MASTER TRAINING COURSE

For Line Operators

A short introduction on Why the Ice Cream ?

You will get Basic knowledge of main components of Ice Cream Structure and their key functionalities

MASTER TRAINING FOR OPERATORS

LEARNING OBJECTIVES

You will learn about the mix preparation flow (equipment functions, flow parameters, heat exchange process) and know the key parameters that should be under control

You will learn more about the main components of the freezer and their respective functions You will understand how much the Freezing process is linked to Ice Cream Structure

One practical session around the different parts of a Freezer, to learn the good practices on dismantling a dasher and a beater

3 Introduction Ice Cream Structure Mix Preparation Freezing Practical Session

Why the Ice Cream?

Ice cream is the only food you eat frozen!

✓ Ice cream makes you happy !

✓ Most european consumers say that ice cream is fun to eat (71 %)

✓ Two out of three people think that ice cream is great for socializing (63 %)

✓ The consumer associates ice cream with pure enjoyment

Ice Cream is made of

Components:

50% AIR (in volume)

Water

(55% to 65%)

Fat (8% to 16%)

100 % WEIGHT

Components

MSNF = Milk Solid Non Fat (9% to 12%)

Sugars/Sweeteners (12% to 18%)

Stabilizers

Emulsifiers (0,2 to 0,5%)

Flavors/Colors (others...)

? ? ? 6

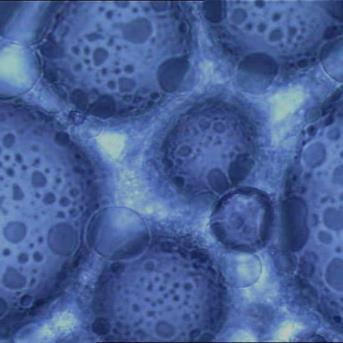

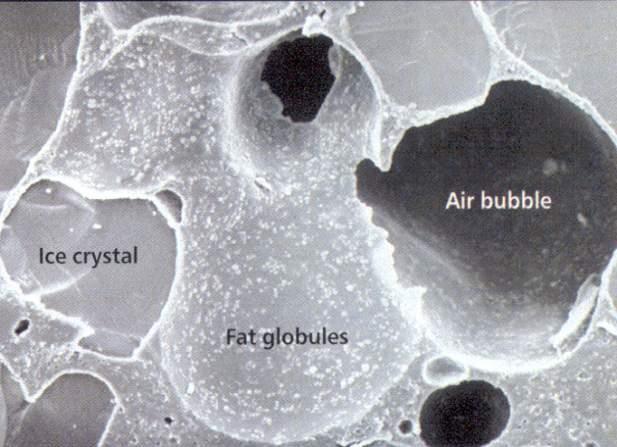

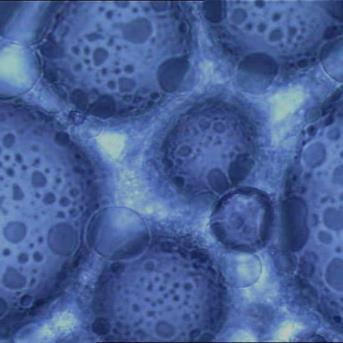

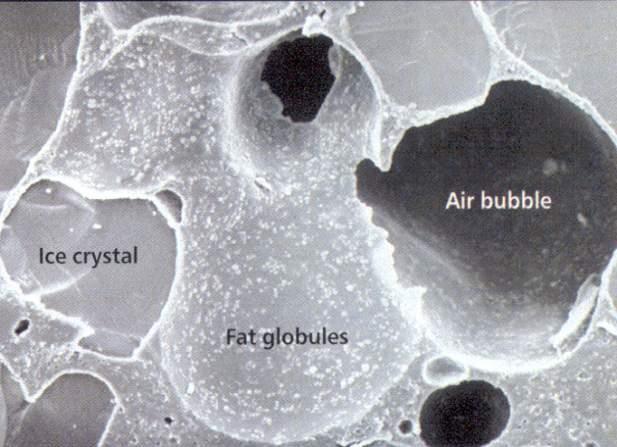

cream… the phases of matter: What is Ice Cream ? A i r Air Bubble (inside) Unfrozen Phase MATRIX A i r B ubble Air Bubble coated by fat 20 µm Ice Crystal Ice Crystal LIQUID phase SOLID phase GAZEOUS phase Optic microscopy Microscopy electronic

Ice

Link between Ice Cream TEXTURE and its STRUCTURE

Ice cream texture is linked to its microstructure

Classify the 5 following products by increasing hardness : 1 2 3 4 Softness Hardness 5

Link between Mix formulation and Ice Cream STRUCTURE

Let's see an Example of composition of different Frozen Desserts …

MSNF 10% FAT 12% SUGAR 16% WATER 56% MSNF FAT 8% SUGAR 16% WATER 61% 14% SUGAR 18% WATER 68%

More Fat Less Water No Fat SUGAR 18% WATER 73% OTHER INGREDIENTS WATER ICE SORBET ICE CREAM PREMIUM IC OTHER INGREDIENTS OTHER INGREDIENTS OTHER INGREDIENTS

More Air No Air

Ice Cream Making = mix [ making & ageing ]+ freezing

- Water - Fat - MNSF (proteins)

- Sugar & Carbohydrates

- Emulsifiers - Stabilizers

- Flavours, Colours

- Customizing ingredients

10% Fat 90% Sugar solution

50% Air 22% Ice crystals

5 % Fat 23% Unfrozen phase

TEXTURE & TASTE

INGREDIENT FORMULATION MIXING HOMOGENIZATION PASTO-COOLING AGEING FREEZING FILLING HARDENING COLD STORE

FATS

1. Structural role

Stabilization of air cell structure

✓ Increase whipping ability

✓ Improve melting resistance

2. Sensory role

Creaminess, Smooth texture

✓ Enhance desired taste

Types

Dairy fats (Animal)

✓ Cream, whole milk

✓ Butter oil (AMF), butter

✓ Whole powder milk

Vegetable fats

✓ Coconut oil (RCO)

✓ Palm oil

10

Milk Solid Non Fat (MSNF) - Proteins source

1. Structural role

Body & Texture

✓ Stabilize air/oil/water interface

2. Sensory role

Smooth texture

✓ Give chewiness

Types

Milk (liquid or dehydrated) Solids of skim milk

✓ Proteins (35 %) (caseins, whey proteins)

✓ Lactose (50 %)

✓ Minerals

✓ Vitamins

SUGAR and CARBOHYDRATES

1. Structural role

Bulking agent (total solids)

✓ Main part of unfrozen phase (matrix)

Bind water

2. Sensory role

Sweetness (Relative Sweetness)

✓ Increase flavour perception

✓ Decrease stiffness (scoopability) of ice cream

Types

Solid or liquid form: Common sugar (sucrose) from beet or cane

Glucose syrups

Invert sugars ( hydrolysis of sucrose)

Dextrose, Fructose

Lactose

12

Freezing Point (FP)

Key parameter for AMOUNT OF ICE

Freezing -point is the temperature point at which a liquid solution starts to freeze.

More solute = lower freezing point = freezing later

Examples adding salt in water or alcohol in water

The result of the solution has a lower freezing point than the pure solvent or solid This is why the sea water (a mixture of salt in water) doesn’t freeze; it remains liquid at temperatures below 0 ° C (32 °F), the freezing point of pure water

14

Effect of salt on the road

Solid (frozen) water Liquid water solution

Effect examples of SUGARS on Ice Cream TEXTURE

+ SMOOTH

+ SCOOPABLE

+ CREAMY

15

↑

Point ↓

Bind water

Freezing

Relative Sweetness (RS)

Sugars are sweet … but not all sugars are equally sweet

Relative Sweetness definition: Sucrose is taken as reference and the “Relative Sweetness ” of each sugar is given in comparison to sucrose in given conditions.

16

Relative Sweetness (RS) Freezing Point Dextrose + ++ Fructose +++ ++ Sucrose ++ + Maltose + + Lactose + +

Effect significant or more significant than other carbohydrates

+

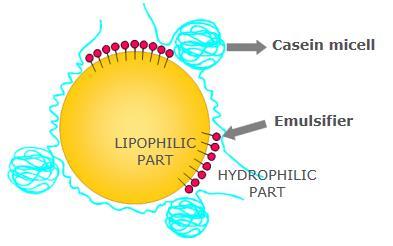

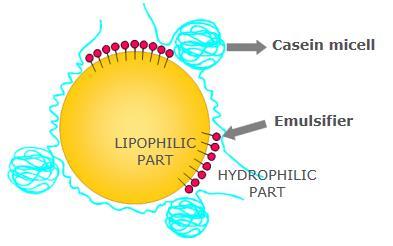

EMULSIFIERS

Structural role

✓ Produce Stable emulsion of 2 liquids that do not mix naturally,

✓ Promote Partial clustering of fat globules, during the process

Oil / Water

Oil / Water

Types

Vegetable fat origins

✓ Mono-diglycerides

✓ Polysorbate

Natural Emulsifiers

✓ Phospolipids from egg yolk

17

Structural role

Gelling agent and thickener by controlling mobility of water

✓ The mix viscosity increases

Keeping quality

✓ Shape retention

Water – non -viscous

Viscosity build-up

Gelling

- Gelling effect +

DuPont

Source:

18

Stabilizers (hydrocolloïds)

STABILIZER (hydrocolloids)

