Special Report on Driving Operational Excellence Through a SOUND Supply Chain Orchestration

Focus section on concepts and methodologies to help select right technologies to reduce Scope 3 emissions.

Special Report on Driving Operational Excellence Through a SOUND Supply Chain Orchestration

Focus section on concepts and methodologies to help select right technologies to reduce Scope 3 emissions.

Dear Readers,

As ESG continues to shape the future of business, it’s the ‘E’—Environment— that remains both a challenge and an opportunity to drive truly sustainable operations. In this issue, we put the spotlight on how ESG can be embedded into risk management strategies and the role technology plays in building sustainable supply chains.

Celerity Supply Chain Tribe recently organized a thought-provoking conference on Sustainable Value Chains, where leading sustainability officers shared their insights. Our Cover Story captures these expert perspectives, focusing on the integration of sustainability into daily operations. The panel discussions provided practical steps for companies to assess, monitor, and improve their supply chain sustainability. Additionally, we explore how ESG is becoming a crucial part of risk management, offering a comprehensive approach to foresee and mitigate environmental and social challenges.

The issue also features a Special Report on Supply Chain Orchestration. In an era where resilience is paramount, leading professionals discuss operational excellence and the role of technology in driving efficiencies and building supply chains that can withstand disruptions.

We believe this issue will serve as a valuable resource to those striving for sustainable, resilient, and forward-thinking supply chain strategies.

Happy Reading!

Charulata Bansal Publisher Charulata.bansal@celerityin.com

www.supplychaintribe.com

Published by: Charulata Bansal on behalf of Celerity India Marketing Services

Edited by: Prerna Lodaya e-mail: prerna.lodaya@celerityin.com

Designed by: Lakshminarayanan G e-mail: lakshdesign@gmail.com

Logistics Partner: Blue Dart Express Limited

Imbibing sustainability in day-to-day operations is no mean feat… it mandates building a sound sustainability strategy in corporates’ supply chain. Our maiden conference on Sustainability emphasized this very tenet and explored the transformation of supply chains into sustainable models that reduce environmental impact and promote social welfare. Through this Cover Story, subject matter experts discuss innovative strategies for incorporating renewable energy, reducing waste, enhancing transparency, and ensuring ethical labor practices. It also puts spotlight on practical steps companies can take to assess, monitor, and improve the sustainability of their supply chains.

Leveraging Technology for Sustainable Supply Chains

As we stand at the tipping point of a climate crisis, organizations are under pressure to ideate and implement appropriate decarbonization strategies. The chemical industry, a significant contributor to total Green House Gas (GHG) emissions, is an important sector for achieving overall GHG reduction targets. This article by Raghavendra Pai, India Sustainable Sourcing Lead, Syngenta, and Dr. Amgad Salah Moussa, Syngenta, Basel, Switzerland, discusses some concepts and methodologies to help the organizations and their suppliers to select right technologies that will eventually help in reducing Scope 3 emissions.

“Embracing the 3Ps of sustainability – Planet, People, and Profit – is essential for organizational success. There can be no trade-offs,” avows Pavan Sharma, Director, Advance SCS and Co-Founder & CEO, PlanetWise Pte. Ltd.

“Establishing a broad network of suppliers across different regions to reduce dependency on a single source and mitigate risks associated with geopolitical or environmental factors will help companies wither the impact of unforeseen situations,” emphasizes Lt Colonel Vijay Nair, Founder & Consultant, Saarthak Solutions.

As companies navigate the complexities of today’s global markets, a strategic focus on supply chain excellence will undoubtedly be a key differentiator for those aiming to thrive in the marketplace of tomorrow. By embracing digital transformation, fostering collaboration, adopting sustainable practices, managing risks, and continuously improving operations, businesses can build resilient supply chains that deliver value to customers while remaining adaptable to future challenges.

views expressed here

solely

of the

in his

“Embracing the 3Ps of sustainability – Planet, People, and Profit – is essential for organizational success. There can be no trade-offs. Climate change is for real and the impact of GHG emissions cannot be ignored. By integrating ESG considerations into risk management, organizations can identify and address potential threats, build resilience, and create long-term value for shareholders, customers, and communities,” avows Pavan Sharma, Director, Advance SCS and Co-Founder & CEO, PlanetWise Pte. Ltd., during this exclusive interview…

What are the strategies to diversify or regionalize supply chains?

Global supply chain facilitates the flow and optimal allocation of production factors such as labour, capital, and information worldwide. The way supply chains functioned experienced a radical shift during the time I was working in the US during the 1990s.

Supply chain managers began to adopt outsourcing, offshoring, single sourcing, lean production, and JIT as core strategies. China became the preferred sourcing destination for many organizations. Until the COVID-19 pandemic disrupted global supply chains, this model was highly successful. The imposition of border restrictions by China during the COVID 19 pandemic led to a complete shutdown of manufacturing activities. The concentration of supply chains in a single country and with a single supplier proved to be a significant risk, as highlighted by the COVID-19 crisis. It was a wakeup call for organisations and the supply chain managers. Diversifying and regionalizing supply chains became increasingly crucial for businesses to mitigate risks, improve resilience, and enhance overall performance.

To begin with, supply chain managers

must implement a multi-sourcing strategy for essential components and raw materials to mitigate supply chain risks. By maintaining optimal inventory levels, organisations can effectively manage risks and ensure operational continuity. Secondly, expand the supply chain footprint to different regions to mitigate risks associated with geopolitical instability, natural disasters, or economic downturns. Finally, build relationships with suppliers of varying sizes, industries, and geographic locations thus increasing flexibility and providing options. Last but not the least, by investing in local suppliers, organizations can create a more resilient, efficient, and sustainable supply chain while also contributing to the growth of their communities.

How do you balance cost efficiency with the need for resilience?

Supply Chain Resilience (SCR) and supply chain costs are classic trade-offs. On the one hand, in recent decades, improving efficiency and reducing cost have become the goal pursued by supply chain practitioners. Lean production that originated from Toyota’s production system and later extended to lean design, lean manufacturing, lean inventory, and

Pavan Sharma is an expert in procurement and supply chain management, industrial engineering and process improvement. He has over 30 years of experience in production, quality, supply chain, sustainability and procurement functions in automotive, manufacturing, consulting and logistics companies. Pavan holds a Master of Business Administration (MBA), a Bachelor of Engineering in Industrial Engineering and holds a Post Graduate Diploma in Industrial Engineering. He has also completed the CIPS UK Level 6 Professional Diploma in Procurement and Supply. He is also a GRI Certified Sustainability Professional.

Supply chain managers must implement multi-sourcing strategy for essential components and raw materials to mitigate supply chain risks. By maintaining optimal inventory levels, organizations can effectively manage risks and ensure operational continuity. They must expand the supply chain footprint to different regions to mitigate risks associated with geopolitical instability, natural disasters, or economic downturns. Additionally, they should build relationships with suppliers of varying sizes, industries, and geographic locations, thus increasing flexibility and providing options.

other lean production management systems. Lean supply chain required optimizing and transforming the whole supply chain link by eliminating nonvalue-added activities between upstream and downstream enterprises. This helped organizations improve quality, reduce costs and increase their profitability.

On the other hand, in recent years, unpredictable events such as COVID-19, natural disasters, geo-political tensions and trade protectionism have brought challenges to the stability of Supply Chains. This has forced supply chain practitioners to shift their perspective to enhancing Supply Chain Resilience (SCR) to reduce the disruption risk of their supply chain and maintain the continuity of business operations. However, there the pressure of reducing costs and improving profitability still remain. So,

how will supply chain managers achieve the balance between cost efficiency and need for resilience. In my opinion, it will be the technology, specifically the Industry 4.0 technology like Big Data Analytics, Internet of Things (IoT), Block Chain, Additive Manufacturing, Artificial Intelligence, etc.

Big Data Analysis will facilitate early warning planning to enable originations to proactively take measures to prevent disruption while at the same provide deep granular information to identity cost savings. Similarly, IoT will improve speed of response and enable real time information sharing with supply chain partners to reduce costs and improve quality. Additive Manufacturing or 3D printing will revolutionise how global supply chains are currently configured. The use of Additive Manufacturing

at all stages of the supply chain will accelerate production and reduce lead times, improving agility, which is a key component of resilience.

How can companies build the ability to withstand disruptions by using technology in order to shift from reactive to predictive risk management?

As I previously mentioned, technology will transform how businesses approach risk. By leveraging data and analytics, companies can move from simply responding to crises to proactively anticipating and mitigating them. For example, collecting data in real time basis from various sources including internal as well as external market data, climate data, social media and IoT devices will enable predictive planning, scenario

Decarbonized supply chains are crucial in mitigating risks associated with volatile fossil fuel prices, regulatory changes, and climate-related disruptions. By reducing reliance on traditional energy sources, companies can shield themselves from price fluctuations and policy shifts that impact operational costs. This shift also helps minimize exposure to carbon taxes and emissions regulations that may arise due to changing environmental policies.

analysis and timely risk management. Artificial Intelligence will help to identify unusual patterns in data that may signal emerging risk, and automated systems will provide options and recommendations to facilitate intelligent decision making. Digital Twin Technology that creates digital representation of physical assets, process or systems will be used to simulate potential disruptions to identify vulnerabilities and develop mitigation strategies. Overall, I am convinced that disruptive technologies will be instrumental in enabling predictive risk management.

