6 minute read

Sustainable Material Assembly

case study “art of Material” report #2 & 3

FND 2011 Sustainable Material Assembly Instructor: Michael Fiorillo, Wei Cheng Date: 21 st , Oct 2019 - 9 th , Dec 2019 Individual work

Advertisement

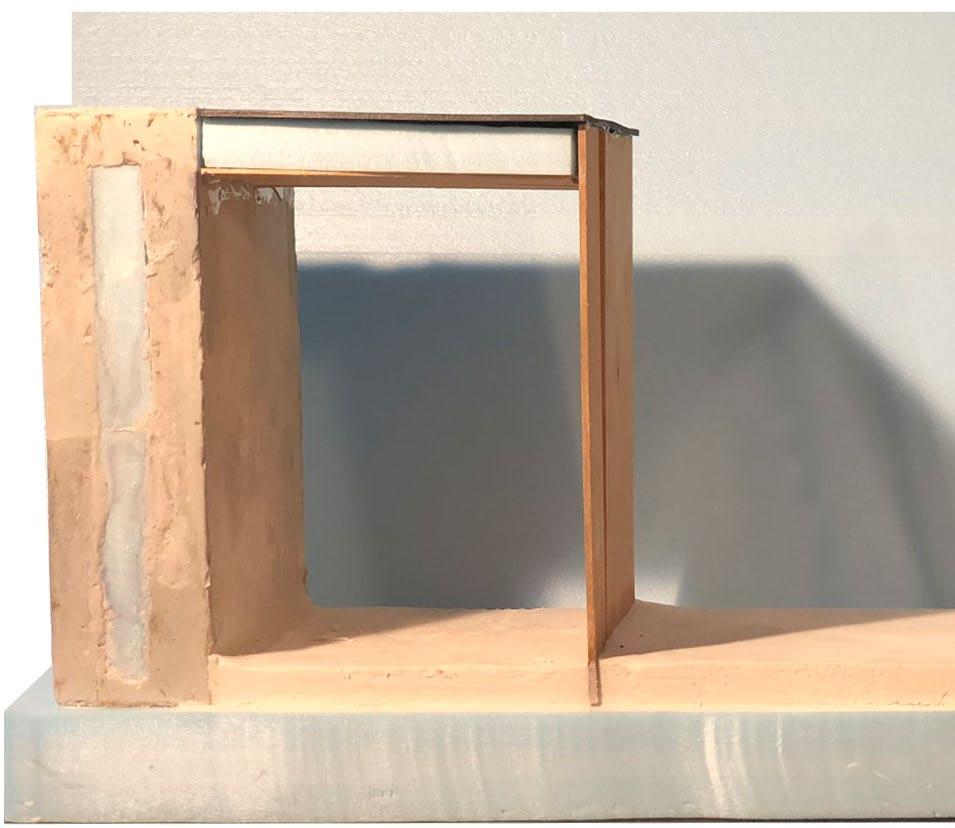

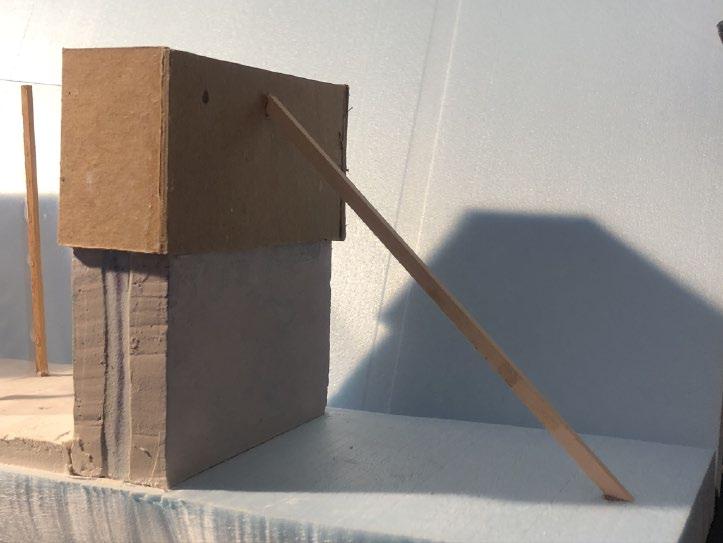

Roof Corner Detail Interior Wooden Partition Detail Exterior Wall & Floor Detail

CASA CALDERA DUST Architect The Casa Caldera is a private holiday house was built in Arizona by DUST architect. The building material used is poured lava-crete. The lava-crete is the mix of scoria, cement and water. Compare to traditional concrete, lava-crete is more environmental friendly, at the same time, lave-crete have better thermal performance and acoustic performance.

