By Brenda Ruggiero CEG CORRESPONDENT

The Pennsylvania Turnpike Commission is nearing the end of a

project to improve both the eastbound and westbound tubes of the Tuscarora Tunnel.

The tunnel is located on the PA Turnpike Mainline (I-76) between mileposts 186 and 187 between the Fort Littleton Interchange (Exit 180) and the Willow Hill Interchange (Exit 189) on the

Huntingdon/Franklin County line. This is approximately 40 mi. west of Carlisle.

According to the commission, the project is needed to improve and modernize the tunnels and to maintain safety for workers and travelers.

Project notice to proceed was

given on July 31, 2019, and the current contract completion date was Jan. 18, 2024. The original contract amount of $109,977,777 was increased to the current amount of $118,685,857.

The prime contractor is Mosites Construction Company of

see TUNNEL page 44

By Lucy Perry CEG CORRESPONDENT

Outback Parts is linked nationwide with three used parts networks, so finding dependable parts fast and conveniently is never a problem.

Outback Parts also supplies replacement parts for Non-Cat® machines. So when you’re needing parts, call or visit us on-line.

The Waterfront Alliance announced that the South Battery Park City Resiliency Project has become the 13th project nationally to achieve WEDG (Waterfront Edge Design Guidelines) Verification.

The almost 28-year-old monorail system that will soon exceed its useful life is to be replaced with a modern cable car system.

12 U.S. MILITARY TO BUILD NEW $30.5M LAB AT DOVER AFB

When complete, Dover Air Force Base (DAFB) in Delaware is set to become the new site of the Armed Services Whole Blood Processing Laboratory-East (ASWBPL-East) facility.

20

The United States Postal Service (USPS) has shown a spotlight on the architectural design and engineering feats of spectacular bridges with the release of four new Presorted First-Class Mail stamps.

22 NEW $300M PA. STATE POLICE ACADEMY BEGINS CONSTRUCTION

A new and ultramodern Pennsylvania State Police Academy began construction in Hershey Dec. 18 following a ceremonial groundbreaking attended by Gov. Josh Shapiro and other state and law enforcement officials.

24 AED GATHERS IN LAS VEGAS FOR ITS ANNUAL SUMMIT/CONDEX

The Associated Equipment Distributors (AED) convened for the group’s annual summit/CONDEX at the Mirage in Las Vegas Jan. 16 to 18, 2024.

34 ASTEC INDUSTRIES ANNOUNCES BEST LINE EQUIPMENT AS DEALER FOR WESTERN PA.

Best Line Equipment, a leader in equipment sales, service and rentals, announced a strategic partnership with Astec Industries, a global pioneer in the manufacture of equipment from rock to road.

34 LICA TO HOST ITS FIRST WATER MANAGEMENT FORUM AT ST. JOSEPH’S COLLEGE IN IND.

The inaugural LICA Water Management Forum will take place at the historic St. Joseph’s College in Rensselaer, Ind., on June 13 and 14, 2024, bringing together water management professionals, contractors, farmers, government officials and educators.

38 WASHINGTON’S METRO HIGH-RISE RESIDENTIAL PROJECT BEGINS

The Washington Metropolitan Area Transit Authority, better known as the Metro, held a groundbreaking Jan. 8 for a new high-rise residential building being constructed at the North Bethesda Metro Station.

42 AMH CALLS FOR IMPROVED SAFETY IN NON-STANDARD LIFTS

All Material Handling (AMH) believes that too many non-traditional lifts are still taking place using the wrong hoist rings and eyebolts, creating unnecessary safety risks.

49 EQUIPMENT HELPS O&G INDUSTRIES WITH GREEN INITIATIVES

Among the largest construction services and products firms in the Northeast, O&G Industries is a fourth-generation company owned by the Oneglia family.

72 MONTABERT HONORS TOP DEALERS AT AED CONFERENCE

Montabert USA has announced its top dealer awards for 2023. Two awards for highest achievement in sales were presented during the AED (Associated Equipment Dealers) Summit and CONDEX event.

86 HD HYUNDAI, GOOGLE CLOUD

The collaboration will introduce generative AI across Hyundai’s core businesses, including its Korea shipbuilding and construction machinery businesses..

• Western Pennsylvania 440/243-9690

Cell 260/760-0521 e-mail nspain@cegltd.com

Teddy McKeon

• Delaware • Maryland 215/885-2900

Cell 215-260-8709

e-mail tmckeonjr@cegltd.com

RIDE CONTROL, AUX HYDRAULICS, 4-IN-1 BUCKET, EXT-HOE, REAR AUX. HYDRAULICS, 24” BUCKET $70,000

23E060 – 2008 CAT 325DL, EROPS W/AC, 9’.6” STICK, AUX. HYDRAULICS, HYDRAULIC Q/C, 31” SHOES $P.O.R. 22JV009ASF – 2013 CAT 336EL, EROPS W/AC, 10’.6”

The Waterfront Alliance announced that the South Battery Park City Resiliency Project has become the 13th project nationally to achieve WEDG (Waterfront Edge Design Guidelines) Verification.

The gold standard for waterfront design, WEDG is an awardwinning national rating system and set of guidelines for resilient, ecological and accessible waterfront design.

The South Battery Park City Resiliency Project is a key component of the Lower Manhattan Coastal Resiliency Master Plan and vital link to protect an area spanning the Museum of Jewish Heritage, Wagner Park and Pier A Plaza, as well as the adjacent Battery Park City and other portions of Lower Manhattan.

Together, the Battery Park City Authority and AECOM’s design team developed a plan to strategically incorporate resilience features into the site that will make it resilient against sea-level rise, coastal flooding, storm surge, increased precipitation and other intensifying climate change impacts.

The transformation of Wagner Park will create an enhanced and cohesive experience for park users. A network of planters, stepped benches and winding pathways through native planting areas will conceal the site’s seawall and resilience infrastructure. A 10-ft. increase in the elevation of much of Wagner Park will provide resilience against the 2050s 100-year storm and facilitate commanding views of New York Harbor. Today’s existing barren stone riprap along Pier A Inlet will be replaced with new habitat space consisting of plantings on stepped terraces that will attract marine life. Park users can engage with the habitat space via an overlook, which also will serve as a passive educational zone.

“This project is a stellar model in how projects can adeptly incorporate resilience features into the design of waterfront spaces,” said Waterfront Alliance President and CEO Cortney Koenig Worrall.

“We applaud the Battery Park City Authority and the project team’s achievement of WEDG Verification and commitment to the rigorous standards. Because of the South Battery Park City Resiliency Project, Lower Manhattan is that much stronger against ever evolving climate change risks.”

Throughout the design process, the project team purposefully integrated access and feedback from stakeholder engagement into the plan for the park. Discussions with residents and other stakeholders changed the scale of the lawn, created safety enhancements and a realigned bikeway, and spurred additional community space. The team also incorporated universal access throughout the site, which will enable all park users to access the site equally, despite the significant elevation changes that sea-level rise protection requires.

At the project’s completion, park users will find a more resilient, accessible and ecological site, while still enjoying views of one of the world’s most iconic waterfront views.

WEDG Verification is only awarded for projects that successfully pass a technical review of the project’s design against the WEDG standards. External specialists in engineering, architecture and landscape architecture determined that the project exceeded the requirements for WEDG Verification, earning 125 out of 215 possible points in the standard (115 are needed to pass). Battery Park City Authority incorporated WEDG into its Request for Proposals for the North/West Battery Park City Resiliency Project and its Battery Park City Green Guidelines.

“In Battery Park City, with the urgency and care the moment demands, we’re adapting our waterfront to address climate change and simultaneously creating an even more beautiful and accessible park space for our residents and visitors,” said Battery Park City Authority President and CEO Raju Mann.

“We are honored to attain WEDG Verification from the Waterfront Alliance, an organization that has helped shape the New York City’s waterfront. The South Battery Park City Resiliency Project, including the redesigned and revitalized Wagner Park, will set the new standard for waterfront design excellence, flood protection and functionality for the next generation of New Yorkers.”

“We are incredibly honored and excited to achieve WEDG verification for Wagner Park as part of the South Battery Park City Resiliency Project. This recognition underscores our commitment to a resilient, enjoyable and sustainable waterfront in Lower Manhattan,” said AECOM’s design lead for Landscape and Urban Design, Gonzalo Cruz.

“Wagner Park and the surrounding areas are being transformed to integrate flood risk reduction, improve continuous public waterfront access, and enhance natural ecosystems. Receiving WEDG Verification is a testament to the collaborative and multidisciplinary approach undertaken by the entire project team.”

“We reviewed a wide variety of available third-party benchmarking systems to identify a certification that aligned

with the ambitious goals of the project. WEDG was a clear choice to ensure forward thinking coastal risk reduction strategies went hand in hand with plentiful safe, open and accessible public space along the edge of lower Manhattan,” said Atelier Ten’s senior environmental designer, Nikita Jathan.

