19 minute read

Dutch Meteoriet consortium tackles MEMS testing bottleneck

Dutch Meteoriet con sortium tackles MEMS testing bottleneck

Currently, MEMS testing basically comes in two fl avors: highly automated but tailored to a very specifi c device that’s manufactured in high volumes, and, essentially, manual inspection for everything else. A consortium of ‘neighboring’ companies and research institutes aims to bridge that gap by developing an all-electric, universal MEMS testing solution suitable for all volumes.

Advertisement

Paul van Gerven

Imagine having to discard a product at the nal stages of its production process because it turns out a chip is malfunctioning. is doesn’t happen very often in the electronics industry because chips are rigorously tested before they’re mounted. But not all companies, particularly manufacturers of specialized MEMS chips, have the luxury of low-cost and highly automated testing procedures.

Because of their mechanical nature, MEMS are more complex to test than electrical ICs. Large MEMS manufacturers like Analog Devices and Bosch can a ord to develop highly specialized testing equipment, but for companies with lower volumes, sometimes as low as a few thousand devices per year, that’s never going to be cost- e ective. Nor are there any speci c ‘MEMS testing houses’ to outsource to. ese companies have to resort to labor-intensive ‘manual’ testing, which often isn’t enough to prevent that a percentage of the nal assembled product won’t work. ree companies and two research institutes, all located in the east of the Netherlands, have partnered up to solve this problem. Co- nanced by the European investment fund OP-Oost, the Meteoriet consortium is looking to develop a universal MEMS testing technology. Make no mistake, though: large manufacturers stand to bene t, too, as their testing time per unit can be reduced. All in all, the new testing methods will remove a major bottleneck for the adoption and application of MEMS technology.

Great value

Most chips only need to have electrical signals run through them to nd out whether they work as intended. MEMS, on the other hand, require another type of physical input for testing, such as a temperature increase, a movement or a changing magnetic eld. A MEMS airbag sensor chip, for example, is tested by subjecting it to a massive deceleration. And a MEMS microphone device is exposed to a range of sound frequencies. Each type of device requiring a di erent physical stimulus makes MEMS testing hard to standardize.

But perhaps it doesn’t need to be. e Meteoriet partnership is convinced that it’s possible to test MEMS chips the same way regular ICs are tested: by electrical means only. “ e movement in a MEMS chip is associated with electrical signals, which can be measured and used to obtain information about the displacement that has occurred. It’s also possible to induce the desired movement electrically. Taking together, you can test a MEMS chip electrically,” explains Paul van Ulsen, CEO of test technology company Salland Engineering, which spearheads Meteoriet.

An all-electrical MEMS test could look like this: an electrical stimulus is applied to induce a displacement of a particular mechanical part of the chip. Next, an appropriate electrical measurement is performed to verify whether the displacement did indeed take place. Other functionalities, such as temperature sensors or heaters, can be tested in a similar fashion.

Credit: University of Twente

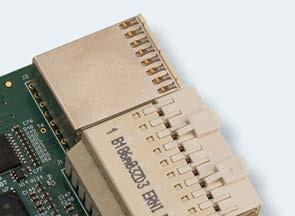

An early version of the MEMS chip Meteoriet will be using for calibration.

Credit: Salland Engineering

Machine learning

A Salland Enginneering 8-channel PXI instrument to measure extremely low capacitance, which is required for electrical MEMS testing.

e advantages of such a relatively simple procedure are myriad. It can be performed on the wafer, allowing for the elimination of malfunctioning devices at the early stages of the production process, reducing waste and saving costs. Wafer-level testing intrinsically also speeds up testing because many chips can be tested at once, and can also be automated quite easily.

“Electrical testing of standard electrical parameters is already part of the MEMS testing toolbox, but a generic, universally applicable test solution for the physical parameters doesn’t yet exist,” says Van Ulsen. Clearly, it would be very lucrative for his company if the Meteoriet partners succeed in developing one, especially given the rosy growth prospects of the MEMS market. “MEMS devices are often sensors, and sensors are an integral part of the IoT and Industry 4.0. us, speeding up and simplifying MEMS testing would help drive maturation of these technologies by reducing production cost.”

For Salland, the deliverable of the Meteoriet project is a testing solution, along with the associated IP. e Zwolle-based company will deploy that in a variety of ways. “We’ll sell stand-alone test instruments, but we’ll also o er add-ons for existing equipment, so they can be made suitable for MEMS testing. Lots of existing IC testing equipment can be upgraded to be able to handle MEMS testing, which we believe is a great value proposition. On top of that, we can start o ering test services for small and medium-sized companies that don’t have the critical mass to do testing in-house.”

