meatbusinesspro.com $7.99 THE BEEF, PORK & POULTRY INDUSTRY DIGITAL MAGAZINE August 2023 Canada Launches Pilot Program to Cut Red Tape for Temporary Foreign Workers Understanding Pest Control for Meat Processing Plants National Beef Strategy Update Let Farmers Farm! Red Tape for Temporary SPECIAL FEATURE - THE FUTURE OF CULTIVATED MEAT FEATURE

https://www.yesgroup.ca

2 MEATBUSINESSPRO August 2023 meatbusinesspro.com

AUGUST 2023

5 6 10 14

Canada Launches Pilot Program to Cut Red Tape for Temporary Foreign Workers

Special Feature - Q+A with Dana McCauley, CEO, Canadian Food Innovation Network - The Future of Cultivated Meat

Understanding Pest Control for Meat Processing Plants

18 20 22

National Beef Strategy Update

Handtmann Launches New High-Performance Line

Persistently High Retail Prices, Soft Demand Cloud Outlook for U.S. Pork Producers Let Farmers Farm!

https://www.yesgroup.ca

THE BEEF, PORK & POULTRY INDUSTRY DIGITAL MAGAZINE

August 2023 Volume 24 Number 8

PUBLISHER

Ray Blumenfeld ray@meatbusiness.ca

MANAGING EDITOR

Scott Taylor publishing@meatbusiness.ca

DIGITAL MEDIA EDITOR

Cam Patterson cam@meatbusiness.ca

CONTRIBUTING WRITERS

Patterson,

CREATIVE DIRECTOR

Patrick Cairns

Meat Business Pro is published 12 times a year by We Communications West Inc

CANADA LAUNCHES PILOT PROGRAM TO CUT RED TAPE FOR TEMPORARY FOREIGN WORKERS

The Canadian government is launching a three-year pilot program aimed at addressing labour shortages for employers who hire migrant workers and to make sure those workers are safe from abuse.

The Recognized Employer Pilot (REP) is designed to ease the administrative burden and simplify the hiring process for employers who have historically complied with the requirements of the Temporary Foreign Worker (TFW) Program. The REP will kick into gear first for employers in the primary agricultural sector this coming September when those employers will be able to apply in time for the 2024 season.

The project "will cut red tape for eligible employers, those who demonstrate the highest level of protection for workers, and make it easier for them to access the labour they need to fill jobs that are essential to Canada's economy and food security," said federal Employment Minister Randy Boissonnault in a statement.

CO MMUNICATIONS W EST IN C

We Communications West Inc. 106-530 Kenaston Boulevard Winnipeg, MB, Canada R3N 1Z4

Phone: 204.985.9502 Fax: 204.582.9800

Toll Free: 1.800.344.7055

E-mail: publishing@meatbusiness.ca

Website: www.meatbusinesspro.com

Meat Business Pro subscriptions are available for $28.00/year or $46.00/two years and includes the annual Buyers Guide issue.

©2020 We Communications West Inc. All rights reserved.

The contents of this publication may not be reproduced by any means in whole or in part, without prior written consent from the publisher. Printed in Canada. ISSN 1715-6726

Traditionally, before submitting an application to hire a migrant worker, employers would need a Labour Market Impact Assessment (LMIA). That assessment is to confirm there is a need for such workers and that there are no Canadian citizens or permanent residents who can do the job.

Under the REP, employers in good standing can access various LMIAs, as well as a simplified LMIA application, the government says.

These employers will also have a designation on the TFW job portal showing their recognized status to prospective employees.

An immigration policy and labour expert says as far as red tape, 98.6% of employer applications to hire migrant workers were approved last year.

"There has been this movement lobbying, very active lobbying, very visible lobbying from the business community to try and reduce the red tape to reduce to make accessing these workers easier," said Mikal Skuterud, an economics professor at the University of Waterloo.

Skuterud says the new pilot is an example of the federal government making it easier for employers to access workers. He added that the TFW program started as a way to bring in agriculture workers but has now expanded to more industries which offer low-wage jobs.

"Increases in temporary foreign workers within workplaces serves to lower wages for everybody within those workplaces and it has the potential, of course, to lead to spillovers and competing firms as well," Skuterud said.

meatbusinesspro.com

Cam

Jack Roberts, Scott Taylor, Bradlee Whidden

THE FUTURE OF CULTIVATED MEAT

Meat Business Pro spoke recently with Dana McCauley, CEO of the Canadian Food Innovation Network (CFIN), one of this country’s top food industry experts. Our discussion focused on the status and future outlook for cultivated meat.

MBP: How long have you been with CFIN? And what interested you about it?

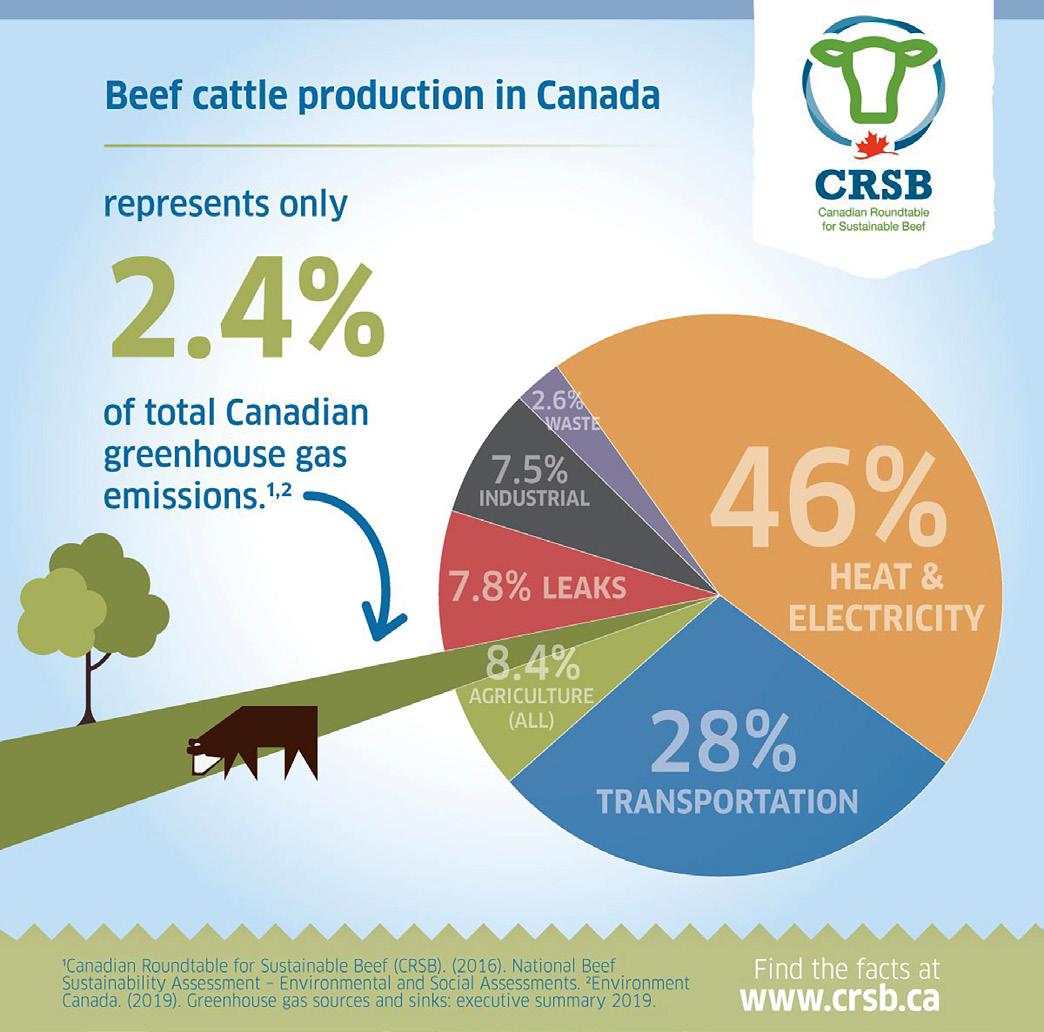

With pressing issues surrounding climate change, greenhouse gases, animal welfare and transportation, a new product is beginning to make inroads to the meat industry.

Cultivated or cultured meat is in fact genuine animal meat that is produced by cultivating animal cells directly. This production method basically eliminates the need to raise and farm animals for food and does not require breeding or slaughtering animals.

The larger philosophical question becomes, what is the real future of meat cultivation? While this segment of the meat industry is very much in its early stages, it does require attention in terms of sustainability issues, food security, regulatory compliance, market growth and other challenges that are unknown at this time.

DM: I joined in August 2021 and I was employee number two. We wanted people to think of us as the place to go to find out about new innovations happening in the food business. But we differ from groups like the Good Food Institute in the U.S., who would be very interested in cellular food, but not so much in say robotics, whereas we are.

