Swanston Equipment Hosts Open House in Alexandria, Minn. ...16

Cranes Hosts Annual CraneFest in Lexington, Ky. ...22

Swanston Equipment Hosts Open House in Alexandria, Minn. ...16

Cranes Hosts Annual CraneFest in Lexington, Ky. ...22

By Chuck MacDonald CEG CORRESPONDENT

Interstate 55 is the backbone of interstate travel in the Midwest. It roughly parallels the Mississippi River and connects New Orleans, Memphis and St. Louis before heading across

the Illinois farmlands terminating in Chicago. In Jefferson County, south of St. Louis, this freeway becomes congested as it works with U.S. 67 in carrying commuters into the city.

The Missouri Department of Transportation

(MoDOT) is leading a project to decrease the bottlenecks where these busy highways intersect. Project planners have determined that the work on this $267 million project will decrease

see MoDOT page 82

By Lucy Perry CEG CORRESPONDENT

Construction theft is not new, but criminals are getting bolder in their efforts to make a buck on anything they can grab quickly at a job site, from the rig itself to the fuel and parts inside it.

The pain of dealing with the theft is obvious, but other issues come into play, including damaged equipment leading to missed deadlines, increased insurance premiums and profits lost on a project.

One Oregon excavation contractor felt the burn this summer over two days of theft and destruction.

see THEFT page 74

Komatsu

its Peoria operations by constructing a new office building that

In 1974, Andy Bazan began his career at Finkbiner Equipment Company in Burr Ridge, Ill. Bazan was hired by Mary Finkbiner when he was a junior in high school.

To thank the community for the hospitality shown toward its newest store, Swanston Equipment held an open house at its newly renovated Bobcat dealership at 3818 Nevada St., Alexandria, Minn., on Sept. 27.

Officials broke ground on the Ohio River Crossing project in Evansville, Ind., on Sept. 17. INDOT is overseeing the $202 million project, with construction beginning late September and continuing through 2026.

Link-Belt Cranes held CraneFest 2024 at its world headquarters in Lexington, Ky., Sept. 16 to 20, 2024. The event was held in two-day sessions with representatives of the company’s dealer network, rental houses and end users.

24

CE

Volvo CE welcomed customers and dealers to its North American headquarters for Volvo Days, showcasing dozens of new and existing products and offering networking, a dynamic machine show, factory tours and more.

32

Thousands of people involved with the global mining industry visited the Las Vegas Convention Center from Sept. 24-26 to attend the National Mining Association’s MINExpo 2024, the once-every-four-years trade show.

49 WRB TAKES ‘BEHIND-THE-SCENES’ TOUR OF O’HARE INTERNATIONAL

On Sept. 12, members and friends of the Women Road Builders (WRB) in Illinois embarked on an unforgettable journey with an exclusive behind-the-scenes tour of O’Hare International Airport, one of the world’s busiest airports.

64 KENTUCKY ISSUES $5.5M FOR PUBLIC RIVERPORT INFRASTRUCTURE PROJECTS

Gov. Andy Beshear recently hailed the issue of $5.5 million in state funding to 16 Kentucky public river port projects to “enhance economic activity and support future expansion” of waterborne cargo activity.

80 TAKEUCHI HOSTS AEM’S MANUFACTURING EXPRESS AT S.C. FACILITY

Takeuchi-US hosted the Association of Equipment Manufacturers (AEM) Manufacturing Express national tour at its compact track loader production facility in Moore, S.C., on Aug. 27, 2024.

83 JOHN DEERE EXTENDS WESTERN SNOWPLOW AGREEMENT

John Deere extended its distribution agreement with Douglas Dynamics, parent company of Western Products, to sell and support Western snow and ice removal products for its compact utility tractor and construction equipment lineups.

Wausau Auctioneers conducted its 27th annual Fall Equipment Auction at its facility in Merrill, Wis., on Sept. 26. A wide variety of iron was available, including excavators, wheel loaders, dozers, paving equipment and more.

2005 HYPAC C766

STK# ZZ2023210, 8837 HRS, Bolingbrook, IL

2021 Case TV450B, S/N JAFTV450KLM487291, 541 Hrs, CAB/AIR/HEAT, 2 SPEED, HYDRAULIC COUPLER, 84" GP BUCKET, HIGH FLOW PERFROMACE PACKAGE, SERVICED AND READY TO GO, UNIT WILL HAVE A NEW DOOR $69,900

2022 Case SV280B, 171 Hours, S/N JAFSV280HMM403668, CAB/AIR/HEAT, HYDRAULIC COUPLER, 72" GP BUCKET, 2 SPEED, RADIO, EXCELLENT CONDITION FULL MACHINE WARRANTY UNTIL 11-2224 $51,900

2017 Case 621G, S/N NGF240021, 13131 Hours, Cab/Air, Ride Control, ACS Coupler, 2.5 Yard GP Bucket, Forks, Z Bar, Heavy Counterweight, Limited Slip Diffs, Cold Weather Package $109,900

2022 Case TR340B, JAFTR340AMM403705, 148 Hours, Cab/Air, 2 Speed, Hyd Coupler, 84” GP Bucket, Radio, E-H Controls $77,900

2022 Case SR270B, JAFSR270HNM410725, 222 Hours, Cab/Air, 2 Speed, High Flow, Hyd. Coupler, 78" GP Bucket Radio, E-H Controls $69,900

2023 Case TR270B, S/N JAFTR270LNM421971, 281 Hours, CAB/AIR/HEAT, E-H CONTROLS, HYDRAULIC COUPLER, 78" GP BUCKET, RIDE CONTROL, SELF LEVEL, HIGH FLOW HYDRAULICS, REARVIEW CAMERA, PREMIUM DISPLAY MODULE, FULL MACHINE WARRANTY UNTIL 1-30-25, JUST SERVICED READY TO GO $59,000

Garrard • (630) 492-9115

IL

2023 Case 521G, S/N NNF254914, 73 Hrs, Cab/Air/Heat, Ride Control, Deluxe Cab, JRB Coupler, 2.5 Yard GP Bkt, Third Valve, Limited Slip Differential, Pro Care Full Machine Warranty until 10-31-25 or 3000 hrs $179,900

2018 Case CX245DSR, S/N NJS7K1152, 1306 Hours, Cab/Air, Kent Coupler, Aux Hydraulics, No Bucket, Bucket available at additional charge, Rental Fleet Roll Out $193,500

McCann Rents a full line of heavy and light construction equipment. Call us today to supply your next rental.

R2H-4 - ’19, approx. 900 hrs. 83” triple drum static $93,800

LIEBHERR L586X - ’18, approx.

8.5cyd, Wide tires, Loadrite scale

Liebherr A904C Wheeled Excavator - ‘16, approx 550 Hrs, 2-piece boom, pin grabber coupler, aux hyd $P.O.R.

Liebherr R946 - ‘14, approx.. 800 Hrs, 12’6” stick, QC66 coupler, aux. hyd $P.O.R.

JCI K400, (’06), Portable Cone Crusher, 400 HP Elec, 42”x30” Feed Conveyor, #40236 $295,000

SUPERIOR BROOM DT74J, (‘18), 1,017 Hrs, noise level in cab, rear leaf spring susp., #C003649 $39,000

RX-300 - ’18, approx.

hrs. 4’ drum

Roadtec RX-100 - ‘18 w/475 Hrs, 20” drum, #C001554 $185,900

ASTEC GT104 - ‘17, 325 Hrs, 5.25cyd Hopper, 4’x9’ Top & Bottom Screens, #C001154 ............ $161,700 KPI FT2650 – ’19, approx. 1800 hrs. Tracked jaw crusher $645,000 Mauldin 1560 paver – ’22,

LOADERS AND EXCAVATORS:

GROVE GHC85, (’23), 164 Hrs, #C005208 $CALL

GROVE GHC130, (’19), 932 Hrs, 130-ton lift capacity, #C004141 ................................................$1,099,000

GROVE GRT880, (’22), 807 Hrs, 80-ton lift capacity, #C005002 $885,850

GROVE GRT880, (’18), 2,476 Hrs, 80-ton lift capacity, #C004982

$628,750

LIEBHERR TA230 LITRONIC, (‘23), 361 Hrs, #C005550

$CALL

LIEBHERR TA230 LITRONIC, (‘23), 367 Hrs, #C005511 $CALL

LIEBHERR L550 XPOWER, (’17), an innovative machine concept which combines performance, fuel efficiency, robustness and comfort. With their power split driveline, XPower wheel loaders work with the greatest level of efficiency in all applications, #C003118

$159,000

LIEBHERR R920 COMPACT LITRONIC, (‘18), 253 Hrs, w/Werk-brau pin grabber coupler, medium & high pressure aux. hydraulic circuits, pattern changer, #C003330 $CALL

LIEBHERR R934 LITRONIC, (‘23), 300 Hrs, The new R934 weighs approx. 35 tons, completely updated design is characteristic of the new range of "generation 8" machines, #C005399 $CALL

LIEBHERR R936 COMPACT LITRONIC, (‘18), 450 Hrs, Convenient and service-friendly, the R 936 Compact makes for safe working. With its tight slewing radius, this machine is especially well suited to urban applications, #C003377 $CALL

LIEBHERR R956 LITRONIC, (‘22), 250 Hrs, 35' boom and 21' stick, #C004867 $CALL SAKAI SW354, (’18), #C003395 $31,900

Komatsu is enhancing its Peoria operations by constructing a new office building that will provide a collaborative space for engineering, sales, manufacturing, management and other functions. Komatsu has ceremonially broken ground on the new building, which is designed for operational efficiency and environmental responsibility.

Komatsu is committed to sustainability, and to further these goals, the new office will incorporate innovative features such as solar panels, stormwater reclamation systems and energy-efficient LED lighting.

This project marks a significant investment in Peoria, replacing the existing office, which was built in the 1970s, and securing Komatsu’s presence in the region for generations to come.

“Komatsu’s commitment to Peoria is a partnership we greatly value,” said Peoria Mayor Rita Ali. “The new facility represents a step forward in sustainable manufacturing and strengthening Peoria’s economy and community. We’re excited to see Komatsu’s continued investment in our city, creating opportunities for the next generation of workers.”

