KELSEY TAIT AND TEAM ARE REVOLUTIONISING THE MINING

3 TECHNOLOGIES THAT WILL TRANSFORM MINING VEHICLES INSIGHTS INTO ON-SITE MENTAL HEALTH HOW AFRICA SHOULD DEAL WITH THE DEMAND FOR LITHIUM

KELSEY TAIT AND TEAM ARE REVOLUTIONISING THE MINING

3 TECHNOLOGIES THAT WILL TRANSFORM MINING VEHICLES INSIGHTS INTO ON-SITE MENTAL HEALTH HOW AFRICA SHOULD DEAL WITH THE DEMAND FOR LITHIUM

Loesche has a long-standing history of being the market leader in original equipment manufacturing and after-market services. It was as a result of having close relationships with our clients that a need was identified to not only improve the performance of its mills but decrease energy consumption, while addressing the skills shortage in the market. These key drivers drove Loesche to create a fully digital software solution that addresses all these concerns without major equipment upgrades or capital investment.

Loesche Mills is now fully automated with artificial intelligence

Loesche established a new digital sales department at the beginning of 2022. We have developed an artificial intelligence (AI) based mill control system, as well as an AI-based machine surveillance software that is helping maintenance managers, production managers and process engineers to run equipment more efficiently at lower energy consumption and higher throughput, and taking care of maintenance requirements through a predictive maintenance software. A significant amount of capital has gone into establishing this department.

In 2024, we sold our first complete solution to the mining company Idwala Carbonates in KwaZulu-Natal, South Africa, which now has an AI mill operation system and also an AI machine surveillance system taking care of the mill gearbox, classifier and fan.

machine surveillance system taking care of the mill gearbox, classifier and fan.

In October 2023, the cement player Dangote Group also signed up for a solution for one of its plants in Delmas, South Africa.

Loesche plans to continue investing in further developing our AI solutions moving forward.

KEY POINTS FOR THESE OPTIMISED FACILITIES:

• Reduced energy consumption

• Increased output

• On-the-job skills development

• Increased equipment lifespan

• No unplanned breakdowns

• Full visibility, monitoring and control of process

PROVEN RESULTS ACHIEVED BY GOING DIGITAL

Loesche’s portfolio of digital products ideally serves the core needs of producers and mining operations.

Loesche, Aixprocess and Dalog are technology partners and digital experts. Integration of process control systems, and combined machine surveillance tools with expert systems, allow our customers to increase operational efficiency and competitiveness.

CONTACT DETAILS

Janie Scholtz (Digital Sales Manager)

Predictive maintenance has increased productivity by 25%, reduced breakdowns by 70%, and lowered maintenance costs by 25%.

Operating a mill with Aixprocess allows for specific energy savings of up to 15%. Remote sites increasingly require autonomous plant operation and remote analysis capabilities. Automated reports keep staff informed regardless of their location, and data collection from remote machines enables monitoring and adaptive control while diminishing the need for on-site human resources.

Tel: +27 12 371 3001 | Cell: +27 83 365 1401; +27 82 787 7306

Email: info@loesche.com www.loesche.com

''Loesche plans to continue investing in further developing our AI solutions moving forward.''

oN THE COVER KLLT Holdings offers a diverse range of products and services tailored to meet various industrial needs including filter press solutions, mining spares, mill solutions, wear and grinding media, conveyor structures, slurry pumps, valves, concrete solutions and tracking devices.

Director Kelsey Tait, 29, runs the company on passion and a dedication to customer experience.

12 FOREWORD

Mzila Mthenjane: CEO of the Minerals Council South Africa

14 FROM THE

16

When you need increased efficiency when maintaining your quarry or mine site, choose the powerful capabilities of Komatsu’s new and robust GD955-7R motor grader to help clear the way.

With best-in-class blade downforce pressure for efficient grading performance and plently of horsepower to boost productivity, this motor grader will help you build and maintain stable, efficient roads for your haulage operation.

Komatsu remains committed to creating value together with it’s customers by providing innovative equipment and technologies to reduce overall machine maintanance and keep costs at a minimum.

34 JUNIOR INDABA

The 2024 Junior Mining Indaba provided valuable insight into the challenges and opportunities faced by junior miners in South Africa and across the continent

40 CLIMATE CHANGE

Yes, carbon capture and storage is controversial—but it is going to be crucial

46 DIAMONDS

De Beers unveils ‘Origins’ strategy to grow value and revitalise desire for natural diamonds

52 CRITICAL MINERALS

The world is rushing to Africa to mine critical minerals like lithium—how the continent should deal with the demand

59 OIL & GAS

Angola drills down on investment incentives and local content support

62

Africa’s energy industry calls on banks and financiers to halt 'financial apartheid' in oil & gas sector

70 WATER

Digital Earth Africa's new Waterbodies Monitoring Service is a major advancement in the observation of Africa’s waterbodies

76 TECHNOLOGY

Three technologies that will revolutionise mining vehicles

82

Insights into on-site mental health: from initial needs analysis to the human element that should never be underestimated

90

Authorities in the Republic of Congo are failing to ensure respect of human rights by big industry

South Africa now has a Government of National Unity with diverse political ideologies, ministers, deputies and new committee heads in parliament. It is time for Mzansi to get to work. President Cyril Ramaphosa outlined a shared vision for South Africa with his new 32-strong cabinet, including 12 ministers from other parties. His speech provided the private sector with a high-level view of the country's direction.There is much reason to believe we can now work together as partners to revive our economy with inclusive growth and job creation, stabilising our society, which is labouring under high unemployment, poverty and crime.

President Ramaphosa clearly defined the obstacles that have prevented economic growth over the past 15 years by throttling incentives to invest in new and existing businesses. We believe we now have a government that can rapidly address these constraints with the urgency they deserve. This strategic vision aligns with that of the Minerals Council South Africa.

The government’s strategic focus for the next five years includes actions to drive inclusive growth and job creation, reduce poverty, tackle the high cost of living, and build a capable, ethical and developmental state.

The success of the first two goals depends entirely on the third. Without clear, pragmatic, investorfriendly regulations and policies, and professional administration of the rules, the private sector will continue to struggle to justify spending money in the country.

The Minerals Council’s members, who account for 90% of annual mineral production, consider the administration and

implementation of regulations, and policy and regulatory uncertainty as their two biggest concerns and risks. We can no longer afford legislation and policies that introduce more onerous conditions and obligations on the sector with every change. Transformation and inclusivity will be a natural consequence of laws and administration that encourage investment in exploration, mine development and expansion.

We agree with President Ramaphosa that red tape and unnecessary bureaucratic interventions stifle the growth of the private sector, which is the largest job creator in our economy. His comments that the government will “pursue every action that contributes to sustainable, rapid economic growth and remove every obstacle that stands in the way of growth” must be met with decisive action from ministers and their departments to realise this objective. Too often, the private sector has heard encouraging words but has been disappointed by the lack of implementation.

One of the Minerals Council’s top priorities is to hold the government accountable and ensure it does what it says it will. As a key stakeholder and corporate citizen in terms of tax generation, export earnings and job creation, our concerns must be heard and acted upon regarding issues that threaten the future of the mining industry. We want urgency, pragmatism, and a sense of being treated as a trusted partner to achieve the vision outlined by President Ramaphosa.

The mining industry needs a policy environment for it to flourish

with an influx of investment in the extraordinary array of minerals South Africa has in its soil. For the broader private sector, the government’s stated aim of turning the country into a vast “construction site” is encouraging. Infrastructure projects will use the minerals we mine, stimulate industry and manufacturing, creating jobs and sustainable livelihoods.South Africa is host to the largest known deposits of platinum group metals, chrome and manganese to name but a few. We have untapped resources of minerals in the underexplored Northern Cape. There is an urgent need to kickstart exploration by attracting local and international investors to this moribund sector in mining. We need it to sustain mining in South Africa and to find and mine the minerals our economy and the world needs for a low-carbon future. Conducive legislation and policies will ensure our mining industry is globally competitive and growing.

We buy into the President’s vision and that of his Cabinet. It’s time for us all to get to work.

Peter Martin Cloete is the founder of PMC Training –born and raised in Nababeep in the Namaqualand region of the Northern Cape. He joined De Beers Mine as a bedrock cleaner after matric in 1994. He came through the ranks and was later appointed as an earthmoving machine operator and eventually a multi-skilled operator. Cloete joined the Training Department in Koingnaas and later became a driver and machine operator instructor. His passion for people development impressed his peers and he was promoted to mine training foreman.

