SPRING OUTDOOR LIVING ISSUE • CO-BRANDING • PLYWOOD UPDATE THE VOICE OF THE LBM SUPPLY CHAIN February 2023 Digital Edition Sponsored by

NO COATING NEEDED HIGHLY DURABLE HIGHLY STABLE NON TOXIC WARRANTY Real Wood. Advanced Performance. Introducing the next generation of high-performance decking. Accoya Color Grey solid wood decking brings you the beauty and benefits of real wood, without the drawbacks. www.accoya.com Accoya Color is non-toxic and sustainable real wood. Kind to you and to the planet.

3 QUESTIONS Meet a series of extraordinary industry members in BPD’s newest regular feature, which kicks off with Christy McDowell, longtime sales rep with Swanson Group

4 • building products digest • February 2023 building-products.com ------------| CONTENTS February 2023 STAY CONNECTED ON SOCIALS: @BPDMERCH THE OFFICIAL PUBLICATION OF PROUD SUPPORTERS OF VOL. 42 • NO. 2 |-----------NEW COLUMN! WWW.BUILDING-PRODUCTS.COM FEATURES DEPARTMENTS 16 20 10 FEATURE STORY 10 hottest trends in deck railings 14 MARGIN BUILDERS How dealers can increase their decking sales via co-branding 16 INDUSTRY TRENDS Simmering thermally modified wood market about to hit full boil 20 INDUSTRY TRENDS Plywood predicted to push forward with slow growth worldwide 28 TRANSFORMING TEAMS Comparing total compensation to total cash compensation 32 SELLING WITH KAHLE The crippling disease of moderate success 08 ACROSS THE BOARD 24 OLSEN ON SALES 30 LUMBER 411 38 MOVERS & SHAKERS 40 NEW PRODUCTS 46 DATEBOOK 48 CLASSIFIED MARKETPLACE 48 IN MEMORIAM 49 ADVERTISERS INDEX 50 FLASHBACK

22

DIGITAL EDITION CHECK OUT THE SPRING OUTDOOR LIVING ISSUE CO-BRANDING PLYWOOD UPDATE February 2023 10

COMMITTED TO EXCELLENCE. The Trusted Brand in Pressure Treated Lumber culpeperwood.com 2X6 DECKING 5/4 DECKING DECK ACCESSORIES STEP STRINGERS LATTICE MAILBOX POSTS BALUSTERS HANDRAIL TURNED SPINDLES ROOF CANTS GRADE STAKES DIMENSIONAL LUMBER KDAT FENCE PANELS FENCE BOARDS SPLIT RAIL ROUNDS SQUARE COLUMNS TURNED COLUMNS PRIMED TRIM BOARDS HEAVY TIMBERS PLYWOOD PORCH FLOORING TONGUE & GROOVE CUSTOM MILLING PILING

PRESIDENT/PUBLISHER

Patrick Adams padams@526mediagroup.com

VICE PRESIDENT

Shelly Smith Adams sadams@526mediagroup.com

PUBLISHER EMERITUS

Alan Oakes

MANAGING EDITOR

David Koenig dkoenig@526mediagroup.com

SENIOR EDITOR

Sara Graves sgraves@526mediagroup.com

COLUMNISTS

James Olsen, Kim Drew, Claudia St. John, Dave Kahle

CONTRIBUTORS

Jeff Easterling, Susan Palé, John Rooks, Brandy Zimmerlee

ADVERTISING SALES (714) 486-2735

Chuck Casey ccasey@526mediagroup.com

Nick Kosan nkosan@526mediagroup.com

VIRTUAL EVENTS

Alek Olson • aolson@526mediagroup.com

CIRCULATION/SUPPORT info@526mediagroup.com

A PUBLICATION OF 526 MEDIA GROUP, INC.

151 Kalmus Dr., Ste. E200, Costa Mesa, CA 92626 Phone (714) 486-2735

BUILDING PRODUCTS DIGEST is published monthly at 151 Kalmus Dr., Ste. E200, Costa Mesa, CA 92626, (714) 4862735, www.building-products.com, by 526 Media Group, Inc. (a California Corporation). It is an independently owned publication for building products retailers and wholesale distributors in 37 states East of the Rockies. Copyright®2023 by 526 Media Group, Inc. Cover and entire contents are fully protected and must not be reproduced in any manner without written permission. All Rights Reserved. BPD reserves the right to accept or reject any editorial or advertising matter, and assumes no liability for materials furnished to it. Opinions expressed are those of the authors or persons quoted and not necessarily those of 526 Media Group, Inc. Articles in this magazine are intended for informational purposes only and should not be construed as legal, financial, or business management advice.

6 • building products digest • February 2023 building-products.com BPD SUBSCRIBE TODAY OUR MARKET MOVES QUICKLY—SO DON’T GET LEFT BEHIND! BPD is available on a qualified requester basis to senior management of U.S.-based dealers and distributors specializing in lumber and building materials, and to others at the rate of $22 per year. Subscribe now at www.building-products.com/subscribe. SUBSCRIBE NOW AT WWW.BUILDING-PRODUCTS.COM/SUBSCRIBE BPD - BUILDING PRODUCTS DIGEST SUBSCRIBE TO RECEIVE PRINT, DIGITAL, ENEWSLETTER & MORE! The LBM supply chain’s leading publication for qualified industry decision makers! • Update your subscription • Sign up key colleagues • Enroll multiple locations

anYthing else

is playing with fire.

anYthing else is playing with fire.

You demand safe, quality products with the same relentless standards as we do. And that’s why you choose ProWood® FR. The structural durability of our fire-retardant treated lumber and plywood has been verified by certified engineers to ensure we are providing you with high-quality code-compliant products.

PLYWOOD | LUMBER | WALL ASSEMBLIES | BACKER BLOCK ProWoodLumber.com/FR

customerservice@prowoodlumber.com

THE WAY IT WAS, THE WAY IT IS

BY PATRICK ADAMS

I SUPPOSE IT HAPPENS to everyone. I remember when I was younger and I would listen intently to older people. I always wanted to get ahead, to escape the life I was living, and to live a life that was filled with more meaning and purpose than those who surrounded me. Their stories seemed to often include the phrase, “The way it was.”

But now, I find myself more and more thinking about how things used to be. Indeed, maybe days of the past were more simple, but then again maybe so was I. Maybe the world is more connected now with technology and social media, but maybe I seek it out more now for hints of wisdom or information that will help me to make good decisions. Perhaps there used to be more time, or maybe my life now is just more demanding.

I find myself pondering this dilemma more and more these days as I struggle to find a “balance,” whatever that is. It is true that things used to be simpler. When you have little, and few people around you who matter, things are “simple” because you simply have fewer choices to consider. It is easy now with a blessed life to fall into the mindset of cursing the demands of your life. As we attempt to run faster and faster on this hamster wheel of life, it can feel exhausting and thankless.

As I’ve challenged myself to dig deeply into these thoughts, they are the thoughts of being tired, or selfish or weak. Yes, things have changed today from the way they used to be… because we changed them. People are different today, because so are we. If we have less time, it’s because we’ve made other things a priority in our lives or taken on too many things that we deem as “top priority.” The way it is is of our own doing and, like so many things in life, the way it was is simply our wonderful way of only remembering the best of what once was.

I believe our lives can be as great as we are willing to make them. I do not subscribe to the news of today that the world is falling apart because I have worked hard to find a “tribe” of individuals around me who have values, who work hard, are caring, giving and selfless individuals.

They inspire me and give me faith that because I am also part of their tribe, there must also be something of value inside of me.

Yes, this is perhaps a more deep and personal article than normal, but, as always, I aspire to be transparent and the humble servant to others that brings me personal happiness. I believe that if I sometimes feel these things, that others must too. I think what has changed is that it takes a more deliberate effort to purposely surround yourself with the things and people that bring out the best in you. Whether it is temptation or bad influences, access to those bad actors are more easily at your fingertips than ever before. I have found that as I’ve gotten older, that young, intent listener seeking out wisdom and insight has gone into hibernation.

However, it is time to wake up. Yes, it is overwhelming to consider changing the world, or what the world is today. But your world is not “Earth;” it is what is at your doorstep today. It is your family, your friends, your colleagues, your community. This is a very small world and well within your ability to influence... for the worst, not at all, or perhaps for the better.

Yes, there are many concerning things going on in the world today, but there always has been. When you look back on history, that is the norm. Never forget that in less than just 300 years, we have founded a nation, had a Revolutionary War and a Civil War and two World Wars, a Great Depression, and untold acts since that could fill a library. And yet, today I sit surrounded by an amazing team, serving an amazing industry of individuals I am lucky enough to call friends and tonight, I will go home to a family that I am blessed to call my own.

