We’re the largest manufacturer of twisted-wire brushes that makes the world’s smallest brushes. Mill-Rose miniature brushes are available in a variety of styles and configurations as small as 0.014” in diameter to deburr, clean and slightly ream very small holes and cavities.

We design, engineer, manufacture and deliver standard and custom brushes in any quantity. Mill-Rose has set the standard for quality, performance, and innovation in brush technology for the past years. Choose from thousands of standard and not so standard sizes and shapes. Call or visit MillRose.com.

What a roller coaster! One week an announcement comes out that Interbrush has officially been canceled and just like that 45 years of history ends. But a few weeks later, the World Brush Expo is announced for 2024. With the ABMA and European Brush Federation driving the show there is good reason for optimism. As associations vested in building and supporting the brush industry community, that certainly sets the table for the World Brush Expo to be in perfect alignment with the needs of the industry.

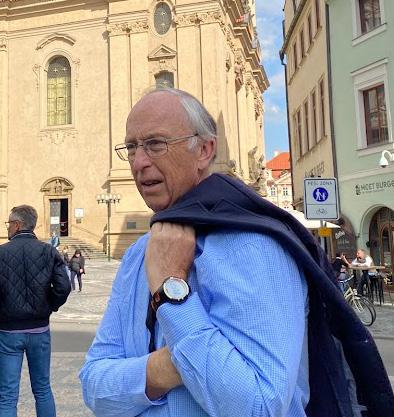

While that was clearly the breaking news story for September, the FEIBP Congress was happily back on track with a visit to Prague, Czech Republic. By all accounts, it was a successful return and we are pleased to have our report in this issue from correspondent Katharina Goldbeck-Hörz on page 20. In particular, I enjoy the FEIBP Innovation Awards and you can see all three winning products on page 24.

I also want to highlight our profile with Alberto Voltolina, CEO and President of MGG North America (p. 16). The expansion and launch of a new machinery company in North America is intriguing enough and Voltolina provides more details on the strategy and benefits of the launch.

Those stories alone are enough to fill up the issue, but in the meantime, brush businesses across the world are working through this challenging period of inflation. We felt compelled to get up to date with the industry on the issue. Starting on page 26, Bob Lawrence does a deep-dive with three separate segments on how brush industry companies view the complicated issues surrounding inflation. Lisa Anderson’s case study on an approach to navigate the inflation challenges doubles down on the issue. Overall, I personally found a hopeful message subtly interwoven into the coverage. Despite round after round of world events converging and seemingly conspiring to trainwreck the business climate, there is something to be said about how prepared brush manufacturers and the industry as a whole have been for this current challenge. Ultimately, it’s not hard to detect a sense of optimism for the industry in both the near-term and long-term.

Finally, I am pleased to introduce the Annual Machinery Showcase and Supplier/Manufacturer Spotlight Combo Issue. This edition is built to be both a showcase and resource and I hope all readers find this over-loaded 80-page issue to be a vital resource for industry information. Please enjoy and have a happy holiday season!

Dylan Goodwin | PublisherBrushware – a bi-monthly publication edited for key personnel in the brush, roller, broom, mop and applicator industry. Published continuously through the years, the one publication that is the spokesman for the brush and allied industries: 1898-1923, called Brooms, Brushes & Handles; 1924-1947, called Brooms, Brushes & Mops, 1948-today, called Brushware

Brushware Magazine

Goodwin World Media LLC P.O. Box 7093 Overland Park, KS 66207 Tel: 913-636-7231

Susan Goodwin

info.brushware@goodwinworldmedia.com

Dylan Goodwin dylan.goodwin@goodwinworldmedia.com

Bob Lawrence Phil Perry Meg Cooper Katharina Goldbeck-Hörz Mark E. Battersby

Lisa Anderson

Conor M. Todd

Brushware (ISSN 00072710) (Canadian Sales Agreement Number 0650153) is published bimonthly by Goodwin World Media LLC, P.O. Box 7093, Overland Park, KS 66207 USA. Periodical postage paid at Overland Park, KS 66207 and at additional mailing offices. Printed in the USA. Subscription: $95/year for US, Canada and Mexico. All other countries $210/year.

POSTMASTER – Send address changes to Brushware Magazine, P.O. Box 7093, Overland Park, KS 66207. Copyright 2022. All rights reserved. Materials in this publication may not be reproduced in any form without permission. Requests for permission should be addressed to: Brushware Magazine, P.O. Box 7093, Overland Park, KS 66207.

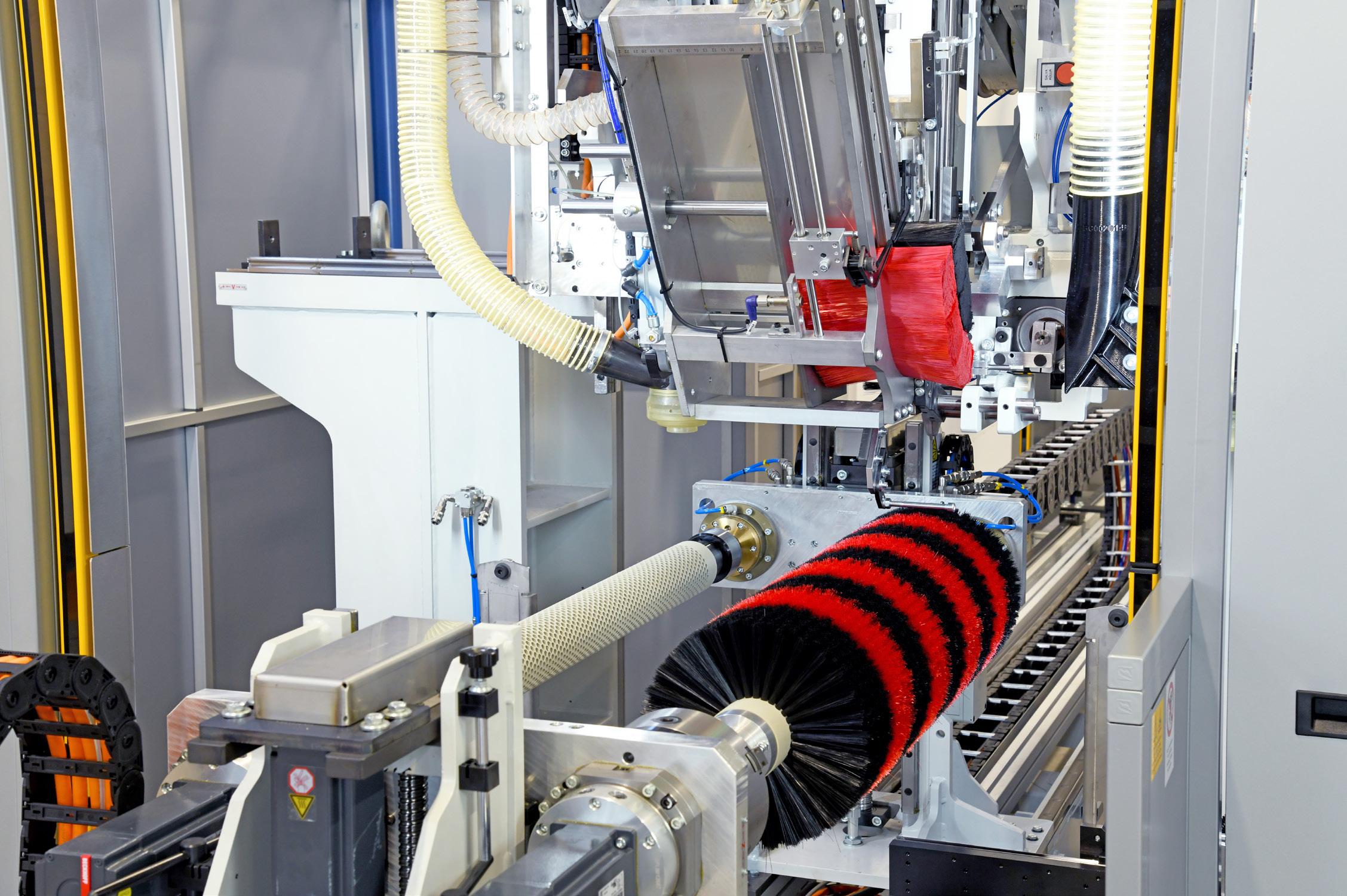

With NM, Boucherie has developed an extremely fast running single tool machine that is more compact, will run at a higher efficiency and will be much safer to run than the traditional vertical double headers. The machine is laid out as a compact carousel with only 3 clamping stations, and with extremely good accessibility for maintenance and change-over.

Just a few weeks after FWTM announced the end of the Interbrush global four-year brush industry trade show, the American Brush Manufacturers Association (ABMA) and the European Brushware Federation (FEIBP) released a brief statement announcing a joint association-owned and coordinated exhibition trade show for the international brush community. The new World Brush Expo will be launched in the spring of 2024 and the statement referred to it as “a show for the industry, by the industry.”

According to the statement key leaders in the industry agreed that an international show is vital to the integrity and growth of the industry and serves to benefit the entire brush community.

“Interbrush was an event that my team and I always looked forward to. Having an international exposition where we could have in-person experience to the newest technologies and be educated on best practices has always been essential to the health of our organization,” says Scott Enchelmaier, The Industrial Brush Company. “As a business owner, Interbrush was a supplemental tool to gauge the trends that we see with our business compared to the larger industry trends, and we have often used the expo to purchase major machinery. It was tremendously disappointing when the announcement was made that Interbrush 2024 would not take place, especially after years of cancelled or virtual conferences. I was then very happy to see the announcement that the ABMA and FEIBP organizations stepped-up and would be sponsoring an international trade fair in Europe. Though I cannot speak to the factors that led to the expo changes, the pandemic has shown me that we must be flexible and adapt to change. It is in the best interest of the brush industry and we must be willing to adjust to the shifting currents that affect us.”

