With a continuous eye on fut and market developments, we ure mprove e iciency, increase yields, you optimize your plant processes to imp nlock new revenue streams. reduce costs, lower CI and u

ure trends and market developments, we help you optimize your plant processes to improve e iciency, increase yields, r CI scores, and unlock new revenue streams.

Let’s talk solutions.

EDITORIAL

President & Editor

Tom Bryan tbryan@bbiinternational.com

Online News Editor

Erin Voegele | evoegele@bbiinternational.com

Staff Writer

Katie Schroeder katie.schroeder@bbiinternational.com

DESIGN

Vice President of Production & Design

Jaci Satterlund | jsatterlund@bbiinternational.com

Graphic Designer

Raquel Boushee | rboushee@bbiinternational.com

PUBLISHING &

CEO

June 12-14, 2023

CHI Health Center, Omaha, NE (866) 746-8385 | FuelEthanolWorkshop.com

From its inception, the mission of this event has remained constant: The FEW delivers timely presentations with a strong focus on commercial-scale ethanol production—from quality control and yield maximization to regulatory compliance and fiscal management. The FEW is the ethanol industry’s premier forum for unveiling new technologies and research findings. The program is primarily focused on optimizing grain ethanol operations while also covering cellulosic and advanced ethanol technologies.

Joe Bryan | jbryan@bbiinternational.com

Vice President of Operations/Marketing & Sales

John Nelson jnelson@bbiinternational.com

Senior Account Manager/Bioenergy Team Leader

Chip Shereck cshereck@bbiinternational.com

Account Manager

Bob Brown bbrown@bbiinternational.com

Circulation Manager

Jessica Tiller | jtiller@bbiinternational.com

Marketing & Advertising Manager

Marla DeFoe | mdefoe@bbiinternational.com

Ringneck Energy Walter Wendland

Little Sioux Corn Processors Steve Roe

Commonwealth Agri-Energy Mick Henderson

Aemetis Advanced Fuels Eric McAfee

Western Plains Energy Derek Peine

Front Range Energy Dan Sanders Jr.

Customer Service Please call 1-866-746-8385 or email us at service@bbiinternational.com.

Subscriptions Subscriptions to Ethanol Producer Magazine are free of charge to everyone with the exception of a shipping and handling charge for anyone outside the United States. To subscribe, visit www.EthanolProducer.com or you can send your mailing address and payment (checks made out to BBI International) to: Ethanol Producer Magazine Subscriptions, 308 Second Ave. N., Suite 304, Grand Forks, ND 58203. You can also fax a subscription form to 701-746-5367. Back Issues, Reprints and Permissions Select back issues are available for $3.95 each, plus shipping. Article reprints are also available for a fee. For more information, contact us at 866-746-8385 or service@bbiinternational.com. Advertising Ethanol Producer Magazine provides a specific topic delivered to a highly targeted audience. We are committed to editorial excellence and high-quality print production. To find out more about Ethanol Producer Magazine advertising opportunities, please contact us at 866-746-8385 or service@bbiinternational.com. Letters to the Editor We welcome letters to the editor. Send to Ethanol Producer Magazine Letters to the Editor, 308 2nd Ave. N., Suite 304, Grand Forks, ND 58203 or email to editor@bbiinternational.com. Please include your name, address and phone number. Letters may be edited for clarity and/or space.

June 12-14, 2023

CHI Health Center, Omaha, NE (866) 746-8385 | BiodieselSummit.com

The Biodiesel Summit: Sustainable Aviation Fuel & Renewable Diesel is a forum designed for biodiesel and renewable diesel producers to learn about cutting-edge process technologies, new techniques and equipment to optimize existing production, and efficiencies to save money while increasing throughput and fuel quality. Produced by Biodiesel Magazine, this world-class event features premium content from technology providers, equipment vendors, consultants, engineers and producers to advance discussion and foster an environment of collaboration and networking through engaging presentations, fruitful discussion and compelling exhibitions with one purpose, to further the biomass-based diesel sector beyond its current limitations.

June 12, 2023

CHI Health Center, Omaha, NE (866) 746-8385 | FuelEthanolWorkshop.com

Capturing and storing carbon dioxide in underground reservoirs has the potential to become the most consequential technological deployment in the history of the broader biofuels industry. Deploying effective carbon capture and storage at biofuels plants will cement ethanol and biodiesel as the lowest carbon liquid fuels commercially available in the marketplace. The Carbon Capture & Storage Summit will offer attendees a comprehensive look at the economics of carbon capture and storage, the infrastructure required to make it possible and the financial and marketplace impacts to participating producers.

August 29-30, 2023

Minneapolis Convention Center, Minneapolis, Minnesota (866) 746-8385 | NationalSAFConference.com

TM Please recycle this magazine and remove inserts or samples before recycling

COPYRIGHT © 2023 by BBI International

Please check our website for upcoming webinars www.ethanolproducer.com/pages/webinar

The National SAF Conference & Expo is designed to promote the development and adoption of practical solutions to produce SAF and decarbonize the aviation sector. Exhibitors will connect with attendees and showcase the latest technologies and services currently offered within the industry. During two days of live sessions, attendees will learn from industry experts and gain knowledge to become better informed to guide business decisions as the SAF industry continues to expand.

The passage of the Inflation Reduction Act is turbo-charging our industry’s involvement in carbon capture and sequestration—not to mention utilization—and helping define our role in the production of sustainable aviation fuel. Both CCS and SAF appear in our coverage this month, as we continue to chronicle the industry’s myriad carbon capture efforts, from aggregated and stand-alone sequestration to conventional and novel forms of CO2 transformation, sprouting up across the nation.

Ethanol plant CCS is a coveted play for developers, as our industry’s fermentation CO2 is remarkably pure, making it easy to transform, move and store. Our facilities are truly the “low-hanging fruit” of industrial carbon capture, and ideal entry points for developers with broader ambitions. Indeed, that’s the case for Colorado-based Carbon America, the focus of our page-16 story, “Capturing Close to Home.” The company is working with Colorado Agri Products, which runs two plants in northeast Colorado and another in Nebraska. While Carbon America wants to eventually develop CCS for hard-to-abate industries like power generation and cement manufacturing, it is starting with ethanol plants because they are “lower cost, faster deployment” opportunities. It makes sense. CAP is a proverbial Goldilocks zone partner—just the right size, just the right geology near its plants, and just the right kind of business to work with. And thanks to the IRA’s passage, a hefty tax credit for CCS (now $85 per ton) makes the economics pretty ideal, too.

