YOU’LL SEE THE DIFFERENCE.

If you think you’ve seen CASE, it’s time to look again. We’re digging deeper, pushing harder and reaching higher to help you win. It starts at CONEXPO, where we’re reloaded with swift, smart, smooth, groundbreaking new products across our line. And a plan to help you do more work with less sweat and drive more profit than ever before. If you’re going to CONEXPO, stop by our exhibit. If you’re not, check out CASECE.com. We’re The New CASE. You’ll see the difference.

MARCH 2023 | CONEXPO

HECK OUT THE NEW CASE at its booth in the West Hall (W40800) and you’ll immediately see the difference. More than 30 new machines, tons of new attachments and loads of knowledgeable team members ready to help you get more done, with greater ease and more profitably than ever before. Case is digging deeper, pushing harder and reaching higher to help its customers win. In addition, you’ll also learn about ingenious new technology, services and business solutions designed to help customers get ahead every day.

Get a close look at the Case Minotaur DL550, the industry’s first compact dozer loader that created an all-new equipment category and put the construction world on notice that you can have true dozing and grading performance, as well as powerful site loading capabilities and compatibility with hundreds of attachments all-in-one platform that sets the bar for versatility, power and precision in a single machine.

The company also will showcase multiple new product introductions including the all-new Case E Series excavators: seven new models, including

two in new size classes. These machines are focused on enhancing the total operator experience in performance and control to deliver even greater productivity, operator satisfaction and operational efficiency while driving down total cost of ownership over the life of the machine.

What else does Case have in store? All-together, the company will introduce more than 20 new models; highlight new ways it is delivering hippocket support; equipment financing; and real world know-how and robust rental and attachment solutions in its commitment to elevate the operator experience and outwork all competition in helping customers build more business success. For more information, visit CaseCE.com/SeeTheDifference.

About Case Minotaur DL550 Compact Dozer Loader

Weighing in at more than 18,000 lbs. and working with 114 hp, the new first-of-its-kind machine delivers true dozing and grading performance, as well as powerful site loading capabilities and compatibility with hundreds of attachments.

The hallmark advancement of the Case

Minotaur DL550 is the chassis-integrated C-frame with six-way dozer blade. The C-frame hydraulically couples into both the chassis of the machine, as well as the attachment coupler. This design provides the stability and smooth operating plane of a small dozer while ensuring that all operating power is channeled through the whole body of the machine. This establishes greater performance and long-term reliability than the simple combination of a dozer blade attachment to a traditional compact track loader.

It also comes standard with Case Universal Machine Control, which makes the machine ready for any of the major three providers of machine control technology, which are sold separately. It’s also available with an optional, industry-exclusive fully integrated ripper for tearing up tough terrain to simplify dozing and earthmoving operations.

The C-frame is then detached to allow the operator to use it as a loader with a heavy-duty 1.25cu.-yd. bucket, or with hundreds of common loader attachments many equipment owners already have in their fleet. For more information, visit CaseCE.com/Minotaur.

DEVELON

DOOSAN CONSTRUCTION EQUIPMENT IS NOW DEVELON and is on the move at ConExpo-Con/AGG. It starts with a new name, bold vision and expansive booth at a new location in the Festival Grounds, where attendees will find a full fleet of equipment on site; an immersive innovation area to learn about exclusive technologies; and daily live demos featuring autonomous equipment and technologies in action. It’s a great opportunity to learn about DEVELON’s plans for the future and experience how DEVELON is helping to solve the challenges of tomorrow — right now.

Featured Equipment

Make plans to visit DEVELON at the show and talk with product experts about the latest equipment that will be on display, including:

-7 Series crawler excavators — Added comfort features and advanced functionality.

-7 Series mini-excavators — Impressive digging and lifting and best-inclass air conditioning, according to the company.

-7 Series wheel loaders — With industry-exclusive Transparent Bucket option.

Log loader — Durable design for working in extreme conditions.

Articulated dump truck — Larger load capacities and superior power and traction.

• Dozer — Impressive horsepower, visibility and ease of operation.

• Future products — Learn about new technologies the company is working on.

Innovative Solutions

Inside the booth, explore several equipment innovations and learn about the new Smart X-Care machine monitoring service that puts a team of experts to work tracking your machine telematics and helping to protect customers’ equipment investment.

Live Machine Demos

MotorTrend TV’s Scott Hoke will emcee live on site demos several times each day featuring Concept-X equipment.

The team will be on-site daily and looks forward to talking about the products, services and plans for the future. The team is eager to discuss opportunities for partners to work with the company to build future success.

Stop by booth F9153 in the Festival Grounds and scan the QR code to get additional updates on what to expect from DEVELON at ConExpo-Con/AGG 2023.

GOMACO

THE GOMACO GP3 SLIPFORM

PAVER is designed for paving up to 30 ft. wide and able to accommodate multiple width changes. It is available as a twotrack or four-track paver with advanced paver controls, automation and intelligent valves. Also included is the G+ control system, which interfaces with stringline and 3D machine guidance.

The GP3 two-track and four-track pavers feature dual-telescoping capabilities of up to 7 ft. on each side of the paver, for a total of 14 ft. of automatic frame widening. The four-track has smart leg positioning, including rotary-sensored slew drives on the pivot arms of each of the paver’s legs. These smart pivots relay information to the G+ control system, which works together with track rotation sensors to maintain the tracks in the straight-ahead steering line.

The GP3’s smart cylinders in the roller frame provide the width reference to the G+controller, which uses that information for steering setup and individual track speed control through radii.

The self-programming valves eliminate the need to set thresholds. The valves, working with the paver’s G+ control system, understand and can automatically react and self-adjust to the dynamics of the machine.

Rotary-sensored slew drives are located on all four tracks for the ultimate in smart steering technology and extreme steering with the tracks having the ability to steer farther than ever before, according to the company.

When the operator fine-tunes or makes sensitivity adjustments from any display at any time, GOMACO’s G+ software recognizes the change requests and immediately makes those adjustments. This allows automatic correction of the paver’s elevation, steering, pivoting, travel control, anti-slip positive traction of the tracks and more.

G+ controls incorporate GOMACO’s vibrator monitoring system with the ability to monitor, control and diagnose each individual vibrator on the paver. The touchscreen display illustrates the performance of each vibrator. The operator can see where adjustments need to be made and can make those adjustments electronically for an instant and on-the-go response.

GOMACO’s Navigator display software brings all G+ paver accessories together for easy control and monitoring on an optional touchscreen display. It is fully Wi-Fi capable to allow wireless control from

multiple display screens anywhere on the paver. A wireless extension allows ground personnel the ability to view and make fine-tuned adjustments to the paver’s performance and configure settings for the GSI, side bar inserters, tie bar inserters and power transition adjuster using any tablet or phone.

Machine-to-machine communication is possible using the GOMACO Navigator display and G+ control. When a GOMACO paving train is at work on a project, the GP3 paver can talk to the other GOMACO equipment on the project with a G+ control system. For example, if a GOMACO placer/spreader is at work in front of a GP3 paver, the paver and the concrete being placed in front of the paver is too low, it can tell the placer/spreader to raise its strike-off and allow more concrete to be placed. Machine-to-machine communication introduces a new era of automation, paver intelligence and ultimate performance to GOMACO equipment.

The technology is advancing throughout GOMACO’s entire line of concrete slipform paving equipment. The new self-programming valves also are being integrated into GOMACO’s full line of curb and gutter machines.

GOMACO Corporation is a worldwide leader in

concrete construction equipment with headquarters in Ida Grove, Iowa, and its subsidiary GOMACO International Limited located in the United Kingdom. GOMACO equipment will slipform concrete streets and highways, airport runways, curb and gutter, sidewalks and recreational trails, farm roads, animal sheds, concrete safety barrier, bridge parapet, slab track for rails, tunnels, irrigation canals and dams.

Support equipment includes grade trimmers, material handling placers, concrete placer/spreaders and concrete surface texturing and curing machines. The company also offers a range of equipment to finish flat slabs, bridge decks and slopes.

GOMACO will consult on unique concrete paving applications and in turn develop suitable equipment. Products are offered through a worldwide distributor network for local sales, parts and service expertise.

GOMACO will be at booth C30280 in Central Hall during ConExpo-Con/AGG March 14 to 18 at the Las Vegas convention center. The company will introduce convention goers to its latest machines and technology, as well as have many of these machines on display.

THE DOER’S DREAM

Loved for the features. Trusted for the performance.

Do more without feeling like it in Hyundai’s new HX mini excavator series.

• Distinctive, award winning ‘Tiger Eye’ design

• Load-sensing hydraulic system (HX40A, HX48A Z)

• 5” color LCD monitor

• Auto safety lock for unintended operation

• Large, quiet, tilting cab delivers excellent service access

• Free Hi MATE telematics access for 5 years

• Bluetooth radio, now a standard option

“Winner of the 2022 Red Dot Design Award”

Date: March 14-18th, 2023

West Hall, Booth #W42501

Las Vegas Convention Center

Las Vegas, Nevada

See the Hyundai difference yourself at CONEXPO, your local dealer, or hceamericas.com

ISUZU HAS PROVEN TO BE RELIABLE, eco-friendly, durable and technologically advanced, according to the company. Its Tier IV and Stage V engines and power units, branded under Isuzu REDTech, provide quiet, low maintenance and fuel-efficient solutions for existing and new applications.

