line.”

The Smyrna acquisition may have put Crown Bakeries on the map for croissants and sweet goods produc -

tion, but the renovation served bigger purposes, starting with Crown’s culture, where Harrington’s high standards have not waivered since the company was founded.

“The value of Crown is not really in the nine facilities or the product diversification,” Yianny said. “I can honestly say it’s in the people who work here. Our equipment is great, but it’s the people that make this place hop.”

Because of that, focusing on employee wellness was an overarching goal for not only the operation but also the total facility. In an era where employee recruitment and retention are constantly top of mind, any baking company undergoing facility

renovation would do well to take a cue from Crown.

“We come into an acquisition or a renovation wanting to hit a higher standard because retaining employees is so important,” Delany said. “We want to make an environment where people feel like they come to work and they’re safe, and it’s a place where they can interact and grow. It’s our first and foremost priority, followed by other quality standards. Then we make the proper investments to achieve all of them.”

Employee wellness is a driving force every time a bakery is integrated into the Crown Bakeries network.

26

FEBRUARY 2023 Q1 CROWN BAKERIES

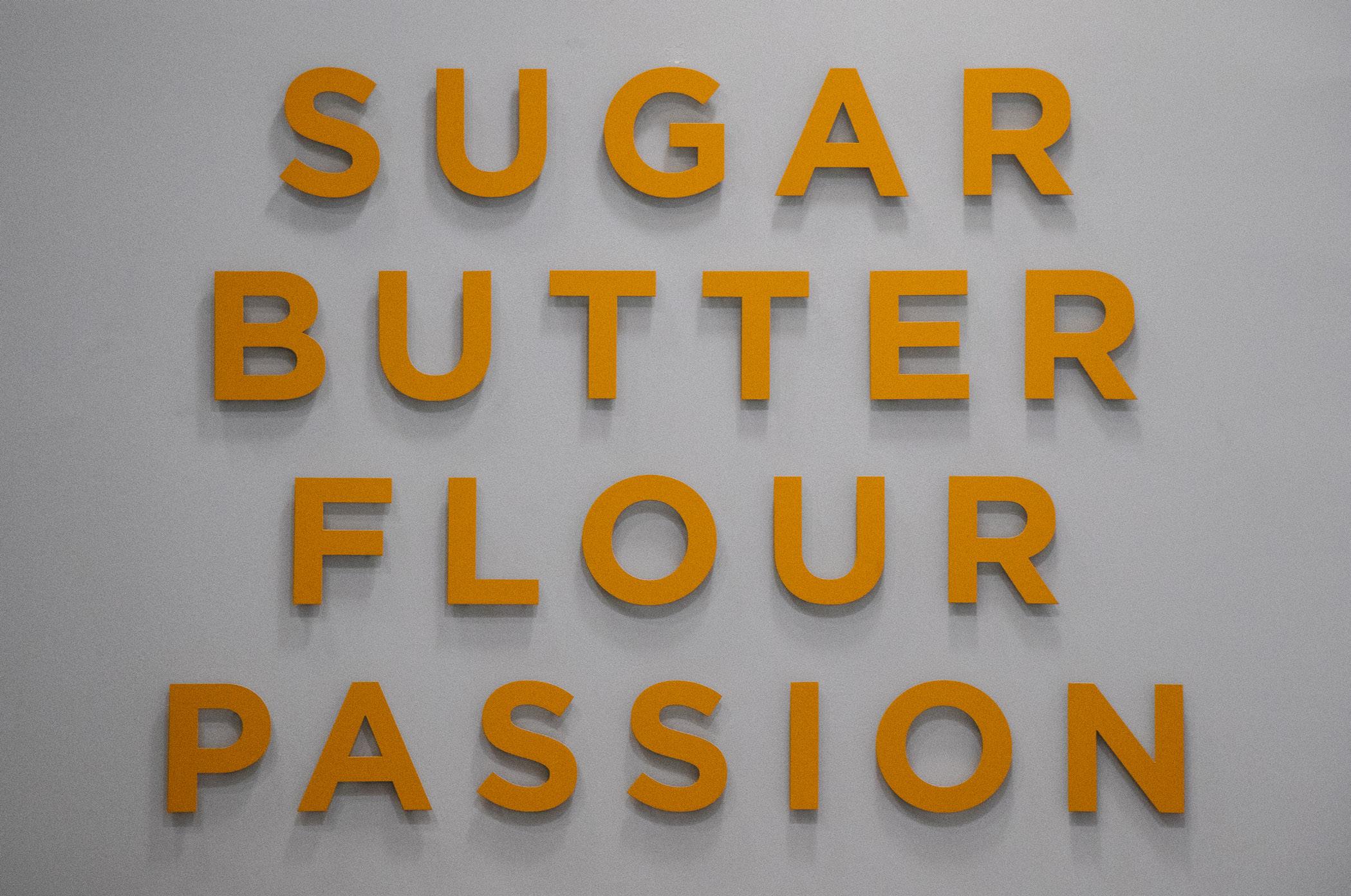

Words on the wall of the bakery’s entry were chosen by employees to exemplify the values at Crown Bakeries.

Photo by Olivia Siddall Avant Food Media

AUTOMATEDSOLUTIONSFORDIVIDING, ROUNDING, SHEETING, MOULDING,ANDPANNING.

AMF Flex means unmatched scaling accuracy and more consistent product quality from the industry's leading extrusion and volumetric dividing, rounding, and makeup systems. Engineered for efficiency, flexibility, and precision, our fully automated Flex equipment has been redesigned with sanitation and food safety in mind.

The new ADD-S Bread Makeup System incorporates the leading sanitary design elements for flexible and precise dividing with quick product changeover. Quick clean manifolds and easy access frame designs are combined with toolless sanitation and maintenance.

BAKERY SYSTEMS A Markel Food Group Company Scan to learn more AMFBAKER�COM I SALES@AMFBAKER�COM © 2023 AMF Bakery Systems

USA I Netherlands I UK I China I Singapore I Canada I Mexico

“We have to be an industry leader in those areas,” Delany added.

Building amenities that came with this renovation include extended locker rooms, a mother’s room and a break area big enough to host company-wide parties and training events. That makes a huge difference for Smyrna’s 150 employees.

Designed with the intention to create a culture of collaboration, the space includes several internal windows that overlook the bakery floor, eliminating separation between the “office” and the “operational” aspects of the business.

To that end, meeting spaces have a bird’s-eye view of the croissant line, and all production supervisors are officed bullpen-style directly off the floor, also with clear views, to promote open communication on all fronts.

The team took inspiration from the best practices of several Fortune 500 companies in how they designed the building.

“We put in great effort to make this a place where people feel proud to work,” Delany said. “People spend so much of their life at work, so we want to make sure they’re comfortable here. We looked at how Fortune 500 companies are empowering their people and their teams. They’re making progress in the labor pool, and we wanted to draw from that and even improve on it.”

From the moment the company moved into Smyrna, Crown’s culture was a flag in the ground. Word of mouth spread quickly, and even those who had worked at the plant years before made their way back to see what the buzz was about.

28 FEBRUARY 2023 Q1 CROWN BAKERIES

The Smyrna facility’s renovation includes additional amenities, which make a positive impact on Crown employees.

Photo by Nigel Marson

ONE CONTINUOUS PERFECT BAKE FROM END TO END

MIDDLEBY’S TURNKEY BAKERY SOLUTIONS HAVE GOT YOU COVERED.

TOP OF THE LINE

Middleby optimizes best in the industry end-to-end solutions and provides you with top tier lines for all your baking needs, with complete customer support throughout equipment development, installation, and production.

Breads | Buns | Cookies | Crackers | Cakes | Muffins | Pastries | Pies | Pizzas

HUNGRY FOR MORE?

“Employees have been reaching out to their network because these changes have boosted morale, and there’s a lot of pride in coming to work here,” George said. “They’re saying to their friends and family, ‘This is a great place to work. This company cares about us.’”

And that leads back to Schlegel. When he comes to work in the R&D lab, he gets to participate in a think tank, where product developers can simultaneously focus on their specific projects and discover new ideas from one another.

“This space allows me to get really detailed in my benchwork,” Schlegel said. “It makes the work efficient, and it also makes it fun. When I’m in here with a customer, they can see my approach and process, and we can solve problems and try new things. At the same time, I could be working on something but see what someone else is doing and say, ‘Hey, that could help us with this customer, too.’”

While Smyrna’s primary focus is sweet goods and croissants, the R&D team can bolster the entire Crown network by prototyping any product from every facility. It’s a juggling act, for sure, but the space was designed to support that. The lab’s circular flow allows for easy scaling of raw materials, mixing, machining, baking and finishing, with the ability to quickly test at scale.

This state-of-the-art lab was designed to be a focal point for the plant and a hub for Crown Bakeries. Located just outside Atlanta, the bakery is close to the headquarters of many customer accounts and easily accessible for the Crown Bakeries network. Here, the Smyrna R&D team can work hand-inhand with customers and other Crown

culinary experts to develop new and custom products.

“With the number of foodservice chains headquartered in or near Atlanta, this lab provides easy access for them to partner with us and collaborate on innovation,” said Kory Mickelson, chief commercial officer of Crown. “The R&D lab wasn’t just built to support this bakery; it was created for all of Crown Bakeries.”

There are pilot labs in other locations, but Smyrna is where innovation comes to fruition. All Crown facilities have the equipment to execute customer specifications, but this lab provides a space to ideate unique formulas that perfectly suit any customer’s needs. It’s in this product development playground where Schlegel gets to help design the games, whether it’s dreaming up new products, assisting customers with formulation tweaks, or problem- s olving with cost reduction or raw materials sourcing. And it’s all done in real time.