Ultimately, doing CCS could lower the carbon intensity (CI) scores of each CAP ethanol plant by 25 points or more, which would add tremendous value to their ethanol in California and other low-carbon fuel markets. CI reduction is an almost ubiquitous thing in ethanol production right now, and while few investments can lower CI as much as sequestering fermentation CO2, reducing fossil fuel use by installing renewable energy, not drying distillers grains and increasing process efficiencies can add up to double-digit CI reduction. Knowing that, Whitefox Technologies is helping producers shed as much as eight CI points by decarbonizing their dehydration centers. As we explain in “CI-Reducing Dehydration,” on page 32, the company’s engineered membrane systems for dehydration, a proven platform called ICE, just got upsized. ICE XL—a complete replacement of molecular sieves—reduces steam consumption in DD&E to 8,000 Btu per gallon (25 percent less than normal), delivers better heat integration into the process and helps reduce natural gas consumption by up to 50 percent. It’s no coincidence that the first adopter of ICE XL is Western Plains Energy LLC, which is on a fast-track to net-zero.

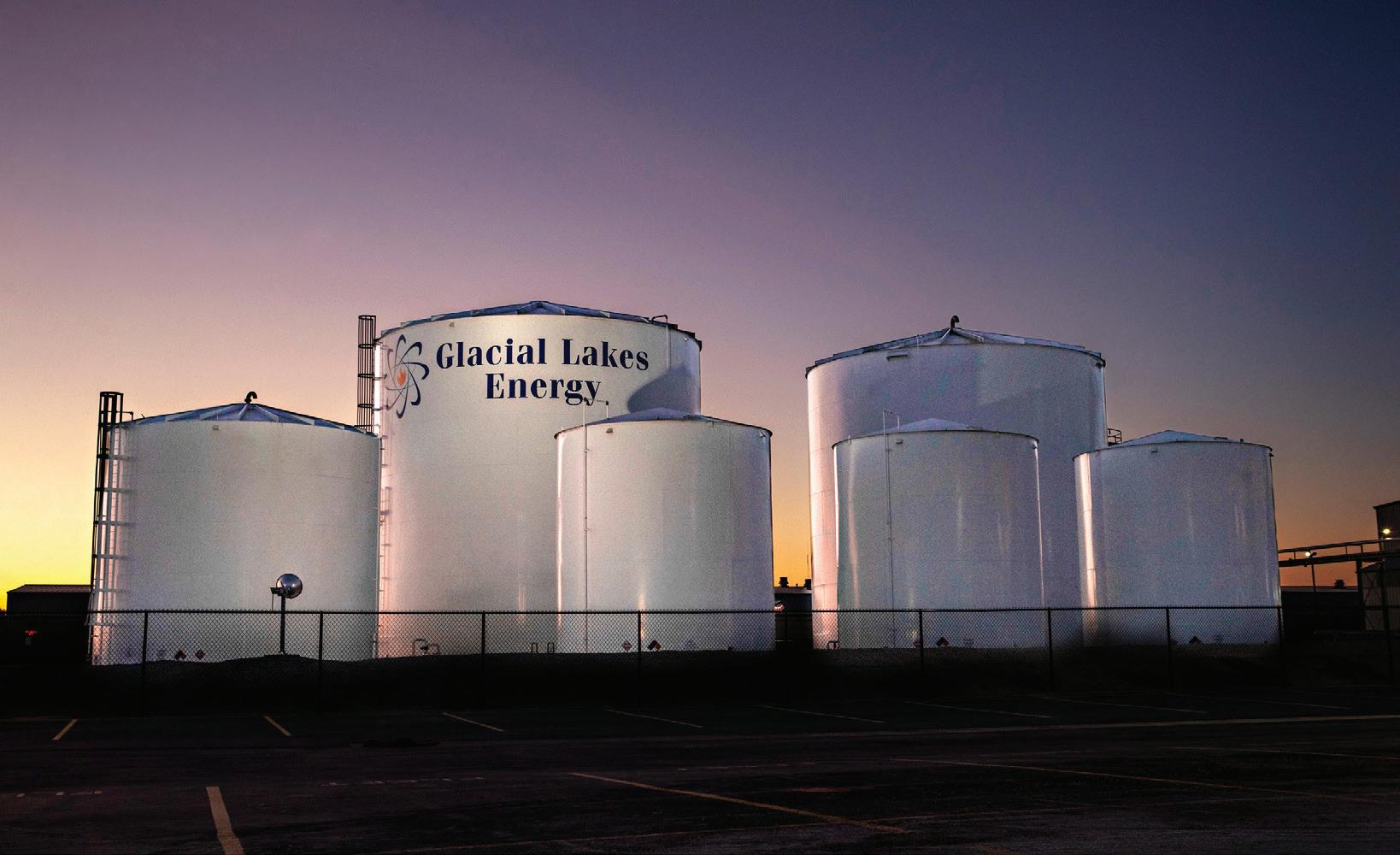

Finally, be sure to read “Gazing Higher: The Quest for E30,” on page 24, which highlights parallel efforts in South Dakota and Nebraska to demonstrate the use of E30 in non-flex-fuel vehicles. The Nebraska Ethanol Board and, separately in South Dakota, Glacial Lakes Energy LLC have both been collecting data on hundreds of vehicles refueling with 30 percent ethanol blends (a fuel that’s technically intended only for FFVs). E30 is fascinating because it has the octane value automakers need, the emissions profile climate hawks desire, and the price consumers are drawn to. And while E15 is our industry’s top priority, the possibility of bringing E30 along for the ride is a tempting proposition.

Brian Jennings CEO American Coalition for Ethanol 605.334.3381

Brian Jennings CEO American Coalition for Ethanol 605.334.3381

bjennings@ethanol.org

ACE is laser focused on increasing ethanol use, and there are several reasons to be optimistic about making real progress for higher ethanol blend demand in 2023.