From 6.7 to 397 kW, these engines and power units are precision tuned for its highest efficiency, while reducing oil and fuel consumption. A longlasting and robust fuel injection system incorporates excellent fuel economy and extended service life.

Stringent criteria to lower NVH (noise, vibration, harshness) are engineered into every Isuzu product. Each application is designed to meet customer specifications and is engineering validated for each environment. Isuzu REDTech engines and power units with reliable performance, durability and high thermal efficiency help reduce downtime.

Isuzu Open GenSet Ready Power Units

Isuzu open GenSet power units provide available power when needed. This is even more important today with unpredictable hurricanes, tornadoes and storms in all parts of the United States.

These Tier IV Certified 4J Series 3.0L, 4 Cylinder, 70.8 kW (95 hp) @ 1,800 rpm and 4H Series 5.2L, 4 Cylinder, 127.5 kW (171 hp) @1,800 rpm, and the new 6H Series 7.8L, 6 Cylinder, 193.8 kW (260 hp) @1,800 rpm can save time, money and resources because they are pre-tested and are more than 90 percent validated, for generator- and alternator-end manufactures and equipped with adjustable bolton mountings for ease of installation for multiple generator applications — saving customers time for their engineering resources when they experience increased workloads and slower market turn-a-rounds.

Isuzu Digital Controller

With industrial-grade sealed connectors, the Isuzu Diesel REDTech digital controller for all current tier engine and power unit models works indoors/outdoors in hot/cold conditions and is sunlight, water and soil resistant. It is technologically advanced for generator monitoring, automatic ramping, maintenance reminders and expandable for future applications and telematics.

Included is a single controller part number system for easy, infinite reprogramming for a variety of engine applications with an auxiliary harness and USB port. The Isuzu REDTech controller can be used with constant and/or variable speed engines and is now available in North and South American markets.

Global Leader of Innovative Power With Caring People

There are more than 28,000,000 Isuzu engines spanning more than 100 countries. Isuzu supports power requirements, from agricultural, construction, industrial, medical and rental markets, providing environmentally responsible and critical power products for specific applications. Building and maintaining a professional organization backed by product warranties that go up to 5 years/5,000 hours with power solutions that work, All Isuzu Diesel products are supported by Genuine Isuzu Parts, a distributor and dealer network along with dedicated professionals to ensure power solutions that are available today and into the future. Isuzu will be located at booth S83906 during ConExpo.

HYUNDAI

Booth #W42501

Hyundai Construction Equipment Americas will introduce three compact excavator models at ConExpo‐Con/AGG — the HX35AZ, the HX40A and the HX48AZ.

HYUNDAI CONSTRUCTION EQUIPMENT

AMERICAS REVEALED PLANS for its participation in ConExpo-Con/AGG 2023, with a major exhibit featuring a wide range of new, current and future machine models, plus demos of machine safety and remote management systems.

The company’s 31,000-sq.-ft. exhibit will be located in the West Hall of the Las Vegas Convention Center, Booth W42501. The triennial construction equipment exposition — the biggest in North America — runs from March 14 to 18.

“Hyundai brings to ConExpo-Con/AGG our strongest and deepest lineup of products, along with exciting, alternative-powered working prototypes and some of the industry’s top safety and support systems, plus our team of sales, support and product experts,” said Stan Park, president, Hyundai Construction Equipment Americas. “This also marks our first ConExpo-Con/AGG since the recent Hyundai acquisition of Doosan Infracore, now known as DEVELON. Visitors will see some of the promising, early results of our collaborative efforts, including one of our new articulated dump truck models.”

New Compact Excavators Feature Award-Winning Design

Among new Hyundai models at the show are three compact excavators — the HX35AZ, HX40A and HX48AZ — that collectively earned a coveted international Red Dot Design Award, honoring the best product and industrial designs from around the globe.

In addition to complying with Tier IV Final emis-

sions standards, the three compact excavators feature a distinctive new “Tiger Eye” design; large cabs; larger windows for increased visibility; enhanced operator comfort; load-sensing hydraulics (HX40A and HX48AZ) incorporating adjustable auxiliary flow; zero-tailswing (HX35AZ and HX48AZ); 5-in. full color LCD monitor; new auto safety lock function which prevents unintended use of a machine both from an engine and hydraulic standpoint; and five years free use of Hyundai’s exclusive HiMATE telematics system. All three of the new HX-A series compact excavators will be offered in both canopy or cabin versions along with the choice of standard or 4-way dozer blade.

Hyundai Re-Enters Skid Steer, Compact Track Loader Categories

Also at ConExpo-Con/AGG, Hyundai will display for the first time its newly available model HS120V skid steer loader and HT100V compact track loader, representing Hyundai’s reentry into these compact equipment categories. The two new Hyundai compact models are powered by a 148-cu.-in. Hyundai 4HTI4 four-cycle, turbocharged, electronic-controlled diesel engine. This new Hyundai engine meets Tier IV Final emissions standards.

New, Largest Wheel Loader Leads Parade of Full-Sized Hyundai Machines

Show-goers looking for full-sized construction machines will find five Hyundai HL wheel loader models, six Hyundai HX excavator models and two Hyundai HW wheeled excavator models, equipped

with a variety of productivity-enhancing attachments and quick-couplers. Some of these workhorse excavators and wheel loaders will be featured in demonstrations of Hyundai safety, technology and telematics systems. Among the wheel loader models is the new Hyundai HL985A, the company’s largest capacity loader with a standard 9-cu.-yd. bucket, available in Q3 2023.

Alternative-Powered Excavator Prototypes Point to Future Direction

The Hyundai exhibit at ConExpo-Con/AGG also will include two alternative-powered, working prototype excavators. The Hyundai HW155H is a prototype wheeled excavator, powered by a hydrogenfueled engine. The prototype Hyundai R19E is an electric-powered compact excavator. The two-tonclass machine is designed for use both indoors and in urban settings.

Win Two-Year Lease

On Hyundai Ioniq 5 Electric Car

ConExpo-Con/AGG attendees may participate in the Hyundai Dream Drive Ioniq 5 Car Giveaway/Photo Contest for a chance to win a two-year lease on a Hyundai Ioniq 5 electric-powered automobile. Sponsored by Hyundai Construction Equipment Americas to demonstrate corporate-wide commitment to environmental sustainability, the contest will launch at ConExpoCon/AGG and remain open to entries throughout 2023.

For more information, visit www.hceamericas.com.

EAGLE CRUSHER

The new UltraMax 1600X‐OC portable impactor plant features Eagle Crusher’s UltraMax 69X impactor with a 69‐in. by 51‐in. feed opening to allow larger material into the impactor to increase throughput up to 1,000 tph.

EAGLE CRUSHER CO., A MANUFACTUR-

ER in the crushing and screening industry, continues its tradition of new product innovation leading into 2023. The company will introduce two new plants on display in the Eagle Crusher booth (C30949) at ConExpo-Con/AGG, March 14 to 18, 2023, in Las Vegas. Also on the show floor will be a proven product favorite.

The new UltraMax 1600X-OC portable impactor plant is designed for larger-size aggregate operations and quarries. It features Eagle Crusher’s UltraMax 69X impactor with a 69-in. by 51-in. feed opening to allow larger material into the impactor to increase throughput up to 1,000 tph. This means producers can prep less and crush more to reduce costs and increase profits.

The plant’s massive, solid-steel, three-bar, sculptured rotor, weighs in excess of 13 tons and

crushes even the largest feed material in a single pass.

Also in the booth is the new 8x20 screen plant with integrated feed conveyor and blending gates. This plant is for producers that demand multi-product screening and can produce up to four products simultaneously, three with absolute sizing, or return the oversized product for further reduction. The integrated 60-in. feed conveyor remains on for transport and eliminates the need for a separate conveyor, while each screen deck features four blending gates to allow for a wide range of custom product mixes to meet specific product needs.

The 2036 jaw crusher, also on the show floor, is one of five jaw crusher models manufactured by Eagle Crusher. Like all the company’s jaw crushers, the 2036 is designed to eliminate premature failures and provide years of component life, durabil-

ity and reliability. It processes abrasive hard rock, using the time tested overhead eccentric design. All moving parts are contained within the main housing, making it ideal for portable or skid mounting.

Partnering with producers worldwide to provide versatile, durable and reliable crushing and screening equipment, Eagle Crusher Co. has been an industry leader for more than 100 years. The company innovated the first solid-steel, three-bar rotor and lifetime rotor replacement warranty (North America only), developed the structural steel-frame jaw crusher and pioneered high volume portable crushing equipment for the construction-and-demolition debris recycling industry.

For more information, visit www.eaglecrusher.com/conexpo-con-agg-2023reveal/

TOPCON

MC‐Max increases processing power, speed, accuracy, versatility and reliability and can be installed on a full range of excavators and doz‐ers, using the same basic modular components.

IN BOOTH 43445 AT CONEXPO-CON/AGG 2023, visitors will be able to see first-hand everything that makes Topcon’s MCMax from the remarkable machine control technology it is. With the demand for construction projects continuing to grow, and the employee pool continuing to become smaller and smaller, there is a great deal of excitement about MC-Max and its ability to help operators dramatically increase the precision and productivity of the machines they are running, according to the company. MC-Max is setting the standard for innovation, enhancing machine control on a wide variety of construction equipment.

