2 For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com 1900 CRW TCC2500 Family CEG ad 12.8.20.indd 1 12/9/2020 2:00:38 PM oven world r P ele-craw e d-class T MERICA! H WLER wlers MEERRIICCAA! NOORTTH R WLEER L#1T L#1T AM TELECRA LINE-UP W A N E-UP -C -U IN A ELLEE-CRAW etts 508-499-1950 02-658-1700 | 68m main boom | 223 ft Massachus mont 8 erVe TELESCOPIC CRAWLER 230 mt | 250 t 4 cameras! Vision packageUltra-wide winch design Superior capacities with full attachment 105m max tip height 348 ft , U entucky exington, K L www.woods ork 3 o New Y Pennsylvani .linkbelt.com SA | www w.com scr 315-676-2008 a 717-795-0700 THE MARKET! IN ABLE AILAVA ACITY A HIGHEST CAP BUY • LEASE • RENT

By Lucy Perry CEG CORRESPONDENT

By Lucy Perry CEG CORRESPONDENT

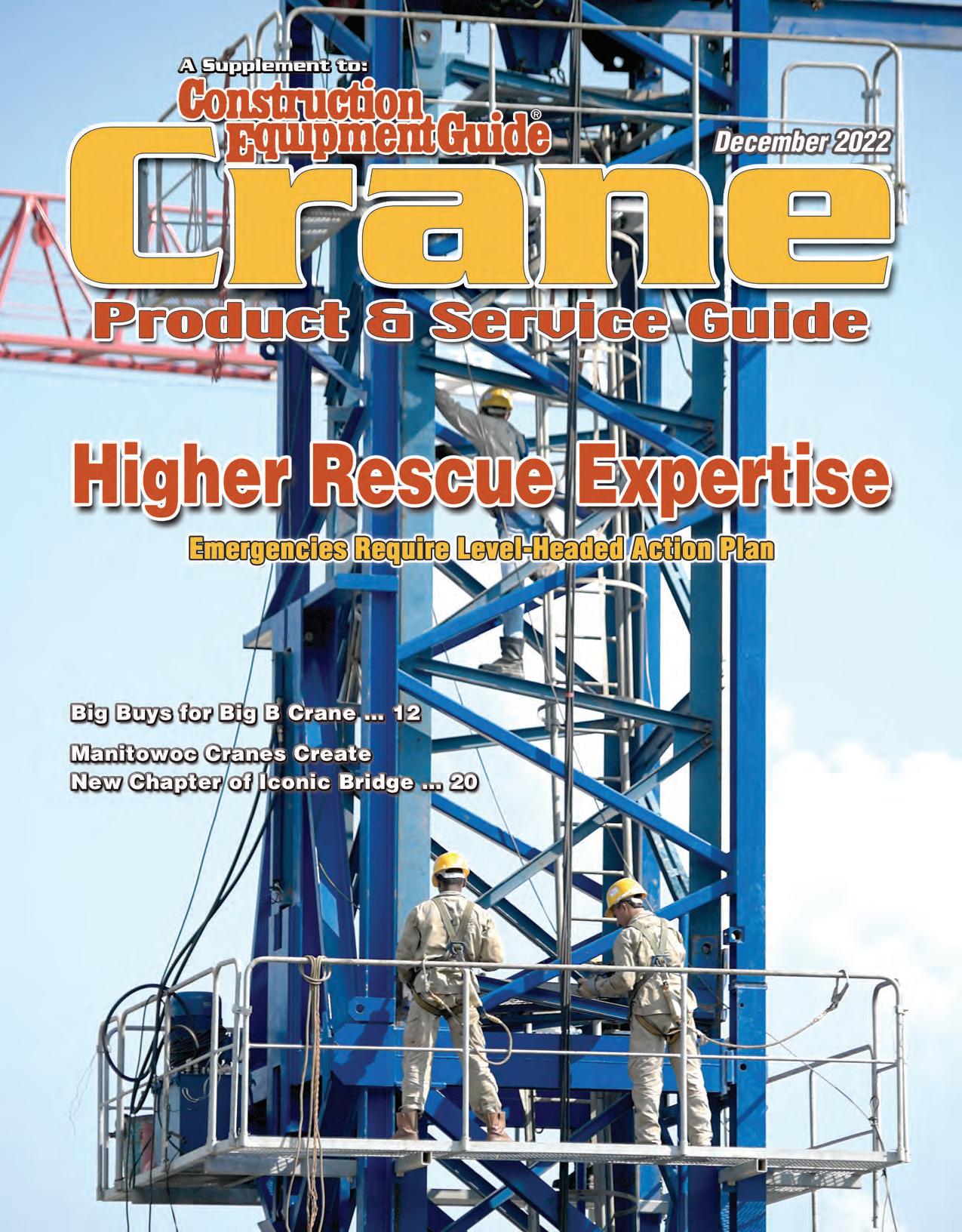

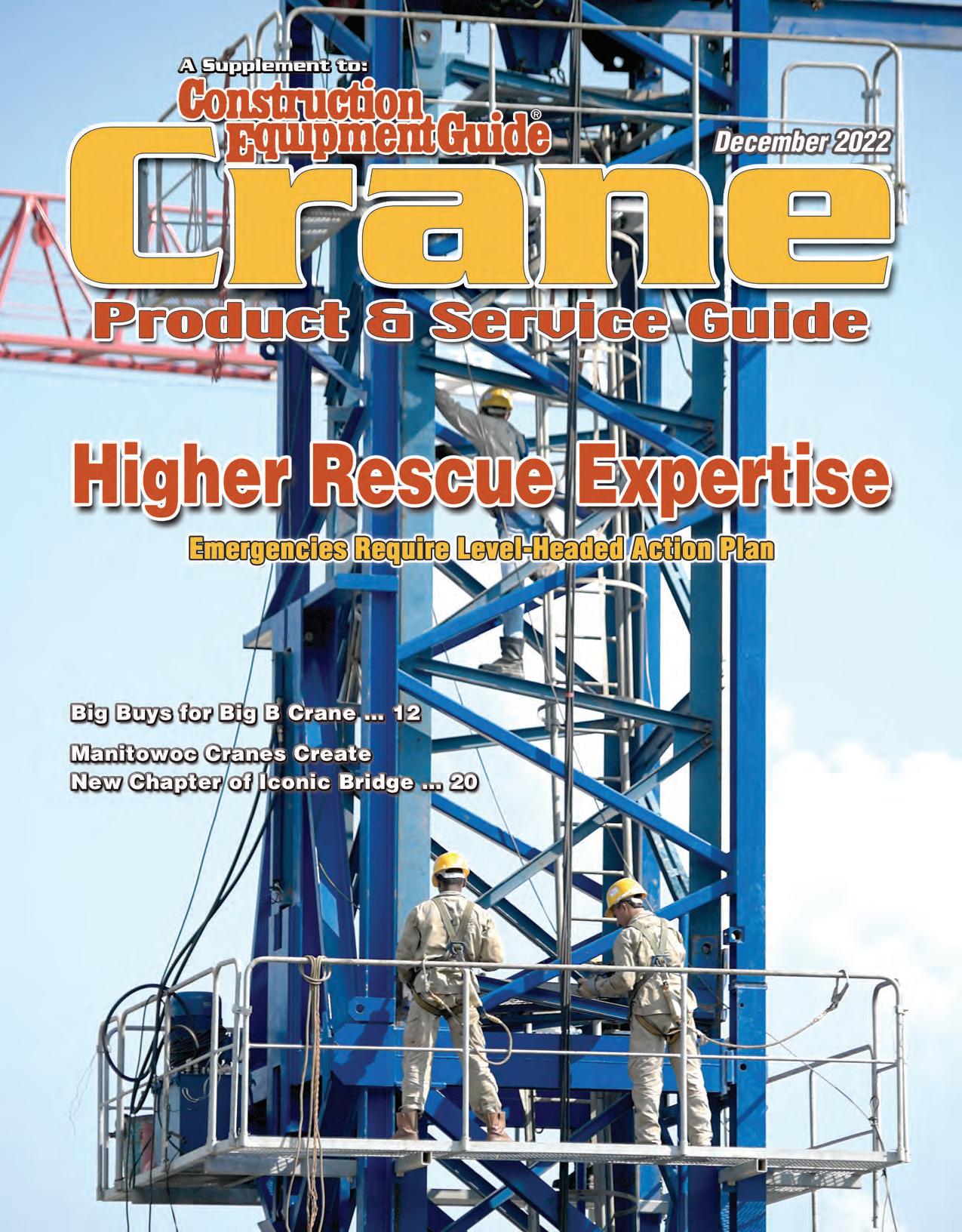

SAFETY IS KEY WHEN ANY CRANE IS ON A JOB SITE, but a tower crane requires safety managers to have a rescue plan in place. A medical emergency can occur any time on the job, even to a crane operator in a tower crane cab. Many crane companies make rescue training sessions a regular part of their safety training programs. And many will get the local fire and rescue team involved.