19

STABILIZER Properties

Properties

Mix viscosity

Heat shock stability

Cold soluble

pH stability

Colloidal stabilisation

Cost in use

Low Acceptable High Source: DuPont 20

Alginate Carrageenan

CMC Guar Locust Bean Gum (LBG) Xanthan

StdStandardutilization use Complementary use Special use

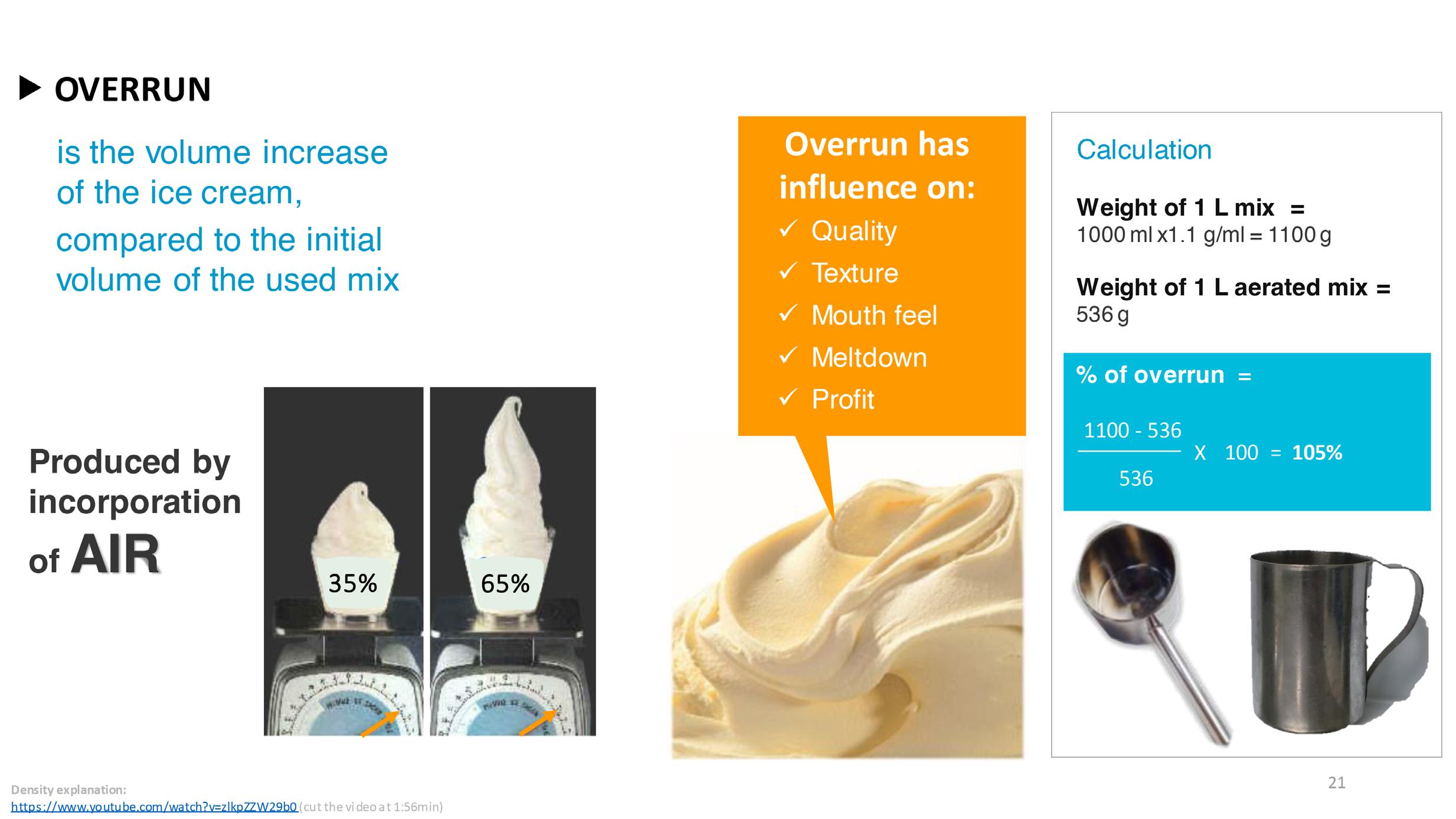

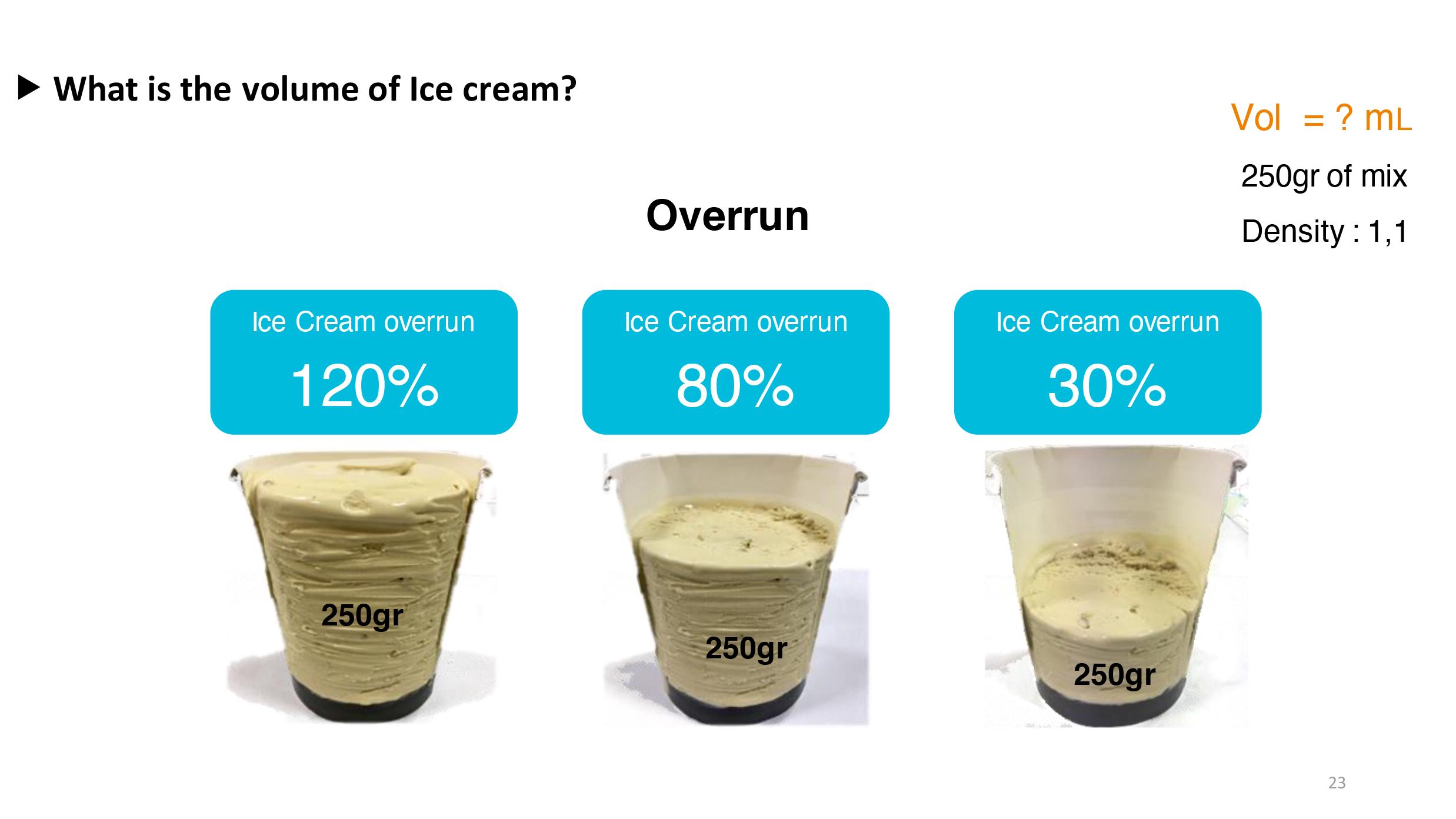

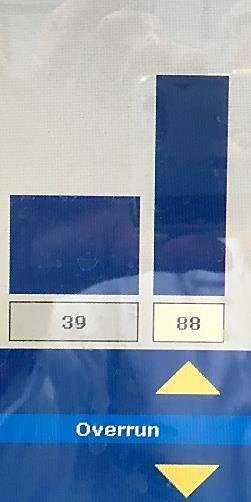

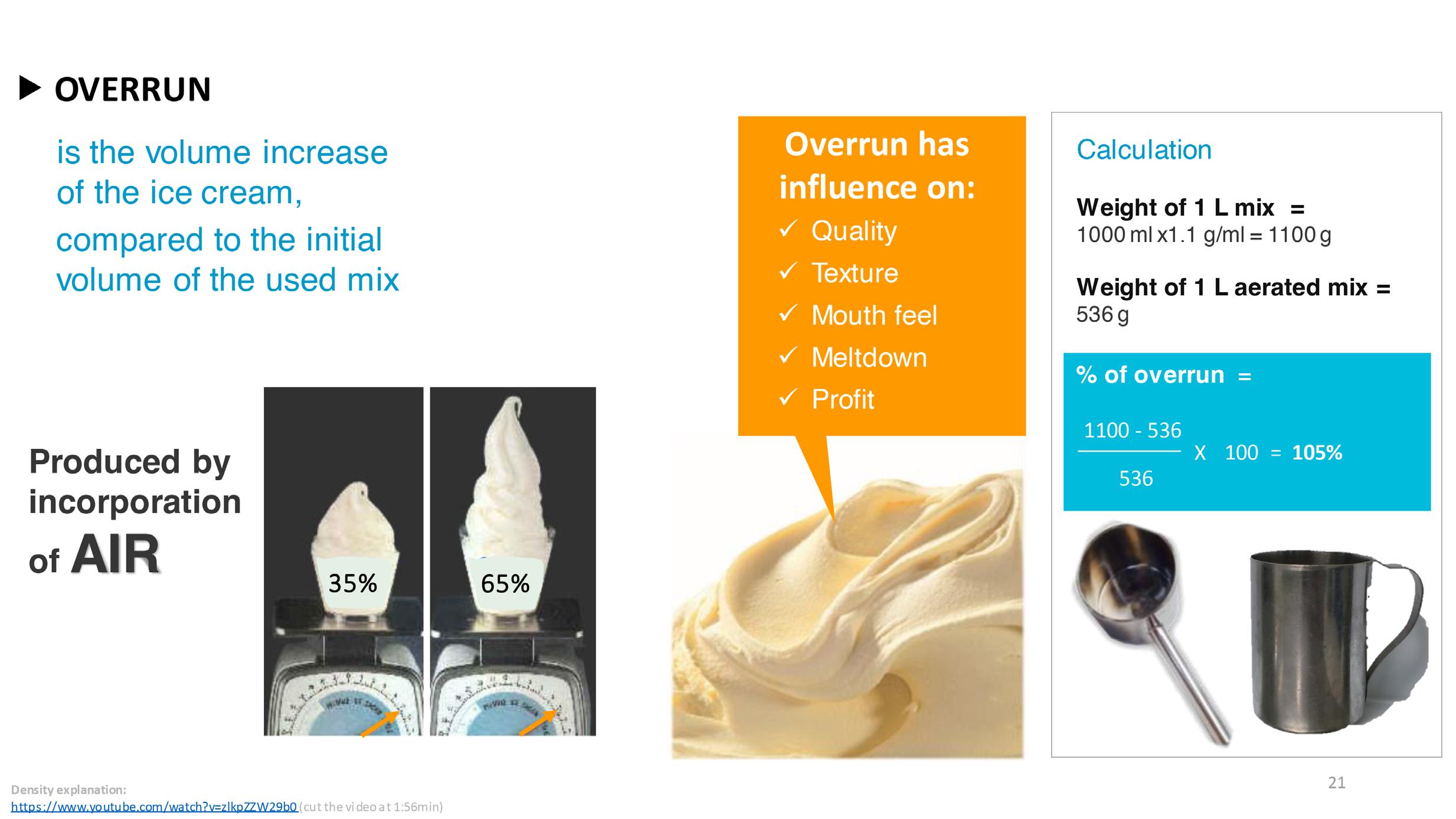

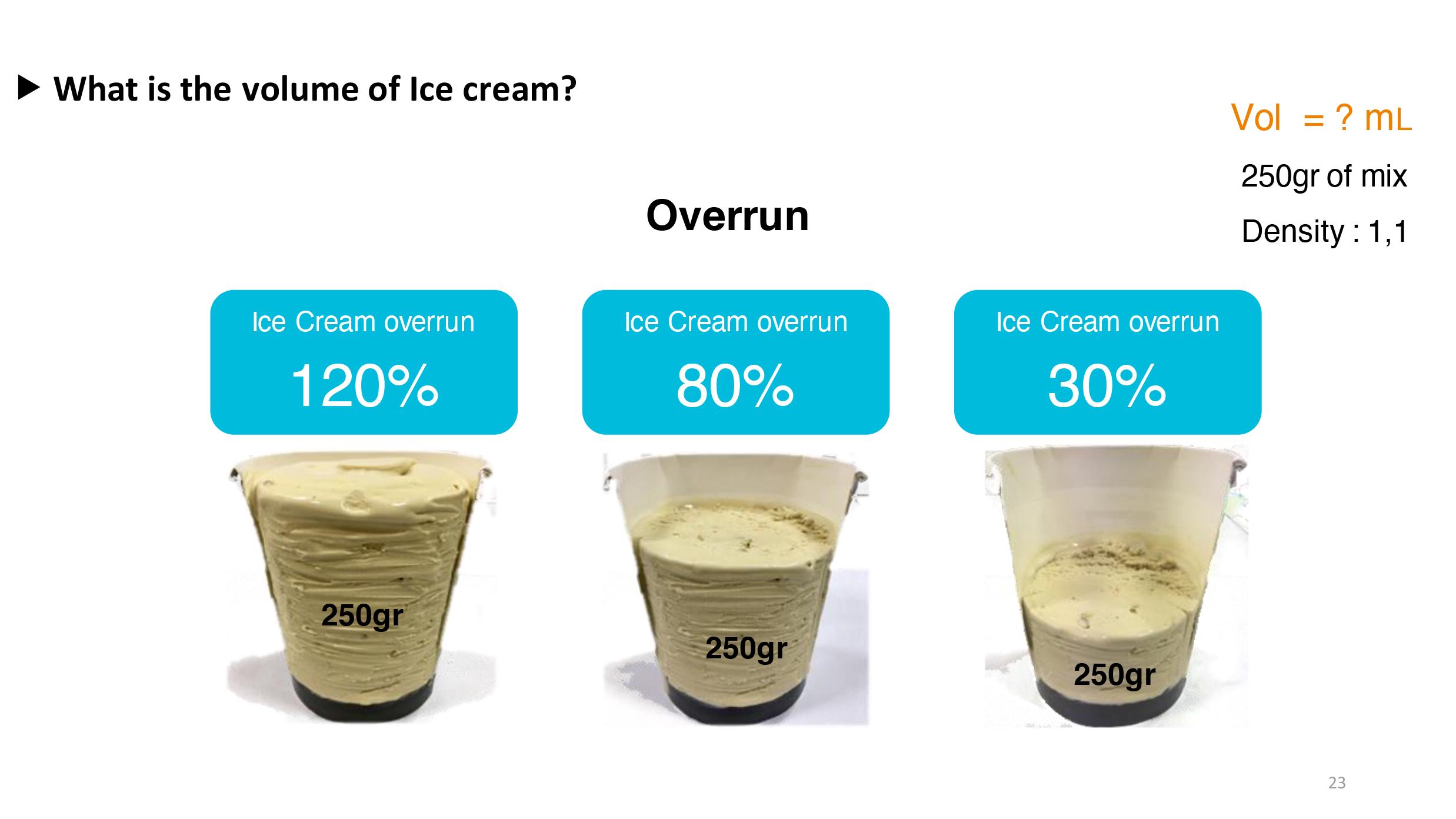

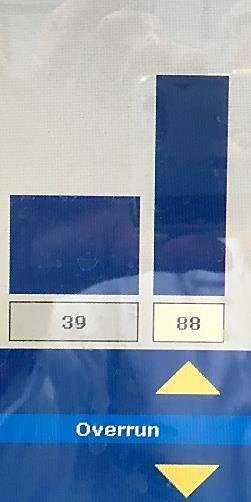

22 How to calculate overrun easily ? 1,15 DENSITY OVERRUN = Mix Density X Mix Volume -1 X100 = 115 % OVERRUN CALCULATION 1000 VOLUME OF MIX Weight of ice cream 536 WEIGHT of IC VOLUME AIR VOLUME MIX X 100 IC Volume = ((Overrun/100 + 1) x IC weight) / Density

To sum-up

Ice Cream is made of Components:

Water

Fat (dairy fats or vegetable fats)

Creaminess and smoothness. The Backbone of Ice Cream. 50% AIR Foaming texture

MSNF (proteins, lactose and minerals )

Sugars/Sweeteners

Sweetness intensity and smoothness. Impact the amount of ice.

Stabilizers

Emulsifiers

Flavors/Colors (others...)

Maintain the shape and a longer shelf life

Flavours (such as fruits) add aroma and influence the taste of the final product. Colours influence the appearance of the product.

100 % WEIGHT

Product Stability (emulsifier properties) - adding texture and body. Components

Ice Cream Making = mix [ making & ageing ]+ freezing

- Water

- Fat - MNSF (proteins)