“The South Battery Park City Resiliency Project is an immensely important undertaking to protect Lower Manhattan from climate change induced sea-level rise at one of its lowest elevations,” said the Manhattan Community Board 1 Chair, Tammy Meltzer. “It also acts as a beacon for the future of resilient design. Congratulations to the project team for this recognition; Community Board 1 looks forward to continued collaboration to help make the entire Lower Manhattan Resiliency Master Plan a resounding success.”

Waterfront Alliance applauds Battery Park City Authority and AECOM’s achievement in the redesign of Wagner Park. The project team includes:

• AECOM NYC Landscape Studio: Landscape Architecture and Public Realm Design Lead

• AECOM Engineering: Civil, Structural & Marine Structural Engineering, Coastal Modeling, Interior Drainage, Permitting, FEMA Compliance

• Arch Street Communications: Community Engagement

• Atelier Ten: Sustainability Certification

• Magnusson Klemencic Associates: Civil Engineering

• Milhouse Engineering: Mechanical, Electrical, and Plumbing

• Nautilus International Development Consulting: Urban Design, Sustainability

• Noel: Permit Expediting

• Oweis Engineering Inc: Geotechnical Engineer

• SiteWorks: Landscape Architect of Record

• Thomas Phifer and Partners: Pavilion Design

• Tillotson Design Associates: Lighting Design For more information, visit waterfrontalliance.org.

Rogers 55 ton Gentle Riser, No-Foot Neck, 25' deck, adjustable width bi-fold front ramps, deep well pocket in deck with inserts & planks on grade, 275's on aluminum outers, extra lights, Strobes in rear, mini strobes on sides, Air Lift 3rd, hangers & supply for optional 4th axle, Black paint. IN STOCK!

Rogers TAG25XXL, 25 Ton Capacity, Premium Specs, Superior Quality, 235’s Aluminum, 7-Year Warranty, Black or Red Paint, 24’ deck + 6’ tail, 8’ Air Ramps IN STOCK!

Rogers 35 Ton Gentle Riser, 24' deck, adjustable width bi-fold ramps, 275's on Aluminum, Extra lights and strobes, Red, Green and Black Paint IN STOCK!

New Rogers 50 Ton, Gentle Riser, No-Foot

New Rogers 55 ton, CobraNeck, 2-position pin, Ratchet Ride Height, 26' deck, 18" ride height, deep well pocket, 275's on aluminum outers, air lift 3rd,& 4th. Night Light Pkg., Strobes, 3 or 4 Axles IN STOCK! Rogers 55 Ton CobraNeck, Severe Service Design. 2-position pin, ratchet ride height, adjustable width bi-fold steel ramps, 26' clear deck, deep well pocket, chain bins, tool boxes, 275's, alum. outers, side reinforcing, extra lights, strobes, night light pkg. 3-axles air lift 3rd, 4-axles air lift 3rd & 4th,

Rogers PT35L, 35 ton Rear Loader, Air Ramps, Air Ride, Air Dump, Low Loading Angle. Storage in sloped neck. 235’s on Aluminum outers, Black Paint IN STOCK Rogers TAG21XL, 22’ + 6’ Tail & TAG21XXL, 24’ + 6’ tail, 235's on Aluminum, Air Ramps, Safety Lighting Pkg. with Strobes. Black or Red Paint IN STOCK!

Dover Air Force Base (DAFB) in Delaware is set to become the new site of the Armed Services Whole Blood Processing Laboratory-East (ASWBPL-East) facility.

Delaware Business Times reported Jan. 9 that the $30.5 million project will replace the 1955 building currently at the base, expand its square footage and make refrigerator and freezer upgrades to store blood properly and safely.

The funding for the new lab was a part of the annual National Defense Authorization Act (NDAA), which received bipartisan support in Congress and was signed into law by President Biden on Dec. 22. In total, the NDAA authorized a record $886 billion in annual military spending, along with a 5.2 percent pay raise for military servicemembers and the Department of Defense’s (DOD) civilian workforce.

“Dover Air Force Base has long been a premier military installation bolstering the readiness of our armed forces,” said U.S. Rep. Lisa Blunt Rochester, D-Del. “Today, with the funding authorization of the Armed Services Whole Blood Processing Laboratory-East facility, DAFB will continue to lead the way in supporting the mission of those in uniform.”

By constructing the new ASWBPL in

The funding for the new lab was a part of the annual National Defense Authorization Act (NDAA), which received bipartisan support in Congress and was signed into law by President Biden on Dec. 22.

facilities and Veterans Affairs medical centers.

“The 2024 NDAA takes meaningful steps to ensure America’s armed forces are prepared for a changing world, and it supports our national security, servicemembers, and veterans,” Delaware’s U.S. Sen. Chris Coons said in a statement. “I am particularly proud of the investment in a new ASWBPLEast facility at Dover Air Force Base, which will make it easier and more efficient for the blood products that travel through Delaware to reach servicemembers around the world.”

Delaware, it will replace the current East Coast facility at Joint Base McGuire-DixLakehurst in New Jersey. It will become one of only two such centers maintained by DOD in the United States; the other is located at Travis Air Force Base in California.

Captain Leslie Riggs, division chief of the Armed Services Blood Program (ASBP), told Delaware Business Times that DAFB was selected for the new facility due to its military flight line.

“I am looking forward to the capabilities this is going to bring us,” he said. “As facilities age, and as requirements have grown

over the years, you need a little more square footage and … more refrigerators and freezers.”

Riggs estimates the new facility will break ground in 2026.

From its new home at Dover Air Force Base, the ASWBPL-East facility will be the primary processing and distribution center for blood products to support the Central, European, and Africa combatant commands in addition to military medical treatment

Established in 1952, the ASBP functions like the American Red Cross and has more than 150 locations. As the U.S. military’s official blood program, it provides blood products for deployment on the front lines and overseas operations, supplies lifesaving transfusion products on the battlefield and in treatment off the frontlines.

Additionally, as a joint operation among the U.S. Army, Navy, Air Force, the ASBP:

• Provides quality blood products for service members, veterans and their families in both peace and war.

• Collects, processes, stores, distributes and transfuses blood worldwide.

• Works closely with its civilian counterparts in times of need.

After several years of fits and starts, plans to construct a new AirTrain system for Newark Liberty International Airport in New Jersey are moving ahead — with a twist.

The almost 28-year-old monorail system that will soon exceed its useful life is to be replaced with a modern cable car system, the Port Authority of New York and New Jersey announced in December.

“It’s a very reliable system based on the centralized propulsion design and proven service in severe weather,” explained James Heitmann, the Port Authority’s chief operating officer. “It also brings superior customer experience by way of enhanced dynamic digital signage.”

Plus, it is much cheaper than original estimates of $2 billion or more to replace the system, NorthJersey.com reported Dec. 28.

The contract awarded to Austrian-based Doppelmayr Group was for $570 million to design and construct the 2.5-mi. automated people-mover system through Newark Liberty, which has a new Terminal A, a new Terminal B in the design phase, and a comprehensive plan being developed for a renovation of the entire complex in Newark and Elizabeth.

Additionally, the contract between the

Port Authority and Doppelmayr includes options, at a value of $385 million in net present value, to operate and maintain the system for 20 years.

Plans call for major construction on the cable car system to begin in the spring of 2025, with the people mover likely becoming fully operational in 2029. It will be built next to the current AirTrain at the northern New Jersey airport, which will stay in operation throughout construction.

Doppelmayr is known for building cable systems for gondolas, ski lifts and airport trams, including BART’s airport connector in San Francisco and the DART connector to London’s Luton Airport. The proposed Newark system is expected to eclipse the customer use at both of those airports.

Currently, Newark’s AirTrain shuttles an average of 33,000 passengers a day. In contrast, the Doppelmayr system in San Francisco transported an average of 3,300 people a day after its first year in service, the San Francisco Chronicle reported.

On its opening day, the new Newark system will be designed to carry double the capacity of the current system using five-car trains and over time will be capable of expanding by 40 percent.

Getting to this point, however, has been a challenge, according to NorthJersey.com.

Gov. Phil Murphy called on the Port

Plans call for major construction on the cable car system to begin in the spring of 2025, with the people mover likely becoming fully operational in 2029.

Authority to replace Newark’s AirTrain in 2019 because of its age and frequent breakdowns, saying it would cost the bistate agency $400 million over a decade to keep repairing it.

At that time, the replacement effort was estimated to cost around $2 billion. When the bids came back in 2022, Port Authority board Chair Kevin O’Toole said, “The numbers came back, for a variety of reasons, higher than anticipated. We’re working internally to see what we can do to make it a more competitive bid.”

In addition to seeking a more innovative approach, the agency opted to break up the bid package and spread out the risk. The new request for proposal was issued earlier this year. Three firms were short-listed, and ultimately Doppelmayr was chosen for providing the “best value” and because it earned “highest technical rating,” Heitmann said.

O’Toole thanked his employees for their hard work in getting the proposal to this point.

“This is a huge deal for the port, [and a] huge deal for the AirTrain project that has been hanging out there for a while,” he said.

