By Brenda Ruggiero CEG CORRESPONDENT

Fay, S&B USA Construction

(Fay) recently started construction on a $29.6 million contract to

demolish the Monongahela River Lock and Dam No. 3 (LD3) in Elizabeth, Pa.

The project is the latest in an ongoing series of efforts by the US Army Corps of Engineers (USACE) to improve the Monongahela River navigation system.

The USACE has been working on the three oldest currently operating facilities on the Monongahela River since 1992. They were first constructed to help coal barges and

other traffic navigate the river. The USACE has collaborated with various contractors, including Fay, to perform upgrades to the Braddock and Charleroi (soon to be renamed John P. Murtha) locks and dams.

see LOCK page 66

By Lucy Perry CEG CORRESPONDENT

Many construction contractors are overlooking a partner in their quest for jobsite safety: their insurers. Taking advantage of safety analysis programs provided by insurance carriers can result in immediate premium discounts for

However, insurers are not pushing their clients often enough to make simple changes to mitigate the

Outback Parts is linked nationwide with three used parts networks, so finding dependable parts fast and conveniently is never a problem.

Outback Parts also supplies replacement parts for Non-Cat® machines. So when you’re needing parts, call or visit us on-line.

Washington, D.C.-based contractor Lenkin Enterprises has selected two Potain MDT 809 tower cranes for important construction projects in Potomac, Md., and Washington, D.C.

In the months after the March 26 collapse of the Francis Scott Key Bridge in Baltimore, Md., state and federal officials maintained a website that posted regular updates of the response to the catastrophe.

The $3.5 million project will add 35 mi. of professionally designed mountain bike trails to the park’s existing trail system, enhancing its reputation in the region as a premier outdoor recreation destination for hikers and mountain bikers.

20

Since 1969, Unadilla MX has been the home of some of the best motorcross racing in the United States. Located in New Berlin, N.Y., the track is often called America’s original motorcross track.

24 UNIVERSITY

The University of Virginia (UVA) is currently building a ground-breaking energy plant at the Charlottesville campus designed to gather wasted heat and store it in subterranean wells until it is needed again.

A plan to replace the bridge that carries the Canadian National/Bessemer & Lake Erie Railroad over U.S. Highway 6N and widen the roadway in Erie County’s Springfield Township is being proposed by PennDOT.

30

As a full-service equipment rental business, Milton Rents exclusively offers Caterpillar products with competitive pricing and outstanding service, according to the company.

Founder Emeritus

32

Tooling choice is a key decision when planning an upcoming auger boring crossing. With a plethora of varying ground conditions, and multiple different styles of cutting heads, how does one make the right choice?

32

While more than 75,000 transportation improvement projects have been initiated and 43,000 construction jobs have been created by 2021’s IIJA, regulatory proposals threaten to hamper the law’s progress ARTBA Chair Tim Duit said.

FleetWatcher announced its participation in the Work Zone Data eXchange — a partnership with I-Cone that offers a breakthrough in work zone safety for the paving industry.

48

BOMAG Americas, a Fayat Company, announced the promotion of Christoph Thiesbrummel to vice president of sales & marketing for North American operations effective July 22, 2024.

Takeuchi is fully

• Western Pennsylvania

Cell 260/760-0521 e-mail nspain@cegltd.com

Teddy McKeon

• Delaware • Maryland 215/885-2900

Cell 215-260-8709 e-mail tmckeonjr@cegltd.com

BACKHOES:

2019 NEW HOLLAND B110SPC, 747 HRS, CAB HVAC, QUICK TACH FRONT BKT, EXTENDAHOE, FRONT HYDRAULICS........................................

$88,995

2021 NEW HOLLAND B95C TLB, 139 HRS, CAB, HVAC, 4 IN 1, EXT HOE.... $107,995

CHIPPERS:

2013 BANDIT 1390XP CHIPPER, 15” CAPACITY, 142 HP PERKINS DIESEL ENGINE, 2511 HRS, AUTOFEED, WINCH..........................................$29,995

2017 BANDIT 250XP 12” CHIPPER, CAT 120HP DIESEL ENGINE, 2305 HRS, AUTO FEED, WINCH..........................................................................$41,995

2021 BANDIT SG-75 STUMP GRINDER, 820 HRS, SELF PROPELLED, REMOTE, NEW CUTTER WHEEL........................................................$56,995

2005 MORBARK 950 TUB GRINDER, JD 6.8L DIESEL ENGINE, 205HP, 735 HRS, EXTRA TEETH, HAS ALL BOOKS & CO, NEW CONVEYOR & LIFT CYLINDERS, HAS EXTRA SHORT CONVEYOR BELT TO RUN W/O EXTENSION........................................................................................

$84,500 MORBARK 950 TUB GRINDER, 2000 HRS, CAT DIESEL ENGINE, 2 SETS OF SCREENS..................................................................................$97,500 OBO

2019 BANDIT 19XPC, 2169 HRS, 5.7 PSI GM V8 WINCH, AUTO FEED, HYD CHUTE, SINGLE AXLE........................................................................$49,995 TRAILERS:

2000 EAGER BEAVER 10HA, 20,000 LB CAPACITY, AIR BRAKES, GOOD WOOD & BRAKES................................................................................$6,000

EXCAVATORS:

SCREENERS:

2017 HITACHI ZX135-6, 3900 HRS, HYD THUMB, FRONT BLADE, COUPLER, PATTERN CHANGER............................................................

$109,000

2019 KOBELCO SK75SR, 2447 HRS, RUBBER TRACKS....................$72,000

2018 KOBELCO SK85LS, HYD THUMB, CAB, HVAC, 631 HRS..........$82,500 SKID STEER LOADERS:

2021 KUBOTA SVL97-2 TRACK SKID STEER, CAB, HVAC, 905 HRS, STD FLOW HYD, HYD COUPLER, 78” BKT, BACKUP CAMERA................$78,995

2018 VIBROSCREEN SCM40C BOX SCREENER W/CONVEYOR $124,995

2021 VIBROSCREEN SCM40 $79,995

2021 VIBROSCREEN SCM27 $62,995

NEW VIBROSCREEN SCM75C BOX SCREEN W/CONVEYOR, TIER 3 ENGINE $195,000

NEW VIBROSCREEN SCM115T TROMMEL, NO DPF, NO DEF........$179,995 2018 VIBROSCREEN SCM115T TROMMEL, 400 HOURS, NO DPF, NO DEF.. $143,500

TRACTORS:

$39,995

2017 NEW HOLLAND L228, 560 HRS, CAB HVAC, PILOT CONTROLS, HIGH FLOW, 2 SPEED RADIO....................................................................

2012 KUBOTA SVL90-2 TRACK SKID STEER, 1446 HRS, CAB HVAC, HIGH FLOW, LEXAN DOOR, COMES W/BKT, FORKS & AFE ROTARY FORESTRY

HEAD..................................................................................................

$78,995

2018 NEW HOLLAND L228, 2230 HRS, CAB HVAC, 2 SPEED, PILOT CONTROLS, HIGH FLOW, AIR RIDE SEAT................................................$29,995

2008 NEW HOLLAND LS190.B, CAB W/HEAT, FOOT CONTROL, APPROX 2200 HRS (METER SHOWS 395), PRE EMISSION MACHINE..........$29,995

WHEEL LOADERS:

2002 DAEWOO MEGA200V, 2YD 4IN1 BKT, 2283 HRS, HYD COUPLER........ $39,995

2000 NEW HOLLAND LW80, CAB W/HEAT, 10,000 HRS, COUPLER BKT AND FORKS, PERKINS DIESEL ENGINE, WAS NURSERY MACHINE $24,995

2014 NEW HOLLAND BOOMER 24, 4WD, MOD PTO, 60” MOWER DECK HYDRO TRANS, R4 TIRES..................................................................

ROKBAK MODEL RA30 OFF ROAD TRUCK: 30 TON CAPACITY WITH TAIL GATE, 276HP SCANIA ENGINE. AVAILABLE FOR SALE OR RENT! +N5027............................................CALL FOR PRICE

NEW ASV RS75 WHEEL SKID STEER: OPEN ROPS, SUSPENSION SEAT, 74" BUCKET, 21.3 GPM, ELECTRIC PLUG ON BOOM FOR ATTACHMENTS, MAX CAB, UNIT# N4200......................$59,900

ANACONDA DF410 SCALPING SCREEN: 2 DECK TRACKED SCREENING PLANT WITH LOW HOURS, UNIT# AG1346........................................................................................CALL FOR PRICE

ANACONDA TR75 TRACKED CONVEYOR: 42” X 75’ CONVEYOR, IT ALLOWS FOR STOCKPILING OR FEEDING OF A RANGE OF APPLICATIONS. THE TR75 HAS A VARIABLE SPEED CONVEYOR IN ORDER TO FACILITATE FOR DIFFERENT APPLICATIONS SUCH AS SAND, GRAVEL, AGGREGATES, COMPOST, COAL AND WOOD CHIP. WE STOCK A FULL RANGE OF SPARE PARTS AS A DISPLAY OF OUR COMMITMENT TO PROVIDE A DEDICATED AND RESPONSIVE SERVICE TO ALL OUR CUSTOMERS, 12 CONVEYORS IN STOCK! CALL FOR PRICE