Komatsu plans to complete the office building by the end of 2025, further cementing its role as a leader in mining technology and a key player in Peoria’s economic future. Primary partners supporting the project include EUA and P.J. Hoerr.

In addition to the office upgrades, Komatsu announced the installation of a 980E-5SE mining truck as a showcase for the community at the entrance to its Peoria operations.

The truck was built in Peoria in January 2020 as an early prototype of the 980E-5SE model, which was commercialized in 2023. This impressive machine was

The 980E-5SE features a hauling capacity of 400 tons and cutting-edge electric drive technology.

recently crowned the winner of the prestigious 2024 “Makers Madness” contest, earning the title of “Coolest Thing Made in Illinois.” This accolade, presented by the Illinois Manufacturers’ Association, capped off an eight-week, bracket-style competition that gathered nearly 315,000 votes from the public.

The 980E-5SE features a hauling capacity of 400 tons and cutting-edge electric drive technology.

“This display truck represents more than just a remark-

able engineering achievement,” said Dan Funcannon, senior vice president of surface haulage for Komatsu. “It symbolizes our Peoria team’s hard work and innovation and reinforces our manufacturing capabilities. We’re excited for employees, visitors and Peoria residents to see firsthand the scale and ingenuity behind our products.”

Several key partners supported the 980E-5SE truck installation, including Boilermakers Local 158 for assembly, P.J. Hoerr as the general contractor, and Mohr & Kerr for site and foundation design.

For more information, visit www.komatsu.com.

(All photos courtesy of Komatsu.)

JD 26G, ROPS, 3’10” Arm, Aux Hydraulics, Blade, #262039 ....................$34,000

JD 290G, Cab, A/C, Coupler, 10’2” Arm, 32” Shoes, New Reman Engine, #250559 ........ $120,000

JD 325G, A/C, Quick Tatch, Ride Control, 2 Speed, #291321 $59,000

JD 844K-III, A/C, Scale, Joystick Steer, 8 YD GP Bucket, Warranty, #261515 .... ................................$238,000

JD 130G, Cab, A/C, Hydraulic Thumb, Aux Hyd, 9’11” Stick, 24” Shoes, #261469 ..$109,000

JD 350G, A/C, Aux Hyd, Coupler, 13’1” Arm, 32” Shoes, #261396 $109,000

JD 550K, A/C, XLT 18” Pads, 6 Way 105” Blade, 4th Function Aux, #262480 $109,000

JD 950K, Cab, A/C, Winch, LGP, 30” Shoes, 6 Way 184” Blade, Warranty, #251233 $295,000

JD 135G, A/C, 9’11” Arm, 24” Shoes, Reduced Tail Swing, #249203 ....................$85,000

JD 350G, A/C, 72’ Long Reach, Rev Fan, 32” Pads, 60” Bkt, #261824 $245,000

JD 650K, New Engine, A/C, LGP 28” Shoes, 6 Way 128” Blade, #261468 $139,000

JD 444K, A/C, JRB Coupler, Ride Control, #262773 ............ $79,000

JD 210G, A/C, Hyd Thumb, Coupler, 9’7” Arm, Rev Fan, #261276 ..................$127,500

JD 672G, Cab, A/C, 14’ Blade, 14.00 Tires, Push Block, Auto Shift, #250229 $140,000

JD 700K, A/C, Smartgrade, LGP 30” Shoes, 6 Way 144” Blade, #261368 $169,000

JD 544K-II, A/C, Rev Fan, 20.5 Tires, Air Seat, GP Bucket, #262551 $139,500

Fenton, MO

Foristell, MO Mitchell, IL

Mt Vernon, IL

Cape Girardeau, MO

Paducah, KY Cuba, MO Owensboro, KY Evansville, IN

JD 245G, A/C, Aux Hydraulics, 9’7” Arm, 32” Shoes, Air Seat, #262242 ..................$204,000

770G, Cab, A/C, 14’ Blade, 14.00 Tires, Scarifier, Aux Hyd, #247935 $115,000

JD 750K, Cab, A/C, 34” Pads, Smartgrade, LGP, 6 Way 156” Blade, #251152 $179,000

JD 644K, A/C, Coupler, 3rd Spool Aux, Tier III Engine, #291319 $165,000

Hamm 3412P, 2012, 84” vibratory padfoot compactor, EROPS w/ heat & A/C, 1,200HMR .

$82,500

Cat 815F, 2006, EROPS cab, 12’4” S-Blade w/ tilt, new paint job, very good condition, 9,400 HMR $195,000

Hamm GRW-5 Pneumatic Roller, 1994, Deutz Diesel, ROPS Canopy, (9) Ea. 7.50-15C1 Tires . . . . . .$15,500

(4) Cat 825C’s, 1981-1990, EROPS, S-blade w/tilt, all work ready From $79,500

Rammax Walk Behind Rollers, over 25 in stock, lever & remote $4,000 to $10,000 (8) Sheepsfoot, 48" and 60", double drum & single drum, tow type

$4,000 - $6,500

Volvo A40, 1998, 40 tons, 10991 hrs, 395 hp, 8WD, 29.5R25, A/C, 29 cy cap. sideboards, tailgate (currently off work), work ready

Broderson IC80-2E, 1997, 8.5 ton, 24’ boom, dual fuel, 10.00R15 tires, 3,400 hrs

$127,500

Volvo A40, 1996, 40 tons, 395 hp, 6WD, A/C, 29.5R25, working everyday

$21,500 Grove RT58C, 1981, down cab, 18 ton r.t., 70' boom anti-two block, GM dsl, clean

$145,000

Volvo A40, 1996, 40 tons, 11,000 hrs, 6WD, 20.5R25, A/C, P/S trans, 29 cy cap., 6/06 hitch rebuilt .$115,000

Volvo A40, 1995, 40 tons, 395 hp, 8WD, 29.5R25, A/C, P/S trans, tailgate, work ready

$115,000

Volvo A35C, 1998, 35 tons, 6WD, 26.5R25 tires, approx 7,000 hrs, good condition

$147,500

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5x25, A/C, P/S trans, working everyday on jobsites

$87,500

$49,500 IR 185’s, JD diesels

CALL

Cat 336EL, 2012, 33.5” TBG pads, Q/C, aux hyd, 6,700 HMR, work ready

$162,500

Cat 336FL, 2015, 33.5” TBG Pads, Q/C, aux hyd, 4,300 HMR, work ready $224,500

Komatsu PC220LC-8 Longreach, 2011, Young Boom/Stick 60’ reach, 3,500 HMR $179,000

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5R25, A/C, P/S trans, 26 cy, working everyday on jobsites

$89,000

Volvo A30C, 1996, 30 tons, 11,000 hrs, 296 hp, 6WD, 23.5R25, 21 cy cap, A/C, P/S trans, works everyday

$122,500

(12) Allmand Light Plants, 2008-2010, diesel, s/a towtype, (4) MH lights, excellent From $5,200 Case 580L Rubber Tire Loader Backhoe, 1997, OROPS, std stick, 24" bkt

$24,500 (2) Balderson Broom Attachment for Cat IT Machines, 8' wide, good condition $4,000 Ea. NUMEROUS Rivinius R600’s, 10’ Wide, Mount on Dozer Blade

Kobelco SK210LC, 2007, Q/C, aux hyd, 31.5” TBG Pads, 3,900 HMR

$72,500

Cat D5NXL, 2006, 10’ PAT Blade, Paccar PA55 winch, 22” Pads, 4,100 HMR

$82,000

$49,500

Cat 613C Water Wagon, 1994, 5000 gal drop tank, ROPS, spray heads

Cat 621F, 1996, Scraper, OROPS, 33.25x2, very good condition CALL

Cat 621E, 1989, Scraper, OROPS, 33.25x29, very nice

CALL

Cat D6NLGP, 2008, VPAT Blade, Drawbar, 33” Pads, 9,900 HMR

$87,500

Cat D6NLGP, 2014, Foldable VPAT Blade, Paccar PA55 winch, 7,200 HMR

$142,500

Komatsu D155AX-6, 2007, Sigma S-U Blade, 4-bbl Single Shank Ripper, 8,400 HMR

$229,500

Over 100 Excavator, Loader, Specialized & Grapple Buckets in Stock -Call For Your Needs FORKS (8) IT28F/G Forks, Balderson qc, 48"-60" pallet style, excellent $4,000 Others Available Call Prices Are Negotiable - At Your Inspection

$152,500

Cat D6TXW, 2013, 13’6” VPAT Blade, Carco 70APS winch, 28” pads, 7,300 HMR

(L-R) are Jay Frederick of Walsh Construction; John “Radar” Bazan, of Finkbiner Equipment Company; Ted Heckler of Walsh Construction; and Tim Hogan of Walsh Construction.

By Katherine Petrik CEG EDITORIAL ASSISTANT

In 1974, Richard Nixon became the first president to resign from office; Hank Aaron topped Babe Ruth’s career home run record; Muhammad Ali won the “Rumble in the Jungle” after knocking out George Foreman; Blazing Saddles was the top movie at the box office; and Andy Bazan began his career at Finkbiner Equipment Company in Burr Ridge, Ill.

Bazan was hired by Mary Finkbiner when he was a junior in high school. He worked after school, over school vacations and during summers. In fact, he recruited his brother to work for the company after his graduation.

“When I went away to school at Illinois State, I got my brother, Radar, to take my spot here,” said Bazan.

Marty Ahrendt, former owner and president of Finkbiner is the one who recommended Bazan for the job.

“We each handed the job down — we all went to high school together and wound up working here for most all our careers,” he said.

Following his graduation from Illinois State, Bazan worked in the parts department under Ed Nita, parts manager. After three or four years, one of the salespeople retired and Bill Finkbiner offered Bazan a territory. The rest, as they say, is history.

