What a great year for decarbonization and renewable energy efforts! New partnerships, projects, and funding opportunities are announced daily. This enables the deployment of systems that will allow us to achieve midcentury climate goals, while creating jobs, boosting the economy, and strengthening industrial and agricultural markets. This issue of Carbon Capture Magazine highlights some of the newest advancements in technology and research, as well as one of the most profound policy enhancements in industry history. Enjoy your read!

Subscriptions Subscriptions to Carbon Capture Magazine are free of charge to everyone with the exception of a shipping and handling charge for any country outside the United States. To subscribe, visit CarbonCaptureMagazine.com or

VOLUME 1 ISSUE 2

THE TEAM

CEO Joe Bryan jbryan@bbiinternational.com

President Tom Bryan tbryan@bbiinternational.com

Vice President of Operations, Marketing & Sales John Nelson jnelson@bbiinternational.com

Vice President of Production & Design Jaci Satterlund jsatterlund@bbiinternational.com

Senior Account Manager Chip Shereck cshereck@bbiinternational.com

Account Manager Bob Brown bbrown@bbiinternational.com

Content & Marketing Coordinator Danielle Piekarski dpiekarski@bbiinternational.com

Circulation Manager Jessica Tiller jtiller@bbiinternational.com

Advertising & Marketing Manager Marla DeFoe mdefoe@bbiinternational.com

find out

Letters to

Suite

Grand Forks,

at 866-746-8385

dpiekarski@bbiinternational.com.

308 Second Ave.

What makes a great attorney? Is it years of experience? An ability to connect with clients? Passion for their work? Avisen Le gal’s renewable energy team has all these qualities and more. For any facility looking to implement green solutions, get the process started with Avisen. Then, rest easy knowing that Avisen’s team will analyze your case thoroughly to guarantee that your options are tai lored specifically to your company’s goals.

As a boutique law firm, Avisen is focused on one specific sec tor of law and practices with a high level of expertise. Avisen is smaller than most firms, ensuring a stronger attention to the client and their wishes. Todd Taylor, CEO and Co-Founder of Avisen said, “We are laser-focused on understanding the client’s business need, and then using our expertise to help them achieve it.” Taylor alone has more than 20 years of experience in renewable energy projects. With the added skill of his colleagues, Taylor and his team have made renewable energy law their largest single practice area.

Avisen’s team consists of businesspeople and entrepreneurs, giving them critical insight to successful business practices. By un derstanding industrial functions, the Avisen team is able to identify opportunities and develop a plan. Avisen also goes a step further by helping clients better understand the market they are entering. “As new opportunities arise, we work with clients to understand how to use the new circumstance to their benefit and how to creatively

structure it,” added Taylor. “We are always looking for a way to tell the client, ‘Yes’.”

Specifically, in the CCUS industry, Avisen covers all legal as pects of project development. They can help analyze your current business model and find where opportunities are for 45Q tax cred its or other opportunities within the carbon market. All contracting for CO2 sequestration, reuse, and sale is covered by Avisen. Real estate matters and brokerage agreements are also in Avisen’s wheel house. Once a deal has closed, Avisen’s work continues as they of fer outside general counsel services to ensure the ongoing success of your venture. “We’re not just providing route legal advice, we are providing counsel and practical business advice that allows the client to thrive. That is our goal as a practice group and as a firm, “added Abby Pettit, Attorney at Law at Avisen Legal.

If you are looking for a partner that will allow your company to grow and explore opportunities in the most effective way, look no further than Avisen. Passion and expertise are combined to produce the most client-focused and result-oriented solutions. At Avisen Le gal, attorneys take pride and find joy in seeing clients succeed. So, if your company is looking to make a positive impact on the envi ronment, go with Avisen and see the positive impact they make on your business.

One of the most critical aspects of a project is delegating tasks. With many working parts, it can take time to find the best person for the job. As a multi-faceted non-profit organization, Battelle tackles ev ery element of a CO2 storage project while also channeling profits back into science and technology development. With more than 25 years of CO2 storage experience, and a focus on charitable contributions, Bat telle’s expertise ensures peace of mind to all clients.

Battelle began working on small studies in geologic modeling in the mid 1990’s. As one of the first groups funded by the DOE to explore CO2 storage for emission reduction, Battelle was able to form three separate programs that would establish the principles of CO2 injection. Between the Regional Carbon Sequestration Partnership and the Mid west Regional Carbon Sequestration Partnership, Battelle proved that large scale CO2 storage could be successful with the correct application and optimized strategies for storage at a commercial scale.

After nearly a quarter of a century, Battelle has grown into a world leader in geologic carbon dioxide storage. Battelle goes beyond the sci ence of projects with their strong commercial geotechnical competence to produce flexible business models for clients. Whether it be permit ting, funding, or construction, Battelle’s dedicated-saline-carbon-storge team guarantees efficient and effective services in all aspects of a CCUS projects.

In response to the emerging demand, Battelle reorganized their CCUS program along two lines. One follows a commercial group, which

oversees commercial clients. The other concentrates on DOE and gov ernment funded programs. Neeraj Gupta, Senior Technical Leader of CCUS at Battelle added, “Underlying all that is making sure you have the right, capable people who are able to look at the opportunity and the project, not from a resource point of view, from a business risk and an environmental risk mitigation point of view to make sure they are finding the safest and most effective locations for CO2 storage.”

Boasting over 350 years of cumulative experience, Battelle’s team has created a phased approach to help clients monetize and decrease overall emissions. When determining a site’s geological storage feasibil ity, Battelle uses existing data and gathers new data for assessment and planning. If a site’s geology is plausible for CO2 storage, a system will be built, and injections and monitoring can begin. By managing each step of the process, Battelle can ensure regulatory compliance and take the pressure off the client.

Battelle prioritizes building trust and a safe environment in all op erations. “Innovation is always going on; we are always looking for ways to improve process by reducing cost and increasing confidence,” said Gupta. “These are exciting times, but it is also the time to be responsi ble and make sure that the science that we are developing has full public confidence that it can be done safely and securely for the long term.” If your facility is looking into carbon storage, Battelle’s team is prepared to offer cost-effective solutions tailored to fit your needs. They have the experience and personnel to handle all tasks.

Battelle’s team of over 100 subsurface and geotechnical experts provide full lifecycle CO2 storage solutions, from initial site screening and characterization, to permitting, construction, monitoring, operational and post operational support.

SCS Engineers is engaged in provid ing Class VI underground injection control (UIC) permitting, design, construction, and operations & maintenance services for clients to support geologic carbon sequestration projects. Leading these ser vices is an interdisciplinary team of scien tists from our existing deep well injection practice. It includes scientists with exper tise ranging from oil and gas production to basin stratigraphy to subsurface modeling. At SCS, we aim to ensure the Class VI per mitting process is completed as effectively as possible, with short- and long-term project risk, cost, and resources in mind.

How will SCS Engineers help mitigate future potential Class VI UIC project risk during the permitting phase?

There is inherent enhanced risk asso ciated with Class VI UIC permitting proj ects resulting from geologic uncertainty, rigorous regulatory requirements, and general public perception. Fortunately, careful planning can mitigate risk during the initial permitting phase.

