Largest Municipal Equipment Show in the East!

Largest Municipal Equipment Show in the East!

Highway Superintendent Fred Schweiger and the Town of Barton..........................................................9

Lots of news, products and services throughout!

President/Publisher Edwin M. McKeon Jr.

Editor In Chief Craig Mongeau

Sales Manager Kent Hogeboom

Production Mgr. John Pinkerton

Controller Judith Nixon

Circulation Mgr. Cathy Printz

Sales/Admin. Asst. Deby Hogeboom

Trade Show Manager Teddy McKeon

Consultant Bob Buckley

315/866-1423 E-Mail - khogeboom@cegltd.com

PRODUCERS OF THE ANNUAL NEW YORK STATE HIGHWAY & PUBLIC WORKS EXPO

Teddy McKeon: General Manager of the NYS Highway and Public Works Show 215-885-2900 email: tmckeonjr@cegltd.com 800/992-7116 email: bbuckley@cegltd.com

OCTOBER 23, 2024 • SYRACUSE, NEW YORK

Mailed 11 times a year by name, to every Town, County, Village and City Highway Superintendent, Public Works Director and D.O.T. official in NY State.

Subscriptions are available to all interested persons at a cost of $25.00 per year within the USA. To subscribe, send your check, voucher or money order for $25.00 to the address above. Single issues $3.00 each

With the exception of Highway Superintendents, Public Works Directors & D.O.T. Officials, material may not be reproduced in any form without the written permission of the publisher.

In this month’s issue, I invited our N.Y.S. Highway & Public Works Expo show manager, Teddy McKeon, to address all of you in this column. Here, without further ado, is the latest news about the upcoming big show:

Every year, right after the N.Y.S. Highway & Public Works Expo concludes, we begin planning for the next one. We talk with vendors and attendees to see how we can improve; we try our best to make those changes for the next show; and we start selling booth space to prior vendors beginning in late February.

We greatly appreciate our loyal customers, but we know that loyalty comes, in part, from your attendance. You make the show successful. We’ve had superintendents bring their entire crew and busses show up full of people waiting to get into the Expo Center. We’ve had attendees drive more than three hours to attend. We appreciate the support you’ve shown us over the past 30 years, and we hope to keep doing this for another 30 and more.

At press time, we are close to being sold out, which is a record for us (typically, we still have a few booths left in late September.) In addition to the show’s long-time, consistent exhibitors, we anticipate more than 25 percent will be new exhibitors. Some vendors from 2023 have prior commitments and expressed disappointment that they cannot exhibit in 2024, but they anticipate returning in 2025. We still have a long list of exhibitors who signed up last year but have yet to commit this year, but we only have five booth spaces remaining. We are working diligently with the Fairgrounds to add more booths and to see if we can make other adjustments to accommodate additional exhibitors, if necessary. That said, if you have a favorite vendor or rep and they have not yet committed, please remind them that the show is selling out quickly and they should act now. And also please remember to schedule meetings with exhibitors beforehand.

We are passionate about this show, and we work hard to put on a great one each year for all of you — because you deserve it. We appreciate what you do every day for your towns, villages, cities, counties and residents (as do our exhibitors). You and your crews plow roads, pave them, fill potholes, landscape, trim trees, clean up after storms, repair culverts and so much more — all vital work for a well-functioning community.

We look forward to seeing you in October!

-Teddy McKeon. P

Craig Mongeau

SW #060122 - A ATTE

Roadway Paving & Maintenance Equipment

SW #011723-HCE

OGS #PC69513

SW #011723-HTI

Wheel Loaders &Excavators

Earthmoving & Material Handling & Excavators

SW #011723-KBL

Excavators: Compact, Full Size & Short-Radius

OCC #0010914

Sewer Vac Trucks

SW #06222-AGI

Snow Blowers, Airport and Municlipal Vehicles

OCC #0010914

OGS #PC68966

Various Models Class 3-8

HGAC #SM10-16

Asphalt & Soil Compaction Rollers

SW #011723-CNH-2

OGS #PC67265

CompactEquipment

Compact Equipment

SW #031721-MBI Tree maintenance Equipment

OCC #0010914

SW #093021-SWZ

Public Utility & Airport

From new buildings to new covers and existing building maintenance, Hybrid Building Solutions is the number 1 fabric building choice for New York State Highway Superintendents.