This summer, Bigge Crane and Rigging teamed up with the San Francisco Fire Department for field training exercises that included rescue instruction.

“The well-being of everyone around our jobs and equipment is an indication of our commitment to safety,” the company said about the field training. “It’s important to us as an organization that we express safety as our number one core value day in and day out.”

San Leandro, Calif.-based Bigge said the goal was to share knowledge and develop practical training in real-world environments.

The training, according to the company, replicated a tower crane medical emergency and the subsequent 911 call to the fire department’s heavy rescue unit.

“As a result of this exercise, firefighters and first responders gained invaluable

insight into the operational function of a tower crane,” said the crane company.

Rescue routes in and out of the site, and a briefing on the project’s emergency action plan (EAP) were part of the session.

The EAP explains the functional roles of construction personnel during such an emergency.

“Our aim is to inspire others to follow the steps we’ve taken to plan and implement mock rescue scenarios on their sites,” said Bigge. “The crane operating company, emergency responders and site personnel then use that information to prepare for such emergencies effectively and save lives.”

4 For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call

or e-mail:

800/523-2200

cmongeau@cegltd.com

continued on page 10

Higher Rescue Expertise

qçïÉê=`ê~åÉ bãÉêÖÉåÅáÉë oÉèìáêÉ= iÉîÉäJeÉ~ÇÉÇ ^Åíáçå=mä~å

Chicago, Denver, New York and San Francisco, along with Toronto, Canada, have seen increases in working cranes.

For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com 5

WESTERN PACIFIC CRANE & EQUIPMENT www.wpcrane.com 8600 Calabash Ave. Fontana, CA 92335 562/286-6618

1500 Madruga Road Lathrop, CA 95330 855/927-2637

275 W. Larch Road Tracy, CA 95304 209/597-3824

3521 Alken Street Bakersfield, CA 93308 855/927-2637

19602 60th Avenue NE Arlington, WA 98223 253/254-7950

91-210 Kalaeloa Blvd. Kapolei, HI 96707 808/682-7263

8912 NE Vancouver Way Portland, OR 97211 971/202-4002

6720 Arctic Blvd. Anchorage, AK 99518 855/342-7263

WPCE - CANADA 9538 195th Street Surrey, BC V4N 4G2 855/342-7263

HAYDEN-MURPHY EQUIPMENT COMPANY www.hayden-murphy.com 9301 E. Bloomington Freeway Minneapolis, MN 55420 952/884-2301 800/352-2757

RING POWER CRANE www.ringpowercrane.com

St. Augustine, FL 904/494-1219

Pompano Beach, FL 954/977-5010 Orlando, FL 407/855-6195

Tampa, FL 813/671-3700

Union City, GA 770/774-7300 Concord, NC 704/795-3636 Aiken, SC 843/818-1954

HOFFMAN EQUIPMENT CO. www.hoffmanequip.com

New Jersey Corporate Headquarters 300 S. Randolphville Rd. Piscataway, NJ 08854 732/752-3600

South Jersey 1330 Hurffville Rd. Deptford, NJ 08096 856/227-6400

New York 1144 Zerega Ave. Bronx, NY 10462 718/822-1180

Mid-Hudson Valley 1440 Route 9W Marlboro, NY 12542 845/236-3000

Long Island 22 Peconic Ave. Medford, NY 11763 631/207-2900

Pennsylvania Philadelphia Metro Area 120 Gordon Dr. Lionville, PA 19341 610/363-9200

CLEVELAND CRANE & SHOVEL SALES INC. www.craneandshovel.net 26781 Cannon Road Cleveland, OH 44146 440/439-4749 Toll Free: 800/362-8494 aforepaugh@ craneandshovel.net