- Sugar & Carbohydrates

- Emulsifiers

- Stabilizers

- Flavours, Colours

- Customizing ingredients

10% Fat 90% Sugar solution

50% Air 22% Ice crystals

5 % Fat 23% Unfrozen phase

TEXTURE & TASTE

MIXING HOMOGENIZATION PASTO-COOLING AGEING FREEZING FILLING HARDENING COLD STORE INGREDIENT FORMULATION

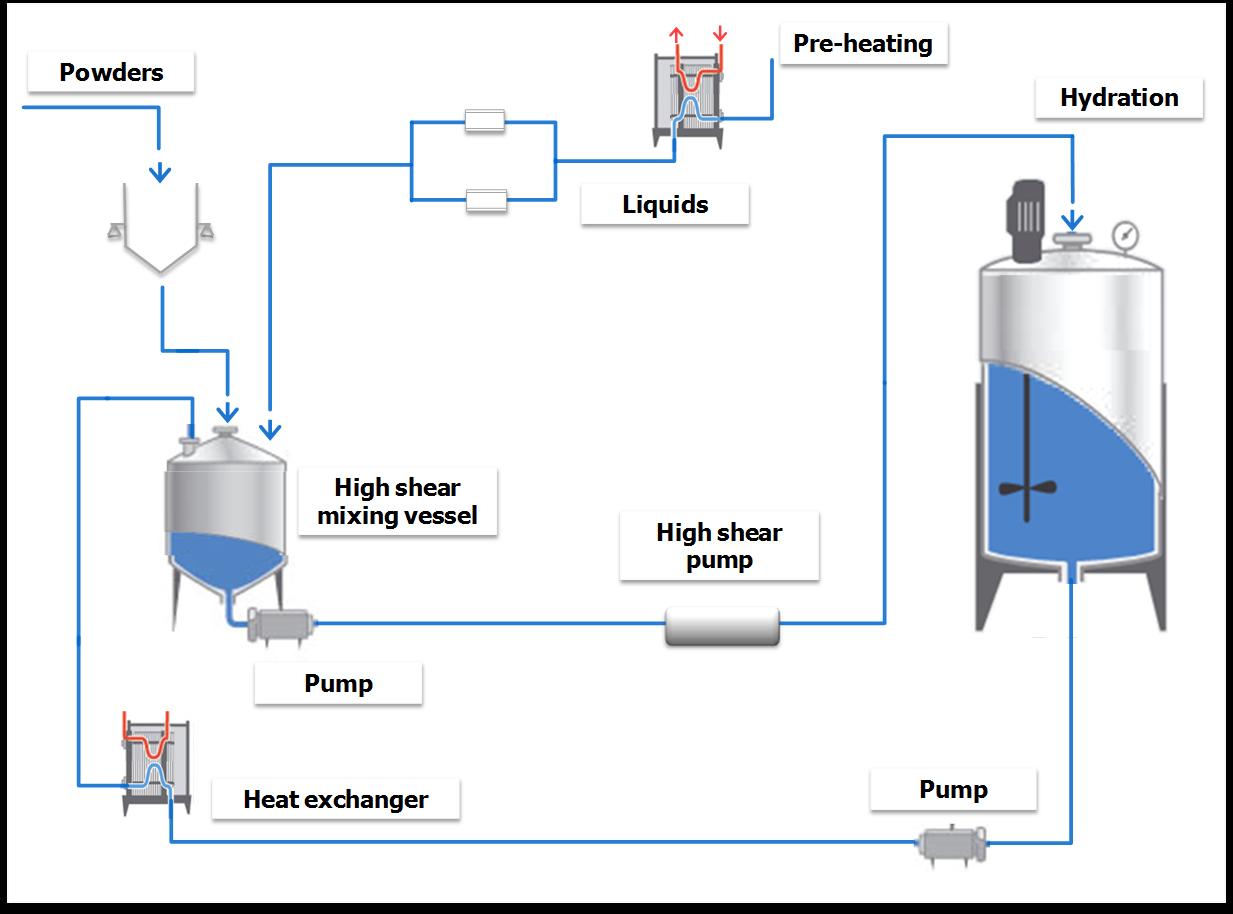

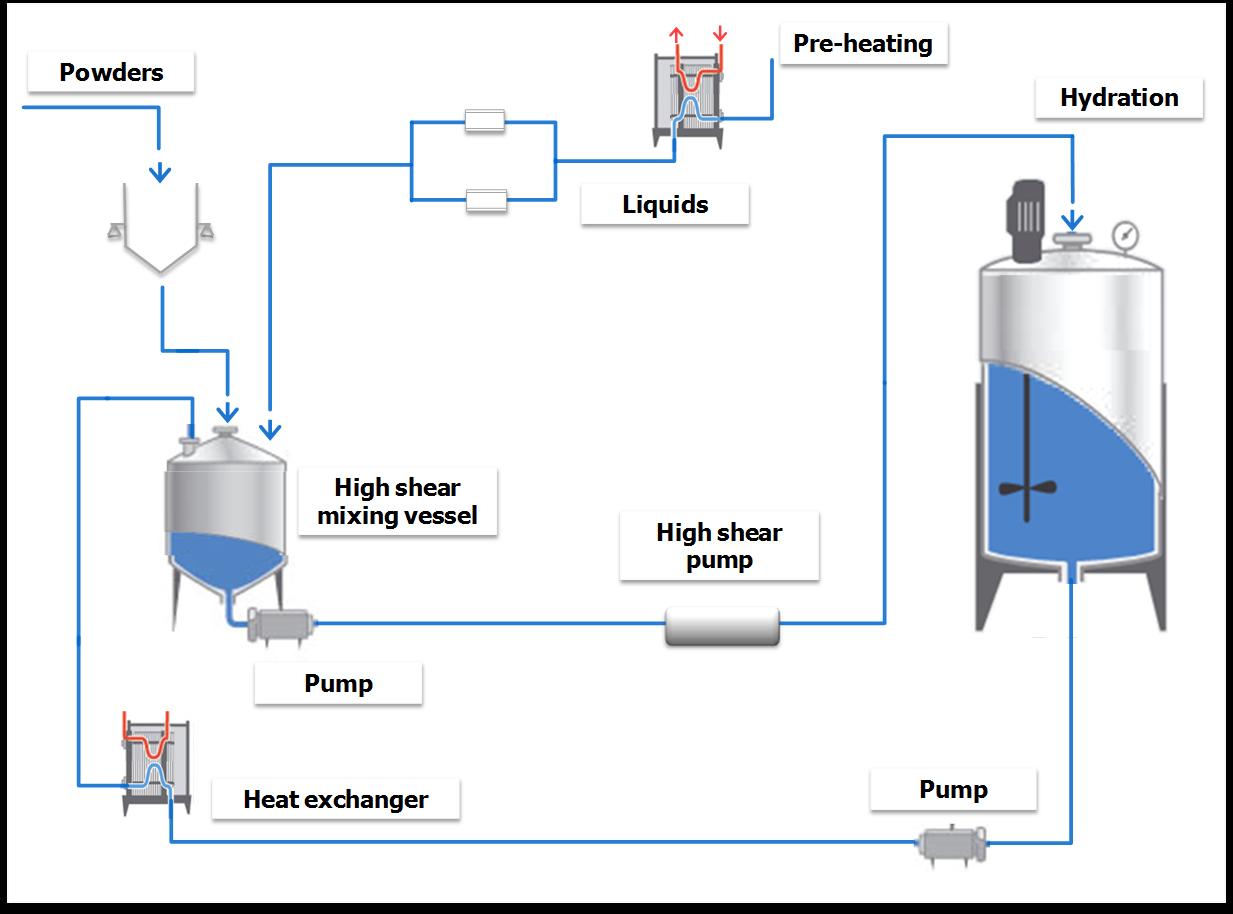

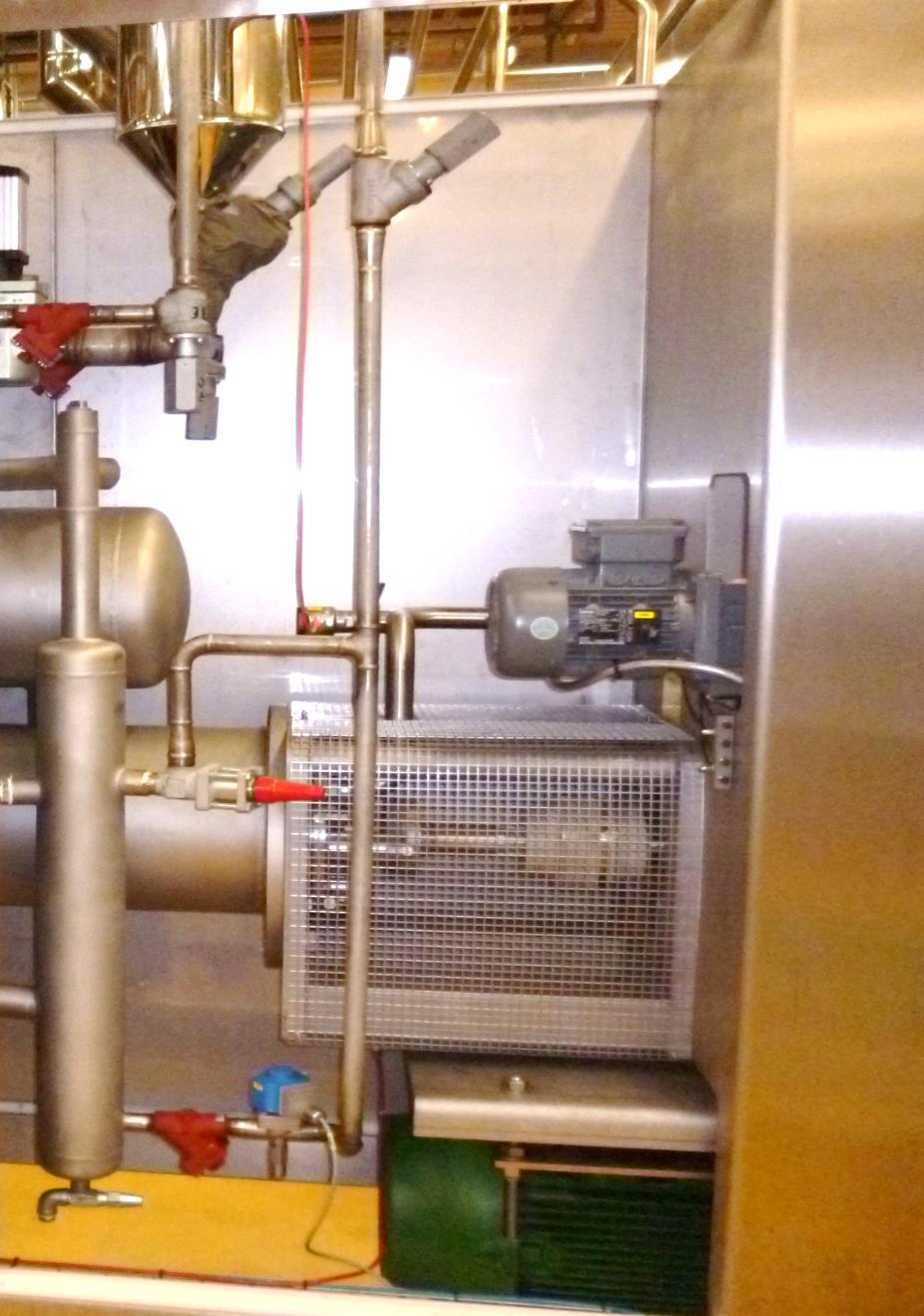

Working principles of Mix Plant

27

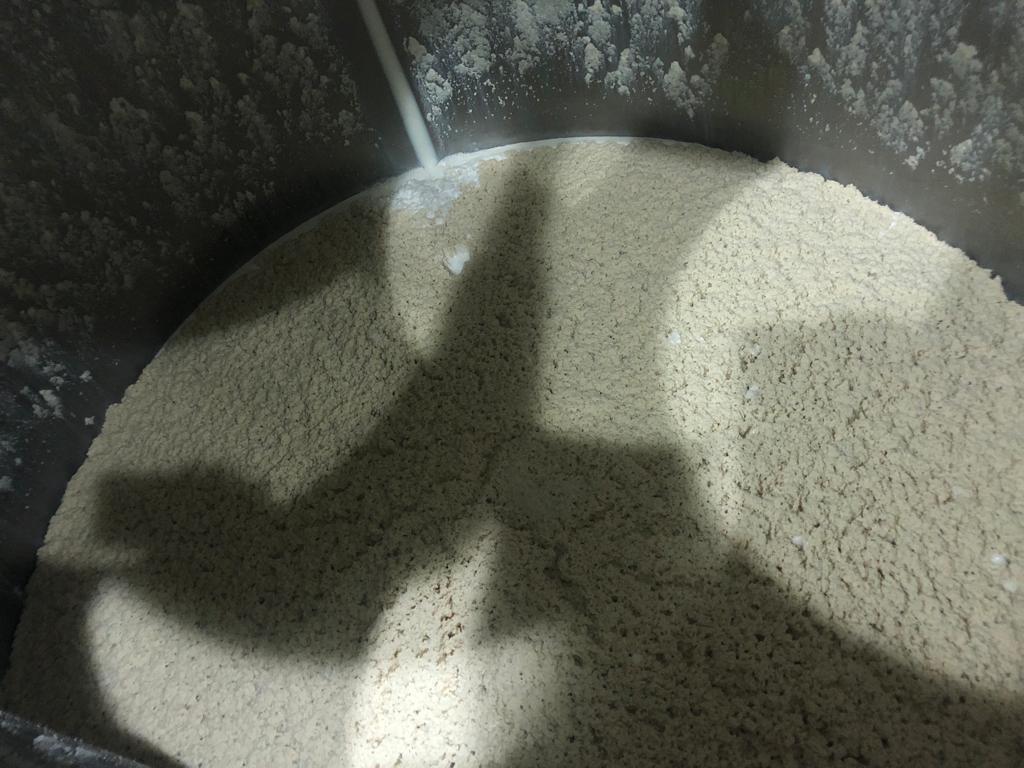

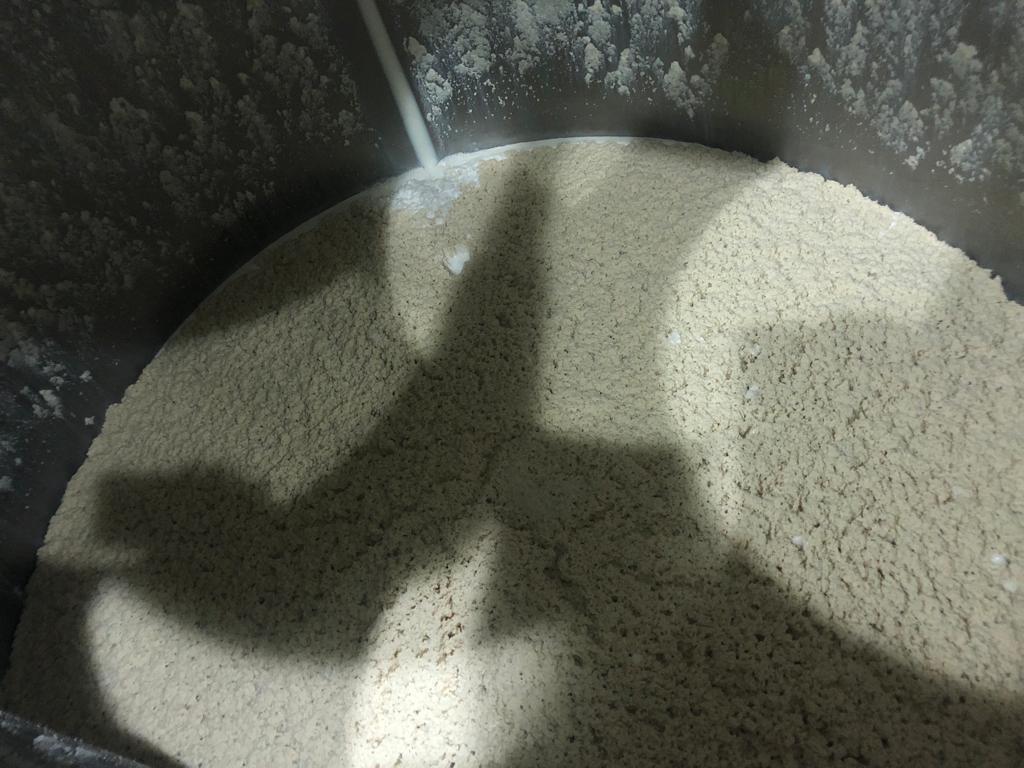

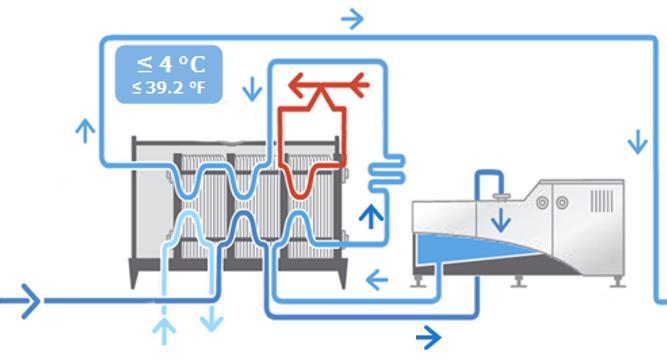

Transfer to freeze - Turbo mixer - High shear mixer Mixing Tank Dispersion Pump Pump LIQUID ingredients DRY ingredients a f ter h eat tr eatment d ue t o h i g her sen sibi li ty to heat Hydration Tank Hydration Homogenizer Homogenization Plate Heat Exchanger Heat Treatment + Cooling to 4 ° C Ageing Tanks Maturation

Mix Preparation

1 . Hot water

2 Sugars & Syrups

3. Stabilizers & Emulsifiers

4. Powders & Proteins

5. Fats

6 Other ingredients + Rework

• Hot water 131°- 149° F

• All form of sugars (Sucrose, inverted sugar, glucose, maltodextrine...), liquid or solid form

• Blend (Emulsifier+Stabilizer)

• Milk derivates, protein and cocoa powders, some thick products

• Cream & Liquid fats (Coconut oil - Butter oil – Fresh milk)

• Nuts, Pistachio, Nougat pasta

Mixing tank

Hydration tank

Achieve the temperature of mix to 140°F / 20 mins

29

BATCH COMMON SET -UPS

CIRCULATION LOOP: COMMON SET -UPS

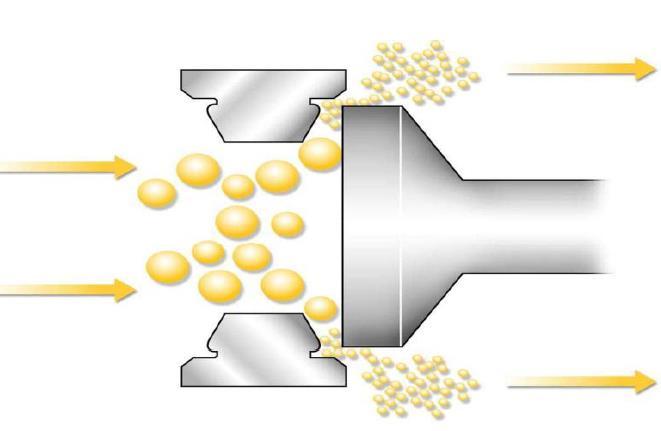

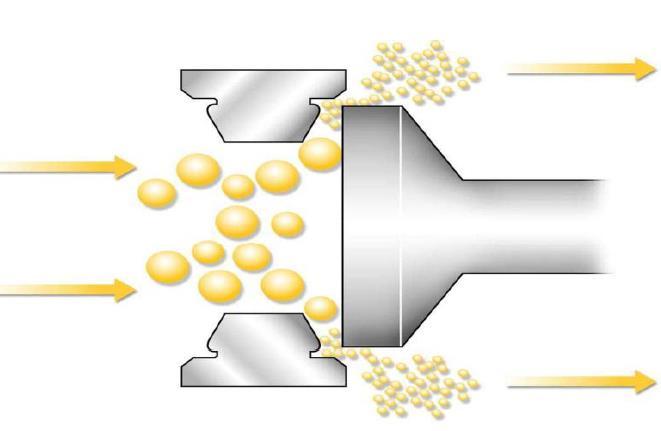

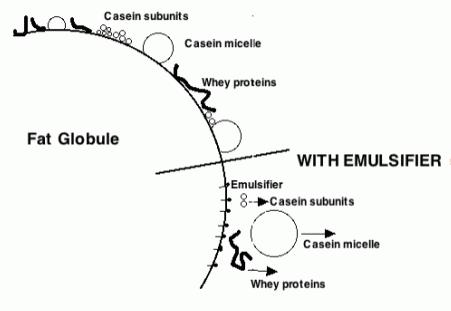

Homogenization

✓ Homogenization breaks down the fat globules into smaller droplets to create an homogeneous and stable fat-in -water emulsion

✓ Process in 2 stages

32

Mean 2ųm Range 1 -10ųm Mean 0.5ųm Range 0.2 -2 ųm Many clusters Mean 0.5ųm Range 0.2 - 2 ųm No clustering <10 microns <1 micron Before After

2 examples of HOMO

Homogenization

Why 2 stages?

Pressure 1st stage

2030 -2900 psi

To reduce size of fat globules Forcer Impact ring Seat

Fat globules

✓ 2000 times increased numbers

✓ 10 times increased surface

✓ 20 times decreased distance

Hydraulic actuator

Pressure 2 nd stage

To prevent fat cluster formation 435 psi

2nd stage

Reduce the fat diameter by 10

1st stage

33

Impact of homogenization on freezing process

Example of BAD and GOOD homogenization process

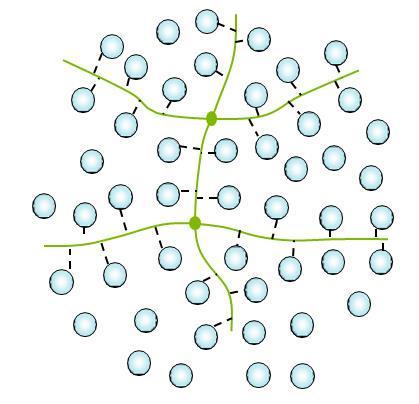

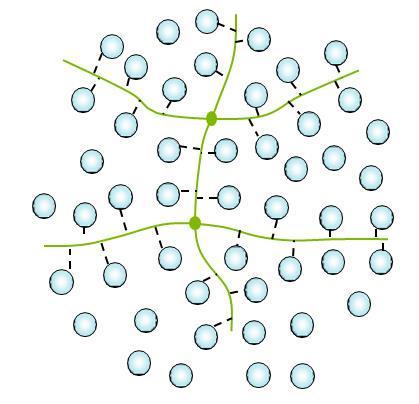

Poorly coated air bubbles with « uncontrolled fat clusters » at the surface are created Very unstable. The uncoated areas result in « degasification » and loss of volume, leading to shrinkage

GOOD with proper mix preparation prior to homogenization « fatty plates at the air bubble surface » are created resulting in flexible and stable air bubbles (well coated )

34

Heat Treatment (Pasteurization)

Working principle of plate heat exchanger

Potential problems

• Increased mix viscosity

• Burning (due to foaming)

• Food safety (destroy pathogenic micro -organisms)

• Dissolve/active ingredients (emulsifiers and stabilizers)

Three types

•

•

•

HTSC

35

= High Temperature Short Time

Batch pasteuriser 133 °F / 30 min

Continues (HTST pasteurizer) 172 -194 °F / 25 -50 sec

Ultra High Temperature (UHT) 290 °F / 4 -12 sec

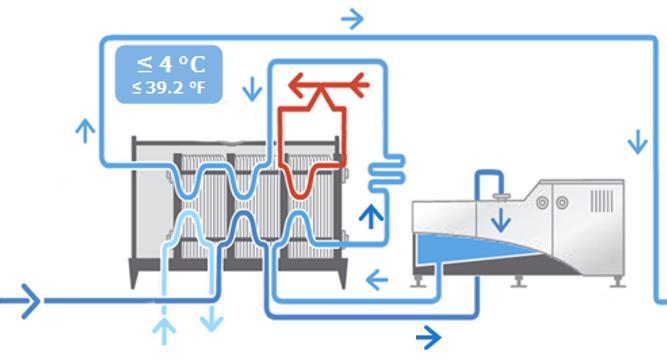

Heat Treatment (Pasteurization) - 3 functions

Pre-heating

To reduce energy utilization, regeneration is recommended by :

• Direct mix / mix exchange

• Direct exchange between hot mix from homogenizer and pasteurized mix

Holding tube

• Ensures the effectiveness of heat treatment (« residence time »)

• Destroy pathogenic microorganisms

• Dissolve/active ingredients (emulsifiers and stabilizers)

2 valve

Cooling 3

T° C: 181 ° F 30s

• Mix immediately cooled after homo-pasteurization at 4°C / 39.2°F ( 2 °C), before pumped to the ageing tanks.

• Prevent the growth of microorganisms

HOMO

• Increase the mix viscosity (consistency )