CEG CORRESPONDENT

When first approached to run for the highway superintendent position in the town of Barton, Fred Schweiger recalls it wasn’t an easy decision.

Knowing the superintendent at that time that he was running against was a challenge.

He also was enjoying his job as concrete batch plant manager/quality assurance manager of Porter’s, where he was completing a five-year stint.

But the conviction that he wanted to make a difference in his town fueled his efforts.

Elected to office in 2020 and re-elected in 2024, Fred is a Barton native, having lived there 56 years and counting.

Fred took on his new role and was dealt his first challenge within months when the pandemic was announced.

Undeterred, he geared his focus toward getting to know the rest of the team as the new employee and new supervisor.

“I like seeing my crew and the comradery involved,” he said. “They are a great group to work with and I feel like a proud parent when they

the span of an hour at the start of the day. Different seasons lead to different work and challenges. Sometimes, there’s a curve ball in the day, sometimes more.”

Even during frustrating scenarios where all parties involved might not see eye-to-eye, Fred’s positive mindset diminishes any conflicts.

“I like bridging the gap between misunderstandings and misconceptions, solving problems and helping people walk away feeling satisfied with the outcome.”

Fred’s proactive attitude has seen multiple projects to fruition.

“The big project we completed over the last three years was to turn all the gravel roads to asphalt,” he said. “Currently, we have in our creeks three retaining walls that need building. There are also two bridges with scoured footings that need work. About 13 miles of chip sealing was completed in May and 5.25 miles of paving in June. We’re now moving onto some driveway culvert requests and starting on the retaining wall projects and then the bridge footings.”

continued on page 12

Local Option:

ONONDAGA COUNTY CONTRACT

BID #8996 & ONGOV-106-9 OGS MINI BID CONTRACT PC68946

National Option: SOURCEWELL CONTRACT #060920-NVS

from page 9

Other projects completed include eliminating gravel roads, improving the equipment line, improving office operations and expanding storage space.

“The team approached me my first year with a project they had been wanting to do cleaning up and expanding our storage yard,” he said. “There was an old stockpile of scrap pipes and steel that had been accumulating for years and a lot of brush that limited the usable yard space. The local scrap company dropped a roll off and the guys started loading it out.”

They ended up with $33,000 in scrap and $72,000 in the sale of the old broken, unneeded and unusable equipment, and the resulting $105,000 paid for the 2019 Dodge with plow and sander plus the purchase of the Broce Broom.

“As time permitted, over the course of a few months, my guys had cleared out two acres and reorganized the yard. Now, I keep a roll off on site and all scrap is deposited into it as it’s created. When full, the scrap

company swaps it out and a check is sent to the town for deposit into our equipment reserve.”

Fred believes his past experiences have all contributed in some way, shape or form toward his current role. And that goes back to being born and raised on the farm his father started in the 1950s from savings during his years in the Navy.

Over time, the farm expanded in both acreage and number of cattle. Fred’s formative years were spent helping around the farm, where selfsufficiency was a way of life.

“We mixed our own concrete, learned to fix, weld, do plumbing, electrical, construction. My father was raised during the depression. They didn’t have a lot and they saved what they had. I did a lot of mechanics work, you didn’t throw anything away, if you’d take parts off, you might be able to use elsewhere.”

continued on page 18

SYRACUSE

5985 Court Street

5985 Court Street Syracuse, NY 1320 (315) 437-2611

Syracuse, NY 1320 (315) 437-2611

LA SYRACUSE

LA

ATTHAM 17 Northway Lane Latham, NY 12110 (518) 220-9500 Road 6

ATTHAM 17 Northway Lane Latham, NY 12110 (518) 220-9500 Road 6

4554 West Saile D Batavia, NY 14020 (585) 344-1931 AltaEquipN Y..com

4554 West Saile D Batavia, NY 14020 (585) 344-1931 AltaEquipN Y..com

from page 12

One of Barton’s board members, Jeff Coleman, has aptly coined this “Schweigerizing.”