To minimize geologic uncertainty and ensure meeting regulatory requirements, SCS gathers the most robust and repre sentative data possible. Often this means collecting additional data for site char acterization purposes, such as drilling a stratigraphic test well, purchasing seismic data, and conducting laboratory analyses on new or existing cores. This level of site characterization, conducted early on in the process, can appear costly; however, collecting the data necessary to minimize geologic uncertainty in your area of review will 1) allow the development of a more refined testing and monitoring program,

thus reducing associated costs over the lifetime of the project; 2) reduce the likeli hood of having to make significant adjust ments to the area of review or monitoring program during the operational phase; and 3) greatly increase the likelihood of over all success with the regulatory agency and likelihood of receiving a permit.

When initiating the permitting pro cess, it is vital to engage with the regula tory agency, stakeholders, and the public and develop relationships early in the pro cess. SCS will help initiate and develop these relationships throughout the permit ting process, ensuring that the permitting process completion is expeditious and to the satisfaction of the regulatory agency, stakeholders, and the public.

There are many factors to consider during the permitting process that will help avoid unintentional consequences once the project is permitted. In particu lar, SCS will ensure that CO2 injection is highly optimized based on client needs and detailed, site-specific modeling re sults. We tailor injection locations, inter vals, and rates to meet client needs and honor the modeling results. Additionally, SCS will compile a testing and monitoring plan that is highly optimized, as this plan relies heavily on the site characterization and modeling efforts. To be as robust and cost-effective as possible, the team designs the testing and monitoring plan based on site characterization data and modeling re sults.

SCS can also help clients strategically reduce costs early in the project for the post-injection site care (PISC) period and potentially shorten the default fifty-year PISC period. Minimizing geologic uncer tainty and synthesizing site-specific data into the model process during the initial permitting phase will reduce long-term project costs. A well-planned and phased testing and monitoring approach is essen tial to save costs throughout the injection phase and allow greatly reduced monitor ing frequencies during the PISC period once injection ceases. In addition, it is pos sible to propose a shortened PISC period in some cases, which will greatly reduce post-closure costs.

Monte Markley, PG, serves clients na tionwide with the SCS Engineers’ team as a senior project director and their National Expert for Deep Injection Wells. Monte may be contacted at MMarkley@scsengi neers.com or 316-315-4501.

Founded in 2003, MicroSeismic’s mission was to bring passive seismic technology to the oilfield. What started as a predominately frac-monitoring business has since expanded into a variety of pas sive seismic services, including the monitoring of CO2 sequestration. MSI anticipates that monitoring of CO2 sequestration projects will become an increasingly important task, as the world undertakes the mitigation of greenhouse gas emissions to meet mid-century goals without compromising energy security. Conventional 2D and 3D seismic imaging does not address the dynamic changes in the res ervoir and its caprock during injection of CO2. MicroSeismic takes passive seismic a step further with CO2SeQure passive seismic moni toring prior to, during, and after injection, ensuring the CO2 stays in the reservoir permanently.

Through CO2SeQure monitoring, MicroSeismic images and monitors reservoir conditions before, during, and after injection achieving one of the most important elements of a CCUS project: monitoring, measuring, and verifying (MMV) sequestered CO2. To comply with their EPA-approved MMV plans, CCUS operators must confirm the injected CO2 is staying within the target formation, verify caprock integrity, and ensure that no hazardous seismicity is induced by the injection. These MMV protocols are required to qualify tax credits associated with CO2 sequestration, and to establish social li cense for the safe and environmentally friendly operation of the in jection project.

BuriedArray® is the apparatus used by MicroSeismic for moni toring CCUS projects. This cost-effective method is custom designed for each project to ensure accurate measurements of passive seismic events. BuriedArray® technology comprises multilevel, multicompo nent geophones cemented in shallow boreholes. Telecommunication devices are installed at each project site to collect and transfer data to a facility where it is processed and analyzed in real-time. These auton omous devices are powered by wind and solar, with battery backup.

To establish an accurate baseline ambient microseismicity, a Bur iedArray® is installed prior to injection. Once injection starts, passive seismic data is continuously transmitted for analysis and detection of any events that might reveal a compromised reservoir at the injection site. MicroSeismic has implemented a “stoplight system” using pas sive seismic, which will automatically notify an operator when events surpassing certain critical levels of magnitude, frequency, or location are identified.

Additionally, the array can be used for surface 3D monitor sur veys with a high-density source effort to mitigate the sparse receiver grid. This provides a more consistent 4D data set as well as cost re ductions compared to traditional 3D acquisition.

With nearly two decades of experience and U.S. Department of Energy funding, MicroSeismic has developed, and will continue to develop state-of-the-art monitoring technology for the growing CCUS industry.

Powered By

CO2SeQure is focused on playing a significant role in the long-term future of CCUS with our proven real-time monitoring for CO2 protocols. Our BuriedArray® is a cost-effective system for monitoring CCUS projects over their lifecycle and mitigating risks. www.microseismic.com

By Justin Walsh

By Justin Walsh

According to the National Climate Assessment (NCA), human activi ties release over 30 billion tons of carbon dioxide into the atmosphere annually. These emissions contribute to the greenhouse effect that is causing temperatures and sea levels to rise as well as a surge in increasingly severe weather events across the globe.

The reality of the climate crisis is forcing many global leaders to commit to significant reduc tions in carbon emissions. For policymakers to meet these important targets, they will need to leverage new technologies to capture, use and store carbon dioxide (CO2) before it is released into the atmosphere. This is supported by recent US federal government investments in R&D and Carbon Capture facilities in both the CHIPS and Inflation Reduction Acts of 2022.

Carbon capture utilization and storage methods present a path forward in ways that can be scaled to make a significant impact. However, as these operations grow, measurement and control challenges arise. The continuous monitoring of CO2 is difficult, as exhaust gases from incinerators can be corrosive and potentially explosive. Until recently, the only solution was to extract samples for analysis outside of the process. However, this method has several inherent flaws, such as the need to remove humidity from the sample line and requirements for frequent recalibration. Additionally, the manual extraction and analysis process means there is also no way to retrieve near real-time data, creating the potential for decreased efficiency.

In a pilot project using Vaisala technology, researchers from the Technical University of Denmark (DTU) demonstrated that it is possible to remove most of the CO2 from the emis sions of a waste incinerator. To simplify the process of capturing CO2 before it enters the atmosphere, Vaisala CO2 sensors are being used to measure reliably in the most demanding environments. By showing the viability of the CCUS process, the researchers believe they have developed a new fundamental technology in the fight against climate change.

The Amager Bakke waste-to-energy plant is one of northern Europe’s largest combined heat and power (CHP) plants, treating 560,000 tons of waste annually. Developed by the Co penhagen-based waste management company ARC (Amager Resource center), the CHP plant plays a significant role in the Danish capital’s ambitions of meeting zero carbon requirements by 2025.

The incineration of 1 ton of municipal waste releases between 0.7 and 1.7 tons of CO2, depending on the content of the waste. Consequently, energy generation from waste incinera tion is more carbon-intensive than burning fossil fuels, so carbon capture and utilization offer a particularly enticing opportunity for this application.

Initially developed to capture CO2 from the emissions of wastewater treatment, biogas production, anaerobic digestion and waste incineration processes, the pilot project saw DTU researchers investigate the optimized processes by which CO2 can be captured and then uti lized to determine economic feasibility.

