Inside Exclusive Conversation with Aparna Sharma, HR Practitioner & Independent Director on Corporate Board

Vishal Kedia, Founder & Director, Complykaro Services Pvt. Ltd.

Sanjay Desai, General Manager –Asia, Supply Technologies

Inside Exclusive Conversation with Aparna Sharma, HR Practitioner & Independent Director on Corporate Board

Vishal Kedia, Founder & Director, Complykaro Services Pvt. Ltd.

Sanjay Desai, General Manager –Asia, Supply Technologies

Dear Readers,

As we step into the new Financial Year 2024-2025 and embrace the heat of Indian summer, our latest issue seeks to champion diversity and inclusion, reflect upon leadership in supply chain, and brace for the summers with cold and frozen food accessible across through our cold chain logistics. And if you are still struggling with the concept of Blockchain and its applications in the supply chain, we have an article just for you.

As a nation we pride ourselves on our diverse cultural, linguistic, and religious mosaic. However, equal opportunities are still a long shot. In this issue’s Cover Story, we delve into how businesses across the subcontinent are redefining their frameworks to be more inclusive, fostering environments where diversity is not just celebrated but is also seen as a keystone for innovation and growth. This narrative is not just about acknowledging differences but leveraging them as a force multiplier to drive India’s economic engine forward.

Our Special Report puts the spotlight back on the criticality of the cold chain infrastructure in India. We explore the advancements and hurdles in this domain. We also shed light on the innovative solutions companies are adopting to keep the cold chain unbroken and resilient.

In India, April marks the commencement of the new financial year. This year is especially significant, as it precedes a period brimming with anticipation—the Lok Sabha elections. Over the next three quarters, we will witness the unfolding of events that will shape the political and economic landscape of our nation.

Whatever be the political and economic situations, the relentless nature of the supply chain and logistics profession will continue. Through the pages of our magazine, our mission has persistently been to provide that additional insight, empowering professionals to excel in their unceasing efforts.

Warm Regards, Charulata Bansal Publisher Charulata.bansal@celerityin.com www.supplychaintribe.com

The traditionally male-dominated domain of supply chain management has undergone a notable shift, welcoming remarkable women into pivotal roles, whether in strategic decision-making, warehouse management, or ensuring seamless last-mile deliveries. Our featured Cover Story delves into this compelling paradigm shift, showcasing women’s ascendancy to the driver’s seat in the supply chain domain.

As experts unequivocally emphasize that India’s cold supply chain faces a pivotal juncture between innovation and adaptation, trends shaping this year set the stage for a stronger industry. This Special Report traces the changing dynamics of cold chain segment and presents the wish lists of user companies from 3PLs to strike the right equilibrium…

Sanjay Desai, General Manager – Asia, Supply Technologies, emphasizes, “Supply chain is at the forefront leading the way for organizations in a convoluted economic environment.”

Aparna Sharma, HR Practitioner & Independent Director on Corporate Board, highlights, “A commitment to full inclusivity is now a leadership and business competency.”

Vishal Kedia, Founder & Director, Complykaro Services Pvt. Ltd., stresses, “Diversity and inclusion (D&I) are not just trendy terms; they are fundamental components of a successful and sustainable organization.”

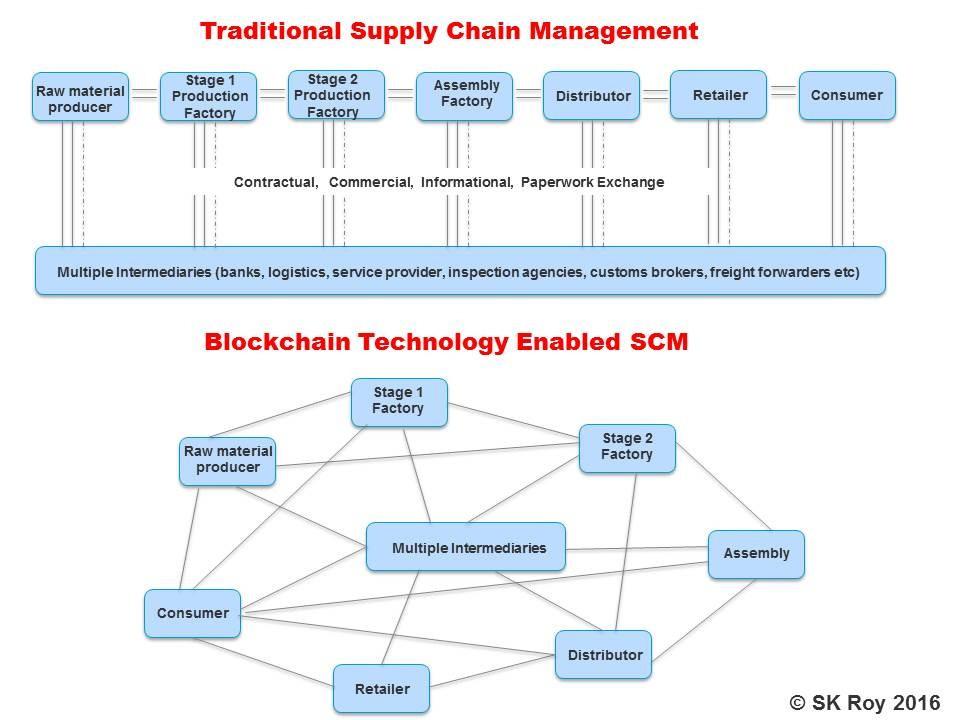

Sanjeev Kumar Roy, Chief Procurement Supply Chain Therapist, introduces the concept of Blockchain technology and discusses its application in revolutionizing the traditional supply chain processes, which are often based on “multiple bilateral links joined together to form a chain” as opposed to the Blockchain, which is based on the “formation of an open ecosystem for collaboration”.

Theme

Ele a ng India's F t re thro gh Integrated Infra De elopment in Road, Rail, Air, Sea, and Water a s No otel, Interna onal Airport, M mbai J ne , . am - pm

(Conference follo ed b A ards, Cocktails & Dinner)

For Delegate registra ons, Speaker opport ni es & Sponsorships packages,

Unfolding the F t re: Roadmap to USD Trillion Econom in Three Years

Panel

Global Hori ons for Make in India: Na iga ng Challenges, Sei ing Opport ni es

Panel

Panel

Unit in Di ersit : Harnessing Cross-Sectoral Collabora on for Accelerated Gro th

Panel

Pioneering Change thro gh Inno a on and Start ps

Panel

S ppl Chain Resilienc & Risk Management

The Indian cold chain market size grew to Rs1,81,490 crore in 2022, and it is expected to reach Rs3,79,870 crore by 2028, exhibiting a CAGR of 12.3% during 2023-2028, per the recent estimates by Imarc. As experts unequivocally emphasize that India’s cold supply chain faces a pivotal juncture between innovation and adaptation, trends shaping this year set the stage for a stronger industry dynamic. In coming years, stakeholders aim to adopt technological advancements, sustainable practices, collaborative efforts across the supply chain and focus on skill development to meet the evolving needs of this vibrant market. The Special Report traces the changing paradigms of cold chain segment and presents the wish lists of user companies from 3PLs to strike the right equilibrium…

THE global cold storage sector has expanded rapidly in the past decade, growing from around 550 million cubic metres in 2014 to an estimated 785 million cubic metres by 2022. This reflects a 4.5% compound annual growth rate (CAGR). Assuming this same CAGR, the market will grow to more than 1.1 billion cubic metres by 2030. Despite strong potential growth, this is arguably a conservative estimate. A JLL research stated that rising interest in the cold storage sector is underpinned by the structural growth drivers of the market. Global disruptions highlighted the importance of resilient supply chains, and the vital role cold storage real estate plays in these networks. Changing consumption patterns and the movement towards e-commerce has led to a surge in the need for efficient cold chain logistics and more cold storage real estate. These factors have and will continue to have long-term demand implications for the

amount of cold storage space needed, how they are designed and operated, and where they are located.