MIX +39 ° F

36

MIX +140 ° F MIX +162 ° F

1

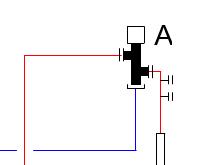

Heat Treatment – Divert Valve System

Working principle of divert valve system

• Temperature sensor at the end of holding tube

• Single seat valve to divert the mix < 178°C to the balance tank

83 37

T°C < 178°F T° C SENSOR T°C ≥ 178°F 149F 162F 167F 181F 39F

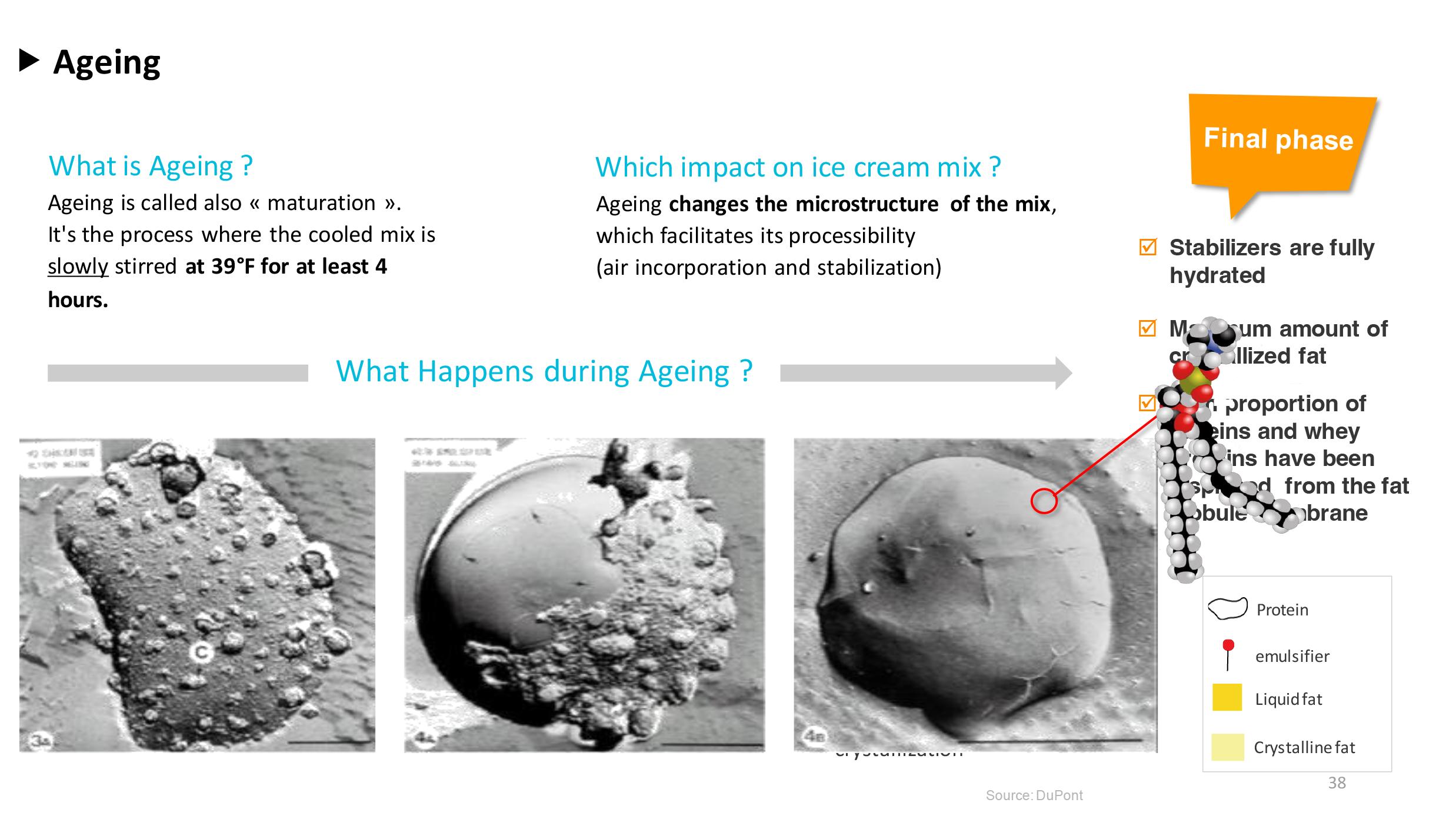

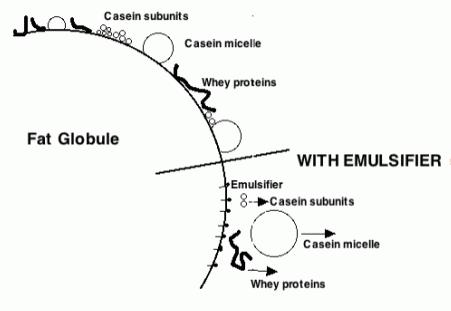

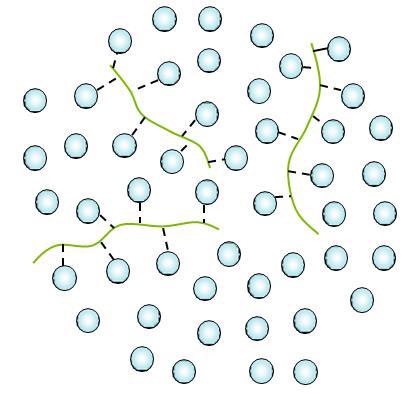

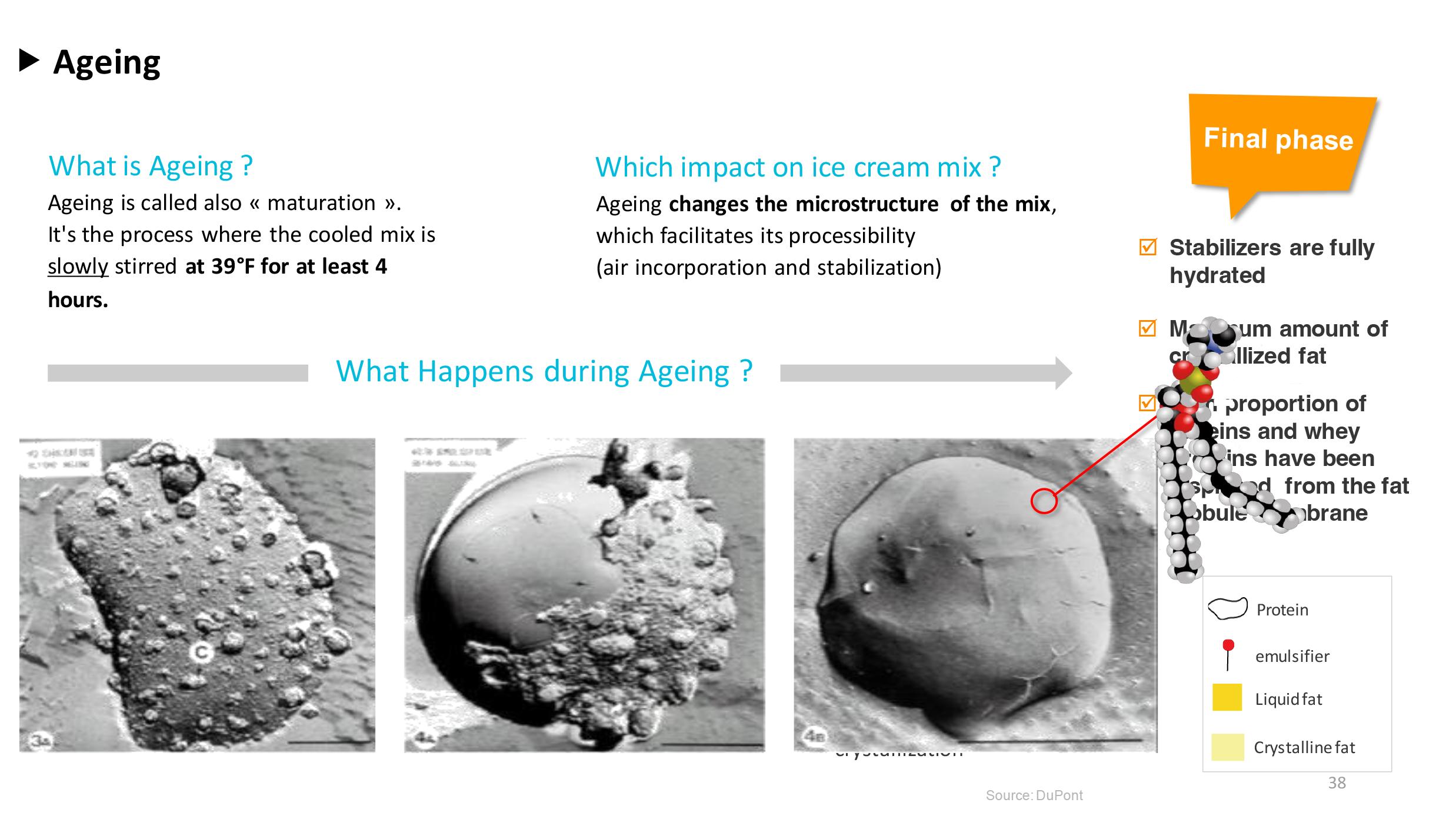

EMULSIFIERS

NO EMULSIFIER

fat clusters ca. 50 µm

Fat Globule

WITH EMULSIFIER

PROTEIN DESORPTION

PARTIAL CLUSTERING of FAT GLOBULES

39

HYDROPHILIC head LIPOPHILIC tail

Key Parameters

RECIPE

MIX MATRIX

✓

✓

✓ Stabilizers & Emulsifiers

+ Food safety : HEAT

41

PREPARATION HOMOGENIZATION AGEING Order of addition Pressure T °C = 39 °F

Fat size particles At least 4 h Hydration

MIX

Dispersion

TREATMENT

COMPOSITION

Total Solids (%)

% Fats

✓

✓

Proteins

(MSNF)

Sugars

MICROSTRUCTURE TO BE ACHIEVED AFTER AGEING

MIXING HOMOGENIZATION PASTO-COOLING AGEING FREEZING FILLING HARDENING COLD STORE INGREDIENT FORMULATION

FREEZING: A critical point of Ice Cream Process

Ice crystallisation

Air bubble introduction

Ice cream structure building: partial agglomeration and rearrangement of fat globules on air/soluble phase surface

High impact on ice cream texture: achieving uniform and smooth texture

42

Ice Cream Making = mix [ making & ageing ]+ freezing

- Sugar & Carbohydrates

- Emulsifiers

- Stabilizers

- Flavours, Colours

- Customizing ingredients

5 % Fat 23%

50% Air 22%

TASTE

Unfrozen phase

Ice crystals TEXTURE &

10% Fat 90% Sugar solution

-

- Water

Fat - MNSF (proteins)

MIXING HOMOGENIZATION PASTO-COOLING AGEING FREEZING FILLING HARDENING COLD STORE INGREDIENT FORMULATION

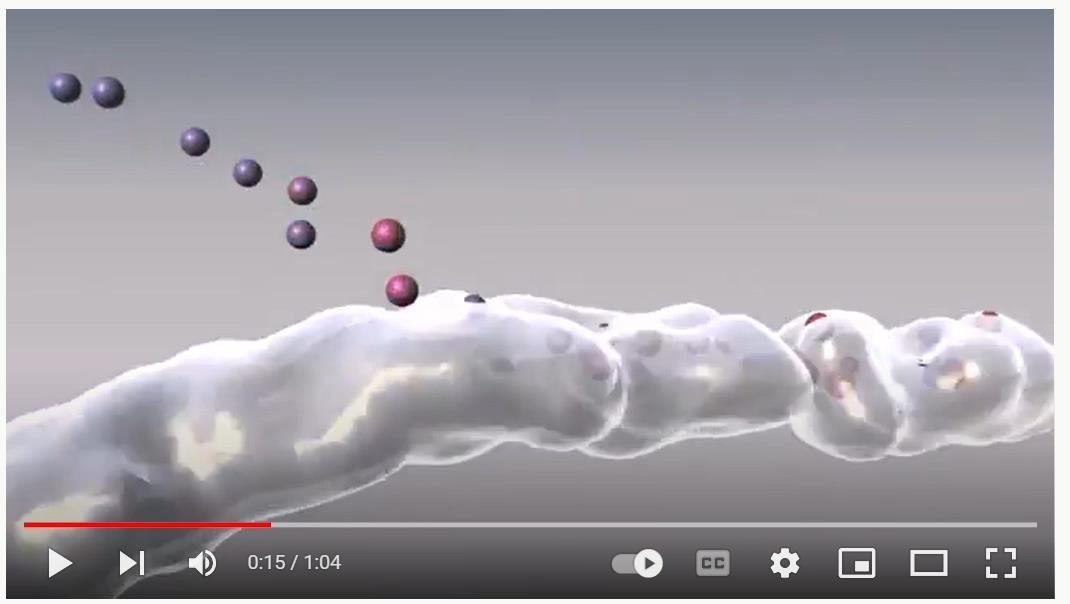

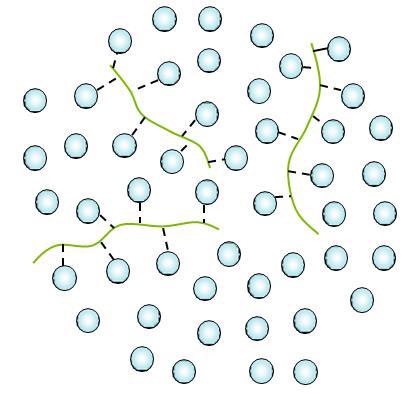

44 How the mix is transformed into ice cream? Freezing Microstructure Unfrozen phase Air Bubble coated by fat Unfrozen phase Air bubble Fat globules I c e C rysta ls

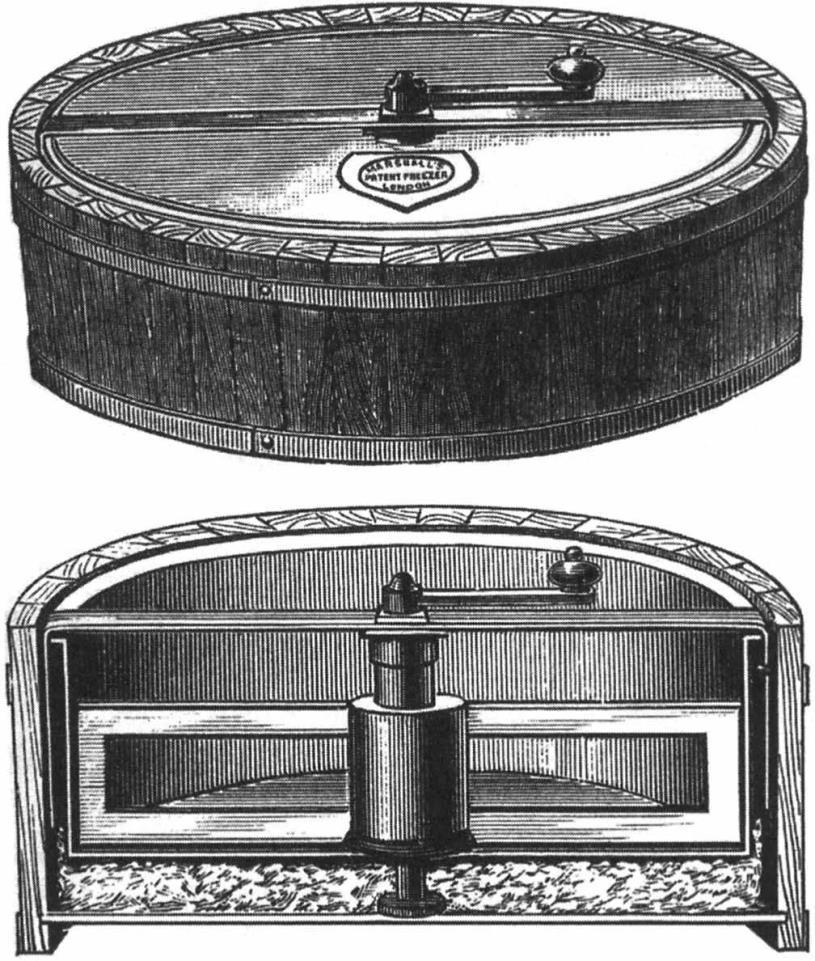

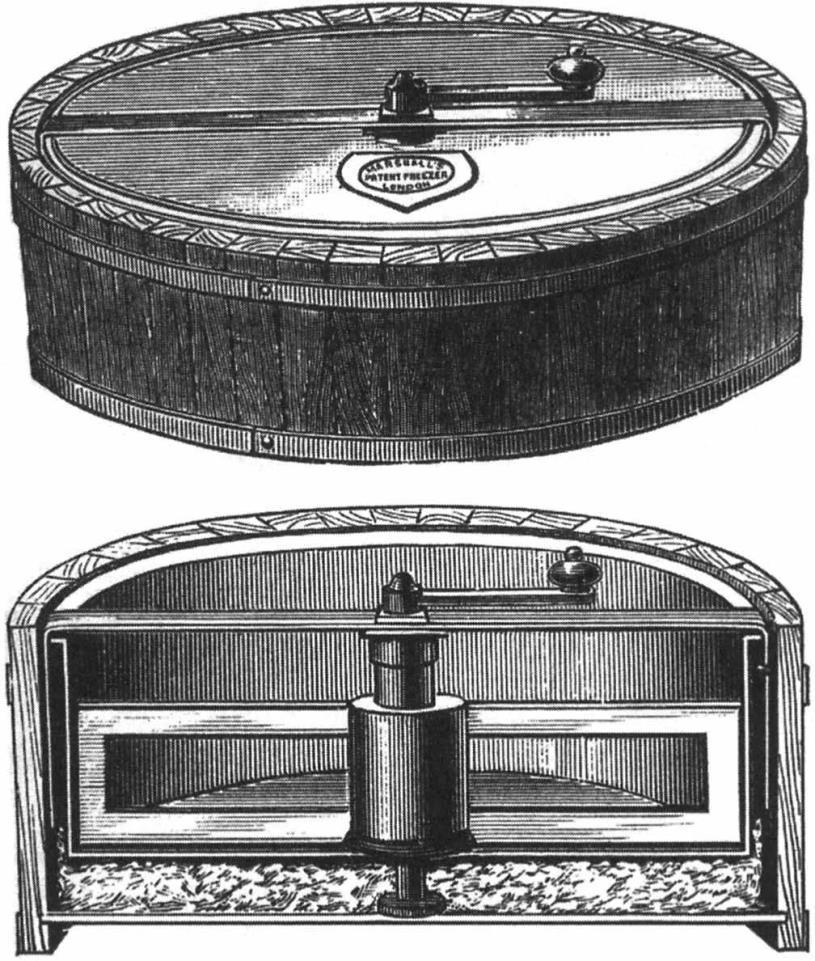

Freezers History

46

Mrs Marshall’s Ice Cream maker 1880

(Courtesy of the London Canal Museum, www.canalmuseum.org.uk)