Clearly, it would be very lucrative for his company if the Meteoriet partners succeed in developing one, especially given the rosy growth prospects of the MEMS market. “MEMS devices are often sensors, and sensors are an integral part of the IoT and Industry 4.0. us, speeding up and simplifying MEMS testing would help drive maturation of these technologies by reducing production cost.”

For Salland, the deliverable of the MeteoOne of the project’s main challenges is to gure out which stimuli and measureto gure out which stimuli and measurements are e ective for testing di erent ments are e ective for testing di erent MEMS chips and their components. is is MEMS chips and their components. is is why the University of Twente (UT) and the why the University of Twente (UT) and the Saxion University of Applied Sciences are Saxion University of Applied Sciences are involved in Meteoriet. ese institutes are involved in Meteoriet. ese institutes are tasked with developing models that relate tasked with developing models that relate the non-electric physical quantities (movethe non-electric physical quantities (movement, temperature, gas ow, and so on) to ment, temperature, gas ow, and so on) to electrical characteristics to test the MEMS. electrical characteristics to test the MEMS.

“Our models are mathematical represen“Our models are mathematical representations of devices that, given the input, retations of devices that, given the input, reveal what the measured output says about veal what the measured output says about the physical quantity that sits in between. the physical quantity that sits in between. From these models, Salland can derive the From these models, Salland can derive the requirements for its testing instruments,” requirements for its testing instruments,” explains Dennis Alveringh, assistant proexplains Dennis Alveringh, assistant professor at UT’s Integrated Devices and Systems group and part-time research scientist at Salland Engineering.

“ e model of a die can be viewed as a black box that takes the mechanics or other quantities like temperature changes out of the equations. e input and output are electrical, yet they yield information about something non-electrical happening inside the device,” adds Aleksandar Andreski, associate professor in nanophysics at Saxion. e goal of the project, however, isn’t just to nd out whether a MEMS chip (or a

MEMS component) works or doesn’t work. Alveringh: “We also want to know how well how well it works. Because of random variations in it works. Because of random variations in the production process, some chips may the production process, some chips may have an above-average sensitivity in a cerhave an above-average sensitivity in a certain measuring range, for example. Others tain measuring range, for example. Others may have an excellent response time. We may have an excellent response time. We can nd out which test results are associatcan nd out which test results are associated with such characteristics. is will allow ed with such characteristics. is will allow manufacturers to select chips and match manufacturers to select chips and match them with di erent product lines that them with di erent product lines that are based on the same chip. is so-called are based on the same chip. is so-called product binning is a common practice in product binning is a common practice in the semiconductor industry. And, nally, the semiconductor industry. And, nally, we might even be able to predict what the we might even be able to predict what the right calibration will be once the nal prodright calibration will be once the nal product has been assembled.”

In addition, Saxion will be validating In addition, Saxion will be validating the results. “At the end of the day, Salland the results. “At the end of the day, Salland needs to prove its claims about purely needs to prove its claims about purely electrical MEMS testing to customers. At electrical MEMS testing to customers. At Saxion, we’ll collect the extensive data set Saxion, we’ll collect the extensive data set to do so. Of course, as research institutes, to do so. Of course, as research institutes, we want to publish our research results, for we want to publish our research results, for which proof is required,” says Andreski. which proof is required,” says Andreski.

Finally, the consortium wants to know Finally, the consortium wants to know more about the nature of the defects and more about the nature of the defects and other anomalies encountered, and what effect these have on the test results. is is where a fourth consortium partner comes in, Enschede-based Maser Engineering, a failure analysis specialist (among other things). “ ere will be defects that won’t show up with electrical testing, and we’d like to know what type of defects these are. Maser has the equipment and expertise to paint a detailed picture. We’re also working on complementary automated testing methods to identify and characterize these defects. We’re developing machine learning software that can do just that from pictures of the wafer. Optical inspection already is more or less standard in MEMS testing, and we can easily upgrade Salland’s testing equipment to handle both electrical and optical testing – adding even more value,” Andreski continues.

Dear to my heart

Now, there’s just one piece of the puzzle missing: MEMS chips to test. is need will be partially satis ed by UT, which will design a state-of-the-art MEMS chip, taking into account requirements for testability. In parallel, a company itching for more effective testing procedures will do the same: mass ow sensor manufacturer Bronkhorst High-Tech from Ruurlo.

The IQ+Flow is one of Bronkhorst’s product series that’s already based on MEMS technology.

“We have MEMS-based products on the market for about 15 years now. Currently, about 5-10 percent of our o erings are MEMS-based. Recently, we’ve identi ed some very interesting new opportunities in the gas ow sensor markets that we’d like to capitalize on. However, scaling up our MEMS activities will require faster and more e ective testing methods,” says Joost Lötters, science o cer at Bronkhorst and professor in micro uidic handling systems at UT.