“This lab is the cat’s meow,” Yianny said. “It’s opened the door for us to entertain customers and work with our people to create exciting products and build p artnerships. It’s a perfect place to treat our customers like royalty and personalize the experience.”

George and Yianny may be the baking industry’s version of the h ouse-flipping Property Brothers , but there’s one key difference: The investments they and Arbor Investments make in Crown Bakeries’ renovations are for the good of the company and its customers.

As the company continues its growth as a unified brand, the new lab, equipment upgrades, added a menities and process improvements make this bakery a standard bearer for Crown Bakeries.

“The value of Crown is not really in the nine facilities or the product diversification. I can honestly say it’s in the people who work here.”

30 FEBRUARY 2023 Q1 CROWN BAKERIES

Yianny Caparos | president | Crown Bakeries

•Ultra Hygiene Stainless ashdo n •Track Glide Z-6000 Reduce Contamination •Ultra Series DDS Intralo SELM Belt •Auto-Pressurization Infiltration Control •Typhoon Belt Washing uto-Cleaning Systems •Powerwash 5000 High Pressure Washer •Sequential Defrost u t o - a s h C o i l s •Series 7000 Stainless Full elded Floors

FREEZING INNOVATION IN MOTION NEWHYGIENETECHNOLOGY! 20 E ecutive Blvd • Farmingdale, N 11735 www.ij hite.com • sales@ij hite.com • (631) 293-2211

SPIRALBLAST

“This investment allows the industry at large see our organization as solutionsoriented,” Mickelson said. “Instead of going through the Rolodex, so to speak, customers can look at Crown Bakeries as a one-stop shop. The breadth of our capabilities encompasses large, important categories for our customers.”

Once known primarily as a regional bun supplier, Crown’s capabilities are becoming limitless.

“We want to see our products on every corner of the intersection,” Yianny said. “Whether it’s a convenience store, supermarket, hotel or foodservice. That’s the goal.”

Getting there requires more than a robust product portfolio. Crown Bakeries’ investment in production, R&D and its workforce, along with a commitment to the culture built by its founder, is the path forward as demonstrated in the makeover at Smyrna.

“We want to make sure the industry knows who we are and what we’re planning to do,” George said. “We’ve had a tremendous amount of improvement here, and when our customers visit, they see the huge differences in what we can do.” CB

INNOVATIONS FROM THE BAKERY FLOOR

In the nearly 200,000-sq.-ft. Smyrna, GA, facility, Crown Bakeries invested around $20 million and spent 18 months completely overhauling the entire bakery, from the plant floor to common spaces, to a more than 1,800-sq.-ft. R&D lab. This BRC- and SQF Level 2-certified location marked Crown Bakeries’ entry into the laminated and sweet baked goods market, an area that has exploded for the company in just two years. Below are the innovations that can be found on the bakery floor and in the lab.

AMF Bakery Systems proofer, oven and spiral cooler

Auto-Bake oven

Bundy Baking Solutions pan system

Empire Bakery Equipment high-speed bowl mixers

GEO/Comas depositing

IJ White spiral freezer

JBT blast freezer

KB Systems flour system

Oakes bowl mixers

Rademaker sheeting, laminating and makeup line

Revent test ovens

RONDO makeup equipment

Syntegon packaging equipment

32

FEBRUARY 2023 Q1 CROWN BAKERIES

The laminated line produces finished frozen products with the flexibility to fold or hand-pinch, depending on customer specifications.

Photo by Olivia Siddall | Avant Food Media

Made for your blending process for process

ROSS Ribbon Blenders meet the toughest requirements for quality materials and heavy-duty construction. Standard features include thick stainless steel troughs, low-maintenance gearmotors, BISSC-certified design and much more.

Need a Ribbon Blender customized for your process? ROSS offers MANY options. Complete control systems, spray nozzles for coating, pressure feed vessels and vacuum operation, to name a few.

Used in a wide range of food applications, from trail mix snacks and sugar confections to cake batters and icings, we can customize a ROSS Ribbon Blender for your application.

Sizes from ½ cu. ft to 1000 cu. ft. A variety of standard models are in stock for faster delivery. Available worldwide.

mixers.com/ribbon-blenders mixers.com 1-800-243-ROSS

CONFIDENCE. BUILT IN.

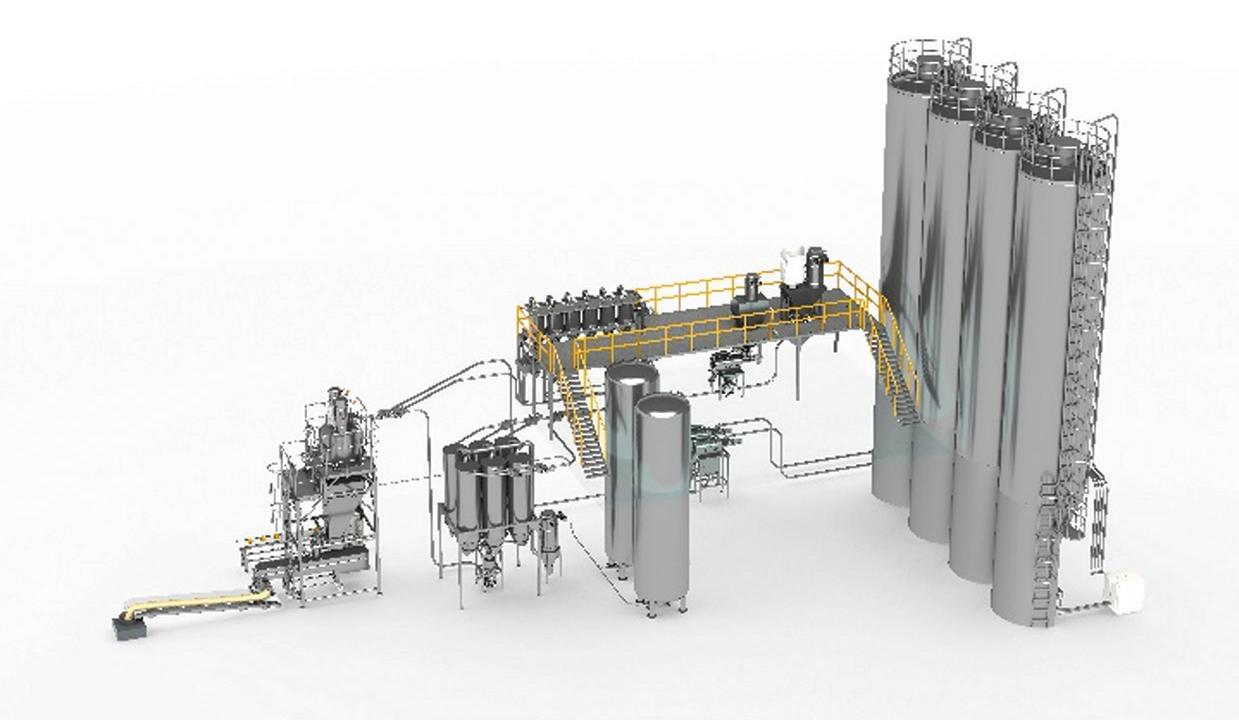

Quality, robust ingredient automation. Reliable, repeatable process management. Unmatched service and exceptional value that create enduring relationships. The only global provider focused solely on food.

Whether it’s storing, sifting, metering, weighing or transferring, Shick Esteve is your complete flour reclaim and ingredient automation systems provider.

Contact us to learn more.

FOLLOW US

shickesteve.com

SCAN ME

Driving Forward

Eric Dell joins ABA as president and CEO with a future-facing mindset.

BY JOANIE SPENCER

BY JOANIE SPENCER

36

All photos courtesy of ABA

FEBRUARY 2023 Q1

Eric Dell has no misconceptions about what it takes to move an industry forward. As the new president and CEO for the American Bakers Association (ABA), he has experience in Washington DC that spans from lobbyist to congressional chief of staff, forming the roots from which his association advocacy work has grown.

Dell has a long list of values that align with ABA and the commercial baking industry, starting with a passion for service that leads to a better future for all.

“Coming from the Hill, I took my knowledge of working with constituents to working with member companies,” he said of his transition from congressional work to association advocacy for the National Automatic Merchandising Association (NAMA).

Spending a decade with NAMA, Dell’s roles included building the association’s government affairs team, heading its external affairs and spending two years as EVP. In that time, Dell fine-tuned the art of the association member experience.

“Constituents elect you in a congressional office,” he said. “Similarly, in an association, the members give you purpose.”

For Dell, that purpose is about doing good for the association and the industry it serves.

While the “NAMA” Dell came from is not to be confused with the flour miller’s association, it is a group steeped in food and beverage, specifically snack vending and office coffee service. This NAMA has also been connected tangentially with the baking industry, with the two associations having some crossover membership and collaborative work over the years.

Both associations have shared involvement in advocacy through the Food & Beverage Issue Alliance, which focused on issues like labeling and other regulatory topics concerning the Food and Drug Administration (FDA) and the US Department of Agriculture (USDA).

From the shared interest in government affairs and advocacy with FDA, USDA and the Environmental Protection Agency, Dell is well versed in issues like front-of-pack calorie disclosure and public health, which has been a personal passion throughout his career. In fact, one of his more notable accomplishments was assisting in the creation of the 2020 commitment to increase better-for-you options in vending machines throughout the US.

“It was truly a commitment by NAMA members — making up the majority of vending sales in the country — who were committed to it,” Dell said. “We teamed up with the Partnership for a Healthier America to find ways to work together with the public health community. It’s a great example of my philosophy that working together creates solutions.”