The way it is today is just as good and the future is bright, if you choose to seek out that lens to look through every day. As always, thank you for the privilege of serving each of you and this great industry.

PATRICK S. ADAMS, Publisher/President padams@526mediagroup.com

8 • building products digest • February 2023 building-products.com

------------| ACROSS THE BOARD

10 HOTTEST TRENDS IN DECK RAILINGS

------------ BY DAVID KOENIG

DECK RAILINGS, once an afterthought, have become a primary focus in outdoor living projects. With the options multiplying, make sure you sell and stock what contractors and homeowners want.

“Since product availability is no longer a major issue and consumers are much more price-conscious than in previous years due to the economic climate, stocking an on-trend product that can satisfy buyer’s design-oriented preferences at a reasonable price point will be critical to maximizing investments up and down the channel,” notes Don Douglas, senior product manager at Fortress Building Products.

Here’s what’s hot in railing materials, colors and styles: Aluminum,

Aluminum, Aluminum

By far, the trend most cited by railing manufacturers was the growth in aluminum. BuyRailings.com, among others, is experiencing particularly strong growth in aluminum railing systems, which offer durability, anodized or

color finishes, infill panels, and easy installation.

Powder-coated aluminum railing provides the low maintenance that is demanded of all outdoor living products, is simple to install, and is available at a lower cost than composite railing,” explains Rob Mitchell, president and CEO of Vista Railings. “It also has growing design versatility available, as picket, framed glass, frameless glass, cable railing, and privacy wall.”

“We’re seeing a lot of people switching from PVC, steel and composites to aluminum,” adds Joseph Moriarty, new business development manager for Specrail Aluminum Products. “It may not be cheaper than wood, but it offers advantages strength-wise, is easy to install, stands up to the elements, and won’t rot or rust. Those are big advantages, especially in any area near water. And it’s so versatile. We offer a lot of options in color and infill materials. Other materials don’t offer as many options.”

Christopher Manduka, co-founder of Cable Bullet, also foresees continued growth for aluminum rail components.

1 10 • building products digest • February 2023 building-products.com

CABLE, glass and bar railings open up sightlines for homeowners with a view. (Photo by Vista Railings)

------------| FEATURE STORY

“Aluminum is not only long-lasting and requires minimal maintenance, but has an expediency and ease-of-install that appeals not only to professional contractors and homeowners, but also DIY builders,” he says. “Aluminum systems, by nature of the materials, are a more applicable option for affixing to existing structures.”

Deckorators, which introduces dozens of new products each year, is banking heavily on aluminum in 2023, with a wealth of new aluminum railing enhancements. New additions include expanded post sizes, two-piece brackets, color-matched cable rail spacers, and bracket install templates to improve ease of installation, and customization for its lines of Aluminum Contemporary Rail, Contemporary Cable Rail, and Aluminum Rapid Rail.

Open-Concept Railing

The second-most-mentioned trend was the rise in cable and glass railings, driven primarily by homeowners who want railings that don’t block their nice views. “Consumers want or need a railing either for safety concern, aesthetics or to meet building codes. But they don’t want this to limit the view of their outdoor living space or the view from the deck or patio,” says Mary Gearhart, marketing manager for Digger Specialties. “Both cable railing and glass railing are growing in popularity allowing the safety of railing while not obscuring the view.”

Robert P. Viviano, president of Invis-A-Rail producer 3G-Industries, also sees the “increasing trend toward the need for transparent railings. (Use on) lakefronts and ocean view areas is a no-brainer. However, we are seeing an uptick in your average backyard for transparent rails where customers want to see the kids and garden areas.”

ALUMINUM Rapid Rail from Deckorators is the direct result of listening to its Certified Pro Network. The new line pairs ease of installation with quality powder-coated aluminum in a stylish textured-black and an overall contemporary design that will work seamlessly with a variety of home styles.

Privacy Railing

While many homeowners do seek railings that open up their views, others want to achieve the opposite. “With the proximity of houses in newer neighborhoods, there is an increasing demand for privacy in your outdoor living space from your noisy neighbor,” notes Vista Railing’s Mitchell. “This can be achieved in a variety of ways using more opaque railing infills including frosted glass, composite slats, or decorative panels.”

Mix & Match

The wide variety of colors and textures now available allows deck designers to better match the exterior of the home, to carry the interior theme outdoors, or to create interesting combinations.

Vista Railings is seeing homeowners mixing black balusters with white railing and posts, which matches their house trim.

“Mixing and matching railing colors and textures can also offset a beautiful composite deck,” says Matthew Bruce, VP–sales for MoistureShield. “For example, composite railings maybe work best in white, matched to the deck color or as an edgy contrast to black.”

5 4 7

“I think the most important thing driving the railing business is matching railing to the decking, either complementary or contrasting,” says NewTechWood America’s Richard Lam. “One of the issues that falls on other composite decking companies is that it doesn’t

Darker Colors

Expect to see more dark, textured colors in railings, primarily driven by the desire to lessen view-blocking. “Darker colors, particularly with black, your eye looks beyond the railing to the view beyond,” explains Vista’s Mitchell. “This effect is enhanced when the railing surface is non-glossy—in other words, a flat or textured black. Think textured black aluminum railing with stainless steel cable infill.”

Fortress’ Douglas says, “Matte black will continue to be in high demand, especially since black has become a popular color choice for house window trim. Homeowners are paying close attention to these types of finishing details because they want their outdoor living space to complement their home’s exterior—creating a truly seamless design aesthetic.”

Customized Options

How the deck will be used should determine how it should be designed. “For function, consider how the homeowner lives on their deck,” says MoistureShield’s Bruce. “If they entertain, a flat cocktail top rail may work well or if they like to relax and take in the view, selecting a round baluster or trendy cable rail will enable them to enjoy the view.”

Personality-Driven Design

Since exterior design trends tend to follow interior trends, 2023 should lead us to a transitional period

2 3 6 building-products.com February 2023 • building products digest • 11

always match. If you look at all the composite railing out there, it’s all smooth with zero embossing. This really creates a dilemma for the customer as they have this nice woodgrained-out deck and when they get the matching color railing, it’s as smooth as can be. For us, it is the opposite; we are able to put a nice grain on all the railing products to give a matching look and feel.”

from neutral tones and blank spaces to a combination of rich colors dotted with modern touches, suggests Chase Moritz, director of marketing and communication for Envision Outdoor Living Products. “Designers are predicting a strong desire to have more fun with surroundings and create a personalized, color-rich space. We crave stimulating color and texture palettes and ‘plain Jane’ decks don’t provide the visual interest that creative installations and colorful accents do.”

He considers homeowners to be more design savvy than ever before and with so many resources online, from Pinterest to their favorite influencers or TV personalities, they’re able to curate a specific look for their space. “The balance to the rich color palette for any space can be balanced with modern railing that mixes materials for an added punch,” Moritz says. “Antique bronze aluminum railing with black horizontal balusters are right on trend for that personality driven design.”

3G Industries responded to more traditional home styles’ demanding railing transparency without looking “too contemporary” by introducing a black powder-coated stainless infill system. The line has quickly grown to 50% of Invis-A-Rail’s sales compared to its all stainless system.

Easier Installation

“DIYers, installers and homeowners are looking for a fast installation,” says Digger’s Gearhart. “With the current workforce issues, being able to install a quality railing in a short amount of time is a money-saver for the consumer when hiring an installer, and the ease of installation for a DIY installer is a must for the self-installation warrior.”

Moritz says, “As homeowners become more comfortable with DIY projects, they will lean toward products that look great and feel simple to install on their own. For those who want a sleek modern look but may be intimidated by cable railing, a horizontal baluster infill is a great option. At a fraction of the cost of cable rail and simple installation, we are anticipating this to be a popular product for the DIY crowd.”

Invis-A-Rail’s Viviano agrees that the need for simpler installations is increasing due to the shortage of skilled labor. “Simpler is better and also fewer SKUs to deal with is better,” he explains. “We keep hearing from dealers how they like the fact Invis-A-Rail is only a two-part system that covers both the level and stairs.”

Low Maintenance

As we have come out of the pandemic, people seem now to be busier than ever with getting back to normal, which means taking advantage of any opportunity to get rid of unnecessary maintenance on chores around the home.

Envision’s Moritz advises, “Low maintenance railing options—like aluminum, vinyl or steel—save real time and money in the long-term for homeowners who don’t want to spend their down time staining or painting their wood deck and railing each spring. They’re instead able to spend that time relaxing or entertaining in their beautiful outdoor space.”

