Strikingly obviously to you all is that a large part of this issue is quite rightly dedicated to promoting the 2023 Plantworx event.

Even those reading the digital edition can’t escape the “belly band” advertisement circling the issue via some nifty digital technology that should have guided you all towards our comprehensive Plantworx preview.

We have been working with Plantworx promoting this great British event over the past few months, culminating in next month’s show, fully four years since the last time the event was staged. My team and I will be there in force and we look forward to enjoying the three days with you all in June.

On the subject of events, we are fresh from the UK Construction Week event from the Excel. It was good to meet readers and contributors and gain some ideas for new features within your construction equipment magazine of choice.

So where next after the East of England Arena? Well, September brings us the fifth annual British Demolition Awards. To find out more about the event visit: www.britishdemolitionawards.com.

In this issue we have an interview with SMT GB Business Development Director Lucy Couturier, who talks about her more than five years at SMT GB and how her team is focused on developing the products, tools and processes needed to deliver an exceptional customer experience across the full lifecycle of the solutions they provide.

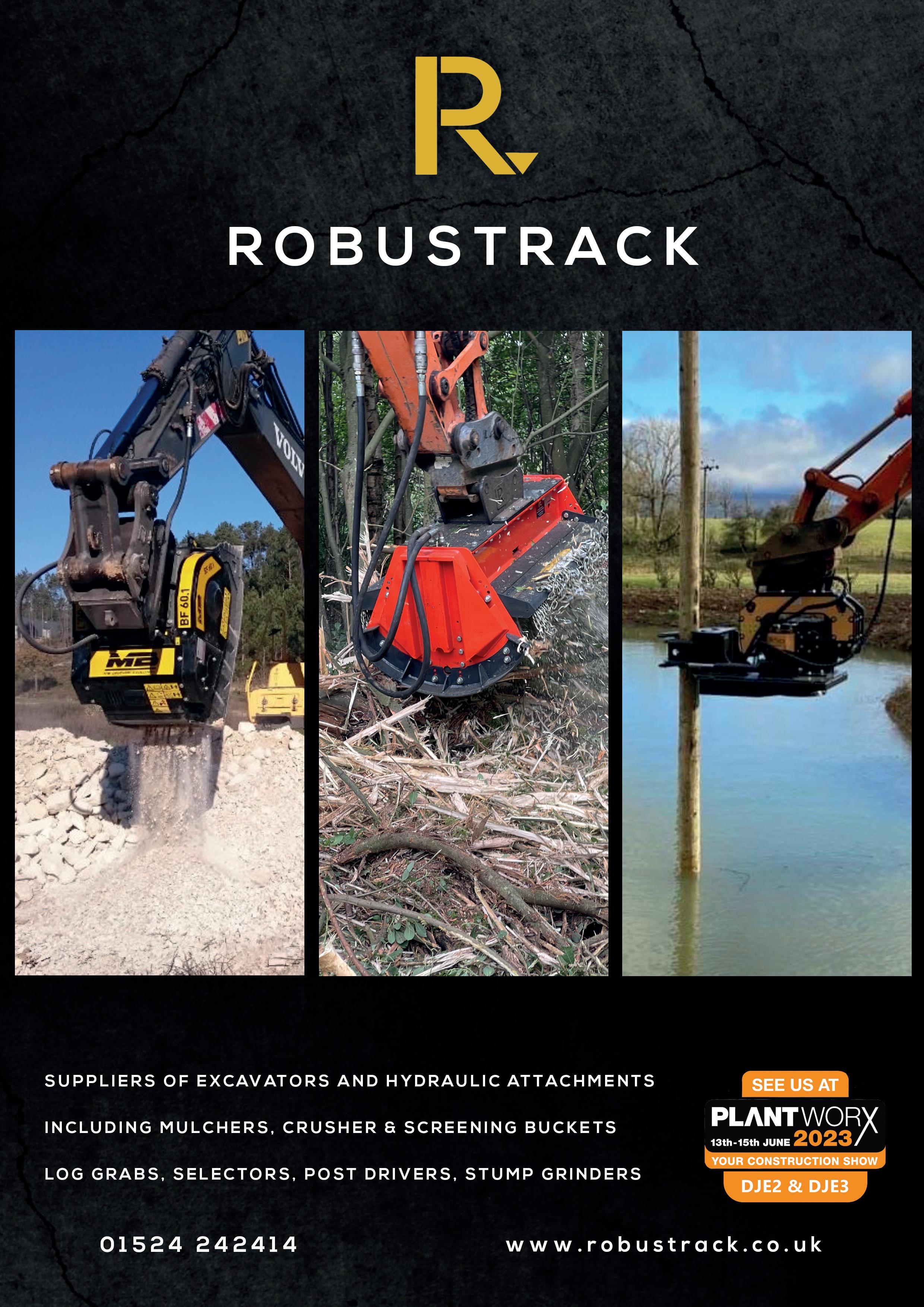

We feature another friend of the magazine in construction, forestry, grounds maintenance, demolition and recycling attachments specialist, Robustrack. Founder and Managing Director Davide Cerca talks us through what has gone on over the nine years since the company’s inception.

With the production of this, the seventeenth issue of Diggers LIVE, we have now somehow completed half of our six issues for the year. I have no idea where the time has gone but it has been a busy one and long may that continue.

To get involved in a future issue, do let my team or me know.

Ben Chambers ben@chambers.media

toby@chambers.media

DESIGNERS

Nicki Chambers nic@chambers.media

Joe Bers joe@globalnews.media

Alex Jarrett

GENERAL ENQUIRIES info@chambers.media 01903 952 640

SALES Luke Chaplin luke@globalnews.media 01903 952 643

Nathan Sandford nathan@globalnews.media 01903 952 642

PRODUCED & PUBLISHED BY Global News Media Ltd Suite 5 & 6 Chapel House 1-6 Chapel Road, Worthing West Sussex BN11 1EX ben@chambers.media 01903 952 640

Diggers LIVE is published six times a year by Global News Media Ltd

Articles and information contained in this publication are the copyright of Global News Media Ltd and may not be reproduced in any form without the written permission of the publishers.

The publishers cannot accept responsibility for loss of, or damage to, uncommissioned photographs or manuscripts.

Datatag extends partnership with Bennetts British Superbike Championship

Scottish Plant Owners Association presses Construction Leadership Council on drug and alcohol abuse

Katie Kelleher joins CPA team

Manitou Q1 2023 sales revenues

PSRO hosts plant-based skills and cards webinar

UK construction equipment sales show strong growth in Q1

With Lucy Couturier, Business Development Director of SMT GB

With Davide Cerca, founder and Managing Director of Robustrack

• The ultimate showcase of construction equipment and technologies

• Plantworx Innovation Awards 2023 shortlist

• Plantworx Get Connected Technology Zone: Driving the future of construction equipment

• MachineMax and PLINX connect to co-sponsor Get Connected Zone

• Exhibitors:

• Yanmar

• SANY

• Gaz Evans Models (GEMs)

• Blue Machinery

• Sunward

• SMT GB

• Tele Radio

• Develon

• Robustrack

• TVH

• BPH Attachments

• Brokk UK / Aquajet

• Excavator Forklift (EFL)

• Rotar Engineering (c/o Worsley Plant)

• Auger Torque

• RSP Suction Excavators

• Spillard Safety Systems

• Gomaco International

• AVANT

• Takeuchi

• Bobcat

• Mecalac Construction Equipment UK

• Arden Equipment

• Manitou UK

• RMC Equipment

• Herbst Machinery

• Bomag GB

• Concrete Services & Supplies

• Miller UK

• DIGGA Attachments

• HPC Compressed Air Systems

• Drainfast

• Fireward Automatic Fire Suppression

• ABAX Telematics & Plant Tracking

• Onwave

• MachineMax

• Rototilt

• Lifos

• Xerotech Battery Systems

• Elite GSS Ltd

• Genquip Groundhog

• Boss Cabins

• Moving Intelligence

• Worsley Plant

• Thursday Property Networking Club – Getting you connected, by Libby Evans

• SaMoTer

• SANY launches new electric mini excavator

• New Bobcat Machine IQ Telematics System

• DEVELON reveals latest innovations

• Growing machine control market leads OnGrade to expand Trimble® systems hire offer

• Electric machines: Europe leads the charge

The Lifting Equipment Store, by George Dunn, Managing Director, LES

86

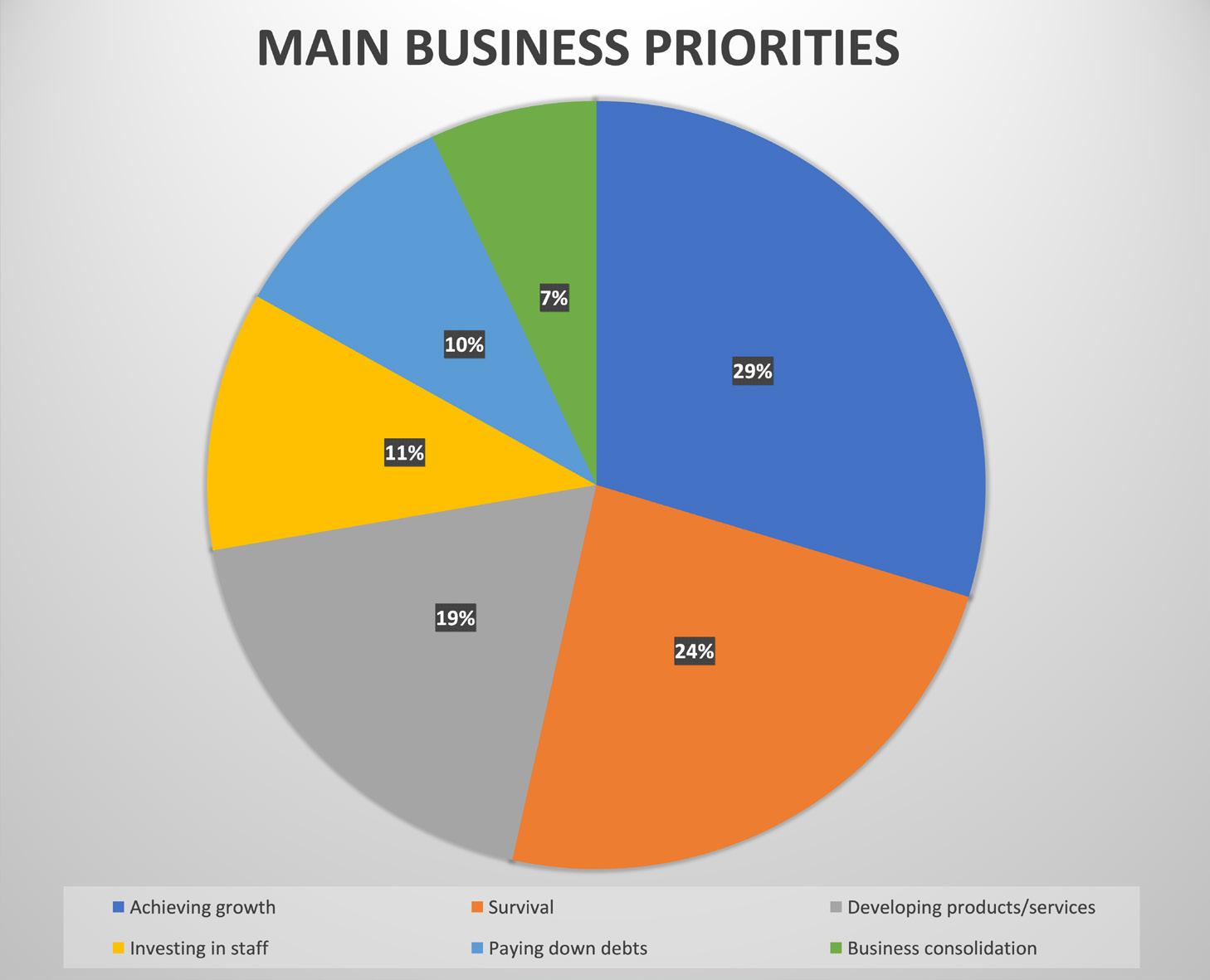

Attitudes to funding....

