3 minute read

PAC IFIC

\|TOOD PRODUCTS CORPORATION AT LOS ANGELES

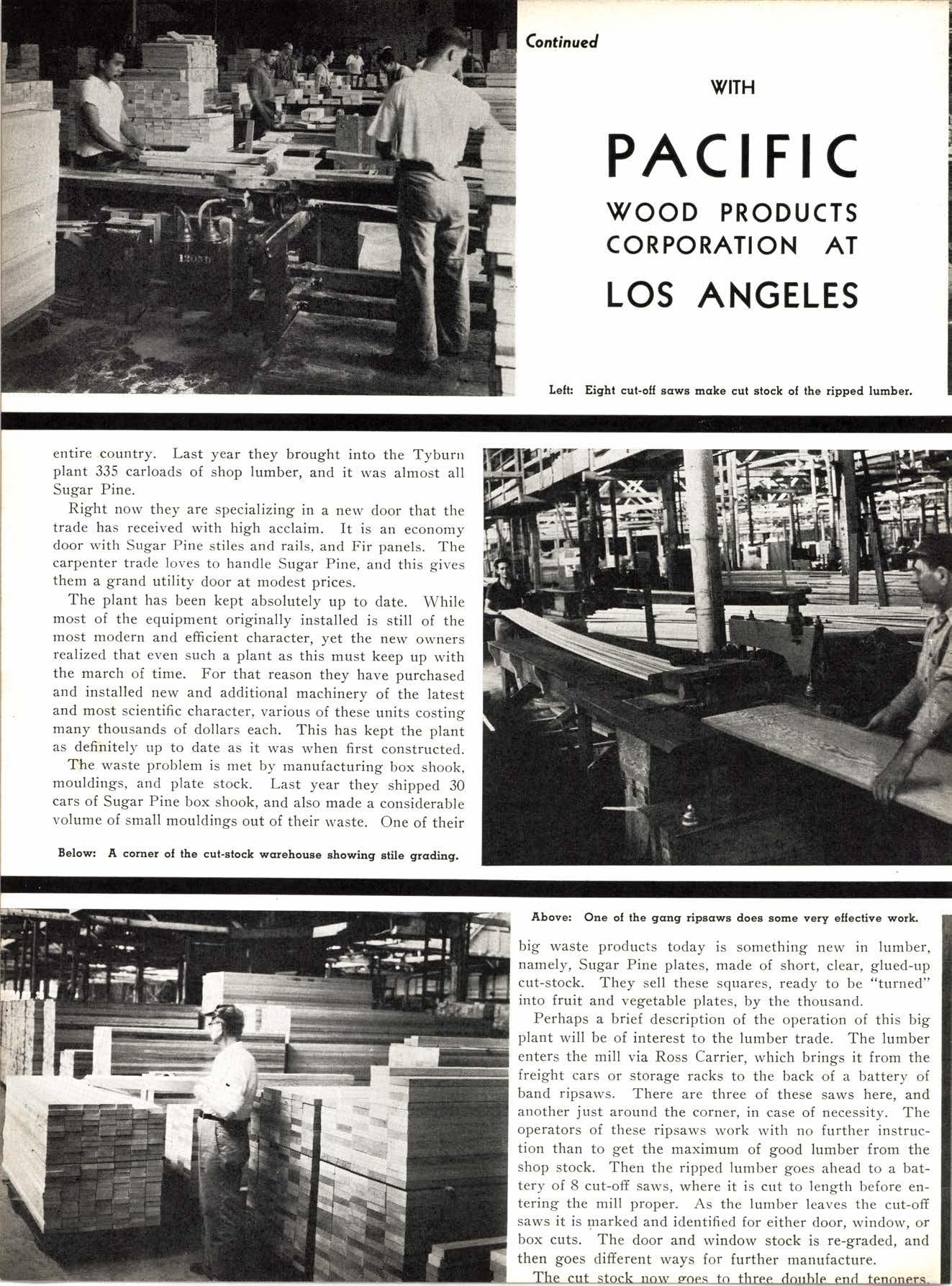

Above: One oI the gcng ripscws does some very ellective work. big waste products today is something new in lumber, namely, Sugar Pine plates, made of short, clear, glued-up cut-stock. They sell these squares, ready to be "turned" into fruit and vegetable plates, by the thousand. Perhaps a brief description of the operation of this big plant will be of interest to the lumber trade. The lumber enters the mill via Ross Carrier, which brings it from the freight cars or storage racks to the back of a battery of band ripsarvs. There are three of these saws here, and another just around the corner, in case of necessity. The operators of these ripsaws work with no further instruction than to get the maximum of good lumber from the shop stock. Then the ripped lumber goes ahead to a battery of 8 cut-off saws, where it is cut to length before entering the mill proper. As the lumber leaves the cut-off saws it is marked and identified for either door, window, or box cuts. The door and window stock is re-graded, and then goes different ways for further manufacture.

one for cloor and two for window stock. Coming from the tenoners it goes to and through five electric moulders, commonly called "stickers," expensive high-speed machines making 8,500 revolutions per minute. All these electric moulders are driven with frequency changers which increase the speed of the heads, and make for perfect machining with a minimum of knife marks. Next come five drum sanders which run stock up to 72 inches wide, and to complete the sanding department there are two belt sanders and one special check-rail window sander; an rlnusual service.

This plant does a certain amount of manufacturing detail material, and while making stock is the preponderance of their business, they nevertheless are very proud of the character of their s,pecial detail products'and service. Detail items are manufactured separately from stock items, there being ample room in this mill to keep them separate.