Bronkhorst manufactures its own MEMS chip in the cleanroom of the MESA+ Institute for Nanotechnology, a shared production facility for micro and nanotechnology located on the UT campus. After production, these chips are subjected to a number of manually performed tests, among which an optical inspection and an electrical test of certain components, but that’s not enough to ensure the product works as intended. During nal testing and calibration of the assembled module, some chips turn out to be malfunctioning after all.

At Bronkhorst’s current needs of several thousands of MEMS devices per year, this situation is manageable. Expecting volumes to grow to tens of thousands of chips per year or more, however, the company’s labor-intensive testing procedures clearly

Credit: Bronkhorst High-Tech

won’t cut it anymore. “ ese volumes are still not high enough for foundries. We really need access to comprehensive, automated testing,” states Lötters. at’s why his company gladly participates in Meteo riet to help Salland develop the testing solutions. Evidently, the chip that’s being designed as a part of the project will be used in next-generation mass ow meters.

And so everything neatly falls into place within Meteoriet. Amazingly, all partners are located no more than 50 kilometers from one another, as the crow ies. “ ere’s a lot of knowledge and expertise in this part of the country, but we nd it di cult to come together. I get it, there are always plenty of other priorities, right? Still, I think that cooperation between Dutch tech companies is very important to be able to compete in the global marketplace,” says Van Ulsen.

“ e Meteoriet project is particularly dear to my heart because it involves automation. anks to automation, costs are lowered, meaning manufacturing operations – and the associated jobs – that have been outsourced to Asia or Eastern Europe could return to the Netherlands,” Van Ulsen concludes. “ at’s why I hope Meteoriet will inspire companies across the country to put in the e ort and start working together more often.”

Hot topics in IC and electronic system testing – from all angles

For already a quarter of a century, the last week of May is reserved for the IEEE European Test Symposium (ETS). The 26th edition has a balanced program where, besides professors and students, all key suppliers and industrial users of test equipment and design-for-test (DfT) software are present. Under pandemic rule, ETS-2021 will take place completely online, be it with several live events.

High-performance parallel parametric testing.

Erik Jan Marinissen Georges Gielen Michele Stucchi Elena-Ioana Vătăjelu

In its rst 25 years, the IEEE European Test Symposium has set up its camps in almost every European country at least once. For example, the Netherlands has hosted it twice: in Maastricht in 2003 by Erik Jan Marinissen (at that time working at Philips Research) and in Amsterdam in 2016 by professor Said Hamdioui of Delft University of Technology. Belgium, on the other hand, was still one of the very few blank spots for ETS on the European map. When a team from Imec and KU Leuven in 2019 proposed to the ETS Steering Committee to host the 2021 edition in the historic city of Bruges, their bid was quickly accepted. en, in early 2020, the Covid-19 virus outbreak struck and forced ETS-2020, originally planned to take place in Estonia’s capital Tallinn, to move to an online conference format. Although at that time, many were convinced that we would be freed from the pandemic and its restrictions on our daily lives well before May 2021, the Belgian organizers of ETS-2021 soon realized that there was no guarantee for a Covid-19-free world when their event would take place.

International meetings such as ETS have a special responsibility with respect

Credit: Imec

to Covid-19 since their participants come from many di erent countries from all over the globe and have the potential to spread an infection at a global level. e only way to mitigate the associated risk was to turn ETS-2021 into a fully online conference. In the summer of 2020, the Leuven-based organization team canceled their reservations in Bruges, to fully concentrate on the virtual edition of ETS-2021.

Quiz

Online conferences o er many bene ts over conventional in-person meetings. No need to travel, since one can participate from the comfort of one’s own home or of ce; obviously, that saves time, money, and also contributes to ‘saving the planet.’ Of course, participants do lack the networking and interactions with peers. For organizers, conference budget items such as meeting rooms, AV equipment and banquets aren’t applicable in a virtual setting. Consequently, the registration rates for the 2021 virtual ETS edition could be reduced drastically. All recorded lectures will also remain online for a full month after the event.

Most likely, everybody has already attended several online conferences and/or other events during the ongoing pandemic. Despite the clear advantages, many of us sense a feeling of remoteness and a lack of interactivity associated with such virtual events. e ETS-2021 organizers have

made extra e orts to address this issue and to maximally stimulate interactivity during the conference. e keynotes will be broadcasted live (and recorded for later viewing). Although all regular paper sessions, as well as the vendor sessions, will be pre-recorded, the speakers will be present during the entire session, so that the audience can directly interact with them via chat – this is a level of interactivity even beyond what’s possible at a regular (non-virtual) conference. To avoid the fatigue of sitting too many hours behind a computer screen, the program is restricted to only ve hours per day (14-19h CET) and sessions are smeared out over four (instead of the usual three) days while keeping the usual amount of technical content. ETS also features a big online social event, where interactivity is of course paramount: the very rst Global Test Community Quiz.

