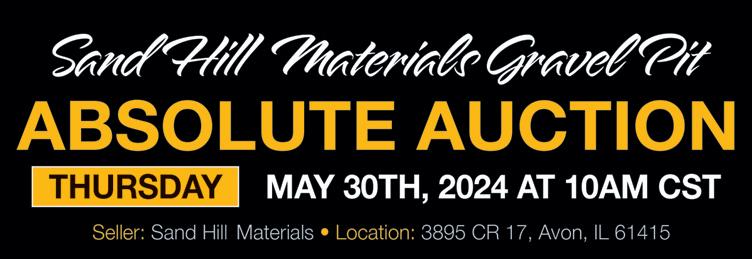

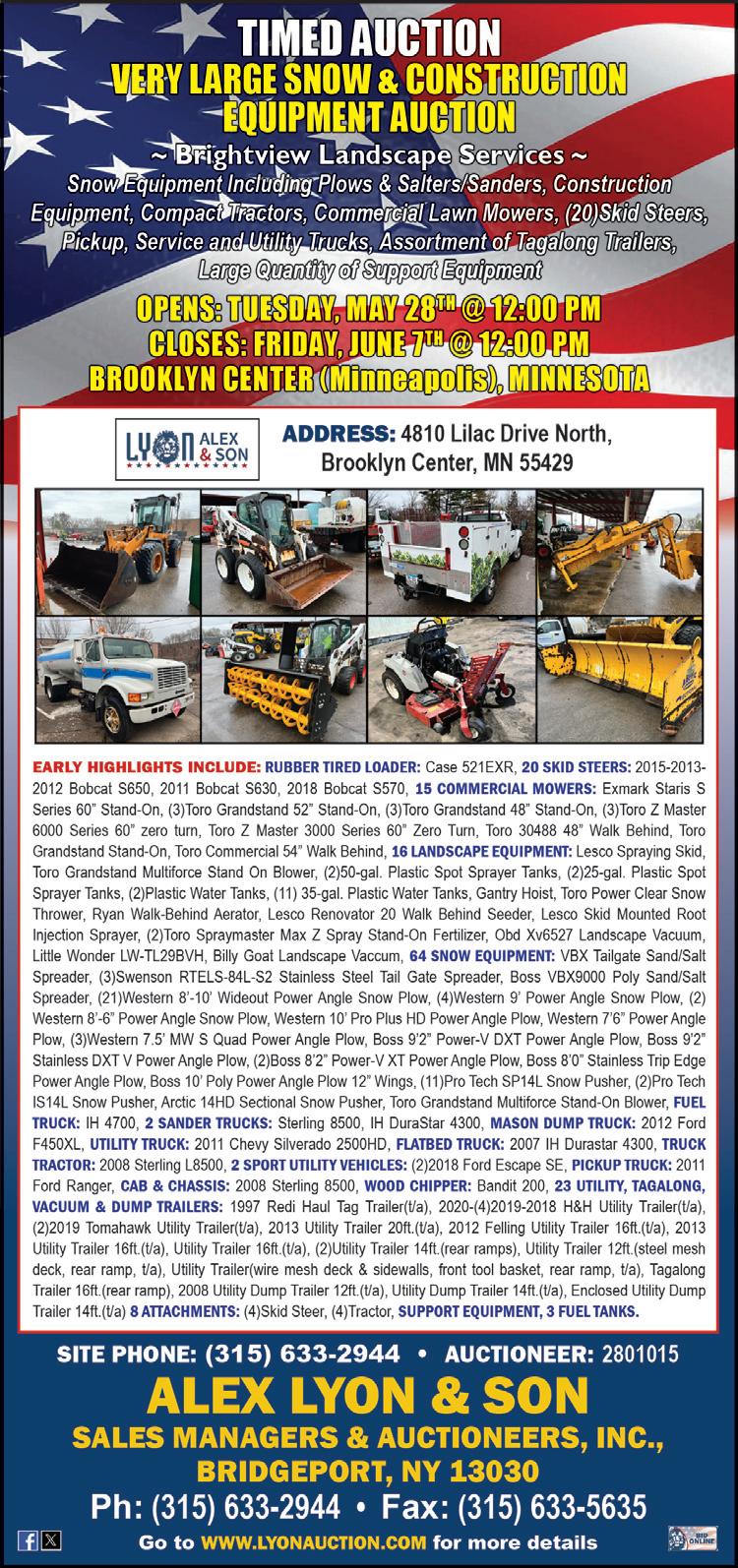

Fabick Cat Hosts Its Two-Day Open House Event in Fenton, Mo. ...20

Anniversary Celebration at HQ...34

By Cindy Riley CEG CORRESPONDENT

By Cindy Riley CEG CORRESPONDENT

Fabick Cat Hosts Its Two-Day Open House Event in Fenton, Mo. ...20

Anniversary Celebration at HQ...34

By Cindy Riley CEG CORRESPONDENT

By Cindy Riley CEG CORRESPONDENT

MoDOT photo

There are currently four cranes on site. Once the towers are farther along, a crane will be added to each.

“The

said Brian Okenfuss, Missouri Department of Transportation (MoDOT) project director. “It’s too narrow to allow for the passage of farm vehicles without police assistance to close the bridge.” see BRIDGE page 101

Heavy equipment operation requires a clear mind and sharp vision. Distractions from electronic devices, fatigue or ground activity can put the operator, the employer and the project at risk. Marking Distracted Driving Month in April, OSHA urged contractors to have a play to prevent operator distraction while driving machinery on the job.

Reducing workplace distractions is everyone’s responsibility, from the newest laborer to the top of the corporate ladder, said NCCER. see SAFETY page 104

Adobe Stock photo Distractions during operations on a job site can cause all kinds of problems for heavy machinery drivers resulting in loss of machinery, down time for repairs and project delays.

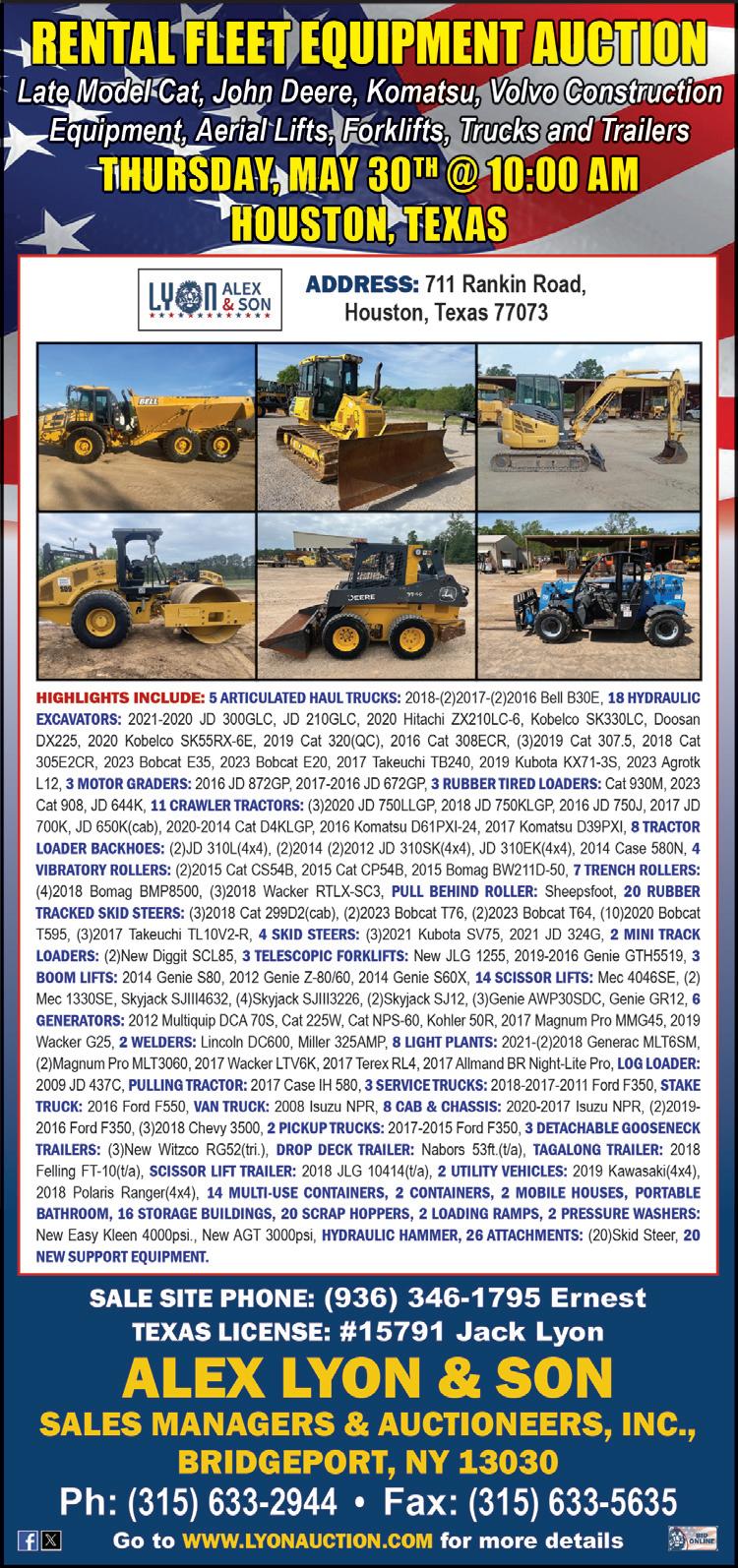

The Chicago Bears announced the team’s plans to privately invest more than $2 billion to cover more than 70 percent of the costs of constructing a new, Chicago Park District-owned enclosed stadium.

RMS Rentals held an open house on April 25 at its facility at 12520 Quentin Ave. S., Suite 100 in Savage, Minn. Guests were asked to bring a non-perishable food item to be donated to the Community Action Partnership (CAP).

More than 100 guests attended Top Notch Equipment’s open house at its facility at 14490 Northdale Blvd. in Rogers, Minn., on April 11. The newest in equipment and technology was available for customers to see up close.

Fabick Cat hosted a two-day Open House and Team Member Appreciation Event at their Fenton, Mo., location May 3 to 4, at Fabick Cat’s headquarters facility (One Fabick Drive, Fenton, MO 63026).

24 LANO EQUIPMENT HOLDS OPEN HOUSE IN SHAKOPEE, MINN.

In addition to manufacturer representatives on hand to show off the latest equipment and technology they have to offer, guests were invited to a DOT class by the Minnesota Department of Transportation. 28 FARM-RITE HOLDS OPEN HOUSES AT ST. CLOUD, DASSEL

April was a busy month for Farm-Rite, as the company held open houses at two of its locations on April 19 in St. Cloud, Minn. (810 Mayhew Lake Rd. NE) and on April 27 at its Dassel, Minn. (901 Parker Ave. W) facility.

34 ALLEN ENGINEERING HOSTS 60TH ANNIVERSARY CELEBRATION

More than 300 dignitaries, guests and associates enjoyed a day of celebration at the Allen Engineering Corporation (AEC) 60th Anniversary event on April 17, 2024, at the company’s headquarters facility in Paragould, Ark.

36 OFFICIALS BREAK GROUND ON $300M TERMINAL 3 AT O’HARE INTERNATIONAL

Mayor Brandon Johnson joined federal and airline partners on April 22 to break ground on the approximately $300 million ElevateT3 project, a massive investment in the airport’s aging terminal facilities.

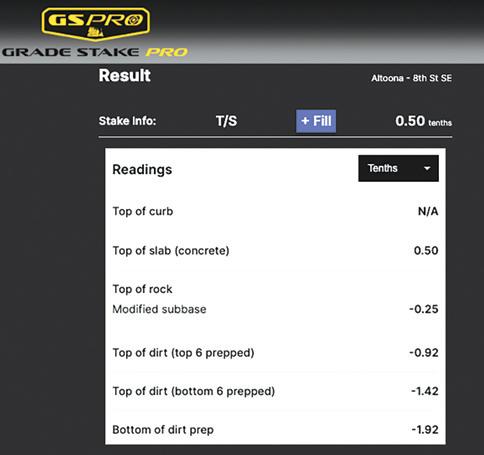

It is not every day that a heavy equipment foreman identifies a problem costing his company profit and then invests his own money to find a solution, but that is precisely what happened in the case of Matt Schwarz’s Grade Stake Pro app.

50 KOMATSU HOLDS DEMO DAYS AT CARTERSVILLE CUSTOMER CENTER

Komatsu held a Demo Days event April 16 to 18, at its Cartersville Customer Center in Georgia. Attendees had opportunities to interact with Komatsu machines and solutions, including Komatsu’s Intelligent Machine Control (iMC).