Not one to focus on the past, Dell is forward-focused for the baking industry, from enhancing ABA’s already powerful government relations, to creating more environmental sustainability opportunities, to finding new ways member companies can contribute to food equity in America.

That’s a lot to bite off in his first month leading an association, but Dell has marked them as priorities in ABA’s strategic development plan, taking place with the executive committee, board and membership this year.

“You can’t tackle it all at once, but these are issues we should have out in front,” he said.

37 COMMERCIAL BAKING EXECUTIVE PROFILE: ERIC DELL

“When we partner up, we can create solutions for the industry’s biggest challenges.”

Eric Dell | president and CEO | American Bakers Association

“If you’re not in front of these issues, you can’t pave the way. And these are areas where our industry can be the leader. Customers and consumers are demanding these things, and it’s where we need to be positioned.”

Looking at those issues like food equity and sustainability, Dell sees opportunities to propel the industry. Doing so requires uncovering member companies that are “hidden gems,” quietly setting standards for best practices, so he plans to focus on members that are leading the way but remain under the radar.

Not only will that open the door for other members to follow new best practices, but it also creates a compelling

narrative, especially for lawmakers and elected officials.

“We need to establish some discovery to determine where we are and what kind of commitment we can make,” Dell said. “What are the right areas for that commitment? I don’t know the answer, yet, but our strategic planning will illuminate that.”

Those kinds of commitments are what ignite Dell’s passion for industry advocacy. It’s a fire that has burned since he volunteered in politics as a teenager in rural South Carolina.

“It’s crucial to help industries navigate the political process and educate lawmakers,” he said.

It’s not just his professional perspective on advocacy that spans both sides of the coin; Dell’s passion comes from his belief that change happens through educating both lawmakers and constituents.

“I learned early on that ‘lobbyist’ is not a dirty word,” he said. “It’s important to the process. It’s important to bring members of the industry from around the country — off the bakery floor — to sit with their elected officials.”

Legislators can’t be educated from the confines of their offices, though. Dell believes in the power of showing, not telling, and he encourages bakers to open their doors and welcome elected

FEBRUARY 2023 Q1 38

EXECUTIVE PROFILE

Starting his post as president and CEO of ABA on the first work day of 2023, Eric Dell (center) brought energy to the staff ... and found energy to match upon his arrival.

Where a mix becomes a better mix. The answer to all your blending needs B.C. Williams Bakery Service | BCW Food Products 800.527.4104 | bcwilliams.com SOURCE•BLEND•INNOVATE

officials inside to show firsthand how the government impacts day-to-day bakery operations.

In Dell’s experience, this kind of bridge building and relationship development is the tangible definition of advocacy. In those terms, ABA can be seen as the “glue” between member companies and lawmakers, and Dell wants to prioritize that for the small- to mid-size baking companies that make up nearly 90% of ABA’s membership.

One area where Dell plans to b enefit members through advocacy is by reigniting ABA’s fly-in events in Washington DC .W hile the a ssociation h as been known for facilitating Hill visits for years, the pandemic has greatly impacted its momentum. But with the return of in-person events, Dell can now use his expertise to bring back the power of the fly-in.

The key is developing value beyond the connection with lawmakers. By making the event a networking opportunity, Dell has discovered that more companies get involved.

When that happens, a fly-in becomes an opportunity that leads to larger, often more diverse representation of the industry on Capitol Hill.

While fly-ins have long been a successful tool for ABA members, Dell brings a new perspective to build from that strength and give it a modern reboot. From his perspective, fly-in events are another effective way to create that two-way education that has been instrumental throughout his career, combining business, networking and advocacy into one experience.

“It’s advocacy, but it’s also getting business done,” Dell said. “If you build things from a business standpoint

from the beginning, people will come, and they’ll have a great experience. You only get one chance with these types of events, and you’ve got to get it right.”

It’s about creating new win-win opportunities for members and the industry.

“There are a lot of regulatory issues for the industry, and we can’t forget that part,” Dell emphasized. “And we also need to find new places for partnership because when we partner up, we can create solutions for the industry’s biggest challenges.”

ABA welcomed Dell to the i ndustry on the first business day of 2023, ushering in waves of change for the association. One transformation already in motion was an overhaul of ABA’s annual convention, set for March 26-29 in Amelia Island, FL. While Dell was not involved with the convention update, he is joining ABA during an exciting time of change.

Disruption has, in many ways, become the status quo. Dell isn’t afraid to shake things up a bit to create positive change in this mature industry. It’s something that was a mutual draw for Dell and ABA’s executive committee, led by board chair, Cordia Harrington, founder and CEO of Nashville, TN-based Crown Bakeries.

With a history of working with forwardfocused leaders, Dell suited just what Harrington and the executive committee

were looking for — and he complements her flair for innovation.

“Cordia is forward leaning and mission focused,” he said. “I work well with those types of leaders.”

Coming from a related industry, with lifelong experience in advocacy and a passion for partnership, Dell is ready to steer ABA and the baking industry ahead. That said, innovation doesn’t have to disrupt a firm foundation.

“ABA is well established on the advocacy front, and we have a strong, stable staff,” he said. “That means I can focus on the future in areas like strategic planning, where we can create new and valuable ways for members to be more involved. That ultimately leads to increased ROI for membership.”

Achieving these goals, of course, can only happen through action. As a husband and father of two active young boys, that’s something Dell knows a thing or two about. And he knows that energy is the precursor to action. Suffice it to say, energy was the first thing Dell brought to the table for ABA … and it’s what he discovered waiting for him.

“There’s energy in this association,” Dell observed. “And we’re using that energy and driving forward.” CB

FEBRUARY 2023 Q1 40

EXECUTIVE PROFILE

“[Advocacy] is crucial to help industries navigate the political process and educate lawmakers.”

Eric Dell | president and CEO | American Bakers Association

It’s ingrained in us © 2023 Ardent Mills, LLC. All rights reserved. At Ardent Mills, we are your supplier partner to solve today’s challenges At Ardent we are your partner to solve and stay ahead of tomorrow’s trends. With our nationwide footprint and stay ahead of tomorrow’s trends. With our nationwide and localized support, we help you respond to market dynamics and localized support, we you to market dynamics. And with our best-in-the-business research and resources, like And with our best-in-the-business research and resources, like our Innovation Center, we’re continually developing concepts and our Innovation we’re concepts and products that that can help you seed can you seed growth. Let’s innovate what’s next. next. Visit ardentmills.com/together today. *Ingredients depicted in raw form and not ready for use.

let’s bring ideas to life

Solutions for today. Growth for tomorrow. Together,

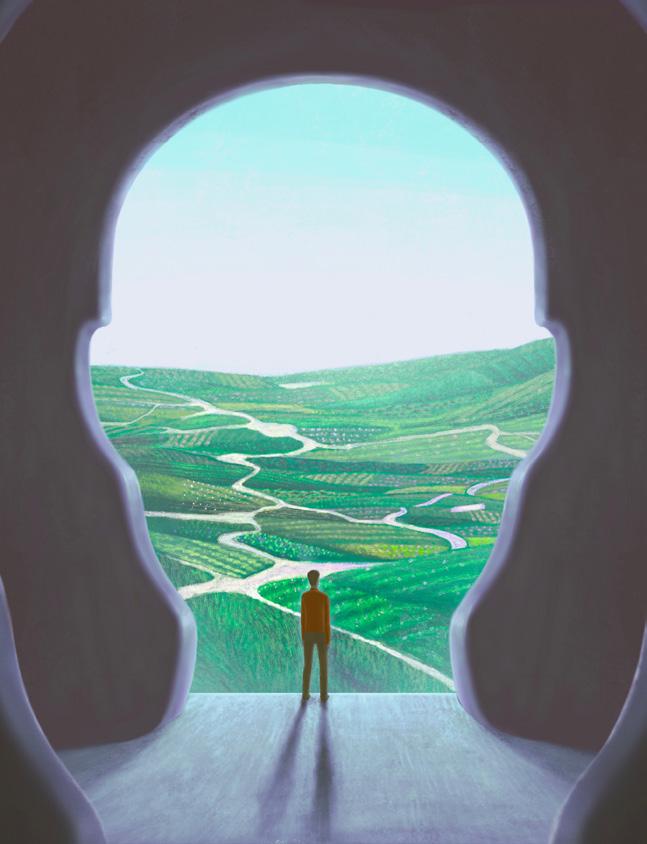

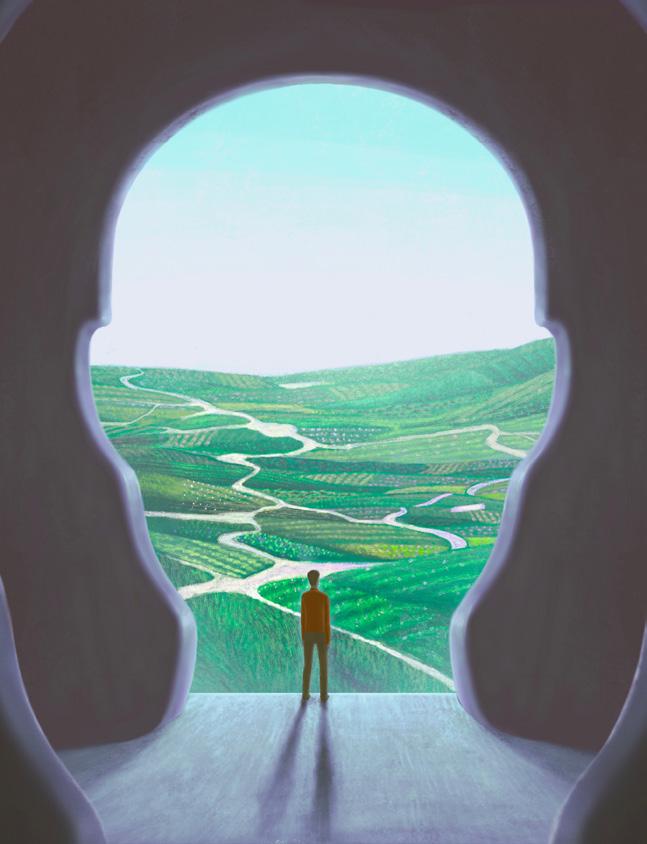

Under Pressure

Industry CEOs take care of their workforce … but are they taking care of themselves?

