TIRED OF BI

Local Option:

ONONDAGA COUNTY CONTRACT

BID #8996 & ONGOV-106-9 OGS MINI BID CONTRACT PC68946

Local Option:

ONONDAGA COUNTY CONTRACT

BID #8996 & ONGOV-106-9 OGS MINI BID CONTRACT PC68946

National Option: SOURCEWELL CONTRACT #060920-NVS

Highway Superintendent Dan Baker and the Town of Coeymans

Lots of news, products and services throughout!

President/Publisher Edwin M. McKeon Jr.

Editor In Chief Craig Mongeau

Sales Manager Kent Hogeboom

Production Mgr. John Pinkerton

Controller Judith Nixon

Circulation Mgr. Cathy Printz

Sales/Admin. Asst. Deby Hogeboom

Trade Show Manager Teddy McKeon

Consultant Bob Buckley

E-Mail - khogeboom@cegltd.com

PRODUCERS OF THE ANNUAL NEW YORK STATE HIGHWAY & PUBLIC WORKS EXPO

Teddy McKeon: General Manager of the NYS Highway and Public Works Show 215-885-2900 email: tmckeonjr@cegltd.com 800/992-7116 email: bbuckley@cegltd.com

OCTOBER 23, 2024 • SYRACUSE, NEW YORK

Mailed 11 times a year by name, to every Town, County, Village and City Highway Superintendent, Public Works Director and D.O.T. official in NY State.

Subscriptions are available to all interested persons at a cost of $25.00 per year within the USA. To subscribe, send your check, voucher or money order for $25.00 to the address above. Single issues $3.00 each

With the exception of Highway Superintendents, Public Works Directors & D.O.T. Officials, material may not be reproduced in any form without the written permission of the publisher.

When Gov. Hochul recently did an abrupt about face on the New York City congestion pricing plan, like everything else these days, there were some who were happy and others who were not.

Count New York City Comptroller Brad Lander among the displeased crowd and like just about everything else these days, multiple lawsuits are being floated as a result of the governor’s sudden reversal. Regardless of how that plays out, the congestion plan, in reality, does have both good and bad aspects to it. Obviously, NYC has a significant congestion problem. The plan was to charge motorists entering Manhattan from 60th Street all the way south varying levels of tolls from as low as $1.2 for taxis and high as $36 for large trucks. Passenger vehicles would be $15. The plan is designed to funnel approximately $1 billion to the MTA. While supporters say it’s necessary, detractors say it’s a tax and in reality, it is, but more like the euphemism “user fee.”

Also, not all vehicles entering Manhattan contain tourists; many people are those who work in the city or have to deliver goods and services to it. Whether it be from the taxis, Ubers or Lyfts or from businesses, the added cost will very likely just be passed on to consumers. So, it could be in some instances, paying twice. But again, NYC has terrible traffic issues, and the plan pause leaves the MTA even shorter in its Capital Funding program. Nevertheless, I still don’t want to drive into Manhattan with or without being charged to do so. What a nightmare.