Conditioned Space

Air flow Conditioned Space

Living spaces Zaguan leeping space S

The Casa Caldera used a thermal massing method to insulate the building. This technique is effective when the temperature gap within a day is big.

The center hallway in the building is a opened space. This space can provide airflow to the building and cool the building down or heat the building up.

This hosuse is devided into 3 parts, each parts are assigned to different functions. The Zaguan is a traditional area in the traditional houses in Arizona State.

Section Model of CASA CALDERA

Interior Wood Ceiling

Case study report #2

Interior Wood Partition

Because the building used poured lava-crete as material, in order to simulate the building process, I decided to use plasma as the material to make my own building model. It is my first time making plasma model. The model is hard to dry especially in the water of Boston. So by the time I photographed this model, it is still a little bit dry. But the plasma model really works for the Casa Caldera and it perfectly simulated the texture and building process or the Casa Caldera.

Customized Window Partition

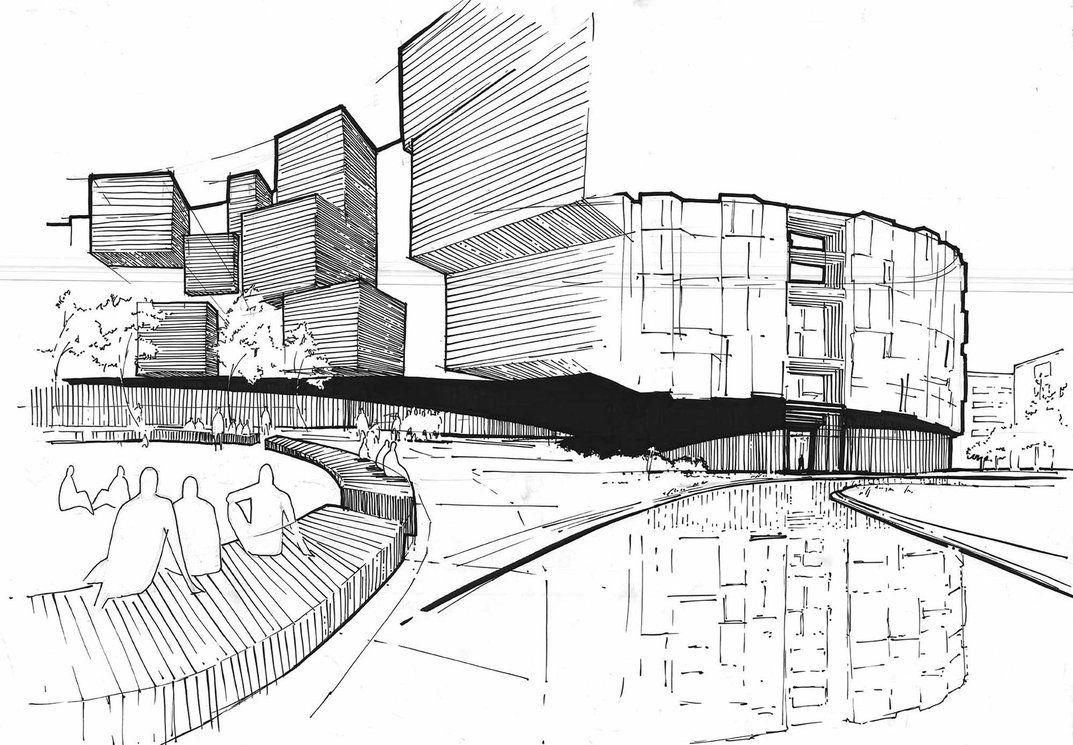

Tietgenkollegiet, in Cobenhagen is a Educational architecture served as the student residence. The conspicuous circular form of the Tietgenkollegiet is originated from the traditional southern Chinese Hakka. The building is 7 stories high and have multiple functional spaces, including 360 separated rooms with restrooms and kitchens, one courtyard, a cafe, several study and computer rooms and laundry rooms. The major materials are used in this building are wood, concrete and steel. The Tietgenkollegiet used a modular construction method. There are 4 basic types of rooms: 26 m 2 , 29 m 2 , 33 m 2 and 42 m 2 . Student Residential Lundgaard & Tranberg Architects Rued Langgaards Vej 10, 2300 København, Denmark

1 stack have several columns of units.

[10]

Central Yard

Load Bearing Walls

[11]

Repeating of the units

Small modular parts are constructed by the Pihl Construction

The modulars are designed by L undgaard & Tranberg Architects

Stacks are built on-site and all modular parts are assemblied on-site

This is the material map of the Tietgenkollegiet. I have to say it is hard to locate where the concrete came from, so instead, I located the contractor and the design firm. In this case, I can present to the audience how the idea of this building is transfered from the design firm to the contractor and how the modulars are assemblied on-site.

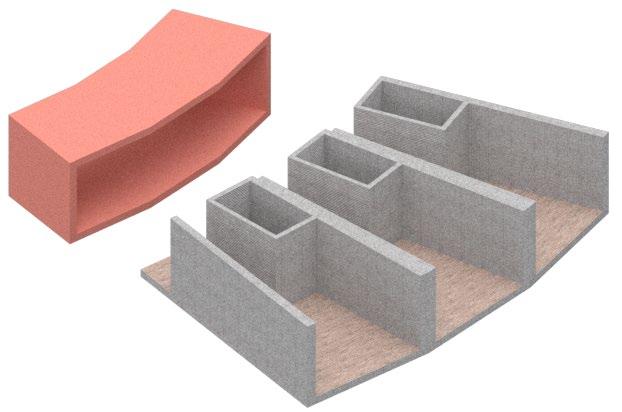

The base form of the Tietgenkollegiet is a circular form consists of the repeating bedroom units. The whole building is splited into 5 blocks. Between the blocks are the staircases. Basic Circular Form

