We’re the largest manufacturer of the world’s smallest brushes. Mill-Rose miniature brushes are available in a variety of styles and configurations as small as 0.014” in diameter to deburr, clean and ream very small holes and cavities.

We also make large brushes and custom-designed brushes. Mill-Rose has set the standard for quality, performance, and innovation in brush technology for the past 100+ years. Choose from thousands of standard and not so standard sizes and shapes. Call or visit MillRose.com.

Issue #24-03

Brushware – a bi-monthly

After witnessing all of the ups and downs of the Interbrush tradeshow since 2020, it is fantastic to see what looks like a wonderful new chapter developing for the brush industry with the launch of the World Brush Expo. With this first edition attracting more than 150 exhibitors, it is clear there is a strong base of global companies willing to support an industry event. Soon we will know if the attendance can also meet expectations, but with the ABMA and FEIBP driving the event going forward, it certainly seems like the Expo is set up for long-term success.

And while a prediction like that may seem a little bold, the ABMA Convention in Florida has me convinced as there was a buzz and enthusiasm in Florida that I hadn’t seen before. Having the World Brush Expo on deck seemed to put a little more energy into all of the conversations. I can’t say that everyone I spoke to is attending, but I can say it was always a topic with many ABMA attendees genuinely excited for the trip to Bologna.

From the Brushware perspective, Susan and I will both attend, and we are thrilled to have the opportunity to interact with the global brush community. We can’t wait to meet face-to-face with readers and advertisers we’ve only known through email and phone calls. And of course, we are looking forward to acquiring new readers as we know there are a lot of people that have come into the industry since 2016. No matter what, we look forward to learning from the brush industry professionals at the Expo on how we can be a better resource for the community.

Whether you are perusing this issue in advance or during the Expo, this is a jam-packed edition featuring ABMA Convention Coverage, a World Brush Expo preview and an update on the industrial brush sector from Bob Lawrence. We hope you enjoy this special edition and we also hope to see you in Bologna!

Countdown is on for the World Brush Expo the must-attend event for brushware professionals in 2024.

Borghi Spa provides you with the best machine solutions for the broom and brush industry.

Flexibility and Versatility, combined with Quality and Reliability at your disposal since more than 75 years. Eager to live an unforgettable experience?

Borghi Spa is waiting for you at World Brush Expo, May 22/24, 2024 - Bologna, Italy

Information from April 8, 2024. Booth #s are subject to change. EXHIBITOR

Information from April 8, 2024. Booth #s are subject to change.

Information from April 8, 2024. Venue map and booth #s are subject to change.

Information from April 8, 2024. Booth #s are subject to change.

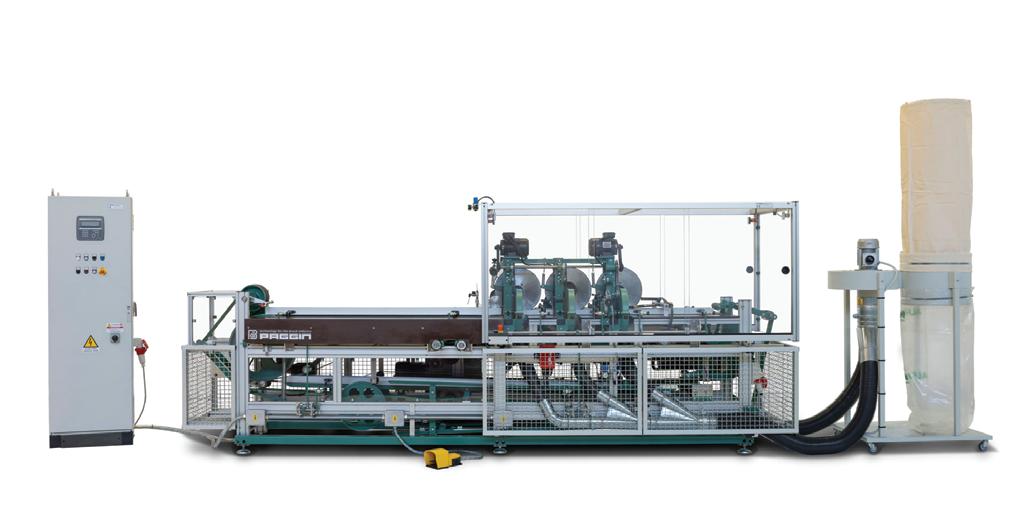

Borghi S.p.A. announces that it has acquired the company Unimac s.r.l. by incorporation. Unimac s.r.l. since 1983 has designed and built complete lines to produce metal handles. It has also specialized in the design and construction of machines and automation for the production of power brushes.

The incorporation operation is part of the broader process of corporate redefinition of the group headed by Borghi, aimed at simplifying its structure and better enhancing its operational, administrative and technological synergies. The merger will in fact make it possible to complete the concentration of the activities carried out by Unimac directly under the Borghi company, allowing not only a rationalization and optimization of decision-making levels, resource management and structural costs, but also an elimination of duplications and overlaps of accounting, fiscal and administrative duties. This project is the natural evolution of a partnership already existing for more than 10 years, during which important synergies have been created between the two companies.

“This is a moment of great importance for us, which establishes the strategic objectives defined already in the acquisition phase,” says Paolo Roversi, President of Borghi S.p.A. “A final step, the merger, which we wanted to make happen in the shortest time possible, to demonstrate our aptitude for rationalization in terms of management and cost savings and to present ourselves to the national and international market with a well-defined corporate identity, thanks to the contribution of the specific and complementary Borghi and Unimac expertise.”

“The acquisition of Unimac by Borghi in 2019 was an effective step to give a concrete future to the Unimac product lines, which expand the range offered by Borghi. With today’s incorporation not much has changed for us at Unimac, we have only moved to the Borghi location while keeping the workforce and roles unchanged, and we have become part of the Borghi family in all respects with the aim of serving the global market by always trying to offer the best technology and services, the hallmark of the Borghi team”, says Davide Ori, General Manager of Unimac S.r.l.

For more information about Borghi S.p.A., please visit their website at www.borghi.com.

Brushtec has launched an exciting new product within their Sweepertec range, the Sweepertec Steel. Made in Britain from ultra-stiff steel wire bristles rather than plastic, the Sweepertec Steel is a powerful fast-change fork attachment for the heavy-duty cleaning of yards and sites.

The Sweepertec Steel uses 55 percent more bristle than the next competitor. Sixteen rows of 3.3 × 0.6 mm patented steel wire bristle provide an extremely dense and strong brush, and the bristles are arranged in a chevron pattern that helps to collect even small debris. The brush also features non-marking HDPE wear edges, enabling the sweeper to brush debris close to walls without damage.

This British-made steel bristle forklift brush is the only one on the market to come as a one-piece, highly durable brush back. With no rows of flimsy bristles bolted together, the Sweepertec can provide excellent performance in whatever scenario and conditions it finds itself. The Sweepertec steel is also a self-supporting brush, so there’s no need to chock the brush in between uses — simply place it down until next required.

The frame is fabricated from high-grade steel which is then hot-dipgalvanised, providing resistance to corrosion and protecting it from harsh environmental conditions. Hot-dip galvanizing also gives steel the ability to self-heal scratches to its surface, and the brush’s highly durable, heavyduty, welded steel chassis has no moving parts to break, further extending the lifespan of this product.

“With the Sweepertec Steel we have produced the best quality, and value, steel-bristle forked vehicle brush possible. With its high performance and ease of use, this brush will allow you to get any sweeping job done swiftly, giving you more time to work through your other tasks,” says Barry Crackett, Product Designer at Brushtec. “Sweepertec Steel brushes are manufactured right here in the U.K., and we work very hard to ensure that they are always in stock and available for purchase. Between the excellent quality of the steel bristle and the high brush density, these brushes should last an extraordinarily long time.”

The Sweepertec Steel measures 2000 mm (79") in length x 580 mm (23") in width x 400 mm (16") in height, with a total weight of 200 kg. Built in Britain from British components, it can be purchased on the Sweepertec website for £1,587.00 (excluding VAT). Replacement brushes are also available.

GB BOUCHERIE NV is pleased to announce that INTERCO S.A. is now its official agent in Mexico, effective March 1, 2024. Boucherie and Interco share a common goal of providing excellent service to all Mexican companies in the industry, building on the good reputation and vast know-how of both companies.

The statement from Boucherie says, “We believe that this alliance will allow us to provide existing and new customers with the best possible experience. Boucherie’s Andres Becker and Interco are looking forward to working with you!”

For more information about Boucherie, visit www.boucherie.com.

The Inspired Home Show 2024 wrapped on March 19 at McCormick Place in Chicago after three highly productive days. The Show featured 1,648 exhibitors from 38 countries. Nearly 30,000 home + housewares professionals from over 120 countries came together to discover new products, connect with colleagues and advance the industry.

“The 2024 Show built on the success of last year’s Show with total square feet of exhibition space being slightly higher. The change to the format was very positive, making the Show incredibly efficient — moving between the three primary Expos, now consolidated into two halls rather than three, was very well received by both exhibitors and buyers,” says Derek Miller, president and CEO of the International Housewares Association.

The Inspired Home Show 2025 will take place March 2-4, 2025, at McCormick Place in Chicago.