by Anton Nebbe, Head of PR and Communications, Close Brothers

Tevva addresses opportunities and challenges of UK Hydrogen Strategy

DEVELON to show DL280-7 wheel loader at WasteExpo 2023

Mitsubishi Heavy Industries EMEA selects advanced software to support move to net zero

SANY UK joins Hire Association Europe

Bobcat TR50.250 rotary telehandler supports projects at great height

SANY UK joins Hire Association Europe

Mecalac to relocate UK production headquarters

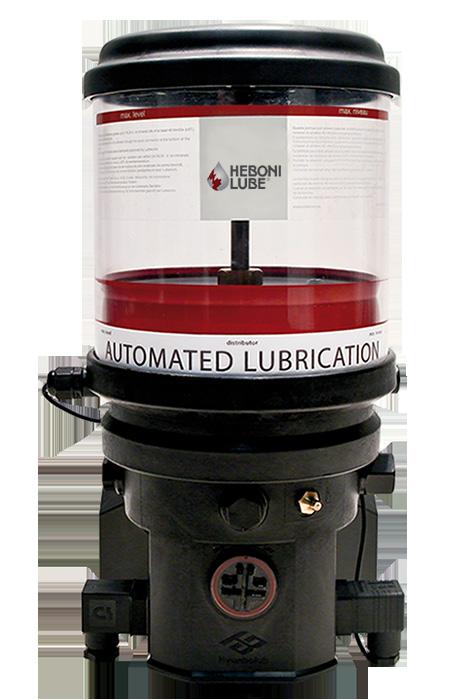

AP Air Europe introduces Hebonilube grease pumps

Tele Radio PrimaTEQ: a new name for T12 compact waist transmitter

Genesis Equipment Sales launches as UK’s only authorised XCMG distributor

New DX140LC-7 excavators expand Kingsheath construction fleet

Komatsu announces switch to HVO as factory-fill fuel

13-15 June 2023

East of England Arena and Events Centre, Peterborough. For

The UK's Only Live Demo Construction Equipment & Technology Event in 2023 FOR

The Bennetts British Superbike Championship is continuing its longstanding association with security specialist Datatag for the 2023 season. Datatag has been involved in the series for a decade and this year’s partnership will be highlighted by the introduction of the Datatag Fast Start Award, which will recognise the leading rider to pass the first sector checkpoint on the opening lap of each race to create a season-long league.

Datatag continues to expand its products to help secure your assets with the UK’s most trusted forensic marking systems and the Construction Equipment Association’s CESAR scheme and Venom, to help prevent fuel theft.

The Datatag motorcycle identification system has been in use since April 1992 and there are currently over 1m motorcycles protected by Datatag in the UK. The theft rate on these tagged machines is less than one-tenth of the rate before Datatag was developed.

Datatag Managing Director Kevin Howells said: “This will be our tenth year working with the Bennetts British Superbike Championship to help raise awareness of bike theft to millions of riders and users of vulnerable machinery and equipment.

“Each year we work with BSB to help with our technical innovation and development and will be announcing a number of exciting progresses in 2023. Crime fighting aside, we look forward to watching the all-new Datatag Fast Start phenomenon, which I’m confident, will be an exciting addition to each round.”

Bennetts British Superbike Championship Series Director Stuart Higgs concluded: “I am delighted to announce our continued partnership with Datatag. The technology used by Datatag is a benefit not only in racing but also to the wider motorcycling community, while the new Datatag Fast Start Award will add another element into each Bennetts BSB race.”

approach this in the same way as the consequences of any driver who drives whilst under the influence. We believe that failure to tackle this issue is a ticking timebomb with a serious accident on a construction site simply waiting to happen.

“Alarming research published by the Considerate Constructors Scheme found that 59% of those surveyed had concerns over the effects of drugs and alcohol in construction, 35% noticed their colleagues under the influence of drugs and alcohol and 25% agreed that drugs and alcohol affected them at work through tiredness. This simply cannot be allowed to continue.

“The CLC’s creation was a result of the 2013 Pye Tait report. That same report also gave the CLC the power to investigate the best ways of establishing a common industry approach to the limited life of all cards, the renewal process and any required revocation processes.

The Scottish Plant Owners Association (SPOA) says that not only is drug and alcohol abuse among plant operators a major problem, but there is no effective sanction available for managers to address it.

Tackling the issue was one of the primary objectives of Callum Mackintosh when he took over as President of the SPOA two years ago. He initially sought support from the Construction Plant-hire Association in England but found there was little interest there in even airing the topic. However, he has not been deterred in trying to get something done.

He has now written to the Construction Leadership Council (CLC) urging it to at least develop a policy on drug and alcohol abuse in the industry.

The SPOA believes that those with substance abuse problems should be offered support by their employers and the wider industry but ultimately

should lose their cards. It has already confirmed with the National Plant Operators Registration Scheme (NPORS) and the Construction Plant Competence Scheme (CPCS) that mechanisms exist for failed drug or alcohol tests to result in temporary or permanent revocation of cards, as happens in the rail industry.

Mr Mackintosh said: “I am extremely disappointed that the CLC does not regard the widespread and very serious issue of drug and alcohol abuse in the construction industry as a priority. The CLC has failed to produce a policy on the issue, which I would regard as the bare minimum. There is currently no deterrent to prevent plant operators from turning up for work while under the influence of drugs or alcohol.

“The SPOA believes that there should be scope to remove competence cards if a plant operator fails a drug or alcohol test. The industry should

“The CLC therefore has the power to act and the whole industry is looking to the council to show leadership on this issue.”

The SPOA’s main concerns, in addition to the health and safety issues on site, are:

• There is currently no real deterrent to prevent plant operators turning up unfit for work or even to remain fit during working hours,

• When plant operators fail a drug or alcohol test, they are often sent home driving the vehicle they arrived in,

• While an employer can be punished if an employee fails a drug or alcohol test, the operative who failed the test is not,

• If a plant operator is dismissed by an employer for failing a drug or alcohol test, they can easily find employment elsewhere without anyone knowing about their past record.

Katie Kelleher has joined the Construction Plant-hire Association (CPA) in the newly created role of CPA Technical and Development Officer. In her new role, she will provide CPA Members with guidance and advice on technical, training and safety subjects, as well as help produce and maintain the CPA’s large range of safety and technical publications. She will also help represent the CPA on a number of industry led initiatives and working groups, and liaise directly with members, official bodies and other organisations.

Katie joins the CPA from Select Plant Hire, where she worked for the past eight years.

active speaker about apprenticeships and the workforce.

She has sat on government boards such as the Strategic Transport Apprenticeship Taskforce and has recently joined the City of London Skills for a Sustainable Skyline Taskforce to ensure the future pipeline of the built environment. Katie first became acquainted with the CPA when she was a panellist at the CPA’s Annual Conference and she has been a judge for the CPA’s Stars of the Future Apprentice Awards for several years.

Katie has already won many accolades in her career so far. In 2021 she was declared one of the Top 100 Women in Construction and she has been selected as a LinkedIn Top Voice. In 2019 she was on the Construction News 15 People to Watch list.

Katie said: “I am very excited to join the CPA in the role of Technical and Development Officer and I truly believe I can be of value to the CPA and its members. I am looking forward to making a noticeable difference within the sector and helping take the association to the next level.”

Her construction story started in 2014 when she was the first woman to commence the Lifting Technician Apprenticeship with Select Plant Hire, before becoming a crane operator working on large projects such as Crossrail and the Tideway Project. More recently, she worked as an appointed person on a number of highprofile infrastructure projects.

Prior to her career in construction, Katie worked in a variety of roles across sales and recruitment before embarking on a change in career. She is well known throughout the construction industry for being a champion for women and young people working in construction and is a passionate and

CPA Chief Executive Kevin Minton added: “We are delighted that Katie has joined the CPA and we warmly welcome her to the Association. Katie has many strengths which will benefit our members and support the wider sector.

“With her customer focus and entry into the sector through the apprenticeship and subsequent site experience, she brings with her technical and training expertise, together with knowledge and current industry experience. With these strengths, Katie will be well placed to look after our technical publications and their content and also be able to represent the CPA on the large array of industry initiatives that the Association is involved with.”

• Revenues of €665m, +47% on Q1 2022 at constant scope and exchange rates

• Order intake on equipment of €455m compared to €637m in Q1 2022

• End of Q1 2023 order book on equipment at €3,414m compared to €3,274m in Q1 2022

• Progressive improvement of operational fluidity

Michel Denis, President and CEO, said: “The group is starting the 2023 financial year with a dynamic first quarter. The increase in production rates achieved during 2022 has enabled us to deliver revenues up by 48% compared with the first quarter of 2022, which was particularly affected by the sanitary crisis and supply difficulties.

“From an operational point of view, we note a slight improvement in the tensions on our supply chain, without considering that this topic is behind us.

“In 2023, the group’s performance will depend on our ability to produce, given the depth of our order book, and so far, the slowdowns we are seeing in the construction in Europe are not affecting our capacity of growth for the year, especially since, outside the United Kingdom, rental companies are still favourably oriented to purchase.

“In this context, we reiterate our expectations of annual revenue growth of around 20% compared with 2022 and an increase in the recurring operating income rate of around 100 basis points.”

The Product division realised quarterly revenues of €562m, up 58% compared to Q1 2022. The division continued its efforts with high production rates to clear its order book. Dealers’ order intakes have been reopened in most regions for 2024 within the known capacity limits. Finally, the division launched two new generations

of product platforms developed in North America. With revenues of €103m, the Services and Solutions division (S&S) recorded an 8% increase in activity compared to Q1 2022 (+7% at constant exchange rates and scope), in the context of continuing supply chain tension. The division continues to develop structural investments in its logistics platforms and in digital.