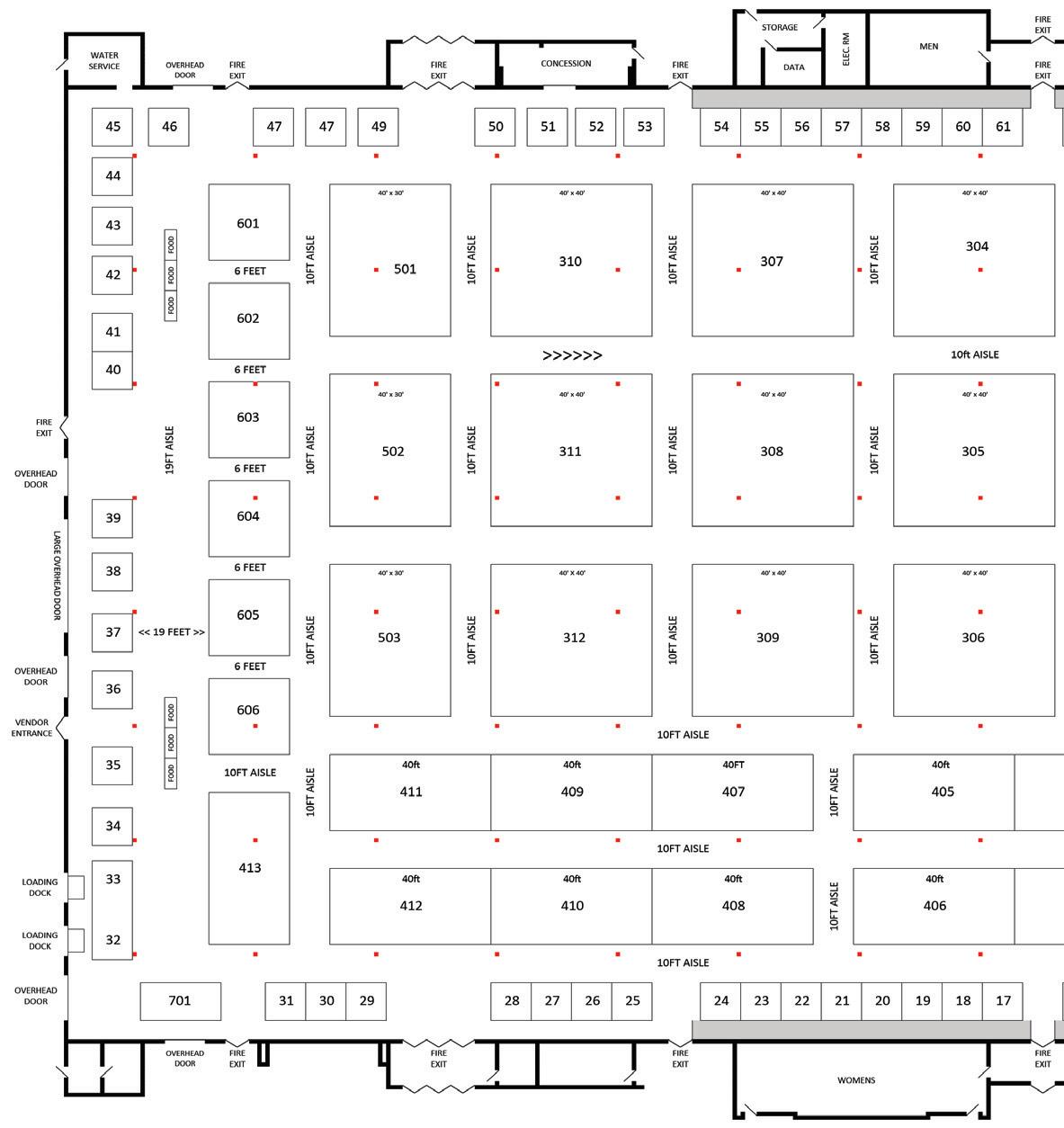

This October 23, we are expecting a pretty big crowd at the annual N.Y.S. Highway & Public Works Expo, but there’ll be no threat of charging anyone to drive there or pass through the doors. As of press time, close to 80 percent of the large exhibit floor space has been sold and approximately 65 percent of the small exhibit floor space is spoken for. Also, please see pages 38 and 39 to check out the current floor plan of the Expo.

Again, thank you for your continued support and we look forward to seeing you when it’s much cooler in October. P

