DeMOLITION HUB

SPECIALS

Focus: Attachments

INMALO

Demolition Elevation

MB CRUSHER Crushing and Recycling optimised for tomorrow

Welcome to the very first edition in the Demolition Hub SPECIALS series, with this issue focusing solely on attachments.

Quite frankly this has been a rather fun side hustle, allowing us to work on something a little bit different and although for a variety of reasons the first Demolition Hub Magazine SPECIAL has had to be delayed a couple of times, the importance of this very edition coming together has been made absolutely clear to us and certainly to those that supply attachments to the demolition industry.

This is the first in a series of Demolition Hub SPECIALS and although we had earmarked other sectors to do a SPECIAL on, the interest in attachments was evident and we can now notify you that we will be doing ATTACHMENTS once again in November this year. So if you like what you see here, as an OEM or a dealer offering attachments to the UK, Europe or globally and haven’t participated this time, but want to for the next, then please do get in touch.

Over the years I have learned a lot about these specialised tools, at any trade show a product specialist will explain to the capabilities, whilst on-site the operatives will explain their methodologies and why what they have put into use for the controlled dismantling and destruction of structure is there.

There isn’t a small nor large global construction event that I have attended in the past five years where I haven’t learned of an as yet undiscovered attachment being on show or been taken aback by an unfamiliar colour piquing my interest into exactly who they are and what they are offering. The world of attachments is huge and with the everincreasing technologies are getting better and better and in the case of what I witnessed in Texas, bigger and bigger.

We hope that our regular circulation of Demolition Hub readers, who will also now receive each and every SPECIAL just like this one, enjoy looking through this as much as we have enjoyed liaising with the brands and engaging with those that supply these essential attachments for a variety of your jobs and that you can now begin to use this yearly guide when it comes to deciding on what is fit for your purchases.

We will be adding to this now bi-annual Demolition Hub Attachments SPECIAL with other sectors in 2025, so this is merely the start of something SPECIAL.

Ben Chambers Publisher, Demolition Hub

Ben Chambers Publisher, Demolition Hub

PUBLISHER

Ben Chambers ben@globalnews.media

01903 952 648

EDITOR

Toby Wilsdon toby@globalnews.media

01903 952 645

CONTRIBUTORS

INMALO, MB Crusher, OSA, Bucket Manufacturing Company, Shearcore, Beilite®, Mantovanibenne, Mutley, Kinshofer, BPH Attachments, Epiroc, Robustrack, Rotar, Trevi Benne & GEM Models

SALES

Ben Chambers ben@globalnews.media

01903 952 648

DESIGN

Nicki Chambers nic@globalnews.media

Joe Bers joe@globalnews.media

PRODUCED & PUBLISHED BY Global News Media Ltd

Suites 5 & 6, Chapel House, 1-6 Chapel Road, Worthing, West Sussex BN11 1EX demolition@globalnews.media 01903 952 640

Demolition Hub is a proud supporter of the National Demolition Association

Demolition Hub is the media partner for the European Demolition Association and the Indian Demolition Association

Demolition Hub is published six times a year. The subscription rate is £60 per year. Subscription records are maintained at Global News Media Ltd, Suites 5 & 6, Chapel House, 1-6 Chapel Road, Worthing, West Sussex BN11 1EX

Articles

Inmalo meets BooBoo Plant Hire

Inmalo Director Charles Polak recently visited Harry Allen, the MD of Booboo Plant Hire based near Kings Langley, Hertfordshire. Harry is a demolition man first and foremost, so when it comes to specialist demolition plant hire, he knows what works best for his clients.

Inmalo have been supplying Booboo with attachments and dust suppression for over 10 years and as we sit in Harry’s office overlooking a lake, the chat starts and Harry asks “How’s business then?”

Of course, the honest answer that we all know is that it’s tough to win new business right now but keeping existing customers happy is just as important.

We both agree that price seems to be more important than ever, however we’re sitting in the office of a man who knows a thing or two about both sides of demolition contracting and the plant hire business.

INMALO

QHarry, considering you run both demolition and plant hire operations, what drives you when buying new kit?

People often focus on cost; we steer clear of cheap equipment. Longterm issues arise with low-quality kit. It’s essential to prioritise reliability and efficiency to avoid additional costs in downtime, spares, and repairs. It saves you money in the long run!

QRunning a demolition company and a Plant Hire business is quite diverse. How did you originally get into the demolition game?

I started by skipping school to work on sites removing roofing. It was a risky but exciting time, they were fun days. I fell into the demolition industry, working for various firms before branching out on my own, initially hiring equipment as needed.

QBooboo Plant Hire emerged as an extension of your demolition work. Could you tell us a bit more about how that started?

As the demolition side expanded, I began buying my own plant. I soon realised that I had so much specialist demo kit standing around, I saw an opportunity to offer it for hire. The demand for machines with operators led us to diversify into plant hire.

QWhen selecting attachments, what’s your primary consideration?

We prioritise reliable and powerful attachments that get the job done without complications. We use you because you supply quality gear and look after us.

QYou recently traded in your large shear for an Eagle III model. What motivated the upgrade?

The Eagle III is a step up in design, it’s more robust, quicker and powerful compared to others in its class. I needed more productivity to keep my customers happy and earn more on a job.

QOverall, how would you describe your experience with Inmalo’s products and service?

We really do prioritise and invest in good equipment and Inmalo consistently meets our needs. Your commitment to provide immediate support sets you apart.