CHIPPERS:

2021 BANDIT SG-75 STUMP GRINDER, 820 HRS, SELF PROPELLED, REMOTE, NEW CUTTER WHEEL

$56,995

EXCAVATORS:

2017 HITACHI ZX135-6, 3900 HRS, HYD THUMB, FRONT BLADE, COUPLER, PATTERN CHANGER

2020 HITACHI ZX135 LC-6, 2500 HRS, HYD COUPLER & THUMB

2018 HITACHI ZX160, 4800 HRS, HYD COUPLER & THUMB

2015 HITACHI ZX225, CAB, HVAC, 4963 HRS, HYD COUPLER, 42” BKT

2018 KOBELCO SK85LS, HYD THUMB, CAB, HVAC, 631 HRS

2016 KOBELCO ED160, CAB, HVAC, 3660 HRS, HYD THUMB

2004 KOBELCO SK210LC, 14,460 HRS, PLUMBED, HVAC, PATTERN CHANGER

$109,000

$82,500

SKID STEER LOADERS:

2021 KUBOTA SVL97-2 TRACK SKID STEER, CAB, HVAC, 905 HRS, STD FLOW HYD, HYD COUPLER, 78” BKT, BACKUP CAMERA

2019 NEW HOLLAND C245 TRACK SKID STEER, 775 HRS, CAB HVAC, 2 SPEED, PILOTS, LOW HOURS, HIGH FLOW, SELF-LEVELING, RIDE CONTROL, RADIO

$67,995

TRACTORS:

2005 JOHN DEERE 5105, 1002 HRS ON METER, LOADER, 4WD, REAR REMOTE, BKT & FORKS, 3PT HITCH

$20,000 2014 NEW HOLLAND BOOMER 24, 4WD, MOD PTO, 60” MOWER DECK HYDRO TRANS, R4 TIRES $9,995

2021 NEW HOLLAND BOOMER 40 TRACTOR W/LOADER, 76 HRS, 4WD, IND TIRES, HYDRO TRANS $25,995

TRAILERS:

2000 EAGER BEAVER 10HA, 20,000 LB CAPACITY, AIR BRAKES, GOOD WOOD & BRAKES $8,300 TLB:

2001 CASE 580L TLB, CAB 4WD, 4 BHOE BKTS, 5148 HRS $28,500

2021 NEW HOLLAND B95C TLB, 139 HRS, CAB, HVAC, 4 IN 1, EXT HOE $107,995

1999 NEW HOLLAND 555E TLB, 8675 HRS, 12” BHOE BKT, 4WD, CAB $18,995

WHEEL LOADERS: 2002 DAEWOO MEGA200V, 2YD 4IN1 BKT, 2283 HRS, HYD COUPLER $44,995 1990 KOMATSU WA350-1, CAB W/HEAT, 13,925 HRS, 3 YD BKT, GOOD RUBBER

D450 CRAWLER LOADER, 4 IN 1 YEAR & HRS UNKNOWN

FFC 11072H SKID

You call Milton CAT when you need to rent a generator:

• Availability. Even when everyone else needs a generator, you’ll get yours.

• Product quality. All EPA-certified, clean, well-serviced gensets.

• Complete range. From 20 to 2,000 kW; Diesel and gas; portable and Tier IV models.

• All the ancillaries.

• Expert support; 7/24 service.

• Priced to fit your budget.

Four locations serve Maryland, Delaware, Washington, D.C. and parts of Virginia, New Jersey, and Pennsylvania

Elliott & Frantz can show you the latest Gradall models, including Series IV excavators with highway speed travel capability. Featuring AutoDrive™, these models integrate a 6-speed automatic transmission and a new transfer case for efficient, simplified travel as well as convenient jobsite repositioning from the upper cab.

Gradall excavators also feature the job-proven telescoping, tilting boom that enables you to do more different jobs with just one machine – even under bridges and trees.

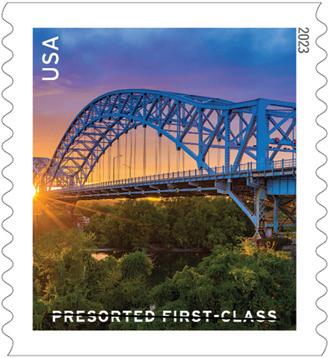

U.S. Postal Service photo

The Arrigoni Bridge connecting Middletown and Portland, Conn., is a 1,200-ft.-long steel through arch bridge that carries Routes 66 and 17 across the Connecticut River. At $3.5 million, it was the most expensive bridge in the state when it opened in 1938.

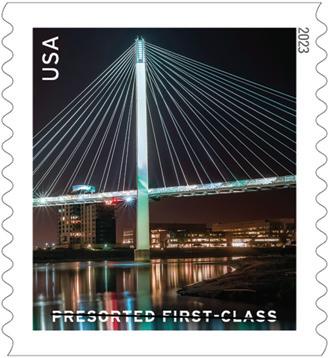

U.S. Postal Service photo

The Bob Kerrey Pedestrian Bridge is a 3,000-ft.-long, S-curved bridge — a $22 million project, which opened late in 2008. It is one of the longest pedestrian bridges ever to be built, allowing travel over the Missouri River. Part of former U.S. Sen. Bob Kerrey’s “Back-to-the-River” efforts, it connects the Port of Omaha’s Miller Landing to One Renaissance Center in Council Bluffs.

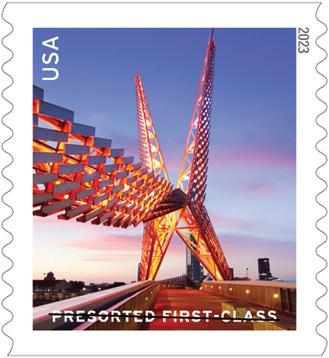

The Skydance Bridge in Oklahoma City is inspired by Oklahoma’s state bird, the scissor-tailed flycatcher, and soars over Interstate 40. This is a 380-ft.-long pedestrian bridge with a 197-ft.-tall sculpture. The bridge opened in 2012, connects upper and lower Scissortail Park, and cost $5.8 million.

The $1 billion basket-handle twin arch Iowa-Illinois Memorial Bridge connecting Bettendorf, Iowa, and Moline, Ill., began construction in 2017 and opened to traffic in 2021. The gateway to the Quad Cities region on the I-74 corridor spans 800 ft., is 6 mi. long and provides four lanes in each direction to address growing traffic concerns in the area.

By Ruksana Hussain CEG CORRESPONDENT

The United States Postal Service (USPS) has shown a spotlight on the architectural design and engineering feats of some of the spectacular bridges that have been connecting people and places across the country for years with the release of four new Presorted First-Class Mail stamps. Ethel Kessler, an art director of USPS, used existing photographs to design these stamps, which include the multispan steel through arch Arrigoni Bridge connecting the Connecticut municipalities of Middletown and Portland; the S-curved cable-stayed Bob Kerrey Pedestrian Bridge between Council Bluffs, Iowa, and Omaha, Neb.; the steel truss Skydance Bridge topped by a public sculpture in Oklahoma City; and the basket-handle twin arch Iowa-Illinois Memorial Bridge connecting Bettendorf, Iowa, and Moline, Ill. The bridges were completed between 1938 and 2022 and chosen for being important landmarks in their communities.

“We’re always looking for imaging or sets of stamps that can work. My first job was for an architectural firm and so I am not just sensitive to but enamoured with construction architecture and grand structures,” said Kessler. “Nobody gave me the assignment of doing bridges, it’s been something that I’ve had in my ‘way back burner folder’ for a long time and then it seemed like there was a need for this calibre of stamp.”

Kessler, who has worked at the USPS for more than 25 years, presented 10 different images from a range of places in the country, each bridge offering something unique. Four were finalized. Presorted First-Class Mail stamps are used for bulk business mailers

and must be used with a permit. They’re only sold in self-adhesive rolls of 3,000 and 10,000.

The Arrigoni Bridge connecting Middletown and Portland, Conn., (photographed by Joe Gowac) also is known as the Portland Bridge. The 1,200-ft.-long steel through arch bridge carries Routes 66 and 17 across the Connecticut River. It features two 600-ft. steel arches which have the longest span length of any bridge in that state. At $3.5 million, it was the most expensive bridge in the state when it opened in 1938.

The bridge underwent safety and pedestrian improvements from 2020 to 2022, which involved new sidewalks; improvements to bridge approaches on both sides; replacing of the bridge deck and bearings; painting; steel and concrete repairs; and other structural upgrades to increase the bridge’s lifespan.

The Bob Kerrey Pedestrian Bridge (photographed by Kyle Henderson) is a 3,000-ft.long, S-curved bridge — a $22 million project which opened late in 2008. It is one of the longest pedestrian bridges ever to be built, allowing travel over the Missouri River. Part of former U.S. Sen. Bob Kerrey’s “Back-tothe-River” efforts, it connects the Port of Omaha’s Miller Landing to One Renaissance Center in Council Bluffs.

The cable-stayed bridge looks like giant sails, standing at 52 ft. above the river and due to the 200-ft.-high single-tower pylons on either side. Dramatic lighting only adds to the visual appeal. The bridge deck has an unobstructed width of 15-ft. over the entire length of the bridge.