“Do the best you can with what you have and make it work because there no use complaining about it,” Fred said. “The way I was raised and the experiences I had definitely helped me for these future roles. No problem getting up early, managing a crew, talking to your hired hands.”

That’s until a catastrophic barn fire in 2008 resulted in an end to farm operations in 2009.

“That was my first traumatic event. It was like a death in the family.” He was 41 when he left to pursue work off site.

As the northeast regional manager of Pruitt Tools, a gas and oilfield sales and service company, a five-year stint saw Fred starting from manager and promoted within a year, establishing stores, running equipment and servicing at gas rigs, and even helping with moving to electronic

billing, until the area dried up and he was unable to relocate.

The next five years at Porter’s Concrete, aggregate testing, concrete mixers and computers and billing became part of Fred’s everyday schedule. Interestingly, the highway department is located right across the road from Porter’s.

Perhaps the path to superintendent was kismet.

“The strong farmer work ethic and the drive to always learn and adapt that came from a farming lifestyle was the foundation that served well in taking on the roles that Pruitt and Porter’s required of me,” Fred said. “The sales and service aspects from Pruitt and Porter’s has helped in communicating to residents, salesmen and the town board. Everyone has different viewpoints and ways of thinking, and my 10 years of sales and service made me mindful of that fact.”

The years at Pruitt and Porter’s also taught Fred that approaching those more experienced or knowledgeable for advice is part of the learning curve.

continued on page 24

from page 18

“You don’t have to know everything, but you must know the right people to call on and be willing to try your hand at whatever is required of you. The only thing that’s rocket science is rocket science itself.”

Fred and his team now at the highway department are responsible for 187.75 total lane miles of roads — all municipal-owned and all paved as of 2023 — and seven bridges. There are seven plowing routes, and a full loop of all routes takes approximately 3.5 hours.

Additional responsibilities include water and sewer — four sewer pump stations are maintained — and marking the lot for digging cemeteries (mowing and lot opening/closing is done by a third party.)

There are six full-time staff members: Deputy Superintendent Dan Shay, Shop Foreman Shane Marshall, and team members Earl Fenton, Kris Swagler, Shawn Engle and Ethan Klossner.

continued on page 28

from page 24

Four part-time staff that help as needed with roadside mowing and truck driving are Lew Cary, Leon Stevens, Bill Shay and Former Deputy Superintendent Keith Shipman.

The team works 6 a.m. to 2:30 p.m. all weekdays December through March and 6 a.m. to 4:30 p.m., Monday through Thursday, rest of the year serving Barton Township’s 8,858 residents along with 4,444 residing in the village of Waverly in Tioga County (2010 Census). The annual operating budget is $2,806,418 and annual CHIPS allocation is $533,418.

Fred is proud of his team. “I’d put them up against any crew out there. I don’t micro-manage. I set the goal, and they knock it out of the park. I am lucky to have them, as is the town.”

That collaborative spirit extends to nearby townships as well, lending a few trucks or other equipment when needed and helping each other in kind.

The highway department’s main building, built in 1956, is heated with two waste oil heaters and has a concrete floor. The 100-ft. by 50-ft. building includes a 12-ft. by 10-ft. office space and a 6-ft. by 10-ft. bathroom.

continued on page 32

Fred Schweiger updates the five-year roadwork budget projections.

Other facilities added on through the late 1990s and early 2000s include a 22-ft. by 20-ft. parts room and a 14-ft. by 20-ft. breakroom on the side of the building.

There also are two cold storage buildings (no heat and dirt floors) — one is 100 ft. by 40 ft. and the other 80 ft. by 45 ft. The salt storage is laid up 2-ft. by 2-ft. by 8-ft. blocks with a roof. Undercover capacity for salt storage is 400 tons.

Fred would like to see the fleet updated in the coming year.

“We currently have on order replacement for the 2006 GMC and 2012 International. The 2010 International will need replacing next, and then we’ll be looking at the 2015 International. That will finish updating the plow trucks and then we’ll look at the Volvo loader and Case backhoe. The plow trucks are something you can’t jump out and rent in a pinch. Heavy equipment you can. The plow trucks, backhoe and loader

are core pieces to operations.”