For each blocks, the additional modulars will be added to the building, and form different spaces to fulfill different functions. Modular Assembly Overview

This is the first time for me to bring Grasshiopper into production process. Since the building implemented a modular construction method, I decided to use grasshopper to generate basic form of this architecture. The algorithm below shows how did I generate the form in Rhino using Grasshopper. Grasshopper Algorithm

This mothod of assembly is the assembly for a base bedroom and it can extend the area of the bed room. This model can extend the size of the bedroom from 26 m 2 to 29 m 2 , 33 m 2 or 42 m 2 . Bedroom Unit

This method of assembly is the space as public kitchens. This model will be added to the building as an extension facing the center courtyard, usually located near the staircase. Public kitchen Unit

Standard Interior View

This method of assembly is the space as a computer lab or a study room. This model will be added to the building as an extension facing the center courtyard. Computer Lab/Study Room Unit

Material Capacity Diagram

Case study report #3

The modular architecture is a building method sepcifically suited for large scale architectures because the technological limitations of pumping large amount of liquid concrete to higher level of the buildings. Comparing with reinforced concrete building method, modularization architectures are safer for the workers and easier to control the logistical services and project schedule. Comparing with prefabricated architecture, modularization architectures can reach larger scale and more program for the architecture. Overall, modularization is can reach the balance between building scale and project management. Modular VS Prefab

Project Catagories

Modularization

Reflection

Prefabrication logistical Pressure Building Scale Safety Project Management

In the Sustainable Material Assembly, I learned about the basic structure and material of the architecture. The SMA helped me to understand what the building is made from, how the building is built and most importantly: why the building is sustainbale. Being an architect need to know these because they will help architects understand the architectures in a professional way. This course helped me understant the building systems like the envelope, landscape and fundation. Before learning this class, I simply care about what the building looks like and works like, however, now I started to think how the building will be built and how can I change how people feels about his building by changing the material or building systems.