20 23 Transportation Issue SEE INSIDE: 16 TECHNOLOGY 20 2023 LEGISLATIVE SUMMIT RECAP 10 TRANSPORTATION 8 MEMBER ACTIVITIES A publication of the California Construction and Industrial Materials Association Summer ISSue Equipment Rodeo puts guests in the driver’s seat TEICHERT

(562)

Bakersfield, CA

(661) 399-3600

Santa Maria, CA

(805) 922-8329

Meridian, ID

(208) 888-3337

McCall, ID

(208) 634-3903

Elko, NV

(7 75) 77 7-7070

(7

Oxnard,

(805) 485-2106

Sylmar, CA

(818) 890-3353

Jerome, ID

(208) 324-2900

Las Vegas, NV

(702) 399-2700

ADVANC ED MAC HINES. EXPERT SUPP ORT. MAXIMUM PRODUC TION. Equipment COASTLINE

Deere Construc tion Equipment is pac ked with tec hnology like JD Link and Smar tgrade mac hine and grade control to help maximize produc tivity and power up your projec t, from the fac tor y. Combined with Wir tgen Group produc ts, and an exper t staff of John Deere trained tec hnicians our customers can take advantage of serious produc tion capabilities. OUT HERE. WE’RE ALL IN. Long Beach, C A

www.coastlineequipment.com John

272-7400

A

Lake Forest, C

14) 265-5500

CA

CHAIRMAN'S LETTER

Engage your communities – Magnify your voice

PRESIDENT & CEO MESSAGE

Keep your feet in the dirt

MEMBER ACTIVITIES

Teichert Equipment Rodeo puts guests in the driver’s seat

TRANSPORTATION

CARB approves Advanced Clean Fleet rule – what to make of it

Revisions to In-Use Off-Road Diesel Rule - Prepare for January 1

TECHNOLOGY

Mobile Asphalt Lab comes to California

Making the Shift: Cummins rolls out new “fuel agnostic” engines

LEGISLATIVE

2023 Legislative Summit recap

EVENT - PLANT TOUR

Women of CalCIMA tours rock quarry

MEMBER SERVICES

CTAC: Improving concrete testing

TRAINING

CalCIMA training opportunities

NATIONAL ASSOCIATION NEWS

ON THE COVER:

Teichert Equipment Rodeo event: photo provided by Silas Barker, Accelerated Video

The Conveyor is a publication of the California Construction and Industrial Materials Association. The views expressed herein are fixed expressions of the contributing writers and not of CalCIMA. All rights reserved.

CalCIMA

455 Capitol Mall, Suite 210 Sacramento, CA 95814 (916) 554-1000 www.calcima.org www.distancematters.org

16

Published By Construction Marketing Services, LLC

P.O. Box 892977 Temecula, CA 92589 (909) 772-3121

Publisher Kerry Hoover khoover@calcontractor.com

Editor Brian Hoover bhoover@ironads.com

22

Editorial Contributors

Johanna Levine, Manager, Off-Road Implementation Section, CARB

Julia Maldonado, Communications Coordinator, CalCIMA

Charley Rea, Director of Communications, Safety & Technical Services, CalCIMA

Suzanne Seivright-Sutherland, Director of Regional Government Affairs & Grassroots Operations, CalCIMA

Chris Vanasdalan, Sr. Product Communications Specialist, Cummins

Graphic Designer Aldo Myftari

The Conveyor is published quarterly each year by Construction Marketing Services, LLC

All rights reserved. Reproduction in whole or in part without permission is prohibited.

2023 SUMMER ISSUE

4

6 8 14 18 16 20 22 24 26 28 10

8

3 The Conveyor • 2023 Summer Issue

Engage your communities – Magnify your voice

As members of the construction materials industry, we are all dedicated to our shared mission of providing the materials necessary to supply California’s critical infrastructure and housing while simultaneously navigating the quicklyevolving climate goals and policies. The historic federal infrastructure package (IIJA) created generational opportunities for our industry as well as the need to transition our operational technologies, equipment and energy systems. As we work together to prosper, grow and help the Golden State meet its goals, the way we operate will be shaped by political, legislative, and regulatory decisions at all levels of government.

As a result, we all need to take time and work together to educate California decision-makers. This effort requires a robust government relations strategy to create an environment of open communication. We have to be invested in encouraging problem-solving that results in manageable change for our operations. One important piece of this strategy is the CalCIMA PAC—an essential vehicle of communication and support for public debate on topics important to us.

Through the CalCIMA PAC, contributors support government leaders that make the time and put the work in to understand the complex reality of an economy in transition and also share the goal of reasonable and achievable change for industry.

If you are already supporting the CalCIMA PAC, thank you. I ask that you consider increasing your contribution, even if it is only a small change. Companies can contribute up to $9,100 per year.

If your company does not yet participate, I hope you will consider contributing. Every amount helps us move forward.

Together, as the producers of materials essential to construction, manufacturing and agriculture, we need to do everything we can to ensure California leaders understand our industry as we face an economy and regulatory environment that are in transition.

Support our sector. Magnify your voice. Invest in the CalCIMA PAC today.

To download the contribution form, visit www.calcima.org//Files/PAC/2023CalCIMAP ACContributionForm.pdf n

Jamie Polomsky President - Western Division Vulcan Materials Company CalCIMA Chairman

CHAIRMAN'S LETTER CALL NOW FOR ADVERTISING RATES & INFORMATION KERRY HOOVER / 909-772-3121 khoover@calcontractor.com 4 The Conveyor • 2023 Summer Issue

Leaders In The Aggregate & Paving Industry www.goodfellowcorp.com Our Parts & Service Teams are here to serve YOU! Visit Our California Office: 590 Crane St., Lake Elsinore, CA 92530 Call Our Sales Team: (909) 874-2700

Keep your feet in the dirt

One lesson I learned from Bill Dorey, then CEO of Granite Construction and my boss at the time, was to always keep my “feet in the dirt,” otherwise there’s no way you can hope to represent our industry well. I took that advice to heart and have maintained it as a priority throughout my career.

Over the last couple of months, I have taken the opportunity to tour several member facilities and meet with operations folks in the mining, asphalt and concrete sectors. During these visits, members engage me in difficult discussions. Two things have stood out in recent months: The level of innovation going on and the challenge recent and unrealistic regulatory actions by the state are creating for members’ ability to produce the critical infrastructure and building blocks for our society. “Regulatory disruption of the supply chain” comes to mind as a description for how these actions impact the supply of everyday products that citizens take for granted.