MBP: What are your thoughts of the analogy that cultivated meat is on the same level as electric vehicles? Even though it's very much in its infancy, the long-term future of it looks very encouraging, especially for Canada.

6 MEATBUSINESSPRO August 2023 meatbusinesspro.com

Special Feature - Q+A with Dana McCauley, CEO, Canadian Food Innovation Network

DM: The numbers tell us there's market opportunity, and so we have folks who want to learn and understand how this effectively fits into their business model. They're generally people who are looking at global opportunities because in Canada we are protein sustainable. We produce enough meat for everybody in in this country because of our prairie grasses; we're much more sustainable than Brazil or other protein producing countries. As we can see a world population of nearly 10 billion people that will have to be fed on the planet in the not so distant future, and their protein needs, then, yes, that’s an amazing export opportunity for Canada to set the standard in this sector.

MBP: How can this opportunity grow the market sector for other parts of the world, especially as the world's population moves away from plant-based diets to protein-based diets? It seems to be an underserved market.

DM: We have biochemists, engineers, food scientists, geneticists, so yes we can create the foods and the equipment that other countries need. And we could easily pivot and start making bio reactors, for instance.

MBP: There are many positives that can come from this new technology for the meat industry as a whole that relate to animal welfare. What are your thoughts on that issue?

Continued on page 8

7 meatbusinesspro.com August 2023 MEATBUSINESSPRO

VEMAG REPLACEMENT PARTS https://www.dhenryandsons.com

DM: Imagine if you are a rancher who has the best sires that create the most delicious meat, and now there’s this opportunity for you to sell your stem cells to a cellular food company. Imagine how that would help increase your profits while also providing a humane solution.

MBP: What are the current challenges facing this industry sector?

DM: One is a lack of capital. Those deep pockets that were burned on the planet-based meats are now more hesitant to jump in on innovative or alternative protein projects. Also a lack of capacity. Today, the largest bioreactor that I'm aware of in Canada is 10,000 litres. To have a national brand that's in grocery stores, you would need several bioreactors operating 24/7. Here in Canada, capacity and money are the two predominant challenges we’re facing.

An offshoot challenge is when companies start going to other markets where they can get those two things, and subsequently encouraged to set up their headquarters in the U.S. or Singapore or Israel. As a result, we lose the potential tax benefit as well as the loss of job creating opportunities of having them be Canadian companies when that IP leaves our country.

We have a report coming out where we gauged consumer and media sentiment about these topics in both U.S. and Canada. We also tracked how IP generation and company formation is happening in both the U.S. and Canada. It clearly shows that the U.S. is much farther ahead of us.

MBP: How do you overcome this challenge of not being properly funded? Is there private money available or are there public organizations that provide grants or subsidy programs?

DM: CFIN has funded a lot of companies to do projects that will validate their value proposition and get them closer to market. In fact, one of the companies in a video we just released has a relationship with Upside Foods in the U.S. that just got approval to sell their chicken products.

There are a lot of partnership opportunities internationally where we're starting to see saleable products. We are focused on helping these companies here in Canada to develop those relationships. One such group in Edmonton, Cult Food Science is very focused in this space. They’re working with the University of Alberta to develop, research and accelerate programs for these companies.

We are also focused on educating people to mitigate the fear factor with positive messaging, explaining the difference between cellular foods, cellular agriculture, cultivated meat, etc. We’re trying to use consistent language because if investors don't understand what somebody's saying, they're going to feel uncomfortable putting their money into it. But the message is getting out there in the food industry.

I know that Agri-Food Canada are very interested in the lab grown meat and are meeting with groups like New Harvest, a not-for-profit started in the U.S. by Canadians.

8 MEATBUSINESSPRO August 2023 meatbusinesspro.com

MBP: There’s also the concern is getting people to trust in technology generated food, which is a polarizing conversation.

NSF INTERNATIONAL FOCUSES ON CANADIAN FOOD INDUSTRY WITH NEW WEBSITE FOR SERVICES IN CANADA

website - www.nsfcanada.ca - to give Canada’s growing and complex food and beverage industry easy access to the global public health organization’s expertise and services in Canada. The website combines information on the depth, experience and capabilities of the NSF International Canadian office with access to NSF International’s global services dedicated to food safety and quality.

MBP: Let’s shift to sustainability of lab grown meat. It's safe to say right now, with the loss of grasslands and forest lands from wildfires this year, it's not going to be long before livestock quotas are going to really suffer. Is there a forecast that you've had in any of your projections that give you an idea of how laboratory meat technology would have to ramp up to absorb conventional livestock loss?

DM: That is an important point. Last September, I sat on a panel at a Canadian Institute of Food Science and Technology event where we discussed how to frame the message so that people can see a benefit for themselves personally. Starting with nonmeat foods seems more palatable to consumers. For instance, an imported product like coffee could be a product to start with in Canada. Regardless, the product development challenges need to be surmounted so that the first foods people try meet their expectations. Even if we can create a steak that is bioidentical to one cut from a cattle carcus, the end product will need to have the familiar texture you know and enjoy while eating. In the end, that will require dozens of cellular produced products being combined in exactly the right way to replicate the muscle an animal creates naturally.

For more information on the Canadian Food

Evolving regulations across countries and increasing complexities associated with a globalized food supply network present challenges for NSF International clients in Canada and around the world. The new Canadian website offers expertise and services to help companies navigate these challenges, including certification and auditing, consulting, technical services, training and education, food and label compliance, packaging, and product and process development.

DM: Canada is protein positive right now and is relatively sustainable in the way we produce beef. However, for this technology to fill a livestock gap, getting enough stem cells is the priority. I’m not sure we fully understand all the sustainability implications that will arise as the world becomes able to make cellular foods at scale. There are pros and cons with any technology. For instance, take the analogy between cellular foods and electric vehicles, if we want more nickel for EV batteries, that will result in open pit mining and that's not good for the environment.

accredited International Association for Continuing Education and Training (IACET) site. Topics include HACCP, food safety and quality, GFSI benchmarked standards, regulations (including FSMA), food science, food packaging, food microbiology and ISO standards. Training modalities include eLearning, on-site, customized and open enrolment. Additionally, the website includes information about management system registrations for the food, automotive, environmental, information security, medical devices, aerospace and chemical industries, as well as for Ontario drinking water programs.

NSF International’s Canadian website provides information on the following services:

Certification & auditing: Third-party food safety audits and certifications, which are integral components of supplier selection and regulatory compliance. Accurate audits are the first step toward successful verification of a company’s food safety system, providing improved

Global public health organization showcases services for Canada’s growing and fast-changing https://www.yesgroup.

9 meatbusinesspro.com August 2023 MEATBUSINESSPRO

September/October 2017 CANADIAN MEAT BUSINESS 23 meatbusiness.ca YesGroup_CanadianMeatBusiness-Qtr-pg.pdf 1 2014-05-16 1:20:17 PM

Training and education: Training for the global food and beverage industry across the supply chain as an

the new Canadian

at

to review the food safety services capabilities video, find a list of Canadian food experts, learn about upcoming events and global news releases, submit a question or read an FAQ.

Visit

website

www.nsfcanada.ca

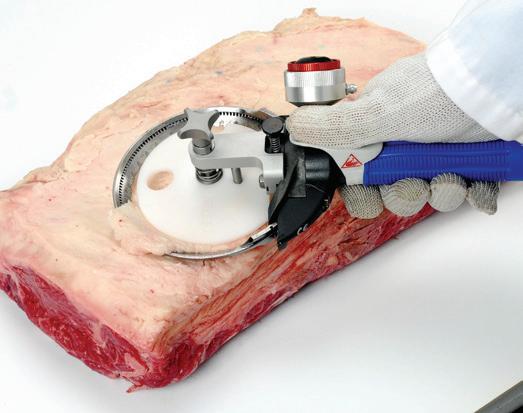

UNDERSTANDING PEST CONTROL FOR MEAT PROCESSING PLANTS

Maintaining a clean, hygienic environment is not just a priority but an absolute necessity in the meat processing industry. Becoming known for having a lessthan-hygienic environment can destroy your reputation, lower the number of businesses willing to work with you, and even lead to legal implications around health and safety. One prominent hygiene issue facing facility managers today is wildlife control.

The presence of pests poses severe risks to the safety and quality of the meat, the plant's overall operations, and, as established, the business's reputation. This article provides an in-depth understanding of pest control in meat processing plants, outlining common wildlife pests, methods for handling infestations, and effective prevention strategies to ensure a sanitary, pest-free environment.