Bazan, Ahrendt and Tom Beckman had the opportunity to purchase Finkbiner. After Beckman passed away, Bazan and Ahrendt eventually sold the business to American State Equipment Company, its current owner.

see BAZAN page 67

Rhonda

accompanied her

Mary

are Robert Krug, president of K-Five Construction; Jason Zeibert, president of Finkbiner Equipment Company; Jon McDonnell, equipment manager of K-Five Construction; and Mark Lindbloom, head of operations of K-Five Construction.

is presented with a bicycle from Jason Zeibert, president of Finkbiner Equipment Company.

To thank the community for the hospitality shown toward its newest store, Swanston Equipment held an open house at its newly renovated Bobcat dealership at 3818 Nevada St., Alexandria, Minn., on Sept. 27.

Customers were invited to register for a Bobcat ZT2000 mower giveaway; win various door prizes; enjoy a lunch of pulled pork sandwiches catered by Depot Smokehouse; and enjoy a 10 percent discount on all Bobcat parts.

The 12,000-sq.-ft- building was completely renovated this past summer, updating the showroom, parts area and service area. The shop houses three double bays with an overhead crane. Air conditioning and a heated floor also were added.

“This building is about bringing Bobcat back to the Alexandria area,” said Adam Becker, branch manager of Swanston Equipment. “The shop now includes air conditioning and in-floor heat and a fully renovated show room with massive parts storage. The building is only matched by the skilled and caring employees inside of it.”

Swanston Equipment, a fourth-generation, family-owned and operated equipment dealer, has been in business more than 90 years.

Swanston’s equipment lineup includes ABU, Arctic Snow & Ice, Astec, ATI, Bearcat, Berlon, Blue Diamond Attachments, Bobcat, Bradco, Broce Broom, Cimline, CMP, Diamond Mowers, DEVELON, DuraTech, Erskine, Etnyre, EZ Spot UR, Felling Trailers, Finn, GOMACO, GrabTec, Green Climber, Harper Turf Equipment, Haugen, KM International, Larue, Midland Machinery, Minnich, Montana Post Driver, Paladin, Rayner, Road Widener, Sakai, Stihl, Stumper, Toro, Virnig, Volvo and WRT.

Headquartered in Fargo, N.D., Swanston's other locations include Minot, N.D., and Fergus Falls, Minn.

For more information, visit swanston.com. CEG

(All photographs in this article are courtesy of Swanston Equipment.)

The all-new CASE B Series skid steers and compact t feature an all-new 8-inch LCD operator screen with ba completely updated and simplified operator controls; comfort; and while the machine looks the same on the

track loaders ackup camera; even greater cab e outside, we’ve o what you and ; re-engineered its critical inner workings to stand up to your jobsites face every day.

Gov. Eric J. Holcomb and Indiana Department of Transportation Commissioner Mike Smith broke ground on the Ohio River Crossing project in Evansville, Ind., on Sept. 17. INDOT is overseeing this project, with construction beginning late September and continuing through 2026. The $202 million project is fully funded.

“This is another day to remember for all Hoosiers,” said Holcomb. “Today signifies a key milestone toward completing the most direct, safe and efficient connection between Evansville and Henderson. This additional crossing will open the door to limitless new opportunities for transportation, economic and community development projects. I’m both grateful and proud to stand here today with so many local leaders who have worked for decades to convert ideas into blueprints, and blueprints into new connections. Indiana continues to pave a road to a brighter future due to our collaborative Hoosier work ethic.”

I-69 ORX Section 3 focuses on the approach roadways and bridges that will provide all-weather construction access to the river to build the future I-69 river crossing. The roads and bridges that are part of Section 3 will be used by construction crews to build the new crossing, and drivers will use the roadways and bridges once the new I-69 bridge is complete.

key connection.”

I-69 ORX is divided into three sections for construction. I-69 ORX Section 2 is a bi-state project between Indiana and Kentucky that will complete the I-69 connection from U.S. 60 in Henderson to I-69 in Evansville. It includes the new four-lane river crossing. Construction is anticipated to begin in 2027 and be complete by 2031. Preconstruction activities will begin in 2025. Both states continue to look for opportunities to accelerate the timeline.

“We know how important this future I-69 bridge is to Evansville and the surrounding region,” said Smith. “Indiana has led the way in investing in I-69. [In August], we made the vital connection between Evansville and Indianapolis a reality and crossed the I-69 Finish Line, making it even more fitting that we’re here today, taking the first steps toward completing another

I-69 ORX Section 1 focuses on improvements in Henderson and is led by the Kentucky Transportation Cabinet. ORX Section 1 extends from KY 425 to U.S. 60. It includes a more than 6-mi. extension of I-69; new interchanges with U.S. 41 and U.S. 60; and a reconstructed KY 351 interchange. Construction began in summer 2022 and will be complete by the end of 2025.

For more information, visit I69OhioRiverCrossing.com.

Earthmoving and material handling technology

Liebherr USA, Co.

Liebherr

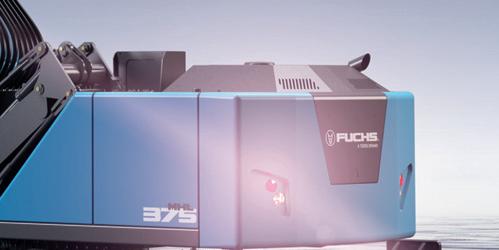

Link-BeltCranes held CraneFest 2024 at its world headquarters in Lexington, Ky., Sept. 16 to 20, 2024. The event was held in two-day sessions with representatives of the company’s dealer network, rental houses and end users in attendance to learn about Link-Belt’s historic beginnings, manufacturing capabilities and lineup of world class cranes.

Link-Belt hosted a reception and dinner at Fasig-Tipton, the oldest Thoroughbred auction company. The reception and dinner provided an excellent opportunity for attendees to network with peers and spend time with Link-Belt representatives.

The following day, the Link-Belt executive team welcomed the group with opening remarks followed by a video presentation which outlined Link-Belt’s history, development and accomplishments. Attendees were then bussed to the Link-Belt Company world headquarters for a tour of the manufacturing facility. After the tour, attendees were led to an outdoor staging area for a live presentation of Link-Belt’s full product line.

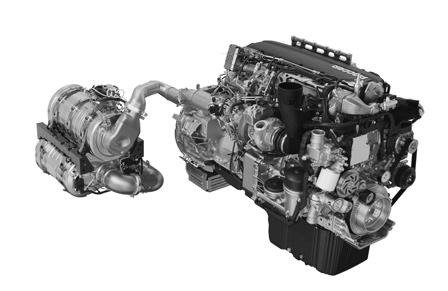

Link-Belt introduced its new 65-ton (60 t) 65 RT to its rough-terrain product line. The 65 RT includes a four-section, full-power, greaseless main boom (38 to 115 ft. [11.6 to 35 m]) and an optional 35 to 58-ft. (10.7 to 17.7-m) offsetable bi-fold lattice fly that are manufactured in the United States at Link-Belt’s headquarters.

The 65 RT features a new hydraulic boom extend system, as well as LED lighting for brighter, more efficient lighting during low-light conditions. The 65 RT also is equipped with a new six-speed Dana transmission with a remote filter for ease of servicing. The transmission is mounted to a 270-hp Cummins QSB6.7L Tier IV engine.

see CRANEFEST page 78

(L-R): Ryan Cooper, Kristopher Newcomb, Kit Cooper, Adam Bushketter and Mason Cooper check out the TCC 2500 telescopic crawler crane.

Volvo Construction Equipment (Volvo CE) welcomed nearly a thousand customers and dealers to its North American headquarters for Volvo Days, showcasing dozens of new and existing products and offering networking, a dynamic machine show, factory tours and hands-on experience with machines and services.

Volvo Construction Equipment (Volvo CE) welcomed nearly a thousand customers and dealers to its North American headquarters for Volvo Days, showcasing dozens of new and existing products and offering networking, a dynamic machine show, factory tours and hands-on experience with machines and services.

Volvo Days is a customer event held every few years in Shippensburg, Pa. The 2024 event is showing customers how the OEM is growing its range of offerings in both conventional and electric power across the company’s extensive lineup.

“Providing an exceptional customer experience is something we’re focused on every day of the year, but Volvo Days gives us a special opportunity to celebrate our customers, strengthen relationships and allow people to talk with our experts and test-drive machines,” said Scott Young, head of Region North America, Volvo CE.

Several new products were introduced to the North American market, including the SD125 soil compactor, the R60 and R70 rigid haul trucks, and the L120 Electric midsize wheel loader and new-generation EC230 Electric midsize excavator.

The event also is the first chance for many customers to have firsthand experience with the new series of Volvo excavators introduced earlier this summer. The series includes several mid-size and large models, with more to be introduced in the coming months, and represents the biggest update to the Volvo CE excavator lineup in two decades.

Volvo Days attendees commented on the power and responsiveness of the new excavators, as well as the thoughtful cab updates.

“I like how they changed the seat and how you can drive with the dials on the joysticks. Everything is more comfortable for an operator who’s going to be in the machine for eight hours or more a day,” said Gavin Craig, an operator at Craig’s Construction in Calhoun, Ga.

Dalton Nokes, general superintendent at Garrett Excavating in northwest Arkansas, agreed.

“These excavators are very responsive and smooth — some of the fastest excavators I’ve ever run,” he said.

Volvo Days is a customer event held every few years in Shippensburg, Pa. The 2024 event is showing customers how the OEM is growing its range of offerings in both conventional and electric power

MAKE YOUR MOVE

Push

... more material with the new Hyundai HD100 crawler dozer's best-inclass power-to-weight ratio.

See ...more than ever with the unobstructed view to the blade.

Engage

...more accurately and more productively with standard 2D or optional 3D machine guidance.

Doze

...with confidence, knowing your new 115 hp Hyundai crawler dozer delivers the quality and value you expect from Hyundai, with the peace of mind that comes with our industry-leading warranty.

No wonder so many first-time Hyundai users become longtime fans. See the Hyundai difference yourself at your local dealer, na.hd-hyundaice.com.

Bobcat Company, a global equipment, innovation and worksite solutions brand, has expanded its North American product lineup with the introduction of the B760 backhoe loader.

The B760 offers the most digging depth in its size class, according to the manufacturer.