Share with us a comprehensive crisis management framework that organizations implement for managing high impact low probability event?

High-impact, low-probability (HILP) events, such as natural disasters, cyberattacks, war or economic crises, can pose significant challenges to organizations. A robust crisis management framework is essential for mitigating their impact. Start with Crisis Management Team comprising of personnel from key departments. Identify potential crises that could affect businesses by carrying out a thorough risk assessment process. For example, cyberattacks and market crashes are real risks in financial services. Develop Response Procedures that outline immediate actions to be taken when a crisis occurs and develop strategies to contain the crisis and prevent it from escalating. Follow it up by initiating recovery actions, including restoring operations and services. For this to succeed, Organisations need to allocate adequate resources to support crisis response activities.

What are the collaboration opportunities that technology can enable?

We are in the era of digital supply chain. There is a growing realization of benefits of collaboration and engagement with upstream and downstream supply chain partners. In many ways, technology has revolutionized the way teams work together, breaking down geographical barriers and fostering innovation. Tools like video conferencing, instant messaging and shared documents enable teams to work together synchronously, regardless of location. Post Covid, remote work and virtual teams are the order of day. Technology is enabling distributed teams to collaborate effectively, fostering a global workforce. I believe AI can significantly enhance efficiency by automating routine tasks, allowing for greater focus on strategic initiatives. Design thinking tools like Miro, Mural, etc., are supporting collaborative problem solving and innovation processes. Collaboration and partnerships with suppliers, customers, and other stakeholders are essential for driving sustainable supply chain initiatives. By working together, companies can achieve greater impact and share best practices. An example of supply chain collaboration is the Fashion Revolution movement, which brings together fashion brands, suppliers, and consumers to promote transparency and ethical practices in the fashion industry. Through partnerships, they advocate for fair wages, safe working conditions, and responsible sourcing.

What are the ways to mitigate cyber threat?

Cyber threats are constantly evolving, making it essential for organizations to adopt a multi-layered approach to protection. This should include

employee training, running awareness campaigns and implementing strong access controls and role-based access to limit unauthorised access. The next step is to conduct regular risk assessments to identify vulnerabilities and prioritize mitigation efforts. Put in place an Incident Response Plan (IRP) as well as a Business Continuity Plan (BCP). Utilize firewalls, intrusion detection and prevention systems (IDPS), and network segmentation to protect the network. Consider adopting established frameworks like NIST Cybersecurity Framework or ISO 27001. Stay informed about emerging threats and vulnerabilities and finally test the IRP to ensure effectiveness.

What are the sustainable or ESG measures that organizations can take related to risk management?

As a supply chain professional, sustainability is a subject close to my heart. Today, there can be no discussion of supply chain without reference to sustainability. Embracing the 3Ps of sustainability – Planet, People, and Profit – is essential for organizational success. There can be no trade-offs. Climate change is for real and the impact of GHG emissions cannot be ignored. By integrating ESG considerations into risk management, organizations can identify and address potential threats, build resilience, and create long-term value for shareholders, customers, and communities. Organisations have to assess the potential impacts of climate change (e.g., extreme weather events, scarcity of resources etc) on operations, supply chain, and assets in order to develop effective adaptation and mitigation strategies. According to ILO report, approximately 40 million people work under forced conditions.

Child labour is still rampant in many developing and underdeveloped countries. Supply chain managers bear responsibility for ensuring ethical and sustainable operations across the entire supply chain, with a particular focus on labour standards and human rights.

Would you like to cite some success stories making way for sustainable supply chains?

A key area of focus in sustainable supply chain practices is the integration of renewable energy sources. By embracing renewable energy, companies can significantly reduce their carbon emissions and dependence on fossil fuels. IKEA is a notable example of a company that has invested in renewable energy integration. The company has installed solar panels on the roofs of its stores and warehouses, generating clean energy to power its operations. Additionally, Amazon has made substantial commitments to renewable energy by investing in wind farms and solar projects. It aims to power its global infrastructure with 100% renewable energy by 2025.

Efficient waste management

and recycling also play a crucial role in sustainable supply chains. Companies across various industries are implementing waste reduction and recycling initiatives. For instance, Unilever has implemented waste reduction strategies through its Zero Waste to Landfill program. This has led to a decrease in waste generation and increase in recycling rates in its manufacturing facilities worldwide.

How do you foresee the sustainable supply chains landscape going forward?

Future supply chains will likely witness increased regulatory frameworks addressing carbon emissions. Companies may face stricter compliance requirements, pushing them to adopt comprehensive carbon management services to meet evolving standards effectively.

As consumers become more environmentally conscious, there is a growing demand for sustainable products and services. This shift is expected to drive businesses towards implementing robust carbon management strategies, leveraging SaaS carbon footprint

solutions to reduce their environmental impact while meeting consumer expectations.

In the end, decarbonizing supply chain is no longer a choice but a must in a world that prioritizes sustainability. Carbon management solutions can help companies minimize their environmental footprint and build a company’s strength for tomorrow. Carbon management solutions are set to evolve with innovative carbon management software and platforms integrating advanced features. These advancements will streamline carbon footprint tracking and enhance carbon management systems, making them more efficient and user-friendly. Make the necessary changes for a more sustainable future. Start creating sustainable practices, utilising technologies, and learning from the experts now. By decarbonising, companies will protect the earth for future generations and establish a competitive edge for the future.

As we stand at the tipping point of a climate crisis, organizations are under pressure to ideate and implement appropriate decarbonization strategies. Global agreements such as the Paris Agreement have resulted in new regulations, new reporting standards, and changing expectations from both shareholders and the public in general. Forward-looking organizations are increasingly shifting from prioritizing only Profits to prioritizing People, Planet, and Profits equally with renewed focus on Sustainability. The chemical industry, a significant contributor to total Green House Gas (GHG) emissions, is an important sector for achieving overall GHG reduction targets. This article by Raghavendra Pai, India Sustainable Sourcing Lead, Syngenta, and Dr. Amgad Salah Moussa, Syngenta, Basel, Switzerland, discusses some concepts and methodologies to help the organizations and their suppliers to select right technologies that will eventually help in reducing Scope 3 emissions.

IN the backdrop of rapidly evolving technologies, organizations are faced with the challenge of evaluating and selection of right technologies and formulate an appropriate decarbonization roadmap. This white paper discusses the challenges, opportunities, and methodologies that can help chemical industries to identify and deploy the right decarbonization technologies.

Climate change due to global warming is an existential threat to humanity. It has rightfully taken centerstage for discussions and deliberations amongst scientists, policy makers, and international think tanks, among others. Fortunately, there is consensus amongst nations, as demonstrated by the overwhelming endorsement of targets set by the Conference of Parties (COP) to limit average global warming

Raghavendra Pai possesses over 32 years’ experience in Hydrocarbon and Chemical Industry in the fields of Process Engineering, Project Engineering, Manufacturing Operations, Project and Portfolio Management, HSE, Sustainability & Energy management and Continuous Improvement. He is a Chemical Engineering graduate from National Institute of Technology, Surathkal and has done Executive MBA from Goa Institute of Management and completed Supply Professionalism Program from University of Warwick, UK.

Dr. Amgad Moussa earned a PhD degree in chemical engineering from ETH Zurich in 2008. He joined Syngenta new Active ingredient manufacturing in 2016 as a senior team leader, where he contributed to the scale up and piloting of several new active ingredients. In 2023 he became Syngenta Fellow with focus on Technology and Sustainability.

to 1.5°C. As a sector, while the chemical industry is a significant contributor to the Green House Gas (GHG) emissions it is also important contributor to the economy. Therefore, decarbonization in the chemical sector is important to achieve overall GHG reduction targets.

The Paris Agreement has obligated member countries to commit to Nationally Determined Contributions (NDC), share of efforts to reduce GHG. Governments are amending and introducing new regulations to deliver the commitment. Further, measures such as Carbon Border Adjustment Mechanisms (CBAM) is forcing organizations to adopt sustainable practices to access such markets. Forward looking organizations have already started working on their decarbonization plans and decarbonization is increasingly gaining attention of the senior management.

Factors such as consolidation amongst major players, the shift of manufacturing to the east etc., have shaped the supply chains of chemical industries that we see today. It is common to see the basic raw materials getting converted to commodity chemicals which are processed into intermediate products, in several stages, at different manufacturing facilities, before transforming into final products.

GHG is quantified by equivalent tons of Carbon dioxide (eCO2), which is a measure of impact on global warming potential due to emission of one ton of carbon di oxide. In the context of GHG emission, Scope 1 refers to the direct emission in the premises, Scope 2 to indirect emissions due to the purchased utilities and Scope 3, emissions embedded in inputs materials, infrastructure, transportation etc.

CHEMICAL

As Scope 3 is the primary subject under discussion, it is important to understand Scope 3 emissions in detail. GHG protocol provides detailed classification within Scope 3. This includes purchased goods and services, capital goods, transportation, fuel- and energy-related activities, distribution, waste generated in operations among others.