Following four days of bustling activity, the EISENWARENMESSE — International Hardware Fair concluded its 2024 edition on Wednesday, March 6, 2024. Held in Cologne, Germany, from March 3-6, the event marked a triumphant return to its traditional March timeframe after a special edition in the autumn of 2022. Renowned as the premier global platform for the hardware industry, the fair drew over 3,200 exhibitors from 54 countries, showcasing the latest trends and innovations across various sectors including tools and accessories, industrial supply, fixing and fastening technology, building supplies and home improvement.

“We are highly satisfied with the EISENWARENMESSE — International Hardware Fair 2024. Our supporting program went down very well and all of the exhibiting companies praised the excellent quality of the visitors,” says Oliver Frese, Chief Operating Officer of Koelnmesse GmbH. “The trade fair underpinned its relevance as the key meeting point for industry trends and product innovations not least with formats like the popular EISENaward. The positive response and the return of many companies confirm the March date fits in perfectly with the innovation cycle of the industry.”

For more than 80 years, Celanese Filaments, formerly owned by Dupont, has been recognized as a leader in innovative synthetic filaments that enable brush manufacturers to address emerging trends and meet evolving consumer expectations.

The most important component of a toothbrush lies in the bristle. With outstanding industry expertise accumulated over the years, coupled with our proven technologies, Celanese Filaments is dedicated to the oral care brush industry with our nylon solutions under the brand names of Celanese Tynex®(nylon 612) and Celanese Herox®(nylon 610). Leading toothbrush brands and manufacturers are able to produce very high quality brushes with a balance of consistent quality, wear performance and unmatched productivities in tufting and end-rounding by using Celanese filaments. As consumer trends in toothbrush are increasingly focused on the six major areas of 1) Visual Attractiveness, 2) Interdental Cleaning, 3) Plaque Removal, 4) Gum Comfort, 5) Gingival Cleaning and 6) Anti-microbial within the filaments, Celanese Filaments has been working closely with the leading global brands in oral care as well as toothbrush manufacturers by fulfilling these needs with our broad range of innovative products in the portfolio

Celanese Natrafil® filaments, a pioneering filament from Celanese’ s unique polyester based material, contain proprietary texturizing additives that create a structured surface that mimics animal hair. Natrafil® filaments offer a synthetic alternative to animal hair in premium cosmetic powder brushes with more consistency in the bristle while maintaining the touch-and-feel of premium animal hair. Studies have shown that brushes made with Natrafil® filaments have equal to superior pickup and release performance versus brushes made with animal hair.

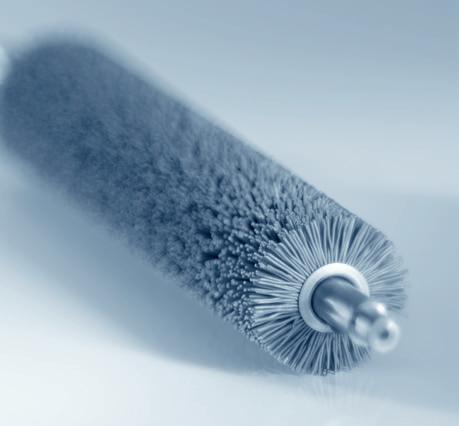

Like most industries, steel manufacturers are always looking forsquare feet of metal through the mill, cleaned and coated faster

than ever before. To accomplish this, steel mills are using more aggressive cleaning solutions. The problem is that the cleaning brushes typically used were quickly degrading because many plastics used in the brush filaments can’t handle the solutions of the extreme PH. The technical resources at Celanese Filaments were able to help solve the problem by adding stabilizers to one of our nylon polymer formulations, effectively extending the pH range where these filaments can be used. Brushes made with our filaments deliver cleaning performance for a longer life, helping over an improved service life, helping steel manufactures to achieve higher productivity.

Another need voiced by customers is higher aggressiveness in metal finishing applications. Celanese Tynex® A filaments, a family of ceramic grit-containing filaments, was developed to meet this need.

CREATIVITY DESERVES THE BEST FILAMENTS – PAINTBRUSH FILAMENTS

When manufacturers began changing their paints to water-based formulations, more people began using paintbrushes made with synthetic bristles because the hog bristles traditionally used in paintbrushes lost stiffness in water-based paints. Synthetics such as Celanese Tynex®, Celanese Chinex® and Celanese Orel® brand filaments quickly became popular choices. As paint manufacturers continue to improve their water-based formulations by reducing volatile organic compound (VOC) content, increasing solid loadings and decreasing drying times, there is an ongoing need for increasingly higher performing brushes. To meet this need, Celanese Filaments continues to innovate and help customize solutions. For example, we developed filaments with stiffer crosssection that can push higher viscosity paints more efficiently. We also changed the shapes of the filaments so that they not only pick up more paint from the can for faster application, but are easier to clean.

Recognition for being the global leader in filaments comes from our customers. You inspire us to make a difference in the world. We will continue to advance our innovations because we believe your BRUSH deserves the best FILAMENTS. 1-800-635-9695 | www.celanese.com

Blue Monster® LUBE-JOB, a superior pipe joint lubricant that simplifies the assembly of all types of pipelines (especially potable water systems) without swelling gaskets, is now available from Clean-Fit Products, a division of The Mill-Rose Company.

LUBE-JOB is formulated from a biodegradable blend of lubricity enhancers and soaps creating a unique lubricant that flows into cavities when mating abutting pipes, effectively sealing joints. Its soft, creamy formula spreads on easily to give superior lubrication, performing well in extreme temperatures from -10° F to 150° F.

LUBE-JOB is petroleum and phosphate-free – a special low-VOC blend of raw materials common in the lubricant and soap industries. LUBE-JOB dissipates and will not leave a residue when flushed in accordance with recommended AWWA procedures. It will not irritate the skin, is non-toxic, and cleans up easily using soap and warm water. Blue Monster LUBE-JOB is certified to meet NSF / ANSI Standard 61-G for potable water pipelines. NSF’s use of strict analytical standards for formulating consistency assures the production of a safe lubricant for water pipe joining requirements. In addition, LUBE-JOB is FBC system compatible.

“LUBE-JOB simplifies assembly of push-on pipe joints with natural or synthetic rubber or plastic gaskets. Its biodegradable,

Blue Monster® LUBE-JOB pipe joining lubricant is available in a two-pound container and sold at leading PHC supply houses. Blue Monster Products are offered exclusively by Clean-Fit Products, a division of The Mill-Rose Company. The Mill-Rose Company is the world’s leading supplier of PTFE thread sealants and the largest U.S. manufacturer of twistedin-wire brushes used in virtually every type of industry throughout the world. Mill-Rose is a family-owned organization now in its fourth generation. The organization has experienced significant growth from its humble beginnings in 1919. Today it operates manufacturing and warehouse facilities throughout the United States and Mexico, with over 100,000 square feet of production facilities in the U.S. and Mexico, complemented by a 70,000 square foot U.S. distribution center with a 42,000 sq. ft. expansion in process.

For further information contact Clean-Fit Products, 7310 Corporate Blvd., Mentor, Ohio 44060. Telephone 1-800-3213598, fax 1-440-255-1072, e-mail info@cleanfit.com or visit www.cleanfit.com.

We are proud to be exhibiting at the World Brush Expo 2024

Visit us in Hall 30 Stand G13 to see our exciting range of winding and finishing machines in action!