QSo, backup and support plays a crucial role then? Absolutely, and Inmalo handles it brilliantly. It’s not just about the equipment; reliable backup and support keeps us and our customers happy!

Elevating customer support and service

Inmalo sets the standard for aftersales support and that’s no surprise when you consider this family business has been supporting the construction and demolition industries for 78 years.

Director Charles Polak states “The family has always believed that investing in the business is the only way forward”. Over the past two to three decades we have built up our stock levels. Large stocks of new equipment, and also for spares, tools, buildings and repair equipment. This way we can offer our customers a fast and reliable service every time.

In this post-Brexit and covid world, supply from the UK has become key.

Inmalo hold huge stock of all equipment, No concern for import delays.

Next day deliveries from UK stocks of spares

Investing in people, Inmalo has the best dedicated team.

Technical training and knowledge a priority, we only employ people who are passionate about what they do and hold the same values as we do.

Making sure we solve the challenge for the customer.

Whether an issue is with an attachment or a machine we will always try to fix it first time. “Urgency is key.”

With our quality equipment not

all of our engineers’ time is spent working on our own kit.

Inmalo also offer Line Boring, Welding and specialist fitting work for any customer on any equipment.

Wessex Demolition case study

Client:

Project:

Wessex Demolition Ltd

Redundant oil tank storage

dismantling – Oil Spill International

Client since: 2007

Industry:

Demolition and waste removal

Products and services: Demolition attachments and dust suppression

Background:

In the summer of 2023, we supplied Wessex Demolition & Salvage with an MBI SH130 Scrap Shear for a project for their client Oil Spill Response in Southampton. This work showcased the efficiency and reliability of Inmalo attachments in this challenging demolition environment. The project aimed to dismantle redundant oil tanks using cutting-edge equipment, with a particular focus on the MBI SH130 Shear.

Equipment in action:

Upon arrival at the project site, it was evident that Wessex relied

on a diverse range of Inmalo attachments. The newly delivered MBI SH130 Shear took centre stage, demonstrating its prowess in cutting through the thick steel obsolete oil tanks. Additionally, the Montabert V2500 Breaker and MBI RP10 Pulveriser were observed in action, seamlessly integrated with Volvo EC300 and Kobelco SK140SR excavators, respectively in removal of the concrete plinths.

Performance highlights:

Both the V2500 Breaker and RP10 Pulveriser exhibited commendable performance on the reinforced concrete base structures that once supported the oil tanks. Notably, attention was drawn to the MBI RP10, renowned for its powerful and effective crushing capabilities on materials fragmented by the V2500 Breaker within the rebar reinforced structure.

Remarkably, the MBI RP10 showcased exceptional durability, still operating with its original set of jaws despite its older model status.

Daryl Grant, Wessex’s Plant Manager, emphasised the significance of Inmalo’s attachment range, stating: “Inmalo’s attachments have proven to be the most reliable and powerful in our fleet. Their unwavering reliability and robust support have been instrumental in our sustained investment in these high-quality brands. The performance and reliability, exemplified by the new Eagle II SH130 Shear, reaffirm our trust in Inmalo to continue meeting our evolving attachment needs.”

Conclusion:

The Wessex Demolition & Salvage Oil Spill Response project stands as a testament to the seamless integration and superior performance of Inmalo attachments. As industry demands evolve, Wessex’s continued partnership with Inmalo reflects their confidence in the products’ reliability, durability, and innovation, ultimately contributing to the success of the complex projects undertaken by Wessex Demolition & Salvage.

The cutting edge, Eagle III Shear range from Inmalo

Inmalo are proud to introduce the cutting-edge MBI Eagle III Shears, a pinnacle of innovation and design.

MBI have been intent on manufacturing the most productive shear on the market, all while ensuring exceptional value for money. The result? A remarkable shear range that boasts an impressive 25-30% increase in power over existing models, covering 20 to 220-t machines.

MBI have achieved this groundbreaking advance by increasing the cylinder size and enhancing wear parts to minimise downtime. The improvements include a revolutionary piercing tip that covers the end of the beak, coupled with Hardox 500 wear plates that provide unparalleled protection to the jaw.

Recognising the paramount concern for customers regarding spare parts costs, MBI have strategically designed the upgrades to significantly lower the lifetime costs for operators, ensuring an optimal balance between performance and affordability.

Adam Blake, from HWM Group, shared his experience with the Eagle III Shear: “Following Inmalo’s recommendation, we’ve equipped our new Kobelco SK300 excavator with the MBI SH250R Eagle III Shear to tackle some extremely tough 1930s steel beams at our Eastleigh Rail Works demolition site.

“Our machine operators were not only delighted but also experienced significantly increased productivity compared to our older shears.”

For a first hand look at the Eagle III Shear in action, scan the QR code and explore the HWM Group video.

MB CRUSHER: Attachments that improve your tomorrow

As the demands of crushing and recycling continue to shape jobs in demolition, the necessity to optimise resources has become paramount – an MB Crusher attachment is the improvement you need.

MB CRUSHER

As Winston Churchill said, “To improve is to change; to be perfect is to change often.” This sentiment rings especially true for the demolition industry today.

Gone are the days of simply disposing of waste materials; now, companies are seeking innovative ways to recycle efficiently and cost-effectively at every stage of the process. To facilitate every single operative step, demolition companies need to constantly upgrade and transform.

Maximise digger and loader efficiency with MB Crusher attachments

What do all demolition, construction and groundwork companies have in common? The usage of heavy equipment.