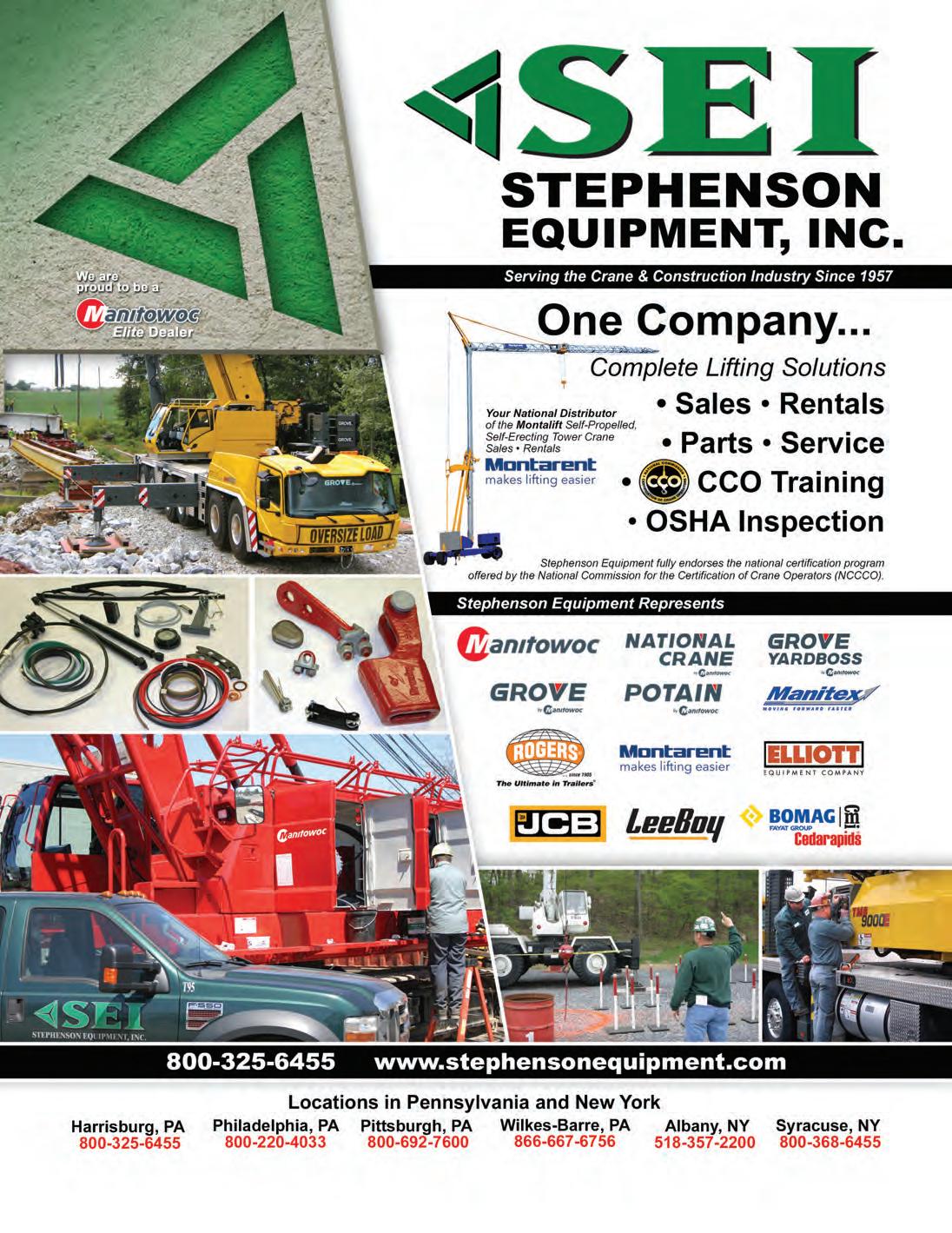

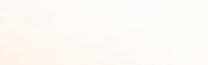

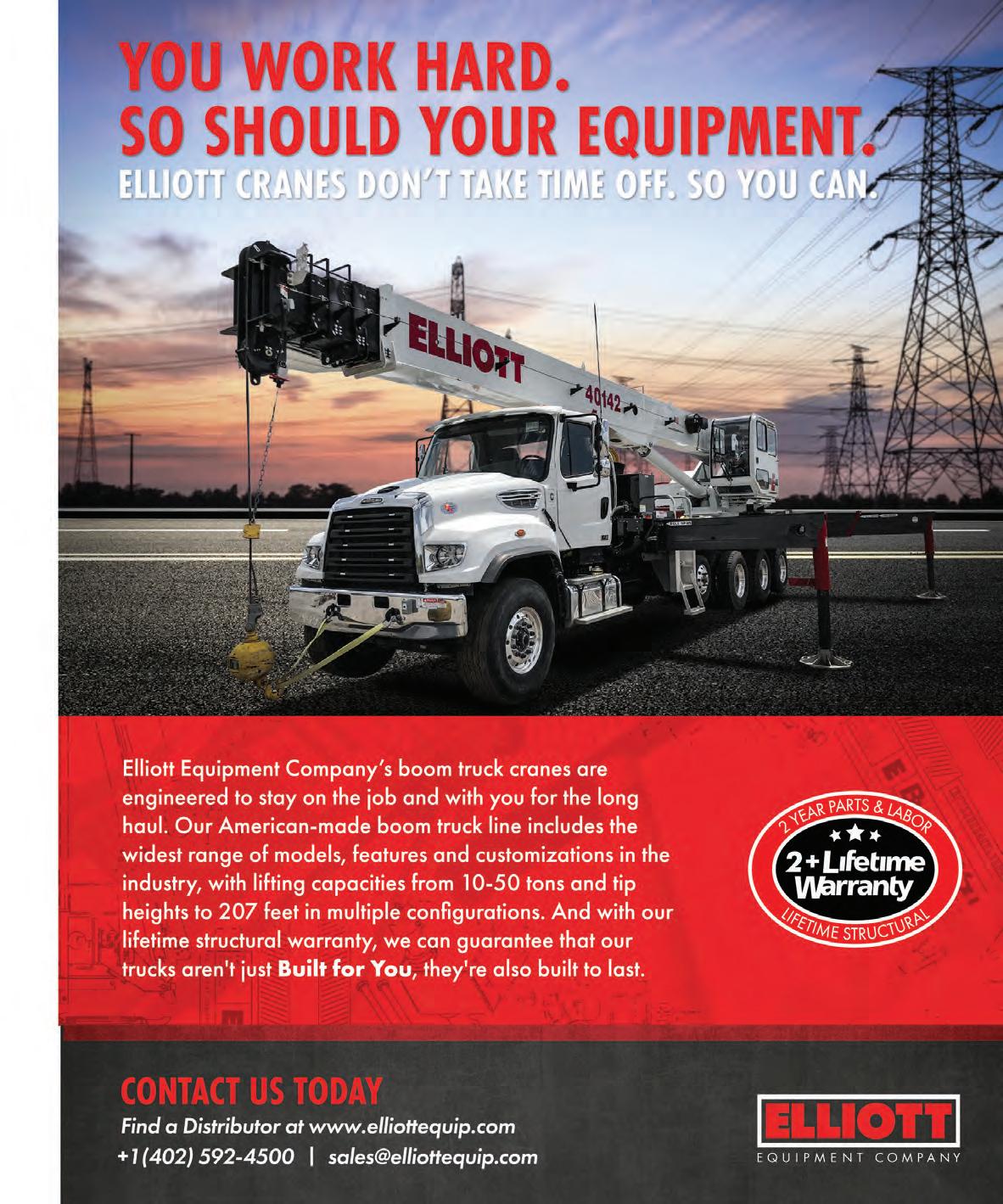

STEPHENSON EQUIPMENT, INC. www.stephensonequipment.com Philadelphia, PA 800/220-4033 Harrisburg, PA 800/325-6455

Wilkes-Barre, PA 866/667-6756

Pittsburgh, PA 800/692-7600 Syracuse, NY 800/368-6455 Albany, NY 518/357-2200

SHAWMUT EQUIPMENT COMPANY, INC. www.shawmutequipment.com

20 Tolland Turnpike Manchester, CT 06042 800/829-4161

136 Eastman St. South Easton, MA 02375 877/526-9213

SHAWMUT EQUIPMENT OF CANADA, INC.

318 Park Rd. Elmsdale, NS B2S 0G2 902/883-7450

6 For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com

For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com 7 Manitowoc productivit crawler cranes ar tyandvalueonthe e built to deliver u emostchallenging nsurpassed gjobsites Manitowoc > Cranes ra > Capacity> Optional boompo ty and value on the c delivers: nging from 80 USt enhancing VPC-MA long-reach booms, ints e most challenging to 2535 USt X® technology and fixed jibs, luffing jib g jobsites. MAX-ER® attachme bs and extended upp nts er boom po > Optional 3.5 m wide boom inserts for MLC300 and MLC650 .manitowwww oc.com

8 For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com

For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com 9 2022 TADANO GR 800XL 80 Ton #99005 $675,000 New Units Avail SALE - RENT - Rental Purchase bl97dq 2019 TADANO GR 350XL 35 TON #78049 $315,000 New Units Avail SALE - RENT - Rental Purchase bp62bu 2017 TADANO MANTIS GTC 600 66 TON TELE CRAWLER #73682 $465,000 SALE RENT RPO - Call aq16so 2017 TADANO GR 900XL 90 TON #72428 $495,000 Sale Rent RPO New Units Available - Call Today aq39sv 2019 TADANO MANTIS GTC 1200 130 TON - #85818 - $925,000 Sale - RENT - RPO - New unit Avail bh62qk 2017 TADANO MANTIS GTC 800 #73683 $575,000 Sale Rent RPO 88 Ton Tele Crawler - Rent Ready ar66xq 2018 MANITEX M150 15 TON #80191 $305,000 Sale Rent RPO 15 Ton Down Cab - Call Today aw48pv 2019 TADANO GR 550XL 55 Ton #78052 $415,000 New Units Avail SALE - RENT - Rental Purchase ay44st 2023 MANITEX 3051T 30 TON #106097 Peterbuilt 567 13 Speed In Stock - Sale Rent RPO - Call br03dw 2023 MANITEX 40124SHL 40 Ton #106072 Peterbuilt 567 13 Speed Unit In Stock - Call For Price br18ek 2019 MANITEX 30100C 30 TON #80863 $265,000 New Units Avail SALE - RENT - Rental Purchase ax71gu 2019 MANITEX 26101C 26 TON #87108 $235,000 New Units Avail SALE - RENT - RPO Options br55eh 2023 TADANO GR 1300XL 130 TON #103592 New Unit - Call For Price SALE - RENT - RPO Call Today bq78zz 2023 MANITEX 2281T 22 TON #99619 SALE - RENT - RPO New Units On the Way - CALL bo25cp 2023 MANITEX 35124C 35 TON #106086 New Unit - Call For Price In The Yard January 2023 br71wy 2021 TADANO MANTIS GTC 350 #94474 $475,000 35 TON Call Today SALE - RENT - Rental Purchase bh96mi 2022 TADANO MANTIS GTC 1600 160 Ton - #101339 Call For Price SALE - RENT - Rental Purchase bm35fg “We Have What You Need – Call Today” 562.273.7013 Headquartered: Long Beach, CA sales@coastlinecd.com Rental Purchase & Leasing Options Available - Call for Details SALES RENTAL PARTS & SERVICE 2023 MANITEX 22101S 22 TON #108831 Freightliner 108SD Auto Enclosed Cab - Unit In Stock br13li www.coastlinecd.com 2018 SKYJACK ZB2044 Stk#80193 $205,000 SALE - RENT - RPO New Units Available - Call Today br70sd 2016 TADANO GR 750XL 75 Ton #67206 $425,000 New Units Avail SALE - RENT - Rental Purchase aq16sf CRANE FILTERS CRANE SEAL KITS WORLD WIDE CRANE PARTS IN STOCK PROVIDING PARTS FOR: 2014 SHUTTLELIFT CD3339 9 TON #41162 $85,000 - New Units Avail SALE - RENT - Rental Purchase al12ca

Having the Right Stuff

When the tower cranes go up, so do the operators, and more operators requires a heightened sense of awareness around the job site.

