Experts’ Backed Insights on Overcoming Challenges and Leveraging Opportunities in Transitioning Towards a Circular Model to Achieve Scope 3 Emission Targets

Experts’ Backed Insights on Overcoming Challenges and Leveraging Opportunities in Transitioning Towards a Circular Model to Achieve Scope 3 Emission Targets

Dear Readers,

Welcome to the November 2024 issue of Supply Chain Tribe! This month, we’re dedicating our entire publication to a subject that is both urgent and transformative: integrating sustainability into the value chain.

Sustainability isn’t just a corporate responsibility—it’s a strategic imperative that reshapes how we conduct business. In this special issue, we’ve gathered insights from leading sustainability experts and practitioners who are actively embedding eco-friendly practices into their operations. Their firsthand experiences provide a roadmap for organizations aiming to make a meaningful environmental impact while sustaining growth.

We delve into the pioneering efforts of cement producers who are championing the circular economy. Learn how they’re turning waste into resources, reducing emissions, and setting new industry standards.

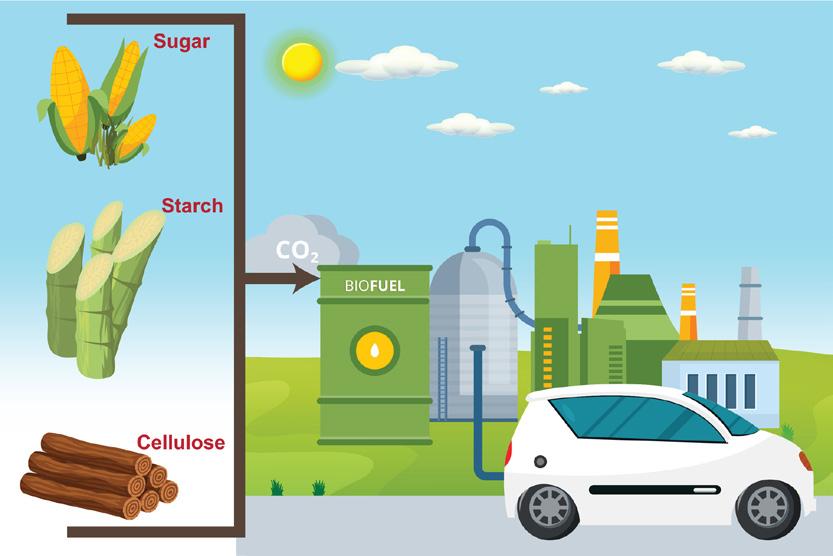

Exploring sustainable alternatives to traditional fuels, we examine how renewable energy sources are not only reducing carbon footprints but also enhancing efficiency and cost-effectiveness. These alternatives are critical in our collective effort to combat climate change and build a more sustainable future.

Discover how large Indian companies are successfully integrating sustainable practices into every facet of their operations—from sourcing and production to distribution and end-of-life management. Their journeys highlight the challenges and triumphs of embracing sustainability in a complex business landscape.

We hope this issue inspires you to reflect on your own practices and consider how sustainability can be woven into the fabric of your value chain.

Thank you for being a valued member of our community. Your commitment to sustainability propels us all forward.

Happy Reading!

Charulata Bansal Publisher Charulata.bansal@celerityin.com

www.supplychaintribe.com

Published by:

Edited by:

Prerna Lodaya e-mail: prerna.lodaya@celerityin.com

Designed by: Lakshminarayanan G e-mail: lakshdesign@gmail.com

Logistics Partner: Blue Dart Express Limited

14 | “At Marico, Sustainability is Regarded as a Business Enabler”

Bipin Odhekar, Head - Sustainability, EHS & Operations excellence, Marico Ltd.

17 | “The Indian Cement Industry has been a Pioneer in Propagating Circular Economy”

Kaustubh Phadke, India Head, Global Cement and Concrete Association (GCCA) India

20 | “Achieving Large-Scale Adoption of Sustainable Alternatives requires a Comprehensive Approach”

Lt Col Monish Ahuja (Retd), CMD - PRESPL and Chairman - CBEII

27 | “It is important to Ensure Capacity Building of Suppliers”

Nishtha Gupta, Group Head – Sustainability & ESG, Suzlon

and

With consumers increasingly appreciating and valuing circular companies, more businesses are now investing in circular value chains and leveraging circularity as a strategic differentiator. The circular economy offers a framework for developing sustainable value chains that minimize waste and promote resource efficiency. Through this Cover Section, subject-matter experts evaluate and offer insights for companies to integrate circular economy principles into their operations and value chains, with the tenets focusing on design innovation, product life extension, and recycling and reuse strategies.

28 | “It’s TIME NOW to Move from INTENT to ACTION”

Jangoo Dalal, Co-Founder & CEO, GovEVA

31 | “Net Zero is great, but it must make Unit Economic Sense”

Varun Chopra, Executive Chairman, GEAR India

33 | “Sustainability needs to Start with a Purpose”

Tapas Majumdar, Director, The Sustainability Practitioners

35 | “Collaboration among Stakeholders is Crucial for scaling Sustainable Initiatives”

Dr. Raj V. Amonkar, Professor and Chair IT & Operations, Goa Institute of Management (GIM)

“Circularity is a key differentiator in the short term, but a qualifier in the mid-tolong term,” a profound assertion stating clearly the dire need for organizations to take the BIG FIRST STEP. With consumers increasingly appreciating and valuing circular companies, more businesses are now investing in circular value chains and leveraging circularity as a strategic differentiator. The Circular Economy offers a framework for developing sustainable value chains that minimize waste and promote resource efficiency. Through this Cover Section, subject-matter experts evaluate and offer insights for companies to integrate circular economy principles into their operations and value chains, with the tenets focusing on design innovation, product life extension, and recycling and reuse strategies. Through this extensive read, readers will also get insights on overcoming challenges and leveraging opportunities in transitioning towards a circular model to achieve Scope 3 emission targets.

AN Ellen MacArthur Foundation report stated that to date, discussions about and efforts to transition to a circular economy have been predominantly focused on the role of circular business models and circular product design. However, as an increasing number of organizations mature in their circular economy journey, the role of circular supply chains in operationalizing and scaling such initiatives is becoming distinctly relevant. Supply chain professionals are responsible for the sourcing, movement, and transformation of the 100 billion tonnes of materials that enter the global economy each year. With such oversight, they can be key players in scaling a resilient and regenerative circular economy.

A World Economic Forum (WEF) study aptly highlights the correlation of supply chains and circular economy. It states, “In an era defined by globalization and the pursuit of efficiency, supply chains have become essential yet vulnerable networks within the global economy. This vulnerability, exacerbated by geopolitical tensions, environmental challenges and trade conflicts, underscores the critical need for resilience — not just for risk mitigation but as a strategic imperative that can serve as a competitive advantage in an uncertain world. Integrating circular economy principles offers a solution. Circular economy principles bolster sustainability and transform these vulnerabilities into strengths. Circular economy principles help supply chains adapt to and maintain operations amidst unforeseen disruptions, fostering sustainable growth and resilience in an interconnected world.”

In recent years, there have been monumental technological advancements that have helped fight climate change. Automotive innovations have allowed electric vehicles to become commonplace on our roads. Today, every major car manufacturer has a line-up of electric vehicles for consumers to choose from. Other solutions are tied to 6G technology and the powerful exchange

of data enabling the Internet of Things (IoT), which is not only transforming the world but also contributing to creating sustainable forms of technology.

Leverage emerging technologies such as blockchain, artificial intelligence, digital twins, or internet of things, to help increase visibility across the supply chain, ensuring sourcing, quality, and design professionals have enough data to make adequate decisions around circular inputs. It is essential to have clear information about the volume, material makeup, and any potential quality issues with secondary products or materials entering the supply chain as inputs to ensure their suitability for their intended use and to avoid waste. Implementing robust tracking and labelling systems (e.g. DPP) that provide comprehensive, verifiable information about the origin, condition, and history of refurbished or reused goods and components will create greater transparency to enable informed decision-making, ease the access to circular inputs, and promote trust within the circular supply chain.

