www.diggers.LIVE November 2022 The gargantuan construction show underway as we get this issue out! Business Insider With Peter Banks, Managing Director of Global Machinery Solutions Ltd ROKBAK A rock-solid first year. We profile the Rokbak’s RA30 and RA40 excavators backhoes construction construction machinery construction equipment #14 PARTS FOR CONSTRUCTION EQUIPMENT Parts suitable for all major makes & models on the market Next day delivery � 46 000 000 part numbers

info@liugong.co.uk 02392 123 392www.liugong.co.uk FROM 1.8 TO 95 TONNES THE ALL NEW F-SERIES BREAKS THE MOULD. SCAN THE QR CODE TO DISCOVER THE DIFFERENCE GROUND BREAKING DESIGNTOUGHNESSCONTRÔLINTELLIGENCE

Welcome to issue #14…

I write this on the cusp of November and must say (from afar) what an event bauma has been.

We are far too late on in our production of this magazine to feature everyone and every new product release or story as they happen (bauma is still in play) but that is why we use our sister site www.diggers.LIVE for the breaking news items, events and time sensitive stories and offer that online service to you.

That said, this magazine has risen over the past two years to be the industry’s place for construction equipment and plant interest. Not to mention occupying many a company’s reception arena.

Back to bauma. I had promised our salesman Nathan a trip over to Germany and we were all booked in, excited and set to go.

That was before Sunday, the day before our supposed 6:30am flight to Munich where I was struck down with a virus that knocked me for six.

Sat in bed for the start of the bauma week I was watching our clients’ and readers’ socials and receiving texts from manufacturers wondering if I could possibly pop by. Pop by I couldn’t and that has been very frustrating.

However our friends in Munich have kept us abreast of all things going down and we have done an eleventh hour bauma feature.

With that in place and an over-egged effort to make good, I plan to go OTT and make it up to myself and hit either bauma India next year or bauma China 2024. Watch this space.

We will be covering all that matters and happened in a comprehensive review in the very next issue.

Inside this issue, alongside the bauma news in this the last issue of the year, we have interviews with supplier TVH and Global Machinery with well supported features on both Dumpers and Loaders.

The next issue will be out just before Christmas, the first one for 2023. Going into the new year we promise to continue to improve, innovate and be the magazine for the industry.

Thank you for supporting us this year.

Best Regards,

Ben Chambers

WELCOME

3DIGGERSLIVE

EDITORIAL TEAM Ben Chambers ben@chambers.media toby@chambers.media DESIGNER Nicki Chambers nic@chambers.media GENERAL ENQUIRIES info@chambers.media 01903 952 640 SALES Luke Chaplin luke@globalnews.media 01903 952 643 Nathan Sandford nathan@globalnews.media 01903 952 642 PRODUCED & PUBLISHED BY Global News Media Ltd Suite 5 & 6 Chapel House 1-6 Chapel Road, Worthing West Sussex BN11 1EX ben@chambers.media 01903 952 640 Diggers LIVE is published six times a year by Global News Media Ltd Articles and information contained in this publication are the copyright of Global News Media Ltd and may not be reproduced in any form without the written permission of the publishers. The publishers cannot accept responsibility for loss of, or damage to, uncommissioned photographs or manuscripts. www.diggers.live International Affiliate Official Publication

CONTENTS DIGGERS 4LIVE 6 NEWS Caterpillar expands battery electric portfolio CDE judged one of Ireland’s Best Managed Companies 2022 Multi million pound logistics contract secures hundreds of jobs Ronn Herity awarded Freedom of the City of London UK construction equipment sales grow in August Wraps come off JCB’s hydrogen refueller 63 42 38 DUMPER FEATURE • Altrad DX 1000HT • AUSA D151AEG electric dumper • Hyundai HA30 and HA45A • JCB 1T-E electric site dumper • HM300-5 ADT • Mecalac 3.5MDX • Takeuchi TCR50-2 • Thwaites all electric 3-tonne dumper prototype 60 EVENTS All roads lead to the Executive Hire Show 2023 www.diggers.live 54 BUSINESS INSIDER Peter Banks, Managing Director of Global Machinery Solutions Ltd 6 50 PROFILE A rock-solid first year for Rokbak 32 THE EQUIPMENT ENGAGEMENT Joris Tijtgat,Team leader at TVH Parts Holding 16 LIVE EVENT Breaking news from bauma

62 LOADERS FEATURE • CASE G-series Evolution wheel loaders supplied by Warwick Ward (machinery) Ltd. • Hyundai HL955AHD and HL955AHDXT • JCB 427 • Komatsu WA475-10 • Mecalac AS750 70 INDUSTRY Why we need to use electric to build electric by Gustav Boberg, Segment Leader, at Volvo Construction Equipment Bobcat launches upgraded BobCARE planned maintenance programme The colour purple – a new standard for pressure washing Latest Cat technologies simplify operation, improve accuracy, reduce costs and improve safety Kubota to increase excavator production with £100m plant expansion Xwatch supports Synergy Hire – putting safety first SVAB launches new control system with open interface for tiltrotators New Brushcat and log grapple attachments designed for Bobcat small articulated loaders O’Donovan adds to plant fleet with Hitachi machine Blue Machinery expands Terex Washing Systems agreement across UK First Volvo EC550E excavators from SMT GB to boost profitability for Ashcourt Group 68 BEARDED EXCAVATION Following on from his account in September’s Diggers LIVE, Lloyd Peckham brings us up to date with the Bearded Excavation story 92 BUILDERS’ CONFERENCE Neil Edwards, CEO of the Builders’ Conference gives his outlook for the construction industry as well as details of Contracts Awarded in July www.diggers.live The UK's Only Live Demo Construction Equipment Event in 2023 BOOK NOW! • Attracting 450 Exhibitors and 15,000 Visitors • Live demonstrations across the site • Exhibition zones including machine innovation and technology Supporting a safer, smarter and more productive industry. Call Angela now - 07807 623640 or email angela.spink@plantworx.co.uk More details at www.plantworx.co.uk FOR THE INDUSTRY, BY THE INDUSTRY 13-15 June 2023 East of England Arena and Events Centre, Peterborough. DIGGERSLIVE 5

Caterpillar expands portfolio with four battery electric machines

Caterpillar is focused on helping customers achieve their sustainability goals by geography, by jobsite and specific customer need. One of many solutions, the battery electric prototypes include the 301.9 mini excavator, 320 medium excavator, 950 GC medium wheel loader and 906 compact wheel loader, which were displayed at bauma. These are powered by Caterpillar battery prototypes and include an onboard AC charger. The company also plans to offer an offboard DC fast charging option.

Construction Industries Group President Tony Fassino said: “Caterpillar is well positioned to help customers reach their sustainability goals, including lowering emissions on the jobsite. It’s important we meet customers on their sustainability journey today with a variety

NEWS

DIGGERS 6LIVE www.diggers.live

of solutions including machines that run on renewable fuels or technology that increases fuel efficiency, as well as supporting them into the future as we power our next generation of machines.”

The Caterpillar-designed batteries in these machines will also be available to power other industrial applications. Built on proven Caterpillar technology, the lithium-ion battery range features a modular design that offers flexible configurations across multiple applications. The batteries are engineered to be scalable to industry and customer performance needs and maximise sustainability throughout their lifecycle, including recycling and reuse at the end of life.

Joe Creed, Energy & Transportation Group President said: “Our electrified products leverage our deep system integration experience and are designed to meet the performance expectations that customers have come to expect from Caterpillar. We’re focused on helping our customers achieve the optimal product and jobsite energy lifecycle, allowing them to maximise value and minimise their total cost of operation.”

The 301.9 and 906 are expected to be the first commercially available models.

NEWS

DIGGERSLIVE www.diggers.live7

CDE has been named as one of the best managed companies on the island of Ireland, having requalified for the Deloitte Best Managed Companies programme for the 14th consecutive year. Winners were announced at a gala event on Thursday, 29 September 2022 in the Convention Centre, Dublin.

Reinforcing its position as a leading supplier of sand and aggregate wet processing solutions for the waste recycling and natural processing sectors on the global market, the Cookstownheadquartered company secured Platinum status as a Best Managed Company in the 2022 programme.

Deloitte Best Managed Companies is a global initiative to identify and recognise

private companies with advanced management ideas and excellent business performance from every perspective.

Launched in Ireland in 2008, the programme recognises superior business performance in Irish and Northern Irish privately owned and managed companies. A symbol of organisational success and achievement, the programme evaluates the calibre of a company’s management capabilities and practices and its approach to strategy, innovation and culture.

Harry Goddard, CEO, Deloitte Ireland said: “A standout from the judging process this year was the distinct focus of the Best Managed Companies on their local communities, despite their own international growth and ambition.

Businesses have a vital role to play in our society. It was clear from the entries this year that they were having a positive impact not only on their own business, but also on the communities around them. I look forward to seeing how these businesses continue to invest, grow and contribute to our wider society.”

CDE’s Chairman and founder, Tony Convery said: “It is testament to the talent we harness here at CDE that for almost half of our company’s existence we have been recognised by the Deloitte Best Managed Companies programme. The award is all the more relevant in our milestone 30th year in business as it represents not only the successes of our team in the past 12 months, but the collective efforts of our accomplished and fiercely innovative colleagues over the past three decades.

NEWS

CDE secures 14th consecutive Deloitte Best Managed Companies award

CDE one of Ireland’s Best Managed Companies 2022 DIGGERS 8LIVE www.diggers.live

All

D151AEG

1,500

New AUSA electric range

T164E

1,600

www.ausa.com

D151AEG dumper T164E telehandler

of AUSA’s electric vehicles are designed with an operating range of at least one working day. The li-ion battery pack is managed electronically to offer maximum power in a smooth way and with all-terrain conditions that match diesel vehicles. Also, when the accelerator is released, the electric motor reduces the speed instantaneously while the energy is regenerated.

DUMPER

kg - Payload Rotating - Tipping system 7.6 kW - Power 15 km/h - Maximum speed Up to 12.3 kWh - Battery capacity 2 h - Charging from 20 to 80% (230V)

TELEHANDLER

kg - Payload 4 m - Maximum lift 8.4 kW - Power 15 km/h - Maximum speed Up to 18.6 kWh - Battery capacity 3:15 h - Charging from 20 to 80% (230V)

Multi million pound logistics contract secures hundreds of jobs

JCB announced the appointment of a new global lead logistics provider with the awarding of a multi-million pound fiveyear contract in September.

The agreement will see Denmarkbased family company Maersk Logistics become the JCB’s lead logistics provider. The contract to manage the company’s global supply chain operations will commence in early 2023 and will see Maersk collaborate with Unipart Logistics in its delivery.

