By Irwin Rapoport CEG CORRESPONDENT

On most projects, cranes are able to meet the needs of general contractors to lift and place heavy pieces of materials, be it pipes, concrete or steel beams, concrete piers, etc. However, in some situations, a crane — despite its size and capabilities — is insufficient.

This is why Sukut Construction LLC made use of an Agusta AW-119 helicopter to place 12 pieces of heavy wire mesh on a slope adjacent to the southbound lanes of State Route 14 (Antelope Valley Freeway) in Santa Clarita as part of a slope protection project by the California Department of

see CHOPPER page 24

By Lucy Perry CEG CORRESPONDENT

Rising highway construction costs are draining more dollars from BIL funds allocated for federal transportation projects across the country. The FHWA admits that what can be purchased today with BIL funds earmarked in 2021 is markedly less that what was pledged. Those construction costs rose an “unprecedented” 26 percent in 2022. The record annual increase was 20 percent in 2005, said the agency. see COSTS page 44

2020 Linkbelt 210X4EX, Stk#: HR-1322, EROPS, A/C & Heat, 4,679 hrs., 35" Bucket, w/Hyd. Thumb, 31% Pads $99,500

2008 Extreme SRM1245, Stk#: 13503, 12,000 lbs., 45 ft., 4,384 hrs., 15.5x25Lx3 Tires $69,500

John Deere 750K LGP, Stk#: 13327, EROPS, A/C & Heat, 6,915 hrs., 90% U/C, 34" Pads, 13 ft. Wide Way Blade, 4,604 $198,500

2020 John Deere 750L LGP, Stk#: HR-1427, EROPS, A/C & Heat, Radio, 6 Way Blade, 6,844 hrs., 33" Pads, 13' 5" Wide $159,500

2020 John Deere 450K LGP, Stk#: HR-1171, OROPS, 6 Way Blade, 2,434 hrs., 100% U/C, 9' 5" Wide $79,500

2019

LT,

HR-1207, EROPS, A/C & Heat, Radio, 6 Way Blade, 6,416 hrs., 90% U/C, 24" Pads, Multi Shank Rear Ripper, 14 ft. Wide

2018 Skyjack SJ1044TH, Stk#: 13490, 10,000 lbs., 44 ft., 1,966 hrs., 72" Forks, 60" Frame, 14.00x24 Tires $89,500

2018 Bell B30E, Stk#: 13464, EROPS, A/C & Heat, Radio, 5,072 hrs., 30 Ton Dump Cap., Auto Greaser, 23.5Rx25 Tubeless Tires $179,500

Tutor

and Stations Project in Honolulu, Hawaii.

8 GSA AWARDS HENSEL PHELPS $174M FOR CALEXICO PORT PROJECT

The U.S. General Services Administration announced its selection of Hensel Phelps to provide design-build services for the final phase of a major project at the Calexico West Land Port of Entry in California.

30 CASE HELPS CONTRACTORS MANEUVER IN TIGHT JOB SITES

Case Construction Equipment is further enhancing its machine lineup, offering a big range of new models and upgrades to empower construction and utility crews facing labor shortages and constrained job sites.

38

With a fleet of more than 750 autonomous haul trucks commissioned worldwide, Komatsu customers have hauled more than 10 billion metric tons of material and are adding to that milestone.

12 KIRBY-SMITH HIRES COLIN BROWN AS OKLAHOMA CITY BRANCH MANAGER

Kirby-Smith hired Colin Brown to serve as branch manager of its Oklahoma City location. The move marks a return to KSM for Brown, having served in roles as a product service manager and governmental sales rep of the Dallas branch.

16 EXPERT ADVICE: THE POWER OF PREVENTIVE MAINTENANCE

Meet Mike Daves, a seasoned service writer at Wilson Equipment in Central Point, Oregon. Mike brings more than 20 years of experience as a field service technician after graduating from WyoTech trade school.

17 ROBUST ATTACHMENT PORTFOLIO CAN ENHANCE VERSATILITY

In an era of labor shortages and projected construction growth, contractors and their crews continue to face both challenges and opportunities on job sites. Seeing quick ROI for new equipment purchases is increasingly important.

26 CATERPILLAR HOSTS FIRST-EVER DEALER TECHNICIAN CHALLENGE

Caterpillar is presenting the first-ever Global Dealer Technician Challenge to celebrate the essential role dealer technicians play in providing an excellent customer service experience.

During the week of June 24 to 27, DSC Dredge attended the WEDA Dredging Summit & Expo ‘24 in Tampa, Fla., where it showcased its innovative technology to the dredging industry.

40 EQUIP EXPOSITION EXHIBIT SPACE SOLD OUT FOR OCTOBER SHOW

Every inch of exhibit space for Equip Exposition to be held in the Kentucky Exposition Center (KEC) Oct. 15 to18, 2024 has now been sold, announced show organizers.

45 AEM HELPS FELLING CELEBRATE 50 YEARS OF MANUFACTURING

Felling Trailers took the opportunity to celebrate its 50th anniversary and team member appreciation with the AEM Manufacturing Express, gathering employees to celebrate the company’s history and continued development.

46 STELLAR’S NXT40 HOOKLIFT OFFERS UNIVERSAL BODY LATCHING SYSTEM

Stellar Industries, a 100 percent employee-owned and -operated manufacturer of high-quality mechanic trucks, cranes, tire service trucks, hooklifts, trailers and service truck and van accessories, is introducing a new NXT40 hooklift.

47 XL SPECIALIZED ADDS NEW KNIGHT 80

XL Specialized Trailers announced the launch of a brand-new trailer model, the

The Knight has an

trailer design.

The U.S. General Services Administration (GSA) announced its selection of Hensel Phelps Construction Company to provide design-build services for the final phase of a major modernization and expansion project at the Calexico West Land Port of Entry in California, one of the busiest ports of entry between the United States and Mexico. GSA awarded the contract for $173.6 million to the Phoenix, Ariz.-based firm to complete the port project.

This critical infrastructure development project, funded by the Bipartisan Infrastructure Law and Inflation Reduction Act, will increase capacity and strengthen security and efficiency at the land port of entry.

“The Calexico West Land Port of Entry is another example of how the Biden Administration is making once-in-ageneration investments that bolster safety and security, while strengthening our economy,” said GSA Administrator Robin Carnahan. “These investments are a triple win — creating good jobs that boost our economy and national security, saving taxpayer dollars through reduced energy costs, and building a stronger and more prosperous future for our communities.”

This project will achieve a reduction of 542 metric tons of CO2 emissions from material selections alone. The scope of the project includes the construction of a new 33,000 sq. ft. pedestrian processing facility. In addition to $122 million from the Bipartisan Infrastructure Law investment, the project will utilize approximately $42 million for low-embodied carbon construction materials and $1.7 million for emerging and sustainable technologies including duct sealing to reduce heating and cooling loads and new highly efficient heat

U.S. General Administration photo This project will achieve a reduction of 542 metric tons of CO2 emissions from material selections alone. The scope of the project includes the construction of a new 33,000-sq.-ft. pedestrian processing facility.

pumps. The announcement furthers the Biden-Harris Administration’s Buy Clean Initiative, under which the federal government is, for the first time, prioritizing the purchase of asphalt, concrete, glass and steel that have lower levels of greenhouse gas emissions associated with their production, use, and disposal.

“The individuals and families I serve from Imperial Valley will see great relief with the expansion project at the Calexico West Land Port of Entry,” said Congressman Raul Ruiz [CA-25]. “This expansion will reduce border wait times, improve air quality, stimulate economic growth and alleviate outdoor wait times in extreme heat.”

“This project not only supports the needs of today, but also lays the groundwork for future advancements in border management and environmental stewardship,” said Sukhee Kang, regional administrator of GSA’s Pacific Rim region. “By incorporating advanced technologies and sustainable materials, we are ensuring that the Calexico West Land Port of Entry meets the highest standards of safety, comfort and environmental responsibility.”

The Bipartisan Infrastructure Law includes a total of $3.4 billion for GSA to build and modernize land ports of entry on the country’s northern and southern borders. The investments will improve commerce and trade, enhance security, create good-paying jobs and incorporate innovative sustainability features.

The Inflation Reduction Act includes a separate $3.4 billion for GSA to use its buying power to promote the development and manufacturing of low-embodied carbon construction materials and to make federal facilities more sustainable and cost-efficient. GSA’s Inflation Reduction Act projects will implement new technologies and accelerate GSA’s efforts toward achieving a net-zero emissions federal building portfolio by 2045. Through these investments, GSA estimates that it could reduce carbon emissions by more than 2 million metric tons in operational greenhouse gas emissions. That’s the equivalent of taking approximately 500,000 gasoline-powered passenger vehicles off the road for one year.

Construction is anticipated to begin in summer 2025, with completion scheduled for winter 2028.