It is a wide industry all connected by the use of machinery that digs, loads and moves. So it only makes sense that the journey toward improvement begins with these machines. By adding an attachment, a carrier machine can be transformed into something extraordinary.

Attachment-equipped machinery can perform a myriad of tasks, eliminating the need for multiple machines for different jobs. From digging and moving materials to crushing, screening, grinding or even extending the operator’s capabilities to lift heavy weights with precision, these attachments make complex processes simpler.

Substituting complex processes with a single-step operation

In the quest for increasing efficiency, the demolition company should turn to MB Crusher attachments.

While standalone machines may offer similar capabilities, they still require heavy equipment for loading, thus not optimising personnel or resources. MB Crusher attachments lead to space efficiency, enhanced productivity and cost-effectiveness.

Designed to be compact, an MB Crusher attachment will fit any brand

of heavy equipment including mini excavators, loaders or skids; using attachment-equipped machinery saves space on construction sites since fewer machines are needed. In urban areas optimising the use of available space is essential, and in remote or hard-to-reach areas, avoiding moving the material in and out of the site will enhance productivity.

MB Crusher attachments streamline demolition processes, enabling operators to switch between tasks quickly without the need to change machines. This leads to increased efficiency and productivity on the job site.

Environmental impact and safety: hot topics

MB Crusher’s attachments don’t just improve efficiency; they also address critical concerns like waste management, environmental impact and workplace safety. By using attachment-equipped machinery, companies reduce fuel consumption

and emissions, contributing to a greener, more sustainable demolition process.

The necessity to optimise available resources has become paramount. By enabling material recycling directly on the job site, MB attachments foster a circular economy model, reducing transportation costs, minimising pollution and promoting sustainable practices in demolition and construction.

The versatility and efficiency of MB Crusher’s attachments have elevated production levels to unprecedented heights, allowing materials to be crushed directly on-site, and eliminating the need for intermediate handling.

Operators can perform demolition tasks from within the cab, reducing their exposure to hazardous materials and risky working conditions. Additionally, using fewer machines can help minimise the risk of accidents on the job site.

MB CRUSHER

The full line

MB Crusher has developed a range of products that revolutionise the management of recycling cycles on site, streamlining the processes of crushing, screening and handling aggregates to save both time and money for companies.

The five lines of MB Crusher attachments are suitable for any brand of excavator, loader or skid steer. The iconic jaw crusher bucket lines offer regular output grading by regulating the jaw’s opening. At the first reduction a high-value product is made and one of the most notable features is their ability to recover valuable materials like railway sleepers and reinforced concrete swiftly and efficiently.

By simplifying complex processes into single-step operations, MB Crusher attachments not only enhance productivity but also create new revenue streams for companies. With integrated iron separators, materials can be processed on site with unparalleled speed and simplicity.

The Screening Bucket, with interchangeable grids easily exchangeable as bolted-on panel sections, can be used in pre or post-crushing as well as where

size separation is needed, giving a good quality product. The Padding Buckets and their interchangeable shafts are a time saver as various types of material can be processed, with four grades of separating and soft material reduction. The Drum Cutters are designed to avoid vibrations, provide precision and low maintenance plus the possibility to have more than one drum set per machine. Last but not least, MB’s Sorting Grapples are equipped with five types of blades, which can be easily replaced on the job site to safely handle any shape and type of material and precision operations.

The weight distribution in all of the machines has been further enhanced to further improve stability and minimise vibration on the primary equipment.

As industries strive to embrace circular economy principles and minimise their environmental footprint, MB Crusher stands at the forefront, offering a comprehensive lineup of attachments tailored to diverse needs and operations.

Whether it’s jaw crushers, screening buckets, padding buckets, drum cutters or sorting grapples, MB’s solutions empower companies to reclaim waste materials, produce high-quality secondary raw materials and contribute to a sustainable future, empowering operators to adapt to varying project requirements seamlessly. With MB attachments companies can significantly reduce costs, mitigate workplace hazards and capitalise on the materials already at their disposal.

MB Crusher’s commitment to innovation, efficiency and sustainability resonates with the evolving needs of the demolition and construction industries. By leveraging the transformative power of machinery attachments, companies can optimise their operations, maximise resource utilisation and embark on a path towards a greener, more profitable future.

OSA Distribution & Partners Built to last; Powered to perform

OSA was founded in 1994, is based in Bari in southern Italy and remains privately owned by Roberto and Giuseppe Sallustio. It currently employs around 80 people and 98% of all products are manufactured in house with the exception of values, seals and rotation motors, which are sourced from leading manufacturers.

Almost 30 years on, we are proud of our track record:

• Product sales within the top three brands in German market

• Robotic production methodology ensuring quality continuity

• Privately owned European manufacturing corporation

• Established for almost three decades

The OSA product range:

• Hydraulic breakers / hammers

• Selector grabs

• Primary crushers

• Multi processors

• Hydraulic scrap shears

• Rotating crushers

• Fixed pulverisers

• Fixed mechanical pulverisers

MC Series 4–19 tonne

OSA

Nitrogen assisted technology with inhouse developed features for improved performance and reliability.

Rotating grab with improved configuration manufactured for selecting, loading, recycling and demolition.

range for cutting through some of the toughest steel materials combining solid body and power cutting with a refined design, available in the following ranges.

Fast, precise, agile and efficient pulveriser for primary and secondary demolition. Rotating pulveriser munchers designed for both primary and secondary demolition.

Dedicated powerful and efficient secondary demolition tool. Fast, efficient pulverisers designed to work on the ground in secondary demolition applications.