BY JOANIE SPENCER

If hindsight were 20/20, the baking industry should enjoy its share of clarity by now. Three years ago, the world shut down, and the only thing more deafening than the silence was the panic that accompanied it.

As consumers scuttled out of supermarkets with shopping carts overflowing with toilet paper, bottled water and loaves of bread, restaurants closed their doors while they figured out how to simultaneously keep patrons out and stay open for business.

Bakery line operators were classified as essential. They were seen as heroes, but they were scared. They looked to their leaders for support, and CEOs throughout the baking industry stepped up, scrambling for PPE, sourcing COVID-19 tests, paying bonuses, supplying meals and gift cards to keep families fed and local restaurants afloat, and much, much more.

In a time of crisis, these leaders acted without vulnerability or fear. They put their teams before themselves and kept the bakeries running.

The pandemic has waned, but its effects linger, with ongoing supply chain and workforce challenges reaching crisis levels and the industry bracing for an impending recession. In the c-suite, the pressure is high as ever.

CEOs put on a brave face, but for many, the cards are starting to show. In 2022, a Deloitte survey of 2,100 employees and c-level executives indicated that 76% of those in the c-suite reported the pandemic had a negative impact on their wellness. And 70% said they were seriously considering leaving their job for one that better supported wellbeing.

Health and wellness, which includes mental health, comes with many qualifiers, but it doesn’t have a job title. There’s

no “chief” in front of the human experience, and there’s no such thing as an “executive human being.” At the end of the day, mental health is a struggle across the board; yet corporate executives are treated — and treat themselves — with a different set of expectations.

It’s almost as if personal wellbeing has become a task that moves up and down the to-do list, depending on the crisis du jour. In the moment, finding equilibrium is key. But when it’s a matter of combining

FEBRUARY 2023 Q1 42

© Jorm Sangsorn on Adobe Stock

the need to protect with the need to grow, self-preservation can end up being the balancing force or collateral damage.

“In human nature, there are often two driving forces,” said Julia Freeland, professional development strategist and executive coach. “There’s a drive to protect, preserve and maintain things as they are, and the drive to explore and expand. Many leaders have a balanced approach because they naturally want to grow their organizations. But, at the same time, there’s pressure to protect and preserve because there are so many people relying on them.”

Taking the helm at any company requires certain characteristics that often m anifest as opposing forces: assertiveness vs. empathy; ambition vs. generosity; self-control vs. risk taking. It’s a dichotomy that can make managing one’s wellbeing a constant challenge.

According to Colleen Saringer, Ph.D., health and productivity consultant and first VP at Alliant Employee Benefits, mental health is part of a general health crisis from an organizational perspective. The stigma occurs when organizations — or society, really — qualify mental health into a silo. Seeing cognitive wellbeing as an overall health issue is the first step to allowing leaders the leeway to prioritize their own care.

“If companies are focusing on organizational change, development and DEI, then mental health has to be folded into that fabric,” Saringer said.

Although on the radar in Western culture now more than ever, mental health is not always widely acknowledged in the manufacturing world, where hard skills and efficiency rule. Here, competition still feels like a zero-sum game. It’s a hard

mindset to steer away from, especially in a mature industry like baking.

But in a bakery manufacturing setting, mental health can easily be tied to safety. Extreme stress — and its side effects such as sleep deprivation — can pose real physical threats. However, safety can’t solely be tied to the plant floor. Those same factors can impact critical decision making that, in turn, affects the business in a variety of ways.

Crisis situations can trigger “fight or flight,” the physiological reaction to an immediate external threat. Human beings have evolved to trigger fight or flight in stressful — but not imminently threatening — situations.

In everyday life, it looks more like a phenomenon called “amygdala hijack,” first introduced in the mid-’90s by Daniel Goldman, author of Emotional Intelligence. Simply put, it’s an emotional response to a stressful situation. In that instance, the amygdala — the part of the brain that controls emotions and responds to threats — overrides a person’s ability to respond rationally to a perceived threat, essentially hijacking the logical part of the brain.

This kind of chemical reaction can shut down access to critical thinking, so the brain becomes reactive. That can inhibit short-term decisions, but it can also lead to lasting impacts on bigger decisions and overall wellbeing, especially when every aspect of the organization falls on one person’s shoulders.

“It’s about being able to find dynamic stability,” Freeland said. “That’s the capacity to feel stable despite everything moving around you. Finding that stability is based on understanding and being at peace with your limitations.”

COMMERCIAL BAKING 43 CRITICAL ISSUES: MENTAL HEALTH

“You have to take care of yourself if you want to fully lead others ... It’s a responsibility as a leader to treat yourself well.”

Daniel Servitje | chairman and CEO | Grupo Bimbo

Small practices such as breathing exercises may seem trivial, but they can make a big difference in maintaining clarity and minimizing emotional responses when managing a heavy load on a daily basis.

For global baking industry leader Daniel Servitje, chairman and CEO of Mexico City-based Grupo Bimbo, health — on every level — is part of his daily routine. For him, it’s a critical element for effective leadership.

“I have a set of practices I try to abide by, like doing a short meditation every day or engaging in a respiratory exercise,” Servitje said. “These things allow me to increase my capacity and also quiet me a bit more.”

Physical and mental wellbeing are not mutually exclusive, and it’s important to Servitje that he incorporates healthful practices wherever he can, including participating in “walking meetings” when possible.

“I exercise every day,” he said. “Sometimes that means multitasking to do physical activity while working. I also try to eat well and get enough sleep.”

While it may feel indulgent to make time for workouts or a midday walk, Servitje encourages leaders to shift that thinking.

“You have to take care of yourself if you want to fully lead others,” Servitje said. “It’s not selfish. If you don’t take care of yourself, you’re going to be leading in an incomplete way. It’s a responsibility as a leader to treat yourself well.”

Additionally, Freeland said, shifting expectations enables leaders to have a

quick reset and reengage critical thinking because when that happens, innovation often follows.

It can be a long way to the pinnacle of a career. People spend decades working toward a “chief” title, and in the baking industry, the journey might begin on the plant floor. There’s often a perception that a wealth of benefits, including power, prestige and the big payday awaits in the c-suite.

That’s often where perception and reality diverge. Sure, there’s clout that comes with the c-level title, but there can also be cost associated with the benefits.

They say it’s lonely at the top, but when things get hard, it gets even lonelier. Veronica Delgado, EVP and chief human resources officer (CHRO) for Centuri Group, a Phoenix-based stra -

tegic infrastructure services company, sees it all the time.

“A lot of people don’t realize there’s no place to go when you’re in the c-suite,” Delgado said. “There’s a certain expectation to show, ‘I can take all this on.’”

Those expectations can inherently inhibit c-level executives from addressing mental health.

“There has to be a more conscious effort on behalf of senior leaders to be okay with saying, ‘I’m not okay,’” Delgado said.

CEOs happily set up employee resource programs for their workforce. But at the same time, their own persona of strength — and the stoicism associated with it — makes those resources seem inaccessible, even if they implemented them in the first place. It’s a Catch-22.

FEBRUARY 2023 Q1 44 MENTAL HEALTH

By using tools that support mindset shifts, leaders can reengage critical thinking and avoid the “amygdala hijack.”

© Anela on Adobe Stock

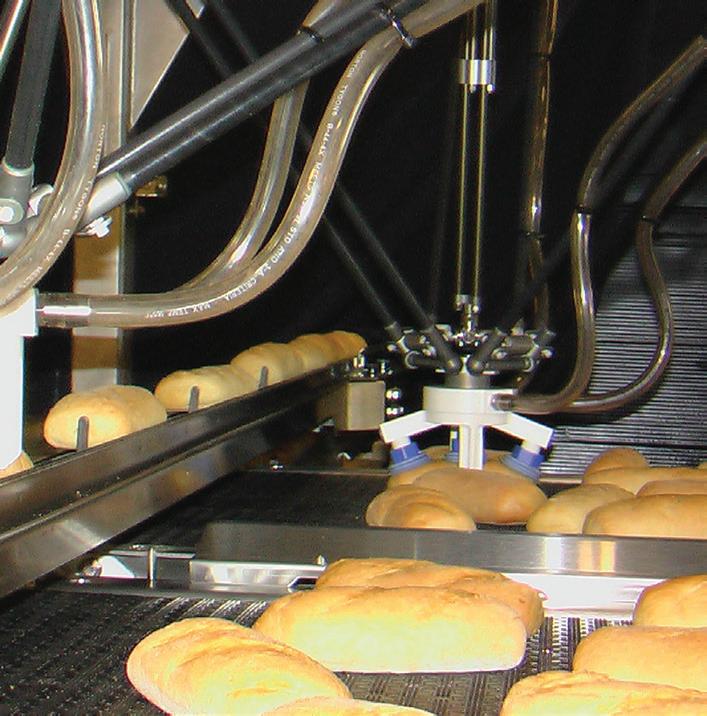

JLS® is the trusted source for flowwrapper loading. Safe, accurate placement with IP69K rated delta robots. Fill labor gaps. Enhance food safety. EXPERIENCE FOR YOURSELF AT jlsautomation.com | 717-505-3800 DO MORE WITH LESS

As a CHRO, Delgado often sees herself as a concierge of sorts, helping c-level executives connect with the right types of resources. Yes, it’s hard to get into the right mindset or accept that it’s okay to ask for help, but sometimes it’s simply the time-space continuum holding them back. A concierge mentality can help an executive put one mental foot in front of the other, so to speak.

