The RAPEVINE G

Your Best Viniculture Information Source

VINEYARD IRRIGATION: Wet Your Plants with Efficiency & Precision

See Full Story on Page 40

From Vine to Wine

The Best Options and Marketing for Modern Winery Packaging, Pg 9

Diving Into Winery Water Usage and Treatment, Pg 22

The 7 Best Ways Wineries Can Grow Their Text Marketing Lists, Pg 26

Vineyard Equipment Choices Designed to Boost Production & Save Money, Pg 46

Portugal: Tip-to-Tow, Pg 56

July - August Issue 2022

President /Publisher & Graphic Design

Jeffrey D. Bricker

Vice President / Editor

Cyndi C. Bowlby

Assistant Editor

Jessica Spengler

Sales Manager

Jo Cloud

Senior Staff Writer

Nan McCreary

Staff Writers

Alyssa L. Ochs

Becky Garrison

Cheryl Gray

Gerald Dlubala

Hanifa Sekandi

Tod Stewart

Contributing Writers

Thomas J. Payette

Vinteractive

Judit Monis, Ph.D.

Annie Klodd, Univ. of MN

Legal Kaider Law

Marketing

WineGlass Marketing

Insurance

Agricultural Risk Mgmt, LLC

Bricker Publishing

Division of: Bricker Group, LLC 1409 13th Street North

Humboldt, IA 50548

E-mail: editor@BrickerPublishing.com

Website: www.brickerpublishing.com

The Grapevine Magazine targets the national viniculture market is located in Fort Dodge, Iowa. The Grapevine Magazine is printed bi-monthly & distributed to the most qualified buyers. Opinions expressed in The Grapevine Magazine are not necessarily those of the publication personnel, but of the writers who contribute stories to The Grapevine Magazine. ERROR RESPONSIBILTY: The Grapevine Magazine is responsible only for the cost of the ad for the first incorrect insertion of the ad. Each insertion of an advertisement is proof of publication and it is the responsibility of the advertiser to check the correctness of each insertion. The Publisher shall not be liable for slight aesthetic changes or typographical errors that do not lessen the intent of the ad. No adjustment can be made for advertisements not published. In the event of any error in an ad for which the publisher is liable, the liablility is limited to adjusting that portion occupied by the error in relationship to the entire value of the advertisement. No adjustments will be made 30 days after initial insertion date.

All Contents of The Grapevine Magazine are

Copyright © by Bricker Group, LLC

CHANGE OF ADDRESS: Please send new address and phone number along with “The Grapevine Magazine” mailing label or email changes to editor@brickerpublishing.com

THE RAPEVINE G Your Best Viniculture Informational Source In The Winery When is the Correct Time to File for a Claim? ... 33 The Canadian Certification Program Application of Tissue Culture at the Nursery ...................... 37 Vineyard Irrigation: Wet Your Plants with Efficiency & Precision .................................... 40 Vineyard Equipment Choices Designed to Boost Production & Save Money ..................... 46 Cristom Vineyards: Creating “Wines of Place” ..... 5 The Best Options and Marketing for Modern Winery Packaging ............................................ 9 How to Clean Winery Hose ............................. 16 Diving into Winery Water Usage and Treatment .............................................. 22 Around The Vineyard Marketing Portugal: Tip-to-Tow ...................................... 56 International News The Grapevine • July - August 2022 Page 2 Editorial Content Bricker

Publishing®

The 7 Best Ways Wineries Can Grow Their Text Marketing Lists ............................... 26 Please Like Me: How to Successfully Navigate Customer Reviews ......................................... 31

Cristom Vineyards: Creating ‘Wines of Place’

By: Nan McCreary

Ask any winemaker the secret to making great wine, and almost everyone will say, “It all starts in the vineyard.” But to Tom Gerrie, second-generation owner of Cristom Vineyards in Oregon’s Eola-Amity Hills, this is more than just an answer to a question; it’s a way of life. From knowing the soil in each of Cristom’s estate vineyards to naming the sheep that maintain and nourish the plants, the staff at Cristom is intimately involved with the origin of their sustainably farmed grapes. “We encourage a proliferation of diverse life in the soil by adding compost to the soil and spraying compost teas and seeding diverse crops, for a few examples.”

And this passion extends to the winery, where winemakers use centuries-old techniques to create the fullest expression of what this land has given them, namely pinot noir and chardonnay. It is this commitment to a “sense of place” that has put Cristom Vineyards on the international wine map and distinguished its wines as among the best in the Willamette Valley.

Since the beginning, soil and site have been the hallmarks of Cristom Vineyards, which was founded in 1992 by Paul Gerrie, a petroleum engineer who had a strong passion for wine, specifically pinot noir. Gerrie’s goal was to grow and craft exception-

In The Winery The Grapevine • July - August 2022 877-892-5332 Page 5

al wines of a place that honor individual sites and old-world techniques. His search for a perfect location led him to a run-down vineyard in the EolaAmity Hills appellation.

“The site spoke to him,” according to Gerrie’s son, Tom, who took over the vineyard when his father retired. “It is geologically complex — the soil is mostly volcanic with some sedimentary and silt from the Missoula floods — and the elevation is similar to Burgundy, with a 500-foot in elevation change from our lowest vineyards to the top of our hillside at Cristom. Our Vineyards rise from above 250 feet to 750 feet. Slopes are eastern-facing. My father was a visionary and could look past the untended vines and imagine a very, very special site.”

When Paul and his wife, Eileen, purchased the vineyard, they named it Cristom after their two children, Chris and Tom. To achieve his goals, Gerrie hired Steve Doerner of Calera to be his winemaker. Not only was Calera one of Gerrie’s favorite producers, but the engineer and the biochemist

also shared a deep-rooted respect for the land, the natural winemaking process and pinot noir. It was to be a collaboration that would last for decades.

Since that inaugural vintage in 1992, the Gerries, along with winemaker Doerner, have constantly produced balanced, dynamic wines of intensity, structure and length. Besides pinot noir, they also make chardonnay (their flagship white wine), viognier and syrah. Cristom was the first to plant viognier in the Willamette Valley and the first to craft estate-grown wines and produced wines from viognier.

Cristom grows grapes on 90 acres of vines across a total of 240 acres. Like Burgundy, their vineyards are definitely vineyards of place. The five estate vineyards – Eileen, Jessie, Louise, Marjorie and Paul Gerrie — are all named for members of the Gerrie family. Each vineyard is differentiated by the slopes, ranging in elevation from Louise at 290 feet and Eileen at 735 feet. In addition, each site is distinguished by natural variances in mineral-rich volcanic soils, with topsoils varying from 18 inches to

The Grapevine • July - August 2022 877-892-5332 Page 6 In The Winery

10 feet. This variation leads to diverse single-vineyard bottlings and harmonious cuvées that pull from each of the vineyard sites.

Each Cristom vineyard is distinguished by climate. The Eola-Amity Hills AVA is defined by the roaring winds that funnel through the Van Duzer Corridor (a gap in the Pacific Coast range) that lowers vineyard temperature after warm summer days. The difference between daytime highs and nighttime lows can be 35 degrees or more, which helps preserve natural acids in the grapes and encourages them to ripen slowly.

“Eileen, our highest vineyard, is defined by the wind,” Tom Gerrie told The Grapevine Magazine “The grapevines can shut down if they get too much wind, and that preserves acidity. Skins get thicker, and tannins become more defined and complex. The grapes from Louise, which is at the bottom of the slope, are more protected because a large forest surrounds the vineyard. The wines are softer and plusher.”

With top-notch fruit in hand — lovingly grown and picked by winegrowers who have more than 200 years of combined vineyard experience — the Cristom winemaking team, which consists of lead winemaker Daniel Estrin, assistant winemaker Chris Butler and veteran Doerner, strives to create wines that reflect both the vineyard and the vintage. The central tenets of the winemaking style include the use of natural yeasts and whole-cluster fermentation.

“Using native yeasts can be risky,” Gerrie said, “but this gives a lot of diversity to our wines. One yeast may start the fermentation, then it dies out and another takes over, so we have different organisms driving the process the entire time. Different yeasts accentuate different terpenes and esters, which results in more complexity on the aromas and the palate.”

Whole-cluster fermentation also adds complexity to the wine, Gerrie said. “We’re very passionate about whole-cluster fermentation,” he told The Grapevine Magazine. “By keeping whole berries intact longer, we get a long, slow fermentation.

What Moves Your Wine?

The Grapevine • July - August 2022 877-892-5332 Page 7 In The Winery Waukesha Positive Displacement & Centrifugal Pumps Gentle, Efficient, Carlsen Quality 707-431-2000 • WWW.CARLSENASSOCIATES.COM

This gives us nice skin contact and extraction without maceration. The stems give a tremendous amount of complexity, with flavors of cinnamon, cardamom, clove and anise, or maybe black tea, herbal flavors or forest floor. Stems also provide additional levels of structure and complexity to the tannin profile, which balances well with acids and allows for greater age ability.”

Typically, Gerrie added, Cristom destems roughly half of the fruit, depending on specific site, growing season, and the age of the vines. “Almost everything we do is based on the question, ‘Does this vineyard need this in this vintage?’” he said.

farming methods — including agro-ecology, permaculture and integrative pest management — to enrich the soil and enhance the quality of fruit.

“We believe and understand this place to be a whole eco-system that we are trying to elevate through the diversity of animals, soil health and cover crops,” Gerrie explained. “We want to showcase this piece of ground, make distinctive wines of place and empower people to know and understand that caring for something properly will help it last generations after we are gone.” At Cristom, sheep and chickens roam the grounds (and soon cows will join them), nourishing the vines with excrement and aerating the soil with their hooves and feet. Composting — made from vine cuttings, wood chips from fruit and oak trees, pomace from post-fermentation solids and mown cover crops — creates rich soils filled with microorganisms that enrich vineyards and gardens and even form the basis of a tea that can be sprayed on the canopy and underneath the vines. Employees give treats to the sheep — and even give them names — knowing that they are all part of something much bigger than any person, animal or plant on the property.

Currently, Cristom vineyards produces around 20,000 cases of wine per vintage. They have distribution in 48 states and over 40 international markets. “We have some of the most widely distributed wines in the world,” Gerrie said. While Gerrie said Cristom would like to grow internationally, he is content to stay at current production levels. “It’s taken us 10 years to hit 20,000 cases, and we have finally found the right size for our business, our team and the land. We have hit a comfortable spot.”

While growth is not on the horizon at Cristom, what is in the future — both short and long-term — is a commitment to organic and biodynamic farming. Tom Gerrie, who joined the Cristom Vineyards production team full-time in 2007 and became majority owner in 2012, began transitioning the estate to biodynamic farming in 2017. Today, using scientist Rudolf Steiner’s view of the integrated farm as a guide, Cristom has employed different

Cristom’s current efforts in sustainability are all part of a 100-year plan of what the land will look like for generations to come. “What we’re doing on the property right now, for the company and for the brand, will put us in a stronger position 10 and 20 and 70 years from now,” Gerrie told The Grapevine Magazine. It’s a mindset that this team has taken on with tremendous responsibility, gusto and energy. The team knows they are stewards of a place and that we’re doing this together to create something distinctive, something that will carry on for years and years, when we expect them to be still naming the sheep.”

For more information on Cristom Vineyards, visit www.cristomvineyards.com

In The Winery The Grapevine • July - August 2022 877-892-5332 Page 8

The Best Options and Methods for Modern Winery Packaging

By: Alyssa L. Ochs

By: Alyssa L. Ochs

Many people view packaging as a functional and practical aspect of the wine business. Still, it is also an opportunity to get creative and help your wines stand out from the competition. These days, there are many different ways to package wine for consumption, especially if you’re looking to go eco-friendly, be innovative or uniquely build your brand.

In this article, we are looking at the importance of modern wine packaging, as well as the most significant considerations to keep in mind and new ideas to possibly add to your current business strategy.

Types of Wine Packaging

There are many different options for packaging

wine, so many wineries choose a combination of methods to save money, entice customers or preserve the best quality. There are various sizes and shapes of wine bottles to consider, as well as wine barrels and wine closures, such as natural and synthetic corks, bar toppers and screwtops. Wineries use other packaging products, such as shrink wrap, Tetra Paks, Styrofoam, cartons, labels and pallets. Miscellaneous packaging supplies that wineries may need include tape, cushioning, newsprint and mailing tubes.

Beyond these basics, there are bag-in-box wine packaging products, paper wine bottle bags, bottle carriers and sampler gift boxes as packaging options. Molded fiber shippers and case pack trays can accommodate different bottle sizes, shapes and

The Grapevine • July - August 2022 877-892-5332 Page 9 In The Winery

quantities. Foam shippers come in stand-up, laydown, and large format options, while airline totes are good six-bottle options. To provide customers with a unique and personalized experience, it may also be worth looking into custom-printed wine totes, custom wooded presentation boxes and custom printed bags with tissue paper.

Machinery Used to Package Wine

In addition to all of these miscellaneous supplies useful for packaging wine, there are also machines available to help automate the process and increase efficiency. There are pros and cons to using automatic vs. manual means of packaging, but something to remember is that you may be able to either buy or lease packaging machinery based on your needs.

Types of machines used for packaging are case sealer machines, palletizers, automatic stretch wrappers, conveyors, case erectors, sealers and inkjet printers that print directly onto boxes. When shopping for wine packaging machinery, it is also beneficial to choose suppliers with factory-trained technicians, service contracts and a full line of replacement parts for future repair needs.

One company specializing in winery packaging is A-B-C Packaging Machine Corporation in Tarpon Springs, Florida. This company supplies packers, case sealers and palletizers for end-of-line wine packaging and has several options available to wineries.

Bryan Sinicrope, the VP of marketing and integrator sales, told The Grapevine Magazine, “From our perspective as a secondary packaging machine supplier, we are seeing an increased interest in automation from wineries of all sizes. Traditionally it was difficult for smaller wineries to justify the

capital equipment expenditures to upgrade, but the current emphasis on ergonomics and worker safety, combined with labor shortages, has changed this perspective. There are multiple options for upgrading end-of-line packaging, including robotics and semi-automatic machines that have a lower cost of entry.”

Sinicrope also said that many wineries are looking for more flexibility in their packaging lines to serve new market segments.

“We are having requests for machinery that easily accommodates different package styles, such as small bottles, cartons and cans, as well as multiple secondary packages, including display cases and trays, in addition to traditional packaging.”

Sinicrope said that A-B-C Packaging stands out in the industry for wine packaging because its equipment ensures reliable performance and low maintenance, which reduces the cost of ownership. He also said that A-B-C’s machines have great flexibility and quick changeover and that the customized solutions they offer from the standard line of equipment keep costs down and minimize delivery time.

Product Recommendations and Highlights

Sinicrope from A-B-C- Packaging told The Grapevine Magazine that for bottled wine, his company generally uses robotic and pick-and-place machines.

“For pouch-packaged or cartoned wine, our robot packer provides maximum flexibility to pack into cases or trays, with a servo-powered product feed, gentle robotic packing and quick changeover at the operator station,” he said. “We also offer a

In The Winery The Grapevine • July - August 2022 877-892-5332 Page 10

semi-automatic carton packer for smaller operations that package wine in cartons, at speeds up to 10 cases per minute.”

A-B-C Packaging offers case sealing machines for a range of speeds to seal the top case flaps with adhesive or tape. The company provides conventional low-level, robot and semi-automatic palletizers for palletizing based on a winery’s budget, available space, flexibility requirements, speed and personal preference.

“Our low-level machines offer easy installation, and the floor-level control and maintenance keep operating costs low,” said Sinicrope. “A-B-C’s robot palletizers offer high flexibility to handle multiple product types with minimal hardware. Finally, our semi-automatic palletizers offer economy and flexibility for small wineries looking to upgrade.”

A-B-C has been supplying end-of-line packaging to the winery industry for over 50 years and understands the importance of maintaining the primary package integrity because many consumers will not

select a bottle with even minor label or seal damage.

“Our decasers and depalletizers unload single-file bottles with minimum contact to eliminate potential damage that can cause failure on the bottling line or in distribution,” Sinicrope said. “Case erectors have exclusive features to ensure square cases for top performance at the packer. And all our packers are no-drop to ensure soft loading while protecting the labels and closures.”

Another company specializing in this industry is Custom Wine Packaging, a husband and wife team who have been in the corrugated box and custom packaging industry for over 30 years. They shifted their focus toward serving wineries and vineyards in 2014, starting with their home state of Texas and then branching out to reach wine businesses all across the U.S.

Garry Clark, the owner of Custom Wine Packaging, told The Grapevine Magazine, “We supply everything from shipping cartons to gift packaging and,

The Grapevine • July - August 2022 877-892-5332 Page 12 In The Winery In The Winery

of course, wine totes. The wine totes are commonly used for wine club pick-up or customer carry-out. These boxes usually display a winery’s logo, address, website, and other information.”

Packaging Considerations

There are a lot of questions that winery owners must ask themselves before committing to a particular packaging strategy. For example, there are questions about how many units are needed, how many variations you would like, how packaging can be an extension of your brand and if you can implement any innovations.

In terms of budget, wineries need to think about the upfront costs for design and products and potential future costs for breakage, additional fillers and other unforeseen needs. It may be beneficial to buy packaging products in bulk for production costs, storage and transportation handling. Also, wineries may benefit from getting professional artistic help with their packaging design if there isn’t a skilled person with extra time to commit on the staff.

Clark from Custom Wine Packaging said, “Wine packing is super important for the wines to make it from point A to point B without breakage. The totes are, in my opinion, a traveling billboard seen by many people, especially at parties and events. A lot of information can be printed directly on the totes.”

A consideration that Sinicrope from A-B-C Packaging pointed out was whether you choose to buy bottles in bulk or reshipper cases.

“Bulk bottles are less expensive per unit, but you will need a much larger initial investment with a depalletizer, case erector and partition inserter,” Sinicrope said. “With reshipper cases, one necksdown decaser or necks-up unpacker can unload and single-file your bottles. Do the math and then decide what is best for your winery.”

He also said that when looking at machines, consider how much automation you need.

The Grapevine • July - August 2022 877-892-5332 Page 13 In The Winery

In The Winery

“It can be a costly mistake to buy machinery for projected speeds or sizes that you may never utilize,” Sinicrope said. “Better to make sure the machinery you buy suits your line now and offers a reasonable degree of flexibility.”

Innovations and Advice

Both new and well-established wineries of all sizes understand how important wine packaging is for product preservation, brand awareness and positively differentiating a product. This can be accomplished with a custom logo, marketing slogan that resonates with customers or appearance that is classic, minimal or colorful. Many people choose a wine based on its packaging, so this is a great chance to show off your creativity with custom shapes, styles, themes and materials.

Lately, there has been a lot of innovation in the wine packaging industry with everything from QR codes that link to wine information to double insulation to keep the wine cool without refrigeration. Recyclable bottle designs and other types of eco-friendly packaging are trending, as well as augmented reality wine labels connected to a smartphone app for enhanced engagement. New glass shapes and textures can make your products stand out and engage the senses, such as flat wine bottles that are compact, eco-friendly, unique and very shippable. Another eco-friendly idea for wine packaging is eliminating foil seals or replacing them with seals from renewable sources. Buying shippers with high recycled content and packing in tight-pack shippers to eliminate the need for case partitions can also help a winery be more environmentally conscious.

Clark from Custom Wine Packaging said that his company developed a few solutions for shipping wine during the hot season, including cold pack shippers that have been a big hit. This product works by allowing the wine to pop the corks when it reaches a specific temperature.

“We have also come out with this year and are about to introduce our new wine sleeve shipping box that uses a sleeve instead of a pulp tray,” Clark said. “Many of the smaller wineries don’t have a

lot of storage space, and this new method will help in that area. The package is a bit smaller than the commonly used box with pulp trays, and it may be cheaper for shipping.”

Clark shared, “We also have several types of gift boxes that hold a bottle of wine and a couple of wine glasses, which make great gift ideas. There is another gift box we offer that holds a wide variety of wine glasses, cheeses and whatever else the mind can run with.”

Sinicrope from A-B-C Packaging advises wineries to define their packaging goals before talking to suppliers so that they can help you find the best solution for your winery.

“You can learn from your potential suppliers, as they live packaging machinery every day,” Sinicrope said. “They may offer important insights that can really help you when designing your line layout, specifying your machines and getting the most out of your packaging automation.”

In The Winery The Grapevine • July - August 2022 877-892-5332 Page 15

How to Clean Winery Hoses

By: Tom Payette, Winemaking Consultant

By: Tom Payette, Winemaking Consultant

In the last issue of The Grapevine Magazine this section addressed how to clean a wine tank. In reality a clean wine tank is of little benefit if the means of getting the juice or wine to that tank is a contamination source in itself. Just as much diligence needs to be applied to the wine transfer hoses to insure a wine arrives at it’s destination in as microbial free state as it left the previous storage container.

Chemistry

The chemistry of cleaning the winery hoses is very similar to cleaning the wine tanks or most anything else in the winery for that matter. One must have physical cleanliness first. In this case this means all of the solid particles are removed from a surface prior to or in conjunction with a high pH cleaner. Once dirt is removed from a surface the chemical may react on that surface to clean and kill certain

microbes that will not survive in the harsh environment of a higher pH. After physical cleanliness is achieved and the high pH cleaner has cleaned the surface, a low pH cleaner such as citric acid may be used to neutralize the high pH cleaner and to kill certain microbes that will not live in those lower pH environments. Make sure all cleaners used are suitable for the wine industry and are safe for the winery.

Items Needed

All safety material to include but not be limited to:

• Safety goggles

• Rubber gloves

• Rubber boots

• Hat and/or chemical resistant rain gear

• High pH cleaner (such as Soda Ash)

• Low pH rinser (such as Citric acid)

The Grapevine • July - August 2022 877-892-5332 Page 16 In The Winery

• Material Safety Data Sheets (MSDS or equivalent) for all chemicals used.

• Eyewash station or portable eyewash

A light citric and water solution (2 tbsp per 2 gallons of water)

Other items needed will include:

• Pump that will handle warm water and the chemicals desired.

• Wine transfer hoses that will stand up to warm water and all chemicals used.

• pH meter (optional but the winery really should have one anyway)

• Flashlight(s)

• Sponge balls at diameter(s) needed for hose inside diameter. (See photo)

• Tub for water circulation

• Water Source

Preparation

Apply all safety gear and prepare a light citric and water solution in a bucket to set aside. This is a light “lemonade strength” water that may come in useful should some of the high pH cleaner come in contact with your skin. [Roughly two tbsp. of citric in two gallons of water depending on the tap water pH] Select a good positive displacement pump from the cellar that will help power a sponge ball through the wine hoses to be cleaned. Collect all of the wine hoses you want to clean. The author prefers to do this on the crush pad just after harvest, in the spring and just prior to harvest at a minimum.

Procedure

1. Apply all safety gear necessary to be safe while doing the tasks described. This is an internal winery decision that the winery will need to address.

2. Move all equipment outside that needs to be used to clean the hoses.

3. Have the “lemonade strength” bucket of water mixture mentioned above placed close by and in a spot that can be easily located.

4. On the suction side of the pump assemble a short section of hose. This hose should be long enough to span from the tub of cleaning water to the pump.

5. Assemble the other remaining sections of hose on the pressure side of the pump from the largest internal diameter size to the smaller internal diameter size. An example may be having all the 2” sections connected, then a reducer to the 1.5 inch sections down to 1 inch and three quarters and so on.

6. Once all the connections are made, start to fill the tub with clean fresh water. Warm, not hot, may be the best water for this process. A good target temperature should be in the 90 degrees F. temperature range.

7. While the tub is filling, one may start and stop the pump to fill the lines with water. Memorize the direction of the flow since we will always run the pump in that direction for this exercise. [This is important so we do not suck the sponge balls we will using back into the head of the pump.]

8. Once the lines are full be sure to pump about 10 gallons of water out on the floor to eliminate any obvious solids that may have collected in the hoses during storage. (This is especially true if wine hose is stored curled up on the floor – not a recommended way to store winery hose).

9. Once the winery lines are completely full with water one may stop the pump.

10. Gently disconnect the discharge side of the pump from the pump head fittings and insert the proper size sponge ball to clean the smallest size internal diameter of hose assembled in this set up.

11. Reconnect the discharge side of the hose back to the pump.

In The Winery The Grapevine • July - August 2022 877-892-5332 Page 17 In The Winery

12. Turn the pump on in the direction to push the sponge ball through to the lines to be cleaned. Leave the discharge end of the hose in the tub for the time being to conserve water.

13. Follow the sponge ball visually, if possible, through the maze of hose making sure the suction line has a continuous source of water supplied.

14. Once the sponge ball reaches the specified diameter of hose it is designed/sized to clean, keep an eye on the hoses since one may see a slight pressurization and accordion type movement in the hoses at this time. Be aware fittings could be blown off under pressure.

15. As the sponge ball makes its way through the lines and the ball has about 7 feet more to go, remove the discharge line from tub of water and allow the water to exit onto the floor or crush pad. You will notice a “tea like” to “coffee like” colored water will start to exit the discharge line just before the sponge ball exits. This is true for even any well kept hoses that have not been cleaned in this fashion for over one year. It is inevitable beyond anyone’s sanitation programs.

16. Recapture the sponge ball and run the ball through again. It will still clean a bit more on the second and third pass.

17. Once one feels this section of hose has “mechanical cleanliness” one may disconnect that size diameter line from the assembly.

18. Select the proper size sponge ball to clean the next diameter size section of hose near the end of the assembly and repeat the procedure gaining mechanical cleanliness on each diameter size hose working your way up to the largest size line.

19. Once all of the lines are cleaned be sure to swap out the suction side supply line with a cleaned section and run the proper sized sponge ball through that section.

20. Now that mechanical cleanliness is achieved, one may reassemble all of the hoses and start the pump for a circulation.

21. Once the circulation is started in the clean tub of water, one may add a high pH cleaner. Always dissolve any solid cleaners in water first before adding to a tub of water. (This will take some trial and error on the operators part to establish just how much may be needed) [Use a pH meter to determine this strength needed].

22. Allow this high pH solution cleaner to circulate for an adequate time. This may be near 15 minutes depending on the length of hose line, sizes, speed of pump and the amount of water in the circulation tub.

23. Once the operator feels the hoses interiors are well exposed to this higher pH water, the operator may then flush the hoses out with copious amounts of fresh water.

24. After a fresh water rinse one should continue to circulate water and add a low pH cleaner, such as citric acid, to the mixture to insure the high pH water has been neutralized.

25. After this neutralizing step, it is best, once again, to do a fresh water rinse.

26. The hoses should now be clean, but not considered sterile, to the satisfaction of most wineries’ sanitation programs.

27. One may disconnect all the winery hoses and store them properly to drain dry. Resist rolling hoses up on the floor and laying them flat because water, moisture and insects/rodents may have a better opportunity to become an issue for them.

When selecting hoses for use at any given time, it is best to make the assembly of the hoses and to flush the hoses or clean them in some fashion just prior to pumping juice or wine. This will clean out any items from the hoses or pump that should not have been in them.

Just prior to harvest consider performing this operation on the hoses but perhaps take the step a bit further. Once the hose lines are cleaned, remove the fittings from the ends of the hoses and either clean them vigorously or cut off the portion of the hose that was in contact with the fitting. Clean the stainless fittings until they are sparkling

The Grapevine • July - August 2022 877-892-5332 Page 18 In The Winery

HAULING AWAY POMACE?

Throwing Away $ Going Down the Drain!

We

202 State Street • Lyons, NE 68038

402.307.0280 • www.nebraskascrewpress.com

Glass Apparatus for the Wine Laboratory

Acclaimed by enologists across the continent!

The RD80 Volatile Acid Still, which now is the Wine Industry standard, is an improvement on the Cash Still for determination of volatile acids in wine.

It features an aspirator pump to remove the spent sample, which speeds testing, saves water, avoids repair bills and prevents cross contamination of samples.

The R&D SO2 Apparatus uses the Aeration Oxidation Method to maximize testing accuracy. It was specifically designed for this mandated test in consultation with enologists.

Flexible spherical joints and interchangeable flasks facilitate simple operation and minimize breakage.

We manufacture a full line of wine laboratory equipment, and also provide Glassware Design Engineering, Custom Fabrication & Repair Services. CONTACT US FOR OUR CATALOG

Research & Development Glass Products & Equipment, Inc.

“Suppliers of Lab Glassware to the Wine Industry since 1967” 1808 Harmon Street • Berkley, CA 94703

Phone: 510-547-6464 • Fax: 510-547-3620

Email: RD1967@aol.com • Website: http://go.to/RandD

and then re-install the fittings and tighten the clamps properly. (Note: when putting hose clamps on have them pull and installed in opposing directions to get a better tightening grip. Also, apply the clamps as close to the end of the stainless fitting that is inside the hose line. If this is not done wine may seep between the fitting and the hose line, especially when ballooning under pressure, and forcing wine between them. Over time, spoilage will occur which will result in a cross-contamination source for every transfer or operation performed with that set of hoses in the future.

Summary

Set up your hose cleaning operation to be as easy as possible and make sure the cellar staff is keenly aware of your expectations. Hoses that are not cleaned properly should not be used and instructions to clean them again would be prudent. Remember, wine is a product that you and others will drink. Use hoses that are cleaned with the same amount of dignity that you would want your foods and other beverages prepared in.

Helpful Hints:

Mono type pumps have been known to pass the mentioned sponge balls easily provided the pumps are not smaller than the actual ball diameter used.

Be sure to keep a watchful eye on the diameter of the sponge ball and the diameter of the wine line you are trying to clean.

Do not run the pump while dry or damage may occur.

Use a pH meter to determine the pH of your cleaning solutions.

Smell your hose before you use them for a wine transfer.

Look inside your hoses before using. What do you see?

Like tanks and other items, don’t let dirt, juice or wine dry on them. Clean immediately after use (inside and out).

Always store the hoses so they will drain and dry completely. Hoses should not be curled up on the

processing experience! Consult • Design Equipment • Commissioning

have a decade of pomace

The Grapevine • July - August 2022 877-892-5332 Page 20 In The Winery

floor with potential standing moisture inside them. Being on the floor also makes them easily available to any winery critters or insects.

If one has cleaned the winery hoses and removed the fittings, the author recommends a way to test their strength. Assemble all the hoses together with a valve at the very end of the discharge side. Circulate fresh water with no chemicals for cleaning. After about 5 minutes of circulation take the discharge side of the hose from the circulation bucket and start to slowly move the valve toward the closed position for a brief moment. Be aware at this moment pressure will be building inside the transfer lines and to be clear of any hoses that may pop off their fittings. Be very careful with this procedure and use common sense knowledge not to shut the valve all the way creating extreme pressure.

Have two people around at all times for safety.

Short Course:

• Always keep the winery hoses clean.

• Use a sponge ball to create mechanical cleanliness.

• Visually inspect and smell all hoses after cleaning and before using for wine transfers.

• Obtain and use all safety gear needed.

References: Verbal conversations with Jacques Boissenot, Jacques Recht, Joachim Hollerith and Chris Johnson.

The Grapevine • July - August 2022 877-892-5332 Page 21

www.winemakingconsultant.com Over 25 Years Experience Phone: 540-672-0387 Winemaking Consultant Thomas J. Payette “Winemaker of the Year” Tom Payette, a premier hands on and analytical winemaking consultant, serves clients throughout the United States. From the construction of your business to the cork in your bottle to your consumers. Call Thomas or check his website for more information... In The Winery

Diving into Winery Water Usage and Treatment

By: Becky Garrison

In recent years, Pacific Northwest-based wineries have faced unprecedented water issues as regional droughts continue to deepen and regulations have become stricter in an effort to limit surface and groundwater contamination and promote more sustainable practices. During the Oregon Wine Symposium, held virtually from February 15 to 17, 2022, a session titled Diving Deep Into Winery Water Usage & Treatment offered a summary of this current situation pertaining to water use and how wineries can manage their water use and treat wastewater.

Panel moderator Emily Terrell, associate winemaker for Brittan Vineyards (McMinnville, OR), opened the session with a brief summary of the current state of water use in the Pacific Northwest. A typ-

ical winery on the West Coast uses between three to 10 gallons of water per gallon of wine produced.

Regulations regarding water may increase due to municipal handling limits and local standards for discharge. Also, over the past few years, Washington State and California both developed new general permits. These are tiered winery permitting systems, with fees, monitoring, inspection and at least quarterly analysis of water discharged from the winery.

These standards help protect groundwater and surface water based on discharge methods and the specifics of the location. Such standards are necessary as improperly treated wastewater can lead to a host of complications, including:

The Grapevine • July - August 2022 877-892-5332 Page 22

In The Winery

• Damage to soil and crops

• Kill aquatic life.

• Contaminate surface water and groundwater.

• Degrade infrastructure in municipal treatment plants.

• Overwhelm municipal treatment systems.

In a general sense, the easiest solution to improve winery water use is to use less water. By tracking water use, wineries can see where and how they are using process water, which can help identify ways to become more efficient. Sometimes this is a simple fix, such as adding water-saving spray guns, reducing wine hose diameter or fixing leaky hose manifolds. Reconsidering the way wine lees (the solids remaining after fermentation) are collected and disposed of can also dramatically decrease the volume and energy intensity of the wastewater, including taking advantage of a collection service available in some areas (not Oregon, unfortunately).

Finally, once the wastewater is generated, how can the energy load be lightened downstream? This comes down to neutralizing pH, removing the solids and perhaps adding a digestion step to fur-

ther deplete the nutrients before discharging into a controlled environment or municipal system. As droughts intensify, some wineries install reclamation systems to treat, digest, filter and reuse all or a portion of their process water.

Treating Wastewater In the Winery

In his presentation, John Haslett, wastewater manager for 12th & Maple Wine Company (Dundee, OR), offered an overview of their winery wastewater treatment process, including the chemicals, equipment and tests involved in this process, which discharges into a small municipal system with strict requirements. The primary wastewater chemicals that he uses are magnesium hydroxide to neutralize the pH and polymer to bind and remove the majority of the solids prior to digestion.

At 12th and Maple Wine Company, they start by mixing and prepping their wastewater in a mixing tank. By running the wastewater through a side screen into their batch tank, they remove all of the large particles and treat it with magnesium hydroxide to neutralize the pH. Then, the water pumps through their Cavitation Air Flotation (CAF)

In The Winery The Grapevine • July - August 2022 877-892-5332 Page 23

device. The CAF is a long trough with a propellor that makes micro-bubbles, which float all the solids to the top after the polymer sticks them together. Next, the paddles scrape the solids off the top and remove them from the system into a solid waste/ compost stream. Flotation removes 90 percent of the BOD, helping the bio system’s ability to digest by reducing process load and filtering solids leaving only dissolved solids for digestion. After that, the clarified water moves to their digestion system for a further reduction in Biological Oxygen Demand (BOD), or the amount of oxygen consumed by bacteria and other microorganisms during digestion under aerobic conditions in a defined period of time. By reducing this energy demand, the winery dramatically reduces the burden on the municipal treatment system downstream and increases the total volume of water it can discharge to the system.

To keep up with the digestion demands of the wastewater stream, Haslett sometimes needs to add bacteria to the system due to changes in the microbe population due to upsets, such as adding or removing nutrients or a rapidly changing pH environment. Among the sources he uses to obtain bacteria are Clearblu and Aquafix. In his presentation, he quoted a statement from Clearblu regarding the types of recommended bacteria used in treating wastewater.

Almost all commercially available bacteria blends only contain Bacillus strains. While Bacillus is an excellent treatment bacteria, it is best suited for treating fats, oils, grasses, and proteins. This is why they are primarily used in wastewater treatment plants. Brewery, winery and food processing waste contains sugars and carbohydrates in very high concentrations. This makes their waste vastly different from sewage treatment plants. The best bacteria for breaking down sugars and carbohydrates are Pseudomonas. Pseudomonas will digest these very effectively and reduce BOD levels far more rapidly.

Historically, Haslett’s digestion system has consisted of a series of aerated holding tanks that the wastewater slowly passes through while undergoing microbial digestion. Recently, he trialed a new system called the BioGill, which consists of a space-efficient square tower filled with a ceramic matrix that pulls oxygen in passively and provides a stable environment for the culture to occupy while the wastewater slowly passes through. These units

have been very successful in improving culture health and digestion time. Haslett cited the example of a pH upset, where the BioGills recovered in three days, whereas the old system would have taken approximately three weeks. They have plans to acquire additional BioGill units but are already taking advantage of the BioGill’s ability to seed the culture of the downstream holding tanks, providing for better overall health and an increased capacity for BOD reduction.

Each week, Haslett tests the wastewater using several different tests. After getting the BOD numbers, he converts them into pounds of BOD and pounds of TSS (Total Suspended Solids) and then report this number when required by city and local governmental entities. Haslett’s optimization of the CAF, BioGill and digestion system continue to reduce these numbers, easing the burden on the city and making some water reclamation a not-toodistant goal of the winery.

For smaller wineries with limited financial resources, Haslett stresses that the first priority is to adjust the pH. At the very least, get a small tank to use for holding, adjustment and mixing. A further investment would be a simple screen filter to remove the larger solids before dumping the effluent. He also emphasized that the BioGill is an accessible, low-power technology for smaller wineries looking to reclaim or further reduce their impact on downstream processing resources.

Reducing Processed Water

Bob Coleman, technical winemaker for Treasury

Wine Estates (Saint Helena, CA), delved into ways to reduce processed water in the winery. He proposed using in-place or in-line wine treatments to minimize the number of tank movements and, therefore, cleaning and water consumption. This avoids the need for more energy-intensive, solids-removal procedures, such as cold setting, decanters and centrifugation that require tank-totank transfers.

To remove solids, this winery is exploring the use of a Jameson Cell. This is a high-intensity froth flotation cell invented for use by the coal industry. While a Jameson Cell can handle wine wastewater, Coleman sees how it can also benefit in reducing water use during wine production. Coleman envisions feeding wine juice in this small set of cells. Air

The Grapevine • July - August 2022 877-892-5332 Page 24

In The Winery

or nitrogen gets entrained in this stream that’s in this downcomer, as they call it. Gas bubbles attach to the solid particles floating them to the top and allows removal as a solid waste stream. The clean juice then goes to the tank and gets inoculated right away.

Also, Coleman references developing protein absorption columns designed for in-place protein removal. These columns have absorption material that will take out heat-unstable proteins. Then, wash out the proteins and reuse the column repeatedly. This process stabilizes the wine and eliminates the need for bentonite – and elimination of bentonite in our waste stream

In addition, Coleman introduced a more efficient cold stabilization process (fluidized bed cold stabilization), a joint project with Professors Roger Boulton and Ron Runnebaum at UC Davis. This in-place cold stabilization process minimizes wine loss and refrigeration needs by using a small, dedicated chiller and counter-current heat exchanger. This avoids lowering the temperature on the main winery refrigeration loop, saving both energy and water. The potassium bitartrate crystals generated in the stabilization process can be reused to form a circular process.

Coleman recommends electropolishing the tanks or purchasing them already electropolished. This keeps solids from attaching to the tank’s surface, thus reducing the water and chemistry to remove bitartrate, grape residue and biofilm stuck to the side of the tanks.

In California, wineries can take advantage of a lees removal service. This involves squeegeeing the lees out of the tanks and putting them into totes, which a service takes away. They can recover bulk wine from it and then send the solids to compost.

Coleman recommends potassium hydroxide over the cheaper sodium hydroxide for the basic wash and potassium bisulfate for the acid wash when assessing cleaning chemicals they use. After use, he suggests running both of these through a nanofilter or semipermeable filter that allows the ions, chemistry and water to pass through while leaving the dirty residue separated. It is possible to reuse the chemistry and water multiple times. After cleaning the tanks, putting these two washes together results in a pH appropriate for wastewater ponds

and does not increase BOD or COD.

Hydrogen peroxide at 0.5 percent can be used as a sanitizer, and this is lower than the three percent hydrogen peroxide available at the supermarket. What hydrogen peroxide isn’t used during sanitization will break down into water and oxygen. An onsite hydrogen peroxide generator can produce the amount of sanitizer needed, thus avoiding safety issues when transporting and handling higher concentrations of this chemical.

The smart controls used on the six wastewater ponds allows for data collection. In particular, Coleman highlighted the need to clean the DO (dissolved oxygen) probes so that they can provide accurate feedback. After some exploration, they found cleaning heads that use compressed air to routinely in-place clean the probes. These DO probes trigger aerators when the oxygen drops below a designated threshold. This process control saves energy and increases the health of the ponds.

The Grapevine • July - August 2022 877-892-5332 Page 25

In The Winery

The 7 Best Ways Wineries Can Grow Their Text Marketing Lists

By: Bryan St. Amant, Founder & CEO of VinterActive

S

ilicon Valley Bank’s latest research on wine marketing shows that fewer than 9% of U.S. wineries took advantage of text messaging in 2021. But those who did report phenomenal success with open rates of 98% and click-thru rates of 12% – generating 32-times more customer engagement than email marketing.

So savvy wine marketers are now asking the same question: How can we grow our text marketing lists as quickly as possible?

The good news is today’s wine consumers – even Baby Boomers – want you to text them. According to PC Magazine, “85% of smartphone users prefer mobile messages to emails or calls.”

The great news is the seven customer touchpoints outlined in this article offer ample opportunity to grow your SMS wine marketing list quickly, so you can delight your customers and sell more wine.

Email Marketing

Since 80% of U.S. wineries already use email marketing, the fastest way for most wine merchants to grow a text marketing list is to reach out to existing email subscribers and offer them a new way to stay in touch.

To convert existing contacts, we recommend introducing text messaging to current customers the same way you’d release a new wine or announce an upcoming wine country event.

Most wine marketers will enjoy the best success with a series of three email messages:

• A straightforward announcement of what you’re offering and why.

• A follow-up email that focuses on what customers miss by not signing up.

• A final email about how your SMS program addresses their main concerns.

If you have a thriving wine club, start with them first and consider offering club members an incen-

tive for joining your SMS list. And as you write your email, it’s worth reflecting on what it means to ask anyone to sign-up for text messages.

Here’s a hint: they’ll be giving you access to the most direct and personal way to reach them. So, successful sign-up campaigns offer unique value to new subscribers in return.

The latest research shows that SMS subscribers want first dibs on flash sales or promotions. With that in mind, you might offer early access to new releases, special discounts, and tickets to upcoming events.

Once you hone your pitch, the wineries we work with enjoy the most success by pointing their email subscribers to a web-based opt-in form. Many text marketing platforms now make it easy to create an opt-in form you can add to any website.

Tasting Rooms & Events

After mining your existing email list, now’s the time to invite your in-person guests to stay in touch

The Grapevine • July - August 2022 877-892-5332 Page 26 Around The Vineyard Marketing

with text messaging.

In tasting rooms or at winery events, QR codes make it easy for consumers to join text marketing lists using their mobile phones. In just a few minutes, you can make it happen by printing tasteful signs that feature a QR code, legal disclaimers, and simple instructions on how and why winery visitors can join your list.

Instead of pushing your tasting room staff to ask customers for their email address – then deciphering hand-written forms – using QR codes to market your SMS list makes it easier for everyone. As a bonus, once your customers sign-up for text messaging, many SMS marketing systems can also automate the process of asking for an email address.

Social Media Channels

DTC wineries report social media is now their most widely used marketing channel. So enticing online followers to join your text messaging list — using the same offers you promote in your tasting room — is one of the most concrete ways to leverage your investment in social media.

Digital wine marketers can use unique text marketing keywords like “Text INSTA to 888-592-2832 to join our text club,” QR codes, or web-based signup forms to invite your followers to join your SMS list.

Since it’s so easy to test marketing ideas using social media, the best practice is to experiment with multiple conversion techniques to see what resonates best with your followers. For the most impact, you might consider creating unique offers explicitly customized for your most vibrant social media communities.

Transactional Messages

If you sell wine online, accept reservations, or manage a wine club, your commerce system already sends order confirmations, appointment reminders, and shipping notices via email.

These transactional messages offer another proven way to grow your text marketing lists. Imagine offering your wine club members the option of receiving a text confirmation when their next shipment is on its way. A keyword like ORDERSTATUS is tailor-made for this application.

The footer of your online order confirmation page is also a perfect place to promote the option of

receiving transactional messages via text. Here’s an example: “PS: Text ORDERSTATUS to 888-592-2832 to receive updates about your wine order via text. No spam, just news you can use.”

Not only do today’s consumers prefer text messaging 2-to-1 over email, transactional messages about orders, shipments, and appointments are among the most popular text messages consumers receive.

Mobile Website

Website visitors using their phones to browse your site are the perfect fit for text marketing offers. Not only are they on their phones already, but they don’t even need to enter any data to subscribe to your text messaging lists.

Without any special software, you can generate a QR code that website visitors can scan to join your list in just one click. Some text messaging platforms popular with wine marketers also offer the ability to generate online pop-ups visible only to visitors using their mobile phones.

Today’s wine marketers can add “click-to-text” buttons or custom mobile pop-ups to any web page. Perfect for building a list of text marketing subscribers, these same tools can engage your customers by enabling two-way text conversations with your hospitality staff.

Desktop Website

If your winery website offers online visitors the opportunity to join an email list, doesn’t it make even more sense to give them a chance to subscribe to text messaging?

(Continued on Page 30)

The Grapevine • July - August 2022 877-892-5332 Page 27

Around The Vineyard Marketing

(Continued From Page 27)

For visitors browsing your website from their desktop computers, web-based sign-up forms are the way to go. Simple text marketing sign-up forms only require a mobile phone number plus consent with the terms of your offer.

But if you offer consumers a choice of text messaging content — from concierge services to weekly tasting room updates — a Text Messaging Preference Center can give your customers the ability to curate their own unique customer journey.

Product Packaging

Your wine labels and the shipments you send to wine consumers can also work to grow your list of SMS wine marketing subscribers.

QR codes printed on your labels can invite consumers to engage your brand at the point of purchase and consumption. For maximum flexibility, use a dedicated landing page that can be re-directed as needed over time.

Wine shipments to consumers offer the perfect opportunity to market lifestyle content like recipes

delivered by text messaging or encourage customers to post their photos and wine reviews via text.

Make Hay While the Sun Shines

With today’s wine consumers thirsty for brands that engage them with text messaging, summer is the perfect time to get started with SMS wine marketing.

If you can print a QR code or send an email message inviting your best customers to join your text marketing list, you’ll soon be on your way to success. With the proven power of SMS wine marketing on your side, even a modest list of 300 contacts can generate the same results as another 10,000 email subscribers.

Summer sales are just the beginning. Once the holiday season arrives, your new text marketing list can drive record sales while delighting your customers with an easy way to order your wines using their favorite way to stay in touch.

We hope the simple methods outlined in this article can help you achieve your goals. Happy Selling!

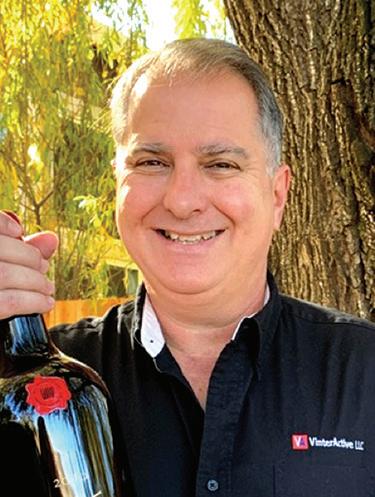

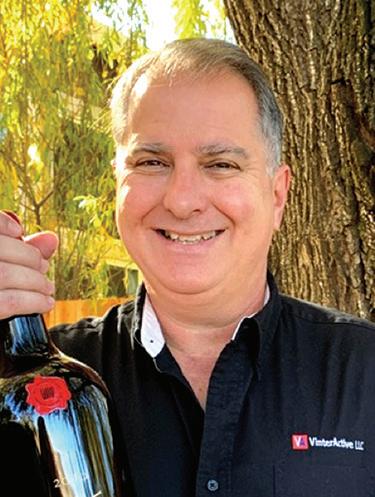

ABOUT THE AUTHOR

Founder & CEO of VinterActive, Bryan St. Amant, is a pioneer in developing preference-based direct marketing and its successful application in the wine industry. His advice has helped hundreds of wineries across the U.S. grow sales and customer satisfaction by leveraging the best practices of DTC wine marketing.

St. Amant holds an MS from M.I.T. and a BS from U.C. Berkeley. His award-winning work has been featured in books, magazines, and seminars, including CFO Magazine, Inc., CNN Money, eMarketing Magazine, Integrated Direct Marketing, Direct Marketing Association, Wine Marketing Report, and the Wine Industry Network.

VinterActive is located in Windsor, California at 707-836-7295 or vinteractive.com

The Grapevine • July - August 2022 877-892-5332 Page 30 Around The Vineyard Marketing

PLEASE LIKE ME

How to Successfully Navigate Customer Reviews

By: Susan DeMatei, Founder of WineGlass Marketing

In the September/October issue of The Grapevine Magazine, I wrote an article entitled “The four reasons you should care about online reviews.” As a quick recap, the four reasons were:

1. We are at the precipice of a cultural shift from Baby Boomer values (externally showing luxury as validation, including professional and published reviews and scores) to Millennial values (internal and self-validation, including being part of a community that shares your beliefs).

2. The internet and modern eCommerce train us to look for the most popular brands and rank the highest among people (we assume) are peers.

3. Google evaluates reviews when delivering search engine responses and ranking.

4. Your customers care about review sites.

• 92% to 97% of customers look for or read a review before doing business with a company.

• 80% of us trust reviews by strangers just as highly as a reference from our friends.

• 72% of us look for only positive reviews, and 86% will not do business with those with negative reviews. (Clutch.co)

For many, this advice proves sound and agree that internet reviews are essential. Maybe you’ve even begun identifying where your target audience congregates and shares thoughts online. But knowing something in principle and achieving that goal are two different things. Your next step is to encourage and collect reviews, which is the topic of this follow-up article.

Asking In Person

The most obvious way to accumulate reviews of your wine and service is to ask a customer when you’re with them at the time of the sale. This is also the most effective way, as the experience is still fresh in the customers’ minds, and you have a captive audience for a couple of minutes. But this is also the most uncomfortable for some. So, before you start squirming in your chair, here are some suggestions for making this awkward interaction more natural.

Build It Into The Banter

The most skilled wine educators weave the request naturally into the conversation. The trick is to have several routine lead-in questions where the response will naturally lead to a review suggestion.

For instance:

• “Did you enjoy your visit?”

• “Do you want to take any wines home with you”?

• “When are you guys heading back home from vacation?”

The expected responses will comfortably lead to:

• “Since you enjoyed yourselves, we welcome you to share your feedback so others can enjoy us.”

•“ Thank you for the purchase! We’re glad you liked the wine. We’d be excited if you’d share your feelings about it to encourage others to try it.”

• “We love having visitors from out of town. Since you’re heading back tomorrow, please consider leaving notes on your experience, so others find us on their vacations.”

It’s best to have this dialog after the entire experience is done, with the bill and tip paid. You want to clarify that any review is not affecting their service, charges, or product quality. And, when you have this interaction, choose words that don’t seem pushy. “Invite you to leave feedback” sounds better than “Can you give us a review.” Finally, don’t hesitate to say why you want a review. “Hey, thanks a lot, we’re trying to get going again after COVID, and good news travels fast.”

Remember that even if you feel uncomfortable, most of the people you ask will be flattered that you’re asking them for feedback, not annoyed that you’re fishing for compliments.

Remove All Obstacles For An Immediate Response

Continuing our roll playing from above, if the customer above says “yes,” you want to be able to actualize that direct call to action. Have the tools ready immediately and seamlessly to review your

The Grapevine • July - August 2022 877-892-5332 Page 31 Around The Vineyard Marketing

location right then and there. Luckily, almost all customers walk into our tasting rooms with tiny computers in their pockets, so offering WiFi for their phones is all that is needed. With a QR code on a napkin, coaster, receipt, or table tent, they could be on your profile on Yelp or Google in less than 15 seconds. If you are remote and WiFi is a challenge, see if you can offer an iPad on your network.

Then thank them. The good news is that when asked, research says ¾ of us will leave a review. So, you’ll be surprised at your success.

Remote Options

If your natural state is being socially distant, so in-person requests just are not your thing, there are still ways you can request reviews. Online you will find many websites selling window clings or table tents to make the subtle request not-so-subtly. If you want these in your tasting room, get some tear-off pads so that you can provide the information in the bag with their purchase. And don’t forget that when you’re working on your email, phone, and text campaigns, you can also include a request for review. No, you won’t annoy your customers. Asking for feedback is standard practice in many industries.

If you ask for after-the-fact reviews, offer a small token of appreciation, such as a tasting voucher, coupon, or discount. Communicate that you will reward satisfied buyers for the time they invest in providing feedback about their experience.

A word of caution: this is a slippery slope. Ideally, you want to earn reviews without offering rewards. Websites like Yelp filter out reviews provided because of incentives, and Google also uses analytics to monitor review traffic.

Also, educate your employees and team leaders on how to ask for reviews effectively as well as excellent customer experience. Be willing to reward your employees for every posted review that they initiate.

How To Maximize Their Impact

Now that you have these great reviews use them. The objective is 1) to position positive reviews so that your audience learns from satisfied customers and 2) to encourage additional reviews. First, incorporate them into your website’s design. Consider one of the many review widgets or direct feedback options on your website’s home page. Emails,

brochures, or newsletters can include individual reviews. On social media, sprinkle them in posts. Please don’t overdo it, and vary the channel and locations as you never know when a satisfied customer’s comment might be why someone else visits or tries your wine.

Haters Gonna Hate

So, what about the not-so-great reviews? Finding a negative review about your company, product, or team out there for the world to see can challenge your faith and motivation. You and your team have spent years creating experiences and products to entertain and please customers, so a negative response can feel like a personal attack.

At these times, try and separate your business practicality from the sting to your ego and remember that there are many reasons why you may get a negative review. You will receive bad reviews from customers visiting with unrealistic expectations who either haven’t researched what is possible at your tasting room or have inaccurate information from a 3rd party. They may be ignorant of the legalities around wine service and sales, new to your wine flavor profile, or just having a bad day.

It is crucial to set internal expectations that a certain percentage of bad reviews will just transpire as an expression of the core values of our culture. The US is about freedom, and the internet has empowered everyone to have a voice. Some people just like pointing out other people’s flaws because it makes them feel better. The unfortunate reality of running a business is that you simply can’t please everyone. Some of your customers are just negative people, and there’s not much you can do about that.

The real downside comes with how their negative reviews can harm your business. Only 13% of customers will do business with a company with only 1 or 2 stars, and small businesses with a 1-1.5 rating out of five generate 33% of the revenue than businesses averaging 2+ stars. (Trustpulse)

Embrace The Noise

But, in most cases, there is value in listening. We can be so close to our own winery experience that we fail to see or acknowledge areas for improvement. A negative review can be an excellent way to prioritize issues and enhancements that bother your customers and hinder your success when looked at without emotion. Pre-internet companies spent months and thousands of dollars on focus

The Grapevine • July - August 2022 877-892-5332 Page 32

Around The Vineyard Marketing

groups to secretly watch customers behind glass, hoping to learn what worked or did not resonate for a target audience. How amazing is it that now we have an immediate and actionable free feedback loop?

Surprisingly, getting negative reviews isn’t always a bad thing. Research tells us that a couple of negative reviews can make a brand seem authentic. Bad reviews give customers a sense of the worstcase scenario, and they want to know what can go wrong to understand how much it will matter to them. The occasional lousy review eliminates any “too good to be true” doubts. When every online review about your brand is a gushingly over-the-top 5-star rating, it can appear fake.

So, when we see the good, we tend to celebrate it by sharing it with our team. Meanwhile, we ignore, forget, or attack poor feedback. Smart companies make the most out of their online reviews by addressing issues with a response to the customer. And consumer expectations are high:

• 53% of customers expect that reviews will be responded to within 1 hour.

• 57% of customers believe brands should respond to reviews on the weekend.

• 63% of customers say that businesses have never responded to their reviews. (Trustpulse)

How to Respond to a Negative Review

Here are some guidelines on how to respond to negative reviews.

• First – take a breath and remember that people are human and flawed, and things happen on both sides. Don’t take it personally and acknowledge that everyone gets negative reviews.

• Make them feel like they’re getting management’s attention. Respond as the business owner, even if you’re not.

• Be consistent and timely. Always respond, even if you’re super busy.

• The goal is to open the lines of communication and let the user know you are listening to them. They aren’t just another metric in your dashboard. Treat them like real human beings. Make your response authentic and personal, as if you were talking with a grumpy friend.

• If it’s a complicated issue, offer to take the case offline by offering to move the conversation to a private chat.

• If you are at fault, do what you say you’ll do to fix it. Take immediate action once you’ve told the visitor how you’ll improve their problem.

• And don’t be shy in asking them to change their rating, or at the very least update their comment that you responded to and tried to make right. And who knows? Maybe that negative review will lead to a killer testimonial that drives even more traffic.

Online reviews are here to stay and can positively or negatively impact your business. The result depends on how well you hand the reviews themselves.

Remember, even a negative review can positively affect your revenue! The goal of addressing and improving your online reviews is to harness the power of social proof. By showing that many other customers loved your winery enough to be vocal about it, you’ll be more likely to get even more business in the future.

Susan DeMatei is the founder of WineGlass Marketing, a full-service direct marketing firm working within the wine industry in Napa, California. Now in its 10th year, the agency offers domestic and international clients assistance with strategy and execution.

WineGlass Marketing is located in Napa, California at 707-927-3334 or wineglassmarketing.com

The Grapevine • July - August 2022 877-892-5332 Page 33 Around The Vineyard Marketing

When is the Correct Time to File for a Claim?

By: Trevor Troyer,

Vice President

Agricultural Risk Management, LLC

When should I file for a claim? That’s a question I get a lot. Some growers think that they should wait until they know that they have a loss. They want to harvest to see if they have a loss. That is not the correct answer to me. You should turn in a claim as soon as there is a weather event or other cause of loss situation. This helps to document what is happening during your growing season as it unfolds.

This spring in California there was a late frost/ freeze event for several nights. Primary buds in many counties were killed. Some areas like Sonoma and Napa Counties had mild to moderate damage. Other counties in California had much worse damage. Oregon also had a lot of areas that were damaged. Some areas were quite severe with all the primaries frozen.

Obviously if the buds were all frozen you should contact your crop insurance agent and have him open a claim up. But what about damage you are not sure about? You know that you will still make a crop but are not sure if it will reduce your tonnage

by any large amount. Depending on your coverage level you may think that you won’t have a loss. At this point don’t worry about the deductible percentage of your crop insurance policy. Call your crop insurance agent and open up a claim.

It is always better to have a claim open than not in this type of situation. There’s no way at this point in the season to determine how much your yield will be down. But if the claim is open and documented its better. This gives time to have an adjuster assigned, time to do an inspection and to document the damage. Damage done may not be as visible several months later. Damage can very well be cumulative as well. During the year you may have several weather events and other things that could reduce your yield.

Here’s what it says in the Basic Provisions of the Common Crop Insurance Policy:

14. Duties in the Event of Damage, Loss, Abandonment, Destruction, or Alternative Use of Crop or Acreage

Around The Vineyard The Grapevine • July - August 2022 877-892-5332 Page 33

(a) In the case of damage or loss of production or revenue to any insured crop, you must protect the crop from further damage by providing sufficient care.

(b) You must provide a notice of loss in accordance with this section. Notice provisions:

(1) For a planted crop, when there is damage or loss of production, you must give us notice, by unit, within 72 hours of your initial discovery of damage or loss of production (but not later than 15 days after the end of the insurance period, even if you have not harvested the crop).

Per the USDA Risk Management Agency you have from 72 hours of the original cause of loss or until you discovery it and up to 15 days after the end of insurance. I do not recommend waiting till 15 days after the insurance period. It does happen though and I am sure I will have growers do it again. I have had vineyard owners call me and say that their tons are down for a certain variety. Then we have to piece together what happened. What was the cause of loss? When was it? Was this the only thing or were there other weather events? Is the loss only showing up only on one variety?

Losses will get paid but it is much easier on everyone if you report causes of loss right after they occur. That doesn’t mean you have to know for sure that you will have a loss, just that some event happened that may cause your crop to be reduced. Here are the Causes of Loss out of the Grape Crop Provisions from the USDA RMA:

10. Causes of Loss.

(a) In accordance with the provisions of section 12 of the Basic Provisions, insurance is provided only against the following causes of loss that occurduring the insurance period:

(1) Adverse weather conditions;

(2) Fire, unless weeds and other forms of undergrowth have not been controlled or pruning debris has not been removed from the vineyard;

(3) Insects, except as excluded in 10(b)(1), but not damage due to insufficient or improper

application of pest control measures;

(4) Plant disease, but not damage due to insufficient or improper application of disease control measures;

(5) Wildlife;

(6) Earthquake;

(7) Volcanic eruption; or

(8) Failure of irrigation water supply, if caused by an insured peril that occurs during the insurance period.

(b) In addition to the causes of loss excluded in section 12 (Causes of Loss) of the Basic Provisions, we will not insure against damage or loss of production due to:

(1) Phylloxera, regardless of cause; or

(2) Inability to market the grapes for any reason other than actual physical damage from an insurable cause specified in this section. For example, we will not pay you an indemnity if you are unable to market due to quarantine, boycott, or refusal of any person to accept production.

Number 1 on the list is Adverse weather conditions. This could be just about anything, frost, freeze, drought, excess moisture, hail etc. Fire is listed as well and because of this there can be damage many miles away from the fire due to smoke. Insect and disease damage are covered but you must show that you have application records for spraying etc. Wildlife is another one that can cause problems – deer, raccoons, birds and so on. I have even had a claim turned in for a bear. Earthquake and Volcanic Eruption I have never seen a claim turned in for. I am sure, unfortunately, that there will be one for an earthquake. Number 8, Failure of irrigation water supply, is something that can be a big problem for growers. Certain areas in California and Washington State rely heavily on irrigation. If there is a drought and your well or reservoir dries up then that is a payable cause of loss.

Don’t wait to contact your agent about a situation or adverse weather that may reduce your crop. That is what we are here for! For more information please contact Agricultural Risk Management LLC Office: (239) 789-4743

Email: info@agriskmgmt.com

Website: www.agriskmgmt.com

Around

Vineyard

The

Your Duties -

The Grapevine • July - August 2022 877-892-5332 Page 35

The Canadian Certification Program Application of Tissue Culture at the Nursery

By: Judit Monis, Ph.D.