Tutor Perini Corporation, a civil, building and specialty construction company, announced recently that it has been awarded a contract valued at approximately $1.66 billion by the Honolulu Authority for Rapid Transportation (HART) for the City Center Guideway and Stations Project in Honolulu, Hawaii.

The contract is expected to be executed in mid-September. The project scope of work includes the design and construction of six rail stations and approximately 3 mi. of elevated rail guideway beginning just east of the existing Middle Street Transit Center Station and ending at the Civic Center Station, which will be located just east of downtown Honolulu. Project design will begin immediately after contract execution, while construction is estimated to start in the second half of 2025 with substantial completion expected in 2030. Parsons Corporation will serve as Tutor Perini’s design subcontractor.

“We are proud and honored to be a part of this transformational project in Honolulu,” said Ronald Tutor, chairman and chief executive officer. “Tutor Perini has a long and successful history of building large, complex light rail projects in various cities in the United States and we look forward to partnering with HART to see this project suc-

existing Middle Street Transit Center Station and ending at the Civic Center Station.

cessfully delivered.”

The contract value will be added to the company’s backlog in the third quarter of 2024.

Tutor Perini Corporation is a civil, building and specialty construction company offering diversified general contracting and

design-build services to private customers and public agencies throughout the world. It has provided construction services since 1894 and has established a strong reputation within its markets by executing large, complex projects on time and within budget, while adhering to strict quality control measures. It offers general contracting, pre-construction planning and comprehensive proj-

ect management services, including planning and scheduling of manpower, equipment, materials and subcontractors required for a project. It also offers self-performed construction services including site work, concrete forming and placement, steel erection, electrical, mechanical, plumbing and heating, ventilation and air conditioning (HVAC).

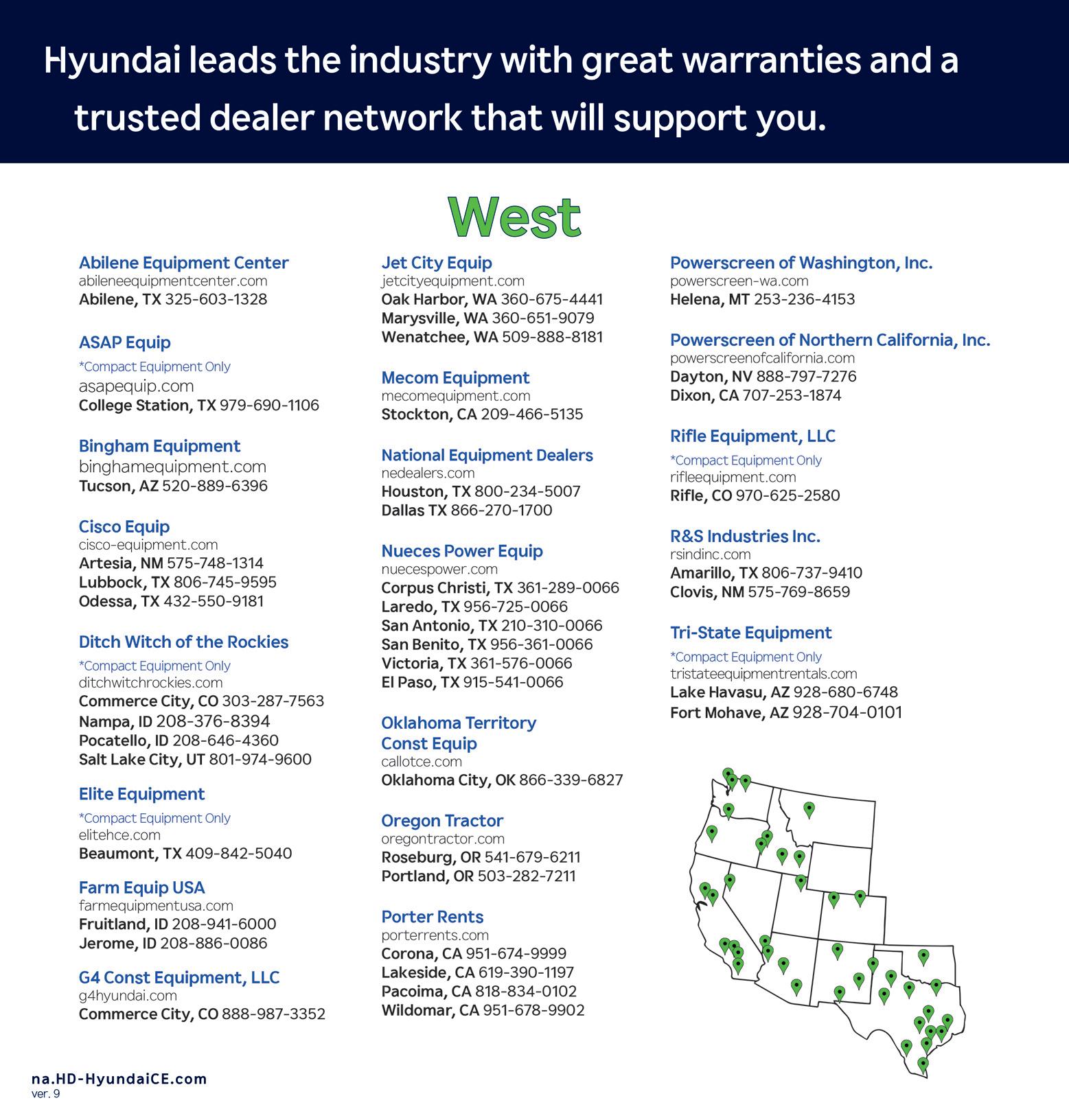

Loved for the features. Trusted for the performance.

Hyundai wheel loaders have the power and performance, not to mention top-notch interiors, accurate onboard weighing system, industry proven drivetrain durability, clear sightlines, and handy tech that make life on the jobsite easier. So you can do more without feeling it. No wonder so many first-time Hyundai users become longtime fans.

See the Hyundai difference yourself at your local dealer or na.hd-hyundaice.com.

With a fleet of more than 750 autonomous haul trucks commissioned worldwide, Komatsu customers have hauled more than 10 billion metric tons of material and are adding to that milestone at a rate of more than 6 million metric tons per day.

Additionally, 10 Komatsu autonomous trucks have achieved a benchmark of 100 thousand autonomous hours each, a first in the mining industry.

Komatsu launched the FrontRunner Autonomous Haulage System (AHS) in 2008, marking the world’s first commercial application of an AHS. In the years since, Komatsu has continued to innovate alongside customers to meet their evolving needs and offer tailored autonomous solutions to promote enhanced operations on a mine-by-mine basis.

The value customers create from implementing a Komatsu AHS is tangible in terms of promoting improved safety practices, productivity and cost reduction.

FrontRunner achieves these benefits through its predictable fleet management, dependable production and enhanced component life by leveraging Komatsu’s people,

process and technological expertise. For instance, customers who have adopted AHS have seen significant improvements in tire and brake life and reductions in overall maintenance.

The FrontRunner system enables increased operational metrics and provides customers a trusted partner with a wealth of industry experience to assist in driving their operations forward, according to the company.

“Since paving the way with the first commercial autonomous haulage operation in the marketplace 17 years ago, Komatsu is proud to continue being an industry leader in autonomy,” said Martin Cavassa, business development manager, autonomous systems at Komatsu.

“Our highly skilled AHS team comprises of application and technical experts, as well as training and support specialists who possess in-depth knowledge and expertise. In every engagement, we bring that expertise to the table to help our customers achieve all the value that FrontRunner can deliver to their operations.”

For more information, visit www.komatsu.com/FrontRunner.

Kirby-Smith Machinery Inc. (KSM) has hired Colin Brown to serve as branch manager of its Oklahoma City location. The move marks a return to KSM for Brown, having served in roles as a product service manager and governmental sales representative of the Dallas branch during his first tour with the heavy equipment distributor. In this role, he will be responsible for managing branch operations in Oklahoma City, including oversight of its parts, service and rental departments.

Jeff Weller, chief operating officer of KSM, is pleased to have Brown back at KSM.

“It is so good to have Colin back home at KirbySmith where he belongs," said Weller. "His experience, industry knowledge, personality and approach will serve our Oklahoma City branch well. I know Colin will serve both customers and employees with the highest levels of efficiency and transparency. Welcome back, Colin! We have very high expectations for your success in growing our brand.”

In his time away, Brown held key management positions for multiple distributors and industry suppliers in Texas, but the strong relationships he formed at KSM left the door open for this homecoming. Brown and his family are excited for the move north of the Red River.

“I couldn't be more humbled to have the opportunity to return to Kirby-Smith Machinery,” said Brown. “Not only is it my pleasure to work for one of the finest equipment dealers in the country, it is also truly a blessing to work with so many people on the Kirby-Smith team who I am fortunate enough to call my friends.”