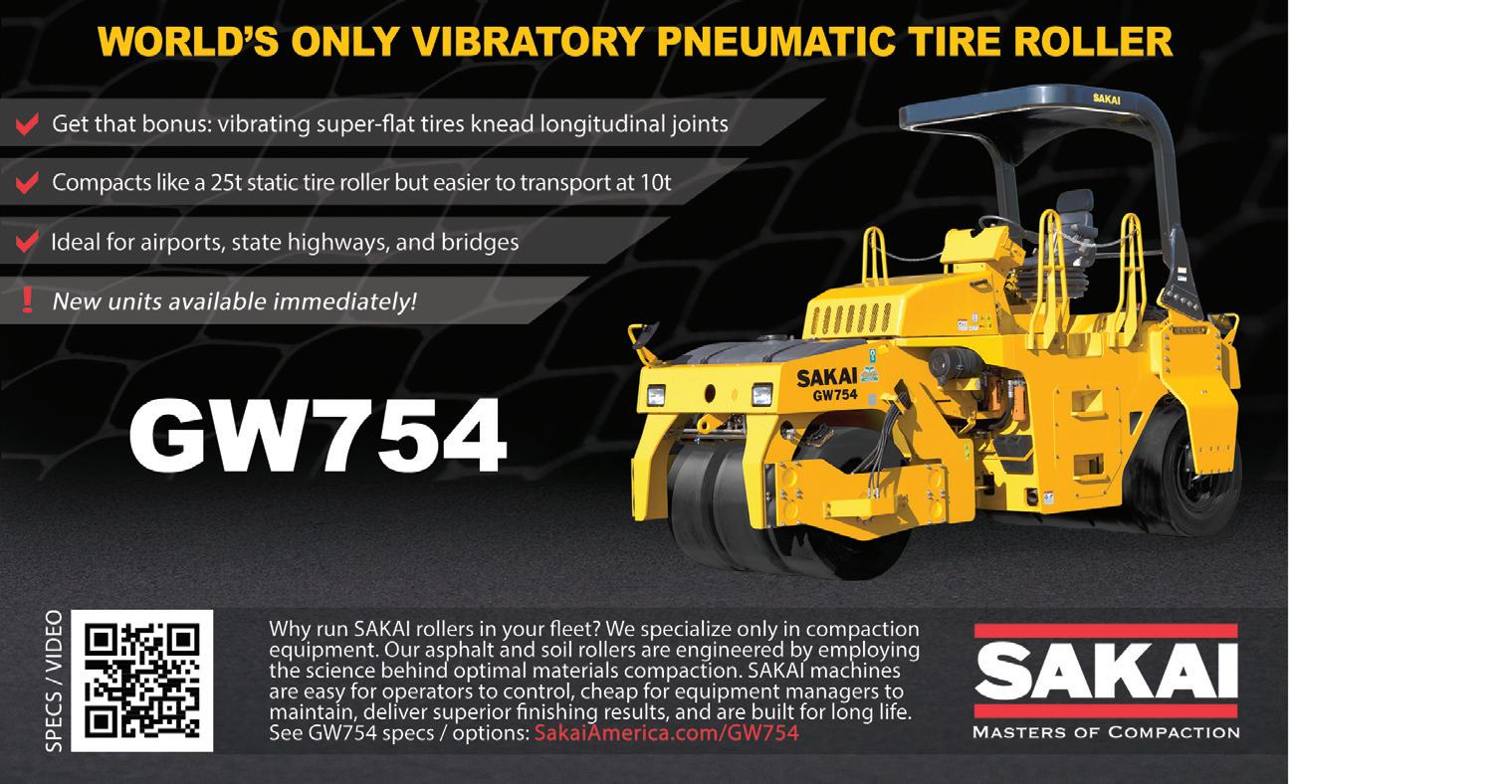

70 SAKAI ACHIEVES RECORD FISCAL YEAR VIA SALES, PRODUCTION

SAKAI America, a manufacturer and supplier of asphalt rollers and soil compactors for the paving and construction site work industries, announced another record-breaking fiscal year with revenue growth exceeding 16 percent.

94 TAKEUCHI RECOGNIZES TOP DEALERS AT 2024 DEALER SUMMIT

Takeuchi recently announced its Dealer of the Year, Dealer Salesperson of the Year and the recipients of its 2023 Dealer 360° awards at the company’s 2024 Dealer Summit in San Antonio.

100 HANSEN HOSTS 59TH ANNUAL SPRING NITKE CONTRACTOR AUCTION

Hansen Auction Group held its 59th annual Spring Nitke contractor auction April 25 to 26 (in person and online) and April 29 to 30 (online only) at its Mosinee, Wis., facility.

SEPPI M E20 FORESTRY MULCHER OFFERS IMPROVED PERFORMANCE

KAGE UPGRADES SNOWFIRE WITH ADVANCED FLOATING TECHNOLOGY

BUILT FOR EVERY SEASON: MAXIMIZING CTLS YEAR-ROUND

‘TILTROTATOR EFFECT’ RISES AS ENERGY CONSUMPTION GOES DOWN 86 ATTACHMENTS INTERNATIONAL DEBUTS SEVERE SERVICE DEMOLITION GRAPPLE 86 IGNITE ATTACHMENTS INTRODUCES ITS NEW DIGITAL FIT FINDER TOOL

WERK-BRAU ‘POWERED BY STEELWRIST’ IDEAL FOR NUMEROUS TASKS

2020 Case 580SN, S/N NLC772103, 3529 Hrs, CAB/AIR DELUXE CAB, RIDE CONTROL, FRONT AND REAR COUPLERS, 4-N-1 GP FRONT BUCKET, NO REAR BUCKET, GOOD RUBBER, E-STICK $72,500

2022

2020 Takeuchi TL12R2, S/N 412103347, 1964 Hrs, Cab/Air/Heat, New 84” GP Bkt, New Tracks, Just Serviced $59,900

2022 Case TR340B, JAFTR340AMM403705, 148 Hours, Cab/Air, 2 Speed, Hyd Coupler, 84” GP Bucket, Radio, E-H Controls $77,900

2022 Case SR270B, JAFSR270HNM410725, 222 Hours, Cab/Air, 2 Speed, High Flow, Hyd. Coupler, 78" GP Bucket Radio, E-H Controls $69,900

Garrard • (630) 492-9115

2023 Case 521G, S/N NNF254914, 73 Hrs, Cab/Air/Heat, Ride Control, Deluxe Cab, JRB Coupler, 2.5 Yard GP Bkt, Third Valve, Limited Slip Differential, Pro Care Full Machine Warranty until 10-31-25 or 3000 hrs $179,900

2020 Case SV280, 2771 Hours, Cab/Air/Heat, S/N JAFSV280HLM485383, Hyd Coupler, 72” GP Bucket, 2 Speed, Self Level, Ride Control, Radio, Serviced & ready to work $39,900

McCann Rents a full line of heavy and light construction equipment. Call us today to supply your next rental.

GROVE GHC85 – (‘23), #C005208, 164 Hrs..$CALL

MANITOWOC 11000-1 – (‘19), #C003848…$CALL

GROVE GHC130 – (’19), 2,327 hrs, C004101...$899,000

LIEBHERR LH40M LITRONIC – (‘18), 12,938 Hrs, #C005799..$315,000

approx 550 Hrs, 2-piece boom, pin grabber coupler, aux hyd $P.O.R.

Liebherr R946 - ‘14, approx.. 800 Hrs, 12’6” stick, QC66 coupler, aux. hyd $P.O.R. ASTEC GT104 - ‘17, 325 Hrs, 5.25cyd Hopper, 4’x9’ Top & Bottom Screens, #C001154 ............ ..........................................................$161,700 ASTEC GT205MF – ’17, approx. 1800 hrs, 5x20 top deck w/high frequency bottom deck, #C001180 ..........................................$275,000

Roadtec RP190 – ’13, 5860 hrs, Carlson EZIV 10-19’ screed w/12” ext,

JCI K400, (’06), Portable Cone Crusher, 400 HP Elec, 42”x30” Feed Conveyor, #40236 $295,000

BROOMS

SUPERIOR BROOM DT74J, (‘19), 2,267 Hrs, noise level in the cab, rear leaf spring suspension, #C003884 $40,500

SUPERIOR BROOM DT74J, (‘18), 1,017 Hrs, noise level in cab, rear leaf spring susp., #C003649 $39,000

GROVE GHC85, (’23), 164 Hrs, #C005208 $CALL

GROVE GHC130, (’19), 932 Hrs, 130-ton lift capacity, #C004141 $1,099,000

GROVE GRT880, (’22), 807 Hrs, 80-ton lift capacity, #C005002 $885,850

GROVE GRT880, (’18), 2,476 Hrs, 80-ton lift capacity, #C004982 $628,750

MANITOWOC 11000-1, (’10), #C003846 $CALL

LOADERS AND EXCAVATORS:

LIEBHERR L550, (‘14), Liebherr diesel, stepless hydrostatic travel drive , traction & ride control systems,, Michelin XHA 23.5R25EM (L3) radial tires, enclosed ROPS cab with a/c 3.92 yard gen purpose bucket. Quick coupler, #C001328 $152,837

Milwaukee, WI

1-800-236-6900

Fax 414-541-1892

Wausau, WI

LIEBHERR L550 XPOWER, (‘18), an innovative machine concept which combines performance, fuel efficiency, robustness and comfort. With their power split driveline, XPower wheel loaders work w/ the greatest level of efficiency in all applications, #C003574 $208,947

LIEBHERR L550 XPOWER, (’17), an innovative machine concept which combines performance, fuel efficiency, robustness and comfort. With their power split driveline, XPower wheel loaders work with the greatest level of efficiency in all applications, #C003118 $159,000

LIEBHERR R936 LC, (’19), EROPS w/ AC & Heat, auto lube, rear camera, 54” bucket, #C004148 $CALL

LIEBHERR R920 COMPACT LITRONIC, (‘18), 253 Hrs, w/Werk-brau pin grabber coupler, medium & high pressure aux. hydraulic circuits, pattern changer, #C003330 $228,600

LIEBHERR R934 COMPACT LITRONIC, (‘23), 300 Hrs, The new R934 weighs approx. 35 tons, completely updated design is characteristic of the new range of "generation 8" machines, #C005399 $CALL

LIEBHERR R936 COMPACT LITRONIC, (‘18), 450 Hrs, Convenient and service-friendly, the R 936 Compact makes for safe working. With its tight slewing radius, this machine is especially well suited to urban applications, #C003377 $CALL

LIEBHERR R956 LITRONIC, (‘22), 250 Hrs, 35' boom and 21' stick, #C004867 $CALL SAKAI SW354, (’18), #C003395 $31,900

1-800-242-7113 Fax 715-675-9748 Crushing & Screening Div.

Fax 920-788-6753

The Chicago Bears announced the team’s plans to privately invest more than $2 billion to cover more than 70 percent of the costs of constructing a new, Chicago Park Districtowned enclosed stadium. This transformative project would expand public open space; create more than $8 billion in regional economic impact; and bring 43,000 construction jobs and 4,200 new annual jobs to the Chicagoland region. The proposed facility would be built to bid for and host Super Bowls, NCAA championships and other significant events that drive tourism dollars to the city.

Sports fields and gardens will replace the current stadium, with Soldier Field’s historic colonnades preserved as a tribute to Chicago’s military veterans. An enclosed stadium is essential for Chicago to attract year-round events like the Super Bowl and major concerts — unlocking billions in tourism revenue.

“This marks a pivotal moment for Chicago as we introduce a visionary project prioritizing the public good,” said Chicago Mayor Brandon Johnson. “The proposed stadium, accompanied by expanded open spaces and recreational facilities, exemplifies my administration’s commitment to enhancing the quality of life for all Chicagoans. The Chicago Bears’ proposal goes beyond mere construction: It will cultivate economic growth, job creation and community enrichment. I commend the team for their dedication to serving the greater good with private investment, and I look forward to the positive impact it will have on our beloved city.

The Chicago Bears’ private investment in a Chicago Park District-owned stadium and park stands as one of the largest commitments of private funds to a public asset nationwide. The Chicago Bears pledge to engage local minority-, women- and veteran-owned construction businesses to bring the stadium to life — ensuring a union workforce reflective of Chicago’s diversity.

“The Chicago Bears’ history in this city runs deep, dating back to 1921 when George Halas moved the franchise here after one year in Decatur, Ill.,” said Chicago Bears Chairman George H. McCaskey. “The team embodies the spirit of Chicago, and we’ve embraced that legacy with pride. This upcoming stadium will be a testament to Chicago’s character, built by its people for the betterment of our beloved city. It’s a proud moment for our franchise, our devoted fans and our hometown.”

“Contributing more than $2 billion in private dollars into this new publicly owned stadium will unlock tremendous economic development opportunities, add jobs for the city and the region and create a tremendous home field advantage for the Chicago

Bears,” said Chicago Bears President and CEO Kevin Warren. “When we complete this investment, Chicago will be able to bid for the Super Bowl, the Final Four, college events, concerts and other mega events that could be hosted in our city. This means billions of tourism dollars that Chicago currently cannot capture — helping our city regain its reputation for hosting global events.”