Doug Legg, service and training manager of Rubicon Safety, Ontario, Canada, urges employers to be aware of their requirements.

In Canada, contractors must consult the Occupational Health and Safety Act (OHSA). In the United States, contractors turn to OSHA, but there are state and local regulations that must be followed as well.

It also is important to tailor the training to the crane in use because there are many different types of cranes, Legg told Canadian Occupational Safety magazine.

“There are different styles and different types of tower crane, so some are easier to work on than others,” he said.

And not only does the work require rescue training, but the ability to climb, and the ease of rescuing another person at height in a confined space.

“Can they manage their emotions?” asked Legg. “Because you’ve got to be able to temper your emotions in those times.”

Brent Wise, career firefighter and co-founder of rescue equipment company Tech Safety Lines, said tower crane rescues are a race against the clock.

“Precious minutes are often lost while people on the ground try and fail to repeatedly contact an incapacitated crane operator,” he said. “Before anyone realizes that something is very wrong up in the cab, the ‘golden hour’ for saving a life after a traumatic event is already ticking away.”

ation to get an incapacitated operator to medical help faster,” he said. “Saving lives isn’t as hard as you think.”

Here is his advice:

• Have an emergency response plan that’s tailored to your job site’s equipment and stick to it;

• Quickly assess the situation and call 911;

• Keep a high-level rescue kit ready to grab and go at all times;

• Get a trained ERT member up to the victim as quickly as possible;

• Assess all available routes into and out of the cab;

• Stabilize or move to evacuate the victim immediately in the event of a fire or other hazardous situation;

• Use the equipment — specific rescue kit to package the victim, transfer the person’s weight to the lowering system and evacuate him or her from the cab; and

• Use the rescue gear to lower the victim to the ground, where emergency medical responders can take over.

High-level rescue training covers pre-emergency planning, choosing the right equipment and assessing and packaging a victim.

It also covers how to find a safe path down, the importance of communications and how to take care of your rescue gear so it’s always ready.

Construction teams should know how to save a crane operator’s life. The best time to think about how to rescue someone is long before an emergency actually happens.

“That may sound like a lot to learn, but high-level rescue does not have to be complicated — especially when operating from a known location using preestablished anchor points and paths of egress,” said Wise. “It’s about having a plan, sticking to it, acting quickly, having the right gear at the right time and focusing on transferring the victim’s weight to the rescue system so that you can lower him or her down.”

He believes arming yourself with knowledge and hands-on training in a realistic emergency scenario is key.

Construction teams can and should know how to save a crane operator’s life, he believes.

Wise said the best time to think about how to rescue someone is long before an emergency actually happens.

Even major cities typically have just one technical rescue team that is capable of handling high-level emergencies.

It can take that specialized team much longer to get there, and first response units rarely have the tools or training for this type of job.

“Meanwhile, someone needs to get up high immediately, find out what’s wrong and act to get the victim back down safely,” said Wise. “It’s extremely important that multiple people on a job site have rescue training.”

Crane Rescue Expertise

Wise believes that every job site should include workers who are part of a trained emergency response team (ERT).

“With equipment and a rescue plan designed for the specific crane, the ERT can perform a simple extraction and lowering oper-

“And practice those skills at least once a quarter with a realistic ‘rescue’ on an actual job site,” said Wise. “Refresh your rescue knowledge frequently, and if you’re ever faced with a real emergency, you’ll switch into automatic response mode.”

He added that then you’ll “know exactly what to do to safely assist in a time-sensitive emergency like a tower crane rescue.”

Where the Machine Comes In

It’s crucial for contractors to understand when it’s appropriate to use a heavy piece of equipment in a rescue operation, said Roco Rescue.

“On the practical side, the use of a crane as a ‘stationary, temporary high-point anchor’ can be a tremendous asset to rescuers.”

But, “because of the dangers involved in moving personnel with heavy equipment, OSHA strictly limits its use,” added the Baton Rouge, La.-based company.

The security of the system’s attachment to the crane and the ability to lock-out any potential movement are a critical part of the planning process.

For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com

10

from page 4

Powered industrial equipment to be used as a highpoint must be treated like any other energized equipment with regard to safety.

Personnel must follow proper Lock-out/Tag-out procedures, and any equipment used in rescue should be properly locked out.

Keys must be removed, power switch disabled, etc. “You also need to check the manufacturer’s limitations to ensure you are not going beyond the approved use of the equipment,” advised Roco.

To utilize a crane in rescue, properly rated personnel platforms or baskets must be used. Platforms suspended from the load line are covered by OSHA’s crane rule, under 1926.1431.

Because there is no specific provision in the General Industry standards, the applicable standard is 1910.180(h)(3)(v).

This provision specifically prohibits hoisting, lowering, swinging or traveling while anyone is on the load or hook.

“OSHA prohibits the hoisting of personnel by crane or derrick except when no safe alternative is possible,” according to Roco. “The use of a crane for rescue does not provide an exception to these requirements unless very specific criteria are met.”

Therefore, the hoisting of personnel is not permitted unless conventional means of transporting employees is not feasible, according to OSHA.

That is, unless conventional means present even greater hazards (regardless of whether the operation is for planned work activities or for rescue).

“Where conventional means would not be considered safe, personnel hoisting operations meeting the terms of this standard would be authorized,” wrote Roco. “OSHA stresses that employee safety, not practicality or convenience, must be the basis for the employer’s choice of this method.”

The company notes that OSHA specifically requires rescue

capabilities in certain instances, such as when entering permitrequired confined spaces or when an employer authorizes personnel to use personal fall arrest systems.

In other cases, the general duty to protect an employee from workplace hazards would require rescue capabilities, said Roco.

“Consequently, being ‘unprepared for rescue’ would not be considered a legitimate basis to claim that moving a victim by crane was the only feasible or safe means of rescue.”

This is where the employer must complete written rescue plans for permit spaces and for workers-at-height using personal fall arrest systems.

“For rescuers, a crane is just another tool in the toolbox — one that can serve as a temporary, stationary high-point making the rescue operation an easier task,” said Roco. CQ

For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com

11

lpe^=ëíêÉëëÉë=íÜ~í=ÉãéäçóÉÉ ë~ÑÉíóI=åçí=éê~ÅíáÅ~äáíó=çê= ÅçåîÉåáÉåÅÉI=ãìëí=ÄÉ=íÜÉ= Ä~ëáë=Ñçê=íÜÉ=ÉãéäçóÉêÛë=ÅÜçáÅÉ çÑ=íÜáë=ãÉíÜçÇKÒ oçÅç=oÉëÅìÉ

Being unprepared for rescue is not considered a legitimate excuse for claiming that moving a victim by crane was the only feasible or safe means of rescue.

BUYS FOR

Company Hits Stride With Link-Belt Cranes

n the last 24 months Big B Crane of Burleson, Texas, has purchased six Link-Belt lattice crawler cranes from local Link-Belt Cranes distributor HOLT Crane & Equipment of Irving, Texas.

In June 2021, Big B Crane purchased two 238 HSLs and a 248 HSL, a 298 HSL in September 2021, a 348 Series 2 in June 2022 and a second 298 HSL in July 2022.

“We have several 200-ton cranes, most of which are Link-Belt 248’s [H5, HSL, H II] and we hang a lot of steel with them. The features I like about the Link-Belt 248s are the size of the cab and the comfort/ location of the controls. The thing I like most is the ease of mobilizing them, four to five people are able to fully selfassemble and disassemble these cranes and in really hard to get places,” said Kenneth Green, operations manager,

Fort Bend County EpiCenter

A recent contract awarded to Big B Crane includes Fort Bend County EpiCenter, a $120 million multi-purpose complex in Rosenberg, Texas.

At Fort Bend County EpiCenter, Big B Crane is responsible for concrete and steel erection of the 195,000 sq. ft. facility. Once completed, the center will be capable of holding 10,400 patrons, and also can be turned into an emergency shelter in times of natural disaster.