Brown and his wife, Amanda, have been married for five years. Their two children, Owen and Dylan, have been raised in the heavy equipment industry and are excited about all the "new diggers" they will see in Oklahoma City.

Kirby-Smith Machinery Inc. was established in 1983 and is recognized as one of the premier new and used heavy construction equipment and crane dealers in the country. KirbySmith Machinery and its hundreds of professional employees are committed to providing reliable new and used equipment for sale and equipment rentals, as well as responsive service and equipment parts for multiple makes and models. Kirby-Smith Machinery has 12 branch locations in Oklahoma, Texas, Kansas and Missouri, as well as a dedicated Pipeline Services Division. For more information about Kirby-Smith Machinery, call 888/861-0219 or visit kirbysmith.com.

Realistic Scale Models of

Meet Mike Daves, a seasoned service writer at Wilson Equipment in Central Point, Oregon. Mike brings more than 20 years of experience as a field service technician after graduating from WyoTech trade school.

Today, Mike handles service inquiries, generates work orders and coordinates with the service team. He’s seen it all. DEVELON asked Mike about the most commonly overlooked maintenance tasks and how you can minimize your service needs.

What are the most overlooked maintenance tasks you see?

Monitoring fluid levels. Customers often neglect daily checks. They might say “It’s good. I checked it.” What they don’t know is that it could have developed a serious leak during operation, and now the machine doesn’t have the oil they thought it had. Inspect fuel and hydraulic fluid levels daily for optimal machine performance. What else do customers commonly miss?

Customers often miss our maintenance matrix, which is displayed in a circular format on every machine. This unique layout provides a clear guide to essential maintenance tasks, including locating greasing

points, to ensure optimal machine care.

What are the most critical daily maintenance tasks?

During morning inspections, it is crucial to recognize such warning signs as unusual track movements or new noises like clinking or squealing. These indicate potential machinery issues. Ignoring a $400 roller replacement can turn into a $14,000 repair.

Any advice for operators?

Allow the engine to idle for 5 to 10 minutes before operation. Warming the fluids is crucial, especially with modern machinery’s tighter tolerances. This practice applies not only to cold climates but also to hotter regions of the United States. I consistently warm up every machine before use.

What’s the best source for maintenance info?

The best place to find preventive maintenance schedules is in the Operation and Maintenance Manual. Familiarizing yourself with the manual ensures self-sufficiency and minimizes the need for assistance.

(This article originally appeared in the Summer 2024 edition of Onward Magazine, a custom publication of DEVELON. All photos courtesy of DEVELON.)

By Olamiposi Agboola SPECIAL TO CEG

In an era of labor shortages and projected construction growth, contractors and their crews continue to face both challenges and opportunities on job sites. It’s no surprise, then, that seeing quick ROI for new equipment purchases is increasingly important.

While a specialized machine can be a great asset on the job site, maximizing your existing machines with the help of attachments may prove more efficient and cost effective.

Compact track loaders, skid steer loaders and excavators are known for their versatility; you may be surprised at how many attachment options also are available for mini track loaders, small articulated loaders, compact wheel loaders, telehandlers and even tractors. To fully optimize your existing fleet, connect with your dealer to understand the full

range of attachment options you can take advantage of.

With the right attachments, your machine can be productive through all seasons across construction, landscaping, agriculture or grounds maintenance jobs. This versatility enables you to seize existing project opportunities while also venturing into new markets.

When considering what attachments to add to your fleet, it’s important to consider a few factors. First, identify essential attachments that are currently missing from your inventory. Second, analyze frequently rented attachments to assess potential cost savings by purchasing. Finally, review missed job contracts to identify potential projects that could be pursued with the right attachments.

Augers, buckets, breakers, clamps and grapples are just a few core attachments that can increase your job site opportunities year-round. Specialty attachments, such as rotary cutters, chippers, flail mowers, drum mulchers, soil conditioners and stump grinders, also can tackle work across a variety of industries with their multi-functional capabilities.

For winter work, you may seek dedicated snow-removal

attachments, such as snow blades, snow pushers or a snowblower.

Due to attachment features like Bobcat’s Bob-Tach attachment mounting system, operators can easily — and quickly — change attachments by manually lifting and lowering two easy-to-handle levers on the attachment mounting bracket.

For added convenience, operators can opt for enhanced systems like Bobcat’s Power Bob-Tach, which give you the ability to change non-hydraulic attachments with the press of a button from inside the cab. This technology lets you change a non-hydraulic attachment in a matter of minutes — all from your seat.

Operators also can use the Bob-Dock attachment mounting system on select Bobcat loaders to switch out hydraulic attachments with the press of a switch. This industry exclusive from Bobcat is an evolution from the Bob-Tach and Power Bob-Tach systems, allowing operators to stay in the cab, keeping productivity high and leaving more time to complete the task at hand.

Bobcat has equipped many of its compact excavators with its exclusive X-Change attachment mounting system for multi-attachment functionality.

For the most convenient attachment changes in the industry, choose the optional Hydraulic X-Change system. Release and secure attachments from inside the cab by pressing a switch.

These hyper-focused features directly impact operator seat time which improves both job site productivity and performance.

Optimizing your fleet with the right attachments can help you get more done in less time, gain versatility, replace less utilized machines and give you the tools to accomplish major projects.

Popular attachments like buckets, augers and trenchers are obvious choices for handling material, digging holes and trenching through even the toughest soil, respectively. Specialty attachments like graders, box blades and land planes can make your fleet even more versatile for projects that require absolute accuracy, precision, and in some cases — finesse.

Whether you need to simply improve your job site performance or lower your operating costs in 2024, evaluating your attachment lineup is a good place to start. The wide variety of attachments available and their breadth of features can provide both immediate and long-term benefits that will help you be successful not only this year but well into the future.

(Olamiposi Agboola is a marketing specialist at Bobcat)

Kubota photo

Kubota’s line of plate compactors are matched to its excavators in the 3- to 8-ton size range. These versatile tools effectively compact soil and aggregate in open trenching, leveling and embankment construction applications. The APPC400/700/1000 compactors are durable and ready for everyday use by construction crews in concrete applications and municipality work.

The new lineup of excavator drum mulchers from Blue Diamond Attachments includes three models (heavy duty, extreme Duty and severe duty) with cutting widths ranging from 30 to 50 in.

Compatible with compact, mid-sized and full-sized excavators ranging from 4 to 20 metric tons, Blue Diamond excavator drum mulchers are built with high-quality components and steel to stand up to the harshest land clearing and mulching conditions.

Many components, including the frame, are made with high-strength structural steel, and the frame of each model has been reinforced for added rigidity and strength. Parts exposed to wear, like the skids and counterblades, are built from wear-resistant steel.

Counterblades on the heavy and extreme duty models are heat treated and reversible to double their life span. The severe duty model features rigid counterblades more suited for aggressive working conditions, according to the manufacturer.

Cutting capacities range from 4 to 7 in., and models are available to work with excavator auxiliary hydraulic flows from 9 to 45

gpm.

Blue Diamond Attachments has designed these mulchers with an adjustable input counterblade that can be brought closer or moved away from the rotor depending on the finish you want. The distance between the hammer and the counterblades also has been optimized to produce the best finish while ensuring optimal machine efficiency.

A manual gate/door is available on the heavy duty model, while the extreme duty and severe duty models feature a hydraulic gate/door.

For more information, visit

Werk-Brau introduces its redesigned high performance loader buckets, which have an enhanced performance profile.

Curved side walls, a beveled design and increased roll back angle provide better material retention, allowing these buckets to hold 5 percent more material, according to the manufacturer. Engineered for strength and durability, they feature high-strength, abrasion-resistant steel in all critical components.

Tapered side plates reduce wear and allow for easier dumping. An inclined bottom reduces loading forces, allowing the bucket to do more and last longer, with less wear and tear. A stout top design withstands the high digging forces exerted by today’s more powerful machines. This allows the bucket to be used is harsh conditions without worry of overloading or breaking.

With capacities from 2.0 to 9.0 cu. yds., Werk-Brau high performance loader buckets are ideal for digging in virgin soil and re-handling material up to 3,200 lbs./cu. yd. in density. In-house design capabilities and finite element analysis allow Werk-Brau engineers to create special designs and capacities upon request.

All seams are welded solid to ensure extra durability. Auxiliary edge and teeth are available upon request to make digging even easier. Every Werk-Brau loader attachment is manufactured to O.E.M specifications for all makes and models of wheel loaders.

Werk-Brau manufactures a complete line of OEM and replacement attachments for excavators, mini excavators, backhoes, mini and full-size loaders, and crawler loaders.

For more information, visit www.Werk-Brau.com.