In addition to its massive regional economic impact, the stadium and surrounding recreational space will create public benefits:

• expanded green and open space for all Chicagoans to enjoy;

• added playfields, creating more safe places for youth and families to gather;

• public restrooms along with food and beverage options to enhance park user experience;

• better infrastructure that improves access to museum campus; and

• a year-round venue that can host community events of all sizes.

“We share Mayor Johnson’s priority of bringing a modern stadium that creates com-

munity benefits to our city,” said Warren. “We are not just building a stadium; through our partnership with the mayor, the park district and the state, we will create a public asset that strengthens Chicago. We can support and host educational opportunities with Chicago Public Schools and increase our already strong support for social services for children and families in need.”

Despite Chicago’s lakefront and its transportation, cultural and academic assets, the Chicagoland region has fallen behind in attracting major sports events and the associated tourism and economic impact. The Sports Business Journal recently listed the “25 Best Sports Business Cities” in the United States. Chicago was one of only two top 10 major markets not to make the list — topped by Orlando, Las Vegas, Los Angeles, Atlanta and Indianapolis. The sports tourism industry generated a direct fiscal tax impact of $6.6B nationally in 2021. In the 2023 Super Bowl alone, the Phoenix Host Committee said it realized $1.3 billion in economic impact.

Investing in the new stadium development is projected to yield hundreds of millions in new tax revenues for the city, county and state, along with billions of dollars in economic impact from construction spending. Economic forecasting firm HR&A estimates the stadium and museum campus infrastructure improvements will generate:

• $4.2 billion of direct capital investment, resulting in 43,000 regional construction jobs.

• More than $8 billion in economic impact, including $3.5 billion in wages.

• 2,300 Chicago jobs annually and 4,200 regionally post-construction.

• Based on new employment, $248 million in annual economic impact for Chicago and $456 million for the region.

• $92 million in annual wages for Chicago and $170 million for the region.

Warren said the time is now to move forward with the Chicago Bears lakefront development, as construction costs for the project increase by roughly $150 to $200 million every year.

“This is truly a unique opportunity for Chicago to reclaim global events and create massive economic and community benefits — and for Chicago to remain the home of the Chicago Bears for generations to come,” Warren said.

The Chicago Bears are investing substantial private funds, totaling more than $2 billion, to bring this development to fruition — marking one of the largest private commitments to a public building in the nation. This private contribution accounts for more than

JD 60G, A/C, 6’1” Arm, Coupler, Aux Hydraulics, #262458 ....................$70,000

JD 290G, Cab, A/C, Coupler, 10’2” Arm, 32” Shoes, New Reman Engine, #250559 ........ $144,000

JD 331G, A/C, Hi Flow Aux, Ride Control, 2 Speed, Rev Fan, #262952 $69,000

JD 624K-II, A/C, Coupler, 3rd Spool Aux, Ride Control, Warranty, #291317 $189,000

JD 130G, Cab, A/C, Hydraulic Thumb, Aux Hyd, 9’11” Stick, 24” Shoes, #261469 ..$129,500

JD 350G, A/C, Coupler, 13’1” Arm, 32” Shoes, Pattern Changer, Bucket, #262200 ...... $125,000

JD 550K, Cab, A/C, XLT, Ripper, 6 Way 105” Blade, 4th Spool Aux, #261723 $129,000

JD 950K, Cab, A/C, Winch, LGP, 30” Shoes, 6 Way 184” Blade, Warranty, #251233 $389,000

JD 160G, A/C, 10’2” Arm, 28” Shoes, Hydraulic Thumb, Warranty, #262585..$194,000

BOMAG BW211, OROPS, 84” Smooth Drum Roller, #262614 $69,000

JD 650K, A/C, LGP, 28” Shoes, 6 Way 128” Blade, IGC, #262371 $122,000

JD 1050K, Cab, A/C, Ripper, 156” Semi U Blade, Trimble Ready, #249082 $379,000

Fenton, MO Foristell, MO Mitchell, IL Mt Vernon, IL Cape Girardeau, MO Paducah, KY Cuba, MO Owensboro, KY Evensville, IN

JD 180G, A/C, HYD Thumb, Coupler, 8’10” Arm, 24” Shoes, #262899 ..................$139,000

JD 672G, Cab, A/C, 14’ Blade, 14.00 Tires, Push Block, Auto Shift, #250229 $155,500

JD 700K, A/C, LGP, 36” Shoes, 132” 6 Way Blade, Rev Fan, #291338 $165,000

JD 544K-II, A/C, Rev Fan, 20.5 Tires, Air Seat, GP Bucket, #262551 $139,500

JD 245G, A/C, Aux Hydraulics, 9’7” Arm, 32” Shoes, Air Seat, #262242 ..................$204,000

JD 770G, Cab, A/C, 14’ Blade, 14.00 Tires, Scarifier, Aux Hyd, #247935 $129,500

JD 750K, Cab, A/C, 34” Pads, Smartgrade, LGP, 6 Way 156” Blade, #251152 $194,000

JD 644K, A/C, Coupler, 3rd Spool Aux, Tier III Engine, #291319 $165,000

Hamm 3412P, 2012, 84” vibratory padfoot compactor, EROPS w/ heat & A/C, 1,200HMR .

$82,500

Cat 815F, 2006, EROPS cab, 12’4” S-Blade w/ tilt, new paint job, very good condition, 9,400 HMR $195,000

Hamm GRW-5 Pneumatic Roller, 1994, Deutz Diesel, ROPS Canopy, (9) Ea. 7.50-15C1 Tires . . . . . .$15,500

(4) Cat 825C’s, 1981-1990, EROPS, S-blade w/tilt, all work ready From $79,500

Rammax Walk Behind Rollers, over 25 in stock, lever & remote $4,000 to $10,000 (8) Sheepsfoot, 48" and 60", double drum & single drum, tow type

$4,000 - $6,500

Volvo A40, 1998, 40 tons, 10991 hrs, 395 hp, 8WD, 29.5R25, A/C, 29 cy cap. sideboards, tailgate (currently off work), work ready

Broderson IC80-2E, 1997, 8.5 ton, 24’ boom, dual fuel, 10.00R15 tires, 3,400 hrs

$127,500

Volvo A40, 1996, 40 tons, 395 hp, 6WD, A/C, 29.5R25, working everyday

$21,500 Grove RT58C, 1981, down cab, 18 ton r.t., 70' boom anti-two block, GM dsl, clean

$145,000

Volvo A40, 1996, 40 tons, 11,000 hrs, 6WD, 20.5R25, A/C, P/S trans, 29 cy cap., 6/06 hitch rebuilt .$115,000

Volvo A40, 1995, 40 tons, 395 hp, 8WD, 29.5R25, A/C, P/S trans, tailgate, work ready

$115,000

Volvo A35C, 1998, 35 tons, 6WD, 26.5R25 tires, approx 7,000 hrs, good condition

$147,500

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5x25, A/C, P/S trans, working everyday on jobsites

$87,500

$49,500 IR 185’s, JD diesels

CALL

Cat 336EL, 2012, 33.5” TBG pads, Q/C, aux hyd, 6,700 HMR, work ready

$162,500

Cat 336FL, 2015, 33.5” TBG Pads, Q/C, aux hyd, 4,300 HMR, work ready $224,500

Komatsu PC220LC-8 Longreach, 2011, Young Boom/Stick 60’ reach, 3,500 HMR $179,000

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5R25, A/C, P/S trans, 26 cy, working everyday on jobsites

$89,000

Volvo A30C, 1996, 30 tons, 11,000 hrs, 296 hp, 6WD, 23.5R25, 21 cy cap, A/C, P/S trans, works everyday

$122,500

(12) Allmand Light Plants, 2008-2010, diesel, s/a towtype, (4) MH lights, excellent From $5,200 Case 580L Rubber Tire Loader Backhoe, 1997, OROPS, std stick, 24" bkt

$24,500 (2) Balderson Broom Attachment for Cat IT Machines, 8' wide, good condition $4,000 Ea. NUMEROUS Rivinius R600’s, 10’ Wide, Mount on Dozer Blade

Kobelco SK210LC, 2007, Q/C, aux hyd, 31.5” TBG Pads, 3,900 HMR

$72,500

Cat D5NXL, 2006, 10’ PAT Blade, Paccar PA55 winch, 22” Pads, 4,100 HMR

$82,000

$49,500

Cat 613C Water Wagon, 1994, 5000 gal drop tank, ROPS, spray heads

Cat 621F, 1996, Scraper, OROPS, 33.25x2, very good condition CALL

Cat 621E, 1989, Scraper, OROPS, 33.25x29, very nice

CALL

Cat D6NLGP, 2008, VPAT Blade, Drawbar, 33” Pads, 9,900 HMR

$87,500

Cat D6NLGP, 2014, Foldable VPAT Blade, Paccar PA55 winch, 7,200 HMR

$142,500

Komatsu D155AX-6, 2007, Sigma S-U Blade, 4-bbl Single Shank Ripper, 8,400 HMR

$229,500

Over 100 Excavator, Loader, Specialized & Grapple Buckets in Stock -Call For Your Needs FORKS (8) IT28F/G Forks, Balderson qc, 48"-60" pallet style, excellent $4,000 Others Available Call Prices Are Negotiable - At Your Inspection

$152,500

Cat D6TXW, 2013, 13’6” VPAT Blade, Carco 70APS winch, 28” pads, 7,300 HMR

RMS Rentals held an open house on April 25 at its facility at 12520 Quentin Ave. S. Suite 100 in Savage, Minn. Guests were asked to bring a non-perishable food item to be donated to the Community Action Partnership (CAP).

Customers were treated to lunch provided by local food trucks as they spoke with vendors and the RMS team about the latest offerings. Equipment demonstrations, tutorials and prize drawings were also part of the festivities.

Grand prize winners were:

• Courtland Acosta of Duininck, winner of a Minnetonka guided fishing tour.

• Billy Bartusek of Northwest Asphalt, winner of a Blackstone griddle with accessories.

Participating vendors included Allmand, Allen Engineering, BOMAG, Canycom; Cratos, Edco, Gar-Bro, Haugen Attachments, Husqvarna, JLG, Komatsu, LeeBoy, MBW, Multiquip, Potain and Wacker Neuson.

For more information, visit rmsrentals.com. CEG

see RMS page 56

Ingram, regional sales manager of Cratos, Pompano Beach, Fla., with the company’s newest product — the battery-powered THR 2000 mini-track skid steer. With zero-emissions, reduced noise and minimal maintenance, its compact size allows it to fit through standard doorways, while the tracks enable travel over various terrains of any job site.

HITACHI

2023 ZX345USLC-6, NEW

$CALL

- CAB W/ HEAT & AC, 2 WAY PATTERN CHANGER, STD ARM 12’4”, AUX HYDRAULICS, ISUZU ENGINE 249 HP, 79,146 LBS OPERATING WEIGHT.

2023 ZX225USLC-6, 1245 HRS

$169,000

- HINO 160 HP ENGINE, CAB W AC & HEAT, TIER 4, STD BOOM/ARM, 22’ MAX DIG, 31’11” MAX REACH, 10’5” TRANSPORT WIDTH.

KOBELCO

2022 SK170LC-11, 2 NEW UNITS

$CALL

- 134HP YANMAR ENGINE, CAB WITH HEAT AND AC, EAGLE EYE CAMERA SYSTEM, BOOM 17’1”, ARM 10’2”, TRACK 23.6”, OPTIONAL CWT-8288 LBS

2022 SK210-11, 5 UNITS

$CALL

- HINO 160 HP ENGINE, CAB W AC & HEAT, TIER 4, STD BOOM/ARM, 22’ MAX DIG, 31’11” MAX REACH, 10’5” TRANSPORT WIDTH.

2022 SK140RLC, 2 UNITS

$CALL

- CAB WITH HEAT AND A/C, EAGLE EYE CAMERA, AIR SUSPENSION SEAT,TRACK WIDTH 23.6”,STANDARD MONO BOOM 15’4”,STANDARD ARM 9’4”. KOMATSU

2014 PC290LC-10, 4002 HRS

$169,000

- 213HP ENGINE, EROPS CAB W A/C, 24” SHOES, 22.7’ DIG DEPTH, 34.3’ MAX REACH, OPERATING WEIGHT: 67400 LBS.

LINKBELT

2023 145X4DZ, 7 UNITS

2022/2021 SY265CLR, 4 UNITS 7 - 515 HRS - $205,000

- CUMMINS 190 HP ENGINE, TIER 4F, CAB W AC & HEAT, 43’8” MAX DIG, 57’9” MAX REACH, 11’1” TRANSPORT WIDTH, 69,500 OP WEIGHT.