ANACONDA FTR150 UNIT AG1353: MID SIZE FEED LOADER RANGE. FULLY EQUIPPED WITH 50' STOCKPILING CONVEYORALLOWS DFOR STOCKPILING OR FEEDINGA WIDE RANGE OF APPLICATIONS. INCLUDES OPTIONAL 2 DECK VIBRATING GRID..................................$187,000

AMMANN ARX36-2: 51.2" WIDE DRUMS, KUBOTA POWER, EXCELLENT VISIBILITY, EXCELLENT SERVICEABILITY, +N4931..................................................................................................$56,387

ASV MODEL RT50: ALL WEATHER CAB WITH HEAT AND AC, SUSPENSION SEAT, 15” RUBBER TRACKS, 60” BUCKET WITH BOLT ON EDGE, UNIVERSAL SKID STEER COUPLER, YANMAR TURBO DIESEL ENGINE, BLOCK HEATER, ATTACHMENT CONTROL KIT, REAR VIEW CAMERA, APPROXIMATELY 168 HRS, UNIT# 4310............................................................CALL FOR PRICE

SIMEX PLC-24 24" WIDE COLD PLANER WITH REVERSIBLE DISCHARGE CONVEYOR: CUTTS UP TO 7" DEEP, 16 DEGREE TILT, 27-40GPM DISSCHARGE CONVEYOR HELPS LEAVE A CLEANER CUT, WINDROWS MATERIAL BEYOND THE CARRIER FOR EASIER CLEAN UP, UNIT# AT4540......

$25,400

2018 KOBELCO 230SRLC-5: SHORT RADIUS 56,400LB W/31.5" TRACK SHOES, TWO WAY AUXILIARY HYDRAULICS, HYDRAULIC COUPLER EXCELENT CONDITION APPROXIMATELY 1780 HOURS +N3592................................................................................................................

$132,900

2017 OKADA OSC200A CONCRETE PULVERIZER: VERY GOOD CONDITION, LOW HOURS FITS KOBELCO 200 CLASS EXCAVATORS, OR MACHINES WITH 80MM PINS, UNIT# AT3464.... $31,000

AG1359, ANACONDA J12 JAW CRUSHER: IS AN AGGRESSIVE & POWERFUL MOBILE JAW CRUSHER. WITH THE PROVEN ABILITY OF THE UNIVERSAL CRUSHERS JAW CHAMBER 28" X 44" WITHIN AN INNOVATIVE ANACONDA TRACKED SOLUTION......................................$596,976

MODEL ST1000 COLD PLANER/SOIL MIXER: 40” MILLING WIDTH, 9” MILLING & MIXING DEPTH. REQUIRES HIGH FLOW MINIMUM 33GPM. THREE LINE SYSTEM W/REMOTE. HYD. SIDE SHIFT & TILT, STABILIZATION FLUID/BINDING INJECTION PORTS. EXTREME DUTY. 4000LB OPERATING WEIGHT. UNIT # AT4787........ $39,900 MCLANAHAN 44” X 33’ FINE MATERIALS WASHER: IN STOCK & READY FOR IMMEDIATE DELIVERY, UNIT# AG1402....................................................................$94,500

BOMAG BW120SL-5: FOLDING ROPS, 47.2” WIDE DRUMS, 5511LBS. OPERATING WEIGHT, KUBOTA 24.8HP DIESEL, FRONT & REAR VIBRATORY, 4320 VPM, .020 IN AMPLITUDE, UNIT# N4538..$49,962

BOMAG BW120AD-5: FOLDING ROPS, 47.2” WIDE DRUMS, 6063LBS. OPERATING WEIGHT, KUBOTA 33HP DIESEL, FRONT & REAR VIBRATORY, 3780 VPM, .020 IN AMPLITUDE, UNIT# N4537....................................$56,000

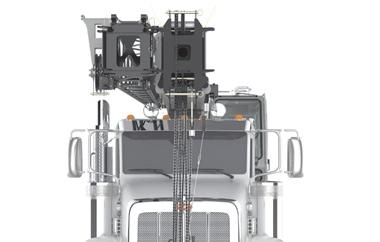

Washington, D.C.-based contractor Lenkin Enterprises has selected two Potain MDT 809 tower cranes for important construction projects in Potomac, Md., and Washington, D.C.

The Potain cranes are essential for two challenging developments: the renovation of a private modern art museum, and the repurposing of an office building at Georgetown University.

Lenkin Enterprises is headed by structural engineer Michael Lenkin, whose career in construction spans nearly 40 years. Faced with the challenges of meeting specific lifting requirements for the two projects, Lenkin worked with Manitowoc Lift Solutions to develop customized solutions.

For the museum project, a crane with a long jib and extended reach was required to minimize disturbance to the museum’s landscape, which is in a meadow with native plants and wild grass. To reduce environmental impact, the project called for the use of a single tower crane instead of two. This meant using one crane to reach most of the building’s perimeter to make the work feasible.

“The Potain team and the Manitowoc Lift Solutions division worked hand in hand with me to find the right solution so we could adapt the MDT 809 to meet my needs,” Lenkin said. “I was able to get an 85-m jib for the crane with the capacity my client wanted on a static base, despite having to shoehorn this crane into an alcove at the museum. There were a lot of different challenges, but the work of the team at Manitowoc both in France and the U.S. made it possible.”

The MDT 809 at the museum project is notable for being the first in North America to use the ZY854 cross-shaped base, which supports high working heights without adversely impacting set-up or operation costs. It’s also the first MDT 809 crane with a 279 ft. jib and the first to support both the 2-part/4-part trolley (SM/DM) and full-time 2-part trolley (SM Pur). The cross base is supported on pile caps and micropiles to transfer the loads below the museum. The crane and foundations were coordinated carefully with existing buried utilities.

“This crane and its long reach are crucial for the renovation of the museum,” Lenkin added.

At Georgetown University, the Potain MDT 809 is the central figure in repurposing a 40-plus-year-old office building. The crane’s strong capacity is crucial in removing and resetting granite-clad precast panels, with estimated weights of approximately 24,000 lbs. The MDT 809 also is setting structural steel and performing demolition tasks.

The project involves significant structural work, and the MDT 809 at the site has a 197 ft. hook reach with an SM/DM trolley, and 12.8 ton tip capacity as required by the project.

The crane is supported on a ZY854 ballasted cross base on top of the existing building structure. The base cross is supported by existing and temporary structural steel columns down to the building’s foundation system.

Lenkin expressed satisfaction with Potain’s performance and support throughout both projects.

“The collaboration with the Potain team has been seamless,” he said. “From local and international engineering support to rapid response times, Potain has consistently

No-Foot Neck, 25' deck, adjustable width bi-fold front ramps, deep well pocket in deck with inserts & planks on grade, 275's on aluminum outers, extra lights, Strobes in rear, mini strobes on sides, Air Lift 3rd, hangers & supply for optional 4th axle, Black paint.

Rogers 55 Ton, No-Foot, 25' deck, deep well pocket, depressed cross members, adjustable width bi-fold ramps. reinforced wheel covers, reinforced front slope & side rails. Safety Lighting Package, Strobes, 275's on Alum. outers, Air Lift 3rd. All Wheel ABS. Rogers Red and Black........ IN STOCK

Rogers TAG21XL, 22’ + 6’ Tail & TAG21XXL, 24’ + 6’ tail, 235's on Aluminum, Air Ramps, Safety Lighting Pkg. with Strobes. Black or Red Paint........IN STOCK!

New Rogers 55 ton, CobraNeck, 2-position pin, Ratchet Ride Height, 26' deck, 18" ride height, deep well pocket, 275's on aluminum outers, air lift 3rd,& 4th. Night Light Pkg., Strobes, 3 or 4 Axles IN STOCK!

New Rogers 50 Ton, Gentle Riser, No-Foot Neck, 24' deck, adjustable width bi-fold front ramps, 275's on aluminum outers, air lift 3rd, Night Lights, Strobes, In Production for Custom Colors. Rogers Red................ IN STOCK!

Rogers 55 Ton CobraNeck, Severe Service Design. 2-position pin, ratchet ride height, adjustable width bi-fold steel ramps, 26' clear deck, deep well pocket, chain bins, tool boxes, 275's, alum. outers, side reinforcing, extra lights, strobes, night light pkg. 3-axles air lift 3rd, 4-axles air lift 3rd & 4th, Black....................IN STOCK!

Rogers 40 ton Tandem, No-Foot Neck, 24' deck, adjustable width ramps, bucket pocket, 275's, aluminum outers, night lights, work lights, strobes. Rogers Black............ IN STOCK!

Rogers 35 Ton Gentle Riser, 24' deck, adjustable width bi-fold ramps, 275's on Aluminum, Extra lights and strobes, Rogers Green......IN STOCK!

Rogers TAG25XXL, 25 Ton Capacity, Premium Specs, Superior Quality, 235’s Aluminum, 7-Year Warranty, Black or Red Paint, 24’ deck + 6’ tail, 8’ Air Ramps.................. IN STOCK!

