12 minute read

Pure yeast and starter cultures for different types of beer

VLB SERVICE

During beer production the yeast ferments the sugar of the wort to alcohol and CO 2 . In this process, a large number of by-products are produced by the yeast that give the beer its characteristic flavor. Traditionally, strains of the genus Saccharomyces are used in the beer industry. The main differentiation is between the bottom fermenting, e.g. for Pilsner type beer, Lager and Export, and the top fermenting yeast, e.g. for Porter, Wheat Beer, Alt and Kölsch.

(BF) The collection of pure culture yeasts and their characterisation for the use in breweries, distilleries and diverse fields of beverage production at the Institute for Fermentation and Biotechnology (IfGB) in Berlin looks back on more than 100 years of tradition. After the large-scale destruction of the institute buildings in World War II, it was Prof. Dr. Siegfried Windisch (1913–2000), who restarted collecting different yeast strains for the brewing industry. Today, various microorganisms are collected at VLB Berlin and preserved by the Biological Laboratory of the VLB Research Institute

for Biotechnology and Water. They provide a wide choice of pure cultures for the development and production of a broad spectrum of alcoholic and non-alcoholic fermented beverages based on different raw materials like wort (distinct beer types including Sour beer and Berliner Weiße), tea (e.g. Kombucha),ordifferentsweetened bases(e.g. WaterKefir,Hard Seltzer, Kwaas):

Our services

The strain collection of the VLB Biological Laboratory offers more than 100 differentyeaststrains and other functional microorganisms for their use in brewing, spirits and beverage industries. These mainly include: • Bottom fermenting yeasts for breweries, e.g. Lager beers, Pils and Bock beers • Top fermenting yeasts for breweries, e.g. Ales, Wheat beers, Alt and Kölsch • Spirits, wine and champagne yeast strains • Pure culture yeast strains for specificproducts,such aslowalcohol beers or specialty beers e.g. Berliner Weiße • Lactic acid bacteria for acidification of mash and wort • Microorganisms for the production of non-alcoholic fermented beverages, e.g. Kombucha and Water Kefir

VLB provides comprehensive services regarding yeast cultures and starters as well as the development ofspecialproducts offeringprofessional advices:

• Isolation,identification and characterization of microorganisms • Third party storage – exclusive storage and management of individual strains • Purity check or purification, respectively, of your brewery yeast • Lyophilization of cultures • Customized screenings and implementation of test fermentations including accompanying analysis • Product development

Yeast distribution worldwide

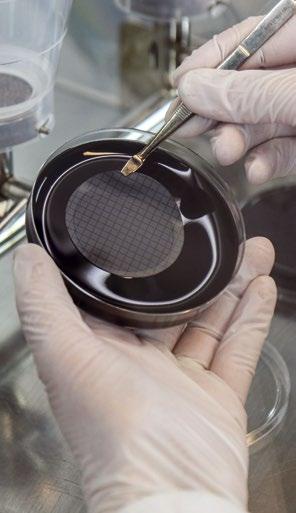

The pure yeast cultures are delivered as liquid concentrate in aluminium bottles, as agar slant or as dry yeast on filter paper.

Contact:

Dr. Martin Hageböck biolab@vlb-berlin.org +49 030 450 80-157 www.vlb-berlin.org/en/yeast

VLB's yeast bank offers more than 100 different yeast strains and other functional microorganisms for beer production

Photos: ew

VLB OCTOBER CONVENTION

“Ongoing research” – an information session turns into the VLB science slam

by Burghard Meyer, Christian Schubert, Laura Knoke, Philipp Zeuschner, Maximilian Schmacht and Stefanie Malchow

“The Future in Brief” was the theme as VLB dedicated an entire block of lectures to internal research projects at its October conference 2019. The short presentations shone a spotlight on the individual projects and gave the experts and representatives of VLB member companies in attendance an overview of the range of scientific topics currently being researched at the VLB.

The panel for the lecture block "Ongoing Research – News from VLB Research Projects", which was on the agenda of the 106 th October Convention in autumn 2019

Burghard Meyer

Gerhard Andreas Schreiber welcomed the participants and gave a general overview of the VLB’s research activities. The VLB Chief Financial Officer and Research Coordinator explained why the Ongoing re

search – news from VLB research pro

jects (Forschung aktuell – Neues aus VLBForschungsprojekten) session formed a separate thematic block in the program for the first time. Schreiber quoted from the VLB’s bylaws, according to which one of the purposes of the association is to promote science and vocational training in the brewing, beverage, and biotechnology industries. The purpose as laid down in the bylaws is served in particular through research projects that are made accessible to the general public, forexample atscientificevents. Plus, transferring results is also part of the overall process of a research project. At present, about 80 researchers are conductingresearch atfive specialized research institutes, which is complemented by a close cooperation with departments at the TU Berlin and other universities and colleges. Financing is provided by national and international funding agencies and by industrial partners – these are inspired not least by public presentations on potential project partnerships.

