Table of contents

NC-Compact twin vices

NC-Compact self centering vices

NC-Compact twin vices

NC-Compact self centering vices

-Highestclampingprecision

-Clampingforcepresetting

-Precise,wear-resistantbody

Features

NC-Compactvices

-Highestclampingprecision

-Withoutclampingforce presetting

-Precise,wear-resistantbody

-Verygoodaccessibility for5-axismachining -Clampingforce presetting -Largeclampingrange

-Designedtoresist deformationforthehighest clampingprecision

-Greatestrepeatability

-Clampingforcepresetting

Clamping system mechanical-mechanical size92:mechanical-hydraulicmechanicalmechanical-mechanicalmechanical-mechanical

Force amplification

Set-up options 3-Side,Duo-Tower Quattro-Tower 3-Side,Duo-Tower Quattro-Tower Base3-Side,Duo-Tower Quattro-Tower

Machiningcenterswith highworkingaccuracy

Universalmillingmachineswithhighworking accuracy

Universalmillingmachinesstandardversion

Jigboringmachines

5-axismachining

Grindingmachines

Seriesproduction

Forlimitedspace

Clampingrange(max.)208312451451208312451451192225215340340

Length(opened)mm345478633633315442607607372372483618618

Widthmm9412616216294126162162126126150205205

Heightmm112140165175112140165175140130148179189

Clampingforce(max.)kN25406060254060604040406060

Weightkg1541798515417985292950107108

Page 4014402240344040

1)withsteppedjaws4)withclaw-typejaws 2)withstandardjaws5)withheightend 3)withcarrierjawssteppedjaws

TYPERKD-MRZMRKZ-M

NC-CompacttwinvicesNC-Compactselfcenteringvices

Features

-Double,centricandcompact wrench(removablemiddlejaw) -Greatestrepeatability -Lowrapidtraverse

-Verylargeclampingstrokedueto patentedguidesystem -Opendesignforoptimalchipflow -Overheadspindleforoptimalpower transmission

-Highestaverageprecisionandrepeatability -Minimumcollisioncontour

Clamping system mechanicalmechanicalmechanical

Machiningcenterswith highworkingaccuracy

Universalmillingmachineswithhighworking accuracy

Universalmillingmachinesstandardversion

Jigboringmachines

5-axismachining

Grindingmachines

Seriesproduction

Forlimitedspace

TYPERB-KOrangeLineRBAW

MachinevicesNC-powervices

-Greataccuracyduetoprecisejawguidance -Fastclampingrangeadjustmentusingthepinsystem

-Integratedangulardrive -Clampingwidthpresetting

Features

Clamping system mechanical-hydraulicmechanical-hydraulic Force amplification

Set-up options Base3-Side

Machiningcenterswith highworkingaccuracy

Universalmillingmachineswithhighworking accuracy

Universalmillingmachinesstandardversion

Jigboringmachines

5-axismachining

Grindingmachines

Seriesproduction

Forlimitedspace

-Fastclampingrangeadjustment usingthepinsystem

Features

Machinevices

-Madeofspecialsteelcastingforflexible application

-Entireclampingrangecanbereachedby turningthecrank

-Centricclamping -Spindlecoveredintheworkingarea

Clamping system mechanicalmechanicalmechanical Force amplification ***

Set-up options

Machiningcenterswith highworkingaccuracy

Universalmillingmachineswithhighworking accuracy

Universalmillingmachinesstandardversion

Jigboringmachines

5-axismachining

Grindingmachines

Seriesproduction

Forlimitedspace

Jaw width mm 12515015017592113135160200113135160200250

Clampingrange(max.)15020030040085105125145185110140180300400 Length(opened)mm401487587701362423510575675358408495655767 Widthmm95125125145160160200240280132152180200220

Heightmm8010010011879,689,6103,6119,6144,692,6105,1123,6141,6147,6 Clampingforce(max.)kN3050506018253545551522242528

Weightkg12,725,629,551,21213,525406512,419315271 Page 408840904094

Features

Clamping system

Clamping force

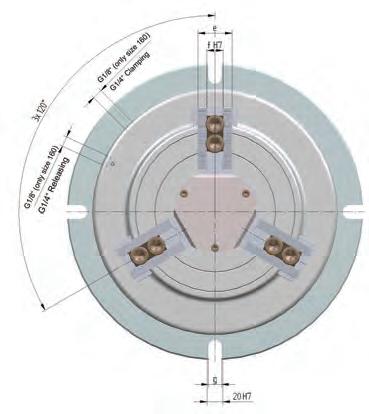

Stationarypowerchucks

-Optimallysuitedforautomatedworksequences -Centricclamping -Jawswithfineserrationandcross-tenoninterface

-Optimallysuitedforautomatedworksequences -Centricclamping -Jawswithfineserrationandcross-tenoninterface -Largejawstroke

Set-up options Base,zeropointclampingsystemBase,zeropointclampingsystem

Machiningcenterswith highworkingaccuracy

Universalmillingmachineswithhighworking accuracy

Universalmillingmachinesstandardversion

Jigboringmachines

5-axismachining

Grindingmachines

Seriesproduction

Forlimitedspace

Jawstrokemm2,32,33,54,8679,51218,2 Clampingforce(max.)kN4,5184552558202421 Weightkg1,253,911,220,432,5411,520,832,8

Page 41014103

Features

-Optimallysuitedforautomated worksequences -Centricclamping -Jawswithfineserrationand cross-tenoninterface

Stationarypowerchucks

-Optimallysuitedforautomatedwork sequences -Centricclamping -Jawswithfineserrationandcross-tenon interface -Largejawstroke

-Optimallysuitedforautomatedwork sequences -Centricclamping -Withoutthrough-hole -Jawswithfineserration

Clamping system hydraulichydraulicpneumatisch

Clamping force

Set-up options Base,zeropointclampingsystemBase,zeropointclampingsystemBase,zeropointclampingsystem

Machiningcenterswith highworkingaccuracy

Universalmillingmachineswithhighworking accuracy

Universalmillingmachinesstandardversion

Jigboringmachines

Drillingmachinevices

Features

-Compactand stableconstruction -Entireclampingrangecan bereachedby turningthe crank

-Compactandstable construction -Entireclampingrange canbereachedby turningthecrank -Longguidanceofthe movablejawsalsointhe outerclampingrange

-Do-it-yourself version -Robustandstable version

-Coveringofthethreadedspindle bycoversleeve

-Constructionallengthremains thesame

-Entireclampingrangecanbe reachedbyturningthecrank

Clamping system

Machiningcenterswith highworkingaccuracy

Universalmillingmachineswithhighworking accuracy

Universalmillingmachinesstandardversion

Jigboringmachines

5-axismachining

Grindingmachines

Seriesproduction

Forlimitedspace

Jaw width mm 1101359011013516065801008010012014080100120150100

Clampingrange(max.)mm100160901301602206585808095110150709211012593

Length(opened)mm510587195315365445125150170200215260300154175225238189 Widthmm175205145175205245105130175140175215220142152180198159

Heightmm72,580,56072,580,595,5434647707585855863,563,56565

Clampingforce(max.)kN10108101215

Weightkg9,513,55,59,513,5251,21,74,2571112,53,64,36,38,15,1 Page 41204120412141224122

Grindingandinspectionvice

-Draw-downeffect

-Simpleclampingandreleasing withallenkey

Features

-Clampingjawadjustableinsteps; engagesautomatically -Nospindle

-Draw-downeffect

-Madeofalloyedtool steel,hardenedand finelyground

-Horizontalandvertical groundprism

-Nospindlewhichcould, becomedirtyduring erosion

-Clampingandreleasingwiththrea dedspindle -Madeofalloyed toolsteel,hardenedandfinely ground