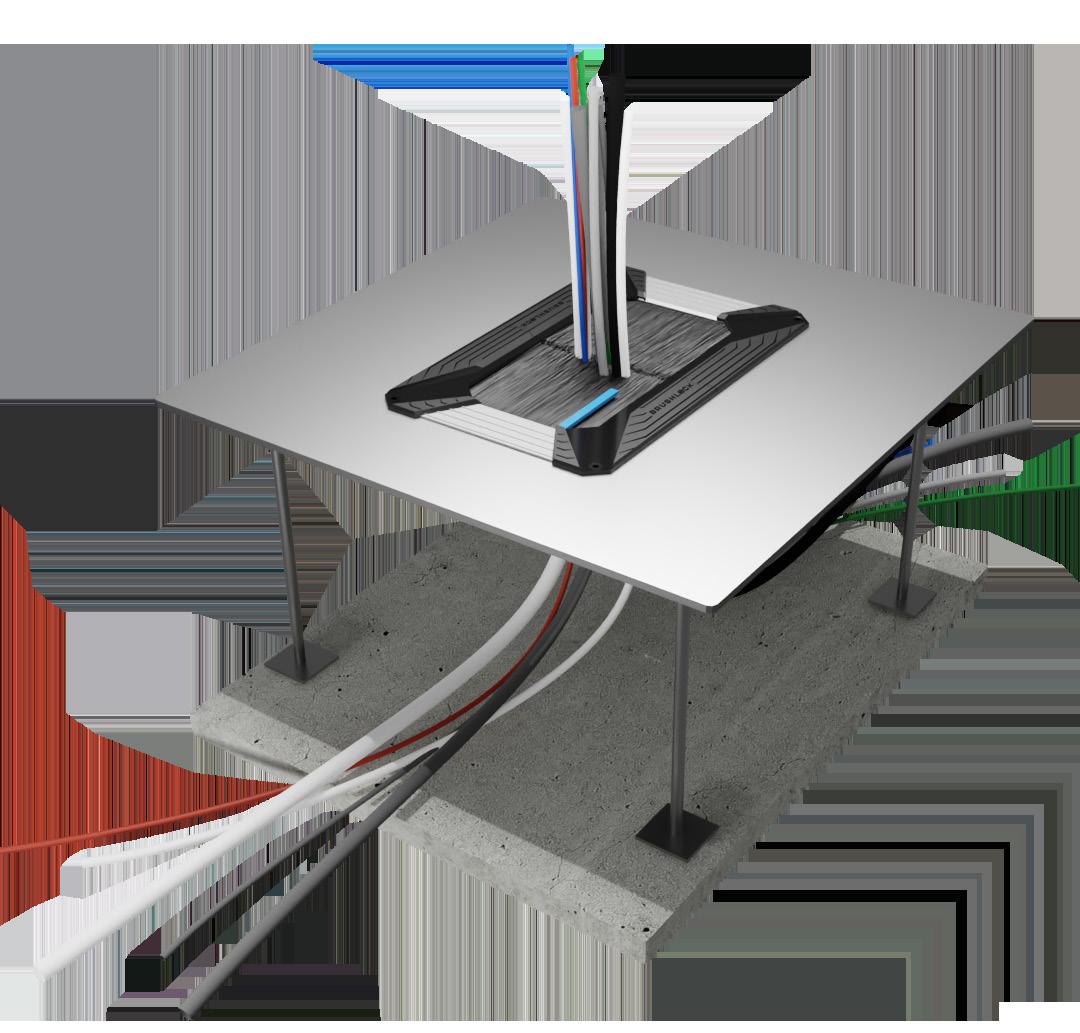

The young company BrushBoxx, based in Hochdorf, Germany, is delighted to have received the international GOOD DESIGN Award 2023 from the Chicago Athenaeum Museum for Architecture and Design for their BrushLock cable entry system. The product is specially developed for data centers and reliably seals cable entries to improve cooling and energy efficiency in data centers.

In collaboration with the renowned design team from Ammerbuch, the focus was not only on the technical property rights but also on developing a holistic appearance from the lettering to the packaging. The innovative functional integration of assembly aid, handling and additional closure options ensures a well-thought-out customer benefit and thus stands out from previous solutions on the market.

André Fischer, Head of the Data Center division, is delighted with the response from customers. He says, “This unique product has been well received by our international customers, who not only expect a technically sophisticated product but also appreciate the user-friendliness supported by the design.”

BrushBoxx, founded in 2022 and certified according to DIN ISO 9001, offers brush solutions that are already used in data centers, agricultural machinery and wind turbines of well-known companies throughout Europe. State-of-the-art machinery and a high level of vertical integration ensure fast and flexible implementation of customer requirements.

Stay up to date with the world leader for brush industry news and get notifications for each issue of Brushware magazine digital issues.

www.brushwaremag.com/enewsletter

The former worldwide event for the oral care brush industry, held in Freiburg, has been discontinued. Instead, a brand new fair called the World Brush Expo is organized by the American Brush Manufacturers Association and the European Brushware Federation. From May 22-24, 2024, manufacturers of various types of brushes from all over the world will unite in the BolognaFiere venue in Bologna, Italy. This is a mustattend event for professionals in the brush industry, where Boucherie will be presenting exciting new, industry-leading toothbrush machinery.

Anchor

Boucherie’s proprietary PTt technology remains on the cutting edge of anchorless toothbrush manufacturing. When it was introduced at the Interbrush show in 2016, it stunned the world and the oral care industry showed massive interest.

Simple as a technology yet allowing for elegant brush head designs with flexibility in materials, PTt has been re-engineered for more output, engineering simplicity, higher product quality and superior efficiency. See the new and improved PTt machine at the World Brush Expo in May along with the following:

Anchorless technology: Two entirely new machines will be revealed!

Anchor technology: Demonstration of the latest Hepta developments.

Interdental: Discover a brand new feature for unsurpassed quality on IDM.

To learn more about Boucherie at the 2024 World Brush Expo, visit www.worldbrushexpo.boucherie.com.

Interdental: Discover a brand new feature for unsurpassed quality on IDM.

As we edge closer to our congress in Ibiza, it’s time to take a moment to appreciate the stunning natural landscape that surrounds us – not just the beautiful beaches, but also the lush countryside and hidden coves that make Ibiza a paradise for nature lovers. Ibiza may be famed for its vibrant nightlife, but it’s also a haven of natural beauty waiting to be explored. From the rustic charm of its pine-clad hills to the crystal-clear waters hugging its coastline, Ibiza offers a tranquil backdrop to our bustling congress schedule.

In a delightful contrast to our serene island setting, we are thrilled to introduce Araceli Segarra – an extraordinary mountain climber, the first Spanish woman to reach the summit of Everest and a prolific author. Her book, “Not That High and Not That Difficult,” mirrors the challenges we face, whether scaling towering peaks, navigating the complexities of business or forging strong partnerships. Segarra will guide us through mastering the seemingly insurmountable, reminding us that “no man/company is an island,” perfectly embodying

the theme of our congress. Her insights promise to inspire and elevate our perspectives on overcoming challenges and enhancing cooperation.

Secure your spot at this unprecedented gathering:

• Book Your Congress Spot: FEIBP Congress Registration

• Secure Your Stay: Ensure your accommodations by visiting the FEIBP Congress Hotel webpage. Booking through other platforms like Booking.com will result in higher rates.

Prepare to be captivated by Ibiza’s enchanting natural beauty and to be inspired by stories of resilience and teamwork from one of the world’s most accomplished climbers. This congress is not just an event; it’s an experience that will challenge, motivate and unite us. Looking forward to exploring both the heights and depths of what we can achieve together in Ibiza.

—Alessandro Acquaderni, President, FEIBP

Borghi USA, Inc., proudly announces the addition of Rob Wilson to its team as the new Field Service Technician. In his capacity, Wilson will play a crucial role in supporting customers by providing expertise in troubleshooting, machine repairs, installation and training, both onsite and remotely. Additionally, he will collaborate closely with the Borghi –Italy engineering team, contributing to the development of new equipment.

In January, Keystone Plastics announced Terry Parsons as the company’s new sales/business development executive. In his role, Parsons will focus on managing business relationships, driving sales growth and building and maintaining distribution programs. His responsibilities involve providing client support, developing new product and business opportunities and actively participating in marketing and events to promote the KPI brand.

Parsons is a highly accomplished senior executive with a dynamic background in developing and implementing transformational strategies aimed at propelling revenue, optimizing operations and fostering sustainable organizational growth. He brings a proven track record of aligning highperforming teams with corporate vision, forging valuable partnerships and delivering tactical roadmaps for business value.

“We’re genuinely excited to welcome Terry to our team! His extensive industry knowledge, stellar reputation and positive attitude are valuable assets that will contribute to our growth and enhance the support we provide to our customers,” says Mike Santos, Director of Sales and Marketing.

Parson’s career highlights include successful tenures as General Manager at Alamo Group Inc. and Chief Operating Officer at Heil of Texas, where he played pivotal roles in transforming operations, driving growth, and instilling a high-performing culture. His professional journey is marked by achievements including tripling company revenue, revitalizing sales efforts, and implementing strategic initiatives that have left a lasting impact.

In fond remembrance, we celebrate the life of Edward Jackson, the visionary founder of Edward Jackson (Engineer) Ltd, who passed away in March. The son of a model engineer, Edward had an innate creativity and imagination that led to several early inventions, including a ‘pilfer-proof’ picture mounting for hotels and a self-extinguishing litter bin, which even resulted in a brief television appearance.

It was his other lifelong interest, music, that led him into the brush industry. In 1968, while singing in a local choir, Edward crossed paths with the factory manager of the Briton Brush Company, who commissioned Edward to create a paintbrush knot-picking machine. This was followed by a series of machines Edward developed for the firm, including the first prototype paint roller-making machines.

In 1977 Edward married Rachel, and with her business skills together they founded Edward Jackson (Engineer) Ltd the following year.

Edward’s first paint roller machine — the GW1 winding machine — was demonstrated at the inaugural InterBrossa exhibition in Freiburg, Germany. The company has exhibited machinery at every show since, continuing the tradition with the World Brush Expo this year in Bologna.

From the 1980s until his retirement, Edward continued to innovate, securing patents for several groundbreaking machine designs, including the continuous winding process and cutting-edge finishing systems. The help of Rob Coleman, who served as the company’s global sales representative, enabled worldwide dissemination of Edward’s machines, leaving an indelible mark on the global market.

business after graduating in 2001. In the following years, they worked together, with Tim absorbing Edward’s unique design style and approach to engineering quality. Tim continues to develop the company, staying true to Edward’s principles and commitment to innovation by incorporating the latest design and manufacturing techniques.

Inspired by his father’s love of engineering, Edward’s eldest son, Tim, joined the family

It is a testament to the originality and enduring value of his ideas that Edward Jackson (Engineer) Limited continues to thrive, crafting successful paint roller machinery derived from Edward’s pioneering designs.

Beyond his professional endeavors, Edward’s life was enriched by his passions for music and architecture. His dedication to choral singing and conducting remained a source of joy and solace throughout his life, while his family provided the bedrock of his inspiration and support.

In his later years, Edward faced the challenges of progressing dementia with resilience and grace. Though his passing may have been sudden, it was not entirely unexpected. His family is consoled that he was surrounded by friends and family for his 80th birthday just days earlier.

Donations in Edward’s memory can be made through edward-jackson-1944-2024.muchloved.com in aid of Sing Your Heart Out and Dementia Adventure.