Adopting low-carbon technology practices and developing and co-creating innovative and sustainable solutions for all stakeholders along the value chain could help us get closer to net-zero emissions. Moreover, transitioning towards new technologies and implementing ecodesign principles across operations not only accelerates net-zero plans but also reduces operational costs and efforts.

The latest McKinsey Global Survey on environmental, social, and governance (ESG) issues reported how organizations are rising to this challenge. While environmental topics are recently the ones making headlines, just one-third of respondents rank environmental issues as their organization’s greatest ESG priority. The biggest positive is that the survey respondents report that their organizations are not just paying lip service to ESG: many say their organizations are making meaningful ESG changes that have demonstrable benefits. More than two-thirds of respondents say their organizations have achieved broad impact from their ESG efforts in the past three years, and 43% report that their organizations have captured financial

value from their ESG investments over that span—suggesting that the full effects of ESG are multivariable and may take time to fully capture. For example, one-third of respondents say their organizations’ work with ESG topics has a strong positive effect on their own commitment to the organization and, in turn, to overall employee retention, consistent with the notion that ESG can underpin both value and values.

Supply chain leaders can incorporate circular economy criteria (e.g. around sourcing durable, circular inputs) into procurement negotiations, proposals, agreements, and supplier evaluations. To facilitate the cost-effective circulation of products and materials, new processes, such as those around disassembly, can be incorporated into proposals or requests for proposals (RFPs) for suppliers that may be unfamiliar with such practices today. Creating standardized documentation within proposals that mandate processes like disassembly can also help drive the adoption of circular practices. This way all relevant

considerations to enable effective operation of circular supply chains can be formally embedded into the ways in which supply chain partners operate, ensuring that everyone’s activities contribute to the common goals. For example, Danone has established long-term contracts with dairy farmers, helping alleviate shortterm market volatility, thereby allowing them to adopt practices that can support regenerative outcomes. Working with the planning team to use circular inputs effectively should start from the S&OP (Sales and Operations Planning) process through production planning, as supply and demand will vary for material that is scarcer in the current marketplace.

Just like the above example, organizations in many industries are going beyond merely trying to meet regulatory requirements and view ESG as a growth opportunity. Promoting growth is the reason that respondents most frequently cite for their organizations

addressing ESG topics. Let’s take a look at some of them…

Philips, a global leader in healthcare technology, aims to generate 25% of revenue from circular products & solutions and is committed for 100% of

products meet the company’s EcoDesign principles (of which circularity is a key pillar). In pursuit of these objectives, Philips introduced a rental model for its

IPL Lumea, a hair removal beauty device. However, this circular economy offering posed a new challenge for the company’s supply chain professionals: striking the delicate balance between high quality and operational efficiency in collaboration

with partners.

To address the new challenge, Philips’ supply chain teams decided to work closely with their network partners. They developed a comprehensive tenstep protocol for approved partners that outlined procedures for inspecting, grading, sorting, cleaning, testing, repackaging, relabelling, recording product data, and releasing the

A proactive approach is vital when securing sustainable supply chains, with an emphasis on continuous improvement. Only by adopting a smarter approach to procurement can organizations benefit from greater visibility into their supplier base, work to identify high-emitting suppliers and take steps to collaborate on improvement plans. To make procurement smarter, organizations must embrace technology that gives 360-degree visibility into supply chains, as well as data analytics and collaboration capabilities.

refurbished Lumea devices. Furthermore, Philips provided the necessary test equipment and training, and worked with partners to harvest quality controlled parts, enhance forward-backwards compatibility, and exchange parts. The collaboration involved Philips’ supplier quality engineers, who worked closely with partners to ensure that high-quality standards were met and the refurbished devices could be rented out again.

Choosing refurbished instead of brand new Lumeas reduces the carbon footprint by 78%. Beyond the environmental gains, this model offered insights into product innovation through post-market surveillance, to enable improvements in areas such as scratch resistance. Commercially, this initiative expanded market penetration by offering a broader consumer base access to high-

end Lumea devices, including those with tighter budgets, while simultaneously enhancing the rental business model’s return on investment (ROI).

Instead of repurposing plastic bottles, Lego is now looking to find bio-based and recycled substitutes for the individual chemicals that make up ABS, as well as investigating alternative solutions. "We remain fully committed to making Lego bricks from sustainable materials by 2032," a spokesperson for the company mentioned. "We are currently testing and developing Lego bricks made from a range of alternative sustainable materials, including other recycled plastics and

plastics made from alternative sources such as e-methanol." The company is also exploring the potential of bioplastics, which has formed some of the flora found in Lego kits since 2018 as well as the company's recent Botanical Collection. However, Lego CEO Niels Christiansen believes no single material will be a silver bullet solution.

"We tested hundreds and hundreds of materials," he said. "It's just not been possible to find a material like that." Instead, part of Lego's solution will be a focus on incremental emissions reductions as well as a takeback scheme, which the company is hoping to develop over the next few years so that unwanted bricks can be directly reused in new sets or recycled if they are no longer functional.

IKEA has also embraced circularity by

offering furniture take-back schemes and designing products for easy disassembly and recycling. IWAY, or "The IKEA Way," is IKEA's comprehensive approach to responsible sourcing of products, services, materials and components within its global supply chain. It sets strict standards and expectations regarding environmental, social, working condition and animal welfare for all its suppliers and service providers. This framework not only helps mitigate environmental damage but also unlocks significant cost savings, enhances company reputations and ensures regulatory compliance.

CHEP is exploring switching from the current ‘One-Way Trip’ approach to a ‘Managed Recovery’ one. In the latter, the customer receives CHEP’s pooled (shared and reusable) pallets directly from distribution centres and retailers; sorts them using CHEP quality standards; stores the pallets that pass the test; and returns the rest to CHEP for repair before reuse. CHEP plans to leverage Flow Optimisation software to identify potential opportunities for switching service offers from ‘OneWay Trip’ to ‘Managed Recovery’. By redesigning their network approach and eliminating the need for sending pallets

in good condition back to service centres, CHEP hopes to reduce transportation costs and associated emissions, as well as the energy consumption from their service centre.

Traditional approaches to refurbishing devices are labor intensive, with engineers manually inspecting and testing each device to determine whether they can be fixed or harvested for spare parts. The refurbishment process also holds a wealth of information about the durability and common failure modes of device components—insights that can help inform future considerations around design and product lifecycle management.

“We recognized that AI holds tremendous potential to enhance the efficiency of our sustainable refurbishment initiatives,” comments Aaron Zhang, ISSC Reverse, Repair, Refurbish Director at Lenovo. “For engineers, it could help to automate time-consuming and repetitive device inspections and even recommend personalized refurbishment options for customers. And for Lenovo research and development teams, AI promises to deliver faster access to insights gleaned from the refurbishment process.”

To enhance our refurbishment services, Lenovo harnessed the power of Lenovo edge computing solutions, internet-of-things sensors, machine learning and computer vision technology to develop an AI solution

that automatically detects device issues by analyzing images of internal components.

Built using AI algorithms optimized for quality control and predictive maintenance workflows, the Lenovo solution helps engineers identify faults, find the most effective repair procedures, and select the optimal replacement parts—all in real time. As part of a phased development process, Lenovo uses the solution to optimize and improve efficiency of inspection of used devices in Lenovo’s Mobile Business Group (MBG).