For example, EPA is taking action on petitions from the governors of Iowa, Illinois, Kansas, Minnesota, Missouri, Nebraska, North Dakota, Ohio, South Dakota and Wisconsin to ensure E15 use in these 10 Midwestern states, which collectively represent nearly three-quarters of the existing E15 market. The agency has told us they intend to approve these requests prior to the June 1, 2023, summer driving season. These Midwest governors have submitted data to EPA showing that reducing fuel volatility in their states will significantly cut evaporative emissions and pollution, not to mention save drivers in their states an enormous amount of money at the pump. While this would not achieve nationwide market access for E15, the governors’ initiative is a point of leverage that has mobilized more support for a legislative solution which would.

In fact, the likelihood that 10 or more states will have lower vapor pressure fuel requirements than most of the country has motivated the American Petroleum Institute to join ACE and our biofuel allies who have been pushing hard for bipartisan and bicameral legislation in Congress to permanently allow E15 use across the entire nation. This major development should dramatically improve our chances for finally enacting legislation in Congress, hopefully prior to June 1. If action has not been taken on this legislation by the ACE fly-in March 29-30, we will make it a major priority for our Hill visits.

When the E15 market is indeed nationwide, it will eventually move massive volumes of ethanol, billions of gallons of new demand—just in time, as overall fuel consumption may decline. While we work to make this a reality, we must not overlook the fact that E85 presents a near-term opportunity to significantly increase ethanol use today.

The largest E85 market is California, where ACE has worked to support Pearson Fuels, a company with more than 275 retail locations selling E85 across the state, and more than 100 additional retail stations under contract to open in the next two years. According to Pearson officials, California likely reached 100 million gallons of E85 use in 2022, displacing at least 73 million gallons of gasoline. In 2022, most retail E85 stations partnering with Pearson Fuels priced E85 more than $2.00 per gallon below retail unleaded gas in California. This means the owner of a flexible fuel vehicle (FFV) could have been completely immune from the record-high gas prices California experienced last year because they had the option to use E85.

To keep this momentum going and accelerate domestic ethanol use, ACE will continue capitalizing on the infrastructure incentives for higher blends being made available from USDA and the recently enacted Inflation Reduction Act. Building on the historical steps Secretary of Agriculture Tom Vilsack has taken to provide USDA funds to install biofuel infrastructure, Congress included a record-level commitment of $500 million available until Sept. 30, 2031, for USDA to massively expand this effort. Importantly, Congress also authorized USDA to make 75 percent cost-share grants, which will help make new installations much more affordable and enticing for retail locations.

The opportunities do not stop there. Indeed, new legislation, beyond the E15 RVP fix, will be considered in the 118th Congress which would increase ethanol demand as well. First, support is growing for a national low carbon fuel standard (LCFS) which would require the carbon intensity of fuels to fall over time. When LCFS policy is technology-neutral and science-based, it supports demand for higher ethanol blends. Second, there is an expectation the Next Generation Fuels Act will be reintroduced in Congress as well. This legislation would overcome a host of regulatory barriers currently standing in the way of expanding the use of ethanol from E15 to higher blends such as E25 or E30, and reinstate incentives for the production of more FFVs.

For industry advocates who want to help promote these important opportunities to increase ethanol demand, we invite you to join ACE at the end of March for our D.C. fly-in.

Emily Skor CEO, Growth Energy 202.545.4000

Emily Skor CEO, Growth Energy 202.545.4000

For years, Growth Energy has made it a priority to increase awareness and availability of higher biofuel-blended fuels like E15 (also known as Unleaded 88).

On the retailer side, Growth Energy helps fuel marketers gain a competitive advantage by giving them the tools and resources they need to offer E15. Taking advantage of ethanol’s cleaner burning qualities and better performance (along with strong economics) is one way fuel retailers can separate themselves from their competition. We make it easy for them to do so by offering a host of resources they can use to figure out what changes (if any) they need to make their facilities compatible with E15, how to comply with different regulations related to offering higher biofuel blends, and, once everything is in place, how to maximize sales.

We also work to drive demand and educate consumers through our Get Biofuel initiative. The more consumers know about Unleaded 88/E15 and the advantages it offers, in terms of both lower costs and lower carbon emissions, the more likely they are to seek it out at nearby fuel retailers. Since launching in 2021, visitors to the Get Biofuel homepage (getbiofuel.com) have been able to learn all they want about higher biofuel blends and find where to get them using the Biofuel Finder.

This year, Growth Energy is taking this consumer initiative to the next level. In February we launched The Green American Road Trip—a new multimedia campaign designed to reach even more drivers and show them how they can lower their carbon emissions just by filling up their cars with higher biofuel blends like Unleaded 88. American consumers want to know how they can easily make a positive impact on the environment and lower their overall carbon emissions. The Green American Road Trip will show them that the simplest way to do that is to switch their fuel choice to a higher blend of ethanol.

Growth Energy created this campaign in partnership with Gold Medal Olympian and New York Times Bestselling Author Shawn Johnson East and The East Family. The Green American Road Trip will follow Johnson East and her family on three cleaner cross-country adventures, and provide American drivers everything they need to do the same, including fully planned road-trip itineraries, travel tips, and quick access to the Get Biofuel Trip Planner to help them map out their route to fill up with higher biofuel blends along the way.

“As parents, we want to create a better world for our children. Making the switch to biofuel reduces carbon emissions and keeps the air we breathe cleaner," said Johnson East. "We’re excited to hit the road with Get Biofuel and show everyone how easy it is to make the great American road trip greener.”

While the full campaign launched in January, we’ll be celebrating it this month at our Executive Leadership Conference in Dana Point, California, on March 15, which will feature Johnson East and her husband, former NFL-player Andrew East. We hope to see you there, but in the meantime, if you want to learn how to be a part of this exciting new effort to increase the use of higher biofuel blends, visit greenamericanroadtrip.com.

We put Fermentation First™. You get yeast, yeast nutrition, enzymes and antimicrobial products, alongside the industry leading expertise of our Technical Service Team and education resources. Find the right solution for your ethanol business at LBDS.com.

