DeMOLITION HUB MAGAZINE

THANK YOU MR PRESIDENT

Final interview with William Crooks, President of NFDC

DEMOLITION DISCUSSION

With Mark Taylor, Metro Deconstruction Services

WORLD OF CONCRETE

We break it down

UK, European & worldwide demolition matters

February 2023 | Issue #15

#championingdemolition

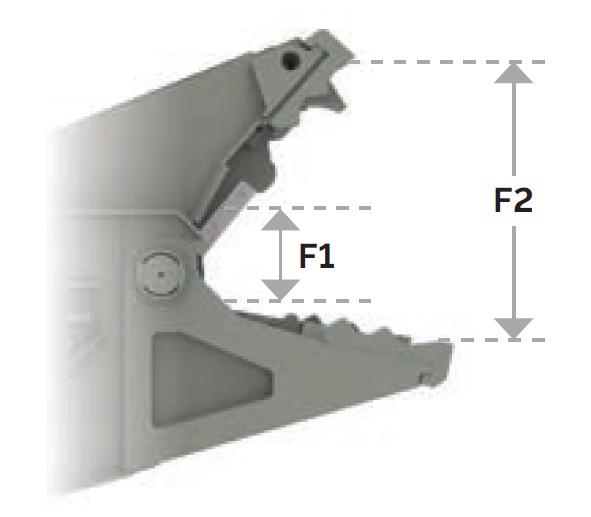

info@liugong.co.uk 02392 123 392 www.liugong.co.uk FROM 1.8 TO 95 TONNES THE ALL NEW F-SERIES BREAKS THE MOULD. SCAN THE QR CODE TO DISCOVER THE DIFFERENCE

BREAKING DESIGN TOUGHNESS CONTRÔL INTELLIGENCE

GROUND

PUBLISHER

Ben Chambers ben@chambers.media 01903 952 648

EDITOR

Toby Wilsdon toby@chambers.media

In issue 15 we bring you possibly the final in-office interview with William Crooks, who leaves his role as President of the NFDC in March.

William has clearly had a successful yet challenging tenure and while we will continue to work with him in his future roles within the federation and with his company, we wish him the very best and thank him for his support from the start, when this was a fledgling magazine.

Continuing the interviews in this issue we are delighted to finally nail down Mark Taylor, MD of Metro Deconstruction for the regular DEMOLITION DISCUSSION interview.

Both Mark and William will be at this year’s British Demolition (and Asbestos) Awards in London this September as we see a huge number of attendees begin to book their tables postChristmas. You can be a part of the event as well by dropping me an email.

In the next issue (April) we will be doing a big promotion on how to enter your company for the many existing and new categories for the fifth running of the event in 2023.

A few days ago I returned from Las Vegas where I had been representing Demolition Hub at the World of Concrete event. It was a pleasure to be able to discuss with suppliers from across the pond their plans for the British marketplace and what technology will be available to British contractors.

We will be drip feeding this in the coming months, starting in this issue, then it’s back to Vegas in March for ConExpo 2023. If you are also attending, let me know, but if not, feel safe in the knowledge that we will be fully showcasing the event to you here and on video.

I mention video as many of you will know that we have had Demolition Hub TV on YouTube for a couple of years now and we will be making a more aggressive presence in that medium.

I feel there is a gap in the market to professionally showcase equipment, on-site action and interviews to compliment your bimonthly printed feed of Demolition Hub.

Have a look at us by searching “Demolition Hub TV” on YouTube.

As ever, I hope you enjoy this issue. Do get in touch to be a part of April…

Publisher, Demolition Hub ben@chambers.media

01903 952 645

DEMOLITION EDITOR

Paul Argent paul@chambers.media

07813 064 590

COLUMNISTS

Richard Dolman Terry Lloyd

SALES

Ben Chambers ben@chambers.media 01903 952 648

Luke Chaplin luke@chambers.media 01903 952 643

DESIGN

Nicki Chambers nic@chambers.media

Joe Bers joe@globalnews.media

Alex Jarrett

PRODUCED & PUBLISHED BY Global News Media Ltd Suites 5 & 6, Chapel House, 1-6 Chapel Road, Worthing, West Sussex BN11 1EX ben@chambers.media 01903 952 640

Demolition Hub are proud supporters of the National Demolition Association

Demolition Hub are the media partner for the European Demolition Association

Demolition Hub is published six times a year. The subscription rate is £60 per year. Subscription records are maintained at Global News Media Ltd, Suite 5 & 6, Chapel House, 1-6 Chapel Road, Worthing, West Sussex BN11 1EX. Articles and information contained in

DemolitionHUB Magazine | 3

Ltd

may not be reproduced in any form

the

of the

The

cannot accept responsibility for loss of, or damage to, uncommissioned photographs or manuscripts.

this publication are the copyright of Global News Media

and

without

written permission

publishers.

publishers

demolitionhub.com

6 NEWS

DEVELON: Hyundai Doosan Infracore reveals new construction equipment brand

JCB’s hydrogen technology set for international debut

Kubota (Europe) launches online ‘Kubota Group Solutions Hub’

YouGov poll: Construction firms failing to support workers through cost-of-living crisis

Rubble Master awards Red Knight 6 full UK dealership

Rental industry appeal targets 10,000 generators for Ukraine

12

EUROPEAN DEMOLITION ASSOCIATION NEWS

EDA welcomes Brazilian demolition and earthworks company, DEMOLIDORA FBI

Construction 2050 Alliance discusses objectives for 2023

FACHTAGUNG ABBRUCH returns

14 NATIONAL DEMOLITION ASSOCIATION NEWS

Bringing down the halls – a coordinated effort

Cutting ties – a bridge too far

18 FEATURE

Brokk showcases latest demolition robots in 2023

20

DEMOLITION DISCUSSION With Mark Taylor of Metro Deconstruction Services

26 CASE STUDY

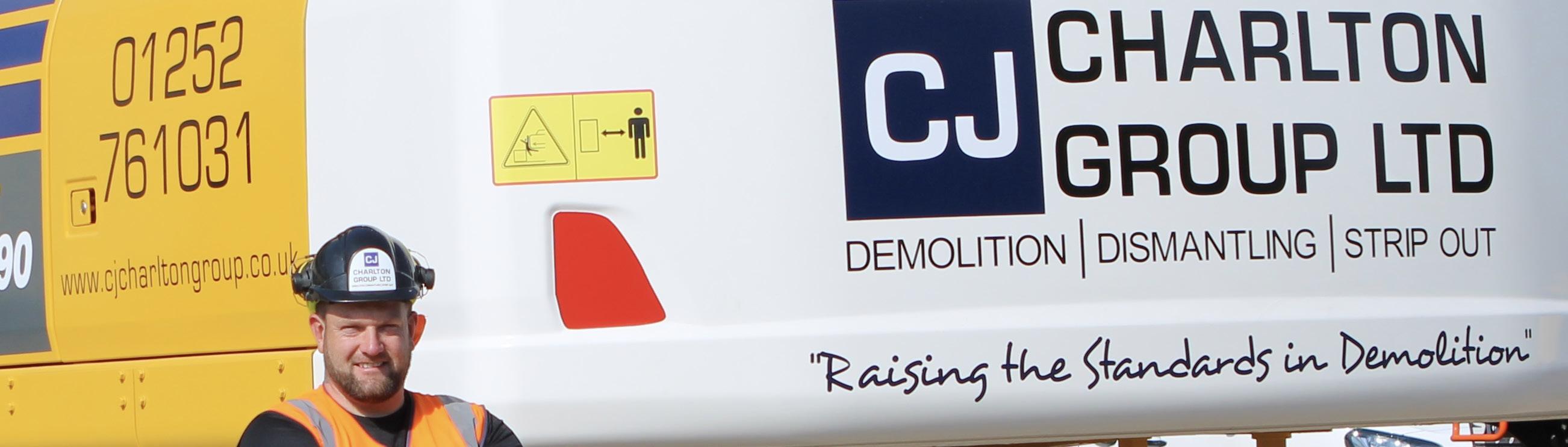

Three’s company, by Paul Argent

28 EVENTS

Demolition Hub reports back from World of Concrete 2023

CONEXPO-CON/AGG 2023: Focusing on the next level of sustainability in construction

Sold out Executive Hire Show has all-star lineup:

• UK debut for Bobcat E19e electric excavator

• Compact JCB loadall set to make mighty impact

• SANY makes its return

demolitionhub.com 70 4 | DemolitionHUB Magazine

20 CONTENTS

26

50 INTERVIEW

Over and out: We speak to William Crooks, outgoing President of the NFDC

52 CASE STUDY

Breaking the bank, by Paul Argent

56 ATTACHMENT FEATURE

Rotar RSS range X LINE, provided by Worsley Plant

New MBI Eagle III shear range, provided by Inmalo

ACDE®Europe ASG-series rotating demolition and sorting grapple

Promove compact light and medium breaker range, provided by TDL

CMB demolition/selector grab attachments

LaBounty attachments, provided by BPH Attachments

VTN PLUS line

Epiroc DP 1820

ACDE®Europe selector grabs, provided by MH Equipment

DCC concrete crusher range, provided by Mutley Plant

Montabert V7000 hydraulic breaker

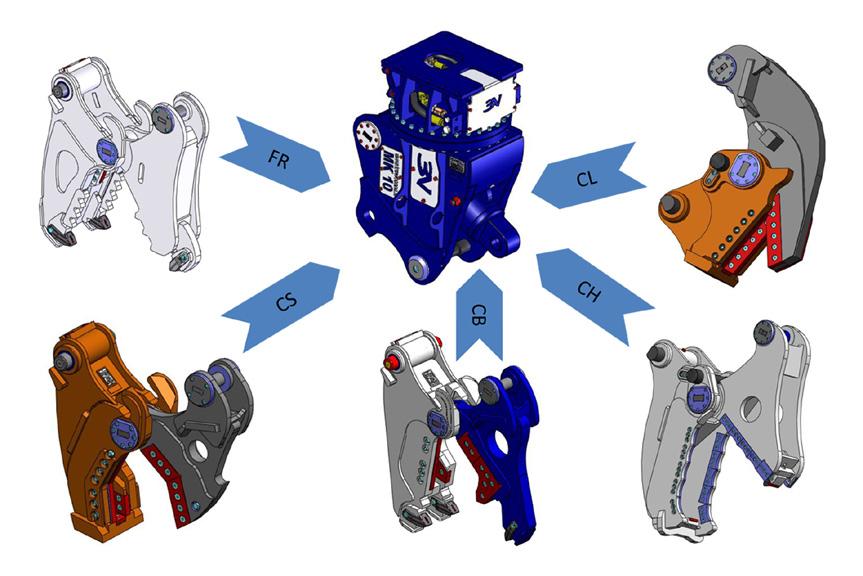

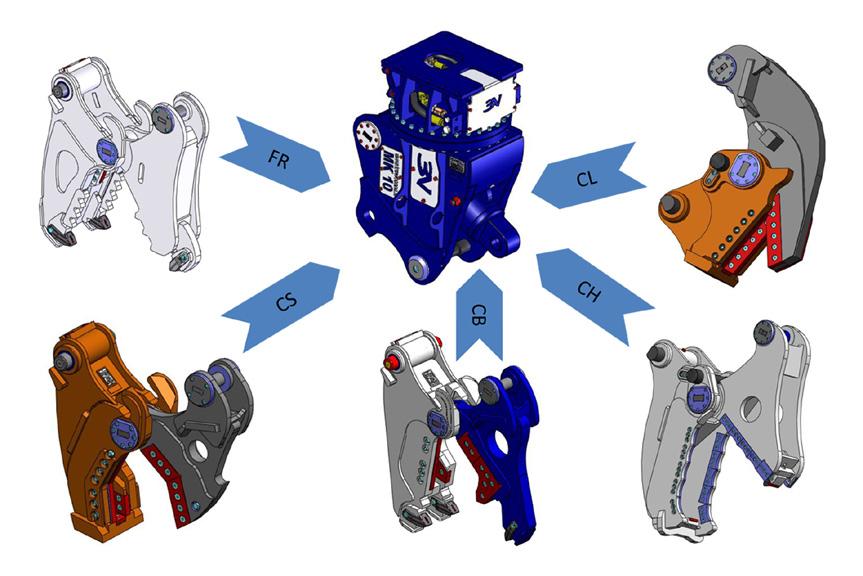

Trevi Benne MK Series, provided by Robustrack Steelwrist SQ-concept

76 CASE STUDY

Raising to the power of V, by Paul Argent

80

INDUSTRY

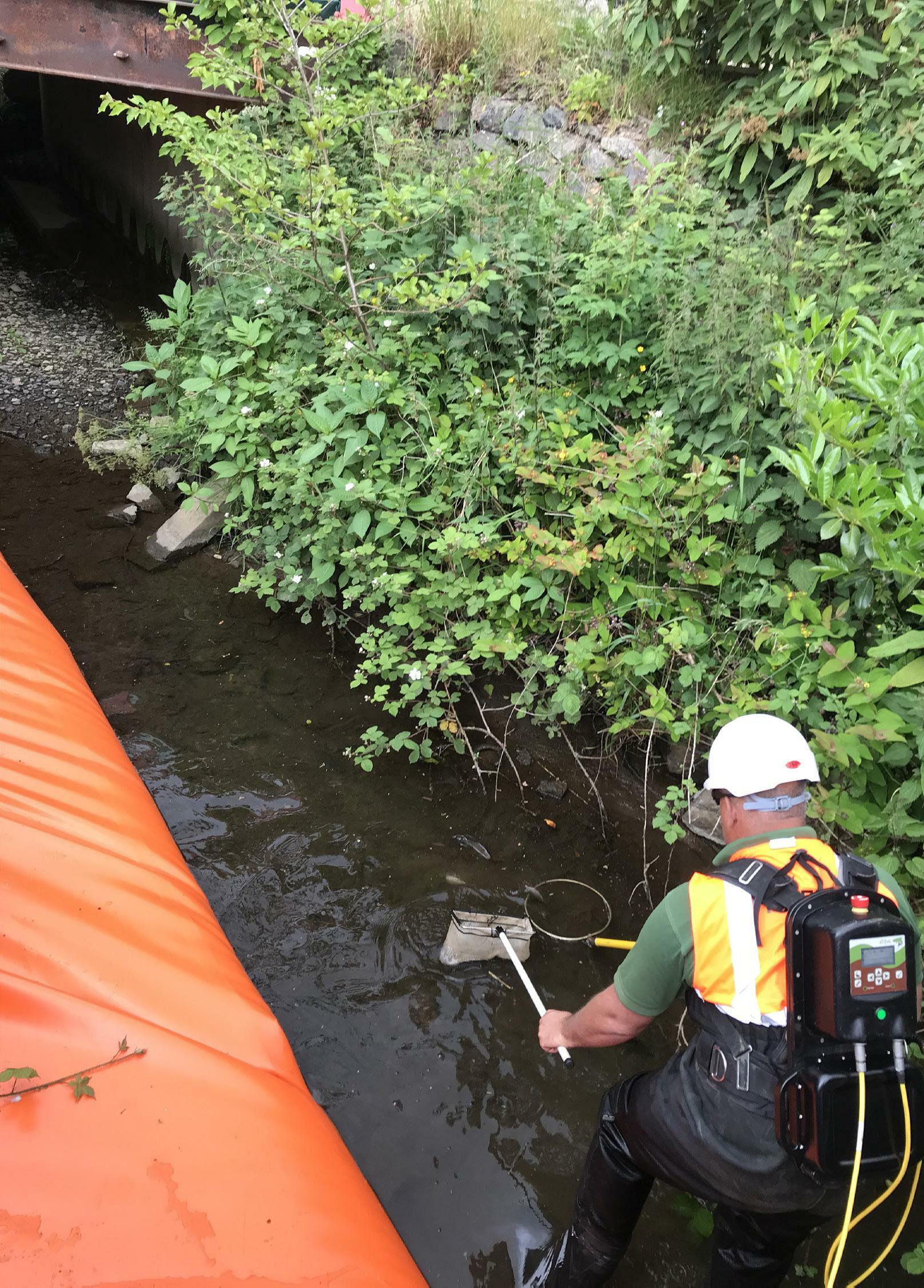

Cawarden triumphs at International Green Apple Environment Awards

What to consider when choosing a jaw crusher as your primary crusher

Indoor atomised dust control creates safer workplaces

Red Rhino brings distributor, Russells on board

Rye Group achieves carbon neutral status after switch to HVO Green D+

SMT GB officially appointed Unicontrol distributor in Great Britain

JCB power systems crushing it for Powerscreen

98

OPINION

Terry Lloyd

Richard Dolman

demolitionhub.com Magazine | 5 Industry leaders in design and manufacture of bespoke excavator equipment and modifications Kocurek Excavators Ltd. 24 Arkwright Road Hadleigh Road Ind Est, Ipswich, Suffolk IP2 0UB t: +44 (0) 1473 217477 e: sales@kocurek.co.uk www.kocurek.com ALWAYS IN REACH

Hyundai Doosan Infracore reveals new brand for construction equipment: DEVELON

Hyundai Doosan Infracore (HDI) is replacing the DOOSAN brand on its construction equipment and introducing its new brand named DEVELON. The change takes place a year and a half since August 2021 when HDI became a subsidiary of HD Hyundai, with the new DEVELON decal now to be used on HDI’s construction equipment.

DEVELON is a combination of the words develop and onwards. The new brand name conveys the direction of HDI to move onwards to the future through innovation and its intention to relentlessly change the world with innovative products and solutions.

HDI has planned the launch of the new brand since it became a subsidiary of HD Hyundai in August 2021. It plans to take a leap forward to becoming a global top-tier player in the construction equipment industry with the launch of the new brand.

Cho Young-cheul, CEO of HDI said: “Our three

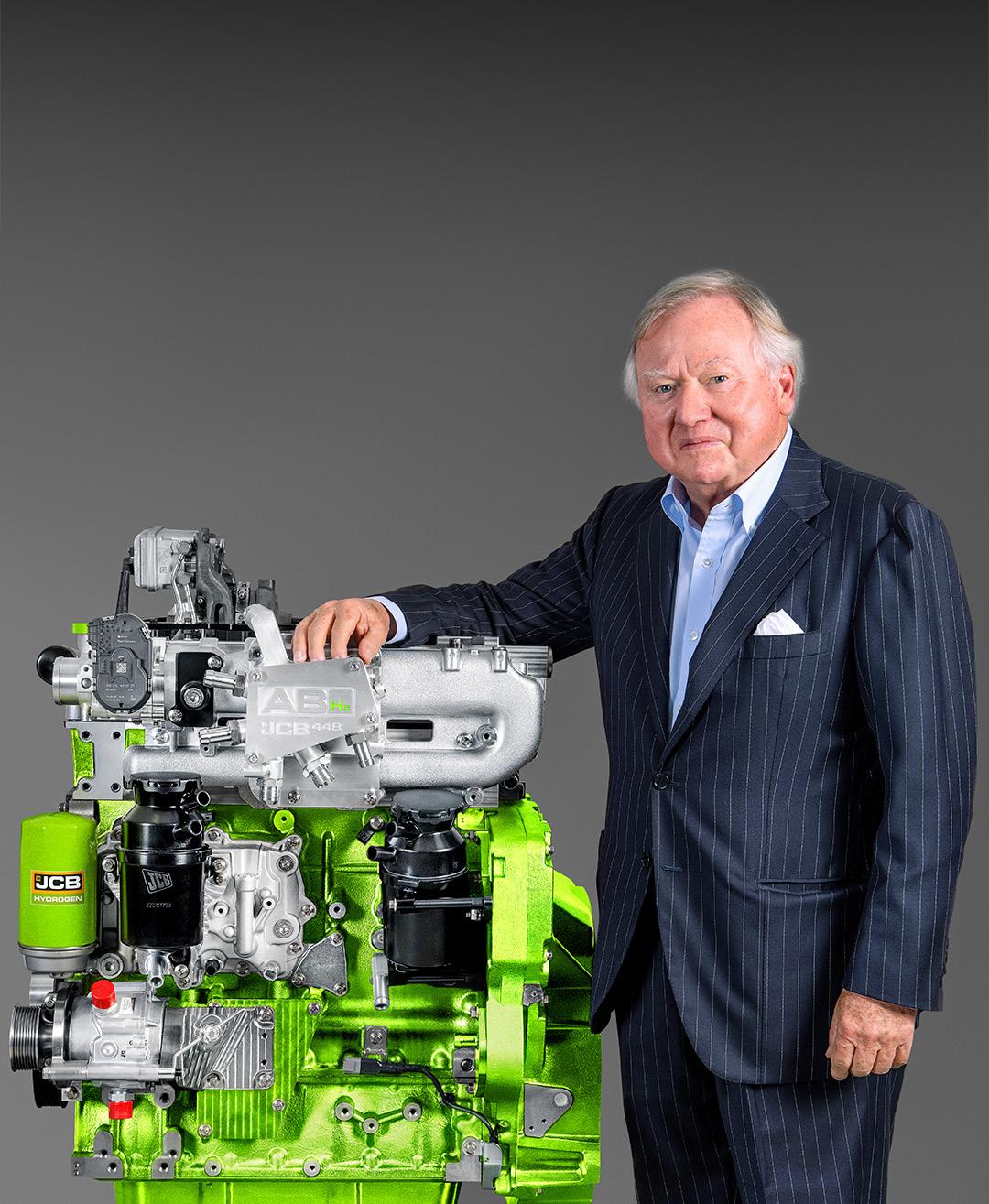

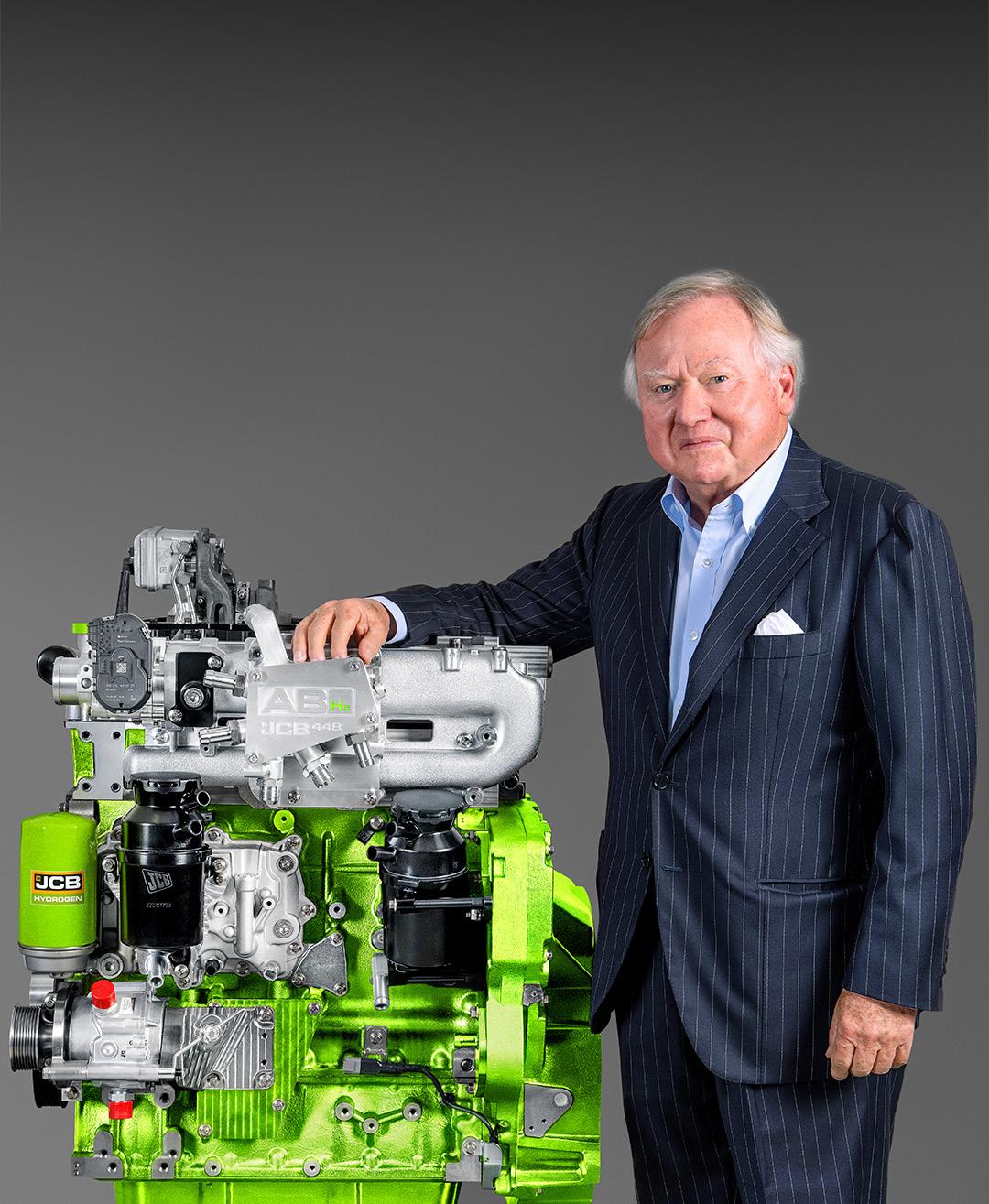

JCB’S hydrogen technology set for international debut

construction equipment businesses have already solidified their status as one of the key business pillars of HD Hyundai and have built an unwavering foundation for achieving performance targets and creating synergistic effects among them. Amid the rapidly changing global economic environment DEVELON will lead the future market of electrification and automation to spur growth and continue to be a brand of choice for our customers.”