26th IEEE European Test Symposium

• live on 24-27 May 2021 • one more month on-demand online • reduced rates until 1 May • discounts: IEEE/CS members, speakers, students • 4 keynote addresses • 10 regular technical paper sessions • 3 industry sessions • 5 vendor sessions • 4 special sessions • 3 embedded tutorials • 1 panel session • poster sessions • European semi- nals of the

Ed J. McCluskey Best Doctoral esis Award • virtual exhibition with 10 exhibitors • social event: Global Test

Community Quiz 2021 ets2021.eu

DfT standard

In the ETS-2021 opening keynote, Oliver Dial of IBM’s TJ Watson Research Center will talk about quantum computers, which hold the promise to be able to crack problems that are simply too hard for today’s computers. While on the application side, the objectives and bene ts are clear, the hardware implementation still has quite a number of tough hurdles to take. And, of course, these new computers will bring their own set of unique test challenges – operation at cryogenic temperatures (just above 0 kelvin) is just one of them.

ICs are also increasingly used in safetyc ritical applications such as automotive and healthcare; as these new domains have very little tolerance for test escapes, test quality needs to be improved. e ETS program has at least four presentations related to automotive quality, while the keynote by Chris Van Hoof, VP R&D at Imec and general manager of the Oneplanet Research Center in Wageningen, the Netherlands, will address disruptive new health devices. ETS also features papers on cell-aware test generation, a new approach that has proven itself with respect to test quality improvement. It explicitly targets realistic open and short defects inside the individual basic digital library cells.

ETS-2021 o ers a quite large number of contributions devoted to memory testing: next to classical charge-based memories such as SRAMs and DRAMs, new memories like resistive (RRAM) and magnetic (MRAM) memories are on the verge of a breakthrough in the market. Another new kid on the block is optical data propagation: silicon photonics. e circuit level addressed at ETS ranges from individual digital library cells, via full ICs, to printed circuit boards containing multiple ICs. Over time, papers on board testing have made way for papers on system-level testing and test and design-for-test solutions for 3D-ICs containing multiple dies stacked on top of each other in a single package. As the test infrastructure of stacked dies needs to work in concert to get test stimuli up and test responses down in the stack, in 2020, a DfT standard was released for such 3D-ICs (IEEE 1838) and several papers address this topic now at ETS-2021.

Revolution

ETS has expanded into domains neighboring to pure manufacturing tests, such as reliability and security. While the main question addressed in test papers is “whether the chip is okay at the start of its lifetime (t = 0),” reliability asks a similar question for t > 0. Hence, it’s no surprise to encounter reliability papers at a test conference.

Having security papers at a test event is less obvious, as testability and security seem fundamental adversaries: testability requires access to the internal components of an IC to be able to control and observe their state, while security typically wants to prevent such access. But the technical skills necessary to address both issues have a large overlap and an increasing number of products simply require to be both testable and secure. Ever since ETS has added security to its topics list, it has become one of the most popular topics, and the ETS-2021 edition is no exception. e keynote of KU Leuven professor Ingrid Verbauwhede will be on secure hardware design. e fourth keynote, delivered by professor Subhasish Mitra from Stanford University, will talk about a Cambrian revolution in system testing that grows beyond testing manufacturing defects to address robustness issues that end users really care about (like design bugs, reliability and security) in applications from (self-driving) cars to the cloud. ese factors create golden opportunities for new system-driven test approaches that deal with the seemingly diverse problems at seemingly diverse scales in the emerging 21st-century designs.

ETS-2021 collocated events

17-23 May 2021 (prior to ETS)

Test Spring School: TSS 2021 “Robustness in new computing paradigms and technologies”

27-28 May 2021 (after ETS)

ree focused workshops: • SURREALIST – Security,

Reliability, Test, Privacy, Safety and Trust of Future Devices • AI-TREATS Workshop on AI hardware – Test, Reliability and

Security • TAAA – International Workshop on Test Access, Automation and

Adoption

Erik Jan Marinissen (Imec, Leuven, Belgium) is the ETS-2021 industrial-relations chair. Georges Gielen (KU Leuven, Belgium) and Michele Stucchi (Imec, Leuven, Belgium) are the general co-chairs. Elena-Ioana Vătăjelu (CNRS/TIMA, Grenoble, France) is the program chair.

Edited by Nieke Roos