Fortunately, members are up to the challenge. During my visits, I was struck by how much material producers do to embrace and undertake innovation. This is particularly the case in reducing carbon impacts. The energy and passion I feel from you, the members, in embracing challenges provides comfort that the task can be done if properly supported. The leadership within the companies certainly exists to meet the challenges, provided society, manufacturers, and utilities do their part to make technology and energy readily available. I cannot leave a discussion with a member without hearing of the plans they may be able to undertake.

The task is particularly challenging given the ambitious regulatory agenda of state agencies. As members know, the California Air Resources Board recently adopted “world leading” mandates for truck fleets in response to global climate change. In short, mandating technology changes before we see the benefit of the last round of mandates fully realized. Fortunately, the latest rule, at least temporarily, has mixer trucks on an exempt list, since the zero emission technology is not yet available. But, overall, there are substantial impacts for fleets delivering construction materials. If you feel the déjà vu, you wouldn’t be wrong: We have done this before.

On a more positive front, Governor Newsom has certainly had the courage to raise Cain by proposing various California Environmental Quality Act (CEQA) reforms designed to enable the permitting and approval of the infrastructure transition our state and transportation sector must achieve to meet climate change reductions. We have strongly supported these changes. While opposition from environment groups have muted some of the proposals–despite the potential benefits for carbon reduction–the result has been some advancement in permitting reforms, particularly as it relates to infrastructure projects. This is good news! n

Sincerely,

Robert Dugan President/CEO CalCIMA

PRESIDENT & CEO MESSAGE

6 The Conveyor • 2023 Summer Issue

Teichert Equipment Rodeo puts guests in the driver’s seat

By Julia Maldonado, Communications Coordinator, CalCIMA

By Julia Maldonado, Communications Coordinator, CalCIMA

After a five year hiatus, Teichert’s Equipment Rodeo is back.

The Teichert Equipment Rodeo was held this May at the Perkins Plant in Sacramento. It is a twoday event which allows guests to test drive Teichert’s heavy equipment used in mining and construction, and doing so in a supervised and controlled environment. The first day of the rodeo was dedicated to industry attendees, while the second day was for the Teichert employees and their families.

With the guidance of Teichert’s heavy equipment operators, visitors were put in the driver’s seat and test drove on Teichert’s current mine site undergoing reclamation. There were 22 pieces of equipment

on the lot available to drive: Six different sized excavators, loaders, water trucks, articulating trucks, compactors, scrapers and bulldozers.

The first Teichert Equipment Rodeo began in the late ‘80s/early ‘90s. Teichert wanted to create an event that guests of all ages, backgrounds and interests could attend and learn more about the industry. This creates a hands-on approach and gives the attendees a small idea of what construction workers do every day.

“The appreciation you gain for operators after an event like this is immeasurable,” said Katie Tonello, an Executive Assistant at Teichert.

Tonello is no stranger to this event; she attended her first one when she was six years old. Now

Leighton Loranger (Rocklin’s daughter).

Above: Attendee getting out of the construction equipment. Guests had the opportunity to operate different construction equipment in a supervised and controlled environment.

a Teichert employee herself, she is able to witness children, teens and adults drive heavy equipment for the first time, and some even come back as Teichert employees.

One of Tonello’s fondest memories of this event is meeting an employee’s nephew when she was Teichert’s recruiter, only to see him five years later as an

MEMBER ACTIVITIES

Left: (First row) Justino Santana, Michael Smith, Buzz Smith, Jeannette Smith and Rocklin Loranger. (Second row) Jennifer and Shane Loranger. (Inside cab) Mackenzie Loranger holding

8 The Conveyor • 2023 Summer Issue

Photo contributed by Ultimate Exposures

equipment operator at the Teichert Equipment Rodeo.

“That’s what we’re all about: Introducing young people to construction,” Tonello said. “For kids, it brings Tonka trucks to life.” Her favorite part about the rodeo is seeing the little kids in the big safety vests.

One of the biggest challenges with putting on the Teichert Equipment Rodeo this year was the weather. The rodeo was originally scheduled for March, but was rained out.

“The rain delay was a bummer and we had to postpone the event,” Tonello said. “However, our committee and crew who did the site prep knew just what to do, and they set it up beautifully and safely.” Their efforts paid off: The

event had a turnout of about 1,300 people over the course of two days.

The rodeo also featured booths highlighting different areas of the construction industry:

• Construction Technology Department: Taught kids how to fly drones over the site in order to learn how the construction industry uses this type of technology.

• Quality Assurance Department: Discussed the different concrete and asphalt products and mixes that are used at plants.

• Women in Operations: Teichert’s organization dedicated to providing leadership, opportunities and support for women across

Teichert. Showed little girls at the rodeo that they can work in construction too.

• Teichert Foundation & Community Connections: Teichert’s philanthropic entity and community service group hosted a sandbox with smaller toy equipment for kids to play with.

As for the future Teichert Equipment Rodeos, they hope to bring the event to other areas in California and Nevada. The event’s return was a success!

CalCIMA would like to thank Teichert for all its hard work to put together the event, and for the opportunity to become an equipment operator for the day.

n

Right and below: Various types of equipment were available for guests to operate at the Teichert Equipment Rodeo, including scrapers, bulldozers, excavators and water trucks.

Left: Teichert Equipment Rodeo patriotic and spectacular entryway.

9 The Conveyor • 2023 Summer Issue

Photo contributed by Silas Barker, Accelerated Video.

CARB approves Advanced Clean Fleet rule – what to make of it

By Suzanne Seivright-Sutherland, Director of Regional Government Affairs & Grassroots Operations, CalCIMA

By Suzanne Seivright-Sutherland, Director of Regional Government Affairs & Grassroots Operations, CalCIMA

This spring, the California Air Resources Board (CARB) unanimously approved a first-of-its-kind rule that requires a phased-in transition toward zero-emission medium- and heavy-duty vehicles (ZEVs). Known as ‘Advanced Clean Fleets (ACF),’ the new rule put California on a path toward accomplishing Governor Gavin Newsom’s goal of fully transitioning the trucks that work in California- to zeroemissions technology by 2045. This sweeping rule was approved after years of proposals, hearings, and a combination of industry pushback and acceptance.

In support of the rule, CARB Chair Liane Randolph states, “We have the technology available to start working toward a zero-emission future now. The

Advanced Clean Fleets rule is a reasonable and innovative approach to clean up the vehicles on our roads and ensure that Californians have the clean air that they want and deserve. At the same time, this rule provides manufacturers, truck owners and fueling providers the assurance that there will be a market and the demand for zero-emissions vehicles, while providing a flexible path to making the transition toward clean air,” Randolph said.