THE IMPORTANCE OF PEST CONTROL

Operating meat plants in Canada has many health and hygiene rules to remember. One of these guidelines is related to the presence of non-food animals. As outlined by the Food Safety and Quality Act, no animals (other than food animals) are permitted to be in any room or area of the meat plant. Contamination occurs when any unhygienic outside source comes in contact with your equipment, and unfortunately, wildlife are known to carry bacteria and diseases that can potentially infect your facility. Apart from that, many pests also cause damage to facility property leading to more adverse issues. Therefore, having pests in your meat plant means your entire facility is no longer compliant with health regulations, so it must be addressed as quickly as possible.

Unfortunately, many meat plant operators have had run-ins with pesky wildlife at least once or twice. Meat processing is one of those industry areas that is very attractive to wildlife. Facilities are generally spacious, providing pests with shelter and offering various food sources. If your facility does not put in place prevention strategies quickly, chances are you’ll run into one of the following pests.

10 MEATBUSINESSPRO August 2023 meatbusinesspro.com

COMMON PESTS IN THE MEAT PROCESSING INDUSTRY

https://www.beaconmetals.com

RODENTS

Rats and mice love nothing more than a good, steady food source, and meat plants represent a huge food source. These creatures are omnivorous; they will jump at the opportunity if any type of scraps are left around. Apart from this source, even if you’re careful not to drop anything, rodents are drawn to your trash bins or lunch area, where scraps are discarded. There are also many nesting opportunities for rats and mice in areas of your facility or behind walls where they won’t be disrupted.

BIRDS

An open window, a bay door, or a small gap in your building’s structure can represent open invites for birds to fly in and try to find a nesting location in your facility. Birds are a scary sight for meat plant operators because their feathers and droppings are contaminants that can be more difficult to control and catch.

RACCOONS

In urban areas in Canada, raccoons are a huge issue, which is even more prevalent for meat processing facilities. Though they won’t commonly nest in your facility, raccoons are highly intelligent and are aware that meat plants represent huge potential food sources for them. That’s why seeing them in and around your dumpster or outside your building can be much more common. While it’s not an inherent hygienic issue to have raccoons outside your facility, they may still enter and track contaminants into your facility.

HANDLING INFESTATIONS

When you notice any signs of pest activity, such as rodent holes in walls or baseboards, nesting materials, droppings, or scratching noises behind the walls, immediate action is necessary. No matter what stage of an infestation your facility is under, the quicker you act, the more efficiently you can tackle the issue.

MINIMIZE FOOD SOURCES

The primary reason pest wildlife enters your plant is for food. So, even though you’re in the market of producing food, you need to cut down on the potential pest food sources around your facility. Dispose of waste properly, and don’t let it sit in cans or dumping stations longer than needed. Ensure that you have accessible deposits for excess meat and unused materials.

SEAL ENTRY POINTS

Do a complete walk-around of your plant, looking at exterior walls, doors, and windows, and see if any gaps could be potential entry points. If your facility has large bay doors for shipping products, keep the interior doors closed, and don’t leave the bay doors open for longer than needed.

MAINTAIN CLEANLINESS

Every meat producer knows how important this step is in maintaining a facility, but it’s most vital when dealing with a pest problem. Pest wildlife generally thrives in less well-maintained areas, so by creating and implementing a rigid cleaning program, you are cutting down on the areas that pests can occupy.

12 MEATBUSINESSPRO August 2023 meatbusinesspro.com

WORK WITH THE PROS

Though there are many steps you can do yourself, you are taking time away from your busy production schedule. Ultimately, your facility should engage experienced pest control professionals with the technology available to manage potential infestations more efficiently and humanely than you can on your own. Search your area for professionals with strong reputations of excellence and whose service specifically mentions the pest you are dealing with.

PREVENTION STRATEGIES

So far, the primary discussion has been around dealing with a pest infestation once it occurs. However, the goal of every meat processing facility should be to be proactive with pest control and prevent animals from accessing in the first place. That’s where pest prevention strategies come in.

Proactive pest control is all about preventative design. Off-the-lot, there may be many different locations around your plant where pests can take shelter and nest. Preventative design is about finding those areas and specifically targeting them to eliminate the risks of pests taking them over. For example, many facilities install bird barriers, such as bird netting, around the exterior of their facility. This closes off nesting locations and ultimately reduces the number of birds around your building.

Another thing you can do is target areas that receive less traffic in general - obviously, your production floor will often be busy with people, well-lit, and cleaned regularly. However, what about the rest of your facility? The less-trafficked areas of your building are where pests begin to build their nests. Install the right lighting and ventilation in these locations to make the area less appealing to pests.

THE BEST DEFENSE A STRONG OFFENSE

PROMOTING THE HEALTH BENEFITS

By Ronnie P. Cons

In the meat processing industry, pest control requires a multi-faceted approach. Rather than simply waiting for an issue to arise, employ multiple strategies at once to help prevent pest problems. When an infestation does occur, it’s important to tackle it from every angle, including food sources, entry points, cleanliness, and more. In many cases, this will require the services of a pest control professional. Whatever the situation may be, dealing with it quickly, humanely, and efficiently will help ensure your business continues to be known for impeccable cleanliness and quality.

Red meat is often wrongly portrayed as being unhealthy. Even some in the media as unhealthy or not environmentally friendly.

Vegan, fish and other non-meat diets have been proposed as healthier alternatives. The result of this onslaught of negative meat messages has influenced many families to cut back on their meat and poultry purchases. Perceptions may reality but truth trumps misinformation. Parents and other consumers want what is best for their health and that of their families. They are also aware that a lot of false information is out there and as such, are open to scientific facts that can correct their misconceptions.

This provides an opportunity for retail meat departments to implement an instore ‘Healthy Meat Facts’ nutritional campaign to set the record straight and convince their customers that meat and poultry are actually good for one’s health and that they should increase rather than decrease their purchases of it. The campaign outlined below can have a direct impact on sales:

liver, 625 spinach. Iron found found in absorption.

2. Eat Meat Being deficient linked with Dr. Charlotte California, Zinc is crucial preserves

3. Boost Due to its antibodies chronic

ABOUT THE AUTHOR

Start by displaying instore posters promoting the nutritional value of meat. They should be innovative, eye catching and be designed to specifically contradict any meat myths. The comments should all be literature based quoting research papers or MDs for maximum effect. Various posters should be made - each with a brief but powerful message covering one theme.

Posters can convey the following healthy meat fact messages:

1. Let’s IRON out the Truth on Meat!

“You would need to eat a massive amount of spinach to equal (the iron content) in a steak,” says Christopher Golden, an ecologist and epidemiologist at Harvard University in Cambridge, Massachusetts. (As quoted by nature.com in the article ‘Brain food- clever eating’.)

For a woman to receive her recommended daily intake of 18 mg of iron, she would need just 300 grams of cooked bovine

Brandon Thorsell is the District Manager of Critter Control in Toronto and the GTA, where he has been exposed to wildlife control for most of his life. After completing university in 2008, Brandon made a full-time commitment to the wildlife control industry, where he worked alongside family in their owned and operated Critter Control franchise, established in 1990. Now part of Rollins, INC, Brandon is excited to see the industry continue to grow and evolve as new markets open, and new techniques and technology emerge.

4. Power The protein Muscles building The protein growth and

5. Meat Meat contains body cannot isoleucine, threonine, protein.

6. Eat Meat Meat contains production functioning Say ‘hello’ acid, vitamin The line only apply meat health Facts’ nutritional and poultry. education