-Madeofalloyedtoolsteel, hardenedandfinelyground

-Bearingandlocationpins hardenedandgroundwitha precisionof0.001mm

-Theclampingdevicecan bepositivelylockedinany angularposition

-Positivelockingin anydesiredangular positionbylocking

screws

-Madeofalloyedtool steel,hardenedand finelyground

-Canberotated 360°

Clamping system

Force amplification

Set-up

Machiningcenterswith highworkingaccuracy

Universalmillingmachineswithhighworking accuracy

Universalmillingmachinesstandardversion

Jigboringmachines

5-axismachining

Grindingmachines

Seriesproduction

Forlimitedspace

Jaw width mm 34457090120507310060738870

Clampingrange(max.)25508012015065100125551001258012080150

Length(opened)mm75110160210280140190245110210250160210180270

Widthmm3445709012050731006073887090110160

Heightmm354562809050679050678893113137210

Clampingforce(max.)kN222,5341,62524467--

Weightkg0,35135,813,51,44,17,31,647,65,31111,143 Page 41264127412741284128

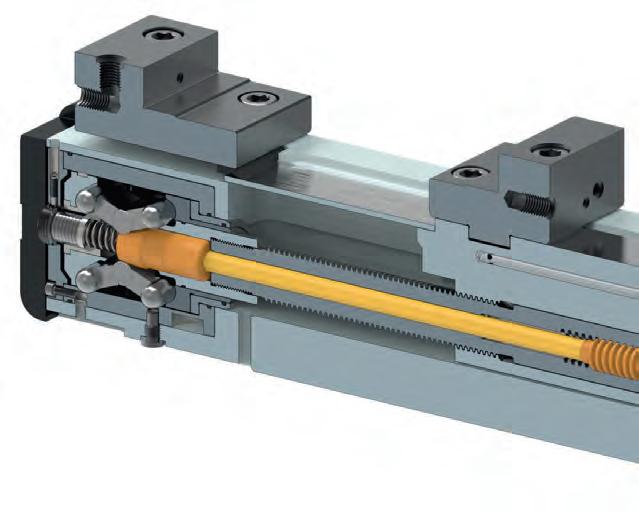

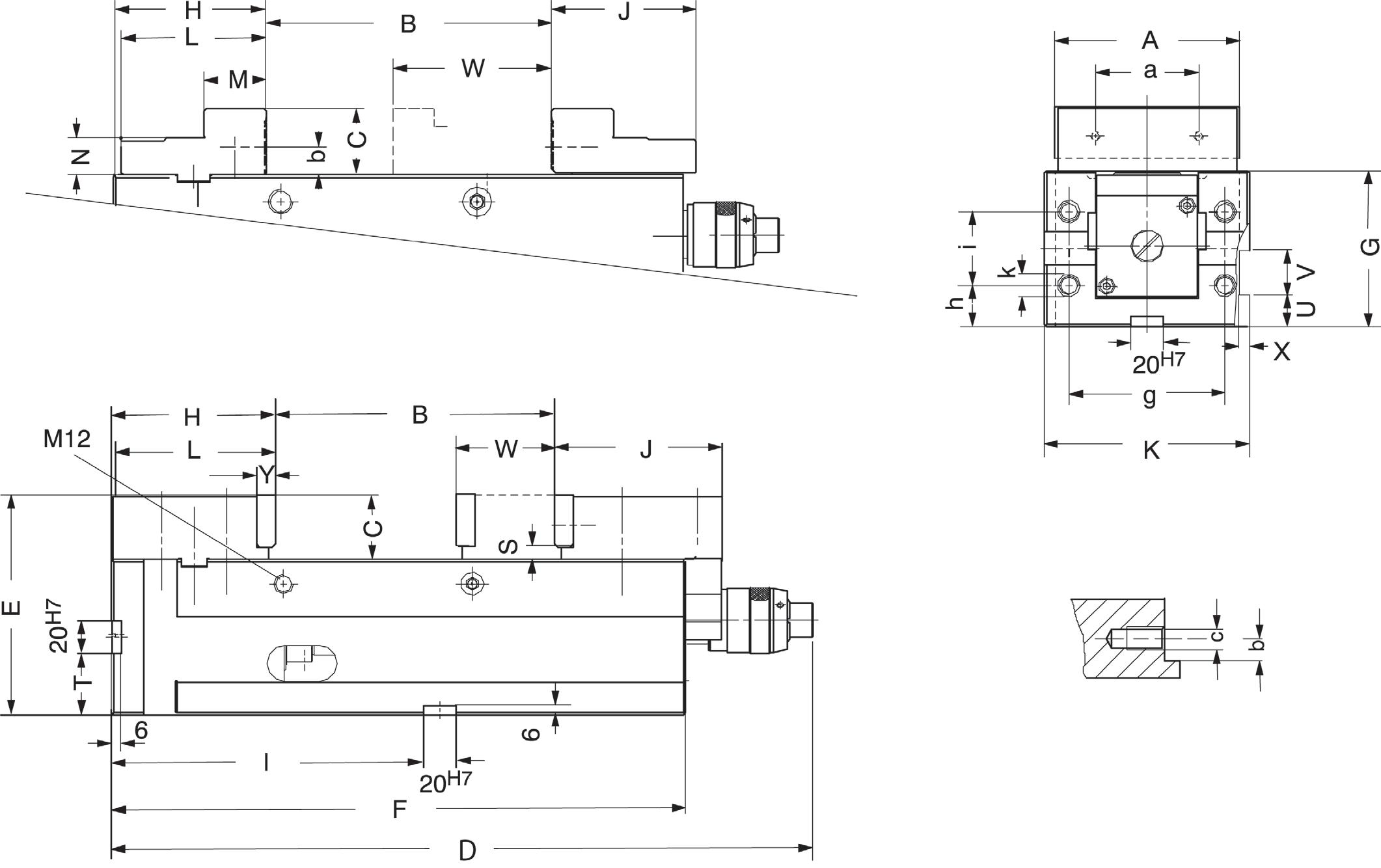

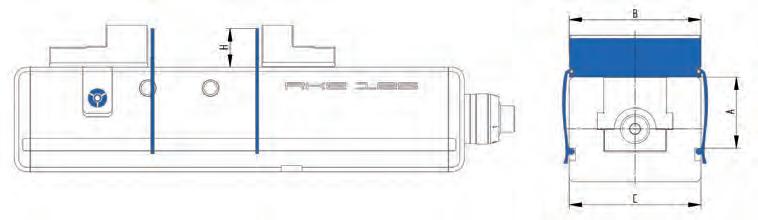

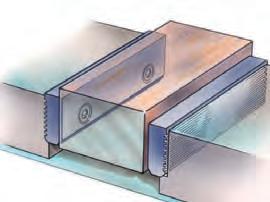

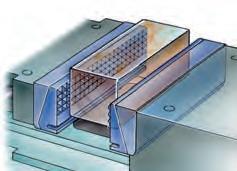

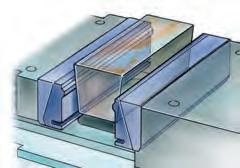

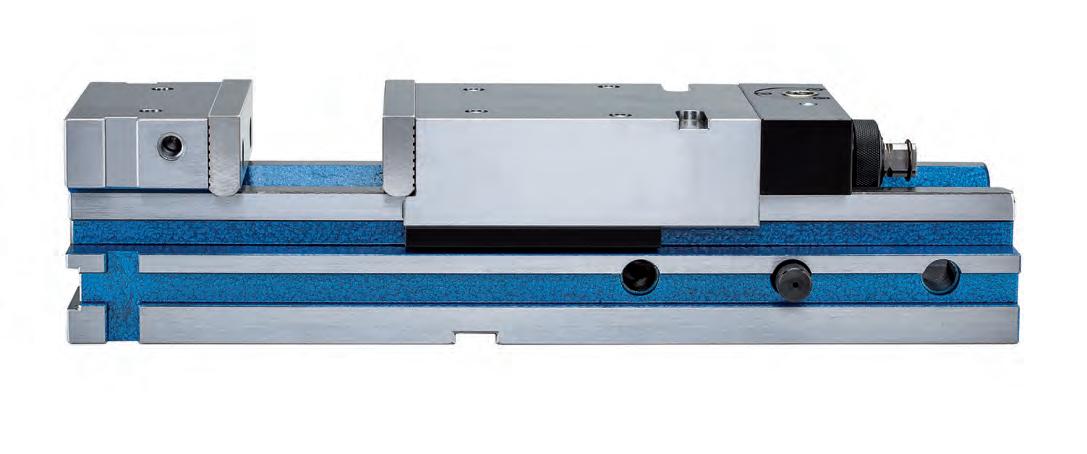

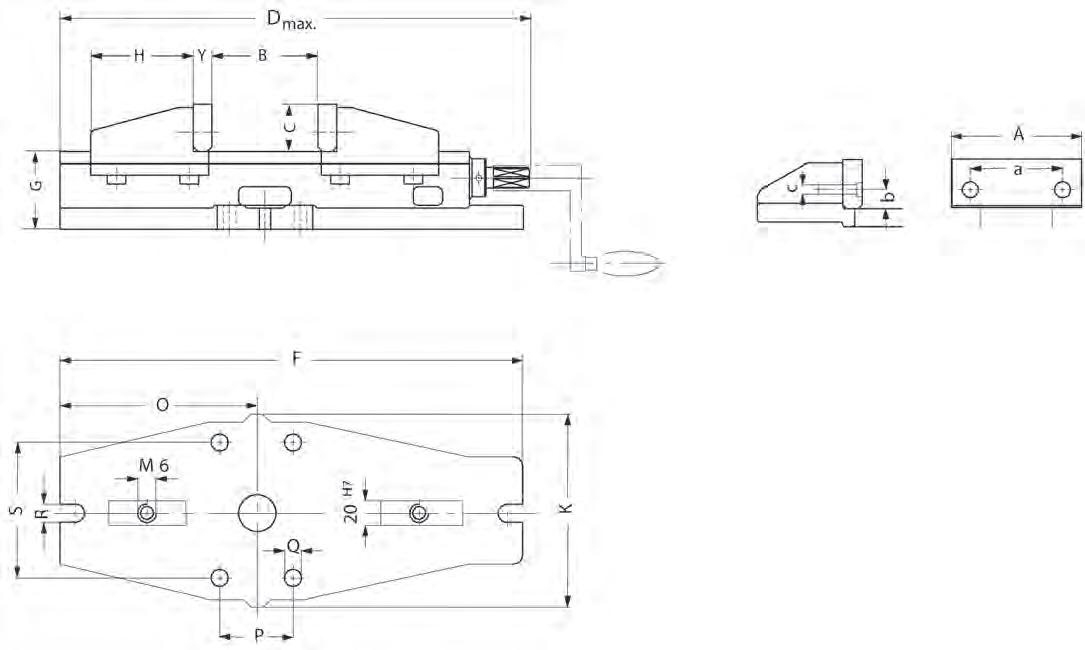

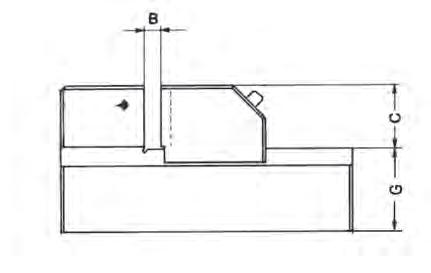

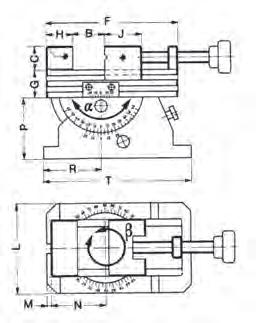

High-endNC-Compactvice.Mountingofthepowertransmitterinthe steelbody.Furtherdesigns(ironcastbody,hydraulicactuationetc.)on request.

NC-Compactviceforveryhighclampingprecision.Clampingslidewith toothingforcontinuouslyvariablepresetting.Thepowertransmitteris mountedinthefixedjaw.Thisformofsupportenableshigh-precision clamping.

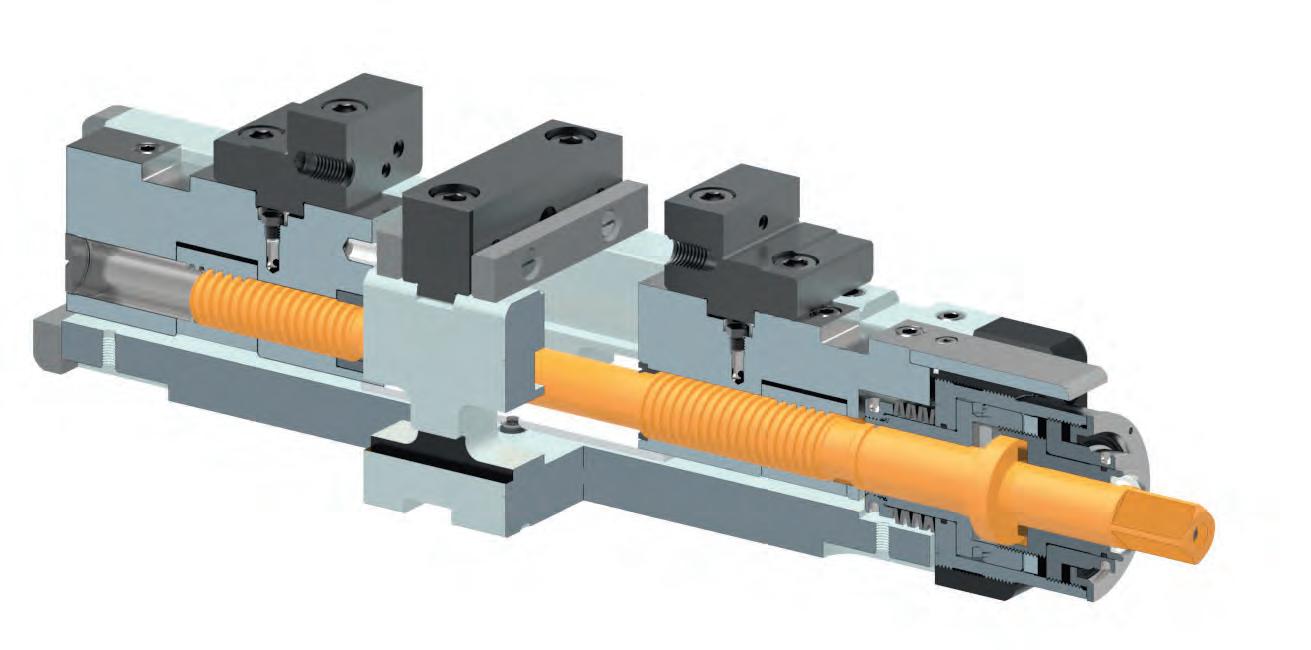

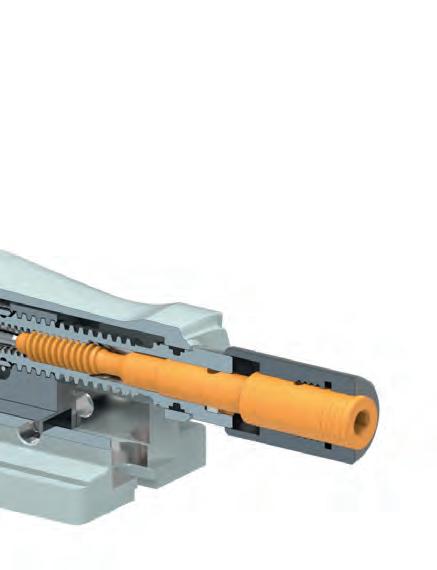

a) Clamping with power transmission

Mechanicalpretensioningisachievedbyturningthehand-crank. Thethreadedspindlewiththelargeinclinebringsthemovable clampingjawintocontactwiththeworkpiece,wherebyresistance canbenotedonthehand-crank.Continuingtoturnthecrankin clockwisedirectiontriggersautomaticdisengagementandswitch tomechanicaltransmission.Furtherturningofthecrankmovesa pressurepinaxially,whichgeneratesthehighclampingforcethrough spreadingofthetogglelever.

b) Presetting of different clamping forces

Toavoiddamagetosensitiveworkpiecescausedbyexcessive clampingforce,differentclampingforcescanbepreset.Thepresetting canbeperformedsimplybyturningtheadjustmentcollarontheendof thespindle.

c) Mechanical clamping without power transmission

Forconsecutiveclampingofmultipleworkpieceshavingunevencontact surfaces,greaterpretensioningisrequired.Turningtheadjustmentcollar to“0”deactivatesthemechanicalpowertransmission.Theworkpieces canthenbemechanicallypretensioneduntiltheyieldintheworkpieces iseliminated.Theadjustmentcollarcanthenbesettothedesired clampingforce,andthehighclampingforceintroduced.

RKK:Thepowertransmissionguaranteesthatthebodyremains freefromdeformation;averyhighclampingaccuracyisachieved.

Theanchoringnutonthedrivespindleisturnedtotheright(delivery condition).Themoveableclampingjaw1isadjusteduptotheworkpieceinstation1byturningthespindleinaclockwisedirectionwiththe handcrankandheldwithca.1kN(thirdmanualfunction).Bycontinuingtoturnthehandcrankinaclockwisedirectionasfarasitgoes, clampingjaw2isalsoplacedontheworkpieceonstation2.Thebuildupofforceactsontheclampingjawsviathemechanicalspindle.The balancespringscompensatefordimensionaldifferencesofupto±3 mmfromworkpiece1toworkpiece2.Whenclamping,bothclamping positionsmustbefilledwiththesameworkpieces.Toinducetheexact clampingforcerepeatedly,theexact,specifiedtorquemustbeinduced viaatorquewrench(seeclampingforcechartintheBDA).

Theanchoringnutonthedrivespindleisturnedtotheleft.Thespindle isrigid.Thecentrejawisremoved.Themoveableclampingjaws1and 2areadjusteduptotheworkpiecebyturningthespindleinaclockwisedirectionwiththehandcrank.Thebuild-upofforceactsonthe clampingjaws.Thepositionofthecentreoftheworkpieceisalways thesamewithrespecttothetransversegroove.Toachievetheexact clampingforcerepeatedly,theexact,specifiedtorquemustbeinduced viaatorquewrench(seeclampingforcechartintheBDA).

Theanchoringnutonthedrivespindleisturnedtotheleft.Thespindle isrigid.Asteppedjawmustbeusedhere(notindeliverycontents), andmoveableclampingjaw1removed.Alsoremovethecentrejaw. Themoveableclampingjaw2isadjusteduptotheworkpiecein station1byturningthespindleinaclockwisedirectionwiththehand crank.Thebuild-upofforceactsontheclampingjawsuniformlyvia themechanicalspindle.Toinducetheexactclampingforcerepeatedly, theexact,specifiedtorquemustbeinducedviaatorquewrench(see clampingforcechartintheBDA).

TheNC-compactvicesfromRÖHMareexcellentlysuited foruseinsingleorseriesproduction.Differenttypesand constructionallengthsenabletheoptimaladaptationto theworkarea,workpieceandmachiningtask.

NC-compactvicesareparticularlysuitedforuseonmachiningcenters,millingmachinesandareideal for5-axismachining.Thesepremiumvicesareveryimpressivewiththeirstableandcompactdesign formaximumclampingaccuracyandoptimalworkpieceaccessibility.Bysimplyturningtheclamping forcepresetting,aclampingforceofupto60kNcanbeachieved.Withworkpiecesthataresensitive todeformation,theforceamplificationcanbedisabled.

Largeclampingrangeandprecisepositioningduetofixedclampingjaw

Thecompactdesignresistsdeformationforthegreatestpossibleclampingprecision

Consistentclampingforceandmaximumrepeatabilityof0.01mm

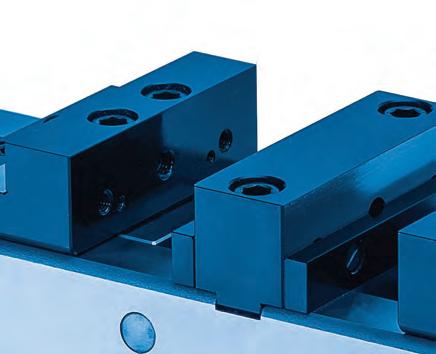

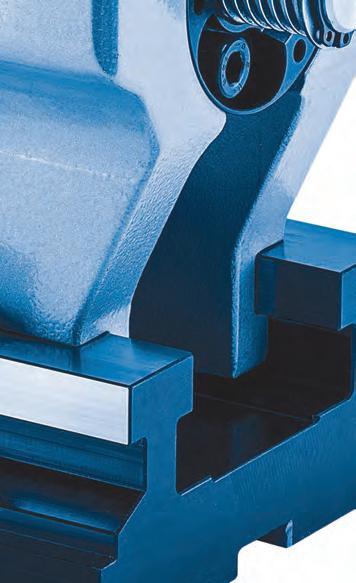

Robuststeelbodywithsupportsurfacesandguidesthat havebeenhardenedand groundonallsides

Fixedclampingjawforprecise positioning

Stablechipprotectionprevents chipsfrompenetratingintothe interiorofthebody

Centrallubricationforquick lubricationofallfunctional surfaces

Drivespindlewith clampingforce presetting

APPLICATION

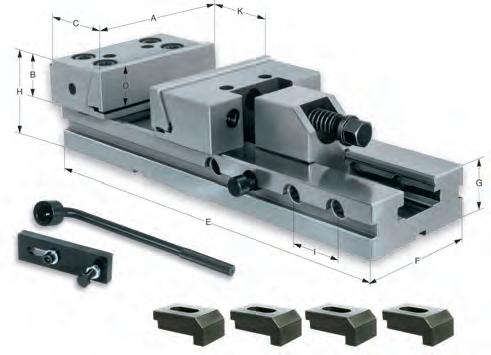

Particularlysuitableforuseonmachiningcenters.

TYPE

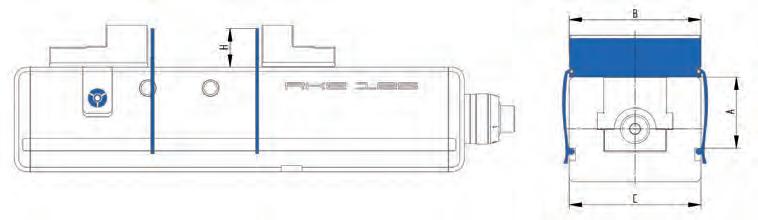

Size 92 -clampingsystemmechanical-hydraulicalwithpowertransmitter, manuallyoperated. Size 125, 160 and 200 -clampingsystemmechanicalmechanicalwithpowertransmitter,manuallyoperated. Hydraulicactuationonrequest.