De Beers had other plans for this dynamic leader and Cloete was transferred to Venetia Mine in Limpopo during 2006 where he holds the position of chief training officer of Mining.

He eventually joined Assmang Khumani Mine where he was responsible for the HR department. Cloete holds various qualifications including a Trainer Development Diploma, National Diploma in ETD Practices and Lead Auditor.

PMC Training is accredited by various SETAs, of which the MQA is the primary SETA. The company is an SME, ISO certified, youth owned and fully female owned.

The assessors, moderators, administrators and consultants are registered as assessors and moderators with the relevant SETAs and have vast

experience in their respective fields of expertise. They also have come through the ranks in the mining and construction environment and are experts in the facilitation, presentation and assessment of various training programmes.

Peter’s daughter, Cassidy Manique Brandt, was also born in Nababeep. Both her grandfathers were employed in the Okiep Copper Company, today better known as Copper 360. She came through the ranks with dedication, smart work and commitment. Cassidy has sound knowledge and experience in ISO processes, training operations and auditing. She is the heartbeat of the day-to-day training activities at PMC Training. She was recently appointed as the operations manager after seven years of intensive on-the-job training, coaching, mentoring and various training programmes. She is also the majority shareholder of PMC Training.

Mining Training, Health and Safety Training, Construction, Lifting Equipment Training, Compliance Training, Community Training, BBBEE and WSP/ATR Assistance, MIE Verifications

The South African mining sector is one of the most significant contributors to the country's economy, with a rich history dating back over a century. It is a major player on the global stage.

One of the key aspects of the sector is its mineral wealth. As one of the world’s largest producers of platinum, gold, diamonds and chromium, it is a cornerstone of the South African economy, contributing significantly to gross domestic product, employment and export revenues. With a large portion of its minerals exported to markets in Asia, Europe and North America, the sector is crucial for foreign exchange earnings.

mining news

PUBLISHER: Donovan Abrahams

EDITOR: Allister Arendse

CHIEF SUB-EDITOR: Tania Griffin

DESIGN: Shadon Carsten

EDITORIAL SOURCES: TheConversation.com, Kaspersky, De Beers Group, African Energy Chamber, Charissa Bloomberg, Steven Coates, Amnesty International, IDTechEx

IMAGES: Adobe Stock, Unsplash, Freepik

PROJECT MANAGER: Viwe Ncapai

However, there are challenges. The regulatory and policy environment, labour relations, infrastructure and energy, and environmental concerns all place a strain on the sector— although opportunities and future trends such as technological advancements, exploration and resource development, the green energy transition, as well as economic and social transformation do offer encouragement for a brighter future.

Also, recent developments such as the investment climate and global market dynamics are helping to grow the sector.

Despite challenges, there have been recent investments in the sector, including expansions of existing mines and new exploration projects. But attracting sustained investment requires addressing regulatory uncertainty and improving the overall business environment.

I do not doubt this sector will continue to blossom following the establishment of the Government of National Unity. The infusion of new blood can only be beneficial.

On that note of change, I am stepping down as editor of African Mining . After five incredible years of being part of this amazing journey, I am embarking on a new

I am confident the publication will continue to thrive and evolve under its new leadership

Ashley van Schalkwyk. We welcome on board

Allister Arendse

ADVERTISING EXECUTIVES: Viwe Ncapai, Lunga Ziwele, Reginald Motsoahae, Andre Evans, Mellouise Thomas,

ONLINE CO-ORDINATORS: Majdah Rogers, Tania Griffin, Tharwuah Slemang

IT & SOCIAL MEDIA: Tharwuah Slemang

ACCOUNTS: Benita Abrahams, Bianca Alfos, Anthea Botha

HUMAN RESOURCES MANAGER: Colin Samuels

CLIENT LIAISON: Majdah Rogers

PRINTER: Novus Print

DISTRIBUTION: www.africanminingnews.co.za, www.issuu.com

DIRECTORS: Donovan Abrahams, Colin Samuels

PUBLISHED BY: Aveng Media

Boland Bank Building, 5th Floor 18 Lower Burg Street Cape Town, 8000

Tel: 021 418 3090

Fax: 021 418 3064

Email: allister@avengmedia.co.za Website: www.avengmedia.co.za

DISCLAIMER: © 2024 African Mining News magazine is published by Aveng Media (Pty) Ltd. The Publisher and Editor are not responsible for any unsolicited material. All information correct at time of print.

Rub shoulders and conduct business with high-flIers in the African mining industry

HYDROMETALLURGY CONFERENCE 2024

vvvvvaHazendal Wine Estate, Stellenbosch, Western Cape, South Africa www.saimm.co.za

This conference will bring together internationally and locally recognised scientists and engineers from mining and metal-producing companies, project design and implementation entities, equipment and reagent suppliers, research and academic institutions to discuss and share innovative technologies that can assist the global world in meeting the current and future metal demands.

Johannesburg Expo Centre, South Africa

www.electramining.co.za

At this event, you will find all the latest cutting-edge technology on display, hear talks from trailblazers in the industry, and meet hundreds of exhibitors across the areas of mining, electrical, automation, manufacturing, power and transport all in one place. Hundreds of live demonstrations will bring machinery and equipment to life, with thousands of new products and innovations displayed throughout the five exhibition halls and outside exhibit areas.

ESG IN THE MINERALS INDUSTRY – CHALLENGES AND OPPORTUNITIES

16 & 17

Focus Rooms, Modderfontein, Johannesburg, South Africa www.saimm.co.za

Environmental, social and governance (ESG) considerations have become increasingly important in the business world, as they contribute to longterm sustainability and responsible corporate behaviour. In the minerals industry, ESG considerations are particularly important due to the sector’s significant environmental and social impacts. The purpose and focus of this conference is to influence professional behaviour, and foster industry dialogue on sustainability and responsible mining through ESG and sustainability-related matters.

6 & 7 NOVEMBER

Cape Town International Convention Centre, South Africa criticalmineralsafrica.com

The second Critical Minerals Africa event will unite governments from all corners of the African continent; international presidential and ministerial delegations; provincial governments; global finance companies; and mining, manufacturing and technology firms. This is the African critical minerals deal-making space, standing at the intersection of energy and mining, linking global consumers and producers, and bringing global capital to African projects.

4 TO 8 NOVEMBER

Cape Town International Convention Centre, South Africa aecweek.com

African Energy Week (AEW) is the African Energy Chamber’s annual event, uniting African energy leaders, global investors and executives from across the public and private sector for four days of intense dialogue on the future of the African energy industry. At the forefront of the African energy industry, AEW promotes the role Africa plays in global energy matters, centred around African-led dialogue and decision-making. Covering the entire energy sector and value chain, AEW represents the only conference on the continent representative of the entire sector.

MINE HEALTH AND SAFETY CONFERENCE 2024

6 & 7 NOVEMBER

Emperors Palace Convention Centre, Johannesburg, South Africa www.saimm.co.za

The conference is centred on improving safety, health and environmental practices within the mining and metallurgical industry. It seeks to create a platform for knowledge-sharing and idea exchange among various stakeholders including mining companies, Department of Mineral Resources and Energy, Minerals Council South Africa, labour unions, and health and safety practitioners at all levels within the industry.

Thanks to decades of experience we understand the complex requirements of the process control and automation industry. The diversity of applications and process conditions demand robust and smart yet simple solutions. No matter whether solids, liquids or gases: VEGA has the right sensor for the job. Reliable. Proven in the field. Easy to service.

At just 29 years old, Kelsey Tait is charting an ambitious course for KLLT Holdings, a company named after his daughter and dedicated to transforming the mining industry. KLLT is not just another name in the mining sector; it is becoming a powerhouse, positioning itself as a leading original equipment manufacturer (OEM). With a clear vision and a strong determination, Tait is set on making KLLT a key player, offering a comprehensive range of solutions tailored to meet the diverse needs of mining companies.

Tait's journey to establishing KLLT began over eight years ago when he first entered the mining industry. Throughout his career, he has worked in various roles that gave him first-hand experience of the challenges and opportunities within the sector. These experiences, both in South Africa and internationally, have shaped his understanding of the market and fuelled his desire to create a company that offers more than just standard services.