Originally founded as Interbrossa, the internationally oriented trade fair Interbrush had been organized by FWTM in Freiburg since 1977 and followed a four year rotation starting in 1980. In 2024, the world’s leading trade fair for machinery, materials and accessories for the brush, paintbrush, paint roller and mop industry would have entered its 13th edition. In 2016, more than 7,500 professionals from around 90 nations came to see the latest developments from 200 exhibitors.

Planning is currently underway with target destinations in Italy under consideration.

Interbrush show organizer FWTM (Freiburg Wirtschaft Touristik und Messe GmbH & Co. KG) released the announcement that Interbrush would end after 45 years came on September 8, 2022. FWTM said in the announcement that a dialog was initiated with the ABMA and FEIBP and other leading exhibitors after the show’s largest exhibitor, Zahoransky AG, changed its corporate orientation last year and announced that it would no longer participate in Interbrush.

FWTM said various concept ideas for a new content orientation, including possible new locations in German-speaking countries were presented. In further discussions, the exhibitors as well as the ABMA and European Brushware Federation (FEIBP) wanted a rolling system with alternating European locations.

“We very much regret this development and the decision of the associations and a few, but in terms of external impact, very important exhibitors. In our opinion, values and competencies such as experience, quality, industry knowledge and also the partnership that has existed for over four decades were not included in the evaluation and resulting determination –but which are an essential pillar of the event,” says FWTM Managing Director Daniel Strowitzki. “We wish the entire industry, of which we were able to be a part for many years, all the best for the future and thank everyone who has accompanied the Interbrush format over many decades.”

For the new World Brush Expo, the ABMA/FEIBP statement said additional details including the show dates and location are still being finalized and would be released as soon as they are available. Visit www.worldbrushexpo.com for updates.

Blue Monster® VelocityTM, a new specially-formulated tankless water-heater flush product, has been introduced by the Clean-Fit Products division of The Mill-Rose Company. Developed for use on commercial and residential tankless water heaters, Velocity is a fast-acting compound with the strength needed to remove scale, lime, rust and other corrosive water-formed deposits. Velocity is easy to use, consists of odorless granules that eliminate splashes and spills and restores circulation and pressure in under 20 minutes.

The cleaning process consists of mixing Blue Monster Velocity with water that is circulated through the tankless water heater for a complete flush that restores water flow and heating efficiency for like-new performance. Velocity contains sulfamic acid, a highly effective agent used to clean heat exchangers, boilers and condensers. It’s compatible with copper, CPVC, PEX and PERT piping systems.

“Velocity offers the best of both worlds – it’s an aggressive cleaning compound with the strength needed to remove scale lime and rust, yet safe for potable water systems,” says John Kirkland, National Sales Manager for Clean-Fit Products.

Velocity is non-corrosive and NSF Nonfood Compounds A3 listed, assuring it is safe for use in food processing environments.

Blue Monster® Velocity is available in a 1.2 net lbs. container and sold at leading PHC supply houses. Blue Monster products are offered exclusively by Clean-Fit Products, a division of The Mill-Rose Company. Mill-Rose is the world’s leading supplier of PTFE thread sealants and the largest manufacturer of twisted-in-wire brushes in the U.S.

For further information contact Clean-Fit Products, 7310 Corporate Blvd., Mentor, Ohio 44060. Telephone 1-800-321-3598, fax 1-440-255-1072, e-mail info@cleanfit.com or visit www.cleanfit.com.

The National Painting and Decorating Show is the industry’s biggest annual UK event held at Ricoh Arena. If you use, sell, stock or specify P&D products, the exhibition is one you can’t afford to miss. www.paintshow.co.uk

The National Hardware Show is the most comprehensive event, education and networking platform serving the hardware and home improvement industries. www.nationalhardwareshow.com

Creativeworld is the world’s most important trade fair for the international hobby, craft and artists’ supplies sector and an inspiring treasure chest for the creative community. www.creativeworld.messefrankfurt.com

We connect not only buyer to seller, but also product to lifestyle and the industry to the consumer mindset. More than 52,000 home and housewares professionals from more than 130 countries converge upon Chicago for the Show. www.theinspiredhomeshow.com

The American Brush Manufacturer Association’s 2023 Annual Convention is planned for San Diego, California. www.abma.org/abma-annual-convention

2nd Edition INBRUSH 2023

India’s only B2B event for brush manufacturing machinery and finished brushes. The event provides a unique opportunity for the brush industry – brush product manufacturers, brushmaking machinery suppliers, raw material suppliers, component suppliers, etc. to showcase their product range and services to a focused audience of B2B end users and OEMs. www.indiabrushexpo.com

The Annual Congress of the European Brushware Federation is a great opportunity to meet fellow manufacturers, contact suppliers and receive up-to-date information on the brush industry in Europe. www.eurobrush.com

October 17-19, 2023

Staying up to date on the latest trends and solutions for cleaning, disinfection, and infection prevention and pursuing accreditation, training, and certification helps us further evolve the industry and change the way the world views cleaning. www.issashow.com

Interclean Amsterdam | Amsterdam, The Netherlands

From May 10-13, 2022, RAI Amsterdam will turn into the capital of cleaning and hygiene. Join us for a four-day journey of forward-thinking, doing business with leading manufacturers and meeting industry professionals from all over the world. www.intercleanshow.com/amsterdam

For more than 80 years, DuPont Filaments has been recognized as a leader in innovative synthetic filaments that enable brush manufacturers to address emerging trends and meet evolving consumer expectations.

The most important component of a toothbrush lies in the bristle. With outstanding industry expertise accumulated over the years, coupled with our proven technologies, DuPont Filaments is dedicated to the oral care brush industry with our nylon solutions under the brand names of DuPont™ Tynex®(nylon 612) and DuPont™ Herox®(nylon 610) . Leading toothbrush brands and manufacturers are able to produce very high quality brushes with a balance of consistent quality, wear performance and unmatched productivities in tufting and end-rounding by using DuPont filaments. As consumer trends in toothbrush are increasingly focused on the six major areas of 1) Visual Attractiveness, 2) Interdental Cleaning, 3) Plaque Removal, 4) Gum Comfort, 5) Gingival Cleaning and 6) Anti-microbial within the filaments, DuPont Filaments has been working closely with the leading global brands in oral care as well as toothbrush manufacturers by fulfilling these needs with our broad range of innovative products in the portfolio

DuPont™ Natrafil® filaments, a pioneering filament from DuPont’s unique polyester based material, contain proprietary texturizing additives that create a structured surface that mimics animal hair. Natrafil® filaments offer a synthetic alternative to animal hair in premium cosmetic powder brushes with more consistency in the bristle while maintaining the touch-and-feel of premium animal hair. Studies have shown that brushes made with Natrafil® filaments have equal to superior pickup and release performance versus brushes made with animal hair.

Like most industries, steel manufacturers are always looking for

ways to increase productivity. The emphasis is on getting more square feet of metal through the mill, cleaned and coated faster than ever before. To accomplish this, steel mills are using more aggressive cleaning solutions. The problem is that the cleaning brushes typically used were quickly degrading because many plastics used in the brush filaments can’t handle the solutions of the extremes of the PH scale. The technical resources at DuPont Filaments were able to help solve the problem by adding stabilizers to one of our nylon polymer formulations, effectively extending the pH range that these filaments can be used in. Brushes made with these filaments deliver cleaning performance over an improved service life, helping steel manufactures to achieve higher productivity. Another need voiced by customers is higher aggressiveness in metal finishing applications. DuPont™ Tynex® A filaments, a family of ceramic grit-containing filaments, was developed to meet this need.

When manufacturers began changing their paints to water-based formulations, more people began using paintbrushes made with synthetic bristles because the hog bristles traditionally used in paintbrushes lost stiffness in water-based paints. Synthetics such as DuPont™ Tynex®, DuPont™ Chinex® and DuPont™ Orel® brand filaments quickly became popular choices. As paint manufacturers continue to improve their water-based formulations by reducing volatile organic compound (VOC) content, increasing solid loadings and decreasing drying times, there is an ongoing need for increasingly higher performing brushes. To meet this need, DuPont Filaments continues to innovate and help customize solutions. For example, we developed filaments with stiffer cross-section that can push higher viscosity paints more efficiently. We also changed the shapes of the filaments so that they not only pick up more paint from the can for faster application, but are easier to clean.

OPT Industries, a leader in ultra-precise additive manufacturing technology and roll-to-roll production, recently announced the launch of PolyBrush, a vibratory brush mat product that will replace the discontinued Brushlon™ series products. PolyBrush is developed in partnership with the Industrial Brush Company, Inc., an industrial brush manufacturer that has served the industry since 1946. Pre-orders for the PolyBrush alternative to the discontinued Brushlon 331B and 321B mats are now open and the product is on track to begin shipping to customers in Q4 of 2022.

PolyBrush features a 100 percent American-made single-piece construction that uses angled polymer bristles to safely move a variety of delicate parts with minimal chance of damage and ensures that parts never reverse direction.

EASY TO INSTALL AND REPLACE: PolyBrush is easily cut with a band saw, box cutter or razor, and secured with standard methods, such as hook and loop tape. Pieces can be cut to size to enable spot replacing, reducing the need to replace entire panels.

OPT Industries and The Industrial Brush Company, Inc. will continue to expand the PolyBrush line and develop further

solutions for the industrial machinery industry by combining each company’s unique expertise.

“At The Industrial Brush Company, we take pride in finding the best way to build a brush solution, which often means looking outside of the norm for manufacturing solutions,” says Scott Enchelmaier, Vice President at The Industrial Brush Company, Inc. “We explored traditional manufacturing methods but were not getting the results we were looking for. OPT’s unique additive manufacturing solution was exactly what we needed. They’ve been an excellent development partner throughout the design and iteration process, and seeing PolyBrush go into production at OPT is really the first step through the door towards an additive manufacturing future for industrial consumables.”