It increases processing power, speed, accuracy, versatility and reliability; and can be installed on a full range of excavators and dozers, using the same basic modular components. Modern user and product interfaces were developed based on real-world applications and customer feedback to provide a simplified and immersive user experience that allows operators to learn the system easily.

The multi-facet approach Topcon took when creating MC-Max lets the operator expand the versatility of construction equipment. In essence, construction equipment can now act as surveyor, operator and grade checker very quickly and easily. Also, MC-Max is incredibly flexible, allowing the operator to switch guidance modes on the fly for any job situation. That operator will be

in control at every phase, which is a very appealing feature for the success on job sites of all sizes.

MC-Max is a solution that is flexible and grows as a contractor’s needs and capabilities expand. It provides improved precision and overall accuracy in the field, while offering business owners real-time data integration, connectivity, and resource management capabilities across the entire workflow.

In addition to its ease-of-use, the MC-Max solution makes installation on all equipment easy, no matter the make or models of the machine. Flexible mounting solutions, as well as optional automatic blade and bucket control for a variety of machines are standard. The system also provides a full battery of positioning technologies ranging from slope control to laser, multi-constellation GNSS, robotic total station and Millimeter GPS systems.

The solution allows the user to keep track of everything happening on jobs as well. Project managers get a real-time view of machine positions, activities and onsite progress, and MC-Max is compatible with a wide range of existing site communications systems.

For more information on MC-Max, visit Booth #43445 at ConExpo 2023 or visit www.topconpsitioning.com/na/brawnmeetsbrains

MANITOU

Manitou will display its full line of material handling, lifting and earthmoving equipment at ConExpo 2023, while also introducing all‐new solutions — including significant new electrified models of popular product lines such as telehandlers, MEWPs and rotating telehandlers.

MANITOU WILL DISPLAY ITS FULL LINE of material handling, lifting and earthmoving equipment at ConExpo 2023, while also introducing all-new solutions — including significant new electrified models of popular product lines such as telehandlers, MEWPs and rotating telehandlers. The company also will make major product line introductions that will span numerous markets and affect some of the industry’s highest-volume product categories.

Manitou will showcase its service and solutions products, such as the EasyMANAGER telematics platform, countless attachments and accessories, financing programs and maintenance agreements — all focused on the mission of lowering total cost of ownership.

Electrification will be one of the hottest topics again at ConExpo 2023, and Manitou will be at the forefront of new electrified equipment with mobile elevating work platforms, rotating telehandlers and construction telehandlers designed to lower emissions and deliver a lower total cost of ownership over the life of the machine.

This includes models in popular size ranges and product categories, such as:

• MRT 2260 360 e and MRT 2660 360 e rotating telehandlers — Two new electric models of the popular rotating telehandler line feature a lift capacity of 13,200 lbs. with a maximum lift height of 71 ft. 6 in. and 85 ft., respectively. These MRT models enjoy the same performance level as diesel models, even while allowing for simultaneous boom movements. The 700 V/65 kW lithium-ion battery ensures optimum use of these models, even in difficult climate conditions. To boost the range by an additional four hours, a second 700 V/65 kW battery can be added. Users have a third option with a

hybrid version of these models using a range extender.

• MT 625 e compact construction telehandler — The Manitou MT 625 e telehandler offers the benefits of electric while maintaining high performance, working in the same footprint as the diesel model. This compact telehandler has a machine height of 6 ft. 3 in., width of 5 ft. 9 in., zero emissions and low overall machine noise — making it a perfect match for confined job sites and indoor applications. This new electric telehandler has a lift capacity of 5,500 lbs. and a maximum lift-height of 19 ft. 2 in. The MT 625 e is easy to operate fitted with a 25 or 33kW lithium-ion battery reducing maintenance by 56 percent and drastically decreases the total cost of ownership for the user.

• The Manitou Ultra-Light ULM compact telehandler — Launched in 2022 and a winner of numerous year-end awards, the Manitou ULM compact telehandler provides a unique solution due to its lightweight design, compact dimensions and ease of operation. Its empty vehicle weight is under 6,000 lbs., allowing these machines to be easily transported by a pick-up truck and trailer to almost any job site.

Additional Product Launches

In addition to the launch of the larger range of electrified machines, Manitou will be launching all new models that will impact some of the most common and largest-volume equipment categories in the construction industry. With each new introduction, Manitou is focused on lowering total cost of ownership for business owners and fleet managers — and Manitou will deliver on that promise in a big way at ConExpo 2023.

For more information, visit Manitou.com.

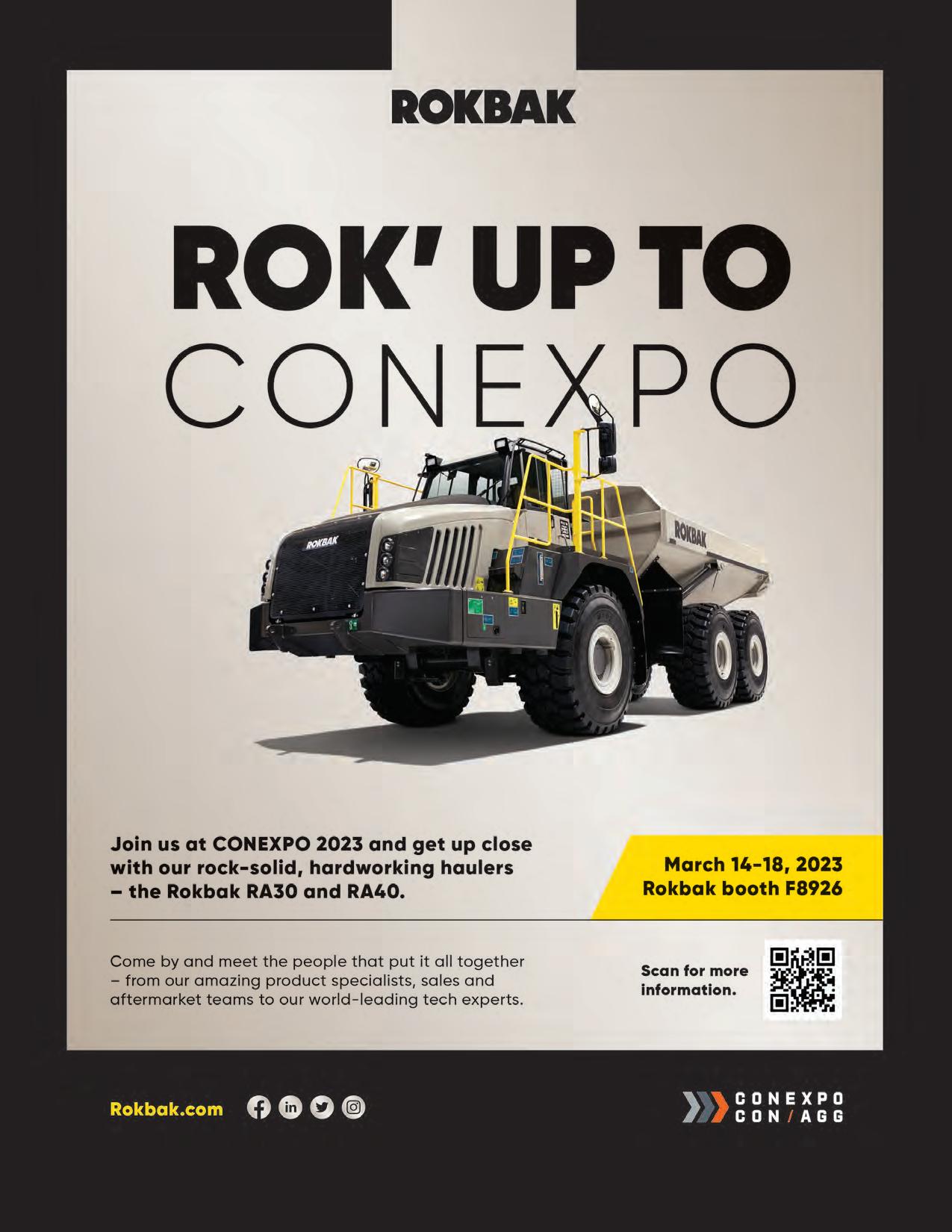

LBX

LBX COMPANY, HEADQUARTERED IN LEXINGTON,

KY., manufactures and markets Link-Belt excavators, forestry and material handling equipment.

William Dana Ewart patented the Link-Belt drive chain in 1874, laying the groundwork for a company based on problem-solving through hard work, creativity and innovation. When Link-Belt later introduced power hydraulic controls, they quickly rendered all other systems outdated and established a benchmark for the industry for years to come.

In 1998, LBX Company became a stand-alone company, representing the Link-Belt excavator, forestry and material handling equipment lines. Continuing to make strides in power and reliability, LBX Company is excited to announce its new 40B Series of forestry equipment and X4S Series of excavators.

The 40B Series boasts design improvements

that increase cooling performance, debris management and serviceability. The 4040B TL seeing an increase in engine horsepower of 20 percent. Coupled with increased cooling performance and airflow management, the 4040B TL is sure to keep going as long as you will.