One of the most important aspects of ERP software for manufacturers is the stability of the software provider. Global Shop Solutions, a family-owned ERP provider for almost 50 years, is proud to recognize Chris Pinaire, MBA, Director of New Implementations, for his 20 years of dedicated service to the manufacturing industry.

Pinaire began his career with Global Shop Solutions as a customer service representative. With his background in management information systems and keen problem-solving abilities, he was quickly promoted to helping manufacturers successfully implement ERP software and consulting with existing customers to simplify their manufacturing processes. After several years as a senior consultant, Pinaire was elevated to his current position where he has had a significant impact on the manufacturing industry.

“Chris is smart, hardworking and constantly looking for ways to make the implementation process faster and easier,” says Dusty Alexander, Global Shop Solutions President and CEO. “He manages a team of more than 70 implementation specialists, who average a 95 percent success rate for new implementations. His commitment to excellence makes us better every day.”

Pinaire attributes his tenure at Global Shop Solutions to the work, the people and the satisfaction of helping manufacturers solve problems and find the best solutions for their businesses.

“The work is interesting and challenging,” says Pinaire. “There’s never a dull moment, and I love the people I work with. We operate as a unified team and always support each other to find the best solutions for our customers.”

“I also admire the way Global Shop Solutions grows its people internally,” adds Pinaire. “Keeping people interested requires having a path for them to grow. Five, 10 or 15 years ago we didn’t have a lot of positions that exist today. Adding new positions as the business grew provided a path to keep our employees hungry and growing, playing a key role in the stability of our workforce.”

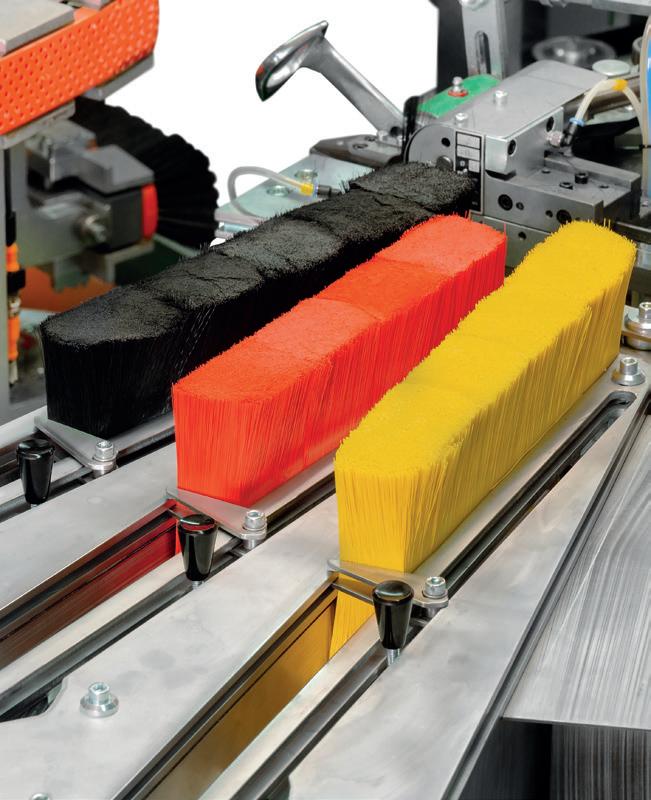

Wöhler Brush Tech, a leading provider of brush production machinery, is excited to participate in the highly anticipated World Brush Expo 2024. This global event will serve as a platform for the industry to showcase its latest innovations and product highlights directly to customers. On Stand E1 in Hall 30, attendees can expect to explore Wöhler’s diverse array of cutting-edge solutions, including:

Wöhler introduces a comprehensive line enabling companies to effortlessly roll and spool their own flat wire. The renowned FWR 250 flat wire rolling machine rolls the wire flat with a thickness tolerance of just +/- 0.01 mm. The accompanying FWW 250 cooling unit facilitates continuous cooling of the wire, while the DC 510 wire winder enables rapid spooling at speeds of up to 240 m/min. A crane is integrated into the DC 510 for easy handling of the spooled wire with up to 400 kg on cardboard cores or optionally on metal spools.

Step into the future with Wöhler’s virtual reality showcase, offering an immersive journey into the full range of production machines for street sweeping brushes. Walk around machines for the production of street sweeper roll brush segments like the PVM 100 or gutter brooms and segments like the high-speed GB 100. Take a closer look than it would ever be safe to in reality. Witness the unveiling of the new Wöhler gutter broom machine GB 50, a simple and low-priced entry into the automated production of gutter brooms and segments incorporating an industrial robot to move segments or plates during drilling and filling.

Wöhler will be presenting the SBM 840 strip brush machine with the BUD 300 automatic bundle feeder and the BLS 700 wheel picker for even and fast separation of various natural and synthetic materials. At the same time, the SBM 840 is equipped with the new DSA 500 wire strand laying device processing wire strands from spools. New features of the SBM 840 are the continuous monitoring of the profile width ensuring perfect fitting of the profiles into their holders and the brush height monitoring. One of the highlights is the new filament density closed-loop control which ensures permanent quality control of the brush density and relieves the operator.

Wöhler presents a new customer service portal that provides all the necessary machine data quickly and easily when servicing is required. Customers have a quick and comprehensive overview of their machines. Spare and wear parts that have already been ordered can be viewed and easily requested again.

The big advantage, however, is the integrated ticket system for service cases. This makes it much easier for both the customer and Wöhler to keep track of individual service cases on a chat basis. All tickets remain in the system and can be searched so that the customer can find solutions to recurring service cases independently. In addition, customers can access the documentation and accompanying documents for their machines at any time in the new customer portal. Wöhler Service will be happy to introduce the new customer portal to all interested customers.

Don’t miss the opportunity to explore these innovations and more at Wöhler’s booth at the World Brush Expo. Visit Stand E1 in Hall 30 to discover the future of brush production technology.

To learn more about Wöhler, visit bt.woehler.com/en/.

We are thrilled to announce that we will participate in the WORLD BRUSH EXPO 2024, which will be held from May 22-24, 2024, in the 29 and 30 halls of the Bolognafiere Venue, Bologna, Italy. We sincerely welcome all brush manufacturers and customers from any industries visit our booth L9 to share our innovative filament products and the best-customized filament solution.

The World Brush Expo is the brand new trade fair for the global brushware industry that includes technical brushes, paintbrushes, paint rollers, hygiene brushes, oral care brushes and the mop industry.

At WORLD BRUSH EXPO 2024, we will display our professional filament varieties with different characteristics applied in various brush applications. There are Lasson™, Soclean™, Tuboss™, Beauty™Fil, Sentec™, Superball™, Nexvan™, GrindFil™, Doclean™, Videfense™, Maskfit™ etc. These filaments are widely applied in industrial brush, toothbrush, paintbrush, household cleaning brush, artist brush, hairbrush, road sweeping brush, hygiene brush and mask industries, etc.

With the development of society, people’s health and environmental protection awareness has been greatly improved. They will prefer the environmental brush products that reduce the pollution of the ecological environment. Therefore, our new filament materials, BioFil biodegradable filament and PCR post-consumed recycled filament, are very popular in the brush industry.

BioFil contains renewable plant raw materials, such as wheat, corn and sugar beet. Compared to petroleum-based plastic, BioFil can be degraded into carbon dioxide and water under composting conditions. According to the testing standard DIN EN13462:2000-12, ASTM D 6400:2019-01, it was reported that the bio-degradation rate of BioFil achieved 90.75% within 145 days. BioFil has been certificated by the chemical limitation test, bio-degradation test, ecotoxicological test and the earthworm ecotoxicity test.

It is suitable for making toothbrushes, makeup brushes, false eyelashes, household cleaning brushes and hygiene brushes. The application of BioFil helps brush manufacturers produce biodegradable brushes without causing any pollution to the environment in the production and final treatment process.

PCR filament, another eco-friendly filament material, is competitive with new nylon filament materials in terms of working performance, toughness and durability after the special treatment process.

The raw material of PCR filament recycles the abandoned plastic (PBT/PET/PP/NYLON 6 material) within 50 kilometers from the coast, which ensures that consumers can purchase the product beneficial to reducing ocean pollution.

Compared to the original plastic, it is reported that PCR filament effectively reduces the cumulative energy by 43 percent and water consumption by 15 percent, which is offered by our PCR raw material suppliers.

Additionally, GrindFil, abrasive filament, has been a highly anticipated product since its launch. It is made of nylon 6/66/612 base material and is combined with silicon carbide/ Aluminum Oxide/Diamond abrasive material.

GrindFil has better characteristics of wear resistance, toughness, resilience, chemical resistance, etc. It has excellent working performance when it is applied in polishing, deburring, grinding, finishing and coating removal industries.

Tai Hing looks forward to your visit to L9 booth, where we will demonstrate the exceptional performance and versatility of our nylon brush filaments. Join us as we embark on a journey of innovation and discover the future of industrial brushes together.

For further information, please contact us at marketing@taihingnylon.com.

See you in the WORLD BRUSH EXPO 2024 in Bologna, Italy.