While still in its early stages, Lenovo’s AI-powered refurbishment initiative shows tremendous potential to enhance sustainability by helping more customers refurbish their devices. For example, in a recent study it was found that 70% of laptops discarded by first-time users can have double the lifetime by being reused. At Lenovo, 71% of devices collected by Lenovo are refurbished or re-used for parts, supporting a circular economy. Leveraging AI to support device refurbishment for Lenovo MBG has already delivered significant efficiency improvements. Since deploying the AI solution, Lenovo has increased the average output units per hour for a single model from 30 units an hour to more than 65 units—representing a 116% increase in efficiency.

Yogesh Mishra, Executive Director – Supply Chain, HUL, during an interview, mentioned, “Sustainability is deeply integrated into our supply-chain

The reasons for exploring the circular economy—supply chain nexus is twofold. First, a supply chain reconfiguration is urgently needed to help shape a more resilient, net-positive future; the circular economy offers a toolkit for supply chain professionals to achieve this. Second, to ensure the success of the circular economy transition, the skills and knowledge of supply chain professionals will be crucially required.

practices. We've implemented energy management systems to monitor and optimise energy consumption, reducing greenhouse gas emissions and enhancing operational efficiency. Initiatives like the Boiler Digital Twin, which utilises agricultural waste, curb environmental impact and support local communities by providing sustainable livelihoods.”

He added, “We're focused on establishing a Supply Chain Nerve Centre to enhance decision-making and visibility across our operations. This will act as an enterprise brain to drive faster decisionmaking, providing end-to-end visibility and enabling global optimisation across plan, source, make, and deliver instead of localised decision-making. Additionally, we're committed to adopting futureoriented manufacturing practices and continuous improvement initiatives to achieve significant cost savings and operational efficiencies. Innovation and continuous improvement are at the core of our supply-chain strategy, enabling us to optimize processes, enhance agility, and deliver superior products and services promptly to our consumers.”

Embedding ESG in an organization manifests in well-considered, focused ESG initiatives that are core to the business model. While embedding ESG is complex, the value that ESG efforts can protect—and create—can be compelling. Here are 7 commandments or Traits that organizations can imbibe to gain ESG momentum…

1. Approach ESG from a growth perspective. The organization’s priorities exceed merely conforming to industry standards or regulatory requirements and aim toward unlocking new opportunities.

2. Strive to connect with external stakeholders and to be accountable to them. According to the survey, the higher the external engagement

is on their board’s and CEO’s agenda, the more progress the organization has made with its ESG impact over the years.

3. Identify specific stakeholder priorities for which the organizations are uniquely placed to excel. These leading organizations identify and concentrate on the specific stakeholder priorities for which their organizations are uniquely placed to excel rather than diffuse ESG efforts across many avenues.

4. Empower a specific executive in the C-suite to work with the CEO in defining and achieving ESG ambitions. This executive is empowered to define ESG ambitions and strategy with the CEO, ensure collaboration among the other members of the executive team, and orchestrate initiatives across the organization.

5. Build a central ESG team—which is not the same as building a large team. Bring together talent from across the organization to help meet ESG goals. These teams can manage ESG-strategy-and target-setting processes, coordinate delivery of initiatives and ESG reporting across the organization and ensure that ESG considerations are embedded into employees’ day-to-day behaviors. They also coordinate across functions so that efforts are not siloed within one department.

6. Make considered efforts to embed purpose into multiple aspects of their business. By embedding purpose into organizational culture, the survey suggests, organizations can build an appetite for change that can bolster ESG initiatives.

7. Tie ESG metrics to compensation, using KPIs to gauge progress on ESG objectives. Embedding key ESG impact metrics into leaders’ and employees’ incentives can demonstrate, both internally and externally, that ESG is a priority for the organization. It also helps ensure accountability for initiatives. An effective ESG incentive structure uses clear metrics, based on

meaningful KPIs that gauge progress on key ESG objectives.

As WEF report mentions… The path forward calls for a fundamental reimagining of how products are designed, produced and consumed. To do this, organizations should start with a thorough audit of current practices, developing a strategic vision for circularity and implementing pilot projects to test and refine circular initiatives. This is a journey that requires a shift in mindset, from viewing waste and end-of-life products as problems to seeing them as opportunities for value creation and innovation.

Overcoming this resistance requires persistence, leadership and a clear vision for the future — a future where circular economy principles are a central pillar of supply chain strategy. For organizations willing to lead the way, it offers the promise of a future where business success is aligned with environmental stewardship and societal well-being. The time to start is now.

With these compiled insights from WEF & McKinsey, the ensuing pages offer subject-matter experts’ thought leadership for others to drive the ESG Momentum!

“To successfully drive the shift towards sustainability, companies need to follow a structured, step-by-step approach. The first crucial step is conducting a materiality assessment. This helps identify the key environmental, social, and governance (ESG) factors that are most relevant to the business and its stakeholders. By pinpointing what matters the most, companies can prioritize efforts that will have the greatest impact,” shares Bipin Odhekar, Head - Sustainability, EHS & Operations excellence, Marico Ltd., during this interview…

How is the industry perceiving circular economy and taking efforts in the same direction?

I feel, appreciation about circular economy in the industry is increasing in the recent past. Initiatives around Sustainable Development Goals (SDGs) and other regular changes have played a significant role in this.

At Marico, we have adopted ‘Sustainable packaging’ program to drive circular economy in packaging. This creates multiple opportunities for improving circularity of our products. We are committed to transitioning towards a circular economy by minimizing waste generation and adopting a holistic approach for waste management, which includes the use of low impact practices and innovative, resource-efficient technologies. Our efforts towards a circular economy include diverting waste to value added by-products, co-processing of hazardous waste, sending fly ash to brick manufacturers, recycling of used oil, extended producer responsibility, etc. Marico has taken multiple initiatives to divert hazardous waste to alternative treatment to ensure “ZHWL”. We aspire to achieve “Zero Hazardous Waste to

Landfill (ZHWL)” for the organization in the next two years.

How are you and your organization aligning value chain partners to your sustainability vision?

At Marico, sustainability is regarded as a business enabler that influences key strategic decisions. Having ingrained sustainability into its culture, Marico has spurred towards a carbon neutral future. This transformation is driven by robust sustainability governance structure, ethical business conduct, ESG risk mitigation strategies, ambitious targets towards transitioning to lowcarbon sources, lowering GHG emission intensity, achieving water stewardship, incorporating responsible sourcing principles, and mapping product sustainability footprint. Considering the company’s deep focus on sustainability, ESG is considered a Board level mandate from a governance standpoint and discussed periodically as part of Board meetings.

As part of our commitment to drive sustainable value creation and stakeholder capitalism, we have continued to drive impactful initiatives and actions

efficiencies and manufacturing cost.

under the Sustainability 2.0 Framework launched in FY 22. Covering over 50 KPIs across the environmental, social, and governance pillars - the framework defines Marico’s long-term sustainability goals that we aim to achieve by 2030.

Marico has adopted Responsible Sourcing program called “SAMYUT” to share our sustainability vision with our business associates. Program aims at educating our value chain partners through Code of conduct, selfassessment, capacity building, driving sustainability initiatives with external third party assessment.

How do you see circularity playing out with your value chain partners in your respective industries? What are the trends you are witnessing?

Circular economy is a wider concept, which started with what we used to call as 3R and 4R strategies. For an FMCG company, packaging materials are becoming a very important aspect, which are mostly made out of plastics. We have observed a few key changes in FMCG industry in recent years which include reduction in packaging material with design changes, improving recyclability of materials and usage of post-consumer recycled plastic in packaging.

New technologies are coming up in waste processing, segregation and recycling. With implementation of Extended Producers Responsibility (EPR) by the government, overall recycling industry is getting organized and efficient. Marico Innovation Foundation has conducted nation wide study and identified important innovators working in this space. ‘Innovation in Plastics: The Potential and Possibilities’ a one-ofits-kind playbook analyses & provides holistic insights on the potential solutions for plastic waste management in India. There are vital lessons from across the globe that can be implemented in India along with avenues for cutting down single-use plastics. All stakeholders – government, corporates, civil society, and entrepreneurs have an equally critical role in ensuring this.