On the bright side, too, CalCIMA was able to secure a request for a fleet advisory group to support successful implementation of the ACF rule and dates for CARB to review varying status updates with its Governing Board. The final rule language clarifies that concrete mixer trucks will be included on

the ‘ZEV Purchase Exemption List’ that will be maintained on CARB’s website by January 1, 2025 meaning that this specific vehicle configuration is currently not available for purchase. It is inconclusive when this exemption for concrete trucks will sunset.

However, there were dissenters. American Trucking Associations

President Chris Spear explained, “Fleets are just beginning to understand what it takes to successfully operate these [ZEV] trucks, but what they have learned so far is they are significantly more expensive, charging and refueling infrastructure is nonexistent, and ZEVs are not necessarily a one-for-one replacement – meaning more trucks will be needed on California roads to move the same amount of freight.”

TRANSPORTATION

10 The Conveyor • 2023 Summer Issue

Fleets impacted –

Fleets that have either $50 million or more in gross annual revenues, or that own or operate 50 or more vehicles with a gross vehicle weight rating greater than 8,500 pounds or more.

Components of the ACF –

ZEV unavailability –

• The ACF rule has an exemption for cases in which a ZEV is not available for purchase and is needed to comply allowing fleets to purchase new internal combustion engine vehicles and exclude it from the vehicle removal requirement of the Model Year Schedule or exclude it from the ZEV Milestones calculation. A list of vehicles that are not available ZEVs will be kept on CARB’s website and fleet owners can apply for fleet-specific exemptions if the needed vehicle is not listed.

• Manufacturer sales mandate – Manufacturers may sell only zeroemission medium and heavy-duty vehicles starting in 2036.

• High priority fleets – High priority fleets must comply with the Model Year Schedule or may elect to use the optional ZEV Milestones

Options to phase-in ZEVs into their fleets:

○ Model Year Schedule: Fleets must purchase only ZEVs beginning 2024 and, starting January 1, 2025, must remove internal combustion engine vehicles at the end of their useful life.

○ ZEV Milestone Option: Fleets may elect to meet ZEV targets as a percentage of the total fleet starting with vehicle types that are most suitable for electrification.

ZEV Milestone Option –

Model Year Schedule Option –

• The rule's default Model Year Schedule begins in 2024 and allows drayage, high priority, and federal fleets to continue using their existing trucks until they reach the earlier of 18 years, 800,000 miles, or a minimum of 13 years if the truck has accumulated over 800,000 miles.

• As an alternative to the Model Year Schedule, the ZEV Milestones Option is phased-in over almost two decades and allows fleets full flexibility to manage their fleet composition over the phase-in period, as long as the ZEV Milestones targets are met.

Percentage of vehicles that must be zero-emission

Milestone Group 1: Box trucks, vans, buses with two axles, yard tractors, light-duty package delivery vehicles

Milestone Group 2: Work trucks, day cab tractors, buses with three axles

Milestone Group 3: Sleeper cab tractors and specialty vehicles

Beyond the rhetoric, ACF requirements are developed by CARB using their established principles:

• Maximize ZEVs deployed to meet air quality and GHG goals

• Focus action in disadvantaged communities

• Simplify and streamline compliance and enforcement

• Match vehicle capabilities with fleet operational needs

• Expand infrastructure access to enable new markets

Encourage use of smaller vehicles and innovation

• Support workforce training

• Ensure a level playing field

About the ACF Rule

ACF follows the 2020 adoption of the Advanced Clean Trucks (ACT) rule, which put in place a requirement for manufacturers to increase the sale of zero-emission trucks and its waiver was recently granted by the Biden Administration’s Environmental Protection Agency. Under the ACF rule, fleets will begin the transition toward zero-emission vehicles starting in 2024.

10% 25% 50% 75% 100% 2025 2028 2031 2033 2035 and beyond 2027 2030 2033 2036 2039 and beyond 2030 2033 2036 2039 2042 and beyond

11 The Conveyor • 2023 Summer Issue

Funding for purchasing zero-emission trucks –

• The 2021 and 2022 State budget includes a total investment of $10 billion over 6 years to reduce CO2 emissions from the transportation sector by supporting ZEVs and ZEV infrastructure. This funding will be administered by CARB, the California Energy Commission, the California State Transportation Agency, and the Governor’s Office of Economic and Business Development. Funding programs only pay for early adoption, not for compliance. Some current programs include:

○ Hybrid and Zero-Emission Truck and Bus Voucher Incentive Project

○ Innovative Small e-Fleet Pilot Project

○ Carl Moyer Memorial Air Quality Attainment Program

○ Truck Loan Assistance Program

○ Fiscal Year 2022-23 Funding Plan for Clean Transportation Incentives

○ The federal Inflation Reduction Act of 2022 provides funding for zero-emission trucks and related infrastructure

○ The federal Infrastructure Investment and Jobs Act of 2021 provides funding for new infrastructure investments

The rule includes the ability to continue operating existing vehicles through their useful life. Fleet owners have the option to transition a percentage of their vehicles to meet expected zero-emission milestones, which gives the flexibility to continue operating combustion-powered vehicles as needed during the move toward cleaner technology. The flexibility is intended to take into consideration the available technology and the need to target the highest polluting vehicles. The rule allows fleet owners to receive exemptions based on available technology. And, the ACF rule also includes an end to combustion truck sales in 2036, a first-in-the-world requirement.

To support the needed infrastructure and services to make this transition, agencies across government have committed to the Zero-Emission Infrastructure Joint Agency Statement of Intent. California has been making investments in infrastructure and to support the development and adoption of zero-emissions vehicles. The Joint Statement of Intent lays out the basic tools for direct communication and collaboration between CARB, the California Energy Commission, the California State Transportation

Funding for infrastructure –

• California Public Utilities Commission has approved $1.054 billion to support medium and heavy-duty charging installation pursuant to SB 350.

• Investor owned utilities are authorized to make investments in utilityside infrastructure upgrades to support transportation electrification pursuant to AB 841.

• California Energy Commission will invest $2.69 billion from the State budget in both charging and hydrogen refueling infrastructure inclusive of their EnergIIZE program for commercial fleets.

Increased charging and hydrogen fueling infrastructure for ZEVs –

• The California Energy Commission is investing in the expansion of charging and hydrogen fueling infrastructure via their draft ZeroEmission Vehicle Infrastructure Plan and their Electric Vehicle Charging Infrastructure Assessment. Their Integrated Energy Policy Report is the State’s blueprint for energy generation and supply.

Agency, California Transportation Commission, California Department of Transportation, the Department of General Services and the Governor’s Office of Economic and Business Development. These agencies plan to develop and deploy and help to fund the extensive network of electric charging and hydrogen stations required to help get California to zero-emissions by 2045.