ABILENE, TX • 877-577-5729

AMARILLO, TX • 800-283-1247

DALLAS, TX • 800-753-1247

FT. WORTH, TX • 877-851-9977

HEWITT (WACO), TX • 254-261-1370

LUBBOCK, TX • 866-289-6087

OK • 918-310-1550 ODESSA, TX • 877-794-1800 OKLAHOMA CITY, OK • 800-375-3339 TULSA, OK • 800-375-3733

MISSOULA, MT • 800-332-1617

BILLINGS, MT • 800-735-2589

BOISE, ID • 800-221-5211

COLUMBIA FALLS, MT • 800-434-4190

EUGENE, OR • 800-826-9811

JEROME, ID • 800-221-5211 KENT, WA • 800-869-2425

POCATELLO, ID • 800-829-4450

PORTLAND, OR • 800-950-7779

ROCHESTER, WA • 800-304-4421

SPOKANE, WA • 800-541-0754

Transportation (Caltrans).

Approximately 554,000 sq. ft. of wire mesh have been placed during this project, which started in late 2022.

The construction zone covers the area along the shoulder of southbound Highway 14 between Golden Valley Road and Placerita Canyon Road in northern Los Angeles County.

The helicopter lifted the wire mesh from a site 500 ft. away to the site near Golden Valley Road.

This $16.1 million project that is re-grading, improving and protecting the slopes from erosion began in September 2022 and should be completed in May 2026.

“By placing turf-reinforced wire mesh, this project will control erosion and stabilize this cut slope which is exposed to surface runoff,” said Michael Comeaux, a public information officer of Caltrans District 7 (Los Angeles and Ventura counties). “Similar work has been performed on SR 14 hillsides. This is an area of hills and valleys on the north side of the San Gabriel Mountains, a major mountain range in Los Angeles County. This highway connects the city of Los Angeles to the cities of Santa Clarita, Palmdale and Lancaster as well as other communities farther north, which makes SR-14 a key route for commuters.”

The average weight of each wire mesh piece lifted by the chopper was approximately 600 lbs.

“It took the manufacturer about three weeks to produce the wire mesh pieces,” said Project Engineer Nathan Garcia. “They were delivered to the site via flatbed trucks, ensuring they arrived in excellent condition. The planning was meticulous and involved collaboration between our subcontractor, Access Limited, who installed the wire mesh, the engineers, safety officers, and the helicopter crew [HP Helicopters]. We conducted multiple safety meetings to ensure precision and safety during the lifting and placing process.”

“We did not have a back-up helicopter, but HP Helicopters had a team of trained mechanics on-site to address any potential issues immediately, ensuring no delays in the operation,” he added. “It took approximately 5-10 minutes to lift and place each piece. The operation went smoothly, with no significant deviations from the plan.”

The slopes were prepared by grading, removing 200,000 cu. yds. of soil and ensuring proper grades utilizing GPS systems to create a stable base. Erosion control measures, such as silt fences and sediment traps, also were put in place.

“The wire mesh pieces were attached using grouted anchor rods that were drilled 10 feet into the slope,” said Garcia. “A grid of 10 feet by 10 feet was used by Access Limited drillers using spider drills to complete the task. Immediate work included securing the edges and ensuring each piece was tensioned correctly to maximize stability. The next steps involve completing the attachment of the wire mesh and then pouring concrete along each graded bench on the slope for additional stability, stormwater measures and protection.”

Approximately 30 people were involved in the helicopter operation, including pilot, ground crews, safety officers, construction crew and engineers.

In addition to the chopper, high-strength static and dynamic ropes specifically designed for industrial and construction use were employed, as well as full-body safety harnesses compliant with OSHA standards, equipped with multiple attachment points for versatility and safety; repelling equipment: descenders and ascenders for controlled descent and ascent on slopes, carabiners and connectors made from highstrength alloy for secure attachment points, anchoring

devices such as ground anchors and rock bolts to ensure stability during operations; and personal protective equipment (PPE): helmets with chin straps for head protection, heavyduty gloves to protect hands and provide a better grip, and high-visibility clothing to ensure crew members are easily seen.

Training for the operation was meticulous. This included extensive training in rope access techniques and fall protection; regular safety drills and refresher courses to maintain high safety standards; certification in working at heights and rope access from recognized training organizations, and emergency response training to handle potential incidents efficiently.

“We realized the importance of meticulous planning and coordination among all team members,” Garcia said. “This includes detailed pre-flight briefings and continuous communication during operations. We worked with Access Limited and improved scheduling to minimize downtime and ensure that all materials and personnel were ready before each lift. Safety protocols were refined based on our experiences. Sukut and Access Limited implemented additional safety drills and emergency response exercises to better prepare the crew for unforeseen circumstances.”

Executing this project was never going to be easy.

“A large challenge of this project consists of excavating and operating within such a steep and tight space alongside the existing highway,” said Garcia. “Access is always a challenge and safety is always our main goal in accomplishing and delivering a successful project which is why the helicopter was used to promote safely moving materials to the steep slope. The project is progressing well and on schedule.”

Savala Equipment Company of Irvine was a key rental

equipment provider for the project. Savala supplied Sukut with an operated John Deere JD 470 excavator that was able to quickly load out semi-bottom dump trucks (14 cu. yds.).

“The highly skilled machine operator that Savala provided was instrumental in ensuring that the slope excavation was performed safely and on schedule,” said Garcia.

Quinn Company of the city of Industry also was an important provider of rental equipment, which included skip loaders and small dozers.

The project primarily operates during day shifts to maximize efficiency and ensure safety.

“Our relationship with Caltrans has been collaborative and positive,” said Garcia. “Their support and guidance have been invaluable in ensuring the project meets all regulatory requirements and standards.”

To date, Sukut has completed the following: excavation of two large slopes alongside the highway removing over 200,000 cu. yds. of dirt to protect the hillside from further erosion; installation of new stormwater drainage features; installation of a turf mat and wire mesh system to protect the newly graded slope; and erosion control measures.

The remaining work consists of highway civil improvements including guardrail, concrete barrier, new asphalt paving, asphalt curb and fence.

The operation for re-grading, improving, and protecting the slopes from erosion also required serious planning.

“We are stabilizing the slopes by grading, installing erosion control measures and reinforcing them with wire mesh and turf mats,” said Garcia. “The plan includes phased work to minimize disruption and ensure each section is secure before moving to the next. The main challenges include tight equipment access, managing weather conditions, ensuring the safety of the crews and the operating highway adjacent to the project, and coordinating logistics for the delivery and installation of materials.”

When grading the slope to prepare for the wire mesh installation, Sukut utilized a Cat D9 dozer, a Cat D3 Dozer, a 190,000-lb. JD 470 excavator and a fleet of double bottom dump trucks.

The Sukut management team consists of Garcia, Project Manager Jorge Becerra, Vice President of Public Works Lawrence Damore and Foreman Matt Healy.

“The team dynamic is highly collaborative and focused on safety and efficiency,” said Garcia. “Strong communication and a shared commitment to the project's success characterize our team. The crews have been exceptional, demonstrating dedication, skill, and attention to detail. Their hard work and professionalism have been key to the project’s progress.”

Typical days have 20 Sukut and subcontractor employees on-site. The subcontractors are Access Limited (wire mesh and turf mat installation); Acacia (final erosion control hydroseed); A.C. Dike Co. (asphalt dike installation); Ace Fence Company (guardrail and fence); Dees Burke Engineering Constructors (concrete barrier); Traffic Management Systems (traffic control); Full Traffic Maintenance (traffic control); LA Steel Services ( reinforcing bar); Southwest V-Ditch, Inc. (concrete surface drainage); Statewide Traffic Safety & Signs (traffic signs).

Excavated soil removed and hauled off-site. New materials include over 5,000 rock dowels and hardware for the wire mesh system, and approximately 580,000 sq. ft. of wire mesh and turf reinforcement mat. CEG

(All photos courtesy of Sukut Construction.)

role of dealer technicians.

Caterpillar is presenting the first-ever Global Dealer Technician Challenge to celebrate the essential role dealer technicians play in providing an excellent customer service experience.

This challenge, for independent Cat dealers that choose to participate, is designed to showcase how skilled technicians are part of a high-tech, high-impact, high-demand career.

“This hands-on, skills-based competition will test the technicians’ agility, resilience and versatility,” said Caterpillar Global Service Vice President Henry Venneman. “These trained experts are on the front line of support, working to keep machines and engines up and running to help ensure our customers’ critical projects are completed.”

Cat dealers globally are experiencing a growing opportunity for technicians. By the end of 2026, it is estimated that Cat dealers may need to hire more than 44,000 technicians. This competition also is designed to help raise awareness of the opportunities in this career field.

“There are thousands of opportunities available globally for those who are interested in a hands-on career,” said Venneman. “Cat dealers are often looking for individuals who are problem solvers, mechanically inclined and tech savvy.”