With serviceability and debris management in mind, customers can remove the dust screen from the ground or catwalk to clean and reinstall it quickly and easily. Site awareness is always key. With 40B Series, you get a 270-degree birds-eye view with the WAVES system standard. Couple all this with fuel consumption and productivity, it’s a win-win, according to the company.

Link-Belt X4S excavators are Tier IV Final certified and built to save money on fuel without sacrificing strength. The new 355 X4S has a shortened tail swing with plenty of balance and power, giving it the versatility to meet the growing needs of today’s busy contractors. A 270-degree birds-eye

view with the WAVES system standard and a 10in. monitor offers better visibility during operation, while superior cycle time, lower fuel consumption, and fuel monitoring are included.

LBX has always been at the forefront of advancements in construction equipment technology. Precision Grade technology — powered by Trimble Earthworks — enables operators of all skill levels to see the bucket position relative to the desired grade as they work. Visual and audible cues ensure operators meet their target grade precisely the first time.

Equipment advancements like these are supported by a strong LBX dealer network, offering its owners ongoing sales, parts, service and technical support. Visit the ConExpo Festival Grounds and West Hall to see the Link-Belt excavators and innovations in action at Booth #W42000 and F9241.

AUSA

AUSA,

A MANUFACTURER OF COMPACT

ALL-TERRAIN

INDUS-

TRIAL VEHICLES, will be located at outdoor Festival Lot stand F9576 at ConExpo-Con/AGG.

The brand will be showcasing machines from all of its product ranges: dumpers, rough-terrain forklifts and telehandlers.

The dumper, AUSA’s flagship product, improves profitability for work sites as it is able to carry out earthwork much faster than a buggy, and when combined with a mini-excavator, this makes for a winning pair compared to skid steer or backhoe loaders, which are much slower due to the large number of tasks they have to perform, the manufacturer said.

AUSA will be presenting its recently-launched D151AEG electric dumper at the 2023 edition, with a 3,300-lb. payload and swivel-skip. Its new 100 percent electric technology provides sufficient range for a complete and intense shift, and it can be charged directly via 110 V or 230 V sockets, taking just two hours to charge from 20 percent to 80 percent (230 V).

The DR601AHG reversible drive dumper also will be on display, presenting its 13,200-lb. capacity and swivel-skip, along with its reversible driver’s seat, meaning the vehicle can always be driven forward for better visibility and safety.

AUSA will be showcasing machines from all of its product ranges: dumpers, rough‐terrain forklifts and telehandlers.

Apart from these two models, AUSA also will be presenting its 7,700-lb.

FAE USA

capacity D350AHG dumper; the 5,000-lb. and 11,000-lb. capacity C251H and C501H rough-terrain forklifts; and the T235H telehandler, with a 5,000lb. payload and a maximum lift of 16.4 ft.

FAE USA WILL BE DISPLAYING

ITS MOST EXTENSIVE EQUIPMENT selection ever with 17 machines on display that will include seven all new machine releases. At the heart of this vast display will be the new FAE remote-controlled track carriers for mulching applications. The largest FAE offering in this class — the RCU-75 model — is a compact, professional and powerful remote-controlled tracked carrier, which is the result of merging FAE’s extensive experience in designing track carriers for the PT series and remote-control systems for its Demining line vehicles.

The RCU-75 is designed to work in hard-toaccess areas and steeply sloping terrain that requires dedicated equipment to ensure operator safety and operating efficiency. It’s the perfect machine for working in hilly wooded areas, near railroad tracks, power lines, gas and oil pipelines, gardens, roadsides, highways, canals, rivers and lakes. The new FAE tracked carrier is powered by the Kohler Common Rail electronic fuel injection engine — a compact, powerful and fuelefficient 74-hp propulsion system that complies with the most stringent emission standards. The heavy-duty undercarriage features a hydraulic extendable and retractable independ-

ent track gauge system and an automatic tensioning system. Due to high-profile rubber tracks — 86 mm pitch and 13 in. width — oscillating rollers and triple-flange style idlers, it can operate in the strongest conditions.

High-tech solutions give the RCU strong traction enabling it to work on steep slopes up to 55 percent. Add the optional steel track undercarriage and gain even more traction on the most difficult terrains you might encounter.

A dual hydrostatic transmission provides better traction and optimal management of the attachment. Electronically controlled piston pumps com-

bined with a dedicated electronic control unit provide an integrated technological system. The result is high performance and reliability that lasts, plus simple and intuitive operation.

The RCU-75 is guided by an ergonomic remote control with a large 3.5-in. display for management of all vehicle and attachment functions and with customizable function keys. A 2.4 GHz transmission frequency ensures reliable communication. The layout of the controls, the well-balanced shoulder straps support, make the FAE RCU remote control ergonomic and easy to use.

The RCU-75 can be paired with the BL2/RCU mulcher, designed to mulch vegetation up to 6-in. in diameter. This mulcher features a fixed tooth rotor and Bite Limiter technology that provides higher productivity with even less horsepower required, due to low power absorption.

The new RCU-55 also will be on display. This unit is powered by the Kohler Common Rail electronic fuel injection engine — a compact, powerful and fuel-efficient 56-hp propulsion system that complies with the most stringent emission standards. This model is based on all the technology built into the larger RCU-75 model but in a smaller package.

At the heart of FAE’s vast display will be the new remote‐controlled track carriers for mulching applications.

THUNDER CREEK

THUNDER CREEK EQUIPMENT HAS REVOLUTIONIZED how contractors fuel, service and maintain their heavy equipment fleets.

ConExpo 2023 represents Thunder Creek at its most powerful — with fuel and service solutions designed to meet almost every need of the off-road construction and heavy equipment market. The company rocked the construction industry back in 2015 when it introduced its line of multi-tank trailers (MTT) that allowed for the easy hauling and transfer of bulk diesel with no HAZMAT endorsement or CDL*. As emissions regulations evolved and diesel exhaust fluid (DEF) became more prevalent, the manufacturer set the standard for how DEF is handled and dispensed in the field through its proprietary two-in-one system.

The construction industry has embraced Thunder Creek with open arms — and trailer solutions that were born on the American farm have evolved to heavy industrial designs for the demands of the construction and earthmoving markets. The company has helped contractors save time, money, hassle and resources with arguably the most practical lineup of products to hit the construction industry in the last 20 years.

smooth ride at highway speeds, as well as in the most rugged, off-highway conditions. Each trailer can be complemented with a 100-gal., two-in-one DEF system and a utility box that allows you to customize the back end with greasing systems, welders, generators, air compressors and more. A truckmounted version of the system (the Multi-Tank Upfit, or MTU) also is available.

• Multi-Tank Oil Trailers (MTO) — The Thunder Creek MTO is a multi-tank oil trailer that can provide bulk diesel, oil, reclaim, coolant, grease and DEF. It comes in three different models/capacities up to 920 gal. of fluid combinations tailored to your jobsite needs. The MTO utilizes multiple tanks isolated through a manifold. The result is a trailer that legally mitigates the need for the driver to carry a HAZMAT endorsement. In many cases, a CDL* may not even be required.

The original multi‐tank, bulk diesel trailer that allows customers to haul bulk diesel without a HAZMAT or CDL comes in capacities of 460, 690 (shown) and 920 gal.

Of Interest at ConExpo 2023

Multi-Tank Trailers (MTT) — The original multi-tank, bulk diesel trailer that allows customers to haul bulk diesel without a HAZMAT or CDL* comes in capacities of 460, 690 and 920 gal. It is made possible by isolating diesel in four, six or eight separate, 115-gal., DOT-compliant, non-bulk tanks. Tanks are joined by a manifold to a common pump, creating complete isolation during transport and controlled dispensing of fuel at the jobsite. Each trailer is built to maintain a low profile and is configured to provide optimal balance and a

MONTABERT

TODAY, PEOPLE

OFTEN TALK ABOUT TOPICS

such as industry 4.0 or IoT (Internet of Things) in their business. Behind this jargon is a simple idea: it is about being able to track data relating to a device, wherever it is and however it works.

This need also is valid for breakers. This is why Montabert decided to work on a device that is as ergonomic as it is reliable, which will allow users of Montabert hammers to be able to monitor their equipment remotely. Also, after several years of testing and research, the company is able to offer a solution to its customers: the OMNI-M.

Here are the main features:

• Fleet locator: For the largest fleets as for the smallest, OMNI-M allows you to know where your equipment is from any place, at any time.

• Scheduled maintenance: Equipment will be

• Service & Lube Trailers (SLT) — The Thunder Creek SLT features a modular tank design that is capable of holding up to 690 gal. of fluid in up to eight tanks with combinations of 25, 55 and 115 gal. This can include tanks for diesel fuel, oil delivery (engine or hydraulic), used oil and coolant reclamation, coolant, and other fluids based on field maintenance needs. The SLT also can be equipped for grease and DEF delivery. This modular design allows it to be hauled without a HAZMAT endorsement and, in some configurations, without a CDL*. A truckmounted version of the system (the Service andLube Upfit, or SLU) also is available.

For more on the full lineup of Thunder Creek solutions, visit the company at ConExpo or visit ThunderCreek.com.

