A dverti $ er Component manufaCturing

Serving the Structural Building componentS induStry S

New ways to equip you for success.

The business of construction has never been more challenging. That’s why Simpson Strong-Tie keeps working to develop new solutions. Focused on customers, we’re constantly exploring innovative ways to support component manufacturers. Our truss connectors have become the industry standard. Our design and management software streamlines operations. And now, with advanced, automated cutting equipment, we’re bringing even more powerful tools to sharpen your edge. From ultra-precise component machines by Hundegger to brilliantly simple cutting and marking technology with EasyFrame, we’re fully equipped to keep you moving ahead. Build your business with all the right components. To learn more, visit go.strongtie.com/componentsolutions or call (800 ) 999-5099.

A dverti $ er Component manufaCturing

Anna Stamm – Advertiser Forum: Correlation, Causation, or Coincidence

Joe Kannapell: Wall Panel Technology, Part V: Whole House Evolution

Wendy Boyd – Spida Machinery: Spida’s Jacksonville Open House

Todd Drummond Consulting, LLC: Retaining Profits Amid Margin Compression

Glenn Traylor: What Can We Learn From the Recent CrowdStrike Debacle?

Edmond Lim, P.Eng. –LimTek Solutions: Doing Your BCMC Homework

Alpine Staff: BCMC 2024 is Around the Corner

Carl Villella – Acceptance Leasing: Playing the Interest Rate Game

Lesko Financial Services: Economy Still Signaling Growth at Mid-Year But Not Among All Sectors

Thomas McAnally – The JobLine: What Time is It?

Geordie Secord – Design Connections: Making the Most of Mass Timber

Tuomo Poutanen – G-Joist: Glued Trussed Floor Joists

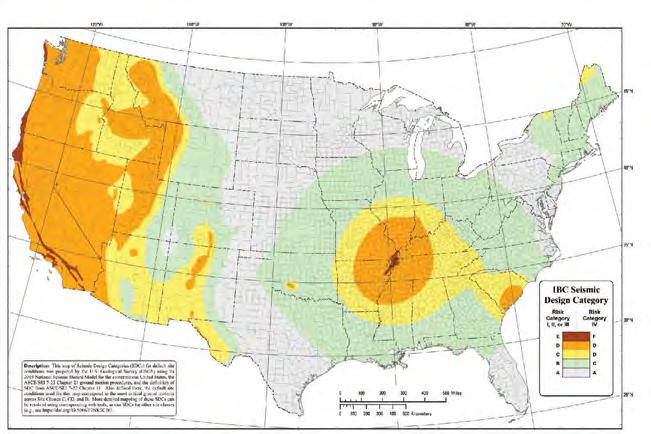

Buddy Showalter, PE & Sandra Hyde, PE – ICC: 2024 IBC Significant Structural Changes — Loads

MiTek Staff: New to the IRC 2024 Sec. R502.11

Simpson Strong-Tie Staff: Mass Timber for the Masses — How Simpson Strong-Tie Innovation Is Enabling More Efficient Construction

Joe Kannapell – The Last Word The Rise, Fall, and Rise of Big Truss Plants

West

Publisher Thomas McAnally twm@componentadvertiser.org

Editor Anna L. Stamm 800-289-5627 x 3 anna@componentadvertiser.org

Distributed FREE Via e-mail subscription Download PDF or Read on line at www.componentadvertiser.com

News of Interest and Advertising inquiries can be submitted to: anna@componentadvertiser.org An Open Forum for many sources.

Deadline 20th of each month. Articles, Trade Names, and Logos are the property of their respective owner or creator unless otherwise noted

Disclaimer: We reserve the right to refuse any advertisement or material that we deem not in the interest of the industry or the Advertiser. Permission to use content is the responsibility of the contributor including permissions to use any likeness of persons.

The Advertiser is provided “As Is” including typographical errors, omissions, and mistakes both intentional and unintentional.

Believe it at your own risk! Copyright 2008-2024

Component Manufacturing Advertiser

The Advertiser 7586 Becks Grove Road Freetown, Indiana 47235 no reproduction in whole or in part without permission from the component manufacturing advertiser

Archive Copies Available On Line www.componentadvertiser.com

Anna L. Stamm Director of Communications and Marketing Component Manufacturing Advertiser.

DAdvertiser F Forum

Correlation, Causation, or Coincidence

etermining a genuine cause and effect relationship can be tricker than it seems. Some situations are obvious, but others may be only coincidental. How do we know for certain?

When Causation is Obvious

Thankfully, some cause and effect relationships are easy to prove. You fall down and break a bone – that’s a very clear outcome. It may not be a good outcome, but at least you know where you stand and that an impact caused the break.

When Correlation Comes Into Play

Taking the simple example of falling down, we can do a little more investigating. Do you have weaker bones than you should? Are you not getting enough calcium in your diet? As a person who still drinks milk at lunch and dinner (yes, we drink milk in my home), when I tripped off a curb and broke my foot a few years ago, I knew calcium was not my problem, but it might be an issue for other people. There may be underlying causes that are contributing factors, and we may or may not be fully aware of them.

When Coincidence Feels Like Correlation

For whatever reason, I can never keep the doorbell working. Honestly, in both Wisconsin and Oklahoma, I have tried replacing the doorbell myself and even hired experts, but the doorbell never stays working for very long. No one ever can ever give me a good reason why they stop working, and I have given up trying to fix the problem. Is there something about my electromagnetic field that disables doorbells? I doubt it, but the common denominator is my presence and the coincidence is strange nonetheless.

Cause and effect can be direct or obscure. Correlation can be striking but irrelevant. When we’re not certain, we may have to keep looking for proof before passing judgement on coincidences.

In my house, when opportunity comes knocking, I only know for certain that it can’t ring the bell!

Monet DeSauw FWA 500 Floor Web Cutter

• Push Button Powered Blade Angulations

• Single Push Button Setting for 2 Blades per Side

• Electronic Digital Readouts

• Backup Mechanical Indicators

• Cuts 4 Angle Webs, Cantilever Webs (2 piece webs) & Square Blocks

• Magazine Lumber Feed for 3x2, 4x2 and 6x2 Lumber 12 1/2” to 48 1/2” Length Capacity (7” Minimum on Square Blocks)

• 60 Pieces per Minute

• (4) Internal 16” Blades & (1) External 16” Cut-Off Blade

• Pneumatic Blade Brake on External Blade

• Dust Hoods

• Belt Waste Conveyor (under saw)

• Add $4,300 for 12’ Incline Waste Conveyor (adjacent to saw)

• Add $2,100 for Extra Set of Blades

• 480 Volt / 3 Phase

FOBMO Call For Pricing

Linear Saw

• Automated (Truss Design Software Download) or SemiAutomated (Touch Screen Entry) Operation

• All Movements are Computer & PLC Controlled

• Comprehensive Setup Screens Display Each Piece with Setup Data

• 22” x 40 Tooth Blade on PAE Cut 1 or 2 Boards up to 20’ (2 Second Plunge Cut)

• Cut Chords, Webs, Rafters, Wedges & Stair Stringers

• Cut Long Scarfs by MultiPlunging

• Servo Positioning on Infeed, Angle & Outfeed Pusher

• Over Travel Protection

• Ink Jet Printer

• Lumber Optimization Program

• Belt Waste Conveyor

• 480 Volt / 3 Phase / 60 Amp

• Includes 5 Day Onsite Installation & Training

• Optional Monet DeSauw Live Deck, Bunk Feeder & Incline Belt Waste Conveyor FOB MO Call For Pricing

DeSawyer

2000 Automated Saw

• Touch Screen User Interface with Backup Mechanical Controls

• 3 Operating Modes: Auto, SemiAuto & Manual

• All 20 Axes of Movements are Computer & PLC Controlled

• Comprehensive Setup Screens Display Each Piece with Setup Data

• Anti-Collision & Optimizing Programming

• Auto Calibration Productivity & Time Tracking

• Maintenance Diagnostics

• Variable Speed Conveyor (0-50 Flights per Minute)with Powered Hold Downs

• (1) 30” x 80 Tooth Blade (27 3/4” Scarf on PAE)

• (4) 16” x 40 Tooth Blades (13 1/2” Scarf on Centerline)

• Pneumatic Blade Brakes on all 5 Blades

• 16 1/2” to 20’ Length Capacity (11” Minimum on Square End Blocks)

• Vibrating Waste Conveyor Under Saw

• 480 Volt / 3 Phase

• Includes 4 Day Onsite Installation & Training

• Add $2,900 for Extra Set of Blades

• Optional Live Deck, Label Printer, Ink Jet Printer, Catcher Display & Incline Belt Waste Conveyor.

Call For Pricing FOB MO

Buy Factory Direct From Wasserman & Associates at the same price as the Manufacturer, and get the added support and care you need to be up and running FAST! WE’LL EVEN HELP SELL YOUR USED EQUIPMENT TOO!

EZ-SET AUTO JIGGING EXCLUSIVE & PATENTED DESIGN

Automatic Truss Jigging System to drastically reduce setup times. Allows for 100% embedment on the table, with top & bottom chord pucks in the same slot. TopSider or standard configurations available for conventional kick-leg, walk-thru, or our new trackless 8' and 10' continuous table systems. Systems for other roller & hydraulic gantries are coming soon. Available in new machine installations or for retro-fitting your existing table. The TopSider is exclusively applicable for “kick or flip leg” style truss presses such as the Tri-Axis & Lumbermater®

FEATURES / APPLICATIONS

• Capable of 100% On-Table Nail Plate Embedment

• Two Pucks Per Slot

• 24", 26", and/or 30" Spacing

• Compatible with all current major design software

• Multiple Simultaneous Layouts

Hain Systems Framer

The Hain Systems Framer (HSF) will help you build square and accurate wall panels for residential or commercial construction applications. It will help you cut building costs by saving time and improving your quality. It’s a reliable, efficient and proven system that features a ruggedly simple design. The HSF is based on a proven design with over 20 years of actual production use and maintenance experience. It comes fully assembled and is designed for portable job site framing or in-plant permanent installation. The table has many optional attachments and will support Mylar Tape wall layout or any other type of layout. The optional gun rails can also be retro-fit to any table.

Details:

Table Construction: Thick-wall Structural Steel Tubing, Jig Welded for Accuracy

Length: 5 feet (60”) to 60 feet (720”)

Height: 12 inches

Air Supply: 90 psi (10 CFM Air Flow Recommended)

Depth: 12 inches

Electrical Supply: 120 VAC

Powder Coat: Industrial Gray

Dimensions: Height: 43”

Length: 16’ or 20’

Width: Adjustable 8’ to 10’ or 8’ to 12’

Shipping Weight: 3000 lbs

If you are looking for the fastest, most consistent way to measure and cut your product, then the Hain Measuring System (MEA) is your answer. The MEA changes from one length t any length instantly, up to 60’, without changing the operator’s position on the line. It is also highly accurate (+/- .010) and quickly moves from one length to the next in seconds. The MEA is designed for quick and easy setup and is simple to use. Even a first time user will be productive with little or no training required. It can adapt to any saw and can be mounted to any surface so that you can integrate the MEA with your existing setup. The MEA is versatile allowing “left” or “right” handed operation and measurement in “feet and inches” or “inches” depending on your preference. The MEA is also available in a “Skid Mounted” version.

By Joe Kannapell

Wall Panel Technology, Part V: Whole House Evolution

The dream of having a single person model an entire structure was admirable, but developing the software to do that turned into a decade-long struggle. Five years ago, I chronicled the development saga in my series on Fifty Years of Truss Design, Parts XI – XV As the story told, the result was workable software, but let’s consider some additional elements in the story not mentioned there. Did these advancements increase productivity in the design effort? Or, more importantly, did they increase sales of components? With the adoption of trusses being nearly universal, whole house software won’t grow truss sales noticeably. But, if viable, whole house software should grow wall panel sales, and the history of wall panel acceptance tells part of this story.

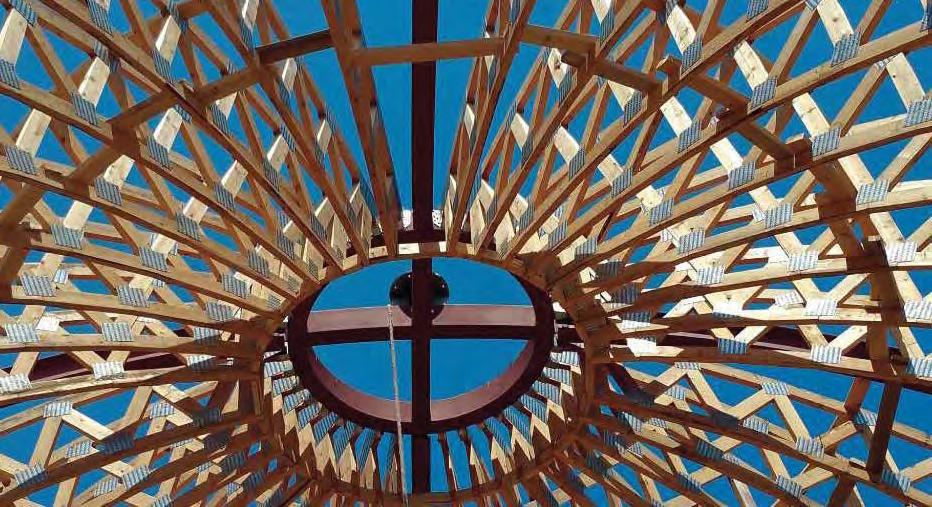

1950 to 1980 – After the midpoint of the 20th century, whole house packages went into the construction of a considerable portion of home sales, especially in the Midwest. These were efficiently designed, well-built homes that were built offsite and shipped compactly by panelizers like National Homes and many dozens of others. Yet these companies didn’t survive past the 1980s and were displaced largely by onsite framing. In the aftermath, offsite panelization took a hit, except in certain pockets where component manufacturers supplied whole house components, four of which are shown in the image. The demise of panelizers in the period should dispel the notion that there is a sales advantage to supplying whole house packages.

1980 to present – Sinking lumber prices in the early 1980s also shrank the competitiveness of wall panels, as factory labor costs became a higher percentage of the sales price of panels. However, Lenny Sylk initiated a new strategy, emphasizing the value of componentizing the whole house, and underscored his approach by renaming his company from Material Fabrication to Shelter Systems. In 1985, he pioneered what came to be known as Framing the American Dream (FAD), gaining hard data on the cost savings of panelization by erecting a componentized house next to a stickframed house. When the economy began its long march upward in the 1990s, Framing the American Dream was repeated at the International Builders Show for a national audience, encouraging CMs to pursue panelization and the software to support it.

In the mid-1990s, Tommy Wood, the panel software supplier of Lenny Sylk and others, propelled panels to a leading role in whole house design by rebranding his business as Intelligent Building Systems (IBS). Tommy astutely deployed the term “parametrics” to describe the ease of reworking panel layouts to accommodate design changes. This underscored one of the main differentiators between his software, which defined panels from reference lines, and the software from other suppliers. And having this capability enabled Tommy to combine with truss software supplier Truswal, which supplied many of his users. Combining IBS software with truss software was complicated by ITW’s acquisition of Truswal and Alpine software, each with unique capabilities. Likewise, MiTek faced similar challenges combining their legacy software with TrusJoist’s in the OptiFrame joint effort. In fact, truss and panel programs couldn’t be merged, so new code had to be written. This extended the development cycle through the severe 2008–2009 downturn, the untimely death of Tommy Wood in 2011, and later the Covid pandemic, but it can be argued that we have finally reached a new era for whole house design.

Utilization in the present day – So now that robust whole house software is available, is it being used? Surprisingly, after software investments of hundreds of millions of dollars, most CMs, including Builders FirstSource’s large cadre of panel designers, mainly compartmentalize panel design and separate it from truss design. Both tasks require a mastery of the intricate details of building plans and an intimate understanding of potential framing solutions. However, both the details and the solutions are radically different for trusses vs. panels. As a result, designers attempting both may become “a jack of all trades, and a master of none.” And two sets of expert eyeballs on a plan can provide a valuable quality check and may be necessary to meet builder ’s deadlines.

Whole House Development Benefits

1Updated infrastructure

2Common interface

3Shared databases

4 Uniform file structure

Protects from hacking and minimizes crashes

Better administration, supervision, and training

Material inventories and prices stay consistent

Expedites retrieval and lessens errors

So, even if all the industry’s efforts have fallen short of the dream of a single user modeling the entire structure, the payoff has been substantial. Although dealing with software updates can be a painful process, good designers understand that it is a way of life.1 And designers will accept the pain if they have substantial gain.

Next Month: Panel Equipment Innovations

1. For more on the development of specific software programs, see the 2016 LinkedIn article by Christopher Gould, “6 Reasons Why MiTek Sapphire is Superior to eFrame.”

Increase the value of the advanced component package you provide to builder customers with open web floor trusses.

Builders who partner with their component manufacturer to design their builds using floor trusses can gain efficiencies in shorter cycle times and reduced waste compared to I-Joists.

Are you ready to help builders design for floor trusses from the start? Talk to a MiTek Representative to get started.

TheJobLine.com

Software Territory Sales Representative –Component ManufacturersJ15336

You want to be an important member of a strong team of other makers who take pride in their work and support each other. As a Territory Sales Representative (TSR) – Component Manufacturing, you will be responsible for growing Truss sales in the Kansas, Missouri, Oklahoma, and Northern Arkansas Territory while creating and maintaining effective relationships with component manufacturing customers. Your goal for these relationships will be to promote the company's software suite and related hardware products. This encompasses job management, design and analysis for prefabricated metal plate connected wood trusses and engineered wood products. You will coordinate with and contribute to the overall branch and company efforts to profitably grow our business. You will also lead and participate in training sessions/workshops in and out of the territory. These workshops require scheduling, promotion, set-up, presentation, and take-down, as well as providing observation and suggestions for improvement. You will work with Regional Sales Managers, Product Management, Marketing, and other TSRs to develop/coordinate sales strategies and programs; and communicate appropriate market trends and field intelligence to provide to Management and Operations to ensure customer satisfaction. If career growth is important to you, we not only know how to help you with that, it’s what we love to do.

DESIGN SOLUTIONS

DESIGN

Elevate Your Wall Panel, Floor Truss or Roof Truss

Manufacturing with 4Ward Design Solutions’

Precision Component Design Services!

When you work with us, you get: and best of all...

Speed and Scalability

Adjustable Hours

No Need for Training

Reduced Regulatory Burdens

Reliable Timelines

Excellence

Extend your existing capabilities with 4Ward's design expertise. Without the hassle and expense of training your own designers, partnering with us guarantees that each wall panel, floor truss or roof truss will be designed for structural integrity and production and field efficiency.

Achieve cost efficiency without compromising on excellence. Our costsensitive approach ensures maximum value for your investment.

Leverage our expertise, ensuring every component is attentively designed for optimal performance and durability.

We understand that every component project is unique. At 4Ward, we create custom designs, tailored to your exact specifications. Contact us today for a complimentary consultation.

‘Set

& Forget’ With The Sheather 5 Gun 2 Saw

A fantastic addition to your wall frame line! You’ll have perfectly sheathed walls in minutes, without being labor intensive.

ONE TOUCH AUTOMATION PREVENTS SHINERS KEEPS UP WITH WALL EXTRUDER +

Suitable for all common walls and most raked walls, the Sheather 5 Gun 2 Saw is the ultimate in wall sheathing!

Wendy Boyd Chief Customer Officer Machinery Group Spida Machinery

Spida’s Jacksonville Open House

What an amazing week we had in July—we had the privilege of welcoming a number of suppliers and fabricators to our Jacksonville Open Days! This was a tremendous way to welcome everyone to our new facility in Jacksonville, FL.

We really appreciate everyone giving up their time to come visit us and learn more about Spida Machinery and what makes us who we are. It allowed us to connect with others in the industry and spend time understanding their businesses, their manufacturing pain points, and goals for the future.

It was way back in May 2022 that we purchased this large new factory in Jacksonville. This well-established site has eight acres of land and the factory itself is three times as big as our previous one in Shelbyville, IN. We’ve been really excited about this factory as it’s fit for purpose and allows for expansion. The factory has extra dedicated office space and will be a central hub for our customers. You’ll be able to come visit and look at your machines being built. You’ll also be able to see machinery in action in the testing phase.

We manufacture machinery, but at our core is our people-focused approach and the partnerships we develop with our customers. We’re passionate about what we do and we genuinely care about our people, our customers, and delivering the best results. We listen to your pain points, understand your challenges, and then recommend a solution that is best for you and your factory

If you’re interested in learning more about us and our approach, please get in touch. We’d welcome you to come visit, too!

● PlanSwift Lumber & Bldg Mat Takeoffs

● Truss & Wall Panel Design Staff

● EWP Layouts and much more!

www.AllPoints.Tech

Dave Walstad - Panama City Beach, FL

Cell - 941-713-4395

Dave.AllPoints@gmail.com All Points integrates with Epicor’s BisTrack So you can be More Accurate, Faster.

European Glued Truss - Joist Licensees, Partnerships, or Investment Opportunity U.S. & Globally protected product and process

This first-of-its-kind G-Joist offers unique parallel chord options

• Can use bottom OR top chord support

• Manufacture as a custom joist, chase opening, and support or

• manufacture as fixed length, arbitrary cut, and support

• Can be cut arbitrarily AND trimmed on one OR both ends

• No hanger required when top chord support

• No proof loading required Dr. Tuomo Poutanen Kuninkaankatu 41 B 33200 Tampere Finland tuomo.poutanen@tuni.fi +358408490900, www.gjoist.com

• Can be configured with large chase openings Contact me for details: Dr. Tuomo Poutanen tuomo.poutanen@gjoist.com +358408490900 www.gjoist.com Material Takeoffs Slowing You Down? All Points Can Help You Sell More in 2024!

To see meaningful labor savings, quality improvement and production gains, SL Lasers with their easy-to-see green light are nothing short of illuminating. They enhance worker accuracy and productivity, regardless of experience or primary language. They can reduce tedious setup time by up to 70%. No complex training or costly service agreements are required. And SL Lasers integrate seamlessly with any component design software and are quickly installed over existing equipment.

We’ve been trailblazers in wood component laser projection since its very beginning, and we’re still delivering more rapid ROI for roof truss, wall and floor panel producers every day. Contact our enlightening team at Wood Tech Systems to see how SL Laser can deliver for you.

One month after installing a Double Lumber PickLine to feed two TCT Linear Saws:

"We are getting 3,000 to 5,000 bdft more each saw, than we were getting before the install.

We have shut down one Cybersaw and one TCT chord saw.

This equals about 3 less people 10 hours, and 2 less forklifts 10 hours.

Overall, it is a major improvement to our operation. We hope to have the chance to run it two shifts to further accelerate the payback.”

Tom Hollinshed, Owner

Honest, Direct, and Unbiased Expert Advisement.

For over twenty years, TDC has consistently proven to be the go to expert for reducing costs and improving productivity in all areas. All this is achieved with no equipment vendor referral fees.

Willie Boyatt VP Operations, Whitley City, KY

"The market and competition is growing more challenging, and we must stay competitive. Our truss plant was struggling in several areas, so we hired Todd Drummond to come in and assess our truss operation to help get us a game plan together to improve our operation and help us develop a growth plan. This investment was well spent because we learned so much in just a short time. Todd walked us through the things we needed to change immediately, why we needed to change them, and things we would need to change or improve as we grow. After the consultation, we went right to work changing the things he recommended, and the results have been a huge value increase in our operations. Thanks, Todd."

A gain of only one net profit point would easily be more than 10x the TDC investment for most companies.

www.todd drummond.com todd@todd drummond.com (603) 748 1051

Retaining Profits Amid Margin Compression

What was widely expected has finally happened. Years of very profitable high sales led to vast increases in capacity to meet that demand, but now we have declining sales volume—the classic too much supply versus not enough demand to maintain margins. Some like to call this margin compression, while others see it as lowering prices to keep paying the bills. Suddenly, what was considered safe or reliable customers are now offered attractive quotes from your competitors. As a component manufacturer (CM), how can you effectively counter margin compression while maintaining profits? Besides the constant battle of lowering manufacturing costs, there is one major thing your company may do to combat this never-ending struggle. Those who have done this have been very successful (though they prefer to remain quiet about it).

“If you change the way you look at things, the things you look at change.”

— Wayne Dyer

Product Material is Irrelevant, and Time is Far More Important — This may shock many, but when you sell roof/floor trusses, you are not selling lumber units. You are selling products that happen to be made with lumber and truss plates. If it were cheaper, faster, and comparable material, would anyone care if they were made of other materials? Think about all the time and effort needed for communicating information, engineering designs, processing purchase orders, manufacturing, and delivery. There are a whole lot of steps involved in the entire process. One overriding common element is time. When orders are processed, everyone consumes the resources of your operation by varying degrees of time. Regardless of size or automation, every CM only has a limited number of hours in a day to process all the orders, and all have limitations. Knowing that time is the crucial element, not material, is vital to improving margins.

Board

Foot Pricing is Highly

Renting the Manufacturing Table Time to Each Customer — For over twenty years of providing my services, I have claimed that every CM should be comparing the cost markup pricing method versus a margin based on work minutes (Man-minutes, R.E. or S.U.). Every single client who started using the work minutes per margin dollar method has improved their net profits. Let me repeat this to you. Every single client improved their net earnings by using a pricing method of establishing their margin based on work minutes, which is calculated time, and comparing this to the cost markup pricing methods. To understand why margin per work hour is so effective, all you need to think about is each time an order is being processed, you are renting the table time to the customer.

Flawed

for Roof Trusses and Should Not Be Used — A margin per work minute time is not the same as any Board Foot (BF) pricing calculation, which is a highly flawed pricing method for roof trusses. BF truss pricing falls apart when you compare roof truss orders with larger material chord orders versus smaller chord orders, such as 2x4 vs. 2x8, or orders with long runs versus many setups, such as common runs versus hip roofs. With BF pricing, you must constantly mentally adjust to account for all varying discrepancies. If you have correctly developed work minutes into the truss program, no matter the setups or lumber size, the time needed to complete the order is calculated. Again, BF is NOT the same as work minute calculations for roof trusses.

Lumber Prices Do Not Matter

— When a CM starts using the margin per work minute pricing method, how much the lumber pricing fluctuates is irrelevant. The processing time does not fluctuate based on the cost of lumber, so why should the shop’s baseline margin dollars per hour fluctuate? Each CM should establish a margin per hour baseline rate for the roof truss tables to charge their customers. They then add the margin per hour estimate to the material and labor cost to establish the sales price, which is all done with the plate vendor software reports. The same pricing report compares the margin per hour costs to the traditional cost markup methods to see if it is above, at, or below the margin per hour baseline. Establish the minimum margin rate per hour and watch how much more your operations produce in margin dollars per any given time period. This method will weed out poor margin-per-hour orders while improving orders that produce at a much higher rate per hour. You can expand this same method to know your actual profits daily because the margin per work hour is correctly calculated on every order when properly functioning. Why wait until the month’s or quarter’s end to know your net profits?

More information may be found in these past articles:

• Change Your Pricing Formula and Make More Net Profit

• How One Wood Truss Industry Leader Uses Industrial Engineering Practices of Work Minutes to Excel

To enhance your communications and reduce errors, please see last month’s article, Maintaining Successful Project Management Communications

If your location is using Eagle Metal software, ask them about using TDC roof and floor truss time standards. TDC and Eagle have an agreement for this service. Then, start using properly developed work minutes for your pricing, scheduling, and shop efficiencies.

The TDC team is your best source for learning about proven and practical lean manufacturing best practices combined with industrial engineering principles to keep your company at the leading edge of competitiveness. No one is better at providing your team with proven results for good employee practices, pricing, truss labor estimation, and so many other best-in-class practices. TDC’s tailored solutions are for the client’s specific needs. Go beyond the typical software and equipment vendor recommendations for your operations and do what many have dared to do. Embrace the Drummond Method, and your company can experience cost savings and net profit gains that usually take months or years. These gains can be accomplished in weeks or months, resulting in an average of 3 to 6 point net profit gains for CMs. All areas are addressed, not just manufacturing. Please do not take my word about TDC’s services, though. Read the public testimonials many current and past clients with decades of expertise and experience have been willing to give: https://todd-drummond.com/testimonials/

Website: www.todd-drummond.com • Phone (USA): 603-748-1051

E-mail: todd@todd-drummond.com • Copyrights © 2024

“We’ve

— Tolga Adak Florida Quality Truss Inc.

2006 Alpine AutoMill SC Automated Component Saw

• Model 348B

• Automated Setup via Download or Semi-Automated Setup via Touch Screen Input

• 23 Axes of Automation

• Sets up in 2 to 15 Seconds

• Five Blades cut 2x3 thru 2x12 up to 20'

• Waste Conveyor (under saw)

• Excludes Incline Waste Conveyor (adjacent to saw) and Live Deck (in fronnt of saw)

• 480 Volt / 3 Phase

• Video available upon request

$38,900 NOW $10,000 FOB TX Wasserman & Associates 800-382-0329 www.wasserman-associates.com

A dverti$er Component manufaCturing

Work Smar ter

Safety Speed Manufacturing Model 7400 XL Panel Saw

Safety Speed Manufacturing, model 7400 XL*, vertical panel saw, 3 HP induction motor, 64 inch crosscut, 2 1/8" maximum thickness, accuracy within 0.005 inches, 13 foot long welded steel frame with integrated stand and linear V-guides, enclosed counterweight system, adjustable vertical and horizontal rules. Quick changes from vertical to horizontal cutting. Includes machined aluminum material rollers, hold down bar, wheels, quick stop gauges and material hold downs. Dust collection ready. Options available include digital readouts for vertical cuts, automated length measuring, laser guide, stop bar, vacuum and midway fence. 208-230/460 volt, 3 phase electrical (208-230 single phase, 2 HP power optional +$100.00).

$14,499 Base, FOB MN. Wood Tech Systems 765-751-9990 www.woodtechsystems.com

Safety Speed Cut Model 7000 Panel Saw

Safety Speed Manufacturing model 7000, vertical panel saw, 3 HP induction motor, 64 inch crosscut, 2 inch maximum thickness, accuracy within 1/64th of an inch, 10 foot welded steel frame with integrated stand and linear V-guides, enclosed counterweight system, adjustable vertical and horizontal rules. Quick changes from vertical to horizontal cutting. Includes machined aluminum material rollers, hold down bar, wheels, quick stop gauges and material hold downs. Dust collection ready. Options available include lower frame extensions, digital readouts, laser guide, stop bar, vacuum and midway fence. 208-230/460 volt, 3 phase electrical (208-230 single phase, 2 HP power optional +$100.00). $10,199 Base, FOB MN.

That'sallthetimeittakes todrillstudsforrunningRomexorotherelectricalwireinthewallpanels

Motor: HeavyDuty5HP-3phase-220vor440v(Pleasespecifywhenordering)

MotorcarriagebearingandspindleassemblymountedonBlanchardgroundsteelplate

LinealmotionishardenedandgroundVbearingsandrails

BlockSizes: 2x4through2x12infiniteheightsettingtocenter

AirSupply: 100psi10CFM

Drills: 2wing3/4'”CarbideTippedcanaccommodatesmallerorlarger

Spindles: AlloySteelpolishedandgroundprecisionshafting

Frame: 2"SteelWithPowderCoatFinish

Covers: 10Gauge(1/8"Thick)Aluminumremovable

Dimensions: Height-60inches,Width-33inches,Depth-33inches

Shippingweight: 750lbs.-(Includingcrate)

MADEINAMERICABYAMERICANS

Cutting & Material Solutions For Your Line!

Precise cutting up to 4-boards high! The ProCut™ UC Linear Saw Series is configurable to any assembly line; providing a safe, accurate way to cut your lumber, while keeping your materials moving on your line.

ProCut™ UC Linear Saw

For all Roof, Floor, & Wall Panel Components; webs, chords, sliders & wedges - up to 4-boards high! 6-Position clamping squares & holds lumber for spot-on accuracy.

Enhance efficiency by eliminating carts & reducing congestion. ProDeck™ & Custom Material Handling Systems optimize material flow & deliver cut parts directly to your assembly stations.

ProCut™ Material Handling Systems Parts & Accessories

Whether you’re looking to enhance your ProCut™ Saw, replace parts, or simply add convenience to your plant, our selection of products will help keep your ProCut™ running safe, clean, & efficiently.

The ProCut™ UC Linear Saw Series offers many variations to suit your plant & assembly line. Let us design a system for you.

• High Performance Linear Feed Saw

• (does not bevel cut)

• Touchscreen Monitor

• Automated Infeed System

• Inkjet Printer

• Outfeed Conveyor System

• Waste Conveyor

• 240 Volt / 3 Phase / 100 Amp

• Air Requirements: 25 CFM at 100 PSI

• Excludes Dust Collector

• Video available upon request

The truss industry relies on 3rd party quality assurance services to provide random visits to review the plants Quality Assurance program along with their operations. If your plant needs to comply with the IRC, IBC and to those who depend on solid, experienced QA expertise, we ask you to consider selecting Timber Products Inspection, Inc. (TP) as your choice for 3rd party inspections.

Proudly serving the forest products industry for over 50 years, TP brings the expertise you need to ensure your business is successful. As a responsible partner, TP delivers to clients, employees, and the industries we serve the confidence to drive value through the effective use of our diverse professional team.

TP would like to welcome the following authorized agents to our inspection team, each of whom have many years of experience in the truss industry! • Al Coffman

Jean Hart

Curt Holler

Chuck Ray

Glenn Traylor

Elliot Wilson

If you have questions about how you can make this selection, please contact your authorized agent above or Glenn Traylor at 919-280-5905 or trusguy@gmail.com. https://www.tpinspection.com/ https://www.tpinspection.com/auditing-services/truss

By Glenn Traylor

What Can We Learn From the Recent CrowdStrike Debacle?

In the early morning hours of July 19, 2024, there was a major collapse of world commerce.

According to the company CrowdStrike, a defect in a content update to its Falcon cybersecurity defense software for Windows caused a world-wide crash that impacted many businesses, most notably the airline industry. According to Microsoft, the CrowdStrike IT outage affected 8.5 million Windows devices. This incident immediately resulted in work stoppages, stranded passengers, and lost revenue. No explanation has been given to justify releasing the software update without adequately testing it first.

The good news is that the Georgia-based restaurant Waffle House was not impacted!1

What did the impacted businesses do? Unfortunately, some were paralyzed and unable to conduct business. Others instituted emergency protocols that allowed them to continue operating albeit in modified fashion. One interesting example was an overseas airline that switched to handwritten baggage claim tickets and boarding passes so that they could move passengers in spite of the computer crash. Personally, I was very lucky that my normal carrier successfully transported me out of Houston on time Friday night; although I did then spend five hours cooling my heels in Atlanta, I was very glad I did not have to rent a car, as many of my fellow travelers did, or have to wait until the next day for a flight home.

The millions of people affected by this major disruption of global commerce had one very simple thing in common—in some way, their lives were directly affected by their dependence on computers. In particular, the computers were dependent on Cloud-based resources that had stopped working.

What Is Your Level of Preparedness?

Seeing so many people face the so-called “blue screen of death” on their computers should give us all pause. Do you have any contingency plans for situations like this or other emergencies? Will your team members know how to keep your business operating? Ask your team these questions:

1. Do we have a plan in place to manage a general emergency? If not, what do we need to cement one?

2. Could our shop set up a truss without a laser?

3. What would happen if GPS systems went down? Could drivers find the delivery addresses?

4. What if our only finish roller went down?

5. Could we cut on a manual saw if necessary?

6. Do we have a way to output cutting without a terminal connection?

7. Do we have designs archived in more than one format?

8. Is our computer system or database vulnerable to malware attacks, bad actors, or other service interruptions?

9. Does our computer system have adequate backups of all our essential data? And, has anyone checked to see if our backed-up data can be restored?

Technology has helped us in many ways, but technology has also made us dependent upon computer systems. When those systems are compromised, whether it be by malware or power outages or faulty code updates, we should be able to figure out how to get back to work before we incur serious cost.

This is a great reminder that backing up job files is an important aspect of risk management. You must consider what you may need to maintain your production and operations. I may not want to go back to the days when I depended on a Rand McNally Gazetteer for my directions, but I know I still have several maps in my car. The maps may be outdated, but they would be better than nothing if ever needed.

Are you putting all your eggs in one basket? Is this a smart move? Through mergers and acquisitions, many companies have sought to centralize their entire structure, while others continue to operate as independent segments. Highly centralized companies can tout their presumed efficiencies, but looser networks may be better able to diversify their risk. What plans should you be considering to manage your risk?

An ANSI/TPI 1 3rd Party Quality Assurance Authorized Agent covering the Southeastern United States, Glenn Traylor is an independent consultant with almost four decades of experience in the structural building components industry. Glenn serves as a trainer-evaluator-auditor covering sales, design, PM, QA, customer service, and production elements of the truss industry. He also provides project management specifically pertaining to structural building components, including on-site inspections and ANSI/TPI 1 compliance assessments. Glenn provides new plant and retrofit designs, equipment evaluations, ROI, capacity analysis, and CPM analysis.

Glenn Traylor Structural Building Components Industry Consultant http://www.linkedin.com/in/glenntraylor

Building Trust. Creating Together.

Equipment Solutions for the Offsite Construction Industry

Timber Frame Wall Panel Line

CONSISTS OF:

• X-Frame Framing Table

• X-Square Squaring Table

• X-Multi CNC Bridge with Tool Changer

• X-Tilt Butterfly Table

LINE DETAILS:

• Panel Capacity: 40ft x 10ft

• Production Capacity: 800 houses / annually

• X-Floc CNC Insulation Bridge

• X-Square Squaring Table

• X-Multi CNC Bridge

• X-Square Squaring Table

Modular Building Automation designs and manufactures equipment for the offsite construction industry worldwide. A range of solutions available from individual machines and production lines to full modular factory setups.

• Capable of manufacturing standard wall panels and triangular panel trusses

Saws

• Automated Component & Linear Saws (2010 & Newer)

• Monet DeSauw or TimberMill Manual Component Saws

• Floor Web Saws

• Spida (Apollo) Saws with Truss Automation

• Bunk Cutters

Truss Equipment

• Roller Gantry & Hydraulic Press Systems

• Finish Rollers

• Truss Stackers

• Floor Truss Machines

• Lumber Splicers

• Jack Tables

• C-Clamp Presses

1999 Speed Cut Metra Cut Saw with Hain Measuring System

1999 Speed Cut Metra Cut saw, model SSA17, S/N: AD2479 features turntable cutting, 16″ blade with 1” diameter arbor bore, maximum cutting depth of 6″, maximum length of scarf cut is 36″, 164 deg. cutting range and 5HP motor. Includes 10 foot long out-feed conveyor, push-button on/off controls, analog angle measure on turntable, and (1) spare blade. This saw is paired with a 2022 Hain Measuring System, 120v, 18′ Ft/In, with Metra Cut style low–profile stops mounted on 15′ 2022 HD Hytrol roller-conveyor.

$12,990 FOB IN Wood Tech Systems 765-751-9990 www.woodtechsystems.com

Trucks & Trailers

• Stretch Roll-Off Trailers

• Go oseneck Roll-Off Trailers

Modular Equipment

• Pacific Automation or MiTek Mobile Home Press

Contact Wasserman & Associates for a Fair Market Value Assessment of your Used Equipment Operational, Needs Work, and Parts Only equipment will be considered!

Whirlwind Model 1000 Cut-Off Saw

• 5 HP Motor with 14" Blade

• 2 3/16" x 8 1/4" Capacity

• Pneumatic Blade Guard/Lumber Clamp

• Foot Pedal Control

• Dust Collection Outlet

• 460 Volt / 3 Phase

• 1 Left Hand & 1 Right Hand Model Available

$3,500 NOW $2,800 Each FOB NC Wasserman & Associates 800-382-0329 www.wasserman-associates.com

Price: $229,900

FOB: ND

Don’t just do it, nail it. It’s a brand new day in wall-panel production, with a whole new way of doing things better.

Terminailer®, a revolutionary, event-driven, nailing machine that completely defies any preconceived notions about sub-component assembly.

Terminailer all but shatters the stereotypical myth that subcomponent equipment is essentially peripheral – unimportant. And it does so by quickly and accurately driving far more framing nails in your wall panel jobs than ever before. Whether in your shop or in the field, one operator sets the pace for production and quality. And that reduces labor costs and other aspects of overhead.

Terminailer is an event-driven, sub-component assembler that will quickly and accurately drive 30% to 70% of the framing nails in any wall panel job. In your shop or in the field, one operator sets the pace for production and quality. The Terminailer functions independent of design software, requires zero set-up time when switching between any configuration, and requires no special operator training.

The Terminailer is easy to move around the shop so it’s location can evolve as your shop evolves. With all of the nailing occurring in the closed main chamber, nail injuries and nail location miss-fires are eliminated, making your plant that much safer.

With nearly ten years of development from people that know machinery it is assembled to exacting standards, well supported, and it is easily maintained with shelf-item parts. Terminailer: vetted, tested, and ready to drive maximum productivity for you. Be sure to check out our videos below for a quick review of this revolutionary machine!

To see meaningful labor savings, quality improvement and production gains, SL Lasers with their easy-to-see green light are nothing short of illuminating. They enhance worker accuracy and productivity, regardless of experience or primary language. They can reduce tedious setup time by up to 70%. No complex training or costly service agreements are required. And SL Lasers integrate seamlessly with any component design software and are quickly installed over existing equipment.

We’ve been trailblazers in wood component laser projection since its very beginning, and we’re still delivering more rapid ROI for roof truss, wall and floor panel producers every day. Contact our enlightening team at Wood Tech Systems to see how SL Laser can deliver for you.

2021 Powermatic Model 511 Panel Saw 2021 Powermatic model 511 panel saw. Vertical panel saw features a powerful 3HP worm-drive motor which rotates in the carriage, adding the versatility to perform rip cuts. The solid aluminum rollers assure smooth feeding of stock and perfect 90° cuts every time. This saw will handle panels up to 5-ft tall in unlimited length. Includes horizontal and vertical scales and casters for mobility, the counterweight system keeps the saw carriage in the desired position when loading or unloading panels. Features dual 4″ dust collection ports with nylon brush surrounding the blade for superior dust collection from the front and the rear side of the panel. 115v, 1-phase electrical required.

$6,799 FOB AZ

Wood Tech Systems

765-751-9990

www.woodtechsystems.com

2023 Northfield Model 410 Upcut Saw NEW 2023 Northfield model 410 upcut saw available for immediate shipment. 90/90 degree cuts to 4″ x 10″ capacity (fence forward position) to 2″ x 14″ (fence rearward position). Saw is configured for material from left to right, with 3″ x 6″ air operated cylinder, filter, regulator, lubricator, 10 HP motor, enclosed steel base with cast iron table, magnetic starter and adjustable operating speed from 20 to 60 CPM. Includes optional two-palm controls, additional 4″ dust outlet, NEMA 12 electrics with fused disconnect and two 18″ diameter 60 tooth blades with 1″ diameter bore. 460 volt, 3 phase electrical required.

$18,630 FOB MN

Wood Tech Systems

765-751-9990

www.woodtechsystems.com

Time To Hire?

We’re here when you need help! visit: www.thejobline.com email: twm@thejobline.com STRICTLY CONFIDENTIAL!

2008 Alpine PF90 Wall Panel Saw 2008 Alpine PF 90 wall panel cutting and marking system. 3.5″ x 12″ maximum cutting profile, Inkjet option, cuts to 16 ft long. From the OEM’s literature, “Effortlessly handles two of the most critical and difficult processes in any wall panel operation – plate cutting and panel layout. At the rate of 1,000 linear feet per hour or more, uses data from the design software and accurately marks stud, cripple and jack locations, job and panel number, subcomponent and window/door locations, and even sheathing locations on both top and bottom plates simultaneously with ink-jet printing.

$8,499 FOB NY

Wood Tech Systems 765-751-9990 www.woodtechsystems.com

Monet DeRobo Linear Saw

New, DeRobo linear saw by Monet organizes "fill" boards to increase optimization of each board, can produce unlimited scarf cuts, cuts 1 or 2 boards at a time and cuts webs, chords, wedges, rafters and open-stair stringers. Works with all major connector plate manufacturer's software. Features include 22 inch blade, left-to-right feed direction standard, lumber push and pull grippers for more accuracy, ink marking on the 1 1/2" face of the incoming boards and small piece capture and delivery to the front of the saw for easy access. Infeed deck and bunk feed are shown as options only. 480 volt, 3phase.

www.woodtechsystems.com

Edmond Lim, P.Eng. LimTek Solutions Inc.

Doing Your BCMC Homework

It is that time of year again. With just two months until BCMC 2024 in Milwaukee, WI, here is some BCMC homework as you begin considering capital expenditures (CapEx). It is crucial to go beyond just the financial metrics like ROI and take into account several qualitative factors. And yes, all of these qualitative factors were on full display during our Feed the Beast! Plant Tour at Tindell’s last month.

Reliability, after-sales support, availability of offthe-shelf spare parts, and easy routine maintenance requirements go hand-inhand to significantly reduce downtime if and when something goes wrong. For examples of how easily existing plant personnel can effectively keep Enventek automation and machinery running smoothly, check out my previous article, “Turning Supply Chain Constraints Into Opportunities.”

In fact, ease of use and training has become mission critical for all industries in today’s labor tight labor market, but fortunately some systems are up to the challenge. Each of our automation elements can be taught to run in less than 30 minutes. Our automation and processes are user-friendly, intuitive, easy, and safe to operate, as I reported earlier this summer in “Automation Elements That Can Benefit Any Size Truss Plant.”

So when you are evaluating new equipment to increase your production capacity, you need to think beyond what you see in front of you. Do not just simply replace existing capacity with a new machine. Our solutions are designed to meet growing demand and are scalable incrementally, as I explore in “Incremental CapEx and Accelerated ROI.”

In particular, long-term cost savings by reducing operating costs is a much-overlooked ROI attribute. Reduced operating costs, however, must be sustainable. Will a new machine or automation process continue to reduce operating costs years after the initial ROI or will it become a maintenance nightmare?

When it comes to Incremental CapEx, you can feed any automated saw with an Enventek Lumber PickLine. This will significantly reduce expensive forklift lumber picking, reclaim saw idle time, and increase truss production at the truss build tables by better organization and collation of cut lumber.

When you’re thinking about saws, you have to think about throughput and efficient material handling. For example, in the photo, a Lumber PickLine (on the right) feeds an Alpine 4.0 Linear saw by dispatching boards down the lumber waterfall skate wheel arms to the 10 ft Alpine autofeed deck. This reclaims saw idle time which significantly boosts saw output.

When evaluating your legacy sawing machinery, the most important qualifier is the accuracy of the cut pieces at the tables. Problems at the truss build tables due to cutting inaccuracy is telling you that your saw is past its service life. Did you know that Enventek maintains an extensive supply of used parts for all MiTek series component saws? Just visit our MiTek used saw parts page and submit a picture of the specific part(s) you are looking for on your MiTek Easy-Set saw, MiTek SmartSet saw or MiTek Cyber A/T saw (sorry, only MiTek saws), then we will reply with a used part quote.

When planning for capital expenditures, it’s essential to balance quantitative metrics like ROI with qualitative factors such as reliability, ease of use, production impact, and long-term cost savings. By doing so, you can score high in your ROI homework assignment by also demonstrating sustained operational excellence and growth.

When you’re ready to Feed Your Beast and see these efficient and effective systems for yourself, let us know! Inside and out, LimTek Process Organization Technology will help you squeeze out more truss production and deliver quality trusses with shorter lead times to better service your customers by organizing your truss fabrication processes to maximize your investment in automation. https://limteksolutions.com/#solutions.

$315,000 Location: MO

New, Monet DeSawyer 2000, computerized, five-bladed component saw, sets up in 15 to 17 seconds, can run in manual mode, downloads projects from a network or manually using display screen controls. Features all powered movements, cuts from 15" 90/90 cuts to 20 foot length, 2 x 3" to 2 x 12" lumber depths and internal brakes are standard. Options include enhanced servo controls featuring autocalibration, catcher's display and either shaker or belt scrap conveyor and incline. 440 volt, 3 phase electrical.

Training. Support. Partnership. Experience service as a solution.

Strong businesses thrive on solid relationships. Working with Simpson Strong-Tie, you have direct access to dedicated professionals who are focused on customer success.

As part of our services, experienced designers and licensed engineers take the time to listen and understand your unique project challenges. We also offer accredited training on truss connectors and comprehensive training on our design and management software. Plus, our innovative products are widely available and backed by expert service and support. It all adds up to solutions that are every bit as reliable as the people behind them.

Team up with a proven industry partner. To learn more, visit go.strongtie.com/componentsolutions or call (800 ) 999-5099.

SAWS

2006 Alpine Speed Rafter Cutter

• Simplified compound cutting for hip, valley and jack rafters (double & single compound cuts)

• Two Worm-Drive Circular Saws (110 Volt / 30 Amps)

• Saw Turntable (for angle cutting)

• Saw Carriage (for up to 45 degree bevel cutting)

• Infeed & Outfeed Roller Conveyor with Stands

$4,900 NOW $4,250 FOB CA Wasserman & Associates 800-382-0329 www.wasserman-associates.com

2017 Vekta S5 Linear Saw (L2)

2017 Vekta model S5 linear saw, plunge-cuts and marks roof and wall parts. Cuts from 0 to 180 degrees (no bevel / compound cutting), unlimited maximum cutting length (minimum length 31 1/2″), one or two 2×4’s dimensional lumber boards at a time. Does angle cutting and birdsmouth (under or overcut) and rip cuts. Includes 5.35 Horsepower blade motor, HP cartridge printer marking on one 3 1/2″ face and one 1 1/2″ edge. Includes infeed, outfeed, scrap incline conveyor and vacuum option.

Current computer O/S is Windows 10 (supported until Oct’ 24). Requires upgrade of Vekta software to their version 14. Vekta estimates repairs of approximately $70k are necessary. OEM available to perform repairs at the Vekta facility in MN. 480 volt, 3 phase, 50 Amp electrical required at saw. 120 volt, 1 phase electrical required for computer. 14.2 CFM at 100 PSI air required.

$69,997 FOB NM

Wood Tech Systems

765-751-9990

www.woodtechsystems.com

2013 Monet DeRobo Linear Saw Generation I computer numeric controlled linear saw with touch screen user interface and two operating modes: auto (download setups from, LAN or diskette) or semi-auto (touch screen setup entry). Configured for roof truss parts, and manually fed boards. Includes computer and PLC (programmable logic controlled) for blade settings, overtravel protection, setup screens. Features 22” x 40 tooth blade on PAE, making plunge cuts. Can cut up to 2 boards at once to produce webs, chords and wedges. Servo position on in-feed, angle, and out-feed pusher. Lumber optimization program standard, 20ft. max. material length. Includes Matthews DOD 8400 Ink-Jet marking on up to two (2) 1 1/2″ edges, and includes all available spare parts. Voltage 480/3/60 – 60 Amp electrical required, 100 psi air required.

$64,995

Wood Tech Systems 765-751-9990

www.woodtechsystems.com

2005 MiTek SmartSet Pro 5-Blade Component Saw

2005 MiTek SmartSet Pro 5-blade component saw with 2×16”, 2×20”, 1×32” blades, swing-arm central control system with rugged industrial touchscreen for simple input of cutting data including cutting angles, centerline, length, etc. Includes belt waste conveyor, scrap incline, and dust-hoods, cuts from 11″@ 90/90, 45º four angle webs from 16″, 2×3 through 2×12 up to 20′, Maximum scarf cut 29″ w/32″ blade. Includes a spare set of blades. 230/460v, 3-Ph, 152.1 full-load Amps / 77.2 Amps for controls required.

$68,497 FOB IN

Wood Tech Systems 765-751-9990

www.woodtechsystems.com

IntelliVIEW Suite Manage. Design. Build.

The industry’s most powerful integrated component design, engineering, and management software for steel and wood-framed structures.

iCommand

Manage projects, customers, materials, pricing & inventory

iModel

Design truss layout & profiles

iDesign

Optimize material usage & engineer trusses

iPanel

Design wall layouts, panelize, bundle, break & stack

eShop

Maximize crew productivity & improve manufacturing efficiency

The IntelliVIEW Suite is a fully integrated software solution for the layout and design of a building’s rough framing elements—including roof and floor trusses, wall panels, solid sawn, EWP, sheathing and various ancillaries.

The IntelliVIEW Suite provides the industry’s most complete analysis of the design, cost information and bill of materials—promoting increased profits by reducing plate and lumber use.

Ask those who know. They’ll tell you about the people at Alpine who make a difference.

BCMC 2024 is Around the Corner

By Alpine Staff

With only two months until the next Building Component Manufacturers Conference (BCMC), everyone is hard at work preparing for the show! BCMC last year was successful. We look forward to this opportunity each year to connect with our customers, industry professionals as well as showcasing the latest innovations.

Are you getting readying for BCMC on October 7–11, 2024? We hope you’ll come see us at the Baird Convention Center in downtown Milwaukee, WI –Alpine will be in Booth #337 this year.

We’re also excited to be sponsoring the second “Celebrating Women in Construction: Coffee and Connections” on Wednesday, October 9 from 7:30 – 8:30 am in room N205. This promises to be a fun networking opportunity, where everyone is welcome to attend for coffee and conversation.

To register for the show, please visit the registration page on the BCMC website. We’ll see you in Milwaukee!

and Auto-Nesting and Auto-Nesting

AutoFill button for Maximum Material Utilization

Labels parts as they cut. (printer optional)

Easy manual cuts and re-cuts

Import files from most major design suites

Industry-first sheathing saw that cuts angles.

Cuts OSB, CDX, Zip, Dense Glass and more.

Minimal airborne dust, even while cutting gypsum.

Monet FWA 500 CA Automated Floor Web Saw

In answer to the demands of high-volume customers comes the Monet DeSauw FWA 500 CA (Automated Controls) floor web saw. The 500 CA is perfect for component manufacturers who routinely run floor trusses in high volumes with variable web geometry. Another primary feature is enhanced safety through automation which eliminates the need to open the saw motor cabinets other than for periodic service. The 500 CA includes automation for all blades, including the fixed cut-off blade for minimal waste. Lumber infeed speed is variable up to sixty (60) boards per minute, while the powered carriage utilizes rack and pinion drive with airlock for set accuracy throughout the production run. Your operator will easily download batches to the 500 CA saw from your design software via an ethernet connection to a MS Windows 10 industrial PC with a 17″ monitor housed in a stand-alone console. If you frequently batch floor web cutting, and if enhanced safety with increased productivity are a concern, then an automated Monet FWA 500 CA may be the right selection for you. Mofe information Here

Carl Villella, CLFP President, Acceptance Leasing & Financing Service

Playing the Interest Rate Game

At the time this article was being written, the U.S. Bureau of Labor Statistics announced that the inflation rate for June fell to 3%. Given the stubborn nature of inflation over the past year, the 3% figure was a welcome surprise. Economists and the business community in general already began asking, “Is 3% inflation low enough to lower interest rates?”

It’s well known that the Fed is targeting a 2% inflation rate for the economy. But the uneven yet steady decline of inflation points to a possible lowering of rates by the end of summer.

If you are standing on the sidelines, waiting for rates to drop before you decide to finance, you may want to reconsider your strategy.

At the end of 2023, economists were predicting a series of rate cuts in 2024. July has come and gone, and we are still waiting for the first one. Secondly, a Fed Funds rate cut of 25 basis points does not translate into a 25-basis point rate cut for banks and other funders. Thirdly, and most important to you, is that a rate cut may not deliver a substantial savings for you.

Looking back over the recent rate increase, the monthly payment for a premium client financing $50K for a five-year term showed a $29 increase in the monthly payment. If rates decline in the same way, you can see that the savings are not worth holding off improvements and the additional sales that new or used equipment can generate.

We invite you to contact us at 412 262-3225 to discuss your particular situation. We offer various types of financing programs that suit all types of borrowers and business scenarios.

We are Acceptance Leasing and Financing Service, Inc. We were established in 1992, which puts us in our 32nd year of business. We pride ourselves on our Certified Leasing and Financing Professional designation. We are a member of SBCA and a frequent attendee of the BCMC tradeshows. We can provide financing for any new and, regardless of age, used equipment.

•

• Foot Pedal Operation

• Dust Outlet (excludes dust collector)

• 2015 TigerStop 24' Programmable Stop

• Automatic Positioning of Stop via Simple and Intuitive Controls

• Infeed/Outfeed Roller Conveyor with Stands

• Video available upon request $16,900 FOB WI Wasserman & Associates 800-382-0329 www.wasserman-associates.com

Safety Speed Manufacturing Model 7400 XL Panel Saw

Safety Speed Manufacturing, model 7400 XL*, vertical panel saw, 3 HP induction motor, 64 inch crosscut, 2 1/8" maximum thickness, accuracy within 0.005 inches, 13 foot long welded steel frame with integrated stand and linear V-guides, enclosed counterweight system, adjustable vertical and horizontal rules. Quick changes from vertical to horizontal cutting. Includes machined aluminum material rollers, hold down bar, wheels, quick stop gauges and material hold downs. Dust collection ready. Options available include digital readouts for vertical cuts, automated length measuring, laser guide, stop bar, vacuum and midway fence. 208-230/460 volt, 3 phase electrical (208-230 single phase, 2 HP power optional +$100.00).

DO SOMETHING BRILLIANT WITHOUT HAVING TO BANG YOUR HEAD AGAINST THE WALL.

Stacking wall panels at the end of your production line can be a real labor-intensive and safety-challenging task. But it doesn’t have to be now, thanks to ProStack . This innovative wall panel stacker literally stacks from the bottom up, reducing awkward overhead lifting & placement, and the risk of head injury. Plus, ProStack frees up at least one worker to return more productively to your core task—building wall panels. Enhanced worker safety and productivity is what ProStack is all about.

ProStack

By: DAK Automation

Setup and installation is easy too, without the need for complex training or disruption to workflow. So, free up your team to do what they do best, and you need to do most, and let ProStack stack your wall panels instead. Contact us to learn more today. For a ProStack demonstration video, scan the QR code below.

New Monet DeSawyer ESC (Servo Controlled) Component Saw

Monet DeSauw model Desawyer ESC enhanced servo-controlled ( ESC) component saw with touch screen user interface with backup mechanical controls. Includes three operating modes: Auto (download setups from LAN or USB), Semi-auto (touch screen setup entry), and Manual (backup push-button switches for powering all movements). Includes over-travel protection, comprehensive setup screens, auto sequencing, auto-calibration and pneumatic brakes on all five () blades. One (1) 30” blade and four (4) 16” blades. Manual cut limits are 18” min., 11” min. square edge blocks, 20’ max cut. Belt under-saw waste conveyor. Voltage: 480 volt/3 phase/60 Amp. Air: 50 PSI at 5 CFM. One-year warranty included. Can be paired with a model PD-6 lumber feed system at an additional cost. Heavy duty 80 RIV chain feed system. 16’ wide x 20’ long x 36” deck height. Transfers 3’ to 20’ lumber. Includes auto-feed control, foot pedal override, forward & reverse, variable speed control with HD double-bearing construction. Other additional-cost options include, inkjet marking, label printing, backside screen display, spare blades and incline scrap conveyor.

$349,900 FOB MO

ACER INC

· Simplified Re-Design

· Robust low maintenance

· No upper hold downs

· Electronic braking

· Auto feeding lumber

· Holds calibration

· Out cuts any linear saw

· Cut-by-Truss or Batch cut

• 3 3/8" Maximum Thickness

• 13 1/2" Maximum Distance from Rip Fence to Outer Saw

• 100 HP Arbor Motor

• 2 HP Feed Motor

• 7 1/2 HP Dust Collector

• 480 Volt / 3 Phase

• Waste Conveyor with Short Incline $35,000 NOW $21,900 FOB MN Wasserman & Associates 800-382-0329

www.wasserman-associates.com

2005 PCS / MiTek Twin Axis Sheathing Saw 2005 PCS/MiTek Twin Axis sheathing saw: Cuts X and Y axis simultaneously in one pass through the saw. Cuts up to 1″ thick, wood sheathing material, minimum width 3″. Fully enclosed to reduce noise, dust, and improve operator safety; automated via downloaded sheathing cutting files from wall design software. Includes 8 foot long idler infeed conveyor and outfeed conveyor with pop-up skate wheels, (1) spare blade and all available spare parts. 220v/440v, 3phase electrical saw, 120v, 1 phase electrical PC. 100 PSI at 14 CFM air required.

$17,991 NOW $11,950 FOB VA Wood Tech Systems 765-751-9990 www.woodtechsystems.com

•

•

• 4" Maximum Thickness (when using 18" Blade)

• 48" Throat

• Adjustable Rip Fence

• Overhead Holddown

• Automatic Chain Oiler

• Dust Outlets $10,500 FOB MI

Custom 3-Arm Infeed Decks

Two custom-built powered infeed decks, 3-arms each, 12′ x 12′ footprint each, touchpad controls and chain conveyors. One deck has a 5 HP drive and the other has a 10 HP drive. 480 volt, 3-phase electrical required.

10 HP price is $7,993 & the 5 HP price is $6,993. Wood Tech Systems 765-751-9990 www.woodtechsystems.com

2021 Oliver Upcut Saw with 16' TigerStop

• Oliver Model 5025.002 Upcut Saw

• 7.5 HP / 230 Volt - 3 Phase

• 18" Blade (4" x 9", 2" x 12" Capacity)

• Foot Pedal Control

• Open Interface to TigerStop (SET)

• 16' TigerStop (TS16) with 18' Roller Table (TABR16)

• Saw Attachment Plate (SAP)

$19,900 NOW $18,900 FOB TX Wasserman & Associates 800-382-0329 www.wasserman-associates.com

2017 Vekta S5 Linear Saw (T1)

2017 Vekta model S5 linear saw, plunge-cuts and marks roof and wall parts. Cuts from 0 to 180 degrees (no bevel / compound cutting), unlimited maximum cutting length (minimum length 31 1/2″), one or two 2×4’s dimensional lumber boards at a time. Does angle cutting and birdsmouth (under or overcut) and rip cuts. Includes 5.35 Horsepower blade motor, HP cartridge printer marking on one 3 1/2″ face and one 1 1/2″ edge. Includes infeed, outfeed, scrap incline conveyor and vacuum option.

Requires upgrade of Windows 7 and upgrade of Vekta software to their version 14. Vekta estimates repairs of approximately $60k to $70k are necessary. OEM available to perform repairs at the Vekta facility in MN. 480 volt, 3 phase, 50 Amp electrical required at saw. 120 volt, 1 phase electrical required for computer. 14.2 CFM at 100 PSI air required.

$78,887 FOB NM

Economy Still Signaling Growth at Mid-Year But Not Among All Sectors

By The Lesko Financial Services Team

The U.S. economy at mid-year continued to show signs of continued resilience and growth— even if such strength remains uneven throughout all sectors.

The labor market consistently added jobs in the second quarter but has not kept up with expectations and, more recently, showed signs of slowing. The report for June showed the U.S. added 206,000 jobs but that number was heavily boosted by government hiring. In addition, there were downward revisions to the job numbers for April and May, lowering the 3-month job growth average to 177,000, the slowest pace since January 2021. The unemployment rate also ticked up in June—a further signal that job growth may be slowing.

Inflation numbers for May and June showed a return to a downward trend after increasing unexpectedly at the end of Quarter 1. The Federal Reserve viewed this as what chair Jerome Powell called “progress” but it has not been enough for the Fed to announce a definite date for interest rate cuts.

The stock market is up for the year to date with the S&P 500 reaching historic highs on heavy gains in technology. In June, Amazon joined Google’s parent Alphabet, Microsoft, Apple and chip maker Nvidia as part of the exclusive $2 trillion club. Also in June, Nvidia hit $3 trillion and briefly became the most valuable company on Wall Street.

Third Quarter and Beyond

Interest rates: Hopes for as many as three interest rate cuts by the Federal Reserve this year faded with the uptick in prices in March. The economic mood turned pessimistic as some analysts began to foresee the possibility of another interest rate hike.

But optimism had returned by summer as prices began to ease and the Fed left rates unchanged for the seventh consecutive time in mid-June. Many Fed-watchers now believe the Fed will leave rates alone at its end-of-July meeting and are predicting a rate cut in September.

Consumer sentiment: One additional sign the economy may be cooling is the slowing of consumer sentiment, which had been robust and was responsible for GDP growth earlier this year.

A huge demand in travel and leisure for the summer season may help extend the willingness to spend. But recent surveys reveal households are still feeling inflation fatigue on day-to-day essentials, even if post-Covid demand for fun and vacations lingers.

Stock market: Stocks are expected to continue to remain volatile throughout the rest of this year. Stocks are also likely to continue to be sensitive to global and political developments such as conflicts in Ukraine and the Middle East and the upcoming U.S. election.

Not surprisingly, Artificial Intelligence technology and obesity drugs have been responsible for much of the buzz and the upward trend on Wall Street, especially in the S&P 500.

Our Outlook

The latest Lesko Financial Services Investment Committee outlook remains optimistic for the economy and capital markets through the end of 2024, even if seasonality, Fed policy and uncertainty related to the U.S. presidential election lend caution to the current signals.

Signs of inflation are easing but not enough for the Fed to make significant multiple interest rate cuts this year. We anticipate one rate cut in September or December.

We note that all major indexes are positive to date with the DJIA at +3.83%, the technology-heavy S&P 500 at +14.73, and the mostly technology NASDAQ Composite at +18.98%, while the US Total Bond Market is at -3.01%. This shows that stock market returns this year haven’t been equally distributed and the largest gains have been concentrated in a handful of companies and sectors.

It’s critical to remember this when comparing your returns to what you hear from others and in the news. A diversified portfolio is still a solid strategy because it generally carries less risk than a concentrated portfolio and can help protect you when markets turn negative. Diversified portfolios also tend to generate income, regardless of market direction.

The LFS Investment Committee is anticipating that participation in the stock market rally will broaden as summer continues and as we move into fall. We also see the broader bond market becoming positive as the Fed gets nearer to cutting interest rates. We continue to recommend that most investors maintain a core diversified allocation to stocks, bonds, and cash. This may be the ideal time to review your own portfolio with your Advisor to help you stay on track with your financial goals this year. We look forward to serving you and hope you enjoy the best that summer has to offer.

2001 MiTek Peak-Up Stacker (A)

2001 MiTek peak-up, vertical truss dual stacker system Model 71300 Mechanical only system includes (2) heavy-duty drives, auto-indexing, spring assisted receiver arms, holds up to 30 trusses from 16 foot to 80 foot in length, up to 14 foot height, with 40 sec. average cycle time. System control panel (NOT included) controls two separate setups or both units for long-span trusses. Arms work in sets of four adjacent arms or all eight arms at once per side. Includes (8) lifting arms, (8) stacking arms, (2) bridge targets, and (2) stacker units. Moveable activating starts the cycling process, bundle indexes back 1 1/2″ as each truss is stacked. NO conveyors or control panel is included. (Control Panel from OEM/Mii required at approximately $8,500) 230v, 3Ph electrical required. (Can be combined with the second system listed here to create opposing stackers for a double gantry line with a common center out-feed conveyor).

$24,900 Each FOB IL

2001 MiTek Peak-Up Stacker (B)

MiTek peak-up, vertical truss dual stacker system Model 71300 Mechanical only system includes (2) heavy-duty drives, autoindexing, spring assisted receiver arms, holds up to 30 trusses from 16 foot to 80 foot in length, up to 14 foot height, with 40 sec. average cycle time. System control panel (NOT included) controls two separate setups or both units for long-span trusses. Arms work in sets of four adjacent arms or all eight arms at once per side. Includes (8) lifting arms, (8) stacking arms, (2) bridge targets, and (2) stacker units. Moveable activating starts the cycling process, bundle indexes back 1 1/2″ as each truss is stacked. NO conveyors or control panel is included. (Control Panel from OEM/Mii required at approximately $8,500) 230v, 3Ph electrical required.

Prestage Tabl

Capabilities*

Wall Heights: 7' 11 ½" to 10' 3" - 12 ' 3" - 14' 3" or 16' 3"

Wall Lengths: 16', 20' or 24'

Pre-Stage Area: 16', 20' or 24' (matches wall length)

*Subject to change without notice

Why a Prestage Framing Table?

The new field-tested Triad PreStage Framing Table, designed and built with customer input, can bring increased productivity to your panel shop.

Triad's exclusive and unique design merges a pre-layout material-staging area with a fast and efficient framing station -- into a single unit that can assist with rapid throughput in your plant.

A powerful, built-in continuous track system lifts and conveys components and material to framers and then the finished panels to your next station.

Initial customer field production, from a Texas plant, has shown an average of 3600 linear feet per day (8 hr shift) of framed walls in their facility!

Used - Metra Cut Radial Arm Saw (2x) Parts Machine

$500 – Make Offer

Eide Machinery Sales, Inc.

612-521-9193 www.eidemachinery.com

Used - 2005 Model 305 Infeed Conveyor Designed for use with all component saws. To include: Soft Start ~ Soft Stop Inverter System. Programmable load sensing; Overload / Jamb sensing shut down feature. Gear motor providing conveyor speed of 36' per minute. Forward and reversing controls for location at both ends of conveyor unit. Material capacity range - 4' through 24' lumber. Chain deck pedestals 20' long with cross bracing. Staging area at the saw independent of the live deck system. 30,000lb. Deck capacity. Call for pricing Eide Machinery Sales, Inc. 612-521-9193 www.eidemachinery.com

2007 Alpine ALS 276 Linear Saw

• Servo Controlled Single Blade Saw

• Automated Angle, Bevel & Scarf Cutting

• Motion Control Upgrade in 2014

• 7.5 HP Motor with 20" Blade

• Infeed & Outfeed Roller Tables

• 8' Auto Deck Extension (not seen in photos)

• Touch Screen Computer (does not work, currently using separate monitors)

• Ink Jet Printer

• Waste Conveyor (needs new belt)

• Recently installed New L1/L2 Motors and refurbished the L1/L2 Gearboxes

• The L1/L2 Belts should be replaced

• 0 Volt / 3 Phase

• Price is in US Dollars $62,900