Safety & Accessibility

Deck safety is always a critical aspect of any outdoor space and ensuring the products homeowners and contractors choose to put on their projects meet code compliance and testing requirements is extremely important. You want to know that the products chosen will keep family and friends safe.

Likewise, adds Moritz, “as the Boomer generation retires, they’ll be spending more time at home in these spaces they’ve worked so hard to build for themselves. Aging in place becomes a big factor in that next phase and building a space that’s accessible as they age is important. Choosing products that enable that accessibility, like railing with a graspable top rail or even an ADAcompliant secondary handrail, ensure they can use and enjoy that outdoor space for as long as possible.”

Lock on these 10 deck railing trends to help your contractor and homeowner clientele build the decks of their dreams. BP

10 8 9 12 • building products digest • February 2023 building-products.com

ON-TREND DIY project features Envision’s CP315 composite railing with cable infill and Distinction Rustic Walnut composite decking and drink rail.

NEW COMPASS Series Aluminum Railing from MoistureShield, in black or bronze, adds a contemporary, sophisticated look to any deck design and has a superior powder-coating to resist the elements.

1-800-347-2860 Orgill.com Help our customers be successful Knowledge Dedication & Count on your Orgill sales rep for: • Regular in-store service • Indust ry knowledge • Purchase planning & support • Guidanc e with specialty programs, services ...and much mor e!

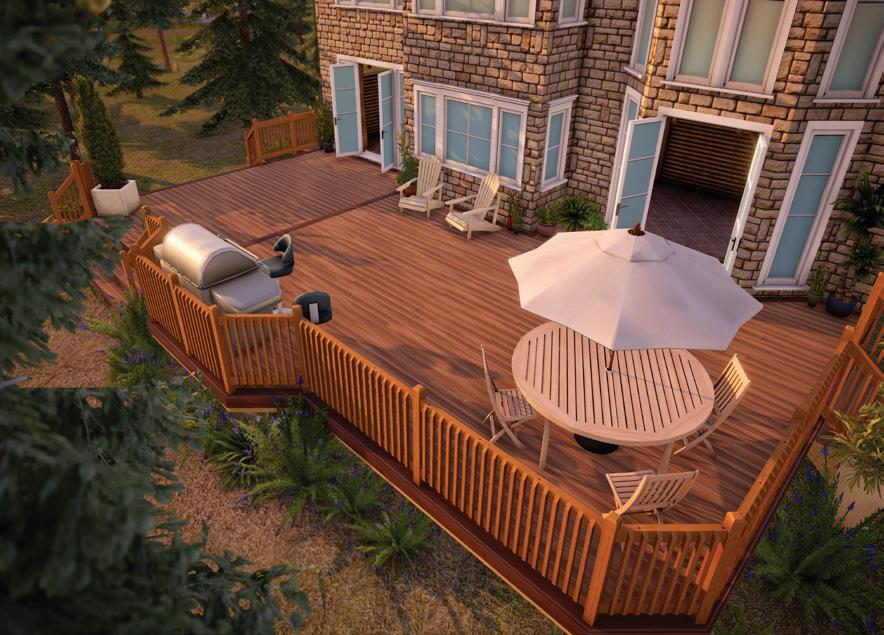

UP DECKING SALES VIA CO-BRANDING

------------ BY BRANDY ZIMMERLE

BRIDGING THE BRAND EXPERIENCE FROM POINT A TO POINT-OF-SALE

THEY SAY YOU only have one chance to make a first impression and, for decking dealers, that first impression is most often made online where contractors and homeowners typically begin their research. Connecting the dots between that first impression and the final sale is a journey with numerous touchpoints and opportunities to either land—or lose—a prospective customer. The key to effectively capturing and converting those leads in your favor lies in your ability to carry them from one point to the next in their decision-making process

without disrupting the factors and feelings that attracted them in the first place.

I have become a firm believer in the power of co-branded marketing. Co-branding is a powerful strategy that can take your business to new heights by:

• Increasing your customer base

• Enhancing credibility/recognition

• Strengthening customer loyalty

• Boosting sales

National-to-local co-branding occurs when a local business partners

with a nationally known brand. The goal of this partnership is to increase national brand awareness while increasing small business revenue. For decking dealers, partnering with a nationally recognized brand can help boost consumer confidence and facilitate a smooth transition for prospective buyers from Point A to the point of sale.

At Trex, we work with our channel partners to execute a three-pronged co-branded marketing strategy focused on delivering a consistent brand experience from inspiration to installation.

1. Online

Like most consumers, decking contractors and homeowners tend to begin their project planning online. Thus, our co-branded marketing approach starts at Trex.com where visitors are introduced to our brand and

14 • building products digest • February 2023 building-products.com

LOCALIZING national brand commercials with dealer logos is a smart and easy way to drive local awareness and traffic.

------------| MARGIN BUILDERS

CO-BRANDED landing pages serve to seamlessly transition visitors from Trex.com to their local dealer’s website.

products. If they like what they see, they can click a convenient “Where to Buy” button that is visible at the top of every page to be directed to local dealers and retail locations in their area. Dealers with co-branded pages on their websites are then able to continue the brand experience uninterrupted via messaging and visuals that mirror the national brand site.

When executed as a cooperative effort between branding partners, the transition from the national platform to the local destination should be so seamless that visitors don’t even realize that they have migrated from one space to the other.

2. Showroom

Decisions about decking are not typically made without at least one visit to a retail store or dealer showroom. Unfortunately, this is where things often fall short. A showroom cluttered with conflicting messages, outdated collateral, and displays in disarray can be overwhelming and counterproductive. To keep potential buyers excited and engaged during this critical point in the purchase process, make sure your showroom is playing off the first impressions created online. Consistent messaging, branding and visuals from the online space to the physical showroom space are key!

We find that dealers who fully embrace the co-branded marketing approach are most successful when it comes to converting leads into sales. One dealer reported a $30,000 sale driven by the impact of a co-branded in-store display. The lifestyle imagery echoing the national advertising campaign, combined with product brochures and board samples featuring visuals and messaging consistent with our website, armed the showroom sales team with all the tools needed to pay off the brand’s promise and close the sale. In just a matter of days, the display had more than paid for itself in booked projects.

3. Local Advertising

One of the most effective ways to help area consumers learn more about your business and the prod-

ucts and brands you carry is through advertising. This is the third prong in our co-branded marketing strategy. Each year, we spend millions of dollars in national advertising to drive brand awareness and preference among consumers. Our most successful dealers are those that leverage these national assets by tagging our national commercials, using imagery from our national campaigns in their local advertising efforts, and taking advantage of a whole host of other assets at their disposal.

By leveraging the profile and reach of a national partner, co-branding campaigns can deliver more leads, buzz and awareness for your

business, with a lot less work. They also allow manufacturers and retailers to collaborate more closely on the creation of marketing strategies that connect the dots for consumers from the first brand impression to lasting local loyalty. BP

building-products.com February 2023 • building products digest • 15

IN-STORE MERCHANDISING tells the Trex brand story and reinforces the local dealer’s connection to the national brand.

BRANDY ZIMMERLE

Brandy Zimmerle is channel marketing manager for decking and railing manufacturer Trex Co. (www.trex.com).

SIMMERING THERMALLY MODIFIED WOOD MARKET READY TO HIT FULL BOIL

------------ BY DAVID KOENIG

ALTHOUGH thermally modified timber (TMT) is a staple of construction markets in Europe, the products have yet to gain widespread acceptance in North America. Over the past 15 years, companies, primarily from Europe, have had a tough time trying to plant a foothold in the U.S.

Yet a confluence of factors—from new facilities to expansions to new distributors—suggests that TMT may

finally be on the precipice of taking off in the U.S.

The Temperature’s Changing

Modified wood producers fundamentally change the cellular makeup of the wood, most commonly by heating it in a low-oxygen chamber. Sugars are burned away, eliminating the target of decay and insects. The

wood reacts differently to moisture— the primary cause of rot. The wood’s color becomes darker, more closely resembling that of tropical imports. Durability and dimensional stability increase. And, the TMT treatment process uses only heat and steam, so it’s green.

At $534.59 million in 2021, TMT currently holds less than 1% of the $690-billion global wood market, growing 3.5% annually from 2016 to 2020. TMT is forecast to reach $892.70 million by 2028 and $1.95 billion by 2031.

“We can feel the growth,” says Chase Morrison of Sunset Moulding, Live Oak, Ca., manufacturer of Pakari thermally modified decking. “Until recently, the crossover between our fingerjoint customers and our Pakari customers has been basically zero. That’s starting to change. Longtime customers are starting to ask about thermal modification and how it can be used with their products. On top of that, we are getting weekly calls from completely new companies asking about Pakari and about the possibility for us to thermally modify their own lumber.”