Given the nature of supply chain of chemical manufacture as explained in sub section above, Scope 3 emissions account for 70% to 90% of the total product carbon footprint. Of the Scope 3 emission, significant contribution is attributed to emissions embedded in raw materials and intermediates sourced from other manufacturers. Although activities such as transportation of material, employee commute, contribute to scope 3 emissions, in most cases, energy required for processing, at preceding stages, is the largest contributor. Therefore, to achieve substantial reduction in Scope 3 emissions, it is imperative that organizations engage suppliers of major input materials.

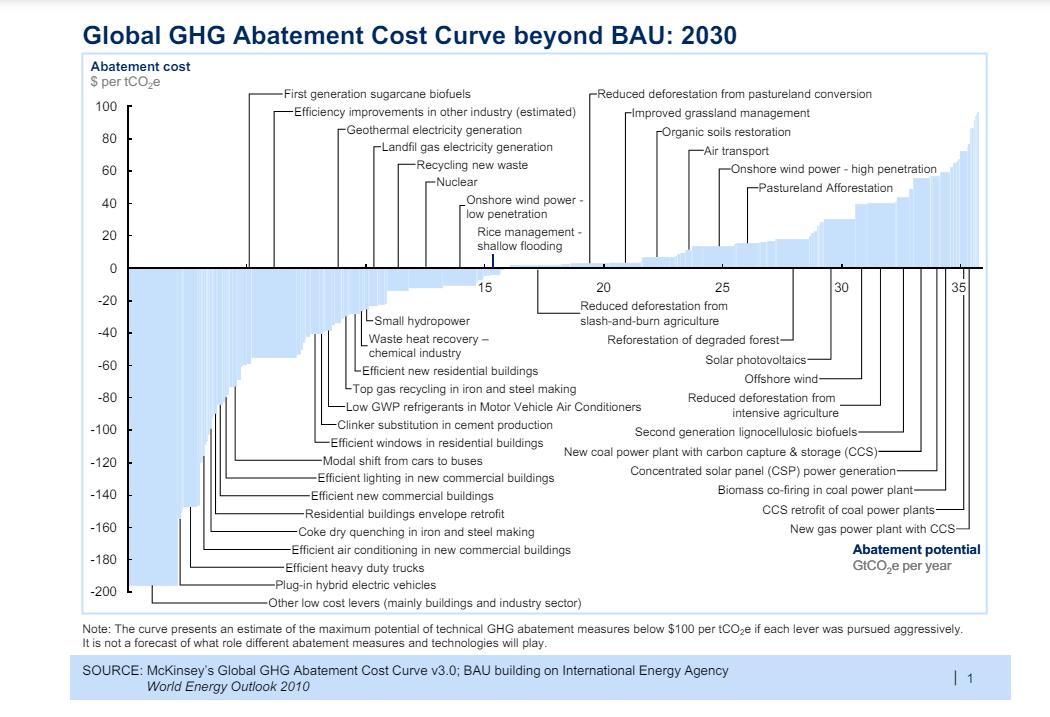

It is important to recognize the varying levels of maturity and commercialization of different technologies. Abatement costs refer to the costs required to reduce one ton emission reduction of eCO2

using a particular technology. This is a good guide to understand readiness and attractiveness of a particular technology. Exhibit 1 in the following page (Abatement Cost Curve, 2010) provides a general idea about the concept.

Abatement costs provide a good direction in identification of relevant technologies. However as getting accurate values is a challenge, this cannot be a tool by itself to identify workable technologies. In the next section, a methodology to help organizations to identify and select appropriate technologies for decarbonization is discussed.

In this section, a methodology for selection of right decarbonization technologies, based on Onion model and multicriteria technology selection is proposed and discussed. Organizations are increasingly involving their key suppliers to reduce their carbon footprints and achieve targets. The proposed methodology can be applied both by the primary organization and its suppliers to screen and select appropriate technologies. Further, it is assumed that the primary organization has already taken the suppliers on board and a collaborative relation already exists.

1 Readiness of Technology

Novel technology – No or very few in actual operation

2 Risk of Obsolescence. Technology likely to lose attractiveness in 2 years

3 Readiness of the organization.

Organization is not yet mature to execute plans

4 Cost implication High cost of decarbonization. payback of over 8 years

5 Magnitude of GHG emissions mitigation

GHG reduction less than 0.2% of the target reduction

TECHNOLOGY SELECTION

METHODOLOGY

Balancing capital expenditure on modern technologies against the expected benefits is a challenge for organizations. In the context of GHG abatement technologies, there are several innovative technologies at various stages of development and commercialization. Global warming crisis has accelerated the development of new green energy as demonstrated by falling prices of solar and wind power. Technologies such as Solarthermal power, Green Hydrogen, CO2 sequestration are examples for supplyside decarbonization. On the demand side, efficiency improvement measures like Energy Management Systems, highefficiency equipment & systems, process improvements are good examples.

Figure below depicts the layers of chemicals manufacturing according to the modified nested multilayer “onion” model.

The color code is indicative of the ease

Technology has been in use for at least 5 years

Stable technology relevant for a longtime

Organization has a competent team.

Has payback of less than 2 years

GHG reduction more than 2% of the target reduction

manufacturer. This model is useful in setting a hierarchy of areas considered while formulating a decarbonization road map.