The Board of Alder Fuels has appointed Tim Obitts as the company's Acting CEO. Obitts has more than 27 years of legal and executive experience. Before joining Alder Fuels, he was president and CEO of the National Air Transportation Association. Obitts also served as the chief operating officer and general counsel for NATA. Prior to that, he was a manag-

Pending a review, China is reportedly extending its standing anti-dumping, anti-subsidy tariffs on U.S. distillers grains imports for another five years, according to several sources. While China has, at times, been the world’s top importer of DDGS—taking well over 5 million metric tons per year at peak trade—exports have been negligible over the past half decade

Green Impact Partners has received final land use approval from the city of Calgary, Alberta, to move forward with an energy complex that will produce both renewable natural gas (RNG) and ethanol. Located on the city’s southeast side, the Future Energy Park is a proposed netnegative CO2 biofuels plant that would use non-food-grade waste wheat as feedstock.

ing shareholder of the law firm Gammon & Grange P.C.

“At Alder, we remain focused on a singular goal: to deliver commercial deployment of our proprietary Alder Greencrude technology and support the decarbonization efforts of critical sectors of our economy,” Obitts said.

due to prohibitive duties, which effectively amount to a 66 percent countervailing fee on U.S. DDGS. The country’s Ministry of Commerce made the announcement in mid-January when the tariff came up for review.

The facility is expected to produce approximately 3.5 million MMBtu per year of RNG, over 300 million liters (80 million gallons) of ethanol and approximately 235,000 metric tons of cattle feed annually, while also generating carbon credits. Construction is expected to be completed in 2025.

In January, both houses of the Illinois General Assembly approved a legislative package that creates a $1.50 per gallon tax credit for sustainable aviation fuel (SAF). At press time, the Invest in Illinois Act, or SB 2951, was expected to be signed into law by Illinois Gov. JB Pritzker. The credit, starting this June, would apply to SAF sold to or used by an air car-

The U.S. EPA has approved a fuel pathway filed by LanzaJet Inc. under the Renewable Fuel Standard that will allow the company’s biorefinery near Soperton, Georgia, to generate D4 biomass-based diesel renewable identification numbers (RINs) for renewable jet fuel and renewable diesel produced from sugarcane ethanol. The approved pathway applies to renewable jet fuel and renewable die-

USD Clean Fuels LLC has announced its intention to build a new biofuels terminal in National City, California, that will have the capability to transload renewable diesel, biodiesel, ethanol and sustainable aviation fuel (SAF). The terminal will be served by the BNSF Railway and will provide efficient transportation of clean fuels

rier. To be eligible, SAF must achieve a 50 percent lifecycle GHG reduction when compared to petroleum-based jet fuel using either the lifecycle methodology developed by the International Civil Aviation Organization or Argonne National Laboratory’s GREET model.

Our full service team of experts have 20 years of ethanol plant maintenance reliability and uptime history 24/7 support and ready access to a full inventory and all Fluid Quip equipment parts, ensures that you maintain your plant’s uptime status.

sel produced from undenatured ethanol through a process of dehydration, oligomerization and hydrotreating using grid electricity, natural gas and hydrogen as process inputs. The ethanol used in the process will be produced using sugarcane feedstock and is considered a biointermediate under an RFS rulemaking finalized in mid-2022.

• OEM Parts Warehouse

• $1 million+ on-hand inventory

• Fully stocked trucks

• Overnight/hot shot shipping

• Factory Trained & Certified

to the area from the Midwest and Gulf Coast. Pending receipt of all local and state permits, the terminal is expected to be operational by early 2024. The facility will have a self-switching rail rack and four truck loading spots equipped with in-line injection capabilities to provide finished product to customers.

• MSC™ Systems

• SGT™ Grind Systems

• FBP™ Fiber By-Pass Systems

• MZSA™ Screens

• Paddle Screens

• Grind Mills

• Centrifuges

Carbon America is implementing carbon capture and sequestration at three commonly owned ethanol plants in Colorado and Nebraska. With enhanced incentives to sequester and decarbonize—and the nearby geology to do it—the plan has momentum.

By Katie SchroederCarbon capture and sequestration projects of all types continue to make headlines across the nation, with stories involving ethanol plants in the news almost daily. High-profile CCS pipeline projects in the Upper Midwest, which

would aggregate CO2 from dozens of ethanol plants across multiple states to central injection points, have dominated the coverage, along with a few independent CCS projects making early progress. Much of the action has been up north—Iowa, Minnesota, eastern Nebraska and the Dakotas—but a Colorado company has been quietly developing its own approach to ethanol CCS

further west, seeking the benefits of both independent and aggregated sequestration without the arduous challenges of multistate pipeline development.

Carbon America, a Denver-based CCS company, is planning projects with Yuma Ethanol LLC, Sterling Ethanol LLC— both located in northeast Colorado—and Bridgeport Ethanol LLC, in western Ne-

braska. David Kramer, president of Colorado Agri Products (the company that operates all three plants) and general manager of Sterling Ethanol, explains that Carbon America started discussing the possibility of CCS with CAP a few years ago. “We’ve been working through all the logistics for over three years, trying to put a package together that’s good for the environment, good for the ethanol plants and good for carbon sequestration,” Kramer says.

Carbon America's proposed plan with CAP's Sterling and Yuma facilities includes carbon capture, pipeline transport and geologic storage. The Bridgeport Ethanol project, 80 miles to the north in Nebraska, will

be an individual project, with sequestration planned to happen near the facility. Estimates suggest CCS will lower the carbon intensity of these plants by 25 to 30 points, depending on whether solar or wind energy is implemented, explains Brent Lewis, CEO of Carbon America.

For Kramer, the local nature of Carbon America was an important factor in deciding to move forward. “The team worked by being so local and working together from day one,” he says. “Now, the incentives came about where we can feasibly make it work, it was just a natural fit. And it wasn’t one of those big [aggregation projects] that was going to try to take it and put it in a

[long, multi-state] pipeline and have all the stars align to make it work.”

Although many of the projects that have been making headlines lately are large with an extensive pipeline network, Carbon America is taking a different approach. “We’re are purposely starting small, I mean not only from a capital cost perspective but also a distance between a capture system and the target sequestration site, so that we don’t have a lot of headwind related to getting rights of way for pipelines [and] things of that nature. We’re trying to avoid that,” explains Lewis. The company is following a turnkey model, building small on individual sites and making short pipelines.