Exhaust gas from the Amager Bakke incinerator is passed through an electrostatic precipi tator to remove particulates, NOx compounds are removed by selective catalytic reduction and a scrubber removes oxides of sulfur. The gas then passes upwards through a column packed with beads and a monoethanolamine (MEA) solvent which separates the CO2 from the gas. The solvent is then passed to a desorber which removes the CO2, which is now almost pure, and regenerates the MEA for re-use.With its primary purpose being the investigation of the

feasibility of its capture, the pilot carbon capture plant employs three Vaisala probes to measure CO2 levels. The MGP261 moni tors incoming incinerator exhaust gas, the MGP262 measures the purity of the ex tracted CO2, and the GMP251, a Vaisala CARBOCAP® CO2 probe, checks the lev els of CO2 (after carbon capture) in the pi lot plant’s exhaust gas.

Measuring CO2 levels at every stage is crucial to verify the validity of this process. Demonstrating that carbon can be removed from emissions before they go into the at mosphere, and that the CO2 captured dur ing this process is nearly pure and able to be stored for later use, highlights the pos sibility of employing a solution like this to

reduce emissions. As this process is more widely recognized, it can be utilized more cost-effectively in waste treatment facilities across the globe.

“The recent COP26 climate change conference in Glasgow highlighted the ur gent need for technologies that can help re duce global emissions of greenhouse gases such as CO2,” said Jens Jørsboe, a DTU researcher. “Many countries have commit ted to net-zero targets, so our work at the Amager Bakke waste-to-energy plant pro vides an opportunity for them to invest in one of the ways in which that objective can be achieved.”

While the technology is not new, re searchers from DTU are now focused on lowering the cost of carbon capture, mak ing it more feasible for other plants to im plement similar solutions.

There are many different industrial ap plications in which CO2 can be utilized. For example, CO2 can be combined with hydro gen to produce methane (renewable natural gas, RNG). This can be a green method for manufacturing fuel, depending on how the hydrogen is generated. Since CO2 is also used in various other industries, including food and beverage, refrigeration, medical, horticulture, firefighting, and welding, a va riety of potential markets are available if the heat-trapping gas can be easily produced on a commercial quality and scale.

By validating the carbon capture pro cess with Vaisala’s measurement solutions, DTU researchers have shown that this process is a viable solution to the waste emissions problem. With continuous inline monitoring, the researchers have optimized carbon capture performance in 12 different pilot plant configurations.

Having proven the viability of the car bon capture process at Amager Bakke, the next step is to evaluate the advantages of carbon storage and utilization. CO2 utiliza tion, however, is more costly as it requires further refinement of the CO2. Neverthe less, researchers hope this technology will be leveraged in waste treatment facilities worldwide. With the proper regulatory framework and subsidization, the tons of carbon dioxide that would usually be re leased into the air could now be used across myriad industries to improve our world.

The impact of climate change is be coming increasingly apparent in our ev eryday lives. We must utilize technology as we push toward a future where the com ing generations can enjoy environmental safety and prosperity by leveraging sustain able practices. Carbon capture, utilization and storage technologies, such as the gas probes and sensors used in this case, will play a progressively more significant role in the fight against climate change by provid ing accurate, real-time data in even the most extreme environments to validate and opti mize processes.

Author: Justin Walsh Business Development Engineer Vaisala justin.walsh@vaisala.com

By Drew Burns

By Drew Burns

The concrete industry is working to reduce its carbon footprint, but despite the amount of work already accomplished, there is still much to do. In a significant step to help meet carbon reduction goals, the American Con crete Institute (ACI) has established a uniquely posi tioned center, NEU: An ACI Center of Excellence for Carbon Neutral Concrete. This Center is significant as it will drive research, education, awareness, and global adoption of the use of carbon neutral materials and technologies in the built environment. NEU’s vision is a concrete industry where all stakeholders have access to technologies and the knowledge needed to effectively and safely produce and place carbon neutral concrete and concrete products.

The establishment of this Center is noteworthy be cause with the wealth of information available, it is not easy for companies to decipher the best technologies and materials to use. It is increasingly important that as new materials and technologies come forward, they are evaluated for their efficacy. NEU will create a process to validate the claims of innovative and new materials and technologies associated with low carbon concrete pro duction and placement.

With the concrete industry inherently risk-adverse in regard to new ideas, NEU’s pathway to validation will as sist those in the concrete industry to evaluate and choose the appropriate method for their application.

So, how do we begin to evaluate new materials and technology? The best way is through an independent, peer review evaluation based on upon set thresholds specific to that product. NEU is developing a process for companies to submit proposals for validation con sideration. This begins with a procedure that is directed by a validation committee with oversight to the process. NEU has outlined the basic phases of validation. These include:

• Initial application and review

• Subject matter expert (SME) panel formation

• Review of product, claims and supporting data

• Report generation and validation committee review/approval

An advantage of this process is that it is an individualized approach, with the end goal of validating spe cific claims put forth by the applicant.

NEU is not producing broad reviews of a material or technology, but rather each specific product is reviewed based on its own individual merits. The re sult is that users will know the specifics of what to expect in concrete perfor mance and carbon reduction from us ing that product.

NEU anticipates accepting proposals beginning in Spring 2023. However, validation is only one of the core functions of NEU and other functions are just as essential to pursue a carbonneutral goal.

NEU has several other areas it will pursue to ensure that information and education about low carbon options is spread throughout the industry.

Technology Transfer. This is the education and dissemina tion of best practices associated with carbon neutral concrete and is central to NEU’s success. It is important that the industry understands the issues associated with carbon neutrality and the advancements that are being made along the way. It is through educating the industry on the most recent information acquired through vetting and testing that those throughout the industry have the opportunity to make choices that are best for their con crete application. NEU comes with the built-in advantage of be ing founded by the American Concrete Institute (ACI) and can

capitalize on ACI’s established network of professionals within industry, as well as higher education institutions worldwide.

Some of the resources NEU will be setting up to provide the industry with vital information include short courses (vir tual and in-person), webinars, training programs (ACI Resource Centers), industry presentations, technical information sheets, Carbon Neutral Concrete Summits, and future professional cer tification programs.

NEU has already begun making inroads in education:

• A new Sustainable Concrete Guide in the works and will be released in late 2022.

• The first two webinars have been released and are on the NEU website.

o How ACI is Working to Address Carbon Neutrality in Concrete

o An Overview of Sustainable Concrete Design

• Another valuable educational resource on NEU’s website includes FAQs about carbon neutral concrete, which are updated regularly.

A special upcoming event is NEU’s first Carbon Neutral Specialty Day at the ACI Spring Convention in April 2023. This event will include presentations and case studies by industry lead ers.

Other core values of NEU include:

Advocacy and Technical Support. NEU will be able to use ACI’s network to help with advocating for the use of sound technical information and the application of existing knowledge.

NEU looks to assist in advancing local jurisdiction adoption while keeping an eye on local procurement and building code is sues. Additionally, NEU will be a resource for ACI committees in developing language for guides, specifications, and codes as sociated with carbon neutral concrete materials and technologies.

Manufacturing a cubic yard of concrete is responsible for the emissions of about 400 pounds of CO2. That same 400 lb. of CO2 equates the same emissions as: an average tank of gas in a car, using a home computer for a year, or using a microwave oven in a home for a year.