Our Q&A with experts from various industry domains brought forth intriguing insights into the transformational cold chain landscape. Here’s what they highlight…

How is the cold chain segment performing over the years?

Preeti Saluja, Pharma Cold Chain Expert and Consultant: While the cold chain market was always growing, it came into limelight and especially the pharma cold chain, when Covid-19 hit us and the rest is really the history. More so, the growth of the pharmaceutical cold chain market can be directly proportional to the increasing demand of therapeutic modalities, such as biologics, more than 85% of which require cold chain management. Great number of biologics are currently being tested in clinical trials. Cell and gene therapy is another segment requiring cold chain

among other biological segments. Therefore, the anticipated success of these drugs is likely to act as an impetus to the growth of market. Moreover, the need for importing / exporting goods (food, pharmaceuticals, and chemicals) from / to other geographical regions has emerged as the major driving force for the cold chain transportation industry segment. As a result, the cold chain market is expected to grow considerably in the coming years.

Further, the cold chain market is benefiting greatly from the integration of internet of things, artificial intelligence, and real-time temperature monitoring devices, which aid in ensuring the safety and quality of pharmaceutical products in transit. The only from here is the growth path.

Kartik Jalan, Founder & CEO, Indicold: As per industry estimates, the Indian cold chain market size reached Rs2,052.7 billion in 2023. Looking forward, the burgeoning Indian cold

In India, the cold chain industry is poised for significant growth, driven by factors like increasing investments in infrastructure, government initiatives to get nutritious food to consumers, and the adoption of advanced technologies. The global warming phenomenon presents both challenges and opportunities for the cold chain sector, as rising temperatures necessitate more stringent temperature control measures while also creating greater demand for cold storage and transportation services. Indicold's mission aligns with addressing these challenges by providing sustainable and technologically advanced cold chain solutions to meet the evolving needs of the market. The future of the cold chain industry through our lens will likely see continued investments in warehouse automation, such as automated storage systems and robotic picking technologies, to further enhance operational efficiency and meet growing demand.

chain market is expected to reach Rs5,596.9 billion by 2032. The cold chain segment in India has demonstrated remarkable growth in recent years, with the market size expanding at a CAGR of around 14-15% annually. This growth is propelled by various factors including increasing consumer demand for fresh and frozen foods, rapid urbanization, and the expansion of organized retail and e-commerce sectors. To meet these demands, a range of cold chain solutions have emerged, such as refrigerated transportation, cold storage warehouses, and advanced temperature-controlled packaging. Additionally, warehouse automation is set to play a crucial role in optimizing cold chain operations going forward, with technologies like robotic palletizing, automated storage and retrieval systems (AS/RS), and conveyor systems streamlining inventory management and order fulfilment processes.

Mandar Kulkarni, Head – Warehouse & Logistics, Sun Pharma: The “Cold Chain” in Pharmaceutical Industry is the end-to-end system of manufacturing of vaccines, transporting, storing and distribution till end user often within the temperature range of 35°F (2°C) to 45°F (8°C). The cold chain in the Pharma industry has been on a steady incline in recent years. The global cold chain market for pharmaceuticals is estimated to be worth $6 billion in 2023 and expected to grow at 9% CAGR and may go up to $11 billion the forecast period 2023-2027. The continuous R&D

in pharma sector along with launch of the National Health Protection Scheme (NHPS) in India in 2018, with the objective of extending healthcare insurance, is adding into the growth in demand for pharmaceutical products in India. Also, the growing consolidation in the global healthcare logistics market will facilitate the global pharmaceutical cold chain logistics market for pharmaceutical industry growth. Hence to cater the larger volume requirements, the pharma/end user companies will look for designing and building the efficient warehousing, transportation and distribution specialized in coldchain healthcare logistics services. Apart from this, the pharma establishments and related service providers will use market consolidation as a strategic tool for overall business expansions. This market consolidation strategy will adopt the regional technologies developed from regional players and expanding their market presence in the competitive market. These factors will increase the cold chain logistics for pharmaceuticals market growth during the forecast period.

Tushar Ghai, Senior Manager — Supply Planning & Operations, Bira 91

The India Cold Chain Logistics Market size is estimated at US$10.30 billion in 2024, and is expected to reach US$13.58 billion by 2029, growing at a CAGR of 5.67% during the forecast period (2024-2029). The rising demand for perishable goods has been propelling

market growth. Furthermore, a shift in consumer behavior is driving the market tremendously. The India cold chain logistics market is a fragmented market consisting of a large number of local players to cater to the growing demand. Companies investing in streamlining the supply chain and having advanced technology have an edge in getting a good share of the market. Global players can partner with local companies to invest in the market and gain profits.

Preeti Saluja: There are many challenges. If we look deeper into the figures of the damage and wastage of pharma product due to broken cold chain, numbers are quite alarming. Alarming enough to swing into action to ensure to provide correct ambience for temperature control management. Challenges in broader terms could be categorized as challenges related to correct packaging and cold chain storage, which could include disrupted temperature control, risk of contamination and damage. The very fact that broken cold chain in pharmaceuticals could lead to ineffectiveness and loss of efficacy, more so, poses a risk of it becoming fatal for humans. There have been instances when people have lost their lives due to ignorance in the matter and therefore it cannot be overstressed.

While we may think that we can control 100% of the cold chain journey, in reality, we cannot. Simple reason is the many links in the cold chain journey and at times, there could be

anticipated challenges and there could be unanticipated challenges like equipment breakdown, incorrect storage of the samples, mix ups, incorrect handling of the packages containing temperature control products and sometimes when you try to control all other aspects, tarmac happens.

Kartik Jalan: Challenges within the cold chain industry include maintaining consistent temperature control throughout the supply chain, managing operational costs, adhering to stringent regulatory requirements, handling the complexities of international shipments, and minimizing the environmental impact of cold chain operations. To address these challenges, various solutions are implemented. Automation technologies, such as IoT sensors and automated monitoring systems, enable real-time data collection and temperature monitoring, ensuring compliance with regulatory standards and minimizing product spoilage. Additionally, advanced warehouse automation solutions, such as robotic palletizing and automated storage and retrieval systems (AS/RS), streamline inventory management and order fulfilment processes, reducing operational costs and improving efficiency. Furthermore, investments in greener technologies for refrigeration and packaging contribute to minimizing the environmental footprint of cold chain operations, aligning with sustainability goals. Overall, the integration of these solutions helps overcome challenges and ensures the reliability and efficiency of the cold chain process.

Mandar Kulkarni: The Cold chain begins when vaccine gets manufactured, moves through to the state or national distribution centres and ends with the local immunization provider. Since the vaccines are consumed by human beings, each stakeholder involved in handling vaccines is responsible for maintaining the temperature controlled condition (avoiding temperature excursions) and preserve the potency at each and every step during storage transportation. The altered potency and integrity of vaccines is irreversible & can affect the quality and its effectiveness if not controlled within the prescribed temperature range (on either side of temperature range-up/ down). The Cold chain involves several complex challenges under distribution,

technology, warehousing, packaging solutions, standardization in packing, process oriented, business challenges, quality and temperature excursion challenges. Distribution challenges can be haul capacity utilization, reefer vehicle load formation, PTL shipments facing airline connectivity issues, packaging issues may include proper shipper material & sizes along with right type of gel packs, business challenges due to demand fluctuations, process & technology challenges may involve visibility & monitoring system. The challenges/risk areas can be addressed through proper storage/transport, effective communication & coordination among several stakeholders involved in supply chain, vehicle quality, addressing power failure/breakdown issues, etc. There is need to monitor the movement and temperature of plug in the cargo transport unit throughout its journey. The vaccines/pharma cold chain products are very expensive and hence needs proper control on all parameters to prevent losses.