Global Shop Solutions, a leading provider of ERP software to manufacturers around the globe, is proud to celebrate the fifth year anniversary of its Cloud ERP product. Designed to make technical support easier and reduce the total cost of ownership for manufacturers, Cloud ERP simplifies the software through increased speed, improved accessibility, stronger security, automatic data and systems backups and more.

According to George Thuo, Director of Cloud Technology for Global Shop Solutions, Cloud ERP caught the attention of current and prospective customers from the start and product adoption greatly surpassed the five-year forecast.

“Like most new Global Shop Solutions products, our Cloud ERP is a result of listening to customers and responding to their needs,” says Thuo. “Several years ago, a growing number of prospective ERP buyers began asking if our ERP system was offered in the cloud. Based on the demand, I assembled a team to develop the product, which we launched in 2017. Five years later I am proud to say we have more than doubled our forecasts for the number of Cloud ERP users and made ERP software better for hundreds of manufacturers.”

Cloud-based ERP software offers many advantages, starting with lower system costs. With Cloud-based ERP, companies can maintain ERP at a very reasonable price because the ERP vendor performs these tasks for the customer. Another advantage is the ability for employees to access their company’s ERP system from anywhere, including at-home workstations or in real-time at multiple facilities. In 2017, about 25 percent of new Global Shop Solutions customers opted for Cloud-based ERP. Currently, about 65 percent of new customers choose that route. Thuo expects these numbers to continue to climb largely due to security concerns.

“With cyberattacks increasing in the manufacturing market, Cloud-based ERP costs less to protect the integrity of the system, especially for smaller manufacturers who can’t afford to have IT or security experts on staff,” says Thuo. “Our Cloud ERP helps customers avoid malware attacks because it’s protected with the best technology. Going forward, ERP providers will have to integrate security into their product, and the cloud is a great option.”

25 YEAR PARTNERSHIP: When a manufacturing customer stays with the same ERP provider for 25 years, the relationship is undoubtedly working to benefit both organizations. Global Shop Solutions, is pleased to recognize the 25th anniversary of House of Doolittle® as a loyal customer. Based in Arlington Heights, Ill., House of Doolittle makes calendars, planners, desk pads and other paper-based productivity products for office, promotional, collegiate and personal use. The company implemented Global Shop Solutions ERP software in 1997 and has been using it to grow its business and serve customers more effectively ever since.

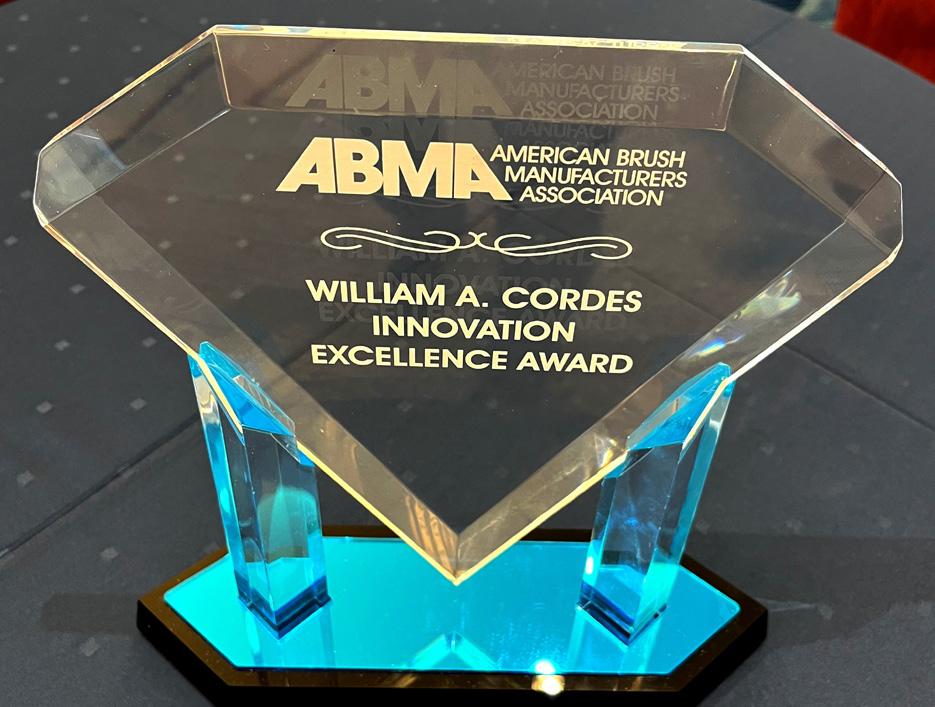

The ABMA is inviting member companies to enter new products for the ABMA William A. Cordes Innovation Excellence Award for 2023. “The Willie” is given to recognize outstanding innovation in any manufactured product, component or service in the brush industry. Submitted entries will be showcased during the 2023 ABMA Annual Convention next March in San Diego, Calif.

The Innovation Award recognizes outstanding innovation of manufactured products, components or services in the Brush, Broom, Mop and Roller Industry and is named after William A. Cordes, who served as the ABMA’s first President from 1917-1928.

Manufactured products, marketed products, components and services must be readily available in the year for which they are being submitted for consideration. To be eligible, any nominated product, component or service must have been introduced into the marketplace up to 18 months prior to the convention in which it will be voted on. Any and all manufactured and marketed products, components and services that pertain to the broom, brush, mop and roller industry are eligible for consideration.

Submissions must include a signed nomination form, actual production pieces, copies of patents or patent applications, copyrights, trademarks, permissions, design drawings, description of service, where applicable, along with proof service is actually in use in the industry, such as certification letters or warranties. Proof of introduction into the marketplace within the previous 18 calendar months is also required. A one-page description summary may also be included. Nomination forms may be found at: http://www.abma.org/upload/ ABMAInnovationAwardOutlineandFormupd2022.pdf

Borghi USA of Aberdeen, Maryland, is happy to announce we have hired a Spare Parts Manager. Please welcome Armando Ercole who recently completed a fourmonth training program for customer service, inventory control and processing spare parts orders.

We are excited to have Ercole on our team who is originally from Italy and has lived in the USA for the past 20 years. He is fluent in English, Spanish and Italian and is comfortable in communicating in any of these languages. Please be sure to welcome Borghi USA’s newest Team Member, Armando.

Tom Friedl, the president and CEO of the Tranzonic Companies, parent company to Hospeco Brands Group, has been named executive officer on the board of ISSA, the worldwide cleaning industry association. Hospeco is a charter member of ISSA and Friedl previously served on the board as manufacturer director. He has also championed ISSA’s Government Affairs Advisory Committee, a board that represents the industry’s interests in pending legislation, from controlling the supply chain to navigating tariffs and more.

Friedl’s new ISSA role as executive officer is one of five board positions filled as part of ISSA’s recent election of 2023 leadership.

ISSA has more than 10,500 members, including distributors, manufacturers, manufacturer representatives, wholesalers, building service contractors, in-house service providers, residential cleaners and associated service members.

Three new directors have been elected to the board of directors of the International Housewares Association (IHA), the fullservice trade association for the housewares industry. They are: Scott Felsenthal, CEO, Whitmor, Inc.; Sal Gabbay, CEO, Gibson Homewares; and Michael Hayes, chief customer officer, Newell Brands. Their three-year terms begin October 1, 2022, and end September 30, 2025.

Also elected were new board officers:

• Chairman – Steve Greenspon, CEO, Honey-Can-Do International LLC

• Vice Chairman/Chairman Elect – Neal Asbury, president & CEO, The Legacy Companies

• Treasurer – Paul Cosaro, CEO, Picnic Time Family of Brands

All officers serve one-year terms from October 1, 2022, to September 30, 2023.

Retiring from the board are William Endres, president, Select Brands; Melissa Kieling, CEO, PackIt, LLC; and Kristine Malkoski, business unit CEO, Food, Newell Brands. Re-appointed for a second three-year term were Paul Cosaro and Kavita Shukla, CEO, The FRESHGLOW Co.

Inflation continues to plague the world with escalating prices across a spectrum of products and services. The price of oil and gas has continued to rise and supply chain challenges persist, creating inflationary pressures across the board. Even though interest rates are rising, inflation isn’t yet getting under control. Thus, what are the best of the best doing to thrive under these extraordinary pressures?

One strategy to successfully navigate inflation is to quickly understand and evaluate your sales forecast in conjunction with customer and product profitability analysis to make appropriate decisions. For example, an industrial equipment manufacturer saw a dramatically increased need for their large filter product. Although the growth was exciting, this increase created a capacity shortfall. Of course, not all capacity shortfalls are as easy to solve as others. In this case, they increased output as much as possible but were limited by the lack of people and the appropriate infrastructure to expand the capabilities of the larger-size filters. Additionally, although their offload suppliers could support the expansion of small and medium filters, they didn’t have the appropriate infrastructure to expand the production capacity quickly for large filters. Thus, lead times were extended.

Of course, as is true with every manufacturer, the prices of raw materials and components remain high. However, not all margins are created equal. In analyzing these filters from a product profitability standpoint, they saw lower margins in comparison to the rest of their product line. Although they would be willing to invest in the appropriate infrastructure if it made sense from a strategic standpoint, based on the customer and product profitability analysis, it was determined that it wouldn’t make sense to prioritize investment in this product line. This analysis prompted the sales team to re-review large filter orders, customer profitability, priorities and pricing strategies.

In addition, the company looked at strategies to offset inflationary pressures by getting ahead of demand with suppliers and increasing efficiencies in operations while keeping customer service intact. Since material shortages continued to plague production, they prioritized material forecasts and

worked proactively with suppliers to prioritize deliveries. Sales and operations worked together to align on a sales forecast and converted that forecast into a product line forecast so that they knew how many of which types of products would be needed. From there, they could derive a directionally correct materials forecast so that they could align with key suppliers, get ahead of the curve to minimize prices and prioritize critical purchases.