After identifying a significant gap in the market for turnkey solutions, Tait founded KLLT in July 2023. His decision to leave his previous roles and focus entirely on building KLLT was driven by a desire to offer comprehensive services, from mining operations to processing plants and beyond.

“We are building a company that offers a complete solution,” says Tait. “We can provide a wide range

of products and services. Our goal is to bring all these elements together to deliver a comprehensive package to the mining sector. Whether it’s machinery, engineering expertise or on-site support, we want to be the first and only call our clients need to make.”

Tait's role involves securing business opportunities, meeting with suppliers and customers, and ensuring KLLT can deliver all necessary parts, services and labour. His extensive experience across South Africa, Africa—including Tanzania, Congo, Zambia, Botswana— and America has equipped him with a deep understanding of the industry and the ability to adapt to various challenges. This background has fuelled his ambition to make KLLT an OEM of choice for mining companies.

What sets Tait apart in his line of work is his keen ability to listen to what the end user needs and find practical solutions. This focus on client communication is central to KLLT’s philosophy. Tait believes understanding the unique challenges faced by each client is the key to developing effective solutions that enhance productivity and efficiency.

He is currently pursuing a trade test to become a certified fitter, adding technical credibility to his business acumen. This pursuit of technical certification demonstrates Tait’s commitment to understanding the intricate details of the services his company provides. By gaining hands-on technical skills, he is better

positioned to lead his team and troubleshoot issues.

“There are times when I need to roll up my sleeves and handle things myself,” he admits, reflecting on his hands-on approach. Tait's willingness to get involved in the technical aspects of the business not only sets a strong example for his team but also instils confidence in clients.

KLLT is actively involved in projects both locally and internationally, including test work for equipment like tower presses and vertical presses. Domestically, the company is conducting trials for electrical actuators and working on concrete solutions and process valve installations. Upcoming projects include a significant mill installation, slurry tank manufacturing and a large-scale pump solution for the chrome industry.

The success of KLLT can be attributed to the passion that drives Tait and his team. “Passion is our numberone value,” Tait emphasises. “We are committed to delivering exceptional quality, service and value to our customers. We stand out in the market because of our focus on quality and cost efficiency.”

KLLT’s commitment to quality is not just about using the best materials and latest technology; it’s about creating a culture where every team member takes pride in their work and strives for excellence. Tait believes this passion is infectious

“We are committed to delivering exceptional quality, service, and value to our customers. We stand out in the market because of our focus on quality and cost efficiency.”

and that it drives his team to go the extra mile, whether they are working on-site installations, conducting audit or developing innovative solutions for complex problems.

Despite daily challenges, Tait remains focused on securing work and building the company's reputation. “We want to be recognised as an OEM that offers unparalleled solutions in the mining industry,” he says.

KLLT views its role in the mining industry as more than just business; it's about making a lasting impact on future generations. Tait is particularly passionate about the upliftment of youth, recognising that investing in education and skills development is crucial for sustainable community growth. "We want to create opportunities for the next generation, inspiring them to see the potential in their own backyards and providing the tools they need to achieve their dreams.”

KLLT is also dedicated to community development. Tait is exploring ways to reinvest a portion of the company's revenue into uplifting rural mining areas. This initiative is part of KLLT’s broader commitment to corporate social responsibility. By supporting educational and infrastructure projects, he hopes to improve the quality of life in communities affected by mining operations, creating a positive legacy that extends beyond business success. “Giving back is a part of our ethos,” he adds, emphasising that KLLT’s growth should benefit not only its employees and clients but also the communities in which it operates.

For Tait, the future is about forming long-lasting partnerships rather than just short-term business transactions. “We aim to build relationships that last for decades,” he says. “Our slogan, ‘Solutions beyond limits,’ reflects our commitment to solving problems for

“We want to create opportunities for the next generation, inspiring them to see the potential in their own backyards and providing the tools they need to achieve their dreams.”

our clients and providing them with peace of mind.”

Tait’s drive to succeed is fuelled by a desire to prove that local companies can offer solutions that are on par with, if not superior to, international OEMs. He is committed to showing that the best quality and service can be found right here in South Africa. By leveraging local talent, resources and knowledge, he believes KLLT can compete with global giants while maintaining a strong connection to the communities and markets it serves.

Tait’s path to leadership has been shaped by diverse experiences that extend beyond the mining industry. After matriculating, he pursued a professional rugby career from 2013 to 2016, playing both nationally and internationally. This time on the field not only honed his physical abilities but also instilled in him a strong sense of discipline, teamwork and perseverance. These qualities have proven invaluable in his approach to business, where the same principles apply. “Rugby taught me the importance of resilience, strategy and working as part of a team,” Tait reflects. “These are lessons I carry with me every day at KLLT Holdings.”

When not immersed in his business, he maintains a balanced lifestyle by hitting the gym and spending quality time with his family. This balance is important to him, as it helps him stay grounded and focused. Whether he’s working on business strategies or relaxing with loved ones, Tait approaches life with the same passion and commitment that drives his professional success.

Afrinov was founded in 2017 with the mission to drive innovation in the engineering sector. As a BBBEE Level 1 contributor, it has established itself as a leader in the industry, offering a comprehensive range of services including the supply of steel-fabricated equipment, engineering, manufacturing, equipment supply, site installation, plant maintenance, and project management.

Afrinov is certified under both ISO 9001 and ISO 45001 standards, Afrinov is deeply committed to ensuring quality and safety are integral to every aspect of its operations. ISO 9001 certification demonstrates the company's dedication to maintaining highquality standards across its products and services. Meanwhile, ISO 45001 certification reflects Afrinov’s unwavering commitment to providing a safe and healthy work environment for all employees, proactively managing and mitigating risks to prevent workplace injuries and illnesses. By embedding these standards into daily practices, Afrinov fosters a culture where excellence in quality and safety is a fundamental priority.

Afrinov is engaged in several key projects that highlight its expertise in delivering turnkey solutions. Notable projects include the refurbishment, manufacturing,

installation and commissioning of slipping devices for furnaces in Burgersfort and Mooinooi. Afrinov successfully manufactured and installed an autoclave discharge tank, weighing over seven tonnes, for a client in Northam. It also decommissioned and installed new furnace feed bins, ranging in size from 18 to 22 tonnes.

Afrinov is also actively engaged in tendering for and competing in a diverse range of potential projects, continually open to exploring opportunities with new clients and addressing unique challenges with innovative solutions.

Afrinov has implemented several initiatives to promote gender equity, including targeted recruitment efforts that have resulted in an increase in the number of women in technical roles. Six women have started on the workshop floor, filling roles in rigging, boilermaking, and welding.

Launched in 2024 in partnership with Ekurhuleni Artisans & Skills Training, this was created to address the skills gap in the engineering sector and to provide young professionals with practical experience. Many apprentices have gone on to secure positions within Afrinov. The company offers hands-on training in various aspects of engineering, from design and manufacturing to testing and project management.

The company is actively involved in aiding disadvantaged communities through a variety of corporate social investment programmes. These initiatives are focused on education, skills development and community upliftment. Recent projects include the donation of school uniforms, shoes and care packages to schools as well as sponsoring sports in underprivileged areas.

Afrinov plans to expand its service offerings, particularly in advanced manufacturing and testing. As Afrinov continues to grow, it will stay true to its core values of quality, integrity and customer satisfaction, collaborating with other industry leaders to drive innovation and deliver even greater value to clients.

At Metsop, we're not just shaping metals; we're shaping the future of the metallurgical industry across South Africa and subSaharan Africa

With a steadfast commitment to innovation, quality, and sustainability, Metsop stands as a beacon of excellence in the metallurgical landscape.

To redefine metallurgical standards and lead the industry toward sustainable growth, driving economic prosperity and environmental stewardship.

We forge lasting partnerships with clients across diverse sectors including mining, automotive, construction and manufacturing. With tailored solutions and unparalleled expertise, we empower our clients to achieve their goals and surpass expectations.

Metsop is dedicated to continuous improvement and technological advancement. Our goal is to set new benchmarks for efficiency, reliability and safety, while minimising environmental impact and maximising value for our stakeholders.

With operations spanning South Africa and subSaharan Africa, Metsop is at the forefront of regional development, driving progress and prosperity in communities across the continent.