HDI plans to introduce a more detailed brand story and vision by releasing a ‘New Brand Showcase’ through social media by the end of February. It will also unveil equipment with the new brand name DEVELON at CONEXPOCON/AGG 2023, which will be held in Las Vegas in the US this coming March.

JCB is set to showcase its superefficient hydrogen combustion technology on the international stage with a debut in North America. The wraps will come off JCB’s brand new hydrogen combustion engine – the company’s zero-carbon emissions solution for construction and agricultural equipment – at March’s Conexpo 2023 show in Las Vegas as part of the International Fluid Power Exposition (IFPE).

JCB Chairman Lord Bamford is leading the project to develop JCB’s hydrogen technology. He said: “The JCB engineering team has made enormous strides in a short space of time to develop a hydrogen internal combustion engine and it already powers a JCB prototype backhoe loader and a loadall telescopic hander. As the first construction equipment company to develop a fully working combustion engine fuelled by hydrogen, I’m delighted we are now able to present this technology on the international stage.”

Leading the way in environmental, social and governance (ESG) for the construction equipment sector, JCB has been responsible for a series of industry innovations on its ‘Road to Zero’.

news NEWS

“Move onwards to the future with innovation”

demolitionhub.com 6 | DemolitionHUB Magazine

JCB developed the world’s first battery-electric mini excavator and has been at the forefront of electric technology development to meet customers’ demands for zero-carbon products with its E-TECH range. Today JCB has the largest electric lineup available in the construction industry and the company’s expertise in this sector will also be on show at the exhibition.

JCB’s commitment to reducing emissions goes back almost 25 years and its latest diesel engines have already delivered a 97% reduction in NOx emissions since 1999 and a 98% reduction in particulates. Today JCB’s diesel-powered machines also emit 50% less CO2 compared with those manufactured in 2010. JCB’s clean diesel engine technology will also be showcased on the stand in Las Vegas.

Kubota (Europe) launches online ‘Kubota Group Solutions Hub’

Kubota has launched an exciting online communication website called Kubota Group Solutions Hub. This new platform, found at www.kubota-group.eu, is a joint initiative out of the European Kubota Organisation (KHE), bringing innovative customer solutions from the various brands under the Kubota Group umbrella, such as Kubota, Great Plains, Vicon, Kverneland, Fede and ROC.

How should we address the great challenges of our time? Can we shape a better future together?

Kubota puts high focus on the development of innovative solutions that meet our sustainable goals and mission: For Earth, For Life.

The Kubota Group Solutions Hub brings various stories about customer solutions with technologies that enable customers to successfully overcome challenges and pain points, under the themes of

Innovations, Sustainability, Connectivity, Automation and Efficiency.

Each story describes the challenge faced, the solution provided from each brand, along with videos and customer testimonials. Moreover, at the conclusion of each story, there is a description of how these solutions specifically contribute towards the achievement of the United Nations’ Sustainable Development Goals (SDGs).

Visitors can discover various stories shared by Kubota’s Tractor, Construction and Engine divisions, as well as from Fede, Kverneland Group (Kverneland, Vicon and ROC) and Great Plains Manufacturing. This new platform also enables the various Kubota Group companies to progressively ramp up communications towards key industry events later this year like the next AGRITECHNICA that will take place from 12 to 18 November 2023 in Hannover, Germany.

news demolitionhub.com DemolitionHUB Magazine | 7

YouGov poll: Construction firms failing to support workers through cost-ofliving crisis

Construction industry workers are being failed by their employers, who are offering some of the lowest levels of mental health and wellbeing support to staff across the entire economy, a survey of 3,000 companies and employees has revealed.

Despite there being a high demand for support – to help them through the cost-of-living crisis and for issues such as stress and anxiety – people working in the industry appear to be among the poorest served by bosses, according to the YouGov poll.

A little more than a third of construction businesses (37%) said they regarded improving staff morale as their responsibility, while most saw attracting and retaining talent and improving productivity as their main priority.

The online poll of 3,000 British employers and employees, commissioned by welltech company Frog Systems, also revealed that one in ten construction businesses said they spent nothing at all on mental health and wellness support for their workforces, with a further 18% spending £100 or less, peremployee-per-year.

Construction workers received among the lowest levels of support across a range of areas, the findings reveal. Just 19% of employees said they had access to an employee assistance programme (EAP), compared with 42% of staff in IT and telecoms and 52% in finance

and accounting.

Just 13% said their firm had employer supported volunteering – compared with 35% in IT and telecoms and 45% in finance and accounting – while only 18% were offered life insurance and 24% private medical care.

This compared with higher proportions in other industries; for example, 25% of manufacturing workers said they were offered life insurance by their employer.

Just two per cent of construction workers said they felt confident about going to their boss if they had a problem in their personal life or with their finances, while only one per cent would talk to a work colleague. More people said they would search the internet before going to their line manager with an issue.

The survey follows the recent publication of another report by the Joseph Rowntree Foundation, which showed worrying levels of in-work poverty.

It said employers should be doing more to ease the pressure on staff facing financial difficulties, including offering flexible working and more secure shifts, creating a compassionate workplace culture, and signposting employees to specialist support.

Marcus Herbert, head of wellbeing at the British Safety Council, said: “Employers who don’t invest in employee wellbeing may be missing out on the productivity

benefits it can provide.

“SMEs are more likely to suffer if an employee, who is crucial to their operation, has to take time off work to deal with stress or because they have a repetitive strain injury.”

Mental health adviser and former CBI Deputy Director General, Henrietta Jowitt, said: “Wellbeing is an output – it is the result of a whole range of inputs that support your people. It is not a package, off the shelf.

“If you don’t understand your colleagues’ needs and look after their wellbeing, so that they feel they are safe, belong and are supported in a way that works for them, they will neither stay nor produce their best work.”

The online poll showed that while demand for mental health and wellbeing services among construction workers was high –particularly for stress and anxiety and the cost-of-living crisis – a

news

Former CBI Deputy Director General, Henrietta Jowitt

demolitionhub.com 8 | DemolitionHUB Magazine

Marcus Herbert - Head of Wellbeng, BritSafe

significant number said they received little or no support from bosses. The services that were provided were not always of value to them.

While more than one in four businesses (28%) said they ran wellbeing workshops, those were used by just four per cent of staff. More than one in three businesses (34%) said they offered support from a mental health first aid trainer, but this was taken up by just three per cent of employees.

And while 29% and 23% of employers said they provided EAPs and wellbeing apps respectively, both solutions were used by just three per cent of staff.

Phil Worms, CEO of Frog Systems, said the report showed a gulf in trust in the workplace around wellbeing support for employees.

“While many employers seem to understand the emotional and physical challenges being faced by their employees, they don’t appear to be able to provide the right wellbeing tools and information to support them.

“Solutions which are reactive, standalone, ‘tick box’, not trusted, or do not provide sufficient insight will not enable the deployment of early intervention and support strategies.

“By listening to, and understanding what employees need, companies can start to build stronger, more empathetic and productive work environments. Access to wellbeing support should not be a lottery or a privilege.”

Rubble Master awards Red Knight 6 full UK dealership

Rubble Master, manufacturer of world leading impact crushers and scalping and sizing screens has installed Red Knight 6 as its sole UK distributor. Rubble Master has taken the decision to reorganise its UK dealer network and the change sees RK6 take on the whole of the UK having previously focused on the Midlands, East Anglia, the south and south-west.

Previously, Rubble Master had been working with two dealers in the UK, but with a new streamlined approach the company will move to just one dealer. Red Knight 6 has worked with Rubble Master for the past six years and will be bringing experienced sales and service teams to support customers in the region.

Paul Donnelly, Managing Director of Red Knight 6 Ltd said: “We have worked tirelessly for six years to ensure the market not only understands the quality of the Rubble Master machines, but also has support from our market leading sales, service and spare parts teams. We are delighted to be given the opportunity to work across the rest of the UK and continue to grow the excellence of the Rubble Master offering.”

Frog Systems CEO, Phil Worms

Frog Systems CEO, Phil Worms

news demolitionhub.com DemolitionHUB Magazine | 9

Rental industry appeal targets

10,000 generators for Ukraine

impassioned plea to an emergency conference in Paris, Zelensky described the latest Russian bombardment as “blackout and energy terror”, creating a desperate situation that has left as many as 12 million Ukrainians without power to heat their homes in the depths of winter.

Generators are already saving lives

Ninety-five generators have already been sent directly from the factory to Ukraine as part of the Alliance Christmas appeal. This was thanks to a very generous donation of £25,000 from Gary McArdle, President of Rail Services in the US.

These generators are already saving lives at the main hospital in Kharkiv in north-east Ukraine. They have been put to use in the Institutes of Neurology, Psychiatry and Narcology, where dedicated staff treat both military and civilian casualties from the war.

Ukraine needs you

As freezing winter temperatures grip eastern Europe, the humanitarian need in Ukraine is more urgent than ever. In response, following several highly successful campaigns in 2022, the Plant and Hire Aid Alliance has launched its latest appeal, Power to Ukraine, in association with Rotary International. The ambitious appeal aims to send no less than 10,000 desperately needed generators to Ukraine.

Why are generators needed?

Following repeated attacks on the power grid and other critical infrastructure, many Ukrainians get just three hours of electricity per day, not nearly enough to combat temperatures that rarely rise above freezing. Winter temperatures in the capital, Kyiv, can reach as low as -4°C in the daytime and -11°C at night, putting thousands of lives at risk.

Ukraine’s President Zelensky said that generators had become

By donating to the Power to Ukraine appeal, you or your company can make a real difference, providing life saving winter heating to a desperate Ukrainian family, or essential power to a medical facility like those above.

“A donation of £270 is enough to buy and send a generator to Ukraine, to help keep these families warm,” said Jeremy Fish, the CEO of Ardent Hire, which set up the Alliance. “This includes the elderly, as well as small children and

news

demolitionhub.com 10 | DemolitionHUB Magazine

recently experienced the misery of bitterly cold weather, but just imagine going through that with no power for heating. It doesn’t bear thinking about.

“Working with Rotary International, we’re appealing to colleagues across the UK and around the world to join us to help reach this ambitious target of 10,000 generators.”

Targeted help

To ensure that the generators reach those in the greatest need, the Alliance is working with the 69

and confirm that they have only been provided directly to those intended.