CUSTOMERBENEFITS

Horizontal,sideorinconnectionwithabaseplateverticalmounting,for exampleasDUOclampingtower(backtoback) Sturdychipprotectionpreventschipsfrompenetrating Drivespindlewithclampingforcepresetting Clampingsurfaceforclampingclaws Centrallubricationofguidesandspindlethread Threadforfasteningangledrive

TECHNICALFEATURES

-Sturdysteelbodyandallguidesarehardenedandgroundonallsides -Longclampingslidewithcrossslots,hardenedonallsides,functional -surfacesgroundThreadedboresfortakingupallRÖHMflatclampingjawswithjawwidth 125/160mm

RKE =RÖHM,compact,singleclamping

JawwidthAmm92125160200 Jawdesignsteppedjawssteppedjawssteppedjawssteppedjaws B2mm0-1380-2160-3200-315 B3mm71-20897-312131-451131-451 Cmm32405060 Dmm345478633633 Emm112140165175 Fmm276400530530 G-0,02mm80100115115 H2mm80112,5130135 H3mm4156,56464 J2mm56709797 Kmm94126162162 L2mm649498103 Mmm25403439 M*mm253032,532,5 N-0,01mm16202525 Q3950,559,559,5 Umm20202020 Vmm12121212 Wmm681x1082x102,52x102,5 Xmm10101010 Ymm15151515 Zmm70109117117 amm6380100125 bmm13,615,619,624,6 c1M6x14M8x14M8x14M10x15 c2M5x9M5x10M5x9M5x10 c3M10x16M10x18M10x18M14x20 c4M5M5M5M5 dmm486080110 emm8121212 fmm14182025 gmm7095125125 hmm202517,517,5 imm40458080 ØkM10x18M12x22M16x25M16x25 lmm140240200200 m2±0,02mm60127,57065 n±0,02mm99183,5136136 ØxØ10 H7Ø10H7Ø10H7Ø10H7 o486088110 p66612 y+0,01mm4047,557,557,5 zmm72100135135 ClampingforcekN25406060 Weightkg15417985

A37 Tensioner, forcarrierjaws743-72

One-piece steel top jaws,forself-productionofformedjawsorforclampingformedparts

A37

Normal jaw SGN, onesidesmooth,onesidegrooved,bothsidesground

A37

Includingfixingscrews

Normal jaw finely checkered SGNf, reversible,toincreasethespecificcontactpressure(higherholdingforces),onesidefinelycheckered,onesidelongitudinallygrooved

Includingfixingscrews

2.5mmclampingdepth

Includingfixingscrews

A37

Claw jaws SKB without step,universalforclampingdepth>2.5mm

A37

Support rails Cliparc,setwith10differentpairsofrailsand4clampsinwoodenbox

A37

V-jaw SPR,withverticallyandhorizontallyground-inprisms,hardened,forcombinationwithSGN

A37

Normal jaw SGNA,withmovableworkpiecestop,hardenedandground

A37

Draw-down jaws SNF,withspringplate,hardenedandground

APPLICATION

Particularlysuitableforuseonmachiningcentersandpalletisers.

TYPE

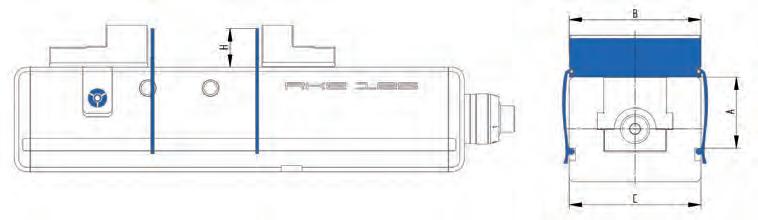

Clamping system mechanical without power transmitter, manually operated.

CUSTOMERBENEFITS

Horizontal,sideorinconnectionwithabaseplateverticalmounting,for exampleasDUOclampingtower(backtoback)

Sturdychipprotectionpreventschipsfrompenetrating Largeclampingstroke Clampingsurfaceforclampingclaws Centrallubricationofguidesandspindlethread Constantclampingforceforeveryclampingoperationandhighclamping repeatabilitywhenatorquewrenchisused

TECHNICALFEATURES

-Sturdysteelbodyandallguidesarehardenedandgroundonallsides -Longclampingslidewithcrossslots,hardenedonallsides,functional -surfacesgroundThreadedboresfortakingupallRÖHMflatclampingjawswithjawwidth 125/160mm

RKE-M =RÖHM,compact,singleclamping,manual

JawwidthAmm92125160200 Jawdesignsteppedjawssteppedjawssteppedjawssteppedjaws B2mm0-1380-2160-3200-315 B3mm71-20897-312131-451131-451 Cmm32405060 Dmm315442607607 Emm112140165175 Fmm276400530530 G-0,02mm80100115115 H2mm80112,5130135 H3mm4156,56464 J2mm56709797 Kmm94126162162 L2mm649498103 Mmm25403439 M*mm253032,532,5 N-0,01mm16202525 Q3950,559,559,5 Umm20202020 Vmm12121212 Wmm681x1082x102,52x102,5 Xmm15151515 Ymm10101010 Zmm70109117117 amm6380100125 bmm13,615,619,624,6 c1M6x14M8x14M8x14M10x15 c2M5x9M5x10M5x9M5x10 c3M10x16M10x18M10x18M14x20 c4M5M5M5M5 dmm486080110 emm8121212 fmm14182025 gmm7095125125 h202517,517,5 i40458080 ØkM10x18M12x22M16x25M16x25 lmm140240200200 m2±0,02mm60127,57065 n±0,02mm99183,5136136 o486088110 p66612 y +0,01mm4047,557,557,5 zmm72100135135 SquareAF12141919 ØXH710101010 ClampingforcekN25406060 Weightkg15417985

A37 Tensioner, forcarrierjaws743-72 A37 One-piece steel top jaws,forself-productionofformedjawsorforclampingformedparts

A37 Claw jaws SKB without step,universalforclampingdepth>2.5mm

Support rails Cliparc,setwith10differentpairsofrailsand4clampsinwoodenbox

A37 V-jaw SPR,withverticallyandhorizontallyground-inprisms,hardened,forcombinationwithSGN

A37 Normal jaw SGNA,withmovableworkpiecestop,hardenedandground

A37 Draw-down jaws SNF,withspringplate,hardenedandground

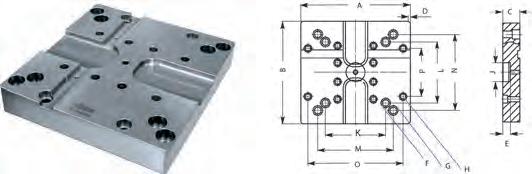

APPLICATION

SuitableforthecompletesetupoftwoNCcompactclamps,back-to-back.

TYPE

Withcenteringformachinetable/pallet. Withoutmountingorheightadjustmentoftheclamps. Incl.T-nuts,clampingclawsandscrewsforaligningandfasteningtheclampsonthe basicplate.

TECHNICALFEATURES

-Boresformodulargrid40/50/63 -Withoutaligninggroove/bore(machineside)

ForRKD-M92RKE92/RKE-M92RKE125/RKE-M125/ RKD-M125 RKK135RKK160/RKK200RKE160/(RKE200)/ RKE-M160/(RKE-M200) Amm250250290290350350 Bmm250250270270350350 Cmm454545454545 Dmm5x45°5x45°5x45°5x45°5x45°5x45° Emm202020202020 FKM12KM12KM16KM16KM16KM16 GKM16KM16KM16KM16KM12KM12 HKM16KM16KM12KM12KM16KM16 Jmm505050505050 Kmm126126160200240240 Lmm126126160200160160 Mmm160160200240252252 Nmm160160200240252252 Omm200200252252300300 Pmm200200126126300300 Weightkg242429294545

A37 Extension GKV, forextensionofclampingcapacityforextra-longworkpieces (only RKE, RKE-M) Fasteningwithscrews(includedinthescopeofdelivery)

Duo-clamping towers (on request)

Quattro-clamping towers (on request)

Technical data

4545

200230

578741

APPLICATION

Optimizedforcollision-free5-axismachininginoneset-up. Speciallysuitedfor5-axismachinesincombinationwithabaseplate.

TYPE

Clampingsystemmechanical-mechanicalwithpowertransmitter,manually operated. Short,compactdesign.

CUSTOMERBENEFITS

Withtensionclamping,zeropointoftheworkpieceontheoperatorside Largeclampingrange High-precisionpositioning Stablechipguardforlongerlife

TECHNICALFEATURES

-Sturdysteelbodyandallguidesarehardenedandgroundonallsides -Carrierjawsincl.swivelableclawinsertsforroundandrectangular workpieces

- Clamping ranges carrier jaws: Rightangularworkpieces:35-215mm Circularworkpieces:65-225mm

RKE-LV =RÖHM,compact,singleclamping,lightdesign,shortdesign

JawwidthAmm125125 Jawdesignsteppedjawscarrierjaws B2mm0-9635-215 B3mm96-19265-225

L2mm94105 Mmm40M*mm30N-0,01mm2020 Omm3030 Qmm53,553,5 Rmm87,587,5 Umm2020 Vmm1212 Ymm1313 amm60bmm15,6c1M8c2M5c3M10dmm80emm12fmm18m2±0,02mm27,5n±0,02mm83,5omm3030 vmm120120 wmm4646 xmm9595 ØmxdepthM12x20M12x20 ClampingforcekN4040 A1mm-28 A2mm-26,5 C1mm-10 W1mm-38 W2mm-17 W3mm-22 W4mm-15 Weightkg2929

A37 Swivelling claw inserts, forcarrierjaws743-72

A37 Tensioner, forcarrierjaws743-72

A37

Claw jaws SKB with fine step, 2.5mmclampingdepth

A37 Claw jaws SKB without step,universalforclampingdepth>2.5mm

A37 Support rails Cliparc,setwith10differentpairsofrailsand4clampsinwoodenbox

A37

Standard jaws SGN,onesidesmooth,onesidegrooved,hardenedandground

A37

Standard jaws finely checkered SGNf,reversible,toincreasethespecificcontactpressure(higherholdingforces),onesidefinelycheckered,onesidelongitudinallygrooved

A37

V-jaw SPR,withverticallyandhorizontallyground-inprisms,hardened,forcombinationwithSGN

A37

Includingfixingscrews

Normal jaw SGNA,withmovableworkpiecestop,hardenedandground

A37

Includingfixingscrews

Draw-down jaws SNF,withspringplate,hardenedandground

A37

Includingfixingscrews

V-jaw and standard jaw SBO,unhardenedandburnished,withworkpiecesupport

Includingfixingscrews

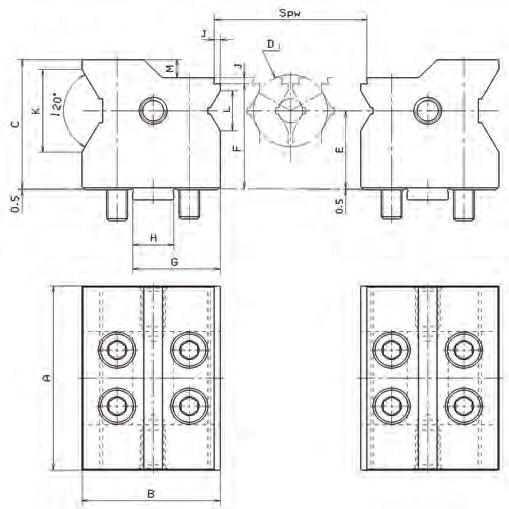

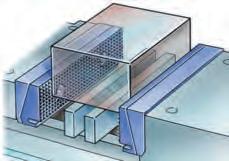

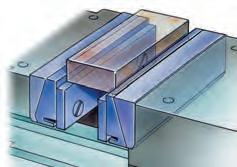

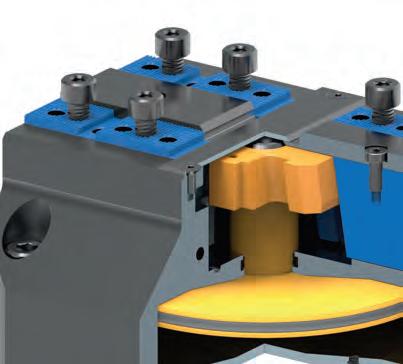

APPLICATION

OptimizedformodernCNCmillingmachinesandmachiningcenterswithvery highworkingprecision.

TYPE

Size 3-5: clampingsystemmechanical-mechanicalwithpowertransmitter, manuallyoperated.

CUSTOMERBENEFITS

Drivespindlewithclampingforcepresetting Deformation-resistantdesignformaximumclampingprecision Fasteningthreadforworkpiecestop Clampingsurfaceforclampingclaws

Withgreasenipplesinstalledonbothsides,thatallguidesandthespindle threadcanbelubricatedquicklyandeasily

TECHNICALFEATURES

-Sturdysteelbodyandallguidesarehardenedandgroundonallsides

- Sizes 3-5: longclampingslidewithtoothing

RKK =RÖHM,compact,poweramplified

Size345 JawwidthAmm135160200 ClampingcapacityBmm0-2150-3400-340 Cmm496070 Dmm483618618 Emm148179189 Fmm400525525 G-0,02mm100120120 H-0,05mm110,5130130 Jmm102110110 Kmm150205205 Lmm109128128 Smm9,410,47,4 T-0,02mm405050 Umm202020 Vmm404040 Wmm168235235 Xmm6,56,56,5 Ymm15,615,619,6 Clampingtravelmm60108108 amm80100125 bmm15,619,624,6 cmmM8x13M8x13M10x15 gmm110145145 hmm22,52020 imm558080 kxdepthM12x22M16x20M16x20 l-0,02mm240365365 ClampingforcekN406060 Weightkg50107108

size 3-5

A37

Standard top jaws SA,reversible,forscrewingonclampingjaws,withfixingscrews

A37

Top jaws SN,reversible,forhookinginquick-changeclampinginsertsandforscrewingonclampingjaws,withfixingscrews

A37

jaws TB,reversible,forscrewingonclawinsertsorspecialjaws,withfixingscrews

A37

Normal jaw SGN, onesidesmooth,onesidegrooved,bothsidesground

A37

Normal jaw finely checkered SGNf, reversible,toincreasethespecificcontactpressure(higherholdingforces),onesidefinelycheckered,onesidelongitudinallygrooved

A37

Includingfixingscrews

V-jaw SPR,withverticallyandhorizontallyground-inprisms,hardened,forcombinationwithSGN

Includingfixingscrews

A37 Draw-down jaws SNF,withspringplate,hardenedandground

Includingfixingscrews

A37

V-jaw and standard jaw SBO,unhardenedandburnished,withworkpiecesupport

A37

Normal jaw SGNA,withmovableworkpiecestop,hardenedandground

Standard inserts NCS,hardenedandground,formachinedworkpieceswithoutangularerror

A37

Standard inserts finely checkered NCSf,withsmallsurfaceareatoincreasethespecificsurfaceclamping(higherholdingForces)

Claw inserts NCK,hardenedandground,forunmachinedworkpieces

Duo-clamping towers (on request)

Technical data

Quattro-clamping towers (on request)

angledrive angledrive

SizeRKK 135 RKK 160 RKK 200

Jaw width 135160200

A 290350350

B 270350350 C 454545

D 528663663

E 200240240

F 606744744 G* H 110,5130130 J*

125260260

*Oninquiryinsertdimensionsplease

Winkeltrieb

SizeRKK 135 RKK 160 RKK 200

Jaw width 135160200

400500500

400500500

454545

528663663

350445445

606744744

110,5130130

250530530

Standard top jaws SA, reversible

Clamping ranges: External clamping RKK

Function description

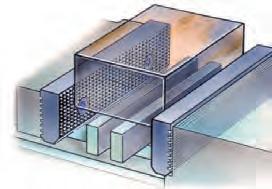

Twomovableclampingjawsandafixedmiddle jawallowaset-upandworkingtimereducing twinclamping.Themovableclampingjawis placedbyturningthespindlewiththecrank againsttheworkpieceandheldwithabout1kN (third-handfunction).

Thenthecrankisturnedfurther,theother movableclampingjawisplacedagainstthe workpiece,fixedandforceisbuiltupviathe mechanicalspindle.

Balancespringscompensatedimensional diescrepanciesfromupto±3mmbetween workpieceIandworkpieceII.

Especiallyfortheseriesproduction,settingupandcycletimesarethecriticalfactors.Duetotheir twinclamping,theNC-compacttwinvicesfromRÖHMareideallysuitedforefficientmachining.Two movableclampingjawsandafixedmiddlejawenableahighrepeatabilityof0.01mmandconstant clampingforceduringeveryclampingoperation.