In the months after the March 26 collapse of the Francis Scott Key Bridge in Baltimore, Md., state and federal officials maintained a website that posted regular updates of the response to the catastrophe.

Now, Maryland officials are directing the public to a new site: Key Bridge Rebuild.

“It’s a great website for everybody. We talk and we have information there for communities. We have information for industry. If you want us to come out and talk to your group, pop-up, flea market — you name it, we’ll come,” said Melissa Williams, director of planning and program development at the Maryland Transportation Authority (MTA), which administers toll facilities.

That shift reflects the larger movement away from the removal and reclamation operations that consumed the weeks and months after the collapse, and toward the fasttracked rebuilding of the bridge. Officials in both Annapolis and Washington said that is proceeding at a steady pace.

The process took a big step forward in late July when the Federal Highway Administration (FHWA) agreed to grant a categorical exclusion to environmental and other regulatory reviews, since the new bridge will follow the same footprint as the old one, with no new areas likely to be disturbed by construction.

“We saw a major development recently, where the Biden administration essentially greenlighted going forward without a complete environmental review. That’s because the bridge will be essentially rebuilt along its current alignment,” Maryland Democratic Sen. Chris Van Hollen explained to Maryland Matters.

He and the MDTA have each said the exclusion has cut considerable time from the project’s timeline.

Still, Williams emphasized that there were no shortcuts taken in the process of evaluating the environmental impact of rebuilding the bridge.

“Nothing was skipped. Everything was done. All of the environmental resources were fully analyzed,” she said of the 143-page categorical exclusion. “But based on the fact that we’re not going outside of [the] MDTA right of way, we’re building in the same spot, we’re building the same number of lanes, just bringing things up to state standards. The impacts were very minor.”

Her comments were echoed by MDTA Executive Director Bruce Gartner, who said the exclusion just makes sense.

“When you evaluate different alternatives, different locations, different types, it’s a long-involved process,” he noted. “This was simply evaluating a replacement bridge.”

It may be seen as a replacement bridge, but there will be some differences, Maryland Matters reported. According to the MDTA’s document, the new bridge will still be a toll facility that will follow the same path and still carry two lanes of traffic in each direction, although the shoulders will be wider.

For instance, the proposed structure itself will be much higher — 230 ft. above the river at its highest point, compared to 185 ft. before the collapse — and the piers supporting the center span will be 1,400 ft. apart instead of 1,200, both to allow for the possibility of even larger cargo ships in

the future.

Additionally, the bridge will stretch 2.4 mi. over the Patapsco River, compared to 1.7 mi. before, to allow for the slope to the higher center point, and the bridge’s towers will go from 358 ft. high to as much as 550 ft. above the water in the new version.

Final design has not been chosen, according to Maryland Matters, but in order for the bridge to accommodate the higher and longer center span, the state expects the new bridge will likely be a cable-stayed design as opposed the truss style of the old span.

The next milestone on the project will come this month when the bids are due on the first of three procurement requests the state is pursuing on the project.

Gartner said the first procurement for the replacement bridge will be a design-build contract.

The second procurement is for the general engineering consultant contract to oversee the design-build team, and the third is the construction management inspection contract to handle the cost estimation and construction inspection of the bridge.

Gartner told Maryland Matters that it is difficult to give exact timelines, but that the design-build contract would be awarded in the fall, with proposals due Aug. 19. He also mentioned that the general engineering consultant contract and the construction management inspection contract would be awarded between the fall and winter of 2025.

“Progressive design-builds give us the flexibility to work with that team. An early package, for instance, might be this fall: a demo of the existing piers,” he explained. “So that would probably be the earliest work that people would see.”

The next step could be the fight for federal funding.

Van Hollen and Sen. Ben Cardin, Maryland’s other Democrat in the U.S. Senate, have jointly introduced a bill that calls on the federal government to fully fund the bridge’s replacement. A companion bill was introduced in the U.S. House by Rep. Kweisi Mfume, D-7th District, but neither bill has moved out of committee yet.

Van Hollen said that could change in September, when Congress will have to pass the federal budget or approve a continuing resolution to keep the government functioning at current levels. The Key Bridge’s funding could be rolled into that resolution, he added, as an emergency disaster supplement.

The original Francis Scott Key bridge opened on March 23, 1977, and was destroyed in spectacular fashion almost exactly 47 years later when the container ship Dali lost power as it was leaving the Port of Baltimore and slammed into one of the bridge’s central piers. The center span fell in a matter of seconds, pinning the Dali and killing six of the eight construction workers who were on the bridge doing road work at the time.

The collapse severed a main truck route around Baltimore and stopped all ship traffic in and out of the port. State, federal and private crews scrambled for weeks to free the Dali, remove the debris and clear the river, before officials finally fully reopened the shipping channel in and out of the port on June 11.

West Virginia State Parks officials announced that construction on a major bike trail expansion at Cacapon Resort State Park has begun.

The $3.5 million project will add 35 mi. of professionally designed mountain bike trails to the park’s existing trail system, enhancing its reputation in the region as a premier outdoor recreation destination for hikers and mountain bikers.

“This is an incredible day for Cacapon Resort and West Virginia as we continue to invest in our world-class parks system,” said Brett McMillion, director of the West Virginia Division of Natural Resources. “We are excited to get started on this ambitious project and look forward to all of the ways it will improve the experience at Cacapon Resort and attract new people to come and visit our beautiful state.”

The goal of the project is to diversify the trail system at Cacapon Resort by adding professionally designed mountain biking trails that utilize the park’s mountain landscape and appeal to riders of all ability levels. Other aspects of the project include introducing bike amenities to park visitors and community members, creating youth-focused bike amenities and constructing a signature trail to attract riders throughout the state and region.

The project will progress in two phases and is estimated to be completed in 2026. The first phase of construction, led by Greenstone Trailcraft, is now under way. The second phase will start in the spring of 2025, and the project is expected to be completed in 2026.

The trail expansion project at Cacapon Resort is part of an ongoing investment in the West Virginia State Parks system. Over the last seven years, more than $250 million in improvement projects have been completed.

For more information, visit WVstateparks.com.

Since 1969, Unadilla MX has been the home of some of the best motorcross racing in the United States.

Located in New Berlin, N.Y., the track is often called America’s original motorcross track. On Aug. 10, 2024, Anderson Equipment was a key sponsor for the track’s Unadilla Pro National MX event. Anderson

Equipment took advantage of this opportunity to hold a Mecalac demo event at the track that allowed potential customers to get some Mecalac seat time.

According to Eric Montalvo of Anderson Equipment, the Unadilla MX event was an ideal opportunity to introduce potential buyers to the Mecalac product and to enjoy motorcross racing’s biggest event of the year.

“Greg Robinson, the president and co-

owner of the track, along with his sister Jill, recently purchased a Mecalac machine from Anderson Equipment and has been very excited about the product,” said Montalvo.

“He came to Anderson Equipment to give us the opportunity to hold live demonstrations along with sponsorship. We looked at the demographics of the typical Unadilla attendee to find that there was about a 40 percent match for entrepreneurs in various business categories that would be potential

Mecalac customers. We invited close to a hundred contractors, landscapers, loggers and other business owners to get some oneon-one time with the equipment and factory representatives from Mecalac.” CEG (All photographs in this article are Copyright 2024 Construction Equipment Guide. All Rights Reserved.)

effectively replace two machines from his fleet. After getting some seat time, he left the event fully convinced.

4,545 hours, 10k lb lift, 42 ft lift height, 4x4, orops, 5 ft forks, tilt body, 4 cyl Cummins turbo, stk#FL324....................................................$44,500

2)2015 Hitachi ZX35U-5N, 2,059 hours, 18" bucket, hyd thumb, manual coupler, cab w/ a/c, 2 speed, 68" blade, swing boom, 3 cyl Yanmar, 7.6k lbs, stk#MX055..$39,500

2017 Doosan DX140LCR-5, 4,288 hours, 32" bucket, hydraulic thumb, a/c, 4 cyl Perkins turbo, 2 speed, backup camera, 33k lbs, stk#XC730....................................$77,500

2014 Caterpillar CB22B, 1,352 hours, 40" smooth double drum, vibratory, orops, 3 cyl Cat C1.5 turbo, 6k lbs, stk#CO137..............................................................$24,500

2017 Vermeer RTX250, 738 hours, walk-behind trencher, 4 ft blade, 6" trencher width, crumber, 2 cyl Kohler gas, good rubber tracks, stk#TH977..........................................$7,500

2011 JLG 800S, 4,326 hours, 80 ft boom lift, 4x4, 8 ft basket, 3-phase skypower, 4 cyl Deutz dsl, stk#AE321..........$29,950

Hamm 3412P, 2012, 84” vibratory padfoot compactor, EROPS w/ heat & A/C, 1,200HMR .