ACI Committee Assistance. The technical, educational, and certification committees of ACI are recognized worldwide as a resource for unbiased consensus information on topics related to concrete. NEU will be recognized as an entity that supports the resources developed by these committees including dissemination. Additionally, NEU will respond to research needs identified by ACI committee experts and provide investor feedback on new docu ments, codes, and specifications that are required.

Technology Acceleration. NEU is envisioned as the gateway for new technologies to enter the industry and can direct necessary resources to accelerate the adoption of those technologies. Cur rently, no such entity serves the concrete construction industry in this way, and the lack of such an entity is a major hurdle to innova tion.

Research. Even though much research and development has been conducted on technologies that support a reduced carbon footprint for the cement and concrete industry, more needs to be done to ensure the effective and efficient deployment of these de carbonization technologies are focused.

In the current fragmented world of cement and concrete re search, significant resources are being channeled into ideas and technologies that simply will never be implemented. High-risk, high-reward research has its place, but this Center will keep its fo cus on technologies that experts can support as being realistic, ap plicable, cost effective, and technologically effective. It has been said that bringing the cement and concrete industry to carbon neu trality by 2050 is akin to the U.S. mission to travel to the moon in the last century. It will take a well-focused, informed, technologi cally advanced organization to develop the necessary technologies. NEU will assume the responsibility to work directly with other ma jor entities worldwide to achieve the desired outcomes.

International and Student Outreach. NEU will work with international ACI Chapters to meet global needs. Additionally, empowering and motivating the next generation of engineers and technologists to be actively involved and support the decarboniza tion efforts is imperative. To this end, NEU will engage with ACI’s contingent of student members and student chapters.

Organizations across the value chain are financially and philo sophically supporting and collaborating on executing the Center’s objectives. Many companies that have committed to help with NEU’s mission at various levels of involvement, including Sustain ing Members, Supporting Members, Affiliate Members and Allied Members. All are united in the goal of finding the best methods to reduce carbon emissions in concrete.

Interest and involvement are being seen from project owners, specifying agencies, architects / engineers, developers, contractors, material / product suppliers, trade associations, related NGOs, ed ucational Institutes, and federal and state agencies.

NEU is new and beginning its journey in assisting the concrete industry in this monumental transformation toward a greener fu ture. Through thoroughly vetting new materials and technologies and educating the industry, the road to reduced carbon neutrality can become a reality.

For more information on NEU and how to get involved, go to www.neuconcrete.org, or email info@neuconcrete.org.

Author: Drew Burns Executive DirectorNEU: An ACI Center of Excellence for Carbon Neutral Concrete drew.burns@neuconcrete.org 248-848-3780

Rising CO2 emissions since the industrial revolution have prompted action by lawmakers and corpora tions to set optimistic zero carbon emission goals. Improvement of CO2 capture adsorbents is clearly a large roadblock to deploy ment of carbon capture, utilization, and sequestra tion (CCUS). Innovation in both the sorbent mate rials and processes space is of utmost importance for CO2 emissions curtailment. While reducing CO2 emissions is a challenge, another significant concern is plastic pollution. Annually, millions of tons of plastics are disposed improperly each year, with only a small fraction fully recycled by any type of recy cling method due to the current limitation in plastic waste recycling technologies. For example, physical recycling is high in cost as it requires human sorting, detergent washing, melting, and reshaping. Further more, the plastic produced via physical recycling is lower in grade than virgin plastic and has limited ap plications. Chemical recycling, on the other hand, is conducted via the thermal cracking of plastic to pro duce polymer building blocks that are used to syn thesize virgin plastic, while also producing lubricat ing oils and waxes. Thermal cracking is economically viable and produces usable chemicals, but it results on the production of large quantities of carbon char that has no useful applications, making the overall process low in circularity. Clearly, both CO2 emis sions and plastic pollution issues must be addressed to mitigate their environmental damage. The ques tion remains, how can these problems be lessened?

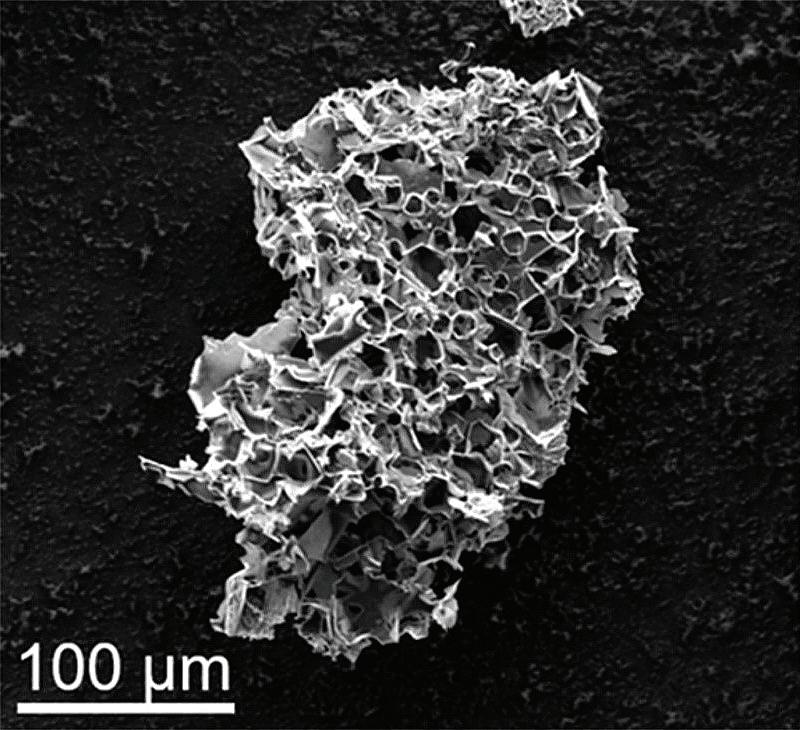

At Rice University, we have developed a solu tion to reducing CO2 emissions while also alleviating the plastic waste burden. By pyrolyzing waste com modity thermoplastics, such as high-density polyeth ylene (HDPE), low-density polyethylene (LDPE), and polypropylene (PP), in the presence of potas sium acetate (KOAc) at 600 °C for 45 minutes, a high surface area porous carbon CO2 adsorbent can be synthesized. Typically, plastic pyrolysis methods yield an unusable char in addition to distilled mono mers, oils, and waxes; however, when thermally treating HDPE, LDPE, and PP with mild KOAc, the unusable char is upgraded to a CO2 adsorbent. This adsorbent has many properties like other ac