Craig Mongeau

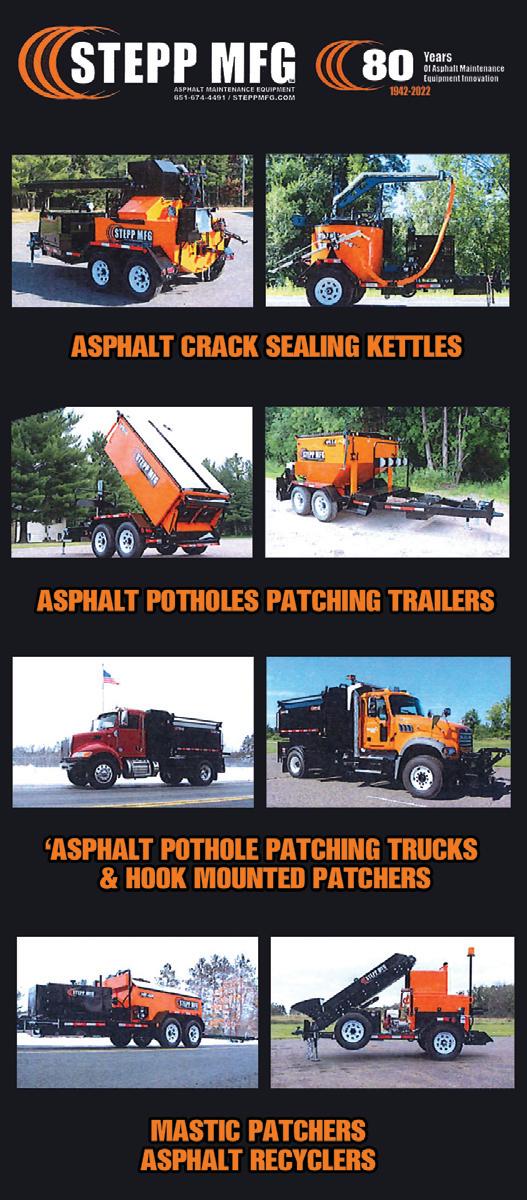

SW #060122 - A ATTE Roadway Paving & Maintenance Equipment

SW#011723HCE SW #011723 - HCE OGS #PC69513 Earthmoving & Material Handling

SW #011723-HTI

WhlLd Wheel Loaders & Excavators

SW #011723-KBL

Excavators: Compact, Full Size & Short-Radius

OCC #0010914

OGS #PC68966

Various Models Class 3-8

HGAC #SM10-16

Asphalt & Soil Compaction Rollers

SW #011723-CNH-2 OGS#PC67265

SW #031721-MBI Tree maintenance Equipment OGS #PC67265 Compact Equipment

OCC #0010914 SW #093021-SWZ Public Utility & Airport

From new buildings to new covers and existing building maintenance, Hybrid Building Solutions is the number 1 fabric building choice for New York State Highway Superintendents.

50 x 70 Calhoun HT • 9’8” frost-depth precast wall foundation 25 year warranty Town of Albion Sourcewell Awarded

Town of Canadice

www.sourcewell-mn.gov

By Lori Lovely PROFILE CORRESPONDENT

continued on page 12

from page 9

That sort of fluidity in customer service can result in his crew skipping tree trimming if a tree is “iffy” and the homeowner is staunchly averse to having it pruned.

“It’s a case-by-case basis,” he said, but he’ll never forget one call from an unhappy homeowner after a prized cherry tree that had been on her property for generations was trimmed. That call influenced his presentday mindset on tree trimming, as well as on customer service.

The Coeymans native first took office as highway superintendent in 2021, appointed in February. He had to run for re-election that

November to finish the term of his predecessor, who retired suddenly due to ill health.

To take the job, Dan had to resign from the town board, where he held one of four elected seats. Not only did he forge important connections on the board, but it also was good experience for what was to come.

“The board basically runs the town,” he said, listing duties such as financial oversight, voucher approval and creating local laws.

“I always worked for the good of the community,” he added. “I pushed for a public comment period at the beginning of every meeting, so people don’t have to wait through the whole meeting to comment.”

It gained traction, he said, and was popular with the public.

continued on page 18

5985 Court Street Syracuse, NY 1320 (315) 437-2611

17 Northway Lane Latham, NY 12110 (518) 220-9500 Road

from page 12

Not only did he bring that spirit of open communication with him to the highway department, but he also credits his tenure on the town board for helping him in his current position.

“I know how to make the town board members understand our department’s needs,” he said.

While he was campaigning for the office, the biggest complaint he heard from constituents was about the highway department garage. When the general public doesn’t see the crew out and about, they tend to wonder what they’re accomplishing. Dan wanted to make sure the public knew his crew was working for them.