For the project in Fort Bend County, Big B Crane purchased a new Link-Belt Cranes 300-ton 348 Series 2 lattice crawler crane. The crane delivered directly to the job site from HOLT Crane

& Equipment and went into service the second week of June 2022. Three months later, in early September 2022, the crane already logged more than 500 hours.

“We were in the market for a 300-ton lattice crawler and so we did all the obvious research, looking at charts in this class. We work with our sister-company Deem Structural Services, a steel erector, and found that with this 348 Series 2 we could get 300 feet of reach with 220 feet of main boom and 80 feet of jib. That was big because some of the others in this class at that configuration can only get to 245 feet of radius. That, and then HOLT had cranes on hand, they had this 348 Series 2 available and ready for delivery,” said Kenneth Green, operations manager at Big B Crane.

BIG

For the project in Fort Bend County, Big B Crane purchased a new Link-Belt Cranes 300-ton 348 Series 2 lattice crawler crane.

commercial construction division at Big B Cranes.

I

12 For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com

The heaviest loads for the 348 Series 2 have been 120,000-lb. precast panels for the new building’s exterior.

The heaviest loads for the 348 Series 2 have been 120,000 lb. precast panels for the new building’s exterior. There are four sections of poured in place tilt panels that the 348 Series 2 lifts, leaving one end open so that the crane can work from the center of the building hanging remaining steel and lowering precast concrete sections that will later become the stands for the new building.

“HOLT’s service department has been exemplary. Their service managers are very responsive and their parts availability is great. In most cases, needed parts are in stock and shipped out same day. This greatly helps our customers reduce downtime and keeps their project flowing smoothly,” said Green.

348 Series 2 Innovations

Announcement of the 348 Series 2 came in June 2018. Over the years, Link-Belt’s 348 class of lattice crawler has been job proven on projects from Prudoe Bay, Alaska to Miami, Fla. First shipments of the new 348 Series 2 began in fourth quarter 2018 following extensive testing at Link-Belt Cranes in Lexington, Ky.

The 348 Series 2 features a Cummins QSL 9, 350 hp Tier IV Final and Tier III engine options with a Kawasaki pump and motor package for fast, responsive, fingertip control providing simultaneous operation wherever it is needed. Dual swing motors provide dynamic control for the incredibly smooth free swing all Link-Belt lattice cranes are famous for having. The operator also can dial swing up or down with a speed control knob in the cab.

Greater fuel economy is just one of the benefits offered with Series 2 ECO winch system, resulting in lower operating cost, less engine RPM under load, fewer emissions, and all the line pull you need with 28 mm rope. When activated by the operator, ECO hoist provides maximum line speed with lighter loads all with the engine under 1,000 rpm.

Also, standard equipped is operator-selectable “auto-engine

At Fort Bend County EpiCenter, Big B Crane is responsible for concrete and steel erection of the 195,000-sq.-ft. facility. Once completed, the center will be capable of holding 10,400 patrons, and also can be turned into an emergency shelter in times of natural disaster.

shutdown” allowing the engine to shut down automatically after extended periods of inactivity, so long as critical operating criteria are met.

At ConExpo 2020, Link-Belt Cranes made its first display of the new combination top for the 348 Series 2. The heavy-duty combination top boom section is built for conventional boom makeup or luffing boom configuration. Bar pendants connect main boom, luffing jib, and luffer back stay — making for easier assembly.

New to the heavy-duty boom extension is backstay bar pendant storage. This allows the 348 Series 2 to go to work with heavy-duty boom while the luffer backstay pendants are stored on the conventional boom. This makes the job of converting to luffing attachment faster, saving time and money, according to the manufacturer.

The hook and pin design greatly simplifies the process of mating the combination top with the luffing jib base section. Lattice style front and rear posts further reduce transport weight.

For more information, visit www.linkbelt.com.

for

13

The crane delivered directly to the job site from HOLT Crane & Equipment and went into service the second week of June 2022. Three months later, in early September 2022, the crane already logged more than 500 hours.

For information about advertising in or submitting articles

Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com

Utility Crane & Equipment, Inc. www.utilityce.com

8800 W Buckeye Road Tolleson, AZ 85353 866-832-4831 Richmond, CA 866-832-4831

Albuquerque, NM 505-342-9378 El Paso, TX 915-852-7201 Tucson, AZ 520-408-9378 Fontana, CA 909-419-8000

Versalift Midwest LLC inquiries@cannonequip.com

51761 Danview Technology Court Shelby Twp., MI 48315 586-991-0054

Coastline Equipment Crane Division

www.coastlinecd.com

325 N. 5th Street, Bldg. A Sacramento, CA 95811 916-440-8090

Santa Ana 714-265-6550

L & M Truck Sales, Inc. www.lmtrucks.com

4001 E. Boone Ave. Spokane, WA 99202 509-535-4175

Long Beach, CA 562-273-7013

Bakersfield, CA 661-399-3600

Oxnard, CA 805-485-2106

Santa Maria, CA 805-922-8329

Las Vegas, NV 702-399-2700

Hydraulic Machinery consteqguide@craneworx.com

5024 N 56th Street Tampa, FL 33610 813-621-8002

Stephenson Equipment www.stephensonequipment.com

Harrisburg, PA 800-325-6455 Philadelphia, PA 800-220-4033 Pittsburgh, PA 800-692-7600

Wilkes-Barre, PA 866-667-6756

Albany, NY 518-357-2200 Syracuse, NY 800-368-6455

Elko, NV 775-777-7070

Meridian, ID 208-888-3337

Jerome, ID 208-324-2900

McCall, ID 208-634-3903

Nixon-Egli Equipment Co. www.nixonegli.com

2044 South Vineyard Avenue Ontario, CA 91761 909-930-1822

800 East Grantline Road Tracy, CA 95304 209-830-8600

14 For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service

call

or

For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com 15

Guide,

800/523-2200

e-mail: cmongeau@cegltd.com

Both the Liebherr LR 11000 and Liebherr LR 1800-1.0 are actively working jobs across the ALL Family footprint.

Two Lattice Crawlers Ready to Rent in Southeast POWERHOUSES POWERHOUSES 16 For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com

Two heavyweight lattice boom crawler cranes are making their presence felt in the southeastern states.

The Liebherr LR 11000 and Liebherr LR 1800-1.0 are recent acquisitions by the ALL Family of Companies, with branches in Florida, Georgia, Alabama, Louisiana, North Carolina and Tennessee.

The 11000 is now the largest crane in the fleet, with an eye-popping 1,200-ton capacity and 551 ft. of main boom. The 1800 also is a powerhouse, with an 880-ton capacity, 663 ft. of hoist height, and a maximum radius of 498 ft.

Both machines are in high demand within the still-burgeoning wind market, but their size and reach also makes them ideal for a host of other jobs including industrial work, construction, and repair at refineries, plants and mills, according to the company.

LR 11000

The LR 11000 was built to ensure lowercost transport, designed with a transport width of 11.5 ft. and a height of 10.5 ft. The newly developed V-frame with an adjustment distance of 56 ft. moves the derrick ballast into the required position and reduces the workload for ballast handling.

LR 1800-1.0

The LR 1800-1.0 also is easy to transport from job to job and branch to branch across ALL’s southeast footprint. Features that reduce transport costs include a less than 10-ft. transport width, a maximum transport weight of 50 tons, and, for the first time, a boom system with lattice sections that can be telescoped into each other for transport.

Packed With Features

The power and reach of both units is undeniable, but their secret weapon might be Liebherr’s onboard LICCON2 control system. Lift planners can map out lifts ahead of time then share that screen with operators as they’re sitting in the cab. Operators can use the actual crane controls to simulate the lift onscreen. Before they ever boom or swing the crane, operators already have a practical familiarity with the job to be done.

The LICCON2 also accommodates Liebherr’s BTT Bluetooth remote control, which allows the operator to assemble and disassemble the cranes while standing outside of the cab. This gives the operator a wider view of the work area and also allows these tasks to be performed with fewer people. The operator is able to be part of the

The 11000 is now the largest crane in the fleet, with an eye-popping 1,200-ton capacity and 551 ft. of main boom. The 1800 also is a powerhouse, with an 880-ton capacity, 663 ft. of hoist height, and a maximum radius of 498 ft.

assembly crew and not have to sit in the cab taking signals from the erector or the crew.