The ACF and ACT rules together limit the ability of ICE vehicles to be sold into the state. Truck

owners affected and not directly affected by the rules won’t find the same marketplace providing opportunities to buy and sell new or used ICE trucks.

What happens in California, isn’t just staying here. Six states have said they will follow California’s lead in adopting ACF rules: New York,New Jersey, Oregon, Massachusetts, Washington and Vermont. n

12 The Conveyor • 2023 Summer Issue

Revisions to In-Use Off-Road Diesel Rule - Prepare for January 1

By Johanna Levine, Manager, Off-Road Implementation Section, CARB

Since the adoption of the In-Use Off-Road Diesel-Fueled Fleets Regulation (Off-Road Regulation) in 2007, the off-road diesel sector has achieved roughly a 17 percent reduction in oxides of nitrogen and 21 percent reduction in fine particulate matter in California. The California Air Resources Board (CARB) thanks its industry partners for over a decade of dedication to compliance with this vital regulation, which has made these emission reductions a reality. However, more needs to be done in order to meet the State’s public health and air quality goals. In November 2022, CARB adopted proposed amendments to the Off-Road Regulation, which are summarized below with a focus on those changes taking effect January 1, 2024.

Tier Phase-Out

Phase out the oldest and highest-emitting off-road engines-Tiers 0, 1, and 2-- from operation in California. Engine “tier” refers to the emissions certification level of an engine and is defined in the Off-Road Regulation section 2449(c). This provision has a staggered implementation by fleet size and engine tier. Large fleets may no longer operate vehicles with Tier 0 off-road engines. Permanent low-use vehicles are not subject to the 2024 phase-out. However, Tier 0 low-use vehicles can no longer operate as of 2036.

Expansion of the Adding Vehicle Requirement

Tier 3 vehicles may no longer be added to any fleet. In addition, medium and large fleets are also

restricted from adding Tier 4 interim vehicles and model year 2006 or older on-road vehicles. Small fleets have an extended timeline for adding Tier 4 interim vehicles.

Low-Use Changes

The year-by-year low-use compliance option expires. Previously, year-by-year low-use vehicles operated in California less than 200 hours during the previous calendar year, but did not need to continue operating less than 200 hours in future years. To add flexibility, permanent low-use vehicles now will be allowed to operate less than 600 hours over three consecutive years. Fleets will be required to maintain records through dated photos or written logs of vehicle usage hours to verify low-use status.

Renewable Diesel Requirements

All fleets are required to procure and use renewable diesel in all vehicles owned or operated in California that are subject to the Off-Road Regulation, with some limited exceptions, including for lack of availability. Fleets must document and retain records related to the fleet’s procurement of renewable diesel.

Contracting Requirements

Prime contractors and public works awarding bodies are required to obtain and retain copies of the valid Certificate of Reported Compliance (Certificate) for the fleet selected for the contract and their listed subcontractors, if applicable. Neither contracting entity may award a contract or hire a fleet without a valid Certificate.

Prime Contractor Requirements

Additional requirements for prime contractors include:

• Collecting valid Certificates from ongoing contract fleets for the current compliance year,

• Allowing only fleets with valid Certificates on the prime contractor's job sites,

• Reporting observed noncompliance to CARB,

• Displaying informative signs at job sites

• Disclosing responsible parties upon request.

Optional Zero-Emission Compliance Flexibility

The Proposed Amendments also introduce two compliance flexibility provisions as incentives to promote the adoption of zero-emission off-road vehicles.

For additional information regarding the proposed amendments to the Off-Road Regulation, visit www.arb.ca.gov/ ordiesel, email doors@arb.ca.gov or call (877) 593-6677.

Disclaimer

The proposed amendments to the In-Use Off-Road Diesel-Fueled Fleets Regulation have been adopted by CARB’s Board but have not been submitted to the Office of Administrative Law (OAL) yet. The rulemaking is ongoing, and modifications could still be made. The information provided is a high-level summary of major changes only and for general informational purposes. The information does not constitute legal or other professional advice. n

TRANSPORTATION

14 The Conveyor • 2023 Summer Issue

PROVEN TECHNOLOGY HIGH UPTIME

Sandvik we have combined years of industry expertise and the latest advances in technology to develop pioneering mobile crushing and screening solutions for you. Utilizing Sandvik’s renowned, proven technology and smart process solutions, such as My Fleet remote monitoring, our equipment is designed to increase operational efficiency, optimize productivity and maximize uptime.

Bakersfield, CA 661.387.6090

Corona, CA 951.277.7620

Fresno, CA 559.834.4420

Lakeside, CA 619.441.3690

Redding 279.201.4869

Sacramento, CA 916.504.2300

Find

San Leandro, CA 510.357.9131

Turlock, CA 209.410.6710 volvoces

VolvoCES facebook.com/volvoces

ph: 714-587-2595 Scott Taylor scott.taylor@tayloresinc.com Ex: 101 Susana Mitchell susana.mitchell@tayloresinc.com Ex: 102 tayloresinc.com

volvoces

ww w vce s volvo.com Construction Equipment & Services

15 The Conveyor • 2023 Summer Issue

us on social media:

Mobile Asphalt Lab comes to California

By Julia Maldonado, Communications Coordinator, CalCIMA

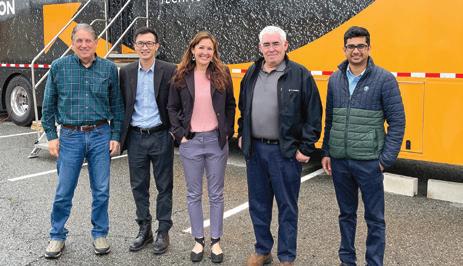

This spring, the Federal Highway Administration (FHWA) held an open house for its Mobile Asphalt Technology Center (MATC) which was stationed at Caltrans’ Southern Regional Lab in Fontana, CA.

The MATC is a mobile laboratory that travels to different transportation departments across the United States. The lab provides “hands-on education, technology demonstrations, field pavement evaluations, and asphalt materials and mixture testing straight to transportation departments and their partners,” according to FHWA. This traveling lab has a knowledgeable team of technicians and contains many different pieces of asphalt testing equipment that industry, academia and transportation departments can learn from, and even borrow and utilize through the FHWA’s Equipment Loan Program.

“The MATC was created to share technology nationwide and put national perspective on it, all towards the goal of creating longer lasting pavements,” said Brendan Morris, project manager for the FHWA’s MATC.

Created in the late 1980s, the MATC was put together to share technology nationwide. Originally focusing on volumetric mix properties, its focuses have evolved over the decades, such as Statistical Pay Factors (SPF) pavement life cycle, material performance properties, introduction and implementation of the Superpave system, balanced mix design (BMD) and much more.