This spring, Arbor Wood Co. will begin production at a larger facility in Grand Rapids, Mi. Accoya USA (an Accsys joint venture) is building a new plant in Kingsport, Tn., to double the company’s capacity when it

16 • building products digest • February 2023 building-products.com

------------| INDUSTRY TRENDS

NEW TO THE U.S.: Nova USA Wood Products, Portland, Or., is introducing Rhino Wood, thermally modified wood produced in South Africa from plantation-grown South African pine.

is completed in early 2024. Kebony North America, which like Accsys is currently running at maximum capacity, reportedly has a U.S. build in the works. And Tantimber recently invested $12 million expanding its plant in Turkey primarily to supply product to the U.S.

South African TMT producer Rhino Wood is entering the U.S. through Nova USA Wood Products, Portland, Or.

Tantimber began targeting the U.S. last year, and continues to add to its list of regional distributors, including Holbrook Lumber Co., Guilderland Center, N.Y.; J. Gibson McIlvain, White Marsh, Md.; and U.S. Lumber Brokers, Del Valle, Tx.

“When you see the Europeans starting to market and sell in North America, you know that the market is starting to take off,” says Bob Lennon, president of Thermalwood Canada.

Last year, Thermory USA increased sales 12%. Kebony volume rose 30%. Accoya’s North American sales in 2022 grew 44%. That could be just the beginning.

ty due to the square footage involved, TM wood holds an imperceptibly small slice of the siding market. As a result, there’s really just one direction to go.”

Pakari’s Morrison agrees: “There’s no doubt that decking and siding make up the lion’s share of TMT usage. I believe siding has the largest growth potential in millwork, but there are so many other uses for the tech. TMT is used for outdoor furniture, musical instruments (guitars/violins), gunstocks. Thermally modified wood has even made it into the wine industry. TMT oak chips are used to flavor wine when being aged in steel containers.”

the explorer mindset, focusing on bigger picture things in the materials they seek and eventually choose to design with.”

Consequently, Kebony and others have targeted architects more than other sectors to build a foundation of sales.

The Slow Burn

TMT’s properties and aesthetics make it ideal for exterior applications. Decking and cladding have been the primary uses of thermally modified wood in the U.S. and offer the greatest potential for growth. “Decking is a traditional entry point for TM producers because it is the most common use for outdoor wood today,” explained Matt Pryor, director of specialty sales for Bingaman & Son Lumber, Kreamer, Pa., supplier of Americana TMT. “Decking is also the harshest environment for any product, making it a good proving ground. Although siding is a larger opportuni-

So why hasn’t TMT caught on already in the U.S.? “TM wood is a niche within a niche, a curiosity in a world dominated by imitations, but we are growing,” says Bingaman’s Pryor. “It takes a lot of infrastructure and a ‘craft-brewing’ approach to pull it off. That’s part of the charm. At this stage, interest spreads largely by word of mouth.”

Most proponents of TMT attribute America’s slow acceptance to the industry’s reflexive reluctance to change. “The U.S. builder is traditionally slow to adopt new materials, and for good reason as many have come and gone,” says Ben Roberts, marketing director for Kebony North America. “Architects carry more of

“The biggest thing is legacy thinking in the United States,” echoes Mehmet Zenginler, managing partner for Tantimber. “It’s an industry that moves forward really slowly. Change is very difficult for this industry. We want to educate the market. The lack of education is almost scary, but also exciting because there’s so much potential. We believe in 10 years thermally modified wood can be just as big as composites.”

Roberts adds, “I do not think it is a stretch to visualize modified woods being 20% to 25% of the overall decking and cladding markets in the U.S. over the coming few years. They are just too logical and common sense-driven not to.”

Pakari’s Chase Morrison predicts that before too long the term “thermally modified” will be as ubiquitous as “pressure treated.” He says, “My sales pitch to architects would always start with explaining what thermal modification is and how the process works. I don’t have to do that anymore. Architects already know what thermal modification is and are

building-products.com February 2023 • building products digest • 17

WOOD’S PROPERTIES are transformed on a cellular level inside a heating/steaming chamber, such as a Thermory Thermokiln.

“THERMALLY MODIFIED WOOD IS A NICHE WITHIN A NICHE, A CURIOSITY IN A WORLD DOMINATED BY IMITATIONS, BUT WE ARE GROWING.”

actively seeking it out. They only have two questions for me now: ‘What colors does it come in?’ and ‘How long is the lead time?’”

Time to Cook

To be honest, you probably can’t count the number of times you’ve heard about a maturing product that’s finally ready to break through... and doesn’t. But there are numerous reasons to believe that this may really be TMT’s time to shine. Consider:

• The growing desire for green building products. “We would attribute much of the growth to consumer preference toward more natural, and sustainable building materials that don’t contain harmful chemicals and retain the natural beauty of wood,” says Arbor Wood director of sales & marketing Andrew Ellingson. “There are also a growing number of certifications for green building that the use of thermally modified wood can contribute to.”

• TMT’s exotic look. “Consumers are realizing that they do not need to use exotic woods for that aesthetic, but they could use indigenous species from North America to get the same look,” says Thermalwood Canada’s Lennon.

• Increased availability. In addition to rising production and a growing number of TMT manufacturers focused on the U.S., global transportation conditions have also improved since the pandemic tied up containers and sent shipping cost soaring. “The price (to ship containers) is getting better, congestion is getting better,” says Tantimber’s Mehmet Zenginler. “Last year, it cost us $14,000 to ship a container to Stella-Jones. It’s down to $7,000.”

• Adaptability to new species. Most manufacturers specialize in a particular type of wood, since each species and thickness requires a different treatment temperature and duration to achieve proper modification levels. Thermory USA recently released a new product utilizing red oak since ash has been experiencing fiber constraints due to the emerald ash borer beetle.

Bingaman & Son Lumber saw most of the industry focused on low-cost softwoods like pine, SPF and radiata

Not All Modified Wood Is Created Equal

The majority of what is considered modified wood is thermally modified. It undergoes a non-proprietary heating process to remove the sugars in the wood to make it insect resistant. You are essentially removing mass from the wood, making it less durable.

But wood can also be chemically modified. These treatments similarly change the structure of the cell walls to make the wood more insect and rot resistant, but without removing mass from the wood, preserving durability. Accoya uses acetylation to treat the wood with a non-toxic, vinegar-like chemical that basically “pickles” the wood, transforming a softwood into a hardwood.

Kebony modifies wood both thermally and chemically. Kebony uses furfurylation, which treats the wood with furfuryl alcohol then heat-treats it to polymerize the wood. The dual process provides greater durability, rot/insect resistance, and an “ipé” color.

pine. So it decided to go with North American hardwoods for its Americana thermally modified products.

• Programs that make adoption easier. Manufacturers and their partners are devising creative ways to convince distributors, dealers, builders and architects to take a closer look at modified wood. Kebony now focuses on “off-the-shelf” systems to give the marketplace ease of accessibility and use. As Roberts explains, “Architects like well-designed systems that save them time, that are superior as a building design/practice, and save them callbacks. Distributors and retailers like well-designed, off-the-shelf systems to stock and easily turn with few issues.”

G Wood Pro, Tantimber’s U.S. distribution arm, is coming to market with its Upfront program, which allows distributors to pre-book a container for the following year at the current year’s prices. They’ll also provide an exclusive distribution territory, elite customer service, marketing support, sales materials, in-person training— it’s all a “no-risk value proposition.” If for any reason the partnership fails to meet distributors’ expectations, G Wood Pro will buy back any unsold inventory.

• A now-proven track record. Thermal modification isn’t a brand new technology that the industry is being asked to adopt with blind faith. Just look overseas at its 30 years of proven performance.

“If you take Europe and leading the way, when it comes to wood technology we are always 10 years behind,” says Thermalwood Canada’s Lennon. “The biggest opportunity of growth is education. It is still surprising to hear people who have not heard about this technology. But once they do, they are interested. I have been educating architects and end-users for the last 14 years, and those activities are starting to pay off.”