However, Lewis says he wants to see CCS projects of all sizes do well, since those success stories are a step forward for the CCS industry. “I think there’s a lot of models that are going to be successful with carbon capture and sequestration,” he says, adding that the team at Carbon America is excited to see Red Trail Energy LLC in Richardton, North Dakota, actively doing CCS on site, starting in 2022.

Since its founding in 2019, Carbon America has built up a strong team of experts in everything CCS related. The company’s creation was primarily based on two driving factors: the enhanced value of the Section 45Q tax credits and the opportunity to accelerate the CCS industry through ethanol decarbonization, since ethanol plants are high-purity emitters, explains Lewis. “We saw that as a lower-cost, faster deployment opportunity, and there weren’t many companies that were really going after it aggressively yet,” he says. “There was a win-

LOCAL FEED, LESS ENERGY: While two of the three co-owned ethanol plants pursuing CCS with Carbon America are in northeastern Colorado, Bridgeport Ethanol LLC, shown here, is in western Nebraska, and will be a stand-alone CCS project. All three plants produce wet distillers grains for area cattle operations, which already gives them a carbon intensity advantage.

PHOTO: CAP

dow there. But the other thing that we have is a technology that really isn’t for ethanol or for high-purity emissions, it’s more for flue gas at power plants, and other industrial plants. We have a novel technology at the other side of our business that we’re hopeful is going to be low-cost, carbon capture technology.”

A key differentiator that sets Carbon America apart is the level of expertise it has deployed across the CCS landscape. Lewis says this has been vital and allowed the company to make decisions based on in-house information instead of relying on consultants for information needed to make deci-

sions. The company’s experts bring knowledge from all across the CCS value chain, including policy and regulatory experts, geology and geotechnology, reservoir engineering, pipeline and drilling experts, as well as experts in monetizing tax credits.

“Our mission is to capture and sequester as much carbon dioxide as possible as quickly as possible, so that’s what drives us,” Lewis says. “We’ve got a very strong culture of folks that really believe [in] what we’re

doing, and that carbon capture and sequestration is really important [to] our big puzzle of how ... we address that total challenge associated with climate change.”

Although the original 45Q tax credit, set at $50 per ton of sequestered CO2, was the initial factor that made CCS economically viable, the passage of the Inflation Reduction Act, which upped the tax credit

to $85 per ton, increased interest in CCS projects dramatically, according to Lewis. “Moving from $50 to $85 starts to make what were probably uneconomic opportunities in the carbon capture and sequestration space—whether it’s in ethanol or other areas—much more economically viable,” he says.

California’s Low Carbon Fuel Standard, as well as other similar policies in the western U.S., are also market drivers for

CCS. Despite values from the Californian LCFS credits dropping in October and November, Lewis believes many ethanol producers are actively trying to find the best fit for their low-CI ethanol. Low carbon fuel markets are one option, but there are also options for it to be used as a feedstock for sustainable aviation fuel. Whether corn ethanol-based SAF will be eligible for the new federal SAF credit remains dubious. However, a recently passed bill in Illinois (await-

ing the governor's signature at press time) would offer $1.50 per gallon of qualifying SAF, and it appears that renewable jet fuel made from very low-carbon corn ethanol could meet the requirements.

Carbon America will develop, finance, build, own and operate the capture, transportation and sequestration systems for the Yuma, Sterling and Bridgeport facilities, each of which have the capacity to produce about 60 MMgy of ethanol. All three plants produce wet distillers grains, avoiding the natural gas use associated with coproduct drying, which helps garner a lower CI score. Kramer explains that this is not CAP’s first effort to decarbonize; its plants use steam turbines to produce 80 percent of their electricity. “We’re always looking at trying to get more green and be more efficient, and looking at all different options, whether it be solar or anything else; wind ... anything to do with being more energy efficient,” he says.

Carbon America engineers and geologists are currently evaluating the technical and environmental plans for the Yuma and Sterling facilities, which are located about 50 miles apart. Both facilities will require a pipeline to transport the CO2 to a Class VI well site. “Our success is linked to fostering mutually beneficial partnerships with our stakeholders—including communities, landowners, local governments and regulators—to deliver CCS projects that provide environmental and community benefits while supporting good-paying jobs and regional communities,” Lewis says. The two plants produce the majority of the ethanol supply for the Denver and Colorado Springs metro areas. These projects will be the first CCS projects in Colorado and will reduce the plants’ fermenter CO2 emissions by 95 percent. “Early on, we identified some really good areas where we could permanently sequester carbon dioxide,” Lewis says. “For us that was the low-hanging fruit. It was geo-

graphically close, and geologically [viable], so we were able to say, ‘Well, we won’t really need to build a big pipeline, we’ll be able to build a short pipeline into an area that we have high confidence that it’s going to be a good place to sequester the CO2.”

The Bridgeport location will have its own unique Class VI well for sequestration. Ethanol Producer Magazine reported in October 2022 that the project would sequester 175,000 tons of carbon dioxide each year, equivalent to 95 percent of the plant’s fermentation emissions.

The ethanol plants do not have any of the capital risk involved in the project, Lewis says. Carbon America will take the risk and responsibility for developing and operating the CCS system. “They’re earning revenue off the model of the project that is not dependent on LCFS, and they’re also sharing a large portion of the LCFS values,” Lewis says.

Currently, the team is working through the logistics of designing the capture and transportation system and permitting for the different sites, Kramer explains. The permitting process in Nebraska has moved a little faster than the process in Colorado. The Bridgeport project may be finished before the other two, even though it was announced second.

The CCS systems at these three plants are only the tip of the iceberg. Lewis explains that there are several other projects currently underway, some with high purity emitters, and some not, which have not yet been announced publicly. In the long-term, Lewis and his team plan to undertake projects with a less pure stream of CO2 that are more difficult to abate, such as cement and power plants.