“There’s likely a point in a person’s career where they would be apt to get help, but when they reach a leadership level, it’s like all hands are off,” Delgado said. “There’s a stigma that when people reach a certain level in their career and make a certain amount of money that they should just suck it up. But that’s not acceptable behavior anymore.”

Delgado believes that an executive resource group (ERG) can serve as a mental health parity for leaders. It creates a safe space for CEOs to share their struggles and allows them a realistic way to break free from packed schedules and work through the stress.

These kinds of groups can allow executives the opportunity to express the empathy that might be missing from their daily interactions because often the struggles don’t just live in — or come from — what’s happening in the job. Corporate demands make it harder to manage the demands of everyday life, and sometimes, one side feeds the other.

Resources like ERGs, executive coaches or even symposiums or cohorts can give CEOs a safe space to talk about mental health issues like anxiety management and work-life balance.

As the industry experiences a generational shift in its workforce and leadership, company cultures are being

viewed through a new lens, and mental health is playing a bigger role from which leaders are not always exempt. Today, many baking companies are making cultural changes to become primarily collaborative, and that bodes well to foster an environment of wellbeing for all.

The Deloitte study revealed an inverse relationship between the c-suite’s concern for employees’ wellbeing and the workforce’s perception of it. While 91% of top executives said they believe their employees feel their leadership cares about them, just 56% of rank-andfile workers shared that perception.

Breaking down these misconceptions can enable leaders to show a more vulnerable side, which can open doors to their own wellbeing. That requires balance on a deeper level than just the typical idea of work-life balance.

“The idea of collaborative, community success bakes in the need for vulnerabil -

ity to happen because culture has to be supported and built together,” Freeland suggested.

With baking facilities around the world, Servitje prioritizes being involved with what is going on in the company as much as possible.

“I visit plants and talk with customers and associates so that I’m in touch with the reality of the business,” he said. “But then I make sure to take a step back to focus on the big picture. You cannot micromanage everything as a leader because it’s exhausting. But it’s important to connect and to have a sense of what’s happening in the business.”

Self-awareness and authenticity are also keys to creating a sense of balance.

“In business relationships, you have to be authentic and be yourself,” Servitje added. “You have to be humble to hear

FEBRUARY 2023 Q1 46

MENTAL HEALTH

“If companies are focusing on organizational change, development and DEI, then mental health has to be folded into that fabric.”

Colleen Saringer, Ph.D. | health and productivity consultant | Alliant Employee Benefits

Pfening’s in-house production capabilities allow full control over our equipment design and quality. www.pfening.com | sales@pfening.com WITH PFENING IT’S ALWAYS Customer First Delivering Superior Value Since 1919 • Water and liquid dosing systems • Dough conditioning systems • Comprehensive engineered systems • Automated ingredient handling systems • Turnkey projects from design to startup • Integrated control systems

your strengths and weaknesses because nobody is perfect.”

Servitje not only obtains feedback from Grupo Bimbo associates; he also uses it as guideposts for his own professional development. In fact, he keeps a card on his desk with notes organized in two columns: One side lists associate feedback, and the other side contains impactful suggestions from an executive coach.

Servitje’s card serves as a reminder that leadership is a work in progress that is often the result of feedback and collaboration.

“At the end of the day, leaders are human beings who were raised a certain way and taught to deal with these issues

in certain ways,” Saringer said. “But when you layer in the fact that they’re also the ones keeping the lights on in an organization, that becomes a heavy weight to carry.”

Servitje often thinks of advice once given to him by a board member of his company: “There will always be more work than time.”

Creating a rhythm for managing business is one way that Servitje tries to bring those two forces into balance. It’s not an easy task, but it’s a priority he sets when looking at the year ahead. He then considers that rhythm within the context of his time overall.

“I do a personal review on what brings me energy,” he explained. “Then I look at the

things that are draining to my energy or wellbeing. I have to focus on doing things that don’t drain me in those ways.”

The past three years have taught the baking industry resilience and reminded executives to expect the unexpected. Peace can live in chaos, but it requires

MENTAL HEALTH

©

Paul Craft on Adobe Stock

flexibility, vulnerability and, perhaps above all, grace.

There is a reason why preflight safety protocols direct adult passengers to put their oxygen mask on first. For leaders to be their most effective, they must care for themselves first.

It’s a hard habit to break, but when leaders prioritize their own care, they are able to make better decisions and bring the best of themselves for their companies and associates. After all, a life that is focused only on work is often not a life well-lived.

“In a sense, it’s about being practical,” Servitje said. “Because your life is your time, and that’s it. You only live once. If you have a purpose in life, and you

want to do things in business, with your family and for the community, you have to prioritize yourself accordingly. And you have to surround yourself with good people to help along the way.”

There must come a moment when the title is separated from the person. When that happens, c-level leaders can finally allow themselves to be mentally well. And in the end, they can become better executives from it.

“Every industry is waiting to be disrupted,” Freeland suggested. “The more that leaders are willing to share their difficulties, the more they’re willing to get together and open up and question those shoes they wear, the more they’ll be able to move into the future, together, and better.” CB

“The idea of collaborative, community success bakes in the need for vulnerability to happen because culture has to be supported and built together.”

Julia Freeland | executive coach

Removing eggs from a formula can not only remove an allergen, but also save on costs, make raw material storage easier and simplify the production process.

Brolite’s egg replacers can work as a total egg replacement in yeast raised products and up to 30% in cakes. Even with a partial replacement, a baker can have more consistent costs of ingredients and more supply stability.

Lose the eggs, keep the functionality, supply and cost savings of an egg replacer.

CUTTING EDGE TECHNOLOGY AND THE ART OF OLD WORLD BAKING Egg Replacers

BROLITE PRODUCTS, INC (630) 830-0340 | TOLL FREE (888) 276-5483 | FAX (630) 830-0356 1335 SCHIFERL ROAD, BARTLETT, IL 60103 | 1900 S PARK AVE, STREAMWOOD, IL 60107

PRODUCT DEVELOPMENT: HURDLE TECHNOLOGY

A Winning Combination

New food preservation technology could be the future for longer shelf life.