The Global Dealer Technician Challenge will take place over a series of regional and semifinal competitions around the world. The top 10 finalists will have the opportunity to compete in the finals in March 2026 at ConExpoCON/AGG in Las Vegas. For

visit

Fresh off the heels of the largest number of product launches in the company’s history, Case Construction Equipment is further enhancing its machine lineup, offering a big range of new models and upgrades to empower construction and utility crews facing labor shortages and constrained job sites.

Adding more versatility, maneuverability and muscle on machines ranging from backhoes to rough-terrain forklifts, Case is continuing its mission to solve problems on the job site through practical innovation, allowing teams to accomplish more with less amidst growing demands from booming infrastructure investment.

“Labor shortages continue to shrink the workforce, while at the same time companies are challenged to work more productively and more profitably,” said Terry Dolan, vice president — North America, Case Construction Equipment. “We geared our latest round of Case innovations toward helping crews maneuver these challenges more effectively and efficiently than ever before.”

The new lineup of Case machines includes three new Construction King backhoe loaders, a new 5-metric ton class mini excavator and an all-new, full-sized wheel loader that ups the ante on power and versatility. Case also is launching new upgrades to existing machines, including maintenancefree emissions solutions and linkage improvements for compact wheel loaders and enclosed cab options for Case H Series all-terrain forklifts.

Case Construction King backhoe loaders have made a name for themselves as the original two-in-one tool-carrying machines. Now, Case is taking innovation further with two new models that offer side-shift capabilities — letting operators move the boom left or right to work more efficiently parallel to walls or around obstacles.

Previewed at last year’s ConExpo, the new 97-hp Case 580SV Construction King side shift and the larger, 110-hp Case 695SV side-shift and 695SV center-pivot models are now available, in addition to the N Series lineup. The new machines carry over many popular features from the N Series, like ProControl swing dampening, auto ride control and ECO modes for fuel savings, along with significant upgrades to maneuverability.

“The new side-shift models take the legendary Case Construction King capabilities to new frontiers, putting them smack dab into confined spaces and up next to structures,” said George MacIntyre, product manager — backhoe loaders. “With a hydraulic

Previewed at last year’s ConExpo, the new 97-hp Case 580SV Construction King side shift and the larger, 110-hp Case 695SV side-shift and 695SV center-pivot models are now available, in addition to the N Series lineup.

side-shift boom and vertical outriggers, these machines can get more done in tight spaces. They also let operators dig rectangular trenches without having to reposition.”

The Case 580SV side shift features a tool carrier design that improves stability and material retention, while its side-shift configuration and narrow width make for more productive work in confined spaces. For bigger, tougher jobs, the powerful Case 695SV side-shift and center-pivot models feature a tool carrier loader arm, allowing them to do double duty as a wheel loader, meaning one less machine to bring to the job site.

Both 695SV models are equipped with 4WD, 4-wheel steer and four equal-sized tires and include a PowerShift transmission. The expanded Case backhoe offering also is compatible with numerous attachments, giving crews a big toolkit for improving productivity, speed and accuracy on highly varied jobs.

For construction and utility crews who are scaling up work on bigger jobs but still need to work in tight spaces, the all-new Case CX50D mini excavator delivers more punch in a compact design. This 5-metric ton class machine offers greater lifting capacity and better digging performance for jobs that demand more production in shorter time from operators.

When it comes to attachment versatility, the new mini excavator powers a wide range of specialized attachments for highly varied jobs. It comes standard with multifunctional hydraulics and a second auxiliary circuit, as well as an optional third auxiliary circuit for advanced attachments like tilt rotators and grapples. It also offers another optional ded-

icated auxiliary circuit to power mulchers.

Crews also can improve the safety and efficiency of material handling with the optional object handling kit that includes check valves on the boom and arm.

Operators also will be able to work longer and more comfortably in the CX50D due to the automotive-style cab. Here, Case goes all in on comfort, control and convenience, including features like auto climate control with heat and A/C, Bluetooth radio, a fiveway adjustable seat and a customizable LCD screen that provides important data on the machine and attachments.

For teams that need a tough workhorse that doesn’t compromise on control, comfort or versatility, the newest addition to the Case large wheel loader family offers a robust solution to boost productivity on the job site. The Case 651G delivers breakout force of nearly 24,000 lbs. and lifting capacity of over 16,100 lbs. to help teams plow through tougher jobs. The new model also features a larger hydraulic pump for increased cycle times, a curved bucket for better material retention and a higher hinge pin for better dumping clearance.

Case makes it easier to manage all the muscle of their new full-sized wheel loader with features like a touchscreen display and adjustable, intuitive electrohydraulic controls that allow the operator to independently set boom and bucket responsiveness to smooth, moderate or aggressive. Operators can even weigh loads and track material moved with an integrated onboard scale. And with a variety of axle options to match jobsite conditions, they’ll be able to get the best traction performance possible.

The new Case 651G also helps operators stay productive longer with a roomy cab that boasts all the comforts operators love. Features like AC and heat, heated seats, Bluetooth radio and phone connectivity let operators work comfortably, while the rear sloping hood and optional backup camera improve visibility.

“When production demands on difficult jobsites require long days of uninterrupted work, operator comfort is key to productivity for the long haul,” said Neil Detra, product manager — full-size and compact wheel loaders. “We designed this new machine with operators top of mind to provide an experience that’s like taking your office to the job site.”

Updates to Case F Series compact wheel loaders will help teams working in confined job sites with new features that improve visibility and control. An elevated driving position, an abundance of curved glass in the cab and four-corner strobe lights ensure maximum visibility on the job site, while new Zbar linkage upgrades let operators push their machine further with maximum breakout force.

Case 21F, 121F, 221F and 321F models also feature time-saving, maintenance-free Tier IV Final emissions solutions that improve uptime by eliminating regeneration and expensive diesel particulate filters.

Control-enhancing features like parallel lift capabilities on Case 21F and 121F models help keep loads stable and allow for better visibility of the coupler during attachment changeouts. Case 221F and 321F models combine auxiliary high-flow hydraulics and a creep speed mode to provide max hydraulic flow at constant speeds for smoother operation of attachments like brooms and snowblowers. All the models also feature improved LCD screens with simplified controls to make operation easier.

Case H Series rough-terrain forklifts offer construction crews and utility teams a versatile, easy-to-operate solution for lifting heavy loads in off-road environments. Now, a new factory-designed, built and installed enclosed cab option protects the operator from the elements and helps teams work in more extreme conditions. With heat, AC and comfort features such as Bluetooth radio and USB charging ports, operators can continue working in sweltering heat or frigid cold. For more information, visit CaseCE.com.

By Eric Olson CEG CONTRIBUTING EDITOR

Sand Science Inc., a Beaufort, S.C., supplier of screening, conveying, crushing and recycling equipment, is currently undergoing a major effort to expand the availability of the Roto-Screen portable trommel screening plant in the United States through the formation of Roto-Screen USA and the development of a full-service dealer network.

As a long-time distributor of the product line, Sand Science has become the primary dealership of Roto-Screens in this country.

Located just off the busy Interstate 95 corridor in South Carolina’s Low Country, approximately 30 mi. north of Savannah, Ga., Sand Science has significantly grown from a local and regional distributor of material handling equipment when it was first established in 1985 to a nationwide one.

That fact alone made Sand Science an obvious choice for Roto-Screen Canada in selecting the South Carolina distributor to represent its products in the United States. Another point in Sand Science’s favor is that for three decades it has been an outstanding partner to Roto-Screen in the sales, rental and service of its trommel screens.

Now, Sand Science is the largest RotoScreen dealer in America, said Eoin Kenny, vice president of marketing and sales for the distributor.

He, along with his brother, Adam, Sand Science’s vice president of operations, work alongside their father, Gerry, the company’s owner and founder.

Roto-Screen Canada began to express more of an interest in expanding its nationwide product availability following the end of the pandemic, according to Eoin Kenny.

“We were asked by the factory in Canada to take over its American distribution,” he said. “So, over the past eight months, we have begun the process of building a master distributorship with dealers across the U.S. to fully focus on rentals and sales of the Roto-Screen in different regions of the country.”

As a result, Roto-Screen USA was formed and has helped to bring on three new distributors for the Roto-Screen 454 trommel screener in that time, Kenny said.

“We have JGB Recycled Aggregate Materials, in Marshfield, Mass., which will be focusing on the Northeast for us. It already serves Massachusetts and Rhode Island, but now includes Maine and New Hampshire, as well,” he said, “and MHK Equipment Services, based in Michigan, will be concentrating on the Midwest. Additionally, we just signed up another distributor, RTL Equipment Inc., that will cover Minnesota, Iowa and North and South Dakota. And more dealership opportunities are available.”