We would like to know about the responsible sourcing strategies that Marico follows…

Marico has a developed a comprehensive

Marico’s Samyut initiative uses a three-pronged progressive approach based on the maturity of ESG appetites of our value-chain partners.

Level 1 (Educate) is based on enhancing knowledge of our suppliers on ESG material issues and helping them identify the risks and opportunities related to their businesses. A selfdeclaration questionnaire is used to mark the completion of Level 1 certification.

Level 2 (Evaluate) aims at monitoring the performance of value-chain partners against the identified ESG metrics. Structured third-party audits, screening and documentation review marks the completion of this level.

Level 3 (Evolve) is a collaborative phase where Marico ideates with its partners to design market-leading ESG practices at each stage of the value chain. The aim of this level is to build a strong, robust and sustainable nexus towards shared ESG goals.

responsible sourcing framework, titled ‘Samyut’. The objective of this framework is to integrate environmental conservation principles, ethical standards, and socially responsible practices throughout the value chain by capacitating suppliers to commit sustainability goals. The framework is directly aligned with global standards including SDG 12 that promote responsible consumption and production. The Samyut program is applicable across 5 types of critical valuechain partners: raw material suppliers, packaging material suppliers, depots and warehouses, convertors and logistics.

The following principles are used to integrate ESG excellence within Marico’s value chain: Ethical standards: Any business without ethics cannot win the trust of the stakeholders. Our philosophy is to conduct the business with high ethical standards in our dealings with all the stakeholders.

Environmental Protection: An ESG-focused organization ensures its processes to have minimal environmental footprint. We expect our suppliers and business associates to follow this and comply with all environment regulations.

Social value creation: Local communities and society provide the social license to conduct the business. Hence, we believe it is vital to demonstrate social responsibility by promoting values.

Marico’s Samyut initiative uses a three-pronged progressive approach based on the maturity of ESG appetites of our value-chain partners. Level 1 (Educate) is based on enhancing knowledge of our suppliers on ESG material issues and helping them identify the risks and opportunities related to their businesses. A self-declaration questionnaire is used to mark the completion of Level 1 certification. Level 2 (Evaluate) aims at monitoring the performance of valuechain partners against the identified ESG

Considering the company’s deep focus on sustainability, ESG is considered a Board level mandate from a governance standpoint and discussed periodically as part of Board meetings.

metrics. Structured third-party audits, screening and documentation review marks the completion of this level. Level 3 (Evolve) is a collaborative phase where Marico ideates with its partners to design market-leading ESG practices at each stage of the value chain. The aim of this level is to build a strong, robust and sustainable nexus towards shared ESG goals.

Would you like to brief us on the sustainable packaging initiatives of Marico?

The growing awareness of environmental issues is driving demand for sustainable packaging solutions. This shift is noticed across diverse facets including consumer behaviour, government policies and industry leadership. At Marico, we recognise this shift and are committed to embed circularity principles into our operations including development of sustainable packaging solutions. Sustainable packaging program aims at minimizing environmental impact of packaging materials throughout value chain by carrying out ‘Life Cycle Analysis’ and take initiatives.

Our sustainable packaging program is designed over 9 levers to create an irreversible positive impact on overall product sustainability. These levers include Zero pallet loss, minimize materials of concern, improve recyclability, consume self-waste, dematerialise nonvalue added content, usage of recycled material, extended producer responsibility, design for reuse and transport efficiency and usage of lower emission materials.

Despite operating in consumer products sector where products are sensitive and packaging material properties play a significant role for product safety, we have achieved few milestones related to sustainable packaging – 95.3% recyclable packaging material share; two successful projects rolled out with Recycled plastic content.

We do not use single-use plastic in our packaging, and we are working closely to reduce & eliminate other “Material of Concern”. We have started procuring Forest Stewardship Council (FSC) certified papers from FY 24 with 10% of the corrugated fibre cartons made up of FSC-certified material. We aspire to increase recycled paper share in FY25. Marico is the founding member of the IPP (India Plastic Pact) and is actively contributing to drive changes in the industry through thought leadership.

According to you, what challenges are companies facing in shifting gears to more sustainable alternatives?

Adopting more sustainable alternatives presents several challenges, particularly when it comes to packaging. One of the key hurdles is sourcing high-quality recyclable materials, which are often scarce in many markets. The inconsistent availability of good quality recycled materials can compromise the quality and performance of packaging of the products. Additionally, integrating these recyclable materials into existing manufacturing processes can be complex, as they may behave differently from conventional materials. This often necessitates adjustments in production techniques or even investments in new technology to ensure that product quality remains uncompromised. Another significant issue is the reliability of the supply chain for these materials. Variations in supply due to inefficiencies in recycling infrastructure, regional differences, or fluctuating market demand can make it difficult to secure a consistent, highquality supply, potentially hindering the ability to meet long-term sustainability objectives.

How do you foresee the sustainability landscape moving from here on?

We may anticipate a greater focus on circular economies in the future, where commodities are continuously recycled

or reused and waste is reduced. Industrywide adoption of innovations in carbon-neutral operations, sustainable packaging, and renewable energy will likely be inevitable. Furthermore, the emphasis will shift from only lessening the impact on the environment to actively promoting environmental restoration through initiatives like reforestation, biodiversity conservation, and regenerative agriculture. Businesses who can effectively incorporate sustainability into their core strategy and adapt to these changes will be able to reduce risks and seize new growth prospects in the dynamic marketplace.

Share with us the step-by-step approach that will help companies in taking the first step right in driving the change?

To successfully drive the shift towards sustainability, companies need to follow a structured, step-by-step approach. The first crucial step is conducting a materiality assessment. This helps identify the key environmental, social, and governance (ESG) factors that are most relevant to the business and its stakeholders. By pinpointing what matters the most, companies can prioritize efforts that will have the greatest impact. Next, it is essential to identify potential risks and opportunities that come with adopting sustainable practices. Assessing risks, such as regulatory changes, supply chain disruptions, or consumer expectations, allows companies to mitigate potential setbacks. Benchmarking against industry peers is another key step. By comparing sustainability efforts with leading competitors and global standards, companies can set realistic goals and understand where they stand in their journey. Once risks are managed and opportunities identified, it is important to integrate these insights into the overall company strategy. The final step is to capitalize on the identified opportunities and seamlessly integrate them into the company’s overall strategy. This ensures that sustainability is not treated as a separate initiative but rather becomes embedded in the core business model, driving long-term value and resilience.

“The sustainability landscape will continue to evolve rapidly. With unified disclosures and increasing regulations, it might become easier yet challenging. The sustainability landscape in the cement and concrete sector will be driven by newer technologies for accelerating decarbonization, innovations in SCMs, Carbon trading, and technologically and policy supported pathways to zero,” shares Kaustubh Phadke, India Head, Global Cement and Concrete Association (GCCA) India, during an interview…

How is the industry perceiving circular economy, and is it making efforts in the same direction?

India is the second largest producer of cement in the world. Cement has the highest CO2 footprint among construction materials despite being the least expensive. It’s a challenging sector to address in terms of emissions. The cement is produced by heating limestone, which releases CO2... But at the same time, you will be surprised to know that the Indian Cement sector is the most energy-efficient sector in the world. The cement industry in India has been a pioneer in the circular economy; close to 73% of cement produced in India is blended cement.

Blended cements are formulated by blending of portland clinker with other finely ground materials such as pozzolana, fly ash and granulated blast furnace slag. Both fly ash and slag are waste components from the thermal power plants and the steel industry, respectively. The partial replacement of clinker, which is not only the more

expensive component of cement but also the most resource, energy and emission-intensive, with mineral additives improves the sustainability of the material. Most importantly, the performance of cement can be improved through this replacement, making blended cement the most attractive means to achieve sustainable infrastructure development.