2021 SY135, 5 UNITS 116 - 461 HRS - $CALL

- ISUZU 103 HP ENGINE, TIER 4F, CAB W AC & HEAT, 8’2” STICK, 18’1” MAX DIG, 27’2” MAX REACH, 8’6” TRANSPORT WIDTH, AUX HYDRAULICS.

HITACHI

2022 ZX26U-5N, 3 NEW UNITS

$CALL

- CANOPY, STANDARD ARM 3’10”, RUBBER TRACKS, AUX HYDRAULICS, YANMAR 3TNV80F- ENGINE W/ 20 HP, BLADE, 5556 LBS OP. WEIGHT. KOBELCO

2022 SK35SR-6E, 232 HRS

$CALL

- YANMAR 23 HP ENGINE, TIER 4F, AUX HYDRAULICS, COUPLER, 7’11” MAX DIG, 17’7” MAX REACH, 5’7” WIDTH. SANY

2022/2021 SY35U, 20 UNITS 0 - 130 HRS - $45,400+

- YANMAR 24.4 HP ENGINE, TIER 4F, 4’7” STICK, AUX HYDRAULICS, 24” BUCKET, 10’2” MAX DIG, 5’8” TRANSPORT WIDTH.

2022 SY16, 4 UNITS 1 HR - 66 HRS - $CALL

- YANMAR 15HP ENGINE, OROPS CAB, 3’8” STICK, 5’11” BOOM, 7’9” MAX DIG DEPTH, 13’1” MAX REACH AT GL.

2022 SY80U, 3 UNITS 2 HRS - 38 HRS - $CALL

$CALL

- 102 HP ISUZU ENGINE, STICK: 9’11”, AUX HYDRAULICS, TRACK: 23.6”, MAX DIG: 19’2”, MAX REACH: 28’3”, OPERATING WEIGHT: 33,600 LBS.

2023 160X4, 2 UNITS

$CALL

- 112hp ISUZU AR-4JJ1X FINAL TIER 4 TURBO-CHARGED, CAB HEAT/AC, STICK LENGTH 10’, STEEL TRACKS 23.6”, DIG DEPTH 21’ 4. 2022/2016 80X3, 2 UNITS 18 HRS - $CALL 2128 HRS - $76,500 - EROPS W/ HEAT & AC, 54HP ENGINE, 7’2” ARM, 11’6” BOOM, MULTI HYDRAULICS, TRANSPORT WIDTH: 7’7”, OP. WEIGHT: 18,900.

2023 350X4, 159 HRS

$CALL

- ISUZU 268 HP ENGINE, TIER 4F, 10’8” STICK, 24’1” MAX DIG, 36’ MAX REACH, 11’2” TRANSPORT WIDTH.

SANY

2022 SY155U, 283 HRS

$CALL

- 105 HP ENGINE, CAB W/ HEAT & AC, AUX HYDRAULICS, SHORT RADIUS, 8’2” STICK, 17’11” DIG DEPTH, 27’4” MAX REACH, 24’ SHOES.

2022 SY95C, 3 NEW UNITS

$CALL

- YANMAR 71 HP ENGINE, TIER 4F, CAB W AC & HEAT, 6’7” STICK, 14’2” MAX DIG, 20’7” MAX REACH, 7’5” WIDTH, 18” SHOES.

2022/2021 SY225C, 5 UNITS 121 HRS - 611 HRS - $CALL

- CUMMINS 164 HP ENGINE, 31” SHOES, CAB EROPS HEAT/AC, 9’7” ARM, 18’8” BOOM, 11’1” TRANSPORT WIDTH, 54,000 LB OPERATING WEIGHT.

2022-2017 SY215, 9 UNITS 42 - 753 HRS - $CALL

- CUMMINS 164 HP ENGINE, TIER 4F, CAB W AC & HEAT, 31” SHOES, 9’7” STICK, 21’8” MAX DIG, 33’10” MAX REACH, 10’5” WIDTH.

- 73HP YANMAR, STICK: 6’ 9”, CAB W HEAT AND A/C, AUX HYDRAULICS, 18” RUBBER TRACKS, AX DIG DEPTH: 14’ 10”, TRANSPORT WIDTH: 7’ 3”.

2022/2021 SY50U, 3 UNITS 27 HRS - 124 HRS - $59,000+

- 39HP TIER 4 FINAL YANMAR 4THV88C DIESEL, 11,684LB OP. WEIGHT, 11’ 3” DIG DEPTH, 6’ 5” TRANSPORT WIDTH, 16” RUBBER TRACKS.

2022/2021 SY26U, 7 UNITS 0 HRS - 88 HRS - $35,000+

- 20.4HP ENGINE, STICK: 4’ 3”, OROPS, 12” RUBBER TRACKS, AUX HYDRAULICS, DIG DEPTH: 9’ 3”, OP. WEIGHT: 6,085LBS, TRANSPORT WIDTH: 5’ 1”

2022/2021 SY60, 10 UNITS

- YANMAR 57 HP ENGINE, TIER 4F, 5’7” STICK, AUX HYDRAULICS, 13’ MAX DIG, 20’9” MAX REACH, 6’7” TRANSPORT WIDTH.

2022 SY75, 2 UNITS

CATERPILLAR

2019 440 TRACTOR, 420 HRS

$165,000

- CAT ENGINE, EROPS HEAT/AC, RIDE CONTROL, EXTENDAHOE, AUX HYDRUALICS, REAR QC, 24” REAR DIGGING BUCKET.

CATERPILLAR

2012 D6N XL, 4461 HRS

$165,000

- 145HP ENGINE, EROPS CAB W AC AND HEAT, 24” SHOES, 36,610 LB OPERATING WEIGHT, BLADE WIDTH 10.8ft in.

KOMATSU

2017 D37-24PK, 2185 HRS

$108,000

KOMATSU 91HP ENGINE, TIER 4F, CAB EROPS, 24” SHOES, OPERATING WEIGHT: 20,503 LBS

2021 D51PX-24, 409 HRS

$214,500

- KOMATSU 133HP EPA TIER 4 FINAL,CAB WITH AC,6 WAY BLADE,TRACK WIDTH: 28”,OPERATING WEIGHT: 31 438 LBS,TRANSPORT WIDTH: 8’ 6”.

CASE

1998 CASE W24C LOADER

$CALL

- 158HP ENGINE, EROPS CAB, 4 SPEED POWER SHIFT, 2,44M TRANSPORT WIDTH, 23,500LBS OPERATING WEIGHT.

CATERPILLAR

2021 950GC, 2 UNITS

$CALL

- CAT 7.1 DIESEL ENGINE, EROPS W/ AC & HEAT, BACK UP CAMERA, RIDE CONTROL, COUPLER READY, 4.25 YD BUCKET, 23.5 R25 TIRES

2020 930M, 4187 HRS

$CALL

$CALL

- 57.7HP Isuzu CP-4LE2XA3C-01,CAB HEAT & A/C,STICK LENGTH 6’9,HYDRAULICS 39.4 GPM,RUBBER TRACKS 18”,BACKFILL BLADE

YANMAR

2022 SV40 EXCAVATOR, 131 HRS

$CALL - 39 HP YANMAR ENGINE, 0ROPS- HEAT & AC, STICK: 5’3”, HYDRAULICS, 14” RUBBER TRACKS, DIG DEPTH: 11’10”, OP. WEIGHT: 9,206 LBS.

2022 SV100-2A, 3 HRS

$CALL - 72 HP YANMAR ENGINE, EROPS WITH HEAT/AC, STICK: 13’2”, RUBBER TRACKS, DIG DEPTH: 15’9”, MAX REACH: 25’4”, OP. WEIGHT: 21,550.

2022 SV08-1D, 14 HRS

$CALL

- 10.3 HP ENGINE, WATER-COOLED 2-CYLINDER DIESEL, OROPS, STICK: 3’10”, HYDRAULICS: 5.2 GPM, RUBBER TRACKS: 7”, BACKFILL BLADE.

$CALL

2022/2021 ZW180-6, 5 UNITS 17 HRS - 1260 HRS - $189,000+

- 3.4 GP BKT W/EDGE, ENGINE 168 HP, LIMITED SLIP FRONT/REAR, 3RD VALVE, RIDE CONTROL, REAR CAM, COUNTERWEIGHT.

2022 ZW100-6, 3 UNITS

$CALL - STANDARD TIRES, HYDRAULIC COUPLER 416 TYPE, GENERAL PURPOSE 1.3 CU YD BUCKET, BELLYGUARD, FRONT CHASSIS, HEATED MIRRORS. 2022-2014 ZW220-6, 3 UNITS

$CALL

- CUMMINS 200 HP ENGINE, TIER 4F, CAB EROPS W AC & HEAT, 3RD VALVE HYDRAULICS, JRB QC, 108” TRANSPORT WIDTH.

2018 ZW150, 727 HRS

$117,500 - CUMMINS 145 HP DIESEL ENGINE, TIER 4F, EROPS CAB A/C, 20.5 R25 (L-3) TIRES, RIDE CONTROL, 27,000LB OP WEIGHT.

CATERPILLAR

2019 289D

$CALL

- CAT C3.3B DIT, CAB EROPS AC&HEAT, HIGH FLOW AUX HYDRAULICS, 2 SPEED, ELECTRONIC COUPLER, RUBBER TRACKS, 10,533 LB OP. WEIGHT. GEHL

2022 RT215, 130 HRS

$CALL

- YANMAR 72 HP, TIER 4, CAB W HEAT & AC, 17.7” RUBBER TRACKS, 74”, 16.1 CUFT HD BUCKET, OP WEIGHT: 9,900 LBS, TRANSPORT WIDTH: 69.5”.

2021 RT255, 504 HRS

$79,000 - 74HP, TIER 4, CAB W HEAT & AC, HIGH HYDRAULICS, 17.7” TRACKS, 84”, 18.4 CUFT BUCKET, OP. WEIGHT: 11,600 LBS, TIPPING LOAD: 7,286 LBS.

2020 V270, 2 UNITS 156 HRS/390 HRS - $59,000

- CAB WITH HEATING & A/C, JOYSTICK W/ HYDRAULIC SELF-LEVELING, TWO SPEED, REAR CAMERA, BUCKET 74” CUTTING EDGE, AUX HYDRAULICS. MANITOU

$CALL

- CAT DIESEL ENGINE, EROPS WITH HEAT & AC, FUSION QUICK COUPLER, GP BUCKET, 20.5R25 RUBBER TIRES. 2019 926M, 4216 HRS

- CAB W/ HEAT & A/C, CAT DIESEL ENGINE, DELUXE CAB, HYDRAULIC COUPLER, 3.5 YD QC BUCKET, 20.5R25 TIRES

KAWASAKI

2012 90Z7, 19,087 HRS $CALL

- 295HP ENGINE, RIDE CONTROL, BELLY GUARD KIT, COUNTERWEIGHT, 5.5 CU. YD. GP BKT, 26.5X25 RADIAL L3 TIRES, AXLE COOLING KIT.

HITACHI

2022/2021 ZW80-5B, 6 UNITS 2 HRS - 70 HRS - $83,500+

- DEUTZ 63 HP ENGINE, TIER 4F, CAB EROPS AC & HEAT, 3RD VALVE HYDRAULICS, 6.3’ TRANSPORT WIDTH, RADIO.

2021 2700V, 42 HRS $CALL - YANMAR, CAB W HEAT AND A/C, TIRES, HIGH FLOW, UNIVERSAL COUPLER, 2 SPD, OP WEIGHT 8,150LBS, TRANSPORT WIDTH 70”.

2021 2550RT, 490 HRS $CALL - 74.3HP DEUTZ 3.6L TIER 4F, CAB WITH HEAT AND A/C, AIR RIDE SEAT, HIGH FLOW, 17.7” 4 SEASON TRACKS, UNIVERSAL QC, 84” HD BUCKET.

TAKEUCHI

2022/2021 TL12R2 CR/TL12V2, 11 UNITS

$CALL - KUBOTA 111 HP, ENCLOSED CAB, HYDRAULICS, 17.7 “ TRACKS, OPERATING WEIGHT: 13,190 LBS,TRANSPORTATION WIDTH: 6’ 5”

More than 100 guests attended Top Notch Equipment’s open house at its facility at 14490 Northdale Blvd. in Rogers, Minn., on April 11.

The newest in equipment and technology was available for customers to see up close, including the SCAG Jackal (mini-skid steer); the VersaTran (Freightliner) truck system; KAGE Innovation’s GreatER Bar attachment; the Manitou 2750V Nemesis series loader; the CMC 75I insulated aerial lift; the Snorkel scissor lift; Kress; and TNAttachments’ log dolly.

Manufacturer representatives and Top Notch staff were on hand for live equipment demonstrations and food and drinks were available for all, including a pig roast lunch. Customers were eligible for exclusive deals on equipment and were entered for the many give aways.