Sustainability is at the heart of everything we do. From responsible sourcing and resource management to waste reduction and energy efficiency, Metsop is committed to minimising our environmental footprint and contributing to a greener, more sustainable future.

Metsop thrives on innovation and forward-thinking. Through research, development and collaboration, we harness the power of cutting-edge technologies to deliver transformative solutions that meet the evolving needs of our clients and the industry.

Join us on our journey to excellence and experience the unparalleled quality, reliability and expertise that define Metsop.

Together, let's forge a brighter, more prosperous future for the metallurgical industry and beyond.

Ipfi Manenzhe is honoured to serve as the operations director at Metsop, a renowned metallurgical company operating across South Africa and sub-Saharan Africa. His journey in the metallurgical field began after graduating with a Bachelor of Technology degree in Metallurgy from Vaal University of Technology.

"I embarked on a fulfilling career as a metallurgist, where I gained invaluable experience and honed my skills over the course of several years. However, in 2019, driven by a deep passion for metallurgy and a vision for innovation, I, together with my colleague, made the bold decision to found Metsop.

"Since its inception, MetSoP has rapidly grown into a leading player in the industry, thanks to our unwavering commitment to excellence and customer satisfaction.

"As an avid traveller, I find great joy in exploring new destinations and experiencing diverse cultures, which not only enriches my personal life but also broadens my perspective as a business leader.

"I am deeply grateful for the opportunity to lead Metsop and look forward to continuing our journey of success and growth in the years to come.

"As the operations director, my role is multifaceted and pivotal in ensuring the seamless functioning of our operational activities. I oversee all aspects of our metallurgical operations: from

production processes and quality control to resource management and regulatory compliance. By developing and implementing strategic plans, I drive our company toward operational excellence, optimising workflows and maximising efficiency while upholding the highest standards of safety and quality.

"I foster a culture of continuous improvement within the

organisation, constantly seeking out opportunities to enhance processes and streamline operations.

"Through effective leadership and collaboration with crossfunctional teams, I strive to align our operational activities with the company's strategic objectives, ultimately contributing to Metsop's success and prominence in the metallurgical industry."

Torque Africa has been in business for over 10 years and keeps striving to greater heights and lower depths

Torque Africa was established in 2014, driven by a vision to provide specialised drilling services across Africa.

The company was founded by Nardus Bezuidenhout, an industry expert with a deep understanding of the region's unique geological challenges and opportunities.

Over the years, Torque Africa has grown from a three-drill rig operation to a leading provider of air rotary drilling solutions, recognised for its commitment to excellence and innovation. Among its many aspirations, the company places a premium on customer service and satisfaction.

“We pride ourselves in creating a personal relationship with clients,” says Bezuidenhout. “Each project is thoroughly examined, planned and deliberated with clients to provide a tailor-made solution for their requirements. Through a wealth of knowledge and experience, we are able to provide better options, tailor-made hole design and specialised drilling techniques for every project—creating lasting partnerships.”

The company has undertaken some major projects so far, including:

• RENERGEN: A large-scale gas exploration project for the extraction of a major helium and methane gas deposit.

This included a well drilled at a 50° angle up to 1 200 metres deep—a first of its kind using air rotary drilling.

• SCATEC: Drilling the foundation holes for the largest solar farm in South Africa located close to Kenhardt in the Northern Cape. A complex construction piling drilling project that provided critical data for a major infrastructure development.

"Torque Africa has grown from a threedrill rig operation to a leading provider of air rotary drilling solutions"

• BEAUFORT WEST: Drilling of a 1 148m exploration well for the Council for Geoscience, one of the deepest wells drilled with percussion air drilling.

• AMAM: Drilling a 1 019m reverse circulation (RC) well for exploration purposes in the Northern Cape. It was previously thought RC could not be drilled to these depths.

• BOOI BROTHERS

PETROLEUM: Drilling the first oil and gas exploration well in the Pafuri area up to 1 300m.

Torque Africa is dedicated to pushing the boundaries of what is possible in its industry. “

We remain committed to innovation, sustainability and excellence in all our endeavours,” says Bezuidenhout.

In the next three to five years, Torque Africa aims to:

• EXPAND OPERATIONS –entering new markets and expanding its service offerings;

• MAKE TECHNOLOGICAL ADVANCEMENTS –continuing investing in the latest technologies to improve efficiency and outcomes;

• PROMOTE SUSTAINABILITY INITIATIVES – enhancing the company's sustainability efforts to ensure long-term environmental and social benefits;

• DEVELOP TALENT – focusing on attracting and retaining top talent to drive innovation and growth;

• STRENGTHEN CLIENT PARTNERSHIPS –strengthening relationships with existing clients and building new partnerships to support its growth strategy; and

• BUILD ITS REPUTATION – not only setting the benchmark for air rotary drilling but becoming the leading expert within this field in southern Africa and beyond.

Bezuidenhout concludes, “We are grateful for the trust our clients place in us and look forward to continuing to deliver exceptional results that drive progress and prosperity across Africa.”