The Indian cement sector utilizes close to 30% of the fly ash produced in India. The cement and concrete sector in India also co-processes the non-recyclable segregated combustible fraction of the municipal solid waste in their kilns to use as alternative fuels. In India, the consumption of blended cement like Portland Pozzolana Cement (PPC), Portland Slag Cement (PSC), and Composite Cement is significant. Other cement formulations, such as Limestone Calcined Clay Cement (LC3), which is standard by BIS, have been released recently, and Portland Limestone Cement is at different stages of development in India.

Environmental

and a certified Green Building

with 20+ years of experience in sustainability, carbon footprint mapping, water stewardship, sustainable supply chain management, and EHS management systems. He is NEBOSH certified, an accredited safety professional, and an alumnus of the Swedish Institute, Sweden. He is currently responsible for driving sustainability & innovation programs across the Indian cement and concrete industry and working towards the Net Zero CO2 roadmap of the sector.

We need to create awareness among the value chain partners, comprising architects, structural engineers, the construction industry, contractors, etc., of the adoption of sustainable manufacturing practices and the efficient use of cement. In 2021, at the COP-26 in Glasglow, GCCA (global) released a Net Zero roadmap for the cement and concrete industry, an ambition to be net zero at the concrete level by 2050 in alignment with the Paris Climate Agreement. We also have an intermediate target for 2030. Our purpose is to create awareness among the value chain partners as to how they can build a sustainable infrastructure with the least CO2 footprint.

The cement and concrete sectors are highly focused on sustainability. GCCA India, along with TERI, is working on

an India-specific roadmap for net zero CO2 in the cement and concrete sector in alignment with the government’s commitment to net zero.

What exactly are sustainable business practices? Would you like to share a few success stories with us?

Cement industry has emerged as the solution provider to all the other sectors in circular economy. The Indian cement sector is leading the way in utilizing byproducts like fly ash from thermal power plants and Ground Granulated BlastFurnace Slag (GGBS) from steel plants. This not only reduces the need for virgin raw materials but also promotes the circular economy by repurposing waste materials.

Around 30% of fly ash generated in India is used by the cement industry.

Before the term circular economy was coined, the cement industry was already practising it. Similarly, the slag which is generated from the steel plants is used in manufacturing the – Portland Slag Cement,

India generates approximately 4 million tonnes of plastic waste annually, with only a quarter being recycled or treated. To address this issue, the government implemented the Extended Producer Responsibility (EPR) rules, mandating that plastic users are responsible for collecting and recycling their waste. This system operates through an online EPR trading platform where recyclers receive certificates for recycled plastic that can be purchased by companies falling short of their recycling targets.

However, the EPR system has

faced significant challenges. While the market-driven approach shows promise, addressing India’s plastic waste problem requires improving the recycling system, focusing on reducing plastic production, and promoting sustainable alternatives.

Co-processing plastic waste is a great alternative as it provides the cement company with needed energy, is a greener alternative to coal/pet coke, and completely tackles plastic waste. Plastic waste is a very good substitute for coal. With a temperature beyond 1500 degrees, you are able to completely destroy the hazardous properties of plastic. These are successful business cases for implementing a circular economy within the cement industry. Another one is AFR—Alternative Fuel and Raw Material. In countries like the US and Europe, some cement plants run on 80-90% alternative fuels.

According to you, what challenges are companies facing in shifting gears to more sustainable alternatives?

The challenges are funding the sustainability alternatives and supportive policy measures. Every transition requires investment in terms of technology, operation and talent. The Cement and Concrete sectors in India have already made many transitions to be more sustainable – moving from wet process to dry process, using Captive Power plants, Waste heat recovery systems, and increasing renewable energy use. However, larger, more effective, and newer technologies like carbon capture utilization and storage (CCUS), such as Kiln electrification, require huge investment, which will require considerable funding and support from the government or financing institutions.

What are the tenets of GOOD sustainability practices?

At the GCCA, we have a GCCA Sustainability Charter, and we encourage the member companies to focus on the five pillars (Health & Safety, Climate Change & Energy, Social Responsibility, Environment and Nature, and Circular Economy). Our charter also places great importance on monitoring and reporting the data because data is the most reliable indication of performance. So, the data has to be relevant, complete, consistent,

Aligning the sustainability vision with all the value chain partners is one of the critical tasks. But here are a few ways to help align the value chain partners with the organisation's sustainability vision…

• Integrating sustainability criteria in the procurement process

• Creating awareness of embodied CO2 emissions for construction projects

• Collaboratively working with the suppliers to expand the company's sustainability goals

• Transitioning into integrated reporting

• Utilizing technology to streamline the process

transparent and accurate. Each of the pillars has a set number of KPIs set by industry experts, which we use to create GNR (database of country-wide cement industry numbers). So, the tenet of Good Sustainability practices is reporting fair data and monitoring progress on the set KPIs or targets.

How can companies assess suppliers on various ESG parameters? How can technology adoption drive significant change in this regard?

Companies can use questionnaires and checklists to assess suppliers on ESG parameters. And yes, technology would make the entire process much more efficient by streamlining, creating a database and maybe with further technology adoption also rating the supplier will be become easy.

How do you foresee the sustainability landscape moving from here on?

The sustainability landscape will continue to evolve rapidly. With unified disclosures and increasing regulations, it might become easier yet challenging. The sustainability landscape in the cement and concrete sector will be driven by newer technologies for accelerating decarbonization, innovations in SCMs, Carbon trading, and technologically and policy supported pathways to zero.

How can companies take the first step right in driving the change?

The first step would be to conduct a materiality assessment to better comprehend, understand, and prioritize sustainability issues based on the company and the sector you are operating in.

“The sustainability landscape in the coming years will likely shift towards a more integrated approach to carbon trading and offset markets, particularly through carbon credits generated by bioenergy projects. Firms that generate biochar, sequester carbon, or use renewable biomass can contribute to India’s efforts to create a vibrant carbon market. India’s Long-Term LowCarbon Strategy will likely encourage the use of carbon markets to finance decarbonization efforts across sectors, aligning with global trends toward net-zero emissions,” shares Lt Col Monish Ahuja (Retd), CMD, M/s Punjab Renewable Energy Systems Pvt. Ltd. (PRESPL) and Chairman, Confederation of Biomass Energy Industry of India (CBEII), during this interview.

What exactly are sustainable business practices?

I believe in ‘Keep It Sweet and Simple’ philosophy when it comes to sustainable technology adoption. This needs to be actionable and within your Scope 1 targets and externally achieve Scope 2 & 3 mission reduction. When it comes to biomass industry, compliances of EHSG & sustainable biomass-bioenergy are with critical aspect being the sustainability & delivery of energy in a cost effective manner & more importantly has to be reliable clean energy. It’s more important to ‘Walk the Talk’. The green washing & eyewash of processes by large corporations is sad & deplorable to say the least.

The recent accidents in boiler operations across India & with large corporations makes it evident that laid out processes & procedures are not being implemented in their entirety. There needs to be strict actions against companies where the cause of accidents is owing to the lack of safety measures

& lack of proper procedures being implemented. The accidents which have resulted in loss of life, loss of limbs & loss of plant operations, loss of revenue -> merits a deep-dive audit, rectification, review across India for safety & more particularly EHSG compliant operations is paramount.

As we delve into the diverse applications of biomass across various industry sectors, such as Boiler Plant Operations, CBG, 2G Ethanol, and Green Hydrogen, it’s crucial to maintain a strong focus on Environment, Health, and Safety (EHS) practices amidst this rapid transformation. The shift towards organized processes underscores the significance of prioritizing human safety alongside operational advancements.