Maximumflexibilityandversatilethankstothepossibilityof3-sidedclamping Highrepeatabilityof0.01mmaswellasconsistentclampingforceforeachclampingprocess Set-upandworkingtimereductionbydoubleclamping

Steelbodyandallguideshave beenhardenedandgroundonall side

Realizecentricclampingby removingthecentraljaw

Greasenipplesinstalledon bothsidesreducewearofall guidesandthespindlethread

Chipprotectioninevery clampingposition

Function:

ToadjustmobilejawIwithregardtotheworkpieceofstationIturnthespindle totherightbymeansofthehandle(left-righthandedthread).About1kN areappliedtokeepthejawintheadjustedposition(third-handfunction). Byfurtherturningthelever,mobilejawIIisadjustedwithregardtoworkpiecein stationII,lockedandpowerviathemechanicalspindleistransmitted. Bymeansofcompensatingsprings,variationsbetweenworkpieceIandIIofup to±3mmarecompensated.

Both stations must always be equipped with identical workpieces for clamping!

Fixingnut-stopontheright(spindleprovidescompensation)

Jawstroke:“Z”StationI:50mm StationII:56mm

Removecentraljaw

Fixingnut-stopontheleft(spindlerigid)

Strokeperjaw:“Z”53mm

RemovecentraljawandmovablemountingjawI. Installfixedmountingjaw(accessory-notinscopeofdelivery). Fixingnut-stopontheleft(spindlerigid)

Strokeofmovingjaw:“Z”53mm

APPLICATION

Forflexibleclampingtasksonmachiningcentersandotherproductionsystems. Tripleclampingfunction:Doubleclamping-Centricclamping-Singleclamping.

TYPE

RKD-M,

Clamping system mechanical without power transmitter, manually operated. Withone-sideddrivespindle.

CUSTOMERBENEFITS

Largeclampstroke(50mmperjaw) Theclampingthreadofthespindleisprotectedfromdirtandchipsinevery basicjawposition

Withgreasenipplesinstalledonbothsides,thatallguidesandthespindle threadcanbelubricatedquicklyandeasily Horizontal,verticalorsidemounting

TECHNICALFEATURES

-Vicewithtwomovableclampingjawsandastationarycenterjaw -Steelbasicbodyaswellasallguideshardenedandgroundonallsides -Fasteningonlypossiblewithclampingclaws(directfasteningonrequest) -Constantclampingforceforeveryclampingoperationandhighrepeatability whenatorquewrenchisused

RKD-M =RÖHM,compact,doubleclamping,manual

B2slot3mm-132-180 Cmm3240 Dmm492630 Emm117145 Fmm366495 G-0,02mm85105 H-0,02mm3040 Jmm5670 Kmm94126 Lmm1010 Mmm2530 N-0,01mm1620 Omm3636 Pmm114122 Rmm143201 Smm3132 T-0,02mm3037,5 Umm2020 Vmm1212 Wmm1x482x46 Ymm1213 Zmm50/5350/53 Key-widthSW1719 amm6380 bmm13,615,6 c1M6x14M8x14 c2M5x9M5x10 c3M10x16M10x18 dmm4860 emm812 fmm1418 gmm7095 hmm2025 imm5045 kxdepthM10x18M12x22 l-0,02mm177237 y±0,01mm4047,5 zmm72100 ClampingforcekN2540 Weightkg2452

A37 Stepped jaws SB,reversible,withfixingscrews

A37

Standard jaws SGN,onesidesmooth,onesidegrooved,hardenedandground

A37

Standard jaws finely checkered SGNf,onesidefinelycheckered,onesidegrooved,hardenedandground

A37 V-jaw PB,horizontalandvertical

2.5mmclampingdepth

,universalforclampingdepth>2.5mm

A37 Support rails Cliparc,setwith10differentpairsofrailsand4clampsinwoodenbox

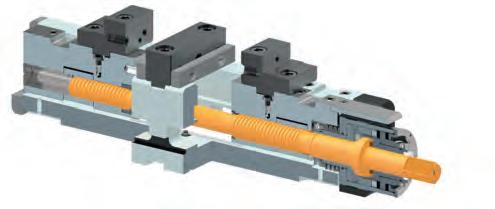

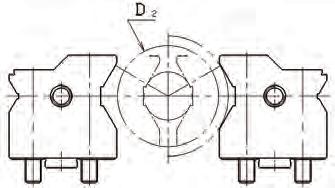

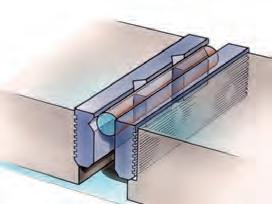

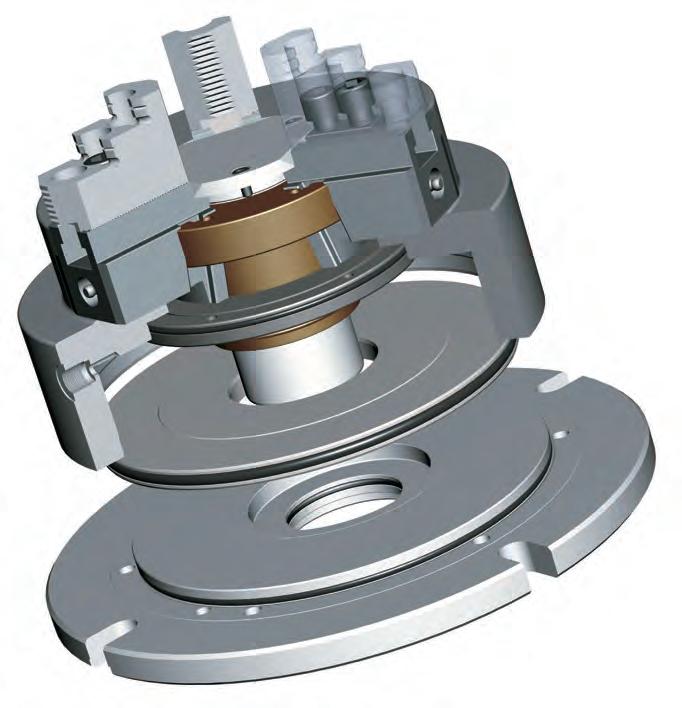

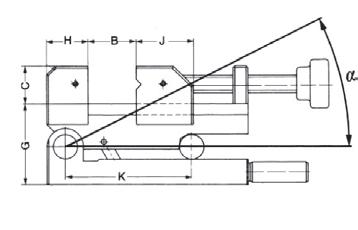

Withoutadditionalfoundationsorspecialjaws, theRZMcentricviceholdstheworkpiecesecurely–anddoesthiswithaminimalinterferencecontour.Theclampingspindleislocated veryclosetotheworkpiece,creatingan effectiveforceflowandprovidinganextremely rigidclamping.Thepatentedguidesystemof thejawsmakesaverylargeclampingrange possible.

Thankstoitscompactandrobustdesign,theNC-compactselfcenteringvicesfromRÖHMhavea minimalinterferencecontour,enablingoptimalworkpieceaccessibilityin5-axismachining.Twomovableclampingjawsensureaconstantclampingforce,highrepeatabilityandlargeclampingstroke.

Idealfor5-axismachiningduetoitsminimalcollisioncontour

Hardenedandgroundonallsidesforlongservicelife Constantclampingforceandhighrepeatability

Verylargeclampingrangedueto thejaws‘patentedguidesystem

Compactremovaldesignfor optimalworkpieceaccessibility fromfivesidesExtremelyrigidclampingandeffectiveforceflowbecausetheclamping spindleisveryclosetotheworkpiece

Opendesignfor optimizedchipflow

APPLICATION

Optimizedfor5-axismachining.

TYPE

Clamping system mechanical without power transmitter, manually operated. Centricclampingwithtwomovingjaws.

CUSTOMERBENEFITS

Idealguidancecharacteristicsofthejawsthankstopatentedguidance system

Verylargeclampingstroke Opendesignforoptimizedchipflow,whichpermitseasycleaning,evenafter heavydutymachining

Constantclampingforceforeveryclampingoperationandhighclamping repeatabilitywhenatorquewrenchisused

OptimallysuitableforuseofSKBclawedjaws.Thesetopjawscansecurely clamprawandsawedpartswithamax.strengthofupto900N/mm2toa cuttingdepthof2.5mm

TECHNICALFEATURES

-Steelbasicbodyhardenedandground -Highlypositionedclampingjaw -Topspindlelyingneartheclampingjawsforoptimalforcetransfer -Longjawguideandcompactdesign -IncludingSKBclawedjaws -Clampingrepeatability0.02mm

RZM =RÖHM,centrical,manual

A37

Claw jaws SKB without step,universalforclampingdepth>2.5mm

A37

Claw jaws SKB with fine step, 2.5mmclampingdepth

A37

Includingfixingscrews

Normal jaw SGN, onesidesmooth,onesidegrooved,bothsidesground

Includingfixingscrews

A37

Normal jaw finely checkered SGNf, reversible,toincreasethespecificcontactpressure(higherholdingforces),onesidefinelycheckered,onesidelongitudinallygrooved

Includingfixingscrews

APPLICATION

Optimizedfor5-axismachining.

TYPE

Clamping system mechanical without power transmitter, manually operated. Centricclampingwithtwomovingjaws.

CUSTOMERBENEFITS

Short,compactdesign

Largeclampingstroke

Constantclampingforceforeveryclampingoperationandhighclamping repeatabilitywhenatorquewrenchisused Clampingaccuracyatthecentre:±0.02-clampingrepeatability:0.01

TECHNICALFEATURES

-Steelbasicbodyaswellasallguideshardenedandgroundonallsides -Standard-equippedwithsteppedtopjaws

RKZ-M =RÖHM,compact,centrical,manual

Omm10101313 Pmm1122 Qmm314041,553 Umm15202020 Vmm12121212 Wmm18243546 Ymm10101213 Zmm20,5303949,5 amm--6380 bmm--13,615,6 c1--M6x10M8x14 c2M4x8M5x8M5x8M5x8 c3--M10x16M10x18 c4M3x6M4x8M5x8M5x8 dmm26374860 emm56812 fmm--1418 lmm6085120155 pmm3,54,566 qmm38525555 rmm20303232 smm15192020 tmm6kt-SW86kt-SW106kt-SW146kt-SW14 umm4kt-SW124kt-SW144kt-SW194kt-SW19 ØJxdepthmm--Ø20H 7/8Ø20H7/8 ClampingforcekN10152025 Weightkg3,571832,5 1)Withenlargedstepped-jaws

illustraed without coverplate

A37 Stepped jaws SB,reversible,withfixingscrews

A37 Double V-jaw,reversible,withfinestep,forjawdimensionsofthedoubleV-jawspleaseseepage4070!

jaws finely checkered SGNf,onesidefinelycheckered,onesidegrooved,hardenedandground

Fixedduringmachiningandwhenreleased! TheprecisionsupportrailswiththeCliparc-Systemremainintheiroriginal positionduringthemachiningandreleasingprocess.Nomoretimeintensive repositioningnecessary.InserttheCliparcclampsintotherailsandsnap themintothevice.Notoolsnecessary.

Technical features:

-Differentheightsteppings

-Widthonly3mm(fromsize160:4mmwidth) -Rimnearthroughholescanbemachinedwithoutstepjawsorproblems duetheslimprecisionsupportrails.

-Precisionandqualityparallelismbetterthan0.005mm -Quickcleaning

Contents of delivery: Setwith10differentpairofrailsand4clampsin woodenbox

A37 Dual clamp DSP formutualsupportinthecaseoffront-sidedset-up,inpairs

A37

clamp SPE,formountingvicesonendandonthebase

,hardenedandground,withfixingscrew

A37

locator WSA, universallyadjustable,forscrewingontotheNC-compactviceormachinevice,connectingthreadM12

locator WSA, universallyadjustable,forfasteningtothemachinetable(size14T-slot)orforscrewingontotheNC-compactvice/machinevice(M12)

A37 Precision vice locator PSA, universallyadjustable,forscrewingontotheNC-compactviceormachinevice,connectingthreadM12

Clamping jaws to screw onto stepped jaws and standard top jaw

ClampingjawscompatiblewithNC-compactvices,NC-powervicesandmachineviceswiththesamejawwidth

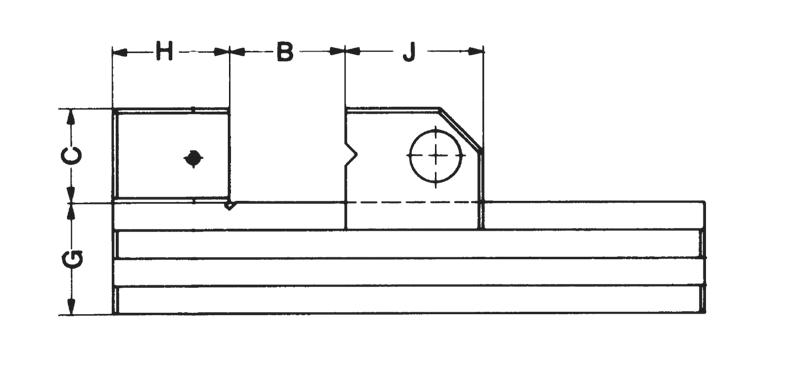

SGN normal jaw – reversible, one side smooth, one side longitudinally Serratedforpreciseclampingofparallelpartswithdelicateclampingsurfaces.

APPLICATION

Dependingontheapplicationand theworkpiecetobemachined, theclampingjawsshownonthe rightcanbescrewedontothe steppedjawandstandardtop jaw.

SGN normal jaw, finely checkered– reversible, one side finely checkered, one side longitudinally Serratedtoincreasethespecificsurfacepressure(highholdingforce).

SPR prism jaw

Forpreciseclampingofroundmaterialinverticalandhorizontalposition. Thejawsaretobeusedincombinationwithanormaljaw,sinceageometricallyclearpositionisonly achievedwithathree-pointclamping.

Pull-down jaws with SNF

Springleafareespeciallysuitableforclampingrawparts. Theleafspringsarepressedbytheclampingforcedownwards,therebycausingpull-downforce.

Draw-down base jaws with permanent magnet and quick changeable clamping inserts ClampingjawcomparabletotheNC-compactviceandmachineviceswiththesamejawwidth

RNS standard insert Formachinedworkpieceswithoutangleerror.

RNS standard insert, finely checkered Toincreasethespecificsurfacepressure(higherholdingforce).

RNK claw insert

Toincreasethespecificsurfacepressure(higherholdingforce).

RNG base jaw with permanent magnet fortakingupofquickchangeabledraw-downclampinginserts. Forscrewingonatthefixedand movablejaws.

Insert with round RNR clamping base – line-shaped clamping base Formachinedworkpieceswithandwithoutangleerror.

RWA workpiece support Forfasteningtothestandardinserts.Forraisingtheheightoftheworkpieces duringtheclampingprocess.

Othersizesandversionsavailableuponrequest.