Tushar Ghai: Cold chain logistics in India is growing rapidly and is currently the most focused area in the supply chain management industry. A few common gaps currently in the ecosystem include:

Limited Tech Integration: Several cold chain logistics facilities still rely on manual temperature monitoring and inventory management processes. This lack of tech integration leads to data inaccuracies and delays in decision-making, increasing the risk of product spoilage. It directly impacts the safety, quality and profitability of temperature-sensitive goods. However, the introduction of artificial intelligence, the Internet of Things, and machine learning are accessible, and it is ideal to incorporate these technologies into the cold chain management structure.

Inefficient Infrastructure: The cold chain infrastructure in India is still developing and needs to improve its efficiency. Many regions, particularly remote and rural areas, need proper storage facilities and transportation networks for a seamless cold chain. This infrastructure needs to be improved to enable seamless distribution of temperature-sensitive goods, which is otherwise hindering its reach till the end

consumers.

No Cost Efficiency: Business operations with cold chain logistics are capitalintensive, and energy costs comprise a significant portion of the total expenses. Inefficient refrigeration systems and a lack of cost-effective energy solutions certainly increase operational costs, making it challenging for businesses to maintain a profitable cold chain.

Unorganized Industry: Despite growing rapidly, India’s cold chain logistics remains largely distorted and unorganized. Several small players operate independently, generally needing more standardized practices and quality controls.

Scope of Human Error: While most of the cold chain facilities in India function manually, the scope of human error remains a significant concern. From incorrect temperature settings to mishandling of products during transportation, the potential for error is high.

What are the wish lists of user companies in managing temperature sensitive goods?

Preeti Saluja: There could be a long list of wish lists:

The robust packaging systems, which lasts longer than standard 72/96/120 hrs with minimal external management to manage parcel size shipments.

Predictive temperature management for Pharma using AI which enables selection of right packaging for specific routes.

AI interference for selecting the shortest and effective routes.

Better infrastructure at the airports, no matter how much we boast of having seamless processes and perfect infrastructure, I think at a global level, we are far from achieving the perfection. In case of heavy loads at the airports, ground handling agencies still struggle for the space in their freezers and cold rooms. Better infrastructure across the globe is one of the major wish lists for sure.

Managing offloads with the airlines,

The cold chain market is benefiting greatly from the integration of internet of things, artificial intelligence, and real-time temperature monitoring devices, which aid in ensuring the safety and quality of pharmaceutical products in transit. Sustainable and intelligent packaging solutions are a talk of the town now. Smart packaging which could not only be able to provide the real time tracking but also do predictive analysis based on AI. Technologies like big data, predictive analysis, and AI are ushering significant benefits to the pharma sector’s cold supply chain. Real-time temperature-monitoring and control in smart storage warehouses, facilitated by AI, robotics and IoT, are facilitating accurate and consistent temperaturecontrolled environments, reducing the risk of product spoilage.

not sure, how this could be controlled though.

Temperature management at TARMAC would take my biggest vote.

When it comes to cold chain sea shipments, the biggest challenge is managing the plug off timings, so better thermal blankets with PCMs could be the answer amongst other solutions.

For pallet size shipments, availability of active/passive systems at the remote locations could be an answer to many challenges.

Supply chain management through drones for remotest of the locations is another chapter to be read. Understandably some trials are on their way for sure.

Kartik Jalan: Clients managing temperature-sensitive goods seek greater efficiency, reliability, and sustainability in the cold chain process. This includes real-time monitoring, automated systems for temperature control, and environmentally friendly packaging solutions. Indicold, a leading player in the Indian cold chain industry, aligns with this vision by providing end-to-end cold chain solutions with a commitment to sustainability and innovation. Through warehouse automation, Indicold enhances operational efficiency and product integrity, ensuring that temperature-sensitive goods are handled

with precision and care throughout the supply chain.

Mandar Kulkarni: The basic wish lists consist of maintaining temperature condition (NIL temperature excursion cases), timely deliveries to locations wherever urgencies exist for serving cancer patients and addressing critical illnesses. The express delivery solutions at optimum cost, zero missed deliveries are desirable. Other expectations may be for freight cost reduction by optimizing the right packaging solutions for different sizes of packed vaccine shippers. In case there is expected delay in deliveries (> 48 hours) due to any issues like air connectivity, road challenges, etc., then there should be back-up plans for arranging separate facilities/re-packing infrastructure for replacement of gel packs so that the current maintained temperature condition gets extended for few more days. The online tracking of temperature and deliveries, timely alerts through SMS/mails and on time actions could be the requirements. Need to have adhered vehicle checklist points along with data loggers/GPS enabled FTL, Milk run and PTL temperature controlled solutions to ensure that each shipment is shipped in the most optimum mode of transport, increasing its reliability. It’s also important to have drivers trained and equipped for quality monitoring, risk management, repairs, sensitivity and escalations through matrix to address any unforeseen issues.

Tushar Ghai: In my view, the most important wish list in managing the

temperature sensitive goods is the adoption of more mature ecosystem to handle temperature sensitive and shelf life sensitive products. Secondly, end to end tracking of vital parameters for maintaining and ensuring the product quality & integrity is crucial. Moreover, there needs to be competitive pricing for maintaining cold chain and transporting temperature sensitive goods in order to ensure high customer satisfaction and great brand execution. Lastly, there is always a challenge of availability of a “Good Fit Vehicle” which should be resolved as part of ecosystem transformation and necessary training sessions.

Are logistics companies preparing to brace the latent demand and do we have state-of-the-art cold chain infrastructure in place to cater to the demand when it comes to cold chain shipments by air?

Preeti Saluja: Logistics companies may want to do many things but the reality of the situation is that logistics companies alone cannot do everything as they are also dependent on many other service providers to ensure that cold chain is maintained, to name a few, correct packaging is required to ensure that the qualification time of the box should be enough for it to last for its total transit time, once the shipment is handed over to the airlines, airlines and ground handling agencies must ensure the correct storage of the shipment and ensure to have the least of the tarmac exposure. Some agencies are also introducing cool dollies for this reason. Human Resources at the airlines and

The basic wish lists consist of maintaining temperature condition (NIL temperature excursion cases), timely deliveries to locations wherever urgencies exist for serving cancer patients and addressing critical illnesses. The express delivery solutions at optimum cost, zero missed deliveries are desirable. Other expectations may be for freight cost reduction by optimizing the right packaging solutions for different sizes of packed vaccine shippers. In case there is expected delay in deliveries (> 48 hours) due to any issues like air connectivity, road challenges, etc., then there should be back-up plans for arranging separate facilities/re-packing infrastructure for replacement of gel packs so that the current maintained temperature condition gets extended for few more days. The online tracking of temperature and deliveries, timely alerts through SMS/mails and on time actions could be the requirements.

GHAs must be properly trained to handle temperature sensitive products .After the shipment has successfully reached destination, correct storage is required until the time it is custom cleared and delivered. As for the state of the art cold chain infrastructure, it will be, of course, a wish list for many stakeholders but so far, we have miles to go.

Mandar Kulkarni: It is important to have the stocking of pharma products/ vaccines near consumption points to reduce the transit time and meeting on time requirement of hospitals/ patients. The planning of right quantum of stocking SKUs against inventory norms at central distribution centres as well as at regional depots can help in addressing this issue. The strategic location of warehouses can be based on market volume demand/needs and also can be supported by inputs on statewise variated electricity rates. Secondly, there are many 3PL companies coming up with large cold storage facilities and may provide logistical extension too. There are couple of service providers/ partners working in collaboration for building large sized upgraded warehouses nearby metro cities with technological advancements. If there is high variation in demand at client end, then if required, such kind of facilities can be availed based on variable cost basis with actual usage per pallet cost basis. There can be an advantage of consolidation and reducing overall supply chain costs. The collaborative approach across several companies within industry would be

the future. There are various innovative initiatives that would play out well in the future such as warehouses near consumption point, multi-temperature modular partitions to reduce electricity consumption and costs (also vehicles with partitions), etc. It is also important how the segmentation within cold room/ cool room is done along with modular partitions for reducing electricity costs.