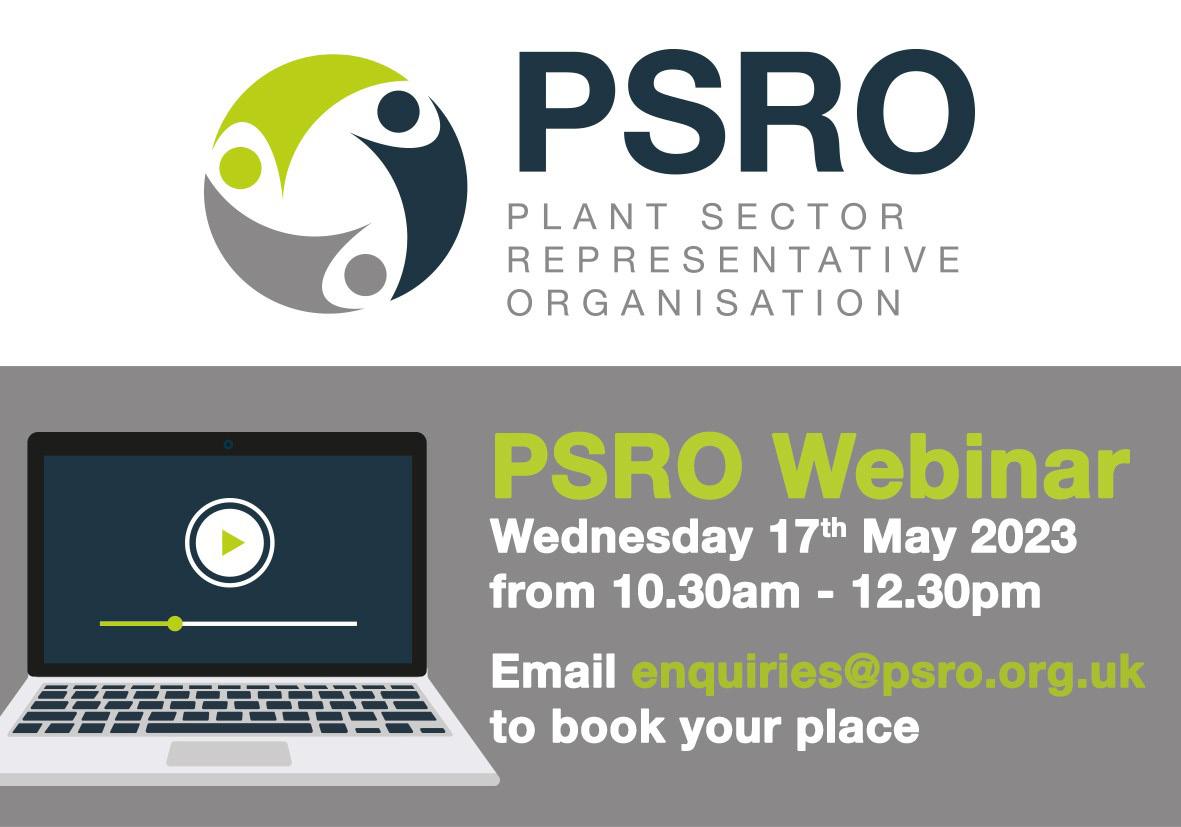

In order to help keep the construction sector informed about plant-based skills and cards, the industry’s Plant Sector Representative Organisation (PSRO) is hosting a webinar on Wednesday 17 May from 10.30 am to 12.30 pm.

The webinar is open to all and will provide an update on the PSRO and its formation, function, work undertaken and future activities in supporting the Construction Leadership Council (CLC) to achieve objectives set out within the CLC Skills Strategy. This will include consideration of the implications of the strategy on the construction plant sector.

The webinar will be hosted by Kevin Minton, Chair of the PSRO. Alasdair Reisner, Chief Executive of the Civil Engineering Contractors Association (CECA), a PSRO board member and a member of the CLC People and Skills Committee will provide an update on the progress being made with the CLC Skills Strategy.

The impact of this skills strategy –designed to help ensure competence across the industry – will then be considered by an expert panel drawn from the PSRO Technical Review Group (TRG) which comprises representation from the Health & Safety Executive (HSE) and trade unions, as well as employers and

Agenda:

employer representative bodies. At the end of the webinar there will be an opportunity to pose questions to Alasdair and the panel.

To secure your place on the webinar, please send an email to enquiries@psro.org.uk with the title “webinar”. You will then be sent a link to the zoom webinar.

• 10.30 am – Welcome and introductions

• The PSRO and its achievements to date (PSRO Chair)

• Update to the CLC Skills Strategy (Alasdair Reisner, Chief Executive of CECA and PSRO Board Member)

• Panel discussion with the PSRO Technical Review Group on ensuring and certificating competence within the plant sector (Convened by the PSRO Chair)

• Delegate questions and answers session (Convened by the PSRO Chair)

• Summary

• 12.30 pm – close

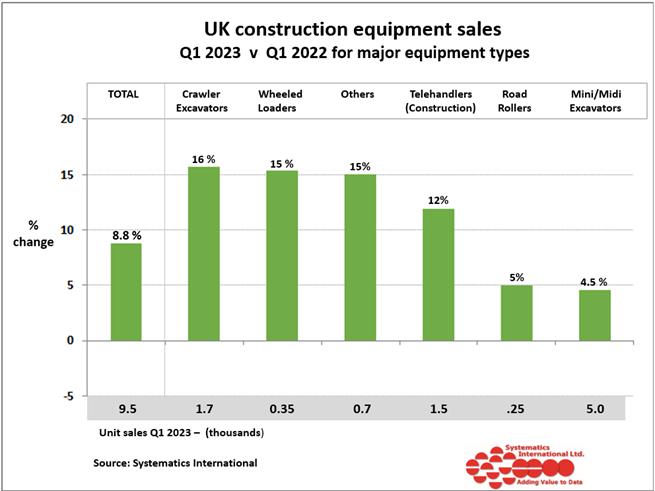

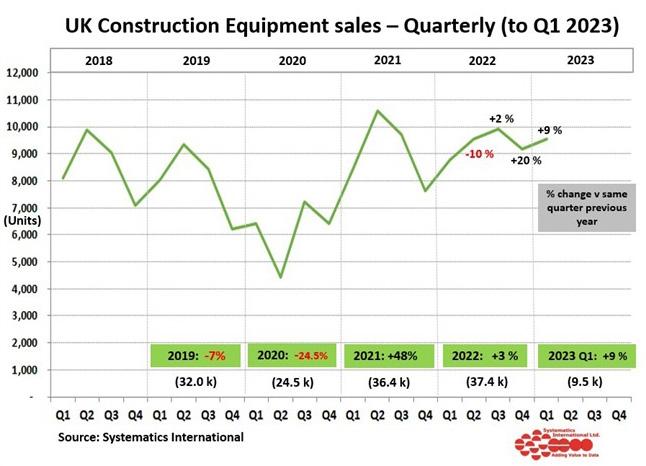

Retail sales of construction and earthmoving equipment in March were at very high levels at over 15% above sales in the same month last year. This took sales in the first quarter to 9,500 units, which was nearly 9% above the levels seen in Q1 2022, as shown in the chart.

Following strong sales at the end of last year, feedback from members is suggesting that sales in Q1 were still benefiting from orders placed last year on long lead times. It is expected that sales will slow down during the year when the “catch-up” is complete and the impact of more moderate construction activity is experienced.

The pattern of sales for the major equipment types is shown in the second chart below, comparing Q1 2023 levels with the first quarter of last year. This shows percentage changes in sales for the different machine types. Crawler excavators and wheeled loaders have shown the strongest growth in Q1 at 15% up on last year. The most popular product, mini/midi excavators have shown the weakest growth at 4.5% above the levels seen last year.

The pattern of sales on a regional basis in the UK and N Ireland is shown in the map below for Q1 2023 compared with the first quarter of 2022. This continues to show a mixed pattern across the regions. The strongest sales in Q1 were in Wales (+32%) and the south-east (26%), while the weakest sales were in Northern Ireland (-14%) and the north-west (-7.5%).

Equipment sales in the Republic of Ireland are also reported in the statistics exchange. Sales in March were also very strong at 20% above 2022 levels. This took sales in the first quarter to 11% above last year’s levels and represents a strong recovery after sales last year ended up 8% below 2021 levels.

Interviewee: Lucy Couturier

Role: Business Development Director

Company: SMT GB

With more than 15 years’ experience working in the construction industry, Lucy Couturier has been working at SMT GB now for just over five of these and is currently Business Development Director. In this role her team is focused on developing the products, tools and processes needed to deliver an exceptional customer experience across the full life cycle of the solutions provided by SMT.

QTell us about the history and development of SMT GB

Originally established in 1965, SMT GB is the exclusive dealer of Volvo Construction Equipment, as well as Unicontrol and K-Tec Earthmover products in Great Britain. In addition to delivering industryleading product support throughout England, Scotland and Wales, SMT GB provides a range of end-to-end efficiency and productivity boosting solutions, which ensure customer investments are protected and profits are maximised.

QTell us about your team and the working culture. Is there a fundamental company philosophy or ethic?

As SMT GB’s Business Development team, we are constantly analysing the industry’s current working environment to identify innovative new ways of doing things. As a team, we are more than happy to challenge the status quo if the evidence indicates there may be a more effective way of working, and to work collaboratively with our other teams across the SMT network and customers to provide best in class products, services and solutions. Using a combined approach of “MVP” (Minimum Viable Product) and Continuous Improvement methodologies, we strive to deliver initial solutions quickly and then to constantly refine these based on user feedback to evolve in line with what our customers need.

QTell us about SMT GB’s relationship with its customers For SMT, it’s not just about selling machines, it’s about building long lasting relationships with customers that are based on trust, open communication and a shared passion for excellence.

From our biggest customers to our owner-operators, our customers can expect us to work with them to ensure that the products, services and solutions we supply are being put to the best use. We have some great examples of where this close collaborations can be seen such as:

Ashcourt Group had the confidence to purchase the first EC550E delivered to Great Britain,

We have supplied over 1,000 machines to Chepstow Plant over the course of 21 years,

Parkinson Plant Services trusted our used equipment team to provide them with their first owned excavator,

KKB Group knew SMT GB could be relied upon to support its launch event for a new Volvo hybrid fleet for a range of customers and representatives from the Lower Thames Crossing management team.

QTell us about any apprenticeships or trainee schemes

SMT GB firmly believes that our apprentices are our future. In fact, we have been offering apprenticeships for over 40 years and the schemes have produced some of our most successful senior managers.

SMT GB and Reaseheath College have worked together to develop a three-year intensive Land-Based Service Engineering Technician Apprenticeship, which includes a thorough assessment on completion by the IMI (Institute of the Motor Industry). This programme works

recently sat down with our marketing team to talk about the apprenticeship programme and said: “It’s really tough and a proper graft, but I love it. There’s tonnes to learn and it’s super complex. One day I’ll think I know everything and the next day they’ll introduce something new that

Academy. On this portal, employees are provided with access to an extensive range of courses, seminars and learning tools to allow them to develop their soft skills, identify areas of professional interest and to engage with colleagues across the SMT network.

Not only does this empower people to proactively seek enrichment in any area they desire, it also provides them with the ability to identify what areas they need to develop in order to further their careers, and proactively pursue this progression.

QWhat can we do to attract more young people into the plant industry?

to support SMT’s Customer Support Centres located throughout Great Britain and our apprentices have an amazing opportunity to train on the latest Volvo Construction Equipment at our SMT GB Academy and depots.

While being employed by SMT GB, apprentices learn a combination of technical and life skills including knowledge, skills and behaviours through on job training, formal college-based education and hands-on experience. The fourth and final year of the SMT GB apprenticeship is an in-house improver year working at one of our locations across Great Britain where apprentices demonstrate learning gained throughout their apprenticeship.