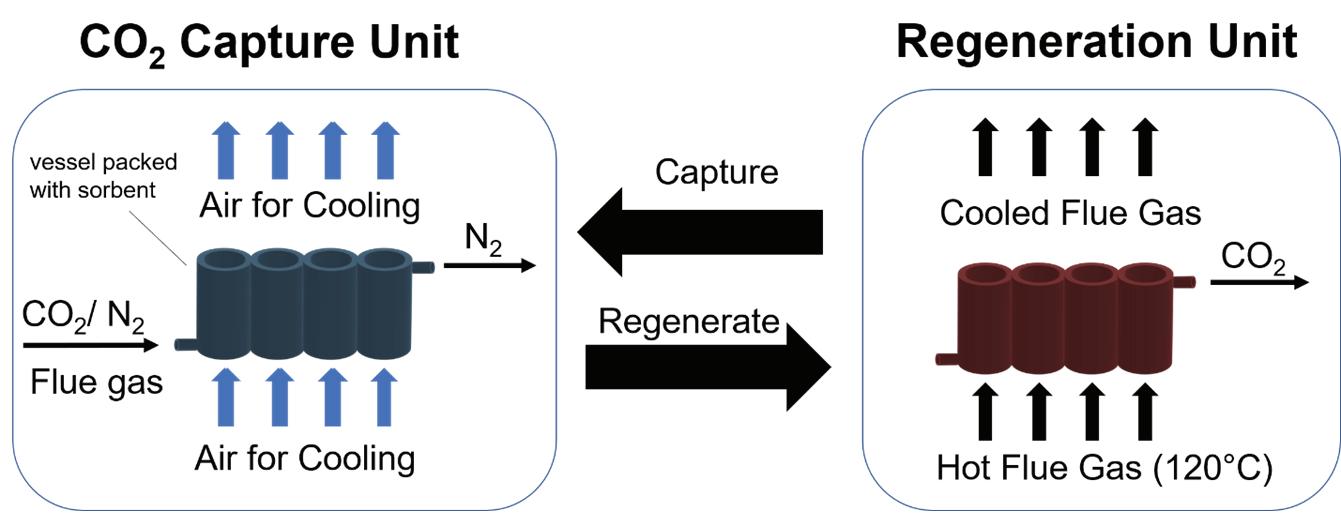

tivated carbons, namely good CO2 uptake capacity, good CO2 to nitrogen (N2) selectivity, resilience un der elevated temperatures, and excellent cycling sta bility. These properties lend itself to flue gas carbon capture implementation. The optimized reaction temperature and time produce a CO2-capture ma terial that can bind up to 18% of its weight in flue gas CO2 at room temperature. Pores of 0.7 nano meters are produced by this process, the perfect size for selective CO2 capture. This waste plastic-derived sorbent is a highly stable solid carbon material. Our tests demonstrate CO2 capture stability up to 100 adsorption and desorption cycles when using pres sure swings. Temperatures up to 275 °C under air will not cause any significant structural or perfor mance deterioration. Therefore, any issues regard ing the traditionally used liquid amine CCUS deg radation, volatilization, and corrosivity are avoided. Additionally, the estimated capital and operational expenditures of such solid systems is much lower than when using traditional liquid amines systems. A proposed capture system contains multiple sor bent beds that are either in a capture state or regen eration state. The sorbent actively captures flue gas CO2 during the capture stage, and this captured CO2 is driven off by heat, vacuum, or a combination of the two during regeneration. Owing to the low CO2 desorption temperature of the adsorbent (75 to 110 °C under pure CO2), hot flue gas could be used to provide some heat to release captured CO2 during the regeneration mode.

This process, the first of its kind in convert ing HDPE, LDPE, and PP into a CO2 adsorbent, contains a high degree of circularity. With minimal modifications to current chemical recycling ap proaches, plastic waste recycling could be greener than ever. The sorbent allows chemical recycling to be carbon negative by capturing emissions asso ciated with the pyrolysis process if a sorbent cap ture vessel is attached. When pyrolyzing HDPE with KOAc, any polymer not converted to porous carbon decomposes and distills out, forming the monomers, oils, and waxy byproducts. We demon strated the distilled waxes can be mixed with KOAc again to form a comparable CO2 adsorbent. These waxes could also be further recycled into lubricants,

Figure 2. Scanning electron microscope image of HDPE sorbent.1 Reprinted with permission from ref 1.

SOURCE: 2022 AMERICAN CHEMICAL SOCIETY

detergents, or virgin PE via closed or open loop chemical recycling. Virgin PE could be fed back into the sorbent synthesis process at the end of its product life to make more adsorbent. Another circular feature of this process is the use of nonhazardous chemi cal activating agents.

Chemical activation of carbon mate rials often use hazardous phosphoric acid (H3PO4) or potassium hydroxide (KOH). Both chemicals are corrosive and difficult to handle. In the specific case of KOH, the full benefits of using KOH as an activating agent are typically gleaned above 700 °C; however, flammable potassium (K) metal also forms above 700 °C. KOAc, which thermally decomposes into environmen tally friendly potassium carbonate (K2CO3) and acetone byproducts at 430 °C, acts as a plastic carbonization substrate at 600 °C and greatly reduces the risk of flammable K metal formation. Rather than forming K metal, K2CO3 remains stable until 730 °C. Typically, 12% of the plastic waste converts into an activated carbon. The environmen tally friendly salt KOAc, which finds use as a deicer, has no known human toxicity or corrosive behavior. Further, the K2CO3 can be used to form KOAc and re-used as a chemical activator after it is rinsed from the activated carbon.

Through our process described here, the upcycling of HDPE, LDPE, and PP waste into a CO2 sorbent with good uptake capacity, CO2/N2 selectivity, cycling, and thermal stability is now attainable. Minimal waste can be produced from this process since non-carbonized plastic waste could be further recycled into useful chemicals. Used virgin plastic and distilled waxes could even tually be reincorporated back into sorbent production. Additionally, the CO2 footprint of pyrolysis processes could be lowered by the CO2 sorbent. Incorporation of KOAc into thermal cracking processes of com

modity thermoplastics will lead to greener and more circular chemical recycling.

Author: Paul E. Savas1, Wala A. Algozeeb, PhD.1,2, and Professor James M. Tour1,3,4

AFFLICATION(S)

1. Department of Chemistry, Rice University, 6100 Main Street, Houston, Texas 77005, United States

2. Research and Development Center, Technical Services Division, Saudi Aramco, Dhahran, Saudi Arabia

3. Department of Materials Science and NanoEngineering, Rice University, 4. Smalley-Curl Institute, The NanoCarbon Center and the Welch Institute for Advanced Materials, Rice University, 6100 Main Street, Houston, Texas 77005, United States

REFERENCE

1. Algozeeb, W.A.; Savas, P.E.; Yuan, Z.; Wang, Z.; Kittrell, C.; Hall, J.N.; Chen, W.; Bollini, P.; Tour, J.M. Plastic Waste Product Captures Carbon Dioxide in Nanometer Pores. ACS Nano. 2022, 16, 7284–7290.

Figure 3. Suggested design for CO2 capture unit, in which CO2 desorption is assisted by hot flue gas.1 Reprinted with permission from ref 1.

SOURCE:

Capturing

By Melissa Leung and Saad El Kassab

By Melissa Leung and Saad El Kassab

If you happen to be part of the carbon capture ecosystem, chances are that you have heard about biochar several times. However, compared to direct-air capture (DAC) and geologic storage, bio char is seldom discussed outside of the vol untary market. Why does biochar command such interest from the voluntary market, yet command little investment compared to other CCS methods? Why should investors, regulators, and industrialists spend more time exploring this solution; one that com bines both engineering and nature?

Climate change issues are both numer ous and multi-sectorial. As one of the most studied, recognized and alarming prob lematics, greenhouse gas emissions have been the focus of climate actions. Emission reductions bring a necessary deceleration to the amount of CO2 released in our atmo sphere. Is a deceleration enough to attain global goals set by the international scien tific community and signatories of the Paris Agreement? According to the IPCC, carbon

dioxide removal solutions are necessary to reach our goals. And biochar has been rec ognized officially as one of those solutions, providing a long-awaited recognition to the industry.