Cold chain solution can have insulated pallet blankets, collapsible pallet storages, or which provides thermal barrier systems cover pallet loads to provide an enclosed thermal environment that passively manage product temperature during storage and transport. Pre-qualified offthe-shelf temperature-sensitive courier shippers designed temperature-sensitive deliveries in specific insulation like PU, EPS, PU polyurethane, Vacuum insulated panels, etc.

How are logistics companies preparing to brace the latent demand and do we have state-ofthe-art cold chain infrastructure in place to cater to the demand?

What’s happening on warehousing front as well in this regard?

Kartik Jalan: In India, the cold chain industry is poised for significant growth, driven by factors like increasing investments in infrastructure, government initiatives to get nutritious food to consumers, and the adoption of advanced technologies. The global warming phenomenon presents both challenges and opportunities for the cold chain sector, as rising temperatures

necessitate more stringent temperature control measures while also creating greater demand for cold storage and transportation services. Indicold's mission aligns with addressing these challenges by providing sustainable and technologically advanced cold chain solutions to meet the evolving needs of the market. The future of the cold chain industry through our lens will likely see continued investments in warehouse automation, such as automated storage systems and robotic picking technologies, to further enhance operational efficiency and meet growing demand.

What are the innovations happening in this space?

Preeti Saluja: There are several innovations happening. Cold chain market stakeholders have started talking about and implementing a lot of newer technologies. The cold chain market is benefiting greatly from the integration of internet of things, artificial intelligence, and real-time temperature monitoring devices, which aid in ensuring the safety and quality of pharmaceutical products in transit. Sustainable and intelligent packaging solutions are a talk of the town now.

Smart packaging which could not only be able to provide the real time tracking but also do predictive analysis based on AI. Technologies like big data, predictive analysis, and AI are ushering significant benefits to the pharma sector’s cold supply chain. Real-time temperature-monitoring and control in smart storage warehouses, facilitated

by AI, robotics and IoT, are facilitating accurate and consistent temperaturecontrolled environments, reducing the risk of product spoilage. There is so much that is being tested at the moment and if I can say so, also being used when the budget and operational requirements meet each other.

Kartik Jalan: The cold storage industry is buzzing with innovation. First off, there's a significant focus on automation, with smart cold storage systems utilizing IoT sensors for real-time monitoring and automated storage and retrieval systems revolutionizing warehouse operations. Energy-efficient refrigeration technologies are also making waves, using variable frequency drives and evaporative cooling to minimize energy consumption. Then, there's the exciting development of traceability solutions like blockchain and RFID tags, ensuring product quality and compliance throughout the cold chain. Lastly, we're seeing advancements in insulation materials like vacuum insulated panels and aerogels, enhancing temperature stability within storage facilities. These innovations collectively drive efficiency, reliability, and sustainability in cold storage operations, marking an exciting evolution in the industry.

What are the regulations in place to enable such a highly specialized cold supply chain?

Preeti Saluja: Maintaining product quality and integrity requires a coordinated effort by stakeholders involved across the supply chain. It requires clear communication of risk mitigation guidelines. GDP (Good Distribution Practices) guidelines are needed to monitor and control pharmaceutical products from manufacturers to end consumers. Major pharmaceutical regulators like US-FDA, WHO, European Union, and PIC/S have issued GDP guidelines in their respective jurisdictions. The Indian regulator - the Central Drugs Standard Control Organization (CDSCO), has developed and issued draft guidelines for Good Distribution Practices (GDP) for pharmaceuticals in 2018 for comments.

What are the emerging trends in cold chain packaging?

Kartik Jalan: From an outsider's perspective, emerging trends in

Traditional warehouses with 40-foot ceiling heights are not conducive to efficient refrigeration because the square footage of the roof introduces heat from solar energy, increasing the load on the refrigeration system. Additionally, there may be an opportunity to increase the pallet capacity of a building footprint by 12% to 25% by raising the clearance height to 11 metres, up from 10 metres.

Source: JLL

cold chain packaging include a focus on sustainability with eco-friendly materials, integration of smart packaging technologies for real-time monitoring, emphasis on convenience and efficiency with lightweight and pre-packaged solutions, and customization to meet specific product and branding needs. These trends are shaping the industry towards sustainability, efficiency, and customer satisfaction. Indicold currently looks to partner with companies to provide such services as and when required by its customers.

What are the conducive policy mechanisms from the government?

Preeti Saluja: For India - National Logistics Policy (NLP) was launched on 17th September 2022 by the Prime Minister, Shri Narendra Modi. The targets of the NLP are to: (i) Reduce cost of logistics in India; (ii) improve the Logistics Performance Index ranking. As per Invest India Forty air cargo ports have been built to increase exports, and thirty airports have been equipped with cold storage facilities. There will soon be 35 multi-modal hubs nationwide, enabling seamless freight movement. The government of India has permitted 100% FDI in warehousing, which is especially needed for developing the growth of state of art cold storage facilities. With the imminent need for specialized equipment and storage solutions to maintain product integrity, FDI also helps accelerate Tech integration, which is a pressing need of the sector.

Funding from the government plus FDIs will bridge the gap and empower logistics companies to build cutting-edge infrastructure to upgrade and modernise the cold supply chain.

How is new age technology shaping the cold chain segment?

Kartik Jalan: New age technology is redefining the way goods are being transported, stored and distributed. Blockchain technology is being increasingly adopted to enhance transparency and traceability in the cold chain. Real-Time Monitoring: IoT (Internet of Things) devices and sensors are being integrated into cold storage facilities and transportation vehicles, enabling real-time monitoring of temperature, humidity, and other crucial parameters. Predictive maintenance techniques powered by AI (Artificial Intelligence) are helping cold chain operators anticipate equipment failures before they occur. Innovations in cold energy storage technologies are making cold chain operations more sustainable and environmentally friendly. Automation and robotics are streamlining cold chain operations, reducing dependency on manual labor and minimizing the risk of human error. Drones and autonomous vehicles are being explored for last-mile delivery in the cold chain segment. New-age technology is revolutionizing the cold chain segment, driving increased efficiency, sustainability, and reliability across the entire supply chain. At Indicold,

Higher quality insights are decisive for refrigerated products, therefore 2024 will see more investments in software that can improve visibility on the whole supply chain. Better tools will need to come in place to effectively monitor temperature-sensitive cargo and create an unbroken cold chain that has real-time visibility on the product conditions using uninterrupted data. Real-time monitoring will become even more precise, with GPS-enabled devices placed in the containers.

we are using data analytics, real time monitoring, predictive maintenance and building unique, state-of-the-art, future ready sustainable cold storage marked by cutting edge technologies.

Tushar Ghai: At present, the industry is undergoing rapid transformation, fueled by technological advancements in packaging materials and monitoring systems. Innovations in insulation, like the use of advanced aerogels and phase change materials, are enabling more efficient and longer-lasting temperature control. Concurrently, the integration of the Internet of Things (IoT)-based monitoring systems in packaging solutions is enhancing the traceability and reliability of the cold chain. These technologies enable real-time tracking of temperature and humidity levels, ensuring product integrity throughout the supply chain. This technological leap is crucial for sectors like pharmaceuticals where the efficacy of temperature-sensitive drugs and vaccines hinges on consistent cold chain management.

How do you foresee the expanse of pharma cold chain in times to come?