Some of the equipment shown at the MATC include asphalt mixture performance testers (AMPT), handheld x-ray fluorescence,

indirect tensile asphalt cracking test (IDEAL-CT), automatic asphalt cores drying units, and much more.

The FHWA demonstrates its asphalt testing equipment from the MATC at each state department of transportation visit to anyone interested in the asphalt industry and technology. Some of the asphalt testing demonstrations include non nuclear dielectric profile systems (measures density of the asphalt pavement), paver mounted thermal profiler (measures temperature segregation and density of asphalt pavements) and rapid shear rutting test (IDEAL-RT), to name a few.

The MATC made its way back to California for the first time in 20 years, the last time being in

Downey, CA in 2003-2004. The MATC has been to all 50 states except Hawaii, where smaller demonstrations have been conducted in place of the MATC. FHWA determines where the MATC goes based on a variety of factors and receives about 10 to 12 requests for visits every year, though usually can accommodate about six.

“One of the determinations of project selection is when the last time (the MATC) was there,” Morris said. “Another factor is the level of interest? Can we provide some relevant technical assistance?”

The MATC is one-of-a-kind. As of right now, there are no set plans to make another trailer, but other countries have taken interest.

TECHNOLOGY

16 The Conveyor • 2023 Summer Issue

Above: (L to R) Tony Limas, CalCIMA, Chu Wei, FHWA California Division, Leslie Myers, FHWA Office of Pavement and Materials, Brendan Morris, MATC Project Manager and Ram Veeraragavan, MATC Project Engineer gather in Fontana, CA to visit the Mobile Asphalt Technology Center.

Above: Professionals from across the asphalt industry gathered in Fontana, CA in early spring to visit the Mobile Asphalt Technology Center - a traveling asphalt laboratory. Some of the equipment included, but not limited to, asphalt mixture performance testers (AMPT), handheld x-ray fluorescence, indirect tensile asphalt cracking test (IDEAL-CT) and automatic drying units.

possibly looking into deploying one,” Morris said.

The MATC provides an excellent opportunity and resource to learn more about new asphalt testing methods and witness equipment

demonstrations. Learn more about the MATC, its technology, tours and Equipment Loan Program by visiting

https://www.fhwa.dot.gov/matc. n

• Utilizing Type 1L (HS) low carbon cement to reduce embodied carbon and CO2 emissions.

• Providing innovative, high performance mix designs with third party verified Environmental Product Declarations (EPDs) available with every mix.

• Incorporating a large fleet of bulk material haulers (aggregate and cement) and concrete mixers that run on renewable natural gas RNG, reducing GHG emissions.

• Technically advanced, high production facilities providing superior quality and service throughout Los Angeles, Orange and Ventura Counties.

“As far as we know, we are the only country/agency that has such a program. I’ve talked with some folks in Australia who are interested in what we’re doing with the MATC and they’re

nrmcc.com 17 The Conveyor • 2023 Summer Issue

Making the Shift: Cummins rolls out new “fuel agnostic” engines

By Chris Vanasdalan – Sr. Product Communications Specialist, Cummins

In early 2022, Cummins rocked the trucking industry with an announcement: It was expanding its product portfolio with a range of engines built on a common platform and optimized to run on different fuel types. Cummins described the new line-up as “fuel agnostic” internal combustion engines that would expand its proven B, L and X-Series with variants fueled by gasoline, propane and hydrogen.

This isn’t an entirely new idea for the 104-year-old engine maker. Cummins already has natural gas versions of its 6.7, 9 and 12-liter engines. But the fuel agnostic announcement was a clear sign that Cummins is still committed to the internal combustion engine. In fact, the company is making big investments at manufacturing sites and service locations to support these products.

The first product to hit the market will be the X15N, a big-bore natural gas engine designed for line haul and vocational markets. Cummins plans to move into limited production of X15N at the end of this year, with full production slated for 2024. Natural gas powertrains currently make up a small percentage of the North American truck market, but Cummins has seen growing interest recently as end users look at the operation, financial and environmental benefits of natural gas, specifically renewable natural gas (RNG).

To that end, Cummins is investing significant time, resources, and training across manufacturing sites and sales and service channels to ensure a successful launch of the

X15N and the additional products coming behind it.

“We have nearly 30 different channel readiness projects in the works, and the initiatives go far beyond simple facility upgrades to manufacturing and service locations,” said Puneet Jhawar, General Manager – Global Spark Ignited and Fuel Delivery System Business. “We’re designing products in ways that make integration easier for OEMs. We’re reshaping the way we conduct skills-based training programs to ensure technicians are prepared to work on new products with fuel types. We’re developing strong relationships with fuel suppliers and channel partners, launching the Cummins Clean Fuel Technologies joint venture, and extensive field testing of the X15N,” Jhawar said.

That field testing is already well under way. Cummins says there are a total of 16 major fleets that will be operating a combined 25 X15N powered vehicles across a variety of applications and duty cycles. Many of those units are already logging real-world miles.

Expanding the number of public refueling options along major travel corridors is another important part of wider scale adoption of natural gas in line-haul applications. Jhawar says Cummins can use telematics data from engines on the road today to identify high density routes fleets are using. They can then create heat maps of those routes, overlaid with maps of natural gas fuel stations and certified service locations to identify corridors that can already support natural gas deployment, or spot gaps in infrastructure and offer guidance to fuel suppliers about where it makes sense to add more public options.

Given the investments Cummins is making, it’s clear the company believes in the long-term viability of the internal combustion engine. Time will tell how the “all of the above” strategy will play out with fleets.

For more information, contact chris.vanasdalan@cummins.com or (463) 201-4051. n

TECHNOLOGY

18 The Conveyor • 2023 Summer Issue

For every production challenge, Quinn Company has a solution Metso has delivered dependable solutions for demanding aggregate applications the past 150 years, including crushers, screens, feeders, trackmounted and wheelmounted units, stationary plants and automation breakthroughs. Backed by OEM spare and wear parts, maintenance and repairs, extended warranties and full Life Cycle Services, Metso takes your business personally. Contact Quinn Company to learn more. quinncompany.com | 888-987-8466 A Metso distributor 19 The Conveyor • 2023 Summer Issue

2023 Legislative Summit Recap

By Julia Maldonado,

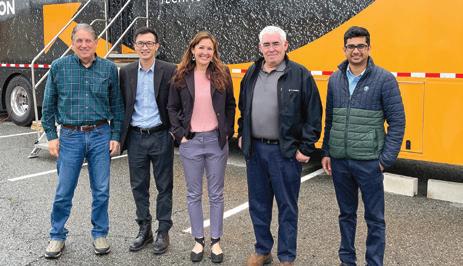

CalCIMA members from throughout California gathered this Spring at our state’s capital for the 2023 Legislative Summit. Kicking off the day at The Citizen Hotel, members had a full day. In the morning, they heard from policy leaders, in the afternoon, they met with legislators and their staff, and, in the evening, they hosted a reception for legislators.