Looking forward, Lewis hopes to see progress in these more complex projects. Federal support for CCS, like the IRA, is helping de-risk the industry and Lewis believes that costs will come down as there are more CCS success stories and the technology becomes more developed. “The risks

are going to be better understood, so by extension that means the cost of capital for these projects should come down as well, as Wall Street and main street get a better understanding of what it means to capture and sequester CO2,” he says. “I think that a lot of the friction around getting commercial deals done should become easier as more and more transactions get across the goal line.”

Ethanol producers have a lot of choices when it comes to pursuing carbon capture and sequestration or utilization. Every producer may have a different financial model or a different CI reduction goal, but one thing is certain, the window of opportunity for decarbonized ethanol is here.

Author: Katie SchroederContact: katie.schroeder@bbiinternational.com

Whether your goal is increased yield, robustness or plant throughput, we have the right yeast or yeast blend tailored to your specific process and market conditions

SYNERXIA® SAPPHIRE – Our most robust yeast delivering a power ful combination of yield and glucoamylase expression

SYNERXIA® RUBY – Our highest yielding yeast driving plants to the peak of performance

SYNERXIA® EMER ALD – Our fastest yeast geared for maximum plant throughput

E30 has the octane value automakers want, the emissions numbers policymakers need and the price consumers look for. But is it the future?

By Luke GeiverE30 could be the future of ethanol. The blend has so much going for it, even if it's not yet in widespread use. For starters, E30 provides an engine with more octane per gallon when compared to regular unleaded, E10 or even E15, which means more power when you punch the pedal. It doesn’t take much effort by researchers or policy makers alike to figure that out. Next, considering that most automakers are infusing electric vehicles into their lineups, overall transportation fuel demand for light-duty vehicles is expected to go down over time. E30, even if achieving only half the market penetration of E10, would allow ethanol producers to maintain or exceed existing production levels as the overall fuel pool shrinks. Then, apart from the octane boost or fuel mix security, E30 is cheaper for the consumer to buy and a cleaner alternative for the environment—neither point being a hard sell to

consumers right now. Add it all up and E30 certainly could be the future of ethanol. But before that happens, several factors related to the mid-level blend must be figured out, accepted or demonstrated.

In both South Dakota and Nebraska, there are major ethanol players working to demonstrate the capabilities of E30. Reid Wagner, executive director of the Nebraska Ethanol Board, and Marcy Kohl, director of communications and corporate affairs for Glacial Lakes Energy LLC, (an ethanol producer based out of Watertown, South Dakota), both emphasize the word “demonstrate” versus “prove.” Both NEB and GLE are in the midst of their own versions of E30 demonstration programs that use non-flex-fuel vehicles to collect data on the higher blend’s use. Both entities have performed demonstrations over the past three years and continue to do so.

“The purpose ... is to demonstrate what we have known in the industry for some time,” Wagner says. “E30 performs.”

In late 2022, Wagner and his team at NEB announced that the U.S. Environmental Protection Agency had approved the continuation of a 2019 study looking at E30-fueled state vehicles. Their initial work helped show how well E30 can perform in non-FFVs. “We looked at onboard diagnostics and tracked 16 different data points every second across the vehicles,” Wagner says. “Through the demo, we saw that across all vehicles, there were no issues.”

That work by the NEB was performed on state-owned sedans (roughly 50 total vehicles). The new work by the NEB will greatly expand the data portfolio. Using

state-owned infrastructure to the tune of roughly 90,000 gallons per month of E30, the NEB is now working with the University of Nebraska-Lincoln to test and monitor 825 non-FFVs. “We are looking at what E30 could bring in terms of fuel economy, engine performance and emissions data,” Wagner says. After running the program for a few months now, Wagner reports zero engine lights on the E30 fueled vehicles.

The overall goal is to put as much peer reviewed data and research as possible into the demonstrations. “We are trying to operate in a true real-world operation that is mimicking what we would see today,” Wagner says. The NEB’s work on E30 will last another year and a half, but so far, Wagner believes the demos have already been a success at demonstrating (not proving) how well E30 can perform.

Up in South Dakota, Kohl and her coworkers are familiar with what the NEB is doing, and they're on a parallel track. GLE

actually began demonstrating the effectiveness of E30 in 2016, and its efforts are ongoing.

Their purpose was a bit different from the NEB’s. “We wanted to inform the consumers and increase demand,” Kohl says. “We wanted to give people in our region more choice at the pump, and we knew we had to do it right the first time.”

Doing it “right the first time,” for Kohl and her team, meant setting up a multipronged approach to inform consumers on E30. The team brought on a local technician that had founded DynoTune Speed and Performance in Watertown.

Andy Wick, founder of DynoTune, specializes in high-performance, fuel-injected engines. Working with Wick, Kohl and her team researched the EPA tests used on fuel. They purchased data loggers to record info

directly from engines, and they asked residents and people from in and around town to be part of their test.

For the tests, the participants would fill their respective tanks (the vehicles used were not part of a government fleet) with E10 three times consecutively and then E30 three times consecutively. “We tested roughly 40 cars. They were pickups, vans, Jeeps,” Kohl says. “We tried to do our best to use the popular makes and models. I think there was even a BMW in there.”

“When you averaged everything together, the results showed that fuel economy was maintained or increased overall, and there were no check engine lights that came up,” Kohl says, adding that all of the E30 used was much cheaper than the non-E30 alternative.

In addition to the real-world testing by locals and verified by an expert in Wicks, the Glacial Lakes team also held a series of educational meetings over a span of two

years. At most meetings, there were 100 vehicle techs in attendance. “Wicks talked to them and dispelled some of the myths that are out there. And, we went through the data,” she says. “I really think that was a game changer for the region.”

After doing the testing and meeting with vehicle techs or other interested parties, Glacial Lakes began working with government agencies in the area. Today, several entities, including the police department, transit and some ambulances use E30. The sheriff's department was initially hesitant to use E30 because Kohl says they don’t always fill up at the same fueling station. After trying the fuel, they are now using E30, she says.

Glacial Lakes also established a connection with the local technical school and sent results of their work to the EPA, Ford Motor Co., Chevrolet and others.

“The biggest thing was being able to tell our general story to the consumer,” Kohl says, “and then let them make the choice.”

Doug Durante with the Clean Fuels Development Coalition has been studying and verifying the benefits of E30 for multiple years. Durante remembers when the octane value of E30 and ethanol fuels was the big talking point among producers and automakers. “A couple of years ago the whole industry was very interested in octane,” he says.