Preeti Saluja: Given the inclination of industry stakeholders towards forging strategic alliances focused on the development of cold chain products, we believe that the cold chain market is likely to evolve at a rapid pace in times to come. If I can say so, this is the era of the mergers and acquisitions, many stakeholders are undertaking initiatives to forge alliances with other industry

/ non-industry players and link the activities together to provide seamless cold chain services. stakeholders are actively engaged in providing multiple services related to the temperature controlled packaging solutions, such as reuse and rental services that involve reusing and leasing of the container / shipper for the transportation of pharmaceutical products. Drug distribution companies are tying knots with specialised logistics companies. Marriage between specialised temperature control packaging systems and logistic companies are proving to be a successful association. Passive and active containers collaborations and many others could be seen. In this era, the expanse of Pharma Cold chain is only going to get bigger and bigger, the aim is clear – expansion of portfolios for respective stakeholders and also their geographical reach.

Kartik Jalan: In the future, the cold chain is set to expand significantly due to globalization, technological advancements, evolving consumer preferences, climate change and regulatory requirements. This growth will be driven by increased demand for perishable goods and the need for more sophisticated infrastructure to meet rising expectations for quality and safety. Tier 1 and 2 cities are more likely to attract significant capital inflow and new capacity creation in the forthcoming years. India’s cold supply chain faces a pivotal juncture between innovation and adaptation. Trends shaping this year set the stage for a stronger industry. In coming years, stakeholders aim to adopt technological advancements, sustainable

practices, collaborative efforts across the supply chain and focus on skill development to meet the evolving needs of a dynamic market.

Mandar Kulkarni: The constant market surveys by the teams, predictive analysis, symptom analysis would constantly evolve the distribution pattern of pharma products. Companies are investing in healthcare supply chain and cold chain capabilities by providing cold chain facilities worldwide. They can offer tailored solutions for transport of temperature-controlled healthcare shipments within India to for 6,000+ postal codes. The express logistics (road/ air) by consolidation of shipments across whole pharma industry would be key for faster deliveries at optimum cost shared among them. Service partners will be integrating IoT technology for near realtime monitoring, ensuring visibility and product integrity. The growth in pharma industry will be accelerated with digital transformation journey along with innovations backed by data to strengthen the pharma eco-system. Also, the life science companies along with service partners would be proactively working on building the intelligent supply chain, which is customer-centric supported by technology and innovation.

The advocacy for Women @ Work has resonated across all sectors, igniting a fervent call for change. While the seeds of change are already sprouting, the pace of growth needs to be aggressive. Both globally and within India, we have enough and more inspiring tales of women taking charge and leading their organizations with unparalleled grace and skill. The traditionally male-dominated domain of supply chain management has undergone a notable shift, welcoming remarkable women into pivotal roles, whether in strategic decision-making, warehouse management, or ensuring seamless last-mile deliveries. Our featured Cover Story delves into this compelling paradigm shift, showcasing women’s ascendancy to the driver’s seat in the supply chain domain. Additionally, this section offers the perspectives of leading change agents committed to fostering diversity and inclusivity within organizations, ensuring environments where women thrive with safety and motivation.

WOMEN have made a strong comeback to the supply chain workforce in 2023, with gains at nearly every level of leadership, according to a survey by Gartner, Inc. The advances were particularly prominent at the C-Suite and executive level, where 26% of those roles (CSCO, SVP, EVP, CPO) are now filled by women, an all-time high and up from 19% in 2022. The survey showed that women now make up 41% of the supply chain workforce, up from 39% in 2022. However, frontline representation continues to lag, with women filling just 31% of these roles. “It’s particularly encouraging to see women make gains at the senior executive level, as we know that when a woman holds the top supply chain position this has a positive correlation with more women in leadership and in all roles through that organization,” said Caroline Chumakov, Director Analyst, Gartner Supply Chain Practice.

An increase in organizational goals around gender equality since 2020, as well as growth in the number of supply chain owned initiatives are clearly having a measurably positive impact on women in supply chain. The data suggests a virtuous cycle is possible as more women reach top leadership roles in their supply chain organizations, with a clear finding this year that a woman in the senior-most role leads to more women in leadership and all roles within the organization.

“This connection between female leaders and the effect on women in the workforce has positive implications for how supply chain leaders can better design their efforts to improve representation of women in supply chain,” said Chumakov.

Chief Supply Chain Officers (CSCOs) routinely report challenges with attrition broadly at frontline roles in manufacturing and logistics, particularly when compared to roles at desk-based jobs. The ability to attract more women to frontline roles— and especially in leadership roles in the physical operations ranks—could form a material competitive advantage over those who are unable to do so.

Providing flexibility was the most effective initiative in attracting and retaining women to frontline roles, significantly outperforming other areas such as benefits, employee engagement programs and even a focus on pay equity. However, only 41% of supply chain leaders had implemented an initiative dedicated to workplace flexibility at their organizations. “There remains a mismatch between employers’ fears of chaos and instability as a result of workplace flexibility policies and the realities of what we see in our research and case studies of successful supply chain organizations. What we see in our research is that flexibility is benefiting both the organization and their female employees,” said Chumakov.

Drawing inspiration back home, in a move that's testament to gender parity across workplaces, Dabur India has set up an all-women production line with

100% women employees at its largestever greenfield plant near Indore. In this first-of-its-kind development, a crew of 20 women are engaged in the production of Dabur's range of Vatika Hair Oils – a range of products 'Made by Women, for Women'. The move is part of Dabur's efforts to build a more diverse workforce and promote women empowerment in the manufacturing industry. The company will be further expanding this initiative with the inclusion of 30 more women in its factory workforce, going forward.

This all-women production line has been established at Dabur's Rs 550-crore greenfield manufacturing unit being set up near Indore in Madhya Pradesh. This line has been established to meet the growing demand for its range of natural personal care products, particularly hair oils. This line has a capacity to produce over 2.5 million packs per annum and will be operating in 3 shifts.

"Our groundbreaking move is not just a powerful statement for gender equality and women's empowerment in the workplace, but also serves as a shining example of breaking stereotypes and providing equal opportunities. This unit exclusively produces a range of hair care products designed by women, produced by women, for women. This unique approach ensures that the products cater to the diverse needs and preferences of the female consumer base, fostering a strong sense of connection between the brand and its consumers. And in the process, this unit is also significantly contributing to economic independence," Rahul Awasthi, Global Head of Operations, Dabur India Ltd.,

An increase in organizational goals around gender equality since 2020, as well as growth in the number of supply chain owned initiatives are clearly having a measurably positive impact on women in supply chain. The data suggests a virtuous cycle is possible as more women reach top leadership roles in their supply chain organizations, with a clear finding this year that a woman in the senior-most role leads to more women in leadership and all roles within the organization.

said.

The introduction of an all-women workforce, Awasthi added, has proven to be a catalyst for higher productivity, enhanced team cohesion, exceptional efficiency, attention to detail, and commitment to quality, translating into a 10% increase in the factory's overall productivity.

Since September 2023, Flipkart has been actively hiring women for fulfilment and sortation centres in Haryana. Amazon India also recently announced the launch of Women in Night Shifts (WINS) at one of its large Sort Centre in Haryana. In addition to Amazon’s existing initiatives, WINS is designed to provide a safe and supportive work environment for women, ensuring equal opportunities for both men and women to work in various shifts, and championing inclusivity for all.

In some states in India, regulations prohibit the employment of women in night shifts in warehousing operations facilities primarily stemming from concerns about women's safety and wellbeing. Amazon India has actively engaged with state governments to advocate for equal work opportunity for all. Through dedicated efforts and collaboration with authorities, the company has successfully enabled night shift operations for women across select sites in Tamil Nadu, Rajasthan, Gujarat, Maharashtra, Karnataka, Uttar Pradesh, Telangana, Punjab, and now, in Haryana.