Today, he said, “everyone loves to visit the highway garage.” And if

they aren’t able to visit, they can read his social media posts that detail what the crew will be working on each day — part of his pledge of transparency. “I wanted to get the message out about what we’re doing. People look for my posts and if I miss one, they ask about it.”

Prior to serving on the town board, Dan worked at Lafarge/Holcim, the town’s cement plant, which is one of the biggest employers in the small town located south of the state capitol, Albany. Starting as a union millwright, he moved into management as a maintenance supervisor, leading people.

continued on page 22

The highway crew hangs veterans banners in town.

from page 18

“I acquired skills in managing budgets and employees and working with unions,” Dan said.

They’re skills that serve him well as a highway superintendent who leads by example.

“I don’t expect my guys to do anything I won’t do,” Dan said.

He’s been known to jump in a ditch when necessary. “I’ve had a Class A license for 40 years, so I’ve run a plow when one of the guys can’t make it in.”

Even when he has a full crew on the six plow routes covering 51 lane miles, he’s out there plowing with his pickup, always supporting his crew.

Appreciative of his crew, which consists of a deputy supervisor, six operators, a shop mechanic, one trainee and three part-time seasonal employees, he praises their attitudes and work ethics.

“They’re the ones doing the work — and they do a good job,” he said.

continued on page 26

Working 7 a.m.-3:30 p.m., Monday-Friday, the highway department maintains three gravel roads, 106 paved roads, two parks and four cemeteries in the town of Coeymans in southern Albany County.

Road paving is an ongoing task. “A lot of our roads are in rough shape,” Dan said. “Every year, we pick a few roads to re-pave.”

His CHIPS allocation of $225,000 enables him to continuously work on the roads in his town.

essary culvert replacements.

Dan also doesn’t think there’s much point in replacing a rotting corrugated, galvanized culvert with a newer version of the same, which is why he uses recycled plastic smooth-bore corrugated culverts. The plastic culverts don’t retain debris and are not suitable hosts for beaver dams, so water flows freely to its destination. “You want water to go where it belongs,” he said. from page 22

While they let to bid the paving work, Dan’s crew first completes nec-

“It is a humongous injustice to repave a road without replacing the pipes,” he said. “There’s little point in paving over a rotting corrugated, galvanized culvert that could collapse, taking the roadway with it.”

continued on page 28

Other reasons Dan prefers them include their lighter weight, which makes for easier installation, and the fact that they last virtually forever. The department replaces a lot of culverts every year and is currently working to replace 60 ft. of 6-ft.diameter culvert.

Water is a theme for the Coeymans highway department. Dan applied for and was awarded a $30,000 grant from Albany County for soil and water restoration along a streambank for erosion protection. There was steep run-off in three areas, he said. The highway crew installed new pipe and large rock to redirect and slow down the flow of water.

Although he declares himself not a grant writer, Dan also was awarded a safety grant this year for $3,000 to purchase new road signs, cones and hardhats.

“If it’s a big grant, I probably couldn’t do it, but these were simple,” he said. “I just had to describe the work, the equipment and the labor needed to do the job.”

from page 28

Given a sizeable crew and an annual budget of $1 million, Dan’s equipment list is relatively short, although the department makes up for some of it by sharing trucking and equipment service with the town of New Baltimore and the village of Ravena.

Their equipment inventory consists of:

• Four pickup trucks

• Two small F350, F450 trucks

• Seven large plow dump trucks

• Two wheel loaders

• One roller

• One Gradall excavator — 29 years old and $400,000 to replace

• One skid steer

• One mini-excavator

• One backhoe

• One welder

• Torches

• One press hydraulic

• Shop tools

• One vehicle lift

Everything is housed in either the main garage or the parks garage, facilities that were built in 1934. And once a year, everything gets routine service. Nevertheless, the fleet needs updating, Dan said. Their main loader is a 2008 model and two of the plow trucks are 2007s. “They’ve got rust, rot and salt. It’s time to replace them.” When he gets around to replacing them, he said he might take the old equipment to Auctions International to recoup a little money, although he has been known to keep some equipment for back-up because “even new stuff breaks down.”