*Confirm configurations and full hauling details with your Thunder Creek dealer or Thunder Creek representative.

tracked, so no maintenance deadlines can be missed. Visits can be scheduled so as not to conflict with dates of major job sites.

• Keeping equipment safe: OMNI-M will be a dissuasive device, which can discourage theft attempts. Should this nevertheless happen, the device can facilitate the recovery of stolen equipment.

• Measure productivity: Working hours can be related to extracted m3, diesel consumption, or any other metric data to monitor and optimize a job site.

• Working hours tracking: Each piece of equipment will have its own “odometer”. OMNI-M will make it possible to evaluate and optimize the rate of use of materials.

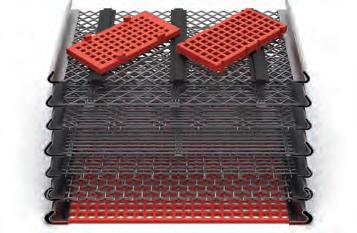

DUREX

DUREX PRODUCTS INC., BASED IN LUCK, WIS., will display its screen media, liners, wear parts and screen accessories in booth #C32567 at the Las Vegas Convention Center, March 14 to 18, 2023.

The company offers numerous innovative urethane, rubber and wire screen media options, which allow customers to fine-tune production and increase tons per hour, while keeping products in spec and lowering operating costs.

Durex has offered premium screen media technologies since 1965, including its Livewire, Armor, Accuslot, Vibraspan and Vibraclean wire screens, as well as Modular Urethane and Rubber screens.

Wear liners for aggregate and concrete equipment, wear parts and screen accessories round out the company’s offerings.

• Modular Urethane, Rubber Screens — Available in modular snap-in, pin-style, knock-in and bolt-in systems, these panels feature tapered openings that are wider at the bottom, which reduces plugging and increases throughput.

• Livewire Screens — A self-cleaning-type screen, featuring molded rubber strips that hold its high-strength wires in place, providing better screening action and greater open area.

• Armor Screens — A combination of high-grade woven-wire cloth with molded open-cast premium polyurethane, designed to increase throughput, as it reduces plugging and noise.

• Accuslot Screens — A self-cleaning-type screen that helps eliminate plugging and/or blinding, while minimizing the passing of slivers and chips.

• Vibraspan Screens — A self-cleaning-type screen featuring longitudinal slots and either straight or intercrimp wires for more open area, without sacri-

DEWEZE

DEWEZE HAS INTRODUCED THE XRT REEL LIFT BODY to the work truck market. Built upon customer feedback, the XRT is built exclusively for the work truck industry to aid with underground construction and logistic challenges.

With a 5,500-lb. lift capacity, the XRT is taking efficiency to the next level. The self-loading reel lift is designed to safely load and transport any material supplied on a reel. Simply lift and load utility wire, innerduct reels or fiber with this one-man operation.

Extensive testing went into the design and construction to ensure it meets the needs of customers, the manufacturer said.

“Labor is one of the biggest challenges our customers face,” said Drew Gerber, vice president of product. “The concept of reallocating resources to other projects due to the efficiency realized with the XRT is growing rapidly.”

A workshop on wheels, the DewEze XRT helps users navigate tight areas, getting reels closer to where the work is happening. Under the hood, hydraulics power the lift arms; coupled with parallel squeeze, an extra level of versatility is added to the trucks, while eliminating the need for an arbor. The XRT offers the ability for power take-up or pay-out with an integrated brake, increasing that value to the end-user.

ficing product size control.

• Vibraclean Screens — A self-cleaning-type screen with alternating crimped and straight wires, allowing increased load capacity, while maintaining self-cleaning benefits.

• Woven and Slotted Wire Screens — Made of high-quality, XT, oil-tempered, stainless or high-carbon steel. Woven-wire screen allows the use of lighter-gauge wire, while still providing excellent wear life. Long slot triple shoot screens are crimped to provide better screening accuracy and eliminate blinding and plugging.

• Wear Liners — Including magnetic, plugweldable and bolt-on liners for screen boxes, crusher mainframes, feed boxes, chutes, flumes and discharge openings.

• Concrete Wear Liners — Including urethane, urethane-ceramic, rubber-ceramic and rubber solutions for concrete plants and concrete trucks.

• Wear Parts — Including urethane and rubber, used in sizing and separating on screens, classifiers, dewatering screws and various chutes and transfer areas.

• Screen Accessories — Including, but not limited to, side-tension rails, J-bolts, U-bolts, donuts, stringers and ferrules.

During the show, on March 15, from 1 p.m. to 5 p.m., Durex will host a Happy Hour in its booth, with two choices of beer poured into Durex-branded cups — some of which will have a sticker on the bottom that correlates with a prize for the lucky bearer. Prizes include a Durex cooler or a Durex tumbler.

For more information, call 715/472-2111, email customerservice@durexproducts.com or visit www.durexproducts.com.

Booth #D2503

The DewEze RT Bed is available in four core combinations: risers and reel bar; spindle system; overspin brake; and reel power winder. For more information, visit www.deweze.com.

MECALAC

SOMETIMES, IT SEEMS AS IF JUST THE PASSING OF TIME RESULTS IN CHANGE.

Factors such as necessity for greater efficiency or more production drive changes in processes and industries. What once was seen as the ideal method or solution becomes old school as new and more productive methods take root. Such is the case with compact wheeled excavators in the North American market.

Although they have been popular in Europe for quite some time, wheeled excavators enjoyed less popularity in North America because the open spaces and greater distances to travel favored larger equipment. Today, however, the winds are shifting.

Skyrocketing trucking costs make hauling large pieces of equipment a less viable option. Many job sites are more congested than they were in the past and require a more compact equipment footprint, while at the same time, labor shortages are plaguing just about everyone and require urgent, creative solutions. All of these factors have made the time right for North America to consider new ways of working and embrace advantages innovative new wheeled excavator designs offer.

Get Any Job Done

Speed is important, but some might raise the question: Can a wheeled excavator actually boost efficiency through power and performance onsite? Simply put, yes. On an average job site, you’ll notice several pieces of idle equipment each day. In an ideal world, every machine would be running and earning money 100 percent of the time. However, that target is rarely realized as owneroperators with multiple machines on site see 30to 35-percent efficiency out of any one unit. When operators can replace multiple machines with a wheeled excavator, though, the 100-percent efficiency goal becomes attainable — plus they don’t have to do the heavy hauling of trailers full of large machines, according to the company.

The key is finding a design that is truly multipurpose without sacrificing performance. With a wheeled excavator’s speed, it’s possible to quickly drive to wherever your attachments are on the site, switch the bucket out for a set of forks, lift and load the pallet and switch back to continue digging all within minutes. Previously, this process might have taken up to three times longer or required another unit, such as a telescopic handler or rough-terrain forklift and another operator. With a single opera-

tor, equipment then stands idle.

Consider the benefits of a machine that has four-wheel steering, allowing an incredibly tight turn radius, paired with the power and range to lift 3 tons to 10 ft. up through a 360-degree rotation. This is a machine that can park in a single space, if needed, and with its offset, three-part boom work outside the width of the machine in any direction, including below grade — all while maintaining perfect stability.

A single machine that offers power and speed in a compact footprint, along with the functionality of multiple machines while requiring only one operator is game changing for many industries, including construction, landscaping, forestry, municipal work and utility construction.

Safety First

Safety is of utmost importance. With some wheeled excavators, prioritizing safety may mean sacrificing productivity. One that is designed to address both should have a low center of gravity that is placed directly in the center of the machine. This offers stability, even when driving the machine on slopes or down inclines. Some designs feature the capability to carry loads safely in these situations and are designed in a way that even with the low center of gravity, the ground clearance remains high enough to maneuver over a variety of uneven terrain. Older, top-heavy designs, with higher centers of gravity and too much weight in the front, do

not lend themselves as well to off road operations.

Another design feature to consider is operator accessibility to the cab and fuel tank. Wheeled excavators that allow operators to fill the tank without stepping on the tire of the machine, but rather standing on the ground, eliminate the risk of a preventable accident. Additionally, when operators can access the fuel tank, grease points and filters from the ground, regular maintenance can be performed quickly and safely.

No Fairytale

Wheeled excavators may have taken some time to become popular in North America, but the performance is noteworthy.

Consider the example of a contractor who does work for utility companies putting in underground piping and electrical wiring. He leveraged the advantages of a compact wheeled excavator and outperformed competitors that still used backhoes, allowing him to earn bids over his peers, even though he charged more.

Stories such as this are increasingly common across North America. Operations willing to consider the many benefits that new compact equipment options such as wheeled excavators offer are reaping the rewards. As time and conditions change, those willing to challenge the way they think and work will find ways to not only survive, but to thrive and achieve even greater levels of success.

Fasterr, , safer, and more p

AUSA dumpers ensure more cost-effective projects, allo ator machinery. When combined with a mini excav r, , it is e slower vehicles due to the multiple tasks that they must or other materials at any direction with a simple movem

roductive

owing earthworks to be performed quicker than with traditional ven more advantageous, forming a winning duo versus other t perform. The swivel skip also allows you to dump earth, rubble, ment of the joystick.

www.ausa.com

WEIR ESCO

W

EIR ESCO IS EXPANDING ITS PRESENCE at ConExpoCon/AGG with a larger exhibit space in the new West Hall in order to include more new and innovative products. Following is a partial preview of the products on display in booth W42201 in the West Hall.