For me, SMT GB delivers an exceptional apprenticeship programme, but don’t just take my word for it. One of our second year apprentices, Lee Chapelle,

leaves me thinking ‘I have no idea what that is at all,’ but you soon learn, and I think that’s great.”

QHow about Continuous Professional Development or ongoing training? How does this influence or reflect the company’s culture?

SMT GB is a great place to work with highly skilled and inspired teams. We strive for excellence in all that we do and invest in our people to ensure this is a reality. Learning is encouraged and accessible for everyone, whether it be through coaching, on the job learning to achieve NVQs, classroom training accredited through the IMI or professional qualifications, we support all employees to achieve greatness.

To support this goal we have introduced an interactive online staff enrichment portal called the SMT

By listening to our employees and ensuring our workforce understands the needs of different generations, we can tailor our management styles and communication methods to continue to attract the best talent and ensure that as the generations change, SMT GB remains a top employer. We recognise that the “millennial” and “Gen Z” groups may have different values from the generations before and strive to encourage diversity and be as inclusive as possible in recognition of this.

QHow do you see the medium-term future for SMT GB ’s product development?

What Covid has taught SMT is that the company can pursue agility in many different ways and can actually help our customers to do the same.

Globally, supply chain issues continue for many industries and construction equipment manufacturers are no

“We recognise that the “millennial” and “Gen Z” groups may have different values from the generations before and strive to encourage diversity and be as inclusive as possible in recognition of this”

exception. We have seen this change our customers’ behaviour, and the drive to ensure that machines are in every way as efficient and productive as they possibly can be has never been stronger.

With SMT GB being the sole official distributor of Volvo CE’s high quality equipment, we enjoy the strong advantage of having pieces of equipment that already perform exceptionally well, but also a manufacturer that is just as keen as we are to ensure that the machines are truly giving everything they have on the jobsite.

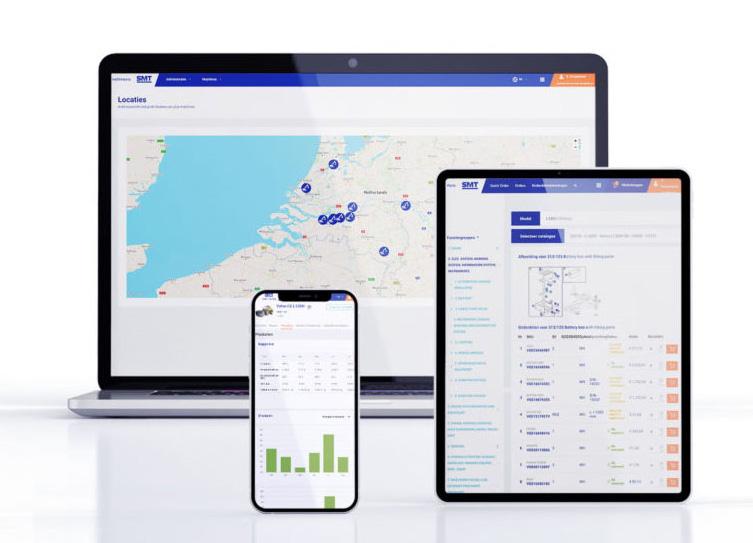

This has allowed us to build on the solutions that Volvo has created, such as Volvo Site Simulation, CareTrack and Insight Reports, and refine these into our suite of solutions that add considerable value for our customers, including our online MySMT self-service portal, ProCare advanced machine monitoring and our Advanced Operator Training programme (“EcoOperator”).

QWhat is SMT GB doing with regard to the sustainability agenda? What new technologies are you embracing? How do you envisage the future in this respect?

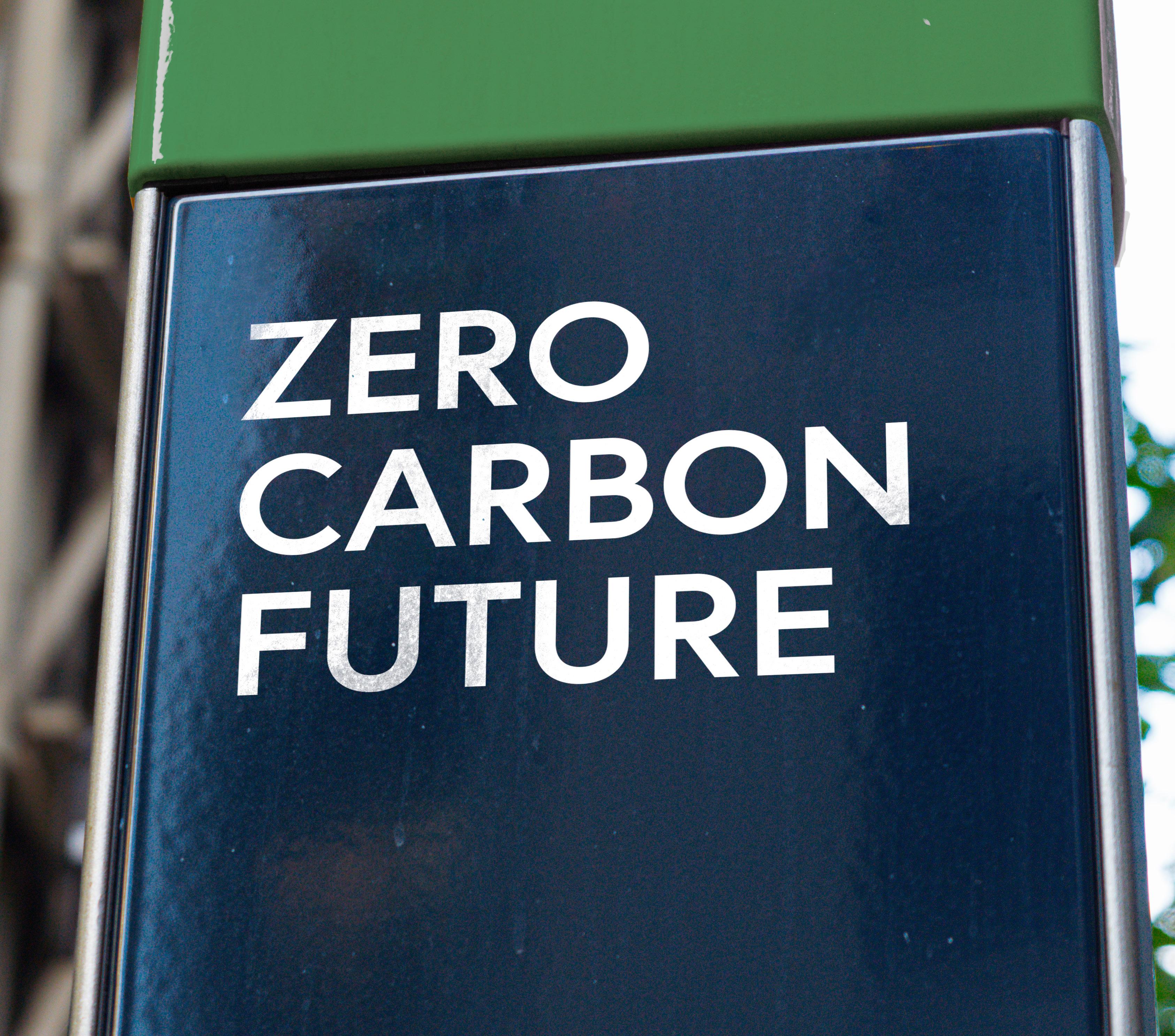

SMT GB is fully committed to sustainability and has made great strides to address its own impact on the environment. Not only do we provide Volvo’s full electric machine range, but we were also one of the first companies in the industry to switch to a fully electric company fleet and the use of HVO fuel to fill all customer machines that visit any one of our sites.

QTell us about one of your key products

One of our key new product offerings is our Fleet Optimisation service using the Volvo Site Simulation (SiteSim) tool.

QOutline the key functions/ specifications of the product

SiteSim uses a commercial grade surveying drone to create a highly detailed 3D model of a customer site. This 3D model is then combined with telematics and machine performance data to provide you with to-the-second haul cycles, the current condition of haul roads and accurate production information, as well as offering you an invaluable insight into exactly what impact the current configuration of the site has on the machines working.

It can also quantify the impact that proposed changes will have on fuel burn, emissions and offsets generated, as

well as both machine efficiency and site productivity, whether that be through haul road improvements, improved forecasting through accurate production information, upgrading the fleet or optimised machine pairing.

QHow is this product critical for potential users? How will it improve their bottom line?

The focus of the modern site manager is very much placed on reducing waste, emissions and offsets as much as possible, but this is juxtaposed with a need to maximise efficiency and productivity. As a result, there is only so much that focusing on the machines in isolation will help you with this, and the greater context of the site configuration itself, operator behaviour and how machines interact with each other onsite is something that very much needs to be taken into consideration.

QHave you had any feedback?

We have delivered SiteSim to several customers already, and have received outstanding feedback. Please keep an eye out for future editions of Diggers LIVE for more details on these.

QHow long have you been in the industry and how did you start out?

I’ve been in the industry for just over 15 years. My first position after graduating was in the aerospace sector but I moved to construction in 2017.

QWhat attracted you to the industry?

I love the variety and the challenges, understanding what our customers need and coming up with innovative solutions to support them. My role covers developments in both the sales and service areas of our business and this gives me a wide range of projects to manage.

importantly, how do we use data efficiently to drive intelligence and action based outputs? I love this aspect of my work and as we move into the era of machine learning and AI this will only get more exciting.

QTell us about the different aspects of your work.

I have a total team of 14 people working across both the sales and service areas of our business so the range of projects managed and input to the business is wide. A core area of the group are our product development managers who cover the physical aspects of our offering as well as three relatively new team members tasked with our more recent site, operator and digital solutions. Some examples of other projects delivered include launching a new engineer field service tool, CRM, developing new types of customer support agreements and of course, our web based services.

QWhat do you find most rewarding and challenging in work?

The variety and the “what if” – I love finding solutions to problems or coming up with new ways to deliver results. The most challenging is that I can be very impatient and things don’t always come quickly enough.

Who/what would you be in an alternative life?

I’m currently helping my youngest daughter choose her university options and the more I look at civil engineering, the more I think I would have enjoyed that.

Who is your favourite artist?

This is a difficult one as it can vary depending on the day. Probably the band James for music, Jane Austin for literature and either Lord of the Rings or Star Wars for cinema.

When and where are you happiest?

On holiday in Greece with my family. We have had some our best holidays in the Greek islands and I would go there in a shot.

What’s the most expensive nonessential thing you’ve ever bought? A designer handbag

What’s your bucket list activity?

I think like many people it would be to see the Northern Lights – such an amazing phenomenon I can only imagine what it would be like to see them in person.

QHave you been involved with any particularly interesting projects in your career?

Over the last few years we have been rapidly developing our web based services, which has been an incredibly interesting and exciting project. Developing services such as our ProCare condition based monitoring service and our MySMT customer portal (launched this year) continues to be one of the highlights of my time in SMT since they are focused on how we use the wealth of data around us in the most efficient way. How do we help our customers have access to the information they need day to day but also very

QWhat kind of projects would you most like to be involved with before retirement?