Although recent snowfall totals have been below the average 60 inches per year, Coeymans can get some residual Ontario Lake-effect snow. The concerned superintendent doesn’t want equipment failure when his crew is out plowing, so having a back-up gives him peace of mind, especially considering the school buses and the hills in town where a population of 7,200 have to get around.

He’s currently waiting on a new plow truck for 2025/26 and has dreams of a 45 or 50 series miniexcavator because he said they need something bigger than their 35.

continued on page 40

Y needs are unique. You are not contractors; competition is not a driver

e know that your environment is different, and that your ou’ve told us what matters to you. W Yo

open communication, and respect. Our equipment is for the long run – so are we. listened. Our focus is on establishing relationships that are built on clear understanding, e have , but trust is. W r, Yo

Despite enjoying snowmobiling with his family at their hunting camp in the Adirondacks, Dan is much less fond of snow on the job. “We have cameras outside the garage. I don’t sleep much in the winter because I constantly check them for snow.”

His worst days are when the plow trucks get stuck or when the town braces for an ice storm. To prepare for the inevitable winter weather, he stores 300 tons salt and 300 tons mix.

Vacations for the Albany County Association of Superintendents member, Dan, Aimee — his wife of 15 years — and their kids are often spent along the coast of Maine, where he said the beaches can’t be beat.

Weekends in town are busy, commonly consumed by accommodating the busy sports schedules of his children, Isla Lee and Dannie, who are active both in school sports and travel sports, necessitating frequent road trips.

page 32 continued on page 44

from page 40

There’s plenty to see and do around town, with Coeymans Landing Park, Joralemon Park and nearby Schodack Island State Park. During the summer, there’s the Evening on the Green concert series.

Local historical attractions include The Martin Van Buren National Historic Site in nearby Kinderhook — home of the 8th president — and the Valley papermill. Coeymans Landing — now the Hamlet of Coeymans — was the first settlement. Situated along the Hudson River,

commerce and industry quickly developed. Mills were one of the first industries in the area, along with ice harvesting, ship building and brick making. In fact, the town founder, Barent Pieteres Koijemans, was an apprentice at a mill owned by the Van Rensselaers shortly after his arrival from Holland in 1639. In 1673, he purchased the land and obtained a patent. Coeymans was formed from part of the town of Watervliet in 1791.

continued on page 46

Although recent snowfall totals have been below the average 60 inches per year, Coeymans can get some residual Ontario Lake-effect snow.

from page 44

The Port of Coeymans was built over the former site of the Powell and Minnock brick plant along the river. Bricks have given way to cement: The Lafarge Cement Plant has become the primary industry in town, generating approximately 1.8 million tons of cement annually.

The town manager-turned highway superintendent takes pride in

delivering high-end service to the taxpayers of Coeymans and making sure the roads are safe. He enjoys talking with residents and solving problems.

Because he likes working for the public, when Dan’s current fouryear term expires in 2025, he plans to run for office again, campaigning on communication, transparency and making the community better — in other words, all the things he’s currently accomplishing. P

(All photos courtesy of the town of Coeymans.)

The L110H and L120H mid-size wheel loaders have become mainstays in the Volvo Construction Equipment lineup over the past decade due to their compatibility with a range of attachments and their productivity levels, ease of maintenance and superior operator comfort.

Now, these two workhorses have been given a comprehensive makeover that focuses on increased uptime and convenience for both operators and technicians.

The highlight of this upgrade is a new Volvo D8M 8-liter engine that offers 256 hp on the L110H and 272 hp on the L120H. Unlike its predecessor, the D8M engine automatically regenerates while working — a technology that’s been proven on the company’s larger wheel loaders.

The engine also features a new electric pump for priming the fuel system, making the process quicker and more convenient than with the former manual pump. And when fuel gets to the engine, users can be confident that it is clean due to new captive fuel filters. These not only ensure good water separation but also help extend engine service intervals to 1,000 hours.

“I think every owner and operator will notice and appreciate the upgraded performance and efficiency,” said Chris Connolly, product manager — mid-size wheel loaders, Volvo CE. “They are popular models for a reason, and now they’re even better.”