"We believe in creating equal opportunities and addressing barriers that women face in the workplace and are thankful to the government for their support in enabling women to work in night shifts.," said Liju Thomas, Director – HR, India Operations, Amazon India. "The launch of WINS reiterates our commitment to promoting gender equality and nurturing a safe work environment for our employees and associates. We prioritize the safety and wellbeing of our associates offering comprehensive measures, such as transportation facilities, and enhanced security arrangements for those working in night shifts. We intend to extend this initiative to other sites in Haryana, reinforcing our commitment to a diverse and secure work environment.”

These efforts align with the broader

objective of increasing the representation of women in blue-collar roles within the industry.

Flipkart boasts a workforce comprising close to 30% women in its supply chain, including last-mile delivery roles. The company reportedly has over 800 women currently working night shifts across various locations in Haryana. Zomato also boasts over 2,000 female delivery partners nationwide. Presently, women constitute approximately 10% of the overall workforce in e-commerce companies. However, this figure is expected to see a significant uptick, with projections indicating a 25% growth in the size of the women workforce in the industry by 2024.

While working on the Women @ Work Cover Story, we received an interesting report by Reuters which honored Trailblazing Women 2024 In Supply Chain. We picked up few of the most impressive and thought-provoking insights of winners for others to get inspired and take challenges head on…

Andrea Fuder, Executive Vice President, Chief Purchasing Officer, Volvo Group, in Reuters’ report, was quoted as saying, “Investing in women and unleashing the potential of diversity is not just the right thing to – it’s also a clear business driver for Volvo Group. We are a people centric company, where all individuals can contribute and thrive to their fullest potential! I’m proud to lead our Purchasing team, with over 40% women, in building an ecosystem of supply partners to shape the world we want to live in!”

Karen Jordan, CSCO, PepsiCo, “Seeing is believing. Women need to see the opportunities that exist for them at all levels of any organization. At PepsiCo Beverages, we use our scale to ensure that women have the vision to see how they can thrive in any role from frontline to leadership.”

Kathryn Wengel, Chief Global Supply Chain Officer, Johnson & Johnson, “Women are catalysts for creating healthier people, healthier communities and a healthier world, and I’m proud

I believe the stereotyping around supply chain is the reason more women are not picking supply chain as a career option. Organizations need to make changes to ensure these stereotypes are broken. We need more women at leadership roles. We also need to encourage senior women leaders need to support the younger ones thru mentoring and sharing of own experiences. Young girls should find safe space to voice concerns and get them addressed. While some of these things are taking place as we speak, the pace is frustratingly slow. We need more urgency in this agenda with visible movement across the industry.

of the work we’re doing to advance women’s leadership in the fields of science, technology, engineering and manufacturing, and to inspire and develop the next generation of leaders. At Johnson & Johnson, everything we do is guided by Our Credo. It codifies our commitment to patients, the world community, stakeholders and our employees who work with us throughout the world. For more than 130 years, diversity and inclusion has been key to the success of Johnson & Johnson—starting as far back as 1908, when the company hired its first female scientist. And although this longstanding commitment is engrained in our Company heritage, we know there is

still much more work to do.”

Taking a leaf from these awe-inspiring quotes, we reached out to women professionals in supply chain and dived deeper into the changing dynamics of Women @ Work. Here’s what they said…

Women in supply chain used to be rare. However, inspiring stories of women leaders like you in this field are changing that narrative,

At Horizon, we prioritize capability and skills above all else. We hold a positive bias towards women with equal qualifications, ensuring a fair and inclusive workplace. Further to make our workplace safe, healthy, and supportive, we have internally established a POSH cell, which I personally lead to guarantee a thriving environment for our female employees. With three of our nine leadership members being women, Horizon demonstrates its commitment to diversity. Additionally, we sponsor skill development initiatives for all employees, including women, and foster networking through our Women’s Mentorship program, connecting them with women leaders across various industries for valuable exchange and growth opportunities.

inspiring others to join. Could you share your journey into supply chain and a message for women professionals?

Aarti Garde, Sr. Team Leader – Supply Chain Analytics & Digitalization, Elanco Innovation and Alliance Centre India, IAC: I began my journey in the supply chain industry as an eager engineering graduate, taking on the role of a planning analyst for Johnson & Johnson's medical devices business. This experience was instrumental in providing me with a comprehensive understanding of supply chain planning. I was fortunate to be under the guidance of exceptional leaders and mentors who encouraged me to further my education with an MBA. After 3.5 years in the corporate world, I pursued my PGDM from the Goa Institute of Management. This further broadened my perspective, teaching me how the supply chain is interlinked with other organizational functions.

Following my post-graduation, I joined Elanco in 2018, which was then a division of Eli Lilly, and have been part of this organization for the past six years. I embarked on my career at Elanco as a Demand Analyst and also played a pivotal role in the SAP Integration Project after our acquisition of Bayer Animal Health, serving as the Integration Process Owner for Demand Planning and Deployment. Today, I am proud to lead and develop the Supply Chain Analytics and Digitalization Team. Our team focuses on statistical forecasting, inventory analytics, Six Sigma and digital projects and business processes. In 2021, I also achieved my APICS CPIM certification.

In my decade-long career, I have primarily focused on planning and analytics. As I look towards the future, I am keen on delving into the manufacturing side of the business. I believe this will allow me to better understand the processes and intricacies involved, thereby enhancing my holistic understanding of the supply chain.

To all the professionals out there, my message is straightforward:

Love what you do. Passion is a driving force that can propel you to great heights.

Focus on the impact you are making within your organization. It's not just about the role you play, but the value you add.

Clearly define and work towards your essential wins, development goals, and career plan.

Seek out mentors and maintain regular connect with them. Their guidance can be invaluable.

Keep your mentors, seniors and leadership team informed about your career aspirations.

If you adhere to these principles, success is not just a possibility, but a certainty. And remember, always strive to broaden your horizons and seek out new learning opportunities. The more diverse your experience, the more wellrounded and adaptable you become. This adaptability is crucial in today's everevolving business landscape.

Pooja Malik, Head – Leasing, Horizon Industrial Parks: Throughout my career, I've remained rooted in the real estate sector and have been driven by the desire to expand my knowledge across various business functions within the industry. In my initial years, I contributed to the growth and development functions of retail giants such as Carrefour, Walmart India, and Decathlon Sports India, with a focus on expansion and business development strategies. From there, in a natural transition to a higher leadership role, I took on the position of Senior Vice President – Leasing, IndoSpace, learning all about the logistics real estate sector here. Progressing from a regional to a national head of leasing at Horizon Industrial Parks, I've continued to evolve and learn in this dynamic field and hope to continue in the coming years.

As a woman in this field, I've always believed in the power of hard work and competence, allowing my abilities to speak for themselves. I firmly believe that dedication and capability are the true keys to success. Secondly, and perhaps most importantly, establish a supportive ecosystem that nurtures your career and ambitious goals, allowing you to focus your energy on activities that

directly contribute to your success. This means effective delegation both at home and in the workplace.

Himani Kanwal, Senior Principal, Miebach Consulting GCC: I chose supply chain because it was a wonderful intersection between engineering and management which worked well for me to leverage my strengths. I never viewed it from a gender point of view. And that’s what I would recommend to all young women also. Find your strengths and interests and then a job/role/startup that helps you leverage those. Skills are not gender based; else world’s best Chefs won’t mostly be men.

Dr Seema Narera, FMCG Vertical Head, South Asia, Maersk: I started my journey in Supply chain with Unilever, while working in the front-end supply chain and managing Order to Cash process. Since then, I moved across different legs of supply chain leading Demand Planning, Supply Planning, procurement, WnD, etc. Today I am heading South Asia FMCG vertical for Maersk Integrated logistics. Please note that traditionally people confuse supply chain with only trucking, running factory operations or managing “godowns” while today supply chain is a vast function which is increasingly getting automated, safe and transparent. There is a plethora of opportunities in demand planning, procurement, vendor management in addition to traditional logistics. Also, with businesses relying more and more on supply chain to drive competitive advantage for their businesses, there is a need for smart multitaskers and not just execution specialists in this field. I would highly urge women to consider Supply Chain as a career option and delve deeper into it before cancelling it out as “Not for Women” work.