“This not only maximises the impact of the campaign, but also gives our generous donors the reassurance that their contribution is making a real difference,” said Jeremy Fish.

The alliance has also created a website where the aid workers will register each recipient including the details of the family or group, along with a declaration that the generator is being used as intended.

The people of Ukraine need all the help they can get to stay warm this winter. If you would like to help, either as an individual or as a company, you can rest assured that every penny of your donation will go directly towards generator orders for immediate dispatch. There are no paid staff and no overheads or other such costs. If you are located in the UK, Gift Aid will add a further 25% to your donation at no extra cost to you.

The Ukrainian people are literally freezing to death right now, so your donation, however large or small, will genuinely save lives.

To find out more, and to make your donation, please visit aid-alliance.com, email ukraine@ ardenthire.com or donate by visiting: www.justgiving.com/ fundraising/ukraine-gensets.

news demolitionhub.com DemolitionHUB Magazine | 11

European Demolition Association welcomes FBI DEMOLIDORA

FBI DEMOLIDORA has been in the market since 1986 and since then has become one of the most renowned demolition and earthworks companies in Brazil.

Currently, FBI DEMOLIDORA’s greatest concern is meeting client demands, as well as safety requirements and other demands that regulate the industry.

Another of its major concerns has long been practicing actions of commitment with the environment. The conscious

execution of the work, correct and documented disposal and transport of materials according to their classification and the use of recycled material in its deposits for commercialisation are just a few examples of its commitment to the cause.

One of its most recognised works was the work it did in Nova Grecia (Osasco) in 2016.

FACHTAGUNG ABBRUCH returns

The German Demolition Association (DA) is holding the FACHTAGUNG ABBRUCH 2023 (Demolition Conference) at the STATION-Berlin again. This former railway station and postal depot, now an industrial monument and venue particularly suited to the demolition industry.

More than 1,100 participants and 127 exhibitors attended the last annual meeting of European players in demolition and dismantling in 2020. After the inevitable pause during the pandemic, expectations for 2023 are high.

Highlights of the programme include “Sustainable solutions in NRW – Use of recycled building materials and reuse of building components” as well as “Demolition of KSC Stadium”. Other interesting lectures such as “Complex use of different demolition methods for 250,000 t of reinforced concrete” and “Selected best practices of controlled blasting of buildings” contribute to the proven mix of topics, as do various other specialist lectures, such as “Technical rules (TV) demolition works 2023 – New edition of a successful rulebook” and many more.

As a main attraction Dr Hajo Schumacher, the well-known journalist and publicist, will give the keynote speech on the topic – “Demolition, change, awakening – Govern in uncertain times”. Simultaneous translation into English will be offered throughout the event.

Construction 2050 Alliance discusses objectives for 2023

On 13 January members of the EU Construction 2050 Alliance took stock of its achievements since its launch three years ago, while discussing objectives for 2023 and beyond.

The Construction 2050 Alliance comprises more than 50 European organisations, including the EDA, representing the actors of the built environment working together to advance the needs and priorities of the wider construction and

built-environment sector at the European level.

The alliance was established to coordinate common political messages of the construction value chain and raise the political importance of the sector, which is crucial to deliver on the European Union’s ambitions.

Demolition Hub is the media partner for the European Demolition Association

Demolition Hub is the media partner for the European Demolition Association

demolitionhub.com 12 | DemolitionHUB Magazine

A new level of performance.

United. Inspired.

Demolition pulverisers - a new level of performance

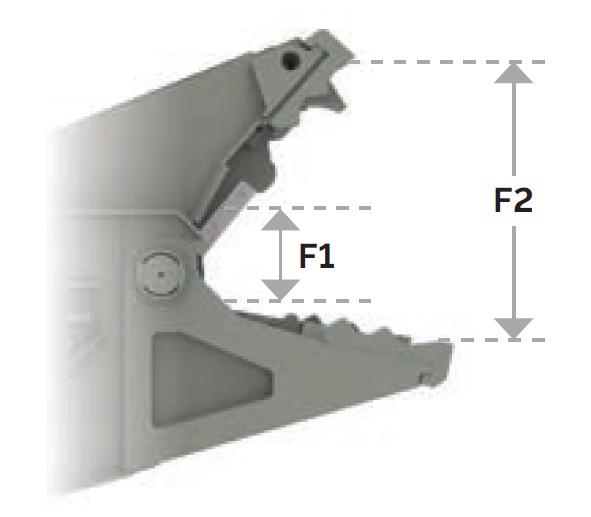

The straight design of Epiroc’s Demolition Pulverisers makes them ideal for primary demolition and secondary reduction of non-reinforced and reinforced concrete structures.

Ideal for smaller jobsites, Epiroc’s robust Demolition Pulverisers are highly versatile, making light work of both demolition tasks and secondary breaking of demolition debris. With the introduction of the DP 1820, the range now includes options for all carriers between 15 - 35 tons.

Epiroc UK & Ireland Ltd Email : hat.uk@epiroc.com Tel : 07971 650455 www.epiroc.com

A coordinated effort by

Alexa Schlosser

Alexa Schlosser

D.H. Griffin Wrecking Company Inc. (DHG) began discussions with the University of Alabama (UA) for the demolition of the Tutwiler Residence Hall after successfully imploding its sister dorm, Rose Towers, on 4 July, 2012. The Tutwiler was a 13-storey, 270,000-square-foot (25,000 m3), concrete women’s residence hall on the university campus in Tuscaloosa, Alabama.

unoccupied time for the university to make upgrades.

UA began advertising for bids in November 2021 and requested all interested bidders to submit a prequalification packet by the end of that month. A week later, the university notified six potential bidders of their successful prequalification. The university held a pre-bid meeting in mid-December,

immediately began discussions with the university on planning for the set implosion date of 4 July, 2022. Due to classes beginning in early August, the debris from this implosion would have to be removed by 30 July. Students were set to move out of the 13-storey dorm on 7 May. DHG and UA agreed to use the following week for first responder training in the building.

It’s not often a city’s police and fire department can use a structure of this size for live training, so when the opportunity arose, the university’s police department led a week-long training exercise for first responders from across the state until 15 May. The university also used this time to salvage numerous items from the building that could be reused around campus.

With only 50 days until a scheduled implosion date, DHG had to prepare the building for demolition. Before that could begin, a massive asbestos abatement job had to take place. DHG contracted Winter Environmental to take on this task. Before asbestos abatement could begin, DHG and Winter had to remove all furniture and trash left behind after the 1,029 residents moved out.

During the first three days on the site, 45 23 m3 dumpers were filled with trash and debris from the building. As the abatement work progressed, numerous areas with additional asbestos were found in the building that were not on the original asbestos survey.

Winter completed the asbestos abatement in 31 days with the help of up to 105 workers on the site at its maximum capacity.

It was built in 1966 to house freshmen female students, as it did until 2022. Over the years, it also housed many different summer camp participants, not leaving much

and bids were to be turned in on 18 January 2022, when the lowest bidder was awarded the contract.

As it was the successful low bidder on the Tutwiler project, DHG

DHG and Winter coordinated the abatement schedule to allow preparation for the building implosion to begin approximately two weeks after abatement began.

demolitionhub.com 14 | DemolitionHUB Magazine

“DHG has also recycled over 600 tonnes of metals from this project, resulting in 97% of the construction and demolition debris being diverted from disposal in a landfill”

DHG contracted Dykon Explosive Demolition as the blasting contractor for this project. With the guidance of professional engineer Paul Rose, a plan was developed where five floors of the building would be completely stripped out and loaded with explosives. DHG began stripping out floors 1, 2, 4, 7 and 10 to prep them for drilling.

The construction of the Tutwiler Residence Hall was concrete with six columns in the core and shear walls down each of the three wings of the building. Rose engineered a plan to remove sections of the shear walls to make columns that could be drilled and loaded with explosives. DHG used a crane to lift compact utility loaders to each of the four upper floors to complete this task.

With the help of Dykon, more than 1,600 holes were drilled in the structure and 225 kg of explosives

Article: https://bit.ly/3Y3k7Pc

were loaded for the implosion.

Since the residence hall was located near sorority houses, a new dorm, parking deck, private residences and a retail centre, many protective measures had to be put into place.

Approximately 225 metres of 10-m high blast curtains were installed on three sides of the hall to prevent debris and dust from leaving the project site. HVAC units on the surrounding structures had to be shut down and covered with plastic to prevent dust intake. The protective measures all had to be installed on 3 July due to the high temperatures in Tuscaloosa during the month of July.

At 7 am on 4 July, 2022, the hall was successfully imploded. After initial inspection by DHG and Dykon, the all clear was given and DHG crews immediately began removing

all the protective measures that had been put in place and cleaning the surrounding streets so they could be reopened to the public.

DHG began removing the concrete and debris from the site on 5 July and successfully removed 1,112 loads of rubble from the site in 10 days, totaling 32,100 tonnes of mostly concrete debris.

Removal of foundations and other site improvements were successfully removed by 30 July, allowing the site restoration contractor to begin their work on the project site. All concrete removed from the site was hauled to another location on the UA campus, where it was crushed for reuse on other campus projects. DHG has also recycled over 600 tonnes of metals from the project, resulting in 97% of the construction and demolition debris from this project being diverted from disposal in a landfill.

Demolition Hub is a proud supporter of the National Demolition Association and credit to this article goes to the NDA. Thank you for working with us.

demolitionhub.com DemolitionHUB Magazine | 15

In the heart of the city

by Monica Roselli

For more than 40 years, a pedestrian bridge in Philadelphia’s health care epicentre connected the Perelman Center for Advanced Medicine (PCAM) to the Hospital of the University of Pennsylvania (HUP). Extending over 33rd Street and 34th Street, the bridge was built in the 1970s, followed by a temporary addition that extended over Convention Boulevard in 2015.

But just like the health care industry, the construction industry is ever evolving, and when new buildings and walkways were added to the campus, the pedestrian bridge that once allowed thousands to get from one building to the other became obsolete.

Soon after Penn Medicine opened its Penn First Hospital, which included the addition of three new pedestrian bridges and an underground tunnel that connected the Penn Medicine properties together, NDA member Geppert Bros. Inc. began work on removing the old bridge.

Bringing a local level of proficiency and comfortability to demolition work performed in the Philadelphia region, the L.F. Driscoll/Balfour Beatty Construction joint venture (JV) contracted with Geppert Bros. to determine the best demolition plan of action.

“Thackray Crane provided the team with possible crane locations and capacities,” says Pasquale Marconi, Geppert Bros. Vice President. “From there, we worked with structural engineer, Wing Au

and E&K Scaffolding to determine locations where the bridge would be separated and how.”

Additionally, Geppert Bros. superintendents and the project management team worked with their subcontractors to determine the best way to remove the bridge under the restrictions set forth by the medical campus’s property managers.

“Throughout the entire process, it was made known that we were guests in the area,” Marconi says. “Other than nightly lane closures and weekend street/sidewalk closures, one of the goals of the project was to minimise the impact to the surrounding healthcare community, which included cleaning up and readying surrounding areas for both pedestrian and vehicular traffic.”

After several months of extensive planning and meetings, it was determined that the bridge would be removed in seven separate sections over the course of two long weekends. In December 2021, demolition work began. To reduce the weight of the bridge sections, Geppert Bros. removed all the architectural components. Anything that didn’t contribute to their stability was removed. Interior fit-out, exterior curtain wall, roof structure and floor structure were all removed, leaving only the structural steel skeleton.

“The first weekend consisted of picking and removing the three bridge sections that crossed over Convention Boulevard,” says Adam

Budin, Geppert Bros. Project Manager. “The featured pick of the first weekend was the longest (90 feet in length) and heaviest (63,000 pounds) section that was partially tucked under the PCAM building with about one foot (30 cm) of clearance between the top of the bridge steel and the PCAM building structure.

“This section was being picked past its original design splice; our engineer designed and Geppert fabricated stiffeners to be attached to the splice to keep the section from buckling when picked. The centre of gravity was determined, and the pick points were all verified by our engineer. Once freed up, the section remained 100% level and did not touch the PCAM overhang.”