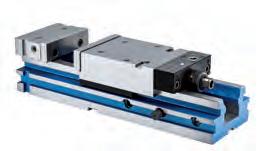

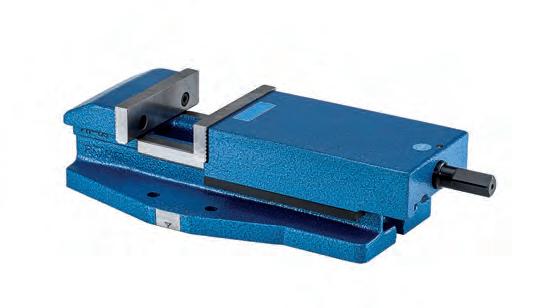

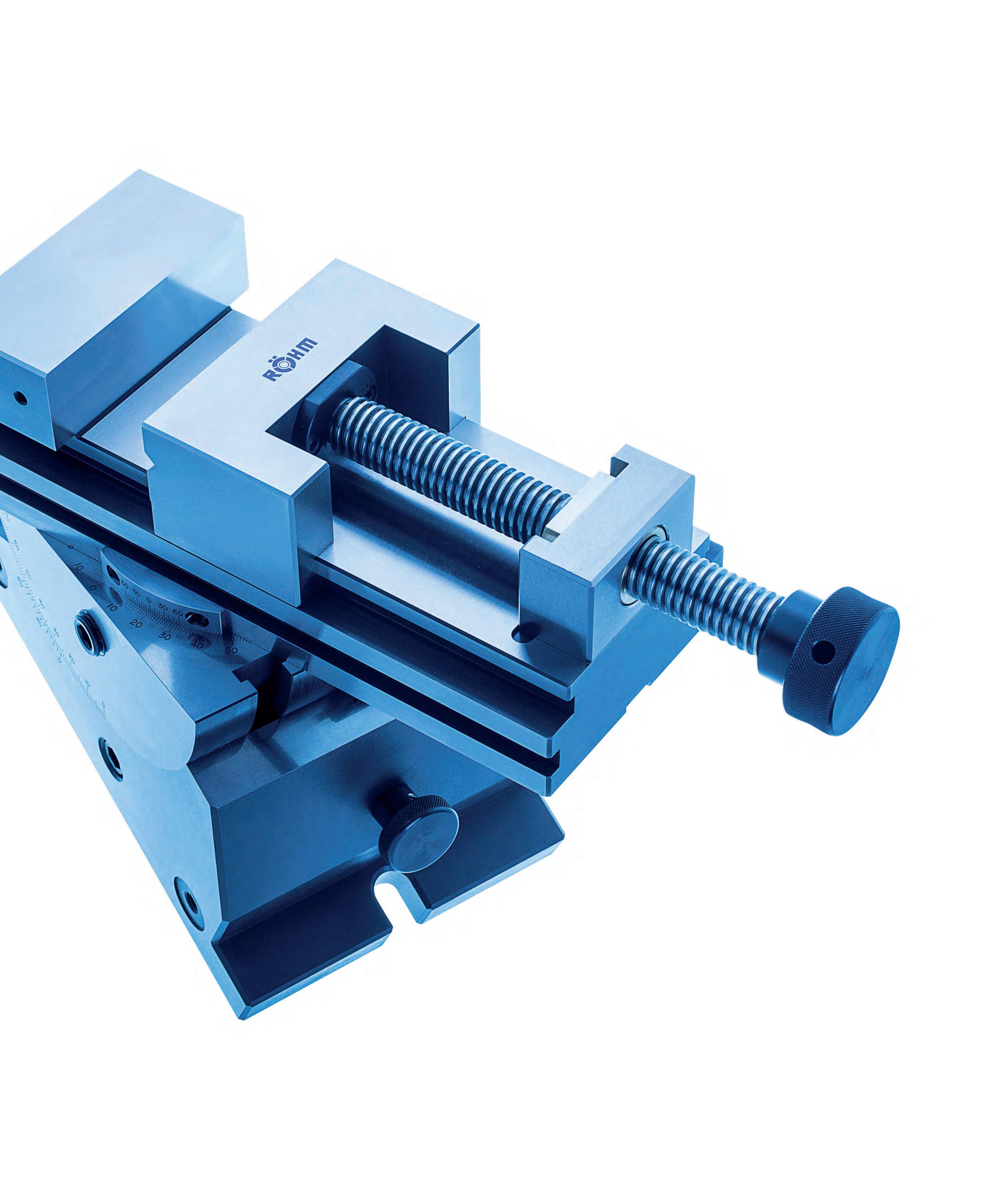

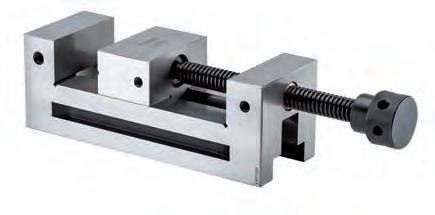

TheRÖHMmachineviceissuitableforuniversal applicationonmillingmachinesandmachiningcenters.Thebaseisequippedwithgroovestoensurea precisefasteningonthemachinetable.

RÖHMmachinevicesareideallysuitedforuniversaluseonmillingmachinesandmachiningcenters andfeatureimpressivelyhighreliabilityandlongservicelives.Theclampingareaabovethepinsystemcanbequicklyandeasilyadjustedandtheprecisejawguideenablesgreatprecision.

Universallyusableandprovenmanytimesoverfornumerousmachiningprocesses

Impressivereliability,servicelifeandprecision

Fastandsimpleadjustmentoftheclampingrangebypinsystem

Optimalcoolantandchip drainduetonewdesign

Extensivejaw programmeSimpleandfastadjustmentofthe clampingrangebypinsystem

Steppedclamping forcepresetting

APPLICATION

Foruniversaluseonmillingmachinesandmachiningcenters.

TYPE

Manualclampingsystemwithpowertransmitter. Hydraulicactuationonrequest.

CUSTOMERBENEFITS

Steppedclampingforcepresetting Highprecisionthankstoprecisejawguides Fastclampingrangeadjustmentviaboltsystem Optimalcoolantandchipdrain Highwear-resistancethankstohardenedjawguides Usewithoutforceamplificationpossibleforsensitiveclamping

TECHNICALFEATURES

-Basewithlongitudinalandtransversalgrooveforexactfixationonthe machinetable

-Useonrotaryplatewithgraduation

-Set-upoptionwithclampingclaws -Encapsulatedspindle

Size12345

JawwidthAmm92113135160200 ClampingcapacityBmm100170220310350 Cmm31,631,639,649,666,6 Dmm4935836798171022 Emm9597112133171 Fmm320390468574685 G±0,02mm6365,572,583,5104,5 Hmm5455708090 Jmm218236,5262298375 Kmm160160200240280 Omm119160180220230 Pmm90909090160 Qmm1313131721 Smm100100135180180 Ymm1212161620 amm636380100140 bmm13,613,615,619,625 cM6M6M8M8M10 dmm1212131316 ClampingforcekN25304050100 Weightkg15,5243960112

A37

Insert with round clamping shoulder RNR, heldbytwopermanentmagnets

A37

Draw-down jaws STB, forparallel,angularorflatworkpieces,hardenedandground

A37 Floating jaws SRP, hardenedandground,forworkpieceswith/withoutangularandparallelismerrors

A37 Draw-down jaws SNF,withspringplate,hardenedandground

A37

Normal jaw SGN, onesidesmooth,onesidegrooved,bothsidesground

A37

Normal jaw finely checkered SGNf, reversible,toincreasethespecificcontactpressure(higherholdingforces),onesidefinelycheckered,onesidelongitudinallygrooved

A37

V-jaw SPR,withverticallyandhorizontallyground-inprisms,hardened,forcombinationwithSGN

Includingfixingscrews

A37 Normal jaw SGNA,withmovableworkpiecestop,hardenedandground

A37

Floating jaw horizontal PEB, forclampingnon-parallelworkpieces

A37 Hand crank,turnablehandle,hexagonsocket

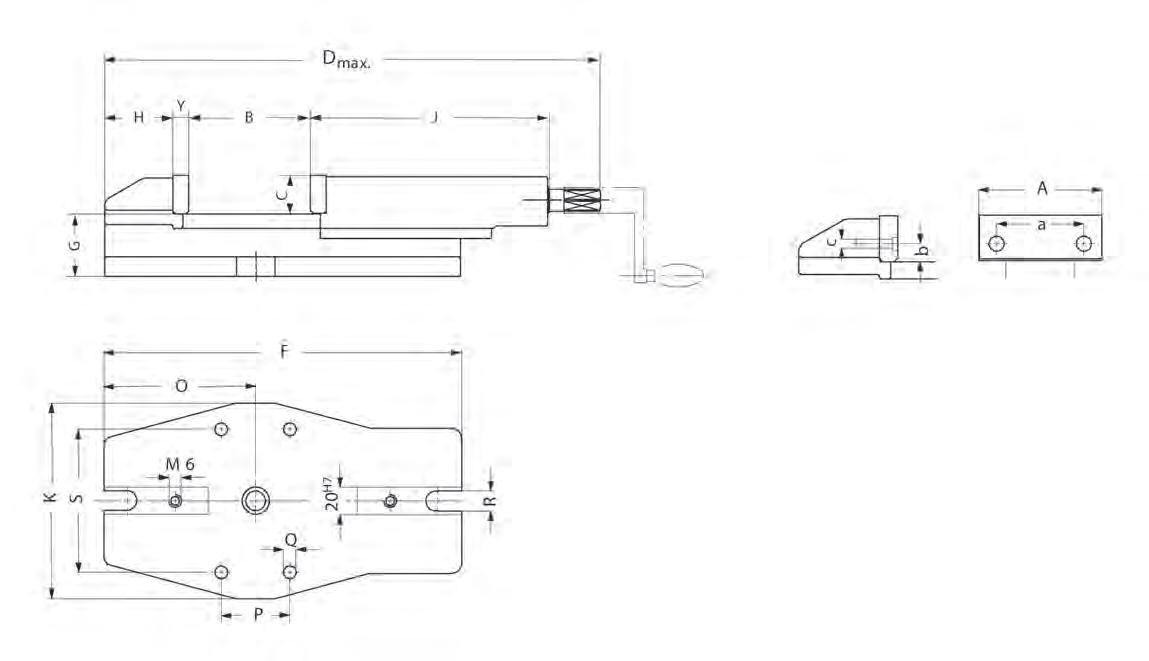

APPLICATION

Foruniversaluseonmillingmachinesandmachiningcenters.

TYPE

Clamping system mechanical-hydraulic with power transmitter, manually operated.

CUSTOMERBENEFITS

Horizontal,verticalandlaterallyclampablewithheightadjustment±0.02

Sturdy,maintenance-freespindle

Additionalsteppedjawsorspecialformjawscanbefastenedtothesurface ofthestationaryandmovingjaw Drivespindleisprotectedagainstdirtandchips

Largeclampingrange

Shortversionofmovingjaw(madeofsteel)resultsinshortdesignlength, evenformax.clampingwidth

Withangledrive

TECHNICALFEATURES

-Steelbodywithstationaryclampingjaw,dropforged -Automaticreclampinginthehydraulicunitbymeansofbuilt-indiscsprings -Allwearparts,especiallythejawguides,arehardenedandground -Robustflat-trajectoryguideofmovingjaw -Withnormaljawsandhandcrank

Cmm31,639,649,6 Dmaxmm500578702

E±0,02mm97,7112,7133,7 Fmm390468574

G±0,02mm65,572,583,5 H±0,02mm557080 Jmm211213240

K±0,02mm115137162 L±0,02mm190190240 Mmm73,580,596

T±0,02mm17,517,522,5 Y-0,01mm11,615,615,6 amm6380100 bmm13,615,619,6 cmmM6M8M8 dmm121313

e±0,02mm96111132 fmm8280100 gmm163030 hmmM8x14M10x16M12x20 imm6380100 kmm303030 lmm85105120 mmm303535 nmm527096 omm135135142 pH7mm121414 qmm555 ClampingforcekN304050 Weightkg223662

A37

Draw-down jaws SNF,withspringplate,hardenedandground

A37

Normal jaw SGN, onesidesmooth,onesidegrooved,bothsidesground

A37

Normal jaw finely checkered SGNf, reversible,toincreasethespecificcontactpressure(higherholdingforces),onesidefinelycheckered,onesidelongitudinallygrooved

A37

V-jaw SPR,withverticallyandhorizontallyground-inprisms,hardened,forcombinationwithSGN

A37

V-jaw and standard jaw SBO,unhardenedandburnished,withworkpiecesupport

A37 Dual clamp DSP, formutualsupportinthecaseoffront-sidedset-up,inpairs

A37 Single clamp SPE,formountingvicesonendandonthebase

A37 Fixed slot nuts NTS,hardenedandground,withfixingscrew

Work locator WSA, universallyadjustable,forscrewingontotheNC-compactviceormachinevice,connectingthreadM12

A37 Work locator WSA, universallyadjustable,forfasteningtothemachinetable(size14T-slot)orforscrewingontotheNC-compactvice/machinevice(M12)

A37

Precision vice locator PSA, universallyadjustable,forscrewingontotheNC-compactviceormachinevice,connectingthreadM12

APPLICATION

Foruniversaluseonmillingmachinesandmachiningcenters.

TYPE

Clamping system mechanical without power transmitter, manually operated.

CUSTOMERBENEFITS

Optimalprice/performanceratio Fastclampingrangeadjustmentviaboltsystem

TECHNICALFEATURES

-Scopeofdelivery,completewithclampingwrench,workpiecestopandfour clampingclaws

-Withdraw-downjaws

-Hardenedsteelbody(60HRC) -Clampingrepeatability0.02mm

APPLICATION

Forconventionalmachinetools.

TYPE

Clamping system mechanical without power transmitter, manually operated.

CUSTOMERBENEFITS

Optimalprice/performanceratio Entireclampingrangecanbebridgedoverbyturningthehandcrank Spindleisprotectedfromdirtandchips Extensiveassortmentofjaws

TECHNICALFEATURES

-Madeofspecialcastironforversatileuse -Longguidanceofmovingjaw -Forcetransferbymeansofthreadedspindle -WithnormaljawsSGNandhandcrank -Useonrotaryplatewithgraduation

A37

Draw-down jaws SNF,withspringplate,hardenedandground

A37

Normal jaw SGN,onesidesmooth,onesidegrooved,bothsidesground

A37

Normal jaw finely checkered SGNf, reversible,toincreasethespecificcontactpressure(higherholdingforces),onesidefinelycheckered,onesidelongitudinallygrooved

A37

V-jaw SPR,withverticallyandhorizontallyground-inprisms,hardened,forcombinationwithSGN

A37

Normal jaw SGNA,withmovableworkpiecestop,hardenedandground

APPLICATION

Forconventionalmachinetools.

TYPE

Clamping system mechanical without power transmitter, manually operated.

CUSTOMERBENEFITS

Optimalprice/performanceratio Spindlecoveredintheworkarea

Extensiveassortmentofjaws Lowdesign Thelateraljawguidesallowthevicetobeeasilyandexactlyaligned

TECHNICALFEATURES

-Madeofspecialcastironforversatileuse -Useonrotaryplatewithgraduation

-WithnormaljawsSGNandhandcrank

-Centricclampingthroughtheleft-handandright-handthreadofthespindle

A37

Draw-down jaws SNF,withspringplate,hardenedandground

A37

Includingfixingscrews

Normal jaw SGN, onesidesmooth,onesidegrooved,bothsidesground

Includingfixingscrews

A37

Normal jaw finely checkered SGNf, reversible,toincreasethespecificcontactpressure(higherholdingforces),onesidefinelycheckered,onesidelongitudinallygrooved

A37

V-jaw SPR,withverticallyandhorizontallyground-inprisms,hardened,forcombinationwithSGN

SBO,unhardenedandburnished,withworkpiecesupport

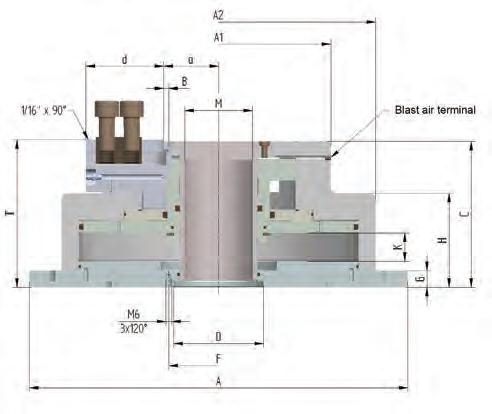

ThestationarypowerclampingdevicesfromRÖHMarepredestinedforstationary,centricclampingofroundandangular workpiecesonmillingmachinesormachiningcentersorfortherationalclampinginautomatedworksequences.

Stationarypowerclampingdevicesarecharacterizedbymanyproductadvantages,whichare essentialforstationary,centricclampingonmillingmachinesormachiningcentersorfortherational clampinginautomatedworksequences:Compactdesignforbestpossibleworkareautilization, highrepeatabilityandconstantclampingforceatthesamepressure,aswellasmaximumflexibility thankstothecentricclampingofroundandangularworkpieces.