TMT producers are ramping up, anticipating America is finally ready. Bingaman’s Pryor says, “We, and others like us, see the unmet appetite for authentic, long-lasting, locally harvested outdoor wood, and we’re investing in its future. Does the world really need more plastic? More fiberglass? Solid wood remains the only building material that grows back. Thermal modification allows the best of nature to once again live where it was formed—outside.” BP

18 • building products digest • February 2023 building-products.com

DECKING and cladding dominate the thermally modified wood market in the U.S., although TMT can be used for windows, doors, furniture and a host of other applications. (Photo by Pakari)

Transform

The Outdoor Living Experience

Whether you are adding railing to a front porch, single or multi-level deck, or balcony, we have an option to fit any style. Westbury® Aluminum Railing by Digger Specialties, Inc. offers safety, durability, and lasting beauty. Designed for easy installation, Westbury® Aluminum Railing is the superior choice for contractors.

Scan QR Code to request a FREE Aluminum Color Selector and Product Packet to begin Transforming the Outdoor Living Experience®

PLYWOOD PREDICTED TO PUSH FORWARD

THE WORLDWIDE market for plywood is estimated to grow 6.2% annually over the next five years, rising from a market size of $54.2 billion in 2022 to $73.3 billion by 2027, according to a recent forecast by MarketsandMarkets.

Based on application, construction is expected to be the largest segment during the forecast period. Over the medium term, construction will be a growth engine for the global economy, with growth averaging 4.4% between 2020 and 2025. The global construction market is expected to grow by $4.5 trillion between 2020 and 2030, reaching $15.2 trillion. Of this total, $8.9 trillion will be in emerging markets in 2030.

The positive predictions are welcome news to manufacturers. “Being in the trenches of the panel industry, we tend to look at the glass half empty,” says Tyler

Freres, VP of Freres Lumber, Lyons, Or. “I think that 2023 is going to start with a very challenging economic environment. We need to see some moderation in inflation, a stabilization of the Fed’s interest rate hikes, and indications from consumers that they are willing to invest in housing at higher rate levels. A modest decrease in housing starts, say down to the 1.3 million level, is something that the producers can adjust to. A more significant reduction in starts would be difficult.”

He notes that the last three years for panels have been a series of six-month boom-and-bust cycles, alternating in the beginning and end of each year.

According to the forecast, growth is projected to be concentrated in a few nations. China, India, the United States, and Indonesia should account for 58.3% of worldwide building growth between 2020 and 2030. Over the next decade, 10 markets will likely contribute about 70% of the $4.5 trillion in growth.

Because softwood plywood is used mainly in the construction industry for structural purposes, demand for softwood plywood should considerably outpace demand for hardwood plywood.

The Asia Pacific region has become the largest market for plywood across the globe. China accounted for the largest share of 80.0% of the Asia Pacific plywood market in terms of value. India and China have experienced close to double-digit Gross Domestic Product growth in recent years, as well as a population boom. The stable economy and growing building and construction industry has augmented the growth of plywood in India and China. Furthermore, the furniture sector is one of the main consumers of plywood in India.

During the 2018 to 2023 period, it is predicted that the India furniture market by commercial sector will experience annual growth of 11.97%. India is the fourth-largest consumer of furniture worldwide and the fifth-largest producer of furniture. The Indian furniture industry is estimated to be worth $8 billion and represented 0.5% of the GDP in 2022. BP

20 • building products digest • February 2023 building-products.com

------------| INDUSTRY TRENDS

MEDIUM-TERM FORECAST for plywood production globally is for modest growth.

NEVER SETTLE. Become a Dealer ProWoodLumber.com/Dealer built to last. DECKING | FENCING | RAILING | TIMBERS built to last. partnershipS partnershipS FORFOR

You stock your shelves with the best lumber. And your customers depend on you for it. We get it. For ProWood®, that’s not enough. It’s about selection and availability. It’s about standing behind our product. It’s about trust and relationships. It’s about building something. Together.

3 QUESTIONS:

SWANSON GROUP’S CHRISTY McDOWELL

THIS MONTH, BPD begins a new series of brief interviews with extraordiary members of the industry, beginning with Christy McDowell, 50+-year sales veteran with Swanson Group, Glendale, Or.

The company was founded in 1951 by her father, Rod Swanson, and uncles Dean and Harry Swanson. Dean’s son, Steve Swanson, currently serves as CEO, overseeing facilities in Glendale, Roseburg and Springfield, Or.

1

Tell us about your start at Swanson. Did you work directly with your father and uncle?

McDowell: Not at first. When I started full time in 1972, I was in my 20s. They called me back just to answer the phones. I’d been in an accident. My neck had been broken, and I’m a quadriplegic. So they called me back just to answer the phones, and I got bored real quick. So it worked into typing invoices and bills of lading for the railroad—we did not have computers back then. I only had use of my left hand, so one-fingered typing.

In the 70s when everything shut down, we used to take turns, working two weeks on, two weeks off, and do whatever was needed—payroll, accounts receivable. I became a jack of all trades.

I tried to stay away from (moving into) management because of

the fact that with my disability I can’t travel and it could be difficult trying to go into places. It seemed like I could get there, but then couldn’t get into the building. So I stayed away from management and, until the company could find another salesperson, I moved into sales when my brother left the company.

I’m still in sales. I’ve cut back to where I’m just basically the lowgrade side. I have banker hours.

2What have been the greatest challenges over the years? There couldn’t have been many women in lumber sales in the 1970s.

McDowell: No, there were not. But actually, all the guys I met I’d already been talking on the phone with them through my brother. It wasn’t that hard of a transition. Everybody was very upfront and cordial, so we didn’t really have a problem.

For myself, there weren’t any challenges that I couldn’t overcome, and the company has helped me in many ways.

Technology in production has increased, and Swanson Group is always trying to improve and be among the best in the industry. We

are proud of our product. The mills have grown. The mills are faster. Low-grade is only about 4% to 5% of our production, so I can have a pretty laid-back visit with my customers.

3 What’s the most important lesson your father and uncle instilled in you?

McDowell: My dad always stressed customer relations and that honesty is the best policy. Always be up front with our customers. If I can’t do something for you, I can usually find somebody else who can.

I’ll probably keep working, as long as my health will allow me and my husband doesn’t get too ornery. He’s retired and he wants to know when I’m going to retire.

– Send suggestions for future interviews to David Koenig at dkoenig@526mediagroup.com.

22 • building products digest • February 2023 building-products.com

------------| 3 QUESTIONS

Swanson Group’s Christy McDowell (right), with husband Steve

Help your customers build their dream backyard with Deck Planner Software™ and Pergola Planner Software™ from Simpson Strong-Tie. Easily design a strong and beautiful deck, pergola or other popular structure in just minutes using prebuilt templates or custom dimensions. Work in 2D or 3D environments and select wood species or additional features from a full library of options. Then just print out the plan view and materials list. Your clients, and your business, will thank you. To learn more about our free downloadable software, visit our website at go.strongtie.com/pergolaplannersoftware or call (800) 999-5099. DPS Deck Planner Software™ PPS Pergola Planner Software™ Great software for building great outdoor structures. ©2023 Simpson Strong-Tie Company Inc. PERGDECKPLAN20-D

MASTER SELLERS BRING VALUE

------------ BY JAMES OLSEN

------------ BY JAMES OLSEN

MANY SELLERS are confused by the sales process. They are caught up in their desperate struggle to get business, but don’t understand where they fit into the buy/sell relationship and how to bring value to their customers. Master Sellers, on the other hand, have a multi-pronged approach to bring value to their customers, to stand out from the crowd, and most importantly to get more business.

Multiples of Multiples

A simple yet rarely used approach with customers is to offer them multiples of multiple items. I listen to a lot of sales calls where the salesperson offers a single of one item. These are often short calls. “No thanks, call me next week.”

The Master Seller offers “multiples of multiples.”

Master Seller: “Good morning, Cynthia. We spoke last week, and you told me you would be looking for some 2x4 16’s. I have four trucks of 16’s out of ABC Sawmill, which is a mill you love, the market is firming on 16’s, and I can work with you on the shipment. How many would you like to pick up?”

Cynthia: “I picked up a killer deal on three trucks of 16’s yesterday afternoon. I won’t be needing any 16’s for a month and a half.”

(This is the end of the call for 90% of the salespeople you compete against every day. Not so for the Master Seller.)

Master Seller: “OK. I also have three trucks of 2x4 9’ premium studs out of XYZ. I’ve got a smokin’ price, the market is firming on 9’s also, so how many of these can you use?”

Cynthia: “My partner bought five trucks of 9’s last week, plus our contract is coming in this week, so we’re fine on 9’s also.”

Master Seller: “Alright. Finally, we picked up a block of 7/16” OSB out of LMNOP Sawmill. We bought 20 an hour ago. I have 12 left and 7/16” is definitely moving. How many of these do you want to pick up?”

Cynthia: “What’s the price?”