On the second weekend, the remaining four bridge sections were picked and removed. These sections were lighter, as they were from the original HUP bridge, they were only 10 feet (three metres) away from the new connector bridge that had been constructed to take its place. After the removal of the bridge was complete, the crew had to remove the five concrete support piers that held up the bridge’s two structures.

“Because of the construction and location of the piers, it was determined that the piers would need to be saw-cut to be removed in lieu of using large hydraulic hammers that would cause both extensive noise and vibration,” Budin says.

“The piers were large concrete structures, and due to the sheer size of them, they needed to be cut into sections and rigged with a crane into a truck for removal. Each cut and pick needed to be planned with both the crane capacity and truck capacity in mind.”

Working exclusively at night during February and March, Geppert’s subcontractor, Chesco

demolitionhub.com 16 | DemolitionHUB Magazine

Coring & Cutting Inc., provided over 45 wire cuts, and Thackray Crane performed 50 crane picks so that the piers could be safely removed. Overall, 500 tonnes of concrete piers were saw-cut, picked and taken off-site.

After four months, Geppert Bros. wrapped up demolition in March 2022. The job was considered a great success, with the work completed on schedule, within budget, with zero loss time accidents and minimal disruptions to the surrounding health care institutional neighbourhood.

Demolition Hub is a proud supporter of the National Demolition Association and credit to this article goes to the NDA. Thank you for working with us

Article: https://bit.ly/3Y9XcSA

demolitionhub.com DemolitionHUB Magazine | 17

Brokk showcases latest demolition robots in 2023

Brokk, the world’s leading manufacturer of remotecontrolled demolition machines, is showing off its latest products in 2023

Brokk 70

The Brokk 70, the smallest electric robot in the Brokk range is just 880 mm tall and 600 mm wide, fitting through narrow doorways and into tight spaces, making it ideal for interior demolition applications. With a base weight of just 560 kg, it can be transported on an ordinary passenger elevator, making it ideal for top-down demolition projects in urban areas.

As with all Brokk machines, the Brokk 70 offers superior reach and movement. The three-part arm extends to 3.2 m vertically and 2.7 m horizontally.

Outfitted with a BHB 105 hydraulic breaker with 159 joules of hitting power, the Brokk 70 can be equipped with advanced features, including water spray to suppress dust and air cooling for hot environments. The machine also pairs seamlessly with concrete crushers, drum cutters, grapples, scoop buckets and more.

The Brokk 70 incorporates the SmartConcept™ system, which ensures improved performance and uptime. SmartConcept consists of three features:

SmartPower™, SmartDesign™ and SmartRemote™. SmartPower senses when the power supply is poor or faulty then compensates before damage to components occurs, allowing contractors to use the machine with generators or unreliable power sources. With 70% fewer cables, rugged components, LED headlights and easily accessible grease points and hydraulic hoses, SmartDesign extends machine life and provides unprecedented ease of maintenance. An ergonomic remote control — the SmartRemote — incorporates adjustable straps, intuitive controls and professional-grade radio technology with almost 300 m of wireless working range.

feature demolitionhub.com 18 | DemolitionHUB Magazine

Brokk 70

Brokk 900

The Brokk 900 is the world’s largest and most powerful demolition robot. This demolition tool builds upon and improves on the success of its predecessor, taking a big step up in power and performance.

The design and engineering of the machine is reinforced, overall power is increased and the new breaker is more powerful, which means its operation is even more precise. All this comes with almost no increase in size and weight.

Like its smaller brother, the Brokk 900 uses SmartPower™ technology to improve the powertrain. The Brokk 900 delivers a 25% increase in output power. At the same time, reliability and machine uptime meets the new industry benchmark for demolition robots set by the introduction of Brokk SmartPower™ a few years ago.

The Brokk 900 comes with the option of two different hydraulic breakers:

• BHB 1500: A 1,500 kg breaker for the hardest materials. Paired with the hydraulic power of the Brokk 900, this delivers a phenomenal punch in each blow and is excellent for breaking hard rock,

• BHB 1300: A slightly lighter breaker for maximum productivity in heavy concrete demolition. The higher blow frequency and more nimble size of this breaker maximise the production rate.

The Brokk 900 comes with the option of electric or diesel powertrain. The electric motor offers the lowest cost of operation and is the most environmentally friendly option. However, the new diesel engine is not far behind,

My Brokk – the new online service platform

My Brokk is a comprehensive online support platform that offers multiple services in a single resource. The portal offers two new online services — a library of manuals and other technical documents along with a Webshop for ordering parts and attachments — as well as access to Brokk Connect, Brokk’s robot and fleet management system.

The new portal makes it easier than ever for Brokk customers to access essential services any time of day, from any device or location.

Through My Brokk, Brokk owners have online access to equipment manuals, technical data, CE markings and diagrams for the first time. The information is available through My Brokk’s Documents module, allowing a customer to find and download accurate, up-todate materials at any time. The documentation is available for all current Brokk models and

meeting the toughest emissions standards that exist today. It is compliant with both the USA standard EPA Tier 4 Final and the EU Stage V standard.

Finally, serviceability has also stepped up a notch for the Brokk 900. Even though the machine weighs more than 11 t, it is designed to be serviced by one person, with no heavy lifting needed.

attachments, as well as older models.

The Webshop also offers online purchasing for the first time, providing faster order processing and shortened delivery times. Users can view and order a full range of Brokk original spare parts and attachments, such as extra hydraulic breakers. Users can easily locate the correct parts for their robots and see prices listed in their local currency. The Webshop also includes parts for older Brokk models.

Brokk Connect also continues to evolve, providing real-time updates on machine run time, upcoming maintenance needs and machine location. Wi-Fi is new and optional in addition to the mobile network connection. If a robot loses connection to the mobile network, offline mode is activated. The offline mode saves machine data to be uploaded to the mobile network when the connection is reestablished.

feature demolitionhub.com DemolitionHUB Magazine | 19

Brokk 900

DEMOLITION DISCUSSION

Interviewee: Mark Taylor

Role: Managing Director

Company: Metro Deconstruction Services

“I’m a family man, running a business to the best of my ability, while always trying to provide for my family, having a smile on my face, and some fun along the way”

QHow did you start out in the industry and what attracted you to it?

I grew up with my father running a construction business and he later moved into demolition to start Metro. I completed my degree in project management at Southbank University, with the aim of becoming a project manager in construction. I then cut my teeth out on site with Kyle Stuart (now BAM Construction) as a trainee project manager working on several different types of interesting projects.

After knocking on my old man’s door several times and it not opening, at the age of 27 I knocked

loudly enough and he opened the door into Metro.

I was excited to transfer my understanding of construction over to demolition, and took my skills and knowledge to expand and grow Metro as a business. I took over as Managing Director at the age of 35 in 2008, with my father fully retiring from the business in 2013.

I have run the business ever since and the rest is history.

QHow did Metro start and how has it evolved in size, scope and range of services? My father started Metro pretty much as a one-man band back in 1995 after diversifying from running a house building construction business to demolition.

When I joined the business, turnover was approximately £350,000, offering minor demolition services to a select client base around the south-east of England. I looked to pull the old man into the modern day, the way forward for future demolition. I rebranded the company and started to structure and market the company to look to expand our client base and increase the size of projects that Metro undertook.

Now, 15 years later, Metro offers a wide selection of demolition services, along with environmental and remediation services. It is now a £7m company with ambitions to push forward to being a £10m business while maintaining the high level of personal services that we provide to our clients.

Interview demolitionhub.com 20 | DemolitionHUB Magazine

QTell us about your working culture. Is there a fundamental company philosophy or ethic?

My employer ethic is that I like to run a friendly, personal approach to employment. I am proud of the retention of employees that I have, with some employees being with us for over 15 years, some even starting from a labouring role and now working with me as senior management.

My aim is to ensure employees are looked after, helped and have a friendly place of work with a positive environment and modern approach to working.

Some of the aspects of the company I am proud of are the service it provides, staff retention and repeat business with clients we have long lasting personal relationships with.

We’re still a family run business. Although the old man is retired, he still very much enjoys jumping in with our delivery driver every now and again to visit our sites, still telling me what I’m doing right or wrong.

QWhat kind of projects does Metro work on most frequently? How has this developed and are there plans to develop it further?

Our bread and butter is industrial demolition where we work directly for industrial developers that we have long lasting relationships with. We have grown as a company with many of our clients as they have grown in size and project scope through professional relationships.

Over the last few years we have carried out several projects in central London involving top-down demolition, a more complex method that we are actively pushing to carry out more of.

We vary in a range of size and scope of projects to suit our clients, from small housing demolition to larger industrial sites that our client purchases.

I have a constant drive to push Metro to be a leading deconstruction contractor in the industry, and to continue to strive to this aim, while maintaining the personal relationship we have with our clients.

That is what drives me, seeing Metro carry out these complex and detailed projects to a high standard.

QWhat are the standout projects from Metro’s history? Why are they special? Did they pose any particular challenges?

Going back a few years now, my first standout project with Metro was back in 2010, when we purchased our first high-reach. This was the first larger scale project that we had completed, being a sixstorey office building in Reading town centre.