2 Fast, powerful, reliable mechanical pulveriser. Fast, strong and effective mechanical pulveriser an alternative option to the hydraulic version.

Rotating double guide crushers for the most arduous primary demolition sites. Large opening, reduced weight for agile and fast movement, with powerful in-house manufactured cylinder for increased power and precise ratio. Operates in high reach working conditions on larger sized excavators.

Unique 3-year structural warranty (excluding wear parts), 2-year warranty (T&Cs apply)

2-year warranty (T&Cs apply)

2-year warranty (T&Cs apply)

2-year warranty (T&Cs apply)

2-year warranty (T&Cs apply)

2-year warranty (T&Cs apply)

2-year warranty (T&Cs apply)

4

The ‘Swiss army knife’ of demolition tools, remains the most versatile in the market. This multi functional tool enables users to carry out various on-site tasks, including cutting, cracking pulverising etc. versatility at its best. Rotating crushers with interchangeable jaws available in the following sizes.

2-year warranty (T&Cs apply)

It is particularly designed for secondary demolition, separating rods from concrete.

It has been designed specifically for demolition of concrete structures.

2,000-hour warranty

It has been designed for cutting iron, structural steel, pipelines, tanks, sheets and steel cases.

It is ideal for mixed demolitions of concrete and metallic structures.

for primary and secondary demolition, it permits the cutting of reinforced bars, together with the concrete.

warranty (T&Cs apply)

warranty (T&Cs apply)

OSA Warranty

• All OSA products are supplied with a two-year warranty (T&Cs apply), excluding breakers which are covered for three years structural warranty

• All product warranties (complete product range) exclude replaceable wear parts

• Detailed warranty terms and conditions are available on request

• NOTE: Over 97% of all products require no aftersales support, provided all setup procedures are followed completely. Our dedicated aftersales team are always on hand to promptly deal with any warranty issues to minimise your downtime

OSA Distribution: What our clients say…

This customer represents the OSA product range for the German marketplace and since their partnership with ourselves they have achieved…

• 150 customers using OSA products

• Over 700 products in the field

• Medium and heavy-sized hydraulic breakers, third in German market

• Products with over 18,000 hours with ZERO failure

• Less than 1% warranty claims per annum

Mr Daniel Thynen – Managing Director OSA Germany

For all sales enquiries please contact:

Mr Rob Macnaughton

Director of International Sales

Tel: +353 (86) 265 8588

Email: rob@osadistribution.com

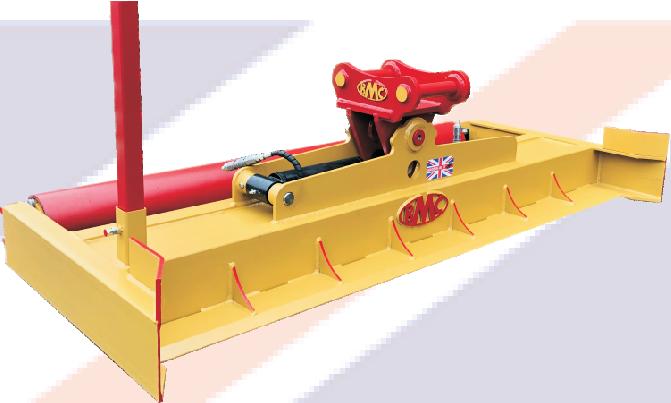

Bucket Manufacturing Company: Taking pride in the job

The Bucket Manufacturing Company is a privately owned British SME and this year will be celebrating its 21st anniversary

Under Wayne Ridings, who took over in 2012, the Bucket Manufacturing Company (BMC) made a strategic move away from supplying the cheaper type of product into producing higher quality products equivalent to or an improvement on the more established manufacturers. Providing bespoke buckets in a busy market.

BMC started producing more bespoke attachments to complement

establishing a foothold in the market.

The tidal wave of cheaply produced products from overseas is phenomenal and UK markets keep buying it. We could produce the equivalent for a very similar price, but the market will not pay the little extra.

At present, bespoke design has become very important to the survival of heavy engineering in the UK and we are eager to accommodate a customer looking for the odd or unusual attachment they have in mind.

Our philosophy is about customer satisfaction and supplying them with a quality product while still providing value for money, priding ourselves on exceeding customer expectations whenever possible.

To help us achieve our goals, we have experienced staff to assess what the customer needs and in the case of experienced customers, we give them confidence in our ability to supply what they need. If we give the customer a positive experience with the initial enquiry and eventual

purchase, it helps to maintain the manufacturing skill base in the local area.

BMC have taken lads through apprenticeships, helping to maintain a skilled workforce within this country but find that the willing lads supply chain is continuing to get smaller all the time.

Training the next generation of skilled manufacturers in the UK Wayne started his career as a lad at Geith International and worked his way up to workshop manager at

their Tredegar site in South Wales and stayed with them for 30 years until they moved their manufacturing from both Slane Ireland and Tredegar in South Wales to abroad.

We believe there needs to be more information about work opportunities and apprenticeships given to both young school leavers and manufacturing companies. Higher education is not for everyone, yet schools assume that all want to go to universities.

The world may be getting smaller but BMC’s market is only getting bigger

We manufacture most of our products in Chepstow, supporting local suppliers where possible. This is vital to both consistent quality and creating a wealthier locality and could be replicated across the

country to national benefit.

There are some big, exciting changes happening in the excavation market at present and it helps our cause here at BMC. These tilt-and-turn couplers have been a revelation since being introduced a couple of years ago and become a common tool on most building sites.