The Skydance Bridge in Oklahoma City (photographed by Christina Woods) is inspired by Oklahoma’s state bird, the scissor-tailed flycatcher, and soars over Interstate 40. This is a 380-ft.-long pedestrian bridge with a 197-ft.-tall sculpture.

The bridge opened in 2012, connects upper and lower Scissortail Park, and cost $5.8 million. It was named as one of the nation’s top 50 public arts projects by The Oklahoman at that time. The design was the winning entry in a national competition hosted by Oklahoma City. It has a steel hybrid structure with a vertically cantilevered tricord truss and simple span truss bridge as well as durable and recycled construction materials.

“It is an honor for Oklahoma City, and Skydance Bridge, to be represented on this historic U.S. postage stamp commemorating this iconic landmark,” said Shannon Cox, Public Works Public Information Officer.

The $1 billion basket-handle twin arch Iowa-Illinois Memorial Bridge connecting Bettendorf, Iowa, and Moline, Ill., (photographed by Miller + Miller Architectural Photography) began construction in 2017 and opened to traffic in 2021.

The gateway to the Quad Cities region on the I-74 corridor spans 800 ft., 6 mi. long and provides four lanes in each direction to address growing traffic concerns in the area. The final bridge design was completed by leading bridge engineering firm Modjeski and Masters. The westbound span was announced a winner in the major span category at the 2022 Prize Bridge Awards by The American Institute of Steel Construction and

the National Steel Bridge Alliance. Kessler found the images she worked with and works on Adobe Creative Suite for design. She has, in fact, maintained a folder titled Bridges with samples in it for at least 15 years now.

“One of the first stamps that I worked on was for Frederick Law Olmstead who is the father of landscape architecture and designed Central Park. I had worked for an architectural firm and so I had the sensitivity to that subject and before I started doing stamps, I had a design firm that did work for a lot of architecture construction and landscape architecture firms so it’s right up my alley.”

Four art directors meet monthly with the staff of the stamp staff division (in addition to others involved in visual research, text writing, photo assistance, etc.) presenting the different projects they’re working on. The decision on the number of designs to be released happens then. Suggestions from the public are considered but they are advised to do so at least three years out because it takes quite a while to get through legal clearance for many things especially stamps featuring people but sometimes stamps featuring previously used art.

A significant legal process follows in order to get images and rights to use those images. The Citizens’ Stamp Advisory Committee (CSAC), appointed by the Postmaster General, approves any ideas coming in from the public or the art directors. They determine subjects based on specific stamp selection criteria. Names of current members of the advisory committee as well as detailed information on the process is available on the USPS website.

For more information, visit usps.com/. CEG

A new and ultramodern Pennsylvania State Police Academy began construction in Hershey Dec. 18 following a ceremonial groundbreaking attended by Gov. Josh Shapiro and other state and law enforcement officials.

When complete in 2028, the estimated $300 million facility will be the most comprehensive update to the Academy since it opened in 1960 and will help the Pennsylvania State Police (PSP) and municipal police departments across the state to remain well-staffed, trained, funded, and equipped, according to a news release from the governor’s office.

Shapiro, standing alongside Lieutenant Governor Austin Davis, Department of General Services (DGS) Secretary Reggie McNeil, and PSP Commissioner Col. Christopher Paris, also unveiled design plans for the new world-class law enforcement training facility.

The modernization project will replace outdated infrastructure with multiple new buildings totaling 366,000 sq. ft. on the 146acre site in Hershey, including a five-story Marquee Building with modern classrooms and administrative offices, 300 individual cadet dormitories, a 500-seat auditorium and a spacious cafeteria.

In addition, the new PSP facility will

include a physical education building with two gymnasiums, a training tank and a weight room to provide space and equipment for self-defense training, water safety courses and fitness conditioning. Indoor and outdoor tactical villages will host simulations of high-risk incidents such as active shooters, hostage situations and barricaded subjects.

“The new Pennsylvania State Police Academy will be a state-of-the-art facility second to none in [this] country that will give cadets hands-on learning opportunities that will better prepare them for service in our communities,” Shapiro said in the statement released by his office. “I firmly believe that every Pennsylvanian deserves to be safe and feel safe in their community.

“Policing is a noble profession, and good people want to come here to this academy and train for a career in public service,” he continued. “It’s on us to invest in them and give them the resources they need to succeed.”

Additional facilities at the new PSP Academy will include a new headquarters for the Bureau of Emergency and Special Operations, horse stables for the Mounted Unit, a central supply warehouse and a vehicle garage at the Pennsylvania State Police Historical, Educational and Memorial

Center.

“I want to thank all of the cadets for your selfless commitment to keeping our communities safe,” noted Lt. Gov. Davis. “For the folks that live in rural communities, the state police are their police department, and many Pennsylvanians come from those small towns and townships to attend this academy because they are inspired by the state troopers they meet in their communities.”

Davis added “our state troopers deserve the best training and the best facilities to ensure they are prepared for what lies ahead. We can never thank them enough for their service to the Commonwealth.”

The existing Academy facilities will remain operational throughout the next several years of construction, according to the governor’s office, which will include the demolition of several existing structures.

To build the new PSP Academy, the Pennsylvania DGS awarded a $205.5 million general construction contract to Wohlsen Construction Co. in Lancaster; a $37 million HVAC contract to Midline Mechanical LLC, in Ephrata; a $42.8 million electrical contract to Glenmoore, Pa.based Philips Brothers Electrical Contractors

Inc.; and a $20.1 million plumbing contract to Jay R. Reynolds Inc., in Willow Street, Pa.

“Updated facilities and amenities are long overdue here at the Pennsylvania State Police Academy, the nation’s premier law enforcement training facility,” said the PSP’s Paris. “The new Academy will support the highest level of instruction for cadets, troopers, and our law enforcement partners.”

Next year marks 100 years of training law enforcement recruits in Hershey. The Pennsylvania State Highway Patrol secured the use of the former Hershey Inn, on Cocoa Avenue, from Milton S. Hershey and began training there in 1924. The Highway Patrol later merged with the PSP in 1937 and continued training at that site until 1960.

In the 2023-24 Pennsylvania budget, Shapiro secured new funding for four PSP cadet classes to train 384 new troopers, filling staffing gaps and ensuring that the PSP force is well-funded and well-trained.

In August, he and Paris announced that the PSP would remove the college credit requirement for Pennsylvanians who want to serve as state troopers to expand opportunities for individuals seeking careers in state law enforcement. In the two months following that announcement, the PSP saw a 258 percent increase in applicants taking the test to become state troopers.

Hamm 3412P, 2012, 84” vibratory padfoot compactor, EROPS w/ heat & A/C, 1,200HMR .

.$82,500

Cat 815F, 2006, EROPS cab, 12’4” S-Blade w/ tilt, new paint job, very good condition, 9,400 HMR $195,000

Hamm GRW-5 Pneumatic Roller, 1994, Deutz Diesel, ROPS Canopy, (9) Ea. 7.50-15C1 Tires . . . . . .$15,500

(4) Cat 825C’s, 1981-1990, EROPS, S-blade w/tilt, all work ready From $79,500

Rammax Walk Behind Rollers, over 25 in stock, lever & remote $4,000 to $10,000 (8) Sheepsfoot, 48" and 60", double drum & single drum, tow type

$4,000 - $6,500

Volvo A40, 1998, 40 tons, 10991 hrs, 395 hp, 8WD, 29.5R25, A/C, 29 cy cap. sideboards, tailgate (currently off work), work ready

Broderson IC80-2E, 1997, 8.5 ton, 24’ boom, dual fuel, 10.00R15 tires, 3,400 hrs

$127,500

Volvo A40, 1996, 40 tons, 395 hp, 6WD, A/C, 29.5R25, working everyday

$21,500 Grove RT58C, 1981, down cab, 18 ton r.t., 70' boom anti-two block, GM dsl, clean

$145,000

Volvo A40, 1996, 40 tons, 11,000 hrs, 6WD, 20.5R25, A/C, P/S trans, 29 cy cap., 6/06 hitch rebuilt .$115,000

Volvo A40, 1995, 40 tons, 395 hp, 8WD, 29.5R25, A/C, P/S trans, tailgate, work ready

$115,000

Volvo A35C, 1998, 35 tons, 6WD, 26.5R25 tires, approx 7,000 hrs, good condition

$147,500

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5x25, A/C, P/S trans, working everyday on jobsites

$87,500

$49,500 IR 185’s, JD diesels

CALL

Cat 336EL, 2012, 33.5” TBG pads, Q/C, aux hyd, 6,700 HMR, work ready

$162,500

Cat 336FL, 2015, 33.5” TBG Pads, Q/C, aux hyd, 4,300 HMR, work ready $224,500

Komatsu PC220LC-8 Longreach, 2011, Young Boom/Stick 60’ reach, 3,500 HMR $179,000

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5R25, A/C, P/S trans, 26 cy, working everyday on jobsites

$89,000

Volvo A30C, 1996, 30 tons, 11,000 hrs, 296 hp, 6WD, 23.5R25, 21 cy cap, A/C, P/S trans, works everyday