Under the new agreement, both Maersk and Unipart Logistics will play a critical role in keeping JCB’s 10 UK production facilities in Staffordshire, Derbyshire and Wrexham supplied with parts from the JCB World Logistics Centre, Newcastle-under-Lyme.

Employment at the centre has more than quadrupled since opening in 2013 and the new contract secures the jobs of the 260 people working there, as well as those of an additional 160 people working across JCB’s Staffordshire plants.

JCB Chief Operating Officer Mark Turner said: “JCB’s business is going through a period of unprecedented growth around the world and as we grow, keeping production lines supplied with parts and components on a just-in-time basis is imperative. The appointment of Maersk Logistics as JCB’s global lead logistics provider, along with Unipart Logistics, will bring about a transformation in our global supply chain operations and support our manufacturing growth plans.”

Gary Jeffreys, Managing Director

of Maersk UK and Ireland said: “We are privileged that Maersk has been selected to be the global lead logistics partner for JCB. Our collective strengths and experience will deliver an agile, efficient, and sustainable global supply chain for JCB.”

Ian Truesdale, Managing Director of Unipart Logistics, said: “Unipart’s heritage and expertise across manufacturing and production supply chains, combined with its innovation and proprietary system for continuous improvement, will enable us to drive and deliver sustainability and growth targets across JCB’s UK operations.”

Maersk and Unipart will work closely with current lead logistics provider DHL during the handover period between now and next year.

NEWS

DIGGERS 10LIVE www.diggers.live

On 11 October I became a Freeman of the City of London, which was a great honour. I had only started in business in early 2020, which as far as recent years go, was the most uncertain I’d ever witnessed.

We worked hard in 2020 and have grown and grown over the last couple

How I was awarded the Freedom of the City of London

by Ronan Herity, Director of Retec Equipment exclusively for Diggers LIVE

of years. During this short time I made a very good friend in Vince Dignam, Business Performance and Transport Group Manager at the City of London.

Vince mentioned about becoming a Freeman of the City of London on the back of what he’d seen us doing in the Square Mile, (supplying Sandvik crushers and recycling London’s old infrastructure). It wasn’t until I met him that I fully understood what Freedom of the City meant, the honour, respect and the integrity

in one’s beliefs and actions that it so greatly values.

The Freedom of the City of London – the historic square mile governed by the City of London Corporation – dates back to around 1237 during the reign of King Henry III, making it one of the oldest ceremonies in the world.

Before 1996 it was only open to British or Commonwealth citizens –with select figures of global standing gaining Honorary Freedom of the City – but it has now been extended to people of any nationality. About 1,800 people are given the freedom of the city per year and in modern times we have seen the likes of Winston Churchill, Nelson Mandela and recently, Ed Sheeran becoming freemen of the city.

I would like to thank Vince for my nomination and also my second nominee, John Tobin from FM Conway, for putting their trust into me to carry on this great tradition at a young age.

Getting the freedom meant an awful lot to me, being one of the first freeman under our new King and, as someone of Irish heritage, being granted the Freedom of the City by the first Irish Lord Mayor, Vincent Keavney. To be a part of the ceremony in the presence of my father and closest friends was very special and a day I will remember for the rest of my life.

NEWS

Ronan holds his parchment denoting the Freedom of the City of London with father, Ian Herity

Ronan signs the ledger at The Guildhall

DIGGERSLIVE www.diggers.live11

in

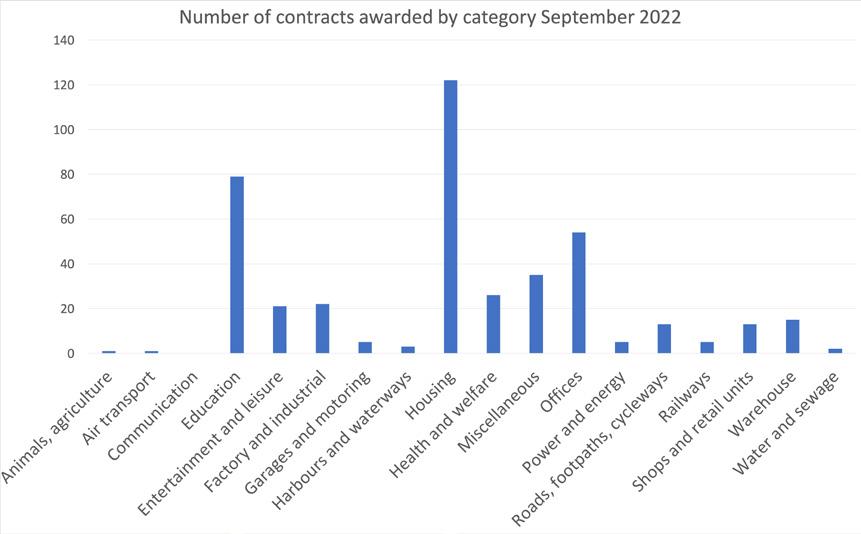

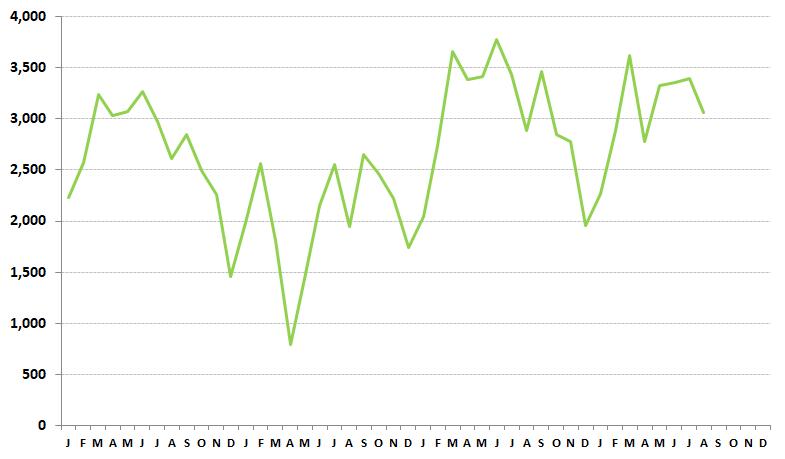

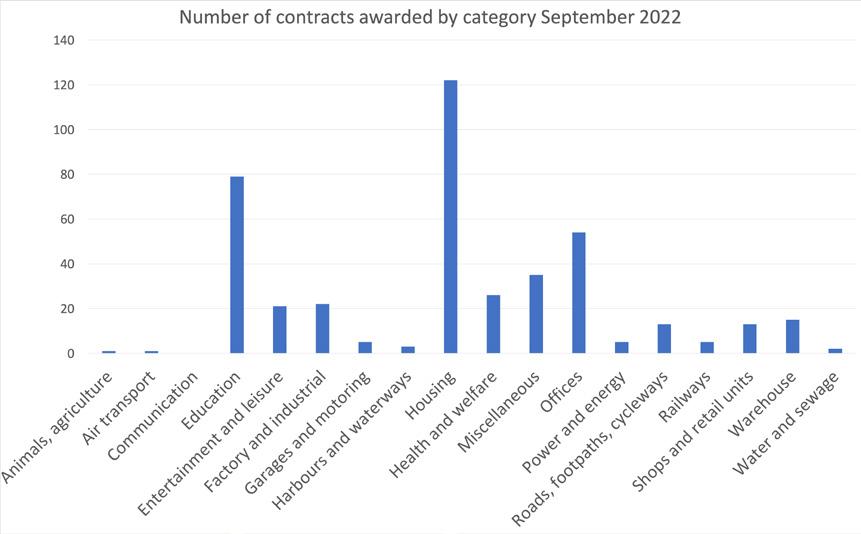

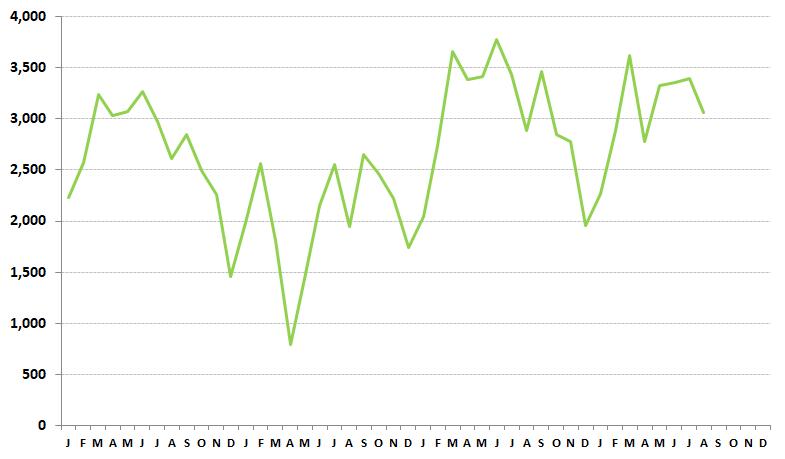

Retail sales of construction and earthmoving equipment in August were 6% above sales in the same month last year. This was the strongest performance since February when sales were ahead of last year’s levels by a similar amount. Following this, sales in the first eight months of the year are catching up with last year’s levels and are only 2.5% behind 2021 after reaching 24,700 units. Members are still highlighting that a range of supply chain issues are impacting sales of equipment and this suggests that without these problems, sales this year would probably be ahead of the “record” levels seen in 2021.

The pattern of sales for the major equipment types in the first eight months of the year to August is shown in the chart (centre right) compared with the same period last year. This shows percentage changes in sales year on year, ranked from highest to the lowest, and demonstrates a mixed pattern for the different machine types.

Telehandlers (for the construction industry), continue to show the strongest growth by a significant margin this year, at 24% up on 2021 levels. Sales of road rollers remain weakest, at 9.5% down on last year’s levels. Sales of mini/midi excavators and crawler excavators, which are the most popular equipment types, are between 7% and 8% below last year’s levels in the first eight months of the year. A significant contribution to this is believed to be supply chain constraints associated with the supply of machines from some Asian countries, particularly Japan.