Other equipment like a skid steer or mini-excavator can be rented, as needed. The municipality engineering firm is Delta.

Fred is working on a standard operating procedures manual for future highway superintendents, based on his experience creating similar documents during his time at both Pruitt and Porter’s.

“I started writing SOPs when I became the trainer for all new site managers at Pruitt. A how-to manual with pointers and reminders helps when you’re training someone and gives them something to fall back on when needed. My plans are to get the town on a better road maintenance rotation. We have made a lot of headway toward that goal despite a 40 percent increase in costs.”

continued on page 42

Our team can put together customized acquisition options, piggy-backing, revising e make it happen. We our purchasing process is complex, but our governmental and municipal experts know their business.

equipment, we’re very successful at finding buyers for any equipment, any make, any age. s time to get rid of a piece of ’s e help you get out. We number of hours make no difference. , type or r, e take trade-ins. We . the specs or sharing ownership with another municipality

from page 32

He feels fortunate to have a board with Don Foster (town supervisor), Kevin Everly (deputy town supervisor), Dave Shipman, Mike Rice and Jeff Coleman to work with. Other key staff members include Melanie Sinsabaugh with town bookkeeping, Arrah Richards McCarty as town clerk in 2020, Rebeka Peck as deputy clerk, Catherine Kozemko as assessor, Jennifer Monahan as assessor clerk, Chris Robinson in code enforcement, Wayne Searles handling dog control and Mike Myers and Nancy Perry as town justice and court clerk, respectively.

“No one is irreplaceable, but with everything running well with the good people we have I hope it is a long time before we break up the band. With age and the few hard right turns, I’ve had in life, I realize nothing is forever. All the fame, accolades and prestige are immaterial and easily forgotten. What matters is we had a positive impact, and leave our friends, family and co-workers with fond memories and maybe a little better off when we move on from a job or this world.”

continued on page 48

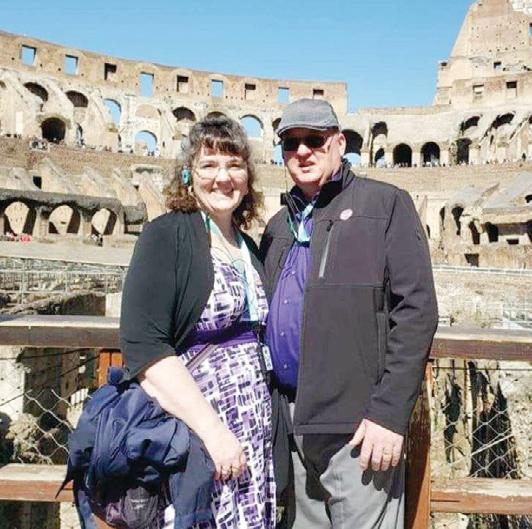

“I take pride in my work and love doing it. But that pales in comparison to the pride and love I have for my wife, kids, son and daughters-in-law and grandchildren. First and foremost, I’m a husband, father and grandfather. Family first. That’s how I run my department.”

Fred and his wife, Kelly, have been married for 35 years. They have four children — Sarah, 34, is a special education teacher; Matthew, 32, is a police detective; Jacob, 29, is a doctor of physical therapy and director for his clinic; and Noah, 26, is a speech and language pathologist. All four are married. Sarah (Josh), Matthew (Katrina), and Jacob (Annette) have two children each and Noah (Lauren) is expecting his first child in November.

“Fred is a highly adaptable, intelligent person,” Kelly said. “He can quite literally learn and excel at whatever job he is currently in. He is a ‘work smarter’ kind of guy as well, having invented tools, techniques and procedures to make his (and those of his coworkers or employees) easier. He truly enjoys being the highway superintendent and working with his crew and our town board. He has a very strict work ethic. He will do the same tasks that he asks his crew to do. He is not above doing the hard, dirty work.

continued on page 52 Seen here is the town of Barton highway department’s mowing tractor.