Launching at ConExpo is the ESCO PosiGrab II hydraulic coupler for construction excavators. The advanced PosiGrab hydraulic coupler was developed to increase productivity and optimize site safety; with feedback from customers, the design has been finetuned to provide the best-in-market offering.

The coupler is a top choice for construction professionals. Precision manufactured to exacting standards, it engineered to reduce stress points for improved machine performance. The PosiGrab coupler will pick up attachments within the same machine weight class for increased machine versatility.

An ESCO SXDP excavator rock bucket with Ultralok U60 tooth system with adapter wear caps will be on display. Weir ESCO delivers a full line of excavator attachments developed to meet the demanding needs of contractors, rental customers and quarry operators — especially in the toughest applications.

The comprehensive bucket offering includes standard-duty ditch and clean-out buckets to heavy-duty options to extremeduty buckets with full wear protection for severe abrasion and impact conditions. All tooth-style buckets come standard with ESCO’s Ultralok tooth system for exceptional performance.

Visit the booth to see an ESCO HD wheel loader bucket with Nemisys N65 tooth system to fit a 992K loader. ESCO produces reliable, performance-driven wheel loader buckets built for the world’s most demanding conditions. Engineered to deliver payloads meeting site production requirements, buckets are available in extra heavy-duty (XHD), heavy-duty (HD) and general purpose (GP) duty classes. Attachment lugs wrap under the bucket to spread stress loads evenly. Single-beam HD or triple-formed XHD beams are engineered to meet application demands.

The Ultralok construction tooth system will be featured, including extensions of the product line. Ultralok is a leader in high-performance tooth systems for the earthmoving industry. The costefficient, low profile Ultralok tooth system performs in a full range of machine applications. The integrated lock makes it a true two-piece system, reducing inventory over traditional three-piece systems. The system includes a comprehensive package of points and adapters for 6- to 75-metric ton excavators and 1.8- to 12-cu. yd. class wheel loaders.

Motion Metrics products, including LoaderMetrics, PortaMetrics, BeltMetrics and TruckMetrics work together to create a detailed view of quarry productivity and efficiency, while increasing safety and decreasing operational downtime associated with crusher jams and equipment maintenance.

Detailed, on-demand reports at every stage production bring critical data to life. LoaderMetrics missing tooth detection system for loader alerts operators to missing teeth before they travel downstream and obstruct crushers. The hand-held PortaMetrics device can improve the safety and accuracy of your blast assessment by providing AI-enabled particle size analysis at your fingertips.

For more information, visit www.esco.weir.

ConExpo will host more than 1,800 exhibitors across 2.8 million square feet.ESCO SXDP excavator bucket with Ultralok tooth system.

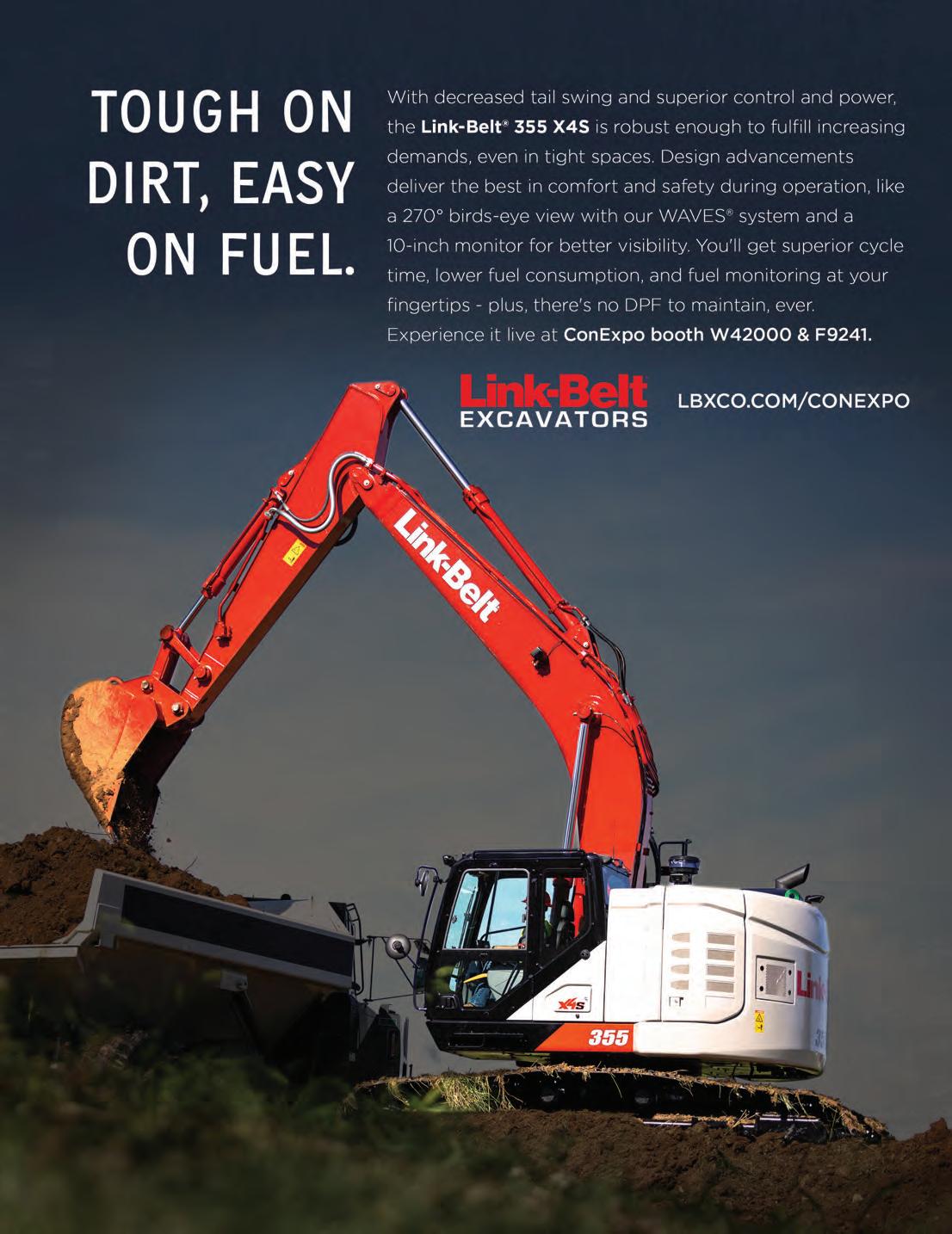

ROKBAK

ConExpo will be the first time Rokbak haulers have been on display at a North American trade show.

ROKBAK HAULERS WILL BE ON DISPLAY for the first time ever at a North American tradeshow when the RA30 and RA40 arrive at ConExpo 2023 in Las Vegas, from March 14 to 18.

The Scottish articulated hauler manufacturer is bringing both models to the largest construction show in North America, providing attendees with the chance to get up close and personal with the earth-moving machines and demonstrate exactly how they can offer grounded ‘Rok-solid’ performance Stateside.

“We cannot wait to get back to ConExpo and give the RA30 and RA40 pride of place on our stand,” said Paul Douglas, managing director of Rokbak. “We’re looking forward to getting as many attendees interacting with what we’ve got lined up as possible, as well as introducing people to our knowledgeable team who are keen to show off our robust and hardworking haulers. Rokbak will be there to show customers first-hand the quality our machines and why we’ve become known as one of the most reliable and trusted articulated hauler manufacturers in the market.”

Strength of Volvo Group

Rokbak will be located at Booth F8926 in the Festival Grounds, together with fellow Volvo Group companies Volvo Construction Equipment and Volvo Penta.

ConExpo will be the perfect opportunity to highlight the machines’ abilities to benefit construction projects, talk to customers about how the haulers deliver new benchmarks in both performance and total cost of ownership, and reinforce the company’s commitment to sustainability and journey to net-zero as part of the Volvo Group.

With sustainability in mind, the Rokbak event booth materials are all recycled or reusable. Two 40-ft. customized shipping containers, adorned in the recognizable Rokbak aesthetic, will be used for meeting rooms and product information displays. Following the event, these will be shipped back to Motherwell, North Lanarkshire, Scotland for reuse at future events.

Product experts will be ready and waiting to discuss the technical capabilities and key aspects of the haulers, welcoming everyone to the booth where there will be merchandise giveaways and competition prizes up for grabs throughout the event — as well as plenty of refreshments.

Robust, Reliable Haulers

“Rokbak is seeing huge demand for its RA30 and RA40 articulated haulers in the U.S.,” said Robert Franklin, Rokbak’s director of sales–Americas. “The U.S. is leading articulated hauler demand globally with huge infrastructure spend. There is a lot of construction activity at the moment around house and road building, so we are keen to meet with customers and potential customers at ConExpo and discuss how the RA30 and RA40 can help with these projects.”

It was to the United States that Motherwell-based Rokbak’s first sand-colored machines were delivered following the rebrand in September 2021, with a pair of RA30s sold to earthmoving, utility and clearing company Linco Construction of Houston, Texas, via Easton Sales and Rentals, to assist with earthworks, underground utility and clearing work. Most U.S. dealers went on to confirm orders within the first few months.