From the operations perspective, they focused on creating a master production schedule to see what was coming down the pike and plan appropriately. This longer-term view allowed them to put together cross-training, hiring and equipment plans. In addition, instead of jumping through hoops daily to determine if they had the materials for production and adjusting schedules constantly, they put together a production schedule for the week that was sequenced optimally in advance. This allowed them to check material availability and establish a flow with materials delivered when needed and schedules stabilized. The overall result was a 40 percent increase in output, improving efficiencies and profitability.

By staying resilient amidst changing conditions, this manufacturer successfully navigated inflationary pressures, partially offset the negative cost impacts and was able to successfully serve customers. Establishing a collaborative sales and product forecast was key to analyzing changing demand patterns and customer and product profitability while proactively managing materials deliveries and operational plans, which allowed the company to grow revenue substantially and gain market share.

Lisa Anderson is the founder and president of LMA Consulting Group Inc., a consulting firm that specializes in manufacturing strategy and end-to-end supply chain transformation that maximizes the customer experience and enables profitable, scalable, dramatic business growth. She recently released a new “Thriving in 2022” eBook download that offers insights from 22 experts in manufacturing, supply chain and technology to thrive amid the current challenges facing businesses. To download the ebook, visit: www.lma-consultinggroup.com/thriving-in-2022.

COMPANY: MGG North America

LOCATION: Charlotte, North Carolina

TITLE: CEO and President of MGG North America Inc.

What year did you start in the industry and how did you get started?

I started in 2021. I got in contact with MGG in May 2021. I previously worked in USA and Mexico with a large plant maker company that supplied equipment in the steel industry worldwide. MGG’s idea was to increase the presence in North America. Officially, I joined MGG in September 2021.

So you’re pretty new to the brush industry?

Yes and I consider it a very interesting industry with a lot of cultural and historical knowledge. It is nice to listen to the old stories. Like from one of our major customers, they have a plant in Maryland, I asked them why they chose the location. That area is very famous for blue crabs, so several decades ago, people in the area were used to going to the beach and working with their hands to pick up the blue crabs. So they developed the manual ability to work with small things and they converted from working with crabs to working with paint brushes.

What’s your favorite part so far of working in the brush industry?

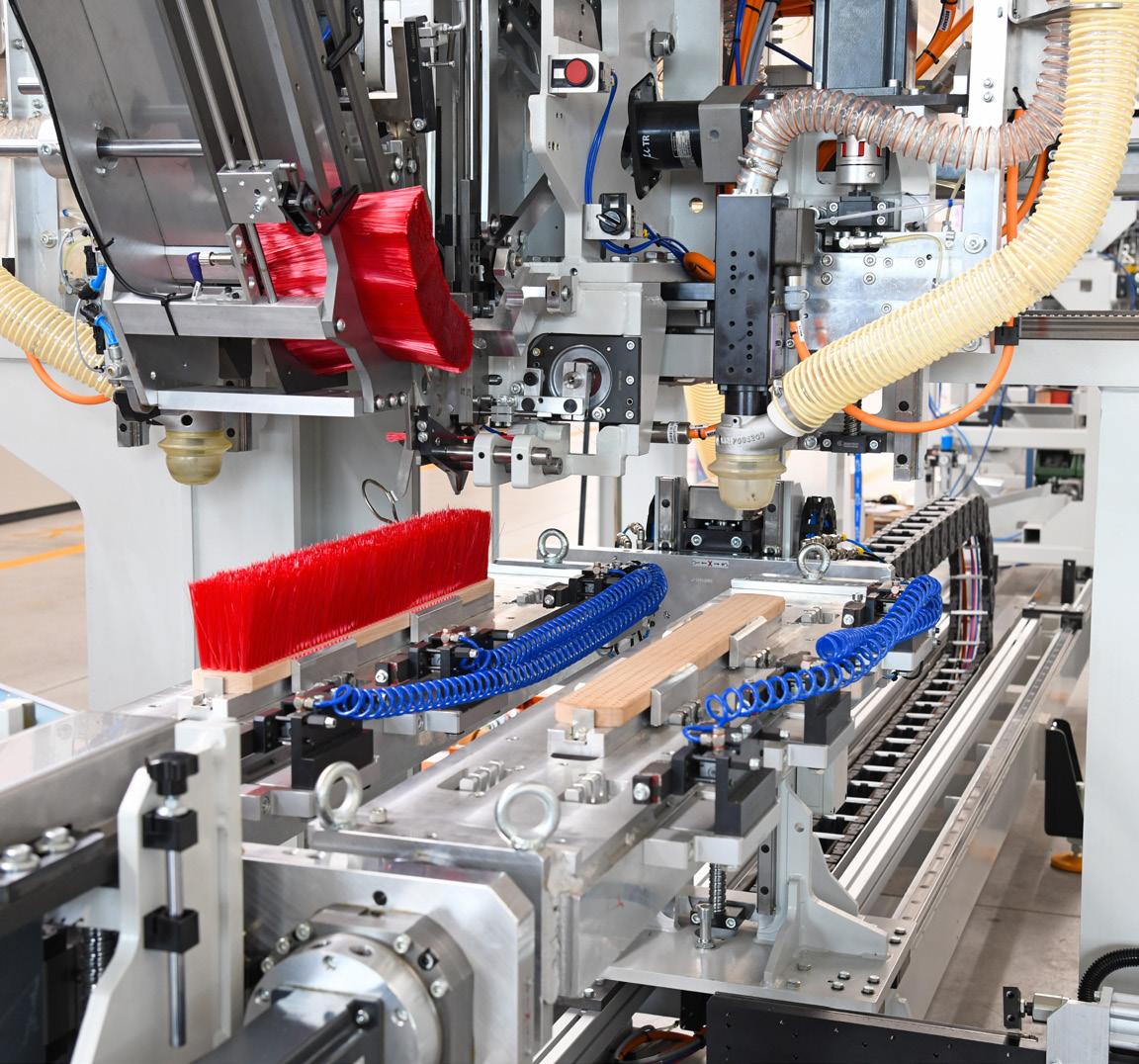

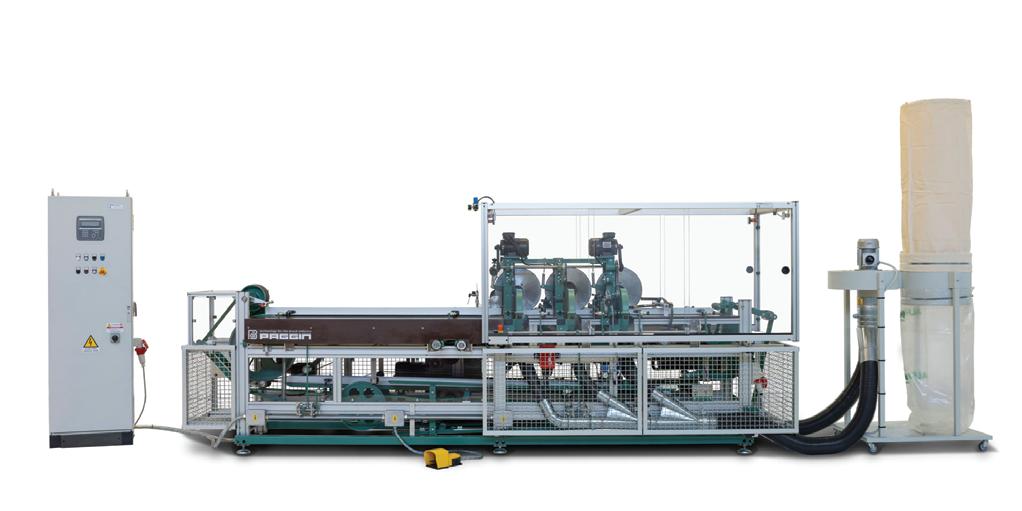

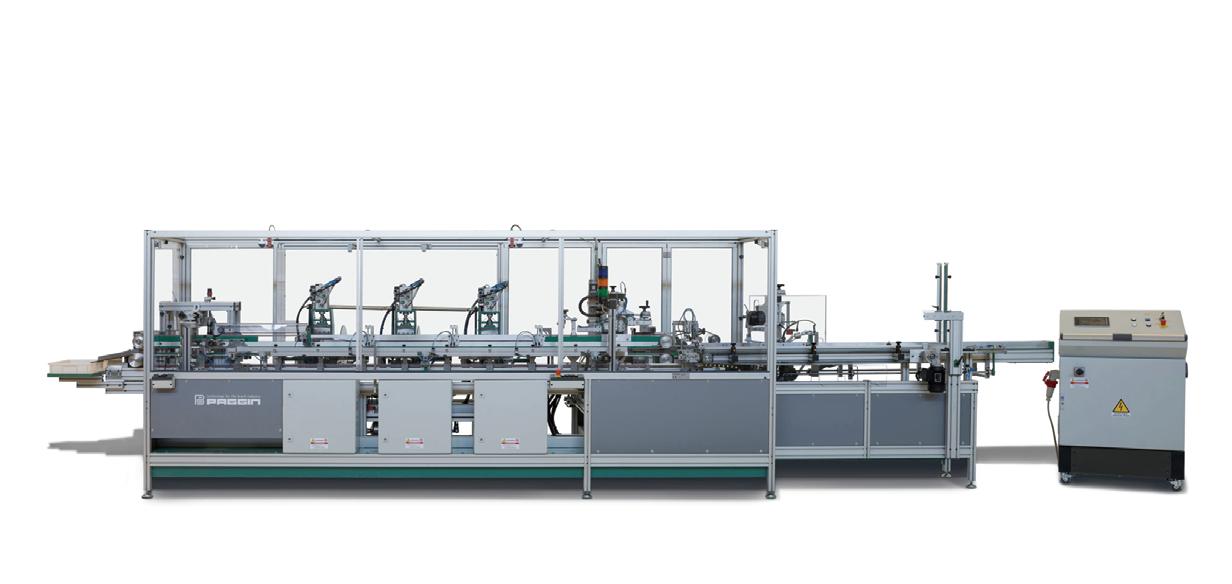

It’s a pretty dynamic industry that’s looking to improve in terms of automation and robotics. From a technology perspective, it’s not stuck to what it was in the past. From my previous experience, steel is going towards green. And I see that the paintbrush industry is going towards automation and robotics while maintaining the same quality for the products.