The voluntary carbon market has ex ploded over the past two years, and with it the demand for biochar carbon remov als. Emitters rightfully believe that to stay compliant, their organization must com pensate carbon emissions and improve their ESG reporting. But even world-renowned organizations, revered for their dedication to social impact and environmental consid erations, find it difficult to align financial goals with their sustainability commitments. Although there has been a surge in demand, and supply have been difficult to secure for buyers due to limited production ca pacity and commercially operational facili ties, meaningful investment in the biochar

project lifecycle remains limited. One would think that such a situation would promote access to capital for producers; however cash-flow remains difficult to secure for early biochar projects.

GECA has seen a rise in investment interest for high-quality projects across the world, with private venture capital, alterna tive financing firms and even multinational corporations exploring equity, debt, royalty or direct offtake opportunities. Such entities have been, and are still reluctant to commit to biochar projects due to perceived risks and limited knowledge of biochar project implications. More specifically, they are not so familiar with biochar project develop ment steps and requirements. These steps differ when contrasted with nature-based solution projects.

Afforestation projects, to use one ex ample amongst many, generally involve limited initial risk that increase with time as reversals are made possible from natural and non-natural causes. When all goes well, nature takes over and does the work re quired to remove large amounts of carbon from the atmosphere, enabled by project

Is the market ready to acknowledge and invest in proven impact? Perspectives on biochar carbon removal

developers through photosynthesis. Many of these projects rely heavily, if not com pletely, on the income of the carbon market to make the venture financially feasible and further profitable. For some corporate buy ers and actors within this class of projects, permanence over time, monitoring, and risk of reversal may have been understated in early days to the point of public controver sies and market skepticism. Authentic, in tegrated, and transformative collaboration could positively impact market stakeholder trust and reduce future risks of controver sies. Our removal buyers believe that risk mitigation could be summarized as a cari catural choice: either spend your time and talents denying allegations, or prepare and prevent risks with a genuine commitment and execution.

At GECA, we provide tailored guide lines so buyers can always have a helping hand to leverage best-in -class impact for their investment. Biochar projects depend on a consistent technology component that enables the long-term removal of carbon from the atmosphere. For a project devel oper to be issued removals through any certifications, it must produce and place, so sell or donate, the physical biochar before issuance of the credits. The production of biochar is one of the complexities of this type of project, since it necessitates dedi cated industrial facilities, most of them run ning 24/7, with specialized human capital, markets for the biochar, and monitoring of the biochar itself through tracking. Pyroly sis, the main type of biochar production processes, is however well-known and mas tered, having been used for centuries. Tech nology, when carefully selected by experts in the field, represents a relatively low risk for carbon projects. While the tracking of the biochar to its final application can be daunting, it indirectly provides the advan

tage of reducing reversal risks to almost zero. Once the removals are issued and a buyer has purchased and cancelled them, their risks, including reversals and contro versy, are limited.

In fact, biochar projects also require several verticals to be profitable – in almost all “projects”, relying on the carbon market to be economically feasible does not suffice given the current price for carbon removals. Carbon projects now have been catalyzing the development of biochar projects across all continents, simultaneously raising shy, but persistent interest from capital markets and promoting sustainability in many sec tors such as agriculture. The catalytic role of carbon markets in the biochar industry has been highlighted indirectly by Verra in their new methodology via the use of mar ket penetration as the basis for additionality. Other standards consider additionality as de facto for biochar, such as Carbon Stan dard International, or push for financial ad ditionality, such as Puro.earth. That being said, all the above standards strive to estab lish strict conservative guidelines for one purpose: to allow the market to hold bio char removal procurement agreements to the highest standard. Delegate the technical risk analysis to an expert, and you are al most geared up to invest in a real and much needed legacy for decarbonisation.

In spite of that, the time to commer cialisation for biochar projects has been an important barrier with financing entities looking to see a relatively rapid return on investment. Project development timelines have increased over the past year mainly due to equipment manufacturing delays, exacerbated by limited manufacturing sites and components shortage, as well as cost of capital in a bearish market. New riskmitigation frameworks are currently being developed to provide removal buyers and

investors assurance that their investments are somewhat protected. An example is Kita, a new UK-based insurance company specialized in the carbon market who is developing, with inputs from stakeholders such as Puro.earth and GECA, an insurance product for biochar removal buyers.

Finally, biochar carbon removal is one of the best opportunities to invest in a du rable, low-risk solution with high co-ben efits in a market where demand will only keep growing. Given the important carbon price of the removals, the need for capital and the flexibility of financial models in the industry, biochar projects represent a real opportunity to invest in a multi-lateral solu tion to our climate problems. While carbon is a catalyst, it is not the only environmen tally positive outcome of such ventures, but a tip of the iceberg. It is then not surpris ing that Meta, Swiss Re, Zurich Insurance, Shopify, and the Chan Zuckerberg Initiative are betting on biochar with upfront and/or long-term involvement. Deployment of a proven large-scale removal strategy requires a systemic change and a genuine desire to do good for the planet and its people. Is the market ready to acknowledge and invest in proven impact? Are we truly educating stakeholders on sustainability? New and returning actors will surely influence the deployment of biochar as a global carbon removal method. True collective commit ments affect how sustainable markets grow, and as a consequence, whether we can reach global sustainability targets.

For financiers looking to understand the biochar market further, offtake or invest in this solution, contact Saad El Kassab or Melissa Leung at GECA Environnement.

Authors: Melissa Leung melissa.leung@gecaenviro.com Saad El Kassab saad.elkassab@gecaenviro.com www.gecaenviro.com

By Leo Duke and Madelyn Morrison

By Leo Duke and Madelyn Morrison

The enactment of the Inflation Reduction Act of 2022 represents the most robust and comprehensive climate and energy policy in our na tion’s history. The law includes groundbreak ing federal policies needed to realize economywide deployment of carbon management technologies, prioritize industrial decarbonization, and scale in frastructure at the rate required to meet midcentury climate goals, foster domestic energy and industrial production, and provide environmental and eco nomic benefits to affected communities.

Coupled with historic investments in the Bi partisan Infrastructure Law, this package provides the most transformative and far-reaching policy support in the world for the economywide deploy ment of carbon management technologies, mak ing a critical down payment on the investments in American innovation required to achieve net-zero emissions. The law makes several critical enhance ments to the federal Section 45Q tax credit pro viding investment certainty, additional credit value, and the flexibility needed to drive greater project deployment across multiple sectors. These incen tives are critical to the continued growth and devel opment of the carbon management industry, and their enactment into law is yet another indication of the vital role these technologies must play in meeting both net-zero emissions and midcentury climate goals.

Though the Inflation Reduction Act (IRA) was passed through the budget reconciliation process, this landmark law contains broadly supported carbon man agement priorities drawn from bipartisan legislation introduced earlier this year by Congress and subsequently endorsed in President Biden’s American Jobs Plan, in cluding:

Recent analyses and commercial ex perience underscore that 45Q credit val ues established by the 2018 passage of the FUTURE Act are insufficient to drive the early deployment of carbon capture tech nologies in industry, electric power genera tion, and direct air capture. Higher credit levels are necessary to bring costs down and reduce commercial risk to carbon management project deployment in highemitting sectors. The IRA makes critical increases to the credit values for these projects, which traditionally feature higher costs of capture and greater commercial risk, providing the necessary federal policy

support to adequately incentivize private investment in these sectors.