Why do you think women tend to avoid supply chain careers? How can companies address these barriers, and do you see the situation improving?

Aarti Garde: Historically, the supply chain industry has been male dominated, a trend largely attributed to misconceptions about the nature of the field and the lack of visibility of successful

women in this sector. Many women may not choose supply chain as their career path due to a limited understanding of what the field entails, often perceiving it as purely operational or technical, and overlooking the strategic and managerial aspects. However, I'm witnessing a significant shift in this landscape. More and more women are exploring careers in supply chain, breaking barriers, and making their mark in the industry. This is a promising trend that showcases the evolving dynamics of the field.

Corporations can further accelerate this change by taking proactive measures. They can foster an inclusive culture that values diversity, ensuring that their policies support women in the workplace. Promoting the diverse roles within the supply chain industry is another crucial step. By highlighting the strategic, analytical, and managerial aspects of these roles, companies can appeal to a broader range of talents, including women. Mentorship programs can also play a significant role. Pairing aspiring women professionals with established leaders in the field can provide valuable guidance, support, and role models, encouraging more women to consider careers in supply chain.

Moreover, educational institutions can contribute to this change. By integrating more supply chain-related subjects into their curriculums, especially in engineering and business courses and organizing guest lectures they can provide students with a comprehensive understanding of the field, thereby encouraging more women to consider this as a viable and rewarding career path.

Pooja Malik: One of the probable reasons behind women not choosing supply chain previously and even to some extent presently as their preferred career stream is safety concerns in warehousing locations. Factors such as distance, transportation issues, and the inability to take up late-night shifts due to security concerns pose barriers for female employees. While gated parks provide a level of safety within the premises, they don’t extend beyond the gates when the employees commute home.

On the other hand, last-mile delivery roles, situated within cities, are more conducive to employing women. In recent

In the journey towards a more inclusive supply chain ecosystem, women can break biases and build support systems through a combination of clarity, communication, and organization culture. Having clear career goals and voicing these ambitions is crucial. When women articulate their aspirations and seek support, they not only pave the way for their own advancement but also set a precedent for their colleagues. With determination, support, and a conducive work environment, women can break through barriers and contribute significantly to an inclusive supply chain ecosystem.

times, there has been a growing realization that women are good workers. They work hard, stick with their jobs, and don't quit easily. This is beneficial for businesses because it costs time and money to train new employees, so it's better when people stay in their jobs. To address these barriers, corporates can focus on enhancing safety measures, providing transportation facilities, and offering flexible working hours to accommodate the needs of female employees. Moreover, promoting a culture of inclusivity and actively encouraging women to pursue careers in supply chain through targeted recruitment and retention strategies can

Women in supply chain need to vocalize their stories to other aspiring youngsters to encourage them to join supply chain ecosystem. Also, existing women need to vocalize their needs to organizations to make a more conducive work environment for future. Senior leaders should encourage newcomers to take risks, try unconventional roles which prove a support system and fall-back plan. Unless we try, we will not know what all is possible in breaking these barrier.

contribute to further improving gender parity in the sector.

Himani Kanwal: I believe the stereotyping around supply chain is the reason more women are not picking supply chain as a career option. Organizations need to make changes to ensure these stereotypes are broken. We need more women at leadership roles. We also need to encourage senior women leaders need to support the younger ones thru mentoring and sharing of own experiences. Young girls should find safe space to voice concerns and get them addressed. While some of these things are taking place as we speak, the pace is frustratingly slow. We need more urgency in this agenda with visible movement across the industry.

Dr Seema Narera: Like I said,

traditionally supply chain is viewed as running operations in far-flung areas where godowns and factories are established. Due to lack of accessibility and infrastructure, these places were considered unsafe for women to work in, which ultimately became a deterrent for women as well as businesses to see them as possible work option for women. However, now infra is rapidly getting better. Physical and network accessibility improvement has made the areas safer. Businesses are also making conscious efforts to define Safe travel SOPs, provide company monitored and managed transport while also driving gender diversity in hiring agenda. Also, today, as we have some women leaders rising to the top in supply chain function, more women would get encouraged to make supply chain a career option without worrying about growth options.

Diversity and inclusion have become one of the key corporate strategic pillars. How is it shaping up in the supply chain and logistics domain?

Aarti Garde: In the supply chain and logistics sector, diversity and inclusion are paving the way for innovation and improved decision-making. Diverse teams bring a wealth of perspectives, sparking creativity and comprehensive problem-solving. Moreover, an inclusive culture attracts a broader talent pool, essential in an industry often facing talent shortages.

However, we must recognize that the journey towards true diversity and inclusion begins at the educational and knowledge level. While many organizations are committed to their D&I initiatives, the challenge often lies in the lack of diverse applicants. This is where educational institutions and early career guidance play a critical role. By promoting supply chain and logistics as a viable career path to a diverse student population, we can ensure a more balanced pool of applicants.

Additionally, organizations can proactively reach out to underrepresented groups through career fairs, internships, and mentorship programs. This not only increases awareness about the opportunities in the sector but also demonstrates the organization's

commitment to diversity and inclusion. In essence, while we are making strides in fostering a diverse and inclusive environment, the journey begins much earlier. We need to ensure that the path leading to our industry is accessible and appealing to all.

Pooja Malik: At Horizon, we prioritize capability and skills above all else. We hold a positive bias towards women with equal qualifications, ensuring a fair and inclusive workplace. Further to make our workplace safe, healthy, and supportive, we have internally established a POSH cell, which I personally lead to guarantee a thriving environment for our female employees.

With three of our nine leadership members being women, Horizon demonstrates its commitment to diversity. Additionally, we sponsor skill development initiatives for all employees, including women, and foster networking through our Women's Mentorship program, connecting them with women leaders across various industries for valuable exchange and growth opportunities.

Himani Kanwal: Supply chain functions have a lot to catch up on in the coming time. The average no of women in SC functions usually ranges from 10-12% compared to 30-35% in finance or marketing. Some organizations have made progress to hit 30% in supply chain after years of efforts. We need more focus from the corporates on female talent in supply chain.

Dr Seema Narera: There is a diversity agenda drive for increasing women workforce across levels in supply chain. Some interesting developments are occurring because of that. The warehouses are being designed to have infra which is conducive for women to work. Necessities like ladies’ washrooms were not available in earlier days. While now we have an example of “Pink Warehouses” where every single job is being done by a woman. Maersk inaugurated one such warehouse last year in Dadri. Similarly, there are Pink Multiplexes, Pink QSR stores, etc., which are making bold statements that women can handle every single job at any hour of

Flipkart boasts a workforce comprising close to 30% women in its supply chain, including last-mile delivery roles. The company reportedly has over 800 women currently working night shifts across various locations in Haryana. Zomato also boasts over 2,000 female delivery partners nationwide. Presently, women constitute approximately 10% of the overall workforce in e-commerce companies. However, this figure is expected to see a significant uptick, with projections indicating a 25% growth in the size of the women workforce in the industry by 2024.

the day/night and run a very successful business operation.

Moving towards a more inclusive supply chain ecosystem, how can women break the biases, address challenges, and build support systems for each other in this evolutionary journey?

Aarti Garde: In the journey towards a more inclusive supply chain ecosystem, women can break biases and build support systems through a combination of clarity, communication, and organization culture. Having clear career goals and voicing these ambitions is crucial. When women articulate their aspirations and seek support, they not only pave the way for their own advancement but also set a precedent for their colleagues.