“This job has made him realize that he is good at being a public servant and enjoys making improvements to his hometown and helping his friends, neighbors and family that live in Barton. I hope he will continue to serve as superintendent for as long as he and the people in our town are happy with the arrangement. I am proud of all he has accomplished in his first term and look forward to all he will do in the future.”

Fred and Kelly are self-proclaimed homebodies. A regular weekend includes going to church and dinner afterward at a local spot such as Yanuzzi’s or Beeman’s. Perusing Lowe’s for their next project, going to the movies or reading are among other favorite pastimes. They like visiting the Renaissance Festival in Sterling, Fairhaven and the Strawberry Festival closer home.

“We always hit Barnes and Noble and pick up another book, put it on our shelf and hopefully, eventually we get to it,” Fred said.

He is currently reading Ernest Hemingway’s The Sun Also Rises, and lists hiking through the woods, playing paintball, or even better, a good session of Dungeons & Dragons, among other hobbies.

“I’ve got a huge Tolkien collection. I lean toward fantasy, sci-fi and medieval genres because I’ve always had a pull toward that era. I thought I was born in the wrong era.”

He credits his literary streak to his mother, who was an avid reader.

“We always had Reader’s Digest and it gave you different viewpoints and windows on the world.”

Fred is a member of the Tioga County Highway Superintendent Association Council and The Knights of Columbus, and a charter member of the nonprofit Tioga Actors Guild.

“Most of our performances were packaged as a dinner theater event

and a few were just a stage play. All proceeds went to a local charity. The group had to disband when we lost our venue. We were pretty much an all-male ensemble, but I still think my portrayal of Cinderella was right up there with Lily James.” P

(All photos courtesy of the town of Barton highway department.)

The town of Barton highway crew (L-R) are Shane Marshall, shop lead; Earl Fenton; Ethan Klossner; Keith Shipman, former deputy, now retired and part-time; Lew Cary, mower operator, part-time; Dan Shay, deputy; Kris Swagler and Shawn Engle.

The 29th annual N.Y.S. Highway & Public Works Expo was held Oct. 18, 2023, at the NYS Fairgrounds Expo Center in Syracuse.

Breaking all previous attendance records, 1,400 representatives of highway departments, public works officials, DOT officials, as well as managers of parks and recreation facilities and road maintenance contractors enjoyed the show.

Exhibitors included manufacturers and distributors of roadbuilding, earthmoving and highway maintenance equipment, as well as every item highway superintendents could ever need to maintain the various properties and facilities that fall under their domain.

With the overwhelming success of last year’s show, we’re excited for the 30th annual N.Y.S. Highway & Public Works Expo that’ll be held Oct. 23, 2024, and we expect even bigger numbers for attendance and exhibitors. We look forward to seeing you there. P

(All photographs in this article are Copyright 2023 Superintendent’s Profile. All Rights Reserved.)

LaGasse Machine & Fabrication, manufacturer of the Harder Dump Box Spreader, is headquartered in Lyons, N.Y., a small town just south of Lake Ontario.

With its roots as a fabrication facility, LaGasse was originally founded by Cliff LaGasse, who made his mark as a master craftsman in the fabrication industry building specialty equipment. In 1983, Cliff turned the company over to his son, Dan, who expanded the company into a solid engineering and manufacturing company. But, perhaps most importantly, Dan led the way for LaGasse to become the manufacturing and marketing company for the Harder Dump Box Spreader.

As LaGasse continued to grow over the years, Dan also began pushing LaGasse into the agricultural industry where the company developed its own branded ag equipment, leading to the creations of LaGasse Ag Equipment. LaGasse Ag Equipment manufactures its own orchard equipment (bin trailers, hedgers, tree planters, remote tractor steer capabilities, maintenance trailers) and also are dealers for various brands of sprayers, automated picking platforms, root pruners, crop equipment, chemicals and bins. Inside the core business, LaGasse also works very closely with the local municipalities on truck repairs and custom fabrication work.

The Harder Dump Box Spreader was invented by a highway superintendent for highway superintendents. It is named for its inventor, Kenneth A. Harder, who envisioned and created the spreader as he served as highway superintendent of the town of Arcadia, N.Y.