The IRA includes a seven-year exten sion of the current commence construc tion window deadline, which will allow for additional investment certainty around projects and increase 45Q’s efficacy. Mov ing forward, any carbon capture, direct air capture, or carbon utilization project that commences construction before January 1, 2033 will qualify for 45Q, altered from the January 1, 2026 deadline extended by the fiscal year 2021 Omnibus. This exten sion establishes a crucially needed invest ment horizon to give carbon management projects the necessary lead time to reach a critical mass between now and 2030.

Based on 2021 data from the EPA, approximately 54 percent of power plants and 75 percent of industrial facilities fall below 45Q eligibility thresholds — tons of CO2 captured on an annual basis. Ad

ditionally, more nascent carbon manage ment technologies simply lack the scale to meet these capture requirements. With this in mind, the IRA expands the number of projects which are eligible for 45Q by dra matically lowering the capture thresholds required to claim the tax credit. Previous thresholds hinder the overall technologi cal innovation and emissions reduction potential of the incentive. These lowered thresholds will enable more projects to qualify for the 45Q program, significantly expanding the program and carbon man agement technologies’ climate mitigation potential captured on an annual basis. Ad ditionally, more nascent carbon manage ment technologies simply lack the scale to meet these capture requirements.

The IRA provides additional

estab lishing

pay provides project developers, for the first time, the option to directly receive the full value of the

filings rather than en

credit as an overpayment on their annual

New 45Q Annual Carbon Capture Thresholds in the 2018 FUTURE Act in Metric tons of CO2/CO/yr

or more

Industrial facilities (e.g., ethanol, steel, cement and chemicals

Electric generating unites (e.g., coal, natural gas and biomass- red powered plants

tering complex and inefficient tax equity financing structures.

Going forward, project developers may elect direct pay for the first five years after carbon capture equipment has been placed in service; the remaining seven years of the credit still must be financed through alternative means. These enhance ments are even more expansive for taxexempt organizations (including nonprofit projects, cooperatives, and municipal utili ties) which may access direct pay for the entire twelve years of the credit. Providing a direct pay option allows project develop ers to directly access the full value of the tax credits and leverage greater private cap ital for investment in projects, given that traditional tax equity investors typically re quire a significant portion of the value of the tax credit for less commercially mature technologies such as carbon capture, and direct air capture.

Additionally, the bill creates a trans ferability mechanism, allowing project de velopers to transfer tax credits to another taxpaying entity, receiving a cash payment for the transfer, not included in the cap ture owner’s taxable income. This option

- 500,000

New 45Q Annual Carbon Capture Thresholds in IRA in Metric tons of CO2/CO/yr

1,000 or more

Carbon utilization projects are subject to the invidual project thresholds

or more

12,500 or more

or more

provides additional flexibility to project developers to transfer tax credits to tax payers with tax liability, in turn, creating a significantly larger market for monetizing the 45Q tax credits. This will further in centivize the deployment of new carbon capture technologies by increasing the uni verse of potential investors and allow for project developers to fully realize the ben efits of the credit.

For every dollar expended by the federal government through the 45Q in centive, direct pay and transferability will deliver greater value for the American tax payer by yielding more deployment of car bon capture, removal, and utilization tech nologies—and thus greater climate, jobs, and economic benefits.

The Inflation Reduction Act of 2022 represents the most significant policy sup port for carbon management technolo gies since the foundational 45Q tax credit was significantly restructured in the 2018 FUTURE Act. In tandem with the histori cal investments made in the 2021 Bipar tisan Infrastructure Law, the portfolio of complementary policies included in this package will deliver an estimated 13-fold

18,750 or more

scale-up of carbon management capacity and 210-250 million metric tons in annual emissions reductions by 2035. There is still more work to be done, but the IRA is a major step in putting America’s economy on the track toward midcentury decar bonization, while ensuring the long-term viability of key domestic industries, safe guarding high-wage jobs that sustain fami lies and regions, and providing economic and environmental benefits from project deployment to affected communities.

Authors: Leo Duke and Madelyn Morrison ccc@gpisd.netConvened by the Great Plains Institute, the Carbon Capture Coalition is a non partisan collaboration of more than 100 companies, unions, conservation and environmental policy organizations, building federal policy support to enable economywide, commercial scale deployment of carbon management technolo gies. This includes carbon capture, removal, transport, utilization, and storage from industrial facilities, power plants, and ambient air.

When comparing methods for capturing carbon with the least expense, businesses consider plant ing trees, mangroves, sea grasses, cover crops, etc. to offset the estimated volumes of CO2 that they are releasing into the atmosphere.

They estimate that for every ton of CO2 emitted, one tree needs to be planted and reach maturity.

However, the carbon captured from new land and aquatic planting needs large amounts of wa ter and land to grow, and energy to harvest and transport.

Some companies capture CO2 emissions during the process of generating electricity or heat. Others capture directly from the atmosphere for ‘direct air carbon capture and storage’ (DACS) us ing industrial-scale fans to draw air into the DACS sys tem. The captured CO2 can then be compressed under high pressure and pumped via pipelines into deep geologi cal formations such as depleted oil and gas reservoirs, deep saline formations, and un-mineable coal seams. This permanent storage process is known as ‘sequestration’. Oil and gas compa nies have been pumping or injecting carbon directly into the ground before it reaches the atmosphere to enhance recovery of fossil fuels. Alternatively, the CO2 can be pumped under low pressure for im mediate use in commercial processes, such as carbonating drinks or cement manufacturing.

Some scientists are engineering microbes to “eat” carbon monox ide and carbon dioxide and produce chemicals like acetone and isopro panol, which are used in disinfectants and rubbing alcohols, and are the basis for acrylic glass and polypropylene plastics.

While of great significance, these methods cannot suffi ciently sequester the billions of tons of CO2 emitted every day that need to be either captured or reduced.

We focus on methods that capture carbon from vari ous sustainable sources called renewable feedstocks, which vary in cost, supply reliability, quality, and efficiency for downstream processing into products that can replace petroleum-based products such as biofuels and biobased durable goods that take much longer to break down back into carbon. Renewable feedstocks include agricultural wastes (herbaceous residues, woody residues, crop resi dues), municipal solid wastes (that contain an average of 40% organic material, food waste), gaseous resources (re newable natural gas, methane), wet resources, and plastics.

We first highlight microalgae for both carbon cap ture and as a much-overlooked renewable feedstock. Algae produces more oxygen than the world’s rainforests, absorb ing 300x more CO2 than a tree and 700x more than most land plants1. While the term ‘algae’ can refer to a large group of diverse, sometimes unrelated species of photosynthetic organisms that grow in fresh and salt water from unicellular microalgae to giant kelp, we as

sess ways to improve the cultivation of microalgae because it is easy to grow anywhere that temperatures are between 0 and 34 degrees C° as long as it has light, water (including saline, brackish and recycled water), and CO2.