An organization's culture plays a significant role in this process. A culture that encourages open dialogue, values diversity, and supports career development can help women overcome challenges and biases. As women receive support, they are often inspired to extend the same to their colleagues, fostering a cycle of empowerment. Lastly, it's essential to remember that no goal is unattainable. With determination, support, and a conducive work environment, women can break through barriers and contribute significantly to an inclusive supply chain ecosystem.

Himani Kanwal: I believe women should focus on 3 areas – 1) Build sponsors amongst senior leaders in the organization; 2) Support other women at

work be it their peers, junior or seniors. Build your community and support system at work; 3) Call out biases more openly at workplace especially in instances of micro aggression.

Dr Seema Narera: Women in supply chain need to vocalize their stories to other aspiring youngsters to encourage them to join supply chain ecosystem. Also, existing women need to vocalize their needs to organizations to make a more conducive work environment for future. Senior leaders should encourage newcomers to take risks, try unconventional roles which prove a support system and fall-back plan. Unless we try, we will not know what all is possible in breaking these barriers.

What steps can organizations take to empower women in supply chain?

Aarti Garde: To empower women in the supply chain industry, organizations can start by offering mentorship programs to college students, providing early exposure to the industry and guidance. They should also cultivate an inclusive culture, addressing biases and valuing every contribution. Policies that support career advancement, such as equal opportunity initiatives and flexible work arrangements, are essential. Finally, ensuring women's representation in leadership roles can inspire and motivate others, showing what's achievable in this field.

Pooja Malik: To empower women in

the supply chain, organizations can take several proactive steps. Firstly, they can invest in improving infrastructure, especially connectivity to warehousing parks from urban areas, and provide better public amenities to ensure safe access for female employees. However, I do not advocate for implementing reservation quotas as a quick-fix solution. Instead, fostering an organic and inclusive environment through initiatives such as targeted recruitment, mentorship programs, and leadership development opportunities can create a more sustainable approach to gender diversity and empowerment in the supply chain.

Himani Kanwal: It’s often seen that organizations measure men and women on different standards. While men are measured and promoted on potential, women must demonstrate multiple cycles of success for the same promotion. There are more doubters than sponsors for women. Women are expected to meet a much higher standard of performance. This needs to be addressed at the earliest possible.

Dr Seema Narera: Organizations need to make gender neutrality not as a Code of conduct but as a part of day DNA of the company. It starts with basics like gender neutral language, encouraging diverse interest in team while planning team connects, meetings, offsites or travels. Showcasing their women workforce to the front to attract more women and a healthier gender mix across levels.

“The changing workforce demographics expect its leaders to be socially and environmentally responsible, to better understand Talent Management, and to create places where diverse contributions are maximized for the enterprise’s strategic benefit. In short, a commitment to full inclusivity is now a leadership and business competency. Deficiencies here will limit a leader’s effectiveness and advancement in much the same way as a lack of financial acumen,” highlights Aparna Sharma, HR Practitioner & Independent Director on Corporate Board.

What are the challenges that women face at the Workplace?

What are the strategies that can help them address and work on the challenges?

Even well into the 21st Century, women continue to face unique challenges at the workplace. Long-standing issues like the wage gap, the glass ceiling, and hostile work environments persist and new challenges caused by the COVID-19 pandemic have disproportionately affected women. Some of the persistent challenges such as Societal mindset; Gender Stereotypes; Pay Disparity; Imposter syndrome; Lack of Equal Opportunities; Difficult to overcome Career gap/ Rejoining the workforce; Bias in Hiring decisions; and Lack of sensitivity are constantly challenging women to prove their mettle time and again and sometimes even dissuade them from charting their professional journey.

While such eventualities will persist, there are ways, which can help them

reach their goalpost. First & foremost, they must be confident about their capabilities. Women should find a Mentor who can guide them to take on the desired career path. They must be able to advocate for themselves. Women should build a support system on whom they can bank upon and shouldn’t hesitate to ask for help. Most importantly, women must be proactive and celebrate their successes. Ultimately, the challenges that women face at the workplace are not just women’s issues, they are everyone’s issues.

Even if you are not directly impacted, you can still have an important role to play in recognizing and overcoming gender bias at work. One of the most important things you can do is to educate yourself on the issues and understand the experiences of women around you. Listen to their stories and be willing to learn from them. You can also start by examining your own biases and assumptions, and actively work to

address them.

If you are a manager or an employer, you can take steps to address these issues by conducting regular pay equity audits, establishing a clear career path for employees, and providing opportunities for training and mentoring. You can also create a safe reporting system for employees to report any incidents of harassment or discrimination.

If you are a coworker or colleague, you can be an ally to women by speaking up when you witness discriminatory behaviour and creating a supportive and inclusive work environment. This can include actively listening to women’s experiences and perspectives, offering to help with projects or assignments, and advocating for policies and practices that promote gender equality in the workplace.

It’s important to remember that change takes time & efforts and addressing these challenges is an ongoing process that requires commitment and dedication from everyone. We may not see immediate results, but every small step we take towards gender equality is a step in the right direction.

How can HR professionals aim to strike the right equilibrium when it comes to diversity & inclusion?

Promoting and improving diversity and inclusion at the workplace is a crucial initiative that many companies are now taking. A diverse workforce, in terms of age, race, religion, nationality, sexual orientations, gender, gender identity, brings diverse viewpoints and perspectives to the company. Diversity at the workplace does not necessarily mean inclusivity at the workplace. Making Diversity a priority is important; so is

Creating a Culture where people from all backgrounds feel Included. Inclusivity is the key to maintaining (not just creating) Workplace Diversity.

What are the best practices that companies can implement to offer a safe & sound working culture for women?

w Know the Diversity Goals and Vision of your organization and its connection to the overall business objectives. Commit to the process by understanding how diversity impacts your role, and how your role impacts the success of the diversity initiative.

w Participate in Employee Engagement Surveys and respond as openly and honestly as possible. Finding an Internal Champion with whom you can comfortably express concerns and/or elicit advice can be instrumental in supporting your efforts.

w Actively engage in the Diversity effort. You can take part in or start an Employee Resource Group (ERG), or volunteer to chair or serve on committees that organize diversityrelated events and activities. Consider becoming a mentor, mentee, or part of a co-mentoring relationship. These activities require commitment of time but represent a valuable opportunity for personal and professional development.

w Become Culturally Competent. Take the time to learn about different cultures, races, religions and backgrounds represented by your colleagues. Ask your co-workers

to share some of the customs and practices associated with their cultures. Become familiar with diversity-related terms and, if you err, apologize and ask for help.

w Treat people in a way they wish to be treated rather than the way you wish to be treated. Common social activities and practices that are comfortable for you may not be comfortable for everyone. Most importantly, be Respectful always. Diversity exists everywhere — not just in the office. Take these diversity principles into your community and your home.

w Drive Positive change in the organization. Be a Spokesperson for diversity issues that are not necessarily your own. Any organization will find it difficult to ignore the powerful voice created when groups representing different diversity dimensions unite.

w Welcome Ideas that are different from your own and support fellow teammates. The creativity that comes with diversity can help you generate new ideas or improve a process already in place. It can also make work more interesting, engaging, and fun.

w Understand the diversity elements you personally bring to the organization. Diversity comes not only in the form of Culture, Race, and Gender but also includes elements such as Socio-Economic background, Education level, Geographic location, Sexual Orientation, Thought process,

Diversity work is a journey, not a destination. It takes time, patience, and perseverance. Be tolerant of co-workers who do not yet appreciate the value of diversity or who may not always behave respectfully. Often, negative behaviour comes from ignorance rather than malice. A willingness to educate can go a long way.

and many others. Each of us brings to the table a lifetime of experiences and knowledge. Each of us is different and adds value to the organization because of these differences.

w Commit to Continuous Improvement. Be willing to learn, accept feedback, and listen to the concerns of those around you. Even the most enlightened individual can find opportunities for growth.