With a wide range of job site solutions built into one tough machine, the backhoe loader features an impressive lift capacity of more than 2,200 lbs. at full reach; digging depth of 18 ft. 5 in.; and nearly 180 degrees of backhoe swing for less repositioning and fast cycle times.

The backhoe loader comes with a standard-equipped extendable arm that provides up to 8 in. of additional dig depth compared to other machines of the same size. The B760’s performance and versatility extend throughout the machine, with the front-end loader providing a lift capacity of 7,985 lbs. with its standard, general purpose bucket.

“The new B760 helps operators accomplish more on the job site with its dig, load and carry versatility,” said Jamison Wood, Bobcat product development specialist.

“The backhoe loader is designed for durability, easy operation, simple maintenance and incredible performance. Its size keeps it accessible on sites with limited space, while

its impressive travel speeds keep operators productive across large job sites.”

Powered by a turbocharged 3.4-L Bobcat engine, the B760 delivers powerful, hightorque performance and efficiency. It achieves emissions compliance without the use of a diesel particulate filter (DPF).

With powerful backhoe and loader break-

out forces, operators can confidently dig in and conquer some of the most challenging job site tasks such as excavation, site preparation, material handling, trenching, snow removal and more. The power shift transmission provides quick direction changes while the backhoe loader’s swift travel speeds allow operators to minimize the need

for a trailer.

With controls that are thoughtfully laid out and easy to use, new operators can reach maximum productivity in less time, according to the manufacturer. The easy-to-read, 5in., color display panel provides full-featured machine interaction and monitoring capabilities for efficient and productive operation. The operator station and optional cab are designed for all-day comfort, with controls designed for easy use and minimal operator fatigue.

Additional standard features that enhance operator productivity include:

• Ride control for reduced bucket spillage and enhanced operator comfort.

• Automatic return-to-dig positioning to maximize cycle time efficiency.

• Eight work lights for long days of loader and backhoe operations.

• A 1.4-cu.-yd. general purpose loader bucket for greater job site versatility.

• Pilot controls for smooth, fast and precise backhoe workgroup operations.

• Auxiliary hydraulics to power attachments from the front and rear.

The B760 backhoe loader will be available at Bobcat dealerships across North America in late 2024/early 2025.

For more information, visit bobcat.com.

Vogele Super 1900-5i Tracked Paver, 1:50 scale $175

Bucyrus Erie 22B Cable Shovel, 1:50

Bucyrus Erie 22B Dragline, 1:50 scale

Backhoe/Loader, 1:50 scale $160

Allis Chalmers HD-3 Dozer, w/Backhoe, 1:16

Caterpillar D6H Track-Type Tractor, 1:50

Bantam Lattice Crane on White WC22 Carrier

Hamm 7i Pad Foot Compactor, 1:50 scale ................................................

Caterpillar 941 Traxcavator, 1:24 scale ....................................................

Case 1488 Excavator, 1:50 scale

Caterpillar 325L Excavator, 1:50 scale

Caterpillar 325B L Excavator, 1:50 scale ..................................................

Hamm HC-119 Soil Compactor, 1:50 scale

Caterpillar 988F Wheel Loader, 1:50 scale

Caterpillar D9N Track-Type Tractor w/black tracks, 1:50 scale

Caterpillar D9N Track-Type Tractor w/yellow tracks, 1:50 scale ..............

Caterpillar D7C Track-Type Tractor, 1:50 scale $110

Roadtec RP190 Paver, 1:50 scale

$110

Case 850B Angle/Tilt Dozer, 1:35 scale ....................................................$100

Case 580F Backhoe/Loader, 1:35 scale ....................................................$100

Doosan DL420A Wheel Loader, 1:40 scale

Hitachi EX200 Excavator, 1:40 scale

$100

$100

Case DH4B Trencher, 1:35 scale ................................................................$90

Caterpillar D11R Track-Type Tractor, 1:50 scale ........................................

John Deere 470G LC Excavator, 1:50 scale

Caterpillar AP-1000 Asphalt Paver, 1:50 scale

Caterpillar M318 Wheel Excavator, 1:50 scale ........................................

Allis Chalmers Forty-Five Motor Grader, 1:50 scale

$90

$90

$110

$100

$100

Caterpillar 416 Backhoe/Loader, 1:50 scale $75

Caterpillar 936 Wheel Loader, 1:50 scale $75

451 Grayhound Track/wheel Paver, 1:50 scale

Caterpillar 428 Silver Backhoe/Loader, 1:50 scale ....................................

Thousands of people involved with the global mining industry visited the Las Vegas Convention Center from Sept. 24-26 to attend the National Mining Association’s MINExpo 2024, the once-every-four-years trade show.

Attendees and exhibitors explored three halls where hun-

dreds of exhibitors displayed equipment and the latest technology, including AI, robotics and sensors.

The opening day keynote speaker was Mike Rowe of TV show “Dirty Jobs” fame, while the second day featured former professional race car driver Danica Patrick and former Philadelphia Eagles player, magician and motivational

team

speaker Jon Dorenbos. The final day featured entrepreneur Kevin Leary, known as “Mr. Wonderful” on TV’s “Shark Tank.” CEG

(All photographs in this article are Copyright 2024 Construction Equipment Guide. All Rights Reserved.)

see MINEXPO page 66

(L-R): K-Tec representatives Paul Camasto; Dallas Foster of NDK Scrapers Inc., an authorized K-Tec dealer; and Chris O’Connell at their booth with a model of the ADT scraper.

Kaeser’s Michael Camber (L) and Al Moreno showcased a wide range of compressed air equipment for all types of mining operations.

For more information on crushing, screening and recycling equipment, visit CEG's Web site at www.constructionequipmentguide.com

In response to the growing demands of its mining customers, Metso is strengthening its position as a supplier of innovative sustainable solutions with the introduction of its unique circularity process to the North American market.

The mill liner recycling service is a concrete example of how Metso can drive the mining industry towards more sustainable practices and a circular economy. With less unprocessed waste material sent to landfills, recycling helps to reduce CO2 emissions and improve environmental efficiency.

“Metso is expanding its recycling capabilities for the North American market by leveraging our experience with previous operations and customer cases in Europe and South America. Our service model in North America will be based on a modular solution, which gives us an interesting opportunity to bring the recycling process close to customer locations in the United States, Canada and Mexico. The availability of the service will be based on customer needs and demand,” said Giuseppe Campanelli, president North America market area, Metso.

Metso is committed to developing pioneering sustainable technologies and solutions for the global mining industry. Circular economy is one of the important areas of sustainability development throughout the industry. As part of Metso’s extensive mill lining offering, the company is developing ways to increase the use of recycled materials in liners to further close the circularity loop.

The recycling service is facilitated by an innovative technology that enables safe and efficient separation of different rubber and metal liner components, like cast inserts, wear plates and backing plates. Composite liners, like Megaliner and Poly-Met liners, can be processed using this solution.

“As a responsible supplier and partner for sustainable wear solutions, we have set ambitious targets to help our customers reduce the environmental impact of mining in the different stages of the production process. Metso’s unique solution enables the efficient separation of different liner materials so that the valuable components can be reused in the manufacturing of new products,” said Markus Marttiini, vice president, Optimized Mill Lining products, Metso.

The pioneering recycling service is a part of Metso’s Planet Positive offering.

Metso has a long history in solutions for mill liner recycling. The first feasibility studies were conducted back in 2009, with a formal recycling program initiated in 2015, and the important milestone of 1,000 recycled Megaliner liners achieved in 2016. After careful studies and customer pilots, in 2022 Metso launched a new separation unit for its customers in Europe, followed by its introduction in March 2024 to the South American market in Chile.

Metso also has an existing recycling process for metallic mill liners.

For more information, visit www.metso.com.

Metso highlighted its industry-leading sustainable technology and pit-toport aftermarket solutions including the revolutionary mill liner recycling concept at MINExpo INTERNATIONAL 2024, in Las Vegas.

The new PMM/RCU75 swinging hammer mulcher features a hydraulic hood for better control of the outflowing material, a support roller with integrated skids, a trapezoidal belt transmission and interchangeable protection chains.

The PMM/RCU75 is an efficient solution for mulching grass, brambles, twigs and small shrubs up to 3 in. in diameter.

FAE enhanced the versatility of its RCU75 remote controlled tracked carrier with the new PMM/RCU75 swinging hammer mulcher.

The PMM/RCU75 is an efficient solution for mulching grass, brambles, twigs and small shrubs up to 3 in. in diameter. This head features a hydraulic hood for better control of the outflowing material, a support roller with integrated skids, a trapezoidal belt transmission and interchangeable protection chains.

The PMM/RCU can be equipped with PMM hammers or Y/3 flails.

