8 minute read

NLR takes the controls to bring propeller noise down

As the number of aircraft continues to increase, noise is becoming a headache. As part of a public-private collaboration known as the Taste project, aviation propeller manufacturer Dowty is turning to NLR and its in-house developed technologies to precisely measure, and ultimately mitigate the noise at the source.

Collin Arocho

Advertisement

With drones of all sizes, personal air transport and smaller planes increasingly lling the sky, propellers will be a mainstay of sky-bound transportation. is comes with its own set of challenges – speci cally in the aviation industry. One challenge coming to light is the noise generated by the open blades of these aircraft ying at lower altitudes.

As a propeller rotates, it creates thrust due to the forces on its blades. is rotation also results in an acoustic eld that’s perceived, particularly in the far eld (at a distance from the source), as noise. e level of the disturbance directly correlates with the amount of force on, and the subsequent speed of, the turning blade and is seen as a growing nuisance, for both people

Taste

Within the Techniques for Acoustic Measurements in High-Speed Test Environments (Taste) project, the Royal Netherlands Aerospace Centre (NLR) is looking into possible methods to accurately measure and mitigate the noise produced by propeller- driven aircraft. Partners include UK-based Dowty Propellers and NLR’s sister organization GermanDutch Wind Tunnels (DNW). NLR participation is co-funded by Holland High Tech, Top Sector HTSM, with a public- private partnership grant for research and innovation. on the ground, as well as those in the sky. Enter the British engineering company Dowty Propellers.

Taste

e UK-based aerospace experts, which specializes in the design and manufacturing of integrated propeller systems, wanted to investigate if these sound issues could be mitigated by identifying the sources. But before Dowty could set a hard goal of reducing noise, they rst needed to determine if it was possible to get more accurate acoustic measurements. To do this, the British engineering company initiated a study, called Techniques for Acoustic Measurements in High-Speed Test Environments (Taste), and reached across the North Sea to the Royal

Netherlands Aerospace Centre (NLR) for assistance in the project. In this collaboration, Dowty would provide its knowledge and expertise on propellers and rely on NLR’s experience in algorithm development and industrial testing, before nally turning to the low-speed wind tunnel facilities of NLR’s sister institute German-Dutch Wind Tunnels (DNW), the third arm of this public-private alliance.

“Essentially, Dowty turned to us to see if we could get more accurate acoustic measurements from the propellers in a highspeed environment, which is certainly not a trivial task,” describes Marthijn Tuinstra, a principal scientist at NLR. “To achieve this, though, we’ll need to advance the state-ofthe-art in measuring techniques.”

Credit: NLR

Acoustic array

One main issue with measuring in a highspeed environment is that these tests use scale models and take place in wind tunnels, which are in no way constructed to provide interference-free sound testing. “Ideally, you’d need a large-scale tunnel that’s completely covered with acoustic materials to block re ective sounds and ensure you’re measuring the desired sound source – a model propeller in this case. e problem is, for high-speed measurements, these facilities don’t really exist,” poses Tuinstra. erefore, NLR is developing algorithms and measurement techniques to be able to

deal with the challenges coming with such a nonideal test environment. One of these acoustic measurement techniques to be employed is the acoustic array.

“ ink of the array as a camera, but the lens is replaced with an array of microphones. Employing digital processing techniques, all the microphones are focused on a xed point in space and used to measure the sound,” illustrates Tuinstra. “ e easiest way to explain it is, if you were to point two microphones in space to record a sound. e sound rst will be picked up on one microphone, and at a di erent time on the second microphone, due to the location and trajectory of the sound waves. is is what we call a phase delay. With this phase delay, we can determine from where that sound is emanating. By using more microphones, we’re able to record much more accurate measurements.”

Soap bubbles

To avoid re ections contaminating acoustic measurements in a closed wind tunnel, NLR has another trick up its sleeve. Instead of measuring sound directly, researchers will look to measure the velocity eld in the wake of the propeller blades. From this velocity eld, blade loading – the amount of thrust on the propeller blades as they rotate – can be determined. By employing this method, investigators can measure the acoustic pressure uctuations generated by the propellers.