One of the upcoming areas of work that I am very excited to be involved with is our “e-mob” project – the electrification of Volvo’s equipment range and the drive to becoming carbon neutral. Over the next few years the transformation from diesel machines to electric or hydrogen cell powered equipment is going to bring significant challenges but challenges that I am happy to be involved in. At SMT we are committed to working with our customers to achieve all of our environmental goals and this is going to be a key area in this journey.

What would you do for a company excursion, money no object? Go on the Orient Express. I’m a big fan of Agatha Christie’s Poirot so this would be fantastic.

Autumn, winter, spring or summer? Summer

What’s your favourite cuisine? Greek

What’s your tipple of choice? A nice sauvignon blanc

Be or do? Which represents you best? Do

“We are committed to working with customers to achieve our environmental goals”

Interviewee: Davide Cerca

Role and company: Managing Director at Robustrack

Sectors: Construction, forestry, agriculture, grounds maintenance, railway, demolition and recycling, landscaping, fencing

Geographical reach: Throughout the UK for sales and hire, and worldwide when called for

Products: Flails, mulchers, concrete mixing buckets, post drivers, crusher buckets, screening buckets, tree shears, log grabs…

Established: 2014

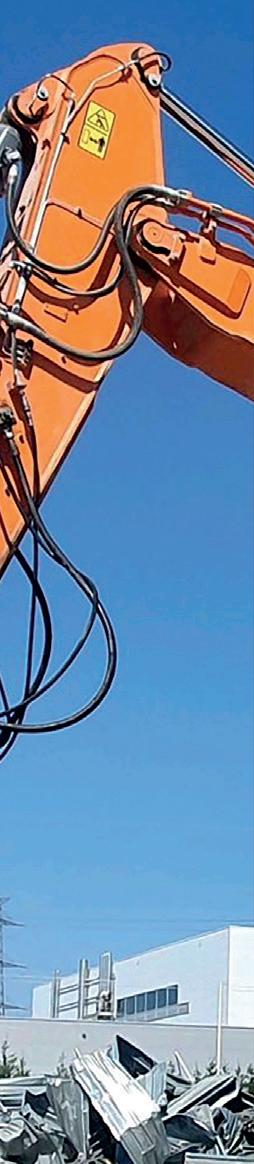

Davide Cerca founded Robustrack Ltd with his wife, Bobby, back in 2014. Located in Ingleton, North Yorkshire, Robustrack has quickly made a name for itself as one of the leading suppliers of hydraulic attachments for excavators, including flails, mulchers, log grabs, tree shears, concrete mixing buckets, crusher buckets, screening buckets and much more. Robustrack is the sole UK dealer for Eurocomach excavators, Agriforest forestry equipment and Malaguti, manufacturers of post drivers, stump grinders and augers. Also in the Robustrack portfolio you’ll find demolition attachments from Trevi Benne and MB Crusher and Robustrack’s popular range of flails and mulchers. Robustrack is a regular show fixture and is looking forward to this year’s Plantworx event, which promises to be its biggest and best show to date, with static and working attachments on display.

QTell us about your career progression

I started my career as a technical engineer but soon developed into sales, first as area manager and then as commercial director. In 2009 I started my first business in Italy, importing rubber tracks for excavators from China. When I moved to the UK some of the producers of attachments I knew in Italy asked me to market and sell their products in the UK and that’s how Robustrack started.

QHow has what you do personally developed?

People have always been at the core of our operations: customers, suppliers and staff. When Bobby and I started our own business we covered many different roles in a day; one moment you are the salesman, the next you organise a delivery, in the morning you create an advert on social media and in the evening you send invoices. The natural next step, in order to grow, is to surround yourself with good collaborators that allow you to scale the operations to the next level.

Robustrack developed accordingly. We started with a business model based on drop shipping and a strong “digital attitude”. Running Google ads and Facebook ads was still a bit unusual back in 2014, when social media was still a

niche, especially in the construction sector, where traditional advertising was still the way to communicate with customers.

QHow about the balance between your expertise in your products/ industry, and your role in business? Transferring the knowledge we have accumulated in the last 10 years is a fundamental part of what we do. When a customer calls, our goal is to understand his needs and expectations and deliver not just any attachment, but the right attachment, for the right job, for the right excavator. That’s our way to add value to the product we deliver.

Q

What is it about your role that attracts you?

I have always liked challenges and running a company is an exciting one. Flexibility, adaptability, strategic planning and fast-paced decision making is what is required in my job.

QHow do you think your colleagues see you (or you would like them to)?

I would like to think that my colleagues see me as the coach of a team, where every single player is a much better athlete than the coach. The coach simply coordinates

and plans the game. My goal is for the team to be made up of people that are much better than me at what they do, to achieve together the objectives and targets we have.

QTell us about the company, its history and development

We started Robustrack on the back of the contact we already had with some Italian producers of attachments. The idea was to become the bridge between a market with growing demand for attachments and the Italian producers, not always equipped with the commercial tools to approach the UK market. Flails, mulchers and concrete mixing buckets were the first products we marketed and we soon realised that the demand for attachments within the British market was quickly growing. Until then, most of the attachments sold in the UK had been demolition and recycling attachments and generally speaking were very expensive, with a limited target of potential customers. What we realised is that there was a strong demand for smaller attachments and that anybody with an excavator was a potential customer. This led us to increase the types of attachments we offered, always focusing on the quality of the products and the aftermarket service. For us, having spare parts for the attachments we sell is absolutely essential,

and we are proud of the fact that we have customers that purchased from us 10 years ago and we still stock spare parts for their machines.

QTell us about Robustrack’s growth path up until now – and perhaps the future

Apart from the obvious growth in people and in space (Robustrack started life in our back garden) the range of products in which we offer has grown significantly. It was an honour to be made the UK importers of Eurocomach excavators. They have a quality which is unmatched and being optimally set up for use with hydraulic attachments made them the perfect brand for us and our customers.

I am really proud of the way Robustrack has grown while remaining true to its mission – supply customers with the best possible product and service so that they become our ambassadors and our most valuable adverts. When I see customers on social media and specialised groups recommending us, I feel a mixture of gratitude and pride in having our revolutionary approach recognised.

Our mission was to deliver a better service then a local dealer could, even

if we were 300 miles away. Today, we have happy customers from Cornwall to Scotland that have experienced and like the way in which we do business.

We have also established a network of business partners and resellers happy to share our vision. With the demand for hydraulic attachments in constant growth, a lot more people have now entered this sector, but Robustrack is one of the very few companies focused exclusively on hydraulic attachments, with an unmatched wealth of knowledge and experience, and probably the largest stock of attachments with spare parts in the UK.

In the future I hope we can keep doing more of what we have been. Plantworx this year is an exciting event for us: the biggest stand we’ve ever done and a demo stand to boot. As with all our shows, it is a great opportunity to reconnect with customers and colleagues and I love the buzz of a show. We have a huge range of attachments on display, both static and working, and I can’t wait.

When you buy from Robustrack your

customer experience is different: we investigate your needs, your situation and your expectation. By doing so, we make sure that the attachment we deliver is exactly what you expect and does exactly the job we discussed. We care about people and, since we don’t like surprises when we are customers ourselves, we make sure that there are no surprises when we are the suppliers.

We like to deliver “plug and play” attachments, ready for the customer to use: whether delivered and installed by us or delivered on a pallet by a courier, the same applies. To achieve this, we have the in-house facility to fabricate brackets, adaptors and hoses to the customers specification and deliver complete with hydraulic fittings.

When we work with dealers, we are happy to give them the bare attachment for them to add value and take care of their customers themselves. The range of our potential customers is very wide – construction, farming, ground maintenance, railway, demolition and recycling, forestry, landscapers, fencing contractors. Excavators are becoming less of a digging machine and more of a tool carrier. We’ve seen the demand there,

hence the increase in our attachment catalogue. Operators can do so much more and whatever the job, we have the attachment.

We care about our customers and we want them to be happy with the purchase they are making and this is reflected in the products and services we propose. Honesty is a core value in our company so we’d rather under promise and over deliver than the other way around. If problems ever arise, we keep a line of communication with the customer. It is not about not having problems, but much more about how you deal with them. Aftersales service and spare parts is a very important focus at Robustrack and something our customers can count on. We like to think that what we sell are money making solutions. We like to listen to our customers, share with them other customers’ experiences and best practices using the attachments to generate revenue, to make the most of the investment when they buy our machines. When our customers choose one of our products, we haven’t convinced him to do so, we have instead managed to share with him the value that our product can add to his organisation.

QTell us about your team and working culture. Is there a fundamental company philosophy or ethic?

I feel really lucky to collaborate with an amazing team full of young and enthusiastic people. At Robustrack we believe that it is all about people.

“It is all about people. People don’t do business with companies, they do business with people”

People don’t do business with companies, they do business with people. The people element is crucial in our company, whether they are customers, suppliers or members of our team. For this reason we work hard to create and maintain a happy working environment, with no space for a blame culture. I have always thought that we spend a lot of time in our workplace and waking up every morning just looking forward to the weekend is an awful place to be.

QWhat is your experience of the labour market?

We live in a period where the difficulty for companies to find people, skilled or unskilled, is probably one of the main limiting factors for growth or

Who/what would you be in an alternative life?

A bird, to be able to fly

Who is your favourite artist(s)? Pink Floyd and Dire Straits

SME. Personally, I believe that staff turnover is one of the big hidden costs for companies to be avoided, within reason, as much as possible. Brexit and a mismatch between company needs and what is available in the labour market are two of the reasons for labour shortages. We have been incredibly lucky however and found fantastic people.

QWhat can we do to attract young people into the industry?

I do believe that a better and stronger collaboration between schools and companies could be one way to start closing the gap between the skills of the candidate which companies are looking for and the skills acquired in schools.

QHow do you see the company in five or ten years?

I’d like to see Robustrack becoming the point of reference for the UK market when we talk about hydraulic attachments.

Who do you most admire?

I admire the creative minds of true geniuses

– Galileo, Mozart, Steve Jobs, Albert Einstein

What would be your desert island luxury?

Well, as an Italian, it would have to be a pizza oven (and ingredients)

When and where are you happiest?

When I am skiing in the Dolomites with my family

What’s the most expensive non-essential thing you’ve ever bought?

A remote controlled aeroplane

What’s your ideal weekend?

Barbecue with family or a zip out on the Vespa in the sunshine

What would you do for a company excursion, money no object? Take everyone on a skiing holiday in Colorado

What’s your tipple of choice?

After several visits to Scotland and its distilleries, whisky

We offer the world‘s best-selling quick coupler system. We have decades of experience and testing behind us. Our solutions work and you get an outstanding combination of quality, performance and safety.

• Lightning fast change of hydraulic, electrical and mechanical attachments from inside the cab.

• Always the right attachment for the job.

• Distributes oil, grease, water and electricity.

• No staff around the machine during tool changes.

• Improved safety.

• Meets and exceeds safety standards globally.

• Increased productivity.

• Increased profitability.

• Reduce the number of machines on the site.

• Reduced transport costs.

• Minimises oil spills.

• Protected hose run.

• Less dirt in the cab.

• For machines 1-120 tonnes.

With a plethora of innovations and new zones, visitors to Plantworx will witness cutting-edge market offerings and the latest technology pipeline developments.