Producing attachments for these has been a pleasure because we’re now making buckets for the Scandinavians, which is a privilege given their high standards for equipment.

The world is getting smaller now and our clientele are from all over the world buying a single bespoke product. We have sent Manual Quick Couplers to the US, buckets to

Poland and our flagship four-in-one buckets go everywhere so, we must be doing something right and are proud of it.

Fortress by ShearCore –manufactured in the USA

ShearCore proudly stands as the premier manufacturer of the Fortress product line, meticulously produced exclusively in the United States at our headquarters in Superior, Wisconsin.

Nestled on the shores of Lake Superior’s western tip, our stateof-the-art factory is equipped with advanced manufacturing technologies, including robotic welding stations, CNC machining centres, a press brake, burn table, cut-off saw and a comprehensive parts department. Additionally, we house a rebuild centre staffed by a team of skilled manufacturing experts.

At the heart of our Fortress design philosophy lies a simple yet powerful objective: to maximise both power and durability. Drawing upon our extensive engineering and

manufacturing prowess, we have engineered attachments that excel in both performance and structural integrity.

Among our flagship products, the FS mobile shears series stands out for its unparalleled power-toweight ratio, ensuring sustained performance and longevity.

Complementing this, the Fortress FC demolition shears redefine primary demolition, excelling in the crushing and processing of concrete with unmatched force, right down to the tip.

One satisfied customer attests: “If it wasn’t for the Fortress shear product, I would be out of business today. I just ordered my third shear and business has never been better.”

Fortress has rapidly established itself as the global standard in demolition and scrap recycling

attachments, renowned for our innovative design, worldclass engineering and top-notch manufacturing.

Choosing a Fortress attachment means joining our family, where excellence permeates through our unparalleled service and support. Our team of skilled Fortress field technicians stands ready to provide on-site technical support and training, ensuring your equipment operates at its peak performance.

Reflecting on our service, another customer shares: “The ShearCore service is outstanding. There are not very many companies that I go out of the way to recommend to people and ShearCore is one of them. My downtime is pretty much nothing with ShearCore.”

BladeCore serves as the perfect complement to ShearCore, serving

SHEARCORE

as the exclusive blade provider for all Fortress shears. They maintain a vast inventory of blades for all major mobile and stationary shears. With extensive expertise in the demolition and recycling industries, BladeCore designs premium replacement blades that offer extended life, increased flexibility and reduced cracking.

Is your shear built like a Fortress? It should be. Learn more at shearcore.com or contact us at info@shearcore.com.

ShearCore is part of the Exodus Global family, which includes BladeCore, Connect Work Tools, OilQuick Americas, and RockZone Americas. Exodus Global is a family-founded, privately owned company headquartered in Superior, Wisconsin, USA.

Beilite® Europe launches innovative new Series 3 hydraulic breaker for hire in the south-east of the UK

Beilite® Europe launches innovative new Series 3 hydraulic breaker for hire in the south-east of the UK Beilite Europe, a leading manufacturer of hydraulic breakers, is proud to announce the launch of its latest Series 3 hydraulic breaker. This series represents a significant technical improvement in Beilite Europe’s product line, further enhancing the breakers’ capabilities. While the four specific models –BLTB-53-3, BLTB-70-3, BLTB-100A-3 and BLTB-125A-3 – are available for

hire in the south-east of the UK, the Series 3 range is available in a wider product range for hire and sale across Europe.

An innovative extension for all projects

The Series 3 is a response to the ever-increasing demands of the market for versatile and efficient attachments. With the launch of the Series 3, Beilite Europe shows its commitment to innovation and its ability to respond to customer needs

and industry trends. The Series 3 is more than just an extension of the product offering; it is a reflection of continuous improvement and the pursuit of excellence.

Unrivalled economy and flexibility

The Beilite Europe Series 3 hydraulic breakers are the ideal solution for companies and contractors looking for cost effective, flexible and reliable equipment for their projects. The breakers are not only affordable to purchase, but are also characterised by low service costs, making them an extremely economical option for the rental market.

Thanks to its versatility and adaptability, the Series 3 offers a solution for almost every situation on the construction site. From light demolition to heavy rock work, these hydraulic breakers can be used with ease, making them an indispensable tool for a variety of jobs.

Innovative technology as standard

An outstanding feature of the BLTB100A-3 and BLTB-125A-3 Series 3 range is the standard B Lube automatic lubrication system, which ensures constant and efficient lubrication, extends the service life of the device and reduces maintenance times. The lower weight of the breaker

and increased performance, ensures efficiency gains and significant savings in fuel and transportation costs.

ACDE Europe: Three decades of innovation in the demolition industry

With over 30 years of industry experience, ACDE Europe, which includes Beilite Europe, is driving innovation in the demolition sector. Our aim is to offer first-class quality at competitive prices. The BLTBSeries 3 is the latest example of our commitment to excellence.

Discover how this groundbreaking tool can revolutionise your demolition and construction work. For more information, visit www.beilite-europe.com or contact us directly at info@beilite-europe.com.

MBI’s Eagle III Shears

Mantovanibenne proudly announces the introduction of new models for 2024, marking yet another milestone in the realm of demolition and recycling equipment. Building upon the resounding success of 2023, where the SH600R Eagle III garnered the prestigious SaMoTer Innovation Award in the Attachments Demolition and Recycling category, this year witnesses the launch of additional SH Eagle III models, poised to redefine industry benchmarks.