BY MAGGIE GLISAN

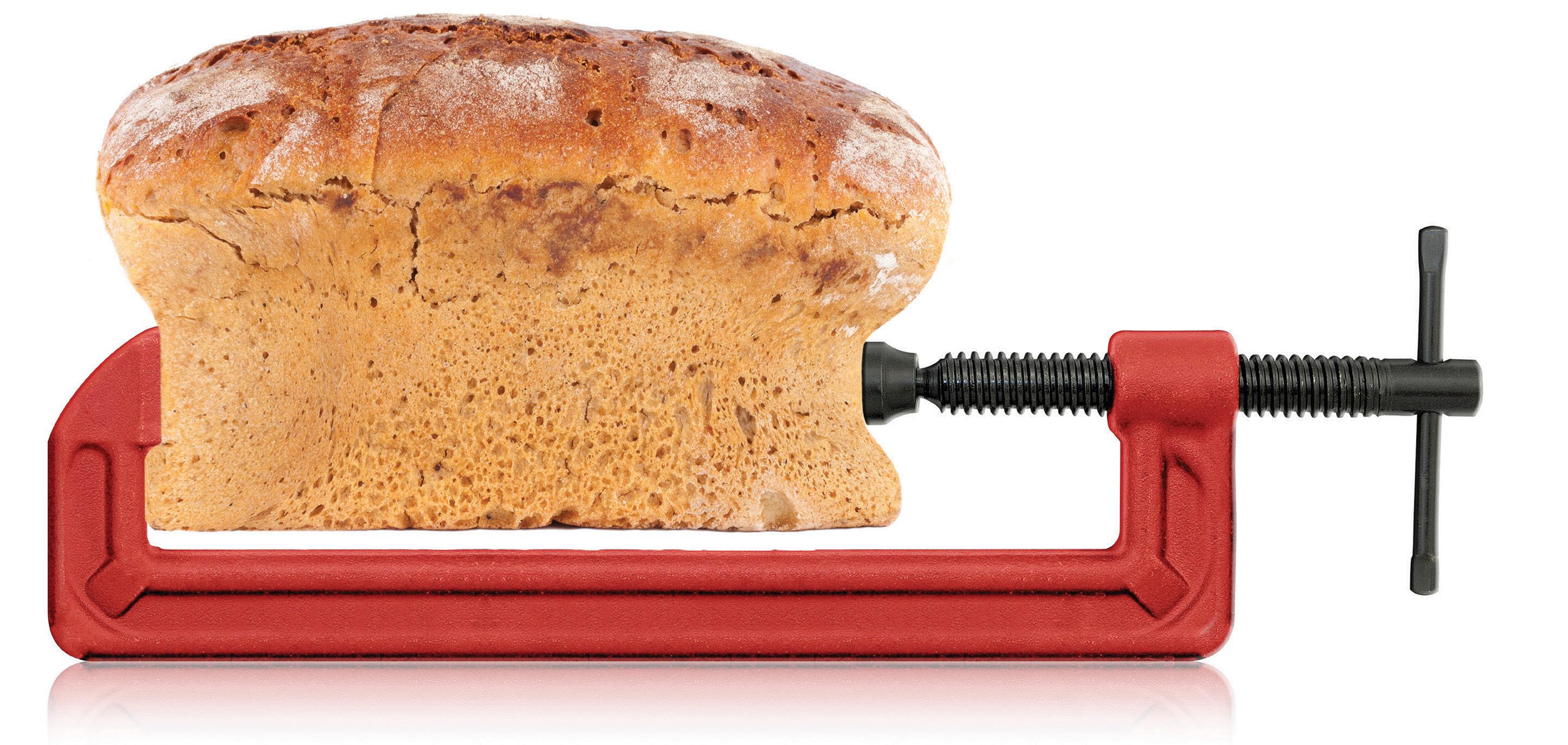

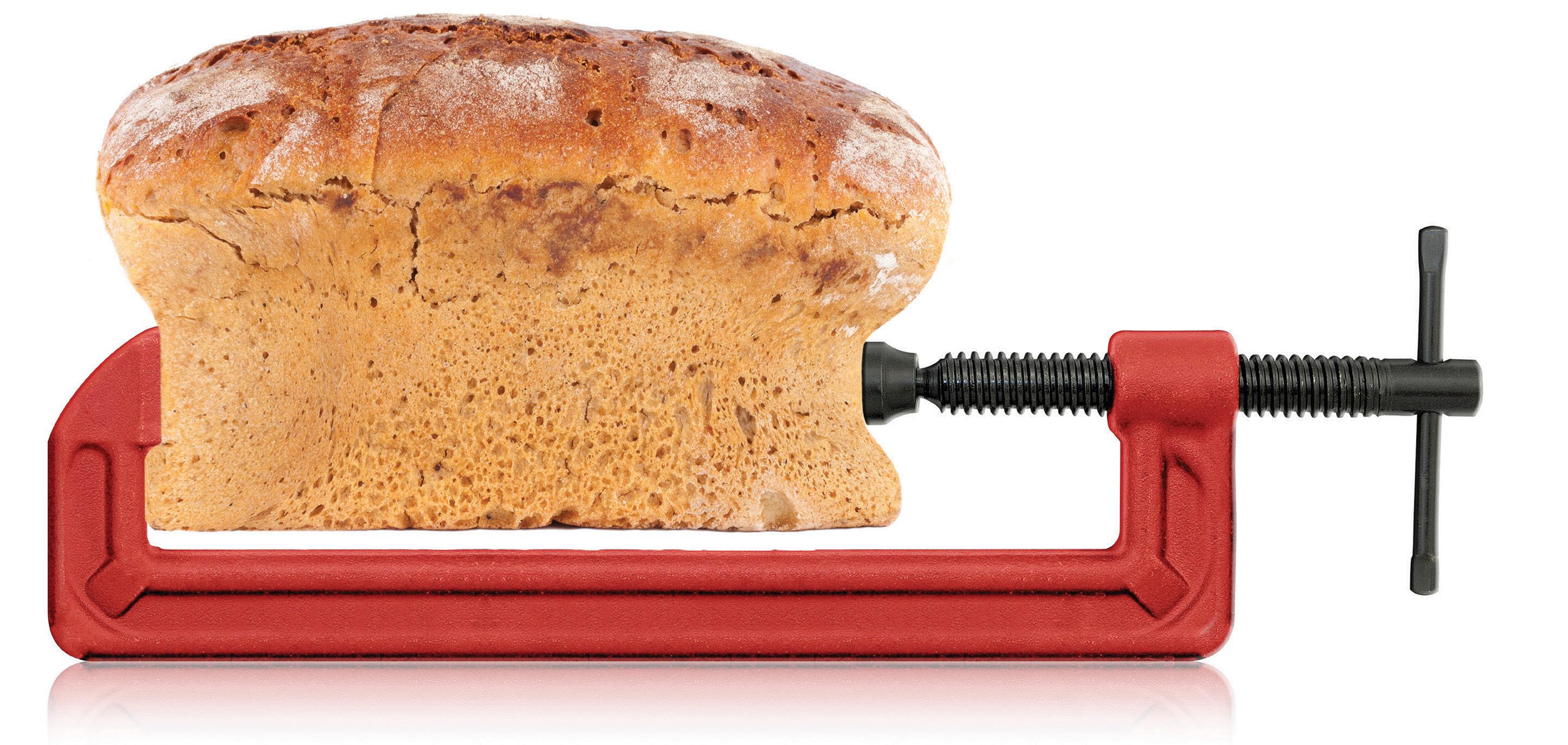

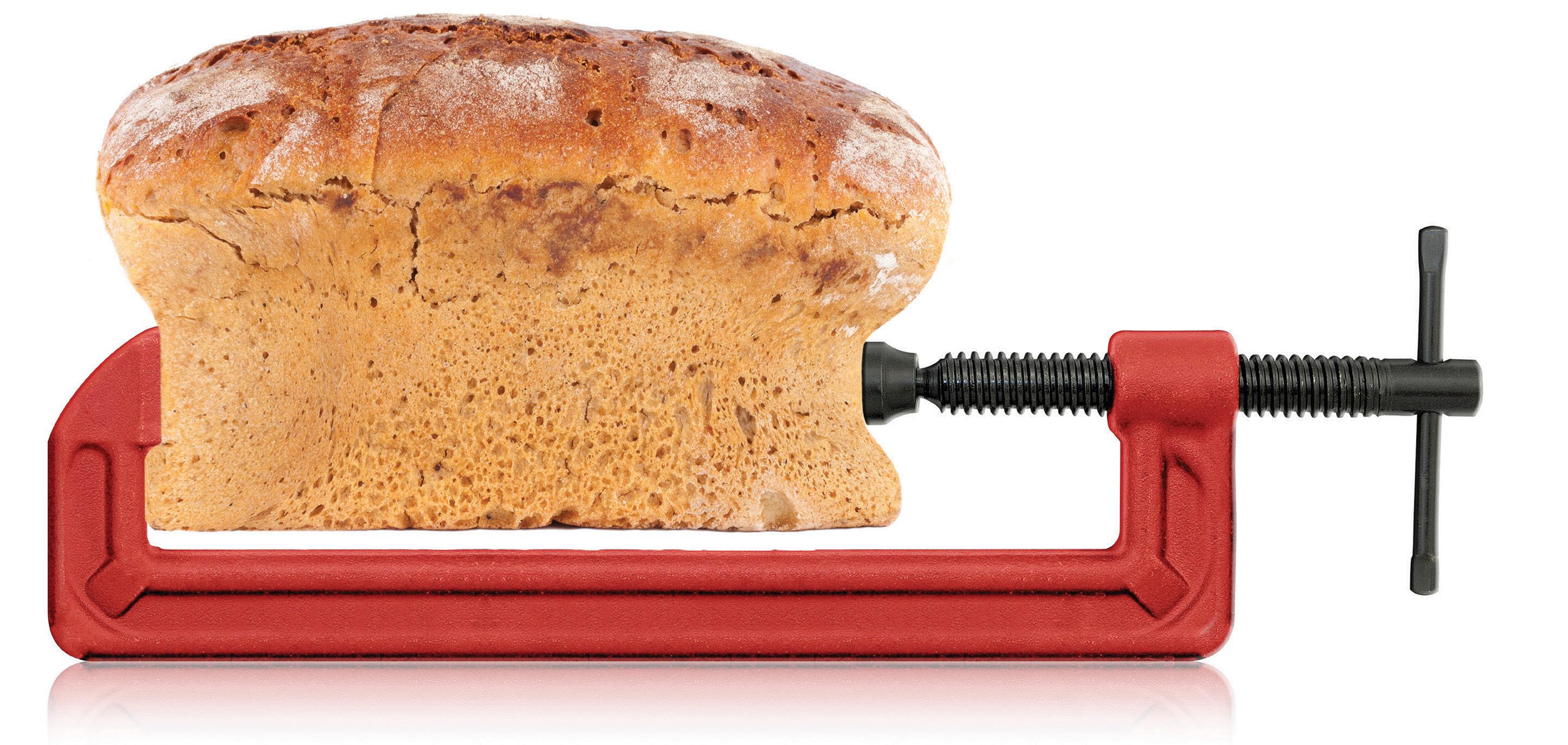

Finding new ways to prolong the shelf life of bread and other baked goods while maintaining that just-baked taste and fresh-from-the-oven texture — not to mention peak nutritional value — is a challenging endeavor. But for bakers up for the tricky task, hurdle technology might unlock the key to success.

Hurdle technology utilizes a combination of mild, reliable food preservation techniques to combat microbial spoilage while maintaining a high level of product quality, safety and stability. Applying hurdle technology along with predictive

microbiology and Hazard Analysis Critical Control Point (HACCP) principles can optimize the food manufacturing and preservation process.

One might think of hurdle technology as an obstacle course for microorganisms, and it’s the job of the course designers — formulators, engineers and manufacturers — to create a series of hurdles that prevent any single microorganism from getting through to the end. This multitargeted approach is an effective way to ensure food safety and extend shelf life without sacrificing product quality.

Keep in mind, this is a relatively new concept. The term “hurdle” was coined by professors Lothar Leistner and Grahame Gould in 1976. The phrase “hurdle technology” was later derived by Leistner in 1985.

The method is still evolving as new technological advances are introduced, and there are significant benefits, especially in the baking industry, according to Kathy Sargent, senior director of technical services for Horsham, PA-based Bimbo Bakeries USA (BBU).

COMMERCIAL BAKING 51

© Maksim Shebeko on Adobe Stock

The concept of hurdle technology has been around since the 1980s, and it’s still evolving as new technologies are developed.