Top Notch Equipment is an authorized dealer of Manitou, Gehl, CMC, Cast Loaders, GiANT, Boxer, SCAG Power Equipment, Wright, Rayco, Fisher, Erskin, Paladin, Virnig, TNAttachments, Blue Diamond and RedMax. CEG

Notch

Plenty of Manitou equipment was in the yard for guests to inspect.

Dustin Breiwick (L), president and CEO of Top Notch Equipment, and Harry Fleegel, sales manager, were on hand to greet customers at the open house.

CEG photo

Dan Nissen, director of sales of VersaTran Versatile Transport Equipment, Beaver Dam, Wis., demonstrated the reliability of the company’s Retriever 6T, which features a 3-position ramp; non-CDL option; a high strength steel deck; and can load up to 12,000 lbs., depending on options.

Kage’s “dream team” (L-R): Kaydence

creative marketing assistant; Philip

Midwest region account executive; and

Customers were interested in the new SCAG Jackal mini-skid steer, seen here with a TNAttachments log grapple.

Fabick Cat hosted a two-day Open House and Team Member Appreciation Event at their Fenton, Mo., location May 3 to 4. Held at Fabick Cat’s headquarters facility (One Fabick Drive, Fenton, MO 63026), the Friday event focused on customers with equipment demonstrations, facility tours, product displays, the latest technology offerings, door prizes and lunch — while the Saturday portion invited Fabick Cat team members and their families to a day filled with fun for all ages. The two-day event drew an impressive crowd of more than 800 people.

Customers focused their attention on the new Cat 255 (replacing the 259D3) and 265 (replacing the 279D3 and 289D3). Offered throughout the demo area, customers had a chance to experience the upgraded power, performance and comfort of these brand-new machines. In addition, a variety of Cat equipment was on display including skid steers, dozers, excavators, pavers, trucks and generators as well as some allied rental equipment offerings like boom lifts and scissor lifts. Representatives of Caterpillar attended to promote the benefits of the Cat Card (offered by Cat Financial) and the newest technology offerings from Fabick Technology Services were showcased as well.

(L-R) are Wyatt Bust of Utiliworx; Adam Johnson of A.E. Johnson; Craig Harris, territory manager, Fabick Cat; Brad Cabral of Cabral Farms; Josh Shuh of Ultra Excavating; Meghan Billings of Ultra Excavating; and Jim Tidwell, product support sales representative, Fabick Cat.

Cat

This service truck — a 1955 Ford cab and chassis, equipped with a Powers tool bed — was restored in 1992 to mark Fabick Cat’s 75th anniversary. The truck had been sold to a customer and repurchased by Fabick in 1990.

Jeff Meshach, of the World Bird Sanctuary, brought Liberty the bald eagle to the Fabick Cat open house. At age 10 months, Liberty was hit by a car and suffered a dislocated shoulder and neurological damage, preventing him from being released back into the wild. Liberty is now 35 years old, and part of the World Bird Sanctuary’s education department.

Taking time for a photo op with this Cat 308 excavator (L-R) are Scott Crean, regional sales manager, Fabick Cat; Christopher Masters, president of Masters Excavating; Jim Masters of Masters Excavating; Jeré Fabick, chairman and CEO of Fabick Cat; Pat Meyer, sales operations manager Fabick Cat; and Matt Jundt, account manager of Fabick Cat.

(L-R) are Nathan Walck of Ballast Tools & Equipment; Jeré Fabick, chairman and CEO of Fabick Cat; Ned Williams of Ballast Tools & Equipment; and Tim Fritz vice president of machine sales, Fabick Cat.

(L-R): Danielle Richter and Jason Richter of Groundworks Contracting Inc. spoke with Mike Malone, territory manager; Jim Howerton, paving specialist; and Aaron Bryan, territory manager, all of Fabick Cat about this Cat 326 Next Generation excavator.

Fabick Cat team members and their families gathered for equipment demos, shop tours and door prizes while the kids enjoyed bounce houses, face painting and a petting zoo.

In addition to the many customer guests, Fabick Cat team members and their families, members of the Fabick family — Jere ́ Fabick, chairman, CEO and dealer principal; John Fabick IV, president; and Kelli Fabick, general manager, Fabick Rents — were also in attendance to join in the two-day celebration.

“Over the two-day event, we were honored to host not only our customers but our team members and their families — providing a small token of appreciation for their contributions and unwavering support,” said Kelli Fabick. “In order to fulfill our company vision ‘To Ever Serve Our Customers Better’ we rely on an incredible team of hard working, dedicated employees. So, we truly enjoyed the opportunity to celebrate both our customers and our employees this year.”

For more than 100 years, Fabick Cat has employed and served the hard-working men and women that improve the quality of life in its community. From Cat machines that help maintain infrastructure and support farmers, to aerial lifts and emergency power generation, Fabick Cat supplies the essential products to help make progress possible.

see FABICK page 102

(L-R): Stewart England, territory manager, Fabick Cat, shows this Cat 326 NextGen excavator to Kolan Schoenbeck and Matt Fehr of Kaskaskia Valley Farms Inc.

(L-R): Parker Blackorby, CCE specialist, Fabick Cat, shows this Cat 239D3 tracked skid steer with a Caterpillar GB120 grader blade to Bobby Ross and Rob Ross of Ross Excavating in Collinsville, Ill.

The Weiler P385c paver offers performance reliability and outstanding mat quality in a wide range of applications, according to the company.

(L-R) are Tom Schuman, territory manager, Fabick Cat; Rick Swantner of Swantner Industries; and Bo Matthews of Thoughtsub Consulting.

Lano Equipment welcomed customers to its Shakopee, Minn., location at 3021 West 133rd St. for an open house on April 25.

In addition to manufacturer representatives on hand to show off the latest equipment and technology they have to offer, guests were invited to a DOT class by the Minnesota Department of Transportation.

A “Show Us Your Tracks” skills challenge also was part of the open house, and guests were treated to lunch, prepared by The Pork Chop Guys.

The winner of the contractor giveaway package — a SANY SY16C excavator with a Liberty Trailer — was Al Bauer.

For more information, visit lanoequip.com. CEG

CEG photo

Lano Equipment had a display by Dirty Graphics of Stillwater, Minn. Dirty Graphics provides custom wraps for any machine.

The Lano family — (L-R) are Roger, Juston, Evan, Nick and Kurt. (not pictured are David and Gary Lano).

CEG photo

This DEVELON DX140LCR excavator was ready for the next entrant in the ‘Show Us Your Tracks’ skills challenge.

were invited to a DOT class by the Minnesota Department of Transportation.

were able to view demonstrations of the machines.

Nick Lano (L), grade control specialist of Lano Equipment, and John Raemisch, product representative of SANY America, Peachtree, Ga., with the grand prize contractor giveaway package — a SANY SY16C excavator with a Liberty Trailer. The grand prize winner was Al Bauer.

Huge attachment inventory. Over 300 attachments in stock. We Buy, Sell, and Trade. Inventory changes daily, please call to discuss your needs and how we can help.

DOZER BLADES IN STOCK

D10R/T, D9R/T, D8R/T, D7R, D7R LGP, D7E, D6R LGP, D6K, D5G, D5C.

DOZER RIPPERS IN STOCK

D10R/T SS ripper, D11R/T SS ripper, D7R MS ripper, D6N MS ripper, D5K MS ripper, D5C/D4C/D3C ripper.

EXCAVATOR ATTACHMENTS IN STOCK

Quick Couplers for Most Models from Mini - 374D/E

336 Excavator - 30”, 36”, 42”, 54”, 60” all in stock.

315 Excavator - Most Sizes from 24” - 60” ditch cleaner

312/314 Excavator - 24”, 30”, 36”, 60” ditch cleaner

320/321/312 Excavator - 24”, 30”, 42”, 54”, 80” ditch cleaner

345/349 Excavator - 36”, 48”, 54”, 60”, 72”

QUICK COUPLER FORKS IN STOCK

420 D/E/F, 950-972 Fusion, 953, 972 HPL, Cat Telehandler

WHEEL LOADER BUCKETS FROM 914-992

Many sizes and styles available. Pin-on and Quick Coupler.

M/H SERIES GRADER RIPPERS IN STOCK Also front pushblock counterweights.

RECENTLY PARTED MACHINES INCLUDE

D4c, TH83, 988F, 769C, TH460B, TH360B, 242B, 320C, 345C, 420E IT, 836G, 345CMH, M325DMH, D6T

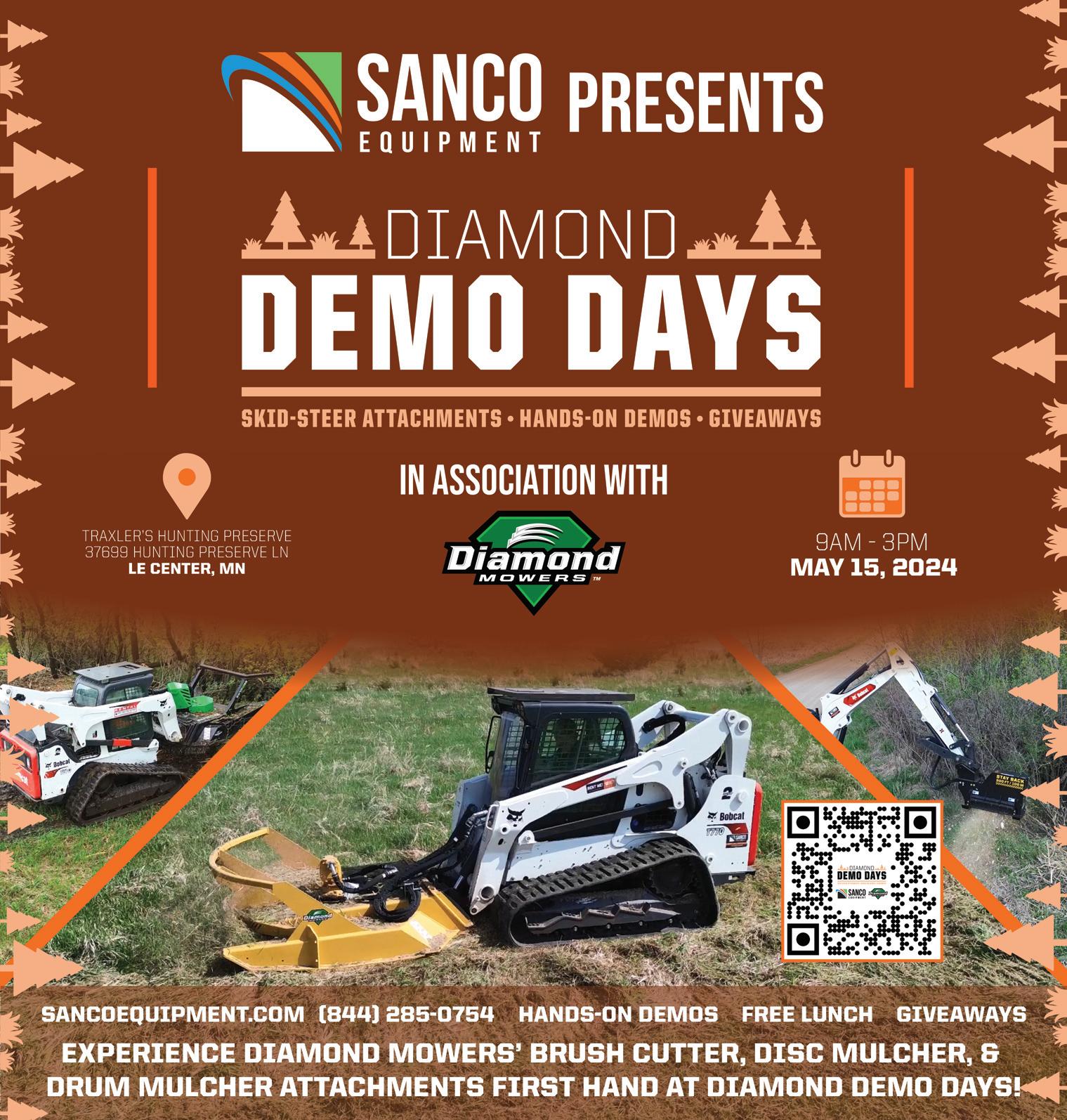

April was a busy month for Farm-Rite, as the company held open houses at two of its locations on April 19 in St. Cloud, Minn. (810 Mayhew Lake Rd. NE) and on April 27 at its Dassel, Minn. (901 Parker Ave. W) facility.

More than 400 people attended the event in St. Cloud, where attendees enjoyed pork chops from St. Joe Meat Market. Representatives of Midsota, Felling and Diamond Mowers provided information on their products. A demonstration by CMP was held in the lot showing the all-new Grapple Grab bucket.

“This event is our way to thank our customers; it truly is a customer appreciation event for us,” said Jay Kockler, general manager of the Farm-Rite, St. Cloud location. “The support from our customers is invaluable, and we are grateful for their trust in our products/services.”