President and CEO Robert Dugan provided guidance on how to communicate effectively and develop relationships with legislators and their staff, including who should develop these relationships, how to create success when forming connections, the do’s and don’ts, how to prepare when it comes to building these relationships, and much more. Keep an eye out for future educational opportunities from CalCIMA on developiong stakeholder relationships.

CalCIMA’s Senior Director of Policy Adam Harper and VP of Policy Charley Rea discussed hot topics with members, including legislation on climate change, disadvantaged communities, transportation, batteries and electrification, and more. The two also discussed what CalCIMA is doing in regard to material-specific legislation, such as providing feedback to the authors on several

Legislators were featured speakers in the morning session. Assemblymember Juan Carrillo (D-Palmdale), who represents an important area of mineral and aggregate production in San Bernardino County and is a former Surface Mining and Reclamation (SMARA) inspector, discussed current challenges with land use planning, permitting, and endangered species. State Senator Roger Niello (R-Fair Oaks) focused

bills.

LEGISLATIVE

Communications Coordinator, CalCIMA

Above: CalCIMA members from all across California gathered at the State Capitol for the 2023 Legislative Summit.

20 The Conveyor • 2023 Summer Issue

Left: Barry Moline from the California Municipal Utilities Association (left) CalCIMA President/CEO Robert Dugan (right) discuss all things energy.

on the challenges and opportunities that come with infrastructure development.

CalCIMA members were also joined by Tanisha Taylor, acting executive director for the California Transportation Commission, who discussed transportation funding, programs and policy. Barry Moline from the California Municipal Utilities Association later joined to discuss the status of and challenges with the state’s net-zero energy goals.

Following the presentations and discussions, members split into groups to visit Capitol offices. They met with over 20 members of the Assembly, Senate and their staff.

In the meetings, CalCIMA members introduced themselves, their businesses and gave insight on the construction and industrial materials industries, including their operations, products, workforces, and community activities, and how it is impacted by legislation. In

many meetings, members invited legislators to tour their operations.

To conclude the day, members, legislators and Capitol staff made their way over to the legislative reception, where they could meet, mingle, and continue their conversations from the meetings earlier in the day.

Thank you to the members, guest speakers, legislators, and staff for attending the Legislative Summit.

Above: Senator Roger Niello (left) CalCIMA President/CEO Robert Dugan (right) discuss infrastructure development.

Above: Assemblymember Juan Carrillo (left) CalCIMA President/CEO Robert Dugan (right) discuss city planning, California transportation and infrastructure.

n Setting the standard for Quarry and Construction drilling and blasting in the West since 1988.

21 The Conveyor • 2023 Summer Issue

(800) 748-7260 McCallumRock.com

Women of CalCIMA tours rock quarry

By Julia Maldonado, Communications Coordinator, CalCIMA

In May, The Women of CalCIMA (WoCIMA) Committee took a trip to the Bay Area to tour Martin Marietta’s Clayton Aggregates facility in Concord, California. This was the first WoCIMA-hosted site tour, with about 20 members in attendance.

WoCIMA members gathered for a safety briefing and background presentation before hopping in a bus to tour the plant. The tour included circling around the southwest corner of the site, as well as the west hill facing the operations. Marc McNeil, the quarry's plant manager, guided WoCIMA while discussing the plant, the team and the products.

Henry Kaiser built Clayton Aggregates in 1956 in order to

supply aggregate base materials and concrete aggregates to complement cement production from the Kaiser Permanente Cement Plant in Cupertino. Now, the shift in focus is toward road repairs and high-quality aggregates - rock and sand.

Along with producing hundreds of thousands of tons of quality aggregates a year, the site's team has a great safety record. Operating under Martin Marietta's companywide safety culture, Guardian Angel, the Clayton team meets weekly to discuss safety and how to work in alignment with company and Mine Safety & Healthy Administration (MSHA) priorities. The result has been two consecutive zero-citation MSHA

inspections and only one lost-time incident in the past nine years. In order to maintain this record, there is a safety committee composed of McNeil, two managers and three hourly workers. The Managers each, along with a unionized employee, make time to walk around the plant, take notes and sit down together to discuss what they saw and what actions need to be taken to improve safety.

Martin Marietta does its part to educate and work with the neighbors and community. One neighboring ranch allowed tour participants to park on their property; that does not happen without goodwill. This site frequently hosts local high schools, allowing students to learn about the

EVENT - PLANT TOUR

22 The Conveyor • 2023 Summer Issue

Above: The Women of CalCIMA visited Martin Marietta’s Clayton Aggregates facility in Concord, CA, where they had the chance to learn more about the pit and operations. Clayton Plant Manager Marc McNeil, gave the group a guided tour.

The point of reference for land, mineral, and environmental strategy b enc hm a r k r eso u rc e s.co m

Left and above: WoCIMA recently toured Martin Marietta's Clayton facility, which hundreds of tons of valuable aggregates.

Left and above: WoCIMA recently toured Martin Marietta's Clayton facility, which hundreds of tons of valuable aggregates.

23 The Conveyor • 2023 Summer Issue

CTAC Improves Concrete Testing

By Charley Rea, Director of Communications, Safety & Technical Services

“v erybody complains about the weather, but nobody does anything about it,” by

EMark Twain

Well, Mark Twain may have been prescient about the concrete industry, too. Too often poor testing procedures are witnessed, but nobody does anything about it.

Now, a unique service is available for CalCIMA members to take charge and do something about poor testing. The Concrete Testing Adherence Collaboration (CTAC) is an opportunity for concrete producers to elevate the standard for concrete testing throughout the construction value chain. Its goal is fair and consistent assessments of ready mixed concrete, per the American Society of Testing and Materials (ASTM) and American Concrete Institute (ACI) standards and guidelines.

It is all too familiar of a story. Concrete producers carefully prepare and test their mixes to meet job site requirements, whether for strength, modulus of rupture, set time, flowability, or sustainability. Yet, how often do you find a technician on site that does not have all the necessary equipment, like a shovel or a wheelbarrow? Fills the test cylinders directly from the discharge chute? Creates more then one set of test cylinders from the same load instead of testing multiple loads as a way to save time? Stores the cylinders or beams incorrectly on the job site? Transports it haphazardly? How often has that resulted in

wasted materials or financial penalties?

The CTAC program helps educate laboratories and contractors about how their testers are performing, where improvements can be made, and how they can contribute to advancing the overall quality of placed concrete. It is not an enforcement program, but a way to provide the concrete producer with more information and tools to engage with the 3rd party testers.