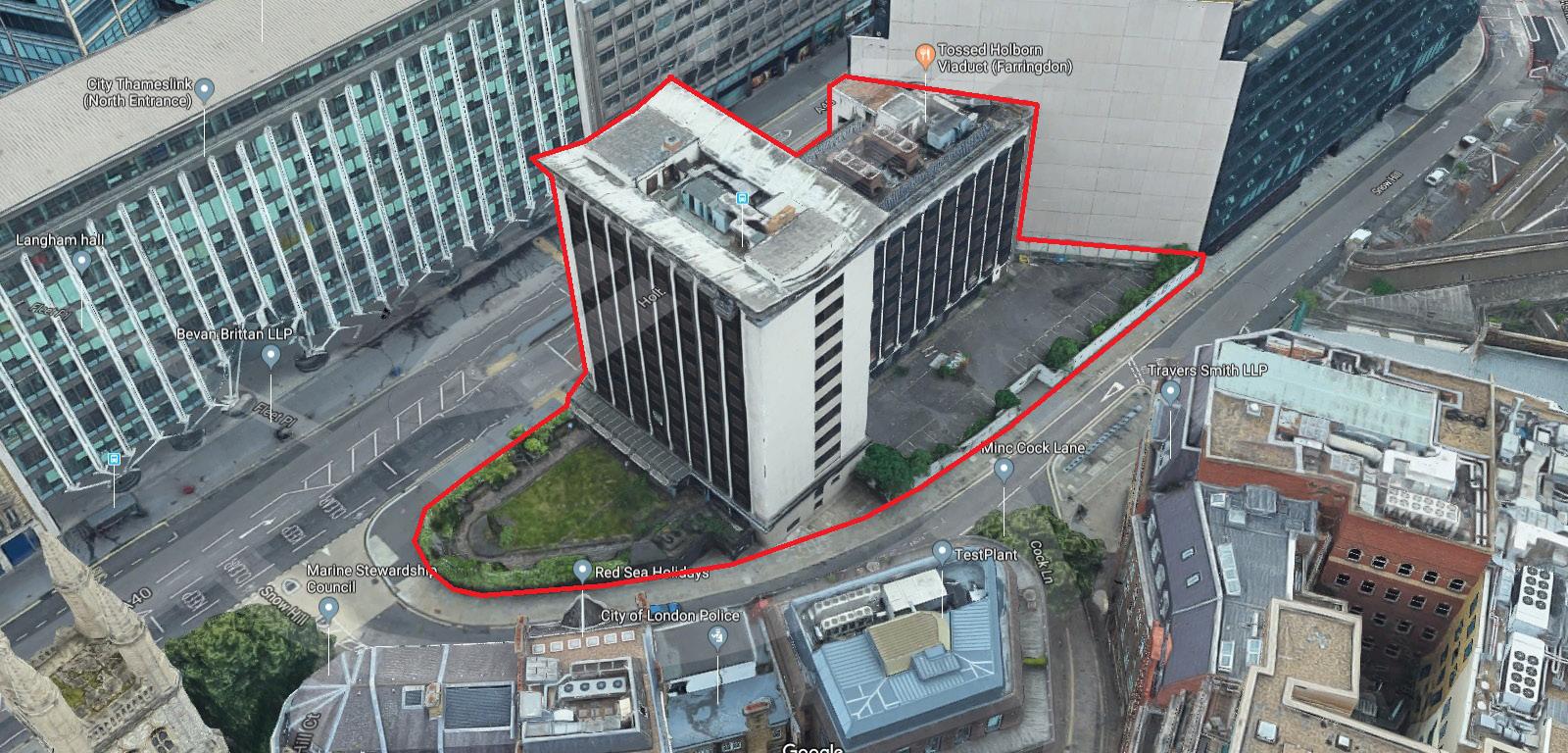

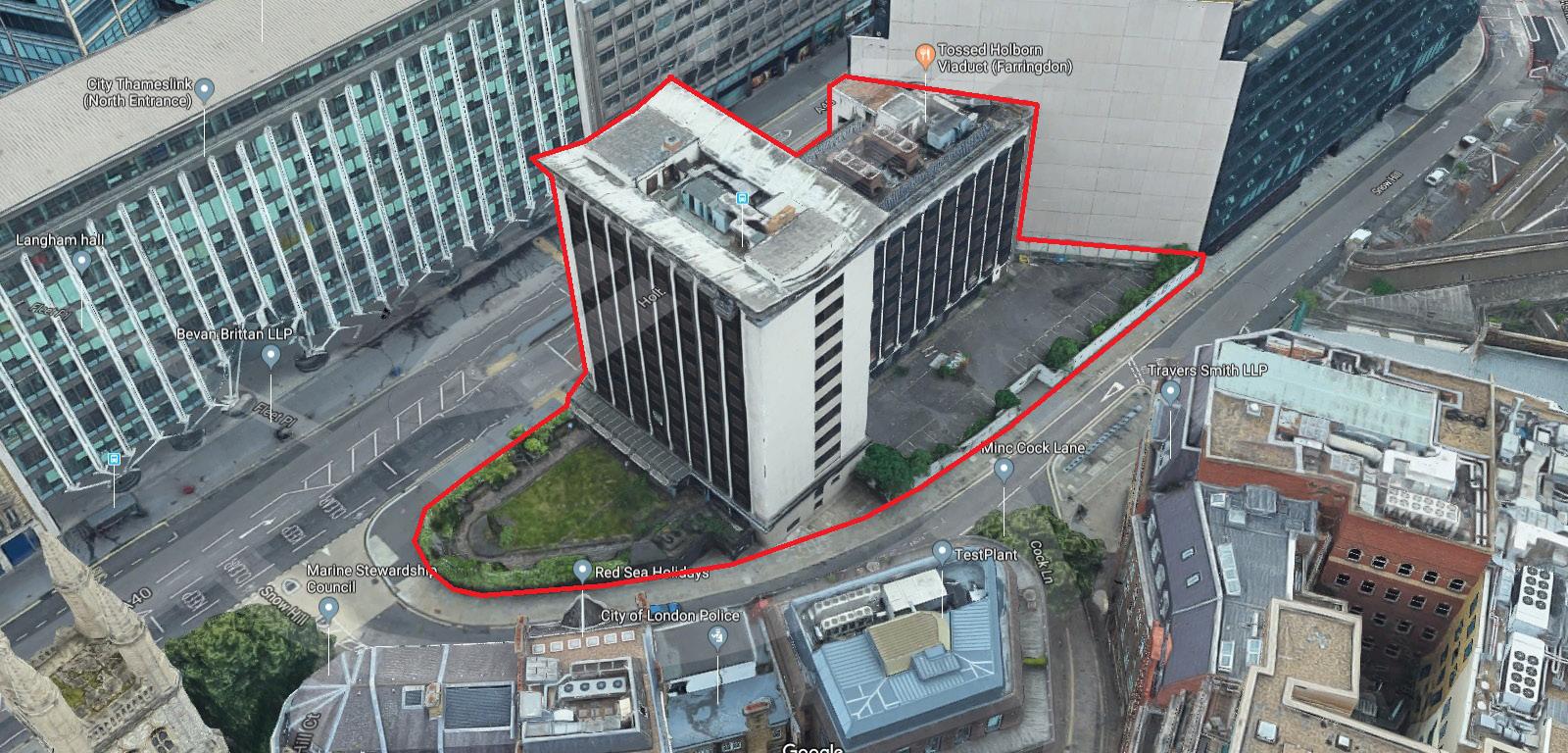

Another would be Metro’s first major project in central London, where we completed the top-down demolition of an existing 14-storey office block. This was a complex project with lots of constraints and the team carried it out professionally and safely and to our client’s requirements.

These two would be my standouts but every project that Metro undertakes has its own challenges and constraints and

Interview demolitionhub.com DemolitionHUB Magazine | 21

“Where it all began”

we have to look at each individual job on its own merit and apply our professional knowledge and approach to the project using our experience to deliver it safely and to the client’s requirements.

That is certainly one thing I love about demolition – no project is the same and every single project challenges me and my team in different ways.

QWhat makes Metro different? What are your USPs?

Our USP is that we deliver on what we say we are going to do and we offer our clients a professional service that gives them the confidence to return to Metro to deliver their project for them.

Metro prides itself on the repeat business we receive from long lasting clients that we have built up incredible relationships with over the years.

We are able to offer complete turnkey services for our clients, where acting as principal contractor throughout the demolition phase provides our clients the time needed for their construction phase planning. We deliver the demolition/ enabling phase without fuss and to a high standard, ready for smooth handover to our clients.

The relationships we have grown, allow us to do just that.

QTell us about the marketing and tendering process. How do you gain business and spread the word about your services?

We believe that we present ourselves in a clean and contemporary fashion that reflects the running of the business, with our tender returns being professionally completed to a high standard and most importantly, being returned fully compliant in accordance to all client requirements.

We pride ourselves on the presentation of our paperwork and documentation throughout all phases of a project, from estimating tender stage, all the way to the health and safety file on completion. All our documentation is branded the Metro way throughout.

In regards to marketing, Metro does not actively go looking for business, we pride ourselves on repeat business and recommendations from our existing clients. This approach has led Metro to now having an extensive client base with some of the best clients, Project Management and Quantity Surveyor companies out there in the industry today.

QTell us about any memberships or accreditations you or the company have

We are proud to have been

accredited with CHAS and SMAS for many years, ensuring the company operations are correct, safe and compliant to SSIP status.

As a company, we are heading into 2023 with many objectives regarding obtaining memberships and accreditations. To name a few, we are currently in the staging process of obtaining our ISO 14001 accreditation, with ISO45001 and ISO9001 to follow.

One of our main objectives is to implement new environmental standards across Metro, including objectives to Net Zero. Therefore, we are currently in the process of focusing on becoming members of the UKGBC (UK Green Building Council) and working with PlanetMark on our journey to Net Zero.

In addition to the above, we are working towards becoming members of the NFDC, which will introduce Metro to other professional companies, therefore opening doors to a range of additional clients we’d have the opportunity to work with.

On a more personal level, I am hoping to begin the process of obtaining my IDE membership this year.

QTell us about any apprenticeships or trainee schemes Metro has. What about the availability of labour, experienced and inexperienced? What can we do to attract young people into the industry?

We have built our team by bringing on young starters/apprentices and training them up the Metro way, resulting in those young starters now being key, experienced members of staff.

Metro continues this programme, recently enrolling one of our young apprentices on the NDTG Demolition Trailblazer Scheme, and we have recently taken on a young starter as a machine operator.

I believe that investing to entice youth into demolition is one of the

Interview demolitionhub.com 22 | DemolitionHUB Magazine

The Silvertown redevelopment project in the east end of London Image: Sky Revolutions

most important areas that we need to concentrate on, as without the new blood of employees coming through, we will not sustain the current levels of experience and knowledge within our company and the industry.

Bringing on the youth also allows us to incorporate up-to-date industry standards and new innovative work methods within Metro.

QDo you undertake any ongoing training or Continuous Professional Development?

We have a dedicated and extensive training matrix incorporating all staff training. This document works alongside individual staff training plans for qualifications, extra training and continued professional development in all areas.

I strive to ensure all my staff have the training they require available to them, so they are able to carry out their roles safely, correctly and to the best of their ability, as well as helping to push forward in their careers.”

QTell us about any engagement your company has in the community?

Metro understands that as a demolition contractor, we are first on site to represent our clients within the community. Thus, our overall approach is to engage with the community with an aim of successfully carrying out the demolition works with an overall view

that on completion they’re happy that the works have been carried out with minimal disturbance.

We incorporate this service by running community workshops per project, offering a centralised email communication process in which we can liaise directly within the local community in regard to any concerns they have in relation to our works and operations. We find that this direct engaging approach means that we can reassure the public that the works are being completed to the highest standards on behalf of our clients.

QWhat do you think responsible companies need to be doing in regard to their communities and society in general?

Purely engage with the community. Listen to them, their understanding

of the works and what you can do to make the process as painless as possible; even invite them to join in community workshops and become part of the future development in some way (if possible).

On every project, give something back to the community you have worked with. Put yourself in their shoes, and relate to their feelings on a demolition project on their doorstep.

QWhat measures is your company taking in regard to the climate crisis and sustainability?

Metro wants to be at the forefront of tackling the climate crisis and to assist our clients in demonstrating our approach to each individual demolition project that minimises carbon output from the demolition works process.

Interview demolitionhub.com DemolitionHUB Magazine | 23

Top down demolition of Citiscape House at Holborn viaduct Image: Google

We’re driving towards our Net Zero objectives and beginning to work with UKGBC and commitment to Race to Zero.

We are continually improving processes and implementing new ones with the help of ISO standards and PlanetMark expertise. We are hoping to become part of a UKGBC task project in 2023 in assisting with the measurement and reporting of embodied carbon across the construction industry.

QHow do you see the demolition industry developing over the next few years?

I believe that the demolition industry needs to drive itself and not be driven by others, so to embrace new technologies, invest in staff and embrace the drive to net zero achievements, demonstrating that the demolition industry as a whole to be leaders within the construction sector. Acting, rather than reacting.

The biggest development in my opinion is the use of fuel and moving to HVO across the industry, significantly reducing carbon emissions. For those able to use HVO fuel instead of diesel, it will be the game changer for environmental factors and that all important race to zero.

QDo you have any notable projects in progress or in planning?

Metro is currently working on the largest project our company has undertaken, Silvertown, London – due to be completed in April this year.

Our recent tender pipeline has grown and was the greatest number received in Oct/Nov/Dec 2022, varied in type, size and complexity. We are looking forward to finalising these with our clients, carrying out and completing in 2023.

QHow do you envisage Metro in 5 to 10 years?

AND FINALLY...

Who is your favourite artist? Paul Weller – back in the Style Council days

What do you do for fun? Spend time with my family, playing golf and watching my eldest son Mini Challenge racing

What’s your ideal weekend? A spa weekend with my wife, or watching my son race his mini

What would you do for a company excursion, money no object?

Las Vegas

What’s your bucket list activity? To drive a British Touring Car. I think I can drive, but I really can’t.

Q

What are the biggest technological developments you have seen in the industry and what do you envisage will be the future game changers?

One would be the progression of the design of machines and attachments to be able to operate more efficiently and be more environmentally friendly.

Metro will continue to grow in a controlled manner to maintain the professional services we provide to our clients, while joining professional industry bodies and pushing to improve our service to be the best it can be. At the same time, we will continue to invest in modern machinery to carry out our works, all while having a bit of fun along the way”

What’s your favourite cuisine? Thai food

What’s your tipple of choice? Single malt Irish over ice

Winter, spring, summer or autumn?

Summer

Be or do? Which one represents you best? Be

demolitionhub.com Interview 24 | DemolitionHUB Magazine

Continued investment in plant and equipment

Transforming your excavator. And your business.