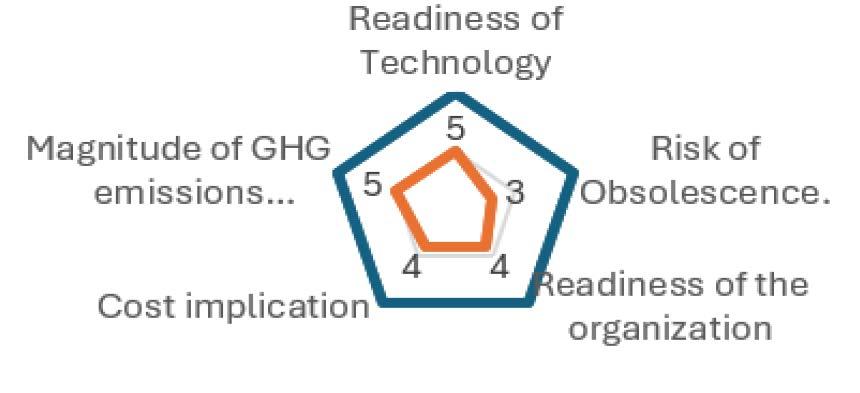

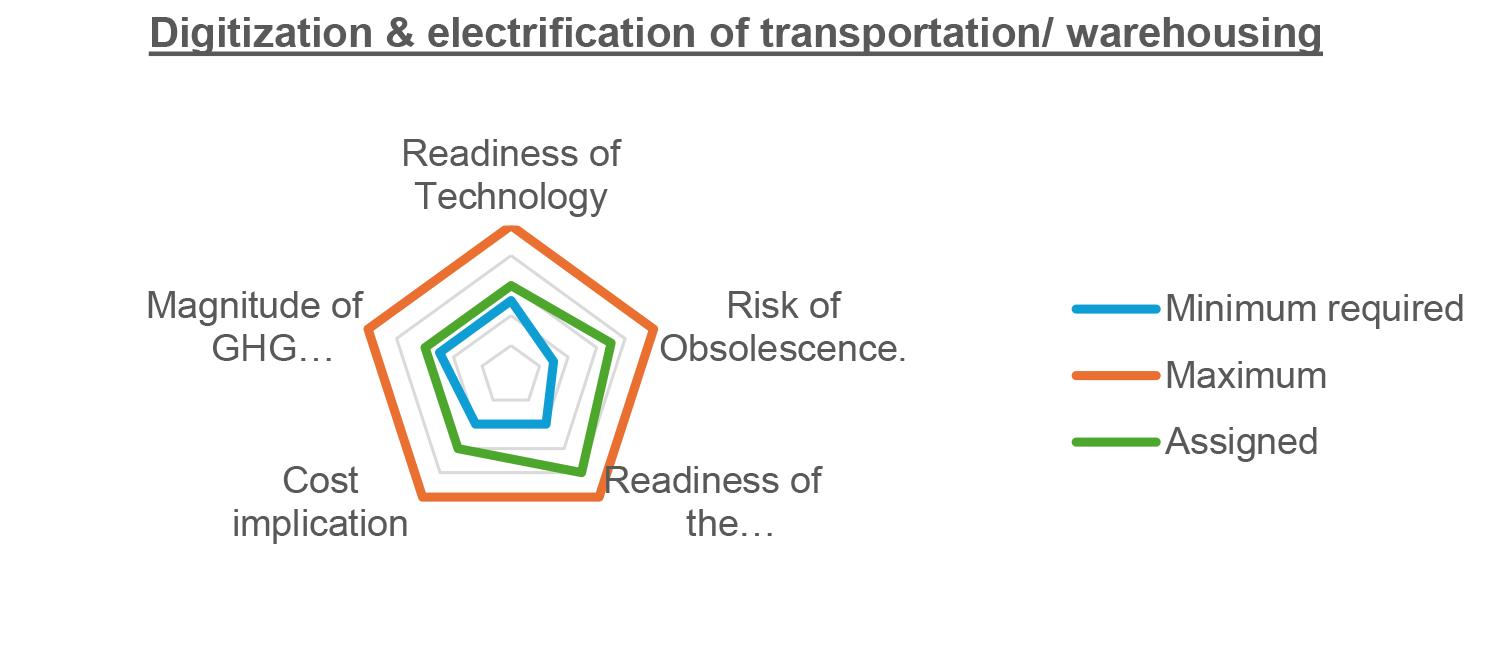

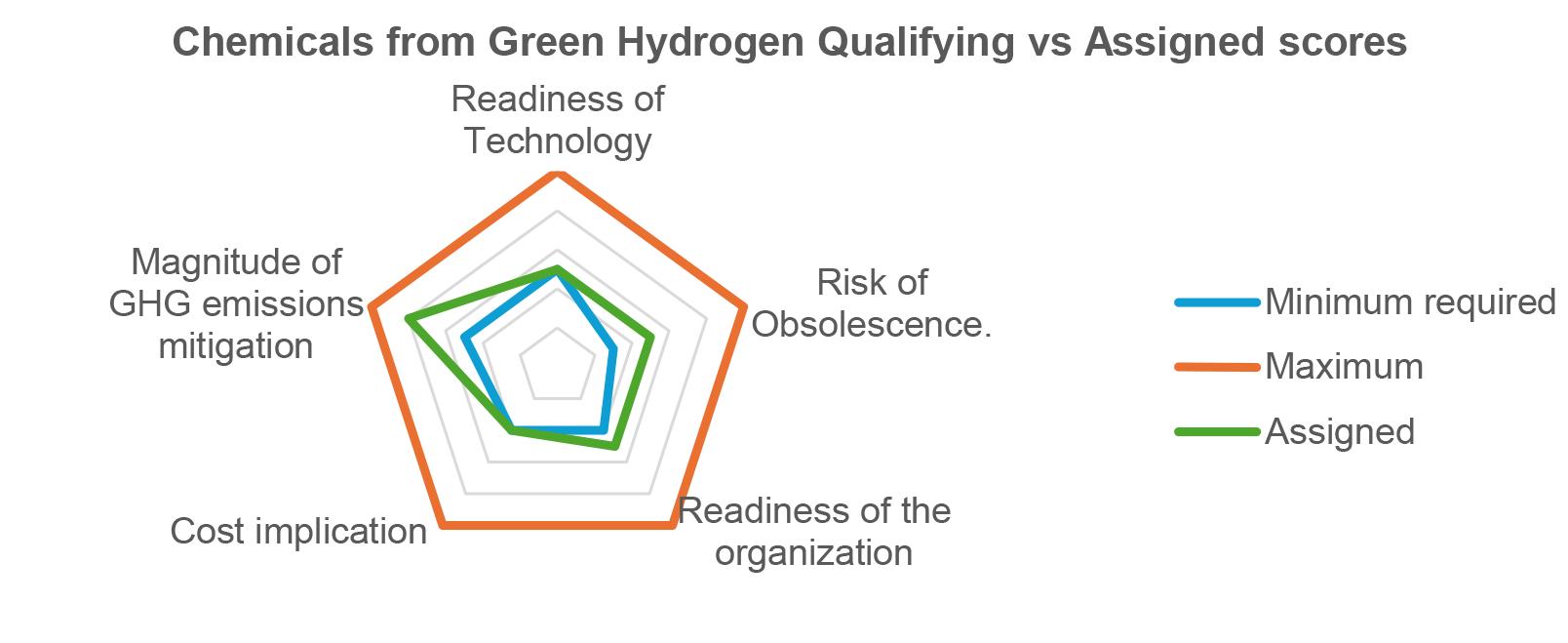

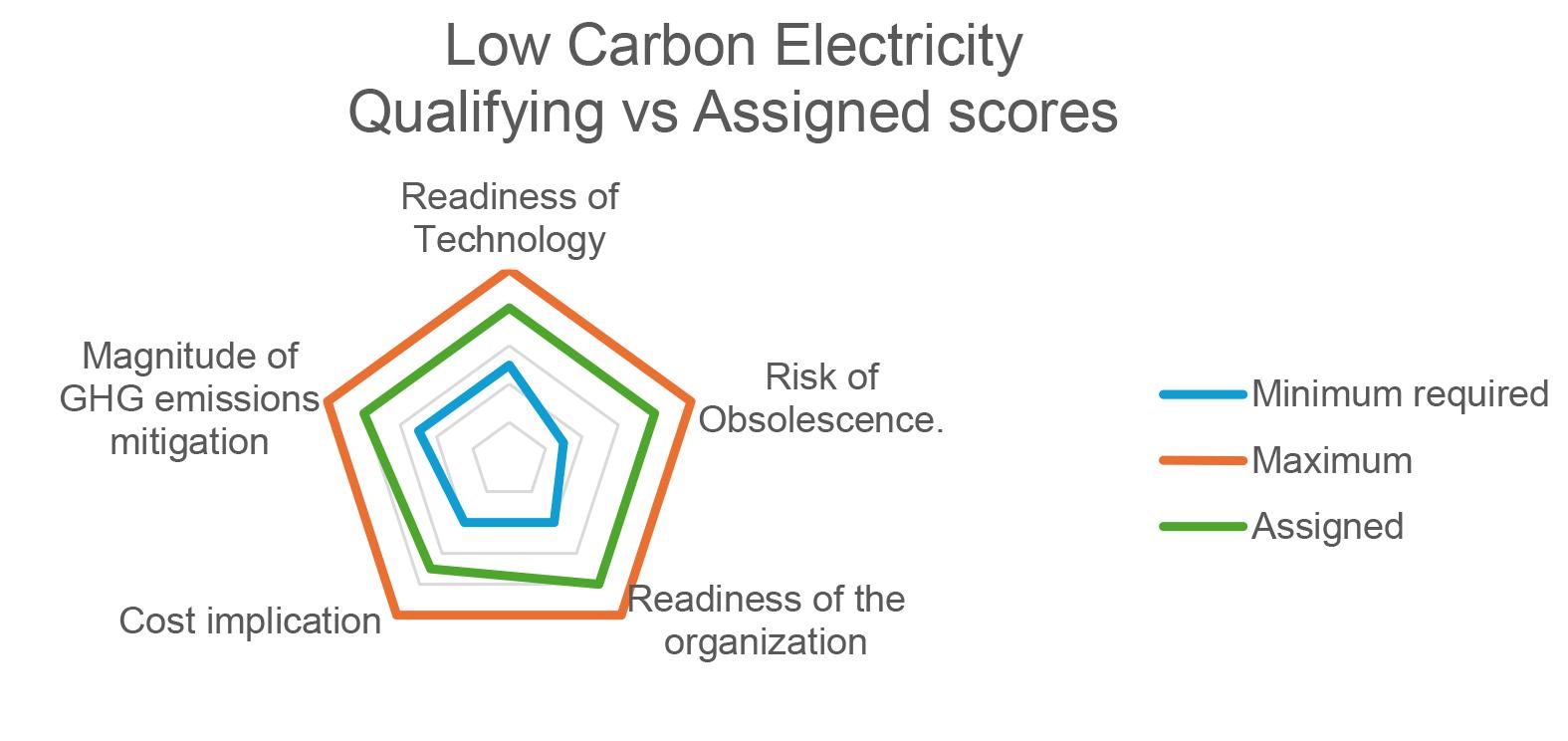

The multicriteria methodology described below is to help select and prioritize options based on multiple criteria listed in the Table 1 below. Each criterion is scored on a scale of 1 to 10, 1 being the least favorable to 10 being the most favorable. The ranking criteria is indicative and can be changed based on requirements of the organization.

The first step is to establish the minimum qualifying score for each of the criterion. The ranking will vary from one organization to the other depending on the kind of decarbonization trajectory. This in turn would depend on factors such as the markets served, regulatory environment, shareholder sentiments, etc. The zone denoting the qualifying zone in the spider diagram would form the basis for making the go / no-go decision.

In the following sections, the methodology is applied to three different popular technologies. The first two can be implemented by the

primary organization and third one can be implemented at upstream supplier’s site that has significant consumption of electrical energy based on fossil fuel.

The proposal comprises of relook at the current modes of transportation, increasing share of electrical mobility, Decarbonization of warehousing using solar power and most importantly digital tools to track and report transportation and warehousing related carbon footprint.

Conclusion and Recommendation:

This is a low risk, low impact but a viable proposition. It is recommended to draw a stage wise program and implement.

Sourcing basic commodity input chemicals is an emerging opportunity to decarbonize Scope 3 emissions. Technologies for Green Hydrogen are gaining popularity and is under rapid development. Due to requirement across sectors, Green Hydrogen, or carriers such as Ammonia, Methanol etc. have ready market. Based on the Onion model, this lever belongs to the Process Technology area, which could have barriers. Scores for this technology are given in table below.

Conclusion and Recommendation:

Sourcing chemicals from green feedstocks can make an enormous impact on the product carbon footprints. Considering

the current maturity of technology, it is recommended to track the progress and actively pursue.