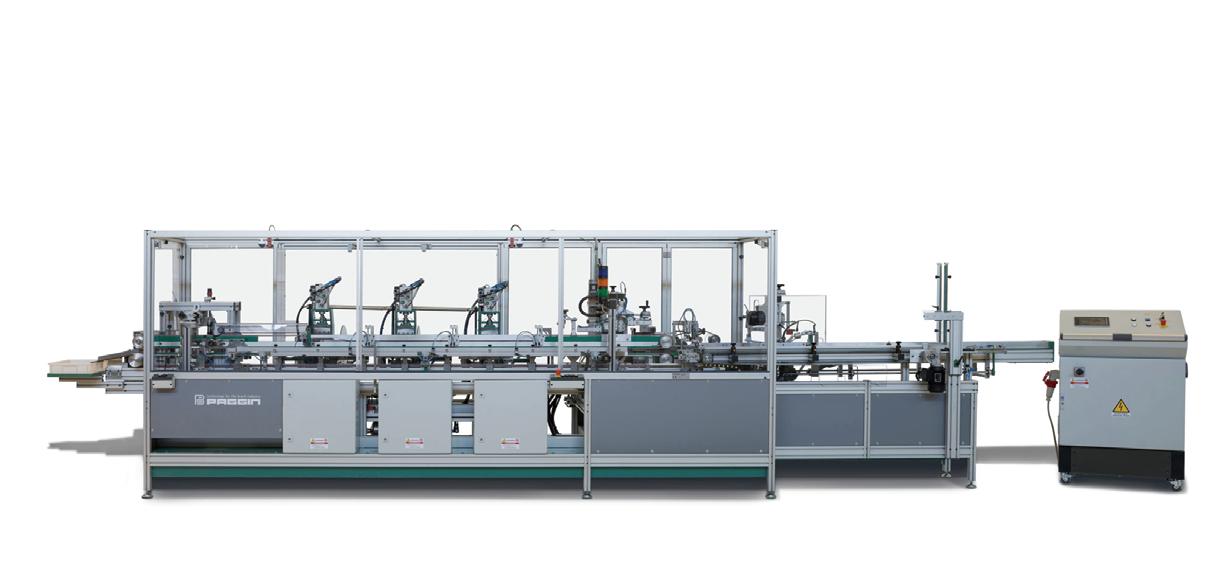

Roth Composite Machinery from Burgwald will be presenting the new development from its own innovation department at the World Brush Expo in Bologna (Hall 30, Stand E15). The fully automatic concept can be used to produce brushes that differ completely in terms of length, geometry and material — and with minimal set-up effort. The new WTR is characterized by shorter set-up times, higher output and greater flexibility in production — making it significantly more efficient and versatile than other machine concepts on the market.

“We want to convince the trade fair visitors in Bologna of all these plus points,” says Dennis Brückner, responsible for the Burgwald plant at Roth Composite Machinery, and sales engineer Thomas Halbrucker, “The machine concept and the high degree of automation fulfill the needs of flexible mass production and meet our high standards of quality and sustainability.”

The “Brushes & Brooms” business unit of Roth Composite Machinery in Burgwald (formerly Schlesinger) has more than one hundred years of experience in the design and realization of machines for brush production. With a mix of experience, expertise and continuous development, the more than 50 employees in Burgwald have established themselves as world leaders in the industry — not least thanks to a global network of contacts for sales and service. The company has attracted attention in recent years with energy-saving, yet particularly powerful drive elements and a highly efficient manufacturing process: The filling tool technology, known as “RoAn”, scores with extremely smooth running, low wear and above-average process reliability. “We stand for first-class product quality and high-performance mechanical engineering worldwide,” says Dennis Brückner, “while our machines are also versatile and user-friendly.”

In Bologna, the organizers are particularly looking forward to the industry coming together again after a long break. “Networking, exchanging ideas, meeting familiar faces and getting to know new potential business partners: we associate all of this with the World Brush Expo, which is why we will be there with an international team of ten people in total,” says Dennis Brückner and Thomas Halbrucker, who are responsible for the event.

Roth Composite Machinery is a specialist in special machine construction the company plans, designs and manufactures units, machines and entire production lines in the following business areas

• Filament Winding & Prepreg

• Pleating & Coating

• Brushes & Brooms

To learn more about Roth Composite Machinery, visit www.roth-composite-machinery.com.

To succeed in the current world dominated by supply chain disruptions and chokepoints, executives must create resiliency and get ahead of the inevitable volatility. The latest, the Francis Scott Key Bridge collapse, has caused massive diversions on the East Coast and in the Baltimore region pointing out the need for backup sources of supply and agility in the supply chain. The level of geopolitical and supply chain risk has remained elevated and should not be ignored in designing supply chain plans.

When the container ship ran into the Francis Scott Key Bridge, causing the bridge to collapse, the regional supply chain came to a screeching halt. The destruction of the bridge cut off the Baltimore port by effectively creating a wall between the port and the Chesapeake Bay. The port is likely to remain closed for a few months and traffic diverted. The Baltimore port is the fifth largest port on the East Coast and the largest port for roll-on/roll-off cargo such as automobiles, light trucks and construction and farm equipment.

The consequences of the bridge collapse are far-reaching, but the most significant industry impact will be the automobile sector. Once the container ships are offloaded at another port, they will need to be transported to the Baltimore region or new sources of supply will be sourced. There are 3,200 sites involved in logistics, distribution and warehousing near the port and bridge. According to the American Trucking Association (AMA), almost 4,900 trucks travel the bridge each day, with $28 billion in goods crossing each year. Severe disruption will remain until the bridge is rebuilt, creating congestion and diversions for the next few months.

The Baltimore bridge collapse is just the latest in a series of disruptions and chokepoints in the global supply chain. The pandemic created a significant chokepoint at the West Coast ports. According to the Journal of Commerce, the West Coast share of imports coming from Asia was down from 61.1 percent in 2021 to 58.8 percent in 2022 while the East Coast and Gulf Coast ports rose. For example, customers started diverting shipments from Northeast Asia destined for the East Coast through the Panama Canal; however, in 2023, the Panama Canal experienced a drought and capacity was

reduced by 50 percent over time. This created a chokepoint in that region with congestion, delays and increased prices for expedited travel through the canal. Thus, customers looked for new routes.

One new route was to ship products from Northeast Asia through the Red Sea and Suez Canal to the East Coast ports. This backup plan worked well until the Iran-backed Houthi rebels started attacking container ships in the Suez Canal creating a new supply chain chokepoint. Container ships had to divert around the southern tip of Africa, adding 10 days and 1,000-5000 nautical miles to the trip, thereby delaying shipments and adding cost. Thus, the Baltimore bridge collapse is simply the latest disruption to hit the global supply chain. Each disruption increases inflationary pressure and creates new diversions. Now some customers are rerouting from Northeast Asia to the West Coast ports and will rail or truck products to the East Coast.

A backup plan is no longer sufficient. In fact, a backup to the backup plan is also not sufficient. Instead, companies are creating resiliency in the supply chain. They are using processes such as SIOP (Sales Inventory Operations Planning) to proactively navigate changing conditions to get ahead of disruptions and chokepoints. Moving towards regional supply chains is also gaining in popularity as companies want to gain control over their supply chain. Advanced technologies such as 3D printing also provide additional options for gaining control and creating resiliency. Being vulnerable to disruptions is no longer an option.

Lisa Anderson is the founder and president of LMA Consulting Group, Inc., a consulting firm that specializes in manufacturing strategy and end-to-end supply chain transformation that maximizes the customer experience and enables profitable, scalable, dramatic business growth. She recently released “SIOP (Sales Inventory Operations Planning): Creating Predictable Revenue and EBITDA Growth”, an e-book on how to better navigate supply chain chaos and ensure profitable, scalable business growth. A complimentary download can be found at www.lma-consultinggroup.com/siop-book/.

Given that industrial brushes are ubiquitous in all facets of society, it is not surprising that its market share in the multibillion dollar global brush industry is enormous. In a 2022 analysis by India-based Maximize Market Research, it reported that the global industrial brush market size was valued at US $654.72 million, with total revenue expected to grow at 8.5% compound annual growth rate (CAGR) from now to 2029.

During that period, the firm projects that the industrial brush market size should reach $1.15895 billion. Factors driving this steady, robust growth include increasing demand from the manufacturing industry for brushes used in such applications as surface finishing, cleaning, and deburring; and demand for specialized/custom made brushes for automation and robotic equipment, 3D printing, and other end-user requirements. None of this is news to those involved in industrial brush manufacturing; they are in the thick of providing products and services to their customers. To gain insight from the ground floor, Brushware sought and received answers to the following questions from those involved:

cylindrical and all other shapes.

CEO Lance Cheney, Braun Brush Company, Albertson, New York: Our company produces a wide array of industrial brushes, including epoxy set, fused, twisted in wire, staple set, wire wound, and wire drawn brushes. Each type is crafted to meet diverse industrial needs, offering durability, precision, flexibility, and strength tailored to specific applications.

2. What industries does your company primarily serve with your industrial brushes?

1. What types of industrial brushes does your company manufacture?

Alessandro Acquaderni, CEO of SITBRUSH, Bologna, Italy: Power brushes, hand scratch brushes, industrial roller brushes, wide-face brushes.

Jim Benjamin, president, Precision Brush, Solon, Ohio: Precision Brush Company manufactures metal channel strip brushes in a variety of shapes and sizes. Straight strip and cylinder brushes are the most common, but we also are experts in making inside disks, outside disks, cup brushes and other odd-shaped brushes. These brushes are used in almost every industry and are unlimited in their uses and applications.

