3 minute read

Filaments for Medical Use

The race is on! Not only to produce filaments that are food friendly but also "body" friendly, here a just a few of the recently developed filaments for the use in the or in support of the medical industry. Though you would be well informed to ensure that you read any instructions that are provided by taulman 3D, as they take no responsibilty for the use of these filament types, all responsibility is with the user!

Advertisement

FilaPrint BVOH

BVOH is a water soluble, easy to print 3D Printing support filament. Suitable for printing with a wide range of materials, such as, ABS, ASA, PLA, PET, PA, PC and TPU.

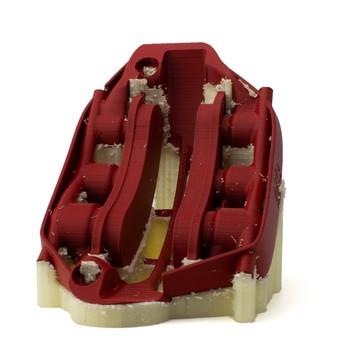

FibreTuff® has excellent bone-like qualities, making it ideal for 3D Desktop printing medical, dental, and veterinary bone models. Use for pre-surgical assessment, simulation, and training.

FACILAN™ ORTHO 1.75mm filament

Facilan™ Ortho is a polyester that is semi-crystalline leading to a clean white final appearance. It is the world's first material designed specifically for orthotics. Unique hot melt properties make Ortho ideally suited for adhesion to leather and textiles. Facilan™ Ortho is based on compostable raw material according to EN 13432.

PLACTIVE AN¹™ Antimicrobial PLA Filament

PLACTIVE AN¹™ by COPPER3D is an innovative Nanocomposite Antibacterial filament with a high quality PLA and a patented, scientifically validated and highly effective Nano-Copper additive.

Arnitel 2045 TPC

The Arnitel ID 2045 3D printing filament, is a material that many of you have been asking for. This unique 3D desktop printing filament has many of the characteristics that will move your 3D printing applications up a notch. The Arnitel ID 2045 filament is bio-degradable, 100% recyclable and made from 50% Bio-feedstock, so already this ticks a lot of your boxes.

An efficient way to keep your filaments dry even when printing ~ The PolyBox™

guidel!ne - A medical grade ISO 10993 FDA reg material. When 3D Printed, guidel!ne has a tensile strength higher than our strongest TECH-G, coming in at 6,850PSI. Elongation is 5.9 and a modulus of 281,469PSI. Heat distortion temp is 70C. Softening temperature is 100C. guidel!ne is also released as a starting point for individuals and companies wishing to obtain eventual FDA/ CE certification for a device knowing that the raw material itself is listed with the FDA and has already passed specific FDA testing. This material can also be used as a support material when dual printing with Nylons.

Nylon 680 is a desktop 3D printing filament specifically designed for use in a wide range of industries, including: medical, dental, food processing, and robotics. A pure polymer that includes no modifiers and registered by the FDA as food safe - US Food & Drug Administration approved. A 3D desktop printing filament capable of holding boiling water!

T-lyne is a unique, crystal clear polyethylene copolymer developed specifically for high durability, flexibility, unique viscosity and a wide temperature range. THE potential candidate for Prosthetics. When placed in hot water you can reshape and it will hold its new shape when cooled!

Nylon 645 is currently being used by CNC shops around the world to support quick turn prototypes for PrePilot and Pilot runs as well as some limited production runs. Nylon 645 has the highest chemical resistance of all of our Nylons and is highly compatible where Nylon 6,6 is required. 1. Bone repair and replacements - US Clinic Evaluations 2. Real-time build of custom prosthetic - Hague University of applied sciences Department: Technology, Innovation & Society 3. Real-time build of custom orthopedic items. - Hague University of applied sciences Department: Technology, Innovation & Society