Current freezer Tetra Pak and Wcb 2016

One of the first ice cream factories developed starting from 1940

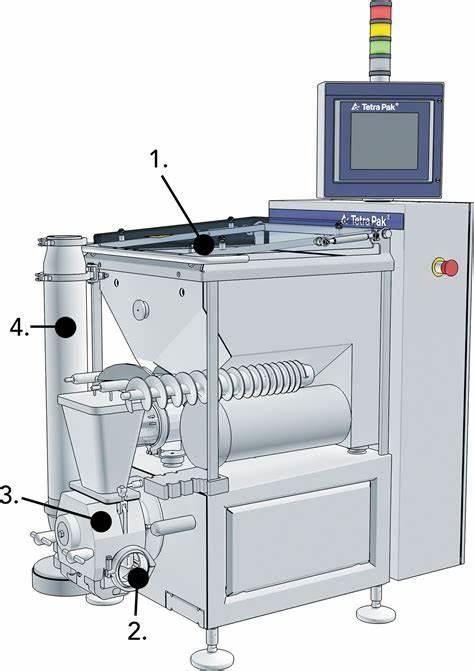

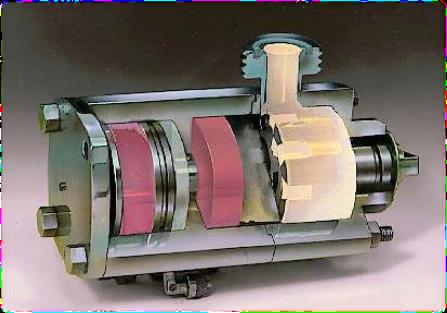

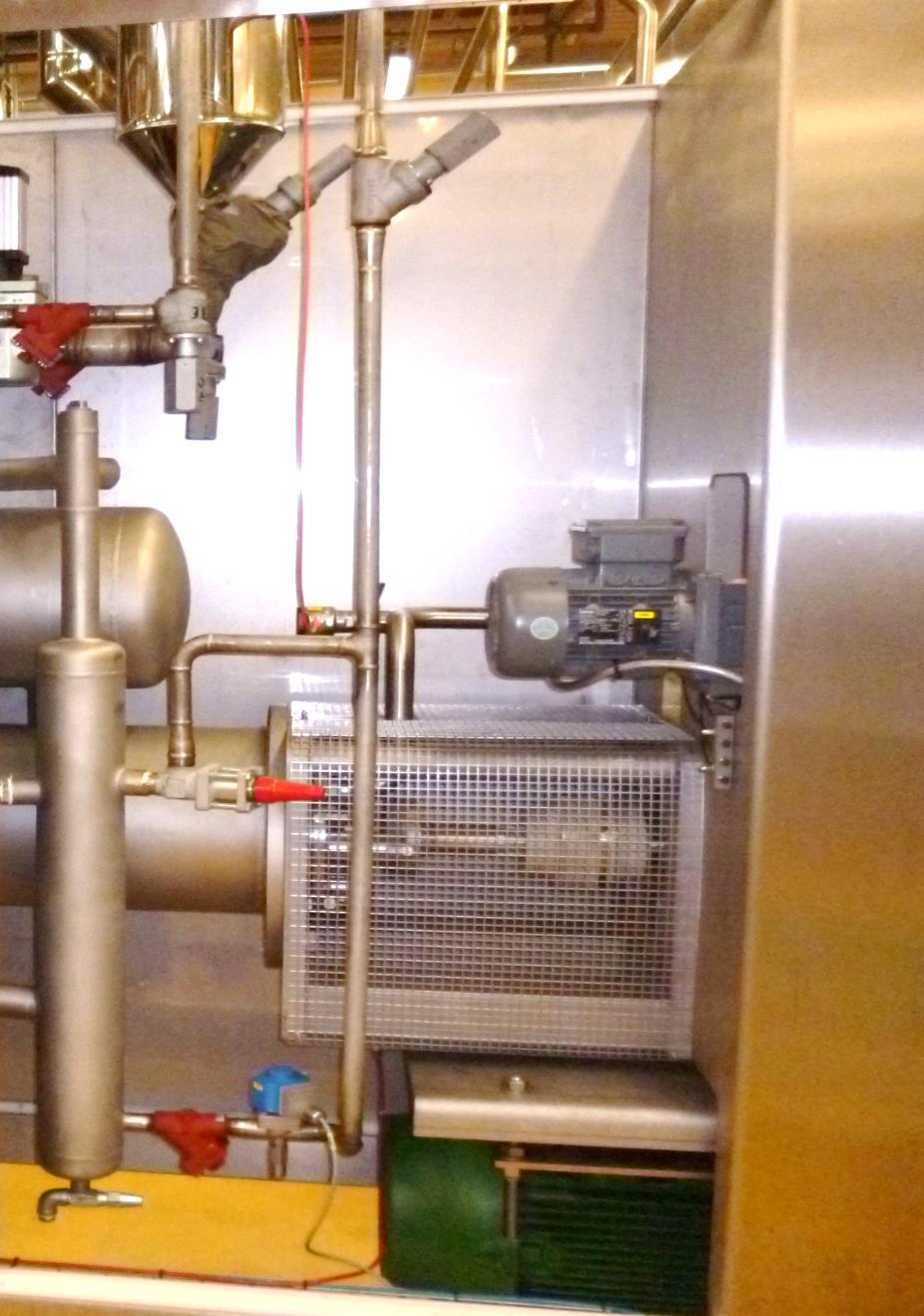

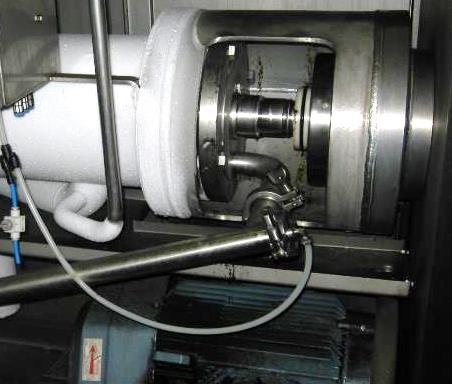

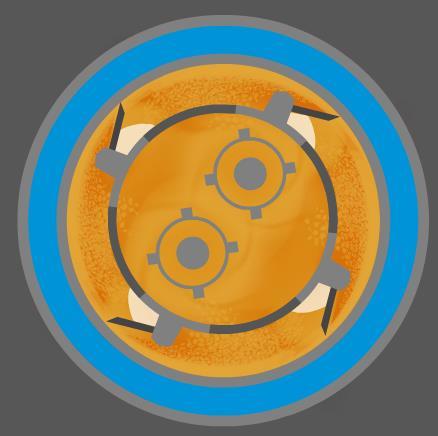

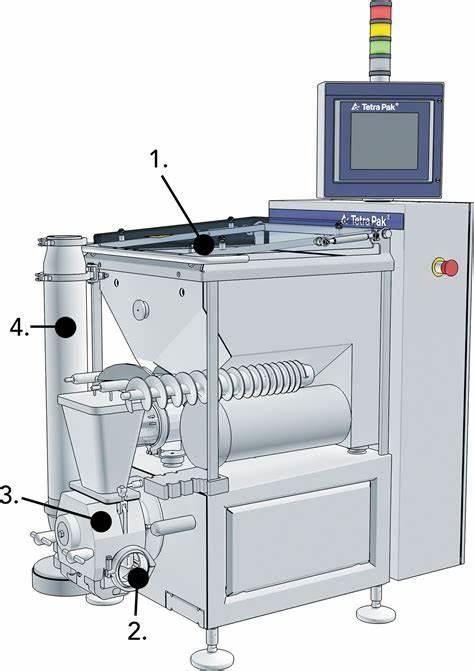

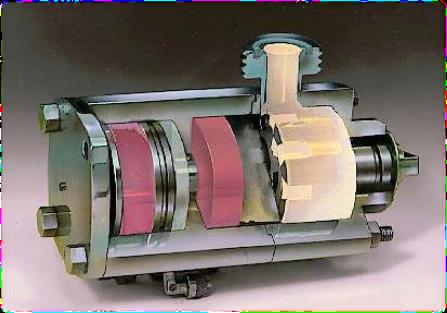

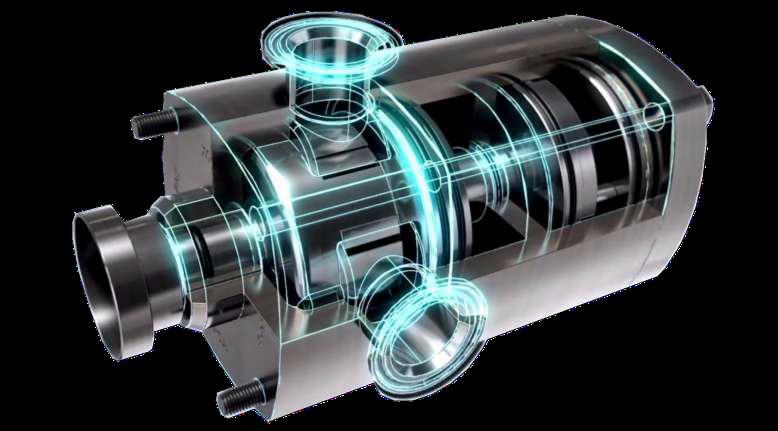

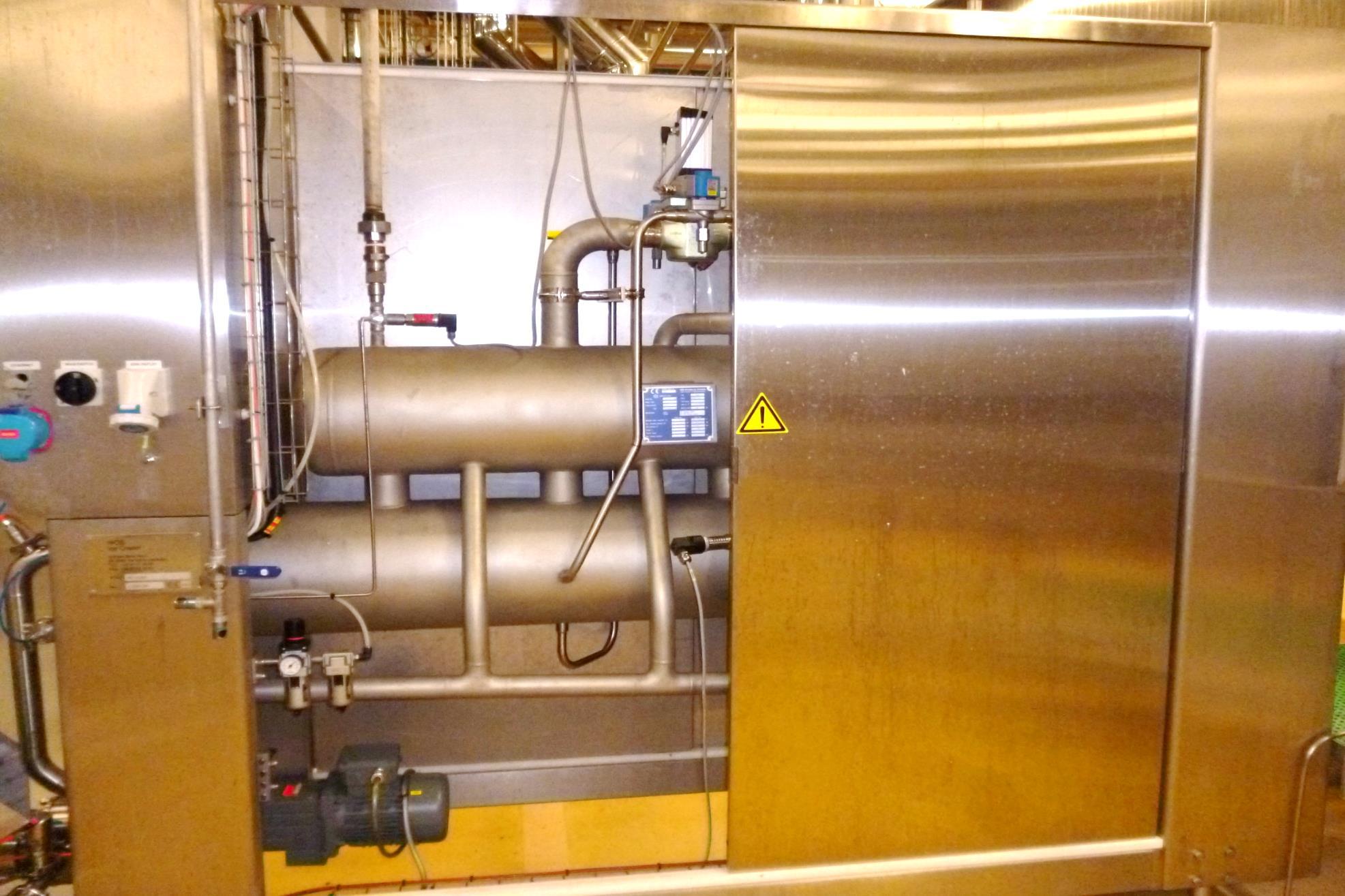

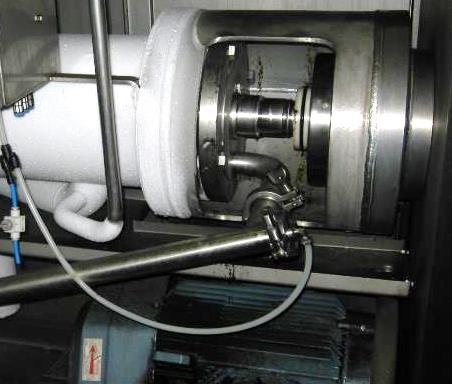

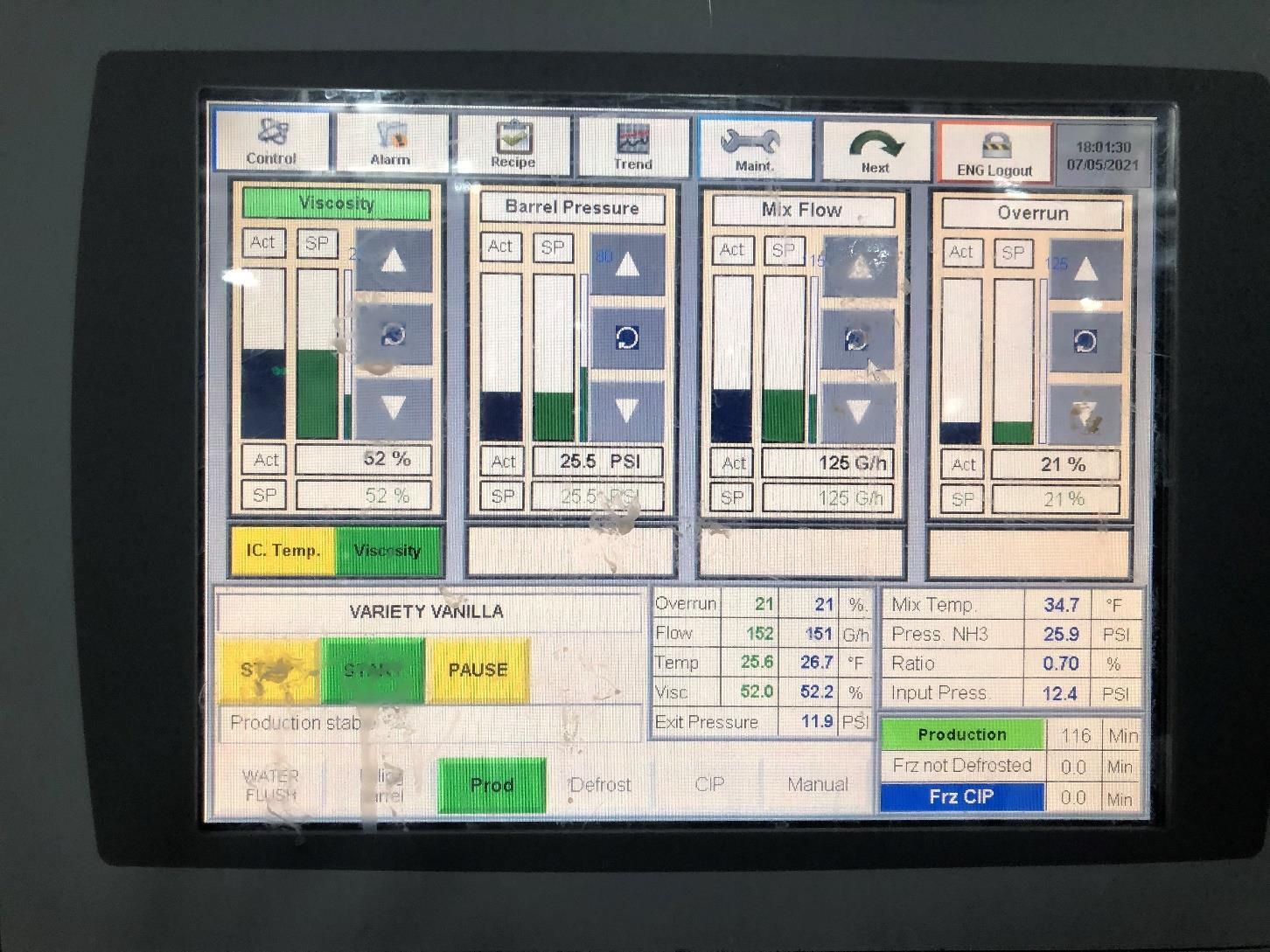

Tetra Pak Continuous Freezer

Separator NH3

Panel control

Cylinder

Ice Cream Outlet

Mix Inlet

Mix pump

Air system

Air inlet

Dasher

Mix flow meter

Ice Cream pumps

48 ةيسيئرلا ةيبيردتلا ةرودلا ةيجاتنلااطوطخلايلغشمل يلمعلا قيبطتلا ديمجتلا ةطلخلا ريضحت ميركسيلاا ةبيكرت ةمدقم Mix flowmeter Mix pump Ice Cream pumps Panel control Cylinder Ice Cream Outlet Mix Inlet Separator NH3 Air Mass Flowmeter Air inlet Dasher motor