Sand Science will serve as the dealer for the Southeastern states, Kenny said, and Roto-Screen USA will continue to expand and serve all remaining territories directly.

The agreements represent the first steps in a controlled, long-term plan to create a nationwide dealer network for the RotoScreen product.

In the months and years ahead, RotoScreen USA also wants to see its products offered through more dealerships in the Deep South, Texas, the Rockies and the Northwest states.

“If we are going to do that, we must also see to it that each dealership can offer the parts and service capabilities to support the Roto-Screen,” Kenny said. “We want our customers to get the best, most timely help possible, no matter where they are.”

Earlier this year, Roto-Screen USA delivered two machines to the JGB facility, south of Boston, where the aggregate recycling outfit intends to rent and aggressively expand its business, he said.

“JGB Aggregates had an open house day there in April where their customers came in and looked over the machines. We were able to explain everything about the RotoScreens and do some training. JGB was really excited to get the machines out there, and the interest in the product is very strong in that area.”

With the New England construction seasons being so short, Kenny said that “everyone has to get going pretty quickly when the

Roto-Screen USA recently delivered a R-545 trommel to JGB Aggregates in Marshfield, Mass. (L-R) are Adam Kenny and Eoin Kenny, both of Roto-Screen USA; and Andrew Backman and Mike Gallant, both of JGB Aggregates.

weather warms, meaning JGB had machines on the ground as soon as possible to service that area, with more machines on the way. It’s the same for MHK in Michigan. They had equipment on the ground and in their rental fleet prepared to move and ready to sell.”

Kenny believes the best feature of the Roto-Screen 454 trommel, designed to be stronger and more versatile than other screeners on the market, is its simplicity and ease of use.

“By that I mean it is easy to work on and a great machine for contractors, site preparation and land clearing crews, and companies making topsoil, mulch, compost and other materials,” he said. “Roto-Screens are also made up of all North American-manufactured parts to keep costs down. It is very efficient, too.

“It might not be the fanciest, but, at the end of the day, the material coming off the discharge conveyor sells for the same price no matter what machine screens it.”

Roto-Screens also make for a great rental product, he said, in that its prospective dealers can offer the machine to their customers to rent and try before making the commit-

ment to buy. Its low cost of operation makes it the perfect machine for both short- and long-term rentals, including rental purchase options (RPOs), he added.

“After they have it rented, they can then put some of that money into the RPO deal, thus lowering the price,” according to Kenny.

“This offers a ‘try before you buy’ situation that we find our customers really like.”

Eoin Kenny’s company has continued on an upward growth trend ever since his father, Gerry, started Sand Science in the Palmetto State almost 40 years ago.

The elder Kenny, a native of Ireland, has more than four decades of experience in the material processing equipment industry working with builders on several continents. Along with his sons, he established a reputation among construction professionals as being very knowledgeable, reliable and personable dealers of high-quality equipment.

The family business’s inventory of RotoScreens joins several other product lines at Sand Science, including a choice selection of portable shaker screens and jaw crushers, conveyors, hoppers, used equipment and parts. For more information, visit www.RotoScreenUSA.com or www.sandscience.com. CEG

(Photo courtesy of Sand Science Inc.)

817-654-2202

616 Jealouse Way Cedar Hill, TX 75104

469-575-5339

6029 N McDonald Melissa, TX 75454 214-307-7350

TX 806-373-2826 Dallas, TX 214-371-7777 Ft. Worth, TX 817-378-0600

UNCOMPROMISING PERFORMANCE - RIGHT AT YOUR FINGERTIPS. The new MOBICONE MCO 11 PRO mobile cone crusher, with its extremely robust construction and fuel-efficient consumption, delivers exceptionally powerful performance. And of course, with its new, innovative SPECTIVE operating concept, which actively supports the user in finding the right setting for any task quickly and precisely - simply via touchscreen. Powerful and user-friendly as never before - the new MCO 11 PRO with SPECTIVE. Oklahoma City, OK 405-495-7820 Tulsa, OK 918-438-1700 McAlester, OK 918-310-1550 Abilene, TX 325-692-6334

www.wirtgen-group.com

EvoQuip, a manufacturer of compact crushing and screening equipment, launched the Bison 170 — the latest addition to its jaw crusher range.

With its 700x500mm jaw chamber and diesel-electric drive technology, the Bison 170 is a smart choice for customers aiming to optimize their operations while meeting both economic and environmental goals.

Suitable for both natural rock and recycling applications, the Bison 170 has a range of environmentally friendly features that also offer customers value, high performance, ease of use and maneuverability.

The Bison 170 utilizes a fuel-efficient diesel electric drive system, with an onboard generator being used to power the plant. It also can be plugged in and driven from an external power source such as mains power, which allows for zero emissions processing. This enables customers to meet regulatory requirements and support their own sustainability goals.

The engine and power unit can be removed completely, allowing the plant to be powered from an external source with no combustion engine on board. As noise pollution also is reduced, the Bison 170 is an ideal machine for working in urban areas.

With its 700x500mm jaw chamber and diesel-electric drive technology, the Bison 170 is a smart choice for customers aiming to optimize their operations while meeting both economic and environmental goals.

The Bison 170 offers all-round efficiency, with the electric drive enabling customers to run in reverse for asphalt recycling and also providing a unblock/jog function to clear a blockage.

The deflector plate, fitted as standard, provides belt protection by allowing uncrushable objects to pass through the crushing chamber safely and onto the discharge belt. Finally, the ability to easily maneuver the machine from site to site and its simple and intuitive control system ensure transport and set up times are minimized, while up time in maximized.

“We are delighted to add the Bison 170 to our jaw crushing range,” said Andrew Armstrong, product manager of EvoQuip. “With a potential output of up to 110 tph and low fuel consumption, the Bison 170 is a high performing, environmentally friendly machine that aligns with the EvoQuip Think Green, Think EvoQuip sustainability campaign.” For more information, visit www.terex.com.

Finlay recently showcased its latest innovations — the J-1170+ jaw crusher and the TR-80 radial conveyor — during its highly anticipated “Open Days” event in Atlanta.

Approximately 200 distributors and customers from across North America attended the Open Days, marking the debut of these new machines’ first production builds following their official launch earlier this year.

The J-1170+ jaw crusher garnered significant attention for its exceptional production capabilities, while the TR-80 radial conveyor highlighted the efficiency and cost savings achievable through the integration of mobile conveyors in material processing applications.

The Open Days featured live demonstrations of seven Finlay machines in quarry and concrete recycling scenarios, each showing productivity and efficiency gains in material processing operations. They also provided an ideal opportunity for industry professionals, including quarry owners, operators and Finlay representatives, to experience firsthand the performance of Finlay equipment, as well as to network and share their insights and experiences.

Finlay experts were available on-site to discuss the capabilities of the showcased equipment, offering valuable insights into machine selection and optimization tailored

to specific job sites and material applications. Additionally, the team highlighted the operational savings and benefits of the TLink telematics system, which comes standard on all Finlay machines.

“The response to our new J-1170+ jaw crusher and TR-80 radial conveyor has been overwhelmingly positive,” said Martin Conway, commercial general manager of Finlay North America.

“Our Open Days in Atlanta allowed us to connect directly with our customers and dis-

this year.

The J-1170+ jaw crusher garnered significant attention for its exceptional production capabilities.

tributors, demonstrating our commitment to delivering innovative and efficient solutions in material processing. We are excited about the future and the opportunities these new machines will bring.”

(All photos courtesy of Finlay.)

ALASKA

NC MACHINERY

www.ncmachinery.com

800-478-7000

Anchorage, AK • 907-786-7500

Dutch Harbor, AK • 07-581-1367

Fairbanks, AK • 907-452-7251

Juneau, AK • 907-789-0181

Prudhoe Bay, AK • 907-659-6900

Wasilla, AK • 907-352-3400

ARIZONA

EMPIRE CAT

www.empire-cat.com

1725 S Country Club Mesa, AZ 85210

800-EMPIRE-1

CALIFORNIA

HOLT OF CALIFORNIA

www.holtca.com

Pleasant Grove • 916-921-8969

NEVADA

EMPIRE CAT

www.empire-cat.com

3300 St. Rose Parkway, Henderson, NV 89052

702-649-8777

Elko • 775-738-9871

Reno/Sparks • 775-358-5111

NORTH DAKOTA TRACTOR AND EQUIPMENT

www.tractorandequipment.com

Williston • 701-572-8377

WYOMING TRACTOR AND EQUIPMENT

www.tractorandequipment.com

Worland • 307-347-4747

TRACTOR AND EQUIPMENT

www.tractorandequipment.com

Billings, MT • 406-656-0202

Billings-Sgt. • 406-245-4426

Bozeman • 406-585-5800

Great Falls • 406-761-7900

Helena • 406-442-2990

MUSTANG CAT

mustangcat.com

Beaumont • 409-892-8412

Bryan • 979-775-0639

El Campo • 979-543-3389

Houston • 713-460-2000

Lufkin • 936-639-5551

NC MACHINERY

www.ncmachinery.com 800-562-4735

Seattle • 425-251-5800

Chehalis • 360-748-8845

Fife • 253-896-0878

Monroe • 360-805-6000

Mt. Vernon • 360-424-4292

Wenatchee • 509-886-5561

Yakima • 509-248-2371

1090 W 2181 N Salt Lake City, UT 84116

801-322-1300

atlasmachinery.us

6565 Smith Avenue Newark, CA 94560 510-400-5024

1535 SE 25th Street Oklahoma City, OK 73129 405-310-8700

2035 W Mountain View Road Phoenix, AZ 85021

480-463-4999

Equipmentshare.com

During the week of June 24 to 27, DSC Dredge attended the WEDA Dredging Summit & Expo ‘24 in Tampa, Fla., where it showcased its innovative technology to the dredging industry.