$82,500

Cat 815F, 2006, EROPS cab, 12’4” S-Blade w/ tilt, new paint job, very good condition, 9,400 HMR . .$195,000

Hamm GRW-5 Pneumatic Roller, 1994, Deutz Diesel, ROPS Canopy, (9) Ea. 7.50-15C1 Tires

$15,500

(4) Cat 825C’s, 1981-1990, EROPS, S-blade w/tilt, all work ready

From $79,500

Rammax Walk Behind Rollers, over 25 in stock, lever & remote

$4,000 to $10,000 (8) Sheepsfoot, 48" and 60", double drum & single drum, tow type

$4,000 - $6,500

Volvo A40, 1998, 40 tons, 10991 hrs, 395 hp, 8WD, 29.5R25, A/C, 29 cy cap. sideboards, tailgate (currently off work), work ready

$127,500

Volvo A40, 1996, 40 tons, 395 hp, 6WD, A/C, 29.5R25, working everyday

$145,000

Volvo A40, 1996, 40 tons, 11,000 hrs, 6WD, 20.5R25, A/C, P/S trans, 29 cy cap., 6/06 hitch rebuilt .$115,000

Volvo A40, 1995, 40 tons, 395 hp, 8WD, 29.5R25, A/C, P/S trans, tailgate, work ready

$115,000

Volvo A35C, 1998, 35 tons, 6WD, 26.5R25 tires, approx 7,000 hrs, good condition

$147,500

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5x25, A/C, P/S trans, working everyday on jobsites

$87,500

Broderson IC80-2E, 1997, 8.5 ton, 24’ boom, dual fuel, 10.00R15 tires, 3,400 hrs .

$21,500

Grove RT58C, 1981, down cab, 18 ton r.t., 70' boom anti-two block, GM dsl, clean

185’s, JD diesels

CALL

(12) Allmand Light Plants, 2008-2010, diesel, s/a towtype, (4) MH lights, excellent

Cat 336EL, 2012, 33.5” TBG pads, Q/C, aux hyd, 6,700 HMR, work ready

$162,500

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5R25, A/C, P/S trans, 26 cy, working everyday on jobsites

$89,000

$224,500

Cat 336FL, 2015, 33.5” TBG Pads, Q/C, aux hyd, 4,300 HMR, work ready

Komatsu PC220LC-8 Longreach, 2011, Young Boom/Stick 60’ reach, 3,500 HMR

Volvo A30C, 1996, 30 tons, 11,000 hrs, 296 hp, 6WD, 23.5R25, 21 cy cap, A/C, P/S trans, works everyday

$179,000

$122,500

$72,500

Kobelco SK210LC, 2007, Q/C, aux hyd, 31.5” TBG Pads, 3,900 HMR

Cat D5NXL, 2006, 10’ PAT Blade, Paccar PA55 winch, 22” Pads, 4,100 HMR

$82,000

$49,500

Cat 613C Water Wagon, 1994, 5000 gal drop tank, ROPS, spray heads

Cat 621F, 1996, Scraper, OROPS, 33.25x2, very good condition

Cat 621E, 1989, Scraper, OROPS, 33.25x29, very nice CALL

Cat D6NLGP, 2008, VPAT Blade, Drawbar, 33” Pads, 9,900 HMR

$87,500

Cat D6NLGP, 2014, Foldable VPAT Blade, Paccar PA55 winch, 7,200 HMR

$142,500

100 Excavator, Loader, Specialized & Grapple Buckets in Stock -Call For Your Needs FORKS (8) IT28F/G Forks, Balderson qc, 48"-60" pallet style, excellent

$229,500

Komatsu D155AX-6, 2007, Sigma S-U Blade, 4-bbl Single Shank Ripper, 8,400 HMR

Cat D6TXW, 2013, 13’6” VPAT Blade, Carco 70APS winch, 28” pads, 7,300 HMR

The University of Virginia (UVA) is currently building a ground-breaking energy plant at the Charlottesville campus designed to gather wasted heat and store it in subterranean wells until it is needed again.

Some news sources have placed the cost of the project at around $70 million, although the university has not confirmed that figure.

UVA Today, an online news site produced by the school’s communications office, reported Aug. 7 that the plant under construction in the Fontaine Research Park will supply thermal energy to the new Paul and Diane Manning Institute of Biotechnology.

Because 90 percent of UVA’s fossil fuel consumption is used for heat, employing new and efficient technologies will help the venerable university reach its goal of being carbon neutral by 2030 and fossil fuel-free by 2050, the campus news outlet noted.

system that captures heated water, stores it underground and retrieves it when it’s needed.

The Fontaine plant will not burn fossil fuels to create heat, said Paul Zmick, UVA’s director of energy and utilities. Rather, it will employ a geo-exchange system that, in simple terms, captures heated water, stores it underground, and retrieves it when needed to provide heating or cooling to a campus building. Initially, the plant will utilize about 100 underground storage wells. The geo-exchange system acts as a very large thermal battery.

The plant is part of a multi-pronged goal to curb the university’s energy use. That effort includes dialing down the temperature of hot water from 200 degrees to 165 or lower and boosting the energy efficiency of new buildings and additions.

The geo-exchange system is highly efficient because it takes heat that would otherwise be vented or wasted and recycles it, according to UVA Today.

“It’s a passive system — a thermal transfer between one substance to another, rather than being generated with carbon or a different energy source,” explained Ashley Morris, a UVA graduate and project engineer with DPR Construction, a worldwide general contractor with offices in Richmond and Reston, on the heat plant project. “As that water is being passed through the loops in the circuits, that thermal transfer is happening. And that is what is providing heat and thermal energy, or lack of it, to the plant. There will still be power needed to operate that equipment, but the source of heating and cooling itself is fossil-fuel-free.”

Morris, a Loudoun County, Va., native, is a 2019 mechanical engineering graduate. A DPR employee since leaving UVA, Morris does a variety of jobs on the site, including quality control, site logistics and schedule management.

Working with Morris at the heat plant site over the summer was Mary Cotter, a rising third-year mechanical engineering student at UVA. Cotter served as a summer intern with the university’s energy and utilities department in the Division of Facilities Management.

She told UVA Today that the internship has altered her view of the school.

“As a student, I did not realize how much goes into the

functioning of this university,” Cotter said. “Just heating and cooling the university is such an undertaking and that has been really interesting for me to learn about. When I’m going to class and walking around [UVA’s] Grounds, I’m going to have much more of an appreciation for every piece of our energy systems.

Working at the heat plant site also has given Cotter practical experience.

“It’s a great learning opportunity,” she elaborated. “What I learn in the classroom — such as physics — is really important and plays into this. But being able to intern during my summer gives me an idea of what being an engineer is actually like. To be able to do it at my own university, where we’re doing pretty cool stuff, is extra special.”

Morris acknowledged she went into the construction field for similar reasons.

“I quickly realized I didn’t want to necessarily sit behind a desk or be a traditional engineer,” she said. “I wanted to physically see the fruits of my labor every day and get my hands dirty a little bit. That’s what the construction industry was for me.

“I also became fascinated with building techniques and watching the folks who have done this for years and who are skilled and what they have learned about their own trade. They’re the subject matter experts.”

Morris, who stayed in Charlottesville after graduation, was able to apply the teamwork she learned as a goalie on UVA’s women’s lacrosse team to her job. A project like the UVA energy plant demands teamwork from a lot of different individuals, she added.

“No one could ever do this or any other construction project by themselves,” Morris said, noting that it requires her general contracting team, made up of the project manager, regional safety and quality personnel, experienced subcontractors and a talented group of designers, to “make things happen.”

Both Morris and Cotter are impressed with how far forward UVA officials are planning in their development of the campus.

“This plant was designed with 30-plus years down the line in mind. The level of planning and forethought that goes into these projects is monumental,” Cotter explained. “With an abundance of forward-thinking technologies being utilized, I am excited for the future of UVA.”

A plan to replace the bridge that carries the Canadian National/Bessemer & Lake Erie Railroad over U.S. Highway 6N and widen the roadway in Erie County’s Springfield Township is being proposed by the Pennsylvania Department of Transportation (PennDOT).

The purpose of the effort is to improve the road near and under the bridge as well as increase the vertical and horizontal clearances for traffic beneath the structure, located in the far northwestern portion of the state.

Currently, the U.S. 6N lanes approaching and passing underneath the span vary from 9-ft.-5-in. to 15 ft., in width while the shoulders vary from zero to 8 ft., PennDOT noted. The planned upgrades will expand the roadway by building 12-ft. lanes and 8-ft. shoulders throughout the corridor.

These improvements will allow for the use of this portion of U.S. 6N as a detour route for Interstate 90 as needed, the agency said in an Aug. 9 news release.

The railroad bridge is located above U.S. 6N between the intersection with Old Albion Road and the intersection with Sanford Road, just south of I-90, near the Ohio state border.

PennDOT noted that the work will not only include replacing the existing railroad span with a single-span steel multi-girder bridge, but also widen the two-lane highway on both sides of the structure, perform pipe and channel realignment, pave approximately 600 ft. of the highway, and update guiderail and pavement markings.

Construction is expected to occur during the 2027 season. A detour will be required during construction and is expected to be in place at various times for approximately nine months. The proposed 21-mi. detour route will be posted using U.S. 6N, Pennsylvania Highway 18 and Interstate 90.

A temporary rail line, known as a shoofly, will be used to provide a runaround for the railroad while the proposed permanent rail structure is constructed.