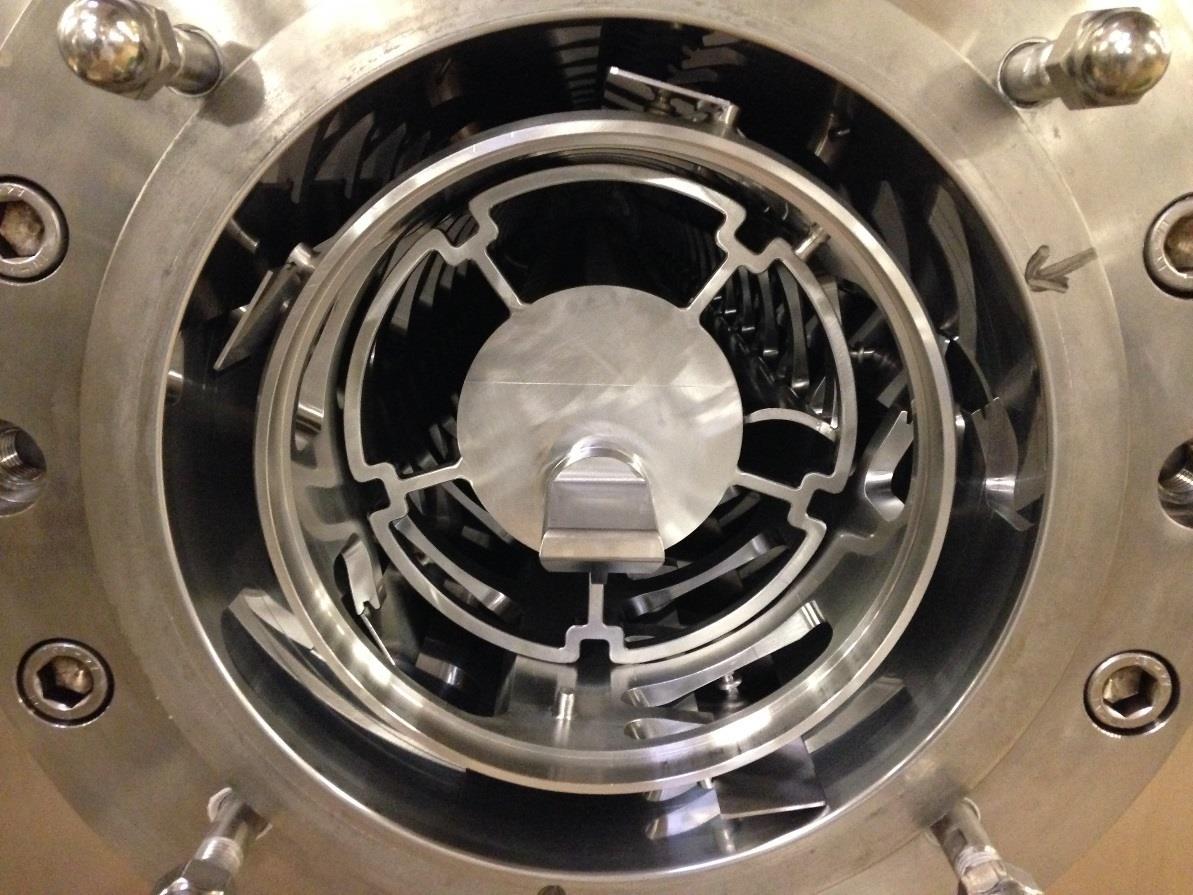

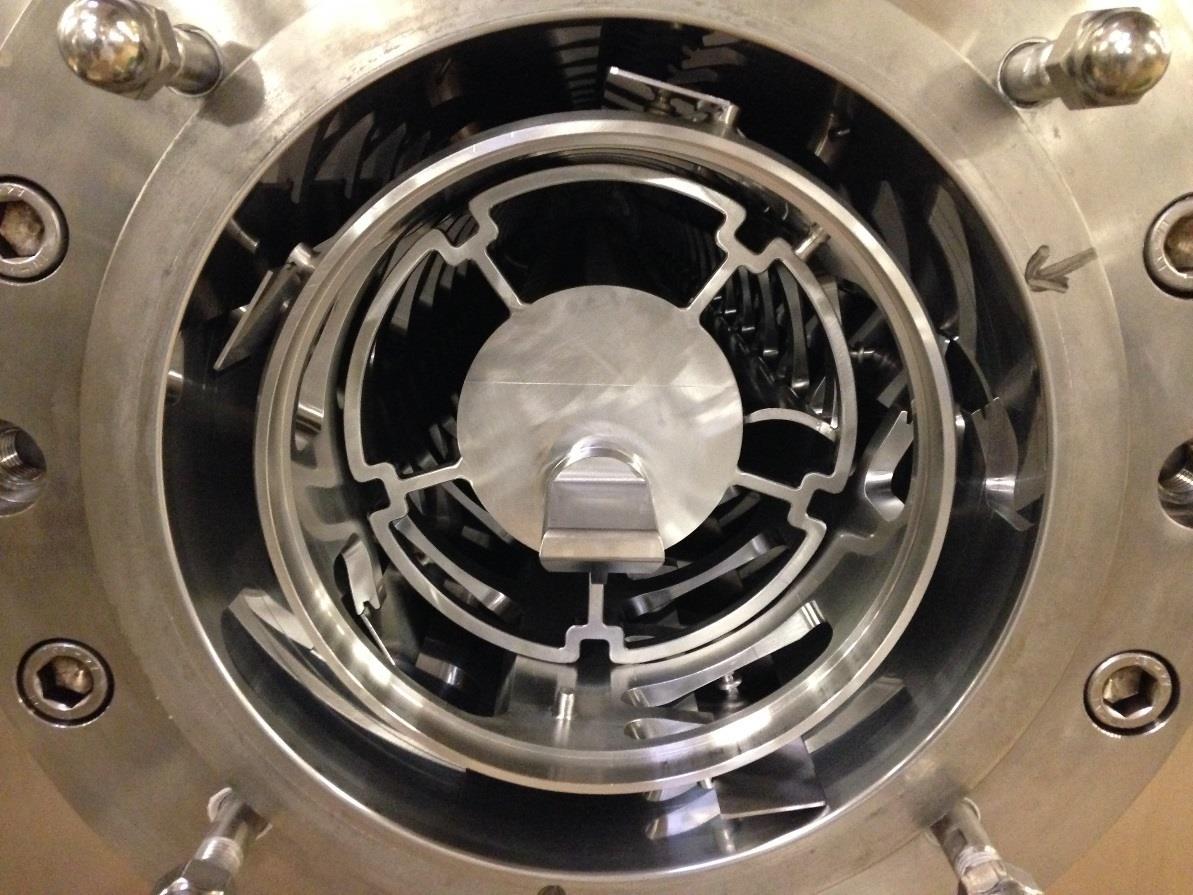

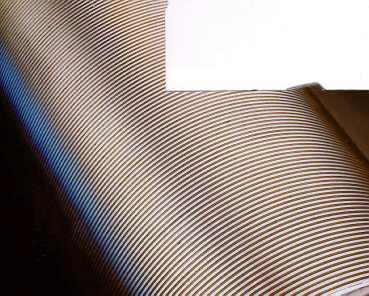

Inside the Barrel

✓ one can not see inside

✓ one can not hear failures in factory context

Regular inspections to be done

Rotation

anticlock wise

50

Front of freezer side

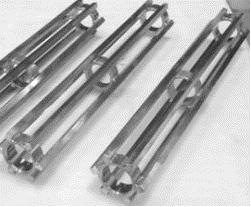

51 Dasher inspection ليمربلا REFRIGERANT ICECREAM BEATER BLADES 47,5cm 95,5cm DASHER WCB TETRAPAK WCB TETRAPAK

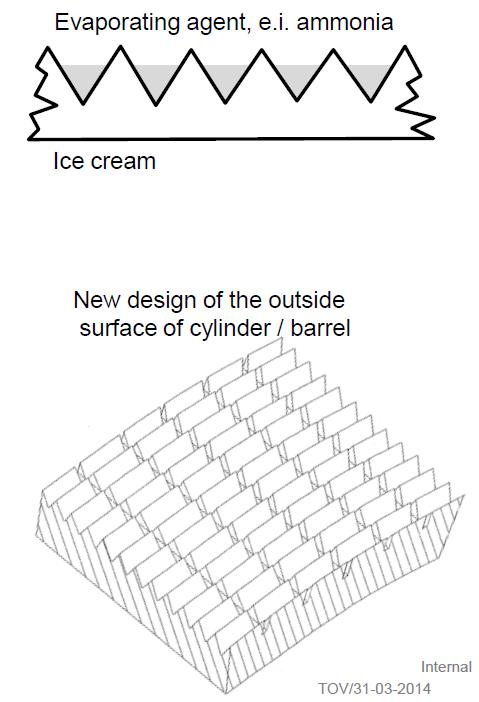

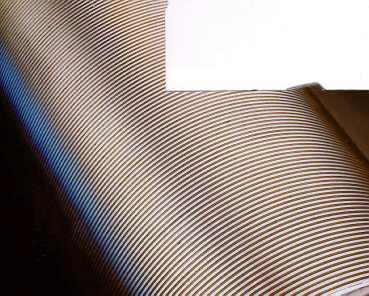

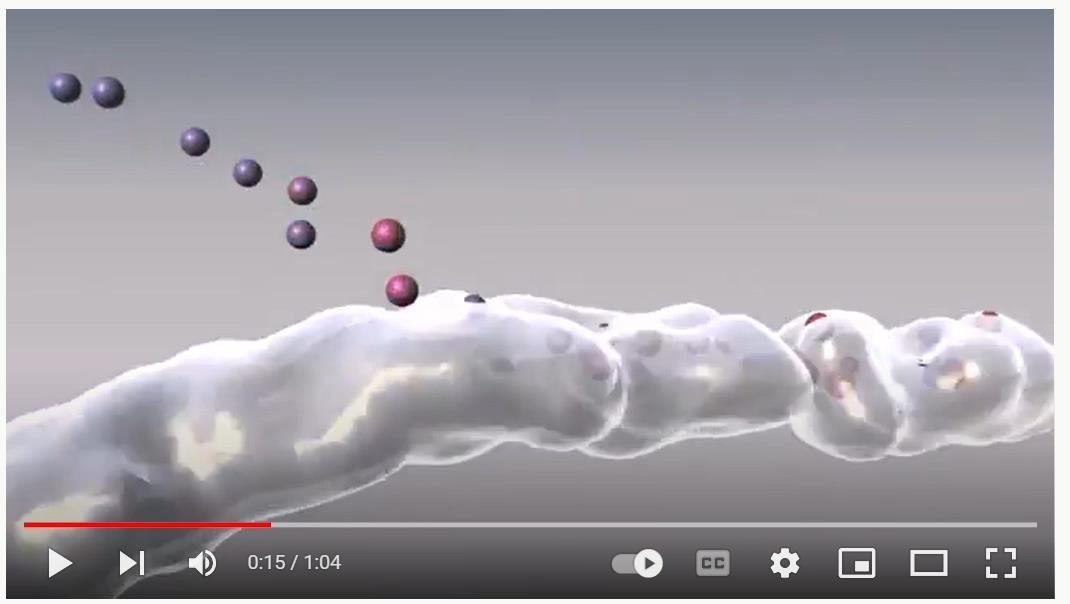

Inside the Dasher – Freezing process

Ripening

Barrel

Dasher

Barrel MICROSTRUCTURE VIDEO

Scraper blades

Vapourizing ammonia

SOURCE: TETRA PAK

52

v

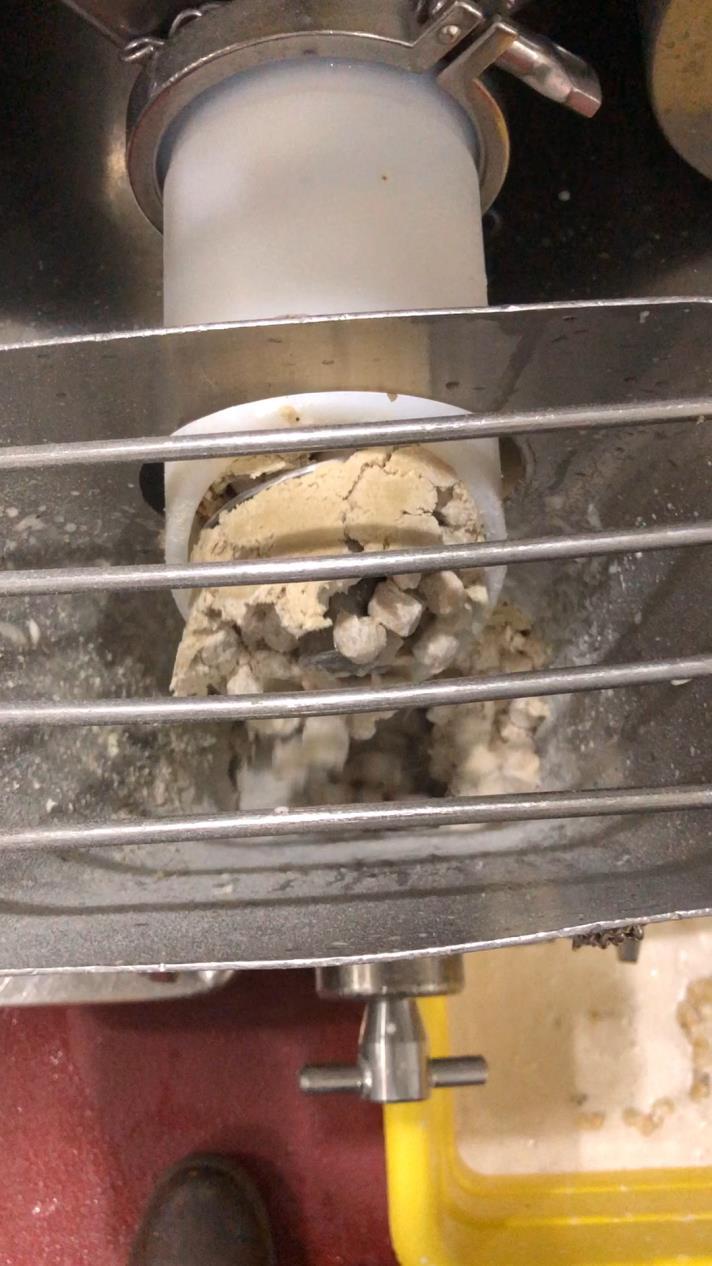

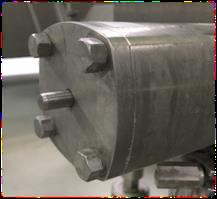

Check for blades width

Replace immediatly blades below minimum width

Hoyer Max 0,5 mm 0,1 to 0,2 mm 53 Scraper blades inspection Cylinder Pin and blade Minimum 32 mm 125°

Tetra pak – dasher assembly video

Tetra pak – dasher assembly video

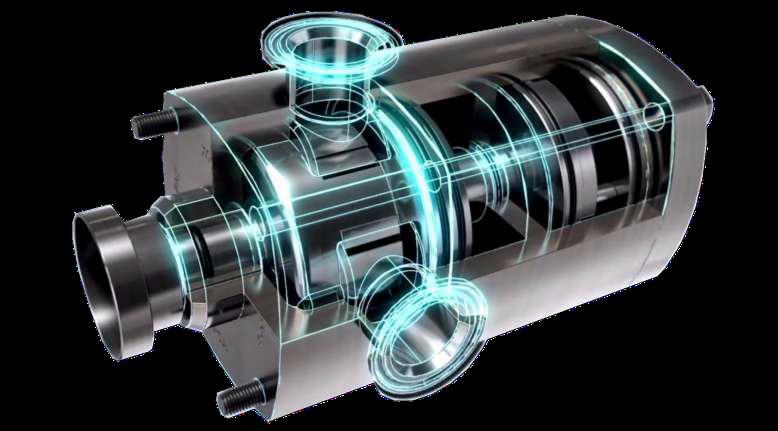

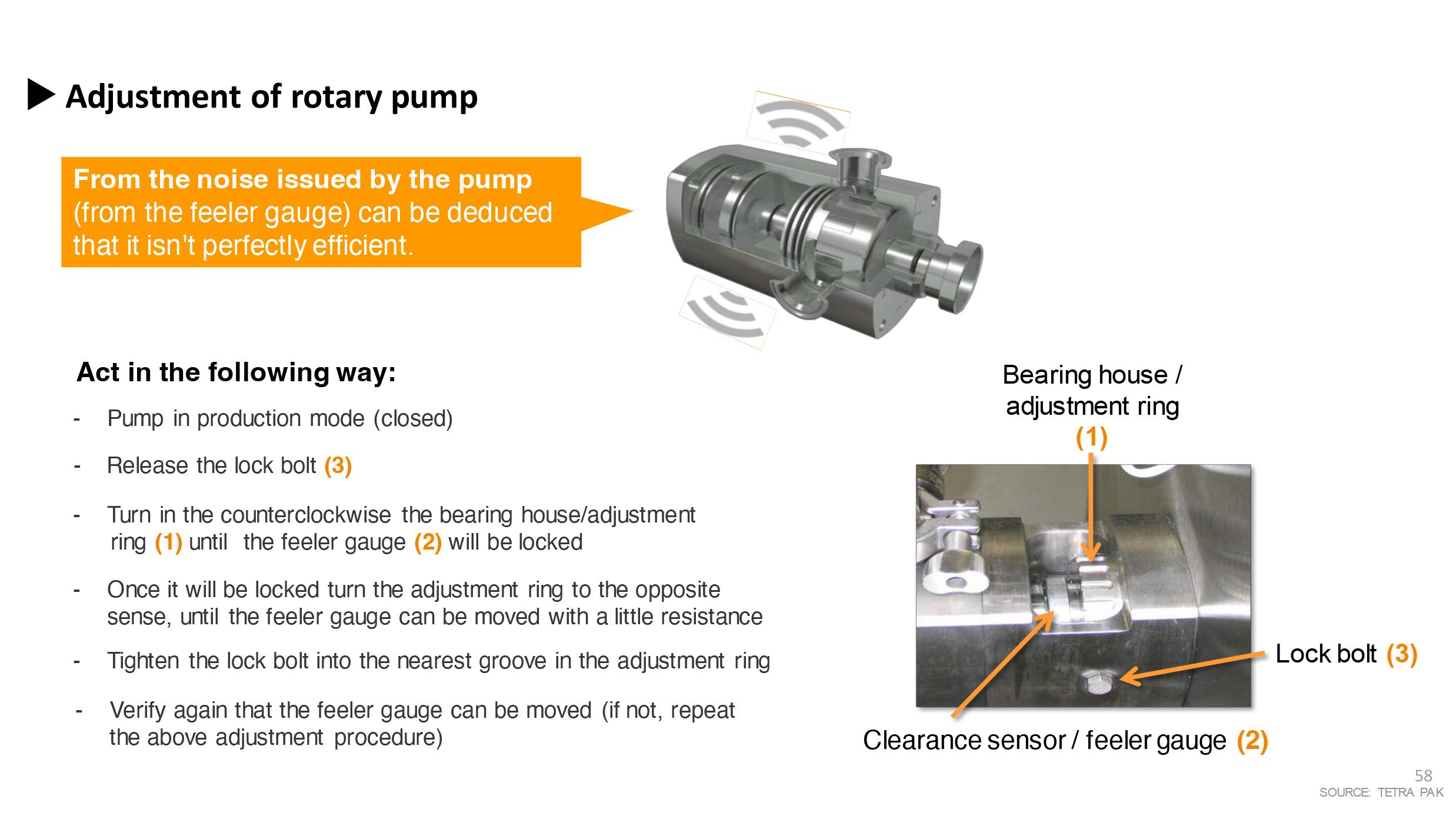

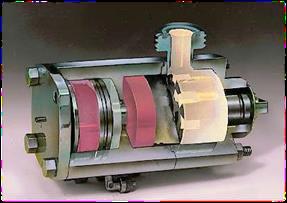

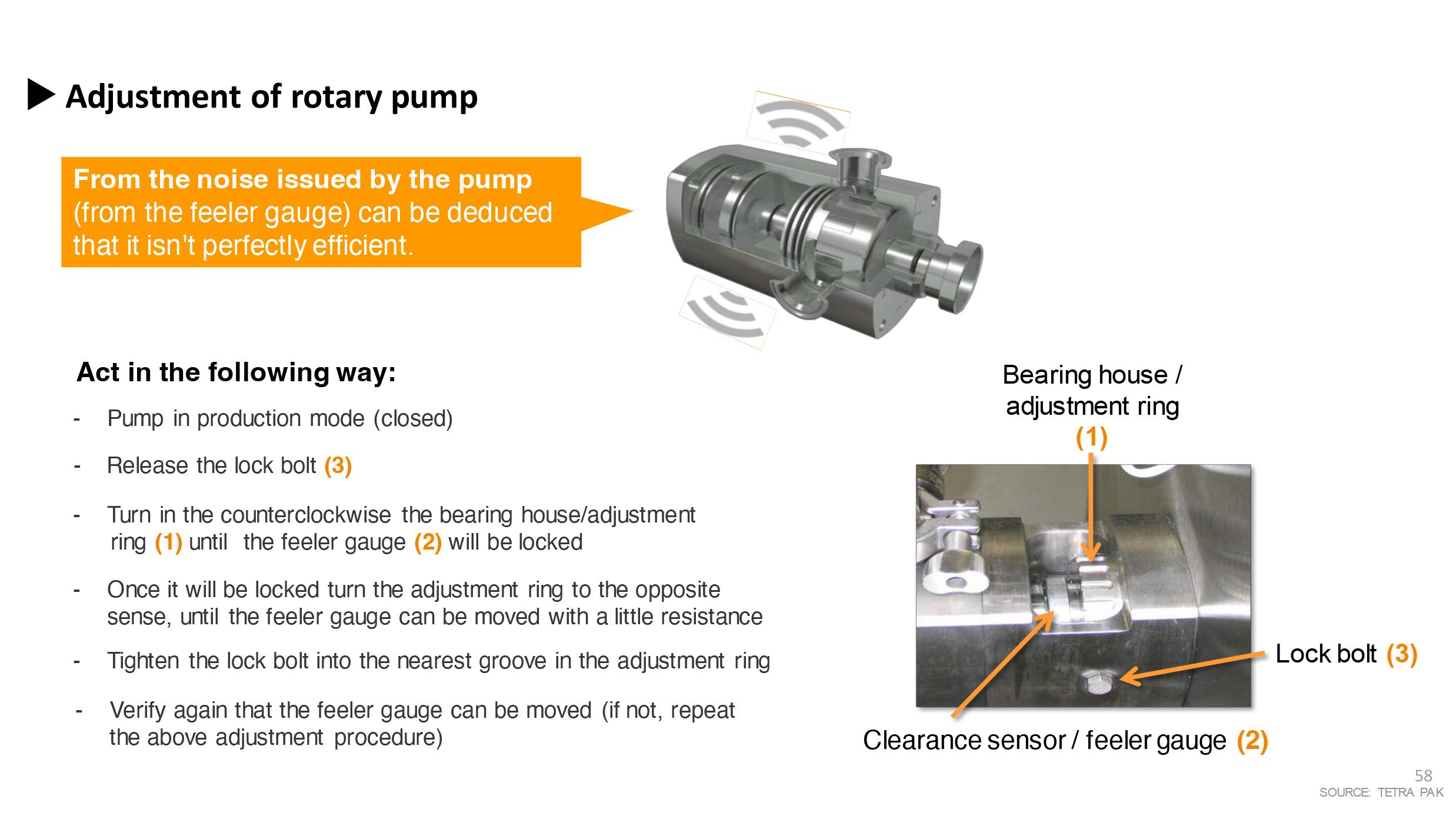

Tetra Pak Freezer pumps

Pump is in normal pump operation

The center wheel (star wheel), mounted on a pneumatically piston

(red colour is compressed air)

Pump in CIP position

The centre wheel is pulled out of pump position, and free flow of detergent through the pump is obtained

SOURCE: TETRA PAK

56

The pump leakage (=loss of efficiency) depends on:

✓ Viscosity of the mix

✓ Pressure difference over the pump

✓ Mechanical condition of the pump

✓

57 Pump

Theoritical flow rate Real flow rate Pressure difference over the pump FLOW 500 l/h 480 l/h

inspection :

Mechanical adjustment of the pump

Half-moon

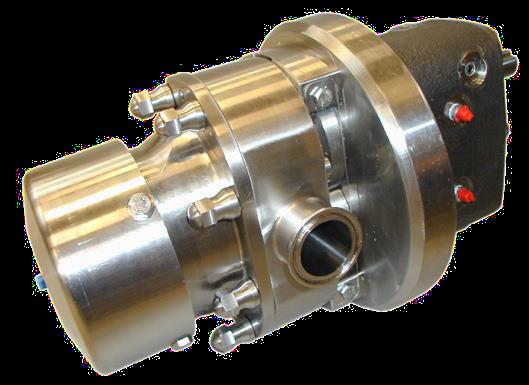

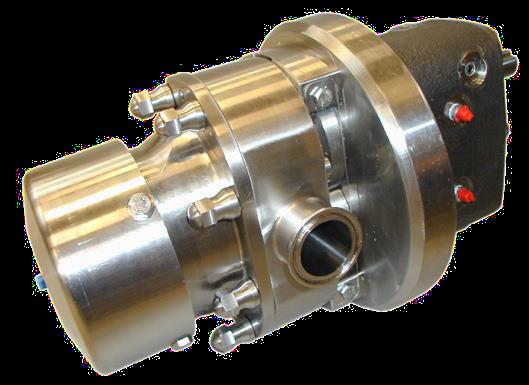

WCB Freezer Pumps

Waukesha metal lobe

✓ All WCB Equipment freezers utilize Waukesha metal lobe Waukesha pumps as standard.