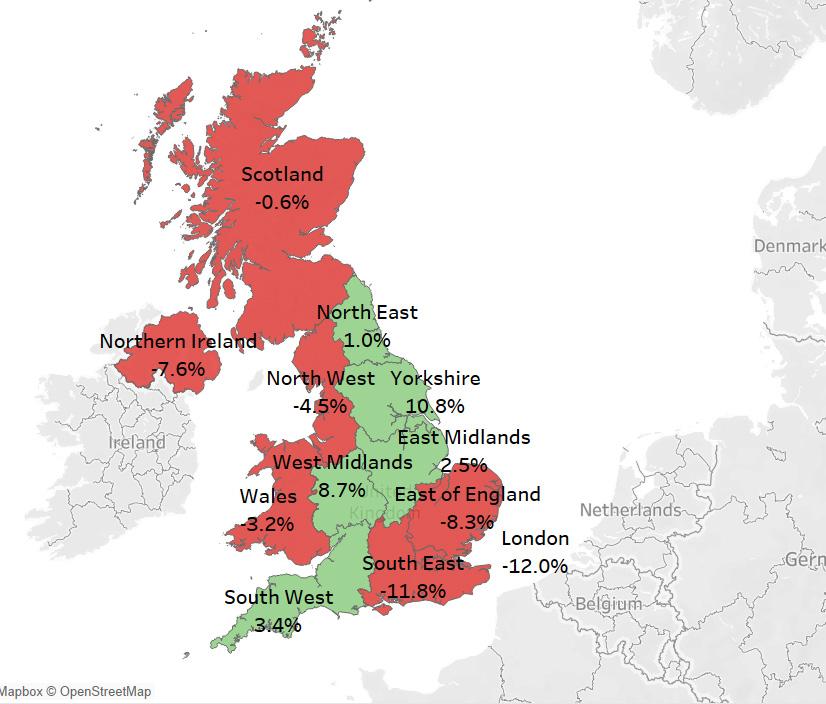

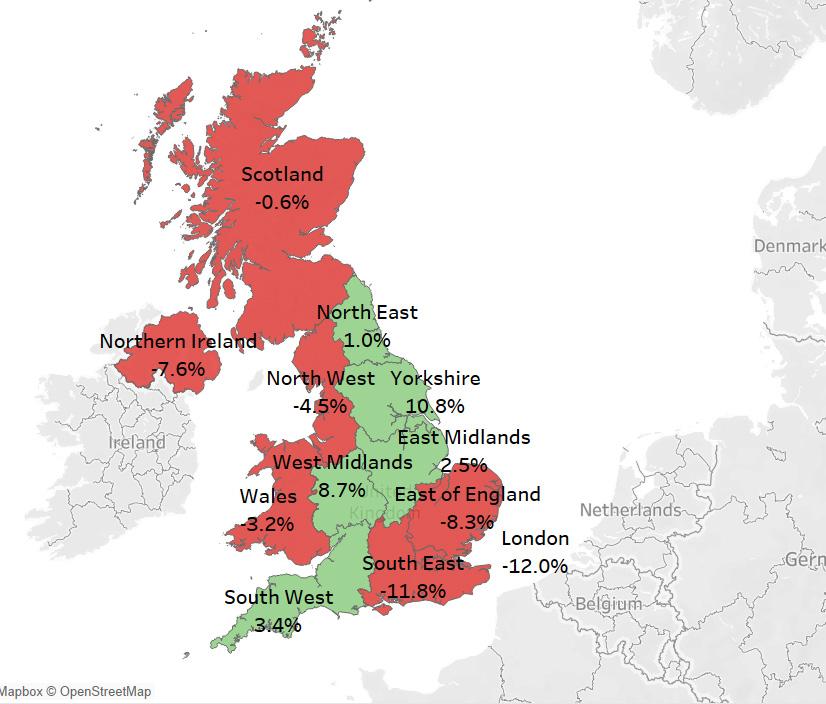

The pattern of sales on a regional basis in the UK and Northern Ireland is shown in the map above for sales from January to August, compared with the same period in 2021. This also shows a mixed pattern. The strongest sales so far this year continue to be in Yorkshire, at nearly 11% up on last year’s levels. In contrast, London and the south-east of England regions have seen the weakest sales at close to 12% down on last year’s levels.

Equipment sales in the Republic of Ireland are also reported. Sales in August fell back again, and were 14% below last year’s levels, after showing a recovery in the last few months. This leaves sales in the first eight months of the year at just under 12% below last year’s levels.

equipment

NEWS

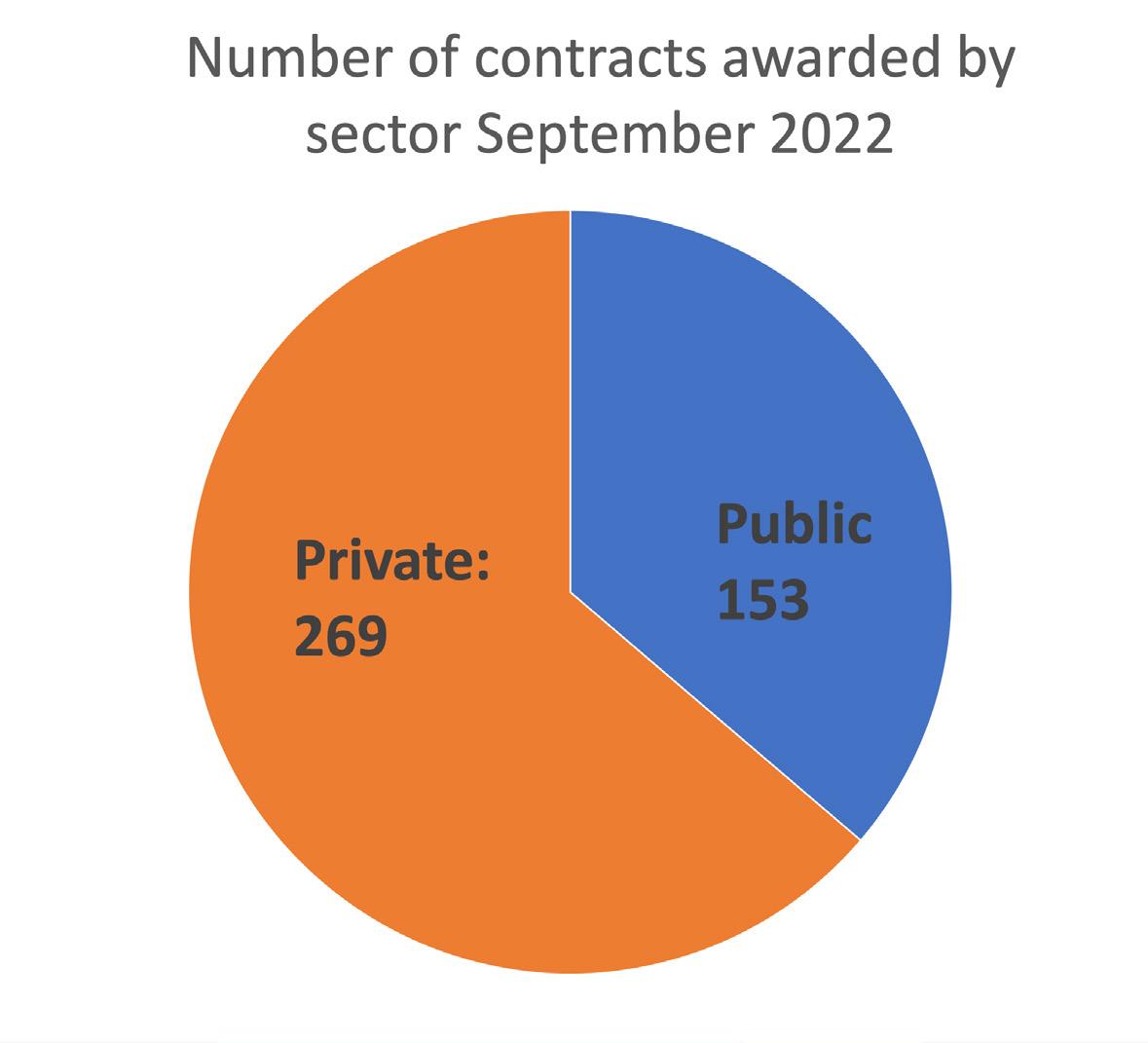

UK construction equipment sales Jan to August 2022 v Jan to August 2021 for major equipment types Source: Systematics International % change Unit sales Jan/August 2022 (thousands) 24.7 4.0 0.8 1.9 4.3 12.9 0.9 TOTAL Telehandlers Wheeled Others Crawler Mini/Midi Road (Construction) Loaders Excavators Excavators Rollers 2.5 % 24 % 7 % 5% 7% 8 % 9.5% Source: Systematics International 2019 2020 2020: 24.5 % UK construction equipment sales Monthly (Units) (24.2 k) % change v same month previous year 2019: 7 % (32.0 k) 2021 2021: + 48 % (36.4 k) 2022 6%6% 2022 (Jan/Aug): 2.5 % (24.7 k) 1% 18% 1%3% UK construction

sales grow

August DIGGERS 12LIVE www.diggers.live

MECALAC to LAUNCH A COMPLETE ZERO-EMISSION ECOSYSTEM FOR URBAN WORKSITES. We are excited to announce that we will become the first manufacturer to develop a full range of medium-sized electric products, along with an on-site high power battery charging solution called M-Power. Intelligent, clean and silent construction sites are just around the corner. For more information visit: www.mecalac.com/en/news-and-press.html mecalac.com - + leading the charge. it’s electrifying.

Wraps come off JCB’s hydrogen refueller

JCB, developer of the world’s first working construction machines powered by hydrogen, has unveiled another world first for the industry – a mobile hydrogen refueller.

The company is investing £100m in a project to produce super-efficient hydrogen engines and has already showcased working prototypes of a backhoe loader and loadall telescopic handler powered by hydrogen.

Now JCB has announced another industry first – a mobile hydrogen refueller, providing a quick and easy way for customers to refuel their machines on site. Around 97% of construction machines have fuel delivered to them while working on site. This means customers are already used to a transportable fuel, allowing refuelling to take place in a matter of minutes.

JCB Chairman Lord Bamford, who is leading JCB’s hydrogen project, said: “Since we became the first construction equipment company to unveil machines powered by hydrogen, many have asked how they can be refuelled.

“Well today we have an answer with our new mobile hydrogen refuelling system, which allows hydrogen to be taken from on-site tube trailers and distributed to machines by our refueller as they work on the job site. This is no different to today when diesel is taken in bowsers to refuel machines.

“Fossil fuels are not the future and hydrogen is the practical solution to powering our machines in the decades to come. Our British engineers are doing a fantastic job in developing this technology and there are many more exciting developments to come.”

A team of 100 engineers is working on the project. The first hydrogen powered machine to be unveiled was a JCB backhoe loader followed, a year ago, by a loadall telescopic handler. The technology was shown in the Green Zone at COP26 in Glasgow as world leaders debated measures to drastically reduce greenhouse emissions.