https://www.mmequip.com

13 meatbusinesspro.com August 2023 MEATBUSINESSPRO

22 CANADIAN MEAT BUSINESS September/October 2017

Ronnie P. meat and

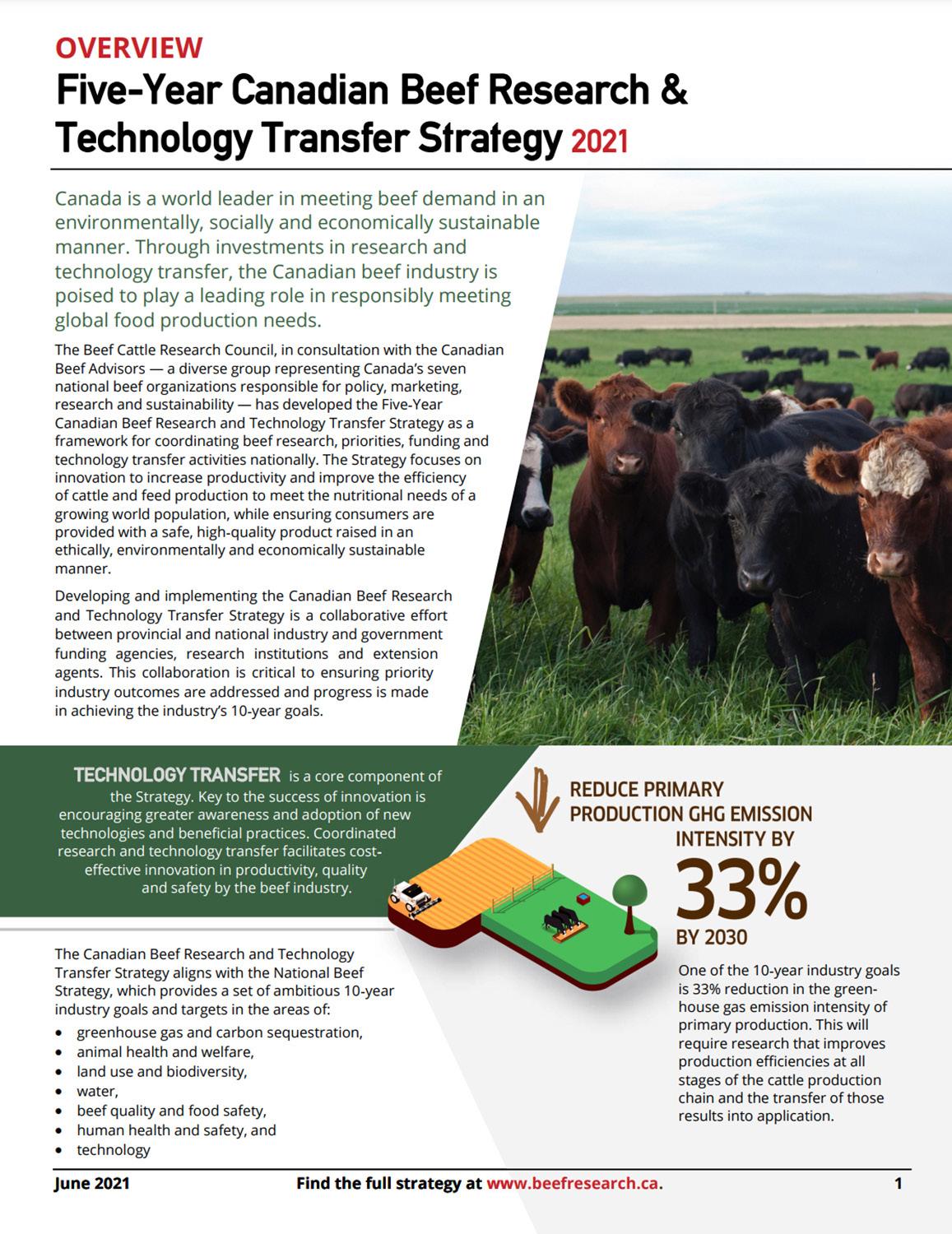

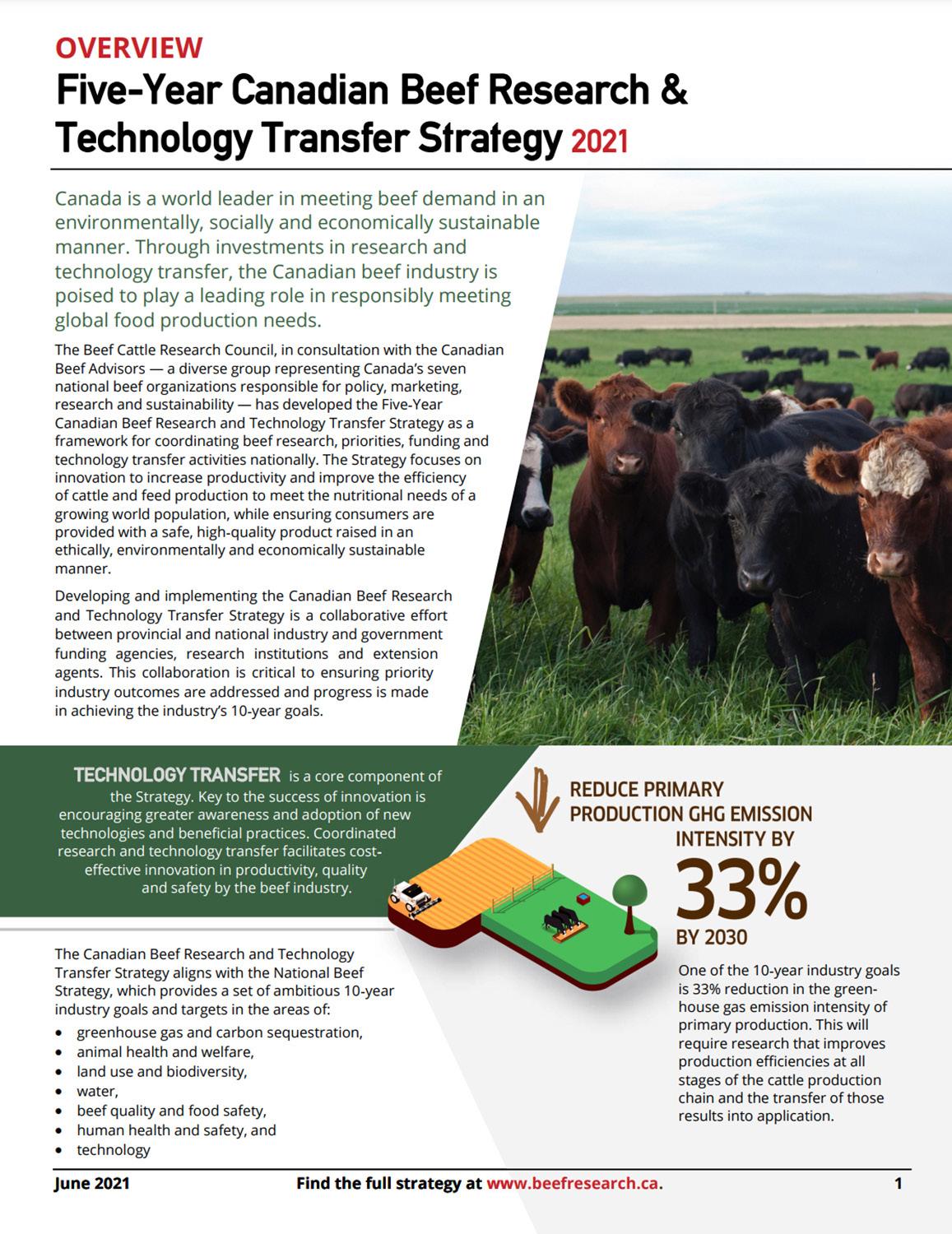

NATIONAL BEEF STRATEGY UPDATE

The Canadian Beef Advisors consist of elected leaders and staff representation of the national beef organizations responsible for policy, marketing, research and sustainability. They are a diverse group of experienced industry representatives who are responsible for advancing the National Beef Strategy, providing recommendations on future direction and reporting results against strategy goals and objectives.

The Canadian Beef Advisors meet quarterly to review one pillar of the 2020-24 National Beef Strategy. This allows for updates on activities and identifies opportunities for collaboration between the groups. The July meeting focused on the Competitiveness Pillar with updates on Youth Involvement and Succession, traceability regulations and labour.

The Canadian Cattle Youth Council developed a capital gains tax deferral fund working group last year to explore opportunities to improve young producers access to capital, including the potential establishment of a Capital Gains Tax Deferral Fund. While the working group concluded there wasn’t a business case at the time for exploring the Capital Gains Tax Deferral Fund concept further, a few key findings included: learning about the financial options and business plan development resources available to young producers (multiple resources exist and need to be communicated to youth council young producer membership); there are financing options to serve most young producers (but requires a strong business plan); provided feedback on Farm Credit Canada’s young producer and new entrant loan portfolio.

14 MEATBUSINESSPRO August 2023 meatbusinesspro.com

In May 2023, the Canadian Cattle Young Leaders (CYL) Program also worked with its Foundation Partner, MNP, to host a Succession Planning Case Study Competition. Young leaders split into teams where they were given an example farm with financials to explore the initial phases of building a farm transition plan based on various scenarios. The teams then presented their findings to a panel of MNP representatives and industry judges. Building on the case study success, the program will look for more ways to incorporate succession planning training into its activities.

NEW SURREY SLAUGHTERHOUSE ‘WOULD OPEN DOOR’ TO NEW BEEF MARKETS

Proposed 30,000-square-foot beef abattoir in Cloverdale would be B.C.’s largest such facility

In March 2023, the Youth Council continued this work by developing a Succession Planning Working Group. Some of the goals of this group include connecting with Farm Management Canada to explore the concept of hosting a “one stop shop” resources/lending options website page aimed at young producers; create a catalogue of farm transition stories and business structures; explore policy (Bill C-208 and Employee transfer); and develop a more coordinated promotion approach to share with the council’s young producer membership.

By Amy Reid, Peace Arch News

A federally licensed beef processing facility is in the works in Surrey, BC.

“There’s a new building coming forward, a new abattoir, I think that’s the French pronunciation of slaughterhouse,” said Councillor Mike Starchuk. “So Surrey will have a newer facility with a better capacity so people will have the ability to not have to ship an animal to Alberta to have it processed. The applications have gone through the Agricultural and Food Sustainability Advisory Committee.”