This is one of the emerging routes for decarbonization in India. Corporates are allowed to invest in green hybrid power projects entering into a power purchase agreement with the promoter and taking wheeled power into the grid. Based on the Onion model, this belongs to Site Infrastructure and External Supply zone, feasible zone. Further the assigned score for this technology is given in the table along with the rationale.

Conclusion and Recommendation:

This decarbonization lever is a good example where the primary organizations can influence their suppliers to take up and implement. As there is a good payback for the consumer investing in green power projects, suppliers are expected to respond favorably to this suggestion.

In the context of chemical industry, given the intricate nature of supply chains, scope 3 reduction plans must include reductions of carbon footprint of input materials from the suppliers. Many of the technology levers are applicable at

multiple places and it is in the interest of the primary organizations to make sure that the suppliers are onboarded, supported, and provided necessary handholding in the decarbonization journey.

A good plan will have both strategic components, such as understanding of technologies under development, policy and regulatory framework changes, and medium-term tactical considerations such as budget allocation, enhancement of competency, tools, and prioritization of immediate actions. The methodology explained in the white paper above covers most of these considerations. Simplicity, scalability, and flexibility of the proposed methodologies should make it easily for organizations to adopt and deploy.

The current generation of customers – comprising of Millennials, GenZ and Gen Alpha – are increasingly preferring eco-conscious brands, which is significantly driving businesses to embed sustainability into their operations. While the push has risen, owing to the growing pressure from regulations, customers, and environmental realities, embracing sustainable practices also has key business impact as it enhances resilience, efficiency, and long-term profitability. Having said that, imbibing sustainability in day-to-day operations is no mean feat… it mandates building a sound sustainability strategy in corporates’ supply chain. Moreover, as governments worldwide impose stricter environmental laws, companies that adopt sustainable practices will have a better chance of being compliant. In lieu to all these imperatives, today sustainability is no longer optional—it’s essential for growth, reputation, and risk management. Our maiden conference on Sustainability emphasized this very tenet and explored the transformation of supply chains into sustainable models that reduce environmental impact and promote social welfare. Through this Cover Story, subject matter experts discuss innovative strategies for incorporating renewable energy, reducing waste, enhancing transparency, and ensuring ethical labor practices. It also puts spotlight on practical steps companies can take to assess, monitor, and improve the sustainability of their supply chains.

Two key elements of a sustainable supply chain are reducing environmental impact through eco-friendly practices and ensuring ethical sourcing with fair labor standards.

Jaswinder Saini, VP - Procurement, Tata Play Ltd.: Sustainability serves as a key factor in attracting customers to an organization. Today’s customers are informed and savvy about a company’s operations. They can readily access information on whether a company sources its raw materials ethically or delivers goods sustainably. Customers tend to favor organizations that adhere to sustainability over those that do not. We, too, are consumers, both individually and corporately. Would you consider endorsing organizations that engage in unsustainable practices? I believe the unanimous response would be negative. At an individual level, we must all be cognizant of ESG principles to progress on this path.

From my experience in the manufacturing sector, implementing ESG is more challenging in manufacturing than in services due to the significant role of technology. Without technological support, contributing to ESG can be difficult, regardless of the resources committed. In contrast, the service industry, with the correct measures, can implement ESG initiatives with greater probability and ease.

Veeshwass Kulkarni, General Manager, Legrand India: Supply chain sustainability is the management of a product’s environmental, social, and economic implications over its entire lifecycle, from raw material procurement to end-of-life disposal or recycling. It means being certain that the processes, materials, and alliances used in the development and distribution of goods and services are not hampering the capacity of future generations to meet their requirements. Two key elements are:

Environmental Responsibility: This includes minimizing the environmental impact

of supply chain operations. It involves actions like reducing waste, conserving water, increasing the use of renewable energy sources, and decreasing carbon emissions. Companies are increasingly adopting circular economy principles, which involve reusing, recycling, or disposing of items and resources sustainably rather than adhering to a linear consumption model.

Social responsibility and Ethical Sourcing: It is vital to ensure that suppliers follow fair labor practices, respect human rights, and provide safe working conditions. This includes working with partners who are committed to environmental and social governance (ESG) principles, such as eliminating child labor and fostering workforce diversity and inclusion.

Organizations that focus on these factors can build resilient and responsible supply chains that correspond with their overall sustainability goals.

Vishal Bhavsar, Head – ESG, Multiples Alternate Asset Management: Supply chain sustainability is the management of environmental and social impacts within and across networks consisting of suppliers, manufacturers, distributors, and customers in line with the UN Sustainable Development Goals. This spans every phase of the supply chain, from raw material sourcing and extraction to product use and end of product life. Two key elements of a sustainable supply chain are reducing environmental impact through eco-friendly practices and ensuring ethical sourcing with fair labor standards.

Sandeep Chatterjee, Supply Chain and Sustainability Leader, IBM: Roughly 60-70% of the greenhouse gas emissions come from supply chain. That’s one of the biggest reasons why supply chains are under a lot of pressure. Lot of people think that sustainability is just about climate. To support one earth, we consume 1.8 Earth. In the UK alone, there are enough clothes for six generations. While it’s good to have many women at the workforce, but can we say that our workplace is safe enough for women to work without any inhibitions? Do we have access to clean water? Those are

the critical aspects from a sustainability standpoint. The third aspect is profit. While a lot of people might debate on sustainability vs profit, we must realize that our matric is still a year-on-year profit. Unless the matrix change, people will not take it seriously. The fourth aspect we have to reflect upon is the Purpose of the organization. Tata Group is a classic example of having sustainability in their ethos. All these elements have to cohesively gel together to create a meaningful world for us. I started my career with Tata Motors in 1998. We launched Indica car, then priced at 2.5 Lakh. We spoke to Nissan Australia, imported the second-hand assembly line of Nissan Australia and that’s how Indica was rolled out. It changed the whole automotive ecosystem then. Another example is of Cement companies. We talk about green cement, but fly ash and waste was already part of the cement. They use less limestone and have better binding properties. Cement companies today are most of the profitable companies in the country. Use less material, that makes you more profitable. We will have to find different ways of looking at striking the right balance between profitability and sustainability.

By embracing sustainability in their supply chain, companies build trust with consumers who want to align their buying decisions with their personal values.

Jaswinder Saini: Sustainability plays a pivotal role in shaping brand reputation. Within the supply chain, sustainable practices contribute significantly to building trust between organizations and their customers. While positive impacts may take time to materialize, even a minor negative incident can quickly escalate, tarnishing an organization’s reputation and goodwill.

Allow me to share our own experience:

Sustainability plays a pivotal role in shaping brand reputation. Within the supply chain, sustainable practices contribute significantly to building trust between organizations and their customers. While positive impacts may take time to materialize, even a minor negative incident can quickly escalate, tarnishing an organization’s reputation and goodwill. When we embarked on our ESG (Environmental, Social, and Governance) journey, we recognized our substantial energy consumption. Determined to make a difference, we optimized our set-top boxes to consume less energy compared to our competitors. Despite the higher costs involved, we prioritized sustainability. As a result, our reputation as a top DTH services provider was built through such deliberate steps.

When we embarked on our ESG (Environmental, Social, and Governance) journey, we recognized our substantial energy consumption. Determined to make a difference, we optimized our set-top boxes to consume less energy compared to our competitors. Despite the higher costs involved, we prioritized sustainability. As a result, our reputation as a top DTH services provider was built through such deliberate steps. Going forward, a transformative shift will occur when end customers become more aware and willing to support sustainable practices. While this awareness is still nascent at least in India, but it holds immense potential in our country.

Vishal Bhavsar: Sustainable supply chains enhance corporate reputation and consumer trust by demonstrating a commitment to ethical practices, including human rights and traceability. Initiatives like the Better Cotton Initiative promote sustainable cotton production while supporting farmers’ rights, appealing to eco-conscious consumers. Addressing issues like conflict minerals also ensures responsible sourcing, fostering trust.

Corporates can leverage this impact by promoting their sustainability initiatives through marketing and social media, sharing success stories such as Trustea, which focuses on sustainable tea sourcing. Transparency in reporting sustainability metrics builds consumer confidence, while third-party certifications enhance credibility. By positioning sustainability as a core value, companies can differentiate themselves

in the market and attract a growing base of socially and environmentally conscious customers and investors focused on ESG criteria.

Sandeep Chatterjee: Today’s consumers are more aware and understand the implications of climate change and bad corporate practices. While consumers may not pay a lot of money for sustainable products currently, but it affects the mind of the consumer positively. Corporates need to communicate and communicate authentically as any greenwashing is likely to be discovered and you will not be able to recover from them.

Sanjay Desai, VP – Asia, Supply Technologies: Sustainable supply chains significantly enhance corporates’ reputation and build consumer trust, creating multiple opportunities for companies to leverage these benefits. Here’s are some of the major impacts…

Brand Building: A sustainable supply chain reflects a company’s commitment to ethical practices such as fair labor conditions, environmental conservation, and responsible sourcing. This alignment helps to increase the company’s reputation as a socially responsible organization.

Scaling organizational capabilities: Corporates who embrace sustainability principles position themselves as leaders in their industries. They are able to differentiate themselves from competitors and create a positive brand image which aligns with customers,

investors, and stakeholders.