NEWS

West Midlands Metro Mayor, Andy Street fills the tanks with hydrogen

Breaking News from

LIVE EVENT DIGGERS 16LIVE www.diggers.live

LIVE EVENT DIGGERSLIVE www.diggers.live17

Brand new ADT concept from Doosan Another world premiere for Doosan at bauma is the launch of the company’s new 4×4 articulated dump truck (ADT). Complementing the company’s standard, market-leading range of 6×6 ADT models, the new 4×4 version of the DA45-7 ADT is intended to compete with rigid dump trucks (RDTs) in the 40-tonne class. In the new 4×4 ADT, the front truck and cab unit is the same as in the original 6×6 model, with modifications being made on the rear dumper unit only. Featuring a ZF EP8420 transmission, the 4×4 DA45-7 is a two-axle ADT with twin wheels at the

Doosan machinery premieres at bauma Doosan premiered a number of products at bauma. Find a selection here. LIVE EVENT DIGGERS 18LIVE www.diggers.live

rear, and with a dumper section similar to that on RDTs in the 40-t class.

The new DL-7 range of wheel loaders Making its first appearance at bauma, the award-winning ‘DL-7’ wheel loader range from Doosan will be represented on the Doosan stand by the DL200-7, DL280-7, DL420CVT-7 andthe topof-the-range DL580-7 models, four of eleven models in the range.

Redesigned buckets offering up to 7% more capacity ensure the new Doosan DL-7 wheel loaders provide easier and faster loading with maximum bucket capacities from 2.0 to 6.4 m3.This provides increased productivity for a very wide range of material-handling applications.

These include the transport and delivery of soil, sand, aggregates and other materials in industry, recycling, waste, construction, demolition, mining and quarrying. Doosan is also offering a wider choice of options to provide more work tools for a better match with applications, further increasing output.

The Z-kinematic lift arm delivers high breakout forces and lifting capacities, especially for heavy materials, and a large dump angle for efficiently unloading sticky materials. An optional high lift arm is available where higher dump heights and increased versatility are required.

The DX225LC-7X – Doosan‘s first ‘smart‘ excavator Shown for the first time in the world at bauma, the new DX225LC-7X –Doosan’s first ‘Smart’ crawler excavator is designed to help operators work faster and more efficiently. To facilitate this, the DX225LC-7X offers a number of exciting new features as standard, including Full Electric Hydraulic (FEH) technology.

Doosan excavators are well known for offering more innovative features as standard than other machines on the market. But the new DX225LC-7X smart model takes this to a new level. As well as the FEH system, other standard features of the DX225LC7X include: Integrated 2D Machine Guidance, Semi-Automatic 2D Machine Control, Laser Receiver, E-Fence Virtual Wall, Weighing System

In the latest development in the DX225LC-7X, the machine is now 3D Trimble-ready andEngcon ready as standard from the factory. Once the machine has been delivered to the customer, they can simply contact their local Trimble dealer for a 3D extension, as well astheir local Engcon dealer to install a tiltrotator.

New medium-sized DX-7 excavator range Doosan‘s new medium-sized ‘DX-7’ range of 17 Stage V crawler and wheeled excavator models from 14 to 25 t also made its first appearance at bauma. Altogether, the new medium-sized DX-7 models provide significantly higher performance in every area than the previous generation Stage IV machines.

They combine enhanced comfort, increased tool carrier capability and novel operator assist technology, with new features to boost fuel efficiency, uptime and return on investment, with a focus on increased power, robustness and agility. Maintenance of the diesel particulate filter (DPF) has also been greatly reduced, with no maintenance required until the machine has operated for 8,000 hours.

Next generation Doosan compact excavators bauma provided a first look at selected models from Doosan’s next generation

compact excavator range, including the DX100W-7 10.7-t wheeled excavator, which offers a high performance solution for customers looking for a wheeled excavator designed primarily for urban and road maintenance applications.

For this type of work, the DX100W-7 offers the best compromise between compactness and agility, complemented by excellent productivity and high-end comfort. It is very important that this type of machine can operate in very restricted areas, so the DX100W-7 can be equipped with the option of four wheel steering and a crabbing mode, with two wheel steering as standard.

The new DX27Z-7 2.8-t, DX35Z-7 3.9-t, DX50Z-7 5.4-t and DX55R-7 5.7-t Stage V compliant mini-excavators are all ideal for confined space work in construction, landscaping and utility projects.

A novel platform design featuring new upper structures has increased durability/robustness and this is complemented in all four new miniexcavators by a larger working range than other equivalent machines on the market, coupled with higher lifting capacities and digging forces.

New compact wheel loaders

Following the signing of an exclusive supply agreement with Netherlandsbased Tobroco-Giant, Doosan has confirmed the details of the new five model range of 3.5 to 5 t compact wheel loaders comprising the DL60-7, DL657, DL80-7, DL85-7 and DL80TL-7 models.

Just like their heavier versions in the Doosan range, the new compact wheel loaders set the industry standard for productivity, flexibility, comfort, safety and reliability. All the new machines offer a full package of modern technology features.

LIVE EVENT DIGGERSLIVE www.diggers.live19

Faresin Industries at bauma: innovation, sustainability, power

The Italian company came to this edition of the prestigious international exhibition with a formidable and complete range of telehandlers that represent the state of the art in the industry. Machines born for the construction site that incorporate all the innovation and smart solutions that Faresin Industries introduces to the market.

Technologies designed to make operators’ work smarter and more efficient that are designed and manufactured in the Breganze plant with the aim of constantly

raising the bar of performance and offering cutting-edge construction solutions.

At bauma Faresin will presented the latest innovations dedicated to the world of construction and industry. The Vicenzabased brand thus follows the innovation path at the service of the customer that includes, for each season, the introduction of new models able to respond in a timely manner to the evolving demand.

bauma 2022 was also an opportunity for the world premiere of a new FULL ELECTRIC telehandler that takes its place

FS Compact

FS Compact

Big Range Full Electric LIVE EVENT DIGGERS 20LIVE www.diggers.live

in perhaps the most important segment for lifting activities for construction and industry. It is the 17.45 FULL ELECTRIC from the new Big Range FULL ELECTRIC range, a machine with construction in its DNA.

FULL ELECTRIC

The FULL ELECTRIC you didn’t expect – a telehandler designed for the modern construction site that can deliver similar performance to machines with endothermic engines and an indispensable partner in areas with eco-sensitive regulations.

Born to work at height

The Big Range FULL ELECTRIC series is presented at Bauma with the new 17.45 FULL ELECTRIC, the world’s first electric telehandler with a maximum lifting height of 17 m and a maximum lifting capacity of 4.5 t. Its front outriggers ensure high performance and great stability on any type of terrain when lifting and handling at high altitudes.

Smart power

At the heart of the new telehandler is a 45.36 kWh high-voltage lithiumion battery pack at 435 V that powers two electric motors: one, 51 kW, for transmission; the other, 23 kW, dedicated to services. The power is delivered as needed thanks to a made-in-Faresin process that avoids wasted energy in favour of charge duration.

Thanks to this “smart” power, performing the Big Range FULL ELECTRIC is absolutely comparable to that achieved with diesel engines. The numbers speak for themselves: peak pulling force 44.3 kN; top speed 25 km/h.

Universal charge

The asymmetrical availability of different power systems has always been a weakness of electrified construction vehicles. For the Big Range FULL ELECTRIC, this problem becomes history. In fact, the onboard system allows batteries to be recharged with absolute flexibility, thanks to a single plug interface for 220 V

single-phase and 400 V three-phase power supplies such as for the fast-charging column.

Full range

The new Big Range FULL ELECTRIC series, like its diesel-powered twin, includes three models:

• 14.42 FULL ELECTRIC, with a capacity of 4.2 t and a maximum lifting height of 14 m,

• 17.40 FULL ELECTRIC, with a capacity of 4 t and a maximum lifting height of 17 m,

• 17.45 FULL ELECTRIC, with a capacity of 4.5 t and a maximum lifting height of 17 m.

The Big Range series kicks off the successful fulfillment of the FARESIN FULL ELECTRIC line-up, which began in 2018 with the 6.26 telehandler, also a world-first. A new and important step along the strategic axis of sustainable innovation, which drives the Faresin Industries brand’s path of constant growth and improvement.

6.26 Full Electric 17.40 LIVE EVENT DIGGERSLIVE www.diggers.live21

Kubota showcases new electric machinery

Kubota unveiled two new electric articulated wheel loaders at this year’s bauma exhibition, enhancing its popular Smart Energy Solutions construction machinery range to offer operators more sustainable options.

Showcased to the public for the first time, the new RT210-2e and RT220-2e are Kubota’s first electric articulated wheel loaders, ideal for construction sites that require low noise levels and no CO2. The launch of the two new Kubota machines follows the recent introduction of an LPGpowered mini-excavator and a fully electric track dumper, giving users more options than ever before to drive down

maximum reach (a lifting height of 2.82 m) and a lifting capacity of 1,450 kg. In addition, the RT220-2e has a shorter arm (a lifting height of 2.45 m) with a lifting capacity of 2,054 kg, perfect for heavy-duty loading applications. With an overall width of only 1.08 m and a machine height of 2.30 m, the new wheel loaders are ideal for use on narrow and compact construction

all-wheel drive machines include a differential lock in the front and rear axles for limited slip, as well as three driving speed levels (0-5 km/h / 0-12 km/h / 0-18 km/h).

Mark O’Brien, Product Manager for Kubota (UK), said: “The topic of sustainability has never been more prevalent in the construction industry and it’s vitally important that we not only provide operators with machinery that is robust and reliable, but also helps reduce our environmental impact on our working environment.

“We take our company motto For Earth, For Life very seriously and the introduction of two new electric wheel loaders is another example of how we can offer our customers more sustainable solutions as we work towards a greener construction industry.”

LIVE EVENT DIGGERS 22LIVE www.diggers.live

Exciting times for Auger Torque

This year Auger Torque launched two new products; the Cone Crusher Bucket and InSite Range, as well as the launch of the Kinshofer Drum Cutter range coming under its portfolio.

The Cone Crusher Bucket is the first of these, suitable for parent machines in the 3-10-t bracket, it quickly and efficiently repurposes rubble into usable hardcore of approximately 40-70 mm in size. Tried and tested on excavators, telehandlers, skid steers and mini loaders, Auger Torque has already seen considerable success in the UK market. One customer states that the cone crusher bucket has saved him nearly £1,000 per day when it comes to repurposing on-site aggregate to use as hardcore across his farm. Demo days are being run across the UK for this product – so get in touch if you want to see it in action for yourself.

In-Site is its new range of data driven tools to give operators knowledge and insight whilst out in the field. A plug and play tool, with one power cable, sensor plugs and a handled touchscreen device, the In-Site range of products provide accuracy, precision and efficiency. There are three exciting products in the InSite range. In-Site Align which ensures accurate alignment when drilling holes, preventing the need for an additional person to help align drilling. In-Site

Data which along with the alignment functionality has the addition of pressure sensors so the operator can be sure the correct torque parameters are being met, Finally In-Site Data Plus, suitable for 13 t machines and above, has all the functionality of the first two models with the addition of temperature and speed sensors assisting in the long term maintenance of the drive, as well as ensuring all the correct operating parameters are met. All come boxed with the sensors and a wireless touch screen handheld tablet, with all data recorded easily viewed for that further level of analysis back at base.