In order to get a high octane value, the kind an auto maker would take notice of, Durante says you have to get to an ethanol blend at or around E30. The E10s and E15s just don’t offer the type of octane boost that is eye-catching to automakers. “Through our work with the auto industry, they have made it clear that if they have high octane (like that found in E30), they could tune their cars to take advantage of that fuel and the compression it gives the engine.”

“Ford,” Durante says, “is on the record and has studies that say if they had 98 octane fuel they could get up to 7 percent increase in fuel mileage.”

E30 is important to Durante because it meets the octane requirements of the automakers to fine-tune their engines for better mileage, but it also does something else. “For a good part of my career, I’ve been talking about and working on the idea of clean octane,” he says.

E30, given its octane levels, would be a viable replacement in regular gasoline fuel that could remove or reduce the toxic aromatics present in the fuel today like benzene. Refiners to this day use aromatic compounds that are classified as toxic that could be replaced with no loss of octane if a blend of 30 percent ethanol was added to the fuel mix, Durante says.

Wagner, Kohl and Durante can all talk at length about the changes they see coming to the nation’s fuel demand mix. Electric vehicles will change everything. But, as the supply of gasoline drops across the U.S., the percentage of ethanol used in that supply mix could go up if a greater percentage of E30 is used. That in turn, would keep the demand for ethanol gallons on a yearly basis stable (or increasing) rather than declining, they all agree.

“If we don't get to higher blends, we can’t maintain the market share we have now,” Durante says. “From a policy standpoint, the industry shouldn’t get so hung up on what the RFS sets.”

Kohl says that, at times, her team has been labeled as the “renegades” of the ethanol industry for going it alone on their work to promote higher blends.

“We have an obligation to promote our own product,” Kohl says. “We aren’t trying to debunk E15. It is there and it has made

COMPARING BLENDS: Testing E30 in non-FFV engines in South Dakota, Glacial Lakes Energy asked participants to fill their vehicle's tank with E10 three times consecutively, and then E30 three times consecutively. The results may help validate E30's broader use.

THE YELLOW TREAMENT: E30 is currently not approved for non-flex fuel vehicles and, like E85, is sold as a fuel suitable only for FFVs. E30 proponents would like to see it treated more like E10 and E15.

PHOTO: GLE

PHOTO: GLE

strides,” she says, “but we feel the next step is E30—nationwide. We’ve demonstrated that and we continue to do so.”

Wagner says the NEB’s work on E30 is primarily focused on showing that the legacy fleet can handle the blend. “We already know this, but we are still trying to demonstrate that,” he says. “We hope our work will have long-term ramifications on legislation in the future.”

The results of the demonstrations, to date, have already shown what greater E30 use in the state of Nebraska could mean. According to the UNL’s research, if only 10 percent of the 1.7 million registered non-FFVs in Nebraska converted from E10 to E30, ethanol consumption would increase by 18.5 million gallons per year and CO2 emissions would decrease by 64,000 tons per year. Extrapolate those numbers to the entire the na-

tion, and the volumes are enormous—not millions, but a few billion additional (or not lost) gallons.

Durante believes the current U.S. administration is already positioning E30 to succeed. He says the internal combustion engine is not going to be regulated out of existence, but will rather be subject to more stringent emissions profiles achieved in part by using cleaner, better fuel. That is where E30 comes in. E30 should and could be used more in the future, he says, because everyone is recognizing that there is no silver bullet to overall emissions reductions— even with more EVs on the road. “We need to be more balanced in our approach to all of this,” he says.

Author: Luke Geiver Contact: editor@bbiinternational.com

‘An E30 blend in use today could have matched what the U.S. was pulling out of the Strategic Petroleum Reserve recently. E30 could displace about a billion barrels of oil per year.’

- Doug Durante, Clean Fuels Development Coalition

Consistently hitting high yields can be a challenge.

By using Innova® Apex – a yeast developed specifically to increase ethanol yield with industry leading robustness – you’ll achieve your production goals without compromising reliability and consistency.

Innova® Apex is the industry’s most robust and highest yielding yeast, helping you to hit your mark for your best performance.

Hit every curve with confidence.

With its engineered membrane systems for dehydration, Whitefox Technologies is helping the ethanol industry in its quest to achieve ultra-low—ultimately zero—net carbon emissions.

By Luke GeiverWhitefox Technologies has earned its place among the list of technology providers capable of helping ethanol plants reduce emissions and lower their carbon intensity scores. Eventually, it’s about getting them to net zero. To date, the industrial engineering firm with offices in the U.K., Calgary and Omaha, has customized alcohol dehydration membrane solutions for several (10 and counting) ethanol plants in the U.S. And in January, the day after Ethanol Producer Magazine spoke with two Whitefox executives about the history of their company and their newest and most popular offering—including what makes their tech ultra-relevant right now— they were off to Iowa to meet with a group of ethanol producers interested in in what they do.

Gillian Harrison is the CEO of Whitefox. She points to 2014 as a pivotal time for the company. Until then, Whitefox had primarily operated in Europe, specifically with industrial firms trying to reduce

water and energy consumption. In 2014, Harrison and her team headed to the U.S. to explore the possibilities of matching what Whitefox could do with what the U.S. ethanol sector needed. They went straight to the largest gathering of ethanol producers in the U.S. to start.

At the International Fuel Ethanol Workshop & Expo, the Whitefox team met with several ethanol producers, plants of all sizes and locations. “We didn’t go into any of our talks with a clear solution in mind,” she says. “But it became apparent that they were all facing very similar bottlenecks.”

Each producer they talked to, in one way or another, had boiler issues and capacity-limiting challenges. On top of that, they all wanted to explore the possibility of reducing their carbon intensity, she says.

“That gave us a need,” Harrison says. “Once we thought about how our technology could be applied to the industry, we talked to a lot of producers and it made sense to them.”

What happened next, Harrison says, was a co-realization by both Whitefox and its soon-to-be ethanol industry customers that a new, bolt-on membrane solution could make a significant impact on a facility’s water consumption, steam requirements and overall carbon intensity. Then, it was simply a matter of which ethanol producers were willing to change the way they approached distillation, dehydration and evaporation (DD&E). Before long, a few early adopters stepped forward.