Highefficiencythankstoautomatedandfastclampinginstationaryuse

Wedgehooksystemforhighloadcapacityandclampingprecision Flexibleusethankstocentricclampingofangularandroundcomponents

Compactdesignfor bestpossible accessibility

Wedgehooksystemwith integratedpneumaticactuation forhighloadcapacity

Serration90°for flexiblejawuse

Wedgehooksystemwithintegratedpneumaticactuationfor highloadcapacity

Reducedinterference contourforoptimum accessibility

NEW: Higherclamping forcesandexpanded clampingrangeby largerjawstroke

APPLICATION

Optimallysuitedforusein3-,4-and5-axismachiningcentersaswellasonall commonzero-pointclampingsystems

TYPE

Pneumaticallyactuatedcenteringviceinstandarddesign. Optionallywithinductivesensors.2-jawsversion.

CUSTOMERBENEFITS

Jawstrokeexpandedbyupto20%foralargerclampingrange Highestclampingforcesofupto55kN,optimalresultsandprocessreliability throughprecisionwedgehooksystem

Optimizedlubricationsystemforconstantlyhighclampingforces Compactdesignwithreducedinterferingcontoursforoptimumworkpiece accessibility,idealworkingspaceutilizationandoptimumchipflow Sturdyandlow-backlashjawguidesforhighrepeatability

TECHNICALFEATURES

-Jawswithcrosstenonandserration

KZS-P =power-operated,centering,vice,pneumatically

Thepower-operatedcenteringvicesarealsoavailablewithintegratedstrokesensor,whichservesforclamping controlandensuresoptimumprocessmonitoringandthusoptimalprocessreliability.

Wmm025.5324860 a mm12.8-17.420.4-2524-3134.4-4434-46 a1mm12.9-15.225.7-2844.5-4853.2-5855-61 a2mm9.9-12.214.7-1718.5-2232-27.224-30 bmm4.858811 cmm57101012 dmm23.337.564.578102 emm304778102125 fg6mm1420324050

APPLICATION

Optimallysuitedforusein3-,4-and5-axismachiningcentersaswellasonall commonzero-pointclampingsystems

TYPE

Pneumaticallyactuatedcenteringvicewithlargejawstroke. Optionallywithinductivesensors.2-jawsversion.

CUSTOMERBENEFITS

Jawstrokeexpandedbyupto20%foralargerclampingrange

Highestclampingforcesofupto55kN,optimalresultsandprocessreliability throughprecisionwedgehooksystem

Optimizedlubricationsystemforconstantlyhighclampingforces

Compactdesignwithreducedinterferingcontoursforoptimumworkpiece accessibility,idealworkingspaceutilizationandoptimumchipflow

Sturdyandlow-backlashjawguidesforhighrepeatability

TECHNICALFEATURES

-Jawswithcrosstenonandserration

KZS-PG =power-operated,centering,vice,pneumatically,largejawstroke

Thepower-operatedcenteringvicesarealsoavailablewithintegratedstrokesensor,whichservesforclamping controlandensuresoptimumprocessmonitoringandthusoptimalprocessreliability.

Smm34.559.772.592.6 Tmm5582110139.6 Vmm447487.7110.8 Wmm25.5324860 a mm20.2-3325-4432-56.241-76.2 a1mm25.5-32.544.8-54.354.5-66.651.5-69.1 a2mm14.5-21.518.8-28.328.5-40.632.5-50.1 bmm7.511.211.515 cmm7101012 dmm40.567.58199 emm4778102125 fg6mm20324050 gmm35608090 hH7mm68810 kM6-9TM8-12TM8-16TM10-19T k15677 mmm2.73.23.24

APPLICATION

Optimallysuitedforusein3-,4-and5-axismachiningcentersaswellasonall commonzero-pointclampingsystems

TYPE

Hydraulicallyactuatedcenteringviceinstandarddesign. Optionallywithinductivesensors.2-jawsversion.

CUSTOMERBENEFITS

Jawstrokeexpandedbyupto20%foralargerclampingrange Highestclampingforcesofupto55kN,optimalresultsandprocessreliability throughprecisionwedgehooksystem

Optimizedlubricationsystemforconstantlyhighclampingforces Compactdesignwithreducedinterferingcontoursforoptimumworkpiece accessibility,idealworkingspaceutilizationandoptimumchipflow Sturdyandlow-backlashjawguidesforhighrepeatability

TECHNICALFEATURES

-Jawswithcrosstenonandserration

KZS-H =power-operated,centering,vice,hydraulically

Thepower-operatedcenteringvicesarealsoavailablewithintegratedstrokesensor,whichservesforclamping controlandensuresoptimumprocessmonitoringandthusoptimalprocessreliability.

Power-operatedcenteringvice KZS-H (standard jaw stroke), basicjawswith serration 1.5 x

SizeKZS-H64KZS-H100KZS-H160 A1mm64100160 JawstrokeBmm2.32.33.5 Cmm55.774.287.2 DH7mm4-7.5T6-12T8-14T E±0.01mm3690146 F±0.01mm5664106 G±0.04mm5080125 H±0.04mm5080125 JmmM6M8M10 Kmm121518 Lmm81113 Mmm44.56 Nmm31.239.836.5 Omm173240 Pmm1729.550 Qmm84130200 Rmm4568106 Smm21.134.559.7 Tmm33.65582 Vmm-27.54474 Wmm025.532 a mm12.8-17.420.4-2524-31

fg6mm142032 gmm243560 hH7mm468 kM4-7TM6-9TM8-12T k1456 mmm2.72.73.2 nmm1.81.81.8 ommM3M4M5

APPLICATION

Optimallysuitedforusein3-,4-and5-axismachiningcentersaswellasonall commonzero-pointclampingsystems

TYPE

Hydraulicallyactuatedcenteringvicewithlargejawstroke. Optionallywithinductivesensors.2-jawsversion.

CUSTOMERBENEFITS

Jawstrokeexpandedbyupto20%foralargerclampingrange

Highestclampingforcesofupto55kN,optimalresultsandprocessreliability throughprecisionwedgehooksystem

Optimizedlubricationsystemforconstantlyhighclampingforces

Compactdesignwithreducedinterferingcontoursforoptimumworkpiece accessibility,idealworkingspaceutilizationandoptimumchipflow

Sturdyandlow-backlashjawguidesforhighrepeatability

TECHNICALFEATURES

-Jawswithcrosstenonandserration

KZS-HG =power-operated,centering,vice,hydraulically,largejawstroke

Thepower-operatedcenteringvicesarealsoavailablewithintegratedstrokesensor,whichservesforclamping controlandensuresoptimumprocessmonitoringandthusoptimalprocessreliability.

Smm34.559.772.550 Tmm5582110140 Vmm447487.770 Wmm25.5324850 a mm20.2-3325-4432-56.241-76.2 a1mm25.5-32.544.8-54.354.5-66.651.5-69.1

APPLICATION

Forstationarycentricclampingofworkpiecesonmillingmachinesormachining centers.

TYPE

Clampingsystemconsistingofa3-jawchuck,includinganintegratedpneumatic cylinder. Serration90°.

CUSTOMERBENEFITS

Compactdesign

Largevarietyofapplicationsispossiblebyusingdifferentclampingjaws Centricclampingofroundandangularworkpieces

Highrepeatabilitythankstosturdychuckconstructionandconstantclamping forceatsamepressure

Purgeairconnectionpossibletopreventcontamination

TECHNICALFEATURES

-Wedgehooksystemwithpneumaticactuation -Clampingforcecanberegulatedbychangingthepressure

Note: Hydraulicactuationonrequest

SSP =stationary,powerchuck,pneumatically

Components: 1.Body

.Basejaw

.Piston

.Protectivebushing

.Intermediatedisc 6.Mount

7.Pistondisc

8.T-nut

9.Topjaws

C15

Stationary power chucks SSP, airoperated3-jawchucks,withoutthrough-hole,serration1/16“x90°

Size160200250315 Numberofjaws3333 Amm260320380415 A1mm178205255320 A2mm210255315350 JawtravelBmm4,24,255 Cmm130,5134146156,5 MountDH6557090110 DM8M12M16M16 Fmm6580100120 Gmm15171721,5 Hmm84,58694104,5 WedgestrokeKmm2423,828,428,4 Possible through-holeMmm38526890 Tmm131,5135,5147,5158 UM8M12M16M16 a min.31,841,25061,5 a max.3645,45566,5 cmm15192525 dmm54,5627899 emm32364444 fH7mm12172121 gmm13171717

Pistonareacm2209323532654

Min.operatingpressurebar2222

Max.operatingpressurebar8888

Max.totalclampingforceatworking pressure- External clamping kN

Max.totalclampingforceatworking pressure- Internal clamping kN

36(at6bar)55(at6bar)90(at6bar)111(at6bar)

38(at6bar)60(at5bar)96(at6bar)118(at6bar)

Weightwithoutjawsapprox.kg25345465

C21

Reversible top jaws, 3-jaw set, hardened serration 90° -material:16MnCr5

C21

046404 1605637,5261/16‘‘x90° 118522 2007549361/16“x90° 046414 250/315103,558501/16‘‘x90° Additionallyorlaterapplied,hardenedjawsmustbegroundoutinthechuck.

Soft top jaws, 3-jaw set, can be hardened serration 90° -material:16MnCr5

C21

Claw-type jaws, 1piece, hardened serration 90° -widthofthegroove 12

C21

Claw-type jaws, 1piece, hardened serration 90° -widthofthegroove 17

137031 2006745531/16“x90°

C21

Claw-type jaws, 1piece, hardened serration 90° -widthofthegroove 21

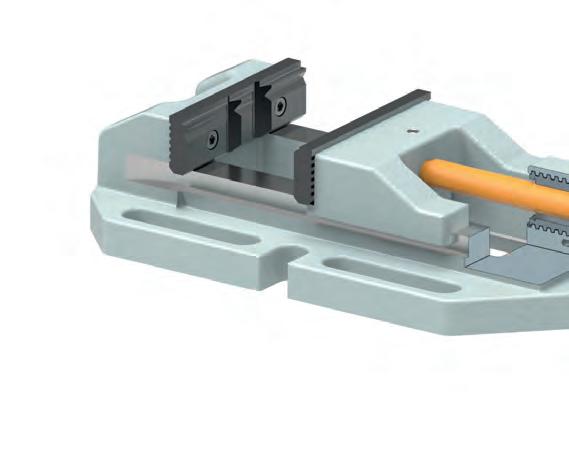

Fordecades,RÖHMdrillingmachinevices havebeenenablingreliableandquickclamping ofworkpiecesondrillingandmeasuringmachines.Theentireclampingrangecanbesetby one-handedturning.

ThedrillingmachinevicesfromRÖHMhaveseendecadesofuseinmachineshopsandproduction facilities.Thevicesareespeciallyimpressiveindrillingandmeasuringmachinesthankstotheirsimple andfastattachmentonthemachinetableaswellastheireasyandsingle-handedoperation.

Reliableandfastclampingofwork piecesondrillingandmeasuringmachines Vicehasprovenitselfoverthedecadeswithgoodprice/performanceratio Entireclampingrangecanbesetbysingle-handedturning

Bodymadeofspecial steelcastingforflexibleapplication

Reversibleclampingjaws: onesidesmoothorrespectivelywith longitudinalandcrossprism,oneside grooved,groundonbothsides

Longguidanceofmovingjaw, evenintheexternalclamping range

Quickclampingsystem optimizedforworkpiece seriesmachining

APPLICATION

Forsecurelyclampingworkpiecesondrillsandmeasuringmachines.

TYPE

Clamping system mechanical, manually operated. Standardversion.

CUSTOMERBENEFITS

Quick-clamping vice Forquickclampingandunclamping,particularlyinthecaseofseriesworkpiecemachining

Optimalprice/performanceratio One-handoperation Longguidanceofmovingjaw,evenintheexternalclampingrange Clampingjawsarereversible,onesidesmoothandgroundonbothsides Solidclampingjawwithonelongitudinalprismandtwotransverseprisms

TECHNICALFEATURES

-Bodymadeoutofspecialsteelcasting

-One-handoperation -Positivelocking

APPLICATION

Forsecurelyclampingworkpiecesondrillsandmeasuringmachines.

TYPE

Clamping system mechanical, manually operated. Standardversion.

CUSTOMERBENEFITS

Optimalprice/performanceratio Entireclampingrangewithinreachbyturning Mountingpossibilitiesonthesideandfrontal Longguidanceofmovingjaw,evenintheexternalclampingrange Clampingjawsarereversible,onesidesmoothandgroundonbothsides Solidclampingjawwithonelongitudinalprismandtwotransverseprisms Bothjawswithsupportsurfaceforclampingflatworkpieces

TECHNICALFEATURES

-Bodymadeoutofspecialsteelcasting -Low,stabledesignwiththreadspindle

APPLICATION

Forsecurelyclampingworkpiecesondrillsandmeasuringmachines.

TYPE

D.I.Y.designforsmalldrillstands. Clamping system mechanical, manually operated.

CUSTOMERBENEFITS

Levermovable(includedinscopeofdelivery) Bothjawshaveaseatforretainingflatworkpieces

TECHNICALFEATURES

-Solidclampingjawwiththreeverticalprismsandonehorizontalprism -Jawsandspindlegunmetal-finished -Bodymadeoutofcastmetal -Longmountingslots

APPLICATION

Forsecurelyclampingworkpiecesondrillsandmeasuringmachines.

TYPE

Sturdyversionfordrillstands,tabledrillsandboxcolumndrills. Clamping system mechanical, manually operated.

CUSTOMERBENEFITS

Longleverformaximalclampingforce Bothjawshaveaseatforretainingflatworkpieces

TECHNICALFEATURES

-Movingsteeljawissupportedbyacastironjawwithinnerguidance -Solidclampingjawwiththreeverticalprismsandonehorizontalprism -Jawsandspindlegunmetal-finished -Bodymadeoutofcastmetal -Longmountingslots

APPLICATION

Forsecurelyclampingworkpiecesondrillsandmeasuringmachines.

TYPE

Clamping system mechanical, manually operated. Standardversion.

CUSTOMERBENEFITS

Entireclampingrangewithinreachbyturning Constantdesignlength,spindlemovesprotectedinthehandle The threadspindleiscoveredbyaprotectingsleeve

TECHNICALFEATURES

-Solidandhandyversion

-Bodymadeoutofcastmetal

-Movablejaw,guidedonside

-Solidclampingjawwiththreeverticalprismsandonehorizontalprism -Bothjawswithsupportsurfaceforclampingflatworkpieces

-Jawsandspindlegunmetal-finished -Longmountingslots

APPLICATION

Forsecurelyclampingworkpiecesondrillsandmeasuringmachines.

TYPE

Clamping system mechanical, manually operated. Standardversion. 3set-upoptionsthankstotwoadditional,perpendicularlymachinedsupport surfaces:bottom,rightandfront.

CUSTOMERBENEFITS

Entireclampingrangewithinreachbyturning Constantdesignlength,spindlemovesprotectedinthehandle The threadspindleiscoveredbyaprotectingsleeve Mountingslots

TECHNICALFEATURES

-Solidandhandyversion

-Bodymadeoutofcastmetal -Movablejaw,guidedonside -Solidclampingjawwiththreeverticalprismsandonehorizontalprism -Bothjawswithsupportsurfaceforclampingflatworkpieces -Jawsandspindlegunmetal-finished -Longmountingslots

A37

V-jaw and standard jaw SBO,unhardenedandburnished,withworkpiecesupportfürBOFundBSS

A37

V-jaw and standard jaw SBO, softandgunmetal-finished,withworksupport,forDPV

RÖHMgrindingandinspectionvicesareprimarilyusedingrinding,millingandengravingmachines, atjigboringmachines,formeasurementandinspectionworkandformanufacturingprocesseswhich requirethehigheststandardsofclampingprecision.