“Any time you put a preventative measure in place to control mold or other microorganisms, you inevitably create some kind of damage, whether that’s to flavor, texture or nutrition,” Sargent said. “But by using multiple hurdles and approaches, you are able to scale everything back to a level that’s more manageable and collectively achieve all your objectives.”

Another advantage is that bakers can prevent microorganisms from figuring out how to overcome their hurdles. Just like a flu strain, microorganisms evolve and develop resistance, but by implementing multiple hurdles, formulators can avoid that with one preservative map. Ultimately, they can also control quality and cost by using several approaches.

Ben Reusser, innovation center manager at Cain Food Industries, shared that one of the biggest advantages to implementing hurdle technology is extending a product’s shelf life.

“I like to think of hurdle technology as compounding interest, each new hurdle adds value to the previous hurdles,” he said. “By using a combination of processing controls, sanitation, standard operating procedures and mold inhibitors, you can create products that stay fresher for longer. Plus, when you use a combination of factors, there’s less reliance on one crucial processing step in the line — if that one step fails, you’re talking about higher customer complaints and possible recalls if it is a food safety issue. Hurdle technology helps mitigate that risk.”

Hurdles are categorized as physical, physico-chemical and microbialderived, and each aims to eliminate or inhibit unwanted microorganisms. Commonly used hurdles include high

or low temperatures (heating/baking or chilling/freezing), reduced water activity, oxidation reduction potential, increased acidity (low pH), preservatives (sorbates, nitrites, sulfites) and competitive floral (microbial fermentations). The intensity of individual hurdles can be adjusted to meet different objectives.

When choosing which hurdles to implement, it’s critical to consider all the steps in the process, from ingredient sourcing, manufacturing and packaging to individual product attributes.

“Anything that’s occurring that would theoretically make it more difficult for a microorganism to grow could be a hurdle — whether that’s inside the product or outside,” said Daniel Unruh, senior scientist at Corbion.

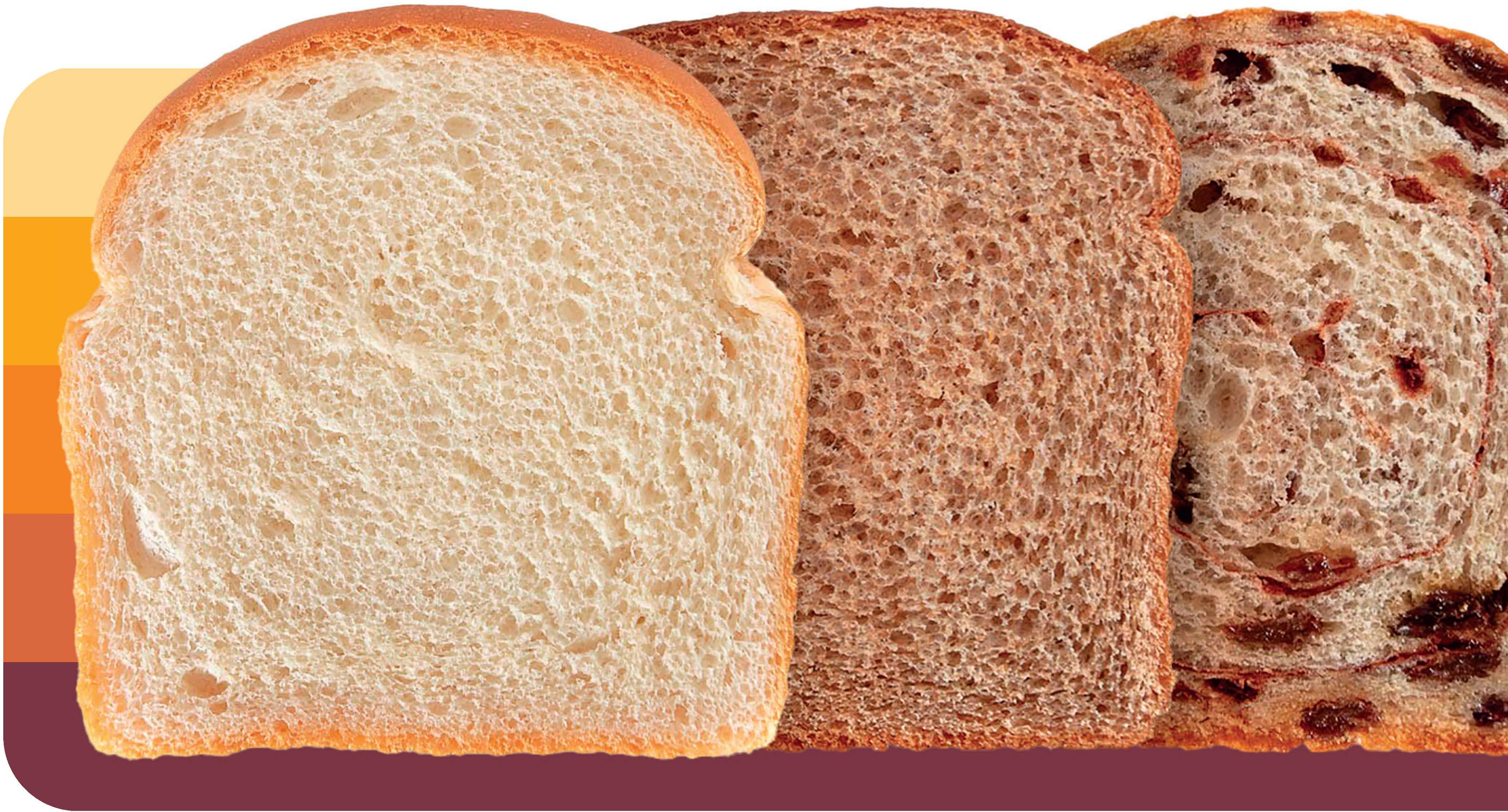

Each product has intrinsic properties that are key to understanding its behavior in terms of shelf life. For example, a baked good with high water activity will

require significantly different hurdles than one with low water activity.

“When you think about baked goods, products like crackers and biscuits are low moisture and have low water activity, so you don’t need nearly as many hurdles or mold inhibitors like bread does,” Reusser said. “Bread, tortillas, buns on the other hand … those all are very high moisture and have high water activity. They also have a lot of surface area, which essentially creates a petri dish for mold to grow. Those types of products in particular really benefit from multiple hurdles.”

Extrinsic factors are just as — if not more — important in hurdle technology. In fact, before defining hurdles based on individual properties, it’s paramount to first address sanitation and process controls.

“You want to have a good sanitation program because no amount of mold

FEBRUARY 2023 Q1 52 HURDLE TECHNOLOGY

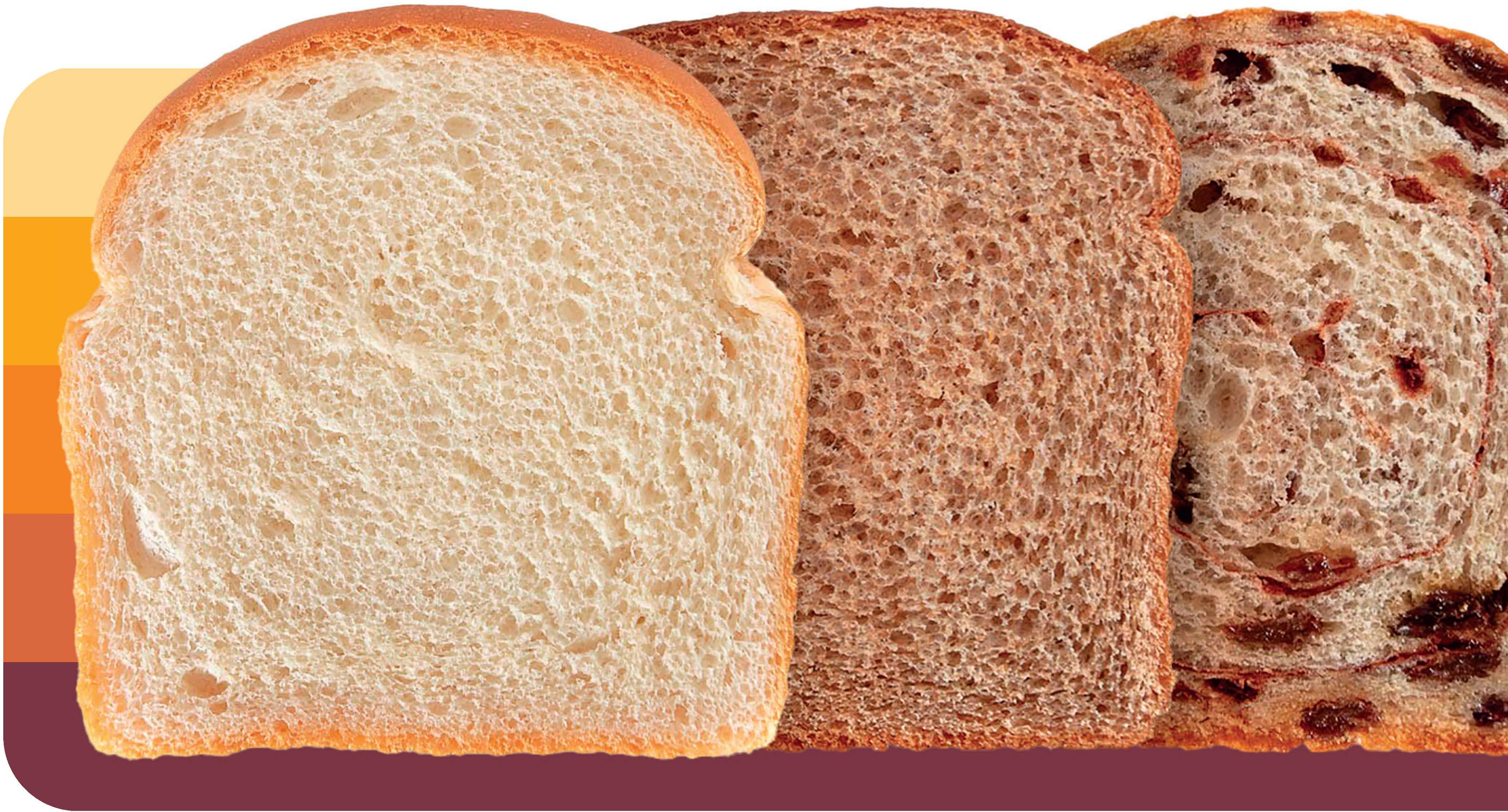

Understanding the shelf life behavior of a product requires knowledge of characteristics including water activity and surface area.