Burghard Meyer from the Research Institute for Beer and Beverage Production (FIBGP) kicked things off with his lecture on Continuous

fermentation by means of mem

brane technology (Kontinuierliche Gärung mittels Membrantechnologie). Continuous fermentation processes have been the subject of brewing science research for a long time. The use of continuous primary fermentation is designed to produce a beer that constantly meets the quality requirements of conventional batch fermentation. An important aspect is the influence that the system used has on the quality parameters of the beer. Different types of reactors can be used and various carrier materials and systems are available. This results in a variety of possible options for carrying out continuous fermentation. In terms of the system used, its influence on parameters that determine quality, such as the physiological state of the yeast, nutrient transport to the cell, nutrient availability, nutrient conversion, or oxygen supply must be factored in. There is a change in the quantities ofdifferent fermentation by-products throughout the fermentation process in the continuous system, especially in the content of vicinal diketones, higher alcohols, and es

ters. The aim of the project was to develop a continuous and immobilized fermentation process using modern crossflow filtration technology. A crossflow fermentation module “immobilizes” the yeast in the system by retaining the yeast used for fermentation in the fermentation area.In thisfirstresearch project – for which a new reactor concept was developed – it was possible to implement a continuous primary fermentation in principle. (Funding program: INNO-KOM, funding code: 49MF190085)

In his lecture Top-fermented, hoppy beers – the market situation and state of research focusing on fla

vor stability (Obergärige hopfenbetonte Biere – Marktsituation und Forschungsstand mit Schwerpunkt Geschmacksstabilität), Christian Schubert from the Research Institute for Beer and Beverage Analytics (FIBGA) first described the aim of the research project. The aim is to create an understanding of the chemical processes and reactions relevant to quality during the aging of top-fermented, hoppy beers. The focus here is on the processes that influencetheflavorstabilitysuch as the influence ofheatduringstorage or strong UV exposure. An initial project phase saw 11 beers selected that represented a cross-section of the beers available on the market, including pale ale, India pale ale, brown ale, double India pale ale, and an alcohol-free IPA. Various analyses were carried out over 6 months. Results regarding carbonyl compounds, hop aroma, and beer bitterness showed that the beers investigated initially showed high carbonyl values that increased strongly over the storage time without any sensory abnormalities such as an oxidized flavor. With regard to hop aroma, it was shown that components such as myrcene or 2-methylbutyl isobutyrate, among others, which degraded during storage, did not correlate with the “hop aroma” attribute. It should also be noted that the analytical bitterness units are not necessarily associated with the sensory attribute of “bitter.” “The bitter composition in these beers is extremely complex and therefore requires new analytical methods,” Schubert concluded. (Funding program: INNOKOM, funding code: 49VF170007)

Laura Knoke from the Research Institute for Beer and Beverage Analytics (FIBGA) emphasized in her lecture The measurement of beer – high-resolution mass spectrome

try as a versatile research tool (Die Vermessung des Bieres – hochauflösende Massenspektrometrie als vielseitiges Forschungswerkzeug) that the explanation of sensory impressions at a chemical level is anything but trivial. “Sensory analysis is a holistic view of a sample, whereas quantitative analysis is an immense simplification,” explained Knoke. However, a combination of sensory impression and analyte is useful in solving brewery-related problems,forexample,an off-flavor that has occurred suddenly. Sensory impressions are also essential for the characterization of new products. The aim of the research project presented was to analyze as many of the non-volatile substances in beer as possible. Subsequent bioinformatic and statistical analysis can determine the differences between sensory and non-sensory samples. These may also be substances that were previously unknown to be contained in beer, which can be included in the quantitative analysis if they are relevant. However, by comparing it with known beer ingredients, specific quantitative analyses can also be carried out, if these are found to be the cause of the differences between the samples that are to be compared. (Funding program: INNO-KOM, funding code: 49MF180110)