$122,500

(12) Allmand Light Plants, 2008-2010, diesel, s/a towtype, (4) MH lights, excellent From $5,200 Case 580L Rubber Tire Loader Backhoe, 1997, OROPS, std stick, 24" bkt

$24,500 (2) Balderson Broom Attachment for Cat IT Machines, 8' wide, good condition $4,000 Ea. NUMEROUS Rivinius R600’s, 10’ Wide, Mount on Dozer Blade

Kobelco SK210LC, 2007, Q/C, aux hyd, 31.5” TBG Pads, 3,900 HMR

$72,500

Cat D5NXL, 2006, 10’ PAT Blade, Paccar PA55 winch, 22” Pads, 4,100 HMR

$82,000

$49,500

Cat 613C Water Wagon, 1994, 5000 gal drop tank, ROPS, spray heads

Cat 621F, 1996, Scraper, OROPS, 33.25x2, very good condition CALL

Cat 621E, 1989, Scraper, OROPS, 33.25x29, very nice

CALL

Cat D6NLGP, 2008, VPAT Blade, Drawbar, 33” Pads, 9,900 HMR

$87,500

Cat D6NLGP, 2014, Foldable VPAT Blade, Paccar PA55 winch, 7,200 HMR

$142,500

Komatsu D155AX-6, 2007, Sigma S-U Blade, 4-bbl Single Shank Ripper, 8,400 HMR

$229,500

Over 100 Excavator, Loader, Specialized & Grapple Buckets in Stock -Call For Your Needs FORKS (8) IT28F/G Forks, Balderson qc, 48"-60" pallet style, excellent $4,000 Others Available Call Prices Are Negotiable - At Your Inspection

$152,500

Cat D6TXW, 2013, 13’6” VPAT Blade, Carco 70APS winch, 28” pads, 7,300 HMR

Ritchie Bros.’ booth was well attended at CONDEX. The company was showing off SmartEquip and Rouse to connect equipment buyers and sellers worldwide.

The Associated Equipment Distributors (AED) convened for the group’s annual summit/CONDEX at the Mirage in Las Vegas Jan. 16 to 18, 2024.

In addition to networking, equipment dealers, manufacturers and service providers could attend seminars, fundraise and see what’s new in the industry. With seminar topics that included discussions on AI, data, hiring military vets, automation, taxes, and so much more, there was something for everyone.

To close out day one, there was a Women in Equipment Reception, which offered the perfect venue to network with peers and make connections. This event was followed by the AED Foundation’s Annual Fundraising Gala and Live Auction, presented by Ritchie Bros. Both live and silent auctions gave everyone a chance to win an item and raise money for the foundation.

On the final evening, a keynote dinner and conversation with General James Mattis was hosted by PEAC Solutions. Mattis served as the 26th Secretary of Defense of the United States and made history by securing special permission from Congress to lead the Pentagon, sooner than he was eligible.

For more information, visit aednet.org. CEG

(All photographs in this article are Copyright 2024 Construction Equipment Guide. All Rights Reserved.)

see AED page 80

going president of the board of directors and Ditch

president; and John Shearer, incoming president of the AED board of directors and CEO of Colorado-based 4Rivers Equipment, cut the ribbon to open the AED Summit/CONDEX.

s largest or smallest s

trenchboxorshoringsystem

• • W

e will show y e while keeping y Get high produ trench box or sh

• world’

• W on time, est shoring the sion. you how with our our workers safe. uction numbers horing system.

e will deliver e s very bes s Contact us for t ervis on-site sup

e can provide you with the e • W world’ EV

wordforit t take our vice”... our ser “No one beats customers that told by our are We • when you want it where you want it, fleet of trucksour Wee’ll bring it with So don’

lobby scored a significant win with IIJA, which included the BABA.

That has the transportation industry nervous for the future.

Last year’s National Highway Construction Cost Index (NHCCI) shows it reached “a new all-time high” in the first quarter of 2023. The Bureau of Transportation Statistics (BTS) reported an increase of 2.7 percent from the last quarter of 2022. During the 2.5-year span, second quarter 2022 grew faster than any other period, at 11.9 percent.

BTS also noted that highway construction costs jumped in the last 9 of 10 quarters through the first quarter of 2023.

“Over the 10 quarters, highway construction costs grew 53.8 percent,” reported the federal bureau.

The Biden administration has heavily campaigned the Buy America Act (BABA) with a goal of growing the policy into new areas. A proposed new rulemaking project with a goal of applying BABA to manufactured products is scheduled to be published in April.

“Until the proposal is published, we cannot gauge likely impacts,” said Marc Scribner, transportation policy analyst of think tank Reason Foundation. “If the rule is expansive in scope, it is likely to impose significant new construction costs on state departments of transportation.”

Scribner said the fed’s eagerness to leverage BABA’s expansion is “especially unfortunate” for state transportation agencies.

States “have seen highway construction costs increase by 50 percent over the past two years.”

Congress imposed BABA procurement requirements for federally funded state highway projects during the Carter administration. The 1978 Surface Transportation Assistance Act made the use of domestic steel, iron and manufactured products mandatory for federally funded projects.

A general waiver was applied back then to products and materials, other than structural steel, used in highway construction.

Scribner said in 1983 Congress find-tuned BABA requirements and maintained the general waiver for manufactured products.

“In doing so, FHWA agreed that it was ‘very difficult to identify the various materials and then trace their origin’ in complex manufactured products,” he said.

The BABA waiver for manufactured products has held its place on the federal policy books since then.

But labor unions and manufacturers both have opposed the general waiver all this time, citing protectionist issues.

According to Scribner, the anti-trade

“BABA expressed a general policy preference against any ‘waiver … not limited to the use of specific products for use in a specific project.’”

The Biden administration has applauded the $92 million increase in highway spending that was a major chunk of IIJA.

“Unfortunately, it is increasingly likely that inflation will wipe out the entirety of that funding increase,” believes Scribner. “New Buy America requirements on manufactured products will make this problem even worse.”

He notes the federal Office of Information and Regulatory Affairs (OIRA) has the impacts of BABA on FHWA projects listed as “undetermined.”

Scribner believes this suggests the final rule will determine where annual costs land on the status scale.

It’s a matter of whether costs reach $100 million, considered “major” status, or $200 million, “significant” status.

“FHWA could choose to combine any narrowing or repeal of the general waiver with a more robust and permissive product-specific waiver process.”

Scribner maintains that policymakers need to understand that in

the “real world of budget constraints,” cost increases translate to less work.

“Federally mandated cost increases necessarily translate to fewer transportation projects and reduced benefits for Americans,” he said. “The best option would be for Congress to reconsider BABA and instead codify a general manufactured products waiver.”

This would reduce uncertainty and avoid cost increases associated with the “significant” interpretation of BABA’s manufactured products application, he said.

As an example of the tenuous situation, Washington State finds its transportation construction activity hamstrung by construction inflation.

WSDOT advertised a Seattle bridge project with a cost of just more than $800 million. The agency received only two bids, and the lowest was approximately $1.3 billion.

“Such a massive overshoot of the estimated price tag is cause for concern to lawmakers on its own,” wrote David Kroman of the Seattle Times.

In July, the state awarded a contract for work on I-405 toll lanes that was $230 million over its estimated price. And a contract for related work on Highway 167 was 40 percent over the estimation. The price to convert three ferries to hybrid-electric went up by $30 million, or 25 percent, according to the Times.

The situation has state lawmakers concerned. Washington is on a “15-year sprint” to build out its transportation network.

“It makes it tough to do all of the projects we’ve voted on to pass and to do,” Sen. Curtis King said. “It makes it tough to meet those promises.”

Several factors are at play, including material costs, supply-chain delays — and inflation.

“But WSDOT has raised particular alarm about a trend noticed over the last year and a half: declining competition for large designbuild contracts,” wrote Kroman.

As recently as 2021, the state averaged more than six bids per project. So far in 2023, that number has dropped to around 2.5, he noted.

“It’s certainly a concerning trend because we have a lot of design builds coming up in the next couple of years,” said Chris Christopher, WSDOT.

(570) 546-8422 Towanda (570) 265-4440 State

(814) 237-9050

(717) 697-1177 Shippensburg (717) 530-8400 Harrisburg (717) 540-7867

(732) 752-3600

(856) 227-6400

(718) 822-1180

(854) 236-3000

(631) 207-2900

(610) 363-9200

(717) 564-3031

(717) 859-3132

769-1070

A. Montano

amontanoco.com

Saugerties, NY 845-247-0206

All Island Equip Corp allislandequipment.com

West Babylon, NY 631-643-2605

Boston Freightliner / New England Road Equip bostonftl.com

Everett, ME 617-389-0707

Butler Equip butlerequip.com

West Hartford, CT 860-233-5439

Chappell Tractor chappelltractor.com

Milford, NH 603-673-2640

Brentwood, NH 800-616-5666 Concord, NH 800-358-6007

Correlli, Inc.