Alto Ingredients, formerly Pacific Ethanol, became the first to install the technology. Today, nine ethanol facilities have added some form of membrane solution from Whitefox, and a tenth is in the process of doing so. Each solution in the portfolio does some things a bit different or creates unique benefits, Harrison says.

Tony Short, head of global sales for Whitefox, says that the company had to demonstrate its capabilities while also debottlenecking plants using molecular sieves. “We recognized that we had to demonstrate

our capabilities step-by-step to not only prove the membrane reliability to a new audience, but to also deliver energy savings and capacity expansion capabilities.”

The membrane technology created by Whitefox is a combination of mechanics and chemistry. Using polymeric materials (natural material made of large molecules) placed into engineered cartridges, liquids pass through the units. The membranes can distinguish between an ethanol molecule and water. There is a unique capability of the combination of the cartridges and the membranes to retain ethanol without outside, energy intensive aid.

With its trademarked suite of ICE solutions, continuous dehydration is established, reducing energy consumption per gallon of ethanol produced. All of that happens by a reconfiguration of existing distillation. The company's latest offering, ICE XL, fully replaces an ethanol plant's molecular sieves, is 100 percent energy neutral and gets to 190 proof with less condensation and evaporation steps. Steam needs are reduced because of 25 percent lower water load.

Conventional molecular sieve dehydration is a pressure swing adsorption technology that is commonly used in ethanol production. Operation of such a system is cyclical with a variety of recycle streams that sometimes create bottlenecks in DD&E. Conventional MSU dehydration methods are energy intensive, often requiring 184 to 190 Proof as the MSU feed.

The Whitefox method, using the ICE XL, reduces steam consumption in DD&E to 8,000 Btu/gal and helps create a stable, continuous operation without pressure swings. There is zero molecular sieve dust contamination and a cooling water reduction. A review of before and after schematics show a dramatic difference in how the DD&E process happens. The same can be said for every other ICE offering in the Whitefox portfolio of systems.

Whitefox has proven that the DD&E reconfiguration can increase capacity, up to 100 percent. Steam consumption in the

evaporation process is reduced by up to 25 percent due to lower water load and improved water balance. The efficiency gains through better heat integration into the process helps reduce natural gas consumption by up to 50 percent—which accounts for a potential carbon intensity score reduction of nearly 8 points.

Despite the numerous core benefits that each system shares, no installation is exactly the same. The Whitefox team does it that way because every ethanol plant is unique and requires a customized solution.

Short and Harrison are both quick to point out that no two ethanol plants are the same. They can each list off several they’ve seen firsthand.

“None of our solutions are off the shelf,” Short says. Ethanol clients need to first understand that Short and his team will take time with every new potential client to fully understand their respective process and operating conditions along with their objectives.

According to Short, all versions of the membrane technology (there are four op-

tions) are able to dehydrate and separate ethanol mixtures continuously to high purity levels in a single pass, 24/7. Every solution will capture and recycle plant energy without the need for chillers or compressors. “Essentially,” Short says, “Whitefox membranes allow customers to produce more and waste less.”

Alto Ingredients installed its Whitefox system over six years ago. Since then, Golden Grain Energy LLC, The Andersons Inc. and others have adopted the technology. And now, Western Plains Energy LLC is following suit. Several years ago, Harrison met Derek Peine, general manager at the Kansas-based WPE facility. She knew right away that Whitefox’s mission to help reduce water usage and energy needs in industrial processes designed to profit would be a good match for the progressive biorefinery Peine runs.

Today, the Kansas plant is installing the first ICE XL in the U.S., and Peine says the integrated membrane technology will contribute to fully decarbonizing the plant’s production process. The project is underway and has an estimated start-up and commissioning date towards the end of 2023. Short, who is working on the project, says the ICE XL will fully replace existing molecular sieves while increasing capacity by 50 percent across distillation and dehydration along with another 50 percent steam decrease.

In North Central Iowa, Whitefox was chosen by Golden Grain Energy LLC for use at its 120 MMgy plant because of its 24/7 capabilities. According to Chad Kuhlers, CEO of Golden Grain Energy, the technology “is a good solution for the plant to debottleneck existing process units,” while offering additional benefits in plant maintenance and overall operational efficiency.

Because the Whitefox systems operate under reduced vacuum pressures, they require minimal maintenance. According to Short, every 18 months basic visual inspection on seals are required. Whitefox also

Their valuable contents are at risk. But if your site planning included J.C. Ramsdell secondary containment systems, you’re protected from the unthinkable. Your contents are safe— the environment is safe. Ramsdell has been protecting them both since 1988.

collects plant operating data, assessing operating parameters to advise producers on possible changes.

Bill Krueger, president of The Andersons' trade and processing segment, chose Whitefox technology because it lowers steam use and energy cost per gallon. “It also helps to drive our objective of reducing carbon intensity across our production facilities,” he says.

In Nebraska, E Energy Adams put in Whitefox technology at its 50 MMgy facility designed by ICM. Carl Sitzmann, CEO, said the company was searching for a way to increase capacity without having to add a whole new distillation system. “Their membrane technology allows us to increase our dehydration capacity and improve our energy efficiency at the same time,” he says.

Short believes producers have embraced the membrane technology because it is easy to use and simplifies the operational process by eliminating regeneration streams. At least that is what his ethanol contacts tell him, he says. “They also like that our solutions are designed for them. We don’t provide anything generic, and they can always expand.”

For Harrison, the reason for the rise of Whitefox across the ethanol industry is based on a big-picture view. “We know, as a company, that we won’t get to big changes in water reduction and energy efficiency by making small changes,” she says. “The ethanol industry knows that. I think the industry is being bold. With our technology they are future-proofing the industry,” she says. “The market is crying out for tech solutions that are going to help them get to net zero.”

Author: Luke Geiver Contact: editor@bbiinternational.com7.5 billion gallons per year of SAF by 2040

The SAFFiRE Edge

• Ultralow CI Score

• Additional Revenue Source

• Reduce Operating Costs

• Produce High-Demand Aviation Fuel