Rob Oliver, former Chief Executive of the CEA and now Director at Plantworx organiser, Construction Equipment Events said: “Plantworx is poised to be the premier platform in the UK for unveiling new products from an array of leading OEMs. As the industry witnesses a surge in companies embracing electricpowered solutions and making strides in hydrogen technology, Plantworx 2023 is set to be the most impressive edition yet, showcasing groundbreaking machines and cutting-edge innovations that will propel the construction sector into the future.”

To date Plantworx is nearing 300 exhibitors and 35% of those will be making their show debut. Visitors can expect to be blown away by the exhibits, many of which will be demonstrating, from renowned brands, such as Hitachi Construction Machinery, and the Chinese heavyweights XCMG, who will be at Plantworx for the first time. Other big names on the list include Caterpillar, Hidromek, Hydrema, Hyundai, SMT (Volvo), Takeuchi, Sany, Sunward Europe, Liugong, Mecalac, Yanmar Compact Equipment, Kubota, Develon (formerly Doosan), Bobcat, AVANT, BOMAG, Brokk UK, RSP Suction Excavators, Merlo, Manitou.

Battery electric

Plantworx is also set to showcase the latest advancements in engine and battery technologies, Xerotech’s Hibernium battery pack and Lifos have been shortlisted for Plantworx Innovation awards and will be exhibiting for the first time. Atlas Copco is a regular exhibitor at Plantworx, this year it’s showing its ZBC Battery Storage System, which is also shortlisted for an Innovation award.

Xerotech’s Hibernium is a highly customisable battery technology that allows users to select their preferred energy content, operating voltage range, physical dimensions, and even battery cell chemistry. What’s more, there are no design or engineering costs involved, making it an attractive option for one-off prototyping projects.

Meanwhile, Lifos is set to impress visitors with its Fort renewable power system in a box. This complete power system is easy to transport and deploy and can be fully hybridised with its own solar panels, genset or wind turbine. With the Lifos Fort, users can save money on diesel charges and lower their energy emissions in any circumstances.

The Atlas Copco Power Technique ZBC Battery Storage System is a modular energy storage solution designed to minimise fuel usage and carbon emissions for construction operators. It operates in hybrid mode, reducing emissions by up to 50%, and

can eliminate up to 100% of CO2 emissions when used with renewable energy sources. The system produces no noise and requires minimal maintenance.

The digital revolution in plant is in full swing, and a deluge of technology and connectivity companies are hitting the market. These technology solution providers are working tirelessly to achieve an all-encompassing connected site.

It’s not just about the excavator; it’s about the telematics, cameras and sensors that work together seamlessly to enhance the excavator’s functionality. The data collected by these systems provides contractors and fleet owners with real-time insights into their equipment’s performance and health. Through a single platform, contractors and fleet owners can monitor the location, usage, and health of their equipment, all in one place.

Plantworx 2023 has managed to attract a host of these businesses, including equipment management platform experts MachineMax, ABAX Telematics and Plant Tracking, as well as connectivity solutions company Plinx and Onwave, which is showcasing Onwave Locator (OWL), an SaaS application developed by Onwave to aid customers with the dissemination and communication of hazard and work site information to remote workers.

Safety

From machine control to telematics, GPS systems and safety systems, digital technology has transformed the way construction sites operate. To showcase the latest advancements in construction equipment technology, Plantworx is launching the Get Connected Technology Zone, a dedicated space for technology providers in the construction equipment sector.

The inaugural Futureworx exhibition in 2022 demonstrated the industry’s appetite for new technology and as a result, the Futureworx team has been asked by leading construction innovators to recreate an element of this event at Plantworx. The Get Connected Technology Zone will showcase the technology and innovation that will drive productivity on construction sites, leading us

Safety is also an essential consideration in the construction industry. With the inherent risks that come with building and infrastructure projects, safety measures must be put in place to protect workers, the public, and the environment. Companies including Spillard Safety Systems, Xwatch Safety Solutions, GKD, SiteZone, Leica, and Prolec are at the forefront of providing innovative safety solutions to the construction industry.

All of these companies will be showcasing their latest safety solutions at Plantworx 2023, Leica and Xwatch will be announcing a world-wide first with a recent collaboration that first debuted in Las Vegas. With such innovative solutions on offer, it is clear that safety will continue to be a top

to the construction site of the future.

The new zone will bring together companies that have new and innovative ways of delivering solutions. The focus will be on the people-plant interface, telematics, the connected site and safety systems. Indoor companies such as Ongrade MC (Thomas Plant), Unicontrol, Sitech, Sodex, cosponsors, Plinx and MachineMax, GKD, and FTC have confirmed their exhibition space in the Get Connected Zone.

The outside exhibitors include main sponsors, Leica Geosystems, Conquip, Hyundai Construction Equipment Europe and Ongrade MC (Thomas Plant). These exhibitors will demonstrate their products in action on working machinery, which will have the technology previously installed. Exhibitors will arrive ready “to plug and play,” demonstrating the ease of integrating new technology into existing construction equipment.

According to Sean Scarah, Plant and Logistics Director for Balfour Beatty Asset and Solutions Division, the focus is no longer on just diggers, but on a whole connected site where 3D machine control and autonomous plant help to deliver a project and help us on our journey to net zero. To achieve this, industry solution and equipment providers, supply chain partners, IT specialists, and clients must work collaboratively together.

priority for the construction industry.

Spillard will be showcasing its AI Human Detection System (HDS), which has been shortlisted for a Plantworx Innovation Award. GKD, SiteZone are other companies that are dedicated to improving safety in the construction sector. Their range of products includes proximity detection systems and access control solutions that help to prevent accidents and unauthorised access to construction sites.

The award-winning Official CESAR Scheme is set to emphasise the critical nature of security and demonstrate how its multi-layered security marking technologies supplied by Datatag can thwart criminals who seek to target plant and machinery. Additionally, the company will be unveiling KIST, a

web-based administration portal. This portal has been crafted to enable effortless creation, management and administration of assets such as tools, vehicles, and equipment, using existing phone and tablet technology to scan QR codes or unique identification numbers. Each asset is assigned to a user or parent asset, for instance, a tool to a storage location or a vehicle, upon creation. With the CESAR or MicroCESAR security label providing each asset with a unique identifier, an audit trail can be established to document the asset’s movement and allocations, facilitating tracking and management of the asset’s complete lifecycle, from acquisition to periodic maintenance and phaseout from inventory. This increased transparency in asset management leads to greater accuracy and accountability across a fleet of assets.

Sustainable welfare cabins are an innovative solution for providing comfortable and environmentallyfriendly temporary accommodation in remote or challenging locations. These cabins are designed to meet the needs of workers who require on-site accommodation and facilities, while also minimising the environmental impact of their operations. Two award-shortlisted companies in this space are Boss Cabins and Genquip Groundhog who will be showing their latest green innovations at the show.

Rob Oliver described excavators as the “polymath” of the contemporary construction landscape and this versatility is often determined by its attachments.

Plantworx 2023 has a record number of attachment manufacturers exhibiting. Leading brands such as Auger Torque, Digga Attachments, Digbits, Arden Equipment, Worsley Plant and BPH Attachments will showcase their latest products, alongside the top tiltrotator companies like Engcon and Steelwrist.

In addition to showcasing the future of the construction site, Plantworx 2023 will also highlight the key challenges facing small and medium-sized construction sector companies in the areas of immersive technologies and data. The event will provide an excellent opportunity for attendees to learn about new technologies and the ways they can benefit their operations. The event has again partnered with National Highways, which is planning to scope out innovations for highways infrastructure projects.

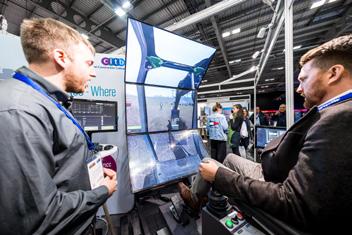

The Simulation Zone at Plantworx, a cutting-edge training platform for construction professionals, is returning for 2023 after its debut in 2019. This innovative and interactive zone offers an opportunity for novices and experienced operators alike to upskill and learn machine control systems, advanced technologies and gain insights into the world of construction.

Plantforce Rentals, a pioneer in simulation training, is once again spearheading The Simulation Zone. The company has introduced this groundbreaking technology to tier one contractors on major infrastructure and rail projects, including HS2 and Hinkley Point C nuclear power station.

Plantforce has partnered with leading industry players like Trimble, Leica Geosystems, and

Tenstar Simulation to provide visitors with a comprehensive and immersive experience. In The Simulation Zone, participants can test their skills using the latest technologies and work together to overcome construction site challenges in a virtual environment.

The Simulation Zone at Plantworx 2023 is open to all visitors, regardless of their experience level. With the guidance of immersive training experts, participants will navigate the virtual world of simulation technology and experience first-hand the benefits of this innovative approach to skill development.

Companies and contractors interested in adopting this state-of-the-art training method are invited to experience all that The Simulation Zone has to offer. No previous experience is necessary, and everyone is welcome.

Plantworx 2023 has announced the shortlist for its 2023 Innovation Awards programme. In this year’s entries, across all the categories, the focus was very much on environmental solutions, sustainability, safety and smart technology, with many of the entries fitting into more than one of the categories, as more companies have adopted a multidisciplinary design approach when designing their products/systems.

THE JUDGES

The judging panel, made up of some of the most highly regarded individuals in their respective fields, deliberated for some considerable time over this year’s nominations, but eventually came up with an outstanding shortlist of companies.

The Plantworx team would like to say a huge congratulations to all finalists and a big thank you to everyone who took the time to enter.

Margo Cole: Engineer and construction journalist - Chair of the Judges

Susan Scurlock MBE : Chief Executive and founder of Primary Engineer

Graham Black : Editor Earthmovers magazine

Mark Lawton: Head of Engineering Surveying at Skanska

Chris Matthew: Strategic Manager at P. Flannery Plant Hire

Amer Essa : Supply Chain Innovation Senior Advisor at National Highways

Lara Young: Global Head of ESG Cromwell Property Group

Sponsored by DATATAG

Elite GSS: Hi-Viz Ballast Block

Hydrotechnik UK Ltd: Minimess Monster

Genquip: i550 Welfare Unit

Environmental Initiative

Sponsored by KGP

Lifos: Lifos Port PV

Auger Torque: Cone Crusher Bucket

SANY: SY19E electric mini excavator

Concrete Services: Conscreed – E1800 100% electric laser screed

Boss Cabins: Deep Green GenFree welfare cabin

Atlas Copco: ZBC energy storage system

Safety

Sponsored by Caterpillar

Spillard: AI Human Detection System (HDS)

Bomag: Articulated tandem roller

Onwave: Onwave OWL

Bomag: Asphalt Pro

Xwatch: Xwatch pitch and roll warning system

Best Use of Technology – Including Digital Innovation

Sponsored by Futureworx 2024

MachineMax: MachineMax technology

MP Filtri: CMP View Software

Filtertechnik: Particle Pal Plus

Bomag: Asphalt Pro

Security Initiative

Sponsored by the CEA Policing Fund

Digger Guard: Digger Guard Vandal Guards

Kist: Datatag KIST (asset management)

Abax: Smart Inventory

Engineering and Design

Sponsored by CEA (Construction Equipment Association)

Digga: HALO auger alignment system

Mecalac: Revotruck

Manitou: MRTe rotary telehandler

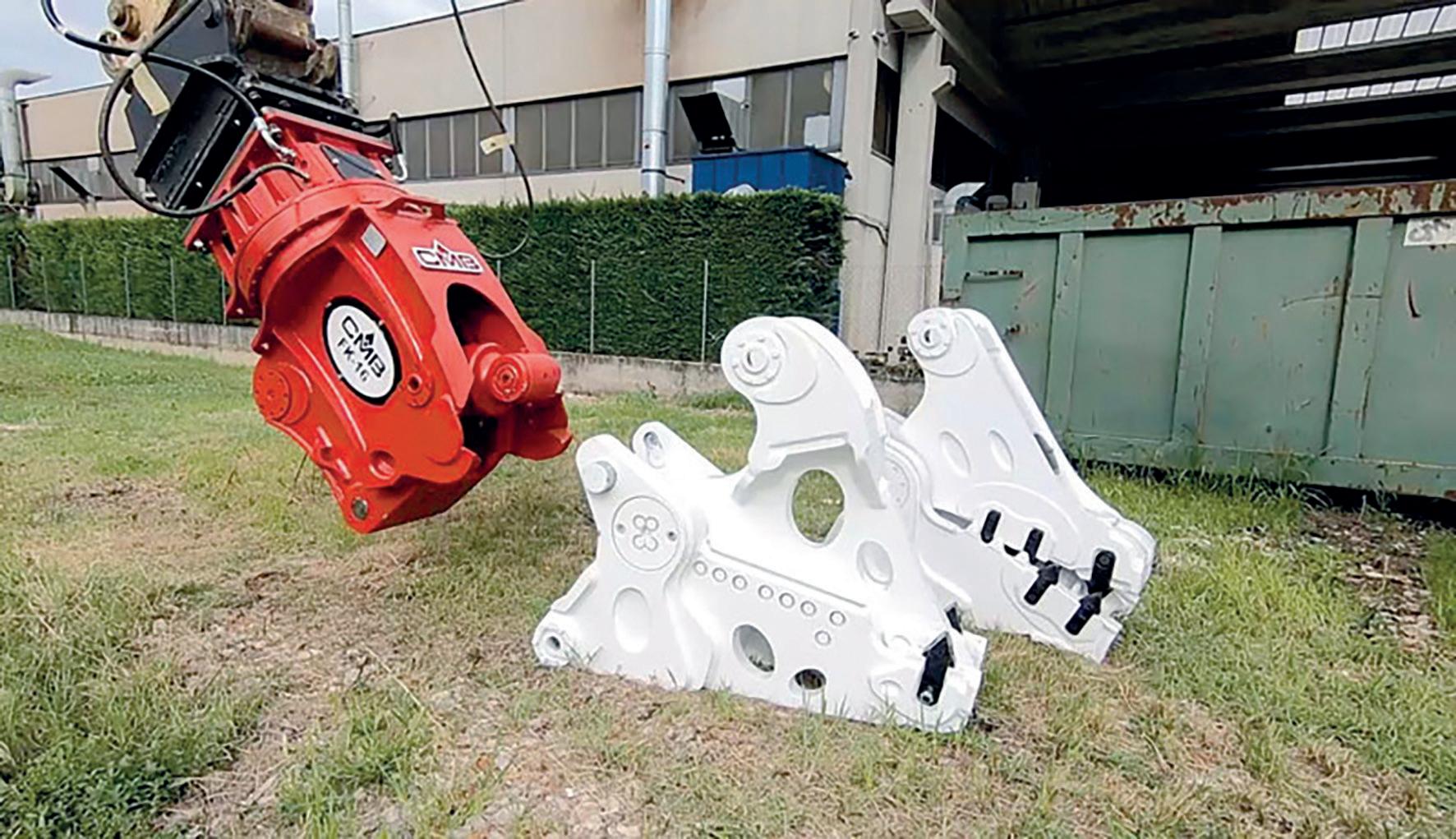

Worsley Plant: Rotar’s fully integrated quick coupler adapter

SANY: SY19E electric mini excavator

Training & Skills Development Programme

Sponsored by Merlo

Leica Training School: For retention and upskilling and ongoing training of operatives

Flannery Plant Hire: Skills Bootcamp in Plant Operations

Special recognition awards

Sponsored by Plantworx

Plant and Hire Aid Alliance: For providing aid to war-torn Ukraine

British Steel: Laser Detection of Surface Defects

Xerotech: Xerotech Hibernium battery pack

Plantworx will be buzzing with excitement as industry leaders, manufacturers and plant specifiers come together to showcase the latest equipment, technologies and techniques in the construction industry.

The construction industry has come a long way in the past few decades and technology has played a significant role in that progress. From machine control to telematics, GPS systems and safety systems, technology has transformed the way construction sites operate.

Machine control systems have dramatically improved the precision of construction equipment such as excavators, bulldozers and graders. By using GPS technology, these systems are able to provide real-time guidance to operators, enabling them to complete tasks with greater accuracy and speed. This in turn minimises the need for rework, saves on material costs and ensures projects are completed on schedule. Telematics, on the other hand, enables remote monitoring and management of construction equipment. By collecting data on equipment usage, fuel consumption, and maintenance requirements, site managers can make informed decisions about asset allocation and maintenance schedules, leading to better use and reduced downtime.

GPS systems have become indispensable tools on construction

sites, allowing for accurate positioning, mapping and tracking of equipment and personnel. This has streamlined workflows and improved coordination among teams, resulting in increased productivity and efficiency. In addition, real-time tracking enables quick response in the event of an emergency or theft, ensuring site safety and security.

To showcase the latest advancements in construction equipment technology, Plantworx is launching the Get Connected Technology Zone, a dedicated space for technology providers in the construction equipment sector.

The inaugural Futureworx exhibition in 2022 was a massive success, demonstrating the industry’s appetite for new technology. As a result, the Futureworx team has been asked by leading construction innovators to recreate an element of this event at Plantworx. The Get Connected Technology Zone will showcase the technology and innovation that will drive productivity on construction sites, leading us into the construction site of the future.

The new zone will bring together companies that have new and innovative ways of delivering solutions. The focus will be on the people-plant interface, telematics, the connected site and safety systems. Companies such as Leica Geosystems, Thomas Plant, Unicontrol, Sitech, Sodex Innovations, Plinx Connect,

MachineMax, GKD and FTC have already confirmed their exhibition space in the Get Connected Zone, hosted in the indoor arena.

The outside Get Connected exhibitors and sponsors include Hyundai Construction Equipment Europe, Conquip Engineering, Sitech and Thomas Plant, as well as having a range of OEM machines in operation. These exhibitors will demonstrate their systems in action on working machinery, which will have had the inside exhibitors’ technology installed. Exhibitors will arrive ready to plug and play, demonstrating the ease of integrating new technology into existing construction equipment.

According to Sean Scarah, Plant and Logistics Director for Balfour Beatty Asset and Solutions Division, the focus is no longer on just diggers, but on a whole connected site where 3D machine control and autonomous plant help to deliver a project and help us on our journey to net zero. To achieve this, industry solution and equipment providers, supply chain partners, IT specialists and clients must work collaboratively together.

In addition to showcasing the future of the construction site, Plantworx 2023 will also highlight the key challenges facing small and medium-sized construction sector companies in the areas of immersive technologies and data. The event will provide an excellent opportunity for attendees to learn about new technologies and the ways they can benefit their operations.

Two leading digital solutions companies, MachineMax and PLINX are proud to announce their partnership as co-sponsors of the brand new Get Connected Zone at PlantWorx 2023.

The PlantWorx Get Connected Zone is a dedicated space for technology providers within the construction equipment sector

designed to showcase how digital solutions are driving changes on projects and sites across the globe.

Jenny Rohde, Growth and Partnerships Director, from PLINX explained: “By ‘Getting Connected’ you can increase the visibility of daily operations; for PLINX and MachineMax this extends beyond individual machines’ telematics. Experience tells us that by integrating systems and data you can generate actionable insights and capability, with far greater return on investment for your business.”

PLINX uses advanced technology solutions to build safer and more connected environments, supporting construction companies to deliver projects on time and send workers home safely at the end of each day. MachineMax is on a mission to enable businesses to make proactive decisions that deliver a better, more sustainable and productive future.

As ConTech disruptors, the businesses are the perfect partners to co-sponsor the Get Connected Zone as their advanced technology and data-driven insights are already

empowering businesses to expedite their digital journey.

Amy Law, Marketing Manager from MachineMax said: “Visiting the Plantworx Get Connected Zone will provide a great opportunity to see a wide range of leading connected technologies that can deliver value to projects and provide a space for networking and exploring how integrating these solutions can add huge-value to business operations and projects.”

“A great opportunity to see leading connected technologies provide a space for networking and exploring how integrating these solutions can add hugevalue to business”

Determined to remain at the forefront of industry innovation, Yanmar CE EMEA (Yanmar) is pulling out all the stops for its class-leading ‘Premium Red’ machines at Plantworx 2023. Stand B-FB10 is where all the action is happening, with machines on show ranging from its core mini excavator models and compact wheel loaders, to allnew and future-ready electric prototypes.

Yanmar’s presence at Plantworx 2023 wouldn’t be complete without its marketleading standard tail swing excavators, such as its urban and landscaping-ready SV26 (2,740 kg Operating Weight (OW)). Other conventional tail swing excavators on display will include the ultra-tough SV15VT (1,685 kg OW), and the highperforming yet compact SV60-6B (5,655 – 5,685 kg OW).

Also present is the ultra-precise and stable ViO27 (2,770 kg OW) and the ViO57 (5,505 kg OW) with first-rate fuel economy. As well as the ViO82 (8,200 kg OW) with maximum stability and exceptional lifting strength comes Yanmar’s smallest zero tail swing model, the ultra mini (yet mighty) SV08 (1,035 kg OW).

Yanmar’s ultra-efficient and productive B95W wheeled excavator (9,100 – 9,500 kg OW) is being showcased alongside the compact C30R-3TV tracked carrier (2,865 kg OW) with 180° turning swivel skip and one of Yanmar’s newest and smallest compact wheel loaders, the V7-HW (4,450 kg OW), with a tipping load of 3,250 kg.

Lastly, pioneering the transition to electric units across the construction industry, an all-new prototype of Yanmar’s V8e electric compact wheel loader takes centre stage (4,500 kg OW, 11 kW charging in standard configuration and 22 kW in optional fast charging).

Our automatic grease pumps are designed to ensure that the right amount of lubricant gets applied throughout the lifetime of your equipment. The automatic distribution of the lubricant is more efficient than manual greasing as it applies grease at a more frequent interval. This will increase your productivity and reduce your downtime significantly.

Reduced repair costs

Increased productivity by reducing vehicle downtime

Works with all standard EP2 grease

Higher residual value of machine

Reduced grease consumption

Improved safety

Pump and pause time fully controllable

We offer a full range of Hebonilube automatic grease pump systems in 12V and 24V, available for next day delivery across mainland UK. We stock 2kg, 4kg, 6kg and 8kg pumps.

SANY UK will take its largest ever stand at PlantWorx 2023 to showcase its latest range of excavators and wheel loaders, along with a host of innovative technologies designed to improve productivity, efficiency, and safety on site.