The existing single-span concrete encased rolled steel Ibeam railroad bridge was built in 1930 and is presently classified by PennDOT as being in poor condition. Approximately six trains a day (three during the day and three at night) use the structure.

Additionally, the state agency said that, on average, approximately 2,300 vehicles a day use the roadway under the bridge, of which 5 percent are trucks. The current vertical clearance for traffic under the bridge is 14 ft.-7 in.

PennDOT invites the public to view more details about the U.S. 6N Railroad Bridge proposal via the department’s online project page, which includes a handout, self-guided presentation, digital plans, and an online comment form. It can be accessed by visiting the PennDOT District 1 website, www.penndot.pa.gov/District1 under the Design and Construction Projects link.

The purpose of the plans display is to introduce the project and receive public input regarding any questions or concerns. It is also an opportunity for the public to review and comment on the construction’s potential effect upon Cultural Resources pursuant to the Advisory Council on Historic Preservation’s 36 CFR Part 800 regulations implementing Section 106 of the National Historic Preservation Act.

Milton Rents recently opened a new 26,700-sq.-ft. facility on 8 acres at 336 Ainsley Drive in Syracuse, N.Y.

As a full-service equipment rental business, Milton Rents exclusively offers Caterpillar products with competitive pricing and outstanding service, according to the company. In addition to Caterpillar earthmoving equipment, Milton Rents also offers a wide assortment of aerial equipment, an extensive selection of tools and power equipment and a diverse selection of building materials and construction options, which allow customers to handle their earthmoving, tooling and materials needs all under one roof.

“Our objective is to offer customers a unique rental experience,” said Tim Chatfield, sales manager of Milton Rents New York. “Milton Cat and Milton Rents are working together to

provide ease and peace of mind for our customers by minimizing the number of pieces involved in completing a job. Each company’s teams are working together with one goal in mind: serving our customers and their needs first every single time. At all of our Milton Rents facilities we pride ourselves on offering new or nearly new, low-hour machines that our customers can absolutely rely on.”

Over the past few years, Milton Rents has been

aggressively expanding with locations across New York State and New England. For more information about these locations, visit www.miltonrents.com. CEG

(All photographs in this article are Copyright 2024 Construction Equipment Guide, except where noted. All Rights Reserved.)

New scissor lifts from respected manufacturers, including Skyjack and JLG, are available for short-term and long-term rentals.

or

Tooling choice is a key decision when planning an upcoming auger boring crossing. With a plethora of varying ground conditions, and multiple different styles of cutting heads, how does one make the right choice? Barbco breaks it down.

“Dirt” can be broken down into many different things. As true as it is, we generally describe dirt as “ground most commonly dug with a backhoe tooth bucket”.

When encountering dirt, you must make one of two distinctions — is the ground stable or unstable? Stable dirt, like “dense clay”, is generally dealt with by using a backhoe style tooth, cutting head. This style head will cut, and pull the “cuttings” back into the auger the fastest. This slight pull effect significantly helps reduce head bawling, in which the ground material is sticky enough to retain itself onto the face of the cutting head. Head bawling increases down hole torque, and can significantly reduce overall production.

Unstable dirt can mean that there is high sand content present in the ground formation, which resists the ground from being fully bonded. When encountering unstable formations, it is important to evaluate the ground water content in the bore path. If there is no ground water, a good choice of head is a 3 or 4-bank dirt head. With the standard head having two banks, an additional bank or two, creates extra surface area on the cutting face of the head, and decreases the size of the entry points for the cuttings.

If low groundwater or controlled groundwater (dewatering in place) is encountered while in unstable ground, a sand head is the most limiting cutting head for auger boring. A sand head has the smallest entry point to cutting surface area ratio, of all cutting heads available.

Glacial till can be a very challenging ground condition to encounter. Glacial till is generally described as dirt, sand, cobble and boulder, combined in varying amounts. The vast possibilities and inconsistencies of this ground condition is what makes glacial till such a challenge.

Considering all the different mixtures of this ground, using a versatile cutting head is the answer.

An appropriate choice of cutting head in this ground condition is a 3-bank DT87, or as Barbco calls them, Sharkteeth, style cutting head. The reason this style of head is a good choice is due to its adaptability. A shark-tooth head can handle consistent dirt, sand or other displaceable ground just fine, all while being able to cut rock. Additionally the sharktooth head provides a stronger “tooth support”, which allows these heads to handle sudden impact, like intermittent cobbles, better than any of its standard counterparts.

Although these heads are very versatile, this comfortability should never supersede the decision to stop, pull augers and address an ever evolving down hole environment, when casing size and permits allow. This decision can be the difference between a successful or unsuccessful trenchless crossing.

Rock is a ground condition that strikes many people as being difficult or something to shy away from. Fortunately,

by asking ourselves some simple questions, we can deal with rock easier than you think.

Some main rock attributes to asses are density (psi) and RQD (Rock Quality Designation).

The best way to analyze rock is to collect a sample and send it to a geological bioengineer. But if time is pressing, the big question is, can you dig it? If a backhoe bucket can scratch, fracture and dig the formation, then most standard rock heads will perform sufficiently in this type of softer formation.

If the rock formation can not be scratched or fractured by a bucket, can a hammer attachment handle the formation or is blasting required? In the case of a hammer attachment being able to fracture the rock formation sufficiently, and the rock is solid and consistent throughout the bore path, there are two options in the more serious class of rock: retractable roller-cone heads and disc-cutter heads.

Disc-cutter heads have been a staple in the industry when it comes to some of the hardest rock bores accomplished over time. While roller-cone heads have not been known to handle the hardest of rock as effectively as a disc-cutters, the roller-cone head is able to be retracted out of the casing, unlike a disc-cutter head which is welded to the front or lead casing. This major design difference plays a big role in the decision making process, especially in an industry where resourcefulness is key.

Non-consistent rock can be encountered due to depth of bore, where the bore path is not fully engaged into the solid rock formation. Barbco calls this type of rock formation a “split-face”, or mixed ground condition.

Another non-consistent rock formation is created by weathering. “Weathered rock” is generally softer than its original state, and can be dealt with by utilizing a variety of standard rock heads. However, generally a roller-cone head will be most productive in this ground condition.

If the split-face ground condition is encountered, it’s typically the most challenging of all ground conditions. When the cutting face is split with rock and dirt, the chances of torque up’s from sudden head impact is heightened. In this type of ground condition, an ample choice of cutting head is the roller-cone head.

Being the most versatile head, the roller-cones can handle rock, cobble, boulder and dirt split-faces. Additionally, the roller-cone heads are based on bearing supported cones. The bearings allow this head to roll through the sudden impacts that a standard head could hang up on.

Most important to note, the ability to stop, pull augers and address the down hole conditions, are not forfeited with a retractable roller-cone head, Barbco said.

Trenchless crossings are an ever evolving environment where sometimes there is no perfect tool for the job. Ground formations can vary so aggressively that it is impossible to have one specific cutting head for any ground condition. Due to this reality, the best way to approach these choices is to narrow down which cutting head provides you with the most versatility in your specific ground condition, and always be prepared to pull auger, before you put yourself and your equipment into an unexpected situation.

For more information, visit barbco.com.

While more than 75,000 transportation improvement projects have been initiated, including one in nearly every congressional district, and 43,000 construction jobs have been created by 2021’s Infrastructure Investment and Jobs Act (IIJA), regulatory proposals threaten to hamper the law’s progress, American Road & Transportation Builders Association (ARTBA) Chair Tim Duit told a congressional panel July 24.

In testimony before the U.S. House Highways & Transit Subcommittee, Duit, president of Edmond, Okla., based Duit

“Historic levels of infrastructure investment ... can result in timely completion of transportation projects that move people and products safely and efficiently.”

Tim Duit American Road & Transportation Builders Association

Construction, said regulatory proposals that are clear and well-defined can achieve their intended purpose. He cited a recent Federal Highway Administration (FHWA) proposal that placed greater emphasis on positive separation between roadway workers on construction sites and motorists. He said such a measure would improve safety for everyone.

“In other instances, however, while the road to regulation is paved with good intentions, the outcomes can cause uncertainty and a lack of clarity for the companies working on transportation projects,” Duit said, referring to a variety of proposals being implemented by federal agencies.

He outlined several major policies making it harder to initiate transportation system improvements:

• The Environmental Protection Agency (EPA)’s noncompliance with the U.S. Supreme Court’s 2023 decision on EPA’s “Waters of the United States” rule, which treats roadside ditches as protected waterways. Despite the Court’s definitive clarification, federal agencies have not fully compiled, resulting in continued confusion.

• Inconsistent implementation of the IIJA’s “Buy America” provisions, especially FHWA’s proposed rollback of its waiver for manufactured products.

• FHWA’s attempt to impose greenhouse gas performance measures on state transportation departments — a provision that members of Congress debated in a bipartisan manner and deliberately left out of the IIJA.

• A Fish and Wildlife Service proposal against accidental harming of migratory birds, which could cause work stoppages on transportation construction sites.

Duit closed by saying, “Historic levels of infrastructure investment, when accompanied by the harmonious regulatory environment intended by Congress, can result in timely completion of transportation projects that move people and products safely and efficiently.”

For more information, visit www.artba.org.