The four-day event was an overall success for the DSC team, featuring significant highlights. One of the many highlights was the presentation of the “Why is Dredging Good” Paper Award. This award, which DSC has sponsored for more than 10 years, was presented by DSC’s Marketing Director, Mercedes James, to Donald Hayes and Ancil Taylor, who accepted the award on behalf of all the contributors.

The contributing team also included Ram Mohan, Mindy Strevig, Alan Kennedy, Daniel Farrar and Katherine Brutsche.

Their paper, titled “Inspiring DredgingRelated Innovation Through Research and Development,” emphasized a variety of innovative dredging approaches and advancements, underscoring the importance of continuous research and development in the field.

In addition to sponsoring the award, DSC introduced its Dredge Simulator at the expo. This simulator, the first of its kind in the industry, allowed attendees to experience hands-on demonstrations, learning and oper-

(L-R): the DSC Team consisted of Mercedes James, Bob Wetta, Charlie Johnson, Josh Louviere, Bryan Landry and Damon Gonzales.

ation of dredging equipment in a controlled, on-site environment. This innovative tool received significant attention and comments from the expo participants.

DSC’s booth also featured a model of the Muddy Water Dredge, the industry’s first dredge model equipped with the most advanced technology to date. This cuttingedge dredge model exemplifies DSC’s commitment to leading the industry through technological innovation and superior design.

The DSC team also played a crucial role in

“Why Dredging Is Good” award presented by Mercedes James of DSC Dredge to Donald Hayes and Ancil Taylor.

WEDA’s education sessions, contributing to the knowledge sharing and educational value of the summit. The Short Courses they were part of included:

• Bryan Landry, DSC vision specialist, “Underwater Visualization for Dredgers” short course.

• Bob Wetta, Charlie Johnson and Damon Gonzales, “Dredging Deconstructed: Explore Dredge Types, Applications, and Operational Strategies” short course.

• Bob Wetta, Josh Louviere and Mercedes

James, “Navigating the Waters: Best Practices and Pitfalls in Dredge Operations” short course.

At the closing of the event out of 177 exhibitors from around the world, DSC was awarded “Best Educational Booth”. This award further supports DSC’s dedication to education and knowledge sharing within the dredging community.

For more information, visit www.dscdredge.com. (All photos courtesy of DSC Dredge.)

Every inch of exhibit space for Equip Exposition to be held in the Kentucky Exposition Center (KEC) Oct. 15 to18, 2024 has now been sold, announced show organizers, who are readying to welcome thousands of landscapers, contractors, dealers, distributors, hardscapers and more to the event.

Equip is the international landscape, outdoor living and equipment exposition held annually in Louisville, and is one of the largest, annual trade shows in the United States. It is co-located with Hardscape North America.

“Maxing out the exhibit space more than two months before the doors open is great news for anyone attending,” said Kris Kiser, president and CEO of the Outdoor Power Equipment Institute (OPEI) which owns the award-winning show.

He added, “Every inch of the more than million square feet of indoor and outdoor exhibits at Equip Expo is loaded with equipment, training and information to help landscapers and contractors run their businesses more efficiently and make more money. Whatever business problems keep you up at night, this trade show addresses.”

“You got to stay up on this stuff. You got to have what’s working,” said Roy Thomas with McIntosh Grounds Maintenance. “I want to come back every year. If you work outside, you need to be here.”

Kiser said a waiting list is already going for exhibitors who want to request space for next year.

“Equip has maxed out yearly and is the destination for showing off the newest and most innovative outdoor power equipment, technology for contractors, and getting ahead of industry trends,” said Kiser.

With more than a million square feet of indoor and out-

OEM authorized mining dealer www.coremachinery.com

Phoenix, AZ 480-545-2400

Phoenix, AZ 602-252-7121

Prescott, AZ 928-778-5621

Tucson, AZ 520-623-8681

Bakersfield, CA 661-695-4830 Mojave, CA 661-824-2319 Perris, CA 909-355-3600

*Formerly Road Machinery

www.wpi.com

12320 S. Main Street Houston, TX 77035 713-723-1050 Buffalo, TX 903-322-7150 Bryan, TX 979-314-1191 Corpus Christi, TX 361-884-8275 Edinburg, TX 956-386-0107

Kilgore, TX 903-984-2011

Lufkin TX 936-243-6056 Pflugerville, TX 512-251-0013 Port Arthur, TX 409-721-5305 San Antonio, TX 210-648-4444 Tomball, TX 281-351-9016

door exhibits at the KEC, including a 30-acre outdoor demo yard where attendees can mow, chop, dig and drive the latest equipment, preparation is more important than ever.

“Book your hotel room, wear your comfortable shoes, prepare in advance for your days at the show, and get your registration done now at the early bird rate for $30,” said Kiser.

Registration pricing doubles to $60 after Sept. 5.

In 2023, Equip Exposition sold its last exhibit space in early October. This year the last spot sold out in early August.

“People want to be at this show to talk about the trends impacting the work you do every day, and you really can’t miss it,” said Kiser.

Equip Exposition broke records last year with more than 27,000 attendees, won two Grand Awards from Trade Show Executive’s Gold 100 Awards program and now has been nominated for three more awards in 2024, and expanded its footprint into the West Wing.

Bringing more than $20 million to the Derby City, the trade show’s impact reverberates into landscape contracting businesses around the country.

“It’s imperative that people be at places like this because live events is where you make the decisions that change your business and therefore your life,” said Keith Kalfas of The Untrapped Podcast.

Registration and hotel reservations can be booked through Equip’s official housing provider, Louisville Tourism, on the Equip website.

For more information, visit www.EquipExposition.com.

www.powermotivecorp.com

Corporate Office 5000 Vasquez Blvd., Denver, CO 80216 303-355-5900 Colorado Springs, CO 719-576-5541 Grand Junction, CO 970-241-1550 Milliken, CO 970-587-1188 Cheyenne, WY 307-634-5149 Durango, CO 970-259-0455 Albuquerque, NM 505-345-8383 Bloomfield, NM 505-324-8601 Carlsbad, NM 505-485-1700

El Paso, TX 915-872-1001 Chandler, AZ 602-986-3003 Phoenix, AZ 602-463-3772 Tucson, AZ 520-649-2858

www.geehm.com

5461 S Nikita Avenue Fresno, CA 93725 559-834-3149

1164 Prestige Way Redding, CA 96003 530-229-3820

3650 Seaport Blvd. West Sacramento, CA 95691 916-375-3540

3350 Regional Parkway Santa Rosa, CA 95403 707-544-4147

45051 Industrial Drive Fremont, CA 94538 Coming Soon

www.kirby-smith.com Oklahoma City, OK 405-495-7820 McAlester, OK 918-310-1550 Tulsa, OK 918-438-1700

Abilene, TX 325-692-6334 Amarillo, TX 806-373-2826 Dallas, TX 214-371-7777

Ft. Worth, TX 817-378-0600

Lubbock, TX 806-745-2112

Odessa, TX 432-333-7000 Waco, TX 254-261-1370

inate potential damage peed qu , cr erators up to s our machines y omfr s Intelligent M Komastu’ our job si y on y oductivit

c ) ol (IMC r achine Cont anced autom tes with adv yg . ned plans ou an help y ation

efully design w and car e

face to design sur uickly

WA 800-304-4421 Spokane, WA 800-541-0754

www.clairemontequipment.com San Diego, CA 858-278-8351

Indio, CA 760-863-5558 San Diego, CA 858-278-8338

Escondido, CA 760-739-9100 Fontana, CA 909-429-9100 Imperial, CA 760-355-7700

Tracking numbers, the DOT Bureau of Transportation Statistics (BTS) found that from the first quarter of 2022 to 2023 costs rose 35 percent.