Furthermore, American paintbrushes are challenging to be produced, in quality and shape more than the European quality requirements. As MGG Group. It is something we are committed to achieve, but it’s not as easy as achieving those qualities for Europe or other countries in the world. All of our customers will be testing their paintbrushes in Italy and Charlotte with their new machines and, together as partners, we will be fine tuning the equipment to cope with those strict standards.

So, to conclude, the American paintbrush industry being so conservative in the past, is nowadays shifting to improved technology through automation and robotics, to face the demanding market needs.

You mentioned the steel industry’s move to green steel. Do you see the move to produce sustainable products gaining momentum in the brush industry?

The green attitude is going to change for the brush industry. It’s not an emissions producing-industry. So I’m talking about paintbrushes, but specifically materials, so the handles, especially the bristles with plastic and the other components. This is probably what we are going to see for an emphasis in the future. I can anticipate that MGG, thru our research department, is studying some breaking thru technologies which goes towards sustainability and environmental green.

What are the key challenges you have faced over the past few years?

Personally speaking, our customers like to talk with the technical people and people who know the industry and the paintbrushes or rollers pretty well. So I’m new in the industry and I keep studying and learning about the industry and all of the technical information that as MGG we can provide to our customers. So, when I first started, my challenge was to be technically accurate in speaking with the customers. Obviously, when customers would speak with my senior partners in Italy, who are very knowledgeable in the paintbrush industry, the customer was very happy with that information. So, my goal was to make them comfortable so that when they would speak to me about technical issues, they would have somebody capable to explain or answer questions about the machines.

From the company perspective, MGG has been working in North America for approximately 20 years with mainly one major customer (probably the biggest one). So the first challenge that we had was to try to spread around our technology and worldwide legacy in the United States.

The number of manufacturing facilities in North America decreased drastically in the last few decades so it has been easier to locate all of the current producers in the United

States, visit them and create business opportunities. I can tell you that MGG is doing pretty well in creating strong partnerships.

The supply chain issues, especially related to China, are pushing most of the U.S. companies to shift their relationship to western countries, even better if they can have U.S. suppliers.

MGG wants surely to be a major player in this scenario.

Do you see any permanent changes ahead for MGG and the brush industry in general?

American customers in general love to have American equipment. So how we can help them is by having MGG potentially producing or final assembling and testing the machines here in the United States. This is the added value we want to give to our customer in the next two or three years.

So rather than taking the flight to Italy to see the machine running — even though this is very nice because they enjoy Italian amenities — they can stay here in North America and avoid travel and extra costs.

Are there any new products or initiatives for MGG that you would like to share?

MGG started producing paintbrushes in 1989 and then in the last seven to 10 years they started to produce paint rollers as well. So we see that the paint roller segment is still booming. Right now we supply finishing lines for rollers, so we are not focused on the upstream, which means the creation of the roller itself. That is something we have been working on and we will be ready potentially next year for that kind of business. We also see a lot of excitement for mini rollers which is another industry where MGG is very keen and focused to do a good job in the next 12 to 16 months.

For paintbrushes, I can tell you that American customers should be excited because finally, they can produce angular paintbrushes inline. This is the core of the market and they can produce them automatically with high repeatability and quality. Right now, they produce the flat brushes, but when

it is time to produce the angular paintbrushes, they produce them manually. Now they can finally have automatically in line a head-making machine plus a vulcanizing epoxy machine and an output of about 1,300 pc/h.

Recruiting skilled workers overall and also young workers has been stated as a concern in the industry. How do you think that is best addressed?

I know that it is pretty tough to find people in the United States. That’s one of the reasons why we moved to Charlotte. It is one of the best American cities to find good people and skilled operators. It’s an important city in the United States with a lot of industries. The school districts are very good, with averages for all ages above the standard in the U.S. And then nearby, like 100 miles from here is the university triangle, with Duke University and the University of Charlotte and other top universities. So we have already had the opportunity to see several young people and we can tell you that their capabilities are well above the national average.

Also, MGG is very keen to offer young operators the ability to train in Italy for a couple of years, gain some international experience and then come back to the United States.

Do you have any key business/leadership tips out there for young people in the industry looking to ascend to a leadership role?

If you want to be a superstar in sports or work, you need to keep training. It is very rare to have genetically self-made superstars like Michael Jordan or Maradona. It’s very rare to be born as them. They were phenomenal one-of-akind players even without training. So if you want to be a leader, if you want to be successful, you need to keep constantly evolving, studying, working and spending time on training. It’s the only way because the world situation is very challenging right now. This is the advice that I am also going to give to Alessandro, my son, “you need to constantly evolve” which means find a way to train yourself and challenge yourself. The world is challenging you, so it’s better that you have anticipated this and challenge yourself first.

I like playing sports because I need to stay healthy and fit. Otherwise, yeah, you put on the weight living here in the United States. So, I love to play padel, which is a new sport that we have in Europe, which is like tennis with the glass all around. It’s like a mix between tennis and squash and you play two versus two. Unfortunately here in North America, it is not so common because they prefer pickleball. Also here in North Carolina, the climate and also the landscape is perfect for outside activities like running and biking. And, I am a soccer player, as an Italian. So I used to play at a decent level when I was younger. But then I followed the university path and so I didn’t have time to do both things.

I watch a lot of soccer and I’m very mad with that. I mean, I love it and my team is AC Milan. I try not to miss any football match when they play. This is my favorite, but I really love also American football. My favorite team is the Pittsburgh Steelers because I spent my first five years up in Pittsburgh and I love to follow them every Sunday.

I like the old glory days movies. Like any movies with all the songs of Ennio Morricone like Once Upon a Time in America. Probably Once Upon a Time in America is my favorite movie ever and also the Godfather series. Being Italian, knowing the history and Italian heritage in United States, all of those are the great movies that I enjoy.

Pick one rental car brand, pick one hotel brand and pick one airline brand and stay with that. So then you will have a lot of points and you will be upgraded. Everybody is traveling, so in all the places you go, everything is congested with long lines and the hotel is full, then the flights are packed and the prices for all the airlines are going up. The only way to have good treatment with low cost is to have a sort of membership with all of the major rental cars, hotels and airlines.

I am an aerospace engineer. However, from when I was 17 to around the age of 26, I worked as the chief activities coordinator in hotels and resorts. I used to plan and organize all the activities and entertainment. So I used to manage this team of 7/8 people in the hotels where I lived nearby Venice. So it sounds like a bit of a contradiction, I am an engineer but I am also very open to interact with people and this probably gives me the ability to be good at sales as well as managing people. Because in my opinion, the most important resource in a company is the people. This experience gave me the ability to understand and work with people to manage a team and interact with people of different ages from two years old all the way up to grandparents.

Not to rush when making judgments. When I was young, I had the bad habit of labeling people immediately … like this person is good at what they do or this one is not good. But, you need to have time to get to know people, because you can learn from all people and they can learn from you. It’s important to give a person some time to show their capabilities. Never judge a book from the cover!

62nd FEIBP Congress | Prague, Czech Republic | September 21-24, 2022

It was a warm welcome in Prague. Finally, after three years, it was possible to see each other in person and FEIBP President Andrew McIlroy and Fons Ceelaert gave a warm welcome to the guests and participants of the Congress of European Brushware Manufacturers in the Golden City. Friends from the ABMA and new members of the European Brushware Association, among others from Denmark and Sri Lanka, were warmly welcomed.

In his welcoming remarks, McIlroy spoke about the challenges of recent years. “Unfortunately, these developments have greatly diverted us from the way we used to do business. We all lacked the time, production capacity and raw materials to develop new products in the last two years. Innovation continues to be a key driver for our industry, and we are pleased to have three candidates for this year’s Innovation Award despite the many obstacles that have been placed in our way.”

The focus of the congress this year was on the current issues of global development with regard to enormous price increases in several areas. Three years of crisis have demanded a lot from companies — and there is no end in sight to the global economic and political challenges. There are many challenges for the members of the FEIBP. However, as entrepreneurs, they remain focused on their goals, namely to find solutions. Even the years of crisis could not deter their innovative spirit.

“Was there a moment when you realized that climate change was something that would affect you or your children in your lifetime?”

With this question, Andrew Griffiths, Planet Mark Director of Community and Partnerships, started his fascinating keynote session and he followed that by saying climate change is affecting us all because we see it and feel it personally. As he said, climate catastrophe is now, not tomorrow or next month. It’s here and now.

Griffith’s Planet Mark offers a sustainability certification that supports organizations to measure and continually reduce carbon emissions and increase their social impact. He also chairs the Institute of Directors National Sustainability Taskforce and was a member of the U.K. Government’s COP26 Small Business Taskforce, as well as the Advisory Board for the Global Sustainability Film Awards.

In his presentation, he spoke about the United Nations Development Program (UNDP) and the key role it has in the implementation of the Sustainable Development Goals of the 2030 Agenda, and also in the implementation of reforms within the UN system. At the 2015 UN Climate Change Conference (COP 21), the global community voted in favor of a new global climate protection agreement with the Paris Agreement. In total, 197 countries agreed to limit average global warming to less than 2 degrees Celsius — if possible 1.5 degrees Celsius — by 2100, compared to the start of the industrialization era.