“To measure the velocity eld, we make use of particle image velocimetry – the

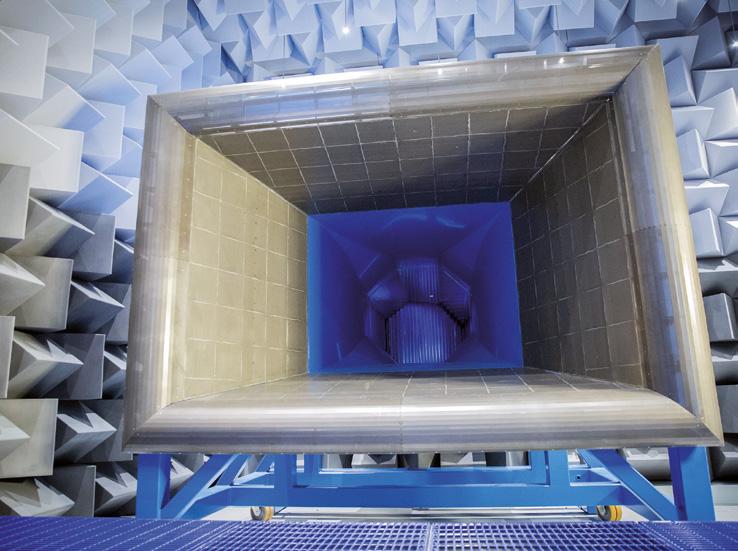

The NLR-AWT aeroacoustic wind tunnel.

measurement of velocity in uids – which uses particle tracers consisting of helium- lled soap bubbles,” tells Evelien van Bokhorst, the project leader of the Taste project and an R&D engineer at NLR. “With these particle tracers, we’re able to capture a large eld of view, which is necessary as each model propeller blade measures 30 cm long. Recently, we developed a system at NLR exactly for this purpose.”

Acoustic processing

Acoustic array and particle tracing, however, are only two of the innovative methods in the Taste project’s three-pronged approach. A third technique that collaborators are looking to utilize is another NLR innovation: in-house developed software systems and enhanced algorithms. “ is is the really innovative part of the project. We’re designing tailor-made acoustic processing algorithms to measure propeller noise. ese algorithms can then be modi ed to t with a speci c facility, allowing us to get more information out of the measurements,” highlights Tuinstra.

Even with these advances in innovation, the Taste project is still in the early stages – the preparation stage. While wind tunnel testing is slated to commence in the summer of 2020, the team is still working on modeling and simulation aspects of the project – meaning there’s still quite some ground to cover. “Currently, our focus is really on data post-processing techniques and adjusting our algorithms. is will allow us to enhance our existing beamforming techniques and get a more accurate picture of the sound eld,” expresses Van Bokhorst. “ e next step is to move into testing at small scale in NLR’s research wind tunnel, NLR-AWT. After that, we’ll move to an industrial-scale test, but still at low speeds. For this, tests will be carried out at the low-speed tunnels of DNW. With these wind tunnel tests, we’ll apply and combine our traditional and novel methods to be able to measure and describe the sound eld generated by propellers in the best way possible,” concludes Van Bokhorst.