For more information, visit www.rokbak.com/rokbak-conexpo-2023/.

OF NE FFER W G E RING GR

“IN THE OFFER ON”IR RINGS

SENNEBOGEN

PURPOSE-BUILT MATERIAL HANDLERS HAVE TAKEN HUGE STRIDES into applications once reserved for re-purposed excavators. Across the board, material handlers are lighter, faster and more efficient than their earthmoving counterparts. These qualities are much in demand by demolition contractors, but the work they do calls for a tougher standard: versatility for multiple operations from teardown to cleanup maximum safety for operators and crews easy transportability between project locations high durability in extreme jobsite conditions

For that, an industry leader in material handlers has stepped beyond “purpose built” to deliver a line of machines specially equipped for the demands of the demolition industry.

Long Reach for Heavy-Duty Teardown

The flagship of SENNEBOGEN’s demolition fleet is the 870 R-HDD. At 228,000 lb. (103,500 kg) with a 118-ft. (36.0 m) boom, this is one of the industry’s largest material handlers.

The 870 gives operators the reach and lift capacity to bring down 10-story structures with remarkable precision. Interchangeable attachments include powerful shears, hammers, grapples, buckets and magnets to quickly dismantle buildings, sort the debris and load trucks with a single machine.

Operators of the 870 R-HDD work in safety and comfort with SENNEBOGEN’s elevating Maxcab, which can tilt back up to 30 degrees to provide straight lines of sight with minimal fatigue when working at height.

870’s footprint from the compact travel position to a wide stance working platform for maximum stability.

Maximum Mobility Between Job Sites

The same package of demolition features is offered on the 830 R-HDD, a 96,780-lb. (43,900 kg) machine with 62 ft. 4 in. (19 m) of reach, designed for more congested job sites.

The smaller footprint of the 830 R-HDD means that, with its crawler tracks retracted for transport, the machine can simply drive onto a standard flatdeck trailer and quickly move on to the next job without waivers.

The 830 R-HDD also is one of three SENNEBOGEN models equipped to install the “Swiss-army knife” of demolition tools: the Vario Tool quick change system.

The Vario Tool turns the 830 R-HDD into the ultimate multifunction demolition machine, able to switch from a scrap shears to any standard lifting attachment in just two minutes. Operators can even complete the switch without leaving their cab, as all connections are made automatically by the tool’s universal adapter.

Complete Uptime Solution

The smaller footprint of the 830 R‐HDD means that, with its crawler tracks retracted for transport, the machine can simply drive onto a standard flatdeck trailer and quickly move on to the next job without waivers.

On large projects, R-HDD demolition models are often complemented by smaller SENNEBOGEN units purpose-built for sorting, picking, sweeping, feeding and loading assignments. Highly maneuverable, compact, efficient, with low operating costs, these utility machines also are built with the same robust engineering and that makes SENNEBOGEN the uptime leaders in the harshest environments.

Bulletproof glass is standard for the windows and skylight, complemented by dual safety cameras. Telescoping undercarriages hydraulically expand the

MOROOKA

MOROOKA IS ONCE AGAIN LEADING

THE WAY, with its newest innovation to the track carrier market. High speed will soon be available and on display at the 2023 ConExpo, being held in Las Vegas, March 14 to 18.

The high-speed MHS1300 Morooka carrier, with a top speed of 15 mph and a payload of more than 4,000 lbs., features a two-man cabin and easy steering controls. The prototype will be on display at the Morooka USA booth in the Festival Grounds, booth F8826.

In 2012, the company began manufacturing carriers in the United States and in 2015

HydroClean 3-micron oil filtration, automatic lubrication, natural flow-through cooling plus a high-capacity reversing fan are all standard equipment on every SENNEBOGEN machine: purpose-built to keep you on the job every day.

Booth #F8826

that U.S. factory re-introduced the rotator series back to the market.

Now Morooka has a complete line-up of rotators from 8,000 to 44,000 lbs. Morooka also was the first to build a “utility specific” carrier, designed to meet the needs of the utility and tree industry. Morooka offers a total of eight utility specific machines working with some of the leaders in the utility industry to solve off-road problems of access and safety.

For more information, visit www.morookacarriers.com.

t K M i a n wh ee u s o e y Hav ? s ’ t su maKo My in wne

ha g c xcitin e e om e s ad e m vWe’ n K ,reto S s t Par ineOnl

ntegratio ) i KCP m ( rogra e P arC

mobi all-new n ! A s nge su omat ,app le su su.komat mykomat

www.brandeismachinery.com

www.linder.com

www.andersonequip.com

www.ceceq.com

www.roadbuildersmachinery.com

83325_Komatsu_CPI_My Komatsu_Have you seen_10_125x10_625.indd 1

www.cn-wood.com

www.dieselmachinery.com

www.powerequipco.com

www.powermotivecorp.com

www.clairemontequipment.com

www.kirby-smith.com

www.roadmachinery.com

2022-03-25 1:15 PM

www.rmsequipment.com

www.tec1943.com

www.rolandmachinery.com

www.wpi.com

LANCO GROUP

MORE THAN A CRANE DEALER, The Lanco Group of Companies is lifting the rigging industry to new heights. With a powerhouse of OEM, distribution and material handling companies, plus a combined 200 years of manufacturing experience under its belt, The Lanco Group is a complete package of lifting solutions.

Headquartered in Illinois, Lanco also specializes in American- and North America-made products. Lanco provides jobs and supports local communities through local manufacturing and distribution, all across the United States and Canada.

Lanco Group of manufacturers include: Broderson Manufacturing Corp., based in Kansas, manufacturers of compact industrial carry deck cranes from 2.5 to 25 tons, and cab-down roughterrain cranes that can withstand the toughest jobs; Mi-Jack Products, located in Illinois, builds rubber-tired gantry cranes that revolutionize bridge construction and other industrial applications; Greenfield Products, operating in Tennessee, engineers of crane and rigging attachments; and Liftking Manufacturing Corp., of Ontario, Canada, producers of rough-terrain forklifts and similar rough-terrain material handling equipment.

But the expertise goes far beyond manufacturing. Lanco also represents three crane distribution

companies, authorized dealers of mobile crane manufacturers, including Manitowoc, Grove and National Crane, through Walter Payton Power Equipment, in the midwestern United States, Western Pacific Crane & Equipment, on the west coast of the United States and Canada, and MiJack Canada, to serve central Canada.

The Lanco Group of Companies also represents Mi-Jack Global Product Support, a network of parts and service technicians across the United States and Canada, and the John J. Lanigan Sr. Training Center, whose mission is to be the industry leader in technical training, industrial crane maintenance and service. No other lifting company offers such a diverse range of products and services.

As the largest Manitowoc and Grove dealer in the world, Lanco also is proud to have priority availability on the Manitowoc family of machines, and will be the exclusive exhibitor at ConExpo 2023 to show two new Grove offerings: the GMK6400-1 all-terrain crane and the TMS875-2 truck mounted crane. These cranes, along with representatives from each of the Lanco companies, will be in the Festival Grounds, at ConExpo Booth #F9441, ready to answer any questions and demonstrate some of their unique solutions in-person.

For more information, visit www.thelancogroup.com/conexpo2023.

ConExpo-Con/AGG 2023 will have the largest focus on sustainability since the show began in 1948.

KOMATSU

FOR CONEXPO 2023, Komatsu will be in booth W42044 and the theme for the show will be “Creating value together.” With the right products, latest technologies, actionable data and dealer support, Komatsu helps its customers create value to help achieve their visions for productivity, efficiency, sustainability and safety.

The Komatsu booth will feature equipment, technology and service solutions that address:

Construction

Energy/utility

Forestry

Quarry

Smart Construction/Smart Quarry

Sustainability and electrification

Waste

To showcase tools that support operation optimization, the Komatsu booth will address:

Sustainability/electrification roadmap

Technology implementation

Workforce optimization

Working together with its customers, the

Komatsu booth will demonstrate how Komatsu’s machines and solutions can help our customers:

• Optimize fleet capabilities

• Extend the life/improve the value of machines

• Operate with safety as a priority and reduce employee downtime

• Leverage the latest technology to improve efficiencies and productivity

• Conserve resources and reduce fuel consumption

• Upskill and retain employees and use them in the most productive ways through leveraging the right training and latest technologies

On the show floor, Komatsu will be featuring our latest electric offerings alongside brand-new and recently introduced machines. A sampling of Komatsu machines that will be on the floor include:

• PC210E (with Smart Construction Retrofit) electric excavator

• PC900LC (with Smart Construction Retrofit) excavator

HB365LC-3 (with Smart Construction Retrofit) hybrid excavator

D71PXi-24 intelligent dozer

HD465-8 mechanical haul truck

PC230F-11 processor

PC360iLC-11 intelligent excavator

WA600-8 wheel loader

Educational Seminar — Digital Transformation of Job Sites

Even small steps toward a digitally transformed job site promote safety, can help optimize production, lower costs and waste and help attract and retain talent. With data management and applications that can be managed from anywhere, get a holistic digital representation of a site.

In this session, learn which operations at the site can be digitized, what the different options are for a fleet to be digitally connected, and what can be remotely accessed from the office.