The facility is proposed on a 25-acre property within the Agricultural Land Reserve at 5175 184th St. The planned 30,000-square foot abattoir in Cloverdale would process up

so as to not emit odours. And while there is an operational 6,000-square-foot abattoir on the property now, it’s can only process a limited number of cattle.

Chris Les is general manager of Meadow Valley Meats, the company behind the project. Meadow Valley Meats is seeking a Canadian Food Inspection Agency license for the proposed abattoir, to become a federally registered meat establishment and expand the operation. This would allow the meat products to be transported beyond B.C.’s boundaries.

Youth involvement in the beef industry has grown withthe Canadian CYL Program and Youth Council including increased presence in CCA advocacy activities and meetings, engagement at international events (i.e. World Food Forum, Global Agenda for Sustainable Livestock, Global Roundtable for Sustainable Beef), a youth representative has been added to the Canadian Beef Checkoff Agency board that is also involved on the Youth Council, and both programs continue to explore how they can be part of the equity, diversity and inclusion conversation. The Beef Advocacy Canada programs continues to be a graduation requirement of the Canadian CYL Program.

“Our focus is on trying to bring a more efficient, sustainable local product to the market, realizing we can do that now in a very limited sense,” said Les. “I caution people when talking to them and they say, ‘What a big plant, that’s going to go allow you to go mainstream.’ Well, yes, if you look in the context of B.C., but this is still a very niche plant and we’ll serve a niche industry for producers and for the market. It’s certainly not going to be a monstrosity of a plant but it’ll be a big upgrade from the site currently.”

Continued on page 32

https://www.tcextrade.com

15 meatbusinesspro.com August 2023 MEATBUSINESSPRO

small by industry standards, compared to the largest meat

The proposed facility would be fully enclosed and designed

The Canadian Cattle Association outlined how Traceability regulations in Gazette 1, generally followed the Cattle Implementation Plan (CIP). However, concerns raised included the need to be efficient and effective, specifically around (1) cost, (2) feasibility, and (3) a pathway to compliance. CCA advised that all of these things must be addressed before Gazette 2. There is also a need for research and technology – this was a focus in the CIP that is currently missing.

The National Cattle Feeders Association outlined the multiple agendas, initiatives and departments currently working on the labour file. The Canadian Agricultural Human Resource Council (CAHRC) is currently updating their Labour Market Impact (LMI) numbers. The truck driver shortage has amplified for rural and agricultural areas with Almost half of the 10-20% labour gap estimated to be for Class 1 truck drivers. The other half is for general and skilled labour (pen riders, feed truck drivers). For the Red meat processing sector, a 2021 Canadian Meat Council survey showed that in a 6-month period, the labour shortage doubled from 4100 to 9500. These numbers show that we cannot mistake activity with achievement, as the situation is getting worse.

RECOMMENDATIONS INCLUDE:

• Make truck driving a skilled trade and ease restrictions for recognition of foreign Class 1 licenses.

• Separate requirements for LMIAs of high skilled and long term Temporary Foreign Workers (TFWs) from seasonal workers (e.g. housing requirements).

• Eliminate the under used housing tax for agriculture.

• Consult industry on development/changes to Training, Education, Experience and Responsibility (TEERs) for agriculture workers.

• Implement measures to increase TFW application processing capacity and reduce processing times.

• Reduce requirements for permanent residency (language and educational requirements).

• Build and implement a Trusted Employer Program. Learn more about the National Beef Strategy at www. beefstrategy.com.

The National Beef Strategy is a collaborative effort by Canadian national beef sector organizations including the Beef Cattle Research Council, Canadian Beef Breeds Council, Canada Beef, Canadian Cattle Association (and its provincial member associations), Canadian Meat Council, Canadian Roundtable for Sustainable Beef, and the National Cattle Feeders’ Association.

16 MEATBUSINESSPRO August 2023 meatbusinesspro.com

17 meatbusinesspro.com August 2023 MEATBUSINESSPRO September/October 2017 CANADIAN MEAT BUSINESS 17 meatbusiness.ca and you won. https://www.yesgroiup.ca

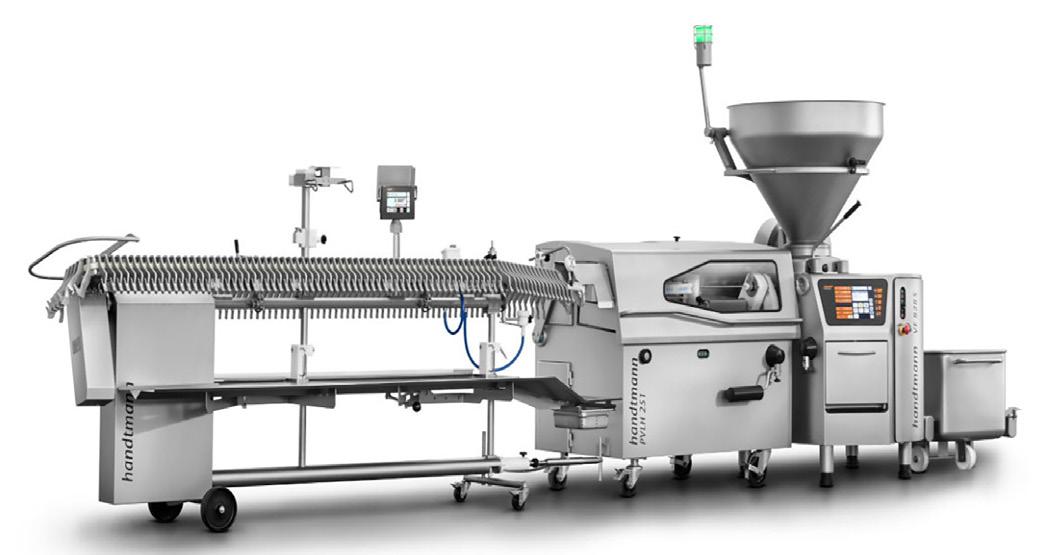

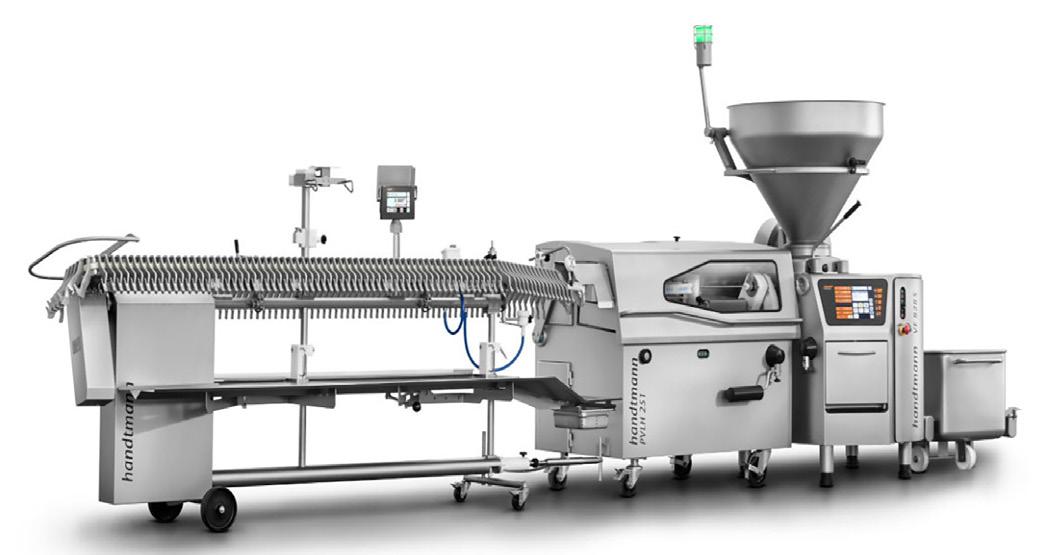

HANDTMANN LAUNCHES NEW HIGH-PERFORMANCE LINE

HOT DOG AND SAUSAGE EFFICIENCY GETS A NEW STANDARD

With the market launch of the new high-performance PVLH 251 AL system, Handtmann offers mediumscale and industrial sausage producers an automated production process for the portioning, linking and hanging of cooked and dry sausages in peel-off and collagen casing that can dramatically improve their efficiency.

This new highspeed line is ideally suited for the dedicated production of hot dogs in peel-off and collagen casing and boiled sausages, but also for dry sausages, vegan/vegetarian and meat substitute products, and the automated production of sausage products for the pet food segment.

This line’s elevated level of productivity includes production at up to 3,750 portions per minute and is also made possible by short set-up times and minimal casing change times with only one linking nozzle. Casing length options are available up to 580 mm for single product lines to maximize effective machine operating time. Reliable casing change is ensured by centring the linking nozzle and simultaneously guiding the casing in the casing spooling unit. A filling product scraper also ensures that the linking nozzle is clean at all times to support the highest level of process reliability with the shortest casing change times of less than 2 seconds.