Positivelockinginanydesired

2-dimensionalangle adjustmentandcanbe rotatedby360°

Finesettingscrewonthe lowerpartallowsprecise angleadjustment

1)Basetostationaryjawclampingsurface

2)Basetoupperguideedge

APPLICATION

Mainlyintoolconstructionongrinding,millingandengravingmachines,onjig boringmachines,formeasuringandcontrolworkandforproductionoperations requiringhighclampingprecision.

CUSTOMERBENEFITS

Easyclampingandunclampingwithallenkey Clampingjawadjustableinstages,snapsinautomatically

TECHNICALFEATURES

-Withdraw-downeffect

-Madeofalloyedtoolsteel,hardenedandveryfinelyground

-Horizontallyandverticallygroundprism

-Nospindlewhichcouldcausecontaminationduringelectricdischarge machining,forexample

APPLICATION

Mainlyintoolconstructionongrinding,millingandengravingmachines,onjig boringmachines,formeasuringandcontrolworkandforproductionoperations requiringhighclampingprecision.

CUSTOMERBENEFITS

Easyclampingandunclampingwithallenkey Clampingjawadjustableinstages,snapsinautomatically

TECHNICALFEATURES

-Withdraw-downeffect

-Madeofalloyedtoolsteel,hardenedandveryfinelyground

-Horizontallyandverticallygroundprism

-Nospindlewhichcouldcausecontaminationduringelectricdischarge machining,forexample

10,0050,00270806230160323345M63 1179517 20,0050,002901208040210404050M55,8 1179518 30,0050,0021201509040280506070M513,5

1)Basetostationaryjawclampingsurface

2)Basetoupperguideedge

APPLICATION

Mainlyintoolconstructionongrinding,millingandengravingmachines,onjig boringmachines,formeasuringandcontrolworkandforproductionoperations requiringhighclampingprecision.

CUSTOMERBENEFITS

Easyclampingandunclampingwithallenkey Clampingjawadjustableinstages,snapsinautomatically

TECHNICALFEATURES

-Withdraw-downeffect

-Madeofalloyedtoolsteel,hardenedandveryfinelyground

-Horizontallyandverticallygroundprism

-Nospindlewhichcouldcausecontaminationduringelectricdischarge machining,forexample

1)Basetostationaryjawclampingsurface

2)Basetoupperguideedge

APPLICATION

Mainlyintoolconstructionongrinding,millingandengravingmachines,onjig boringmachines,formeasuringandcontrolworkandforproductionoperations requiringhighclampingprecision.

CUSTOMERBENEFITS

Clampingandunclampingwiththreadedspindle

TECHNICALFEATURES

-Horizontallyandverticallygroundprism

-Madeofalloyedtoolsteel,hardenedandveryfinelyground

1)Basetostationaryjawclampingsurface

2)Basetoupperguideedge

A29 PS-SV, front swivelling axis

APPLICATION

Mainlyintoolconstructionongrinding,millingandengravingmachines,onjig boringmachines,formeasuringandcontrolworkandforproductionoperations requiringhighclampingprecision.

CUSTOMERBENEFITS

Theclampingdevicecanbepositivelylockedinanyangularposition

TECHNICALFEATURES

-Madeofalloyedtoolsteel,hardenedandveryfinelyground -Bearingandsupportpinshardenedandgroundtoaprecisionof0.001mm

A29 PS-ZD 2-dimensional

APPLICATION

Mainlyintoolconstructionongrinding,millingandengravingmachines,onjig boringmachines,formeasuringandcontrolworkandforproductionoperations requiringhighclampingprecision.

CUSTOMERBENEFITS

2-dimensionalangleadjustmentviavernia,forsize1with3´-vernia,forsize2 with5´-vernia 360°turnable

TECHNICALFEATURES

-Fineadjustmentscrewonbottomsectionmakesexactangularadjustment possible -Size2forheavymachining

-Positivelockinginanydesiredangularpositionusingfixingscrews -Madeofalloyedtoolsteel,hardenedandveryfinelyground

APPLICATION

Suitablefor3jawchucksandvices. The F-senso clamping force measurement device enables you to check the clamping force as well as the rotational speed of your clamping tools. Thecentrifugalbehavioristhusdirectlyrelatedtotheaccompanyingsoftware evaluated.

TYPE

Broadclampingrangeof75-175mmthroughinterchangeablepressurepins Broadmeasuringrangefrom0-100kNperjaw Dynamicclampingforcemeasurementunderrotationupto8250rpm Real-timedatatransmissionviaBluetoothtoincludedtablet Deliveredinthepracticalhard-shellcase

TECHNICALFEATURES

-Noadditionalattachmentsnecessaryonthemachine -Easypositioningthroughpositioningaid -Automatedswitch-off

Directoutputofthecentrifugalforcebehaviorthroughcombinedmeasurementof clampingforceandspeed Flexibilitythroughlargeclampingandmeasuringrange Easyhandlingwithoutadditionalset-upsonthemachine

Included in the scope of delivery: -Basewithfoaminsert

-Clampingforcemeasuringhead,F-sensochuck

-Pressureboltsinlengths5mm,15mm,25mmand30mm -Pressureboltelongationinlength25mm -Practicalinsertionaid

-TabletPCwithpre-installedmeasuringandevaluationprogram

PalletisingsystemssuchastheEASYLOCKzeropoint clampingsystemfromRÖHMachieveaconsiderable productivityincrease.Thismodularsystemmeetsthe requirementsofcustomer-specificsolutionswiththe best-possibleutilisationofmachinecapacity.Althoughthe machinetoolhadtostopfortheset-uptimeuntilnow,the workpiececannowbeclampedandpositionedonthe palletoutsidethemachinetool.Theset-uptimeisnow onlylimitedtoloadingandunloadingthepallet,which happensinseconds.Ifmultiplemanufacturingprocesses arenecessaryformachining,thenthepalletincludingthe workpiececanbeusedwithoutzeropointloss.Dueto therobustandrust-resistantconstruction,EASYLOCK zeropointclampingcanbeusedthroughout,startingwith machininguptothemeasuringmachines.

WiththeRÖHMEASYLOCKzeropointclampingsystem, theclampingpinistheinterfacebetweenthemachine tableandtheworkpieceorfixture.Theexactpositioning guaranteessecureclamping.Atthesametimetheresultingmachiningforcesaretransferredviatheclampingpin tothepressurecup.Thehigh-precisionpressurecupsof theEASYLOCKsystemensureanabsolutelysecureholdof theworkpieceorfixture.Thehighlockingandholdingforces makethesystemsuitableforallkindsofuse.

MachiningwithEASYLOCK?

EASYLOCKisideallysuitedtoallmachiningprocesseslike grinding,milling,drillingandmeasuring.

Whatismeantbyholdingforce?

Holdingforceistheforceatwhichthepalletstillrests securelyontheclampingsystem.Thisforcemustnotbe exceededduringmachining.

Whatismeantbyrepeataccuracy?

Therepeataccuracygivesthetolerancerangeforthe recordedworkpiecereferenceswhentheworkpieceisremovedandsubsequentlyreclamped.Therepeataccuracy oftheEASYLOCKsystemisaround<0.005mm.

Asasystemsupplier,RÖHMoffershighqualityclamping toolsaswellastheappropriatepalletingsolutionswith zeropointclamping.Coordinatedwithoneanother,base carriersanduniversalpalletssupportawiderangeofcombinationoptionstogetherwithRÖHMvices,lathechucks

+optionalwithpositionsensingandcleaningfunction*

+optionalwithindexing

+optionalwithreleasecontrol*

+optionalwithmediafeed-through*

andcolletchucksaswellaswithpneumaticallyorhydraulicallyoperatedchucksandcentricvices.TheEASYLOCK basecarrierscanbeprovidedwithavarietyofoptionson amodularbasis.

INDEXING:

Securingoftheindividualpalletagainstturning,soensuringexactpositioningevery90°.

MEDIAFEED-THROUGH:

Mediatransmissionthroughthepallet,e.g.foractivationof thepneumatically/hydraulicallyoperatedcentricvices.

POSITIONSENSINGINCLUDINGCLEANINGFUNCTION:

Thisoptionincludesaventilationsystemforcleaningchips andmonitoringthecontactface.

RELEASECONTROL:

Basedonautomatedprocesses,thiscommunicatestothe robotthattheinsertionpinsofthepallethavecomeloose.

*Furtheraccessoriesarerequired(notincludedinthescopeofdelivery)

suitableforNC-CompactvicesRKE,RKE-LV,RZM,RKD-M,RKZ-M

suitableforDURO-T/DURO-TAchucks,CAPTIS-Mcolletchucks

PALLET PNEUMATIC CENTRIC VICE

suitableforcentricviceKZS-P/KZS-PG

suitableforchuckSSP

ID OperationDiameterDimensionsInsidemicrometerOptions 1314883 hydraulic112200x200x58-withindexing 1314882 pneumatic112200x200x58-withindexing 1313929 hydraulic138200x200x58-withindexing 1313928 pneumatic138200x200x58-withindexing

ID OperationDiameterDimensionsInsidemicrometerOptions 1314885 hydraulic112200x400x582001314884 pneumatic112200x400x582001313931 hydraulic138200x400x582001313930 pneumatic138200x400x58200-

ID OperationDiameterDimensionsInsidemicrometerOptions 1314887 hydraulic112350x350x582001314886 pneumatic112350x350x582001313933 hydraulic138350x350x582001313932 pneumatic138350x350x58200-

ID OperationDiameterDimensionsInsidemicrometerOptions 1313940 hydraulic112350x600x582001352604 pneumatic112350x600x582001313935 hydraulic138350x600x642001313934 pneumatic138350x600x64200-

TheRÖHMmainplantislocatedinSontheim/Brenz.Inthisultra-modernproductionfacilitycomprising41,000m²optimumconditionshavebeenachievedinordertosolvetheextensiverange ofdiscerningconstructionandproductiontasksmakingthecompanyevenbetter,fasterandmore efficientinthefuture.

Sontheim IAllnationalandinternationalactivitiesareplannedandcoordinatedattheadministrativeheadquartersin Sontheim.Thankstotheexcellentinfrastructureandtransportroutes,thislocationisidealforacompanyrelyingon perfectproductqualityaswellasmaximumflexibility.Furthermore,theregionaroundSontheimoffersanotherkey basisforthesuccessofourcompany:itisrichinqualityawarenessandmotivatedemployeeswiththeresultthatwe areideallypreparedforthechallengesofthefuture.Themainplantuniquelyunitesmassproduction,serialproduction andcustomisedindividualproductionunderasingleroof.

SuchstronggrowthonthepartoftheRÖHMGroupisalsoobviouslyassociatedwithhigher requirementsondevelopmentandproductioncapacities.Thedemandsoftodayandtomorrow canbecompliedwiththetwofacilitiesinDillingenandSt.Georgen.

Plant Dillingen/Danube |ThisbranchplantinDillingen wasputintooperationbytheRÖHMGroupasearlyas1953. Thankstoextremelypositivedevelopment,theplantissubject toconstantexpansionandmodernisation.Forthisreason, newmodernproductionfacilitieswerebuiltin1982and1991. In2007RÖHMbuiltanewproductionhallfortwoportal turningandmillingmachines.Thisenablesmachiningof workpiecesupto4metresinlengthwhichwillsecurea leadingmarketpositionforRÖHMinthefuture.Morethan 300employeesareprimarilyinvolvedinengineeringand manufacturinglathechucks,machinevicesandspecial clampingequipmentforturningandmillingmachineryas wellasformachiningcentres.

Apartfromstandardmandrels,tailor-madesolutionsfor awidevarietyofrequirementsarealsomanufactured hereinthissmallbutaccomplishedhigh-techforge.

RÖHMretainsmechanicalorpower-operatedmandrels,slidingjawmandrelsandhydraulicmandrelsforits customersfortensioningworkpiecesindrillholesor interiorcontours.

CustomerorientationatRÖHMhaslesstodowithmarketingthanwithattitude.Weconsidercustomerproximity asanintensivedialoguewithourpartnersaswellasdirectpresenceonkeyinternationalmarkets.

Manufacturinganddistributionbases

Germany: RÖHMGmbH

Heinrich-Röhm-Straße50 89567Sontheim/Brenz Tel00497325–160 Fax00497325–16510 info@roehm.biz www.roehm.biz

RÖHMGmbH

Röhmstraße6 89407Dillingen

Tel00499071–508-0 Fax00499071–508-174 infodlg@roehm.biz

RÖHMGmbH

Feldbergstr.5 78112St.Georgen

Tel0049–7724–946812 Fax0049–7724–5189 Mobil0152–22887050 stg.info@roehm.biz

Brazil: RÖHMIND.ECOM.DE FERRAMENTASDEFIXAÇÃOLTDA.

Rod.RaposoTavares,Km14-BlocoA 2ºandar-sala2-CEP05576-100 SãoPaulo Tel0055–11–37322222 Fax0055–11–37353097 vendas@rohm.com.br www.br.roehm.biz

China: ROEHMChinaCo.,Ltd. Room702,Building24, No.518XinzhuanRoad, SongjiangDistrict, 201612Shanghai Tel0086–21–37705395 Fax0086–21–37705376 roehmcn@roehm.biz

Czech Republic: RÖHMSLOVAKIAS.R.O. Partizanska73 95701BanovcenadBebravou Slovakia Tel00421–387600222 Fax00421–387600224 Mobil00421–902556777 info@roehm.sk

France: RÖHMS.A.R.L. 325ruePaulLangevin BP90204 F-60744SaintMaximincedex Tel0033–344641000 Fax0033–344640068 fr.roehm@roehm.biz www.rohm.fr

Great Britain: ROHM(GreatBritain)LTD. Unit12theashwaycentre ElmcresentKingston-upon-Thames SurreyKT26HH Tel0044–2085496647 Fax0044–2085411783 rohmgb@roehm.biz www.uk.roehm.biz

Italy: RÖHMItaliaS.R.L. ViaReissRomoli17-19 20019SettimoMilanese(MI) PalazzoRothenberger Tel0039–02–92103531 Fax0039–02–92101753 rohmitalia@roehm.biz www.roehm-italia.it

Mexico: RÖHMProductsMéxicoS.deR.L. EmilioGarzaMeléndez#6606 Col.CampestreMederos Monterrey,N.L.,México,C.P.64970 Tel005281–9627–0686 info@rohm-products.com

Switzerland: RÖHMSpanntechnikAG Feldstraße39,3360Herzogenbuchsee Tel0041–629563020 Fax0041–629563029 roehmch@roehm-spanntechnik.ch www.ch.roehm.biz

Singapore: RÖHMAsiaPacificPte.Ltd. 8UbiRoad2 #07-10Zervex Singapore408538 Tel0065–64437748 Mobil0065–83288980 info@sg.roehm.biz www.sg.roehm.biz

Slovakia: RÖHMSLOVAKIAS.R.O. Partizanska73 95701BanovcenadBebravou Slovakia Tel00421–387600222 Fax00421–387600224 Mobil00421–914122932 info@roehm.sk

Spain: RÖHMIbericaS.A. C/Rejas,No.9Nave11D 28022Madrid Tel0034–91–3135790 Fax0034–91–3135793 rohmiberica@roehm.biz www.roehm-iberica.es

USA: ROHMProductsofAmerica 2500NorthlakeDrive 30024Suwanee,GA Tel001–770–963–8440 Fax001–770–963–8407 rohmusa@roehm.biz www.us.roehm.biz

Poland: RÖHMPolskaSp.zo.o. AlejeJerozolimskie424A 05-800Pruszków Tel0048–22–759–5990 Fax0048–22–759–5999 roehmpolska@roehm.biz

Portugal: RÖHMIbericaS.A. C/Rejas,No.9Nave11D 28022Madrid Tel00351926853881 es.pjfernandes@roehm.com www.roehm-iberica.es

Hungary: RÖHMHungariaKft. Gyáru.2.(BITEPIpariPark) H-2040Budaörs Tel0036–209–324597 jozsef.alker@roehm.biz

PresenceonallcontinentsfromAfor AustraliatoVforVietnam.Youcanreceive thecontactinformationofourworldwide representationseasilythrough www.roehm.biz.