Closing the past chapter and paving way for the future

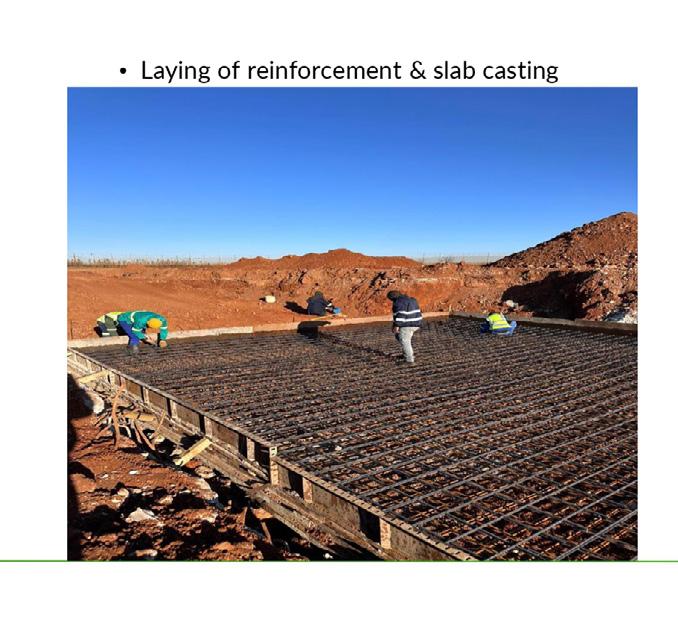

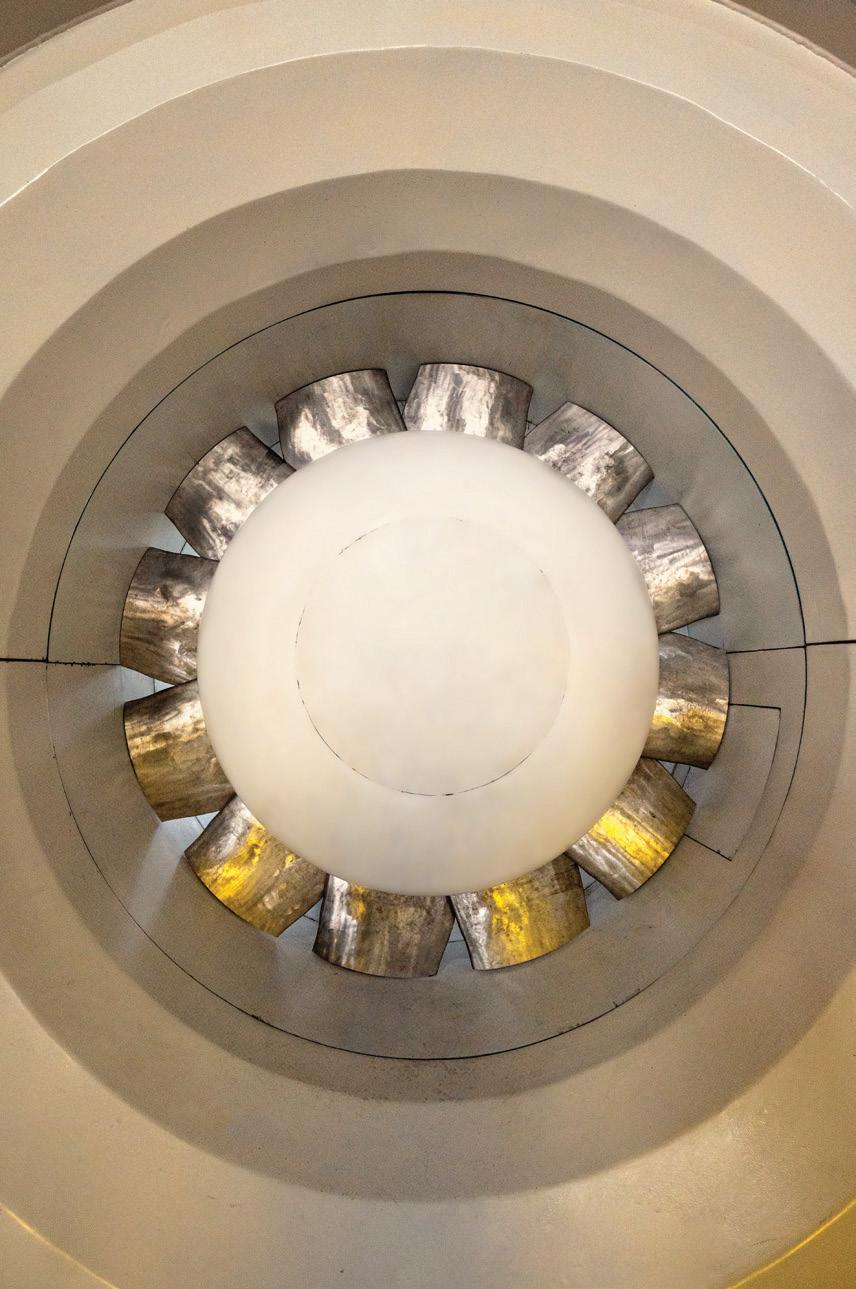

Blacc Engineering Services (Pty) Ltd has an in-house demolition department of which its primary objective is to assist mining companies executing demolition, rehabilitation and shaft capping (plugging) works for their non-performing assets also aiding in reducing the scourge of illegal mining (Zama Zama’s) which has engulfed most of the mining towns in South Africa.

Throughout the years Blacc Engineering Services (Pty) Ltd managed to get its fair share of works in this high risk and highly specialised demolition works, which includes amongst others, demolition of head gears, ventilation shafts, shaft backfilling and capping. Immediately after demolition work is completed, it our standard practise to rehabilitate the area to its original state and or usable state. Shaft Capping (Plugging) can either be an in-situ concrete slab for a backfilled shaft or prefabricated slab for an open shaft. Please see hereunder our pictographic presentation of one of our completed projects.

Blacc Engineering Services (Pty) Ltd, “Blacc” is a multidisciplinary engineering company rendering the services for clients from a wide range of sectors, such as Mining, Minerals & Metals, Water & sanitation, Energy & power as well as infrastructure (Building, Road ,Dams, etc).

Blacc offers Engineering, Procurement, Construction and Management (EPCM) and Engineering, Procurement, Construction (EPC) project delivery contracts covering a full spectrum of project’s lifecycle from scoping study/ preliminary economic assessment, pre-feasibility, feasibility, execution , commissioning, operating and maintenance.

Blacc services are tailor-made to suits our clients specific requirements, whilst ensuring they get quality and return on their investments. Our expertise combine technical knowhow and experience with modern technology and ability to utilise the information technology systems and software’s to provide a new way of doing things effectively and efficiently. This is aiding Blacc to analyse the project’s requirements such as resources, resources availability, environmental

supporting our Clients over the years. We have maintained excellent services to satisfy clients, and We serve varies sectors such as mines, mineral processing and hydrocarbons plants, water & sanitation as well as public entities.

Our team comprises professionally registered engineers, scientists and managers, with Environmental Assessment Practitioner’s

concerns, and eventually determine the prospects of project’s success.

Blacc’s Environmental and Sustainability division, has been

Association of South Africa (EAPASA), and South African Council for natural science professionals (SACNASP). We are a clients’ centric organisation that always attains client’s expectations, whilst providing ecofriendly services on their operations. Clients are always rest assured we handle their environmental and sustainability efforts with great distinction.

The 2024 Junior Mining Indaba provided valuable insight into the challenges and opportunities faced by junior miners in South Africa and across the continent

The 2024 Junior Mining Indaba, held on 21 and 22 May in Johannesburg, brought together key players in the junior mining sector, offering a platform for robust discussions and networking opportunities. The event, now in its ninth edition, has become a staple for industry professionals, providing critical insights into the challenges and opportunities faced by junior miners in South Africa and across the continent.

One of the major themes of the 2024 Indaba was the investment landscape for junior miners. With fluctuating commodity prices and varying investor sentiment, the discussions delved into strategies to attract and sustain investment. Speakers highlighted the importance of transparent communication with investors and the need for junior miners to differentiate themselves in a crowded market.

The event underscored the growing interest in critical minerals, driven by the global push toward green technologies and electric vehicles. This shift has opened new avenues for investment, particularly in minerals like lithium, cobalt and rare earth elements.

Another key focus was the regulatory environment and its impact on the junior mining sector. South Africa's complex regulatory framework was a

central topic, with discussions on how it affects project development timelines and costs.

The Indaba featured panels on navigating the regulatory landscape, with experts offering insights into recent legislative changes and their implications for junior miners. The need for a stable and predictable regulatory environment was emphasised as crucial for attracting both local and international investment.

The role of innovation and technology in exploration and development was another highlight of the Indaba. As the mining industry faces increasing pressure to adopt more sustainable practices, junior miners are exploring

Afrimat Mining Services are leading specialists offering a comprehensive suite of solutions to the mining, construction, and quarry industries throughout Southern Africa.

mine planning mine rehabilitation crushing and screening beneficiation of materials

bulk drilling and blasting load and haul

pit-to-port solutions

rail loadout management & logistics

new technologies to reduce environmental impact and improve efficiency. Sessions covered advancements in geospatial technologies, data analytics and automation, showcasing how these innovations are transforming the exploration process.

The use of drones for surveying and the application of artificial intelligence in data analysis were particularly noted for their potential to enhance exploration success rates and reduce costs.

These were other central themes at the event. With growing awareness of environmental, social and governance (ESG) issues, junior miners are increasingly focusing on

sustainable practices and responsible mining. Discussions highlighted the importance of building strong relationships with local communities and ensuring mining projects deliver tangible benefits to them.

Case studies were presented on successful community engagement initiatives, offering valuable lessons for other junior miners.

The Indaba also explored the impact of geopolitical factors on the sector. With global supply chains becoming increasingly complex and trade tensions rising, the discussions touched on how junior miners can navigate these challenges. The role of South Africa in the global mining landscape

was analysed, with speakers noting the country's rich mineral resources and strategic position. The event underscored the need for junior miners to be agile and adaptable in the face of global economic shifts.

The Indaba provided ample opportunities for networking, with participants expressing appreciation for the chance to connect with peers, investors and industry experts.

The event's format—which included panel discussions, keynote addresses and networking sessions—was praised for facilitating meaningful interactions.

Looking ahead, the outlook for the junior mining sector remains cautiously optimistic. While challenges persist, particularly in terms of regulatory and investment environments, the Indaba highlighted the sector's resilience and potential for growth, particularly in areas aligned with global trends such as the transition to renewable energy.

In conclusion, the 2024 Junior Mining Indaba was a resounding success, offering valuable insights and practical advice for junior miners navigating a complex and rapidly changing industry landscape.

The event underscored the critical role that junior miners play in the broader mining sector, particularly in the exploration and development of new mineral resources.

As the industry continues to evolve, the insights and connections gained at the Indaba will undoubtedly help guide junior miners in their future.

The Joburg Indaba is a highly influential mining industry platform, renowned for its straight talk, refreshing insights and collaborative atmosphere. Since its inception, the Joburg Indaba has developed a reputation as a highly regarded and influential industry platform which unpacks a wide range of critical issues affecting all stakeholders in the mining industry.

This 12th edition of the Joburg Indaba will bring together CEOs and senior representatives from all major mining houses, investment firms, Government, parastatals, communities, organised labour and legal and advisory experts.

Plus, the Gala Dinner will be held on the evening of 1st October, when we will be inducting new members into the SA Mining Hall of Fame!

Follow us on our website for the latest speakers and programme developments

Joburg Indaba 2024 is proudly sponsored by:

Yes, carbon capture and storage is controversial—but it is going to be crucial

Renewable energy sources such as wind and solar are vital tools to help us make cuts to the 36 billion tonnes of greenhouse gases we emit each year (tinyurl.com/5n7pxc6v).

But renewables alone cannot get us to net zero. Sectors such as cement, steel and chemical manufacturing produce significant carbon dioxide emissions difficult to eliminate through renewable energy alone.

This is why carbon capture, utilisation and storage has a place. This technology—invented by the oil & gas industry—is the best solution we have at present to capture these emissions at their source before they can escape into the atmosphere.

Environmentalists have long been sceptical of carbon capture, warning it could be used to prolong fossil fuel dependence. That is a matter for policy; the science is clear. We will need to capture carbon for the time being.

While essential, the rollout of carbon capture is sluggish. As a new report shows (www. stateofcdr.org), we are removing just two billion tonnes of CO2 from the atmosphere each year—and almost all of that is by planting trees. Carbon capture accounts for less than 0.1% so far.

The technology was first used in the 1920s to separate CO2 out from methane in fossil gas deposits.

By the 1970s, it had found use in boosting oil recovery: If you separate out the CO2, you can pump it back down into the

This technology is the best solution we have at present to capture these emissions at their source before they can escape into the atmosphere.

oil field and get more out. To date, the world’s largest carbon capture operation is in Western Australia, where Chevron is pumping CO2 filtered from natural gas back underground (tinyurl. com/55xwmy5b). This history is why there has been so much scepticism about the technology.

This is not entirely fair. The technology itself is neutral. If we detach it from its history, we can better assess its worth.

What carbon capture and storage offers is the ability to capture CO2 emitted by the manufacture of cement and iron/steel. Together these account for about 15% of the world’s emissions total (8% and 7.2% respectively).

Once we capture CO2, we can use it in industrial processes such as chemical synthesis and food preservation. This approach can cut emissions while adding value, if waste CO2 can be used for valuable products.

Alternatively, it can be stored in deep underground in stable

geological formations such as porous sandstone capped with impermeable rock, or salt caverns, either natural or human-made. Here, it should stay for hundreds of years as gas. In some locations, CO2 can react with minerals to form stable carbonates, effectively turning CO2 into rock.

Carbon capture and storage can be added reasonably easily to existing infrastructure such as fossil fuel power plants, oil and gas fields, and gas compression stations—offering a transitional pathway toward clean energy.

Retrofitting existing plants with capture and storage technology can significantly reduce emissions without the need to immediately decommission still-functional power plants.

Critics of carbon capture argue (tinyurl.com/4zu7573f) the

We offer the following service;

MINE IMPACT MANAGEMENT

Mine Administration

Mine Permits and Rights

Applications

Environmental Compliance Audits

Mine Closure Applications

WATER MANAGEMENT

Water Use Authorisation

Applications

Water Use Authorisation

Compliance

Monitoring and Sampling Assistance

Storm Water Management Plans

Waste Water Plans

MONITORING

Dust

Noise

Water

LEGAL

Environmental Related Advisory

Services

Legal Audits

IMPACT MANAGEMENT

Risk Assessment Studies

Alien Clearing Plans

Ecological Surveys

Environmental Impact

Assessment/Basic Assessments

Environmental Control Officer Work

Handling of Public Participation Processes

GIS SUPPORT

Map Making

technology will likely be used to prolong the use of fossil fuels rather than phase them out as quickly as possible. In this view, carbon capture would be used by fossil fuel plant operators and companies as a way to make coal or gas 'green', and delay the full transition.

This concern is valid. There is a risk leaders in fossil-fuel intensive industries may see capture and storage as a way to continue their operations with less pressure to innovate or reduce their reliance on fossil fuels, just as some have embraced carbon offsets to avoid fundamental change.

But again, this does not mean we should discard the technology. While we now have good options for making electricity without emissions, we do not yet have many options in tackling industrial emissions. While methods of making steel and cement without fossil fuels are emerging, change is slow—and the problem of climate change is urgent.

Authorities, from the Intergovernmental Panel on Climate Change (tinyurl. com/23y6wfu2) to the International Energy Agency (tinyurl.com/38wuw8ny), see

Retrofitting existing plants with capture and storage technology can significantly reduce emissions without the need to immediately decommission still-functional power plants.

an unavoidable role for carbon capture and storage.

The European Union’s Green Deal emphasises the role of carbon capture in cutting industrial emissions, while the United States has introduced tax credits and funding to accelerate its adoption.

Australia’s government last year invited companies to explore 10 offshore sedimentary basins for possible carbon storage. But not everywhere is suitable; Queensland’s government recently banned the technology anywhere inside the Great Artesian Basin, due to concerns over the impact of the gas on groundwater.

For carbon capture and storage to grow to the size we need, it will need effective policy support such as tax credits, subsidies and funding for research and development to drive innovation and cut costs.

In my research, I have worked with industry partners to find ways of making carbon capture useful. If a waste product has value, there is an immediate incentive to capture it. For instance, I have worked on converting CO2 into 'solar fuels' such as green methane and methanol (tinyurl.com/5n8uzwjr).

We may think the future of energy will be solar, wind and storage. But it is not going to be that simple. Fossil fuels will be harder to wean ourselves off than we realise. We will need green hydrogen for industrial uses and to make ammonia for green fertilisers. And we will have to ramp up carbon capture and storage for industrial emissions.

We may not like the idea of carbon capture and storage, but we will need it if we are going to get serious about net zero. At present, there is nothing else like it for hard-to-abate sectors. What we must avoid is using it to prop up fossil fuels.

Tianyi Ma

Distinguished Professor: Chemistry and Renewable Energy Royal Melbourne Institute of Technology

De Beers unveils ‘Origins’ strategy to grow value and revitalise desire for natural diamonds

De Beers Group's (www.debeersgroup. com) new Origins strategy aims to enhance value across its business, from mining through to retail. The business will be streamlined and investments will be focused on high-return projects in core upstream assets, midstream technologies, natural diamond retail and synthetic diamond technology solutions.

As the natural diamond market continues to recover, De Beers will harness its industry-leading portfolio of mining assets, its iconic retail brands and its track record of generating desire for diamonds. This will drive sustainable growth against a backdrop of declining global diamond production and positive underlying demand fundamentals.

Al Cook, CEO of De Beers Group, says: “Through delivery of our Origins strategy, De Beers will be streamlined, focused and a leader in diamond technology, provenance and luxury retail. We will recreate the magic of natural diamonds for modern consumers.

“The outlook for natural diamonds is compelling. Global supply is declining, with no new mines discovered in the past decade. Consumers in key regions are becoming more affluent and are increasingly differentiating between natural diamonds and lab-grown diamonds.

“Every part of De Beers must add value in itself. But it is our integration from the upstream to the downstream, from the south of Africa to the north of

“Consumers in key regions are becoming more affluent and are increasingly differentiating between natural diamonds and lab-grown diamonds.”

Canada, across our portfolio of technologies, which makes De Beers unique. And it is through that integration we will create value as brilliant as our diamonds.

De Beers Group is well on the way to delivering over $100 million in sustainable annual cost savings through a reorganisation and by focusing its capital spend. One-off cost savings will also be delivered through the disposal of non-diamond assets, deferments of non-core projects and the disposal of non-strategic equity holdings.

"Global supply is declining, with no new [diamond] mines discovered in the past decade."

De Beers has a highly competitive portfolio of mining assets that are among the best on the cost curve and have substantial production capability and reserves with global natural diamond production forecast to decline over the coming decade, and as G7 sanctions impact the flow of Russian diamonds into key diamond consuming countries, De Beers’ portfolio is well positioned for the future.

De Beers will focus its upstream investments on the major projects that will deliver the highest returns, including the ramp-up of Venetia Underground in South Africa (www.angloamerican.com) and progression of Jwaneng Underground in Botswana (www.debswana.com), with future optionality to deliver

We offer a range of high-quality, South-African designed and manufactured LED luminaires, suitable for the Oil & Gas industry. BEKA Schréder caters for all industry subsegments, namely upstream, midstream and downstream. For a holistic lighting solution suitable for Zoned Environments, contact us today!

additional projects in Namibia and Canada, should industry dynamics warrant.

Exploration expenditure will be refocused toward Angola, which represents the most prospective region in the world and where De Beers’ exploration activities are well underway in the northeast of the country.