Dundalk, MD 443-503-5641

George & Swede georgeandswede.co

Pavillion, NY 585-584-3425

Heavy Equip Loaders and Parts heavyequipmentloaders.com

Lebanon, PA 717-277-7686

Highway Equip Co.

highway-equipment.com

Dubois, PA 814-371-3600

McKean, PA 814-476-7755

Zelienople (Pittsburgh), PA 724-452-7800

Kahn Tractor & Equip Inc.

kahntractor.com N Franklin, CT 860-642-7596

Lorusso Heavy Equip, LLC lhequip.com Walpole, MA 508-660-7600

Modern Group Ltd.

moderngroup.com

Allentown, PA 800-459-4659 Bristol, PA 800-866-3376 Edison, NJ 800-866-3376 Hasbrouck Heights, NJ 201-288-1441

Newlons International newlonsinternational.com Elkins, WV 304-636-4561

Pete’s Equip Sales & Rentals Inc.

petesequipmentvt.com

Morrisville, VT 802-888-5138

Quality Fleet Service, Inc.

qualityfleetservice.com

South Hadley, MA 413-213-0632

Seaview Equipment

seaviewequipment.com

Bridgeport, CT 203-330-0130

TB Equip & Rental tbequipment.net Bangor, ME 207-262-0014

Tracey Road Equip, Inc. traceyroad.com Albany, NY 518-438-1100

Binghamton, NY 607-775-5010

Marcy (Utica), NY 315-765-8746 Queensbury, NY 518-793-9688 Syracuse, NY 315-437-1471

Watertown, NY 315-788-0200

Whited Equipment whitedtruck.com

Auburn, ME 207-786-3673

Presque Isle, ME 207-764-7300 Saco, ME 207-391-6250

Best Line Equipment, a leader in equipment sales, service and rentals, announced a strategic partnership with Astec Industries, a global pioneer in the manufacture of equipment from rock to road.

“This partnership with Astec is a game-changer for us.

The agreement grants Best Line Equipment distribution rights for Astec road construction equipment in western Pennsylvania. This collaboration represents a significant step for Best Line Equipment in expanding its offerings and capabilities in the asphalt paving equipment sector.

“Best Line has been in the business of serving highway contractors for quite some time. Several years ago, Best Line acquired Field Tec Services, bringing multiple years of experience in repairing and rebuilding milling machines, pavers and Shuttle Buggy material transfer vehicles, with considerable expertise on Carlson screed products and all Roadtec machines,” said Adam Houseknecht, president and

Armand Cencetti Best Line Equipment

owner of Best Line Equipment.

“Our partnership with Astec allows Best Line to leverage our experience, facilities and network of locations to serve road and highway contractors at a much higher level. Best Line will be the only authorized dealer for product, parts and service within our territory and will provide full rebuild capabilities to serve customers throughout our network.

“Astec’s distinguished leadership in the asphalt industry aligns with Best Line’s local performance capabilities. We’re excited to partner with Astec and fulfill our customers’ high expectations.”

This collaboration positions Best Line Equipment as a leading provider of Astec’s top-notch asphalt paving equipment, ensuring customers have access to the best products, parts and service in the industry. The partnership reinforces Best Line Equipment’s commitment to delivering exceptional solutions and support to its clients.

Commenting on the partnership, Armand Cencetti, vice president of sales at Best Line Equipment, expressed enthusiasm for the expanded opportunities this collaboration brings: “This partnership with Astec is a game-changer for us. It allows us to broaden our offerings and cater to the specific needs of road and highway contractors. Our customers can expect an elevated level of service, product expertise, and support. We’re excited about the possibilities this collaboration opens up for Best Line Equipment and our valued customers.”

National LICA is set to host a groundbreaking event that will reshape the water management landscape.

The inaugural LICA Water Management Forum will take place at the historic St. Joseph’s College in Rensselaer, Ind., on June 13 and 14, 2024, bringing together water management professionals, contractors, farmers, government officials and educators.

Jerry Biuso Sr., CEO of LICA, has long aspired to organize a comprehensive drainage conference. The perfect venue proved elusive until May when a meeting with St. Joseph’s College, recommended by VP Tony Cain, unveiled the picturesque campus as an ideal space for the LICA Water Management Forum.

This two-day forum offers a comprehensive lineup, including seminars, equipment demonstrations, indoor and outdoor exhibits, an OSHA 10-hour course, first aid training, a heavy equipment mobile simulator donated

by ElectriCom of Paoli, Ind., an Introduction to Heavy Construction Equipment course for veterans and high school students, and a golf outing.

The program is tailored to the interests and needs of current and future water management professionals, ensuring exploration of the latest advancements and cutting-edge technologies.

A key feature is the extensive educational component, with leading university educators in agriculture sharing insights. The Agricultural Drainage Management Coalition (ADMC) also will bring a wealth of knowledge and experience to the table, amplifying the impact of the forum and broadening its reach. Abundant networking opportunities create a platform for professionals from across North America to connect, collaborate and build partnerships.

To encourage broad participation, complimentary booth space has been allocated to each LICA state chapter. Additionally, LICA has extended an

invitation to its Canadian counterpart, the Land Improvement Contractors of Ontario (LICO), making this event international.

St. Joseph’s College, with its historic significance and multi-faceted facilities, serves as an ideal location. The venue features well-equipped classrooms, a spacious auditorium, and over 10 acres of training ground for outdoor exhibits and demonstrations. Given the college staff’s goal of reopening as a vocational school, collaborative efforts with organizations like LICA add momentum to the initiative, fostering awareness and interest in essential careers.

As June 13 approaches, excitement is building for the LICA Water Management Forum. Professionals from various corners of the water management spectrum are gearing up to converge at St. Joseph’s College, ready to explore, learn and contribute to the future of sustainable water management.

39 Jersey Street • West Babylon, NY 11704 631-643-2605 www.allislandequipment.com

East Syracuse, NY 315-437-1471 Kirkwood, NY 607-775-5010 Henrietta, NY 585-334-5120 Adams Center, NY 315-788-0200 Utica, NY 315-765-8746 • 800-872-2390 www.traceyroad.com

Zelienople, PA 724-452-7800 Dubois, PA 814-371-3600 McKean, PA 814-476-7755 Millstone Township, NJ 732-446-7600 www.highway-equipment.com

South Abington Twp., PA 570-489-3642 Tannersville, PA 570-895-4884 marshall-machinery.com

Ahearn Equipment Inc. www.ahearnequipment.com

Spencer, MA 01562

877/624-3276

Cherry Valley Tractor

www.cherryvalleytractor.com

Marlton, NJ 08053

856/983-0111

Erb & Henry Equip., Inc.

www.erbhenry.com

New Berlinville, PA 19545

610/367-2169

ADMAR Construction Equipment & Supplies www.admarsupply.com

Vestal, NY 13850

607/798-0333

Tonawanda, NY 14217

716/873-8000

Canandaigua, NY 14424

585/396-0031

Rochester, NY 14623

585/272-9390

Cicero, NY 13039 315/433-5000

Eagle Power & Equipment Company www.eaglepowerandequipment.com West Chester, PA 19380 610/458-7054

Doylestown, PA 18901 215/348-9041

F&W Equipment www.fwequip.com Orange, CT 06477 203/795-0591

Reading Tractor and Equipment www.readingtractor.com 5538 Pottsville Pike Leesport, PA 19533 610/926-2441

Marshall Machinery, Inc. www.marshall-machinery.com

Honesdale, PA 18431 570/729-7117

Middletown, NY 10940 845/343-6683 South Abington Township, PA 18411 570/489-3642

Tannersville, PA 18372 570/895-4884

Westchester Tractor Inc.

www.wtractor.com

Brewster, NY 10509

845/278-7766

Chappell Tractor www.chappelltractor.com

454 Route 13 South Milford, NH 03055

603/673-2640

Highway Equipment Company

www.highway-equipment.com

Millstone Township, NJ 08535

732/446-7600

The Washington Metropolitan Area Transit Authority, better known as the Metro, held a groundbreaking Jan. 8 for a new high-rise residential building being constructed at the North Bethesda Metro Station.

The project is the final phase of a mixed-use joint development helping spur the transformation of the surrounding North Bethesda Pike District in the Maryland suburbs of Washington.

The 354-unit building — to be named Envoi — will be constructed on a 1.6-acre parcel owned by Metro and ground leased to LCOR, the project’s developer and builder, through Metro’s Joint Development Program.

LCOR rendering

The 354-unit building — to be named Envoi — will be constructed on a 1.6-acre parcel owned by Metro and ground leased to LCOR, the project’s developer and builder, through Metro’s Joint Development Program.

Once completed, the MetroLCOR partnership will result in 2 million sq. ft. of mixed-use development at the transit station. This includes 1,300 residential units, of which 164 will be affordable housing.

“This project at North Bethesda shows the positive impacts of Metro’s partnerships across the region, generating economic benefit, creating new revenue and ridership for Metro, and supporting sustainability through transit-oriented development,” Metro General Manager and Chief Executive Officer Randy Clarke said in a statement.

“We have the most robust joint development program in the nation and plan to accelerate development of Metro’s assets in the District, Maryland, and Virginia to help maintain safe, reliable, and affordable transportation.”