For more information, visit www.fae-group.com. (Photos courtesy of FAE.)

www.aisequip.com

3600 N Grand River Ave Lansing, MI 48906

517-321-8000

Grand Rapids

600 44th Street SW Grand Rapids, MI 49548

616-538-2400

Northeast Detroit 65809 Gratiot Avenue Lenox, MI 48050 586-727-7502

Saginaw 4600 AIS Drive Bridgeport, MI 48722 989-777-0090

Traverse City 8300 M-72 East Williamsburg, MI 49690 231-267-5060

West Detroit 56555 Pontiac Trail New Hudson, MI 48165 248-437-8121 800-457-8121

www.butlermachinery.com

3630 Miriam Ave Bismarck, ND 58502

701-223-0890

7910 US-2

Devils Lake, ND 58301 701-665-3800

2803 I-94 Business Loop E Dickinson, ND 58601

701-456-1400

3402 36th St SW Fargo, ND 58104 701-280-3100

1201 S 46th St Grand Forks, ND 58201 701-775-4238

1910 27th Ave SE Jamestown, ND 58401

701-251-1400

4950 U.S. Highway 12 Aberdeen, SD 57401 605-225-6240

3601 Deadwood Ave N Rapid City, SD 57702 605-342-4850

20571 Truck Stop Ave Pierre, SD 57501 605-224-5400

3201 N Louise Ave Sioux Falls, SD 57107 605-336-3010

603 10th St NW Watertown, SD 57201 605-954-7100

1715 US Hwy 14 W Huron, SD 57350 605-353-1200

1505 Hwy 2, Bypass E Minot, ND 58701 701-852-3508

www.centralsands.com

4219 E 50th St • Des Moines, IA 50317 800-247-2400 • 515-964-8600

www.rbscott.com

1011 Short St Eau Claire, WI 54701 715-832-9792

17403 County Road 75 NW Clearwater, MN 55320 320-558-8100

www.roadbuildersmachinery.com

1001 S 7th St Kansas City, KS 913-371-3822

4115 S 90th St Omaha, NE 402-331-9200

5601 Fletcher Ave Lincoln, NE 402-325-0447

4949 Juergen Rd Grand Island, NE 308-384-2620

1303 S Chestnut St Norfolk, NE 402-316-4640

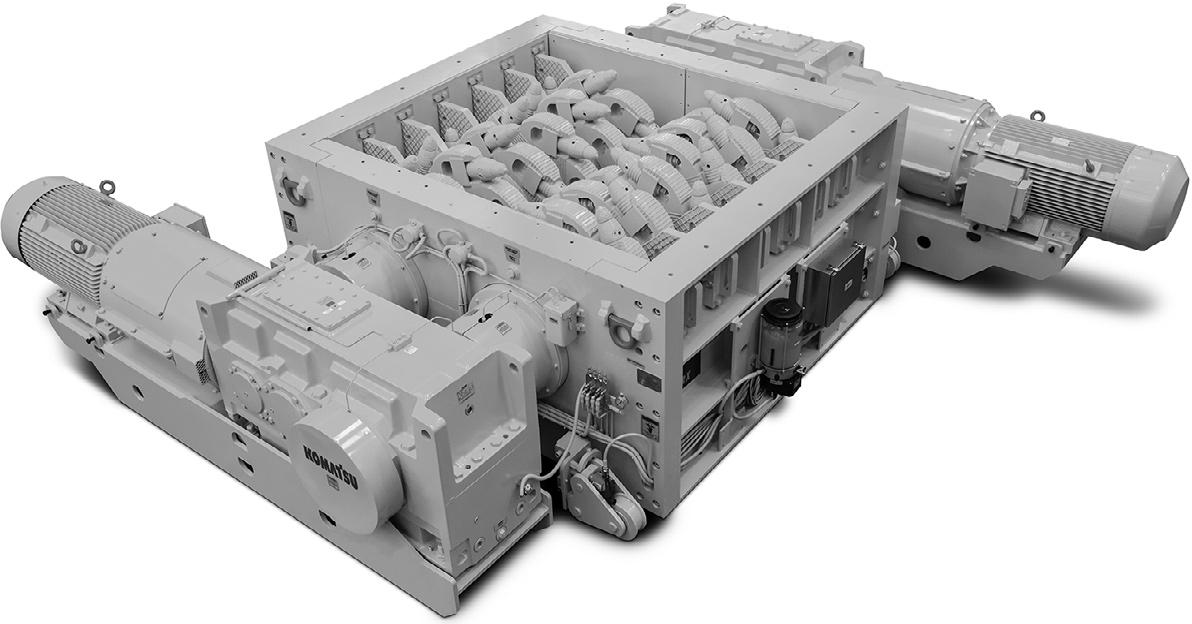

Komatsu announced the expansion of its hard rock crushing equipment portfolio with the introduction of the HRX800 sizer, an innovative solution designed to enhance efficiency and productivity while reducing waste.

This product line extension underscores Komatsu’s commitment to providing cus tomers with robust, high-performing machines that drive production growth and add value to their mining operations, according to the company.

Komatsu’s com prehensive crushing lineup includes feeder breakers, reclaim feeders, mobile crushers and sizers, all engineered to meet the demanding needs of modern mining operations.

The HRX800, launching at MINExpo 2024, represents the next step in Komatsu’s evolution of crushing technology. Designed for hard rock applications, the HRX800 is a smaller-scale alter native to the HRX1000, providing the same high capacity and efficiency in a more compact form. This sizer is ideal for both underground and surface installations, offering the benefits of

Komatsu photo

Designed for hard rock applications, the HRX800 is a smaller-scale alternative to the HRX1000, providing the same high capacity and efficiency in a more compact form.

fines reduction in demanding applications of hard abrasive minerals or wet and sticky material.

“We are excited to introduce the HRX800 to our customers,” said Brandon Phillips, global product manager of sizers and feeder breakers at Komatsu. “The HRX800 is designed to push the envelope on where sizers can be successfully applied, delivering the power and performance our customers expect from Komatsu while offering the flexibility needed in today’s dynamic mining environments.”

The HRX1000 is designed to accept run-of-mine materials and crush them to a size suitable for conveyor transport, making it a crucial component in mining operations that demand high production capacity. The HRX1000’s innovative pick technology efficiently breaks down minerals in tension, reducing the need for multiple crushers and lowering operating costs. Its versatility makes it an invaluable asset in a wide range of mining applications.

For more information, visit www.komatsu.com.

nance.

Lippmann, a manufacturer of aggregate processing equipment, announces its newly enhanced jaw safety pin. Underscoring the company’s dedication to advancing workplace safety, the pin is designed to lock the pitman securely in the forward position during maintenance or repair and is now available for retrofit on select existing jaw models and comes standard on future jaw crushers.

The jaw safety pin is designed to prevent accidental pitman movement, a critical safety feature during servicing. With features such as a pinned locking mechanism and vertical storage location to prevent damage, Lippmann’s latest design aims to enhance safety while offering ease of use.

“We’ve prioritized safety in all our designs, and the jaw safety pin is no exception,” said Danny McElchar, director of engineering of Lippmann. “While safety pins exist on other jaw crushers, we’ve responded quickly to customer feedback to make this feature available not just for future models, but as a retrofit kit for existing customers as well.”

An updated jaw pin is included on all future Lippmann models and can be retrofitted on most current models in the field.

The updated design includes a new hole on each side of the jaw box, a boss and a brace added to the jaw box rib.

Some models also will incorporate a modified cheek plate or side liner to accommodate the new locking pin system, which allows for safe pitman posi-

tioning during service. Additionally, decals provide clear instructions on proper usage of the pin, ensuring operators are aware of the safety features.

For more information, visit Lippmann-Milwaukee.com.

The United States’ metal recycling industry now has greater access to the new, purpose-built Brandt material handler, due to a partnership between Brandt Industries and McCoy Construction & Forestry.

“We are excited to serve the metal recycling industry by partnering with a company that shares our belief in putting customers and their needs first,” said Jason Klassen, Brandt senior vice president of sales — manufactured products. “Teaming up with McCoy Construction & Forestry will help us expand our reach to deliver superior material handling equipment to customers in the Midwest.”

The Brandt material handler is the only material handler designed, manufactured and supported in North America, according to Brandt. It is built on the John Deere platform and delivers productivity and uptime, with easy-to-find components and support through local dealerships.

McCoy Construction & Forestry has 25 locations throughout the Midwest in Michigan, Minnesota, Wisconsin, Illinois, Indiana, Kentucky, Missouri and Tennessee. Adding the Brandt material handler to its product offering will enable McCoy to offer a new reliable and durable option for their metal recycling customers, according to the company.

“The engineering and construction of Brandt products and their focus on reliability, dependability and durability will make a big impact on the market with this new material handler,” said Jeff Herkert, president of McCoy Construction & Forestry.

For more information, visit mccoycf.com and brandt.ca.

(L), corporate product specialist of McCoy Construction & Forestry, and Robert Jordan, director of sales — material handlers of Brandt Group of Companies with a Brandt BMH40A material handler.

Metso has signed an agreement to acquire Diamond Z and Screen Machine Industries from Crane Group, an Ohio-based family-owned investment company.

Diamond Z increases Metso’s offering in mobile equipment for the organic recycling markets. Screen Machine Industries broadens Metso’s portfolio in the North American mobile crushing and screening markets. Together, the companies employ approximately 190 people with locations in Caldwell, Idaho, and Etna, Ohio.

The companies will continue to operate independently in Metso’s Materials Processing Products business line. The value of the transaction is not disclosed, and it has no material impact on Metso’s finances.

“We are very happy to welcome Diamond Z and Screen Machine Industries to the Metso group of companies. Diamond Z allows us to extend our offering in the growing

murphytractor.com

5255 N Deere Rd Park City, KS 67219 316-942-1457

325 S Highway 281 Great Bend, KS 67530 620-792-2748

1141 Kanza Drive, Humboldt, KS 66748 620-473-7020

15854 S US 169 Hwy Olathe, KS 66062 913-298-7373

1621 NW Gage Blvd Topeka, KS 66618 785-233-0556

1410 W Oklahoma Ave Ulysses, KS 67880 620-356-1071

10893 112 Rd Dodge City, KS 67801 620-227-3139

220810 Hwy 92 Gering, NE 69341 308-436-2177

9751 S 148th St Omaha, NE 68138 402-894-1899

“We are very happy to welcome Diamond Z and Screen Machine Industries to the Metso group of companies.

Markku Simula Metso

infrastructure recycling equipment market and Diamond Z mobile grinders portfolio provides a great addition to our Materials Processing Products offering,” said Markku Simula, president, Metso’s Aggregates business area.

“Screen Machine Industries enhances our mobile crushing and screening offering and further strengthens our position as one of the leading providers in the field.”

Diamond Z has established a reputation for manufacturing high quality

and durable mobile and portable grinders for the infrastructure recycling sector. Its offering consists of a broad range of high-speed grinders to suit varying needs from land clearing, construction and demolition, composting to tire disposal. Screen Machine Industries offers a broad range of heavy-duty machines for various aggregates crushing and screening applications.

For more information, visit www.diamondz.com, www.screenmachine.com and www.metso.com.