What challenges are companies facing in shifting gears to more sustainable alternatives?

Shifting to more sustainable alternatives presents multifaceted challenges, especially when dealing with a highly

Lt Col Monish Ahuja (Retd) is an alumnus of the prestigious National Defence Academy, Khadakwasla, Pune and PG (M Tech) in Nuclear Technology (Mechanical) from Bhabha Atomic Research Centre, Mumbai. He is known in the Biomass – Bioenergy fraternity as a dedicated and knowledgeable leader. He has been advocating the barriers faced by Biomass-Bioenergy Project Developers at various seminars and forums and has been instrumental in impressing MNRE, MoPNG, MoA&FW, NITI Aayog, G20 Organisation, CEM14-MI8 (Clean Energy Ministerial & Mission Innovation), Global Biofuel Alliance, IRENA, World Bank, JICA, JBIC, etc., towards the use of farm agri-residues biomass-bioenergy based industry in India and Globally.

decentralized supplier base, such as farmers spread across 18 states. These farmers operate in hinterlands, which are often remote and difficult to access, making the implementation of sustainability initiatives logistically challenging.

The agricultural sector in these regions is primarily unorganized, with traditional practices deeply ingrained. This means that convincing farmers to adopt environmentally sustainable methods, such as waste management and bioenergy practices, requires significant effort in education, training, and infrastructure development.

Additionally, local politics play a significant role in influencing farmer decisions. Politicians, especially in rural areas, often have substantial sway over farming communities, making it difficult for companies to directly engage with the farmers without navigating complex political dynamics. These power structures can delay or even derail sustainability initiatives if they are seen as threatening local interests or control.

Economic constraints also hinder progress. Many farmers are financially dependent on seasonal yields and may resist change due to the perceived risks associated with adopting new, sustainable methods. Without guaranteed economic incentives or subsidies, sustainability goals such as ESG practices remain secondary priorities for these farmers.

As a result, achieving large-scale adoption of sustainable alternatives requires a comprehensive approach involving government support, awareness campaigns, and long-term investments in rural infrastructure. The shift to ESG-aligned practices will take years, if not decades, to fully materialize across such a vast and decentralized sector.

Can you share with us a success story where sustainability has proven to be a great business model too?

The traditional Indian cremation process consumes approximately 400-600 kg of wood per funeral—equivalent to the destruction of two fully grown trees— and requires 5 to 6 hours to complete. This method places a significant burden on fast-depleting natural resources while contributing to environmental

The growth of biomass power is being propelled by mandates for co-firing biomass pellets with coal in thermal power plants. Starting in 2024, thermal power plants are required to co-fire at least 5% biomass, with this target rising to 10% by 2025. Biomass co-firing helps to reduce reliance on coal, lower emissions, and improve energy security. The government has also established benchmark pricing to stabilize the market for biomass pellets, ensuring that pellet production and procurement are financially viable.

degradation.

However, biomass briquettes, a biofuel made from compressed agricultural waste such as straw, sugarcane bagasse, coconut husks, rice husks, maize stalks, and groundnut shells, are emerging as a promising, eco-friendly alternative to wood. These briquettes not only offer a renewable energy source but also help offset the reliance on increasingly expensive and scarce traditional fuels.

From agricultural waste to innovative waste-to-energy solutions, biofuels present a viable path toward reducing environmental impact. PRESPL, a leading player in the biomass sector, processes 600 tonnes of biomass daily and has pioneered a successful model in collaboration with the Aurangabad Municipal Corporation. Between November 2022 and July 2023, they replaced wood with biomass briquettes across 62 pyres at 24 crematoriums, facilitating over 1,000 cremations. Today this number stands at more than 5000+ Eco-cremation done in Aurangabad.

This model, if expanded nationwide, holds immense potential for both environmental and economic benefits. India witnesses approximately 10 million deaths annually, with 75% of the deceased being cremated. Each cremation typically consumes 400-500 kg of wood, whereas biomass briquettes, offering a higher calorific value (3600-3800 kCal per kg compared to wood’s 2500-3000 kCal),

allow for a reduction in fuel quantity. Additionally, biomass briquettes are significantly more affordable, with prices ranging from ₹7.0 to ₹ 8.0 per kg, compared to wood prices of ₹10 to ₹20 per kg.

The use of biomass briquettes not only preserves forests but also supports the rural biomass briquetting industry by providing an avenue for disposing of agricultural residues. The burgeoning industry, which has seen rapid growth thanks to evolving supply chain solutions, is solving critical issues in demand and supply through platforms like BiofuelCircle. This 3-year-old startup connects farmers with buyers, boasting over 6,000 users who have traded 3 million tons of 70 varieties of biomass briquettes.

The increasing demand for agriresidue briquettes, especially for alternative uses like cremation, presents a significant opportunity for expanding the industry and supporting rural economies. By adopting such sustainable alternatives, India can reduce its environmental footprint while promoting economic growth in rural areas. This transition, as championed by industry leaders like PRESPL, represents a major step forward in reducing wood dependency, protecting forests, and fostering a more sustainable and costeffective solution for a deeply traditional practice.

Companies can benefit from the lower lifecycle emissions associated with biomass. PRESPL ensures that biomass is sourced locally, often as a by-product of agricultural operations, which minimizes the energy used in production and transportation. This reduces overall emissions when compared to the extraction, refining, and transportation of fossil fuels. By optimizing the biomass supply chain, companies can also lower Scope 3 emissions (indirect emissions related to procurement).

What is the current state of bioenergy in India and the shaping up trends in biofuels, CBG, and biomass for power generation and industrial heating?

India’s bioenergy sector has undergone substantial growth due to a combination of government policies and rising market demands. Several key initiatives have been introduced to boost bioenergy production, particularly from agricultural waste and industrial by-products, making bioenergy a critical component of the country’s renewable energy strategy.

The Indian Government has introduced several initiatives to support bioenergy, including the National Bioenergy Programme, which encourages biomass power generation and biofuel production from agricultural and industrial residues. The SATAT Initiative, launched in 2018, aims to set up 5,000 CBG (Compressed Biogas) plants to produce clean energy alternatives such as CBG, which also helps reduce pollution caused by the burning of agricultural waste. Additionally, the National Policy on Biofuels 2018 targets the use of biofuels to replace conventional fossil fuels, aiming for a 20% blending of ethanol in petrol by 2025-26.

The growth of biomass power is being propelled by mandates for cofiring biomass pellets with coal in thermal power plants. Starting in 2024, thermal power plants are required to cofire at least 5% biomass, with this target rising to 10% by 2025. Biomass co-firing helps to reduce reliance on coal, lower emissions, and improve energy security. The government has also established benchmark pricing to stabilize the market for biomass pellets, ensuring that pellet production and procurement are financially viable.

The push for CBG production is another key trend in India’s bioenergy landscape. With its ability to replace conventional CNG in transportation and other sectors, CBG is viewed as a sustainable energy source that also addresses the environmental problem of agricultural residue burning. The expansion of CBG production facilities aligns with India’s goals to reduce its carbon footprint and dependence on fossil fuels.

While the bioenergy sector shows great promise, challenges remain.

These include logistical difficulties in aggregating biomass, high transportation costs, and the decentralized nature of the agricultural sector. Technological advancements, such as pelletization and briquetting of biomass, are helping to address these issues by improving the efficiency of biomass handling and usage. Platforms linking farmers with industrial buyers are also helping to streamline the supply chain and ensure a steady supply of biomass for energy production.

What are the innovative technologies that have the potential to make a significant impact in the bioenergy sector?

Innovative technologies in the bioenergy sector are rapidly evolving, providing enhanced solutions for biomass conversion, energy production, and sustainability. Beyond the core technologies like briquetting, pelleting, and boiler designs, several additional advancements are poised to significantly impact the sector.

