High-performance ABS Digimatic Indicator

ID-F

High-performance ABS Digimatic Indicator

ID-F

Supports bidirectional communication to help increase work efficiency

Enables bidirectional communication between the ID-F and computers to easily perform operations such as ID-F batch setting and measurement data collection. This reduces the time and effort required for measurement preparation and data processing.

The maximum digital step is 0.5 μm (0.0005 mm). With an error of indication for the total measuring range corresponding to 0.0025 mm, this indicator can be used in high-precision applications.

Thanks to the external power supply, there is no battery to replace. With an external power supply (AC adapter) this indicator series is perfect for long-term tests or monitoring.

ID-F models feature a wide range of functions, including simple calculation, peak detection, data hold, data output, and counting direction switching functions.

Enhanced work efficiency thanks to superior readability

Large characters and analog bar

Digit

height*

The height of the characters has been increased by about 1.5 times, making them even more visible than the previous model. The analog bar has also been made larger to increase readability.

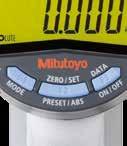

Frequently used functions can be set to the buttons for easy operation

The ease of use has been greatly enhanced thanks to these three large buttons. Users can preset any frequently used function to the buttons for easy operation.

Never miss a calibration

An icon is displayed on the LCD to notify the user of the set calibration schedule. This function facilitates the proper precision management of the measuring instrument.

The calibration schedule warning icon starts blinking at a set time (e.g. 1 week before the calibration date) before the limit. If the limit is exceeded, the entire screen starts blinking to notify the user.

Understand tolerance judgment results at a glance

Built-in tolerance judgment function that shows the judgment result with the lighting color. Staff with no special training can now easily carry out GO/NG work.

Easy to read values in every situation

The face can be rotated to a wide degree to maintain the ease of use and readability of the screen even when the ID-F is used horizontally or at an angle.

Enhanced measurement work efficiency

The result of the spindle movement value multiplied by a calculation coefficient can be displayed in real-time. This prevents additional work when measuring while using jigs or other similar tools.

*1 Error of indication for the total measuring range (EMPE)

● Measures Max., Min., and TIR (amplitude (Max - Min) values. (Peak detection speed: 500 times/s)

● This product is compatible with all Mitutoyo dial indicator contact points having the appropriate thread.

The ID-F features an interface supporting the proprietary bidirectional serial communication standard (DIGIMATIC S1). The indicator can be connected to a computer using the optional USB input tool or another means to enable bidirectional communication and greatly increase work efficiency.

*USB-ITPAK V3.0 or later must be installed on the computer used for communication. Scan for More Info.

USB-ITPAK V3.0

Work time is reduced by performing batch zero setting and batch presetting from the computer.

Reduces the time and effort needed for inspection work

USB-ITPAK V3.0

ID-F + USB-ITPAK V3.0 Batch zero setting is possible from the computer.

USB-ITPAK is a useful software for creating procedures when inputting measurement data into Excel sheets. The latest version allows the user to perform batch zero setting and presetting, batch setting of multiple ID-F devices, data acquisition instruction from a computer, etc

ID-F + USB-ITPAK V3.0

The measuring instrument information and status can be checked from the computer.

Previous ID-F + USB-ITPAK V2.1

Manual zero setting operation is required on each measuring instrument.

Previous ID-F + USB-ITPAK V2.1

The measuring instrument information and status cannot be checked from the computer.

Connection example 2: Easy connection of multiple indicators

Note: A USB-ITN-SF cable is required for each ID-F device.

Work time is reduced by performing batch zero setting and batch presetting from the computer.

1st generation, unidirectional communication, 6-digit / d2: 2nd generation, unidirectional communication, 8-digit

using one or several measuring instruments, the measurement data is input into an Excel sheet from the measuring instruments registered in advance.

measurement data is acquired in batches from several measuring instruments and then input into an Excel sheet.

data is acquired for each measuring instrument and then input into Excel sheets and cells set individually. With this method, measurements performed randomly by multiple operators can be input from each instrument into specified sheets and cells.

it possible to start measuring without prior detailed settings and to sort data in Excel columns by measurement location.

to change the settings (zero set, registration of preset values, unit, counting direction, tolerance setting) of the connected measuring instruments using the USB-ITPAK software.

save information on the measurement operator and measurement tool in the measurement data

on who made the measurement using which tool).

display information (model, serial No., calibration date) about the connected measuring instrument on the computer.

Note: All information regarding our products, and in particular the illustrations, drawings, dimensional and performance data contained in this printed matter as well as other technical data are to be regarded as approximate average values. We therefore reserve the right to make changes to the corresponding designs, dimensions and weights. The stated standards, similar technical regulations, descriptions and illustrations of the products were valid at the time of printing. In addition, the latest applicable version of our General Trading Conditions will apply. Only quotations submitted by ourselves may be regarded as definitive.

Whatever your challenges are, Mitutoyo supports you from start to finish.

Mitutoyo is not only a manufacturer of top quality measuring products but one that also offers qualified support for the lifetime of the equipment, backed up by comprehensive services that ensure your staff can make the very best use of the investment.

Apart from the basics of calibration and repair, Mitutoyo offers product and metrology training, as well as IT support for the sophisticated software used in modern measuring technology. We can also design, build, test and deliver bespoke measuring solutions and even, if deemed cost-effective, take your critical measurement challenges in-house on a sub-contract basis.