Incremental trust and loyalty with customers: By embracing sustainability in their supply chain, companies build trust with consumers who want to align their buying decisions with their personal values. This trust will positively impress customers’ buying preferences and habits.

Pricing advantage over competition: It is proven that the current young generation of customers are more willing to pay a premium for products from brands that prioritize sustainability. This provides an opportunity for companies to increase profitability while aligning their product offerings with consumer values.

Leveraged ESG reporting: Publishing sustainability reports consistently over a period of years, providing stakeholders, investors, and promoters with databacked view of sustainable practices and results, helps Corp to gain easy access to capital needs, Govt subsidies and plethora of other benefits.

Builds a sustainability culture within the organization: Working with organizations that focus on sustainability can enhance credibility and create mutually beneficial partnerships. These collaborations can help corporates address environmental challenges by engaging their employees directly on the job, building an internal culture of responsibility towards social / environmental causes.

As a private market investor, we highlight the benefits of supply chain sustainability to our portfolio companies, emphasizing the importance of building local supply chains. This approach mitigates the risks of disruptions while reducing carbon footprints and enhancing brand reputation. We share best practices that demonstrate how sustainability leads to tangible business benefits, such as improved compliance and meeting stakeholder expectations, including regulatory requirements. We also address the evolving landscape of regulations concerning carbon emissions and the necessary disclosures for value chain sustainability and decarbonization. Failing to adapt can significantly impact supply stability, which in turn affects cash flows.

To balance cost and benefit analysis in building a sustainable supply chain, companies should adopt a staggered investment approach.

Veeshwass Kulkarni: Weighing the costs and benefits of sustainability activities, particularly in terms of reducing Scope 3 emissions, needs a strategic approach that takes into account both current trade-offs and long-term gains. While sustainability activities are typically seen as costly, they can yield significant longterm benefits, ranging from financial savings, risk management, and increased brand value to regulatory compliance and customer loyalty. Here’s how companies might approach this balancing act:

Long-term value development: Instead of considering sustainability as a direct expense, businesses should present it as a venture that can produce lasting profits. This involves ensuring the business is prepared for the future, adapting to

changing regulatory requirements, and remaining competitive in a market where sustainable practices are demanded by consumers and stakeholders.

Opportunities to decrease expenses: Ecofriendly methods like power conservation, waste minimization, and streamlined transportation can reduce operational costs. For instance, implementing energy-saving manufacturing methods and utilizing sustainable energy sources can decrease energy expenses in the long run, while minimizing packaging or transportation can lower transportation costs.

Risk reduction: Allocating resources to sustainability initiatives assists in reducing risks such as supply chain interruptions caused by climate change, penalties imposed by regulations, and harm to reputation stemming from unsustainable operations. These hazards, if left unattended, can result in substantial monetary setbacks.

Phased execution: Companies are not required to execute sustainability measures simultaneously. A gradual method permits them to distribute the expenses over a period, giving priority to areas where immediate economic or ecological advantages can be achieved. This aids in controlling the flow of money while continuing to make progress towards sustainability objectives.

Efforts towards sustainability tend to draw in environmentally aware customers who are willing to spend extra for products that match their beliefs. Businesses have the opportunity to use sustainability as a unique selling point, which may lead to higher prices or a larger share of the market in specific customer groups. A robust dedication to ecofriendliness improves brand standing and promotes customer allegiance. Studies indicate that consumers, particularly the younger demographic, are more inclined to endorse brands that exhibit a firm dedication to environmental responsibility. This brand reputation can result in increased customer loyalty and long-term worth.

Future regulatory compliance: Authorities globally are increasing restrictions on emissions, waste management, and sustainable operations. By taking proactive steps to address sustainability now, businesses can prevent incurring future expenses or fines related to more stringent regulations. At times, early implementation may make companies eligible for tax deductions or perks.

Numerous investors are currently prioritizing Environmental, Social, and Governance (ESG) standards when determining investment choices. By enhancing sustainability measures, businesses can gain access to eco-friendly

bonds or advantageous loan conditions linked to ESG achievements, decreasing their long-term capital expenses.

Vishal Bhavsar: To balance cost and benefit analysis in building a sustainable supply chain, companies should adopt a staggered investment approach:

Phase 1 (Quick Wins): Allocate less than 15% of your sustainability budget to no-cost initiatives, such as developing a supplier code of conduct, establishing criteria for supplier assessments, and modifying assessment templates to include sustainability metrics. These steps can yield immediate benefits with minimal investment.

Phase 2 (Medium-Term Investments): Set aside 40% for moderate projects, such as technology upgrades that enhance supply chain transparency (e.g., using EcoVadis ratings).

Phase 3 (Long-Term Projects): Reserve 45% for larger investments in renewable energy or significant supply chain changes, guided by frameworks like the Carbon Disclosure Project (CDP).

This structured approach allows companies to effectively manage costs while progressively enhancing sustainability efforts.

Sandeep Chatterjee: Yes, it is true that this comes at a cost, but companies have to think about innovative solutions around how to use less material, how to recycle more, how to minimize waste. For example, the technology to recycle lithium will be expensive but certain savings can be done when we use less material, use remanufactured machines. For the poultry industry where margins are very small and any increase in mortality is a serious issue, the waste in terms of internal organs, feathers are powdered and are fed as food to chicken and fishes in fisheries. The consumer will not pay a lot of money for this. Organic food is expensive because the base is small. As more and more agriculturists start adopting, prices will come down.

Practically, there has to be an incentive mechanism in the supply chain as somebody needs to be compensated for the risk premium. Co-creating of solutions, sharing data based on trust are key points. Further, data needs to be used for improvement and not to penalize somebody. In terms of challenges since the supply chains are dispersed and broken, collecting data at a reasonable cost is key. Second is the willingness to share data as this is a tricky issue. Third is it will need some investment and hence the question around who pays for it will be prime.

Sanjay Desai: In the corporate world, there is a Four-letter word, (RONA) which haunts all managers their entire

life!! RONA stands for Return On Net Asset deployed. Balancing cost v/s profit in the sustainability initiative is a challenge like any other upfront investment in other projects, more so as benefits of sustainability are not realized immediately. These benefits start to be realized in long term horizon. Let us understand how companies can balance sustainability investments.

Identify long-term horizon and benefits: Companies need to identify the longterm horizon and the benefits that will be realized in the future period for investments made today. Example, installing solar panels may cost high upfront but will reduce energy bills in the long run.

Phased investment over big-bang approach: Instead of launching comprehensive sustainability execution initiatives all in one go, we can adopt a phased approach. Implementing smaller, more manageable initiatives first and then scaling them to bigger initiatives. Example - Savings in electricity / energy consumption.

Partner with Government: Indian Government offers many benefits for green energy, carbon reduction, water harvesting, etc. Companies should explore these opportunities to offset upfront costs and make sustainability initiatives more financially viable.

Hire specialist services: Corporates need

Lot of people think that a supply chain starts from the supplier. But supply chains actually start from the customer. Therefore, the first factor needs to be the product or service design based on the customer’s needs. Factors like recyclability, reusability, longevity, disposition means, are key to product design. Second aspect is segmented supply chains. One size does not fit all in supply chain. While in marketing we have segmentation, target market and positioning, it is important that the supply chains are segmented as well. Third is the point around partnerships. Today collaboration and competition go hand in hand. The right set of trustbased partners, co-investment in supply chain sustainability solutions is important. Fourth is data capture and analysis. Unless we measure, we will not be able to take decisions. Today there are low-cost solutions for automatic data capture.

Weighing the costs and benefits of sustainability activities, particularly in terms of reducing Scope 3 emissions, needs a strategic approach that takes into account both current trade-offs and long-term gains. While sustainability activities are typically seen as costly, they can yield significant long-term benefits, ranging from financial savings, risk management, and increased brand value to regulatory compliance and customer loyalty. Authorities globally are increasing restrictions on emissions, waste management, and sustainable operations. By taking proactive steps to address sustainability now, businesses can prevent incurring future expenses or fines related to more stringent regulations. At times, early implementation may make companies eligible for tax deductions or perks.

to collaborate with NGOs, industry associations, or sustainability experts to implement cost-effective sustainability solutions. Such partnerships can provide technical expertise and resources that companies might lack internally. It may offer Capex options or partnership with government banks for low interest rates borrowings.

Measure/ monitor & communicate: Clear and transparent communication with investors and shareholders about the longterm financial benefits of sustainability, supported by data and milestones, helps manage expectations and secure ongoing investments in sustainability projects.

Technology plays a pivotal role in helping supply chains achieve sustainability by enabling greater efficiency, reducing waste, and promoting transparency.

Vishal Bhavsar: Yes, technology plays a crucial role in mainstreaming sustainability in supply chain processes. Advanced data analytics tools allow companies to track sustainability metrics, facilitating informed decision-

making and improvement identification. Technologies like blockchain enhance supply chain visibility, ensuring real-time tracking and ethical sourcing.