Linzmeyer-Jelinek: We serve a wide array of industries, catering to sectors such as aerospace, power generation, agriculture, automotive, laboratory, food processing, metalworking, HVAC, chemical processing, and graphic arts. Our clientele spans across diverse sectors, reflecting the versatility and quality of our products tailored to meet the rigorous standards of professional

Rakusin: We have a strong presence in the automotive and aerospace industries, where our brushes play a vital role in various manufacturing procedures. Our offerings include a range of products tailored to their specific needs: from our standard hand industrial brushes to those designed for critical ESD (Electro Static Discharge) environments, custom brushes crafted to address specific challenges, and even paint and artist brushes. Our market has experienced significant growth thanks to our 13 acquisitions. As a result, we have established strong footholds in the janitorial, food service, electronics, paint and sundries, and industrial sectors, where we consistently excel.

Cheney: Our industrial brushes serve a broad spectrum of industries, including automotive detailing, food production, pharmaceutical, aerospace, medical, and general industrial sectors. Our products are designed to meet the rigorous standards and diverse needs of these fields.

Benjamin: Most of our products are used in industrial applications where sealing, wiping, agitation, cleaning, moving of product, holding items or any other imaginable application is possible. We have produced over 200,000 unique brushes,

The World Brush Expo has finally arrived and organizers are pleased to see that the inaugural event has attracted over 150 brushware industry companies that will exhibit at the Bolognafiere venue in Bologna, Italy, from May 22-24, 2024.

The Expo will be held in Halls 29 and 30 of the venue with over 20,000 square meters of event space. Exhibitors will come from all parts of the world representing technology and products in the industrial brush, paintbrush, paint roller, hygiene brush, oral care brush and mop industry segments.

Filling the hole left by the demise of the popular Interbrush show that was last held in Freiburg, Germany, in 2016, the World Brush Expo sets a new precedent for collaboration in the industry as the ABMA and FEIBP have worked in partnership with tradeshow organizer Bolognafiere to bring this event together.

“Organizing this show represented a significant change, achieved in just over 12 months after more than 25 years of its predecessor’s legacy, in a new location, a different country and a definitively transformed business world,” says Alessandro Acquaderni, FEIBP President. “This swift and successful transition is a testament to the extraordinary cooperation between FEIBP, ABMA and many of our members, whom I affectionately call ‘brush-believers.’ Together, we have actively contributed to reshaping the brush industry, demonstrating remarkable adaptability and innovation.”

He also emphasized the overall impact of the event saying the new tradeshow stands as the premier B2B platform that unites the entire brush industry under one roof. With more than 150 exhibitors confirmed, the show floor will be a vibrant marketplace featuring the latest in filament, machinery and brush industry components. Visitors to the Expo will include brush manufacturers and brushware professionals of every conceivable type, creating a unique opportunity for networking, discovery and business development. In addition, themes around innovation and sustainability encapsulate a new vision for the future of the brushware industry.

The skyline of Bologna with the two leaning Towers at dusk by istockphotos/Juergen Sack.

While there is no question that three days of interaction on the tradeshow floor will provide all sorts of new business and networking opportunities, attendees and exhibitors are also fortunate to spend time before and after the show in one of Europe’s most remarkable cities. Bologna offers the perfect combination of culture and knowledge, conviviality and good food, traditions and a mindset that is always open to the future.

The city is the capital of the Emilia Romagna region which is world renowned for both the Food Valley and Motor Valley. Located between the Tuscan-Emilian Apennines and the heart of the Po Valley, Bologna offers easy access by train to cities such as Venice, Florence, Milan and Rome.

Emilia-Romagna’s Food Valley is synonymous with the finest quality ingredients, meticulously crafted dishes, and a deeprooted passion for culinary heritage. Food isn’t just sustenance; it’s an art form, a way of life and a source of immense pride for its inhabitants.

At the heart of the Food Valley are the cherished culinary treasures that have gained international acclaim. Parmigiano Reggiano, the king of cheeses, is meticulously aged in the region’s cheese factories, developing its signature nutty flavor and crystalline texture. Prosciutto di Parma, delicately cured and aged to perfection, embodies the artistry of traditional Italian charcuterie. Aceto Balsamico Tradizionale di Modena is the region’s revered balsamic vinegar, which is produced through a meticulous aging process in wooden barrels, resulting in a sweet, complex elixir prized by chefs around the globe.

The gastronomic landscape of Emilia-Romagna is also shaped by its iconic pasta. From the silky strands of tagliatelle to the delicate pockets of tortellini, handmade pasta is a culinary cornerstone, lovingly prepared by generations of pasta artisans using time-honored techniques.

Beyond its famed exports, the Food Valley delights visitors with an array of regional specialties. Culinary pilgrims can savor the rich, meaty flavors of ragù alla Bolognese, a hearty meat sauce that pairs perfectly with freshly made tagliatelle. EmiliaRomagna’s street markets are highlighted by vibrant displays of seasonal produce, from plump tomatoes to fragrant herbs, inspiring chefs and home cooks as well.

PIAZZA MAGGIORE: Start your exploration of Bologna at its main square, Piazza Maggiore. Admire the beautiful architecture of buildings like the Palazzo d’Accursio and the Basilica di San Petronio. Don’t forget to visit the Fountain of Neptune, a symbol of the city.

ASINELLI AND GARISENDA TOWERS: Climb the iconic Asinelli Tower, one of the Two Towers of Bologna, for panoramic views of the city. The towers are symbols of Bologna and offer a unique perspective of its skyline.

BASILICA OF SAN PETRONIO: Explore one of the largest churches in the world, the Basilica of San Petronio. Marvel at its impressive interior, which features beautiful artwork, sculptures and the meridian line, an astronomical instrument.

ARCHIGINNASIO OF BOLOGNA: Visit the Archiginnasio, once the main building of the University of Bologna, which is the oldest university in the world. It currently houses the Archiginnasio Municipal Library, the stunning anatomical theater and the richly decorated halls.

MERCATO DI MEZZO: Immerse yourself in Bologna’s culinary scene at Mercato di Mezzo, a historic market with a variety of food stalls offering local delicacies, fresh produce, cheeses, meats and more.

BOLOGNA’S PORTICOS: Take a stroll along Bologna’s famous porticos, which are covered walkways that stretch for kilometers throughout the city. These porticos are not only practical but also architecturally beautiful, providing shade and shelter from the elements.

BOLOGNA FOOD TOURS: Indulge in a food tour to taste some of Bologna’s renowned culinary specialties, such as fresh handmade pasta, tortellini, mortadella and gelato. Bologna is often referred to as “La Grassa” (The Fat One) due to its delicious cuisine.

MUSEUM OF MODERN ART OF BOLOGNA (MAMBO): Art enthusiasts shouldn’t miss the Museum of Modern Art of Bologna, which showcases contemporary art from Italy and around the world. The museum’s collection includes works by renowned artist Morandi.

SANTO STEFANO BASILICA: Visit the complex of Santo Stefano, also known as the Seven Churches, which comprises several interconnected churches and chapels. The Basilica of Santo Stefano is a place full of curiosities, which has assumed various functions during its history. Explore the unique architecture and soak in the spiritual atmosphere.

Motorsport is part of the DNA of the Emilia-Romagna region as few other places in the world can match the number of race tracks and sports car and motorcycle manufacturers located in the region.

Via Abetone Inferiore, 4, 41053 Maranello MO, Italy

Synonymous with luxury, performance and Italian flair, Ferrari is one of the most revered automotive brands in the world. Founded in Maranello in 1939 by Enzo Ferrari, the company has a storied history in Formula One racing and produces some of the most sought-after supercars. www.ferrari.com

Via Modena, 12, 40019 Sant’Agata Bolognese BO, Italy

Founded in Sant’Agata Bolognese in 1963 by Ferruccio Lamborghini, Lamborghini is renowned for its avant-garde design, raw power and uncompromising performance. The brand’s supercars, such as the iconic Lamborghini Miura and Aventador, embody the essence of automotive excellence. www.lamborghini.com

Via dell’Artigianato, 5, 41018 San Cesario sul Panaro MO, Italy

Pagani Automobili, based in San Cesario sul Panaro, is a boutique manufacturer known for creating some of the most exclusive and awe-inspiring hypercars in the world. Founded by Horacio Pagani in 1992, the company combines exquisite craftsmanship with cutting-edge engineering to produce limited-production masterpieces like the Huayra and Zonda. www.pagani.com

Via Selice, 42E, 40026 Imola BO, Italy

Tazzari EV specializes in electric vehicles and is particularly known for producing compact electric cars. Founded in 2006 by Alessandro Tazzari, the company has gained recognition for its innovative approach to urban mobility and sustainability. www.tazzari-zero.com

®

A complete range ready to satisfy all your needs in the field of the paint brush production from 1” to 5”. User friendly set-up and quick format change, up to 1400 pieces/hour.

SAVE THE DATE! WORLD BRUSH EXPO BOLOGNA (ITALY) 22- 24 MAY 2024

HALL 29 - STAND A18

READY TO MEET YOU ALL IN BOLOGNA WITH OUR LATEST INNOVATIONS IN THE SECTOR!