And finally Auger Torque is proud to promote the new offering to its portfolio, the Kinshofer Drum Cutter range. Originally a Kinshofer product, Auger Torque is excited to take over the manufacturing, development, sales and support for this attachment range globally. High quality design, manufacturing and parts guarantee high performance levels in the toughest of environments, as well as submerged operation in water of up to 25 m depth. Kelvin Hamilton, Product Manager for the KDC range states, “The KDC drum cutters are the ideal attachment to scale rock or concrete walls, tunnel excavation, trenching in extreme grounds or loosen any hard rocky ground in the most efficient way.”

LIVE EVENT DIGGERSLIVE www.diggers.live23

Merlo showcases latest innovations

bauma is the world’s leading construction trade show. The show represents an opportunity for the construction industry to see the numerous innovations across the sector which led the way in global economic recovery through, and after, the pandemic. At this year’s event, bauma focused on five pillars of digitisation and sustainability for the construction industry. Key amongst these are: Construction methods and materials of tomorrow; The digital construction site; and The road to zero emissions.

In line with this year’s bauma key pillars and Merlo’s recently circulated

environmentally friendly industrial strategy, Merlo is presenting seven new machines, and four new attachments at this year’s bauma, with several of these continuing Merlo’s journey into Generation Zero which was started last year with launch of the eWorker, Merlo’s first fully- electric telehandler.

Compact telehandlers: Following tremendous demand for a 2x2 model to replace Merlo’s previous popular compact P32.6 model, Merlo has developed a range of three compact telehandlers – with a maximum load

capacity of three t, and a maximum reach of 7 m. These new models (P30.7 and TF30.7) will have similar performance and dimensions to the P32.6Top, while offering far more developments (optional lowered cab, new style boom) to increase versatility in the workplace.

These new compact machines will offer three different machine heights and an optional suspended cab (the only compact machine on the market offering cab suspension).

Rotating telehandlers: The ROTO50.18S is the latest development in Merlo’s ROTO400 range. This range has been revamped to meet the continually evolving requirements of the operator. Some of the improvements include: Increased maximum capacity; Improved load charts; Improved dynamic behaviour (slowing the boom to match load, not position); and Increasing functionality.

Stabilised telehandlers: Increasing comfort and performance, Merlo has developed a new telehandler configuration with stabilisers: CS-Top. This new specification does not change the load chart of the machine, and is available for the following models: P40.13, P40.17, P50.18.

There are two new features designed to increase operator comfort with the new CS- Top models: Merlo Cab Suspension (mounting the cab onto the chassis using hydropneumatic suspension); and a new flow sharing hydraulic distributor, offering greater machine performance due to a variable displacement pump capable of delivery of up to 145 l/min.

Dumper: The all-new Merlo DM9 Dumper debuted at this year’s bauma. These rigidchassis machines, designed to handle large quantities of material, will have a maximum load capacity

Overview of the Merlo bauma stand

LIVE EVENT DIGGERS 24LIVE www.diggers.live

of 9 t, and will be able to unload using fixed tipping or using the 180° of rotation standard on the machine for three-sided unloading.

The Merlo DM9 will use an electronically controlled hydrostatic transmission providing a maximum speed of 40 km/h, and will be one of the most compact machines on the market of its capacity, with a width of 2.3 m, length of 4.8 m and height of 3 m.

M600TD-e Carrier:

The newest member of the Merlo Generation Zero family of machines, the fully-electric M600TD-e Cingo Tracked Carrier uses an electrical pump to drive the machine, with two electric gear motors to drive the tracks. Additionally, the machine uses a biodegradable hydraulic oil to further increase the overall sustainability of the machine’s design.

The M600TD-e has a 4-hour runtime, with a recharge time of one and a half to three hours. The machine is compact, high performance and, being electric, is zero noise, zero vibration, and zero emission.

M700TD Carrier: The Cingo M700TD Tracked Carrier uses a Stage V 12HP Honda petrol engine, and has a maximum load capacity of 700 kg. The external width of the machine has recently been reduced to just 750 mm to help with navigation through more confined spaces. The M700TD comes equipped with a HiTip dumper.

At this year’s bauma, Merlo presents its first aerial work platform developed specifically for the fully-electric eWorker. This new two-person aerial work platform has a load capacity of 200 kg, with dimensions of 1,100 mm x 700 mm.

A new sweeper attachment is also on show at bauma. This attachment is designed for cleaning road surfaces, removing fresh snow and more.

Continuing Merlo’s development of dedicated forestry machines and attachments, a brand new log grab is on display at bauma. This new log grab, bespoke for Merlo machines, will be available in three different versions depending on the machine used.

Finally, Merlo extends its range of aerial work platforms with a new

sliding extension version (as opposed to a traditional tilting extension). This aerial work platform is able to rotate up to +/- 90°, and has a width of 3,400 mm, which can be extended, making the platform up to 5,500mm. The platform has a maximum load capacity of 700kg, and is able to carry up to three operators.

MerloMobility 1.1.

The ROTOSPLUS vehicles are equipped with the latest evolution of the MerloMobility telematics system, version 1.1. MerloMobility is an exclusive, Merlo developed technology making machines more connected and intelligent than ever. Using MerloMobility, the operator is able to remotely monitor and manage their Merlo (or fleet of Merlo machines), and is able to analyse all operating and operational data.

Key features include tracking and logistics, remote control of machines, engine block setting, and maintenance alerts. The Merlo service network, using MerloMobility, can monitor and manage fault codes and update machine software remotely.

Merlo DM9 Dumper

Merlo P30.7L

LIVE EVENT DIGGERSLIVE www.diggers.live25

Liebherr hydrogen excavator receives Bauma Innovation Award

The jury has made its decision: The 2022 Bauma Innovation Award in the climate protection category goes to the R 9XX H2 hydrogen excavator. This is the first Liebherr hydraulic excavator to be powered by a hydrogen engine.

Suitable for use under extreme temperatures, shock, and high-dust conditions on construction sites, the 50t operating weight R 9XX H2 may in future offer a robust solution for earthworks and quarrying applications. Suitable for use under extreme temperatures, shock, and high-dust conditions on construction sites, the 50-t operating weight R 9XX H2 may in future offer a robust solution for earthworks and quarrying applications.

Working on alternative drive solutions, Liebherr takes a technology-neutral approach. Hydrogen combustion engines are one technology being explored by the Group. The R 9XX H2, Liebherr’s first hydrogen-powered crawler excavator, has now won the Bauma Innovation Award. The prototype was developed by LiebherrFrance SAS, based in Colmar, France. The machine is powered by an H966 hydrogen combustion engine. It was produced at Liebherr Machines Bulle SA, the Liebherr Group’s engine competence centre in the Swiss canton of Fribourg.

In terms of power, dynamics and responsiveness, the R 9XX H2 hydrogen excavator gives nothing away to any conventionally powered machine. Nor is it dependent on a continuous energy supply either. The emissions make the difference: On a “tank to wheel” basis, i.e. when used on a construction site, a hydrogen excavator emits almost no CO2. “Cradle to grave” or from

production to decommissioning, CO2 emissions are 70% lower than those of comparable conventionally powered excavators. Suitable for use under extreme temperatures, shock, and high-dust conditions on construction sites, the 50 t operating weight R 9XX H2 may in future offer a robust solution for earthworks and quarrying applications.

The R 9XX H2 is powered by a Liebherr H966 hydrogen combustion engine. The engine has six cylinders and uses port fuel injection (PFI), which Liebherr employs along with direct injection (DI) for its hydrogen engines. Liebherr’s components product segment plans to start with the series production of hydrogen motors by 2025.

The prototype six-cylinder H966 hydrogen engine is the heart of Liebherr’s first hydrogen-powered crawler excavator. The prototype six-cylinder H966 hydrogen engine is the heart of Liebherr’s first hydrogen-powered crawler excavator.

LIVE EVENT DIGGERS 26LIVE www.diggers.live

Remotely manage your job site

Do you want to learn more? Visit topconpositioning.com/gb

Stay aware, even when you aren’t there. Sitelink3D v2 is a web-based platform providing managers, personnel and other stakeholders with a suite of tools to help them effectively manage, monitor and support their job sites. Its secure, cloud-based data center provides site-wide data synchronisation between all the site’s machines and users on a pay-by-the-day basis. T: 0845 450 4300 · E: marketing.gb@topcon.com

Steelwrist

At bauma Steelwrist offered visitors the opportunity to see product news first hand and watch demonstrations of how the tiltrotator and the SQ Fully Automatic Quick Coupler system increase excavator efficiency. Steelwrist SQ is a high performing fully automatic oil connection technology, used in quick couplers and tiltrotators on excavators

to connect hydraulic work tools. The SQ50 quick couplers and tiltrotators for mid-sized excavators are new additions to the Steelwrist range of SQ products. Steelwrist also presented X02, a new model in the tiltrotator range, for excavators below 2.5 t.

The new range of SQ50 quick couplers and tiltrotators is targeted toward 7-13

Steelwrist SQ is a high performing fully automatic oil connection technology, used in quick couplers and tiltrotators on excavators to connect hydraulic work tools. Outstanding flow characteristics and competitive building height and weight are significant advantages of SQ50. SQ50 meets the specifications of the Open-S standard for fully automatic quick couplers.

S50 and SQ50 quick couplers are steel cast and have the Steelwrist Front Pin Lock safety solution. Front Pin Lock is a mechanical lock of the front shaft which significantly limits the risk of an unintended drop of work tools.

The X12 and X14 tiltrotators are redesigned with a new top and attachment

tonne excavators.

LIVE EVENT DIGGERS 28LIVE www.diggers.live

coupler in order to make it possible to upgrade from S50 to SQ50 at a later stage, even if the customer did not include SQ in the initial order.

SQ on the top side (upper coupler) of the tiltrotator for rapid change between tiltrotator and other work tools, and SQ on the bottom side (attachment coupler) of the tiltrotator will allow for rapid change between hydraulic work tools. By using SQ, tiltrotator work tools can be made less expensive as the rotation function is included in the tiltrotator.

“With the introduction of SQ50 fully automatic quick couplers and tiltrotators, we will change the game in the growing 10 t excavator segment with flow capacities of 120 l/m with low back pressure. This allows for efficient use of high flow work tools also for mid-size excavators,” says Stefan Stockhaus, CEO of Steelwrist AB.