The L110H and L120H wheel loaders feature an all-new ignition strategy designed to make operators’ lives easier. Just as in Volvo articulated haulers, the ignition key activates and powers the machine with no need to turn on the ground-level main switch at the start of every shift. This functionality also removes the risk of the battery dying overnight when the main switch is accidentally left on.

The ignition change benefits technicians as well with the inclusion of a lockout-tagout (LOTO), making it easier to lock the battery disconnect switch in the off position and prevent an unwelcome energy release

when performing maintenance.

These models will be the first Volvo medium wheel loaders to include the new-generation Co-Pilot tablet and on-board weighing as a standard feature. The larger, higher-resolution screen will display Load Assist applications like on-board weighing, operator coaching, tire pressure monitoring and more. The Co-Pilot also can connect with phones for hands-free calling and audio playback, and it includes high-definition camera feeds, warning sounds for safety, and radar detect and collision mitigation systems.

Operators can customize the home screen with their favorite apps and settings.

The L110H and L120H wheel loaders still include the features and benefits that made them popular like superior fuel efficiency, torque parallel linkage and an adjustable engagement strategy for the lockup torque converter. That engagement strategy combined with Volvo’s exclusive Reverse By Braking makes up their OptiShift feature that is standard on both models. They support bucket sizes from 3.2 to 12.4 cu. yd.

Volvo’s advanced telematics system, ActiveCare Direct, also supports operator efficiency and productivity, while the Lifetime Frame and Structure Warranty provides extra peace of mind.

As a trusted rehandling choice, these loaders fit quarry and aggregate operations well and are advantageous in forestry and waste/recycling applications where on-board weighing comes in handy.

The updated models will continue to be built at Volvo’s North American headquarters in Shippensburg, Pa. They will be available this summer as part of the company’s comprehensive wheel loader lineup that ranges from the 4.5-ton L20 Electric all the way up to the 50-ton L350H.

(Photo courtesy of Volvo.)

BROCE BROOM KR350 with EROPS, 8' brush, water / spray system, hydrostatic drive, and Kubota engine Call

UC. Ditching bucket. Afex fire suppression system. WE HAVE A NUMBER OF LONG REACHES AVAILABLE FOR RENTAL!!!

Kenworth announced it will begin production of Kenworth T680 and T880 models specified with the new Cummins X15N natural gas engine in the third quarter of 2024.

The Cummins X15N, powered by Compressed Natural Gas (CNG), Renewable Natural Gas (RNG) or Liquified Natural Gas (LNG), is the industry’s first 15-liter natural gas engine that delivers diesel-like power, range, and performance, making it appealing for short, regional, and long-haul operations. The X15N produces between 400-500 hp with up to 1,850 lb.-ft. of torque and is compatible with Eaton Cummins Endurant and Allison Transmissions.

“We’re thrilled to soon begin production of Kenworth trucks with the Cummins X15N natural gas engine,” said Kevin Haygood, Kenworth assistant general manager of sales and marketing. “This new engine offering will be a great alternative solution for Kenworth customers seeking to reduce emissions in applications that require the power and performance they’re accustomed to with diesel engines.”

The Cummins X15N meets stringent EPA emission requirements and CARB 2024 Low NOx standards and features up to a 10 percent improvement in fuel economy over Cummins’ 12-liter natural gas engine with similar rating and duty cycle. Kenworth is the first major truck manufacturer to offer an engine that meets CARB’s NOx emission standards.

“We’re pleased to partner with Kenworth and PACCAR to deliver the industry’s first trucks with this new 15-liter natural gas engine,” said José Samperio, Cummins vice president and general manager for North America. “The X15N delivers the performance, durability, and power required in a variety of heavy-duty and vocational applications and is an excellent alternative for fleets looking to significantly reduce their carbon footprint.”

With the Cummins X15N, like with all natural gas-powered Kenworth trucks, customers can select factory frame drilling options for back of cab Cummins Clean Fuel Technologies or Hexagon Agility CNG/RNG fuel systems. Additional non-factory fuel systems are available to ensure flexibility for any application or configuration of the natural gas fuel system, including rail mounted and body mounted fuel storage. Back of cab natural gas fuel delivery systems can deliver up to a 175-diesel gallon equivalent (DGE), making the X15N an efficient diesel alternative for customers that require longer range and power from their engine.