Briquetting is the process of compressing biomass materials, such as agricultural residues, into compact and uniform shapes. Innovations in this field focus on improving the efficiency and scalability of briquette production. Modern highpressure briquetting machines offer enhanced compaction, producing denser briquettes that burn longer and produce less ash. This technology is critical for reducing transportation and storage costs while making biomass more suitable for industrial applications like power generation and heating. The latest advancements also enable the use of a wider variety of raw materials, including crop residues, forest waste, and even municipal waste, making it a versatile technology.

Pelleting involves compressing biomass into small, dense pellets that are easy to store, transport, and use in a variety of applications. Innovations in pelletization technology include the development of high-capacity pellet mills that can process large volumes of biomass efficiently. These mills incorporate better heat management and improved binding agents that enhance the durability and calorific value of pellets. Innovations

in raw material processing, such as torrefaction, help to pre-treat biomass, making the pellets more energy-dense and resistant to moisture, which increases their combustion efficiency in boilers and power plants.

Boilers are essential for converting biomass into heat or electricity. Modern biomass boilers have undergone significant advancements, with innovations focusing on improving combustion efficiency and reducing emissions. Fluidized bed boilers and gasification-based boilers are two key innovations. Fluidized bed boilers allow for more efficient burning of low-quality fuels like biomass by maintaining a consistent combustion temperature. Gasification technology converts biomass into syngas, which can be used to produce electricity or heat with minimal emissions. These boiler designs are also equipped with advanced controls that allow for better regulation of temperature, pressure, and fuel supply, ensuring optimal efficiency and lower operational costs.

Biochar is a carbon-rich material produced by heating biomass in a lowoxygen environment (pyrolysis). It has multiple applications, including soil enhancement, carbon sequestration, and as a bioenergy feedstock. Innovations in biochar production focus on improving the pyrolysis process to increase yields and energy efficiency. Modern biochar production units use integrated energy recovery systems to capture the heat generated during pyrolysis and repurpose it for electricity or heating. Biochar is also being increasingly used in carbon markets, as it can lock carbon in the soil for long periods, contributing to carbon offset efforts. Enhanced pyrolysis technologies allow for the production of biochar from a wide variety of biomass, including agricultural waste, forestry byproducts, and even urban organic waste.

Integrated biochar systems are being developed, where the heat produced during biochar production is captured and used for energy purposes, creating a closed-loop system that maximizes resource efficiency. Biochar’s ability to sequester carbon for long periods

also makes it a valuable tool in efforts to combat climate change by creating carbon credits and participating in carbon markets.

While not directly a bioenergy production technology, blockchain is being used to ensure traceability in biomass supply chains. It allows companies to verify the source, quality, and environmental impact of the biomass they use, ensuring that they meet sustainability goals. Blockchain technology enhances transparency, helping producers, suppliers, and consumers track biomass from its origin to its final use, ensuring compliance with regulations and improving supply chain efficiency.

The integration of bioenergy with other renewable sources such as solar and wind through hybrid energy systems is also gaining attention. These systems combine different energy sources to ensure a more reliable and consistent energy output. For instance, biomass can be used to provide baseload power, while solar and wind contribute during peak times. Such hybrid systems optimize the use of renewable resources and enhance the overall energy efficiency of industrial plants or power stations.

Moreover, combustion optimization technologies are being integrated into modern boilers to ensure better fuel-toair ratios, which minimizes emissions and maximizes energy output. Gasification boilers, for example, use advanced sensors and controls to regulate the gasification process, converting biomass into syngas with high efficiency. This syngas can then be used in combined

heat and power (CHP) plants, offering higher efficiency rates than traditional combustion methods.

The use of Artificial Intelligence (AI) and Internet of Things (IoT) is revolutionizing biomass supply chains. AI-driven systems can optimize the collection, transportation, and storage of biomass, reducing costs and improving efficiency. IoT sensors monitor moisture levels, temperature, and biomass quality in real-time, ensuring that feedstock is stored and used optimally to prevent degradation. Furthermore, machine learning algorithms are being employed to predict biomass availability and optimize plant operations, ensuring a steady supply of biomass for energy production. This reduces downtime and maximizes the operational efficiency of bioenergy plants.

Algae cultivation for bioenergy is gaining traction due to its high yield and ability to absorb CO2 during growth. Algae can be processed into biofuels, biogas, and even bioplastics. The integration of algae in bioenergy systems represents a promising way to generate energy while also addressing carbon emissions.

Photobioreactor technology for algae production is improving, allowing for better light penetration, temperature control, and nutrient management. This results in faster growth cycles and higher biomass yields, making algae an increasingly viable option for large-scale bioenergy production.

Pyrolysis is evolving with the introduction of modular pyrolysis units, which can be deployed in remote locations to convert biomass into biooil, biochar, and syngas. These units are especially useful in rural areas where transporting large amounts of raw biomass is logistically challenging. The decentralized nature of these units ensures that energy production can occur close to the biomass source, reducing transportation emissions and costs.

Gasification systems are also seeing improvements, with the development of small-scale gasifiers that can convert biomass into clean syngas for rural electrification. These systems can be integrated into microgrids, providing reliable energy to communities that are not connected to the national grid.

How blockchain technology is being used to ensure traceability in supply chains?

In biomass supply chains, where agriwaste is aggregated from farmers, processed, and delivered to clients for fossil fuel replacement, ensuring transparency and traceability is critical. Blockchain technology is playing a transformative role in this process by providing an immutable, transparent ledger that tracks every step of the supply chain. The journey begins with aggregating agri-waste from decentralized farming communities. Blockchain enables the capture of key data points such as the origin of the biomass, type of crop residue, quantity collected, and the farmer’s details. This information is securely recorded in a distributed ledger,

As part of its long-term strategy, India is positioning itself as a leader in circular economy models. The waste-to-energy model is at the heart of this transition, particularly with municipal solid waste being converted into bioenergy in urban areas and agricultural residues like paddy straw and sugarcane bagasse being used in rural settings. The government is encouraging the use of these waste materials for energy production, which not only addresses energy needs but also helps solve environmental problems like crop residue burning, which is a major contributor to air pollution.

At the national level, the use of biomass is gaining traction due to its carbon neutrality, especially when substituting for coal and natural gas in industrial applications. Biomass captures CO2 during plant growth, which is then released when used as fuel, creating a closed carbon loop. By utilizing 2.5 lakh tons of biomass annually, firms like PRESPL are setting the example for large-scale industrial decarbonization. The national strategy is moving towards scaling such efforts across sectors, with the goal of reducing dependence on fossil fuels while promoting job creation in rural areas through biomass collection and processing.

accessible to all stakeholders, ensuring that every biomass batch can be traced back to its source.

At collection centres, blockchain further ensures that the handling and transportation of the agri-waste are documented. Information about storage conditions, transportation routes, and timing is logged in real-time. This enables better tracking of biomass as it moves through the supply chain, preventing discrepancies and ensuring quality control. When the biomass is processed and densified (for example, into briquettes or pellets), blockchain tracks the transformation process, including the methods used and any quality assessments. Each step is digitally verified, ensuring that the end product meets the desired specifications for replacing fossil fuels.

Finally, blockchain technology enables traceability up to the client delivery point. Clients can access detailed records of the entire supply chain—from the farm to the processing facility to their location—ensuring confidence in the sustainability, quality, and compliance of the biomass they receive. This transparent process fosters trust and accountability, essential for scaling the use of biomass as a renewable energy alternative.

Pls enlighten us on government policies and perspectives regarding innovations in bioenergy… Government has set its sight on India being carbon neutral by 2070 & for the same sustainable Biomass – Bioenergy is recognized as an important component and contributor for the set target. Multiple Ministries have set roadmaps for use of Biomass with support for R&D and innovations, in technology,

processes, supply chain management, equipment development & deployment, financial engineering and innovation, bio-technology development amongst many more segments which are being supported.