High flow hydraulics and Absolute Rotation Sensor

With the introduction of SQ50 the Qplus technology has been updated to allow for even higher flows, adding another 20% to flow capacity, which allows users to run also the high flow requiring work tools on mid size excavators.

With the introduction of SQ50 Steelwrist is implementing a new Absolute Rotation Sensor on the tiltrotators in order to give higher accuracy to Machine Control Systems. Full implementation is expected in Q1 2023. Together with Steelwrist Autotilt this allows for even higher productivity.

SQ products that meet the demand from the demolition industry

The Steelwrist range of SQ fully automatic quick couplers includes models for excavators up to 70 t. The latest addition to the range of SQ products for

the demolition industry, the SQ90 quick coupler, will also be presented at the Steelwrist stand.

Open-S compliant solution

All Steelwrist SQ products follow the global Open-S industry standard for fully automatic couplers for excavators. This means that the SQ system is designed to be able to connect to other brands following the Open-S standard.

Steelwrist expands the tiltrotator range with X02 for excavators up to 2,5 t.

The installation ratio for tiltrotators on the smallest excavators is starting to grow globally and in response Steelwrist is now introducing the new X02, a tiltrotator suitable for 1.5-2.5 t excavators.

The X02 is accompanied by a complete range of work tools resulting in increased efficiency and versatility which convert also the smallest excavators into true tool carriers.

LIVE EVENT DIGGERSLIVE www.diggers.live29

The SENNEBOGEN 821 E, with its operating weight of approx. 24 t and reach of 12 m, has been shaping the machine landscape in waste recycling for years. It is precisely this machine, which can be universally used for recycling, that the developers at SENNEBOGEN have set out to transform into a new generation of machines. True to the motto “Try new things, make tried-and-tested things even better,” the 824 G series now impresses with increased performance and even lower fuel consumption.

SENNEBOGEN 824 G: universal recycling material handler with impressive service concept

The new 824 G series serves the smaller material handler segment and, with its

reach of 12 m and the wide range of different equipment options, proves to be a versatile all-rounder in the recycling or scrap yard. Whether equipped with crawler or mobile undercarriage, equipment lengths from 10 to 12 m and/or ULM rod variants – equipment with a special deflection mechanism for sorting grabs –the 824G can be used to implement a wide variety of application-specific solutions. In addition to sorting activities, the robust machine is thus also perfect for loading tasks and can cope with demanding continuous use in challenging working environments, such as high dust levels, heat or extreme weather.

The newly implemented service concept of the SENNEBOGEN G series, with clear and simplified access

The SENNEBOGEN 821E becomes 824 G series LIVE EVENT DIGGERS 30LIVE www.diggers.live

to service points such as the central lubrication system and tanks, makes everyday maintenance easier. Further technological innovations also ensure that the service intervals have been extended once again overall.

Higher load capacity, lower consumption

The load capacities of the SENNEBOGEN 824G have also been increased by more than 10% compared to its predecessor. This means that the machine not only lifts more, but can also handle more material per work cycle with the right equipment. The machine also has a highly efficient and environmentally friendly Stage V diesel engine with 118 kW of power. By rightsizing the engine, which now runs at a

speed of 1,725 rpm as standard, both noise emissions and the consumption of the machine have been reduced, thereby also sustainably reducing operating costs.

Special eco-settings as well as largescale lines and hydraulic valves relieve the pressure on the pump system, ensure optimal efficiency and make the material handler particularly efficient and resourcesaving overall.

Increased speed and precision

With the consistently enhanced machine concept, the 824G impresses as another representative of the 6th generation thanks to excellent responsiveness, making sensitive sorting work at the recycling or scrap yard child’s play in the future. Thanks to the state-of-the-art

control technology of the latest machine generation, the working clearance of the machine is perfectly coordinated: combined or overlapping movements with optimal swivel speeds enable fast working processes without having to compromise on precision. Thanks to the memory-based operator profiles, where the hydraulics can be adjusted precisely to the respective operator, valuable time can also be saved at the start of the shift when changing operators.

New comfort cab and safety features In addition to numerous optimisations in terms of seating comfort, air conditioning and control panel, the spacious Maxcab now offers even more options for making day-to-day work particularly comfortable and safe. The large window elements provide a clear view to the front and sides. The windscreen is even made of bulletproof glass as standard, providing optimal protection for the operator. The new elevating cab, which is also installed as standard, is not only even higher than before with a height adjustment of 2.80 m, but is also particularly robust and stable in dynamic use. It allows an eye height of up to 3 m and thus an optimal overview or a direct view into the shredder or scrap press.

An extensive camera system and intelligent control and diagnostic systems also provide support in the daily handling of the machine. The new SENtrack telematic system is also installed as standard, providing the most important machine data such as maintenance requirements, utilisation, fuel consumption and hydraulic pressures in a user-friendly manner, thus facilitating service management of the machine or the entire fleet.

LIVE EVENT

DIGGERSLIVE www.diggers.live31

EQUIPMENT ENGAGEMENT

Joris Tijtgat and TVH go way back. His first introduction to the company was in 2012, as part of his graduation thesis for his bachelor’s degree in electromechanics. Joris loved working at TVH and that love was mutual. So when TVH asked him to become a permanent member of the Hydraulics Team, Joris happily accepted. After having held various roles within that team, he settled into his current position as Team Leader of the SEM Team (Small Earth Moving Equipment Team) in 2019. When not at TVH, Joris enjoys spending time with friends and family, as well as relaxing with his girlfriend. They live together with their guppies (a.k.a. Poecilia reticulata), in Torhout, Belgium.

Founded in 1969, TVH has over 50 years’ experience as a supplier of parts and accessories for forklifts, industrial vehicles, construction and agricultural machinery. What started with two founders has grown into a company of more than 5,000 employees, with offices and distribution facilities on every continent. As such, TVH supplies customers from at least 180 countries as a one-stop shop.

Tell us about TVH and its working culture

TVH’s main goal is to keep our customers going and growing. We are committed to

Interviewee: Joris Tijtgat Role: Team Leader Technical Information Service – Small Earth Moving Equipment Company: TVH Parts Holding (HQ in Belgium)

INTERVIEW

Q

Tell us about the history and development of TVH

Q

About TVH DIGGERS 32LIVE www.diggers.live

providing all products and services to keep equipment running smoothly.

TVH and its employees operate according to five values, abbreviated as PARTS:

Pursue excellence: What we do, we do well, every day. We are skilled, professional and focused on delivering. We learn from our mistakes in our pursuit of perfection.

Act with joy: We bring energy and enthusiasm in everything we do. We care about the personal growth and wellbeing of our people. We have fun working together, share and celebrate our successes. This is what builds our diverse global community and empowers us to make a difference.

Remain open minded: We value clarity, mutual respect, kindness and open communication. We are down-to-earth, easy to work and engage with. We don’t make things complex.

Take initiative: We think and act as responsible owners, ambitious and passionate. We’re always looking to identify opportunities and creatively translate those, making them successful.

S how courage: We challenge the status quo and make courageous decisions. We are brave and willing to take risks to reinvent both ourselves as well as the markets we play in.

QWhat can a customer expect when they buy from TVH?

Customers buying from TVH can expect to find all parts and accessories needed to keep their equipment going. We have a database of over 46,000,000 part numbers, including more than 930,000 different references in stock, and that range is continually growing. More parts and accessories are added every day.

If customers have difficulties locating the parts they need, they can always contact us. Our in-house experts are always happy to assist through various channels, such as email, phone, our online shop, etc. We have 62 different nationalities and 55 spoken languages in the company, so we can offer customers support in their own language.

QWhat is TVH doing with regard to sustainability?

At TVH, we highly value sustainability and environmental friendliness. We are firm believers in the circular economy and are convinced that waste should be avoided at all costs. That is why, rather than discarding malfunctioning or broken parts, we always try to repair them first. Every day, the skilled technicians and engineers

in our Parts Workshop and Electronics Department ensure that remanufactured parts are of the highest possible quality. That way, our customers also have the option to buy parts at a lower price, but with the same warranty and top quality.

INTERVIEW

DIGGERSLIVE www.diggers.live33

QTell us about the focus of your key products and services

Within construction equipment, one of our focuses is small earthmoving equipment (SEM). We specialise in small earthmovers that weigh up to 10 t. For now, that scope contains three types of equipment – mini-excavators, skid steer loaders and compact track loaders, but a fourth type will be added at the start of 2023: the backhoe loader.

For those machines, TVH offers over four million known references. That range includes cabin parts, engine components, filters, electrical components, hydraulics, tracks and undercarriage parts, bucket teeth and blades, pins and bushings, consumables and much more.

Q

Outline the scope of your parts ranges

TVH’s high-quality replacement parts are suitable for all major makes of small earthmoving equipment, including Bobcat, Case, Caterpillar, JCB, John Deere, Kubota, Takeuchi, Volvo and Yanmar. Those nine makes represent the largest global market share within our submarkets, so we take proactive action for them. However, we also reactively develop makes other than our nine focuses, such as Hitachi, Komatsu, Wacker Neuson and more.

QTell us about the backhoe loader ranges and how you came to move into that area

There are several reasons that we wanted to expand our range of backhoe loader parts available to our customers.

Obviously, the needs and requirements of our customers played an important role in this. In the early 1990s, the revolutionary backhoe loader was the best-selling machine in small earthmoving. However, in the late 1990s and early 2000s, the backhoe loader was replaced by new machines such as skid steer loaders, compact track loaders and mini-excavators. Although the backhoe loader may not be as popular as it used to be, many machines are still in use so there are still a lot of customers who need spare parts.

Finally, on a technical level, we see a lot of overlap with other machines (e.g. telehandlers) so we simply have a lot of parts already in stock.

If you have a backhoe loader in your fleet that could use new parts, don’t wait until the official launch in 2023 to shop at TVH. Not only do we have plenty of parts in stock, but we have also been researching and developing backhoe loaders for some time. Therefore, chances are we can help you now.

QTell us about the other services you offer

Our remanufactured service is definitely something that sets us apart from many other suppliers. These parts are a perfect alternative to buying new parts. You get a top-quality part at a lower price, backed up with the same warranty as a brand-new part. How does it work? We repair parts according to strict quality standards, that are placed in stock afterwards.

We also offer free access via our website to our TVH Learning Hub where visitors can view relevant blogs, videos, guides etc, that enhance their expertise.

By filtering on product categories and equipment types, you can find content tailored to everyone’s needs. We share half a century of market experience completely for free.

Furthermore, customers can send us their defective electronic parts for repair.

Our Electronics Department is probably the largest, best equipped and most diverse service centre for electronic parts for all types of electric vehicles.