Master Seller: “That’s the best part. We can get these into you at $550/MBF, which is $25/MBF less than we paid a month ago, so I recommend we pick up five.”

Cynthia: “I’ll take four.”

This “multiples of multiples” approach brings more value to the customer and gives the Master Seller more shots on goal.

Market Calls

Most salespeople are so afraid of being wrong, they give terrible market information. Ninety percent of the salespeople you compete against every day, give a mushy, mealy-mouth response to market queries that bring absolutely no value.

John: “Hey, Pete, what do you think the market is going to do?”

Quotron: “Well, it’s hard to say. It seems to be firming up on some items, but we can’t tell if it’s a head fake or a dead cat bounce. Really hard to say at this point, but it could firm up some with some mills curtailing production.”

The Master Seller has an opinion. Are they wrong sometimes? Yes. But being

correct in their market calls most of the time, brings value to their customers.

John: “What do you think the market is going to do?”

Master Seller: “It’s coming off and will be for the next month. That said, I’ve got 10 cars of 2x10 8’-16’ 2/Btr. Hem-Fir that someone is going to get a good deal on today. I know 2x10’s are your biggest mover. We spoke last week, and you said you have enough to last another two weeks. I would normally tell you to hold off and buy out of distribution, but they are charging $850/MBF for 2x10 right now. I can sell you two cars for $695/ MBF, which is $100/MBF under the market. You want to put these on?”

John: “I appreciate your honesty. I’ll take one off your hands to help you out.”

Note: To have our customer believe and trust our market calls, we must tell the truth. If the market is coming off and we own 10 cars of an item, we must still be honest with our customers. This is a real morality test for us as salespeople. But being honest—even (especially?) when we are losing money—is one of the best ways to build a long-lasting, trustfilled relationship with our customers.

or email james@realitysalestraining.com.

24 • building products digest • February 2023 building-products.com

------------| OLSEN ON SALES

JAMES OLSEN

James Olsen is principal of Reality Sales Training, Portland, Or. Call him at (503) 544-3572

GET OUTSIDE THE EVERYDAY

Everyday living doesn’t have to mean having an everyday life. MoistureShield is the only high-performance composite decking engineered to deliver 360-degree protection, 365 days a year. So you can enjoy the outdoors to the fullest, no matter where you call home.

OutsideTheEveryday.com

WORTHY THE FIRST STAIN OF THE YELLA TAG.

Introducing

YellaWood Protector

Semi-Transparent Stain and Clear Water Repellent.

It takes a whole lot to earn the right to wear the Yella Tag. Backed by fifty years of proven knowledge and quality, YellaWood Protector® products are specifically formulated by the makers of YellaWood® pressure treated pine. YellaWood Protector® products provide long-lasting, rich color and the superior protection savvy homeowners demand. All with a limited warranty against chipping, peeling, water damage, mold, mildew and color fade. Since there are no long drying times or even in-store mixing or tinting required, you’ll love how easy it is to use. Find your local dealer at yellawood.com/protector and finish like a pro.

YellaWood® brand pressure treated products are treated with preservatives (the “Preservatives”) and preservative methods, and technologies of unrelated third parties. For details regarding the Preservatives, methods, and technologies used by Great Southern Wood Preserving, Incorporated, see www.yellawood. com/preservative or write us at P.O. Box 610, Abbeville, AL 36310. Ask dealer for warranty details. For warranty or for important handling and other information concerning our products including the appropriate Safety Data Sheet (SDS), please visit us at www.yellawood.com/warranties or write us at P.O. Box 610, Abbeville, AL 36310. YellaWood and the yellow tag are federally registered trademarks of Great Southern Wood Preserving, Incorporated. All other marks are trademarks of their respective owners and are used with their permission.

®

yellawood.com/protectoryellawood.com/protector

TOTAL COMPENSATION VS. TOTAL CASH COMPENSATION

------------ BY SUSAN PALÉ

AS STRONG DEMAND for qualified workers continues to be a challenge for employers in 2023, compensation remains at the forefront for businesses trying to retain and recruit talent. Having a better understanding of compensation can ensure you spend your dollars wisely and are able to communicate the true value of your employees’ compensation with clarity.

The terms total compensation and total cash compensation are often used interchangeably, but they’re not exactly the same. Read on to learn about what makes them unique.

TOTAL COMPENSATION (sometimes called Total Rewards) includes not just cash payments, but also the value of all employee benefits and perquisites that can be quantified. For many organizations, the cost of benefits, including healthcare premiums, retirement plan contributions, and paid time off can easily amount to 30%-35% of an employee’s salary. That means the total compensation for an employee making $100,000 would be $130,000$135,000.

Many employees don’t realize the value of their benefits and perquisites. One of the best ways to communicate this is to produce some type of benefit statement that shows their value. This information can be a real eye-opener!

TOTAL CASH COMPENSATION means just that—the total value of all cash payments. Many organizations use the terms total compensation when they really are referring to total cash compensation. Total cash compensation includes base salary, overtime payments, short-term bonuses and incentives, commission payments to sales professionals, and long-term bonuses and incentives.

When you’re having conversations about compensation with your employees or recruiting new hires, it’s important to talk in terms of total cash compensation. That means that if the base salary for a position is $80,000,

and the annual incentive opportunity is 25%, annual total cash compensation can be $100,000 or more.

The most common components of total cash compensation are:

Base Salary

For most employees in non-sales roles, the largest portion of their total cash compensation will be their base salary. The term base pay is often used interchangeably with base salary.

By definition, base salary is the amount paid by an employer in return for services performed by an employee before any additions (e.g., overtime payments) or deductions (e.g., taxes) are made. Base salary may be expressed in hourly, weekly, monthly, or annual terms.

Employees considered nonexempt under the terms of the Fair Labor Standards Act (FLSA) are most often paid base salary on an hourly basis, while those considered exempt under the FLSA are paid base salary on a weekly, monthly, or annual basis.

Recruiters and recruitment job sites often quote hourly base salaries for nonexempt positions and annual salaries for exempt positions.

Bonus Payment

A bonus is a payment made in addition to base salary. Bonus payments can be made to an individual employee, a group of employees, or all employees as a reward for past achievements. Bonuses are often awarded for achievement of some organizational milestone such as profit or achievement of other financial goals. Achievement of an organizational milestone generally means that all employees receive the bonus, which may be given as a flat dollar amount or a percentage of base salary.

Individual and group bonuses are also frequently given to recognize achievements. For example, an individual

28 • building products digest • February 2023 building-products.com

------------| TRANSFORMING TEAMS

who performs the job duties of a colleague on disability leave might be granted a bonus for their work. Or a team might be given a bonus to recognize successful implementation of a new system.

Sign-on bonuses, referral bonuses, and spot bonuses are also common. They are generally awarded to individuals.

True bonuses are discretionary. That means that they are awarded solely at the discretion of the employer, rather than expected by the employee as payment for achievement of a specific goal or objective.

Holiday bonuses, often awarded following a successful year, are discretionary bonuses.

Incentive Payment

An incentive payment is also a payment made in addition to base salary. Unlike a bonus, it is tied to the achievement of specific goals and objectives. These goals and objectives are predetermined and communicated in advance. Goals and objectives may be established at the organizational, group, or individual level.

Many executive, technical, and professional level positions offer incentive opportunities in addition to base salary. Depending on position and industry, incentive payments can often be 40% to 50% of base salary and in some situations actually exceed base salary.

An incentive payment is a nondiscretionary bonus. Payment is expected by the employee if stated goals and objectives are achieved.

The use of incentives is increasing. A 2021 World at Work survey reported that 76% of participants offered some type of annual incentive plan. Survey participants represented multiple industries and differing jobs.

Commission Payment

A commission payment is a payment made for completion of a sale or sales-related task. Commission payments may be made in addition to a base salary, or may be paid instead of a base salary.

Compensation for most sales positions includes a base salary plus commission payments. Some jobs, however, are typically paid 100%

commission. These include real estate agents, travel agents, and insurance sales agents.

Commission payments are most frequently made to the salesperson who completes a sale. However, individuals in account executive, business development, and sales manager roles may receive commission payments as well. For example, a sales manager may receive a portion of their sales representatives’ sales as a commission payment or “override” for their role in the sales process.

In some organizations, sales specialists and customer service representatives may also receive commission payments to recognize their contributions to sales success.

Style and Simplicity

building-products.com February 2023 • building products digest • 29

SUSAN PALÉ

vistarailings.com

Susan Palé, CCP, is vice president for compensation with Affinity HR Group. Reach her at (877) 660-6400 or contact@affinityhrgroup.com.