The operator is prompted to refill the casing magazine by an optical signal to maintain continuous production and the innovative design of the new PVLH 251 voider belt and special voider elements provide particularly gentle positioning of the casing and consistent length. Automatic length checks prevent operating errors

with the set portion length and the voider belts automatically matched. The straightforward design of the line offers highly intuitive operation, even for inexperienced operators, preventing incorrect settings and consequently rejects.

Included in the solution is the AHE 228 hanging unit that easily multiplies the advantages of the new PVLH 251. Flexible hook spacing, adjustable in 5 mm increments, ensures that all products are conveyed with optimum spacing for maximum smoke stick efficiency and cost savings in the downstream process. The entire production line can be increased in height by 100 mm or 200 mm for sausage loops up to a maximum length of 850 mm. As an option, the hanging unit can also be equipped with the Handtmann AHE scales that also automatically readjust of the filling volume for optimum product weight control at all times creating cost savings of up to 2%.

The PVLH 251 line creates rapid ROI with its combination of continuous high-speed production with gram-accurate portions, rapid, error free casing handling and trouble-free link hanging that maximizes stick and smokehouse efficiency.

ABOUT THE COMPANY

Handtmann is a leading global capital equipment provider of grinding, mixing, emulsifying, portioning, depositing, forming, filling, in-line grinding, extruding and co-extruding solutions to food processors of all sizes. Advanced Handtmann technologies are known for operational accuracy, safety, and reliability. Handtmann Canada Limited is the wholly owned sales and service subsidiary of the Handtmann Group serving Canada with headquarters in Waterloo, ON.

18 MEATBUSINESSPRO August 2023 meatbusinesspro.com

https://www.cfib.ca

Depressed hog values amid sky-high production costs compound producers’ challenges

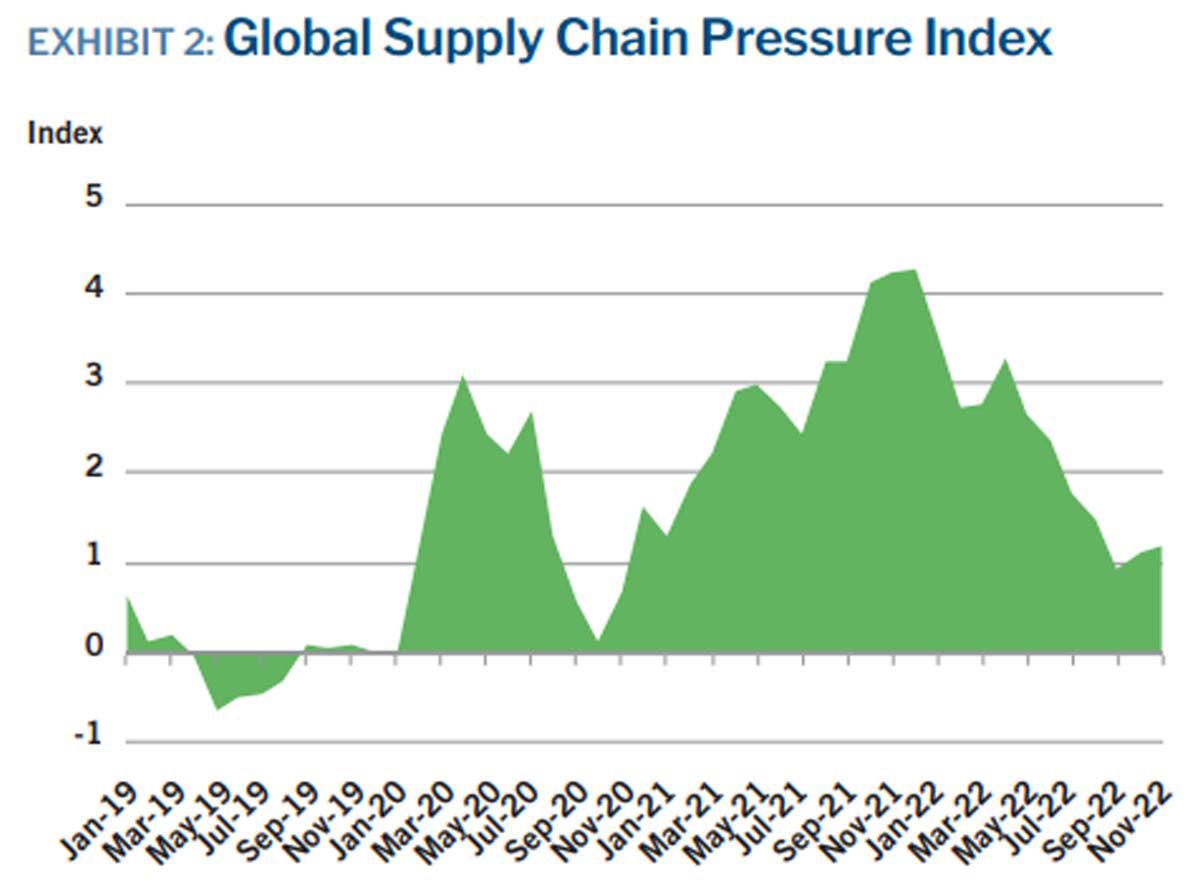

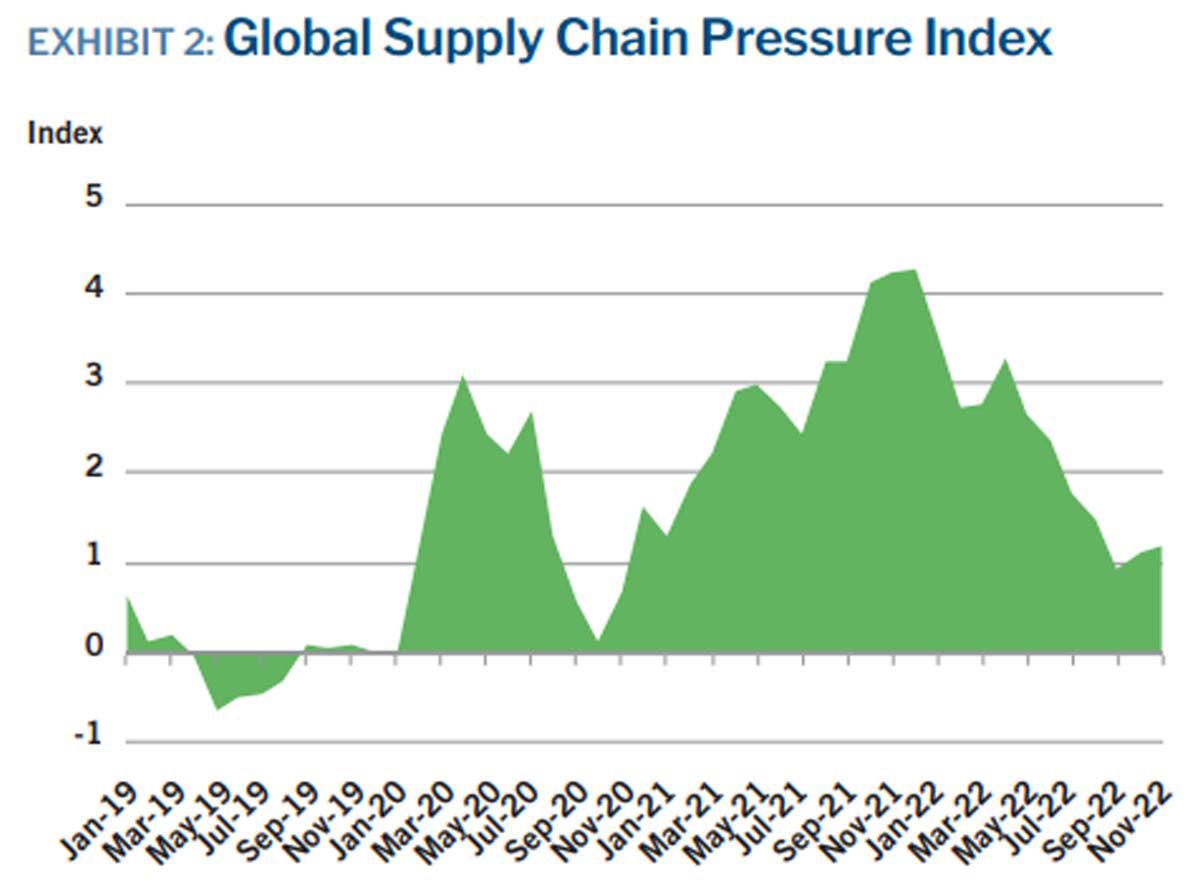

U.S. pork producers are facing an increasingly challenging economic environment that is likely to persist through the remainder of 2023. The combination of elevated operating costs and depressed hog values are evaporating producer returns and limiting overall industry growth. While hog prices have risen this summer, they have not kept pace with skyrocketing costs for feed, labor, construction and other expenses, according to a new report from CoBank’s Knowledge Exchange.