6100 Arbor Rd Lincoln, NE 68517 402-467-1300

3204 S Engleman Rd Grand Island, NE 68803 308-381-0741

3701 S Jeffers St North Platte, NE 69101 308-534-7020

8600 NE Parvin Rd Kansas City, MO 64161 816-483-5000

1401 S State Highway MM Springfield, MO 65802 417-863-1000

5087 E Broadway Ave Des Moines, IA 50317 515-263-0055

1303 3rd Ave NW Fort Dodge, IA 50501 515-576-3184

4900 Harbor Dr Sioux City, IA 51111 712-252-2753

3469 W Airline Hwy Waterloo, IA 50704 319-235-7085

www.BrandeisMachinery.com

1801 Watterson Trail Louisville, KY 40299 502-491-4000

17000 Highway 41 North Evansville, IN 47711 812-425-4491

7310 Venture Lane Fort Wayne, IN 46818 260-489-4551

8410 Zionsville Road Indianapolis, IN 46268 317-872-8410

535 Modern Way Bowling Green, KY 42101 270-780-3004

1484 American Greeting Card Rd Corbin, KY 40701 606-528-3700

1389 Cahill Drive Lexington, KY 40504 859-259-3456

160 County Park Road Paducah, KY 42001 270-444-8390

130 Mare Creek Road Stanville, KY 41659 606-478-9201

IMPRESSIVE FROM A TO Z. Thanks to its robust design and extensive range of screen linings, the MSS 802 EVO can easily adapt to changing locations and new operating conditions – making it ideal for a wide variety of applications. The coarse screening plant features an intuitive system control that reduces the risk of operating error. And all relevant functions can be operated from a safe distance for increased work safety. The MOBISCREEN MSS 802 EVO –the heavy-duty, versatile solution in natural stone and recycling.

www.wirtgen-group.com/kleemann

COMPANY WRENCH

www.companywrench.com

4805 Scooby Lane NW Carroll, OH 43112

866-262-4181

4510 East 71st Street Cleveland, OH 44105 440-439-4567

920 Deneen Avenue Monroe, OH 45050

513-649-8105

1515 W. Epler Avenue Indianapolis, IN 46217 317-782-8850

1330 KY-151 Frankfort, KY 40601

502-699-2681

Terex Washing Systems (TWS), a leader with more than 60 years of expertise in the design and manufacture of washing equipment, celebrated five years of manufacturing filterpresses. This milestone underscores the team’s commitment to environmental responsibility in quarry operations worldwide, with its filterpresses processing approximately 100 million tonnes annually across the globe.

“Our journey in the design and development of our own filterpresses began in 2019 and today, we stand as a global leader in delivering complete ‘Feeder to Filterpress’ solutions,” said Mark Fisher, business line director of Terex Washing Systems. “The evolution of our filterpress technology underscores our commitment to driving efficiency and sustainability in the quarrying industry.”

One of the key advantages of the Terex Washing Systems filterpresses is their efficiency in water recycling, which reclaim over 95 percent of the

water used in the washing process, minimizing water consumption and reducing the need for freshwater input.

Filterpresses also aid in waste reduction by producing a dry filter cake waste product. This dry cake is easily transportable and can be reintegrated into the quarry or used for other applications. By maximizing water recycling and minimizing waste generation, these systems help quarry owners meet environmental regulations and demonstrate a strong commitment to responsible quarrying practices.

Another benefit of filterpresses is improved efficiency of the wash plant by streamlining the water treatment process. By effectively separating solids from liquids, they produce cleaner water for reuse and optimize the performance of downstream equipment.

Quality assurance is another significant advantage as filterpresses provide clean, recycled water to re-enter the washing process, improving the quality of washed sand and aggregates.

Since the inception of in-house fil-

terpress manufacturing in 2019 at the Terex Washing Systems headquarters in Dungannon, Northern Ireland, the team has refined its filterpress technology and integrated it into its comprehensive “Feeder to Filterpress” washing solutions. These systems divert waste from landfills while recycling the water used during the process, significantly reducing environmental impact and improving aggregate production for quarry customers.

Terex Washing Systems offers comprehensive global support and service. With 40 distributors worldwide and regional offices in the United States, Europe, Asia-Pacific and Australia, Terex Washing Systems provides localized expertise and service.

Supported by a dedicated technical team and advanced laboratory facilities, Terex Washing Systems ensures optimal equipment performance and sustainability throughout its customers’ operations.

For more information, visit www.terex.com/washing.

Lippmann announced the addition of Dillon Borchardt as its new territory sales manager. In this role, Borchardt will manage relationships with dealers, provide support to customers and contribute to the company’s sales efforts across the United States, Mexico and Canada.

Borchardt brings seven years of experience in the aggregate and construction industries, with a strong background in both the technical and sales aspects of the field. He has previously worked for two other industrial manufacturers where he specialized in sales engineering, applications engineering, concept drawings, system layouts and materials testing.

“My background has largely been on the technical side of sales, working closely with dealers and regional sales managers,” said Borchardt. “Moving into this role at Lippmann felt like a natural next step for me, as I was looking to transition more into the business side of sales.”

Borchardt holds a mechanical engineering degree, which he credits for giving him a deep understanding of the technical aspects of the industry. However, he knew early on that his strengths lay in working with people rather than in design engineering.

“While the technical side is important, I’ve

always enjoyed building relationships and helping customers find the best solution for their needs,” said Borchardt. “I’m excited to bring that passion to Lippmann, where I can continue to support customers and dealers in finding the right equipment for their operations.”

The Lippmann leadership team is enthusiastic about Borchardt’s deep industry expertise and hands-on experience, recognizing that his technical background and drive make him an ideal fit for the role. His years in the field and proven ability to work closely with dealers and customers ensure that he can step into the role with confidence and impact.

“Dillon’s extensive knowledge of the aggregate and construction industries, combined with his proactive approach, made it clear he was the right person for this position,” said John Megarry, commercial product director at Lippmann. “He’s hit the ground running and has already begun forging strong relationships in the field. We’re fortunate to have someone of his caliber join our team.”

Borchardt can be reached at dborchardt@mpp-global.com or 262/202-1138.

For more information, visit www.Lippmann-Milwaukee.com.

1200 East Highway 13 Burnsville, MN 55337 952-894-0894

Now open Saturday 8am-12pm CST

71 Minnesota Avenue Little Canada, MN 55117 651-407-3727

588 Outpost Circle Hudson, WI 54016 715-531-0801

Now open Saturday 8am-12pm CST

2018 US Highway 8 St. Croix Falls, WI 54024 715-557-6010

www.tristatebobcat.com

Cincinnati, OH 513-874-8945

Mt. Orab, OH 937-444-3865

Hilliard, OH 614-876-1116

Reynoldsburg, OH 614-863-1300

Zanesville, OH 740-868-8528

Elizabethtown, KY 270-506-4530

Lexington, KY 859-254-3936 Louisville, KY 502-245-1911

Walton, KY 859-449-7272

www.bobcat-ent.com

Bobcat of St. Louis

Fairview Heights, IL 618-397-1847

Effingham, IL 217-717-4550

Springfield, IL 217-525-0349

Champaign, IL 217-607-1454

Marion, IL 618-985-8920

Bowling Green, KY 270-842-4253

www.gatewaydealer.com

Ashland, KY 606-327-1709

Cowen, WV 304-226-3299

Beaver, WV 304-255-1525

Cross Lanes, WV 304-204-1818

Pleasant Valley (Fairmont), WV 304-534-5454

Norton, WV 304-636-6421

Pikeville, KY 606-432-0321

Marietta, OH 740-373-5255

www.lec1.com

Madison (Sun Prairie), WI 608-837-5141

Milwaukee, WI 414-462-9790

Green Bay (De Pere), WI 920-336-5711

La Croose (West Salem), WI 608-786-2644

Stevens Point (Plover), WI 715-254-2777

Racine (Mt. Pleasant), WI 262-898-6700

Sparta, WI 608-351-2101

www.brookstractor.com

#111079 2008 TEREX/PEGSON XR400

all-in-one 3-axis angle indicator w/ rear and side cameras. 477 CFM compressor. Still under warranty, VG condition. #112050 ANACONDA I-12 (43X45) TRACK MOUNTED

COMING IN (2003) Tamrock 700-2 Ranger drill w/ 6876 hrs & 2981 impact hrs., Good condition.

#510132 (2022) FRD 1450ED hyd rock drill, with 2753 hours on Cummins 6.7 engine & 1105 impact hrs on 26KW hammer & 353 CFM. compressor. MOBA "all-in-one" 3-axis angle indicator with rear/side view cameras. VG condition.

#510099-Tamrock DHA550 self-contained hydraulic drill, Deutz air cooled engine. Has 1185 impact hours. Good condition.

#580000-Furukawa HD712 drifter, approximately 4786 total impact hours and zero hours on complete reseal. Was used on 1200EDII.

Ready to be installed for operation.

#510128 Atlas Copco T45 Smartroc hydraulic drill, 9600hrs on Cat C9 engine and 3600 hrs on Copco 3060 drifter. Set up for 60mm steel. Drill running daily.

#530029 Ingersol Rand ECM370, self-contained rock drill w/ VL140 hammer & Cummins engine.

#1111085 Portable Pioneer 3042 jaw with 42"x16' VGG, 42" underconveyor, & 150hp motor on shopbuilt chassis.

structure, 1" screen in top deck & 3/4" screen on bottom. Good cond. #142003-Deister 5x16 2-deck horizontal, underslung screen with new bearings

#141164 Pep 6x18, 2-deck high frequency screen on factory chassis with electric motor & switchgear.

#141167 Deister BHT2616 (6x16 2-deck) screen, with polydeck top & bottom. Could be set up for wet screen. #142004 Portable Cedarapids/El-Jay 6x20 3-deck horizontal screen, on 3-axle chassis (set up for two screens, but only one included). Has four (4) 30"x12' cross conveyors, two (2) 36"X12' cross conveyors, & two (2) 42" underconveyors.

#640055 (2021) Sany SY265CLR long-reach excavator (60'), 1750 hrs, Cummins QSB6.7 T4F engine, 190 hp, 70,000lb shipping weight. Has A/C, heat, & radio. Max reach at ground level 57' 9" & max digging depth 43'9", 31" track pads, 60" digging bucket, & plumbed for hydraulic mower. 1-owner machine. Remainder of 5 yr / 5000 hour warranty (though Jan 2026).