Finally, we would also like to highlight our technical training offer. TVH University offers hands-on technical training courses suitable for industrial vehicles such as small earthmovers,

INTERVIEW Products & Services DIGGERS 34LIVE www.diggers.live

forklifts, telehandlers, mobile elevating work platforms and tractors.

Participants can certify in industryrelated topics such as internal combustion engines, electrics/electronics, hydraulics and power electronics. Highly qualified trainers with years of practical experience give their best. Our courses include in-person training classes as well as digital training packages.

QHow do TVH’s product lines make a difference for potential users?

Our main goal is to keep all our customers going. For them, getting the right parts at the right time is crucial to save both time and money. That is why our highly trained staff are always ready to help our customers find the parts and accessories they need.

And if we do not yet have a particular part, our free extensive look-up service will process all requests. In addition, 99.8% of worldwide orders are delivered in the promised timeframe. In many cases, that means customers get their parts within 24 hours.

QTell us about the development of your offering

If I were to oversimplify it, the development of our range can be described as constant. While the official introduction of parts and accessories for small earthmovers took place in 2020, that market was not uncharted territory for us. We were already helping countless SEM owners and had many fitting

parts in stock. But at the same time, we noticed that some of our customers did not know that we could also supply spare parts for small earthmovers, so we decided to grasp that opportunity with both hands. It’s a work in progress, but our range of SEM parts is growing steadily and continuously.

Q

How will TVH be developing its product range in the near future?

Continually expanding our range, especially for small earthmovers, is one of TVH’s main objectives, whether that is with new parts, new brands or new equipment types. But there is always one common denominator – the introduction of a part, brand or equipment type in our range is largely based on the needs of our customers.

Of course, we also keep a close eye on the market and take action according to all trends and developments within small earthmoving. But the most important influences are the needs and expectations of our customers. And by that, I mean all our customers.

INTERVIEW DIGGERSLIVE www.diggers.live35

About Joris

QHow long have you been in the industry and how did you start out?

I have been working at TVH for more than a decade, but I was already familiar with the company before my first day of work in 2012. In fact, when I was still a student, I was actually hosted at TVH for my thesis. Together with some fellow students, I developed a test bench for transmissions and hydraulic pumps. And that project not only earned us high marks, the test bench won an innovation award and is still being used today.

Because of my dissertation, my first role at TVH was within the Product Development – Hydraulics Team. I was responsible for several products and eventually became Team Leader. In 2019, I moved to the SEM Team, which had been established the year before. Initially, I joined the SEM Team as Team Leader, but that role has evolved over the years. I am also active as an ad interim Market Management Specialist for SEM. This means that in addition to operational tasks, I also shape the small earthmoving strategy for EMEA and APAC.

Q

What attracted you to the industry?

In general, of course I am very interested in technology, but I am especially intrigued by the engineering of earthmovers such as mini-excavators, skid steer loaders, etc.

QWhat do you find most rewarding in work?

Q

Tell us about any interesting projects you have been involved with in your career

I have had the opportunity to participate in many interesting projects. During my time as a member of the Hydraulics Team, I have helped some customers create a passenger/goods lift in which I determined and designed the hydraulic pump group. Together with a supplier, I also designed our TVH hydraulic generator, which can be mounted on MEWP related machines.

Now within the SEM Team, the projects I am part of are very diverse. And I really enjoy the trust of the company to be able to outline the strategy around SEM in terms of pricing, go to market, marketing initiatives, development and more.

Q

Tell us about the different aspects of your work

Given my dual role, it is quite broad –managing the team with brand buyers and researchers on the one hand and being able to outline the approach regarding SEM on the other.

The trust I get from the company in developing a strategy for SEM is one thing, but I also get a lot of energy out of the cooperation with the many departments

and the international reach of contacts within TVH. The latter in particular makes it a lot of fun, because one day you are in contact with someone from South Africa, and the next day you are working on a strategy for Australia.

Describe

What do you do for fun?

What’s

INTERVIEW

yourself in three adjectives Passionate, driven and ambitious

Fitness, because it helps me relax

your ideal weekend? Hanging out with friends and family, or just relaxing with my girlfriend Autumn, winter, spring or summer? Summer, no doubt! AND FINALLY DIGGERS 36LIVE www.diggers.live

NEW G - SERIES WHEEL LOADER THE FULL RANGE OF CASE CE PRODUCTS AVAILABLE • WHEEL LOADERS • EXCAVATORS • BACKHOE LOADERS • SKID STEER LOADERS • MINI EXCAVATORS • DOZERS North & Yorkshire (HQ) Blacker Hill Barnsley S74 0RE T: 01226 747260 South 1 Coldharbour Pinnacles Estate Lovet Road Harlow CM19 5JL T: 01279 352900 www.warwick-ward.com Midlands Unit 3, Adams Way Springfield Business Park Alcester B49 6PU T: 01789 713131 CONSTRUCTION & EARTHMOVING EQUIPMENT MORE PRODUCTIVITY, MORE RELIABILITY, MORE PROFITABILITY, MORE CONNECTIVITY

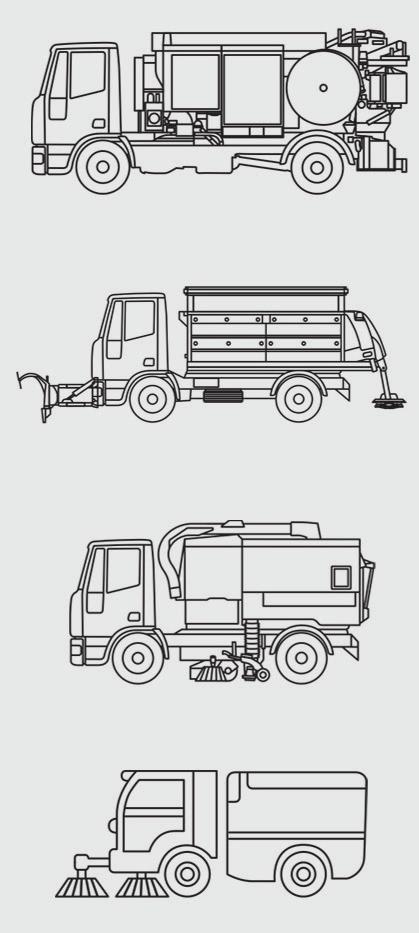

Dumper feature

convenience, machine strength, high productivity and

From climbing aboard and settling on the comfortable seat, everything is laid out logically and within easy reach.

From your comfortable, adjustable perch, you are in easy reach of all control buttons and levers with the advantage of not only a fuel warning light but a gauge too. This is finished off with a USB charger and phone holder for those long working days.

the whole of the machine is shotblasted and two-layer powder coated. This ensures great machine protection and excellent resale values. Along with the bushed and greased steering pivot cylinder, belly plate, front and infill plate, hose cover plates and a strengthened chassis, nothing will break in to stop this machine.

Powering the DX 1000HT through anything that a site can possibly throw at it is a Yanmar diesel engine driving a full 4-wheel hydraulic drive system.

A tight turning circle reduces shunting and time, along with the HiViz contact points, non-slip steps and footplate, retracting seatbelt and ROPS frame improving safety.

The British-built DX 1000HT 1-t HiTip Dumper was researched, designed, developed, and manufactured for the most arduous conditions by ALTRAD Belle with a focus on operator comfort

Nobody wants a machine that spends more time in a workshop than on-site. The DX 1000HT has got you covered. Its skip has fully returned edges that make cleaning a breeze and

Altrad DX 1000HT

Altrad DX 1000HT

FEATURE

Key features: • Altrad fully hydraulic 4-wheel drive for greater traction, • 1-t payload and 500-L heaped skip capacity, • Market leading fuel tank capacity, • Tight turning circle, • High-viz access points and non-slip steps, • Increased legroom, • High quality comfort seat, • USB charger and phone holder, • Easy-clean skip with fully returned edges, • Fully enclosed chassis to reduce ingress by stone and mud, • High quality shot-blasted and two-layer powder coating.DUMPERS DIGGERS 38LIVE www.diggers.live

dumper was designed to offer capacity for a full working day without needing to be recharged, and when necessary, you can connect directly to the mains via a 110 V, 230 V or 415 V socket with a fast charger. The li-ion battery pack is managed electronically to offer maximum power in a smooth way and with all-terrain conditions

match diesel vehicles. When the accelerator is released, the electric motor reduces the speed instantaneously while the energy is regenerated. Thanks to minimal noise emissions, it can be used in more applications than a traditional dumper, including at night, and permanent 4WD delivers the power to tackle the most difficult terrain.

FEATURE The D151AEG

that

AUSA D151AEG electric dumper DUMPERS Key features: • 1,500 kg payload, • Swivel skip, • 7.6 kW power, • 15 km/h maximum speed, • Up to 12.3 kWh battery capacity, • 2 h charging from 20 to 80%, • Li-ion battery. DIGGERSLIVE www.diggers.live39

Hyundai Construction Equipment has added two articulated dump truck models to its rapidly expanding line of heavy construction and earthmoving equipment. The HA30A and HA45A have rated payloads of 28 t and 41 t respectively, providing an ideal haul truck match for Hyundai’s larger crawler excavators and wheeled loaders.

Hyundai Construction Equipment is entering the articular dump truck market with two models, that use proven, innovative design and technology to deliver high productivity and superior mobility on site.

Aimed at the popular 30 and 45-t sectors, the HA30A and HA45A are built around a

full-time six-wheel drive concept, with front and rear limited slip differentials and a longitudinal differential that can be manually locked, for maximum drive and traction on difficult terrain.

The trucks have a compact chassis design to aid manoeuvrability, with a sloping rear frame and a front-mounted differential integrated into the ZF transmission, allowing for a shorter front frame section. This results in the smallest turning radius in the sector and outstanding stability. Selflevelling hydro-gas suspension on the front axle further supports a comfortable ride, delivering maximum tractability in tough ground conditions.

Key features:

• Equal weight distribution with sloping rear chassis frame delivers stability, by distributing more load on the centre of the machine, resulting in a low centre of gravity,

• Tandem rear axle bogie for highest level of ground contact and best-in-class traction,

• Innovative transmission concept results in shorter front chassis frame,

• Articulation joint turning ring mounted close to front axle leads to equal load distribution front to rear and across the front axle during steering,

• Spacious operator’s cab with easy access from the front of the machine.

FEATURE

Hyundai HA30 and HA45A

DUMPERS DIGGERS 40LIVE www.diggers.live

JCB’s first ever electric site dumper is a one-tonne high-tip model powered by lithium-ion battery technology. Designed to work indoors, underground and in emissions-sensitive areas, the 1TE electric dumper is an ideal partner for JCB’s market-leading 19C-1E electric mini excavator. The 1T-E site dumper is a durable, compact machine with a full steel skip

and heavy-duty articulated chassis. The machine replaces the individual wheel motors of the hydrostatic 1T-2 with conventional drive axles and a drop box, to provide full-time all-wheel drive. A 7 kW hydraulic motor delivers drive to the drop box, while a second hydraulic pump is used to power the machine’s standard hydraulic circuit, for steering and skip lift.