Farm-Rite Equipment, Dassel hosted its annual “Customer Appreciation Day, on April 27th. More than 600 people were served hamburgers, hotdogs, and brats. Customers enjoyed testing out the new Bobcat equipment as they moved large piles of dirt from one end of the lot to the other.

Every year, Farm-Rite lights up the grill to show its appreciation and gratitude for its customers, vendors and employees. At both events, attendees received special discounts on Bobcat OEM parts and more.

For more information, visit farmriteequip.com. CEG

(All photographs in this article are Copyright 2024 Construction Equipment Guide. All Rights Reserved.)

Pace, national sales manager of Towmaster Trailers, Litchfield, Minn., was in St. Cloud with one of the company’s most popular trailers — the 16,000-lb. 16-ft. T16DT.

Attendees were invited to the demo area for equipment testing during the Dassel open house.

(L-R): Towmaster Trailers’ Chris Pokornowski, regional sales account manager, and Aebi Schmidt, national sales manager, talk to an interested open house attendee in Dassel.

A variety of equipment was on display at FarmRite’s open house in Dassel, Minn.

A nice combo platter for snow season — a new Bobcat Platinum S76 R series limited-edition machine sports an exclusive paint and decal scheme that makes a bold impression on every job site with a Bobcat KAGE snow system.

This Bobcat E165 is ready for work. Bobcat’s 131-hp full-size excavator in the 16- to 18-ton size class, is ideal for roadways, railroads, bridges, infrastructure and commercial and urban job sites.

Magni Telescopic Handlers photo Magni Telescopic Handlers, manufacturer of rotating, fixed boom and heavy lift telehandlers, announced its alliance with MacAllister, a Caterpillar dealer and provider of heavy construction equipment in Indiana and Michigan.

Magni Telescopic Handlers, manufacturer of rotating, fixed boom and heavy lift telehandlers, announced its alliance with MacAllister, a Caterpillar dealer and provider of heavy construction equipment in Indiana and Michigan.

This partnership signifies a significant expansion in access to Magni’s telehandlers throughout both states. Effective immediately, MacAllister becomes an authorized dealer of Magni’s complete line of telehandlers, including the RTH rotating telehandlers, HTH heavy lift telehandlers and 10k/12K fixed boom TH models.

“Through this partnership, we aim to combine MacAllister’s expertise with Magni’s products to drive safety, efficiency and productivity in Indiana and Michigan’s construction projects,” said Joe Leinwol, chief sales officer of Magni America.

“MacAllister Rentals prides itself on providing the very best equipment to get the job done,” said Joshua Doss, rental service operations manager of MacAllister. “We are excited to announce that MacAllister Rentals has partnered with Magni Telehandlers and now offers the Heavy Lift and Roto line of telehandlers. The Magni rotating telehandler brings an excellent alternative to a crane and will increase safety, efficiency and productivity to our customers and their clients. We are looking forward to seeing the Indiana and Michigan customers experience the Magni line of telehandlers and the value they add to their job site.”

With Magni’s telehandlers now readily available through MacAllister, customers across Indiana and Michigan can expect enhanced efficiency, safety and productivity on their projects. Whether it’s a small-scale endeavor or a large-scale construction proj-

ect, Magni’s telehandlers offer unparalleled performance and versatility, according to the manufacturer.

As part of this collaboration, MacAllister has undergone comprehensive training in the application, sales, parts and service of Magni’s telehandlers. Armed with this expertise, MacAllister is fully equipped to introduce Magni telehandlers, known for safety, lifting heights and capacities, to its customers throughout Indiana and Michigan, according to Magni.

“Through this partnership, we aim to combine MacAllister’s expertise with Magni’s products to drive safety, efficiency and productivity in Indiana and Michigan’s construction projects.”

Joe Leinwol Magni America

“We’re eager to illustrate how Magni rotating telehandlers can streamline operations and drive savings for their customers. With MacAllister now part of our esteemed dealer family, we anticipate a prosperous partnership ahead,” said Jay Jude, Midwest regional sales manager, Magni America. For more information, visit macallister.com and magnith.com.

Liebherr photo

Budrovich Contracting Co. takes delivery of the first Liebherr LTM 1110-5.2 equipped with LICCON3 in the United States.

Midwest based Budrovich Contracting Co. received the first Liebherr LTM 1110-5.2 mobile crane outfitted with LICCON3 in the United States. With another LTM 1110-5.2 mobile crane on the way, Budrovich attributes excellent training and successful implementation of Liebherr machines as valuable criteria during the purchasing process. Featuring a max. load capacity of 125 tons (110 t) and a telescopic boom reaching 197 ft. (60 m), the Liebherr LTM 1110-5.2 mobile crane is an ideal solution for Budrovich Contracting Co.’s hosting needs. The company purchased two Liebherr LTM 1110-5.2 mobile cranes at ConExpo 2023. The mobile crane features an updated cab design,

Budrovich provides support and services across the Midwest, offering one of the largest and most diverse crane rental fleets in the St. Louis area.

gearbox and the third generation crane control system, LICCON3.

With Budrovich’s recent handover in St. Louis, Mo., this is the first LTM 1110-5.2 outfitted with LICCON3 to be delivered in the United States.

Founded in 1945, Budrovich Contracting Co. is comprised of nine business units specializing in crane rental, excavating and grading, land development, site utilities, marine services, mechanical insulation, rebar, equipment repair and structural steel. The company provides support

and services across the Midwest, offering one of the largest and most diverse crane rental fleets in the St. Louis area.

Currently, Budrovich has more than 100 carry deck, rough-terrain, crawler and hydraulic truck cranes ranging in size from 8.5 to 550 tons. The company also will take delivery of an additional Liebherr LTM 1110-5.2 mobile crane and an LTM 1230-5.1 mobile crane this spring.

“Liebherr’s willingness to train our operators and mechanics along with the successful implementation of recent Liebherr cranes into our fleet has been valuable in our see BUDROVICH page 38

2014 Komatsu PC170LC-10

Cab, a/c, 9' 6" stick, GP bucket, 24" tgp KM14231X

$73,000 6,700 hrs.

2016 Komatsu PC228USLC-10 a/c, camera, Coupler, 9’6” arm KM16348

$79,500 6,102 hrs.

2016 Komatsu WA320-7 Enclosed ROPS KM16028X

$65,000 14,686 hrs.

2015 HAMM HD+ 120I VV Vibratory Tandem HA15064

$54,000 2,054 hrs.

2017 Komatsu PC490LC-11

Cab, a/c, QC, 11'1" stick, 35.5" shoes, CWRD KM17569P

$259,500 5,400 hrs.

2017 Komatsu PC138USLC-11

a/c, camera, 8’2” arm, blade, coupler KM17099

$109,500 4,868 hrs.

2019 Komatsu D39PX-24

Cab, a/c, LGP 28" shoes, PAT 128" blade, Enclosed ROPS K191511M

$102,500 2,900 Hrs.

2017 Takeuchi TL12V2 cab, rubber tracks, ride control TL17017

$54,000 3,338 hrs.

2017 Komatsu PC650LC-11 a/c,14’ stick, 36” shoes KM17501

$269,000 8,320 hrs.

2017 Komatsu D85EX-18 a/c, Sigma blade, 26” shoes KM17444

$199,000 4,399 hrs.

2017 Takeuchi TL8CRW cab, rubber tracks, HD bucket w/ teeth TL17037 $43,000 2,146 hrs.

2016 Komatsu PC360LC-11 a/c, aux hydraulics, 10'6" stick, 34" shoes, camera KM16046

$108,000 7,668 hrs.

2019 PC240LC-11 a/c, 31.5" shoes, camera K191571X

$99,000 7,434 hrs.

2016 Komatsu GD655-6 Pushblock, 14' MB KM16099R $129,500 4,791 hrs.

2018 SullairHAF

150 PSI, pintle hitch SU18011U $169,500 1,381 hrs.

2012 Komatsu HB215LC-1 a/c, 9'7" long arm, 32" shoes, hybrid, bucket KM12780U

$64,000 3,818 hrs.

2014 Komatsu HM400-3 8,000 gallon water tank, truck works, reel, 29.5 tires KM14059K $224,000 9,401 hrs.

2015 NPK GH18 Refurbished, PC490LC mounting bracket NP15027 $59,000

More than 300 dignitaries, guests and associates enjoyed a day of celebration at the Allen Engineering Corporation (AEC) 60th Anniversary event on April 17, 2024, at the company’s headquarters facility in Paragould, Ark.

A catered lunch was provided and guests had the opportunity to tour the facility, watch machines being built and see unique displays showing the evolution and the innovation of the Allen product lines.

As the program progressed under the “big top” tent, local and state dignitaries, as well as Jay Allen, CEO, and his mother, Mary Ann Allen, addressed the crowd. Mary Ann gave a warm welcome and paid homage to her late husband and company co-founder, J. Dewayne Allen, and the inspiring story of Allen Engineering’s roots.

Paragould’s County Judge Rusty McMillon and Mayor Josh Agee continued the program by sharing their pride of Paragould and the positive impact that long-standing businesses like Allen Engineering have had on the community. Arkansas State University’s administration officials Vice Chancellor for Intercollegiate Athletics Jeff Purinton and Chancellor Todd Shields delivered energetic speeches on Allen Engineering’s core values and contributions to the community. Even Gov. Sarah Sanders celebrated the event by proclaiming April 17 as “Allen Engineering Day in the state of Arkansas.”

Jay Allen wrapped up the program with a heartfelt thank you to all the speakers, guests and associates who made the event such a celebration and for his mother, Mary Ann Allen, “for without her, AEC would not be where it is today”.

Allen Engineering is a familyowned company specializing in the production of high-quality, innovative equipment for concrete placement, finishing, polishing and paving.

Founded in 1964, Allen Engineering started as a small concrete business and over the years grew to have five plants throughout northeast Arkansas. In 1977, the company launched the Allen Razorback truss screed and shifted its focus from concrete placement to design, manufacturing and distribution of concrete equipment. CEG

(All photographs in this article are Copyright 2024 Construction Equipment Guide, except where noted. All Rights Reserved.)

BURRIS EQUIPMENT www.burrisequipment.com

2216 N. Greenbay Rd. Waukegan, IL 60087

847-336-1205

Ingleside, IL 815-363-4100

Joliet, IL 815-464-6650

CENTRAL POWER SYSTEMS & SERVICES www.cpower.com

9200 Liberty Drive

Liberty, MO 64068

816-781-8070

Wichita, KS

316-943-1231

Woodward, OK

580-256-6014

Salina, KS

785-825-8291

Colby, KS

785-462-8211

Springfield, MO

417-865-0505

Joplin, MO

417-726-5373

Riverside, MO 816-415-6787

Wichita, KS 316-789-7370

Yukon, OK 405-324-2330

Maryland Heights, MO 314-427-4911

Liberty, MO 816-415-6700

Tulsa, OK 918-984-6565

WAKARUSA AG www.wakarusaag.com

711 East Waterford Street Wakarusa, IN 46573 574-862-1163

Mayor Brandon Johnson joined federal and airline partners on April 22 to break ground on the approximately $300 million ElevateT3 project, a massive investment in the airport’s aging terminal facilities supported by $90 million in grant funding from President Joe Biden’s Bipartisan Infrastructure Law (BIL).

“Today marks a significant step forward in redefining the travel experience at O'Hare International Airport through the ElevateT3 project,” said Johnson. “This transformative initiative not only boosts our infrastructure but also strengthens Chicago's position as a global aviation leader, due to substantial support from the Bipartisan Infrastructure Law.”

“Supported by funding from the Biden-Harris Administration’s Bipartisan Infrastructure Law, the Terminal 3 Improvements will include the latest technology, provide enhanced energy efficiencies and reduced emissions,” said FAA Associate Administrator for Airports Shannetta R. Griffin. “This project will have a significant impact on the people who travel in and out of Chicago O’Hare and change the lives of those in the Chicago community as a whole.”

ElevateT3 is a key pillar of O’Hare 21, Chicago’s vision to transform the country’s best-connected airport into an efficient and accessible international gateway for the 21st century. The construction work will upgrade customer amenities; improve security screening and airport operations; expand accessibility for passengers with disabilities at Terminal 3; and includes the following components:

• The reconfiguration of two Transportation Security Administration (TSA) checkpoints into a single screening area, providing space for modern and more efficient equipment

• An expanded passenger corridor between Concourse K and Concourse L, tripling the current corridor’s width.