With Quantification of the gentle delivery characteristics of ro

tary pumps (Quantifizierung der Schonfördereigenschaften von Kreiselpumpen), Philipp Zeuschner from the Research Institute for Beer and Beverage Production (FIBGP) presented a research project that is taking a look at the development of a methodology for the objective assessment of the frequently praised gentle delivery characteristics of rotary pumps. This project makes use ofthe known effect that barley β-glucans subjected to the influence of shear forces are capable of forming a hydrogel via intermolecular cross-linking, which can be quantified under relatively simple conditions in the laboratory. The research project is the continuation of a preliminary research project that was started in 2013 and in which the general functionality of the approach was already confirmed. Disturbance variables such as temperature changes or the molecular size distribution of the β-glucans in thetestfluid,which were already identified during the initial research, could be minimized and standardized in a new pump test section with an adapted test fluid. This was also funded by the German Federal Ministry for Economic Affairs and Energy. The results presented show that this method is now capable of determiningsignificantdifferences in the gentle delivery characteristics between different rotary pumps. This will be offered in VLB’s service portfolio in future. (Funding program: INNO-KOM, funding code: 49MF170021)

In his lecture Increasing productivity efficiently – new approaches

for high-gravity brewing (Produktivität effizient erhöhen – neue Ansätze für High Gravity Brewing), Maximilian Schmacht from the Research Institute for Biotechnology and Water (FIBW) dealt with the latest results from the “High-Gravity FedBatch” project. The aim of the research project, which began in September 2018 and will run through to February 2021, is to realize an alternative brewing process in the form of a fedbatch under highgravity conditions. The miniaturized fermentation platform BioLector ® Pro is being used since it is suitable for carrying out feeding experiments on an ml scale and thus providing a large amount of data quickly.

Christian Schubert

Laura Knoke

Fed-batch means fermentation is started in a certain medium and fresh growth medium is fed in. In this case, a standard wort can be used as a starting point and sugar can be added gradually. This avoids negativeeffectson theyeast,which would have a high sugar concentration right from the start. A mechanistic mathematical model is being developed in parallel with the process. This model can be used to make predictions about promising process parameters. The model that was initially developed for batch operation could easily be adapted to experimental data on a scale with a volume of a few milliliters or liters. In addition, screening experiments were conducted to identify suitable strains for the high-gravity brewing process. The later phases of the project will investigate to what extent the efficiency of the brewing process can be increased by feeding highly concentrated wort in contrast to traditional high-gravity brewing. (Funding program: INNOKOM, funding code: 49VF180009)

Stefanie Malchow, also from the Research Institute for Biotechnology and Water (FIBW), rounded off proceedings with her lecture

Sour-fermented alcohol-free beverages – setting new stand

ards (Sauer fermentierte alkoholfreie Getränke – neue Standards setzen). The product category of sour-fermented beverages is predominantly home to traditional

beverages that differ greatly in terms of the ingredients they contain and their properties due to their regional origin. Using undefined cultures and a large number of organisms of unknown quantity to start the fermentation process, however, is common practice. Increasing demand from consumers has led to producers’ interest in sour-fermented beverages growing as well. However, the lack of application-oriented research in this area makes it difficult to transition from the traditional, undefined process to a controllable and reproducible, industrial manufacturing process. That’s why VLB is devoting this current research project to the development of a standardized fermentation strategy for the production of kombucha and water kefir. Using this strategy as a basis, investigations will then be carried out to look into the influence of the microbiology used on the finalproductproperties and to identify critical process parameters such as temperature or oxygen supply. In addition, physical and thermal treatment methods to increase product stability will be evaluated, which will also factor in sensory characteristics. To be able to evaluate the influence of the individual parameters, it is first necessary to have robust analytics that show hardly any fluctuations and are specially adapted to the products that are to be investigated. That’s why additional analytical methods to determine microbiological and chemical composition as well as storage stability are being developed and tested within the project. Malchow concluded her lecture by looking to the future: “However, I think that by the official end of the project in the middle of next year, we will be a huge step further than we are at the moment, especially in terms of the applied initial research into the production of kombucha and water kefir usingdefined cultures.” (Funding program: INNO-KOM, funding code: 49MF190041) The two-hour session was a success, so it’s safe to say that this won’t be the last time that we see this format –if the topic fits, “News from VLB Research Projects” will also be presented in the future, Schreiber emphasized. After all, there are countless research activities at VLB, including in the fields of brewery raw materials, plant engineering, water/wastewater technology, microbiology, product and process development, and logistics – just to name a few...

left: Philipp Zeuschner below: Maximilian Schmacht, Stefanie Malchow