Baden-Wuerttemberg: ThomasHaas Tel07725/914895 Mobile0152/22887120 thomas.haas@roehm.biz

DominikGotthelf Mobile0152/22887093 dominik.gotthelf@roehm.biz

RichardSedlak Tel07021/9498970 Mobile0152/22887030 richard.sedlak@roehm.biz

Baden-Wuerttemberg / Rhineland-Palatinate / Saarland: MichaelSchmitz Tel0033388720403 Mobile0152/22887018 michael.schmitz@roehm.biz

Baden-Wuerttemberg / Bavaria: DirkGaarz Mobil0152/22887116 dirk.gaarz@roehm.biz

Bavaria: JanBirkholz Mobile0152/22887014 jan.birkholz@roehm.biz

GerhardHäutle Tel09071/7299322 Mobile0152/22887015 gerhard.haeutle@roehm.biz

ChristianHeigl Mobile0152/22887026 christian.heigl@roehm.biz

Bavaria / Thuringia: SteffenBlatz Mobile0152/22887016 steffen.blatz@roehm.biz

North Rhine-Westphalia / Rhineland-Palatinate

RalfSchnichels Tel02152/8973547 Mobile0152/22887025 ralf.schnichels@roehm.biz

North Rhine-Westphalia: FriedhelmSchneider Tel02762/490728 Mobile0152/22887017 friedhelm.schneider@roehm.biz

North Rhine-Westphalia / Lower Saxony ThorstenNolte Tel02721/120182 Mobile0152/22887031 thorsten.nolte@roehm.biz

Lower Saxony / Saxony SusanneBormann Mobile0152/22887088 susanne.bormann@roehm.biz

Berlin, Mecklenburg-Western Pomerania, Brandenburg, Saxony-Anhalt: HendrikSeifert Tel030/70072459 Mobile0152/22887032 hendrik.seifert@roehm.biz

Hesse: KlausDieterHofmann Tel06406/906740 Mobile0152/22887029 k.d.hofmann@roehm.biz

Hamburg / Bremen / Schleswig-Holstein / Lower Saxony: WilliPhillipHövermann Mobile0152/22887148 WilliPhillip.Hoevermann@roehm.biz

Algeria: RÖHMS.A.R.L. 325,ruePaulLangevin 60740St.Maximin,FRANCE Tel0033/344641000 Fax0033/34640068 fr.roehm@roehm.biz www.rohm.fr

Argentina: HimaqS.R.L., Venezuela3652, 1603VillaMartelli Prov.BuenosAires Tel00541/147093505, Fax00541/147093472 himaq@himaq.com.ar

Australia: RÖHMAsiaPacificPte.Ltd. 8UbiRoad2 #07-10Zervex Singapore408538 Tel0065–64437748 Mobil0065–83288980 info@sg.roehm.biz www.sg.roehm.biz

FISHERLAMCOPTYLTD Tel00611300838572 mark.hughes@fisherlamco.com.au

Austria: RichardSchörkhuber Lichtenhof2b 8511St.StefanobStainz Tel0043/3463/81510 Fax0043/3463/81560 Mobil0043/664/9237710 richard.schoerkhuber@roehm.biz

SchachermayerGmbH, SchachermayerStr.2 Postfach3000,4021Linz Tel0043/732/6599-0 Fax0043/732/65991444 maschinenmetall@schachermayer.at

Lackneru.UrnitschGmbH Bahnhofgürtel37,8020Graz Tel0043/316/711480-0 Fax0043/316/71148039 lackner@urnitsch.at

HaberkornUlmerGmbH HoheBrücke,6961Wolfurt Tel0043/5574/695-0 Fax0043/5574/695-99 nfo.wolfurt@haberkorn.com

MetzlerGmbHu.Co.KG ObererPaspelsweg6-8,6830Rankweil Tel.0043/5522/77963-0 Fax0043/5522/77963-6 office@metzler.at

Belarus: RÖHMGmbH

Heinrich-Röhm-Straße50 89567Sontheim(Germany) Tel00497325–160 info@roehm.biz www.roehm.ru

Belgium: RÖHMS.A.R.L. 325,ruePaulLangevin 60740St.Maximin,FRANCE Tel0032495727399 Fax003242866948 frederik.hamels@roehm.biz www.rohm.fr

BELTRACY

Bergensesteenweg189 1600Sint-Pieters-Leeuw BELGIUM Tel.0032/25436890 Fax0032/25385910 info@beltracy.be www.beltracy.be

Canada: ROHMProductsofAmerica 2500NorthlakeDrive,30024Suwanee,GA Tel001–770-963-8440 Fax001–770-963-8407 rohmusa@roehm.biz www.us.roehm.biz

Chile: RobertKralemann SERVICOMPLtda. Av.Departamental1595 LaFlorida-Santiago Tel0056/2/8894700 rkralemann@gmail.com Colombia: RÖHMIND.ECOM.DE FERRAMENTASDEFIXAÇÃOLTDA. Rod.RaposoTavares,Km14-BlocoA 2ºandar-sala2-CEP05576-100 SãoPaulo Tel0055–11–37322222 Fax0055–11–37353097 vendas@rohm.com.br www.br.roehm.biz

Costa Rica: RÖHMIND.ECOM.DE FERRAMENTASDEFIXAÇÃOLTDA. Rod.RaposoTavares,Km14-BlocoA 2ºandar-sala2-CEP05576-100 SãoPaulo Tel0055–11–37322222 Fax0055–11–37353097 vendas@rohm.com.br www.br.roehm.biz

Croatia: PFEIFER-TTID.O.O. 40000Cakovec,Croatia Tel00385-9/8303522 Fax00385-1/3639530 marijan.pfeifer@pfeifer-tti.hr

Denmark: RyttergaardToolsA/S Falkevej13 3400Hillerød Dänemark +4536412266 info@ryttergaard.com

Ecuador: RÖHMIND.ECOM.DE FERRAMENTASDEFIXAÇÃOLTDA. Rod.RaposoTavares,Km14-BlocoA 2ºandar-sala2-CEP05576-100 SãoPaulo Tel0055–11–37322222 Fax0055–11–37353097 vendas@rohm.com.br www.br.roehm.biz

Egypt: DirkJaegemannTradeAgency GmbH&Co.KG 28279Bremen Tel0049/4218392130 Fax0049/4218398921 info@djta.de Finland: TeräskonttoriOy, Muuntotie3, 1510Vantaa Tel00358/102192200 Fax00358/102192245 info@teraskonttori.fi OyInterfiiLtd. Teollisuuskatu35-39LH4 20520Turku,Y-tunnus2374026-3 Tel00358/201474500 Fax00358/201474501 info@interfii.com

Greece: K.S.PAPADOPOULOS&CO EthnikisAntistaseosStr.7-A 55134Thessaloniki-Greece Tel00302310488758 Fax00302310488753 stefanos@agent.com.gr ntinos@agent.com.gr

India: RÖHMAsiaPacificPte.Ltd. 8UbiRoad2 #07-10Zervex Singapore408538 Tel0065–64437748 Mobil0065–83288980 info@sg.roehm.biz www.sg.roehm.biz

Indonesia: RÖHMAsiaPacificPte.Ltd. 8UbiRoad2 #07-10Zervex Singapore408538 Tel0065–64437748 Mobil0065–83288980 info@sg.roehm.biz www.sg.roehm.biz

PT.GermantaraToolingServiceIndonesia Jl.RayaBekasiKm.21 PulogadungTradeCentre(PTC)Blok8A/8 Jakarta13920-Indonesia Tel.+622146834110 Mobile+628119593027 kris@group.gts.co.id www.gts.co.id

PT.SOMAGEDEINDONESIA KomplekGriyaIntiSentosa Jl.GriyaAgungNo.3 SunterAgung,Jakarta14350-Indonesia Tel.+62216410730 avi@somagede.com www.somagede.com

Iran: SakhtAbzarParsCo.(SAP) No.19/4SaebTabriziSt., NorthAbbasShiraziAve, MollaSadraAve.,Tehranpostcode19917 Tel.0098/21/88031888 Fax0098/21/88037733 sales@sap-iran.com

Ireland: ROHM(GreatBritain)LTD. Unit12theashwaycentre ElmcresentKingston-upon-Thames SurreyKT26HH Tel0044-2085496647 Fax0044-2085411783 rohmgb@roehm.biz www.uk.roehm.biz

Iceland: FossbergLtd. Dugguvogi6,104Reykjavik Tel.00354/5757606 E-mail:fossberg@fossberg.is

Israel: ETMOSToolDistributingCo.Ltd. 34HAHOFERST.,5811702Holon Tel.00972-3/5581933 Fax00972-3/5581934 etmos@etmos.co.il

Japan: RÖHMAsiaPacificPte.Ltd. 8UbiRoad2 #07-10Zervex Singapore408538 Tel0065–64437748 Mobil0065–83288980 info@sg.roehm.biz www.sg.roehm.biz

TakedaTradeCo.,Ltd. NAKANOSHIMADAI-BUILDING603,3-3-23, NAKANOSHIMA,KITA-KU 530-6106OSAKA Tel.0081368060757 hata@takeda-trade.co.jp

Luxemburg: RÖHMS.A.R.L. 325ruePaulLangevin 60740St.Maximin,FRANCE Tel0033/344641000 Fax0033/344640068 fr.roehm@roehm.biz

Malaysia: RÖHMAsiaPacificPte.Ltd. 8UbiRoad2 #07-10Zervex Singapore408538 Tel0065–64437748 Mobil0065–83288980 info@sg.roehm.biz www.sg.roehm.biz

KSPrecisionTools(M)SDN.BHD. A1-01-05,1stFloor,JalanSR1/9 TamanSerdangRaya,Section9, 43300SeriKembangan SelangorDarulEhsan,Malaysia Tel.603-89417168 michael@ks-precision.com

Marocco: RÖHMS.A.R.L. 325,ruePaulLangevin 60740St.Maximin,FRANCE Tel0033/344641000 Fax0033/34640068 fr.roehm@roehm.biz www.rohm.fr

New Zealand: RÖHMAsiaPacificPte.Ltd. 8UbiRoad2 #07-10Zervex Singapore408538 Tel0065–64437748 Mobil0065–83288980 info@sg.roehm.biz www.sg.roehm.biz

TradeToolsLtd 23OliveRoad,Penrose POBox112114 Auckland1642,NewZealand Tel006495258882 sales@tradetools.co.nz

Netherlands: BoorwerkB.V., Flevolaan52A, IndustrieterrianNoord 1382JZWeesp Tel0031/294/432050 Fax0031/294/432152 mail@boorwerk.nl

RÖHMS.A.R.L. 325ruePaulLangevin BP90204 F-60744SaintMaximincedex Tel0033–344641000 Fax0033–344640068 fr.roehm@roehm.biz www.rohm.fr

Norway: Ing.YngveEgeA/S Ryenstubben5 0679Oslo11 Tel0047/23241000 Fax0047/23241001 ege@ege.no

Peru: RÖHMIND.ECOM.DE FERRAMENTASDEFIXAÇÃOLTDA. Rod.RaposoTavares,Km14-BlocoA 2ºandar-sala2-CEP05576-100 SãoPaulo Tel0055–11–37322222 Fax0055–11–37353097 vendas@rohm.com.br www.br.roehm.biz

Philippines: RÖHMAsiaPacificPte.Ltd. 8UbiRoad2 #07-10Zervex Singapore408538 Tel0065–64437748 Mobil0065–83288980 info@sg.roehm.biz www.sg.roehm.biz

NicklausMachineryCorporation 1795MalabonStreet Sta.Cruz,Manila1014Philippines Tel.+6327118414 Mobil+639178278812 nmcservice@yahoo.com www.nicklaus-machinery.com

Romania: KSNTechnikSrl Str.Tabacarilor15B/103 400139CLUJ-NAPOCA,Romania Tel0040/264/449-533 Fax0040/264/449-533 office@ksntechnik.ro

Russia: RÖHMGmbH Heinrich-Röhm-Straße50 89567Sontheim(Germany) Tel00497325–160 info@roehm.biz www.roehm.ru

Saudi Arabia, UAE, Bahrain, Kuwait, Oman, Quatar, Kazakhstan, Lebanon: RÖHMAsiaPacificPte.Ltd.

8UbiRoad2 #07-10Zervex Singapore408538 Tel0065–64437748 Mobil0065–83288980 info@sg.roehm.biz www.sg.roehm.biz COBALTMEFZE SAIFZONE QI-05-077/C Sharjah,VAE Tel.+971556834422 sales@cobalt-me.com

Sweden: TechpointSystemteknikAB Nyponvaegen4 19144Sollentuna Tel0046/86231330 Fax0046/86231345 info@techpoint.se

LunaAB

Sandbergsvägen3, 44180Alingsâs Tel.0046/322606000 Fax0046/322606203 info@luna.se

Singapore: RÖHMAsiaPacificPte.Ltd. 8UbiRoad2 #07-10Zervex Singapore408538 Tel0065–64437748 Mobil0065–83288980 info@sg.roehm.biz www.sg.roehm.biz

GPSystemSingapurPTELTD No.51,BukitBatokCrescent, #04-04/05UnityCentre, Singapur658077 Tel.0065/6861-2663 Fax0065/6861-3500 enquiry@gpsystem.com

Slovenia: BTSCOMPANYTRGOVINAIN ZASTOPANJE,D.O.O. Bratislavka5 1000Ljubljana Tel0038/615841440 masa.bitenc@bts-company.si

South Africa:

SupraToolingandAccessoires(Pty)Ltd P.O.Box1892 1460Boksburg,Gauteng SouthAfrica Tel.002764674284 Fax0027119185492 supratoolig@mweb.co.za www.supratooling.co.za

ToolingPromotions P.O.Box3989 Vanderbijlpark1900,Gauteng SouthAfrica Tel00270169311266 Fax00270169311269 info@toolingpromotions.co.za www.toolingpromotions.co.za

South Korea: RÖHMAsiaPacificPte.Ltd. 8UbiRoad2 #07-10Zervex Singapore408538 Tel0065–64437748 Mobil0065–83288980 info@sg.roehm.biz www.sg.roehm.biz

CHEONGDOMACHINETOOLCO.,LTD. RMA-6-103,604-1,KURO-DONG KURO-KU,SEOUL,KOREA Tel+82226784155 cdmt@chol.com www.cdmt.co.kr

KMCCo.,Ltd. Zipcode15090 42-404,204,Gongdan1-daero, Siheung-si,Gyeonggi-do,Korea Tel+82314306789 chelee@naver.com www.entkr.com

Thailand: RÖHMAsiaPacificPte.Ltd. 8UbiRoad2 #07-10Zervex Singapore408538 Tel0065–64437748 Mobil0065–83288980 info@sg.roehm.biz www.sg.roehm.biz

KrasstecCompanyLimited 1205Rama9Soi55,Rama9Rd, SuanLuang,SuanLuang Bangkok10250Thailand Tel66(0)27321144 Mobile66(0)819410509 chaithat@krasstec.com

Tunisia: RÖHMS.A.R.L., 325ruePaulLangevin 60740St.Maximin,FRANCE Tel.0033/344641000 Fax0033/344640068 fr.roehm@roehm.biz

Turkey: