6 minute read

3. 3 Products & Services

3 Products & Services

Eco Oils is an innovative company dedicated to a superior Biodiesel production technique, biodiesel research and development, mechanical operations and safety. The main product of Eco Oils is biodiesel fuel.

Advertisement

3.1 Over 18 Sources of Feedstock

Eco Oils Solutions Corporation has a large advantage over existing biodiesel producers, as its state of the art technology can produce B100 which is the purest form of biodiesel fuel produced from 18 different sources of renewable feedstock.

Eco Oils is not confined to the same sources of feedstock that fluctuate in price as are its competitors. Eco’s production equipment can convert to any one of 18 different feedstocks with only minor adjustment and no downtime.

Of major importance to environmentalists, Eco Oils can process oil bearing seeds that are not acceptable for human consumption or they can process immature crops that are not marketable. Even with this flexibility, Eco continues to explore new sources of feedstock to grow its deep industry knowledge.

The 18 sources of Feedstock are:

▪ Corn Oil ▪ Soybean ▪ Cotton Seed ▪ Palm Oil ▪ Algae ▪ Rapeseed ▪ Pennycress ▪ Camelina

▪ Carinata ▪ Jatropha ▪ Crude Canola Oil ▪ Yellow Grease (recycled cooking oils from restaurants) ▪ White Grease – Animal fats and tallow, poultry fat ▪ Refined (RBD) Soybean Oil ▪ Crude Soybean Oil ▪ Com Oil Extracted from Distillers Grain ▪ Coconut Oil

▪ Brown Grease

3.2 Biofuel Crop Yields

Biofuel Crop Yields

Crop

maize (corn) cashew nut oats lupin (lupine) kenaf calendula cotton soybean coffee flax (linseed) euphorbia pumpkin seed coriander mustard seed camelina

sesame safflower rice sunflowers cacao (cocoa) peanut rapeseed olives

kg oil/ha/yr litres oil/ha

lbs oil/acre

US gal/acre

145 172 129 18 148 176 132 19 183 217 163 23 195 232 175 25 230 273 205 29 256 305 229 33 273 325 244 35 375 446 335 48 386 459 345 49 402 478 359 51 440 524 393 56 449 534 401 57 450 536 402 57 481 572 430 61 490 583 438 62 585 696 522 74 655 779 585 83 696 828 622 88 800 952 714 102 863 1026 771 110 890 1059 795 113 1000 1190 893 127 1019 1212 910 129

castor beans jojoba jatropha macadamia nuts brazil nuts avocado coconut

1188 1413 1061 151 1528 1818 1365 194 1590 1892 1420 202 1887 2246 1685 240 2010 2392 1795 255 2217 2638 1980 282 2260 2689 2018 287 oil palm 5000 5950 4465 635 algae (open pond) 80000 95000 70000 10000

3.3 The Environmental Benefits

The main product of Eco Oils is biodiesel fuel which has the following environmental benefits: • Biodiesel reduces emissions of carbon monoxide by approximately 50% and carbon dioxide by 78% • Contains no Sulfur • Increased lubricity • Biodegradable and non-toxic • Biodiesel can be used in a pure form or blended with fossil fuels such as petroleum diesel. • Biodiesel production creates a meal by-product that can be sold to a number of secondary markets such as to be used for fertilizer, cattle feed etc. Nothing needs to go to waste. • If market prices for fossil fuels drop drastically, the bio oil processed at Eco Oils is edible and can be sold into the food chain offering strong revenues in this fundamental market sector. • Because of the two stage processing system there is no contamination to the edible oil. The advantages are unique, and no other system has this capability. • Eco focuses primarily on edible and non-edible feedstock that can be grown on untilled land that farmers may not be otherwise using. Pennycress can be grown in the winter and actually increases the yield of summer crop if it is planted in the same field. This means more food available to the market, not less.

3.4 The Eco Oils Design Advantages

Eco Oils innovative technology and oil processing systems offers significant advantages over other, older biodiesel production systems. • Can use any oil or fat as a feedstock • Pre-Treatment allows recycle of alcohol (Methanol-Ethanol) • Can use any alcohol (Methanol – Ethanol) • Can be easily and quickly converted to an edible oil inter-esterification plan • Uses proven technology • Continuous or batch processes • Process problems will not affect products • Compact with limited distillation requirements • Complete use of all ingredients • The majority of biodiesel companies use outdated technology and rely on a single input crop, exposing themselves to the risks of availability and price fluctuations.

3.5 Research and Development

The Company has completed years of R&D and will continue to improve its processes and IP. Continued R&D will include: • Feedstock and fatty acid chain profiling • Crude glycerin and free fatty acid refinement techniques • Process water analysis, recovery and decontaminations • Flux of Sulphur and Acid concentrations through production • Feedstock and Mythylesters fatty acid chain research and compilation of data-based results to grow profiling capabilities • Feedstock and fatty acid chain profiling • Biodiesel and jet fuel