De Beers has a rough diamond sales model that adds value and reduces volatility for both De Beers and its partner countries, underpinned by long-term contracts with its Sightholders.

Technology is poised to revolutionise the midstream, and De Beers will be at the forefront of this trend through its digital portfolio. The results will be greater efficiency, lower working capital and lower

rough diamond inventory levels.

De Beers’ Tracr technology (www.tracr.com) is not only valuable for registering the information required under new diamond import rules within G7 countries, but also offers an enhanced consumer proposition through connecting diamonds to their source.

De Beers has a track record for driving growth in demand for natural diamonds and will evolve its approach for a new generation of consumers. This will involve growing desire for natural diamonds through the reinvigoration of category marketing, embracing new approaches that maximise reach and impact.

Collaborations with retailers will be key to the new approach,

De Beers has a track record for driving growth in demand for natural diamonds and will evolve its approach for a new generation of consumers.

reflecting the pivotal role they play in the diamond acquisition journey. The successful Seize the Day pilot campaign (shorturl.at/ Zlk6K) in Q4 2023 saw more than 22 000 retail stores lend their support, clearly demonstrating the potential of the model.

This year, De Beers will progress strategic relationships with leading retailers such as the collaboration recently announced with Signet Jewelers in the United States (shorturl. at/BgBUP), and a collaboration with Chow Tai Fook (www. chowtaifook.com) in China.

De Beers will also evolve its proprietary retail brands, scaling up its global luxury De Beers Jewellers brand while refocusing its Forevermark brand on the fast-growing Indian market.

With the price difference between natural and labgrown diamonds widening fast, De Beers understands how important it is for consumers to be able to differentiate them reliably and quickly. The company has therefore recently launched a new retail-facing diamond verification instrument (shorturl.at/16XAG), bringing the company’s leading lab-grown diamond detection technology to the retail counter for the first time.

De Beers Group’s Element Six (www.e6.com) business has been a global leader in synthetic diamond development and manufacturing for industrial purposes for more than 70 years. Building on its expertise, Element Six will suspend production of lab-grown diamonds for jewellery and focus on its position as a world-leading provider of synthetic diamond technology solutions for industrial applications.

Low Voltage Motors in asynchronous, reluctance, and permanent magnet technology. Highest quality

V M V S O C S

High Voltage Motors outperforming global standards in industrial applications and supporting megatrends in key vertical applications.

more sustainable future in primary and process industry and in all applications, incl. power-to-power.

digitalization solutions for the minerals industry deliver a sustainable advantage for the mine of the future.

Customer Services provides industry-leading services and digitalization to ensure the productivity, availability, and reliability of our customers’ assets.

With a trusted legacy of more than 150 years of engineering expertise, we are and have always been the backbone of reliable motion for industries and infrastructure worldwide. We are now about to tak to the next level. Our mission is to support you, our customers in the mining and minerals sector, on the road to the future - sustainable, digital,

The world is rushing to Africa to mine critical minerals like lithium—how the continent should deal with the demand

Global demand for critical minerals, particularly lithium, is growing rapidly to meet clean energy and decarbonisation objectives.

Africa hosts substantial resources of critical minerals. As a result, foreign mining companies are rushing to invest in exploration and acquire mining licences.

According to the 2023 Critical Minerals Market Review by the International Energy Agency (shorturl.at/V7Zvo), demand for lithium, for example, tripled from 2017 to 2022. Similarly, the critical minerals market doubled in five years, reaching US$320 billion in 2022. The demand for these metals is projected to increase sharply, more than doubling by 2030 and quadrupling by 2050. Annual revenues are projected to reach US$400 billion.

In our recent research (shorturl. at/upVkD), we analysed African countries that produce minerals that the rest of the world has deemed 'critical'. We focused on lithium projects in Namibia, Zimbabwe, the Democratic Republic of Congo (DRC) and Ghana. We discovered these countries do not yet have robust strategies for the critical minerals sector. Instead, they are simply sucked into the global rush for these minerals.

We recommend that the African Union should expedite the development of an African critical minerals strategy

(shorturl.at/wWKAV) that will guide member countries in negotiating mining contracts and agreements. The strategy should draw from leading mining practices around the world.

We also recommend that countries should revise their mining policies and regulations to reflect the opportunities and challenges posed by the increasing global demand for critical minerals. Otherwise, African countries that are rich in critical minerals will not benefit from the current boom in demand.

There is no universal consensus on what critical minerals are. Various regions and institutions have different lists of critical

Countries should revise their mining policies and regulations to reflect the opportunities and challenges posed by the increasing global demand for critical minerals.

minerals, and the contents of these lists keep changing.

For instance, Australia has classified 47 minerals as critical. The European Union has identified a list of 34 critical raw materials that are important to the EU economy and face a risk of disruption. The United States' critical minerals list contains 50 elements, 45 of which are also considered strategic minerals.

Each country or region has reasons these minerals are classified as critical. For most Western countries, minerals are critical if they: are essential for a low-carbon economy or for national security; have no substitutes; or are vulnerable to supply chain disruption.

At the time of our research, there were 18 lithium projects at various stages, from earlystage exploration to production, across Africa. We focused on those in Namibia, Zimbabwe, the DRC and Ghana.

Our research revealed that conversations on Africa’s critical minerals had largely been

shaped by geostrategic and economic opportunities arising from demand from Western countries and China. Less We realised that these countries contributed little to global carbon emissions, and their economies were not driven by industrialisation. The current inadequate infrastructure and policies to deal with the repercussions of lithium mining, for example, underscored the lack of a clear agenda. Lithium mining has impacts on communities, biodiversity, water sources and energy usage.

We also discovered that with over 30% of the world’s critical minerals deposits, African countries could become major global suppliers. They could also trade among themselves to avoid potential supply chain disruption or even monopoly by countries outside Africa.

Our research also highlights that emerging lithium mining in Zimbabwe, the DRC and Namibia is reinforcing and breeding new forms of corruption and illegality in the resources sector. Ghana is still in the early stage of setting up its lithium sector.

There is a need for co-ordinated efforts in Africa to build local capacity along the mining chain, from exploration to the market.

Africa needs stronger resources governance: regulations, accountability and transparency. Mining policies and regulations must reflect the opportunities and challenges of meeting global demand for critical minerals. Mining companies operating in African countries should adhere to leading mining practices and national regulations to minimise the environmental and social impacts of their operations.

The claim that it is urgent to acquire critical minerals must not be an excuse for African governments and foreign mining companies to bypass mining and environmental regulations. Rather, the urgency claims should give African governments greater power

to make mining deals that will benefit people and the environment.

For these countries to use the economic opportunities arising, there must be incentives for local companies to mine and process lithium before exporting it. Processing of lithium in the country of origin would increase local returns, create jobs and drive the growth of other sectors of the economy.

There is a need for coordinated efforts in Africa to build local capacity along the mining chain, from exploration to the market. There is an opportunity also to build industries to support the global decarbonisation agenda. An example would be manufacturing electronic vehicle batteries. In this way, Africa would not only be a source of raw materials but a competitive source of lowcarbon products.

James Boafo Lecturer: Sustainable Development Murdoch University

Eric Stemn

Lecturer: Safety and Engineering

University of Mines and Technology

Jacob Obodai

Postdoctoral Research

Assistant

Edge Hill University

Philip Nti Nkrumah

Researcher

Sustainable Minerals Institute

LinkedIn www.xcaliburmp.com

Xcalibur Smart Mapping

Website ben.young@xcaliburmp.com

Xcalibur Smart Mapping is the global leader in airborne and mapping geophysics industry, providing comprehensive and sustainable solutions for mapping and assessing natural capital, renewable and non-renewable resources with +100 years of accumulated experience.

With a solid experience and a track record of exponential growth, Xcalibur Smart Mapping offers a wide range of advanced services and technologies for the exploration and evaluation of mineral, energy and environmental resources.

Diesel Electric Services has been involved with mining projects since its inception in 1993. During this time, we have seen major changes with regard to utility power supply and quality of utility power supply.

In the energy sector, the term 'curtailment' refers to the reduction of power production (generation curtailment) or – less frequently – power consumption (load curtailment) when there is too much electricity in the grid (generation curtailment) or when there is not enough power in the grid (load curtailment).