The power is supplied by two 5 kWh lithium-ion batteries, capable of providing full shift operation in normal use. The batteries can be recharged from conventional site electrical supplies, with 110 V and 230 V cables available. In addition, the optional JCB Universal Charger can be used to rapid charge the batteries for extended operation.

FEATURE

JCB 1T-E electric site dumper

Key features: • Two 5 kWh lithium-ion batteries, • Zero emissions and low noise levels, • Fast charge capability, • Full shift operation in typical use, • High-tip skip design to allow loading into skips and larger containers.DUMPERS DIGGERS 42LIVE www.diggers.live

With a powerful Komatsu EU Stage V engine, the advanced Komatsu Traction Control System, selectable working modes for on-demand performance adjustments, a robust exterior and state-of-the-art solutions for its suspension and retarder, the HM300-5 is a perfect choice for any jobsite, in any conditions.

The HM300-5 is built from Komatsu-manufactured components that successfully demonstrate their durability,

day after day. Tested and proven by several generations of Komatsu trucks, this top-selling technology sets the mould for all Komatsu ADTs. The entire power train of the HM300-5 is Komatsudesigned and the engine, transmission and axles are perfectly matched, for unsurpassed productivity and durability.

The variable displacement piston pump reduces Power Take-Off (PTO) loss. Improvements in transmission and axles increase energy savings, and

the sophisticated electronic control of the engine operation helps to achieve optimal energy efficiency.

For its world renowned rigid dump trucks, Komatsu developed various wheel slip control systems that were refined and combined with new technologies to produce the advanced traction control system that equips all HM300-5 machines. KTCS automatically provides optimum traction in any ground condition.

•

The HM300-5 has a payload of 28 t that combines with a loading height of only 2,830 mm to enable easy loading. The truck features a low centre of gravity and a high ground clearance.

Komatsu’s exclusive electronically controlled transmission, or K-ATOMiCS, is tuned perfectly for the HM300-5. The “total control system” manages both the engine and transmission by monitoring the vehicle’s condition. This Komatsu-designed technology guarantees smooth shifting and maximises transmission life.

FEATURE Key features:

Engine power: 248 kW @ 2,000 rpm, • Heaped body capacity: 17.1 m³, • Max payload: 28 t, • Low-noise design, • Hydro-pneumatic suspension, • Selectable working modes, • Adjustable idle shutdown, • Komatsu SpaceCabTM – built-in ROPS/FOPS, • Rear-view camera system, • Komatsu Wireless Monitoring System. DUMPERS

Komatsu HM300-5 ADT

DIGGERSLIVE www.diggers.live43

Perfectly blending stylish design with rental-tough build quality, Mecalac’s 3.5MDX cabbed site dumper sets the standards in performance, safety and comfort. A class-leading solution for carrying high payloads in confined job sites, the state-of-the-art model offers all the benefits of the Mecalac MDX range in a 3.5 tonne capacity.

Powered by a Stage V-compliant Kubota D1803 1.8 L turbocharged three-cylinder diesel engine, operators benefit from 37 kW at 2,700 rpm and a peak torque of 150.5 Nm at

1,600 rpm. Thanks to the integration of a diesel particulate filter (DPF) and diesel oxidation catalyst (DOC), emissions are minimised, while fuel economy is optimised.

An operating weight of 2,990 kg, length of 3.8 m, width of 1.9 m and height of 2.8 m make the 3.5MDX highly compact and manoeuvrable. Available with either swivel tip skip with 180° rotation (to enable precise lateral unloading without manoeuvres) or front tip skip, the new model is designed with an articulated

and oscillating chassis to ensure excellent manoeuvrability and off-road capability.

The 3.5MDX uses high and low range gearing for both forward and reverse, as well as permanent hydrostatic four-wheel drive. This means that operators have torque on demand to effortlessly move loads in even the most challenging site conditions. This, combined with a maximum travel speed of 20 km/h (12.4 mph) makes the unit quick and easy to move around site.

FEATURE

Key features: • Payload: 3,500 kg, • Engine power: 37 kW, • Travel speed: 20 km/h, • Transmission: Hydrostatic, • Operator environment: ROPS/FOPS cab.

Mecalac 3.5MDX

DUMPERS DIGGERS 44LIVE www.diggers.live

UPCOMING LEEDS, GB AUCTION 26 th - 29 th October 2022 @ 8.00am Roall Lane, Kellington, Nr Goole, Leeds, DN14 0NY | T: +44 1977 662 255 2018 Case CX210D 2021 Hitachi ZX300LC-7 2021 Hitachi ZX135USBL-7 2018 Hitachi ZX135US-6 - choice 17-20 Komatsu PC138US-11 - choice Unused 2022 Hitachi ZX65USB-6 2019 Bobcat E27Z 2019 Doosan DX160LC-5 2021 Volvo EC18E 2019 Komatsu PW118MR-11 - choice 2019 Komatsu PC210LCi-11 2017 JCB Hydradig 110W - choice 2021 Wacker Neuson EZ80 David Betts +44 7834 600 040 Chris Osborne +44 7769 204 732 Chris Rankin +44 7739 641 518 Mark Pyle +44 7909 119 693 Dermot O’Connor +44 7741 906 132 Jim Malia +44 7738 457 496 www.euroauctions.com WE CAN HELP, TALK TO US TODAY! THINKING ABOUT SELLING? www.euroauctions.com

Takeuchi is best known for excavators but has one unusual machine in the lineup, the TCR50-2 tracked dumper. Launched in 2020 it has proved a worthy addition, with a significant fan club for its massive functionality.

For those looking for a safe rear tipping tracked dumper, the TCR50-2 offers stability, power performance and massive payload (3,700 kg). With 180° skip tip left

and right, the TCR offers versatility on site with the side-tip capability limiting the need to reposition the machine on site.

With an ample 65° dump angle and 3,700 kg maximum loading weight, operators always get maximum discharge with just a single operation. A choice of foot or jogdial throttle allows more economic and intuitive

control of the Stage V Yanmar turbocharged engine. The cab is large and roomy with an adjustable suspension seat and massive all-round visibility. The colour multi-informational display and 180° rear view camera with auto activation and operators can customise the camera settings.

The TCR50-2 is certainly built for site with a roof and cab glass guard

fitted as standard and antislip walkways and steps. Daily and routine servicing is made easy with the wide opening maintenance cover providing exceptional access to engine and routine inspection points. The robust undercarriage has removable steel engine sump guard plates and large heavy-duty rollers, and steel imbeds for outstanding durability.

FEATURE

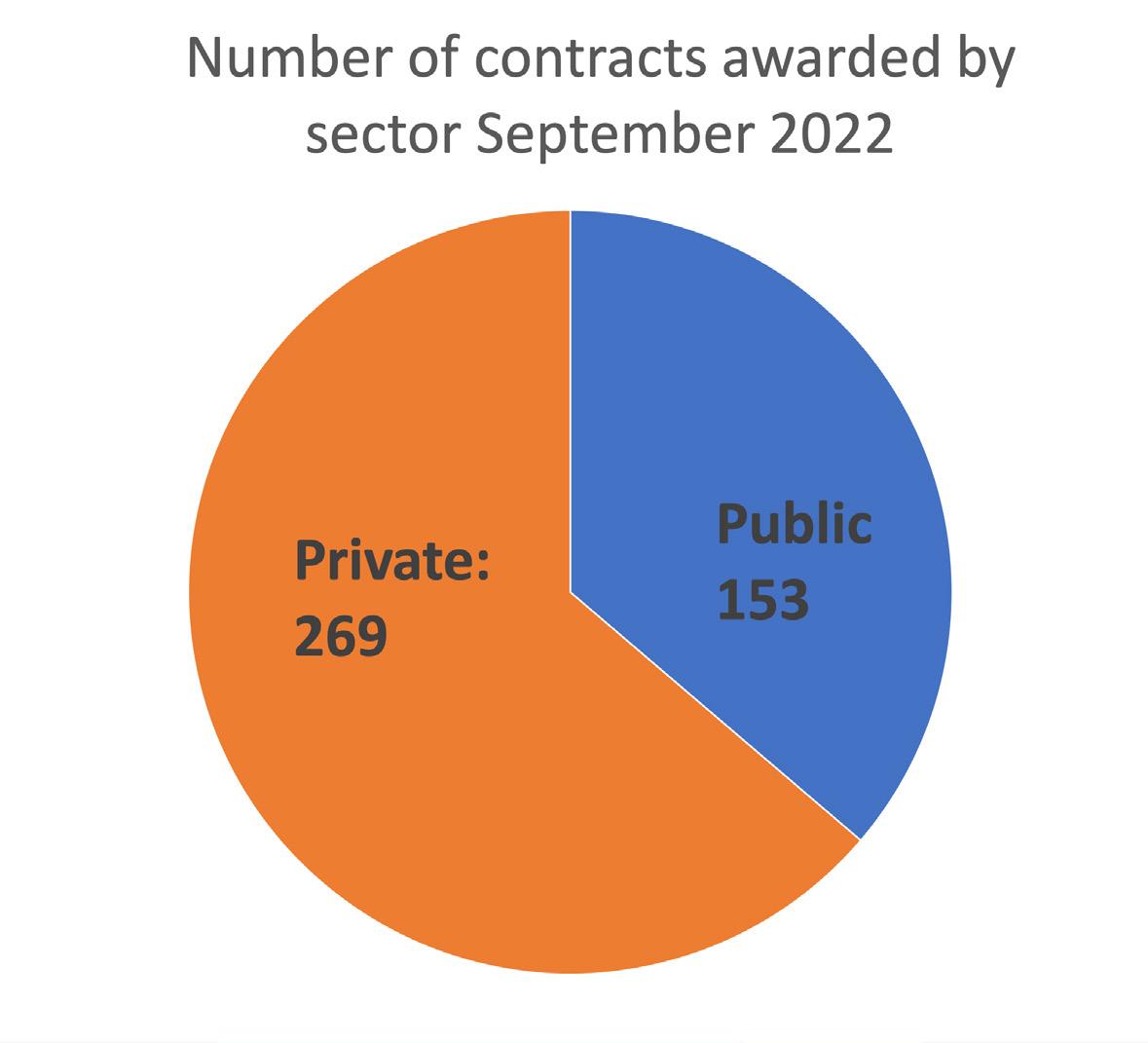

Takeuchi TCR50-2