Viale Ciro Menotti, 322, 41100 Modena MO, Italy

Another giant in the world of sports cars, Maserati is celebrated for its elegant design, refined craftsmanship and exhilarating performance. Established in Bologna in 1914, Maserati continues to produce luxury sports cars that combine Italian passion with cutting-edge technology. www.maserati.com

Via Cavalieri Ducati, 3, 40132 Bologna BO, Italy

Embodying the spirit of Italian motorcycle racing, Ducati is a legendary manufacturer renowned for its high-performance motorcycles. Established in Bologna in 1926, Ducati has a rich racing heritage and produces a range of sport bikes, naked bikes and cruisers that thrill riders around the world. www.ducati.com

Strada Provinciale, 40, 43040 Varano de’ Melegari PR, Italy

Based in Varano de’ Melegari, Dallara is a leading manufacturer of race cars and chassis, with a strong presence in motorsport. Founded by Giampaolo Dallara in 1972, the company has played a significant role in various racing series, including Formula One, IndyCar and sports car racing. www.dallara.it

Via Giuseppe Marconi, 6, 47924 Rimini RN, Italy

Bimota is a boutique motorcycle manufacturer known for its high-performance, handcrafted bikes. Founded in Rimini in 1973, Bimota has garnered a reputation for innovation and engineering excellence, producing limited-production motorcycles that push the boundaries of design and performance. www.bimota.it

Autodromo Internazionale Enzo e Dino Ferrari, Imola, Italy. Photographer: PASCAL SAIVET-Alamy Stock

Santa Monica-Cella

The Misano Circuit is a renowned racetrack situated in Misano Adriatico, Rimini province, within the EmiliaRomagna region of Italy. Named in honor of Marco Simoncelli, the beloved MotoGP champion who tragically passed away in 2011, the circuit boasts a rich history and hosts a variety of motorsport events.

Opened in 1972, the Misano Circuit spans 4,226 meters in length and can accommodate up to 100,000 spectators. It has gained international acclaim for hosting prestigious events such as the MotoGP (San Marino and Rimini Riviera Grand Prix) and the Superbike World Championship, attracting large crowds of racing enthusiasts from around the world.

The circuit’s layout features a mix of fast straights and challenging corners, providing an exhilarating experience for both riders and drivers. In addition to motorcycle racing, Misano World Circuit also hosts events for four-wheeled vehicles, including the Blancpain GT Series Sprint Cup and the Truck Grand Prix.

Imola

Commonly known as the Imola Circuit, is a legendary racetrack located near the town of Imola just 40 minutes from Bologna. Named in honor of Enzo Ferrari, founder of the Ferrari racing team, and his son, Dino Ferrari, the circuit has a storied history dating back to its inauguration in 1952.

The Imola Circuit gained international fame for hosting the Formula 1 Grand Prix of San Marino from 1981 to 2006. With its challenging layout characterized by high-speed straights and technical corners, the track earned a reputation as one of the most demanding and thrilling circuits on the Formula 1 calendar. World Brush attendees arriving the weekend prior to the event also have the opportunity to see an F1 event as the 2024 Emilia Romagna Grand Prix will be held on Sunday, May 19, 2024, at the circuit.

In addition to Formula 1 races, the Imola Circuit has also hosted prestigious events such as the World Superbike Championship, Italian Motor Speed Championship and various other motorsport competitions. Its technical complexity and scenic surroundings make it a favorite among drivers and spectators alike.

Situated in Varano de’ Melegari within the Parma province of Italy’s Emilia-Romagna region, the track is named after former Formula 1 driver Riccardo Paletti. The circuit spans a length of 2,350 meters and offers a diverse range of activities for motorsport enthusiasts. Established in 1991, the track is home to the International Safe Driving Centre, founded by Andrea de Adamich, another former Formula 1 driver. The center specializes in offering courses designed to enhance driving quality and improve car control, making it an ideal destination for drivers looking to refine their skills.

Throughout the year, the Riccardo Paletti Racetrack hosts a variety of races for both cars and motorcycles, as well as rallies and other motorsport events. Additionally, the track provides opportunities for enthusiasts to engage in freestyle test drives, allowing them to experience the thrill of driving on a professional circuit.

Built in 2011, the Autodromo di Modena has a circuit length of 2,007 meters and stands out for its diverse layout featuring various levels and a straight section measuring approximately 400 meters interspersed with tight and wide bends. Initially conceived as a safe driving center, Modena Racetrack offers a range of driving courses aimed at enhancing driving skills and techniques. These courses include sports car driving, daily drive and green drive programs, with a particular focus on promoting fuel-efficient driving practices.

Aside from its educational offerings, Modena Racetrack provides opportunities for enthusiasts to experience the thrill of driving on a professional circuit. The track can be rented for free-style motorcycle or car driving sessions, as well as for track tests, allowing drivers to push their vehicles to the limit in a controlled environment.

With the scenic Omni Resort on Amelia Island in Florida as the backdrop, the 107th edition of the ABMA Convention was held March 19-22, 2024. The event was highlighted by an engaging program that revolved around several key topics for the brush industry, including recruiting, artificial intelligence and the mental well-being of workers.

Similar to previous Interbrush years, the event saw slightly lower overall attendance with the inaugural World Brush Expo on deck in May. ABMA president Chris Monahan (Brush Fibers) reported during the General Business session that the 2024 event had 135 attendees and 29 supplier tables. Despite the smaller footprint, it seemed the anticipation for the new Expo created a buzz and positive energy amongst ABMA attendees. That energy was particularly evident as attendees enjoyed the Wednesday keynote from futurist Michael Rogers that tackled the impact of AI and automation for manufacturing. The presentation easily connected with key issues presented during the previous day’s educational sessions, which included topics on recruiting, cybersecurity and mental well-being for workers. Considering the overall range of issues in business, there’s no question that manufacturing leaders are living through one of the more dynamic periods of change in the industry, which seems to be just in the early stages.

From an ABMA standpoint, the event started with committee meetings on Tuesday, March 19, 2024. The most active discussion occurred during the membership committee meeting where overall membership was discussed as the association saw a slight decline from 2022 to 2023.

Of particular interest was the dilemma of whether or not to allow international brush manufacturers to join the association. The committee discussion indicated that the number of brush manufacturers in America was unlikely to increase, so that would make membership growth challenging. Without membership growth, the existing members would likely see membership dues increase. The counterargument was that it wouldn’t be an “American” brush association if the ABMA opened up to international brush manufacturers. Additionally, that would effectively change the mission of the association.

It was noted that the World Brush Expo was likely driving the increase in the number of international inquiries, which in turn was creating some urgency around enforcing a policy. The issue was left for the ABMA Board to discuss in their closing session on Friday morning.

After the committee sessions on Tuesday and a lunch break, the event officially opened in the afternoon with an introduction from ABMA Vice President R.J. Lindstrom (Zephyr Manufacturing). That was followed by the “breakout” educational sessions which ran concurrent 40-minute sessions that were repeated so attendees could attend all three, which included:

• Mental Health and Well-Being in the Workforce

Heather Noftall, HR Professional

• Data and Device Security, Ransomware

Chad Reinbold, SCS, Inc.

• Attracting Talent to Smaller Companies

Tim Pugh, Candidate Advocates

Kevin Monahan, Monahan Partners, attended all of the sessions and had a positive impression of all three. He says, “The cybersecurity stuff is scary but it hopefully gives a lot of people some tools. Then the attracting talent session was good.

I thought the presenter was really good and knew his stuff. I think we’re all kind of in the same boat as none of us here are enormous companies and most are not in big cities, so it was very relevant.”

Alessandro Acquaderni, FEIBP President (SIT Brush), commented on the success of the sessions as well and said that his favorite was also the one on Attracting Talent. He says, “That was very insightful and also it’s a hot topic nowadays. We are experiencing a lot of things, both in Europe and here in the U.S. Recently, we hired somebody on a Friday, signed the contract and Monday was going to be the first day. On Monday, he doesn’t show up and we see another person coming in. He says, ‘You’re looking for workers right?’ And we said, ‘Yes, well … who are you?’ He replied, ‘There’s a friend of mine that was supposed to start today, but he’s not going to start, but he referred me to you. So I can start if you’re willing.’”

On Wednesday morning, the convention shifted toward the General Business Session led by ABMA President Chris Monahan where all of the committee reports were delivered. Additionally, Acquaderni presented on behalf of the World Brush Expo and the FEIBP. His first segment highlighted a number of key trends for European brush manufacturers as he noted several challenges including inflation, the Russia/Ukraine War, conflict in the Middle East and the issues with the Suez Canal. He highlighted the fact that 90 percent of global transport is by sea and 15 percent of that traffic goes through the Suez Canal. He said the issues there led to a 15 percent increase in shipping costs.

On the positive side, he said the Eurozone GDP is expected to grow by one percent in 2024 and the FEIBP brush manufacturer quarterly surveys indicate optimism from member companies.

Additionally, he presented statistics on social media trends for the FEIBP member companies. He reported 24 percent growth in visibility on social media collectively with LinkedIn as the top social platform from member companies at 31 percent growth and 1.77 million cumulative followers. Facebook and Instagram also saw growth for FEIBP members while X (Twitter) saw a 0.5 percent decrease.

From the World Brush Expo perspective, Acquaderni emphasized the value of the upcoming event and how important it is for all brushware industry companies to take advantage of the opportunity to network, build on existing relationships and discover new opportunities. He was pleased to report the event already had more than 150 exhibitors and says that this was impressive considering the event was announced only 12 months prior. He noted that it was quite an achievement that an event of this scale was coming together so quickly under the collaboration of the ABMA and FEIBP with Bolognafiere.

