8 minute read

Wood-Mizer Newsbriefs

NEW! 60" CANT HOOK & 48" LOG PEAVEY

Give yourself some extra leverage with TWO NEW American-Made logging tools from Wood-Mizer! Our steel cant hooks are now available in 28", 48", and NEW 60" lengths. Plus an all NEW 48" steel log peavey is now available. Order online in the USA at woodmizer.com or contact your local Wood-Mizer representative.

Starting at $4,495* USD

NEW! LX55 PORTABLE SAWMILL Start sawing logs into lumber with the robust, entry level LX55 portable sawmill! Designed for hobbyists and professionals, the LX55 portable sawmill replaces WoodMizer’s current entry-level LT10 sawmill while providing a larger cut capacity, more power options, and many upgraded features. This twin rail entry-level sawmill includes push feed, 9 HP gas, 14 HP gas, or 7 HP electric power options, 26" log diameter, 22" max width of cut, and 12' 5" log length. Order online in the USA at woodmizer.com or contact your local Wood-Mizer representative.

NEW! TURBO 747

HIGH-PERFORMANCE SAWMILL BLADES Introducing Turbo 747 highperformance sawmill blades engineered for all band sawmill and resaw makes and models, horsepower ratings, and sawing applications. Turbo 747 sawmill blades feature a deep capacity gullet for less sawdust on the board, extreme back angle for faster sawing speeds, and sharp penetrating points for increased sawing accuracy. Try the Wood-Mizer exclusive Turbo 747 sawmill blades on everything you saw.

Order online in the USA at woodmizer.com or contact your local Wood-Mizer representative. NEW! SLABMIZER MB200 SLAB FLATTENER

STARTING AT $16,995* USD

Efficiently surface and flatten wood slabs, boards, burls, cookies, and other wide material with the ALL NEW SlabMizer! Compared to a traditional router or planer, the SlabMizer flattens wider and thicker material up to 56" wide (72" option now available) and 8" thick in less time using powered cutter head directional controls with variable feed speed. Contact your local Wood-Mizer representative to order.

MAKE SLAB FURNITURE!

Kelly Griswold Matt Collins Nathan Brown Neil Godden Brian Plath

Neil Godden

The Personal Best Contest, a favorite tradition since 1985, gives Wood-Mizer

sawmillers an opportunity to showcase dream projects built with lumber from

their mills. With nearly 200 projects entered and 11,000+ online votes, 2019 was one of our most popular contests ever!

Thank you to all the talented and creative

people who shared your achievements with us and the entire Wood-Mizer family of sawmill equipment owners. Join us

in congratulating winners of the 2019 Personal Best Contest and read their stories on the following pages.

James Clarke Big Mountain Inc. Steven Harelson Jimmy Foster Chris Heal

Monty Wright Dave Baker Daniel Shade Thomas MacAllister Tommy McCarty

With the high-quality and quantity of projects entered, you will find more projects featured throughout this magazine. See the complete 2019 and 2017 Personal Best collection of 300+ amazing homes, cabins, tables, bridges, barns, and more milled and made by Wood-Mizer owners at pbest.woodmizer.com or pbest.woodmizer.ca.

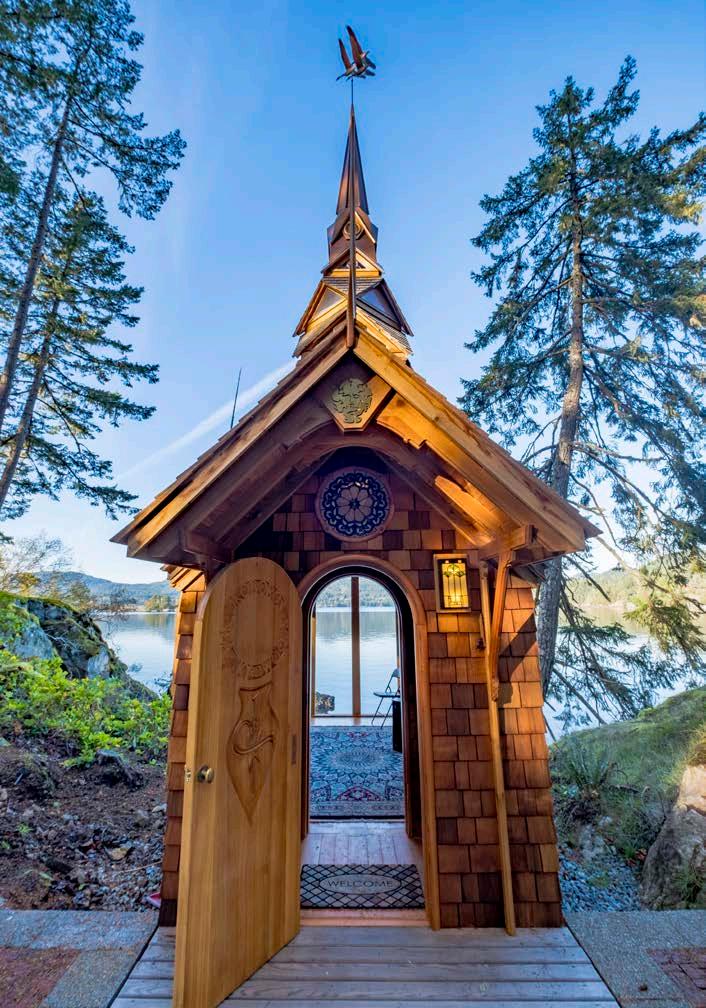

Lowell Hinrichs – Sooke, British Columbia

SAWMILL: LT40 HYDRAULIC BLADES: DOUBLEHARD

By The Numbers - 153 total square feet with a 26 feet high steeple - Western red cedar, douglas fir, and oak - 100% of project completed with Wood-Mizer sawn lumber - 5 years to complete