“Over the last two decades, Kenworth has been instrumental in offering clean fuel solutions for heavy-duty truck fleets. Together, we’re driving adoption of affordable sustainability solutions forward,” said Eric Bippus, Hexagon Agility EVP of sales and systems. “Our CNG/RNG ProCab [back of cab] and ProRail [side-mount] fuel systems are backed by decades of innovation with millions of miles driven by leading fleets that have chosen to partner with us.”

“The integration of the Cummins Clean Fuel Technologies fuel delivery system and X15N engine give Kenworth customers an added level of serviceability of both the engine and fuel delivery system because guidance for all service procedures is available on Cummins platforms like QuickServe Online,” said Mike Zimmerman, Cummins Clean Fuel Technologies general manager.

“We think this powertrain combination enhances the overall value proposition of the vehicle and we’re excited to work with Kenworth and Cummins to continue to bring value to the customers.”

Earlier this year, Kenworth delivered a pre-production Kenworth T680 Daycab equipped with the X15N engine to UPS, marking the industry’s first truck with the new natural gas engine to be delivered.

For more information, visit www.kenworth.com.

TitanX original equipment quality radiators for Mack MR Series and other trucks. Call for availability and price.

Radiators, Charge Air Coolers, Oil Coolers

New, Recores, Repairs, Custom Designed aluminum and copper brass DPF, DOC, and EGR Cleaning

Controlled burn baking and dual forced air and suction ensures all cells are cleaned. Damaged fittings can be repaired or replaced

Burn Off Oven

Complete removal of paint and grease from your parts and equipment. Fluid Lines

Hydraulic, including steel, AC and Brake lines

Other Services

Aluminum and steel welding. Press brake, mill, lathe, notchers and sheers. Wet and dry sand blasting, caustic boil out, acid and solvent cleaning, high pressure wash.

The machine is designed for mass snow clearing in large open areas such as industrial parking lots. Customers can order the retrofit of any make and model of heavy equipment for remote-operated and autonomous operations from Teleo, along with an autonomous-ready snow plow blade properly sized for each machine type from Storm Equipment.

Teleo, a company building autonomous technology for heavy construction equipment, and Storm Equipment, one of the largest distributors of commercial snow plow equipment, introduced the only remoteoperated and autonomous industrial snow plow commercially offered in the United States.

With support from Teleo dealer RDO Equipment Co., the companies worked to retrofit a John Deere 332G skid steer loader with Storm Equipment’s Metal Pless snow plow blade and Teleo Supervised Autonomy, Teleo’s technology that enables remote and autonomous operations.

The machine is designed for mass snow clearing in large open areas such as industrial parking lots. Customers can order the retrofit of any make and model of heavy equipment for remote-operated and autonomous operations from Teleo, along with an autonomous-ready snow plow blade properly sized for each machine type from Storm Equipment.

Once outfitted with Teleo’s retrofit kit, the machines are supervised by an operator sitting in a central command center, a more comfortable and attractive working environment than a traditional snow plow operator working from the equipment’s cab on site. The machines are created to help solve staffing shortages in the commercial snow plow industry, where snow contractors are covering larger regions and working long overnight hours, by allowing a single hired operator to work in multiple regions simultaneously.

Initially, the snow plows will be remote-operated and autonomous capabilities will be added in by mid-2024.

“Remote operation of snow plows is a truly disruptive prospect for

the industry,” said Jordan Smith, owner, Storm Equipment. “Snow removal companies typically don’t have just one make or model in their fleets, so the fact that Teleo’s technology can be retrofitted onto virtually any make and model of heavy machinery makes it a great option for the industry.

“Utilizing Teleo’s game-changing system, the shrinking pool of skilled snow plow operators can cover a lot more ground in a shorter time period. With the click of a button, they can move to a different loader and plow on a job site across town, or even in a different state. This effectively could quadruple the productivity of a single skilled staff member, creating massive operational efficiencies for the snow contractor.