• The expansion of the holdroom space at Gates K1 and L2A

• A reconfigured baggage claim area and other upgrades to the terminal’s baggage facilities and systems that provide sortation for departing passenger baggage

• The development of approximately 10,000 sq. ft. of new concessions and amenity spaces

• Renovated restrooms and a new family restroom

• Other renovations of the terminal’s interior and exterior structures and systems

Part of the $300 million project will be financed by BIL through two competitive grant awards announced over the past two years — a 2023 grant valued at $50 million and a 2024 grant totaling $40 million. Each amount was the largest single grant awarded to any airport in America through the Airport Terminal Program over the past two years. The balance of the Terminal 3 upgrade will be paid for by previously allocated federal funds and airline rates and charges.

Construction work will be performed by COT3 as Construction Manager At-Risk (CMAR). The company is a joint venture of Clark Construction and W.E. O’Neil, and outreach work on available bid packages for the Terminal 3 improvements project began in late 2023. Upcoming bid opportunities can be found at ord21.com/bids.

A key component of the ElevateT3 project is the continued commitment of the Chicago Department of Aviation (CDA) to employment, education and training opportunities for entrepreneurs and young people from diverse backgrounds. This includes the Bid & Resource Center at O’Hare, which alongside the CDA’s Workforce Development team, partners with local, community-based organizations to provide resources across Chicago’s 77 community areas, hosting career expos, visiting neighborhood events, and establishing unique and emerging partnerships with City Colleges of Chicago and Chicago Public Schools. The project is expected to last for just more than three years, with an anticipated completion date of summer 2027. Construction will take a phased approach to allow continuous operations throughout Terminal 3 during construction. Additional components of the O’Hare 21 capital program continue to proceed. Initial work to prepare for future satellite concourses launched in spring 2023.

For more information, visit ord21.com.

murphytractor.com

Park City, KS 316-942-1457

Great Bend, KS 620-792-2748

Humboldt, KS 620-473-7020

Olathe, KS 913-298-7373

Topeka, KS 785-233-0556

Ulysses, KS 620-356-1071

Dodge City, KS 620-227-3139

Gering, NE 308-436-2177

Omaha, NE 402-894-1899 Lincoln, NE 402-467-1300 Grand Island, NE 308-381-0741

North Platte, NE 308-534-7020 Kansas City, MO 816-483-5000 Springfield, MO 417-863-1000

Des Moines, IA 515-263-0055

Fort Dodge, IA 515-576-3184

Sioux City, IA 712-252-2753

Waterloo, IA 319-235-7085

Brunswick, OH 330-220-4999

Cambridge, OH 740-439-2747

Canton, OH 330-477-9304 Cincinnati, OH 513-772-3232

Columbus, OH 614-876-1141

Jackson, OH 740-688-4100 Lima, OH 419-221-3666

Painesville, OH 440-639-0700

Poland (Youngstown), OH 330-629-6299

Rossford, OH 567-352-7001

Vandalia (Dayton), OH 937-898-4198

www.aisequip.com

Bridgeport, MI 989-777-0090

Grand Rapids, MI 616-538-2400 Lenox, MI 586-727-7502

New Hudson, MI 248-437-8121

Williamsburg, MI 231-267-5060

When we designed our new 460 P-Tier and 410 P-Tier Articulated Dump Trucks, we went to real-world owners and operators like you. Then we got to work to deliver Eco mode that reduces fuel use by up to 12%. A quiet, pressurized cab with rear-camera display. Onboard diagnostics to keep you in the know and on the go. Ground-level serviceability. And intuitive options including automatic temperature control (ATC) system, onboard payload weighing, and auto lube. These power players were made to build up your productivity — and your bottom line.

www.lec1.com

Beaver, WV

304-255-1525

Cowen, WV

304-226-3299

Cross Lanes, WV

304-204-1818

Pleasant Valley, WV

304-534-5454

Norton, WV

304-636-6421

Marietta, OH

740-373-5255

Ashland, KY

606-327-1709

Pikeville, KY

606-432-0321

Bemidji, MN

218-759-1996

Duluth, MN

218-722-7456

Grand Rapids, MN 218-326-9427

Ashland, WI

715-682-5522

Chippewa Falls, WI 715-834-2924

Merrill, WI 715-536-0633

Escanaba, MI 906-789-9054

JohnDeere.com/ADT

Marquette, MI

906-789-7689

Fenton, MO 636-349-0200

Foristell, MO 636-463-2500

Mitchell, IL 618-931-1034

Mt. Vernon, IL 618-244-6800

Cape Girardeau, MO 573-334-0563

Paducah, KY 270-554-1131

Cuba, MO

573-885-0500

Owensboro, KY

270-684-2339

Evansville, IN 812-473-0484

Kingsport, TN

423-349-5001

Knoxville, TN

865-546-3207

Chattanooga, TN 423-855-0633

Nashville, TN

615-501-8600

Bowling Green, KY

270-842-3400

Louisville, KY 502-253-3721 Lexington, KY 859-788-3950

London, KY 606-862-8447

www.brookstractor.com

Madison (Sun Prairie), WI 608-837-5141 Milwaukee, WI 414-462-9790

Green Bay (De Pere), WI 920-336-5711

La Crosse (West Salem), WI 608-786-2644

Stevens Point (Plover), WI 715-254-2777

Racine (Mt. Pleasant), WI 262-898-6700

Sparta,WI 608-351-2101

www.westsidetractorsales.com

Lisle, IL

630-355-7150

Rockdale, IL

815-730-9011

Rockford, IL 815-961-3160

South Holland, IL 708-331-6362

Wauconda, IL 847-526-7700

Bloomington, IN 812-333-9677

Fort Wayne, IN

260-482-8576

Indianapolis, IN

317-544-3411

Lafayette, IN

765-447-6933

South Bend, IN

574-232-1461

Terre Haute, IN

812-645-7160

BUDROVICH from page 32

purchasing process,” said Sam Harper, assistant operations manager of Budrovich Cranes.

As experts in commercial and industrial crane hoisting, Budrovich’s services include project evaluation and coordination; crane placement modeling; engineered lift plans; and providing safe, effective lift solutions for customers. The Liebherr LTM 1110-5.2 provides Budrovich with a modern solution to meet its customer needs and evolving industry standards.

The Liebherr LTM 1110-5.2 mobile crane combines existing strengths with modern innovations to deliver greater safety and comfort to the operator, according to the manufacturer. The mobile crane is equipped with the third generation of the LICCON control system. LICCON3 takes the familiar crane controls to a new level featuring new, technologies such as a fast data bus; significantly more

storage space; greater computing power; and preparation for telematics and fleet management systems.

Additional new features of the Liebherr LTM 1110-5.2 include an updated operator’s cab design equipped with automatic heating and climate control, as well as an improved dashboard and display. The 5-axle crane also is outfitted with the ZF

TraXon DynamicPerform gearbox, an oil-cooled multi-disk clutch on this gearbox which has undergone intensive testing and is ready for use on Liebherr mobile cranes, according to the company. Each of these new features represents the future of Liebherr’s all-terrain series.

For more information, visit liebherr.com.

3478

866/539-8106 3509

515/410-9900

The hard-hitting MAX-Series™ VT-100 gives you the tools to impr The vertical-lift machine excels in loading and grading applications

Alex Power Equipment www.alexpowerequipment.com 116 50th Avenue West Alexandria, MN 56308 320-763-4994

Equipment www.qualityequipmentmn.com

3800 Park Ave NW Faribault, MN 55021 507-338-7080

Forklift www.qualityforklift.com

587 Citation Drive Shakopee, MN 55379 952-895-9918 Roeder Implement www.roederimplement.com 2550 Rockdale Road Dubuque, IA 52003 563-557-1184

www.cstk.com 401 Shawnee Avenue Kansas City, KS 66105 913-371-0868 St. Louis, MO 314-771-6666 Park City (Wichita), KS 316-744-2061 Oklahoma City, OK 405-577-2222

Ronson Equipment Co. www.ronsonequipment.com 18030 Wicker Avenue Lowell, IN 46356 219-696-5680

10761 West Coulter Road Westville, IN 46391 219-785-2909

It is not every day that a heavy equipment foreman identifies a problem costing his company profit and then invests his own money to find a solution, but that is precisely what happened in the case of Matt Schwarz’s new Grade Stake Pro application.

Schwarz grew up on a farm in eastern Iowa, where he operated heavy machinery. He went on to a career in law enforcement. After becoming a detective, Schwarz found his calling in forensics, working in management as a consultant and SME for cities like Houston, Texas, and St. Paul, Minn. There, his reputation grew for identifying and removing the risk of human error from critical processes. Today, he consults with local, state, and federal law enforcement to improve the accuracy of their labs.

Approximately 10 years ago, fondly recalling his days working with heavy equipment, Schwarz joined a local company to fill his summers. Most of his projects involve integrating with existing infrastructure where every .04 ft. to .08 ft. matters.

“There are two types of operators: those who have had a costly grading error and those who will,” said Schwarz.

One such error that came to his attention involved five blocks of reconstruction work. The concrete crew identified the prep as .083 ft. low on rock, which cost more than $16,000 to remedy.

Operators must regularly get out of their cabs to manually check grades to avoid such errors. Schwarz observed unnecessary delays as operators struggled to complete the math required for these checks confidently. Between the complexity of the math and the operator’s skill, Schwarz identified a problem he could solve.

As a result, the Grade Stake Pro application is a new tool that lowers the risk of human error when manually checking

grades. The application’s ease of use also reduces the time operators are out of their cabs. To use, an administrator sets up each project with critical specifications. The user selects the project and enters the stake values. The application returns all the layer values the operator will need for the remainder of the project. Jot these values on the back of the stake, and no one needs to recalculate at that stake for the remainder of the project.

GPS has revolutionized the construction industry, yet its vertical limitations still require manual grade checks to achieve accuracy. The standard vertical error of GPS is around .0833 ft. to .1405 ft. Failure to account for blade ware, signal interference and base pole install errors can compound the inaccuracies. Working around existing infrastructure, this is not accurate enough on its

The feedback from testing has been positive.

An operator still in his apprenticeship used the application to run a dozer to prep a 1,700-ft. two-lane stretch with a roundabout. After timing of the rock, there were only four skid-steer buckets of material left over.

Another foreman said, “This app is perfect for guys in their first five years on the job. It is another tool they can use to get their grades spot-on. I remember how often I got yelled at for the wrong calculations when I was checking grades in my first few years. As a foreman, I can trust that my guys now have a tool to backstop them until they are masters. I wish I had this early in my career.”

For more information, visit www.gradestakepro.com or email mattgsp@gradestakepro.com. CEG

(All photos courtesy of Grade Stake Pro.)

4805 Scooby Lane Carroll, OH 43112 740-654-5304

920 Deneen Avenue Monroe, OH 45050 513-649-8105

1330 KY - 151 Frankfort, KY 40601 502-699-2681

1515 W. Epler Avenue Indianapolis, IN 46217 317-782-8850

3600 N. Grand River Ave. Lansing, MI 48906 517-321-8000

600 44th Street S.W. Grand Rapids, MI 49548 616-538-2400

65809 Gratiot Ave. Lenox, MI 48050 586-727-7502

4600 AIS Drive Bridgeport, MI 48722 989-777-0090

8300 M-72 East Williamsburg, MI 49690 231-267-5060

56555 Pontiac Trail New Hudson, MI 48165 248-437-8121

Contact your local authorized Takeuchi dealer:

Columbus Equipment Company

2329 Performance Way • Columbus, OH 43207 614-443-6541

12500 Williams Rd. • Perrysburg, OH 43551 419-872-7101

712 Shepherd Ave. • Cincinnati, OH 45215 513-771-3922

3942 Brecksville Rd. • Richfield, OH 44286 330-659-6681

290 Old Steubenville Pike • Cadiz, OH 43907 740-942-8871

7570 New Carlisle Pike • Dayton, OH 45424 937-879-3154

2200 Venture Circle SE • Massillon, OH 44646 330-833-2420

818 Lee St. • Zanesville, OH 43701 740-455-4036

3668 US Route 23 South • Piketon, OH 45661 740-289-3757

www.columbusequipment.com

Brandeis Machinery & Supply Company

17000 Highway 41 N • Evansville, IN 47725 812-425-4491

7310 Venture Lane • Fort Wayne, IN 46818 260-489-4551

8410 Zionsville Road • Indianapolis, IN 46268-1524 317-872-8410

1801 Watterson Trail • Louisville, KY 40299 502-491-4000

160 County Park Road • Paducah, KY 42001 270-444-8390

www.brandeismachinery.com

8376 I-70 Dr SE • Columbia, MO 65201 573-273-4525 www.equipmentshare.com

Wilson Equipment Company

2180 Old Frankfort Pike • Lexington, KY 40510 859-254-6443 • 800-432-0913

828 W. Cumberland Gap Pkwy • Corbin, KY 40701 606-528-0700 • 800-274-9457

2124 Watergap Road • Prestonsburg, KY 41653 606-874-8036 • 800-955-9457 www.wilsonequipment.com

Alta Equipment Company

5105 Loraine Street • Detroit, MI 48208 313-394-1811

56195 Pontiac Trail • New Hudson, MI 48165 248-356-5200

8840 Byron Commerce SW • Byron Center, MI 49315 616-878-7450

3283 S Dort Hwy. • Flint (Burton), MI 48529 810-744-4840

3725 Old 27 S • Gaylord, MI 49735 989-731-9988

7500 E 15 Mile Road • Sterling Heights, MI 48312 586-474-5063

1061 Stepke Court • Traverse City, MI 49685 231-714-6210

613 E Stevenson Road • Ottawa, IL 61350 815-313-2070 www.altaequipment.com

McCann Industries

543 S. Rohlwing Rd • Addison, IL 60101 630-627-0000

250 E. North Frontage Rd. • Bolingbrook, IL 60440 630-739-7770

23921 S. Northern Illinois Dr. • Channahon, IL 60410 815-467-4480

2350 S. Laflin St. • Chicago, IL 60608 312-942-9200

4701 West 137th Street • Crestwood, IL 60445 708-597-3110

900 Louisiana Street • Merrillville, IN 46410 219-576-7800

1133 Indianapolis Blvd. • Schererville, IN 46375 219-865-6545

1360 N. Rand Rd. • Wauconda, IL 60084 847-526-9444

www.McCannOnline.com

Diamond Equipment Inc.