For individual companies, effective corporate climate action starts with a Corporate Carbon Footprint (CCF). It is the basis for a climate protection plan because it shows how many greenhouse gases a company produces and in which areas most emissions occur. On this basis, reduction targets can be set to reduce the impact of the climate crisis.

Chairman of Hillbrush, Philip Coward, has been working with Planet Mark for three years and is passionate about the benefits of reducing his company’s carbon footprint.

“We have involved all of our employees in the drive to reduce carbon emissions, and it has been imperative that the project has the full support of the company’s directors,” says Coward. “Planet Mark helps us measure our carbon emissions so that we can identify the areas where we can make savings. There are financial as well as environmental benefits to the savings, and we are finding that many of our customers are demanding information regarding our sustainability plans. In some cases, the company’s sustainability record is more important than the company’s product prices. We have a number of ongoing projects to further reduce our carbon emissions such as the reduction of packaging materials, the use of more recycled plastics and the sourcing of raw materials from nearer to the company’s base in the U.K. In addition, the energy usage in all parts of our business is monitored so that savings can be identified. We have installed 450kw of solar PV electricity generating panels and are planning a further installation. I would encourage every company to reduce their carbon emissions, which will make the planet a safer place for our children and grandchildren.”

I cannot remember when previously we ever had such huge problems with our worldwide supply chain service providers — be it sea freight or land freight. Everybody was affected by this issue and I have to apologize to my customers for this.

The contradictory situation right now is that on the one side, we along with our customers are still suffering from the above-mentioned delay of lots of containers, but on the other side we can already see increasing stocks and “clearance sales.”

I am seeing this situation in my daily business discussion in all of our business fields. Partly we still have terribly delayed goods, but on the other hand, everyone is reluctant to buy for 2023.

Sea freight costs did go down from 10.000 USD in January of 2022 per 20 feet TCEU to 6.000 USD per TCEU in September from Shanghai to Hamburg. However, we are still at an all-time high for sea freight rates — remember in the past we paid around 1.200 USD.

Additionally, there is a severe shortage of truck drivers all over Europe and land freight transportation charges have doubled.

First off, for those who are buying in Euros or corresponding currencies, there is a price increase of around 18% depending on the period of time.

Notably, reduced demand has kind of overshadowed the fact that in some items we still have shortages, which are good quality black 51mm in 90 percent tops and long sizes black 89mm and up.

Hörz offered the following statement from Wang Yong of DKSH Shanghai on synthetic substitution:

For the substitution of natural bristle, the availability of synthetic filament is sufficient to supply the paint brush industry requirement. The competition in the synthetic filament business is increasing, especially with the current quiet market situation. The competition is not only on price but also on quality. The HIB is getting more and more close to natural bristle quality. It will speed up the pace of the substitution.

We think the demand will gradually come back in 2023 and the brush filament industry itself has been adapted to supply the new inquiries. But there are still other issues that are uncertain/unpredictable, like how long will the COVID influence continue in China. The government still firmly insists on a zero-tolerance COVID policy, which means keeping manufacturers open and production running is not the top priority when a new COVID outbreak occurs. That will be a challenge to steady and sustainable supply.

It will come as no surprise to hear that in a world of rising prices and high inflation, we now see a fall in the price of sable hair, albeit a rather small one! The fall comes on the back of unprecedented large increases over the last three years where we have seen increases of around 100 percent, meaning average prices of Chinese sable going from 4K to 10K, with some longer lengths of European dressed approaching $20K.

Unsurprisingly, demand has slackened as buyers look for alternative synthetics and sable mixtures, but certain applications still require the real thing. As mentioned, prices have fallen but this is not only because of weak demand but because of the strength of the dollar against the RMB, and if you’re buying in Euros (or worse Sterling) you won’t notice much of a fall.

A further reason for not seeing steeper falls is that supply is still very limited, and it’s unlikely that we’ll see much change in fresh supply when the next season starts this winter.

Squirrel hair prices increased by about 20 percent (more in Euros) and shorter lengths 35-50 mm by even more as demand outstrips supply. Most other types of fine hair have seen small increases as dressing factories close and wages increase.

The situation in Russia has had a limited impact as most supplies are not exported directly to Europe but to China.

Holger Kruse (Gustav Wolf GmbH)

All European market participants, including us as private individuals, have become acutely aware of how closely the economy is networked globally down to the last detail. Decades of globalization always had a positive impact and that was the basis of the economic and thus also political orientation of the community of states, ensuring jobs and prosperity in the west, and especially in Central Europe.

The external disruptive factors in recent years, be it customs barriers or pandemics, or even currently a war in a previously unimaginable proximity to Europe, have shown all participants the extreme vulnerability of the “global division of labor.”

The Europe-wide energy crisis resulting from the Russian war of aggression is certainly the most severe disruption of the entire European economy to date, with significant effects on national GDPs, debt rates, etc. The social consequences are also unknown, with the impact most likely to be seen in the various upcoming national elections.

For the steel industry, its processors and consumers, the energy crisis is indeed threatening the very existence of the industry, as gigantic amounts of electricity and natural gas in the terawatt range are consumed here every year. The extreme rise in energy costs is already causing plant shutdowns in all areas of the steel industry, as well as in other energy-intensive industries such as the chemical or building materials industries.

The Green Steel project promises an almost 95% reduction in CO2 emissions in the steel industry of as much as 60 million tons p.a. through the use of green hydrogen. In addition to the large investment costs (in the 2-digit billion range), the project is heavily dependent on the power supply in the respective economic zones. Thyssen-Krupp, for example, currently calculates the total energy requirement of its biggest site, Duisburg, at 4.5 TWh. For the conversion to climate neutrality, the energy requirement increases tenfold to 45 TWh!

From today’s point of view, there are obviously still many unanswered questions, starting with the technical feasibility to financial viability and availability of resources.

Brosserie Brenet’s Washnet machine is a technical automatic cleaning system, that allows better hygiene control of industrial brushes used in the production of food. It simplifies cleaning considerably. Instead of using a water jet and a random quantity of detergents, we created a hygienically designed system that follows a consistent cleaning validation protocol.

This assortment is what it is. No more, no less. The name says it all: «purus.» means not only pure, but also simple, honest, unvarnished and natural.

The products are aimed at the «new» customer, who is not blinded by unnecessary «frippery» but appreciates the impudence of this assortment. A customer who cares about the environment. A customer who buys what he needs –not more, but also not less – that’s it.

“This prize is of immense importance to us! It rewards five years of research and testing. It shows that Washnet is a real asset for the good use of brushes,” says Simon Lorillière, Brosserie Brenet. “Innovation is not only in product improvement but also in service. We would like to thank all the participants of the congress, the European brush makers, the fiber suppliers and the machine manufacturers who believed in our project and who voted for us.”

Only renewable raw materials were used for this assortment. The handle is made of high-quality FSC®-certified Swiss beech wood and is equipped with bristles out of bio-based plastic. For «purus.», bio-based* means that the plastic is not derived from mineral oil but from castor oil.

Resource-saving design without sacrificing functionality «Perfection is not reached when there is nothing more to add, but when there is nothing more to leave out.» (Antoine de Saint-Exupéry).

This quotation guided us in the development of «purus.», as even the most sustainable materials should not be wasted.

Peter Langenegger is pleased to have won second place in the Innovation Award contest. “This range is for the more idealistic customer,” he says. “It is just what it is. Nothing more and nothing less. The name says everything: ‘purus’ means not only pure, but also plain, fair, undecorated and natural. Only renewable raw materials have been used for this range. The handle is made from high-quality FSC®-certified Swiss beech wood and is stamped with bristles made from bio-based plastic. Bio-based for purus means that the plastic is not derived from petroleum, but from castor oil.”

In order to save natural resources, only the most essential materials are consciously used for this assortment. We have gone to our limits, because the two components of the brushes directly influence each other. The brush bodies are designed to be as narrow as possible but just wide enough to accommodate the optimum amount of bristles. More is

Customers expect unlimited functionality from Ebnat. «purus.» meets these expectations despite its resource-

What has coffee to do with brushes? A lot, says Daniel Zahn from Zahn Pinsel. Global sales of coffee are rising steadily. The market share of high-quality portafilter coffee machines is also increasing in private households. Making coffee is a ceremony and part of a lifestyle. Coffee machines have to be cleaned after each use. For this purpose, Zahn Pinsel has developed a range of professional cleaning brushes, because they are high quality and most functional and save real baristas and semi-professionals a lot of time.

In Europe, we have faced a very turbulent time in the raw material markets for plastic over the past 18 months. In 2021, the raw materials market was dominated by poor availability, long lead times and of course, multiple price increases passed down the supply chain from polymer manufacturers.

After a short period of respite towards the end of 2021 and in early 2022, the start of the war in Ukraine again led to a further increase in prices and added further fuel to the fire in the form of skyrocketing energy prices. The high price of energy is now the main justification from polymer manufacturers for further price increases. For processors of polymer — for monofilament extrusion and injection molding, the main issue is the price of electricity. Companies who had fixed price contracts for energy last year are facing up to ten-fold price increases per KWh. This issue is likely to be just as serious as the raw material price issues we faced in 2021.

Availability of polymer on the whole has improved this year but it is anyone’s guess as to when pricing may stabilize in the future.

After two intense days, the 62nd FEIBP Congress ended with an impressive tour through the many architectural areas of the city of Prague. In the night, during the rich gala dinner in the historic Art Deco style restaurant, the key topics and discussion of the event were discussed once again. In a relaxed atmosphere, Ceelaert warmly thanked McIlroy for his commitment. His time as president will end with the 63rd FEIBP Congress in Northern Ireland in 2023.

