2 minute read

Cargo-Loading

(Continued from Page 36) to be followed, and are as definite and inflexible as those for loading and protecting fragile or perishable merchandise.

Imbued with the spirit of the thing, the loading crews, who are true-blue lumbermen and keenly appreciate the beauty of well manufactured lumber, havi adopted an unwritten loading code which further assures thaf the bright, clean stocks will not become damaged or soiled in the loading process. Greasy hands, grimy gloves and hobnailed and on the floor; the end walls are furred out and covered with heavy paper to protect the caps and square ends of the lumber; the ceiling is covered with heavy paper to protect the load against cinders and dust that may come through the roof and eaves, and finally the non-loading door is stripped with four-inch strips and calked and covered rvith paper.

After all this has been finished, a generous layer of clean shavings or sawdust is placed on the car floor. Then the

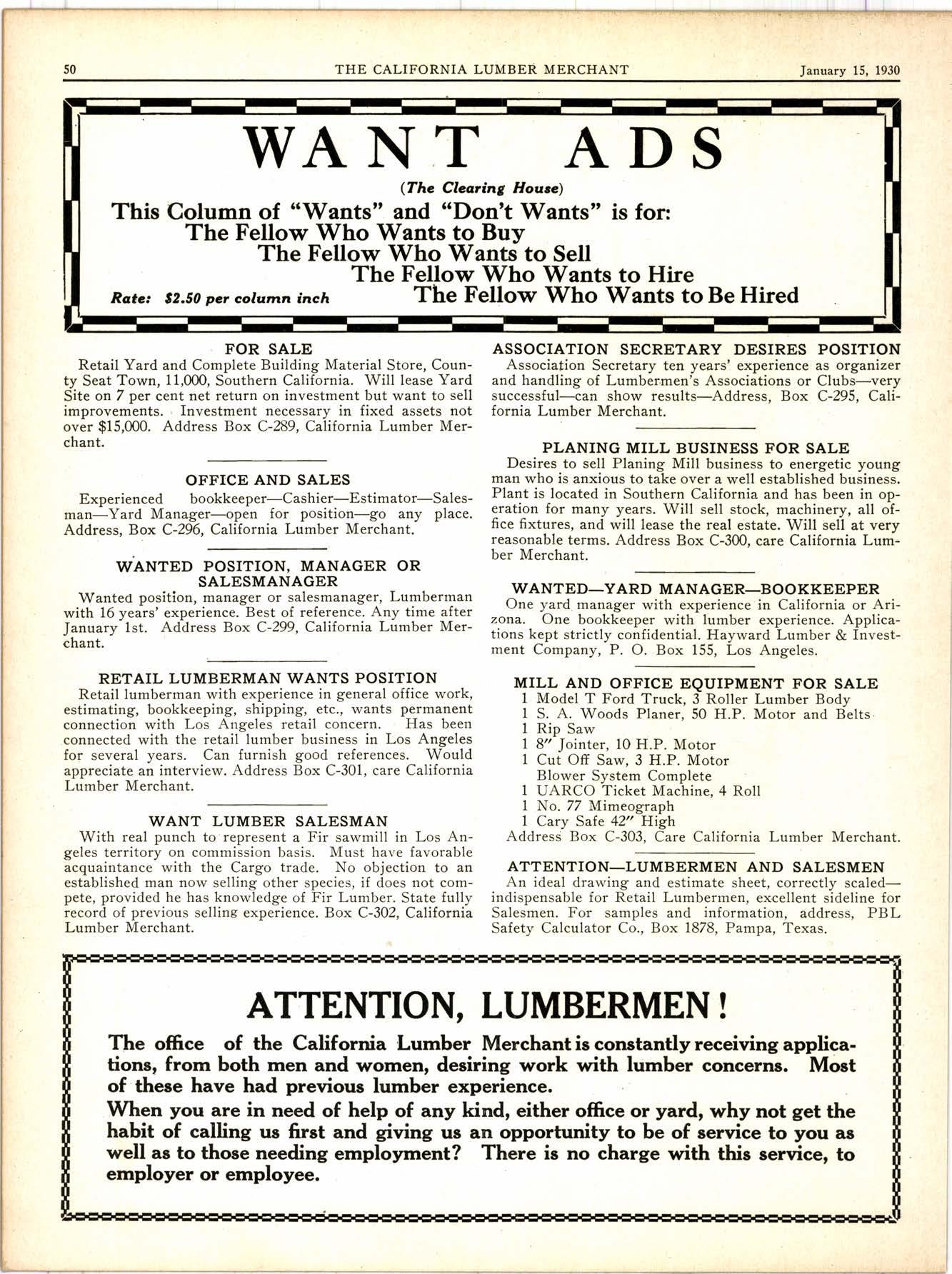

A mell-of-a-hess, and though it is typical of the aaerage empty shunted to the loading platform, it of course cannot be ond will not be used for -Square until ezterything that might mar the tumber is sot riit of , anit ,ririi;j:o:*'pt, or dirty shoes are taboo, for they too readily sully bright, ciean lumber or its colorful caps.

In selecting cars for cargo-loading 4-Square, preference is given to wooden cars because of their tigtrtei construction, and it is well to emphasize that "selecting" means exactly what it implies, for "any old empty" that may be in the yards is not suitable for 4-Square cargoes. The-car selected must be in good condition or one that can be easily made so. After it is decided that an empty is suitable or can be made suitable for 4-Square loading, the car is swept clean of any debris that may be in it. The next step is io remove nails and repair other defects in the car walls and floor. And then to make doubly sure that the car is free from grime or grit that might scratch or deface the lumber, the car is given a thorough cleansing with water. After the car has dried, furring strips are placed on the side walls car is ready for loading with 4-Square packaged lumber. Loading is begun in a corner opposite the loading door. The 4-Square packages, which are grouped by item, are loaded in tiers the full length of the car, up to within five feet of the ceiling. The loaders work across toward the loading door, breaking package joints horizontally and vertically so there will be no lapping and loading each item separately to keep the various items grouped and to avoid the necessity of walking on the packages.

S|ecial attention is given to the end unlls to protect the caps on the 4-Square packages and the square ends of the I* .ber. Protecting strips are placed on both sides of Proiecrtng bolts, iron braces, etc., and faced with conugated fibre board dr chip board. Unli,ned corrugated metal ends are lined with battened door sections to the required height.

This part of the load is then leveled off with ASquare items or better grades of regular stock. After being leveled, a layer of any loose boards or dimensions is applied to make sure that the 4-Square is covered over. This layer of boards is covered with red rosin paper over which another layer of boards is placed.

(Continued on Page 43)