High tech highlights

A series of public-private success stories by Bits&Chips

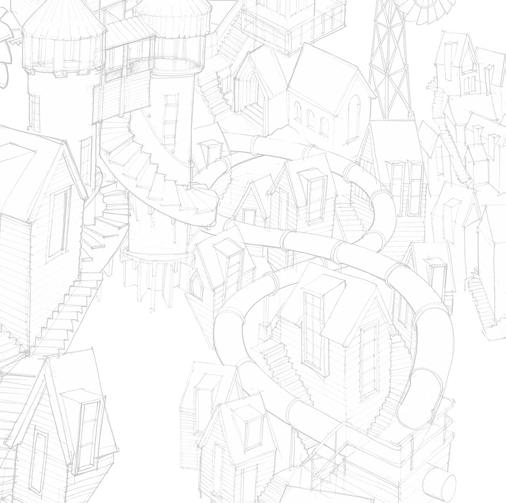

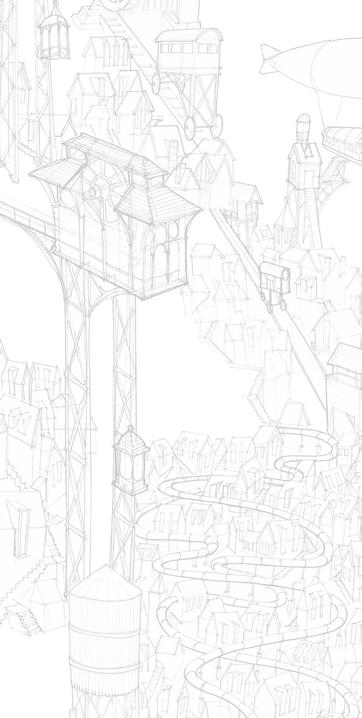

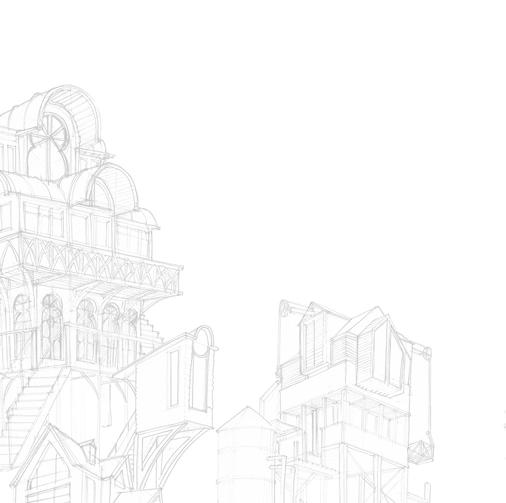

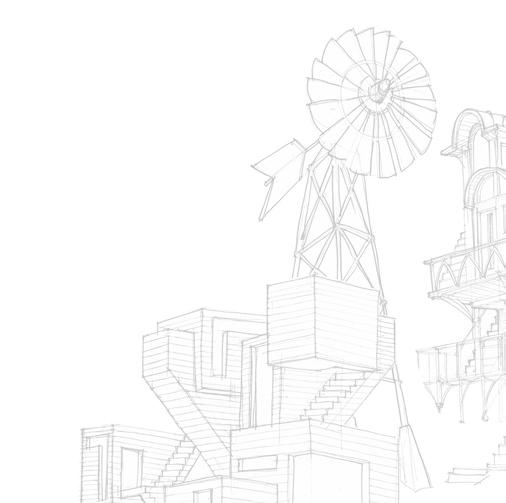

WHAT IF CITY

A profession in design or technology isn’t typically what most youngsters aim for when they’re in high school. Partly this is because of the lack of realization of what design and tech mean for the world. Actively confronting them with their own ability to design something that means a lot to others increases their motivation for an innovative study or job. This is exactly what the project “Invented by All” does.

hat if children were to build models of houses and other infrastructures? And then, after a while, bring their models to one physical area, combining them into one huge city? A city created and designed by youth. How cool would that be?

W

Sustainable Development Goals

In the “What if city” project, the Dutch Design Foundation and the Discovery Factory inspire children to design and present their own cities. Future-proof cities, which take the Sustainable Development Goals of the United Nations as a starting point. These goals are described as a shared blueprint for peace and prosperity for people and the planet, now and in the future. So it’s only natural that children have a say in this. What if they can convert their ideas for the future into new designs?

Quality time for families

The intention was to execute the project primarily at schools. But due to the corona crisis, children have to stay at home. How to deal with this? By making the best of a bad situation! History has taught us that crises can lead to innovation. In this case, children and their parents are looking for ways to spend quality time at home. So the project has been reshaped to facilitate families in building models out of everyday materials. Short fi lms inspire them and invite them to present their creations online. Meanwhile, several designers reach out to the children by digital means of communication. So they too can stimulate and inspire youth to look at things diff erently and reshape our future habitat.

What If City exhibition

After the corona crisis, it will only be a small step to building What If City in the real world. But fi rst, all created models together will form the What If City exhibition in the Discovery Factory. Participate? Check watalsstad.nl and share your vision of the future!

The Discovery Factory is there to inspire youngsters for a future in design and technology. Projects are supported by tech companies such as ASML, Brainport Industries, Daf Trucks, Frencken Europe, Hager, NTS Group, Philips, Stam en De Koning and VDL Group, and by Bits&Chips as the media partner.