The 12-story Envoi building represents the final phase of a 2001 joint development agreement between Metro and LCOR and is the fourth residential building constructed at the site as part of the “The Quad at Pike District.”

Metro has received more than $40 million in upfront ground lease payments, fees and other payments from the development, which also will generate approximately $350 million in state and local tax revenues over the next 30 years.

The project also is supported by the More Housing at Metro Act, enacted by Montgomery County, Md. in 2021, to incentivize development of transit-accessible, affordable housing units on Metro properties

in the county.

In addition, Metro owns another 13 acres of undeveloped property at the North Bethesda Station and is working with the county on an initiative to create a life science anchored transit-oriented development. A future solicitation is planned to select a development team for that site.

The joint development supports Metro’s Strategic Transformation Plan to maximize regional opportunities and partnerships, support sustainability, and deliver revenue to provide service excellence through safe, reliable transit options.

Since 1975, Metro has completed 55 joint development projects totaling 17 million sq. ft. (about half the area of New York’s Central Park) at 30 of the transit authority’s 98 stations, more than any other similar agency in the United States.

Under Metro’s 10-Year Strategic Plan for Joint Development, the Capital-area agency seeks to advance 20 joint development projects by 2032.

Current mixed-use projects are under construction at the College Park-University of Maryland, Grosvenor-Strathmore and New Carrollton stations. Predevelopment efforts are also ongoing for projects at Capitol Heights, Congress Heights, BrooklandCUA, Fort Totten, Deanwood, Forest Glen, Takoma,

Road, West Hyattsville, Landover, Mill Road, Huntington and West Falls Church.

The combined demand for contractors and labor shortages has created a one-two punch in the gut for the state’s transportation build-out.

“We’ve got a lot of large contracts happening and the contractors who are capable … are not as numerous as they need to be,” said Sen. Marko Liias.

As a result, the state is considering ways to create more appeal for smaller contractors, including breaking these megaprojects into multiple, smaller contracts.

For now, Rep. Jake Fey proposed rejecting Highway 520 bids and revisiting the details of the project. “We don’t have another $500 million laying around.”

It’s a situation affecting contractors across the transportation construction spectrum and well beyond Washington State.

In analyzing the latest NHCC index results, FHWA reported that for the second quarter of 2023 a 3.8 percent increase continued from the first quarter.

“Compared to the historical quarterly average of 1.4 percent growth, this is still higher than average inflation,” said FHWA.

The agency said the numbers are “less than the high inflation observed during 2021 and 2022, where average quarterly growth was 5.2 percent.”

They suggested that elevated inflation in 2021 and 2022 may have been driven by supply chain disruptions and fluctuating oil prices.

“Current trends in the index indicate that as these factors stabilize, the NHCCI may revert to its long-term average.”

Overall changes in such construction-related indexes suggests an easing of inflation on material prices, said FHWA.

“Divergence in producer price index [PPI] and NHCCI suggests factors other than material input prices may be contributing to NHCCI inflation,” it said.

“Notably, the PPI for asphalt showed a 20.5 percent increase during 2023 Q2 after showing a 22.2 percent decrease during 2023 Q1.”

Other construction-related PPI such

Other construction-related materials, such as materials, concrete products and fabricated structural metal, are more expensive to purchase for construction projects.

as materials, concrete products and fabricated structural metal showed modest inflation between 0-2 percent.

“The asphalt price volatility combined with relatively stable prices for other material may partially explain why the NHCCI continues to outpace the PPI.”

The Eno Center noted that when FHWA released its latest cost index, it had to admit construction inflation had not slowed.

In fact, the transportation think tank said, the cost of building highways increased by 3.8 percent in the second quarter of 2023. That figure is equivalent to a 15.3 percent annual inflation rate, said the policy organization.

“This shows that, even though inflation had lessened elsewhere in the economy by that point, it was not yet done with highway construction.”

FHWA tracks construction costs quarterly through the NHCC index. In mid-2021, according to Eno, the index began growing rapidly. It peaked in the April-June 2022 quarter, and had a “temporary respite” in the fourth quarter of 2022, after which acceleration began once more.

“Since the end of 2020, the NHCCI says that highway construction costs have increased by 59.3 percent,” reported the Eno Center.

The organization is not surprised by

the fact that the largest share of the increase was from rises in the cost of asphalt, dictated by the price of petroleum.

“But the second-largest cause of the quarterly increase was from traffic control, which is particularly labor-intensive,” said Eno policy analysts.

FHWA concluded that while it’s suggested labor costs are a driving factor in NHCCI inflation, the “relatively low and stable inflation” proves inconsistent

“The disparities in growth among the indices underline that each index’s sensitivity to broader events varies,” said the federal agency.

Those factors include COVID-19 pandemic, supply chain disruptions, material shortages, and oil price swings, FHWA added.

“New FHWA spending obligations in fiscal years 2021, 2022 and the first three quarters of 2023 totaled $152 billion,” noted Eno.

The organization suggests re-basing highway construction costs the last quarter of 2020, then deflate everything after that.

The result is that $152 million in new obligations deflates to a “real” total of $116 billion, according to the Eno Center.

The think tank figures that $35.2 billion in real buying power of the IIJA and regular funding has been lost to highway construction cost inflation since then. CEG

Five Star Equipment, Inc.

60 Paul Rd. Rochester, NY 585/235-3011

1653 NY Route 11 Kirkwood, NY 607/775-2006

284 Ellicott Rd. Orchard Park, NY 716/662-2191

5835 East Taft Road

North Syracuse, NY 315/452-4560

1300 East Dunham Dr. Dunmore, PA 570/346-1701

46 Route 97 Waterford, PA 814/796-2663

2585 Lycoming Creek Rd. Williamsport, PA 570/494-4030

www.fivestarequipment.com

2550 E. Cumberland St. Lebanon, PA 717/273-2616

800/225-4001

3215 State Rd. Sellersville, PA 215/258-5700

800/523-2209

400 Stoke Park Rd. Bethlehem, PA 610/867-4657

800/587-9790

640 Lowther Rd. Lewisberry, PA 717/938-6568

866/787-0001

179 Perry Hwy Harmony, PA 16037 724/776-3636

1973 Sheridan Rd Greensburg, PA 15601 724/837-4500

www.grofftractor.com

Combining serious performance with fuel efficiency, customer-inspired components, and intuitive controls, our new 744 P-Tier, 824 P-Tier, 844 P-Tier, and 904 P-Tier Loaders deliver the muscle operators need to work productively and comfortably. Upgrades over previous series models include increased horsepower and hydraulic pressure, reimagined cab amenities, and simplified service points. With rugged John Deere PowerTech™ diesels, high-capacity heavy-duty axles, and innovative options including Obstacle Intelligence that enhances jobsite safety, these large-scale wheel loaders are built rock solid for the long haul. Prepare to power things up.

Middletown, DE

302/376-0784

Baltimore, MD

410/687-1700

Delmar, MD

410/546-1090

Frederick, MD

301/874-5500

District Heights, MD

301/909-7799

Waldorf, MD

301/861-2323

118 St. Nicholas Ave.

South Plainfield, NJ

908/753-8080

800/241-7070

1275 Bloomfield Ave. Fairfield, NJ

www.jesco.us

973/227-2221

800/321-8080

1790 Route 38

Lumberton, NJ

609/267-2020

888/217-0600

497 Fishkill Avenue Beacon, NY

845/831-1800

800/724-0725

Beaver, WV

304-255-1525

Cowen, WV 304-226-3299

Cross Lanes, WV 304-204-1818

Pleasant Valley, WV

304-534-5454

Norton, WV

304-636-6421

Marietta, OH

740-373-5255

Ashland, KY 606-327-1709

Pikeville, KY 606-432-0321

www.lec1.com

North Oxford, MA 508-987-8786

North Billerica, MA 978-667-4345

Plymouth, MA 508-830-9997

NO. Swansea, MA 508-379-9810

Springfield, MA 413-543-5595

Clifton Park, NY 518-371-5111

Gouverneur, NY 315-287-0703

Hermon, ME 207-947-6786

Houlton, ME 207-532-6517

New Canada, ME 207-834-6701

www.unitedcf.com

JohnDeere.com/Loaders

Westbrook, ME 207-773-3777

Pembroke, NH 603-225-2769

Springfield, VT 802-885-6840

Williston, VT 802-658-2121

The W.I. Clark Company

Wallingford, CT

203/265-6781

Danbury, CT

203/775-1203

Plainfield, CT

860/546-4808

www.wiclark.com

More work is needed to ensure that non-standard lifts are carried out safely, according to a leading expert.

All Material Handling (AMH) believes that too many non-traditional lifts are still taking place using the wrong hoist rings and eyebolts, creating unnecessary safety risks.

Peter Brettner, CEO of “below the hook” equipment supplier All Material Handling, said “Whether on a construction site, in a machine shop, or at a manufacturing facility, there are two primary goals: move the load without damaging it; and make it home safely at the end of your shift.