Being a true innovator, Harder made a declaration one night as he

watched the dump boxes from town trucks being removed to mount Vbox sanders. According to his son, he asserted, “There has to be a better way!”

Harder drew his ideas on napkins at the local coffee shop and teamed up with a metal-fabrication business to make his dreams a reality, ultimately leading to the Harder Dump Box Spreader being patented in the United States and Canada in 1984.

David K. Harder entrusted LaGasse Works (now LaGasse Machine & Fabrication) with the manufacture of his father’s legacy product, which over time has made many improvements and remains today a much sought-after spreader.

The concept behind the Harder Dump Box Spreader was to develop a product for municipalities and other snow and ice removing companies that would eliminate the need for municipalities to go through the burdensome task of removing the dump bodies from their fleet of trucks and replacing those bodies with V-box or hopper spreaders for the application of salt and sand.

The concept at its core was simple: why not add an accessory to a traditional municipal truck’s dump box that would allow the dump box to double as a sand and salt trailer? The end result was a conveyor that can slide in/out of the tailgate of the truck’s dump body and extend the length of the truck. Outside of the tailgate, connected to the conveyor, is the material spreading system, which is secured with a single pin and contains the necessary hydraulic system of hoses to make the entire spreading system operational from inside the cab of the truck.

An installation for the town of Lyons, N.Y. Note that conveying system is fed through a customized opening in the truck’s tailgate.

Besides the convenience of only needing a single truck body for year around truck utilization, according to the company, the Harder Dump Box Spreader has several other advantages:

• The Harder system is designed with a low center of gravity, unlike unstable V-box spreaders.

• All normal maintenance procedures are done at ground level, which is much safer for truck operators.

• The Harder Dump Box Spreader has been engineered and designed to withstand the rigors of year-round municipal use. It features heavyduty pintle chains, 2-in. diameter shafts with cast iron sprockets and a cast iron gear box. All fasteners are made from stainless steel to protect from the corrosive effects of sale. The dual auger version hosts two solid augers made of 304 stainless and is dual counter rotating.

• To give wide distribution. the spinner disc has a 20-in. diameter and is manufactured from urethane.

• When using the dump box equipped with the Harder Dump Box Spreader you are carrying a significantly larger load than when utilizing a V-spreader. The typical municipal dump body has an 18-ton capacity versus a 14-ton capacity in the V-box, thus reducing the number of return trips to the salt pile, hence saving labor, fuel and wear and tear on your truck.

• The spreader’s compact design reduces the amount of storage space needed for equipment during summer storage. The spreaders are stackable to save space.

• The Harder system is economically priced, allowing a highway department to purchase extra units as backup, if needed.

• There are four standard models; however, LaGasse can customize a spreader to any size that is needed.

• One of the key features of the Harder is that you can “bump” the load when you return to the barn. This means that all that needs to be done is chain the tailgate and lift the box (with the spreader in it) and the material will come out. No shoveling is needed.

• The Harder Dump Box Spreader can be taken in/out of the truck body within 15 minutes.

New in 2023, LaGasse developed a dual auger model which fits in the same footprint as the chain model. The dual auger system is ideal for adding/mixing materials and liquid within the truck body to create a slurry to distribute onto the roads. The dual auger also helps to break up material in the truck box. Each auger is 7 in., 304 stainless and dual counter rotating — this makes for an extremely heavy-duty auger system.

The design team at LaGasse understands that everyone has their own preferences when it comes to product design. Therefore, the Harder Dump Box Spreader is available in 304 stainless steel and powder-coated carbon steel.

The existing truck body can be easily converted to a Harder system by purchasing a Harder tailgate kit. The tailgate kit provides an easy opening for the spreader to slide through and into the dump box floor, according to the company. Kits are available in two configurations and fabricated in prime-painted carbon steel, 304 stainless steel or aluminum.