Automation and artificial intelligence optimize logistics and inventory management, reducing waste and energy consumption. Digital platforms simplify sustainable sourcing, connecting companies with eco-friendly materials and suppliers. Lifecycle assessment tools evaluate the environmental impact of products, guiding sustainable design choices.

Additionally, technology fosters collaboration between companies and suppliers, enabling the sharing of best practices. Digital tools streamline tracking and reporting of sustainability metrics, aiding compliance and enhancing communication with stakeholders. By integrating these technologies, companies can strengthen their sustainability efforts and build more resilient supply chains.

Sandeep Chatterjee: Today’s supply chains are driven by data, speed and efficiency. Here technology will play a huge role in automated data collection and generating insights from tons of data. Technology will help speed up the whole process.

Sanjay Desai: Technology plays a pivotal role in helping supply chains achieve sustainability by enabling greater efficiency, reducing waste, and promoting transparency. Here are several ways

technology contributes to sustainable supply chain management.

Supply Chain Transparency and Traceability: Blockchain and other tracking technologies ensure transparency across the supply chain, verifying ethical sourcing, reducing environmental impact, and promoting social responsibility

Real-Time Data and Analytics: Technologies like IoT and AI-driven analytics provide real-time visibility into supply chain operations, allowing for more informed decision-making, optimization of resources, and identification of inefficiencies that reduce waste and carbon emissions.

Green Logistics and Route Optimization: Technologies like AI and machine learning can optimize transportation routes, leading to reduced fuel consumption and lower emissions, while solutions like electric vehicles and eco-friendly packaging contribute to greener logistics

Predictive and preventive analytics: Predictive analytics, digital twins, and AI allow companies to forecast demand, optimize inventory, and prevent disruptions, reducing overproduction, excess inventory, and unnecessary resource use.

Circular economy enablement: Technology facilitates the adoption of circular economy principles by tracking products

and materials throughout their lifecycle, supporting recycling, reuse, and refurbishment, which extends product life and reduces waste

Enabler to full ESG compliance: Sustainability is no longer limited to carbon footprint reduction. Technology enables companies to measure and report their performance on a broader scale which includes labour practices, human rights, biodiversity conservation, and the ethical sourcing of materials.

Sandeep Chatterjee: Regulators devise a framework after consulting various stakeholders and hence incorporate some of the best practices. Growth is good but not at the cost of society. Regulators will be able to ensure this. Right now, there are just too many frameworks, and this creates a lot of confusion. A good starting point is to look at the continent/country specific regulations. Anyone doing business in India need to be aware of BRSR, while someone in Europe needs to look at ESRS and CSRD.

Vishal Bhavsar: Companies can measure and report on the sustainability of their supply chains through practical approaches such as:

• Regular Sustainability Metrics Tracking: Implement a dashboard to monitor key metrics like carbon footprint, water usage, and waste generation, providing real-time data to stakeholders.

• Supplier Sustainability Assessments: Use standardized questionnaires or assessment tools for suppliers to report on their sustainability practices, ensuring consistency and transparency across the supply chain.

• Annual Sustainability Reports: Create comprehensive reports that summarize sustainability efforts, challenges, and achievements, including case studies and specific examples to illustrate impact.

• Sustainability Disclosures: Engage with various frameworks and platforms such as the CDP Supply Chain program, UN Global Compact (UNGC), and EcoVadis assessments to disclose sustainability performance and receive ratings that enhance transparency and credibility.

Establish processes, and policies to ensure consistency of good practice that is set. Measure, record, and report progress aligned tothe guidelines available.

Jaswinder Saini: Each organization faces its unique set of challenges and opportunities related to ESG. The strategy must align with the specific goals, objectives, opportunities, and challenges of that organization or that specific industry. One common mistake that leaders make is to copy what others have done without mapping the differences with that organization. Next step is to set achievable targets and KPIs considering the prevailing circumstances. Leverage available technology to meet and achieve those targets. Establish processes, and policies to ensure consistency of good practice that is set. Finally, measure, record, and report progress aligned to the guidelines available.

Veeshwass Kulkarni: When we talk about considering different aspects of designing a sustainable supply chain, depending on different organizations’ mission, vision, goal, and the KPIs. At an organizational level, we must introspect what we want to accomplish and where do we stand today to achieve that goalpost. Second important focus area is supplier or service providers as they play a major role. The way you deal with them, be it communicating with them, setting the right expectations, will actually impact your performance matrix. You must also set the right criteria of supplier selection. These suppliers must be able to comply with the vision & mission of your organization and then only it will fructify. When you already have a certain set of suppliers onboarded, how are you going to develop them will define the future course of action. Every supplier will have a different knowledge base and different understanding of aspects that you are looking for.

Another critical aspect is collaboration which will set you apart in this race. I would like to share with you an example of our company Legrand where we had launched a program for all the suppliers to inform them about our vision, the key parameters on the basis they will be assessed to be onboarded. We also organize training programs to bring them to a common ground where they are able to clearly understand our requirements and deliver as desired. Based on the requirements, resources get allocated to suppliers. One of the key factors in our KPIs is reducing our packaging weight. We are working on developing a material which has recycled contents which will help us in not only optimizing cost but reduce overall carbon footprint by replacing single use plastic. We are in touch with top-notch academic institutes to develop the same alongside getting help from suppliers. Such is the power of collaboration that I would like to highlight.

Vishal Bhavsar: To frame an effective supply chain sustainability strategy, consider these key factors:

Stakeholder Collaboration: Engage all stakeholders, including suppliers and customers, to align sustainability goals

and drive collective action.

Risk and Impact Assessment: Identify environmental, social, and governance risks in the supply chain and develop strategies to mitigate them.

Clear Sustainability Metrics: Set measurable goals like carbon reduction, waste minimization, and ethical sourcing, with ongoing tracking and reporting.

Innovation and Technology: Leverage technology, such as AI and blockchain, to enhance transparency, optimize processes, and ensure continuous improvement in sustainability efforts.

Sanjay Desai: Achieving sustainability in the supply chain is critical due to increasing environmental pollution, increasing deforestation, increasing greenhouse gas emissions, and rising consumer expectations in current times. Then we have regulatory pressures, and other social challenges. An organization’s brand image gets huge recognition if the organization is seriously practicing principles of ESG (Environmentally Sustainable Governance) with an objective and purpose to be compliant. Achieving a sustainable supply chain will not only reduce environmental pressures but also ensures resilience, cost savings potentials, and builds a competitive advantage in the marketplace. Let us look at a few factors to consider when designing a sustainable supply chain.

Reduce environmental impact: Reducing the carbon footprint and minimizing waste are essential factors in mitigating climate change and help to lower emissions and pollution.

Risk mitigation approach: Managing risks like climate disruption, natural disasters, single v/s dual source supply strategy, regulatory changes, geopolitical developments. It helps your supply chain to be compliant, robust and resilient.

Circular product life cycle: Implementing circular product life cycle principles offer numerous advantages, particularly in contrast to traditional linear models where products are designed, used, and

discarded. A circular approach emphasizes reusing, repairing, refurbishing, and recycling materials to minimize waste and resource consumption (energy, human & financial capital).

Collaborate with Key Supplier: Motivate your major suppliers to be your partners in your sustainable goals through joint programs & trainings. This will increase shared value and commitment from your partners from an “Outside-In” perspective.

Meet compliance: Stay fully compliant with local regulations especially to ESG (Scope 1, 2 and 3 emissions). Adherence to these compliances will enhance your brand image and strengthen goodwill in marketplace.

Use of simple technologies: Use simple technology which are available at optimum price defining your goals. Use Technology to help increase visibility, traceability, and data transparency in the end-to-end supply chain.

Steps corporates need to take to reduce

Veeshwass Kulkarni: Reducing Scope 3 emissions—those indirectly produced by a company’s value chain, including suppliers, transportation, and product usage – necessitates practical measures, creativity, and cooperation throughout the supply chain. These discharges generally make up the largest segment of a company’s carbon footprint, making them difficult to tackle.

Tangible Actions to Minimize Scope

3 Greenhouse Gas Emissions:

Mapping of supply chain: Determine all origins of Scope 3 emissions across the supply chain, from extraction of raw materials to end-of-life of the product. This frequently entails a thorough examination of suppliers’ activities.

Collecting and reporting of data: Collaborate with suppliers and collaborators to acquire precise information regarding emissions. Utilize established approaches, such as the GHG Protocol, to measure Scope 3 emissions throughout the supply chain.

Establish clear goals: Establish reduction targets for Scope 3 emissions based on scientific evidence, in line with overall corporate climate objectives, such as attaining net-zero or decreasing absolute emissions by a specific proportion.

Vendor cooperation: Involve vendors in your sustainability goals by communicating expectations, providing instruction, and creating collaborative sustainability projects. Incorporate sustainability provisions into contracts to compel suppliers to adhere to goals for reducing emissions.

Ethical purchasing policies: Give preference to sourcing from vendors with robust environmental strategies, such as utilizing sustainable energy or eco-friendly manufacturing practices. Think about transitioning to vendors nearer to your manufacturing sites to minimize emissions associated with transportation.

Supplier audits and rewards: Perform routine sustainability assessments to verify suppliers are adhering to emission regulations. Offer rewards to vendors demonstrating leadership in decreasing their emissions.