#131026 Simplicity 36"x16' Vibrating Grizzly Feeder, 4' grizzly section. Very good condition.

#118000-New/never used Universal 2036 jaw crusher parts, including: Jaw plates, toggle seats, toggle plates, spring loaders, and all thread rods.

#111083 (2015) KLEEMAN MZ110i TRACK-MOUNTED JAW CRUSHER, (27X43″) with 5374 HRS SCREENS & WASH EQUIPMENT

#1154001 Self-contained SMI portable wash plant w/ 4x8 3-deck wet screen. a hydraulic driven Greystone 36x25 sandscrew, & a 30"x40 hydraulic driven radial stacker.

#152027 Ortner model 3000 sandscrew. with 5hp electric motor.

Rated at 50-125 TPH capacity. Very Good Condition.

#141163 Allis Chalmers 6x16 2-deck Ripl-Flo incline screen with

#640057 - 2007 Volvo 330BLC, 5800 hours on 6 cyl D12C, 198hp engine. 58" bucket with teeth and hyd. Thumb. 31" track pads, 78,000 lb operating wgt. Overall, good condition. #610137-1995 John Deere 644G Loader, unknown hours and 3 3/4 yard bucket. Good rubber and runs great, overall good condition. #410063-CAT D9H, EROPS cab w/ A/C, straight blade w/tilt. Single shank, 4-barrel ripper. 24" pads. U/C (overall approx 70%). Rebuilt engine, trans, and finals (HMR 2994) Left Trunnion is available but needs to be installed. Overall good condition. #700001 CAT 12F MOTORGRADER (1970),

On Sept. 12, members and friends of the Women Road Builders (WRB) in Illinois embarked on an unforgettable journey with an exclusive behind-the-scenes tour of O’Hare International Airport, one of the world’s busiest airports.

The tour allowed participants to explore the expansive 7,200-acre airport site via bus, making stops at various key locations. Attendees heard from airport staff at cargo loading areas; visited a materials testing lab; observed the fire department training site; and learned about ongoing construction projects — culminating in an up-close look at an airport runway.

This unique opportunity was facilitated by Chicago Department of Aviation Commissioner Jamie Rhee, whose support was instrumental in making the event possible.

“What an incredible day at the O’Hare Airfield Bus Tour,” WRB leadership expressed to members following the event. “From intimate views of runway action to insights into airport operations, it was truly an unforgettable experience. Huge thanks to the Chicago Department of Aviation and Commissioner Jamie Rhee for making it all happen.”

Founded to support women in a predominantly male-driven industry, Women Road Builders is a non-profit organization dedicated to enhancing the field through education, professional development and relationship building. While the organization focuses on empowering women, all individuals are welcome and encouraged to join their mission.

For more information, visit womenroadbuilders.com.

(All photographs in this article are Copyright 2024 Construction Equipment Guide, except where noted. All Rights Reserved.)

In remote, less accessible construction sites, having the right equipment can make all the difference in meeting project deadlines, maximizing profits and just getting the job done.

Since its introduction, Prinoth’s Panther T14R crawler carrier has remained a top choice for contractors looking to boost productivity and tackle work at even the most chal-

lenging job sites.

One of the standout features of the T14R is its efficiency, according to the manufacturer.

“The Panther T14R offers about 32 percent more productivity than other vehicles in the same category,” said Product Manager Eric Fatyol. “This impressive performance is achieved through a combination of high payload capacity, speed and maneuverability on rough terrain.”

With the ability to complete up to a third more work cycles, the T14R can significantly accelerate project timelines, allowing contractors to take on more projects and increase their revenue streams, the manufacturer said.

In addition to its technical capabilities, the T14R also offers environmental advantages. With a maximum speed of 8.1 mph, this crawler carrier can reach remote job sites that would otherwise require expensive and environmentally disruptive road construction or costly helicopter service. By eliminating the need for access infrastructure development, crawler carriers like the T14R help contractors minimize their environmental impact and preserve sensitive ecosystems.

The T14R’s low ground pressure of approximately 3 psi ensures minimal impact on the terrain, leaving a smaller footprint than the roughly 10 psi of a human walker. This low-impact design allows the machine to navigate delicate landscapes without causing significant damage, making it an ideal choice for projects in environmentally sensitive areas.

The Panther T14R features a Cat C7.1 engine, which adheres to the stringent EPA Tier IV Final and EUROMOT Stage V emissions standards. It’s also powerful enough to haul the T14R’s maximum payload of 29,100 lbs. at 33 percent, up a 15-degree slope.

The T14R also incorporates a unique single-touch drivedirection reset. The system allows operators to effortlessly reset cab and chassis alignment during operation, simplifying maneuvers and boosting overall efficiency. The vehicle’s hydrostatic drive motor has been fine-tuned to optimize high travel speeds and improve responsiveness under high-torque demand.

The T14R’s undercarriage is engineered like no other. Rugged large steel wheels and high-travel suspension allow the vehicle to maneuver over the most uneven soil, ruts, mud and ditches with ease. Its tracks are suitable for all soil types, and its self-cleaning undercarriage won’t accumulate mud and debris, allowing the equipment to operate smoothly and efficiently in all weather conditions.

The automatic track tensioning system simplifies maintenance, reducing downtime and allowing the T14R to spend more time on the job. This feature not only improves the machine’s overall efficiency but also helps to extend its lifespan, providing contractors with a better return on their investment.

Safety is paramount on any construction site, and the T14R’s enhanced visibility features contribute to a safer working environment. The machine’s lowered and slanted engine cowling design provides operators with an unobstructed view of their surroundings, increasing confidence and reducing the risk of accidents.

“The overall architecture of the vehicle offers unmatched visibility gains, making it safer for everyone on the job site,” notes Fatyol.

In addition to its visibility advantages, the T14R also is available with a rear-view camera as an optional feature, further enhancing situational awareness and minimizing blind spots. This added layer of safety not only protects the operator but also ensures the well-being of other workers on the construction site.

The T14R’s versatility is further enhanced by its compatibility with a wide range of specialized attachments, making it adaptable to various industries and applications. Whether focused on off-highway construction, mining, utility infrastructure, oil and gas or environmental reclamation applications, the T14R’s power and flexibility make it an indispensable asset on any project.

Prinoth’s commitment to innovation is evident in the T14R’s advanced features, many of which are patented or patent-pending.

In the post-pandemic economy, earth-moving equipment dealers struggle with tight competition and shrinking profit margins.

Industry expert Kelly Russell founded HB Attachments Inc. in 2023 to help excavator dealerships in the United States close more deals with higher profits. The startup designs, manufactures and distributes high-quality aftermarket excavator work tools, including buckets, rippers, quick couplers, rakes, thumbs and grapples.

In September, the family-owned business, based in Springfield, Mo., revealed its new brand name: TRUE Attachments.

The profit margin on a new excavator is quite small, so dealerships have very little room to negotiate with potential customers who are shopping based on price. However, sales are typically bundled with a package that includes several attachments designed for the machine’s boom arm.

Finding the right attachment wholesaler can greatly affect a dealership’s ability to craft a competitive yet profitable sales offer.

“I saw a need in our industry for a supplier of high-quality attachments — based in the central U.S. — offering wholesale products at a price that would give a dealer the slight edge they need to win more deals and increase the average margin per deal,” Russell said.

Russell launched the company with a team comprised of loyal family members and opened a warehouse in southwest Missouri. The company distributes its products to dealerships throughout the United States.

The attachments are designed to perform well in a variety of industries, including timber, quarry and mining, oil and gas, as well as construction and excavation, according to the company.

Kelly Russell founded HB Attachments Inc. in 2023 to help excavator dealerships in the United States close more deals with higher profits.

TRUE Attachments currently offers products to fit the following brands of excavators: Case, Kobelco, Komatsu, Kubota, Hitachi, John Deere, Volvo, DEVELON, Hyundai, Takeuchi, Yanmar and SANY.

The company began as HB Attachments — with a honey badger as the mascot — but recently consulted with Midwest marketing

agency Henderson Media LLC on a rebranding package that included the new TRUE Attachments brand name, logo design, domain name registration and upcoming website launch.

HB Attachments Inc. remains the legal entity, doing business as (DBA) TRUE Attachments. For more information, visit TRUEattachments.com. (All photos courtesy of TRUE Attachments.)

By Olamiposi Agboola SPECIAL TO CEG

In an era of labor shortages and projected construction growth, contractors and their crews continue to face both challenges and opportunities on job sites. It’s no surprise, then, that seeing quick ROI for new equipment purchases is increasingly important. While a specialized machine can be a great asset on the job site, maximizing your existing machines with the help of attachments may prove more efficient and cost effective.

Compact track loaders, skid steer loaders and excavators are known for their versatility; you may be surprised at how many attachment options also are available for mini track loaders, small articulated loaders, compact wheel loaders, telehandlers and even tractors. To fully optimize your existing fleet, connect with your dealer to understand the full range of attachment options you can take advantage of.

With the right attachments, your machine can be productive through all seasons across construction, landscaping, agriculture or grounds maintenance jobs. This versatility enables you to seize existing project opportunities while also venturing into new markets.

When considering what attachments to add to your fleet, it’s important to consider a few factors. First, identify essential attachments that are currently missing from your inventory. Second, analyze frequently rented attachments to assess potential cost savings by purchasing. Finally, review missed

job contracts to identify potential projects that could be pursued with the right attachments.

Augers, buckets, breakers, clamps and grapples are just a few core attachments that can increase your job site opportunities year-round. Specialty attachments, such as rotary cutters, chippers, flail mowers, drum mulchers, soil conditioners and stump grinders, also can tackle work across a variety of industries with their multi-functional capabilities.

For winter work, you may seek dedicated snow-removal attachments, such as snow blades, snow pushers or a snowblower.

Due to attachment features like Bobcat’s Bob-Tach attachment mounting system, operators can easily — and quickly —

change attachments by manually lifting and lowering two easy-to-handle levers on the attachment mounting bracket.