Another newer Liebherr innovation is the VarioTray, which is available on the LR 1800. The ballast system enables the central section of the suspended ballast to be simply unbolted rather than requiring unstacking. The result is a massive increase in flexibility and significantly less work on site. It creates more capabilities for the crane, from lifting heavier loads to easier movement on the job site. Only four bolts and a cable plug have to be released to disconnect the ballast pallet, so it can be done quickly.

Both the Liebherr LR 11000 and Liebherr LR 1800-1.0 are actively working jobs across the ALL Family footprint.

For more information, visit www.allcrane.com.

The power and reach of both units is undeniable, but their secret weapon might be Liebherr’s onboard LICCON2 control system. Lift planners can map out lifts ahead of time then share that screen with operators as they’re sitting in the cab.

The Liebherr LR 11000 and Liebherr LR 1800-1.0 are recent acquisitions by the ALL Family of Companies.

The power and reach of both units is undeniable, but their secret weapon might be Liebherr’s onboard LICCON2 control system. Lift planners can map out lifts ahead of time then share that screen with operators as they’re sitting in the cab.

The Liebherr LR 11000 and Liebherr LR 1800-1.0 are recent acquisitions by the ALL Family of Companies.

For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call

or e-mail:

17

800/523-2200

cmongeau@cegltd.com

N E W CRA N E O BL CKO N THE

MANITOWOC LAUNCHES GROVE GRT8100-1 ROUGH-TERRAIN CRANE

Manitowoc used its attendance at bauma 2022 to launch its latest rough-terrain crane: the Grove GRT8100-1. This upgrade of the hugely popular GRT8100 will be available from 2023 and offers a series of improvements

Many of the enhancements stem from a new chassis that shares commonality with the chassis from the proven 132 ton capacity GRT8120. There’s also an updated engine and transmission package, and a

“The GRT8100 has been a popular choice with customers worldwide. With the GRT81001, we have taken a great crane and made it even better,” said Federico Lovera, product manager for rough-terrain, industrial, and lattice boom crawler cranes at Manitowoc. “The new Grove GRT8100-1 will go into production at our U.S. and Italian factories simultaneously, allowing deliveries to customers around the world to

Many of the enhancements stem from a new chassis that shares commonality with the chassis from the proven 132-ton capacity GRT8120.

The 100 ton capacity GRT8100-1 features the same 360-degree load charts as its predecessor. It also maintains the same overall dimensions, counterweight, and five-section, 39.2 to 154.3 ft. full-power MEGAFORM boom. However, with the new chassis on the GRT8100-1 customers have the option to integrate the highly flexible MAXbase variable position outrigger system, which offers up to 15 percent capacity improvements in certain configurations.

MAXbase also greatly simplifies setup on congested job sites, with each of the four hydraulically telescoping outriggers extended over a range of symmetric and asymmetric positions. Also new to the outrigger design is an auto-level feature for easy jobsite set-up, as well as Manitowoc’s smart, lengthsensing Outrigger Monitoring System (OMS).

18 For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide,

call 800/523-2200 or e-mail: cmongeau@cegltd.com

A host of new standard features include footrest bars, improved foot pedal spacing, all-weather, molded floor mat, fold-down shelves behind the seat, a pivoting cup holder, USB charging port, a windshield sun visor and a windshield washer for the skylight.

Storage is improved, with the addition of space around the front deck plus a box and headache ball tray to the rightfront side. On the left side, below the new cab, there is space to stow cribbing mats, while a compartment just above this includes not only additional storage, but also facilitates easy ground access to carrier electrical components.

Access All Areas

The new carrier paves the way for a host of ergonomic improvements, with its flat, aluminum decking allowing for better rigging and maintenance access. Storage is improved, with the addition of space around the front deck plus a box and headache ball tray to the right-front side. On the left side, below the new cab, there is space to stow cribbing mats, while a compartment just above this includes not only additional storage, but also facilitates easy ground access to carrier electrical components.

Operator comfort is improved due to a new, wider Full Vision cab with features such as a tilt/telescopic steering column, a wider, heated, electrically adjustable seat, and a three-camera package that maximizes visibility around the crane. The larger door and wrap-around hand railing and grab bars encourage more secure access. A new LED lighting package includes new installations on each side of the carrier plus dual, front-mounted lights on the 20degree tiltable cab for a clearer view of the load and fewer blind spots.

A host of new standard features include footrest bars, improved foot pedal spacing, all-weather, molded floor mat, fold-down shelves behind the seat, a pivoting cup holder, USB charging port,

a windshield sun visor and a windshield washer for the skylight. Manitowoc’s Crane Control System (CCS) is now mounted on adjustable arms for easy adaptation with convenient and comfortable control coming from the armrest jog dial. Also included within CCS is the on-Crane Service Interface (0CSI) which provides enhanced diagnostics and monitoring systems for easy maintenance.

Fuel’s Gold

CCS also helps deliver significant savings in total cost of ownership on the GRT8100-1, allowing the new 6-cylinder, turbocharged and water-cooled Cummins B6.7L engine to operate in ECO mode. Here, the reduced engine speeds that promote improvements in fuel efficiency have been aided by the torque convertor installed with the new Rangeshift transmission.

Repowered to ensure compliance with Euromot Stage 5/Tier IV Final regulations, the new crane benefits from approximately 10 percent more power, producing 224 kW (300 hp) at 2,500 rpm, while its single-module aftertreatment system with DEF reduces complexity and saves weight.

For more information, visit www.manitowoc.com.

19

For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com

Manitowoc Crawler

Cranes Create New Chapter of

Iconic Bridge

Landmark Upgrades

The Howard Frankland Bridge has been an iconic Florida landmark for more than half a century, carrying 132,000 vehicles along I-275 between Tampa and St. Petersburg daily. However, its infamous traffic jams have resulted in the bridge becoming a major chokepoint, and multiple expansions since its opening in 1960 have proven only partially successful in reducing congestion and traffic accidents.

Once again, the bridge is undergoing a major upgrade — and an army of Manitowoc cranes is almost exclusively providing the heavy-duty support necessary for the Florida Department of Transportation’s largest-ever plan to cater to future growth in the Tampa Bay area.

The bridge’s design and construction are a 60:40 joint venture between Archer Western Construction LLC, part of The Walsh Group, and Traylor Bros. Inc.

Work began in November 2020 on the $865.3 million project to build a brand-new structure alongside the existing southbound bridge. At just under 3 mi. long, the complex new, 168 ft.-wide design will support more deck area than any other bridge in the state, which explains why 3,000 concrete and steel piles — a potential 43 mi.

worth of them — will be installed into the bay’s limestone bedrock. It also reveals why more than 20 lattice-boom Manitowoc crawlers, including a 4100 ringer, are the workhorse fleet on the project, boasting the best load charts in their class and outstanding performance in bridge-building operations. Models include 14000, 999s, 2250s, 888 and MLC300s, with standard maximum capacities between 220 and 363 tons.

Trusted Choice

Planning for the crane-intensive project started 1,200 mi. away at The Walsh Group’s Chicago headquarters.

“One of the unique challenges of this job is the sheer number of cranes needed. From a business stance, buying all new was not the right option, so we used a mixed strategy. With the volume of Manitowoc crawlers in our fleet, we refurbished many of our existing cranes and supplemented them with four new MLC300 models,” said Chris Stearns, senior manager at Walsh.

“We also purchased used Manitowoc crawlers that were refurbished by the Walsh shops in Chicago and Texas and at Manitowoc dealer Ring Power Crane in Florida.”

Ring Power Crane refurbished and repaired several 2250s, 888s, 14000s and one MLC300, with all work completed inhouse at its Riverview, Fla., location. This included an overhaul of the mechanical and hydraulic systems, tracks and full repainting of each refurbished crane.

Walsh turned to Manitowoc dealer Walter Payton Power Equipment, based in Riverdale, Ill., to help prepare an armada of ready-to-work cranes. In addition to providing parts for the refurb, WPPE offered guidance on crawler selection and configuration, barge loading processes, and special adaptions to fortify the units for marine applications.

The bridge’s construction is linear, starting at both ends concurrently and progressing to the center. This required tight coordination for equipment selection, said Pat Delis, Walsh’s account rep at WPPE.