By Chase Warner - Photography By Terry Lam F ive feet from the shore of the Salish Sea in British Columbia stands a majestic chapel artfully crafted from locally salvaged dead cedar trees. The exercise in geometry combines the architectural features of a Norwegian stave church with a Burmese pagoda and is a culmination of the lifelong works of the 80-year-old retired mathematics professor Lowell Hinrichs. “I have been extremely fortunate in life and I cannot imagine a more appropriate project for this phase of life,” said Lowell. “I began the chapel two years after having received a Stage IV cancer diagnosis and was not at all sure I would be able to finish it.”

The son of a Lutheran pastor, Lowell has a life-long interest in mathematics, geometry and architecture. “Mathematics is the key to understanding everything,” said Lowell. During breaks from teaching at the University of Victoria, Lowell often accompanied his father at new church dedications and was enamored by the church architecture. “I sat in the service and looked at the architecture wondering why did the architect do this rather than that and so forth,” said Lowell. “For

example, I always thought that there shouldn’t be a ceiling above the alter. It should be open and go way up so that light came both literally and figuratively down from above.”

When a neighbor discussed building a chapel, Lowell gained interest and began designing a structure even though he didn’t intend on building anything. However, by the time the design came to fruition, Lowell was convinced that he should build the chapel. “There was a fusion of motives and some of them deepened during the construction process,” said Lowell. “Perhaps the main intent is to provide a meditative space to enhance appreciation for the land, family, friends, and life.”

With help from family and friends, several cedar, douglas fir, and garry oak trees were removed from the property and milled into boards and beams on-site with Lowell’s WoodMizer LT40 hydraulic portable sawmill. “The ability to turn wind falls and dead trees into useful lumber and to do so with considerable accuracy in thickness and relatively smooth surfaces is very valuable,” said Lowell. “Part of the project was intended to be a people thing, so a lot of people helped sawing lumber

because it’s fairly easy. It’s a satisfying thing to turn dead trees into boards.” Most of the chapel is constructed with half lap joints that were created by making several parallel cuts with a table saw, knocking out the pieces with a hammer, and sanding it down. “Structurally it is post and beam, but the structure is a little unusual because the beams are under almost no bending forces,” said Lowell. “Almost all of the beams are under either tension or compression. A major part of the structure is the steeple which is constructed of identical shaped modules of decreasing size.”

Throughout the course of five years, the 9' wide, 17' long and 26' high chapel was completed. No detail was spared including intricate wood carvings, stained glass windows, and many symbolic elements. The carving on the chapel door combines several themes including the burning bush, the fruit of the tree of knowledge and life, and the

“The positive response has been very numerous and gratifying,” said Lowell. “Friends frequently drop by with out of town visitors to show them the project. In addition, my grand niece was married at the chapel and it was a very special and rewarding event. The building has reinforced my awareness of the important things in life, love, respect for others, and an appreciation for the fragile gift of existence.”

e wanted another part of camp where campers could enjoy God’s creation away from the typical comforts, without getting too primitive. Having a Wood-Mizer made this project. The abilities of the machine is what designed the area. “W We did what the machine could do for us and then we designed it that way. There is no way to separate the Wood-Mizer from the project. They are completely connected!” – Tim Hadley

Tim Hadley – Westby, Wisconsin SAWMILL: LT28 BLADES: DOUBLEHARD Project Description: Fort stockade with 6 covered wagons and 48 beds for sleeping at Living Waters Bible Camp By The Numbers - 105’ long x 38’ wide stockade - 6,000 board feet of white pine, tamarack, electric poles - 50% of project completed with Wood-Mizer sawn lumber - 13 years to complete - $5,000+ saved

3RD PLACE TIE Creative Showcase

“I

build wooden boats professionally. I couldn’t do what I do without the flexibility of a Wood-Mizer sawmill. I can go from sawing large tamarack stumps by using the cantilevered head, to sawing cedar logs with all kinds of side bend for planking.” – Joshua Swan

Joshua Swan – Washburn, WisconsinS

SAWMILL: LT35 BLADES: DOUBLEHARD Project Description: 14' rowing dory built from local timber

By The Numbers - 14' long x 52" wide - 60 board feet of white cedar, tamarack, and white oak - 90% of project completed with Wood-Mizer sawn lumber - 300 hours to complete - $1,200 saved e wanted to create something to showcase all of the different flooring, paneling, and ceiling materials that Zeagler Farms Handcrafted Flooring, Inc. produces. This structure that lies “W on a 40' x 60' deck is a heavy timber-framed pond house sitting 100 feet out into a 60+ acre irrigation pond. Nearly every piece of the structure was cut on a Wood-Mizer LT40 Hydraulic.” – Ainsworth Zeagler

Ainsworth Zeagler – Sylvania, GeorgiaS

SAWMILL: LT40 HYDRAULIC BLADES: DOUBLEHARD Project Description: Unique pond house, showroom, and man cave

By The Numbers - 1,104 total square feet - 12,000 board feet of southern yellow pine and poplar - 90% of project completed with Wood-Mizer sawn lumber - 2 years to complete - $70,000 saved