“We’re still seeing a lot of incorrect use of eye bolts in particular. Traditional eyebolts are best used for straight in-line lifts only, or they incur a significant reduction in the working load limit. The old school alternative was often to wrap a round sling around the load and see how it went, but frankly both can be an accident waiting to happen.”

While a sling and some hooks are usually suitable for a standard lift with easy connections such as a shackle and welded eye or plate, a non-traditional lift like a large motor or a flat gear can be much more challenging. In these cases, AMH recommends rotating

hoist rings, as they are specifically designed to lift from the focal point and keep the load centered — traditional eyebolts can tend to sideload.

AMH is adding the Cartec series of lifting points and rotating hoist rings to its product portfolio, ensuring that riggers have easy access to the right tools for the job when it’s a nonstandard load.

The Cartec 807 series of rotating eyebolts provide a 100 percent working load limit at any angle allowed by the corresponding user’s manual — and the load limit is clearly visible on the bolt itself, eliminating guesswork.

“Using the right swivel hoist ring and rotating eyebolt means there is no more second-guessing the reduced working load limit of a standard eyebolt because it is not an inline pull. The load limit is easily checked as it’s forged into the product and doesn’t change,” added Brettner.

“There is also no more shimming the shoulder to get a proper lift angle, which

can happen with traditional eyebolts — or worse, risk having lousy positioning and causing a failure. Contractors are increasingly focused on enhancing safety. While a swivel eyebolt has a slightly higher price than a standard eyebolt, this is nothing compared to the human and financial cost of an incident that causes injury or even death.”

AMH offers a full line of lifting points ranging from 6 mm all the way up to 100 mm, offering 0.3t to 40t WLL, available in both UNC and metric threads. Styles include rotating eyebolts, standard swivel hoist rings, off-set swivel hoist rings, ball bearing options for swiveling under load and even stainless-steel rotating eyebolts. For more information, contact AMH at 877/543-8264 or via email at sales@allmaterialhandling.com.

All Material Handling Inc. is dedicated to making lifting and handling safer and more efficient. The privately-owned company is a provider of material handling equipment and accessories to applications in construction, industrial

There were approximately 27 subcontractors on the project.

Pittsburgh, Pa., where the president is Brian J. Gilkey and the superintendent is Mike Rhoads. The Pennsylvania Turnpike Commission Project Manager is John R. Cottle of Johnson, Mirmiran & Thompson Inc. (JMT) of Pittsburgh, Pa., which serves as the construction consultant under the direction of Anthony Ciarico, project manager.

Ciarico noted that the two tunnels are located in central Pennsylvania. The eastbound tunnel is more than 80 years old.

“Actually, it was first drilled for a railroad company back in the late 1800s, abandoned, and then when the Turnpike did their initial mainline construction in the early 1940s, I believe, they used this tunnel,” he said. “The second tunnel is the westbound, built in the late ’60s, early ’70s. So, the two tunnels being built in different time periods have a little bit different characteristics … so the scope was different for each tunnel.”

He explained that work on the eastbound side included the

removal of all the existing barrier and the ceiling, which brought the tunnel back to basically its original arch shape, installation of new drainage, water infiltration, a new collection system, a new tunnel waterproofing system, new life safety features, CO monitors, alarms and linear heat detection systems. Other additions included lane control signs, dynamic message boards, new LED lighting and a new pavement section both within the tunnel and for the tunnel approaches.

“This, along with a white epoxy coating applied to the walls, resulted in wider lanes and a brighter look,” Ciarico said.

He added that the westbound tunnel maintained its existing shape without removing the ceiling or the barrier, so it was a more traditional rehabilitation. New inlets were added for drainage and a better water infiltration collection system also was installed. Concrete and crack repairs also were done throughout and life safety features similar to those in the first tunnel also were added, as well as LED lights and new pavement.

For the two portal buildings at each end of the tunnel, upgrades included new electric switch gear systems and an

improved ventilation system. Generators also were updated and upgrades were made in the office space where the tunnel guards work.

Late in the design, substructure work was added for two small bridges just west of the tunnel that needed some repairs.

Conducting a construction project during COVID was one of the main challenges with the project.

“Statewide, all construction projects were halted for a minimum of one month during the onset of COVID,” Ciarico said. “Upon resumption, special safety measures were taken to halt spread and a COVID response program was implemented. Later, supply chain issues became a hindrance along with the inflation spike impacting certain material costs.”

He noted that the original completion date was the end of June of last year, but the contract had to be extended by seven months.

Another challenge was the coordination of 28 contractors (one prime and 27 subs), many with specialty work items,

Milford, MA 508-634-3400

Among the largest construction services and products firms in the Northeast, O&G Industries is a fourth-generation company owned by the Oneglia family. Founded 101 years ago in 1923, the company currently has more than 700 employees and a fleet of more than 3,500 vehicles and pieces of equipment.

One of the company’s most distinguishing features is its diversity.

Its portfolio includes the production and distribution of aggregates, concrete and asphalt from its six quarries, and eight concrete plants and nine asphalt plants, strategically located throughout Connecticut and eastern New York. O&G Industries’ mason division is among the east coast’s largest masonry services and solution suppliers. In addition to road, bridge and dam construction, the company’s heavy civil division also has tackled large scale sitework, power and energy projects.

O&G Industries Building Group’s portfolio includes education, healthcare, commercial, office, industrial, manufacturing, municipal, commu-

nity, athletic venues, transit, utility, water and wastewater projects.

The company began when two friends, Andrew Oneglia and Flaviano Gervasini, formed a partnership hauling sand and stone. Despite setbacks, the company experienced rapid growth in its first 50 years and purchased its first quarry in Woodbury, Conn., in 1936.

By the end of the 1950s, the company was involved in major road construction and had built the Thomaston Dam for the Army Corps of Engineers.

The building division was established in the 1960s as O&G Industries expanded into school construction projects and the division continued with rapid growth throughout the 1970s. The next

Company Wrench www.companywrench.com

2636 S Black Horse Pike Williamstown, NJ 08094

855-562-3526 • 856-404-9618

Highway Equipment Company

www.highway-equipment.com

4690 Route 219 DuBois, PA 15801

814-371-3600 • 877-888-4326

5846 West Road McKean, PA 16426 814-476-7755 • 866-476-7755

22035 Perry Highway Zelienople, PA 16063

724-452-7800 • 800-222-8798

C.N. Wood Co. Inc. www.cn-wood.com

200 Merrimac Street Woburn, MA 01801

781-935-1919

140 Wales Avenue Avon, MA 02322 508-584-8484

102 State Road Whately, MA 01093 413-665-7009

3 Rocky Hill Road Smithfield, RI 02917 401-942-9191

283 Pane Road Newington, CT 06111 860-665-7470

All Island Equipment www.allislandequipment.com

39 Jersey Street West Babylon, NY 11704

631-643-2605

Caterpillar Inc. has signed an electrification strategic agreement with CRH to advance the deployment of Caterpillar’s zero-exhaust emissions solutions. CRH is the number one aggregates producer in North America and the first company in that industry to sign such an agreement with Caterpillar.

The agreement is focused on accelerating the deployment of Caterpillar’s 70 to 100-ton-class battery electric off-highway trucks and charging solutions at a CRH site in North America.

Through the agreement, CRH will participate in Caterpillar’s Early Learner program for battery electric off-highway trucks, testing and validating the units in real-world applications. CRH also will provide voice of customer feedback to address safety, performance, operational and compliance requirements for the aggregates industry.

“We are pleased to work with CRH, as our first aggregates industry customer, to expand our electrification solutions beyond mining. When it comes to sustainability, the quarry and aggregates industry requires diverse solutions. Our collaboration with CRH is an exciting opportunity to learn together and gain valuable insights into how our products can best support CRH’s long-term objectives to decarbonize its operations,” said Resource Industries Group President Denise Johnson.

The collaboration supports CRH’s climate-related objective of reducing greenhouse gas emissions from its opera-

tions by utilizing more sustainable equipment. CRH has set a target to deliver a 30 percent reduction in absolute carbon emissions by 2030 (from a 2021 base year) and an ambition to be a net-zero business by 2050.

Scott Parson, president, CRH Americas Materials Solutions said, “At CRH, we recognize that collaboration and innovation are critical to delivering our industry-leading decarbonization targets and achieving our ambition of netzero by 2050. Through this partnership with Caterpillar, we will advance the use of sustainable equipment in our operations and build on our shared commitment to a low-carbon future.”

For more information, visit www.caterpillar.com and www.crh.com.

RubbleCrusher displayed its compact, tracked, mobile jaw crushing unit, the RC150T, and debuted the RubbleCrusher RSC48T Screen at its first World of Concrete show in Las Vegas in January.

The RSC48T enables the screening of material right on site, allowing for the production of three different material sizes on one mobile machine.

The RSC48T weighs just under 8,000 lbs. and has a large 4 ft. by 8 ft. top deck and a 4 ft. by 6 ft. bottom deck. The screen can be fed directly with an excavator or skid steer.

This mobile screen is perfect for those hard-toaccess areas because of its compact size, according to the manufacturer.