MARKETING ANSWERS WITH JOHN ROOKS

------------ BY JEFF EASTERLING

EVER WONDER how wood is marketed to interest customers before they purchase from you? Between hard-working wood associations and various commodity branding programs, there’s a lot of information about wood in the marketplace. Let’s take a closer look through Q&A with someone who has been promoting the use of real, natural, sustainable wood for almost two decades.

Name: John Rooks

Title: Founder, Director of Human and Cultural Insights, The SOAP Group

Who are you, and what do you/your company do?

I am a business consultant focused primarily on marketing and sustainability strategies with solid experience in the built environment sector since 1995. My company, The SOAP Group, works with companies to understand their place in the market and, to a broader extent, in culture at large. We perform research and stakeholder (customers, supply chains, employees) engagement, as well as develop creative marketing campaigns based on these insights. We are a pioneer in Remote Ethnographic Measurement (REM), which provides deep insight into customer attitudes, beliefs, and decision-making behavior.

What are 3 marketing challenges you see in today’s lumber industry?

1. Noise. Understanding, controlling and breaking through all the influences on consumer decision-making is hard. From retailer recommendations to contractor loyalty programs from manufacturers to influencers on social

media, consumers are bombarded by a lot of noise coming at them from different angles.

2. Commodification. More and more competitive products are turning once-specialty products into commodities. How you distinguish your product from the rest can be a challenge.

3. The Reality of Virtual. The experience that the modern (younger) consumer has with a brand no longer happens in a physical showroom. It starts, and in many cases ends, online. The good news is that this creates a treasure trove of data to better understand and sell to consumers—if managed correctly. Does your company have a digital showroom experience? Is it customized to the individual customer? The tools exist to create an online experience based on the data trail left by consumers as they wind their way to a decision point. For bedrock industries steeped in a tradition of brochures and product samples, this is a whole new way of thinking about their relationship with consumers. The newness can be uncomfortable.

What’s one thing retailers should keep in mind when working with customers?

Consumers use a hodgepodge of digital and social media channels as a new kind of project management tool for building improvements. They use these new tools to get inspiration for their projects (Instagram); they use it to curate and share ideas with contractors, designers and architects (Pinterest); they use it to find product and contractor recommendations

A SPECIAL SERIES FROM

(Google Yelp), and they use it to manage budgets, documents and ideas within their own circle of influencers and decision-makers (Google Drive).

Any tips to share for effective communications with customers?

Get found but be patient. Consumers like to discover something. Show up in places that they are and inspire them—get them excited. Think of modern marketing as an attention (not sales) funnel. At the start, we want to inspire and capture attention. Next, show variety in our products. From there, we can get into technical features and benefits. Eventually, you move them into the sales process, but starting that too soon can backfire.

What trends in lumber marketing are you seeing?

With fluctuations in lumber prices, consumers are starting to reprioritize features and benefits when it comes to selecting products for their projects. Brand loyalty is one of those features. Brand loyalty isn’t dead, but it is dying. They’re dropping some product features as “must haves” and relegating them to “nice to haves.” It’s blasphemy to say, but your brand could be losing value as a differentiator. The new strategic advantage is understanding consumer behavior better—and then customizing their experience to reflect the customer back to themselves. Part of your branding strategy should be a mirror in which consumers see themselves. There is a bright spot: our research shows that consumers trust local retailer advice over big box recommendations. Find a way to use this to your advantage! BP

30 • building products digest • February 2023 building-products.com

------------| LUMBER 411

John Rooks

“Growing beyond measure.”

REDWOOD THE POSSIBILITIES KEEP GROWING: Call us at 707.894.4241 Visit us at buyRedwood.com Natu re’s majestic pi l la rs. Re Reddwwood i ood is o s onne o e of t f thhe s e sttrroonnggeesst a t annd f d faasstteesst g t grroowwiinng s g sooffttwwood spe ood specciieess. . It thrives in some of the most productive timberlands in the world. Redwood is known for its timeless durability without the use of chemicals. Due to its flawless formation, there has never been a Redwood recall. There is a grade of Redwood for every application, every budget, and every customer.

Call or visit us today. Our family of Redwood timberland owners will continue to be your reputable and reliable source of Redwood.

THE CRIPPLING DISEASE OF MODERATE SUCCESS

BY DAVE KAHLE

“WE’RE DOING OK.” That’s a thought shared by thousands of executives I have encountered over the years. It also resides in the minds of the majority of B2B salespeople with whom I’ve worked.

“OK” for a business often means that the company grows slowly, at least in most years. It is marginally profitable, in most months. The workforce is relatively stable, and the customers somewhat loyal. No one challenges the status quo.

For a salesperson, it means that the boss isn’t hounding him, he/she is making a decent living, and the customers are relatively accessible. No interest in pursuing anything bigger.

For both groups, doing “OK” is a description of moderate success, and was never a description of the lofty goals and dreams that could motivate them. Instead, it is the default position of business professionals who have settled for the comfortable status quo. “OK” is where people and organizations often settle after they have been in the fray for a while.

While moderate success—doing OK—is a stage every business and every salesperson must pass through, the problem is that many—probably the majority—settle there and make it a permanent resting place. In a world where the pursuit of excellence requires proactive time and effort, the majority settle for the relative comfort of mediocrity.

Once “doing OK” settles into minds and hearts, it engenders a circular set of behaviors that support itself. It becomes the rationale to avoid any initiatives that might shake the status quo and lead to higher levels of success and influence.

“Open a new branch, or develop a new product or service?” Naw, it would stress the company too much. We’re doing OK the way we are.

“Invest in developing the sales force?” Nope, they will just leave and go to a competitor. We’re doing OK just the way we are.

“Automate some time-consuming processes?” Not if it means the current staff will have to learn new skills. We’re doing OK just the way we are.

Since “doing OK” becomes the default response to any initiative, the company’s moderate success undermines any efforts for greater success, excellence and influence. Moderate success becomes the enemy of greater success.

The same is true for professional salespeople. Moderate success squelches any inclination to the hard work of greater success.

“Attend a sales seminar?” Nope, too busy and, besides, I’m doing OK.

“Spend time mastering a new product?” Naw, I’m doing OK with what I’m currently doing.

“Invest in prospecting for new customers?” No, I’m too busy with

my current customers, and besides, I’m doing OK as it is.

Excellence demands commitment. Moderate success lounges in indifference. Excellence requires hard work. Moderate success doesn’t stress anyone. Excellence mandates taking risks. Moderate success avoids them. Excellence requires change. Moderate success protects the status quo.

In my 30 years of practice, I’ve interacted with thousands of executive and owners, and engaged with tens of thousands of B2B salespeople. The overwhelming majority have been lulled by moderate success to a place where they are hesitant to pursue excellence, wary of reaching for their potential, tentative about embracing any new ideas, and afraid of stretching beyond today’s comfort zones.

That’s one of the main reasons why only 5% to 20% of businesses and salespeople ever reach their potential. The rest got waylaid by moderate success.

32 • building products digest • February 2023 building-products.com

------------| SELLING WITH KAHLE

------------

DAVE KAHLE

Dave Kahle is a leading sales authority, having written 12 books and presented in 47 states and 11 countries. For more information, visit davekahle.com.

GREAT SOUTHERN EXPANDING LOUISIANA REMAN

Great Southern Wood Preserving will invest $5.9 million to expand its remanufacturing facility in Mansura, La.

The move will add four new production lines, increasing the facility’s capacity and allowing for the manufacture of components used in the oil field and for storm relief and mitigation. As well, manufacture of supplemental decking components, such as rails and balusters, will shift to the Mansura plant from facilities outside of the state.

“Our expansion in Mansura is phase two of the long-range plan we had in mind when we began operations here in late 2011,” said president and CEO Jimmy Rane. “With the growth of various manufacturing segments in Louisiana, our goal is to be able to support these industries by providing both a greater volume of products as well as more variety in the products they need to continue their growth.”

Construction is forecast to start in January and be completed in October.

The lumberyard that took 130 years to build.

When Ganahl Lumber opened the doors to its new 18.5-acre location in Torrance, CA, you could tell right away it was special. A state-of-the-art gem.

So, where did the vision come from? A combination of Ganahl’s 130 year history of operational excellence and CT Darnell’s experience building on over one thousand LBM facilities. Together, they made a powerful team.

ABC Supply opened a 26,000sq. ft. branch in Austin, Tx.

Beacon added greenfield locations in Augusta, Ga.; Brownsville and Georgetown, Tx.; and acquired both distributor First Coastal Exteriors, Mobile, Al., and Pearl, Ms.; and Whitney Building Products, 77-year-old Boston, Ma.-based distributor of commercial and multifamily waterproofing and restoration products.