For added convenience, operators can opt for enhanced systems like Bobcat’s Power Bob-Tach, which give you the ability to change non-hydraulic attachments with the press of a button from inside the cab. This technology lets you change a non-hydraulic attachment in a matter of minutes — all from your seat.

Operators also can use the Bob-Dock attachment mounting system on select Bobcat loaders to switch out hydraulic attachments with the press of a switch. This industry exclusive from Bobcat is an evolution from the Bob-Tach and Power BobTach systems, allowing operators to stay in the cab, keeping productivity high and leaving more time to complete the task at hand.

Bobcat has equipped many of its compact excavators with its exclusive X-Change attachment mounting system for multiattachment functionality.

For the most convenient attachment changes in the industry, choose the optional Hydraulic X-Change system. Release and secure attachments from inside the cab by pressing a switch.

These hyper-focused features directly impact operator seat time which improves both job site productivity and performance.

Optimizing your fleet with the right attachments can help you get more done in less time, gain versatility, replace less utilized machines and give you the tools to accomplish major projects.

Popular attachments like buckets, augers and trenchers are obvious choices for handling material, digging holes and trenching through even the toughest soil, respectively. Specialty attachments like graders, box blades and land planes can make your fleet even more versatile for projects that require absolute accuracy, precision, and in some cases — finesse.

Whether you need to simply improve your job site performance or lower your operating costs in 2024, evaluating your attachment lineup is a good place to start. The wide variety of attachments available and their breadth of features can provide both immediate and long-term benefits that will help you be successful not only this year but well into the future.

(Olamiposi Agboola is a marketing specialist of Bobcat.)

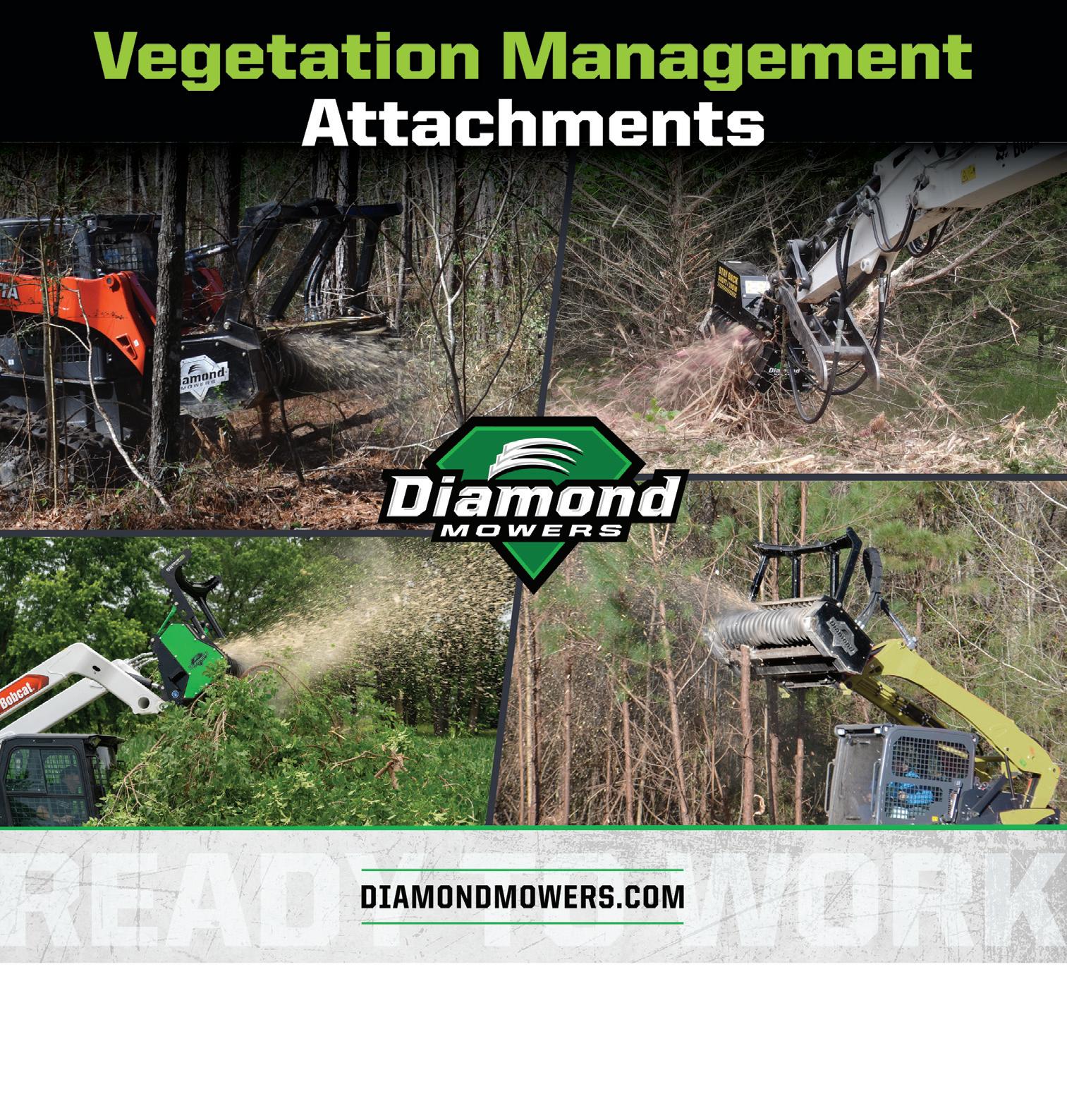

Diamond Mowers, a manufacturer of vegetation management attachments for tractors, skid steers and excavators, has launched a new website and expanded its resources to better serve its customers and dealers. This move reinforces the company’s commitment to being the premier partner for land management professionals.

The brand evolution introduces the tagline, “Attachments that Work as Hard as You Do,” shifting the focus from product features to customer empowerment. It highlights Diamond’s role as a trusted partner, offering innovative solutions and expert support to ensure the success of both cus-

tomers and dealers in tackling their toughest challenges.

“These enhancements represent our ongoing commitment to our customers and dealers,” said Dan Stachel, executive vice president of Diamond Mowers. “We’re focused on providing the resources and support they need to succeed in their work.”

The new Diamond website showcases the company’s product offerings and serves as a hub for industry expertise and customer support. Designed with the user in mind, the site offers tools to assist in identifying the right equipment for the job, ensuring attachments are compatible with customer carriers, and providing transparency around MSRP to support the buying process.

• Enhanced resources to help dealers serve end-users more effectively

The new site features:

• Expanded industry resources and educational content to support customers

• Real-world customer success stories and testimonials

• A refreshed visual identity reflecting the determination of Diamond’s customers

“These new tools and resources are designed to make our customers’ and dealers’ jobs easier,” added Stachel. “We’re committed to providing not just attachments, but the support needed to maximize productivity in the field.”

The website is now live at diamondmowers.com. Rebranding elements will be rolled out across all touchpoints, including marketing materials, social media and dealer communications in the coming months.

Park City, KS (316) 942-1457

Great Bend, KS (620) 792-2748

Humboldt, KS (620) 473-7020

Olathe, KS (913) 298-7373

Topeka, KS (785) 233-0556

Ulysses, KS (620) 356-1071

Dodge City, KS (620) 227-3139

Gering, NE (308) 436-2177

Fort Dodge, IA (515) 576-3184

Sioux City, IA (712) 252-2753

Waterloo, IA (319) 235-7085

Brunswick, OH (330) 220-4999

Cambridge, OH (740) 439-2747

Canton, OH (330) 477-9304

Cincinnati, OH (513) 772-3232

Yanmar Compact Equipment has introduced a new line of branded attachments optimized for use with its compact track loaders.

The Yanmar attachments include a full range of buckets, augers, trenchers, stump grinders, soil conditioners, breakers, sweepers, pallet forks, brush mowers, grapple rakes, grapple buckets and snow and grading blades.

The new branded Yanmar compact track loader attachments include a full range of buckets, augers, trenchers, stump grinders, soil conditioners, breakers, sweepers, pallet forks, brush mowers, grapple rakes, grapple buckets and snow and grading blades. Swanston Equipment

Columbus, OH (614) 876-1141

The introduction of the new attachments streamlines the purchasing process for fleet owners, contractors and rental centers by allowing Yanmar dealers to act as a one-stop shop for a comprehensive package of Yanmar equipment and attachments. Additionally, customers can be confident that their attachments are matched and tested to ensure maximum efficiency and performance when used with their Yanmar compact track loader.

“We’re excited to offer yet another reliable and versatile

set of tools to help fleet customers and contractors be productive right out of the gate and conquer the evolving demands of any construction jobsite head-on,” said Frank Gangi, product manager — attachments, Yanmar Compact Equipment North America.

“Additionally, Yanmar customers can save time by buying their machine and attachments all from one place.”

The attachments, available through Yanmar’s dealer network, allow for seamless compatibility for use with all Yanmar-branded compact track loaders. This allows operators to simply attach the tool and get to work with the confidence to get the job done. Plus, owners have access to the same signature 24-month/2,000-hour warranty offered on Yanmar compact track loaders backed by the manufacturer’s unparalleled reliability and durability standards. This provides peace of mind with parts and support available directly from Yanmar.

In addition to offering the convenience of buying a compatible Yanmar attachment with a matching machine, the new attachment line is simple to finance. Eligible buyers can purchase a Yanmar machine through a Yanmar dealer and finance the attachment with the equipment as a bundle in one convenient package.

The new attachments will be available at Yanmar dealers alongside its full lineup of compact track loaders. Yanmar will continue to expand its attachment line to provide more versatility to its customers.

For more information, visit www.YanmarCE.com. (Photos courtesy of Yanmar Compact Equipment North America)

Omaha, NE (402) 894-1899

Lincoln, NE (402) 467-1300

Grand Island, NE (308) 381-0741

North Platte, NE (308) 534-7020

Kansas City, MO (816) 483-5000

Springfield, MO (417) 863-1000

Des Moines, IA (515) 263-0055

Jackson, OH (740) 688-4100

Lima, OH (419) 221-3666

Painesville, OH (440) 639-0700