The veneer department is an institution in itself. In one corner of the great plant there is a veneer sawmill equipped with two veneer saws. Here they cut specially purchased "cants" into veneers, which then pass into a big and completely equipped veneer room where there is every type of veneering equipment. Here they make beautiful and highly detailed doors for fancy and expensive uses such as movie star homes. This department likewise serves the furniture trade, furnishing it with stock and detailed panel work of unusual character. The veneer department and the build-up and gluing department alone occupy the space of an ordinary millwork plant.

A very important department at the Pacific plant is a battery of 8 big Moore type steam dry kilns. There is likewise a most modern machine shop and a filing room, where they do the up-keep work for all their own equipment. A new electric arc welder has recently been added to this department.

The distribution service is excellent. Unlimited warehouse space takes care of all the stock they want to carry. Railroad facilities for loading carload orders are adequate. A fleet of trucks serves the Metropolitan Los Angeles field. Here a very nice advertising idea is in use, the trucks all

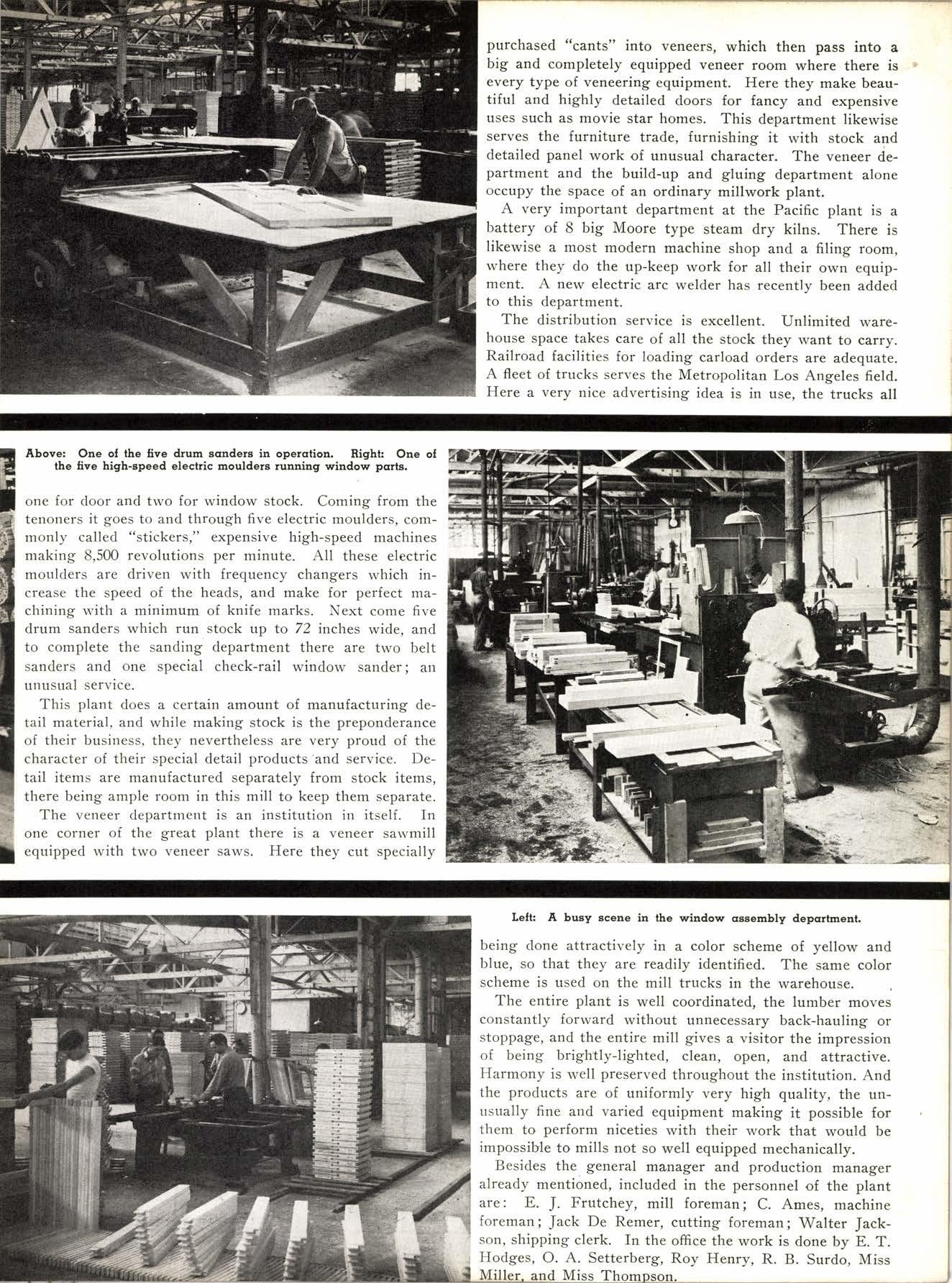

LeIt: A busy scene in the window cssembly depcrtment. bei,ng done attractively in a color scheme of yellow and blue, so that they are readily identified. The same color scheme is used on the mill trucks in the warehouse.

The entire plant is well coordinated, the lumber moves constantly forward without unnecessary back-hauling or stoppage, and the entire mill gives a visitor the impression of being brigh'tly-lighted, clean, open, and attractive. Harmony is well preserved throughout the institution. And the products are of uniformly very high quality, the unusually fine and varied equipment making it possible for them to perform niceties with their work that would be impossible to mills not so well equipped mechanically.

Besides the general manager and production manager already mentioned, included in the personnel of the plant are: E. J. Frutchey, mill foreman; C. Ames, machine foreman; Jack De Remer, cutting foreman; Walter Jackson, shipping clerk. In the office the work is done by E. T. Hodges, O. A. Setterberg, Roy He,nry, R. B. Surdo, Miss Miss