Among recognitions and awards, the Eagle III has been making waves in recent months, spearheading critical demolition projects and featuring prominently in numerous scrap recycling sites. Its exceptional performance has garnered unanimous acclaim, with industry stakeholders acknowledging its unparalleled investment-toperformance ratio, positioning it among the finest offerings on the market.

At the core of the Eagle III are cutting-edge technical innovations meticulously engineered to elevate operational efficiency and reliability. With a shorter frame, an optimised weight-to-performance ratio, and enhanced stability, the SH shear line sets a new standard for adaptability and productivity. The redesigned mouth, boasting a remarkable average 9% increase in opening capacity across all models, ensures seamless efficiency in every task.

Crafted from solid 160-mm thick Hardox® steel plate, the upper jaw of the Eagle III Shears undergoes meticulous machining to withstand extreme temperatures encountered during cutting and machining processes. Innovative interchangeable piercing tips streamline maintenance, reduce costs, and minimise downtime, guaranteeing sustained peak performance. Precision-milled blade seats further enhance durability, bolstering resistance to wear and tear.

Innovative engineering extends to the hydraulic system, featuring a reverse cylinder design for rod protection and an enlarged bore for maximised power output. Crafted from forged solid material, the cylinder rod ensures unparalleled resilience, while premium quality seals promise exceptional longevity, enduring over 3,000 hours of rigorous operation.

Recognising the critical importance of key components, Mantovanibenne reinforces heavily utilised parts with interchangeable Hardox 500 steel plates, reducing the need for frequent maintenance and ensuring continuous operational readiness. This robust armour ensures the Eagle III withstands impacts without compromising structural integrity, maintaining exceptional wear resistance throughout its lifecycle.

MBI

For a comprehensive exploration

of the groundbreaking features of the Eagle III Shears and its entire lineup, visit the dedicated website at eagleshears.com/en/attachments/ sh-eagleshears-3.

Mutley Plant Service

Mutley Plant Service is a dynamic family-run enterprise specialising in the provision and customisation of excavator attachments. Our journey commenced in 1992 as a niche plant repair service, evolving over time to encompass the modification of heavy earthmoving machinery and the bespoke manufacturing of excavator attachments.

Equipped with comprehensive CAD design capabilities, we excel in crafting tailored solutions to fulfil the diverse needs of our clientele. From conceptualisation to execution, we undertake projects with precision and innovation, ensuring that each product meets the exact specifications and expectations of our customers.

Driven by a commitment to quality and customer satisfaction, Mutley Plant Service stands as a trusted partner in the construction industry, delivering reliable and efficient solutions that enhance

MUTLEY

productivity and performance on every job site.

Mutley Plant Service Ltd boasts an expansive inventory comprising both new and preowned attachments tailored for the demolition, construction, recycling, and rail industries. This diverse range of equipment empowers us to offer comprehensive solutions for all your equipment needs, whether for hire or purchase.

Our commitment to excellence ensures that each attachment in our inventory meets stringent quality standards, guaranteeing optimal performance and reliability in diverse industrial applications. Whether you require equipment for short-term projects or long-term operations, we provide flexible options to suit your requirements.

With Mutley Plant Service Ltd, you can count on a seamless and efficient experience, supported by our expertise and dedication to customer satisfaction.

Mutley Plant offer fitment sizes from 1 to 120 tonnes. Our attachments include:

• Demarec multi-quick processors

• Demarec heavy duty demolition sorting grapples

• Kinshofer sorting grapples

• Kinshofer orange peel grapples

• Epiroc hydraulic breakers

• Kinshofer clamshells

• Demarec concrete crushers –DemaPower and Eco-line options available

• Demarec dedicated shears

• Demarec dedicated pulverisers –DemaPower and Eco-line options available

• Epiroc and Mutley hydraulic magnets

• Mutley mechanical grapples

• Mutley mechanical pulverisers

• Kinshofer lorry/crane attachments

• Plus bespoke requirements

• OilQuick couplers and plates

• Kinshofer NOX-tiltrotators

At Mutley Plant Service, we prioritise your peace of mind by providing comprehensive support for all our hire equipment. Our team of experienced field engineers ensures that you have access to 24/7 service assistance whenever you need it. With a hire fleet exceeding 100 units, we offer a wide array of equipment options to meet your specific project requirements.

Beyond equipment hire, we excel in delivering a diverse range of engineering services, including mechanical, electrical and hydraulic upgrades. Our dedicated engineering facility is equipped with advanced machining, welding, and heavy fabrication capabilities,

complemented by state-of-theart 3D bespoke design expertise. This allows us to offer a complete spectrum of excavator modifications and demolition upgrades tailored to your needs.

Mutley Plant Service extends its service and repair coverage throughout the UK, ensuring prompt and efficient assistance for all attachments and excavators. In cases of downtime, we mitigate delays by providing cover from our hire fleet, ensuring uninterrupted progress on your projects. With Mutley Plant Service, you can trust in our commitment to maximising your operational efficiency and minimising disruptions.

Specialists in excavator engineering,

We have a wide Kinshofer & Demarec or purchase.

Attachment range

• Sorting grapples

• Orange peel

• Clamshells

• Multi-Quick-Processors

• Shears

• Pulverisers

• Dedicated demolition

• NOX Tilt-rotators

• Plus more

BPH Attachments

PRODEM PRB series Vibration Dampened Silenced Hydraulic Hammers

The PRODEM PRB series of Vibration Dampened Silenced Hydraulic Hammers offers power, reliability, innovative durability, low operating costs and ultimately, customer satisfaction.