Soft domestic demand for pork and a murky outlook for U.S. pork exports are compounding the market challenges. Persistently high retail pork prices and a decline in food-at-home spending in the U.S. are limiting domestic consumption growth. Globally, demand for U.S. pork has come under pressure as China’s hog supplies have rebounded from the outbreak of African swine fever (ASF). The totality of adverse market conditions, which include higher borrowing costs, will limit U.S. herd expansion and tighten hog supplies.

“Ultimately, these challenges all fall on the shoulders of pork producers,” said Brian Earnest, lead animal protein economist for CoBank. “In addition to pressuring hog and pork supplies, the current market conditions are derailing hog producers’ expansion plans. And even if the cost structure warranted additional production, demand is a part of the puzzle that needs addressing.”

20 MEATBUSINESSPRO August 2023 meatbusinesspro.com

PERSISTENTLY HIGH RETAIL PRICES, SOFT DEMAND CLOUD OUTLOOK FOR U.S. PORK PRODUCERS

Per capita U.S. pork consumption has remained essentially flat since 1990 and averaged 50 pounds annually over the last decade. In the meantime, chicken consumption nearly doubled from 57 pounds in 1987 to 102 pounds. in 2022. Roughly two-thirds of domestic pork winds up in processed items like bacon, sausage or hams, which have performed relatively well in recent years. However, key meat case items like pork loins are struggling to gain the same attraction that boneless skinless breast meat or ground beef enjoy.

Fortunately, Mexico has been a bright spot for U.S. pork. Exports to Mexico eclipsed 2.3 billion pounds in 2022, a record high for any single destination that accounted for about 37% of all U.S. pork exports. And today’s export volume to Mexico represents a 45% jump from 2016 levels. Nonetheless, uncertainty surrounding China, the world’s largest pork importer, and concerns about deteriorating global economic conditions cloud the outlook for U.S. exports.

“Some of the challenges facing pork producers will linger for the foreseeable future,” said Earnest. “But longer term, if retail pork prices begin to return to a normal level it should help domestic demand recover. Also, the popularity of backyard barbecuing has encouraged consumption of some cuts of pork that have historically struggled, which has been helpful in an otherwise difficult situation.”

Outside of bacon, pizza toppings and breakfast-type items, pork is usually consumed at home. And pork thrived during the pandemic-era lockdowns of 20202021, when food options were either take-out or at home cooking. But as food service has fully reopened in 2022-2023, moving retail case pork items has become more challenging.

Exports have long played a key role in the U.S. pork industry. Approximately 25% of U.S. pork goes to export markets, the most of any of the U.S. processed animal proteins. When ASF decimated China’s domestic hog herd in 2018, annual U.S. pork exports to China tripled in 2019, and then doubled the following year. Since then, China’s need for U.S. pork imports have rapidly declined as its domestic herd rebounded.

ABOUT COBANK

CoBank is a cooperative bank serving vital industries across rural America. The bank provides loans, leases, export financing and other financial services to agribusinesses and rural power, water and communications providers in all 50 states. The bank also provides wholesale loans and other financial services to affiliated Farm Credit associations serving more than 76,000 farmers, ranchers and other rural borrowers in 23 states around the country.

21 meatbusinesspro.com August 2023 MEATBUSINESSPRO

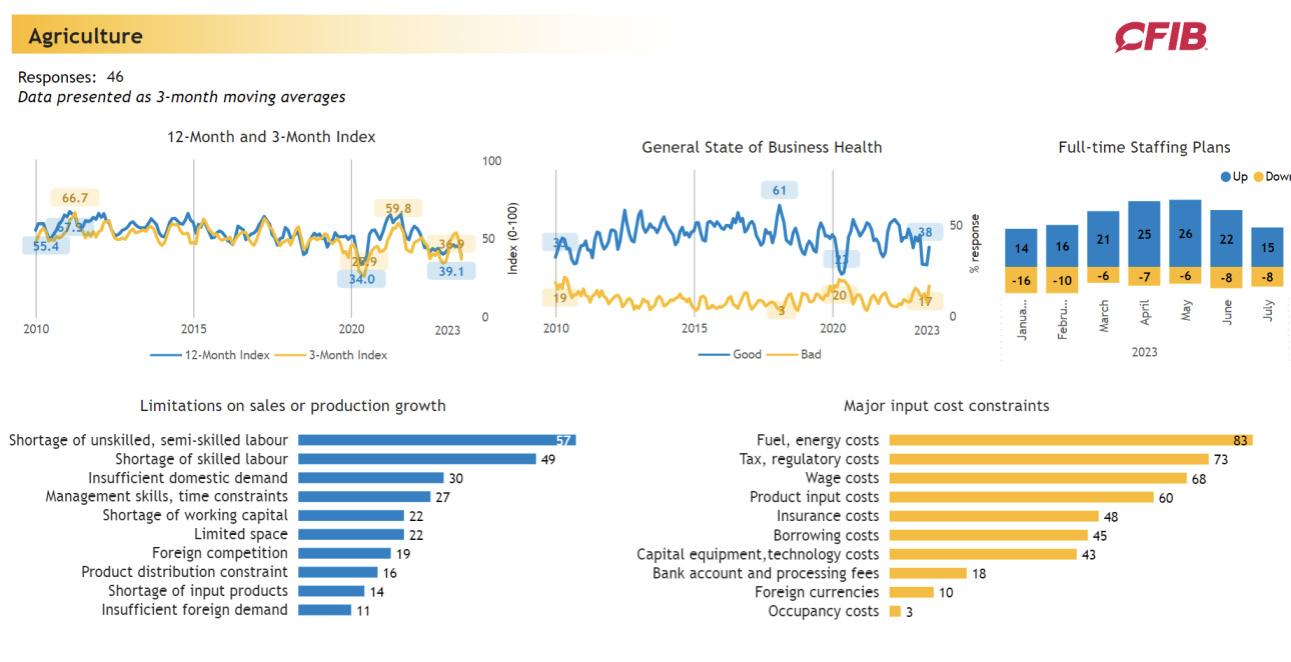

REDUCE THE CARBON TAX BURDEN NOW

Every time I find myself glancing up at the fuel meter at a gas station I flinch at the sight of the dollars adding up, remembering when filling up was more easily affordable. As a consumer, the cost increase hurts but isn’t a detriment to my livelihood. This isn’t true for our nation’s farmers who rely on these increasingly taxed fuels to produce the food that feeds our country and the world.

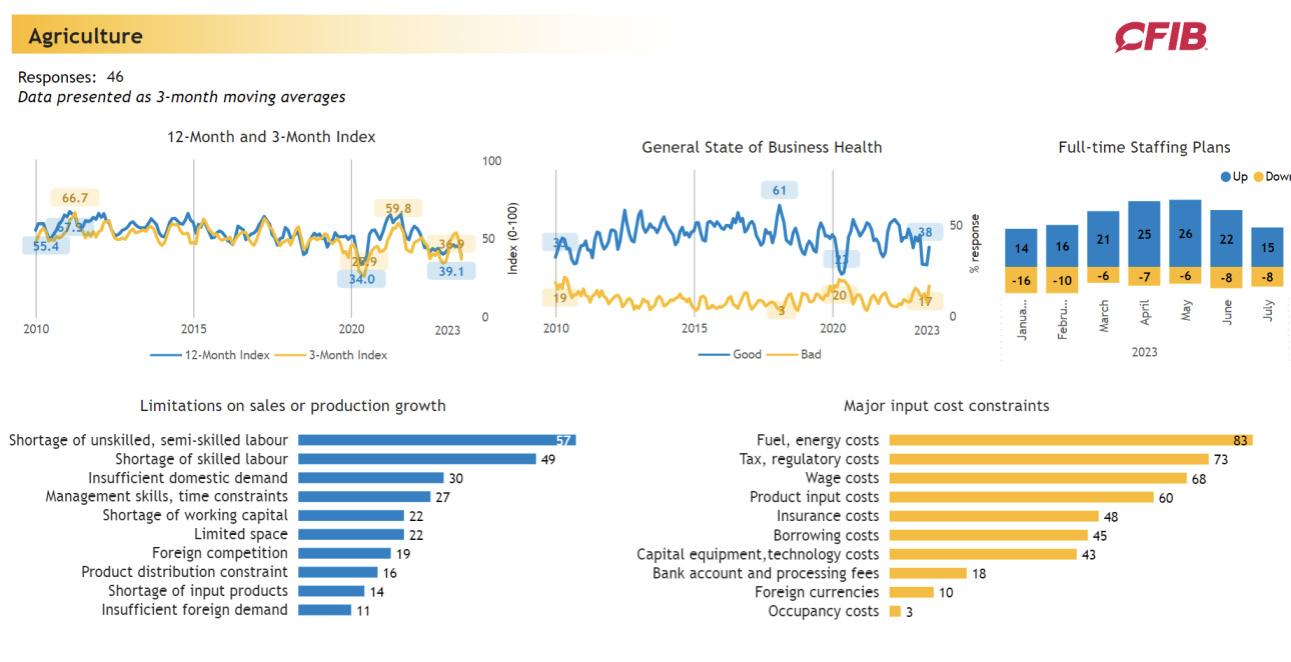

Over the past few years, the fuel costs have become a significant burden on agri-business owners across the country. CFIB’s July Business Barometer® – which tracks the state of small business in Canada – showed that a staggering 83 per cent of agri-business owners identified fuel/energy as the number one cost constraint on their operations.