Today, microalgae is being grown 24/7 in bioreactors - bags or tubes made of transparent materials (plastic, glass) - and located anywhere: in doors, including inside unused building space, basements, garages, and out doors on marginal, inarable land, and even in deserts. They can be installed on building and factory rooftops where they capture CO2 from the air or fed directly from flue pipes. Some architects have clad the outside of build ings with bioreactors. Algae can also be grown in ponds – indoors (covered tanks) or outdoors in most temperate climates (also on inarable land). Some algae ponds today are larger in size than seven football fields.

Since the costs to cultivate and transport dried algae are low when com pared with other crop biomass, algae can be considered the most efficient crop for CO2 capture on the planet.

Algae can also be considered a prized renewable feedstock for harvest ing, drying, and conversion into biofuels and biobased coproducts that can replace thousands of tons of petrochemicals and fossil fuels because it can:

• grow faster and with higher tensile strength than any other terrestrial crop

• be grown for its content of oils, carbohydrates, or proteins

• produce as much as 70% lipids based on dry cell weight

• utilize sugars and other carbon sources

Compare the lipid yields of algae for biodiesel with other seed and grains crops.

Since algae can be cultivated for its oils, carbohydrates, or proteins, it can be converted into a plethora of high-value downstream products:

• bioethanol, succinic acid, carboxylates and 2,3-BDO for biofuels

• HDO and HI for renewable diesel

• PUFAs to polyurethanes, Sterols to surfactants

• Polyurethanes, plastic composites, algal growth media, HTL-based biocrude, carbohydrates, biogas, thermoplastic NIPUS; foams and resins; materials for packaging

Since fossil fuels had been comparatively inexpensive compared to bio fuels over the past ten years, the algae biomass market pivoted to develop uses in higher-margin biobased co-products:

• animal feed

• food (meatless burgers, and other proteins that reduce the carbon footprint of industrial agriculture)

• beta-carotene and omega-3 fatty acids for nutraceuticals

• cosmetics, etc.

• Misc.: fertilizers, in laboratories (agar), as gelling agent in foods, in medicine, ink for 3-D printers, to remediate wastewater and to control pollution (mainly nitrogen and phosphorous), cement (an industry respon sible for more than 8% of global carbon dioxide emissions – more than three times the emissions associated with aviation.

The total algae biomass market is projected to grow at a CAGR of 10.9 from 2022 to 2031 to reach $55.67 billion2. Today, manufacturers wishing to offset carbon emissions and “go green” are incorporating algaebased materials into their products – e.g. NIKE sneaker toppers, flip flops, and surf boards.

Aequor was invited to address several challenges facing algae cultiva tion at commercial scale as a member of the U.S. Department of Energy

(DOE)’s DISCOVR Consortium. At one of the participating Na tional Labs, Aequor developed a non-toxic, “green’ drop-in water treatment for use in any size algae cultivation system that solves pro cess inefficiencies such as clumping (aggregation of biomass that blocks sunlight and nutrients from reaching the microorganisms), and equipment contamination. In bioreactors, Aequor’s treatment boosts algae biomass by 40% in half the time, eliminating the need for costly capital equipment to disrupt the aggregations, enzymes, biostimulants, engineered algae strains and biocides. In open ponds, Aequor’s treatment uniquely protects the algae crop from predator amoeba responsible for incessant pond “crashes.” A technoeconom ic analysis undertaken by the DOE confirmed Aequor’s treatment could lead to significant savings in water, energy, labor, and down time in open pond algae cultivation, and extend as harvest cycles by weeks, making large-scale algae cultivation profitable.

Although algae is also the renewable feedstock that is least likely to experience a shortage because it can be grown so quickly indoors, outdoors, etc., its production capacity pales compared to the abun dant agricultural residues (grain, seed and land crop and forest waste) that are ground and fermented with yeast into bioethanol. In fact, bioethanol is today the #1 U.S. agricultural export as countries blend it into gasoline at the pump as the fastest way to reduce carbon emis sions. The yeast biomass market for sustainable co-products was recorded at $30 billion in 2017 and projected to reach $130 billion in 2025, with biofuels accounting for $132 billion by 20233. Expect a boom in innovations and industrial-scale production of biofuels and coproducts in the U.S. due to provisions in the U.S. Inflation Reduc tion Act that support the Bioeconomy.

As experts in “green” remedies to control fouling and biocon tamination, Aequor was invited to work with one of the U.S. Na tional Labs under a Department of Energy program to address op erational inefficiencies in the fermentation of cellulosic residues into bioethanol. It is widely known that bacteria rapidly attack the yeast used in the fermentation process. This causes biomass production inefficiencies and rapid failure, that requires shutting down and de contaminating the system, and reseeding it to start the process again.

Crop

(L/ha/yr)

5,950

446

Productivity (kg/ha/yr) 862 4,747

562

Crop Sun ower Jatropha Microalgae

Microalgae

Yield (L/ha/yr) 952 1,892 58,700 136,900

Biodiesel Productivity (kg/ha/yr) 946 656 51,927 121,104

Aequor developed a drop-in formulation for any size fermentation system using common stains of algae and yeast that boosts profit ability by up to 30% in less time and without the need for antibiot ics or disinfectants, contributing to a safe, reliable – and profitable – supply of biomass at scale and contributing to the production of more stable biofuels.

Biofuels from cellulosic ethanol are assessed for their stability and storage life compared to fossil fuels. Water can eventually sepa rate out of the biofuels, which rapidly contaminates with bacteria that form biofilm slime, corrosion, and other inefficiencies in stor age tanks, pipelines, injectors, components, etc. Aequor has devel oped products to address stability issues to encourage widespread adoption of renewable fuels.

Since the transportation industry is considered the #1 emitter of greenhouse gases and widespread electrification will take years to be adopted, additional government incentives for the agricultural sector enable the commercial-scale development of greener fuels from renewable feedstocks for cars. Ethanol is considered the high est-octane additive commercially available, increasing mileage and reducing air pollution from fine particulate matter (PM) emitted in gasoline exhaust. Replacing fossil-based aromatics with bioethanol that is blended with gasoline at the pump is today considered the quickest way for countries to meet their UN carbon emission reduc tion targets. It is estimated that ethanol at the current 10% blend level in the U.S. is already displacing more than 8 billion gallons of aromatics; blends up to 30% are projected to be phased in shortly. Bioethanol from crop residues has been the fastest growing U.S. ag ricultural export for the past five years to help many countries meet their emissions reduction commitments.

Other biofuels include biodiesel, renewable diesel, and sustain able aviation fuels (SAFs). Aviation accounts for 2-3% of global CO2 emissions and air travel is expected to double in the next 15 years. The International Air Transport Association (IATA) has al ready committed to achieving carbon neutral growth from 2020 onwards and net-zero carbon emissions by 2050. The use of SAFS reduce greenhouse gas (GHG) emissions by up to 80%* compared to fossil jet fuel. The major airlines are signing on to use SAFs bol stering demand for renewable feedstock production.

Author: Marilyn J. Bruno, Ph.D. contact@aequorinc.com1Algae-fueled bioreactor soaks up CO2 400x more effectively than trees. (2019) Retrieved from https:// newatlas.com/environment/algae-fueled-bioreactor-carbon-sequestration/ 2Algae Market. (2022) Retrieved from https://www.transparencymarketresearch.com/algae-market.html

3Market Research Report. (2020) Retrieved from https://www.fortunebusinessinsights.com/cellulosemarket-102062