Making its UK debut at the show are two brand new SANY wheel loaders, the SW305 and SW405

models with their bucket capacity of 2.3 / 3 m³ and an operating weight of 14.5 / 18 t. The new generation of wheel loaders from SANY are manufactured with well-known components including Kawasaki pumps and ZF transmission and fully equipped as standard including 360° camera, keyless entry, single joystick steering and third function hydraulics.

Also premiering at the event will be the new SY18U. This zero tailswing mini excavator allows you to work with confidence in confined areas and offers the same technology and performance as the popular SY16C and SY18C models.

As with all SANY

excavators, the SY18U is backed by the industry leading five-year/3,000 hour warranty for complete peace of mind.

A number of other machines will also be on display, ranging from the SY16C, 1.6T canopy mini digger to the SY155W wheeled excavator and 21-t SY215C crawler, so there really is, something for everyone.

For those who would like to put their operating skills to the test, the SANY Operator Challenge will also be in full swing over the course of the three-day event. Participants will be able to take part using the recently launched SY19E electric mini excavator, which was unveiled to the UK market at the Executive Hire Show earlier this year.

The SANY stand will also include a large working demonstration area and will also offer visitors the opportunity to operate the machines themselves (appropriate operator’s ticket and PPE required). Seven different machines will be available to try ranging from the SANY SY16C mini to the larger compact SY135C.

Stand A-E1

Gaz Evans Models (GEMs) will be participating in Plantworx for the first time in 2023. GEMs specialises in creating top-notch scale models and accessories for the construction, demolition, and recycling sectors, offering these models at surprisingly reasonable prices.

With permission from original equipment manufacturers (OEMs), GEMs produces all its scale models and attachments in-house. The process begins with obtaining drawings from the OEMs, then creating a hand-built master model using either plastic card or 3D printing. These parts are cast

in high-quality white metal, cleaned, assembled, painted, and detailed by GEMs themselves. Its products cater to OEMs, plant dealers, and collectors.

Gaz, the founder of GEMs, has been making models as a hobby throughout his life. After leaving his job at a demolition company, he turned his passion into a full-time business. In 2021, Lucinda officially joined the growing company.

Gaz Evans says: “In a world where precision and detail matter, Gaz Evans Models prides itself on crafting 1:50 scale model attachments for the construction and demolition industries, showcasing renowned brands like Rotar, Gjerstad, Engcon, and more. We don’t just stop there; we bring dreams to life by customising heavy plant models to represent companies like Collins Earthworks, Ruttle Plant and Plantforce, ensuring every piece is a true representation of its real-life counterpart.”

GEMs also offers customised models and dioramas, perfect for company foyers, events, and client gifts. They can modify base models with company signwriting and colours, adjust booms and add attachments. Models can even be placed on plinths for special presentations. If interested in a custom build, GEMs encourage potential clients to get in touch for a quote by visiting the company on stand A-E1 at Plantworx.

GEM’s dioramas feature accurate scaling and exceptional detail. Their carefully applied livery and weathering effects make GEM dioramas truly stand out from the competition. For more information visit www.gemmodels.co.uk.

Stand B-EC3

Blue Machinery will be exhibiting at Plantworx for the first time this year and will be showcasing its range of market leading attachment brands.

On its main stand located at B-EC3, Blue will be exhibiting the range of Rammer hammers, Fortress Shears, Allu screening buckets, Xcentric crushing buckets, Xcentric rippers, demolition tools and Grabs from VTN and OSA and the OilQuick quick coupling systems.

Alongside its static stand, Blue Machinery will also have a DEVELON excavator on live demonstration in the Get Connected zone. This DEVELON excavator will be paired with a number of attachments to process material and this will encompass a Rammer breaker, Allu screening bucket and Xcentric crushing bucket which will all be fitted with OilQuick coupling systems.

Blue Machinery will also be sponsoring one of the operator challenges at the show, which will include the use of one of its attachment brands. Stay tuned for more information on this one.

To celebrate its first appearance at Plantworx and to show how serious it is about attachments, Blue Group will be giving away a free small rammer breaker at Plantworx. One lucky winner will have the chance to win either a Rammer 111, 222 or 333 breaker, suitable for 1-9 tonne mini excavators. The winner will be announced live at Plantworx (but they don’t have to be attending the show to win) and will be able to choose from one of the three small breakers on offer.

Entries close at 12 pm on 15 June.

Freshfilter cab air quality systems are used on haul trucks and mobile machinery to protect the machine and its operator from toxic substances.

• Keep employees healthy and safe

• All national and international legislation is applicable to the cab air filtration systems

We install various types of reversing fans and only use high end products. Flexxaire is the world’s leading smart airflow developer in the fan industry.

• Clear debris in less than a second

• Save on fuel costs and increase power

• Low maintenance

•

World-leading plant and equipment manufacturer Sunward is debuting at this year’s Plantworx, the UK’s only live demo construction equipment and technology event in 2023.

The 500 m2 stand for the event at the East of England Arena and Events Centre in Peterborough from 13 to 15 June will host the launch of several new products from Sunward, which launched in Europe in 2015.

Just over half of the stand will be set aside to demonstrate to visitors Sunward’s popular and iF award-winning* range of short tail excavators, including the recently launched SWE 155UF medium excavator. This will be on display alongside the existing 2.5-t zero tail swing SWE 25UF mini and SWE 60UF compact excavators.

Plantworx will also act as the UK debut for Sunward’s SWE 20FED – a two-tonne fully electric mini excavator – which will head up the static display. This machine is particularly suitable for urban construction sites with strict requirements for emissions and noise, and thanks to its tail swing radius of just 1,110 mm, for sites with limited and or confined spaces.

The SWE 20FED comes in cab or canopy options and offers exceptional value for money in the new market of electric excavators. It features a lithium-ion battery and a three-phase asynchronous motor, providing an autonomy of more than six hours under full working load. The machine can be fast charged in under two

hours or fully charged in seven. Also debuting in the UK is the new SWE 155UF medium short tail. This is a standout model, weighing 16 t and boasting a short radius, available also with a two-piece boom. It is equipped with a Cummins engine with 90 kW @ 2,200 RPM and hydraulic high-performance Hengli, providing exceptional stability and high performance in its category.

Sunward’s excavator range in Europe spans from micro excavators weighing one tonne to hydraulic excavators weighing 36 tonnes. As well as the new electric SWE 20FED and the new SWE 155UF, Sunward’s SWE 08B, SWE 18UF, SWE 35UF and SWE 90UF excavators will also be on display.

To complete its construction range, Sunward plans to present its compact tracked loader, the SWTL4538, as well as a scissor lift.

Plantworx will see the debut of Sunward’s new SWA 16JE electric articulated boom lift, which is versatile, safe and sustainable for a variety of applications. The machine has all-terrain capabilities and a compact size, making it ideal for indoor and outdoor work. Additionally, it is designed for easy maintenance and has a low total cost of ownership, making it a costeffective investment. Safety features such as an anti-tilt system and emergency lowering valve are also included.

New attachments on exhibit at Plantworx from Sunward Europe include hydraulic quick couplers, augers, sorting grapples, buckets, breakers and Steelwrist tiltrotators.

“New attachments on exhibit at Plantworx from Sunward Europe include hydraulic quick couplers, augers, sorting grapples, buckets, breakers and Steelwrist tiltrotators”

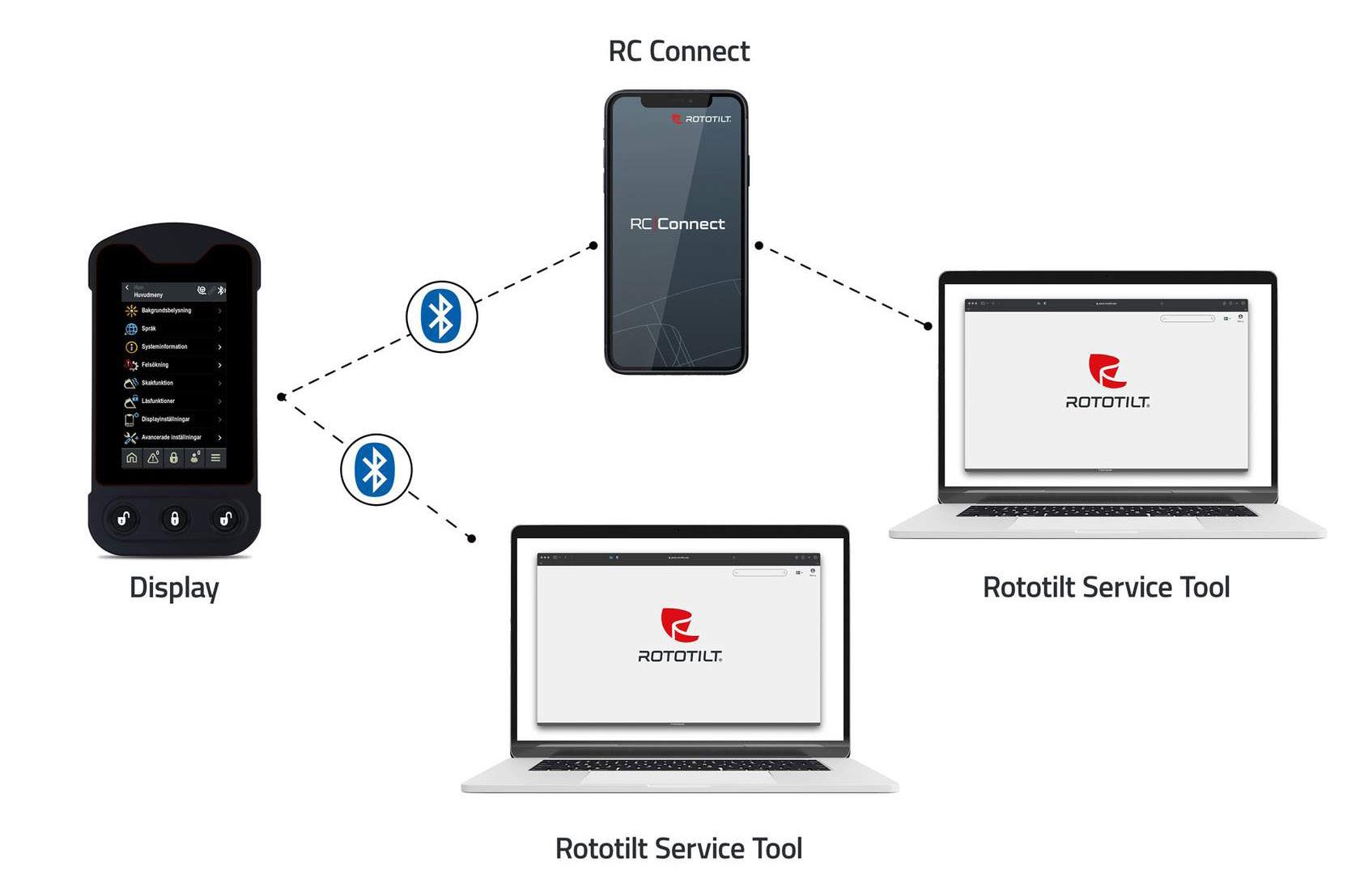

SMT GB has swapped machines out in favour of showcasing the extensive range of services and solutions now available nationwide