The ABMA Foundation Kathy K. Parr Scholarship Awards were also announced during the session with the following students earning scholarships:

JONATHAN CIULLO: Sophomore at Illinois Wesleyan University studying Business Entrepreneurship and Kinesiology. He is the son of Rachel Ciullo, Composite Cutter Technology.

LEALA PATRISS: Freshman at Midlands Technical College studying Sports Medicine, Exercise Science. She is the daughter of an employee at Perlon/Hahl.

BRYCE PENCE: Freshman at Howard Payne University studying Business and Kinesiology. He is the son of an employee at Zephyr Mfg.

CONNOR TIEGS: Junior at the University of WisconsinMilwaukee studying Business-Finance. He is the son of an employee at Osborn International.

JAEDEN TIEGS: Freshman at the University of WisconsinMilwaukee studying Mechanical Engineering. He is the son of an employee at Osborn International.

Thursday was the attendees’ final day, with the Suppliers Face 2 Face session once again proving to be the most valued component of the convention. The “speed dating” style meeting format featured 29 supplier tables with 15-minute meeting sessions that ran from 8:00 a.m. to 12:30 p.m.

Since the introduction of the Face 2 Face format in 2019, manufacturers and suppliers have continued to praise the session as it offers focused discussion opportunities and a methodical approach to meeting with key clients. There’s no question that convention attendees consider the chance to participate in the Face 2 Face session as one of the top benefits of ABMA membership and of attending the convention.

“You do a lot of business in the Face 2 Face, but the networking outside the Face 2 Face is just as important,” says David Kalisz, MFC Ltd. “The main part is the opportunity to learn from customers. You might hear about a problem they are having in production and they didn’t think about a new solution you might have for them. It all comes out of conversations, and if you don’t sit with them, you won’t learn it. The relationships you have with customers are cemented by the Face 2 Face meetings.”

Following the Face 2 Face meetings, Thursday afternoon was left open for attendees and the evening then featured the traditional Suppliers’ Reception, which featured “A Taste of Italy” theme. The final day illustrated how the overall event seemed to have landed on an effective balance between engaging sessions and activities while also providing some space for additional conversations.

As for the overall impressions of the 2024 convention, ABMA Executive Director Donna Frendt says, “I think it’s been a successful event, a great turnout and people have been very happy with the meeting times and everything else that’s going on. They’re having good interactions. A lot of trade shows, I think, are going by the wayside. You really have to see the value in the relationships … you know it’s a long game. You come and you build the relationships and maybe you don’t do business today, but when they need you down the line, they know who you are.”

Kevin Monahan adds, “It’s a good combination of an opportunity to learn from the sessions and keynote, and of course, there are very few opportunities for us to see so many different customers in the same place. That’s one of the huge values of coming to the ABMA Convention. It continues to be unique, not just in that it is kind of a niche industry, but also the people, it is a genuinely friendly environment even amongst competitors and that’s hard to come by.”

Acquaderni says that the convention is always a great opportunity to strengthen business and relationships. “Business is always made based on trust, and the more trust there is between companies the easier the relationship is managed,” he says. “Someone may think the convention takes too much time or there is not enough business. But it’s fundamental in building up the trust that will facilitate a business relationship. Now I have a very good relationship with many suppliers and many other brush companies. When we need something, we know we will have a priority and when they need something, we probably already know what they need, so that makes business easier, faster and more reliable.”

• The 2025 ABMA Convention will be held March 25-28, 2025, at the Hyatt Regency Lost Pines outside Austin, Texas. The event will retain the Tuesday through Friday format introduced to offer better pricing on lodging.

• Looking further ahead, future ABMA convention sites being considered for 2026 and beyond include Bonita Springs, Florida, Puerto Rico and Arizona.

• The ABMA Officers for 2024 are Chris Monahan (Brush Fibers) — President, R.J. Lindstrom (Zephyr Manufacturing) — Vice President, Todd Leventhal (Nexstep Commercial Products) — Treasurer and Greg Miller (The Mill-Rose Company) —Past President.

• The ABMA Board for 2024 includes Ernest “Chip” Preston (Spiral Brushes), Ed Lowder (Monterey Mills), Terry Hogan (Perlon, Hahl), Tim Hack (Epic Resins), Lance Cheney (Braun Brush), Imre Karetka (Pferd, Inc.), Mike Khabibulin (Sherwin Williams) and Rachel Ciullo (Composite Cutter).

• Alessandro Acquaderni reported that the World Brush Expo LinkedIn Page has 468 followers and 240,000 impressions since its launch. In addition, the event website has had 20,000 visitors since June of 2023 from 113 countries.

• Following the 2024 FEIBP Congress this October in Ibiza, Spain, the 2025 Congress is targeted for Ischia, Italy.

Bruce Massey, Gibbs Interwire, with Greg Miller and Jason Riha, The Mill-Rose Company

Dennise Silva, Enrique Mejia and Nora Bravo with PMM - Proveedora Mexicana

Gary Townes, Magnolia Brush, with Jon Monahan, Monahan Filaments

Bruce Massey, Gibbs Interwire, with Greg Miller and Jason Riha, The Mill-Rose Company

Dennise Silva, Enrique Mejia and Nora Bravo with PMM - Proveedora Mexicana

Gary Townes, Magnolia Brush, with Jon Monahan, Monahan Filaments

Given that industrial brushes are ubiquitous in numerous industries, from automotive and aerospace to robotics, automation and food processing, it’s not surprising that its market share is enormous in the multi-billion dollar global brush industry.

In a 2022 analysis by India-based Maximize Market Research, it was reported that the global industrial brush market size was valued at US $654.72 million, with total revenue expected to grow at an 8.5 percent compound annual growth rate (CAGR) from now to 2029. During that period, the firm projects that the industrial brush market size should reach $1.15895 billion. Factors driving this steady, robust growth include increasing demand from the manufacturing industry for brushes used in such applications as surface finishing, cleaning, and deburring and demand for specialized, custom-made brushes for automation and robotic equipment, 3D printing, and other end-user requirements.

None of this is news to those involved in industrial brush manufacturing; they are in the thick of providing products and services to their customers. To gain insight from the ground floor, Brushware sought and received answers to the following questions from those involved in the sector.

What types of industrial brushes does your company manufacture?

Jim Benjamin, President, Precision Brush, Solon, Ohio: Precision Brush Company manufactures metal channel strip brushes in a variety of shapes and sizes. Straight strip and cylinder brushes are the most common, but we also are experts in making inside disks, outside disks, cup brushes and other odd-shaped brushes. These brushes are used in almost every industry and are unlimited in their uses and applications.

CEO Lance Cheney, Braun Brush Company, Albertson, New York: Our company produces a wide array of industrial brushes, including epoxy set, fused, twisted in wire, staple set, wire wound, and wire drawn brushes. Each type is crafted to meet diverse industrial needs, offering durability, precision, flexibility, and strength tailored to specific applications.

Amy Linzmeyer-Jelinek, Sales and Marketing Specialist, Schaefer Brush, Waukesha, Wisconsin: We specialize in crafting industrial brushes tailored to the specific needs and applications of our customers. Our diverse range of brush solutions includes twistedin-wire, staple-set, and metal back strip brushes, catering to various industrial requirements. Additionally, we excel in developing hand-drawn brushes for specialized applications, as well as intricate engineered brush systems designed for such tasks as cleaning broaches, conveyors, I-beams, channels and more. Our commitment lies in providing customized brush solutions that precisely meet the demands of our customers’ unique applications.

Alessandro Acquaderni, CEO of SITBRUSH, Bologna, Italy: Power brushes, hand scratch brushes, industrial roller brushes, wide-face brushes.

is possible. We have produced over 200,000 unique brushes, and often we are unaware of the specific end uses of these brushes.

Ken Rakusin, President & Chief Executive Officer, Gordon Brush, USA, City of Industry, California: Gordon Brush produces over 17,000 different kinds of industrial staple set, hand-tied, twisted in wire brushes that are flat, round, cylindrical and all other shapes.

What industries does your company primarily serve with your industrial brushes?

Linzmeyer-Jelinek: We serve a wide array of industries, catering to sectors such as aerospace, power generation, agriculture, automotive, laboratory, food processing, metalworking, HVAC, chemical processing and graphic arts. Our clientele spans across diverse sectors, reflecting the versatility and quality of our products tailored to meet the rigorous standards of professional applications in each industry.

Rakusin: We have a strong presence in the automotive and aerospace industries, where our brushes play a vital role in various manufacturing procedures. Our offerings include a range of products tailored to their specific needs: from our standard hand industrial brushes to those designed for critical ESD (Electro Static Discharge) environments, custom brushes crafted to address specific challenges and even paint and artist brushes. Our market has experienced significant growth thanks to our 13 acquisitions. As a result, we have established strong footholds in the janitorial, food service, electronics, paint and sundries and industrial sectors, where we consistently excel.

Cheney: Our industrial brushes serve a broad spectrum of industries, including automotive detailing, food production, pharmaceutical, aerospace, medical and general industrial sectors. Our products are designed to meet the rigorous standards and diverse needs of these fields.

Benjamin: Most of our products are used in industrial applications where sealing, wiping, agitation, cleaning, moving of product, holding items or any other imaginable application

Acquaderni: We serve many industries, from automotive to aerospace, from woodworking to primary metal, steel mills, from agriculture, food processing to precision machining.

What sets your industrial brushes apart from those offered by competitors in terms of quality, durability, and performance?