While the PRB series are fully silenced for sound sensitive job sites, they also provide impressive power for the largest of demolition sites. The PRB series (PRB150 upwards) benefit from pro-speed dual speed control system, anti blank firing system, auto stop and auto start, rock claws and a single high pressure accumulator (PRB200 upwards).

demolition and recycling/waste sectors.

Hydraulic hammers and post drivers

With this attachment you get both a powerful breaker and a tool for driving in posts with ease.

Forget sledgehammers, a hydraulic post driver does the job quickly and efficiently. The brackets can be side mounted for extra height and control or top mounted as standard – this is ideal for larger fencing projects and jobs where the ground may be hard.

BPH Attachments, the Excavator Attachment Specialists, exclusively imports PRODEM Attachments to the UK. They have long been a force to be reckoned with in the hydraulic attachments market. Since 2003, PRODEM Attachments has become synonymous with durability, reliability and cost effectiveness – the trilogy of key desirable characteristics in excavator attachments.

This is precisely why PRODEM is the go-to brand for construction, civil engineering and demolition companies and contractors, all of whom require hydraulic attachments that deliver.

These make up one of the largest fleets in the UK, with an extensive range of high quality attachments. From hydraulic hammers, multi processors and crusher buckets, to rotating pulverisers, compactor plates and selector grabs.

BPH is a family run business with more than 50 years’ experience in the construction industry. This means it has the knowledge and experience to advise and support you.

With models in all sizes, from PRB008 all the way up to PRB1000, they’re ideal for any demolition job. All these models range to suit excavators from 0.7 to 140 tonnes.

PRODEM attachments are known for their quality, durability and reliability as well as for being competitively priced. Their customers are in the plant hire, construction, civil engineering,

Co-founder of BPH, Matthew Bastable said: “We also like to think we’re great folk to do business with. We’re quick, our products are reliable and we are there when you need us.

“As a leading supplier of excavator attachments for sale, hire or repairs, we cover the whole of the UK and offer next day delivery for in stock products. We are known for providing high quality products that are right for the customer. If you’re looking for a hydraulic excavator attachment, we’ve got it.”

Epiroc

DP 1820 demolition pulveriser

Epiroc, a leading provider of innovative solutions for the construction and mining industries, is proud to announce the latest enhancement to its Demolition Pulveriser range – the new Performance Booster for its DP 1820 Demolition Pulveriser.

The DP 1820 boasts a slim, modular design to withstand the additional power of a Performance Booster. The DP 1820 is specifically tailored for carriers in the weight class of 15 to 22 tonnes. Now, with the introduction of the Performance Booster, Epiroc takes the DP 1820 to new heights by offering substantially higher performance compared to standard versions.

Key benefits of the Performance Booster

• Enhanced performance: The Epiroc Performance Booster elevates the DP 1820’s performance by up to an impressive 20%, ensuring jobs are completed faster and more efficiently,

• Reduced jaw cycle time: The Performance Booster not only boosts power but also minimises jaw cycle time by up to 25%, contributing to increased productivity on the job site,

• Fuel efficiency: Expect a significant reduction in carrier fuel consumption of up to 35%, making the DP 1820 with Performance Booster a sustainable and cost-effective solution.

A unique opportunity for existing hydraulic attachment tools

The Epiroc DP range stands out as the Performance Booster can be retrofitted to existing attachments, a distinctive feature made possible by the robustness of the standard Epiroc pulveriser body. Unlike other pulverisers on the market that require different bodies to withstand the load of a Performance Booster, the DP 1820 offers a cost-effective and convenient solution.

DP 1820 – a demolition powerhouse

The DP 1820, with a service weight of 1,820 kg and a jaw opening of 746 mm, delivers precise handling and an impressive crushing force.

Its slim, modular design eliminates the need for cylinder rod protection, and the 360° endless hydraulic rotation ensures optimal positioning and precise handling on the job site. The demolition pulveriser’s design eliminates the need for additional cylinder protection, streamlining operations.

Versatility redefined

Epiroc Demolition Pulverisers, including the DP 1820 with Performance Booster, are highly versatile attachments capable of handling both demolition tasks and secondary breaking of debris. This efficiency facilitates material recycling and reuse, making Epiroc’s DP attachments an all-in-one solution for a range of applications.

Robustrack

MB Crusher MB-HDS range of shaft screening buckets

In the realm of construction and excavation, efficiency is paramount.

The MB Crusher MB-HDS range of shaft screening buckets, supplied by Robustrack, stands out as a gamechanger, tailored for excavators weighing between 2 to 40 tonnes. Crafted with precision and innovation, this cutting-edge tool is designed to revolutionise material

processing on-site.

At the heart of its design lies a strategic shape that facilitates the seamless movement of material towards its rotating shafts, ensuring unparalleled productivity. Positioned cleverly at the centre of the machine, the coupler’s connection sits lower than the rest of the structure, alleviating stress on the

frame and enhancing manoeuvrability and precision during material processing.

Protection is paramount and the MB-HDS range excels in safeguarding its integral components. Encased within fixed covers, the gears remain shielded from abrasive materials such as sand and dirt, prolonging their lifespan and ensuring uninterrupted operation. Furthermore, welded covers behind the machine fortify bolts and side casings, providing an extra layer of defence against wear and tear.

Maintenance is made effortless with on-site servicing capabilities. Equipped with a shaft holder, operators can seamlessly replace shafts without the need for costly downtime. Optional extras, including the RQ8-50 Sifting Kits for soil sifting and aeration, the RM Mixer Kit for versatile material processing, the RE8/RE16 Fine Sifting Kits for precision screening, and the RC Compost Kit for organic waste shredding, further enhance the bucket’s adaptability to diverse job requirements.