Alessandro Acquaderni is slated to take over as president in 2024 and he indicated that the theme for his term will be John Donne’s “No man is an island” quote. This in reference to the last years of pandemic and crisis and in particular refers to the months of isolation. “Everyone has different skills, and together we could make more of a difference,” he says in his outlook. Donne’s “No man is an island” quote emphasizes the common humanity of people.

By Bob Lawrence

By Bob Lawrence

With the days dwindling down toward the new year amid the highest worldwide inflation rates in decades, and with the likes of Steve Forbes and Elon Musk predicting a recession, Brushware sought input from European and North American manufacturers, suppliers and machinery companies to learn how they are dealing with inflation, its impact, root causes and opinions on solutions to curtail it.

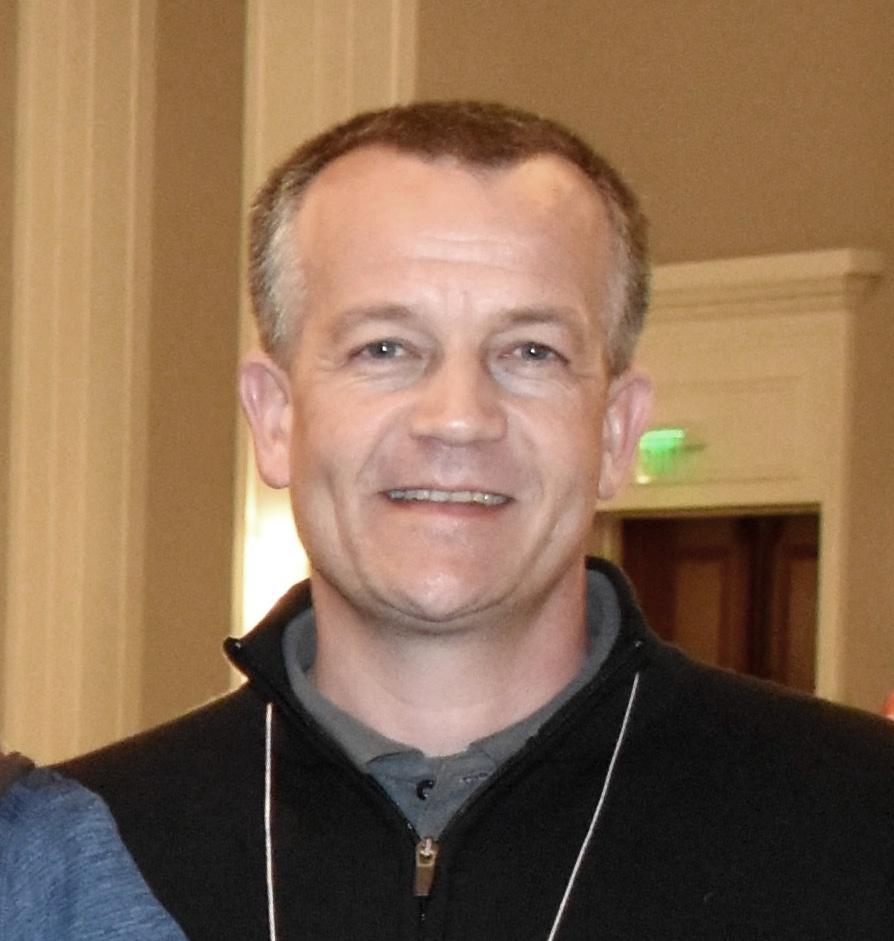

Manufacturer Panel: R.J. Lindstrom-Zephyr Manufacturing Co., Philip Coward-Hillbrush, Ken Rakusin-Gordon Brush and Jeff Malish-Malish Corp. (Clockwise From Top Left, Opposite Page)

Jeff Malish, Malish Corp.: Inflation is impacting nearly every aspect of our business … material, freight, labor, utilities. Everything has gone up substantially in the past 12-24 months.

Ken Rakusin, Gordon Brush: Our cost increases are out of control with some items increasing by 50 percent and up to 100 percent. Of course, many materials are still manageable but every day we receive new, unpleasant surprises.

Philip Coward, Hillbrush: The ever-increasing cost of raw materials is very difficult to manage. However, we have high levels of raw material stocks, and we are continuing to investigate new suppliers and to manufacture more in-house. Fortunately, energy cost increases have not affected us too much because we have a fixed electricity contract and have installed a lot of solar photovoltaic generation. Also, we built a new factory and offices a few years ago, which are very energy efficient.

Inflation impacts every aspect of our business. We are seeing price increases due to the rising cost of raw materials, increased freight costs, increased banking costs and rising costs for quality labor. As a manufacturer, it is impossible to escape the upward price pressure that inflation puts on our business.

Ken Rakusin: We have raised prices across the board, but in many cases not enough to fully cover our cost increases as we need to be competitive in the marketplace. Thus, we continue to absorb a hefty portion of our material costs.

Philip Coward: We have had to pass on some cost increases, but we have also invested in several new production machines which make the products more efficiently and this has enabled us to absorb some cost increases.

R.J. Lindstrom: We have, unfortunately, had to pass along some of our cost increases. When you see cost increases in everything from raw materials to corrugate to shipping costs, it is hard to find efficiencies to help alleviate the pressure. Some of our raw material cost increases have been so large there’s just no way to stop them from affecting the price to our customers.

Philip Coward: Inflation in the U.K. started long before Putin invaded Ukraine and caused the energy crisis. The COVID pandemic caused huge increases in shipping costs and when demand returned around the world, the shortage of materials/products further fueled inflation. Obviously, Putin’s disastrous invasion has added to the problems, but in fact, inflation in the U.K. is not very much higher than it was prior to his invasion.

Jeff Malish: I am not an economist but I believe there are a number of factors. The first is the increase in oil/gas prices due to political posturing and the Russian invasion of Ukraine. Increases in fuel prices impacts freight, which translates to every product that is shipped throughout the world. Oil prices also affect plastics which are part of most products made in the world. Consumers’ costs are going through the roof so now everyone needs to make more to remain salary/cost neutral. There is also supply shortage with the workforce. Businesses need to pay more to keep and attract new employees. There is a ripple effect to everything.

Ken Rakusin: This is an interesting question as one would think that an imbalance in supply and demand would be the sole cause, but the reality is that our governments create a lot of the issues with inflationary laws that are passed. For instance, here in California, Governor Newsom just signed a new law to raise the minimum pay of fast-food workers to $22 per hour. Sadly, both he and the state’s legislature would rather buy votes with this law than try to control inflation. Any reasonable person would know that wage increases of almost 50% will cause a massive increase in the cost of meals at these restaurants, but they don’t care. In addition, how much will every other employer in California have to pay their workers when the employees can go to McDonald’s, KFC or Taco Bell and make $22 per hour?

R.J. Lindstrom: Most of the inflationary pressure originates in the COVID pandemic and the struggles that arose from the economic recovery afterwards. Supply chain problems that persisted during the pandemic have only become worse, causing the shipping costs for domestic and international product to go up at an unprecedented level. Another contributing factor is the extremely tight labor market. With unemployment at such a low level, wages for all types of workers saw the largest increases we have ever experienced. Like a lot of other businesses, we rely on a lot of manual labor to produce our products, and the higher wages have had an outsized effect on our costs.

Philip Coward: In my opinion, no government policy could have prevented the present level of inflation, and opposition parties must be relieved that they are not in power! The government could have invested more in nuclear and renewable energy supply and supported manufacturing industries in the U.K.

R.J. Lindstrom: When our government opens up the checkbook to help out certain individuals, it will obviously have an effect on inflation. Putting more money in people’s hands over an extended period of time will increase demand, and thus the cost of many consumer goods. These increases will leak into other types of products, including our commercial cleaning products.

Ken Rakusin: When governments establish rules, regulations and policies that cause businesses to spend money on things that a prudent businessperson would not normally do, then that increases the cost of their products. While Gordon Brush isn’t a large importer of foreign materials, the tariffs President Trump put in place caused prices to increase for no apparent reason other than his battle with China. Unfortunately, Americans paid the price at the cash register.

Jeff Malish: There is no doubt that government policies play some part in causing inflation. For every action, there is an equal and opposite reaction. If government policies increase the cost of doing business, those cost increases will have to be passed along. The end consumer is ultimately absorbing the increase.

Jeff Malish: There will always be a certain level of inflation. If the government acts responsibly, they should be able to reduce inflation to normal levels.

Ken Rakusin: This is a trick question so maybe we should get an answer from President Jimmy Carter who never got it under control. More seriously, eliminate things like tariffs and then lower taxes and wait for demand to decrease, possibly lowering costs.

Philip Coward: We need Putin to pull out of Ukraine, the demand for materials will reduce which will hopefully force the shipping companies to reduce their prices.

Ken Rakusin: Eliminate some of the obstacles and tariffs that have been put in place to make it easier to do business. This will allow costs to drop across the board.

Jeff Malish: The U.S. government is already raising interest rates to slow down the economy to reduce inflation. They should also allow for all energy sources to be viable options in the U.S. Allowing the U.S. to be energy independent would go a long way to reduce gas/oil prices.

R.J. Lindstrom: The Federal Reserve is already doing everything it can to reduce inflation by increasing the interest rate at the most

aggressive rate in modern history. However, this can only go so far, and I am doubtful that we will get the “soft landing” that they are hoping for. The federal government needs to stop pumping more money into the economy if we are going to have a chance of avoiding a major recession.

Philip Coward: Our government has recently announced assistance to individuals and companies with their energy costs, and this has helped the inflation rate, but they must resist large pay settlements in the public sector. Being more self-sufficient with energy supply would be a help, and although the U.K. government may soon allow fracking, it is going to take some time for this to make any difference. It would be good if the government could put pressure on the shipping companies, but that is not going to happen.