The seminar will be held March 17, 10:45 a.m. to 11:30 a.m. at West Hall, 206.

SMITHCO

SMITHCO SIDE DUMP TRAILERS, AN INDUSTRY

LEADER in side dump trailer design and manufacturing, will display its newest model, the SX7, at ConExpo-Con/AGG in Las Vegas, March 14 to 18.

SmithCo’s SX7 is the industry’s first 7-axle side dump trailer. With a 40-ft. tub and 53-ft. trailer, the SX7’s advanced design allows operators with a standard commercial license to haul up to 40-tons in a single trailer with easier maneuverability and less upfront cost than doubles or train set, according to the manufacturer.

SmithCo also will have its new 6-axle trailer, the SX6, on display.

“We’re excited to introduce these groundbreaking trailers that provide our customers with the ability to haul in one trailer which previously required two and help ease the burden of hiring qualified drivers,” said SmithCo CEO and President Scott Lovell.

“With easier maneuverability, lower upfront costs and exceptional capacity, the SX7 and SX6 lets customers do more with less.”

40-ton Hauling in Single Trailer

The SX7 tub design incorporates three standard axles and four Ridewell steerable lift axel suspensions. The SX7 can comfortably offer a 40-ton hauling capacity in a single trailer without exceeding 129,000

GVW rating with the right truck configuration. To achieve the optimal configuration, SmithCo provides custom bridge drawings which consider truck weight, axle placement, overall length and tub placement to maximize the load capacity. The hauling capacity for the SX6 is 37.4-ton.

Commercial Driver’s License (CDL) meets licensing requirements so there is a larger pool of potential drivers to hire from.

The cylinder placement on SmithCo side dump trailers also offers a distinct advantage. Cylinders are positioned at each end of the tub, rather than in the middle, so the tub can be positioned at any point on the trailer frame. This flexibility is key to achieving the maximum load capacity. This cylinder design also makes the SX series more durable than other side dump trailers on the market, the manufacturer said.

SmithCo also is producing the 6- axle SX6, featuring three standards axels with three Ridewell steerable lift axel suspensions.

Advantages of Single Trailer

For long hauls, a single trailer offers many advantages. Upfront costs are lower with a single trailer. A single trailer also translates to a greater maneuverability for backing up.

Prior to this innovation, achieving a 40-ton haul with side dumps required a train set with a lead trailer, a dolly converter and a pup trailer. Due to the length of the setup, backing up a train is difficult, if not impossible. Additionally, hiring drivers for doubles or a train is challenging due to the required Doubles/Triples endorsement.

With the SX7 built as a single trailer, a standard

HITCHDOC

HITCHDOC WILL SHOW OFF two snowblowers for the construction industry in booth N17738 at the 2023 ConExpo in Las Vegas.

For high-flow skid steers and wheel loaders, the HDS7100 easily chews through deep, hard packed snow. A fully hydraulically-powered blower, the HDS7100 has a cutting width of more than 7 ft. and a cutting height of more than 3 ft.

Tiger teeth on a 20-in. auger combine with a four-paddle fan and standard 68-in. discharge chute, so you can quickly and easily move snow where you want it. For even greater control, a new truck loading spout will allow users to easily fill tall trucks from the cab of their wheel loader or skid steer. This new spout will be on display in HitchDoc’s booth at ConExpo.

In addition to the HDS7100, HitchDoc will be showing its recently released snowblowers specifically designed for mini-skid steers. With interest continuing to grow in mini-skid steers, there’s a corresponding demand for attachments for these small, powerful machines.

The mini-skid steer snowblower taps into the machine’s hydraulic system for power and features heavy gauge steel construction. This allows the blower

The SX6 provides a 37.4-ton payload capacity, maneuverability for backing up and the same operator advantages as the SX7, with added flexibility in truck configuration.

“We’re always looking to innovate to allow our customers to do more with less, and our SX7 is the perfect example,” said Lovell. “We take pride in listening to our customers’ experiences so we can build solutions, not just trailers. In fact, the idea for the SX7 started with a customer’s suggestion.”

The new SX6 and SX7 trailers will be on display, along with the SmithCo construction pup, at D1514 in the Diamond Lot at ConExpo-Con/AGG 2023 in Las Vegas, March 14 to 18.

For more information visit sidedump.com.

Booth #N11738

to be light enough for the machines to push it and still be efficient while remaining heavy enough to be effective in removing snow. Available in both a 48- and 60-in. version, the mini-skid steer blower uses a Quick-Tach mounting plate so it can easily attach to common machines.

While winter has certainly been a topic of discussion, it won’t be long before we’re all deep in construction season and HitchDoc wants to make sure you’ve got all the tools you need. HitchDoc has a history of making a variety of attachments for skid steers including the Dual Dozer and Sandpiper.

Featuring front-mounted casters and a dual-sided cutting edge, the Dual Dozer is ideal for creating a smooth, level finish without leaving tracks, even around obstacles or tight corners. Meanwhile, the Sandpiper provides an efficient way to spread sand or other granular materials across an area from 30 in. to 30 ft.

For more than 30 years, HitchDoc has been manufacturing quality parts for the construction industry from American steel in the Midwest. Be sure to check out all of its products in booth N11738 at ConExpo or by visiting www.hitchdoc.com.

Booth #S61315

TVH PARTS IS A WORLDWIDE DISTRIBUTOR of parts and accessories for the light construction, material handling and industrial equipment industries. A parts specialist since 1969, TVH is an industry leader providing replacement parts and accessories around the world.

Wherever in the world you’re based, know that TVH is committed to delivering products and services to keep your equipment running smoothly. TVH Americas is headquartered in Olathe, Kan., with distribution centers across the United States, Canada, Mexico and Latin America.

The company’s database houses more than 46 million parts from internationally recognized manufacturers and an extensive selection of custommachined parts. Constant part analysis keeps our extensive inventory growing to continue to have the right parts in stock and ready to ship with on-time delivery.

TVH’s technical information service department can help customers find the parts they are looking for. The company has information for equipment as far back as 60 years ago and as recent as last year, covering most makes and models of equipment found in our industry.

Confidence in TVH and its product offerings is the company’s highest priority. To ensure it is offering quality parts, TVH has strict quality control standards in place. Quality audits are performed to ensure the integrity, conformity and effectiveness of each system.

TVH wants to meet customers’ parts needs quickly and efficiently and continually invests in automation and optimization of logistics processes to be able to serve customers even faster from 15 distribution locations throughout the Americas.

TVH offers industry-specific training courses designed to enhance employees’ knowledge of new generation mechanical systems, emerging technologies and professional skills.

TVH will be at ConExpo March 14 to 18, 2023 at booth# S61315 at South Hall 1st Level.

For more information, visit, www.tvh.com.

YOU WANT A FLEET OF VEHICLES with safety lighting products and accessories that keep your drivers safe. These products often become mundane, and the public loses its alertness.

SSI believes all employees should be safe on the job. It has a 45year history of providing a unique variety of safety lighting products and accessories. These bring ingenuity to your fleet that draws attention and adds a layer of safety. SSI will help customers select the right safety lighting for customers’ vehicles, place an order and deliver products in a timely manner to keep fleets on the road and your employees safe. Stop by booth #C30938 during ConExpo to have its representatives assess product needs.

OKADA

OKADA AMERICA INC. HAS A WIDE VARIETY of attachments, including breakers, demolition shears, crushers, pulverizers, processors, grapples, compactors and screening buckets. These attachments are precision-engineered, productive and dependable and expand the versatility of the excavator, mini-excavator, loader/backhoe, skid steer and track loader carriers.

TOP Series Hydraulic Breakers

The Okada America Inc. hydraulic breakers (TOP Series) are custom made for hassle-free mounting on a variety of carriers for many applications. The TOP Series range in size from 150 to 17,000 ft. lbs. There is no need for complete assembly replacements — customized upper mounting brackets and quick-coupler systems are available for all Okada breakers.

Included as standard equipment on the TOP 205J and larger breakers is a “Y” style accumulator the utilizes a diaphragm design and easy to service

body. Medium and heavy class TOP breakers are compatible with auto lube systems.

ORV Series Hydraulic Breakers

The ORV Series hydraulic breakers are the result of decades of field experience and a long-standing record of leadership in the industry. Seventeen ORV Series hydraulic breakers ranging in Energy Classes from 150 to 12,500 ft. lbs. provide a broad range of solutions for skid-steers, compact excavators, track loaders, loader/backhoes and excavators.

OAC Series Compactor/Drivers

Okada’s boom-mounted compactor/drivers are offered in five models: OAC 100, OAC 200, OAC 300, OAC 400 and OAC 500. They are designed for mounting on loader/backhoes or excavators and range from 4,000 to 86,000 lbs. Impulse forces range from 3,150 to 22,000 lbs. and lifts range from 1 to 3 ft. to 5 to 7 ft.

OS Series Scrap Shears

The new OS Series scrap shear packs up to 159 tons of cutting force. A versatile shear made for cutting ferrous and non-ferrous scrap, concrete, pipe, solid round I-beams and plate materials, the OS Series Model OS 60 Shear is perfect for the 13,000- to 20,000-lb. class carrier.

Pedestal Rock Breaker Boom Systems