1501 Lynch Road • Evansville, IN 47711 800-258-4428 • 812-425-4428

120 Flex Park Drive • Bowling Green, KY 42103 800-489-1061 • 270-781-1061

17035 North IL Hwy 37 • Mt. Vernon, IL 62864 800-388-6396 • 618-242-2273

2000 Harlan Drive • Terre Haute, IN 47802 888-343-4747 • 812-299-4747 www.diamondequipment.com

Star Equipment Ltd.

1401 2nd Avenue • Des Moines, IA 50314 515-283-2215 • 800-369-2215

2625 W. Airline Hwy. • Waterloo, IA 50703 319-236-6830 • 800-791-9249

2950 6th Street SW • Cedar Rapids, IA 52404 319-365-5139 • 800-728-5139

2100 E. Lincoln Way • Ames, IA 50010 515-233-9500 • 866-856-2312 www.starequip.com

Kelbe Brothers Equipment Co.

12770 W. Silver Spring Drive • Butler, WI 53007 262-781-4970

4621 Dutch Mill Rd. • Madison, WI 53716 608-221-8300

3101 French Rd. • De Pere, WI 54115 920-343-6496 www.kelbebros.com Kirby-Smith Machinery, Inc.

8320 Ruby Avenue • Kansas City, KS 66111 913-850-6300 • 877-851-5729 www.kirby-smith.com

BUCK & KNOBBY EQUIPMENT CO. www.buckandknobby.com

6220 West Sterns Road Building #2 Ottawa Lake, MI 49267 855-213-2825

CONSTRUCTION MACHINERY COMPANY www.cmcky.com

2911 S English Station Rd Louisville, KY 40299 502-267-4020 6104 Sable Mill Court Jeffersonville, IN 47130 812-850-6160 2235 Ragu Drive Owensboro, KY 42303 270-683-2000

DITCH WITCH OF MINNESOTA & IOWA ditchwitchmnia.com

12826 Emery Way Shakopee, MN 55379 800-252-5811

1320 Frontier Drive Fergus Falls, MN 56537 800-492-4801

1520 Blue Sky Blvd. Huxley, IA 50124 515-685-3521

2801 Beverly Drive Aurora, IL 60502 630-820-3030

1801 179th Street N. East Moline, IL 61244 309-751-9540

120 East Martin Drive Goodfield, IL 61742 309-965-3300

929 McDonough Lake Road Collinsville, IL 62234 618-407-3860

VERMEER MIDWEST vermeermidwest.com

621 Spirit Valley E. Drive Chesterfield, MO 63005 636-532-2332

13402 Britton Park Rd. Fishers, IN 46038 317-842-1040

3310 W. Coliseum Blvd. Fort Wayne, IN 46808 260-484-2494

3566 Citadel Circle Newburgh, IN 47630 812-490-4400

940 Garden Lane Fowlerville, MI 48836 800-336-3889

1098 Franklin Street Marne, MI 49435 616-677-5900

2319 Plum Valley Rd. NE Mancelona, MI 49659 231-258-1290

Discussing Komatsu excavators are Martin Greene (L) of Goodman Excavating in Louisa, Va., and William Apperson of All Roads Equipment in Richmond, Va.

(L-R): Representing Murphy Construction in Indianapolis, Ind., are Dave Morgan, Bryan Orcutt and Steve Milbourne, and representing Brandeis Machinery are Mac and Matt Morris, Jeremy Scott and Curtis Slack.

held a Demo Days event April 16 to 18, 2024, at its Cartersville Customer Center in Georgia.

Demo Days attendees had opportunities to interact with Komatsu machines and solutions, including Komatsu’s Intelligent Machine Control (iMC) and to learn more about My Komatsu, an all-in-one solution for 24/7 access to machine telematics, parts manuals, service manuals, software and parts ordering.

Among the equipment demonstrated during the event, Komatsu highlighted the newly designed WA475-10 wheel loader, the HB365LC-3 hybrid excavator, compact hydraulic excavators and more.

The WA475-10 wheel loader features next-generation technology developed with input from customers to deliver improved productivity and lower fuel costs and is designed

Checking

for quarry, waste, infrastructure, forestry and non-residential construction applications. Its dual-mode engine power selector offers two operating modes: economy and power. According to Komatsu, the innovative Komatsu Hydraulic Mechanical Transmission (KHMT) improves fuel economy by up to 30 percent versus the prior model while providing 18 more horsepower.

The HB365LC-3 hybrid excavator is designed to reduce fuel consumption while driving performance. When swinging, all available hydraulic power is sent to the boom, arm and bucket for improved cycle time and increased production, according to Komatsu. CEG

(All photographs in this article are Copyright 2024 Construction Equipment Guide. All Rights Reserved.)

see KOMATSU page 74

During Demo Days, guests learned about the features and benefits of

www.altaequipment.com

844-GO2-ALTA

18405 115th Avenue Orland Park, IL 60467

420 Nolen Drive South Elgin, IL 60177

26354 N US Hwy 12 Wauconda, IL 60084

480 Blaine St. Gary, IN 46406

613 E Stevenson Road Ottawa, IL 61350

1035 Wylie Drive Bloomington, IL 61705

www.lubyequipment.com

2300 Cassens Drive Fenton, MO 63026 636-343-9970

199 Airport Road Cape Girardeau, MO 63702 573-334-9937

2999 Mexico Road O’Fallon, MO 63366 636-332-9970

2625 North 24th Street Quincy, IL 62305 217-222-5454

4375 Camp Butler Road Springfield, IL 62707 217-744-2233 921 1st Street Fairmont City, IL 62201 618-397-9971

sancoequipment.com

2317 Consul St. Albert Lea, MN 56007 507-373-4490

12251 B 265th St. Mason City, IA 50401 641-450-7126

630 Schumann Dr. NW Stewartville, MN 55976 507-285-0753

2333 7th Ave. Mankato, MN 56001 507-625-4511

www.tristatebobcat.com

1200 Highway 13 East Burnsville, MN 55337 952-894-0894

588 Outpost Circle Hudson, WI 54016 715-531-0801

71 Minnesota Avenue Little Canada, MN 55117 651-407-3727

2018 US Hwy 8 St. Croix, WI 54016 715-557-6010

www.bobcat-ent.com

9605 Princeton Glendale Road Hamilton, OH 45011 513-874-8945

225 Hughes Blvd Mount Orab, OH 45154 937-444-3865

3666 Lacon Road Hilliard, OH 43026 614-876-1116

182 Humphries Drive Reynoldsburg, OH 43068 614-863-1300

3000 Dillon School Drive Zanesville, OH 43701 740-313-0087

13117 Middletown Industrial Blvd. Louisville, KY 40223 502-245-1911

1309 Cahill Drive Lexington, KY 40504 859-254-3936

Atlas Bobcat Elk Grove Village 847-678-3633 88-438-8014

Mokena 708-596-8050 888-438-8014 Wauconda 847-526-4255 888-438-8014

West Chicago 630-293-0606 888-438-8014 Yorkville 630-553-0150 888-438-8014 www.atlasbobcat.com

Bobcat of Champaign Champaign 217-607-1454 www.gatewaydealer.com

Bobcat of Marion Carterville 618-985-8920 www.gatewaydealer.com

Bobcat of Springfield Springfield 217-525-0349 www.gatewaydealer.com

Bobcat of St. Louis Fairview Heights 618-397-1847 www.gatewaydealer.com

Bobcat of Effingham Teutopolis 217-717-4550 www.gatewaydealer.com

Atlas Bobcat Merrillville 219-381-3006 www.atlasbobcat.com

Bobcat of Evansville Evansville 812-422-8200 www.gatewaydealer.com

Bobcat of Michiana Elkhart 574-584-7550 www.bobcatofmichiana.com

Sanco Equipment Mason City 641-450-7126 www.sancoequipment.com

Bobcat of Bowling Green Bowling Green 270-842-4253 www.gatewaydealer.com

Bobcat of Michiana Niles 269-210-2299 www.bobcatofmichiana.com

Bobcat of Columbia Columbia 573-886-9435 www.gatewaydealer.com

Bobcat of St. Louis O’Fallon 636-240-9020 Valley Park 636-225-2900 www.gatewaydealer.com

Bobcat of Bemidji Bemidji 218-751-4660 www.goironhide.com

Bobcat of Brainerd A Division of RTL Equipment Brainerd 218-829-2800 www.rtlequipment.com

RTL Equipment

Big Lake 763-263-0505 www.rtlequipment.com

Farm-Rite Equipment, Inc.

Dassel 320-275-2737 888-679-4857

Long Prairie 866-514-0982 320-732-3715

St. Cloud 844-262-2281

Willmar 877-484-3211 www.farmriteequip.com

Lano Equipment, Inc.

Anoka 763-323-1720 888-448-5266

Loretto 763-479-8200 888-479-4342

Shakopee 952-445-6310 877-753-6100 www.lanoequip.com

Lano Equipment of Norwood, Inc.

Norwood Young America 952-467-2181 www.lanoequipofnorwood.com

Sanco Equipment

Albert Lea 507-373-4490 Stewartville 507-285-0753

Mankato 507-625-4511 www.sancoequipment.com

Swanston Equipment

Bobcat of Alexandria

320-460-8773

Bobcat of Fergus Falls 218-739-4505 www.swanston.com

Tri-State Bobcat Burnsville 952-894-0894 Little Canada 651-407-3727 www.tristatebobcat.com

Bobcat of Devils Lake Devils Lake 701-662-5331 www.goironhide.com

Swanston Equipment

Bobcat of Fargo 701-293-7325

Bobcat of Minot 701-837-9901 www.swanston.com

Bobcat of Grand Forks Grand Forks 701-772-5006 www.goironhide.com

Bobcat of Williston Williston 701-572-5050 www.goironhide.com

Tri-State Bobcat Hudson 715-531-0801

New Location!

2018 US Hwy 8 St. Croix Falls, WI 715-557-6010 www.tristatebobcat.com

Justin Batty, sales manager of Wacker Neuson, Menomonee, Wis., was at the RMS open house to talk with customers about the company’s latest offerings.

Brad Ketcherside, territory sales representative of Allen Engineering, Paragould, Ark. Allen is celebrating 60 years in business this year.

Topcon Positioning Systems has announced the latest evolution of the company’s road construction and resurfacing technology with the introduction of the MCMax Asphalt Paving and MC-Max Milling solutions. The systems offer modularity, simplified configurations and advanced feature sets to increase productivity in asphalt paving and cold milling applications for construction companies and projects of all sizes.

“Today’s municipalities are under constant pressure to maintain existing infrastructure,” said Murray Lodge, executive vice president, Topcon. “With rising maintenance costs, ever-decreasing margins, tighter specifications and an increasing focus on meeting sustainability targets, the industry needs innovative approaches to resurface roads efficiently with smooth and long-lasting results. That is precisely what our decadeslong dedication to designing new technologies for the paving industry positions us to continue to provide with our expanding intelligent paving portfolio.”

The MC-Max Asphalt Paving and MCMax Milling systems, which are made up of GNSS receivers, total stations, displays and other high-precision sensors, are built with the new MC-X machine control platform. This architecture provides highly customized systems and upgradeability paths to grow with a contractor’s needs.

Users can choose from entry-level 2D systems that follow a reference, such as a string or a curb, or automated solutions that track a paver or miller in 3D for drastically improved road smoothness in less time and with lower costs. Contractors can automatically pave and mill at variable depths, providing a better driving experience and meeting DOT-mandated smoothness standards. The solutions also include MC-X licensing options, providing customers with further flexibility to meet their specific project and budget requirements.