By repurposing materials on-site, the MB-HDS screening bucket range eliminates the need for wasteful removal and external processing, simplifying operations while reducing costs and environmental impact. A must-have addition to every operator’s arsenal, this versatile attachment promises unmatched efficiency and productivity.

Backed by a 24-month warranty, this screening bucket exemplifies reliability and performance, setting a new standard in on-site material processing.

Rotar

Introducing the neXt chapter –the X-series of RSS mobile scrap shears

Rotar, whose head office is in Holland, is an award-winning manufacturer of premium attachments for the demolition, recycling and scrap industries. Types of attachments available include shears, pulverisers, processors, grabs, concrete cutters, screening and segregator buckets.

X, representing X-treme, introduces several new models to the RSS range, responding to demand from both the demolition

and scrap processing industries.

The X-series is designed to withstand high operating pressures of up to 380 bar. The shear design has evolved to give more body strength, coupled with a new pivot group design that improves jaw alignment. This improvement enables the shear to handle higher cutting forces. Additionally, the nose blades incorporate a unique design, to keep them firmly in position during operation. These innovative

design features mean that the Rotar X-series of shears performs above and beyond any others available on the market today.

RSS 10 X is a brand-new addition to the RSS series. It is suitable for boom mounted excavators of 9 to 13 tonnes and stick mounted excavators of 12 to 19 tonnes.

RSS 20 X is a redesigned version of the successful RSS 20, featuring a brand-new nose design and incorporating all the innovative features of the new X-series. It is suitable for boom mounted excavators of 13 to 23 tonnes and stick mounted ones of 20 to 32 tonnes.

The whole X-series journey began with the RSS 100 X model. In addition to all the above features, we have incorporated a larger cylinder, transforming the shear into a formidable force. The rotation drive is reinforced and equipped with double gearboxes and motors for enhanced positioning. Combined with a favourable centre of gravity, this configuration prevents the shear from drifting during rotation. With a tool weight of 10 tonnes, we are confident we have introduced the strongest shear to the market. It is suitable for boom mounting on a 50-tonne excavator and stick mounting on one of 75 tonnes or higher.

In response to widespread market demand, we have expanded our shear range with the introduction of the RSS 150 X.

With an operational weight of nearly 20 tonnes and featuring formidable cutting forces of 425 tonnes at the shear’s tip and over 2,100 tonnes in the throat, this specialised equipment is engineered for the decommissioning of power plants, steel mills, ocean vessels and oil rigs.

The RSS X-Series range adds to the existing RSS models on the market giving customers the choice of eight models to suit the size of their machines.

Rotar has been at the forefront of the demolition, recycling and scrap metal industries since the 1970s and is continually introducing innovations onto the market in response to customer demands.

Louis Broekhuizen, Commercial Director said: “I’m extremely proud of the entire Rotar team, who work

hard to bring innovative pieces of equipment to the marketplace. I strongly believe that there is always room for improvement and at Rotar we continually monitor new technologies and react to customer demands in order to create market leading equipment for the demolition industry.”

Trevi

Trevi Benne is a world-leading company in demolition, recycling, earthmoving and mining. In just over 30 years Trevi Benne has achieved the goal of a worldwide distribution operating in 45 different countries with a professional dealer network, with more than 100 exclusive distributors and a steady increasing rate in turnover and employed personnel. The products and the manufacturing system are well known and recognised in the construction yards and in the most relevant international exhibitions.

Trevi Benne is a company with a TÜVcertified Quality and Safety at Work system and is an active sponsor of the major Italian, European and USA Demolition Associations.

The absolute news of this period has been the restyling of the iconic rotating pulveriser FR Series, the most sold model of demolition pulverisers by the Italian company.

The structural characteristics of this FR Series pulveriser allow the operator to tackle the primary and

secondary demolition phases with a single piece of equipment. It is precise and fast like a crusher thanks to the continuous hydraulic rotation, powerful and productive thanks to the typical jaws of a pulveriser. Working in the city, in historic centres or in environments where, however, the manoeuvring radius is limited, involves or obliges the use of a single excavator and in this case the FR Series proves to be the perfect equipment.

The FR Series consists of twelve models: from the smallest of 550 kg (FR 05) to the majestic FR 250 weighing 24,500 kg. First in 2020 and subsequently again this year, the Series was renewed in shape and design and was technologically perfected in the four model from 1,000 to 2,500 kg. The latest efforts have been aimed at increasing the longevity of the equipment by specifically taking care of aspects and components most stressed by the strain of demolition.

These are the technical and

structural features that make it more aggressive, more performing and more resistant to the stress of a demolition:

• Standard rotation with two motors in the FR 10, FR 13, FR 18 and FR 23 models,

• Increased size of the fulcrum pins and cylinder diameters,

• Creation of helical grooves in all pins for better distribution of lubricant,

• The speed multiplier valve has been redesigned with a double oil channel to reduce the pressure drop and a specific system to avoid the unscrewing of the cartridge.

The pulveriser FR 23 model, weighing about 2,500 kg making it perfect for 25 to 30-tonne excavators, will be on display at the next INTERMAT Trade Show, the International Exhibition of Construction Equipment and Materials, held in Paris from 24 to 27 April 2024. Trevi Benne can’t wait to welcome you in Hall 6, Stand D059.

www.gemmodels.co.uk

info@gemmodels.co.uk