The Rototilt® tiltrotator transforms your excavator into a flexible tool carrier. This opens the way for new types of jobs, and maximise both safety and productivity. The whole tiltrotator family is packed with innovative technologies and ingenious design solutions that make your work safer, easier and more profitable. With Rototilt® you get a tiltrotator that fits your specific need, whether you require dexterity and precision, or muscles and capacity.

Rototilt® makes it possible.

Open-S

The open industry standard for fully automatic quick couplers. Read more at www.opens.org

Our tiltrotators

• R1 | 1.5-3.5 tonnes

• R2 | 3–6.5 tonnes

• R3 | 6-12 tonnes

• R4 | 10-16 tonnes

• R5 | 14-19 tonnes

• R6 | 15-24 tonnes

• R8 | 23-32 tonnes

Rototilt Ltd | Sales & Service 0800 772 3355 | info.uk@rototilt.com | rototilt.com

Three’s company by Paul

Argent

Many in the industry will know the Collins name for its position as one of the leading earthworks suppliers in the UK, but alongside this division, the company has been successfully undertaking a variety of demolition projects across the UK and Ireland for more than six years.

The company had undertaken demolition works alongside its other earthmoving and remediation contracting works for several years but in 2016 it decided to form a dedicated demolition arm.

Headed up by experienced demolition man Scott Craddock, Collins Demolition works both hand in hand with the rest of the Collins group undertaking site clearance work ahead of large redevelopment projects, and undertaking its own demolition works for a growing list of select clients.

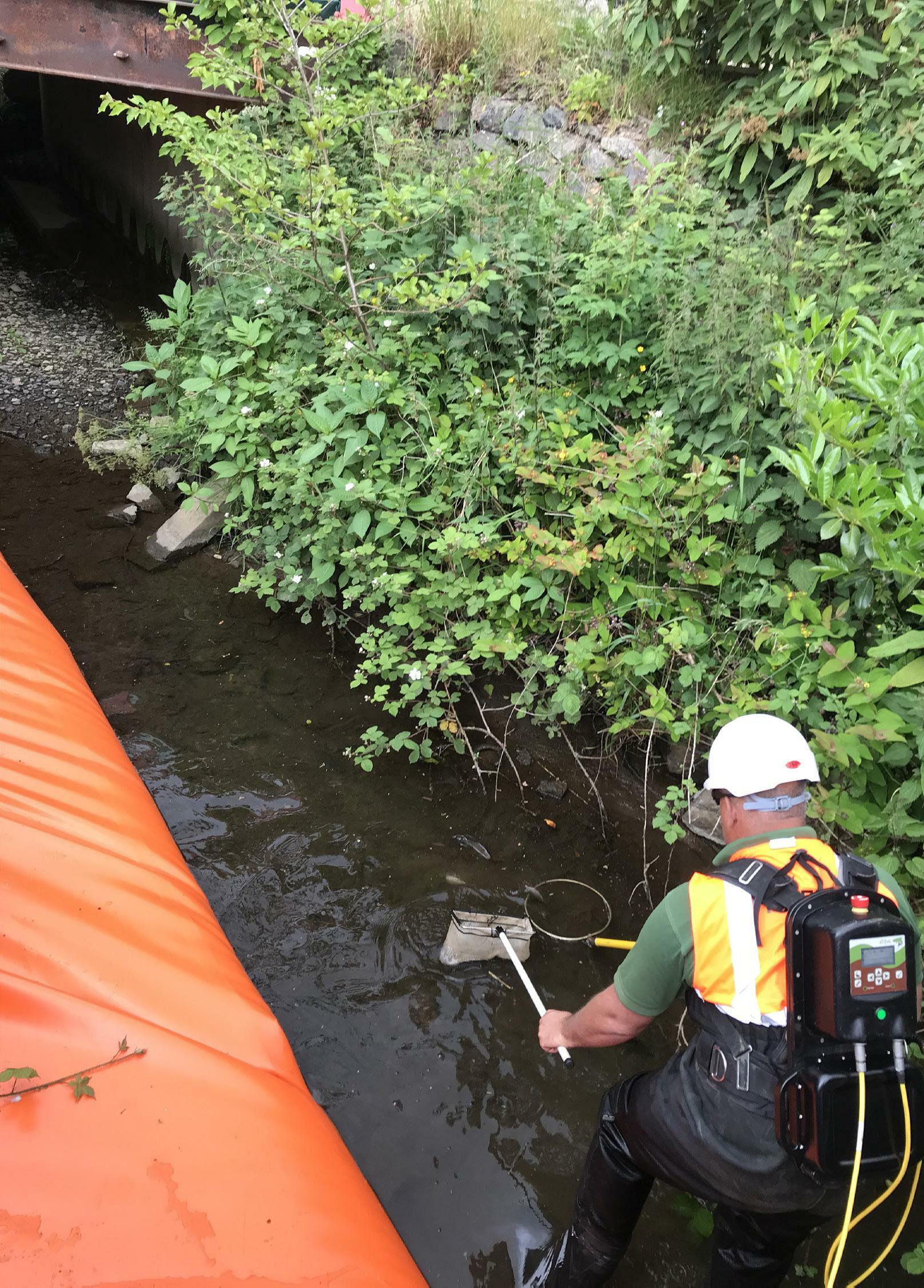

The formation of an in-house asbestos removal team with Cat A&B trained teams has added to

the highly trained and experienced demolition teams. To add further flexibility and the ability to offer clients a full package of abatement, demolition and remediation services, the company also offers a comprehensive bio-remediation service to clean contaminated ground of hydrocarbon impacted soils, asbestos and knotweed.

While the demolition arm possesses its own dedicated demolition spec machinery, it is in the envious position within such a large group where it has the ability to call on a wide range of high specification equipment should the job require additional machinery.

We caught up with some of the Collins team on a large project at Stockley Park near Heathrow Airport where they had been given an ambitious 16-week programme to demolish three, three-storey office blocks that were once home to the global pharmaceutical giant GSK.

The three office blocks had been constructed in the mid-1980s and strangely, featured a semisubmerged ground floor requiring workers to climb a flight of stairs to enter on the middle floor of each block. The large, open plan layout was constructed around a central glass-ceilinged atrium. Constructed from a steel frame with in-situ concrete floors, like many newer office buildings, the ceiling spaces were packed with mechanical and electrical items such as cable trays, air conditioning ducts and the like.

With a tight programme to demolish the three structures and remove the foundations, work was

demolitionhub.com 26 | DemolitionHUB Magazine

Case study

continuing on the three blocks simultaneously. The first block had already been demolished and the material taken away for recycling, leaving a pair of Volvo excavators breaking out the remaining slab and foundations before stockpiling ready for a crusher to come in and process to a 6f2 material for backfilling.

The central building was halfway through the demolition phase, with several Volvo excavators working from one end of the large building taking it down bay by bay.

An EC250E and EC380E were tasked with clearing away the downed material before sorting it and loading into an almost constant

stream of bulk tippers removing the material from site. A 75 t Volvo EC700C equipped with an OilQuick coupler and VTN scrap shear was being used as the frontline machine for the demolition works, quickly slicing through the steel columns and beams and tearing out the tangle of M&E still fixed to the concrete slabs.

Site Supervisor Chris Lythgoe said: “The EC700 and our EC750 both have the OilQuick couplers as they and our EC380 high reach are seen as our frontline demolition machines. The smaller machines are there to assist the bigger units by quickly and effectively clearing up around them. It works very well on some of the larger jobs we have undertaken.”

The third and final building was in the process of being stripped out during Demolition Hub’s visit. Walking around with Site Foreman John Leyland, he explained that they had managed to find an outlet for the masses of computer flooring that was spread throughout the three floors of each building.

“It would be very time consuming for us to strip the timber from each tile just to recycle a small quantity of metal. We have to strip and sort the good tiles out and pallet them up but will end up shipping at least four artic’ loads out for reuse instead of potentially sending them off site

as waste or, at best, low grade, low value recycling.”

With ample space around the building, the soft strip team use segregated areas to throw out different materials where it is gathered up by a machine with selector grab and disposed of into the relevant skips. John said: “Despite the building being constructed in the 80s, we have found several asbestos gaskets in the pipework to the roof mounted plant rooms. We weren’t expecting these due to the relatively young age of the building.”

The demolition works have proved to provide very little in the way of issues for the experienced site team at Stockley. “We do have a live data cable running right through the centre of the site, which feeds the Skyport business at the nearby airport. Initially we thought it was the SkySports VAR cable feeding Stockley Park up the road and were tempted to put a bucket through it,” John said.

Once the demolition works have been completed Collins will undertake a shallow excavation of the site before reinstating with the crushed material from the buildings. The site will then be handed over to the development team to construct a large warehouse complex serving the ever-growing distribution industry.

demolitionhub.com Case study DemolitionHUB Magazine | 27

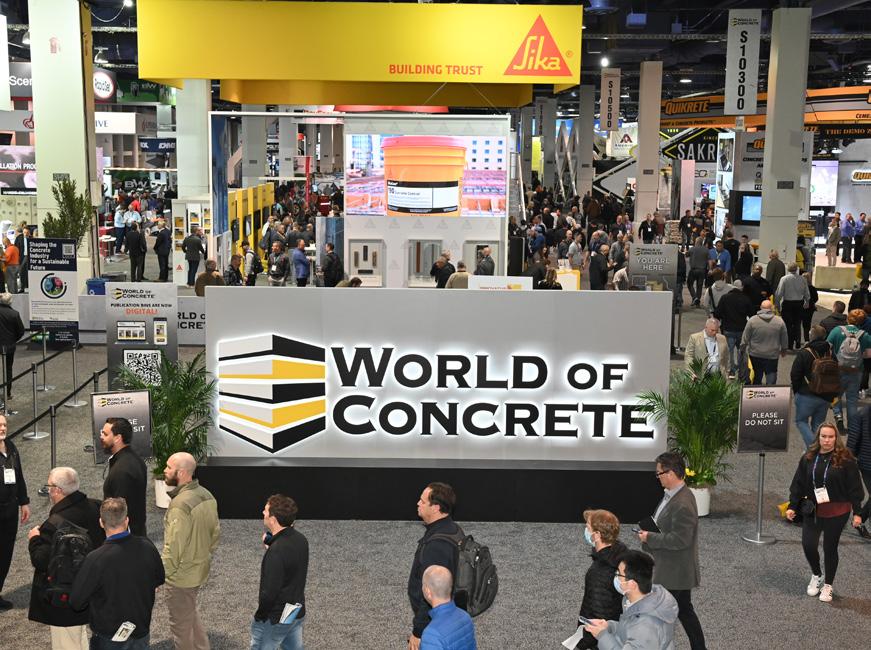

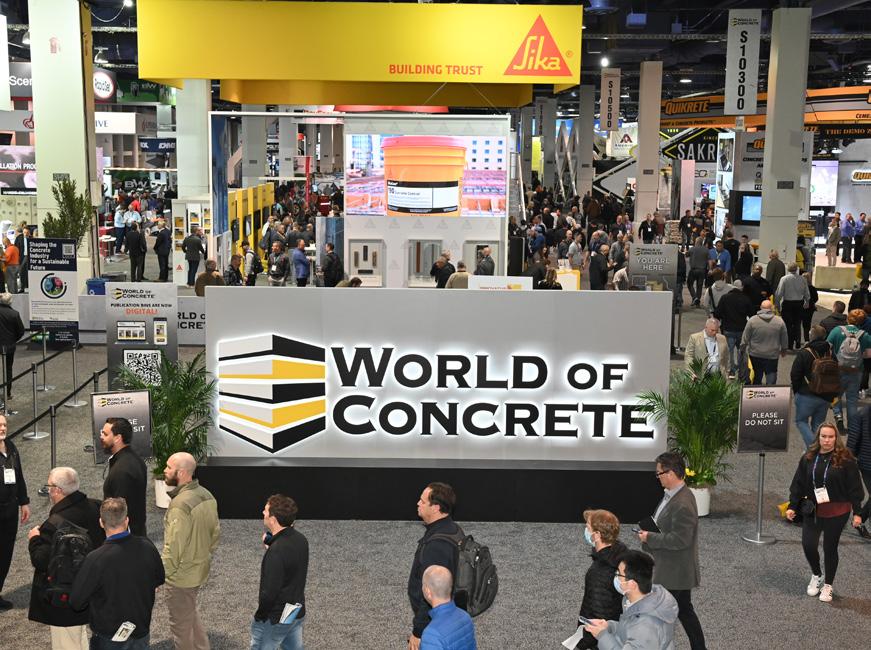

The annual World of Concrete event was back with a bang in January for its 49th staging. I was keen to meet with friends old and new in the fields of demolition, construction and of course concrete in a familiar setting while locating the best new cutting tech

I am a creature of habit and being that way inclined it was comforting to be back in Las Vegas. Being old hands at this our fifth World of Concrete (and fifth as media partners), as well as the third stay at our familiar hotel, all allows me (pre-drinks) to easily navigate the 2,000ish steps and do the familiar wander into the massive Las Vegas Convention Center.