© manyakotic on Adobe Stock

NO MATTER HOW YOU

AB MAURI IS HERE

Whatever your challenge or opportunity is, the technical baking team at AB Mauri North America is ready to help. We understand what it takes to succeed in today's baking industry as we prepare for what the world looks like tomorrow. We play our part so you can bake yours.

IJIm 02023 AB Mauri Food Inc.

abmna.com · 1.800.772.3971

inhibitor or anything you do to the product is going to do a hill of beans if you don’t have the proper sanitation,” Reusser said.

Sargent also noted sanitation is key.

“You have this really great kill step in the oven, but you still must control the raw materials and manufacturing environment, ensuring it is as clean as possible,” she said. “The post-bake environment is critical because once a product comes out of the oven, you still have to manage exposure through cooling, slicing, packaging, and, for some products, filling and coating.”

According to Reusser, one of the biggest threats to any bakery in terms of spoilage is time.

“After baking, once the product is exposed to the air, it starts accumulating mold,” he said. “So, environmental hurdles need to be considered as well.”

Properly cleaning and treating equipment, managing air flow, and following strict hygiene practices must all be a part of the equation.

When it comes to new product development, Unruh said hurdle technology allows for a better understanding of a product’s characteristics. Bakers will want to think about what hurdles they can institute to work in tandem with those that are already occurring naturally to create an optimal shelf life for a particular product.

“If, during the product development process, you’re able to do more acidification to result in a lower pH, or you are able to understand the product’s water activity, or you have the opportunity to add in an antimicrobial,

you’ll be able to better understand the tradeoffs to incorporating those hurdles,” Unruh said. “In turn, you’ll be able to create a product that will not only be satisfying for your customer from a taste perspective but will perhaps also have a more extended shelf life and have those desirable organoleptic properties.”

Sargent said she sees a considerable amount of innovation happening with hurdles alone in terms of what types of treatments can be applied in different environments.

“The possibilities are endless for innovation,” she explained. “An example could be a preservative treatment that’s not pH dependent. As a result, we might now be able to formulate our products at a different pH and that might improve other ingredients’ functionality, flavor and quality. If you remove limitations we have managed for years, we may have the ability to better optimize across the board.”

Packaging is an essential hurdle for most bakery items, and Sargent said she’s interested in the considerable innovation happening in that area. One innovation to consider is active packaging, which interacts directly with the food or food environment to prolong shelf life and protect quality.

“With some of these innovations, bakers can influence the micro load that is in the package without having to add additional ingredients,” she said.

While freshness remains a top priority for consumers, there is increasing demand for better-for-you food options with clean labels and minimal processing. And that growing demand presents new challenges for commercial bakeries.

Source: US Department of Agriculture

“Historically, the baking industry has been very successful in managing pH, water activity and a level of preservation,” Sargent said.

Hard-to-pronounce or chemical-sounding ingredients are concerning to consumers reading labels. Unfortunately, this is the case for some of the preservatives used in the commercial production of breads and baked goods.

Unruh said the clean label trend is spurring research into new shelf-lifeextending ingredients that appeal to an increasingly discerning consumer.

“Calcium propionate used to be the standard mold inhibition ingredient in yeast-raised baked goods, but when the clean label movement really started to gain momentum, a lot of people started to look into ferments (microbes fermenting similar acid profiles to those in calcium propionate) and using those as mold inhibitors instead,” he said.

There are a number of natural mold inhibitors already gaining traction, and more innovation is on the way.

According to “How the Clean-Label Mega Trend Is Changing the Food

FEBRUARY 2023 Q1 54

HURDLE TECHNOLOGY

Food waste in the US is estimated at 30-40% of the food supply.

BAKERY SOLUTIONS Some formulas don’t perform as expected and require a custom solution. We blend dry, clean-label ingredients for bakery formulas that improve performance issues. www.repcoworld.com Extended Shelf-Life Volume Strength Stability Stretch & More

Create Baked Goods That Last

Ingredients Landscape,” a 2019 report from L.E.K. Consulting, some of the top ingredients dominating the clean-label food market include natural mold inhibitors such as sorbic acid, stevia, food enzymes, and fruit and vegetable pieces and powders.

One of the biggest challenges in developing clean-label products, of course, is the potential impacts to appearance, taste and texture, and it’s up to bakers to find the combination of hurdles that help them strike that optimal balance.

“Consumers expect products that are simple and more natural, but they also want products that last,” Sargent said. “With the right technology, we can satisfy both, but it creates an ambitious challenge, and it’s going to require the industry to stretch their thinking around bakery.”

Because hurdle technology has a direct impact on the shelf life of breads and baked goods, new innovations could also have a significant impact on food waste. According to the US Department of Agriculture, food waste in the US is estimated at between 30-40% of the food supply.

“Any time we can be more efficient at getting products to market and into consumers’ hands — and then helping them to be stable until they’re ready to be consumed — the better,” Sargent said. “An extended shelf life gives us more flexibility and reduction of waste as we work through manufacturing and distribution.”

Hurdle technology might also offer opportunities for bakers to repurpose products that don’t meet quality standards but don’t pose any health hazards. For example, if a loaf of bread didn’t meet

certain texture standards but could be repurposed for another use such as breadcrumbs or French toast, having the technology in place to ensure the safety of the repurposed product would allow bakers greater flexibility.

Despite the considerable benefits, there are still potential risks for bakers to keep in mind.

“Hurdle technology as a combined approach tends to mitigate some risks as opposed to creating them, but as with any technology, it’s important to understand the impact,” Sargent advised.

She said bakers should weigh the environmental impacts — understanding carbon emissions or energy outputs — of particular hurdles, as well as any possible safety risks and mitigation techniques for associates in production.

“Hurdle technologies are great, and the theory is sound, but you still need to determine your level of risk,” Unruh said. “You can do that by utilizing p redictive modeling, through literature or you can run a challenge study, which is the gold standard. It’s important to validate those hurdles.”

He also advised seeking expert guidance when implementing hurdle technology. He recommended consulting first with an experienced microbiologist who has the knowledge and modeling capabilities to understand the interaction of different antimicrobials to ensure optimal results.

As with any innovation, there’s still much to unlock with hurdle technology. But it shows promise for the future of developing safe, delicious baked goods with the extended shelf life consumers are seeking. CB

FEBRUARY 2023 Q1 56 HURDLE TECHNOLOGY

“Historically, the baking industry has been very successful in managing pH, water activity and a level of preservation. Now, if we’re trying to be as ‘clean label’ as possible, that’s creating both new obstacles and opportunities.”

Kathy Sargent | senior director of technical services | BBU

Our Essential® portfolio is composed of clean label proprietary enzyme-based blends formulated carefully with specially selected enzymes, providing solutions with built-in tolerance to avoid overdosing. These solutions can be used to replace the functionalities of baking ingredients such as gluten, DATEM, SSL, and mono- and diglycerides.

From baker's yeast to enzyme-based baking solutions, Lallemand Baking's fermentation-based products are infused with science and innovation.

Lallemand Baking: Your partner and supplier of innovative baking solutions.

-------------• IAiiiiw.ill.!ii,. «fifoRIW> LALLEMANDBAKING

FSAIJ!DI

Essential.

Essential®

USA +1 800 687 6483 or +1 901 547 1579 Canada +1 800 840 4047 or +1 514 522 2133 Mexico +1 800 710 4856 or +52 552 6205300 www.lallemandbaking.com baking@lallemand.com

SANITARYSLICINGANO PACKAGINGFORSOFTBREAD, Bl/NS, ANOMORE

For high-speed, reliable packaging solutions, AMF PackTech delivers sanitary solutions for bun, roll, and bread slicing and bagging, and bulk bun packaging. The recipe-driven Saber 75S Slicer and Mark 75S Bagger improve the packaging process by introducing a series of automated adjustments that eliminate operator intervention, improve product consistency, and ensure operator safety. Plus, the new design offers easy access for simple, safe sanitation and maintenance. All PackTech equipment is engineered with reliability in mind for simple operation to ensure optimal package quality and extended product shelf life.

BAKERY SYSTEMS A Markel Food Group Company Scan to learn more AMFBAKER�COM I SALES@AMFBAKER�COM © 2023 AMF Bakery Systems

USA I Netherlands I UK I China I Singapore I Canada I Mexico

Perimeter paving the way

Bread/Bun/Roll Dollar Sales

Bread/Bun/Roll Unit Sales

Resourcefulness can be the mother of invention, and bread’s simple recipe is a medium known to provide just that. Bread in its many forms — loaves, slices, buns, rolls and more — offers consumers a multitude of ways to make mealtime and snacks less predictable. This is pa rticularly important as hybrid work schedules reign supreme for many. A shopper survey conducted by IRI found both at-home and in-office workers primarily source their afternoon meal from home, creating a positive impact on the bread/bun/roll category.