Global Biofuels Alliance, GBA which is the key takeaway from India’s G20 Presidency, and more recently the approval for the GBA secretariat to be established in India paves the way for a full-time global office to further the developments in Bioenergy. Support for new technologies development, financial assistance, calls for startups to work in the Biofuels and Bioenergy sectors and fostering innovation along with sustainable development are amongst the agenda being pursued with a long term vision of energy independence for India.

How can firms like yours help companies in their decarbonization journey? What action steps they can take to harness sustainability?

Firms like PRESPL can play a pivotal role in helping companies decarbonize their operations by leveraging the use of biomass, an eco-friendly and renewable energy source, in place of fossil fuels. Here’s how PRESPL, with its established biomass supply chain and focus on steam production, can assist companies in their decarbonization journey.

PRESPL can help companies replace fossil fuels such as coal, oil, or natural gas with biomass for energy production, particularly in steam generation. Biomass is considered carbon-neutral because the CO₂ released during combustion is offset by the CO₂ absorbed by plants during their growth. By integrating biomass into a company’s energy system, firms can

drastically reduce their carbon footprint, as the carbon emitted is not new but part of the natural carbon cycle. This shift directly contributes to lowering Scope 1 emissions (direct emissions from owned or controlled sources).

One of the most significant contributions PRESPL can offer is the displacement of fossil fuels. Every ton of biomass that replaces coal, for example, avoids the release of stored carbon from fossil fuel sources, significantly reducing greenhouse gas (GHG) emissions. PRESPL’s expertise in sourcing and processing biomass from agricultural waste and residues can allow companies to transition seamlessly from fossil fuelbased systems to cleaner, renewable energy sources.

PRESPL’s use of agricultural residues as a biomass feedstock also helps in reducing methane emissions. When organic waste decomposes naturally, it releases methane, a potent GHG. By diverting this waste for energy production, companies can prevent methane from entering the atmosphere, thereby contributing to overall GHG reduction efforts. This is particularly important in sectors like agriculture, where methane emissions are a major environmental concern.

PRESPL’s use of biomass in steam production offers a direct pathway for industries reliant on thermal energy to decarbonize. Biomass boilers and steam systems can replace coal- or gasfired systems, providing the same level of efficiency with fewer emissions. PRESPL’s advanced boiler systems and integration of biomass supply chains ensure that companies can achieve the desired thermal energy output without compromising operational efficiency.

Moving forward, biomass will not only replace fossil fuels but will also drive carbon sequestration efforts through biochar production, offering dual benefits of energy generation and carbon capture. The integration of bioenergy with other renewable sources, like solar and wind, will foster hybrid systems that can provide reliable, round-the-clock clean energy.

Another innovative action PRESPL can facilitate is the production of biochar during the biomass combustion process. Biochar is a carbon-rich by-product that can be used to enhance soil health while simultaneously sequestering carbon, locking it away from the atmosphere for centuries. This adds an additional layer of carbon reduction, beyond merely replacing fossil fuels, enabling companies to potentially earn carbon credits through biochar applications.

PRESPL’s technical expertise allows companies to quantify GHG reductions effectively. With an annual usage of 2.5 lakh tons of biomass, PRESPL can calculate the carbon dioxide equivalent (CO₂e) emissions avoided by replacing fossil fuels. For example, replacing coal with biomass can lead to an estimated reduction of 1.8 to 2.5 tons of CO₂ per ton of biomass used, depending on the type of biomass and combustion efficiency. This not only helps in meeting sustainability goals but also enhances a company’s ESG (Environmental, Social, and Governance) credentials.

How do you foresee the sustainability landscape moving from here on?

The sustainability landscape is poised for a transformation, with bioenergy and other renewable sources playing an increasingly critical role in global and national strategies for decarbonization. The emphasis is on reducing reliance on fossil fuels, promoting circular economies, and integrating innovative technologies to achieve long-term environmental goals. Here’s a strategic outlook for the sustainability movement in India, grounded in current policies, emerging trends, and the data shared: India’s commitment to reducing carbon emissions is solidified through its National Action Plan on Climate Change (NAPCC), the National Bioenergy Programme, and the Long-Term Low-Carbon Development Strategy.

These initiatives target a transition to renewable energy sources, with biomass taking a central role in decarbonizing energy systems. The push for bioenergy aligns with India’s broader climate goals of achieving net-zero carbon emissions by 2070, as announced during the COP26 Summit. The government is mandating the blending of biomass with coal in thermal power plants and expanding CBG production as part of its Sustainable Alternative Towards Affordable Transportation (SATAT) initiative.

At the national level, the use of biomass is gaining traction due to its carbon neutrality, especially when substituting for coal and natural gas in industrial applications. As discussed, biomass captures CO₂ during plant growth, which is then released when used as fuel, creating a closed carbon loop. By utilizing 2.5 lakh tons of biomass annually, firms like PRESPL are setting the example for large-scale industrial decarbonization. The national strategy is moving towards scaling such efforts across sectors, with the goal of reducing dependence on fossil fuels while promoting job creation in rural areas through biomass collection and processing.

The recent Ministry of Power’s revised biomass policy mandating 5-10% biomass co-firing in thermal power plants by 2025 is a significant step forward. This policy will likely expand to other industries, pushing them toward greater use of biomass-derived fuels and enhancing demand for technologies like briquetting and pelleting. As biomass densification technologies improve, the cost of producing biofuels like briquettes and pellets will fall, making them more attractive for industrial and power applications.

In the coming years, technological innovations will be key drivers of sustainability. Innovations in pelleting,

briquetting, and boiler technologies will make biomass utilization more efficient and cost-effective, enabling industries to meet their energy needs with fewer emissions. Advanced gasification technologies that convert biomass into syngas for electricity generation will likely see increased adoption, particularly in regions with limited access to traditional energy grids. Moreover, innovations in biochar production can help industries sequester carbon while enhancing soil quality, making this a dual-use technology for energy and environmental sustainability.

The National Bioenergy Programme will continue to promote biomass in industries where waste generation is significant, offering financial incentives for industries that adopt sustainable waste-to-energy practices. As global markets demand more sustainable products, companies in India will have to align their supply chains and energy practices with international standards, making sustainability a competitive advantage. This will lead to an increase in green investments, with companies seeking to adopt bioenergy technologies to enhance their ESG performance.

“The holistic sustainability cannot be achieved without the inclusion of suppliers and in order to fulfil sustainability imperatives of organization, working in collaboration is the key,” asserts Nishtha Gupta, Group Head – Sustainability & ESG, Suzlon, during this interview…

What are the main challenges in integrating advanced technologies into supply chains? What are some of the best practices for overcoming these challenges?

The challenges are in terms of know-how, adaptation to changes and cost. The best way for tackling such challenges will be not just to engage with suppliers but to consider them as nosiness partners and provide all requisite support to upgrade suppliers’ competency. It is important to ensure capacity building of suppliers and provide all tools and technical knowhow to ensure alignment of Suppliers to expectations and commitments of an organization. The inclusion of suppliers and MSMEs is essential to work aggressively towards decarbonization targets of organization and with vision of Net Zero Commitments at national level. The holistic sustainability cannot be achieved without inclusion of suppliers and in order to fulfil sustainability imperatives of organization, working in collaboration is the key. The times are changing which requires us to work along with stakeholders for handling common challenges for reducing Scope 3 emissions without which Net Zero Journey cannot be achieved. Furthermore, collaboration can also help in creating demand for procuring more sustainable materials, thereby bridging a gap between demand and supply. A cohesive and collaborative effort in this direction by one and all across all sectors can be instrumental drivers in achieving Net Zero targets well before the target timeline.