Currently, there are a lot of means for field technicians to be fully trained in the proper sampling and test methods for freshly mixed concrete. Training and certification is available from ACI throughout California, as well as through Caltrans’ Joint Training & Certification Program.

Yet, despite all the great training, there has not been a universal means to track sampling and testing practices

prior to CTAC. On its face, it is a simple program. It begins by downloading an app to a cell phone. This allows the recording of 4 aspects of test procedures, including photographs. The result is access to a series of reports.

Concrete personnel attest to the benefits of CTAC. “I like to refer to this program as an add on to your existing insurance plan for ready mix producers,” says Gave Pirruccello, a technician with American Ready Mix. “Ready mix producers invest ample time and money into their operations to deliver a superior product. I think we could agree that the specifications for concrete vary on most

MEMBER SERVICES

24 The Conveyor • 2023 Summer Issue

Above: CTAC allows participants to record data and capture images of concrete testing at the job site.

every jobsite. With testing companies' high turnover rate, you run into a lot of newcomer technicians sampling in the field. This program gives us the opportunity to observe and record accredited testing companies on their technician’s performance as well as a form of insurance in case of poor testing procedures,” said Pirrucello.

The concrete producer can decide how much time to devote to the program. Most ask their technicians to make observations two to three times a week. Each observation takes about 10—15 minutes.

The observations have been helpful for personnel both in the laboratory and at the job site.

“The program has helped us keep better records of how testing is being performed on jobsites – the good, the bad, and the ugly,” says one laboratory technician.

“Observing the 3rd party lab techs has kept me sharp. It reminds me of the consequences of sloppy testing procedures and poor field storage of samples,” said an observer.

The overall CTAC program is operated by the Colorado Ready Mixed Concrete Association in cooperation with the National Ready Mixed Concrete Association. CalCIMA serves as a state program manager.

There is no cost for CalCIMA members to participate. In addition, it is open to laboratories,

local public works departments, and state agencies to participate in; anyone that has a stake in ensuring concrete quality.

Ultimately, the CTAC program provides a means for concrete producers to help themselves. “The more producers that participate in the program, the more we can make meaningful, positive change in how our concrete is being tested and reported,” said a participant.

If you would like to learn more, contact J.T. Mesite at jt@colorasdocaa.org or Charley Rea at crea@calcima.org, review the CTAC website (www.concretetac.com), or ask for a training session. n

25 The Conveyor • 2023 Summer Issue

CalCIMA training opportunities

CalCIMA is partnering with equipment manufacturers to provide CalCIMA members factory-authorized training. Skill development is integral to maintaining a safe, productive, and rewarding work environment. Empower your technical professionals with this training. Participant spaces are limited. Register at www.calcima.org/register.

TRAINING

26 The Conveyor • 2023 Summer Issue

Amcast / Blow Bars

American Eagle / Belt Scrapers

Beltway / Belt Scales

Donaldson / Dust Collectors

Kenco / Cutting Edges

Luff / Idlers

Monarch / Pulleys

Rockshield / Rubber Screen Panels

Terex|Cedarapids / Jaws, Cones, Screens & Feeders

Terex|Canica / VSI Crushers

Weg & Worldwide / Electric Motors

Weir Minerals|Trio / Crushing, Screening & Washing Equipment

Concrete Solutions for the Concrete Industry

On the road to carbon neutrality, there is no silver bullet. Eco Material Technologies products and technologies lower the carbon footprint of concrete while improving its performance:

• The nation’s largest supply of coal fly ash for concrete, with a coast to coast logistics network, extensive inhouse laboratory capabilities, and the industry’s deepest bench of fly ash experts.

• Pozzoslag® products useful in replacing high volumes of carbon-intensive portland cement.

• Kirkland Natural Pozzolan, bringing new supplementary cementitious materials supplies to markets challenged by coal plant closures.

• Micron3® refined pozzolan for high performance concrete applications.

• A full suite of beneficiation technologies enabling utilization of lower quality coal ashes and harvesting of previously disposed coal ashes.

Eco Material Technologies is your partner in a cleaner future.

www.ecomaterial.com

AGGREGATE PROCESSING has been our FIRST LANGUAGE for 25 years... 5594 E. La Palma Ave. Anaheim, CA 92807 (714) 696 7599 email: mikeb@butlerjustice.com website: butlerjustice.com

27 The Conveyor • 2023 Summer Issue

National association news

ESSENTIAL MINERALS ASSOCIATION (EMA) Essential Minerals Association Hosts Surface Transportation Board in May

The Essential Minerals Association (www.essentialminerals.org) was excited to have the opportunity to host all 5 of the Surface Transportation Board (STB) members (www.stb.gov) and their staff at our soda ash operations in Green River, Wyoming the first week of May. The STB oversees rail freight issues in the United States and has been working diligently the last couple of years to level the playing field for shippers across all industries. The railroads have not been providing the type of service necessary for our sector, which provides the raw materials vital for most manufacturing and agriculture. This was the first-time the STB members were able to do this type of multi-day visit to get a stronger appreciation for the needs of our minerals sector and was a strong success. We thank the STB for their renewed focus on this critical issue, and look forward to continuing to work with them in the months ahead.

NATIONAL ASPHALT PAVEMENT ASSOCIATION (NAPA)

First-of-its-Kind Report Publicly Documents GHG Emissions for Asphalt Pavement Mixtures

One year ago, NAPA published GHG Emissions Inventory for Asphalt Mix Production in the United States (SIP 106), the first national cradle-togate assessment of GHG emissions associated with the production of asphalt pavement mixtures. Cradle-to-gate emissions in 2019 represented approximately 0.3% of total U.S. greenhouse gas (GHG) emissions. By comparison, U.S. EPA data indicate that transportation emissions from fossil fuel combustion represented 27.8% of total emissions in 2019, while industrial emissions

represented 25.3%. Meanwhile, the industry avoided 2.9 million metric tons (MMT) CO2e emissions –equivalent to the annual emissions from approximately 630,000 passenger vehicles – by using RAP, WMA, and alternative fuels. “The report puts NAPA and the asphalt pavement industry at the forefront of transparency among carbon emitters,” said NAPA President & CEO Audrey Copeland, Ph.D., P.E. “We’re demonstrating our commitment to doing better, as prescribed in The Road Forward, by taking stock of where we are and identifying proven and innovative strategies to reduce carbon emissions.” The report, along with ways to get involved with The Road Forward, is available for free download at AsphaltPavement.org/ Forward

NATIONAL STONE, SAND & GRAVEL ASSOCIATION (NSSGA)

NSSGA Hosts Congressional Staff for Hands-on Quarry Visit

There is no substitute for seeing a quarry in person. On May 2, NSSGA and our members (Luck Stone, Vulcan Materials and Superior Paving) hosted over 30 congressional staffers at the Luck Stone Bull Run Quarry in Chantilly, VA. Congressional staff participated in informative briefings and was able to see a live blast in the quarry as part of the tour. This engaging event was made possible through the collaborative efforts of Luck Stone, Vulcan Materials and Superior Paving, who provided insightful tours and a unique opportunity for the attendees to witness a controlled blast in the quarry. NSSGA is grateful to our members for their efforts. This event fostered a deeper understanding of the vital role the aggregates industry plays in our nation's infrastructure and showcased the commitment of these companies to responsible and sustainable practices.