Superior Industries is reaching new heights — and that’s not just the company’s TeleStacker conveyor, which already stretches 210 ft. into the sky. As the AEM Manufacturing Express visited Superior Industries July 17, in Morris, Minn., the TeleStacker provided a sliver of shade as more than 200 hardworking men and women of the Superior team gathered to celebrate their role in building America. It was a great opportunity to reflect on the significance of companies like Superior to Morris and towns like it across Minnesota. There was also fun, prizes and double-stacked burgers

(even the burgers are Superior).

Superior leaders attribute the company’s success to a strong culture, and those who build careers with the company can tell.

“When I first got hired, I thought it might have been a two-to-three-year job. But on my first day I fell in love with the culture of the business, and that was 20 and a half years ago,” said Brad Olhoft, weld team lead and 20year Superior employee.

Superior has more than 1,800 employees across 22 locations but has never lost its small-town feel. Founded in 1972 to build portable crushing,

washing and conveying equipment for gravel pits locally in Minnesota, Superior has grown into an international powerhouse of the mining industry.

Even as the equipment now works all around the world, Superior stays true to its identity as a company proudly made in Morris, Minn., a town built largely around agribusiness. Superior’s robust mining equipment product lines provide stability to the local economy even during agricultural downturns.

“If it can’t be grown it must be mined,” said Jason Adams, president of Superior.

Superior is always looking to break new ground. Since the company’s inception, innovation has been central to Superior’s manufacturing prowess. The company recently completed a multi-year partnership with a leading Dutch firm to create an impressive line of autonomous roll welders.

The Superior team in Morris is big, but just like the equipment, each component plays an indispensable role in making the best possible product. Superior’s ESOP, strong investments in training and resources for its employees and material processing equipment are all ways in which Superior Industries lives up to its name.

“Show up, have a good attitude, be courteous and friendly, and you’ll do well,” said Olhoft.

That’s a Superior way of looking at it.

Confusion over swivel hooks is creating safety risks and increasing costs for lifting companies, according to industry veterans.

All Material Handling (AMH) said that the industry using the same name for two types of hooks can lead to the wrong hook being used in a range of applications. There are two types of swivel hooks and mixing them up can have serious consequences.

“There are key differences between a standard swivel hook with a bronze bushing and a ball bearing-style swivel hook, but not everyone understands those differences,” said Lukasz Biela, regional sales manager at AMH.

According to AMH, a bronze bushing hook should really be called a positioning hook because it can swivel into position when attached to the pick point. While this is useful, this type of hook can’t swivel while lifting a load. It will successfully move the load a few times but will also slowly shear the shank — that will ultimately lead to a sling twist or a full failure.

“Make sure you know if the hook is designed to swivel under load, or if it’s only intended to swivel for positioning,” said Biela.

For safely manipulating the load, a swivel hook with ball bearings is the right choice. The hook’s ball bearing system enables it to spin freely, even when under load. An example would be lifting a generator to position it below in a parking garage, in an inset space. You can swivel the hook until it is flush with your pick point to safely lower the load, but the inset space for the generator is often not on the same alignment as the load. You need to adjust the load, so it fits flush into the space and that’s where a ball bearing hook is necessary.

Experienced riggers know that some crane blocks have an integrated ball bearing, meaning the rigging hook doesn’t need them. Similarly, pick points such as rotating eyebolts or swivel hoist rings with ball bearings will negate the need for a swivel hook.

“If you are on a job site with a rented crane that has basic functionality and the load has pre-inserted pick points that do not swivel, you will find yourself in a tough spot without some way to manipulate that load,” added Biela. “Overall, to safely manipulate a load while it is under tension, at some point in the chain of rigging you will need a ball bearingenabled fitting.

“From a safety perspective, the ball bearing gives you an extended life because you are not shearing the shank of the hook when lifting.”

AMH is a leading provider of lifting and material handling equipment. It offers a range of ball bearing swivel hooks in its Grey Classic series, plus pick point products such as rotating eyebolts and swivel hoist rings with bearings.

AMH serves the North American lifting industry through a network of distributors and channel partners, ensuring wide availability of products and short lead times.

For more information, call AMH at 877/543-8264 or email sales@allmaterialhandling.com.

Stepp Manufacturing, a leading innovator in asphalt maintenance equipment, recently unveiled its latest breakthrough in road repair technology: the STPH asphalt pothole patch truck.

Engineered with a blend of durability, reliability and operator simplicity, the STPH is poised to revolutionize road maintenance across the globe, according to the manufacturer.

Designed to tackle the most demanding road maintenance needs, the STPH offers a comprehensive suite of features that empower operators to achieve unparalleled efficiency and precision. From the optional on-board tack tank system to the compactor plate carrier, spoils bin, hydraulic jackhammer, and air blowout options, the STPH is the ultimate patching body for any road maintenance task.

At the heart of the STPH lies its oil-jacketed diesel heating system, setting a new standard for heating efficiency and material quality. With automatic temperature controls and a stainless-steel burner liner, the system ensures consistent and even heating of patch materials, minimizing waste and maximizing performance. Additionally, the 6 in. by 3/8 in. AR 400 hardened auger and auger trough, coupled with the hydraulic direct drive, guarantee smooth and reliable material delivery.

“The STPH represents a significant leap forward in pothole patching technology,” said Jason Stepp, VP/ national sales manager of Stepp Manufacturing. “With its advanced features and user-friendly design, the STPH empowers road maintenance professionals to tackle even the toughest repair challenges with confidence and ease.”

Key features of the STPH include:

• Oil Jacketed for the smoothest heating system on the market.

• 6 in. by 3/8 in. AR 400 hardened auger and auger trough, and hydraulic direct drive.

• Automatic temperature controls with diesel burner.

• Internal oil jacketed baffle to provide heat to the middle of the hopper where it’s needed the most.

• 270-degree full opening hydraulic top doors.

• Folding shovel pan that allows you to dispense material directly on the road for large patches.

• Stainless steel burner liner.

• Electric over hydraulic system.

For more information, visit www.steppmfg.com.

FleetWatcher announced its participation in the Work Zone Data eXchange — a partnership with ICone that offers a breakthrough in work zone safety for the paving industry.

This nationwide initiative brings together technology partners, state, local and federal transportation agencies, and all consumer vehicle navigation systems (Waze, Google Maps, Apple Maps, Trimble and others) to raise awareness of work zones and the reduced speed limits through them. The program is designed to improve work zone safety and limit injuries and fatalities by alerting drivers to the presence of work zones so that they can slow down appropriately.

This is a free service to FleetWatcher users, they merely opt-in to enable the sharing of their data.

“Tragically, work zone deaths occur far too often, but this initiative can help save lives,” said FleetWatcher President Larry Baker. “Alerting drivers to the presence of work zones and the reduced speed limits within them will help to keep paving crews safe. We’re excited to be a part of this life saving program.”

FleetWatcher location data on pavers, shuttle buggies and mills is updated at frequent intervals on all major smartphone navigation apps and some in-car navigation systems.

FleetWatcher location data on pavers, shuttle buggies and mills is updated at frequent intervals on all major smartphone navigation apps and some incar navigation systems. The system sends lat/long location data and location accuracy information to these systems for pavers that are actively running. The navigation apps will use that information to identify work zones and display those zones with the adjusted construction zone speed limit.

This system will apply to all active roadway jobs including city, state, county and federal interstates. The Work Zone Data eXchange is expected to have an immediate impact by increasing safety within the work zones and saving lives.

Several state DOTs are mandating the technology, and some are helping to subsidize the cost of the technology that enables it.

For more information, visit www.fleetwatcher.com/work-zone-safety.

39 Jersey Street West Babylon, NY 11704

631/643-2605 www.allislandequipment.com

JESCO, Inc.

1275 Bloomfield Ave. Fairfield, NJ 07004

973/227-2221

800/321-8080

118 St. Nicholas Ave. S. Plainfield, NJ 07080

908/753-8080

800/241-7070

www.jesco.us

1790 Route 38 Lumberton, NJ 08048

609/267-2020

www.jesco.us

1401 Hookset Rd. Hooksett, NH 03106

603/644-8787 ambroseequipment.com

1440 Route 9W Marlboro, NY 12542 845/236-3000 www.hoffmanequip.com

2350 Greystone Ct. Rockville, VA 23146

804/359-4048 www.richmondmachinery.com

1001 Lehigh Station Road Henrietta, NY 14467

585/334-3867 5035 Genesee Street Buffalo, NY 14225 716/681-7100 monroetractor.com

30 Barnes Ind. Pk. Rd. Wallingford, CT 06492 203/265-6781

17 Eagle Road Danbury, CT 06810 203/775-1203

80 Pratt Rd. Plainfield, CT 06374

860/546-4808 www.wiclark.com

Harrisburg, PA 7201 Paxton Street Harrisburg, PA 17111 800/325-6455

Wilkes-Barre, PA 600 Sathers Drive Pittston, PA 18640 866/667-6756

Butler, PA 796 Unionville Road Prospect, PA 16052 724/865-9221

Philadelphia, PA

135 Lincoln Avenue Prospect Park, PA 19076 800/220-4033

Pittsburgh, PA 8181 Noblestown Road McDonald, PA 15057 800/692-7600

Ebensburg, PA 2350 Munster Road Lilly, PA 15946 814/886-5191

Albany, NY

3 Industry Drive Waterford, NY 12188 518/357-2200

Syracuse, NY

6018 Drott Drive East Syracuse, NY 13057 800/368-6455

www.stephensonequipment.com

8192 Euclid Court Manassas Park, VA 20111 703/330-5579

20332 Leitersburg Pike Hagerstown, MD 21742 301/733-7414

1109 Middle River Rd Middle River, MD 21220 800/633-5077 valleysupplyequipment.com

ALL ISLAND EQUIPMENT

39 Jersey Street West Babylon, NY 11704

631/643-2605

allislandequipment.com

AMBROSE EQUIPMENT / ALTA EQUIPMENT

1401 Hooksett Rd. Hooksett, NH 03106

603/644-8787 ambroseequipment.com

HOFFMAN EQUIPMENT COMPANY

1440 Route 9W Marlboro, NY 12542

845/236-3000

www.hoffmanequip.com

JESCO, Inc.