“Part of the challenge with driving pile in Tampa Bay is that the geology of the rock changes rather rapidly across the entire bay, both in-depth and hardness. Once we’ve selected the correct model for the capacity and radius, each crane needed to be configured specific to its application,” Delis said. “Strong charts were a major concern since the center of gravity is always changing on the water, and Manitowoc crawlers have a reputation for their solid barge charts.”

As of May 2022, crews have sunk more than 1,700 concrete piles, ranging anywhere from 77 to 121 ft. in length due to the uneven floor of the basin.

“Each concrete pile weighs about 1,000 lbs. per foot, so if we’re driving a 121-foot pile, you’re looking for around 121,000 lbs. to trek that pile from just one crane. So, this isn’t a job for just any crane,” said Greg Fullington, project executive of The Walsh Group.

In typical pile driving from barges, beams of this size require two crawlers to tip into position. Seeking a more productive method, Walter Payton collaborated with the Manitowoc Lift Solutions team to design special tilt block adaptors to deftly handle the piles.

20

information

For

about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com

Another complexity of marine piledriving is the constant saltwater spray back from augering. The crawlers were fortified with a special marine-based zinc undercoating to resist corrosion over the five years the cranes will be on the water.

“Now, you can place the pile with a single crane because you can hang two blocks from the same point,” said Dustin Soerens, product support specialist of Walter Payton. “The tilt block adaptor pins into the lower boom point and provides sheave-mounted transverse to the boom, allowing the piles to be tilted side-to-side without exceeding the allowable angles of the wire rope reeving.”

Another complexity of marine piledriving is the constant saltwater spray back from augering. The crawlers were fortified with a special marine-based zinc undercoating to resist corrosion over the five years the cranes will be on the water.

Peak Performance

Uptime is non-negotiable for a project of this scale. Whether driving concrete or sheet piles, the contractor’s intensive regular inspection program, in conjunction with Manitowoc’s legendary high build quality, is ensuring all cranes continue to operate in peak condition.

“We’ve rarely experienced any unexpected downtime,” Stearns said. “With all those vibrations, we must pay close attention to the boom tips. We perform monthly inspections, which equates to servicing a crane each working day.”

Barge servicing is unconventional but efficient. Ranging from a minimum of 290 ft. in the heavy-lift configuration on the 999 to 334.6 ft. on the MLC300, each boom is too long to be laid tip-down while the crane is on its work platform. Instead, a second barge is positioned in front to accommodate the extended boom, while a maintenance barge moors alongside to begin servicing.

“In my opinion, Manitowoc cranes offer a good balance of performance capabilities, and technology without excess complexity,” said Greg Moore, senior equipment manager at The Walsh Group. “The operators like the cranes, they are intuitive to use, and our technicians find them easy to maintain.”

The project underlines the strength of the Manitowoc dealer net-

More than 20 lattice-boom Manitowoc crawlers, including a 4100 ringer, are the workhorse fleet on the project, boasting the best load charts in their class and outstanding performance in bridge-building operations. Models include 14000, 999s, 2250s, 888, and MLC300s.

work to give Walsh, and all customers, a consistently high level of service nationwide.

While Walter Payton provides technical and service support from Illinois, in Tampa, local Manitowoc dealer Ring Power Crane is lending daily boots-on-the-ground personnel.

“We’ve partnered with Walter Payton and Walsh for many years as jobs bring their cranes into our territory. Additionally, the support and flexibility we receive from the Manitowoc factory team in Wisconsin have been exceptional. Whenever we call, we reach a real person and get the issue resolved on the spot,” said David Courtney, vice president, product support and operations manager for Ring Power Crane.

For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com

21

The bridge’s construction is linear, starting at both ends concurrently and progressing to the center. This required tight coordination for equipment selection.

Working in Harmony

Many of the project’s challenges come from the natural world.

“The bay is an environmentally sensitive area, so we’ve hired dedicated personnel to look out for manatees and any other endangered species in the waters around the bridge. Manatees are attracted by the seagrasses, which we mark with buoys to ensure our barges don’t impact them, or that we don’t split down our equipment in those areas. Any time they come within proximity of our equipment, we’re required to shut down until they leave the area before we can work,” Fullington said.

For an added level of environmental protection, the crawlers use a special biodegradable-type hydraulic fluid that was formulated and approved by Manitowoc Lift Solutions to replace standard petroleum-based lubricants.

“We pay a lot of attention to the hydraulic hoses during inspections and replace them scheduled, preventive fashion — the ultimate goal is to make sure no oil gets off the barge,” Moore said.

“Another way we are minimizing our effects on the bay is at the foundations of our piling operations,” Fullington added. “We’re performing underwater acoustic studies with the help of a local university to measure the decibel level of our operation to ensure that we’re below allowable thresholds.”

As one of the U.S.’s largest bridge builders, Archer Western’s expertise is key to keeping the project on pace for a 2025 completion. The new bridge will support eight lanes, comprising four general use and two express (tolled) southbound lanes, and two express northbound lanes, in addition to a 12 ft.-wide shared-use

path for cyclists and pedestrians. With one section built with heavier loads in mind, the new bridge also has been designed to meet future demand for a light-rail transit system and accommodate selfdriving cars.

Once the new bridge is fully opened, demolition of the original span will be the final chapter in its well-traveled story — one in which Manitowoc crawlers will likely play a central role, again.

For more information, visit www.manitowoc.com.

Looking Back: Cranes

22

For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com

While Walter Payton provides technical and service support from Illinois, in Tampa, local Manitowoc dealer Ring Power Crane is lending daily boots-on-the-ground personnel.

Working to preserve the history of the construction equipment that shaped our world . . .

Courtesy of Historical Construction Equipment Association

Besides conventional lifts not requiring special equipment or attachments, marine derricks could be rigged for a wide range of work. Merritt-Chapman & Scott’s Cherokee, based in Cleveland, Ohio, is rigged here for vessel salvage over her stern. She is recovering the sunken tug Sachem on Oct. 22, 1951.

Dunbar & Sullivan Dredging Company collection, HCEA Archives

This restored 1926 Link-Belt K-2 crane, named Big Bertha, is the oldest Link-Belt crane known to exist. She’s one of the main exhibits of the National Construction Equipment Museum, operated by the Historical Construction Equipment Association. In this image, she’s handling equipment at the HCEA’s 1995 International Convention & Old Equipment Exposition at the Museum.

HCEA Archives

For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com 23 For 75 year trust and c class-leadi National Cr > Stand-up s,National Cran onfidence of our ng features,and ane boom trucks a models with capaci e boom trucks co r customers than wide range of av re available in: ties from 10 USt to 3 ntinue to earn th ks to their durab vailable accessori 3 USt e ility, es. > Swing seaat models with capaacities from 30 USt to 60 USt www.manitowoc w .com Corporate Headquarters 300 South Randolphville Rd. Piscataway, NJ 08854 732-752-3600 South Jersey 1330 Hurffville Rd. Deptford, NJ 08096 856-227-6400 Long Island 22 Peconic Ave. Medford, NY 11763 631-207-2900 Mid-Hudson Valley 1440 Route 9W Marlboro, NY 12542 845-236-3000 New York City 1144 Zerega Ave Bronx, NY 10462 718-822-1180 Corporate Headquarters

PA 7201 Paxton Street Harrisburg, PA 17111 800-325-6455

PA 8181 Noblestown Road McDonald, PA 15057 800-692-7600

PA 135 Lincoln Avenue Prospect, PA 19076 800-220-4033

PA

ALT Sales Corp. 4945 Brecksville

Dawes Rigging & Crane Rental

555th Ave

Hyland Ave.