As we navigated that walk every morning, I have to state what a sight it is to see just how the World of Concrete event takes over the city of Las Vegas. Hotels lit up in neon advertising the event, dolled up coaches ferrying some of the many thousands of visitors whizz by and the signposts start from way out, pushing all of Nevada to the once-ayear king of concrete event.

As we walked and talked admiring the organisation of the event before even getting there, our conversation was almost solely on planning exactly who we were going to see and in what order.

Then on arrival immediately

tearing up said plans. We would be caught off guard by a friendly tap on the shoulder from a vendor we have met in the past or the sight and sound of a live demo taking place and like a moth to a flame my attention goes to where the big and loud equipment is on display.

Being press we were thankfully able to bypass the crowds, and what crowds they were, spiralling around the inside of the conference centre, showcasing just what a must-attend this event is if you have a penchant for concrete.

The inside halls are a mass of stands with familiar house brands as well as emerging technology, and you can see our inside tour video on our sister site. Outside is where it all gets in your face, with the ability to try out cutting tools yourself, or failing that watch an expert or indeed a world champion.

We came armed this time with a little more than hard copies of the mag and business cards.

This year in our arsenal were some tasty new AV purchases

including speakers and microphones, meaning we were able to have a good go at using WoC to debut our harder launch into video in Las Vegas and for subsequent shows back on home soil in Coventry for the Executive Hire Show later this month and then again back to the very same venue in Vegas for ConExpo.

We have a few videos winging their way to our YouTube channel now from the event. Search Demolition Hub TV on YouTube and huge thanks to all who participated. As ever, although we’re from the same continent, meeting Alessia from MB Crusher takes a trip to the west side of the United States for our annual catch up, laugh and interview on camera.

We will continue to support the event with video and post event press releases and what the vendors, organiers and visitors have to say. We look forward to continuing our media partnership for the 2024 event, next year celebrating 50 years as one of the

events demolitionhub.com 28 | DemolitionHUB Magazine

Demolition Hub’s

Ben

Chambers reports back from Sin City.

world’s best construction shows. My LinkedIn and emails tend to go quite barmy this time of the year as it is one of the few opportunities for me to actually get face-to-face and meet our North American readers and those that supply to this industry.

WHO ATTENDS WOC?

More than 60,000 industry professionals from all around the world, representing all segments of the construction industry: commercial contractors, concrete contractors, concrete pumpers, construction managers, dealers/ distributors, decorative concrete contractors, designers and specifiers, general contractors, block/segmental unit producers masonry contractors, architects, engineers, block producers, ready mix producers, rental equipment centres, repair contractors, residential contractors, speciality concrete contractors, precast, pipe and block producers, precast/ prestressed producers and more.

A full list of exhibitors can be found at www.worldofconcrete.com

FUTURE DATES:

WOC 2024: 23-25 January;

Education: 22-25 January

WOC 2025: 21-23 January;

Education: 20-23 January

events demolitionhub.com DemolitionHUB Magazine | 29

14 – 18 March, 2023

We are CONEXPO virgins. I had sorted everything with the organisers for us to appear in 2020, but as we all know, events have a habit of impeding the best laid plans of mice and men, never more so than in the year 2020 worldwide.

So now, with a very strong magazine and media brand behind us, we look forward to reporting back in April’s Demolition Hub and way before then on the socials and YouTube.

Ben Chambers

Ben Chambers

CONEXPO-CON/ AGG 2023: Focusing on the next level of sustainability in construction

With construction technology around sustainability significantly advancing in recent years, CONEXPO-CON/AGG 2023 is already set to have the biggest focus on sustainability since the show began in 1948.

CONEXPO-CON/AGG Show Director Dana Wuesthoff said:

“The construction industry and CONEXPO-CON/AGG are evolving in many ways to adapt and showcase sustainable technologies,

products and practices supporting a more sustainable world. More than ever, show attendees will see sustainability in action, from electric and hydrogen powered construction equipment, to more recyclable materials and waste reduction opportunities, to changes we’re making to the show to better support sustainability.”

Here’s how CONEXPO-CON/ AGG is putting sustainability at the forefront.

One of the biggest sustainability efforts on the part of CONEXPO-CON/AGG directly is a newly announced partnership between the show and the Arbor Day Foundation. CONEXPO-CON/AGG and the Arbor Day Foundation are working towards planting 130,000 trees in forests of greatest need, one for every show registrant.

Additionally, CONEXPOCON/AGG exhibitors and attendees can contribute to the Arbor Day Foundation’s funds, allowing them to further their goal of involving themselves in its mission of planting, nurturing and celebrating trees around the globe.

Each dollar contributed to the Arbor Day Foundation

events demolitionhub.com 30 | DemolitionHUB Magazine

The Arbor Day Foundation Partnership

Sustainable Tech on Display

Across the show floor, sustainable technologies, products and practices will be on display. Here is a sample of what will be featured:

Volvo Construction Equipment has already announced they will bring several electric and autonomous pieces to their stand in the Festival Lot, including their EC230 electric excavator pilot, their Zeux autonomous concept wheel loader, and their HX04 prototype hydrogen articulated hauler.

Just steps away, Caterpillar (Booth F-9127) will bring four battery electric machines as well as a series of prototype batteries for off-road equipment ranging from 48600 volts.

will result in one tree being planted in a forest in need.

“The Arbor Day Foundation is excited to be the official nonprofit sustainability partner of CONEXPO-CON/AGG 2023,” said Becca Hebbard, Corporate Partnerships Manager for the Arbor Day Foundation. “As one of the world’s most trusted and experienced tree planting organisations, we work with organisations of all sizes to help them meet their corporate sustainability, ESG, and CSR goals. Whether you’re looking to help protect biodiversity, contribute to wildfire recovery, bring the benefits of trees to a community in need, or add verified forestry carbon credits to your emissions reduction strategy, the Arbor Day Foundation is uniquely positioned to connect you with meaningful projects all over the world.”

CONEXPO-CON/AGG attendees can also expect:

• Aerial work platform specialists Skyjack (Booth F-9427) will have their new SJ120 E on hand, a zero-emissions mast lift with a 30% improvement in duty cycle.

• Asphalt recycling equipment from Pavement Recyclers LLC (Booth S-5966) and VSS Macropaver (Booth C-32073) use different processes for recycling asphalt, keeping it out of landfill. Concrete contractors can also check out Holcim’s (Booth C-20405) ECOPact concrete that can eliminate carbon emissions entirely in some instances.

• Construction pros who want to maximise their energy efficiency can explore Kubota’s V3307 MicroHybrid engine (Booth S-84415) to install in existing equipment, saving fuel with the attachments they use, like Rototilt’s (Booth F-8338) Rototilt Control system.

• With Rapid Barrier Systems’ (Booth S-61515) water-inflatable barriers, contractors who work in disaster recovery could save up to 600 sandbags per barrier and not have to worry about disposal should they become contaminated, not to mention the fuel needed to haul them on and off site.

• Demolition contractors wanting to reduce waste and preserve still-usable material can see Aquajet’s Hydrodemolition robots at the Brokk booth (Booth C-20349), which can help remove damaged concrete while leaving still-good concrete and rebar reinforcement intact.

• Compaction is another place where low-efficiency engines can be replaced with battery

operated equipment, according to Wacker Neuson (Booth W-43501), who will be bringing a number of electric tools including, for the first time, batterypowered, reversible plates.

• Small engine specialists Briggs & Stratton will bring their Vanguard (Booth D-1033) brand’s swappable lithium-ion batteries to CONEXPO-CON/AGG for the first time, available for attendees to test out. And for construction pros who want to make sure their batteries are in proper working condition, Redline Detection (Booth N-10532) is bringing their battery coolant and leak detector.

• When it comes to equipment, diesel or electric-powered, the environmental impact is more than just emissions, but lubricants. B3C Fuel Solutions (Booth S-61545) is bringing products to the show to help contractors eliminate waste by restoring emulsified/damaged oil and make sure lubricant that does find its way to the environment is nontoxic and biodegradable.

• Waste water is a major issue, including when construction equipment needs cleaning. Waste2Water (Booth S-64429) is bringing solutions to CONEXPOCON/AGG to help equipment operators keep waste and chemical-laden water out of the environment.

• Once attendees have all their sustainable equipment picked out and ready, AT&T’s Equipment and Machinery Solutions team (Booth N-12700) is bringing a solution to help track their actual Scope 1 emissions versus their targets.

events demolitionhub.com DemolitionHUB Magazine | 31

Sustainability education

CONEXPO-CON/AGG has given sustainability its own education track in its seminar offerings, now with thirteen sessions dedicated to the topic. Those sessions tackle subjects like reducing the carbon footprint of concrete, getting and managing electric construction equipment, asphalt and concrete recycling, carbon neutrality, and a “Sustainability 101” session for attendees just now starting their sustainability journey.

But construction pros

CONEXPO-CON/AGG and IFPE are committed to reducing the environmental impact of the show. This includes partnering with vendors that are dedicated to sustainable practices and reducing waste, helping exhibitors choose more sustainable options, and measuring our total 2023 environmental impact to identify future improvements.

The sustainability efforts at CONEXPO-CON/AGG reflect the focus on sustainability within the entire construction industry. Many construction

don’t have to wait until they get to Las Vegas to start their sustainability education. The CONEXPO-CON/AGG Podcast has several episodes dedicated to the topic, including:

• Episode 84: “Mining technology improves sustainability, operator comfort, productivity”

• Episode 89: “Advancing cement & concrete sustainability with connected devices”

• Episode 116: “Salvaging the industry”

companies have realised that their clients are demanding sustainable building practices more and more with each project, and contractors themselves are recognising the benefits of moving to more sustainable equipment and practices.

That’s why CONEXPO-CON/ AGG 2023 is already outpacing all previous shows in attendee registration. Contractors wanting to register before 6 January, 2023, can save 30% off their badge by using code MEDIA30.

CONEXPO-CON/AGG is the largest construction trade show in North America and the premier event connecting professionals from every major construction sector. Held every three years, it takes the construction industry to the next level by helping construction professionals elevate their industry expertise, experience the newest equipment and products through demonstrations and industry-leading education, make new professional connections, and grow their own marketability within the industry. The next CONEXPO-CON/AGG will be held 14 – 18 March, 2023 in Las Vegas, Nevada. For more information on CONEXPO-CON/AGG, visit www. conexpoconagg.com.

The Association of Equipment Manufacturers (AEM)

AEM is the North America-based international trade group representing off-road equipment manufacturers and suppliers with more than 1,000 companies and more than 200 product lines in the agriculture and construction-related industry sectors worldwide. The equipment manufacturing industry in the United States supports 2.8m jobs and contributes roughly $288bn to the economy every year.

CONEXPO-CON/AGG events demolitionhub.com 32 | DemolitionHUB Magazine

Making the show itself more sustainable

About

Looking forward to Phoenix Arizona for the 2023 NDA Demolition Expo. All details in the next edition of Demolition Hub Magazine. 22-25 February 2023

Sold out Executive Hire Show has allstar lineup