1275 Bloomfield Ave. Fairfield, NJ 07004

973/227-2221

800/321-8080

118 St. Nicholas Ave. S. Plainfield, NJ 07080

908/753-8080

800/241-7070

1790 Route 38 Lumberton, NJ 08048

609/267-2020 www.jesco.us

MONROE TRACTOR

1001 Lehigh Station Rd. Henrietta, NY 14467

585/334-3867

5035 Genesee Street Buffalo, NY 14225

716/681-7100

www.monroetractor.com

RICHMOND MACHINERY

2350 Greystone Ct. Rockville, VA 23146

804/359-4048 www.richmondmachinery.com

W.I. CLARK COMPANY

30 Barnes Ind. Pk. Rd. Wallingford, CT 06492

203/265-6781 17 Eagle Road Danbury, CT 06810

203/775-1203

80 Pratt Rd. Plainfield, CT 06374

860/546-4808 www.wiclark.com

Harrisburg, PA 7201 Paxton Street Harrisburg, PA 17111

800/325-6455

Wilkes-Barre, PA

600 Sathers Drive Pittston, PA 18640 866/667-6756

Butler, PA 796 Unionville Road Prospect, PA 16052 724/865-9221

Philadelphia, PA

135 Lincoln Avenue Prospect Park, PA 19076 800/220-4033

Pittsburgh, PA 8181 Noblestown Road McDonald, PA 15057 800/692-7600

Ebensburg, PA

2350 Munster Road Lilly, PA 15946 814/886-5191

Albany, NY

3 Industry Drive Waterford, NY 12188 518/357-2200

Syracuse, NY

6018 Drott Drive

East Syracuse, NY 13057

800/368-6455

Valley Supply & Equipment Co., Inc.

8192 Euclid Court Manassas Park, VA 20111

703/330-5579 20332 Leitersburg Pike Hagerstown, MD 21742

301/733-7414

1109 Middle River Rd Middle River, MD 21220

800/633-5077

valleysupplyequipment.com

The National Equipment League is a new entertainment and competition platform that showcases the skills, character and passion of the construction industry through competition.

The newly founded National Equipment League has crowned Bryan Furnace as its first champion after four hotly contested events, hosted by HD Hyundai Construction Equipment North America.

The National Equipment League is a new entertainment and competition platform that showcases the skills, character and passion of the construction industry through competition.

Furnace, of Howell, Mich., is the owner/operator of his own earthmoving business who also hosts his own YouTube channel, Diesel & Iron. The competition has been documented over the course of four events, which can be viewed on HD Hyundai Construction Equipment North America’s YouTube page.

Additional competitors in the first events include Mike Simon (AKA Dirt Perfect), Andrew Camarata, Dave Buchakian and Geoff Dodge. Mr. Digg Ryan Williams served as a member of the broadcast team. All events were filmed at the HD Hyundai Customer Product Center in Carnesville, Ga., and broadcast via YouTube.

“The first events proved that skilled heavy equipment operation in head-to-head competition is entertaining, educational and highlights the talents of the workforce in the construction industry,” said Bill Elverman, commissioner, National Equipment League.

“As in any professional sporting event, we see that lead changes, scoreboard jockeying and often just a few seconds between competitors create compelling entertainment. Hyundai hosted a great competition and has shown its commitment to showcasing the talents and passion of the construction industry.”

The first series of National Equipment League events can be seen on the Hyundai Construction Equipment North America YouTube and Facebook channels.

Additional promotional considera-

tions were made possible by Blue Diamond Attachments. For more information on the National Equipment League, email Commish@EquipmentLeague.com or visit EquipmentLeague.com.

(All photos courtesy of the National Equipment League.)

LESLIE EQUIPMENT COMPANY www.lec1.com

6248 Webster Road Cowen, WV 26206 304/226-3299

2098 Lillian Lane Pleasant Valley, WV 26554 304/534-5454 19 Goff Crossing Drive Cross Lanes, WV 25313 304/204-1818

www.monroetractor.com

1001 Lehigh Station Road Henrietta, NY 14467 585/334-3867

5035 Genesee Street Buffalo, NY 14225 716/681-7100

7300 Eastman Road N. Syracuse, NY 13212 315/452-0000

8194 State Route 415 Campbell, NY 14821 607/739-8741

6 Equipment Drive Binghamton, NY 13904 607/754-6570

GROFF TRACTOR & EQUIPMENT

www.grofftractor.com

800-33-GROFF 800-33-(47633)

6779 Carlisle Pike Mechanicsburg, PA 17050

20 Stauffer Lane Ephrata, PA 17522

210 Rolling Ridge Drive Bellefonte, PA 16823

100 Smith Drive Cranberry Twp, PA 16066

963 South Center Ave New Stanton, PA 15672 4355 Admiral Peary Highway Ebensburg, PA 15931

www.unitedequip.com

80 Southbridge Rd. • Route 20 North Oxford, MA 01537 508/987-8786

2397 GAR Highway • Rte 6 & 136 North Swansea, MA 02777 508/379-9810

88 Camelot Drive • Unit 42 Plymouth, MA 02360 508/830-9997

1620 Page Blvd Springfield, MA 01104 413/543-5595

4 Sterling Road North Billerica, MA 01862 978/667-4345

34 Page Road West Hermon, ME 04401 207/947-6786

106 North Street Houlton, ME 04730

207/532-6517

1505 Caribou Road New Canada, ME 04743 207/834-6701

396 County Road Westbrook, ME 04092 207/773-3777

98 Sheep Davis Road Pembroke, NH 03275 603/225-2769

300 Clinton Street Springfield, VT 05156 802/885-6840

r No for ctedPerfe

caAmeri th r e p x E f o deliveringthe -our machines are ing and milling, ground, in every NSTRUCTION smartsafeandsu to paving, compac climate, condition, , th TECHNOLOGY AS THE GLOBAL L stainableconsistently ction and rehabilitation and terrain. From min e world is our proving EADER IN ROAD CO highest quality and lowest total cost of ownership.

smart, safe, and sustainable, consistently delivering the

Christoph Thiesbrummel

BOMAG Americas, a Fayat Company, announced the promotion of Christoph Thiesbrummel to vice president of sales & marketing for North American operations effective July 22, 2024.

In his new position, Thiesbrummel will lead BOMAG Americas’ dealer channel sales, rental channel sales, sales administration, product management and marketing activities.

“Our entire team is committed to a customer-first approach and will continue to find innovative solutions for our customers’ individual needs.”

Thiesbrummel brings more than 10 years of industry experience to his new position, all within the BOMAG organization. After receiving his doctorate in marketing and business management, he began his career with BOMAG at the Boppard, Germany, headquarters as pricing and business analytics manager. He then moved to BOMAG Americas to assume the position of sales administration manager, where he oversaw the inside sales team. He also worked with the field sales team, managing market and new dealer development for BOMAG Americas.

For the last two years, Thiesbrummel served as BOMAG Americas’ director of sales, dealer channel for the eastern United States.

“Christoph is incredibly talented, has deep knowledge of the BOMAG organization and equipment, and has delivered successful results at every level within the organization he has worked,” said Brian Bieller, president

Christoph Thiesbrummel BOMAG Americas

of BOMAG Americas.

“He recently completed Fayat’s one-year advanced program for high-potential personnel, the Global Fayat Road Academy management training program. His knowledge, dedication and in-depth experience with BOMAG make him the right fit for the position.”

“I am excited for this new opportunity to grow the BOMAG brand in North America, working together with our strong network of partners across all sales channels and the BOMAG team in the U.S. and Canada,” said Thiesbrummel. “Our entire team is committed to a customer-first approach and will continue to find innovative solutions for our customers’ individual needs. Let’s grow together!”

For more information, visit www.bomag.com/us-en.