Sustainable logistics: Integrate ecofriendly transportation alternatives, such as electric or hybrid delivery vehicles, prioritize rail transport over airfreight, and enhance route planning to minimize fuel usage.

Combine shipments: Lower emissions by maximizing load capacity and combining shipments to decrease the number of trips needed to transport goods.

When we talk about considering different aspects of designing a sustainable supply chain, depending on different organizations’ mission, vision, goal, and the KPIs. At an organizational level, we must introspect what we want to accomplish and where do we stand today to achieve that goalpost.

Technology: Employ digital tools such as artificial intelligence and proactive data analysis to enhance logistics functions and diminish inefficiencies in both transportation and warehousing.

Sustainable design: Integrate environmentally friendly materials and methods into product design, decreasing the environmental impact during production, usage, and disposal stages.

Circular economy strategies: Enforce tactics that encourage recycling, product reclaim, or reutilization programs to prolong the lifespan of products and diminish end-of-life discharges.

Energy efficiency in usage: Create energyefficient items that consume less energy during their operational phase, as this frequently makes up a significant part of Scope 3 emissions, particularly in consumer goods such as electronics or appliances.

Promotion of renewable energy: Promote the shift of suppliers towards renewable energy sources for their manufacturing processes, such as wind, solar, or hydropower.

Carbon offsetting: Although not a permanent answer, businesses have the option to buy top-notch carbon credits to neutralize unavoidable emissions in the immediate future. Offsets should be

validated by credible certifications, such as the Gold Standard or Verified Carbon Standard (VCS).

Extended producer responsibility (EPR): Accept accountability for the ecological footprint of a product during all stages of its existence. Promote customers to return items for recycling or provide repair services to prolong product lifespan, decreasing waste and connected emissions.

Client involvement: Inform customers about the significance of sustainability and motivate them to make eco-friendly decisions, like choosing energy-saving items or joining recycling initiatives.

Insufficient View and Management of the Supply Chain

Complicated supply networks: Companies frequently have limited oversight or awareness of their suppliers’ procedures, particularly when working with numerous international suppliers. It becomes challenging to precisely gauge or impact emissions.

Information discrepancies: Numerous vendors, especially small or mid-sized businesses, may lack the capacity or funds to gauge and disclose their carbon footprints precisely. The absence of openness presents difficulties in establishing and monitoring Scope 3 reduction targets.

Reluctance to change: Suppliers may be hesitant to embrace new sustainability practices because of financial worries, lack of know-how, or competing business objectives. Without proper motivations or demands, suppliers may not recognize the necessity to implement substantial alterations.

Willingness to invest: Shifting towards more environmentally friendly practices often entails substantial investment in new technologies, procedures, or sustainable energy sources, which numerous suppliers may struggle to fund.

Sourcing expenses: Environmentally friendly materials and methods may come with a higher price tag compared to conventional choices, resulting in increased expenses for companies. The transition may also necessitate investment in fresh technologies, which can put pressure on finances, particularly in the immediate future.

Expenditure on implementation: Introducing carbon monitoring systems, performing examinations, and shifting logistics operations to more eco-friendly choices can be expensive, necessitating both time and funding.

Inconsistent data standards: Various vendors may employ different approaches

Businesses have the opportunity to use sustainability as a unique selling point, which may lead to higher prices or a larger share of the market in specific customer groups. A robust dedication to eco-friendliness improves brand standing and promotes customer allegiance. This brand reputation can result in increased customer loyalty and long-term worth.

for determining and documenting emissions, posing challenges for companies in obtaining a uniform and precise assessment of their Scope 3 emissions.

Challenges in establishing limits: Scope 3 emissions encompass a broad array of indirect operations, creating difficulties in deciding which operations to incorporate or how to distribute emissions among numerous companies within a supply chain.

Pressure for immediate profitability: Companies frequently encounter pressure from investors and stakeholders to prioritize immediate profitability. Investments in environmentally friendly supply chains, although advantageous in the extended period, may not produce instant economic profits, which complicates the justification of these expenses in the immediate future.

Ambiguity in future regulations: As sustainability regulations continue to grow, the absence of worldwide uniformity and transparency in regulatory structures may lead to ambiguity for businesses, posing challenges in devising and executing long-term strategies.

Vishal Bhavsar: To reduce Scope 3 emissions, corporates can implement the following practical steps:

• Local Procurement: Source materials and products locally to minimize transportation emissions and support regional economies.

• Switch to Green Logistics: Utilize sustainable transportation options, such as electric vehicles or rail, to reduce emissions in logistics and distribution.

• Select Low-Embodied Carbon Materials: Choose materials with low embodied carbon, like recycled or sustainably sourced options, to minimize emissions throughout the product lifecycle.

• Collaborate with Suppliers: Work closely with suppliers to encourage and support their emissions reduction efforts, fostering a culture of sustainability.

• Promote Circular Economy Practices: Implement initiatives that encourage recycling, reusing, and refurbishing materials to reduce waste and emissions.

Challenges corporates may face include difficulties in obtaining accurate emissions data from suppliers, resistance to change among suppliers, a lack of standardization in measuring emissions, and initial costs associated with sustainable practices.

Sanjay Desai: According to my analysis, some of the major challenges corporates will face or are facing already…

Determine the categories of emissions: Probably the biggest challenge is to establish the overarching boundaries for scope 3 data – and which categories to report.

Build standard calculating methodologies for emissions: When calculating emissions, organizations will look to provide as

accurate emissions data as possible. More often this granularity of data is not available for Scope 3 emissions. It takes a good number of resources and excellent process cadence to build this structure.

Building a data repository Data required for scope 3 emissions accounting is determined by the quality of calculation methodology. In case the data is insufficient or not available, the GHG Protocol’s Scope 3 guidance recommends using proxy data.

Resistance in the value chain: Many suppliers, particularly small and medium enterprises (SMEs), may not have the resources, expertise, or technology needed to work on emissions. You will find a lot of resistance here to scale your operations.

Limited control over customer habits: Corporates have little control over how customers use and dispose-off their products. Convincing customers to adopt sustainable behaviors can be difficult, especially if it requires them to change habits or incur additional costs.

Blueprint to run a successful sustainable

Maintain flexibility, agility, and be prepared to adapt your program in response to new technologies, rules, and stakeholder expectations.

Veeshwass

Kulkarni: Supply chain

sustainability manages environmental, social, and economic impacts of a product’s lifecycle, from sourcing to disposal, ensuring resources and partnerships do not compromise future generations’ ability to meet their needs. Below is a blueprint outlining key success factors for building such a program:

Executive Leadership and Commitment: Senior management must champion sustainability projects and set the tone for the organization’s sustainability objectives. They need to clearly define sustainability goals, such as lowering carbon emissions, enhancing working conditions, or reaching zero waste. These should be consistent with broader business ESG strategies and ensure Financial investment, skill, and technology are required to propel sustainable supply chain efforts.

Supplier Collaboration and Partnership: Actively involve suppliers in sustainability goals, ensuring that they understand and agree to ESG principles. Put in place supplier codes of conduct and offer training on the best practices for sustainability. Foster strong, trusting relationships with suppliers that encourage openness and collaboration for continual development. Work with suppliers to investigate innovations such as green technologies, waste reduction approaches, and circular economy models that enhance sustainability.

Evaluation and Transparency: Establish clear, measurable KPIs for sustainability (for example, carbon reduction, energy consumption, waste minimization, and fair labor standards). Use modern analytics and technology, such as blockchain or IoT, to track and analyze sustainability KPIs throughout the supply chain. This data can be used to continually improve processes. Regularly publish reports progress on sustainability through dashboards and reports. This Transparency fosters confidence among stakeholders and enables for external verification of your sustainability claims. Inform consumers about your supply chain’s sustainability efforts and encourage them to contribute through their purchase decisions.

Compliance and Risk Management: Conduct risk evaluations throughout the supply chain to detect environmental and social hazards, including regulatory noncompliance, unethical labor practices, and climate change effects. Align with international standards and frameworks such as the United Nations Sustainable Development Goals (SDGs), the Global Reporting Initiative (GRI), and ISO standards to ensure across the globe compliance.

Ensure new suppliers fulfill your organization’s sustainability

requirements by conducting thorough due diligence processes throughout onboarding. To remain ahead of legislative changes and connect with larger sustainability networks, interact with external stakeholders like as NGOs, governments, and industry peers.

Cross-functional Collaboration: Integrate sustainability goals across departments, including procurement, logistics, operations, marketing, and product design, to develop a common approach. Engage employees in sustainability

Scope 3 emissions are a category of greenhouse gas (GHG) emissions originating from business operations by sources that are not directly owned or controlled by an organization. Such as supply chain, transportation, product usage, or disposal. Also referred to as value chain emissions, they are the hardest to measure and reduce. These are some of the practical steps companies need to take to address Scope 3 emissions:

Enable your organization: Empower your employees to act “boundaryless” and align their thought process to ESG initiatives and their long-term impacts.

Create transparency: Build emissions baseline and exchange data with suppliers; set ambitious targets on Scopes 1, 2 & 3. Monitor and report progress regularly with extended partners to bring a sense of commitment to the goals.