WI

www.stephensonequipment.com www.hoffmanequip.com

Harrisburg,

Pittsburgh,

Philadelphia,

Wilkes-Barre,

600 Sathers Drive Pittston, PA 18640 866-667-6756

Rd. Richfield, OH 44286 330-659-2100

E8670

Elk Mound, WI 54739 800-943-2277 2401

Kaukauna,

54130 800-236-8630

24 For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com Rent & Roll! y s Y pa lo e stributor a o t has you w co lt kbe lin w . . m , USA entucky Lexington, K er ns nline The o a w w www.linkbelt.com | ques Crane Link-Belt our of l a to l y tions. Find us on: Link-Belt Cranes

Alta Equipment Company

www.altaequipment.com

Byron Center, MI (616) 878-7450

New Hudson, MI (248) 356-5200

Flint (Burton), MI (810) 744-4840

Traverse City, MI (231) 943-3700

Detroit, MI (313) 394-1811

Atlantic & Southern Equipment

www.atlanticandsouthern.com

Birmingham, AL (205) 951-6656

Theodore, AL (251) 443-5229

Lake City, GA (404) 361-1100

Central/Eastern, TN (888) 951-6656

Columbus Equipment Company

www.columbusequipment.com

Columbus (614) 443-6541

Toledo (419) 872-7101

Cincinnati (513) 771-3922

Richfield (330) 659-6681

Cadiz (740) 942-8871

Dayton (937) 879-3154

Massillon (330) 833-2420

Zanesville (740) 455-4036

Painesville (440) 352-0452

Piketon (740) 289-3757

General Equipment & Supplies

www.genequip.com

Shakopee, MN (952) 224-1500

Minot, ND (701) 852-0479

Fargo, ND (800) 437-2924

Bismarck, ND (701) 223-9700

Williston, ND (701) 572-0570

Kelly Tractor Co. Crane & Foundation Equipment

www.kellytractor.com

Clewiston, FL (863) 983-8177

Davie, FL (954) 581-8181

Ft. Myers (239) 693-9233

Mulberry, FL (863) 205-2537

Miami, FL (305) 592-5360 Orlando, FL (407) 568-8055

West Palm Beach, FL (561) 683-1231

Rudd Equipment Company www.ruddequipment.com

Louisville, KY (800) 283-7833

Corbin, KY (606) 528-9440

Prestonsburg, KY (606) 874-2104

Evansville, IN (812) 867-6661

Ft. Wayne, IN (260) 482-3681

Indianapolis, IN (317) 247-9125

St. Louis, MO (314) 487-8925

Clearfield, PA (814) 765-8500

Leetsdale, PA (412) 741-1731

Nitro, WV (304) 755-7788

Link-Belt Construction Equipment Mid-Atlantic

www.link-beltmidatlantic.com

Ashland, VA (800) 552-3837

Chesapeake, VA (800) 342-3248 Frederick, MD (833) 546-5235

Transport Equipment Sales www.tes-inc.net

South Kearny, NJ (973) 589-4100

Triad Machinery www.triadmachinery.com

NessCampbell

Crane + Rigging

www.nesscampbell.com Caldwell, ID (208) 366-9727 Portland, OR (503) 486-4150 Bothell, WA (206) 590-3420

Nixon-Egli Equipment Co. www.nixonegli.com Ontario, CA (909) 930-1822 Tracy, CA (209) 830-8600

Rexco Equipment Inc. www.rexcoequipment.com

Burlington, IA (319) 419-6050

Cedar Rapids, IA (319) 393-2820 Davenport, IA (563) 381-1200 Des Moines, IA (515) 287-4910

Portland, OR (503) 254-5100

Eugene, OR (541) 342-7700

Bend/Prineville, OR (541) 447-5293

Seattle/Tacoma, WA (253) 722-5560

Spokane, WA (509) 534-1900

Mt. Vernon, WA (360) 488-3948

Wood’s CRW Corp www.woodscrw.com

Carlisle, PA (717) 795-0700

Central Square, NY (315) 676-2008

Williston, VT (802) 658-1700

North Oxford, MA (508) 499-1950

For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com

25

Altaequipment.com

18405 115th Avenue Orland Park, IL 60467 877-399-6430

420 Nolen Drive South Elgin, IL 60177 877-399-6430

2500 Westward Drive Spring Grove, IL 60081 815-581-1479

613 E Stevenson Road Ottawa, IL 61350 815-587-7610

1035 Wylie Drive Bloomington, IL 61705 888-693-2271

480 Blaine Street Gary, IN 46406 219-240-0268

empirecrane.com

7021 Performance Drive N. Syracuse, NY 13212 800-342-7575

9 Finderne Avenue, Ste 7 Bridgewater, NJ 08807 908-203-0400

12 Mear Road Holbrook, MA 02343 508-868-7734

coastlinecd.com

325 N. 5th Street, Bldg. A Sacramento, CA 95811 916-440-8090

Santa Ana, CA 714-265-6550

Las Vegas, NV 702-399-2700

Meridian, ID 208-888-3337

smequipment.com

14925 South Main St. Houston, TX 77035 713-721-7070

Dallas, TX 214-391-4000

Corpus Christi, TX 361-289-2782 Tulsa, OK 918-224-2000

exactcrane.com

Serving Ohio, Michigan, W. Pennsylvania, Kentucky 28985 Ambina Drive Solon, OH 44139 440-349-1999

26 For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call

or

800/523-2200

e-mail: cmongeau@cegltd.com

TAC Distributor Ad 2021_CEG.indd 1 9/30/2021 11:06:04 AM 1 2 0 2 d t L s utortrib no ad a T © TAC Distributor Ad 2021_CEG.indd 1 9/30/2021 11:06:04 AM tadano w w w com ricasame aCcireomnAada Ts nee2r4WG,2n4oirtopr oa6P 607,X7nTotsu,odH R0 300-9)6188:+2eno h1(

For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com 27 HAYDEN-MURPHY EQUIPMENT COMPANY | www. ayden- urphy.com | Minneapolis, MN QUALITY PRODUCTS | SUPERIOR SUPPORT | COMPETITIVE PRICES 2014 GROVE RT880E Hours: 6,100, Stk# 23624, S/N: 234595, 275 HP, 4Wheel Drive, 80 Ton Capacity, Enclosed ROPS, 90ton 5-Sheave Hook Block, 12 ton O/H Ball, 4-Sheave Boom Nose, 41’-128’ FourSection Megaform Boom, LMI & A2B, Cummins QSB6.7L Engine $325,000 2015 MANITOWOC 11000-1 Hours: 5,430, STK# 22347, S/N: 11001156, 110 Ton Capacity, Hino J08eUv Tier 4 Engine, Hyd Over Hyd Controls, 150ft Heavy-Lift Boom, 3rd Drum, 50 Ton Block, 5-Piece Counterweight, Cab With Safety Glass $495,000 2017 GROVE GRT650 Hours: 1,931, STK# 1665, S/ N: 235986, 164 HP, 4 Wheel Drive, 50 Ton Capacity, Enclosed ROPS, 35 Ton 4-Sheave Quick-Reeve Hook Block, 34’-114’ Four-Section Full-Power Boom, 26’-45’ Off-Settable Telescoping Swing-Away Jib, 2 Hoists, Cummins QSB6.7L Engine . $409,000 2015 GROVE RT890E Hours: 6,086, Stk# N000520, S/N: 235109, 90 ton Capacity, 5 Sheave 90 Ton Block; Ball; 142’ Boom, 33’-56’ Jib $315,000 2014 GROVE RT765E-2 Hours: 4,581, Stk# 1603, S/N: 400023, 65 ton Capacity, 65 ton 5-Sheave Hook Block, 8.3ton Headache Ball with Hook, Graphic LMI & Anti-Two Block System, 4-Sheave Boom Nose, 36’-110’ Boom, 33’-56’ Jib, 2 Hoists, Tier 3 Engine $369,000 2020 GROVE RT540E Hours: 478, Stk# 1716, S/N: 236997, 40 Ton Capacity, Single Hoist, Tier 4 Final Engine, Block, Ball, 102’ Boom, 45’ Jib $419,000 RT540E RT765E-2 RT880E GRT650 GRT650L GRT880 RT890E GRT8090 GRT8100 Multiple Units For Sale / Rent / RPO. CALL FOR MORE INFORMATION

28 For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com

The power and reach of both units is undeniable, but their secret weapon might be Liebherr’s onboard LICCON2 control system. Lift planners can map out lifts ahead of time then share that screen with operators as they’re sitting in the cab.

The Liebherr LR 11000 and Liebherr LR 1800-1.0 are recent acquisitions by the ALL Family of Companies.

The power and reach of both units is undeniable, but their secret weapon might be Liebherr’s onboard LICCON2 control system. Lift planners can map out lifts ahead of time then share that screen with operators as they’re sitting in the cab.

The Liebherr LR 11000 and Liebherr LR 1800-1.0 are recent acquisitions by the ALL Family of Companies.