The Carlson CP100 II sets the standard for versatility, component lifecycle and mat quality. With a powerful 100hp engine, an array of configurations and the class-leading EZCSS single slide screed, it’s time to see why the CP100 II has fast become the contractor’s choice for heavy-duty commercial paver platforms.

www.barryequipment.com

The CP100II sets the standard for versatility, component lifecycle and mat quality. With a powerful 100 horsepower engine, an array of configurations and the class-leading Carlson EZCSS single slide screed, it’s easy to see why the CP100II is the ideal choice for heavy-duty commercial paving. 30

www.traceyroad.com

Center

Albany, NY

518-438-1100

866-740-8853

Kirkwood, NY 607-775-5010 800-370-9488

Henrietta, NY 585-334-5120 866-950-6210

Utica, NY 315-765-8746 800-872-2390 Adams Center, NY 315-788-0200 888-335-0200 BARRY EQUIPMENT

Queensbury, NY 518-793-9688 833-817-2917

7 Harrys Way Webster, MA 01570 508-949-0005 Wilkes-Barre Township, PA 570-410-2123 • 800-872-2390 HOFFMAN EQUIPMENT

www.hoffmanequip.com

1440 Route 9W Marlboro, NY 12542 845-236-3000

22 Peconic Ave. Medford, NY 11763 631-207-2900

1144 Zerega Ave. Bronx, NY 10462 718-822-1180

610-586-2710

Vineland, NJ

856-697-1414

Totowa, NJ 973-785-4900

Freehold, NJ 732-780-4600

Robust, powerful and reliable, the new generation BOMAG BMP 8500 multi-purpose compactor features an improved radio remote control design that allows the controller to be used on every BMP 8500 in the fleet.

The remote control’s unique “teach” function quickly and intuitively pairs the unit to the machine to save contractors time and money. Should the controller be misplaced, a new one can be paired to any machine in the fleet quickly and without special knowledge or tools.

With the BMP 8500, there is a secure, 100 percent connection between the remote-control unit and machine. Multiple trench rollers can be operated simultaneously at the job site without the need to coordinate or adjust individual radio frequencies, increasing operational flexibility, according to the manufacturer.

Now, two batteries are standard for the remote control, delivering a continuous combined worktime of up to 40 hours for more operating time. The two-battery solution allows one battery to charge while the other powers the controller, so the BMP 8500 is always ready for work.

Battery charge status is displayed on the remote-control unit’s screen, alerting operators when the battery needs to be changed. Integrated into the trench roller’s storage compartment, an optional charger allows the second battery to be topped off during machine operation.

The lightweight remote controller features a new ergonomic design with paddle-style joysticks to simplify compactor travel and multiple indicator lights for intuitive control. BOMAG’s radio remote control offers reliable operation, even in direct sunlight.

Built for dependable operation in confined applications like trench and pipeline construction, the BMP 8500 also is

Hunker, PA 724-861-6080 Eighty Four, PA 724-325-9297 miltoncat.com Milford, MA 508-634-3400 North Reading, MA 978-276-2400 Wareham, MA 508-291-1200 Cranston, RI 401-946-6350 Richmond, VT 802-434-4228 Londonderry, NH 603-665-4500 Brewer, ME 207-989-1890

Poughkeepsie, NY 845-452-1200 Bronx, NY 718-863-3800 Bloomingburg, NY 845-733-6400

Holtsville, NY 631-758-7500

Newington, CT 860-666-8401

Piscataway, NJ 732-885-5555 Hammonton, NJ 609-561-0308 Bensalem, PA 215-639-4300 Whitehall, PA 610-261-4887 Bear, DE 302-328-4131 hopenn.com

Jenny Products Inc. offers its G5A60V single-stage air compressor, featuring a 60-gal. vertical air tank and an industrial-grade 5-hp motor. Designed for long-lasting, reliable performance, the compressor is ideal for use in a variety of shops.

The G5A-60V provides 27.8 CFM at 125 psi through an American-made cast-iron compressor pump. The pump offers a splash lubrication system using Jenny “Ultimate Blue” synthetic compressor oil. An oversized flywheel and a directional air shroud further

assist in pump cooling.

For maximum durability, the G5A60V offers a heavy-duty, totally enclosed belt guard, as well as protectively mounted grease fittings, a large canister intake filter with replaceable filter elements and thermal overload motor protection. Other standard features include a manual tank drain, pressure relief safety valve, powdercoated tank finish, magnetic starter and special unloader valves for easier motor startup.

Options include constant run con-

trol, dual control, a low-oil switch, oil sight glass, air lubricator, aftercooler and dryer. In addition to the G5A-60V, Jenny Products offers a full line of stationary air compressors with a wide variety of tank sizes, CFM outputs and pressure ratings.

With roots dating back to the 1870s, Jenny Products Inc. has been an OEM manufacturer for several major manufacturers of air compressors. Today, Jenny manufactures and markets its own line of hand-carry, wheeledportable and industrial-stationary air

compressors. For more information, call 814/445-3400 or visit www.jennyproductsinc.com.

Jenny Products photo For maximum durability, the G5A-60V offers a heavy-duty, totally enclosed belt guard, as well as protectively mounted grease fittings, a large canister intake filter with replaceable filter elements and thermal overload motor protection.

cn-wood.com

Newington: 860-665-7470

New Haven: 203-848-6735

Avon: 508-584-8484

Whately: 413-665-7009

Woburn: 781-935-1919

NEW YORK

Holmes: 845-878-4004

RHODE ISLAND

Smithfield: 401-942-9191

finkeequipment.com

NEW YORK

Selkirk: 518-767-9331

VERMONT finkevt.com

Colchester (Burlington): 802-316-3805

fosterfwineland.com

PENNSYLVANIA

Ebensburg: 814-472-4441

Martinsburg: 814-793-3734

St. Mary’s: 814-781-1365

hwyequip.com

PENNSYLVANIA

Drums: 570-788-1127

Ephrata: 717-859-3132

Harrisburg: 717-564-3031

Lock Haven: 570-769-1070

monroetractor.com

NEW YORK

Binghamton: 607-754-6570

Buffalo: 716-681-7100

Campbell: 607-739-8741

Henrietta: 585-334-3867

N. Syracuse: 315-452-0000

hoffmanequip.com

NEW JERSEY

Deptford: 856-227-6400, Piscataway: 732-752-3600

NEW YORK

Bronx: 718-822-1180, Marlboro: 845-236-3000

Medford: 631-207-2900

PENNSYLVANIA

Lionville: 610-363-9200

hwyequip.com/keystonecme

PENNSYLVANIA

Delmont: 412-775-0051

Atlas Copco has announced the launch of its X-Air⁺ 1200-40, the newest member of its DrillAir portfolio. This brand-new portable air compressor is designed to revolutionize deep drilling applications by offering faster drilling and a notably reduced carbon footprint, the manufacturer said.

“The X-Air⁺ 1200-40 represents a bold leap in our commitment to offering innovative compressed air solutions that benefit both our customers and the planet alike,” said Leslie Van Mulders, product marketing manager of Large Air, from the Portable Air Division. “With enhanced performance capabilities, this 40 bar compressor is our most efficient DrillAir compressor, not only in operating speed but also in fuel efficiency.”

Engineered with precision, the X-Air⁺ 1200-40 achieves at least a 10 percent enhancement in performance metrics over prior models. This enhancement helps users achieve significant savings in fuel and operational costs, while simultaneously reducing the environmental footprint of their activities, according to the manufacturer.

protection functionality, allowing users to limit the flow to ideal hammer settings or unleash the full power of DrillAir as needed.

ing overburden drilling, as well as enabling the same compressor to be used for both geothermal and foundation drilling) and will automatically resume when air is required. The advancements in the XAir⁺ 1200-40 not only ensure faster, deeper and cleaner drilling but also offer an average fuel saving of 11 percent over the total drill cycle, marking a significant step forward in efficiency and environmental responsibility.

Additionally, the X-Air⁺ 1200-40 comes equipped with new robust oil filters utilizing the latest fiber technology, ensuring optimal oil quality under higher pressures. Enhanced with a new array of sensors, this smart machine offers even more accurate remote monitoring and warnings, further improving operational efficiency and reliability.

The X-Air⁺ 1200-40 surpasses Atlas Copco’s previous flagship drilling compressor, the Y35. The model boasts 15 percent more pressure and a 20 percent increase in drilling speed compared to the Y35. It features a new high-pressure element — to withstand even more tough operational conditions — and is protected by software that ensures longer lifetime and durability. The new unit also introduces a hammer

A new “pressure optimizer” function automatically reduces fuel consumption when the machine is not delivering air to the drill, potentially saving customers up to 20 percent during “no load” times. When no air discharge is detected, the pressure will drop to 22 bar and 16 bar for XPR (Atlas Copco’s XPR technology extends the working pressure range downwards, preventing soil cavitation dur-

Engineered for durability and versatility, the XAir⁺ 1200-40 is ideal for a wide range of industries such as construction, mining and energy. It is specifically designed to tackle the most challenging applications, including ground engineering, water well and geothermal drilling, and pipeline pressure testing.

The X-Air⁺ 1200-40 model aims to set new industry standard in deep drilling applications, enhancing productivity, reducing costs and minimizing environmental impact.

For more information, visit www.atlascopco.com/enuk/construction-equipment/products/mobile-air-compressors.

Caterpillar Inc. announced that the company has added Cat CG260 gas generator sets to its portfolio of commercially available power solutions capable of running on hydrogen fuel.