Between 1983 and today, the company has grown and prospered with the Harder Dump Box Spreader serving as a very important part of the company’s growth. In 2019, Kaye Stone-Gansz and her husband, Ross Gansz, purchased the LaGasse Group of Companies. Kaye, who serves as the company’s president, grew up on a family-owned crop farm which also had a retail sales and service business in upstate New York. continued on page 64

from page 64

According to Kaye, “Growing up working on the farm and in the family retail/service business is where I developed an interest in the area of fabrication and engineering. I was always trying to help invent new ideas or fabricate new pieces of equipment to improve the farm’s efficiency. I left the family businesses to get my college degree at RIT in Rochester, N.Y., where I received my engineering degree.”

Kaye joined the Xerox Corporation in 1986 where she worked in engineering, product development and worldwide service. She retired from Xerox in 2011, and in 2012 purchased a local gravel pit and stone quarry where fabrication continued to be a part of her daily activities.

At LaGasse, Kaye is involved in day-to-day operations and is responsible for the overall success of the company’s operations. She is actively involved in driving sales, quoting/estimating fabrication and machining projects, and works very closely with her customer base.

According to Kaye, “I spent more than 25 years working at the Xerox Corporation, where I honed my desire to start my own business in the manufacturing arena. LaGasse is giving me a great opportunity to design and develop and build custom solutions for my own company.”

Kaye and Ross Gansz, as any new company owners are looking to expand the Harder Dump Box Spreader into new markets.

“The Harder system has received a great reception from municipalities in New York State, basically our own back yard,” Kaye said. “However, we have barely scratched the surface of getting our message to highway departments outside of New York. We have really started to focus on Massachusetts and the surrounding New England states and have been attending trade shows in that area to get the word out.

“The Harder conveyor has always been hydraulically powered using 5:1 gearbox ratio 304 stainless steel and 304 stainless steel idler . We see a great growth potential in adding an electric-powered option, which would also help us in satisfying the needs of converting smaller chassis and dump boxes than what we have typically done today.”

The Gansz’s also are looking at expanding into the contractor market.

“We believe our product can be successfully

used for spreading aggregate on the job site, similar to a stone slinger. It would by no means have all of the features of the stone slinger but could be utilized by contractors that want to spread 2-inch minus aggregate over a large area.”

As the overall company goes, the Gansz’ also are working to expand LaGasse’s agricultural offerings. Kaye and Ross still have heavy ties to the agricultural industry. They own a 200-acre farm and roadside market, which consists of 50 acres of orchard and 150 acres of crops. This connection to the land gives them valuable knowledge on how to best expand the agricultural division.

In 2023, Kaye and Ross purchased GD Youngs in Sodus, N.Y., another fabrication shop, to expand the company’s overall capacity and portfolio, specifically, getting into sanitary welding and giving them the ability to take on onsite projects.

“Bringing on GD Youngs has expanded the employee base as well as added more capabilities to the products / services LaGasse Machine & Fabrication can offer to the customer. This purchase adds tremendous value to the LaGasse brand.”

For more information, visit www.lagassefab.com. P

(All photos courtesy of LaGasse.)

Empire Radiator Service

Fuel Tank Restoration and Repair

We are the only full service fuel tank restoration and repair facility in up-state New York. New U.S. made aluminum tanks.

TitanX original equipment quality radiators for Mack MR Series and other trucks.

Call for availability and price.

Radiators, Charge Air Coolers, Oil Coolers

New, Recores, Repairs, Custom Designed aluminum and copper brass

DPF, DOC, and EGR Cleaning

Controlled burn baking and dual forced air and suction ensures all cells are cleaned. Damaged fittings can be repaired or replaced

Burn Off Oven

Complete removal of paint and grease from your parts and equipment.

Fluid Lines

Hydraulic, including steel, AC and Brake lines

Other Services

Aluminum and steel welding. Press brake, mill, lathe, notchers and sheers. Wet and dry sand blasting, caustic boil out, acid and solvent cleaning, high pressure wash.

New & Used Equipment, Dealers & Manufacturers, Editorial Coverage of State & Local News and, of course, Profiles of Your State’s Highway Superintendents & Public Works Officials. Visit us on the web: www.superintendentsprofile.com For Subscription Information & Advertising Rates email: khogeboom@cegltd.com, or Call...