“This technology could also open up snow plowing opportunities to those who are not already heavy equipment operators. We like to joke that today’s streaming gamers could become tomorrow’s remote snow plow operators. Simply put, remote-operated and autonomous snow removal demonstrates undeniable value for contractors looking for the best return on their heavy equipment investments.”

Fleets of machines that are used for applications such as loading gravel, peat moss and other bulk materials in warmer months are used to move snow in the winter months. Teleo’s technology can be easily retrofitted on those fleets, introducing the ability to integrate remote and semi-autonomous technology without the need to purchase new machines. The same machines can be used year-round for snow removal, landscaping, and other site work. This level of flexibility makes the system extremely scalable and cost effective, the company said.

continued on page 68

The Genesis Series offers affordability without compromising on quality and efficiency, according to the manufacturer.

When winter strikes, keeping roads, sidewalks and entryways safe becomes a top priority for businesses and municipalities alike.

Snow and ice removal businesses are crucial in maintaining safety during these challenging times. If you’re considering expanding your services or starting a new venture in this industry, look no further than Boss’ Genesis Liquid Deicing Series.

The Genesis Series offers affordability without compromising on quality and efficiency, according to the manufacturere. Whether you’re a seasoned professional or just starting out, there’s a Genesis model perfectly suited to your needs.

The Genesis Series Brine Buddy is an ideal starting point for those venturing into liquid deicing for the first time. This compact unit boasts a 900 to 1,000-gallon-per-hour capacity, making it perfect for smallscale brine production.

Smart-connected technology lets you conveniently monitor brine salinity from your smartphone or tablet. Its stainless steel and poly construction ensure durability, while the air purge system keeps hoses dry after filling trucks, minimizing downtime.

The Genesis Series offers specialized solutions for targeted applications, such as sidewalks and entryways. The Genesis 110E features a

110-gal. low-profile tank and a 12V electric pump, making it perfect for use in UTVs or Toro Workman vehicles. With its 4 ft. receiver-mount boom, it efficiently covers sidewalks with ease. The Genesis Series Sidewalk Slayer also features dual electric 12V pumps and a 200-gal. capacity, making it the ultimate electric sidewalk and Snowrator support unit. Equipped with a 1 in. fill line and a 50 ft. spring rewind hose reel, it ensures quick and efficient deicing of sidewalks and entryways.

Meanwhile, the Genesis Push Pal takes sidewalk deicing to the next level. This compact walk-behind spray unit allows for quick-change camlock caps and pre-treatment/post-treatment applications. Its innovative design facilitates the use of 5-gal. cube containers, enabling seamless swapping during operation, reducing downtime and maximizing efficiency.

For larger-scale operations, the Genesis Series offers truck-mounted sprayers in various capacities. The Genesis 305E, with its 305-gal. capacity, serves as an entry-level pickup truck sprayer, providing efficient pre-treatment or post-treatment options. Meanwhile, the Genesis 500E offers a higher capacity of 500 gal., catering to more extensive coverage needs.

The Genesis Power Bundle E allows for customization, connecting to your own tank or tote while offering the same reliability and performance as other models in the series.

(Photo courtesy of Boss.)

from page 60

“Commercial snow removal, specifically mass snow clearing in large parking lots and on other long stretches of open, flat surfaces, is yet another ideal application for our technology,” said Vinay Shet, co-founder and CEO, Teleo. “When heavy snowfalls occur, there is an immediate need to clear parking lots and commercial sites so businesses can continue operating. We believe we are offering the only remote-operated and autonomous industrial snow plow available in the U.S.

“The collaborative Teleo-Storm Equipment approach introduces a way to get the job done more efficiently, safely and without customers having to purchase new machines; that makes it a realistic solution for companies of all sizes.”

In addition to the commercial snow removal industry, Teleo also serves customers in construction and material moving. The new snow plow follows Teleo’s recent announcement outlining its growing global dealer network and customer base.

(Photos courtesy of Teleo and Storm Equipment.)