Philip Coward: The rate of inflation has recently reduced slightly in the U.K., but large pay increases could cause a further increase, and the future cost of energy is an unknown factor. We hope that the rate of inflation will start reducing in the first quarter of 2023.

Jeff Malish: With the Fed increasing the Fed Rate another .75 percent in September that should start to slow the economy. If they increase it another .50 percent thereafter, that should really make an impact and possibly push us into a recession if we aren’t there already.

Ken Rakusin: I don’t see the end to the inflation issue we’re dealing with as once businesses can raise prices, they will. Also, as long as there is upward pressure on wages and dramatic increases in interest rates, we will continue to see inflation.

Jeff Malish: There is some correlation between inflation and supply chain issues. Basic economics tells us that if the supply is reduced, price goes up.

Ken Rakusin: This is the basic premise of supply and demand that I was able to stay awake to learn in Econ 101. Excess availability of materials leads to lower prices and vice versa.

Philip Coward: The increased shipping costs and the shortage of products and materials brings price increases due to supply and demand. One questions why shipping costs have not come down a lot yet, and the shipping companies must be held to account.

R.J. Lindstrom: I think it’s a matter of major supply chain issues being one of the original causes for inflation. Our economy relies on a tremendous amount of goods imported from foreign countries. When the shipping costs increase by up to 10x, it is going to raise the price for all of those products.

Ken Rakusin: In my humble opinion, when the world cut back on everything for the unknown of COVID, production stopped or slowed in so many areas. Skilled labor then became an issue with millions of people sick or afraid to come to work, and then factories could no longer produce at the same level. When the world started to return to normal, labor and material shortages meant businesses could not get back to speed and supply chain issues multiplied.

Philip Coward: There was an unexpected demand for products and materials following the reopening of world after the worst part of the COVID pandemic.

R.J. Lindstrom: As with most big problems, there isn’t a single cause for supply chain issues. You can go all the way back to the pandemic

when manufacturers were cutting capacity and trying to stay alive while we adjusted to a new normal. Then demand came roaring back and there was a delay before the supply chain could get caught back up again, causing lots of bottlenecks in the process. If anything, the pandemic showed us just show precarious our supply chain was before, and what we should do to make it more robust in the future.

Jeff Malish: COVID is still impacting supply as many of the supply chains have not caught up from 18+ months ago. Labor shortages, shipping container availability, material shortages are all impacting supply.

Philip Coward: We are not having many problems now, other than the cost increases and the space required for the increased stockholding.

R.J. Lindstrom: Most of our supply chain issues right now are cost related. For quite a while we had issues with availability and the lead times for raw materials. Our suppliers have made good strides in getting caught back up, but the prices aren’t going to be going down for a while.

Jeff Malish: Although they have reduced, we are still having supply chain problems with some items.

Ken Rakusin: It’s been a difficult couple of years waiting 6-12 months for some materials. We always maintain a significant inventory of necessary raw materials, but we couldn’t ever expect to have 6-12 months of everything we needed.

Jeff Malish: Our lead times have been pushed out. We also have found alternative sources to help supplement our supply.

Ken Rakusin: My hair has gotten significantly grayer. Seriously, we’ve found new sources, substituted material and asked our customers to be patient.

Philip Coward: We had fortunately built more warehousing space last year and we have very much higher levels of stock. We have also moved the purchase of some products and materials to suppliers nearer to the U.K. or in the U.K.

R.J. Lindstrom: We are diligent in finding the lowest cost we can for all our raw materials. Buying from multiple sources is the main way we have tried to combat both rising costs and long lead times. This doesn’t always work, but we are building a more robust supply chain so when one supplier is having issues we can still get the product from a secondary source. We are also working to get the maximum output from our factory with the least amount of labor and waste.

Jeff Malish: It will either take more time for businesses to catch up or a reduction in demand. A recession would reduce demand which should correct the supply chain.

Ken Rakusin: I think things are starting to clear up a little as we’ve been able to buy more items in greater quantities lately. Perhaps the recession is slowing demand or perhaps COVID and people missing work is no longer a major hurdle for people and businesses to deal with.

Philip Coward: I don’t think that we are ever going to eliminate supply chain issues, because there will always be national and international issues which will have an effect. Our company manufactures many of the products that we sell, and we have always kept large stocks of raw materials, and these are certainly big advantages.

Andrew McIlroy, Perlon/Hahl and European Brushware Federation President: The cost of pretty much everything we use in our business has increased dramatically over the past 12-18 months – raw material, packaging, spare parts for machines and of course energy.

David Kalisz, MFC: As with most businesses, MFC has had to absorb some rising expenses primarily related to increased overhead.

Sofia Teles, Filkemp: Inflation is impacting our raw material and production costs, as well as the daily lives of our employees.

Andrew McIlroy: Yes we had absolutely no option but to pass on the increases in cost we could not absorb – both for raw material and energy. We have seen an average increase on resin of 50 percent and at the time of writing this, electricity prices are 10 times higher than last year. It would be surprising if any business in our industry could absorb such an additional cost. Pre-2020 pricing is history, but any significant reductions must and will be passed on to customers.

Sofia Teles: Unfortunately, most of the price increases are so dramatic, that they have to be passed on to the customers. These are related to raw materials, additives, packaging, freight and energy.

David Kalisz: We have had to pass on the rise in prices of raw materials.

Andrew McIlroy: Many reasons. On the resin side it was the recovery from COVID initially coupled with a spike in demand and then later the energy cost required to manufacture polymer. Supply and demand is the main driver of all of this – but sadly there is also an element of increasing prices for the sake of it, even though raw material costs potentially haven’t risen as much.

Supplier Panel: Andrew McIlroy-Perlon/Hahl, David Kalisz-MFC, Dave Magner-Deco Products and Sofia Teles-Filkemp (Left to Right)

David Kalisz: In my opinion a combination of our current government’s war on the USA fossil fuel industry, its fiscal policy (government overspending) and our monetary policy.

Sofia Teles: Current inflation is the accumulation of different problems like a sudden surge in the economy after a global pandemic, war in Ukraine and the sanctions imposed on Russia, lack of workers and the consequent lack of production capacity and transportation means, among other more specific situations.

Andrew McIlroy: Difficult to say. But these are decisions we cannot control anyway in the short term. We have to work within the confines of the costs and conditions we have within our own businesses and try to make the best of it.

David Kalisz: I totally agree with those economists.

Dave Magner, Deco Products: Past and current policies such as COVID policies and current Fed actions could impact (inflation).

Andrew McIlroy: A sensible approach to energy, also with regard to renewable resources and climate change. The limits being put on CO² and the reduction of fossil fuels have also caused prices to rise. This is a very important issue, but needs to be realistic and manageable cost-wise. From a consumer behavior point of view, things also need to change. Our throwaway society where people constantly want the newest and the best whether they can afford it or not financially. Using better quality products for longer is also a more sustainable way to live.

David Kalisz: The fed’s actions in raising the interest rates are already affecting demand in some sectors of the economy which will affect pricing.

Andrew McIlroy: In Europe, we have seen interest rates slowly rise this year which is intended to help put a brake on spending. The most pressing issue here is the energy situation – with gas and electricity prices going way beyond what is affordable for many people. This can in the main be attributed to the dependency on Russian gas which is a situation which will not improve anytime soon. Our governments have announced multiple support packages for individuals and businesses to cap energy prices – which may help in the short term but it is not something which can be sustained forever.

David Kalisz: Our government can change their posture on their war on the USA fossil fuel industry, as well as institute better monetary and fiscal policy. Congress should take back control of the purse strings and do proper oversight of the spending.

Andrew McIlroy: I would be surprised if things improved much before 2024.

Dave Magner: Things seem to be getting better.

David Kalisz: I think there will be an easing of inflation but would not venture to guess how quickly.

Andrew McIlroy: Definitely. We can only believe the excuses we were given back in early 2021 as to why many suppliers had supply issues –capacity and stock reduction for several months in 2020 were bound to have an affect. Suppliers were in a position to pass on additional cost without any pushback as supply was so poor and demand so high. This has had a knock-on effect on everything. Whether these increases were justified or how real the supply issue actually was could be questioned. Availability has improved in 2022, but prices remain at near record levels – that is something which is hard to swallow.

David Kalisz: If there is lack of goods caused by supply chain problems while demand is the same, then you will have higher prices (inflation).

Sofia Teles: During the global pandemic, transportation and production capacities were scaled down. Once the post-pandemic surge in economy started, there wasn’t enough production or transportation capacity to meet demand.

David Kalisz: There were many factors affecting the supply chain, but I think the largest ones were caused by the handling of the COVID pandemic by various countries. Closures in the consuming countries caused relocation of the shipping containers as ocean transport was highly affected. As those countries opened up, the pent-up demand could not be met by the current supply and the ocean shipping companies could not handle the volume after they had adjusted to less demand. This added to the closing of cities in producing countries such as China which not only had containers of already produced goods stuck in ports, but also there was no production as the plants were closed.

Dave Magner: The cause is due to many elements, COVID, labor, logistical challenges, etc.

Andrew McIlroy: Freight availability, lack of base materials for some products, lack of staff or a mixture of these, coupled with high demand related to a fear that material could run out are causing supply chain issues.

Sofia Teles: Yes, we are, but the problems have eased since the since the summer vacations as there seems to be also an ease on demand.

Andrew McIlroy: Not anymore. In 2021 we did have issues securing enough raw material to cope with demand. This has improved a lot this year.

David Kalisz: At this point, we are doing well with supply of horsehair from China.

Dave Magner: Relatively minor although we have a mostly domestic (USA) supply chain.

David Kalisz: The issues are handled by increasing the amount of raw materials kept in stock.

Andrew McIlroy: We increased the number of suppliers per product where it was possible to do so and also increased our safety stock levels. This didn’t give us any price leverage but it did minimize the risk of running out of product.