Where we have historically been involved with backup power generator farms to support utility failures, the requirement has now changed to a solution to assist customers with load curtailment during high demand periods.

Our design philosophy incorporates the implementation of medium-speed backup power solutions, rated for continuous operating power as per ISO8528 Part 5, to allow for augmentation of the utility supply during load curtailment periods.

We are currently in the commissioning phase of a bespoke generator farm at one of our mining houses with a capacity of circa 24.8MWe, to act as power augmentation during load curtailment periods. The system voltage is designed at 6 600V with dual

redundant intermediate control interface to allow for generation capacity for actual site demand, while monitoring the utility imported power capacity.

Diesel Electric Services has grown from strength to strength with the initial specialisation in service, maintenance and repair and from there taking the knowledge and experience gained to introduce this into the manufacturing of complete bespoke, clean power solutions – using gas, producer gas or diesel fuelled prime movers, rotary UPS, static UPS and reticulation up to 44kV.

We have in excess of 70 vehicles active in the field and representation nationwide.

Diesel Electric Services has been accredited with both an 8EB and 8EP (Electrical) and 7ME (Mechanical) rating from the Construction Industry Development Board, proving our excellent abilities to perform in our industry.

27/29 Mewett Street Ophirton, Booysens 2091

Tel: 086 110 6633

Email: dieselelec@icon.co.za

Angola drills down on investment incentives and local content support

Angola is leveraging industry-wide reform to not only attract new investments across its oil & gas industry but to unlock a wealth of opportunities for the people of Angola.

Under the guidance of the Minister of Mineral Resources, Petroleum and Gas Diamantino Pedro Azevedo, the ministry has strengthened the environment for doing business in Angola, with regulatory amendments, partnerships with international oil companies (IOCs) and a deliberate intention to empower state-owned institutions making the market more attractive than ever.

In recent years, the Angolan government has implemented a series of measures to enhance the investment landscape, with regulatory reforms and supportive policies laying the foundation for billiondollar deals in the oil & gas space. Instituted reforms

include optimising a focus on deepwater projects, offering attractive terms for onshore exploration, and incentivising local Angolan companies.

Additional measures include the establishment of the New Gas Consortium (shorturl. at/v85Gx) to enhance gas exploration; restructuring the national oil company Sonangol (www.sonangol.co.ao); and the introduction of downstream regulator, the Oil Derivatives Regulatory Institute (IRDP).

Concurrently, Angola is boosting oil production through a six-year licensing round spearheaded by Angola’s upstream regulator, the ANPG (anpg.co.ao). This initiative includes production-sharing negotiations for offshore blocks and aims to revitalise exploration in the Lower Congo and Kwanza Basins.

To support companies doing business in Angola, the country

Various international oil companies are making significant progress in developing large-scale oil and gas projects.

has also imposed a series of travel policy amendments. In 2023, the country implemented a measure that allows citizens from 90 countries to travel to Angola visa-free. The policy supports travel and commerce to Angola, making the country that much more attractive to foreign companies.

Additionally, the country implemented a one-stop shop for local content compliance in the oil & gas industry, enhancing transparency and policy implementation across the sector. In tandem with an amended Local Content Policy—which provides greater clarity on local content requirements and creates new avenues for local service providers—the one-stop shop creates revenue-generating opportunities for the country.

Recent project developments in Angola reflect the positive impact of these reforms, with various IOCs making significant progress in developing largescale oil and gas projects.

TotalEnergies, for example, is driving a multi-energy strategy in Angola, which includes investments in deepwater exploration and the development of the $850-million Begonia field. The company made final investment decision on the $6-billion Kaminho development in May this year, the largest deepwater development in the Kwanza basin. The development comprises the Cameia and Golfinho fields and will come online by late 2025.

Additionally, the Agogo Integrated West Hub Development—operated by international energy company Azule Energy and located in Block 15/06—is expected to produce 120 000 barrels

per day (bpd). Production is set to commence in 2026 and the project forms part of a broader effort to increase national oil output and utilise existing infrastructure efficiently.

ExxonMobil is also making progress with exploration endeavours. The company has plans to invest up to $15 billion in developing hydrocarbons in the company, following the success and outcome of ongoing exploration projects. ExxonMobil recently completed drilling operations at the Likember-01 research well in Block 15 offshore Angola between February and April 2024. The drilling in the Kizomba B development area uncovered high-quality hydrocarbon-bearing sand packages, which indicate significant potential for further exploration and production. This discovery underscores the ongoing success of Angola’s efforts to attract major IOCs and highlights the country’s rich hydrocarbon resources.

On the gas front, the Angola LNG Project (www.angolalng.com)—a partnership between Sonangol and energy majors Chevron, TotalEnergies and Azule Energy— aims to boost the country’s

Angola continues to attract investment through various initiatives, and the results are already showing in the oil & gas industry.

liquefied natural gas production capacity. With a capacity of 5.2 million tonnes per year, the project has been producing and exporting LNG for several years, positioning the country as a gas-driven economy.

Additionally, a new terminal and logistics hub in Soyo will produce 65 000 bpd and store

2 million barrels. This publicprivate partnership project offers importation exemptions and a 10-year tax break, with operations set to begin in 2026 and a licence duration of 15 to 25 years.

“Angola continues to attract investment through various initiatives, and the results are already showing in the oil & gas industry. By offering new exploration blocks, enhancing local content policies to boost domestic industry participation, and improving infrastructure to support project logistics, the country is creating a robust and sustainable energy sector that contributes to Angola’s economic growth,” states NJ Ayuk, executive chairperson of the AEC.

“The government continues to address challenges to doing business by promoting travel and commerce, tackling above-ground risks such as visas, and engaging with Angolan companies. This will catalyse growth in Angola, and the AEC fully supports Minister Azevedo and the country.”

Africa’s energy industry calls on banks and financiers to halt 'financial apartheid' in oil & gas sector

In recent years, several western banks and financial institutions have implemented policies aimed at reducing support for fossil fuel projects, especially in Africa. This has led to a sharp decline in investment in the continent’s oil & gas industry, a sector that is crucial for its economic future and energy needs.

The African Energy Chamber (AEC) argues that these institutions are practising 'financial apartheid', arguing that while similar projects receive support in Europe, Africa’s high-cost energy projects are being neglected.

The decline in investment is already having a noticeable impact, exacerbated by global shifts toward cleaner energy and prioritising of ESG (environmental, social and governance) practices. Major international oil companies are reducing their presence in Africa. For instance, Equinor has withdrawn from offshore exploration in South Africa, and

exited a deepwater oil prospect in Ghana. This decline is contributing to a bleak outlook for Africa’s energy sector.

“As the international community moves to boycott investments in the African energy sector, African people and African development

The decline in investment is already having a noticeable impact

stand to suffer,” says NJ Ayuk, executive chairperson of the AEC. “The role of oil in Africa’s energy and economic future is apparent and, consequently, should be defended as western elites move to disrupt African progress.”

The broader implications of financial divestment are profound. Many African governments rely on fossil fuels as a cost-effective means to alleviate energy poverty and boost state revenues. However, the increasing pressure on financial institutions to cut funding for high-carbon projects creates uncertainty about the future of Africa’s energy sector.

The International Energy Agency (IEA) has added to these challenges with its calls to cease funding for oil and gas projects, highlighting a disparity: While natural gas is considered a ‘green’ energy source for Europe, it does not receive the same treatment in Africa.

According to Ayuk, “The IEA has lost its relevance and its authority.” Originally focused on managing oil supply disruptions, the IEA now prioritises policies aimed at achieving net-zero emissions by 2050. Its 2019 projection that no

new investments in oil, gas or coal are needed if the world continues on this path, has been particularly controversial.

Several key African projects are at risk due to the withdrawal of financial support. Significant initiatives like TotalEnergies’ Mozambique LNG project, ExxonMobil’s Rovuma LNG project, Nigeria’s Train 7 LNG expansion, Senegal’s Sangomar oil field, Uganda’s Tilenga project and the East African Crude Oil Pipeline (EACOP) require substantial financing to advance.

Despite these setbacks, some projects are progressing. TotalEnergies is advancing its $20-billion Mozambique LNG project, aiming to develop the Golfinho and Atum fields with a production capacity of 12.88 million tonnes per year. Eni’s Coral South floating LNG project in Mozambique has achieved a production capacity of 3.4 million tonnes per year.