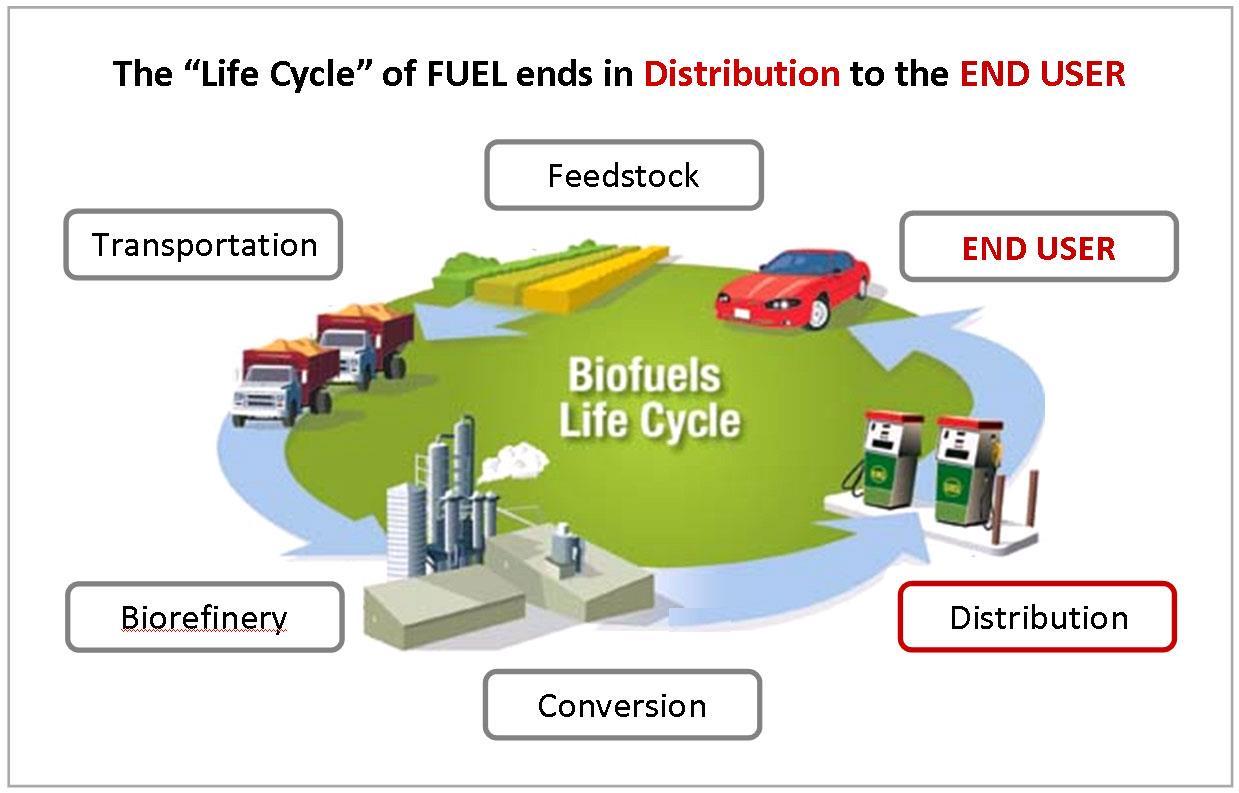

3.6 Plant Life Cycle for Fuel Production and Distribution

3.7 US Manufacturing Plant Rationale

▪ Management is of the opinion that the US presents a larger market opportunity for their products and has determined that this is advantageous to the revenues of the Company.

▪ The US government supports biofuel production and R&D

▪ Management has chosen the State of Iowa as an optimum place for the biodiesel production plant due to the following reasons: o Pacific Junction IA is centrally located to our prime feedstock sources. o By centralizing in Iowa with direct local rail access, we are ideally situated for distribution. o Available and affordable land with facilities

▪ The US Congress provides two tax credits for every US gallon of bio Diesel produced in the US: o Congress has approved one ($1.00) for each one US Gallon of biodiesel produced in the US. o There is another program that provides ($0.85) for each one US gallon of biodiesel produced in the US. This represents a profit over and above the margins of profit of the biodiesel produced and sold.

▪ The size of the plant is designed to facilitate six production plants. As we increase access to more markets and feedstock we will build additional production plants until we have six (6) production plants operating.

▪ In subsequent phases management plans to build plantations in Central and South America. We need to control our source of feedstock; Jatropha is a good source of feedstock and if we have our own plantations of Jatropha we can reduce our feedstock cost by up to 50%. ▪ In each phase, we will build storage tanks and holding tanks to facilitate the additional production plants.

3.8 Plant Plans

▪ See Appendix A: New Iowa Plant for Sale.

3.9 Future Plans & Projects

Phase 2 and 3 will be accommodated on the same footprint as the Pacific Junction Plant. The Phase 2 expansion can be accommodated within the existing on site structures. Phase 3 expansion will require additional plant construction.

The following figures represent the costs to increase the plant capacity to 40,000,000 US gal of B100 Biodiesel fuel.

Crude Oil Storage Tanks: 20 – 30 ft diameter X 48 ft high capacity 1,040,000 US Gal Tanks Biodiesel Storage Tanks: 2 - 30 ft diameter 48 ft high capacity 1,040,000 US Gal Tanks Miscellaneous Storage Tanks: 3 - 10 ft diameter 30 ft high capacity 520,000 US Gal Tanks

Estimated cost $4,000,000

Biodiesel Production Plant $28,000,000

Processing Equipment:

Degumming Bleaching Vacuum Reaction Esterification Distiller Methanol Vapor System Glycerin Refining

Auxiliary Equipment:

Boiler

Incinerator

Cooling Towers

Air Compressor Nitrogen System Waste Water Plant Laboratory Estimated cost $2,500,000

TOTAL COST OF PHASE 2 $34,500,000

Future plans call for the Company to start their own plantations to grow Jatropha and other feedstocks for biodiesel oil. Land can be acquired in countries where the government supports agricultural initiates such as Panama, Costa Rica, and Ghana and potentially Cuba.

Plant installations in offshore regions will cost of $25 to $30M per plant.