West Fraser Timber Co. indefinitely curtailed its Perry, Fl., sawmill due to high fiber costs and softening lumber markets.

Structurlam temporarily suspended operations at its Conway, Ar., mass timber plant due to a customer contract cancellation.

US Lumber Brokers, Del Valle, Tx., is a new stocking distributor of Tantimber’s ThermoWood modified timber.

Palmer-Donavin, Columbus, Oh., now stocks Malarkey Roofing Products’ Highlander NEX AR and Vista AR architectural shingles and accessories, expanding distribution of Malarkey products into the Midwest.

Boise Cascade expects to start production in June at a 10th door shop—a 150,000-sq. ft. millwork facility in Kansas City, Mo.

Shuqualak Lumber saw one dry kiln destroyed and a second damaged by a late-night fire Dec. 26 at its planer mill in Shuqualak, Ms.

Masonite acquired door system component manufacturer Endura Products, Greensboro, N.C.

Ambassador Supply, Fort Wayne, In., bought Continental Carpentry Components, Wanatah, In.

Genesis Products, Goshen, In., has acquired cabinet drawer component manufacturer BHK of America, South Boston, Va.

EGGER will invest $38 million in its particleboard/TFL plant in Lexington, N.C. EGGER subsidiary Timberpak has acquired Novem Industries, a wood recycling facility in Charlotte, N.C., to supply materials to the Lexington facility.

Sightline Commercial Solutions, Minneapolis, Mn., purchased Trex’s commercial products division.

34 • building products digest • February 2023 building-products.com

------------| SUPPLIER BRIEFS

Tom Barclay, General Manager Ganahl Lumber

CT-Darnell.com n Sunbelt-Rack.com n 800-353-0892 © WTD Holdings, Inc., 2023. All rights reserved.

Visit our project page at sunbelt-rack.com to check out the video of Ganahl’s new state-of-the-art facility.

SPECIALTY BUILDING PRODUCTS BUYING AMERHART

Specialty Building Products has agreed to acquire Midwest regional distributor Amerhart.

Founded in 1940, Amerhart is a third-generation, family-run distributor of building materials serving customers from 10 locations in Wisconsin, Illinois, Kansas, Michigan, Minnesota, and Missouri.

Following the completion of the acquisition, expected in first quarter 2023, Amerhart will maintain its current brand name, geographic locations, management team, and team members, led by CEO Mark Kasper and president/COO Chad Warpinski, as part of SBP.

Specialty’s other operating brands are U.S. Lumber, Alexandria Moulding, DW Distribution, Millwork Sales, and Reeb.

SPARTAN LAUNCHES IG RAILING

Spartan Railing, Bloomington, Mn., has rolled out a new brand identity—IG Railing—to better align with its illuminated glass railings. The launch, which includes new logo and website (IGRailing.com),

creates a better connection to global partner and patent holder Illuminated Balustrade Australia. Spartan Railing LLC remains the U.S. business entity.

IG Railing’s frameless glass railing system features over 12 LED color options via WiFi or remote control.

IG Railing also signed up several new partners, including Great Lakes Railing, Grand Rapids, Mi., and The Garham Group, Nunica, Mi., to service Michigan and portions of Indiana and Ohio; sales rep Langenfeld Sales, Oswego, Il., to support existing distribution in Wisconsin, Illinois, northwest Indiana, and eastern Iowa; and BMD, Riverside, Ca., to cover Southern California.

KOOPMAN ADDING IN CAPE COD

Eleven-unit Koopman Lumber, Whitinsville, Ma., is building its first store on Cape Cod with plans to open in April.

The 8,759-sq. ft. store in Dennis, Ma., will feature a window & door showroom, 9,030-sq. ft. drive-thru lumberyard with Auto-Stak racking, and two warehouse buildings totaling 4,759 sq. ft.

------------| DEALER BRIEFS

New Home Building Supply has closed its Macon, Ms., location, but continues in Columbus, Ms.

McNeely’s Do it Center, Man, W.V., closed Dec. 30 after 101 years, with the retirement of owner Gilman Burgess.

J&L Hardware has relocated to a larger 21,000-sq. ft. building in Ely, Mn., and changed its name to KJ’s True Value Hardware.

Pearl Brothers True Value, Joplin, Mo., closed Jan. 28 after 118 years, with the retirement of longtime owner Harold Berger. The property has been acquired by a redeveloper who will reopen the store under the same name, but not for about two years.

Aubuchon Co. agreed to buy 37-year-old Zimmerman’s Hardware, Burtonsville, Md., from Craig Zimmerman, James Dillon, Ronald Zimmerman, and Gary Zimmerman. The store will continue to operate as Zimmerman’s Hardware, and Ron will stay on with Aubuchon.

36 • building products digest • February 2023

DEFINING A HIGHER STANDARD OF SUSTAINABLE PRODUCT ™ Western Forest Products provides architectural appearance solutions that make your clients’ projects westernforest.com/products Visit Our New Products Section

MOVERS & SHAKERS

Clark Spitzer has been installed as president of Snavely Forest Products, Pittsburgh, Pa., effective Jan. 1. Carl J. Lamb has been promoted to the executive VP.

Dave Rush is now CEO of Builders FirstSource, Dallas, Tx.

Tom Ferguson has been promoted to president of Christensen Lumber, Fremont, Ne., a division of Kodiak Building Partners. He succeeds Tom Christensen, who moves into the advisory role of chairman.

Tom Allen, ex-84 Lumber and Dufrene Building Materials, has joined Kodiak Building Partners division Forest Tek, Tavernier, Fl., as president and will oversee all operations for Forest Tek Lumber, Overseas Lumber Supply, and Keys Mercantile in the Florida Keys.

Caleb Grothaus has been named director of business development for Palmer-Donavin, Columbus, Oh. Dave Wall is now regional director of distribution.

Dean Davis has been appointed president of McGowan White Lumber Co., Augusta, Ga.

Bill Wamboldt has retired from JWS Distributing, Greenville, S.C., after 40+ years as a lumber trader.

Derek Santos, ex-E.L. Morse Lumber, is new to outside sales with Koopman Lumber & Hardware, Fairhaven, Ma.

Mike Nagy, ex-Musselman Lumber, has joined the outside sales team at Lezzer Lumber, Manheim, Pa.

Javan Lapp has been promoted to CEO of Key-Link Fencing & Railing and Superior Plastic Products, New Holland, Pa., succeeding Reuben Lapp, who remains owner and board chairman.

Kyle Tiringer, ex-Sherwood Lumber, has joined Westlake Royal Building Products, as Port Jefferson Station, N.Y.based territory mgr.

Michael Collins was promoted to senior VP of International Forest Products, Foxborough, Ma.

Joe Menefee, ex-P&W Builders, has joined R.P. Lumber Co., as store mgr. in Peoria, Il.

Marc Bernstein has been promoted to co-CEO and co-president at LeNoble Lumber Co., Long Island, N.Y.

Stephen Ashcraft is new to Associated Truss & Lumber Co., Sunnyvale, Tx., as director of yard operations.

Christopher Moudy has been elevated to general mgr of 84 Lumber, Kansas City, Mo.

Paul Gilbert has been promoted to head leadership and management development at Ambassador Supply, Fort Wayne, In. Zach Higgins is now CFO.

Benjamin Kitchens was named area sales mgr. for southern Texas with Versatex Building Products, Aliquippa, Pa. Matt Baumeister is now territory sales mgr. for northeast Florida & southern Georgia; Jeff Dahdah, regional sales mgr. for Florida; Josh Diaz, regional sales mgr. for western New England & eastern New York; Kris Fornuto, regional sales mgr. for eastern New England & Atlantic Canada; Cole Hedlund, territory sales mgr. for Upper Midwest and western Canada; Nick Leugers, regional sales mgr. for the Gulf States; and Patrick MacRae, territory sales mgr. for Atlantic Canada.

Chris Carlson, ex-Hartzell Hardwoods, has joined the sales team at Tropical Forest Products, based in Dayton, Oh.

David LaViner is new to sales at Rex Lumber, Troy, Al.

38 • building products digest • February 2023 building-products.com

------------|

Levi Winfrey is the new MDF plant mgr. for Roseburg, El Dorado, Ar.

George Wilkins has been promoted to senior VP of operations at American Builders Supply, Sanford, Fl.

William Heidler has been promoted to president of Heidler Hardwood Lumber Co., Lisle, Il.

the expansion centered across the western United States.

Over the past 18 months, Lowe’s opened more than a dozen facilities, including in Riverside, Ca.