✓ The rotors of these pumps are made of the non -galling lead-free Waukesha “88” alloy.

✓ This alloy allows the rotors run at a very close tolerance without touching, which provides extremely long rotor life.

✓ These pumps are fully CIP -able and have by-pass covers that allowing the necessary high flow during CIP.

✓ A magnetic flow meter is used to provide very accurately closed loop control of the mix flow.

59

ةيسيئرلا ةيبيردتلا ةرودلا ةيجاتنلااطوطخلايلغشمل يلمعلا قيبطتلا ديمجتلا ةطلخلا ريضحت ميركسيلاا ةبيكرت ةمدقم

61

Tetra pak pump - video

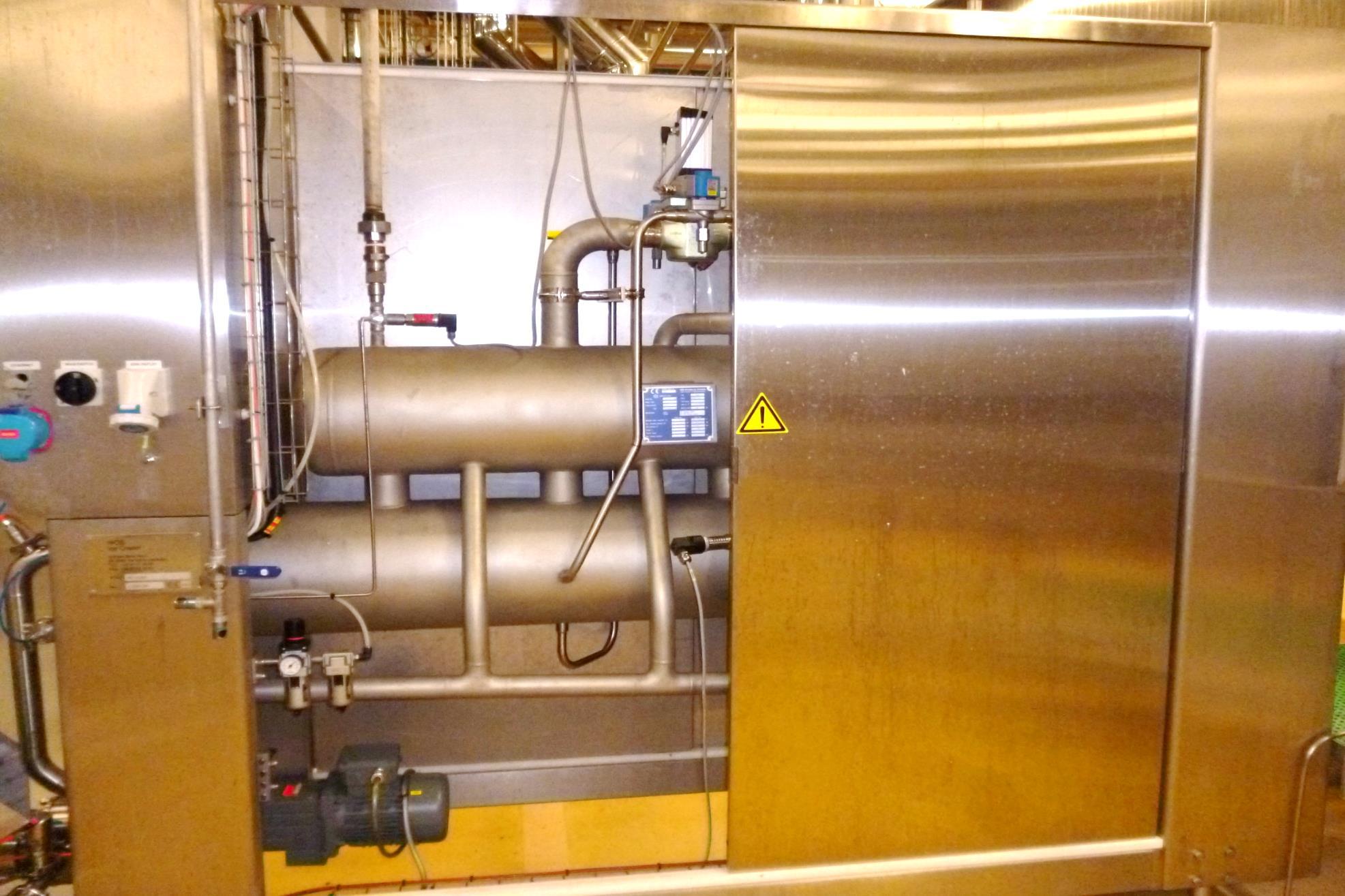

Refrigeration components

Level control (Control liquid valve supply)

Hot gas line

Suction valve (constant pressure suction valve) Hand valve + spring valve

Scraped Heat Exchanger (cylinder)

Liquid separator Oil drain line

Refrigeration components - Pipings

Hot gas line

Ammonia Gas back to compressor (low pressure)

Liquid Ammonia from Cooling Plant (High pressure)

Freezing cylinder/barrel 64

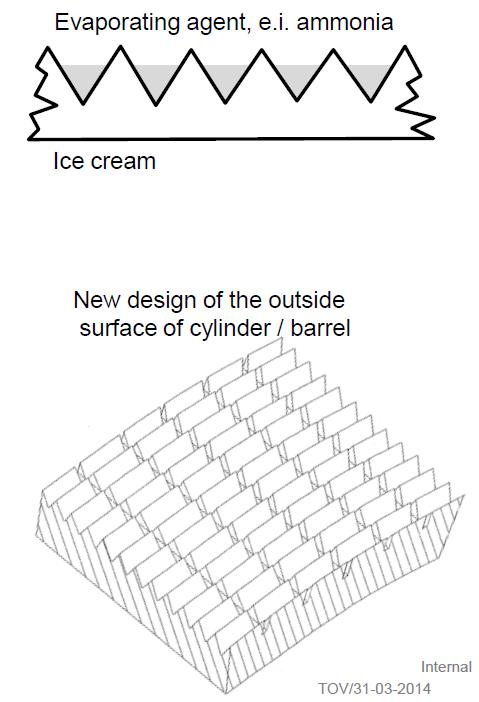

Cylinder walls

SOURCE: TETRA PAK

Refrigeration system : cooling principles

How it works ?

Liquid refrigerant floods the freezer barrel

Liquid refrigerant floods the freezer barrel

While evaporating, liquid refrigerant takes the heat from the product. The product cools down and freezes.

Ice crystals start solidifying on the barrel inner surface. Blades continuously scrape off those crystals from the surface.

65

Refrigeration cycle

160 psi

The gas returns to the cooling plant to be compressed again for a new refrigeration cycle

0,30 psi

The separator collects the refrigerant vapor (gas)

The refrigerant evaporates (boils) around the barrel

Receiver

The cooling plant provides the freezer with liquid refrigerant at high pressure

THE FREEZER 66

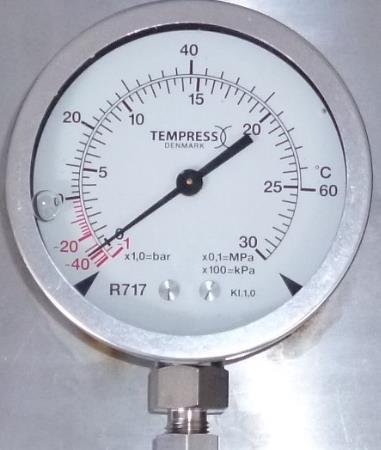

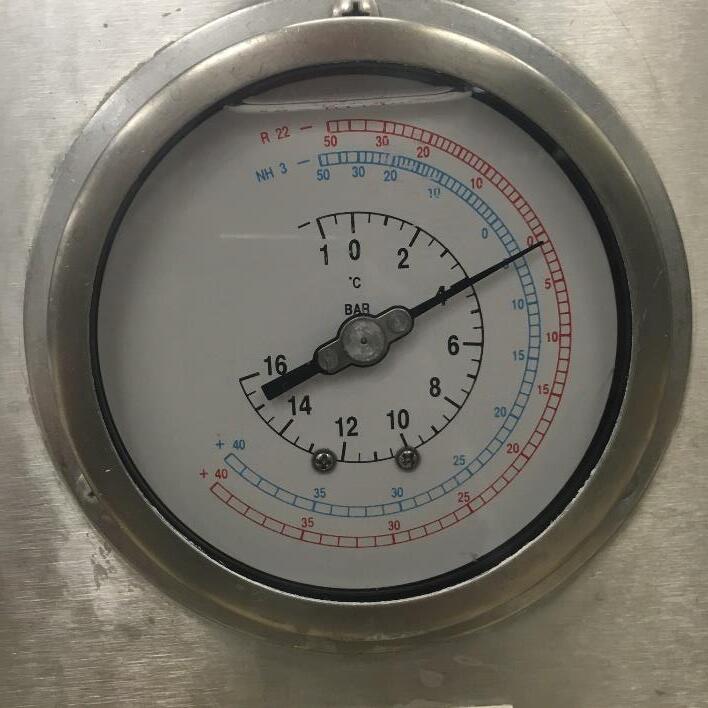

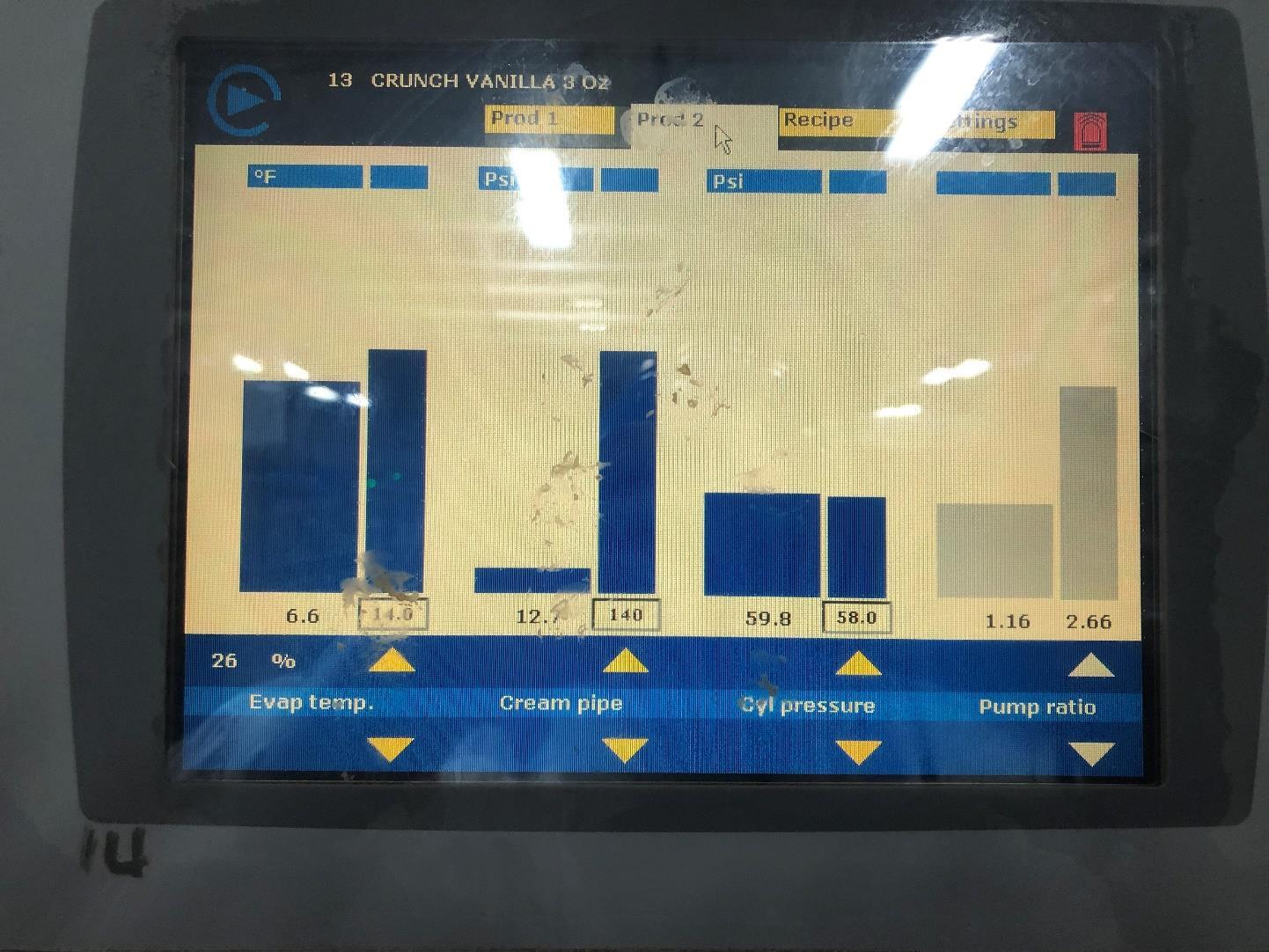

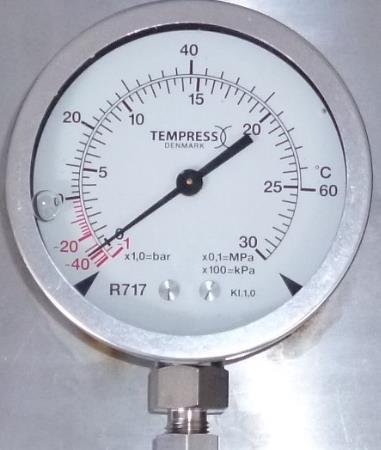

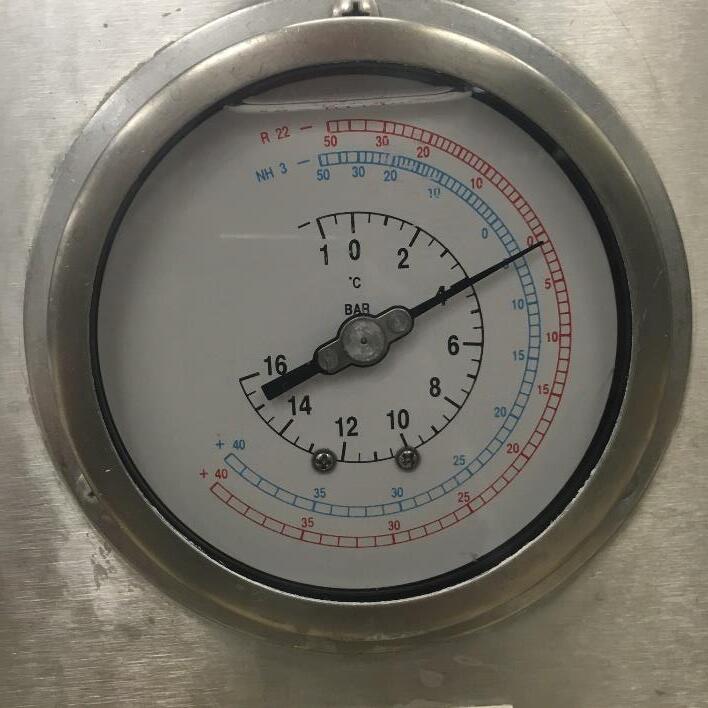

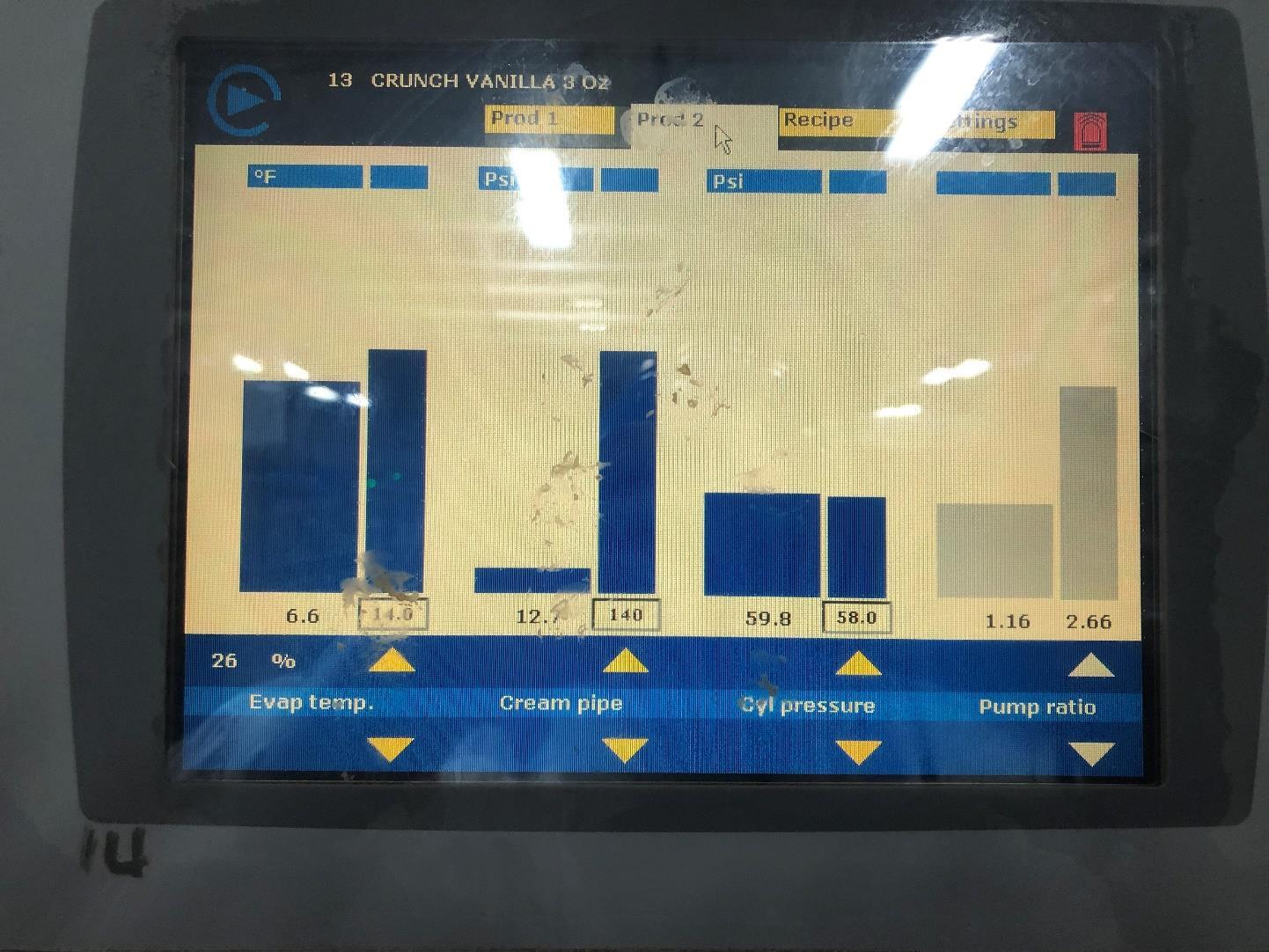

Refrigeration control: T °C / Pressure gauge

67

WCB example , front of freezer side

Evaporation Pressure : 58 psi

T°C Evaporation NH3 : -6.8°F Pressure : 22psi

T°C NH3 Liquid : 73°C

Pressure

: 123psi

T°C Suction NH3 : -18°F Pressure : 6psi

HOYER example , inside of freezer walls

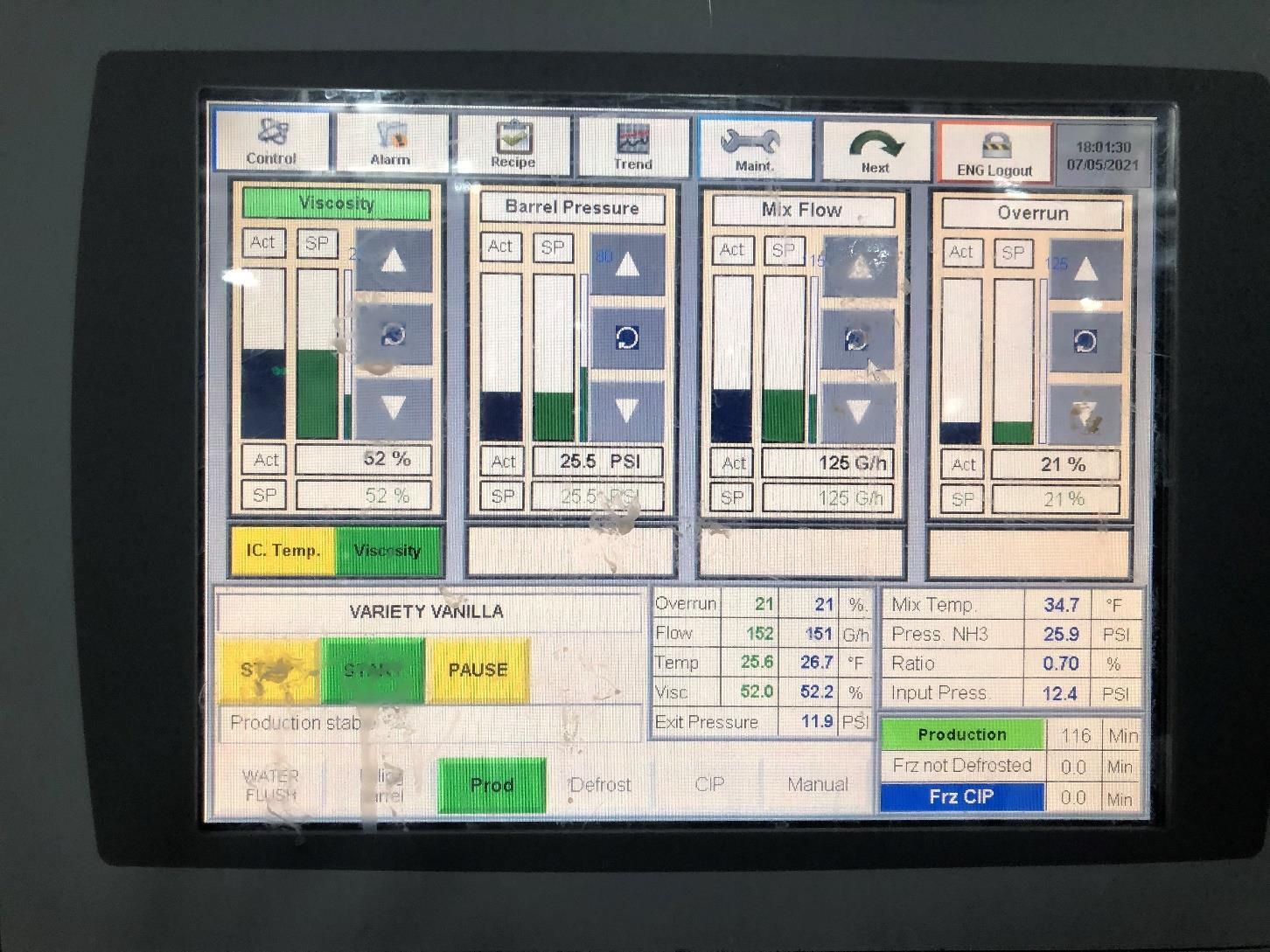

Key process parameters

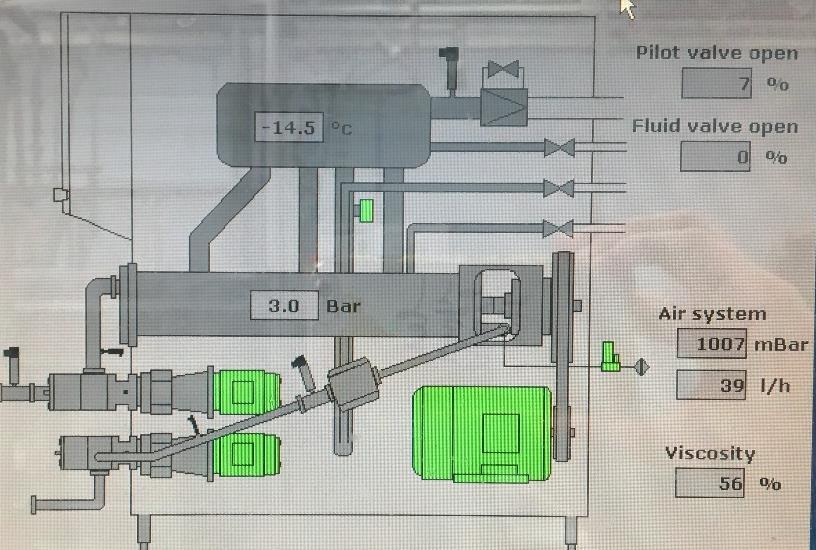

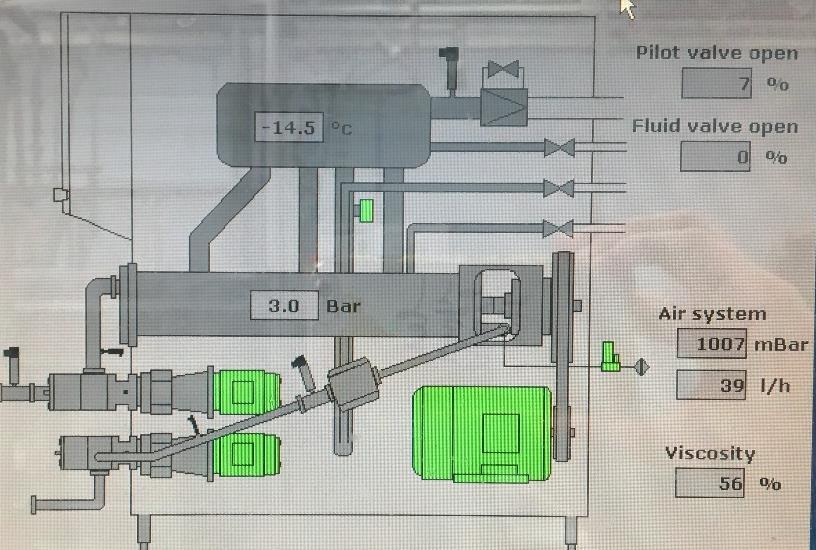

68 How to control the transformation during the Freezing phase

1 . C REAM F LOW 3 . V I SCOSITY Amount of air 2 O VERRUN Refrigeration system 4 I CE C REAM T EMPERATURE Dasher speed

?

Potential ISSUES affecting process parameters

1 . I CE C REAM F LO W

✓ High/low ice cream flow

What can be wrong?

3 . V I SCOSITY 2 . O VERRUN

✓ Fluctuation of overrun

✓ Too high/low

✓ Fluctuation of viscosity

✓ Viscosity drop

4 . I CE C REAM T EMPERATURE

✓ IC T°C

< Set-up

✓ Unstable ice cream flow (pump efficiency )

✓ Overrun not stabilized in Ice cream

Skating/ice formation

✓ IC T°C

> Set-up

69

Potential CAUSES affecting process parameters

1 . I CE C REAM F LOW

✓ Back-pressure too high

✓ Variability of mix flow rate

✓ Pressure of mix inlet

✓ Lack of overrun

✓ Overrun > set-up

✓ Overrun unstable

✓ Pumps

2 . O VERRUN

✓ Leakage of air circuit

✓ Variability of mix flow rate

✓ Bad air regulation

✓ Air pressure too low

✓ Barrel pressure variation

✓ Ageing time < 4h

✓ Homogenization issues (heads , pressure)

✓ Recipe formulation

What can be wrong?

3 . V I SCOSITY

✓ Variability of mix flow rate

✓ Maintenance of belts and dasher motor

4 . I CE C REAM T EMPERATURE

✓ IC T°C < Set-up

✓ Evaporation T°C not correct

✓ Worn blades / barrel surface

✓ Suction valve incorrect opening

✓ Barrel pressure variation

✓ High/low level of liquid refrigerant

✓ IC T°C > Set-up

✓ T°C of mix > 4°C

✓ Evaporation T°C not correct

✓ Recipe formulation (% solids , sugars )

✓ Barrel pressure not correct

70

Freezer Extras

Freezer Extras

Freezer Questions

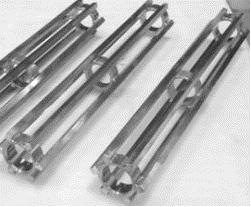

Inclusions

Inclusions are the ingredients that we put into an ice cream product after freezing like cookies, nuts, chocolate chips, etc

Inclusions are dosed into the ice cream using Ingredient Feeders.

GRAM IF Tetrapak IF

GRAM IF Tetrapak IF

Hopper: Place to fill the ingredients

Blender:

Different styles mix different inclusions better. Examples are blade blenders and pin blenders.

Funnel

Rotor:

Turns in the direction of ice cream flow. It has tight tolerances to keep the ice cream from coming up through the funnel.

Auger:

Different sized augers are used for different inclusions, it pulls the ingredients forward

Ingredient feeders lay the inclusions on top of the ice cream stream

Questions:

1) What will happen if the ice cream flow stops?

2) What will happen if the blender isn ’t turned on?

3) What if the rotor is ran too fast? Too slow? How do you know what the correct speed is?

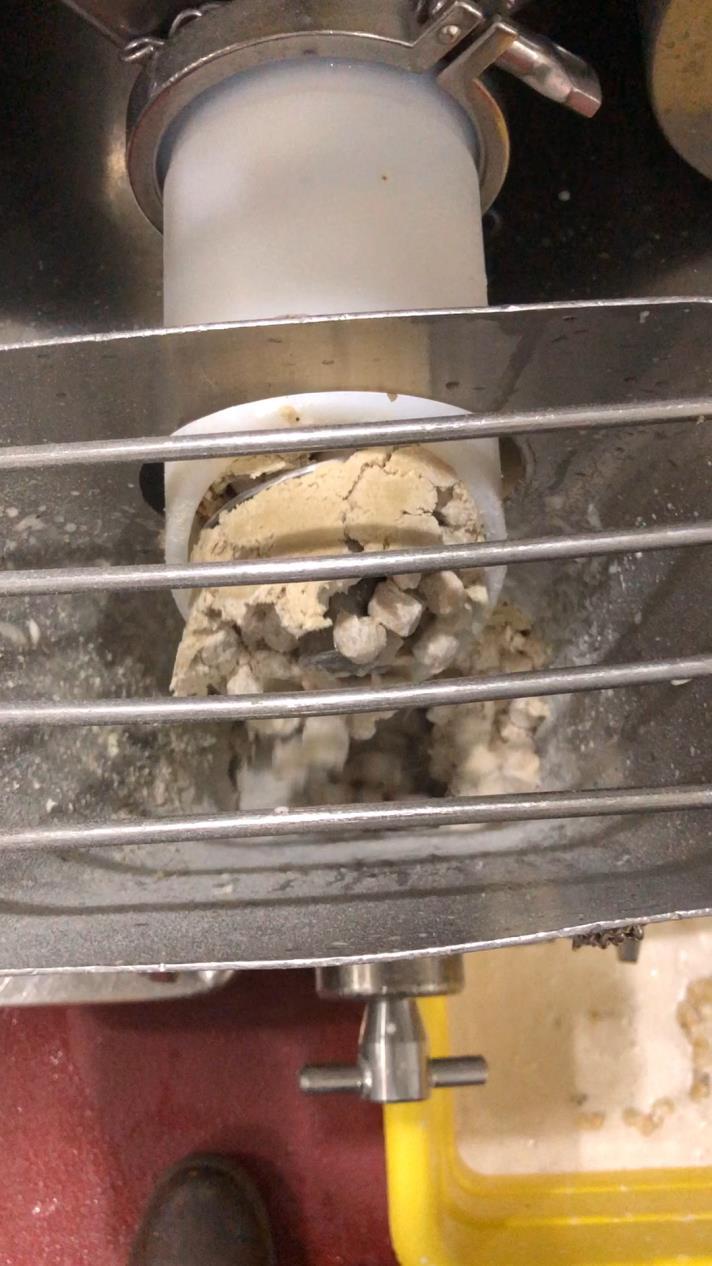

Inclusion Handling

Some Inclusions are sensitive to temperature. Warming up will cause clumping.

This clumping can cause some sensory defects but will cause operational problems like clogging.

Net Content (Weight Vs Volume)

Which is more important, Weight or volume?

VOLUME! Ice cream is released by volume, not weight. We cannot sell ice cream below volume because that ’s what we tell customers on the packaging. We ALWAYS should be just above volume targets.

What makes and loses us $$$Money? Weight or volume?

WEIGHT!!! We make our product weigh less by adding Air which does not cost us anything. We should target below just below target weight so we can make more ice cream. You can take out weight without taking away volume

Can we make our ice cream as light as we want?

Absolutely NOT. There is a lower reject limit on the checkweighers for a few reasons

1) To meet standard of identity for ice cream

2) To Meet the nutritional information

3) To avoid Short counts

4) To preserve product quality

Operational video

Key Parameters

RECIPE

COMPOSITION

✓ Total Solids (%)

✓ % Fats

✓ Proteins (MSNF)

✓ Sugars

✓ Stabilizers & emulsifiers

MIX MATRIX

TEXTURE & TASTE

82

MIX PREPARATION HOMOGENIZATION AGEING Order of addition Pressure T °C = 40 °F Dispersion Fat size particules At least 4 h Hydratation + Food safety : HEAT TREATMENT FREEZING ICE CREAM FLOW OVERRUN VISCOSITY ICE CREAM T° C

MIXING HOMOGENIZATION PASTO-COOLING AGEING FREEZING FILLING HARDENING COLD STORE INGREDIENT FORMULATION

Operational video

Froneri Hygiene

Hygiene and Dry Floors During Operation

Dry Floor ‘Obsession’ & Team Effort Spills Managed Differently

Hygiene and Dry Floors During Operation

More Plastic for Waste

More Plastic for Waste

Hygiene and Dry Floors During Operation

Floor Scrubbers & Investment in Hygiene

Hose ManagementRestricted Access

Waste Management- Giveaway/Process Control PSA Zone: Invest in Accuracy All Physical Waste is Weighed & Accurate

Flexible Fast Changeovers

Changeover Parts Organized Changeover Parts Kitted for the Week

Front Line Leadership Routines

Supervisors are on floor >80% of time & “Own” their results

“Big White” (Shift Mgr) was on the floor and actively involved all day long

Two Packaged - Side Employees came over to squeegee floor while starting up (without being asked) and stayed until line was running and floors were spotless

No mentality of: We’ll clean it up once we’re done…

Captured Shoes & Routine to Entry

1.2 Million dollars of micro destruction 2020 Recall - $250,000 lost because we couldnt see a leak 300 foreign body complaints year to date THIS IS OUR KITCHEN

Why Do we need to do this?

Being a Machine Operator

• Own Safety and GMPs on your line

• Own your line Hygiene

• Own Productivity

• Don’t run to make Waste

• Always get better, Improve your team and line

• Help your supervisor supervise

THANKS FOR YOUR INVOLVEMENT

95

Training course for line operators

MASTER TRAINING COURSE

For Line Operators

Tetra pak – dasher assembly video

Tetra pak – dasher assembly video

GRAM IF Tetrapak IF

GRAM IF Tetrapak IF