It reduces “the amount of highway infrastructure that can be bought today versus what could have been purchased prior to the price increases.”

The agency put it another way: “The same construction project today costs more than yesterday and significantly more than in 2021.”

The AGC noted that prices for construction inputs have risen faster than contractors’ bids every month so far in 2024.

“Persistently long lead times for electrical equipment are adding to the cost of building and infrastructure projects,” said Ken Simonson, chief economist. “Meanwhile, inflexible rules for sourcing materials could drive up prices for federally aided projects such as highways.”

The AGC partnered with ARTBA on a survey tracking the impacts on highway construction of proposed tighter Buy America requirements.

Some 69 percent of respondents said they’d “price” their bids to register uncertainty about costs of Buy America-compliant materials for particular projects.

“This reality usually results in higher project costs and diluted benefits from federal investment,” said Simonson. “In addition, if FHWA rolls back its waiver, respondents expect significant challenges in complying with Buy America requirements for many manufactured products.”

Less than 15 percent of respondents believe these products would be easy or possible to acquire in compliance with the Buy America policy.

Survey respondents listed numerous additional products that would be difficult or impossible to source without waivers.

“Federal officials are attempting to shut down a diversified global supply chain … before enough domestic supply exists,” said Jeffrey D. Shoaf, CEO of the AGC. “That’s a recipe for higher costs and delayed projects that will harm both the U.S. economy and highway safety.”

The BTS warned that if highway construction costs rise above their level at BIL signing, what can be bought with the funds in each fiscal year will decline.

The bureau looked at both High and Modest Inflation Scenarios in predicting what happens in the future. The High Inflation Scenario assumes construction costs continue to rise at their current rate using the average annual growth from 2021 and 2022.

“Under this scenario, only $224.2 billion can be bought with the $379.3 billion allotted for highways,” said BTS. “In other words, only 60 percent of what could have been bought … when BIL was signed can be bought over the five years from 2022 through 2026.”

The agency noted that situation represents a whopping 40 percent reduction.

The Modest Inflation Scenario assumes a more modest growth in construction costs equal to the average annual growth in 2019 and 2021.

“Under this more modest growth scenario, $260.5 billion can be bought with the $379.3 billion allocated … due to increased highway construction costs.”

This amount is 16 percent more than what could be bought if highway construction costs continue to rise at their current higher rate, said BTS.

But it’s still only 69 percent of what could have been bought when BIL was signed.

“In other words, a 31 percent reduction in what could have been constructed in 2021 when highway construction cost less.”

Materials prices are to blame for a lot of the headaches the construction industry faces with BIL projects. The bureau tracked increases in crude oil used to produce asphalt, which it said contributed to the situation. In fact, BTS reports U.S. crude oil increased 594 percent, from $16.55 per barrel in April 2020 to $114.84 per barrel in June 2022.

That’s the second highest price on record and makes asphalt a top contributor to increases in the National Highway Construction Cost Index (NHCCI).

These numbers are from the last quarter of 2021 through the third quarter of 2022.

“Crude oil prices have fallen since the June 2022 high but have risen steadily since the beginning of 2024,” said BTS.

The bureau said that situation suggests construction costs may rise further in the future.

Supply-chain issues, which began in 2020 with COVID, are also contributing to the hike in the cost of highway construction.

The pandemic caused both temporary and permanent business closures. It also increased demand for durable goods.

“This, in turn, caused material prices to rise,” said the bureau. An increase in the producer price index (PPI) for all goods and services shows just how.

The PPI grew by 51 percent from April 2020, the lowest point since May 2016, to a new all-time high in June 2022, said BTS.

The NHCCI actually fell a half a percentage point from October to December of 2023, according to FHWA’s quarterly index.

Jeff Davis of thinktank Eno said that using the new NHCCI seasonal adjustment, the final quarter 2023 was still 4 percent above the previous period.

FHWA economists said, “there is a historically negative seasonal effect during Q4 and Q1 that may be contributing to the slight deflation.”

It’s visible on FHWA’s line chart of the NHCCI going back to its inception in 2003, said Eno.

The original index divots downwards in the fourth quarter of many years, as cold weather curbs construction activity and demand for materials.

“However, when you add it all together, year upon year, there is no real cumulative difference in the old rate vs the seasonally adjusted rate,” said Davis.

In both instances, the cumulative increase in highway construction costs since the October-December 2020 quarter is 68 percent.

“Converting this to actual dollars lost … the FHWA has signed $182.4 billion in contracts and other spending obligations since January 1, 2021,” added Davis.

Once the nominal dollars convert to “real” at the OctoberDecember 2020 quarterly NHCCI, that $182.4 billion drops down to $132.9 billion.

That means “that $49.4 billion has been lost to highway cost inflation since January 2021,” Davis said.

But, he added, even the nominal numbers reveal something interesting about FHWA and state DOTs.

The two signed a smaller dollar amount of contracts in the last two quarters of 2023 than in the last four quarters of 2022.

“This may be linked to the ongoing August Redistribution crisis,” said Davis.

He believes some states may be running out of ready-togo highway projects that can be put out to bid and started quickly.

Federal mandates pushing contractors to hire union labor is “the worst way to do infrastructure projects,” said Ben Brubeck of ABC.

“Taxpayers lose when responsible contractors that do a quality job at the best price are frozen out,” Brubeck wrote for the media outlet Governing.

He said the construction industry’s “perfect storm” of workforce shortage, materials price inflation and controversial public policy is to blame.

It’s “undermining hundreds of billions of dollars of taxpayer investments in federal, state and local government infrastructure projects.”

Brubeck said it’s also hurting clean energy and manufacturing projects procured by private developers.

“This means fewer improvements to roads, schools, water systems and energy infrastructure and fewer well-paying construction jobs.”

He cited President Biden’s Buy America laws, project permitting regulations, workforce development and labor policies as well as the failure to reduce costly red tape.

Combined, the issues are “diminishing the value hardworking taxpayers deserve from investing in America’s infrastructure projects,” said Brubeck.

And he called Biden’s mandatory project labor agreements for contracts of $35 million or more “one of the most controversial Biden administration policies.”

Brubeck said the policy excludes nearly 90 percent of the construction workforce “and some of the best contractors in the industry” from competing.

The project-specific collective bargaining pacts are designed to steer taxpayer-funded contracts to unionized contractors and union labor.

“Government-mandated PLAs needlessly exacerbate the construction industry’s skilled labor shortage,” said Brubeck. They force the replacement of existing employees with workers from specific union halls and the adoption of “inefficient” union work rules, he said.

The result is excessive cost burdens and safety and quality risks for high-performing non-union contractors who can’t compete for taxpayer-funded projects.

“Non-union firms employ a historically high 89.3 percent of the U.S. construction industry,” said Brubeck, ABC vice president of regulatory affairs. “Quality and experienced non-union contractors have built more than half of largescale federal construction projects since 2009.”

These non-union contractors also are more likely to be owned by women and minorities, he added, and research has found PLA mandates increase construction costs by 12 to 20 percent, he said.

That means voters can expect fewer improvements to important local infrastructure projects — and fewer jobs, Brubeck believes.

“This administration’s effort to freeze the majority of experienced contractors … out of competing is sure to create delays and needless infrastructure inflation.”

The act would prohibit PLAs on federal and federally assisted construction projects, he said.

“All Americans would be best served by inclusive, winwin policies that help provide a cost-effective return on federal investment in infrastructure.” CEG COSTS from page 1

Felling Trailers took the opportunity to celebrate its 50th anniversary and team member appreciation with the AEM Manufacturing Express, gathering employees to celebrate the company’s history and continued development.

“2024 is a milestone year for Felling Trailers. Fifty years ago, on November 1st, 1974, my parents, Merle and Kathy Felling, purchased a small welding shop on Pine St. in downtown Sauk Centre, Sauk Centre Welding. Fast forward a few years, and Merle’s trailer designs and quality craftsmanship quickly got noticed. Trailer orders increased, and risk and growth took place. In the mid-late 1980s, the business moved to its current location and became doing business as Felling Trailers Inc.,” said Brenda Jennissen, president/CEO and co-owner of Felling Trailers Inc.

“When we purchased the company from Merle and Kathy nearly a dozen years ago, we knew we had an enormous responsibility to follow in their footsteps, continuing to be good community stewards to our team members, customers, and the communities we call home. This tour serves as a uniquely valuable opportunity to reflect on the people who have made that happen and where we want to take things over the next half-century,” said Jennissen.

More than 200 of Felling’s team members gathered together by the company’s new powder coat facility to enjoy an afternoon filled with games, food and prizes, along with the opportunity to visit with fellow team

More than 200 of Felling’s team members gathered to enjoy an afternoon filled with games, food and prizes, along with the opportunity to visit with fellow team members, policymakers and AEM team members.