Higher energy costs have contributed to record-high food inflation, marking an annual increase of 8.3% as of June. That cost increase is going directly from farm to store, hurting Canadians at the checkout aisle.

The federal government’s carbon tax has made the burden worse with the most recent April increase jumping a whopping 30 per cent from $50 a tonne to $65 a tonne. This increases the price of a litre of propane by more than two cents, which adds up significantly as farmers can use several thousand litres to do their jobs over the course of the year.

That same CO2 that government is taxing is essential to grow the food we all need, from powering grain dryers to heating barns to keep food production and storage safe. Since natural gas and propane are key to agribusiness operations, there is little ability for farmers to reduce their emissions without compromising their production.

“The cost of fuel is having a huge impact and needs to be addressed now. I am a dairy farmer and the cost of producing milk has greatly increased as well as getting it to the processor. We are not at liberty to increase milk prices. Fuel has the greatest multiplier effect on the cost to the economy. Food prices are going to increase greatly, and no one seems to be concerned.”

– Dairy Farmer, B.C.

22 MEATBUSINESSPRO August 2023 meatbusinesspro.com

LET FARMERS FARM!

As someone with a family background in the agriculture sector, I understand the importance of regulating food temperature using propane. If I were to suggest an alternative approach to my family, they would rightfully question how it could be achieved.

The truth is that alternatives are currently inaccessible or impractical for meeting the agri-business operations’ specific requirements.

In a recent CTV News article, Manitoba farmer Chuck Fossay highlighted how the tax “makes us less competitive in the international market” in addition to straining his finances.

Farmers’ concerns around the cost of doing business are indicative of a larger problem across the nation. Canadian agri-businesses are currently in a perilous position, with data from the CFIB Main Street Quarterly report showing that small businesses in the agriculture and retail sector are at the largest risk of closing. Widespread closures would mean more unemployment, less food production in Canada, and even more food inflation.

To allow these small businesses to carry out their essential work, the government needs to alleviate the carbon tax burden. Bill C-234, currently under consideration in parliament, seeks to exempt fuels like natural gas and propane used for drying grain and heating barns from the federal carbon tax. An exemption like this will not only benefit thousands of farmers, but millions of Canadians who are struggling to keep up with the rising cost of food.

A similar member’s bill, Bill C-206, died after the government failed to prioritize it just before the federal election in 2021. Our country cannot afford a similar mistake this time. Farmers need cost relief, which is why passing this bill now is essential. The longer this takes, the greater the possibility of farmers going out of business.

Ultimately, CO2-emitting fuels will remain essential in agriculture for the foreseeable future. Farmers are up for doing their jobs. It’s time for government to do the same.

Bradlee Whidden is a Public Policy and Advocacy Intern for the Canadian Federation of Independent Business (CFIB). CFIB is Canada’s largest association of small and medium-sized businesses with 97,000 members (6,000 agri-business members) across every industry and region. CFIB is dedicated to increasing business owners’ chances of success by driving policy change at all levels of government, providing expert advice and tools, and negotiating exclusive savings. Learn more at cfib.ca.

23 meatbusinesspro.com August 2023 MEATBUSINESSPRO

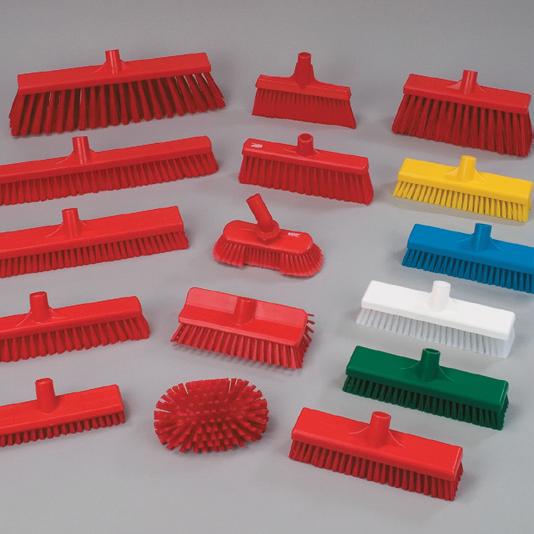

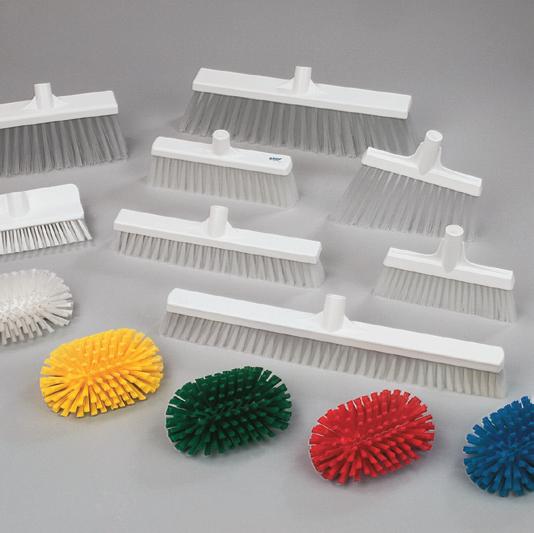

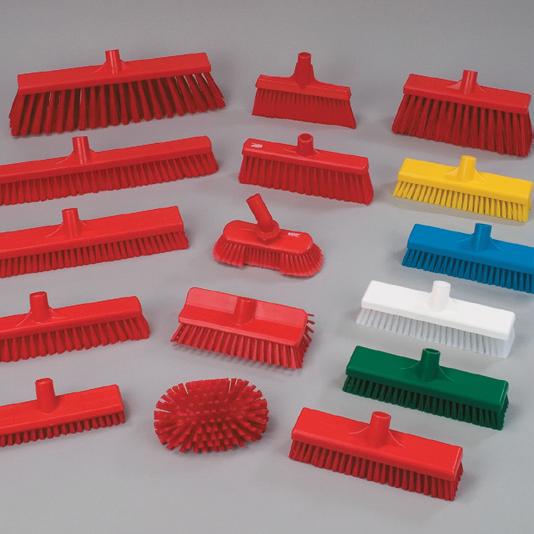

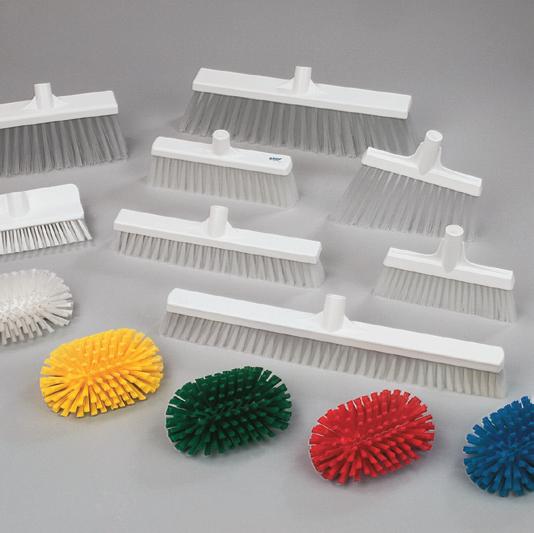

Remco and The Yes Group Protecting

Remco products are colour-coded to help divide the production cycle into different zones. By identifying these zones as different cleaning areas, the movement of bacteria around the production area can be blocked.

Our products were developed with the Hazard Analysis Critical Control Point (HACCP) in mind.

No matter what colour-coding plan is implemented, Remco Products from The Yes Group provides significant added value at no additional cost. From scoops to squeegees, from brushes to shovels, we have the products and the colours to enhance any professional quality assurance program.

24 MEATBUSINESSPRO August 2023 meatbusinesspro.com meatbusinesspro.com 31 September/October 2018

201 Don

Unit 1, Markham, Ontario, L3R 1C2 Phone:

1-800-465-3536 Fax: 905-470-8417 Website: www.yesgroup.ca email: sales@yesgroup.ca

Park Road

905-470-1135

your Customers https://www.yesgroup.ca