NATIONAL READY MIXED CONCRETE ASSOCIATION (NRMCA)

The concrete industry has been actively preparing for projects funded under portions of the Inflation Reduction Act (IRA). These projects are primarily targeted at improving infrastructure with low carbon construction materials, hence the close interaction between the industry, the Federal Highway Administration (FHWA), and the Environmental Protection Agency (EPA).

Industry Preparations

Preparing for these projects, where funds must be allocated by 2026, the cement and concrete industry have been investing in creating cost-efficient, durable, and environmentally friendly products. It has developed low carbon concrete and high-performance variants that can increase the lifespan of infrastructure, thereby reducing overall costs and environmental impact in the long run. The industry is also ramping up production capabilities and streamlining supply chains to accommodate the expected surge in demand.

Interaction with FHWA

The FHWA is directly involved in the administration of federally funded highway projects, making it a critical stakeholder. The concrete industry has been collaborating with the FHWA to ensure the materials produced and delivered meet the needs of the state and local agencies tasked with building the projects funded by the IRA while also meeting the sustainability demands.

The FHWA is developing guidelines and proposed specification language for use of low carbon construction materials and the industry has been engaging with the agency to assist in their development They've jointly hosted sessions and workshops to align on these standards and to keep industry

NATIONAL NEWS

28 The Conveyor • 2023 Summer Issue

The Ultimate Release! Why use anything less and pay more? NON-TOXIC | BIODEGRADABLE Made in the USA TOLL FREE: 800.331.2243 www romixchem com SEE THE ACTION Construction Materials industry comes together in DC. 29 The Conveyor • 2023 Summer Issue

specialists in engineering, safety, planning and the environment

Services:

Land Use and Environmental Planning / CEQA and NEPA Compliance

Construction Materials, Industrial Minerals, and Metal Mining / SMARA Compliance

Air Quality & Permitting Services

Environmental Health and Safety and Regulatory Compliance and Permitting

Hazardous Materials and Hazardous Waste Management

Groundwater and Surface Water Studies and Permitting

Geologic and Mineral Resource Assessment and Characterization

Comprehensive Transactional Due Diligence Services

Environmental Site Assessment and Investigation

Industrial Hygiene / Support to Legal Counsel / Training

VENTURA

P: (805) 275-1515

F: (805) 667-8104

SAN DIEGO P: (619) 894-8669

F: (805) 667-8104

(458) 212-2520

F: (805) 667-8104

805.275.1515 / sespeconsulting.com

We keep your environmental compliance in check so your operations run smoothly

Biology & Wetlands

CEQA & NEPA

SMARA & Permit Compliance

Ecological Restoration Mitigation Solutions

Revegetation & Erosion Control wra-ca com

GRANTS PASS, OR P:

30 The Conveyor • 2023 Summer Issue

PLANT TECHNOLOGY FOR PROCESSING NATURAL STONE AND RECYCLING KLEEMANN supplies a large range of jaw crushers, impact crushers and cone crushers, as well as screening plants for processing minerals and recycling construction materials. California’s Largest General Line Construction and Municipal Equipment Dealer. So. California: 2044 S. Vineyard Ave., Ontario, CA 91761 • (909) 930-1822 No. California: 800 E. Grant Line Rd., Tracy, CA 95304 • (209) 830-8600 Nevada: 2750 Marion Drive, Las Vegas, NV 89115 • (702) 342-8100 www.nixonegli.com TRACK-MOUNTED SCREENING PLANT MOBISCREEN MS 15 Z / MSC 953i EVO IN STOCK AVAILABLE FOR RENT CALL Shari @ 909.938.1021 MOBISCREEN MS 15 Z MOBISCREEN MSC 953i EVO

“Everything That’s Rubber” www. CIR . net • Belting • Belt Lacing • V Belts • Hose • Hose Fittings • Hydraulic Hose, Tube & Couplings • Hydraulic Adapters • Rainwear • Work Gloves • Rubber Boots • Tarp Material • Mats & Matting • Gasket Material • Gaskets • Sponge • Tubing • Sheet Rubber • Plastics • Adhesives • Fabrication Bakersfield Branch 19428 Colombo Street Bakersfield, CA 93308 Phone: 661-392-1912 bakersfield@cir.net Fresno Branch 2539 South Cherry Ave. Fresno, CA 93706 Phone: 559-268-7321 fresno@cir.net Merced Branch 2280 Cooper Avenue Merced, CA 95348 Phone: 209-722-8844 merced@cir.net Tulare Branch 4500 South "K" Street Tulare, CA 93274 Phone: 559-686-1677 tulare@cir.net Yuba City Branch 1690 Sierra Avenue Yuba City, CA 95993 Phone: 530-674-2444 yubacity@cir.net Carlin, NV 1120 Green St. Carlin, NV 89822 Phone: 775-754-6747 carlin@cir.net Sparks, NV 1095 Spice Islands Dr. #103 Sparks, NV 89431 Phone: 775-356-0192 sparks@cir.net Full Service Machine Shop Sliger Machineworks (A division of CIR) 3620 South Bagley Ave Fresno, CA 93725 Phone: 559-442-0211 machineworks@cir.net For all your conveyor belt and industrial rubber and plastics needs, including on-site belt splicing and custom manufactured conveyor systems C I R MANUFACTURED CONVEYOR SYSTEMS Call Today!

By Julia Maldonado, Communications Coordinator, CalCIMA

By Julia Maldonado, Communications Coordinator, CalCIMA

By Suzanne Seivright-Sutherland, Director of Regional Government Affairs & Grassroots Operations, CalCIMA

By Suzanne Seivright-Sutherland, Director of Regional Government Affairs & Grassroots Operations, CalCIMA

Left and above: WoCIMA recently toured Martin Marietta's Clayton facility, which hundreds of tons of valuable aggregates.

Left and above: WoCIMA recently toured Martin Marietta's Clayton facility, which hundreds of tons of valuable aggregates.